Integral noodle processing and packaging device

A noodle and packaging bag technology, applied in the field of noodle production equipment, can solve the problems that the power of the water pump cannot meet the long-distance transportation, affect the production efficiency of the noodle processing line, and the distance between the water source and the boiler is far away, so as to save floor space and labor and Material resources, reduction of noodle loss, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

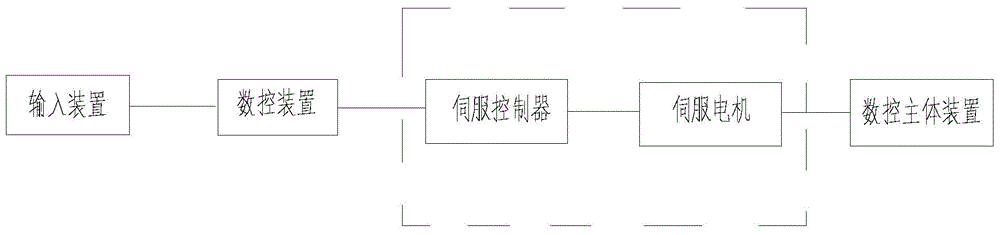

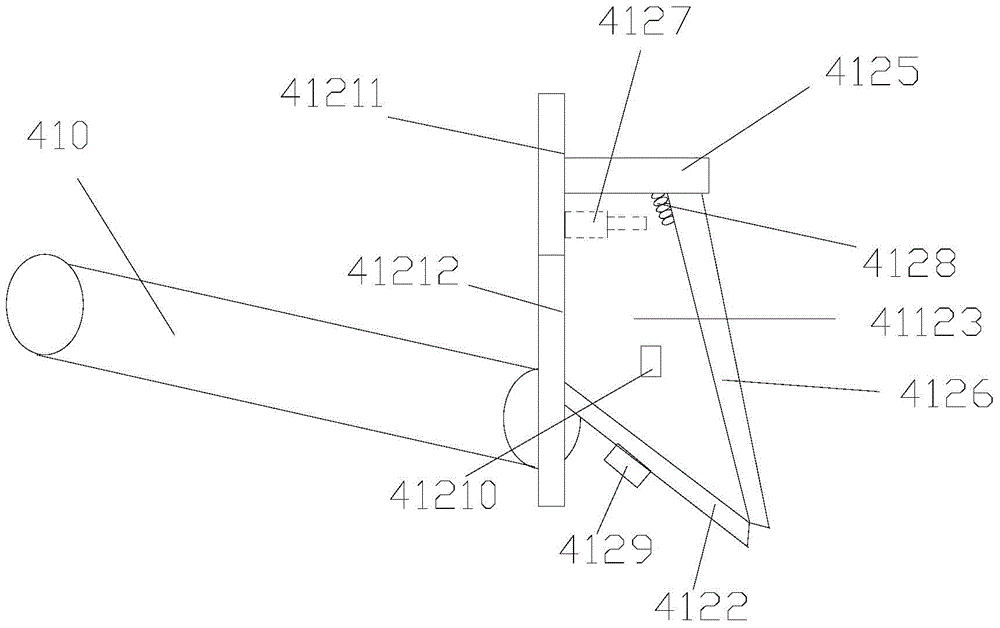

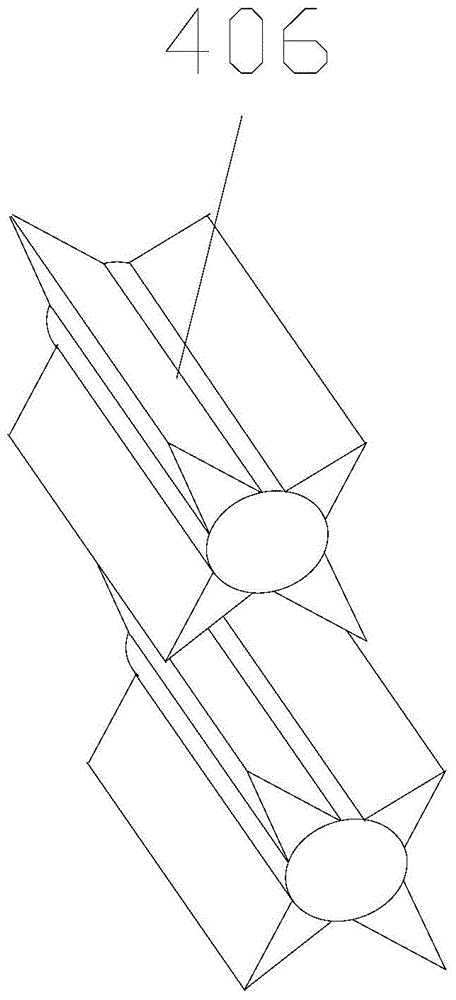

[0034] Such as Figure 1-9As shown, this embodiment includes an input device, a numerical control device, a servo system, a main body device of a machine tool, a water supply system, a drying device 408 and a feeding device 416 . The output end of the input device is connected to the input end of the numerical control device, the output end of the numerical control device is connected to the input end of the servo system, and the output end of the servo system is connected to the main body device of the machine tool; The host device of the machine tool includes a dough mixing device 401, a pre-rolling device, a composite roll 403, a roll 404, a noodle knife 405, a cutting knife 406, a first conveying device 407, an automatic weighing device, a second conveying device 410, a third conveying Device 411 , alignment device, packaging bag supply device 413 , bag maker 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com