Composite wave absorbing material and preparation method thereof

A composite wave absorbing material and mixture technology, which is applied in the field of wave absorbing materials, can solve the problems of low matching of wave absorbing substrates, limited wave absorbing performance, low wave absorbing performance, etc., and achieves good material density and uniformity. Stable and productive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dissolve 6g of MAX phase powder in 50ml of 40wt% HF solution, stir at 60°C for 20h, wash the obtained product with deionized water 6 times until the pH of the solution is >6, centrifuge, filter, and dry , to get MXene powder, the SEM image of the prepared MXene powder is as figure 1 shown.

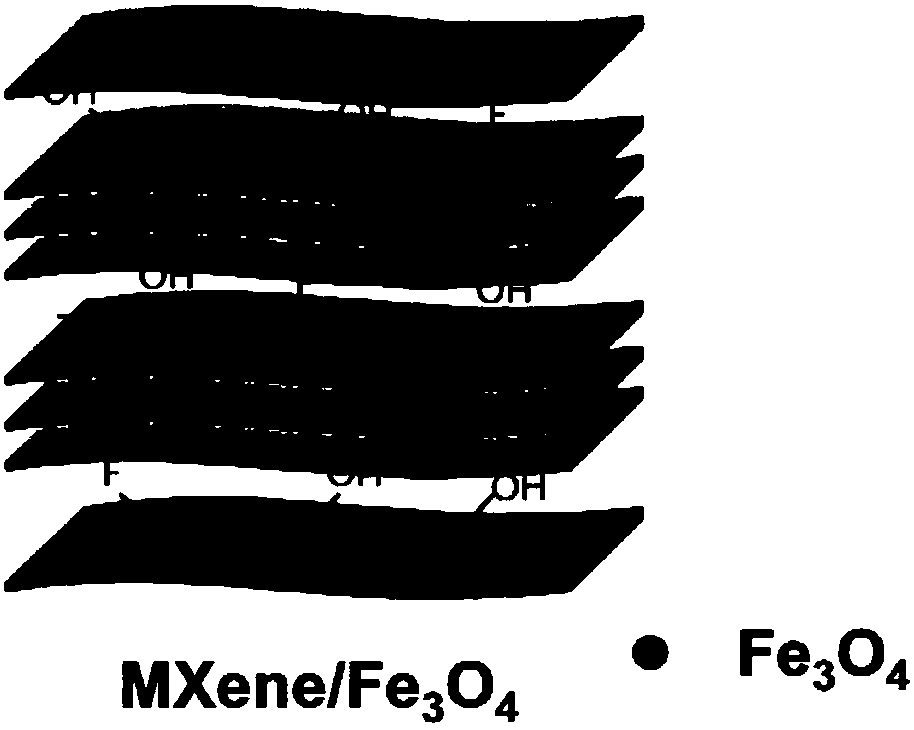

[0050] Get 0.42g of MXene prepared by the above process and dissolve in 20ml of ethylene glycol solution, then add 0.21gFeCl3 6H 2 O, 0.84g of anhydrous sodium acetate, stirred for 3h to obtain a uniformly mixed brown suspension, then put the suspension in a 50ml reaction kettle and heated at 200±5°C for 8h to obtain a sandwich-structured MXene / Fe 3 o 4 Composite absorbing material; the above MXene / Fe 3 o 4 The composite absorbing material is heated at 300±5°C for 1 hour, that is, annealing treatment, and the final absorbing material is obtained. The SEM image results are as follows: figure 2 shown.

[0051] From figure 2 The SEM image shows Fe 3 o 4 Nanoparticles grow ...

Embodiment 2

[0058] Dissolve 3g of MAX phase powder in 30ml of 40wt% HF solution, stir at 40°C for 18h, wash the obtained product with deionized water 6 times until the pH of the solution is >6, centrifuge, filter, and dry , to get MXene powder, the SEM image of the prepared MXene powder is as figure 1 Consistent with that shown.

[0059] Take 0.3g of MXene prepared by the above process and dissolve in 20ml of ethylene glycol solution, then add 0.105gFeCl 3 ·6H 2 O, 0.42g of anhydrous sodium acetate, stirred for 2.5h to obtain a uniformly mixed brown suspension, then put the suspension in a 50ml reaction kettle, and heated at 200±5°C for 8h to obtain a sandwich structure MXene / Fe 3 o 4 Composite absorbing material; the above MXene / Fe 3 o 4 The composite absorbing material is heated at 300±5°C for 1 hour and then annealed to obtain the final absorbing material. The SEM image results are as follows: figure 2 Consistent with that shown.

[0060] Fe can be seen from the SEM image 3 o...

Embodiment 3

[0067] Dissolve 10g of MAX phase powder in 80ml of 40wt% HF solution, stir at 80°C for 24h, wash the obtained product with deionized water 6 times until the pH of the solution is >6, centrifuge, filter, and dry , to get MXene powder, the SEM image of the prepared MXene powder is the same as figure 1 unanimous.

[0068] Take 0.6g of MXene prepared by the above process and dissolve in 20ml of ethylene glycol solution, then add 1.05gFeCl 3 ·6H 2 O, 4.2g of anhydrous sodium acetate, stirred for 3.5h to obtain a uniformly mixed brown suspension, then put the suspension in a 50ml reaction kettle, and heated at 200±5°C for 12h to obtain a sandwich structure MXene / Fe 3 o 4 Composite absorbing material; the above MXene / Fe 3 o 4 The composite absorbing material is heated at 300±5°C for 1 hour, that is, annealing treatment, and the final absorbing material is obtained. The SEM image results are as follows: figure 2 Consistent with that shown.

[0069] Fe can be seen from the SEM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com