Full-view laser cutting bed

A panoramic and laser technology, which is applied in the field of panoramic laser cutting machines, can solve the problems that laser cutting machines cannot cut, and achieve the effects of overcoming inaccuracy, saving user costs, and improving product quality and delivery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

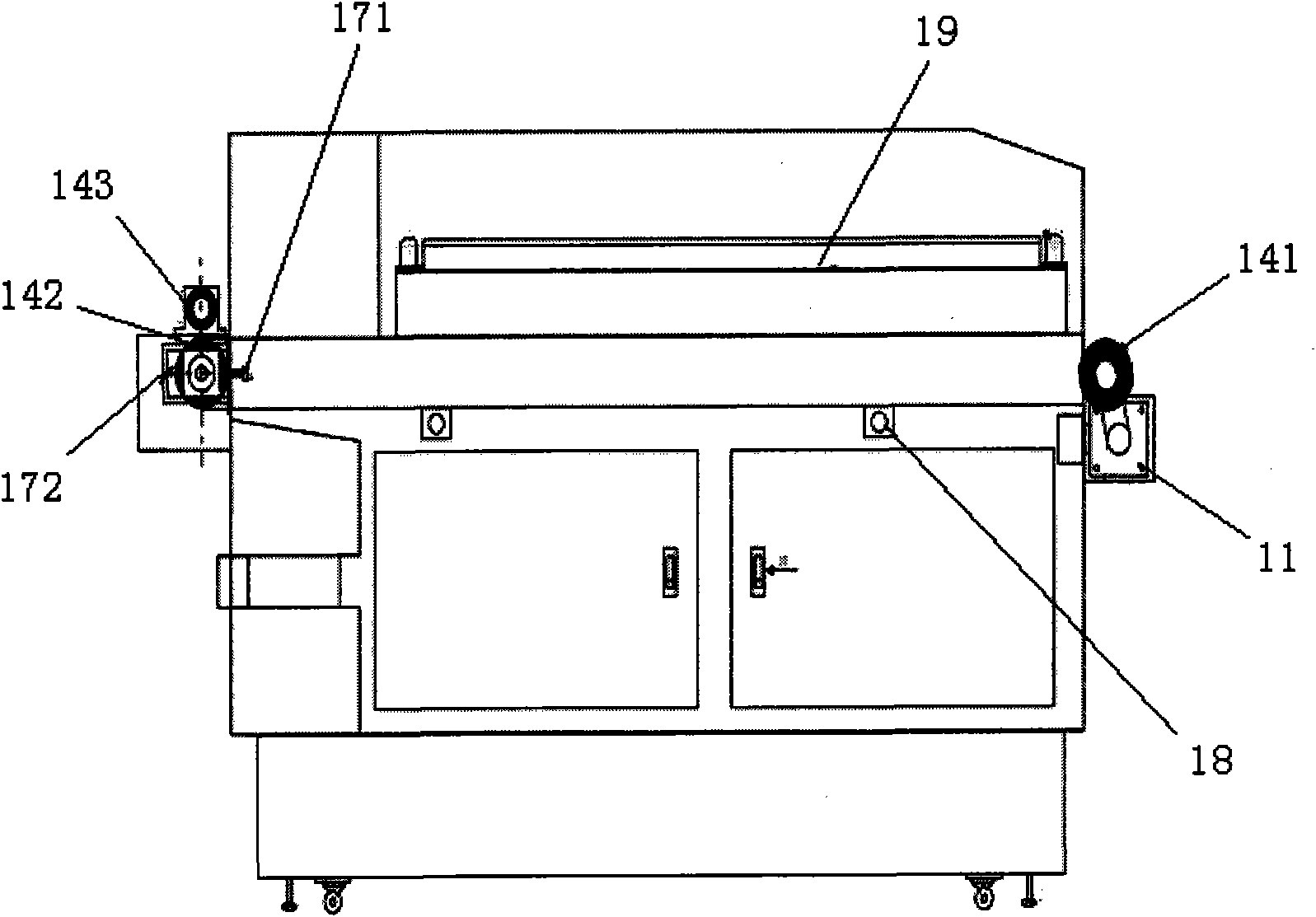

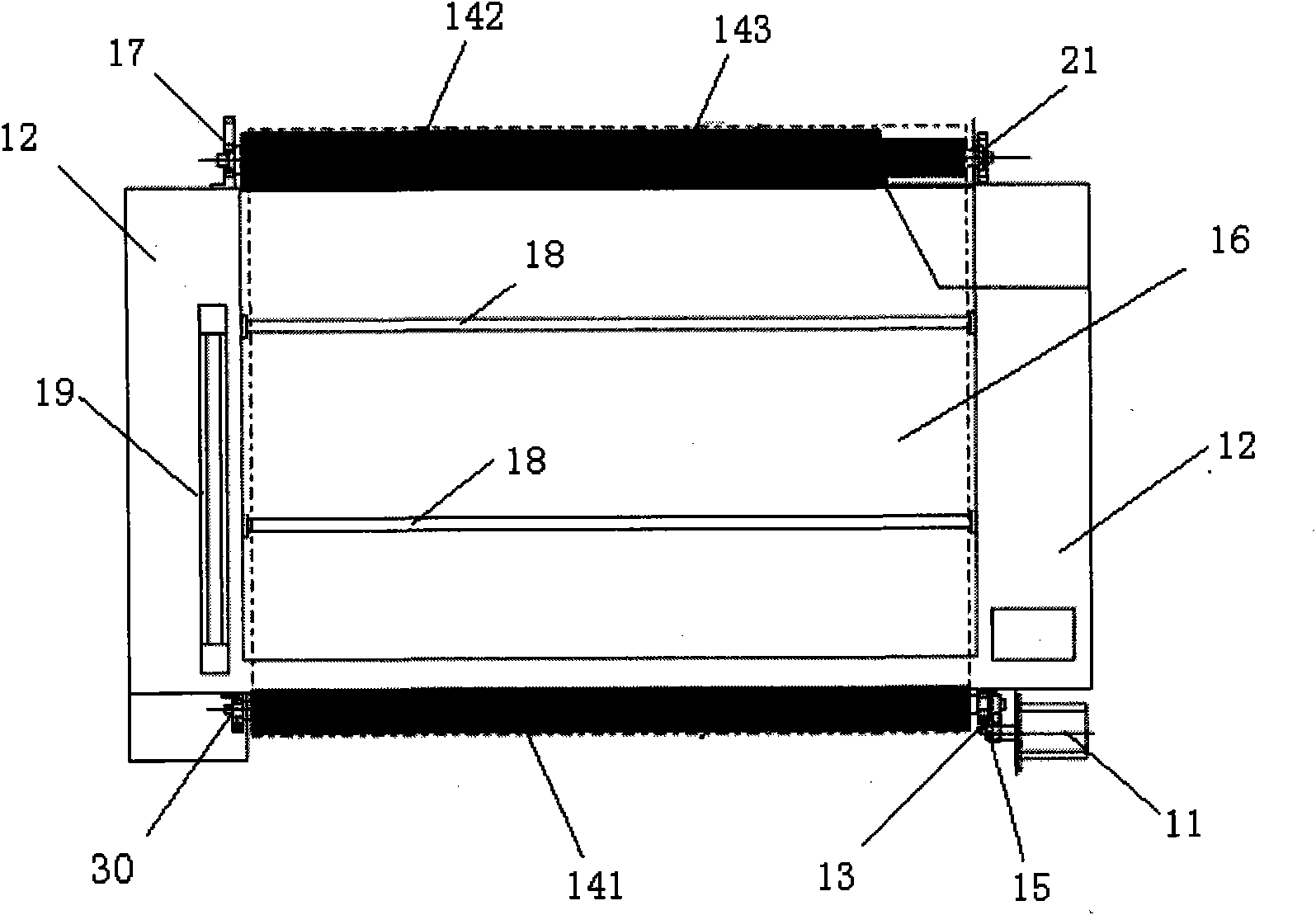

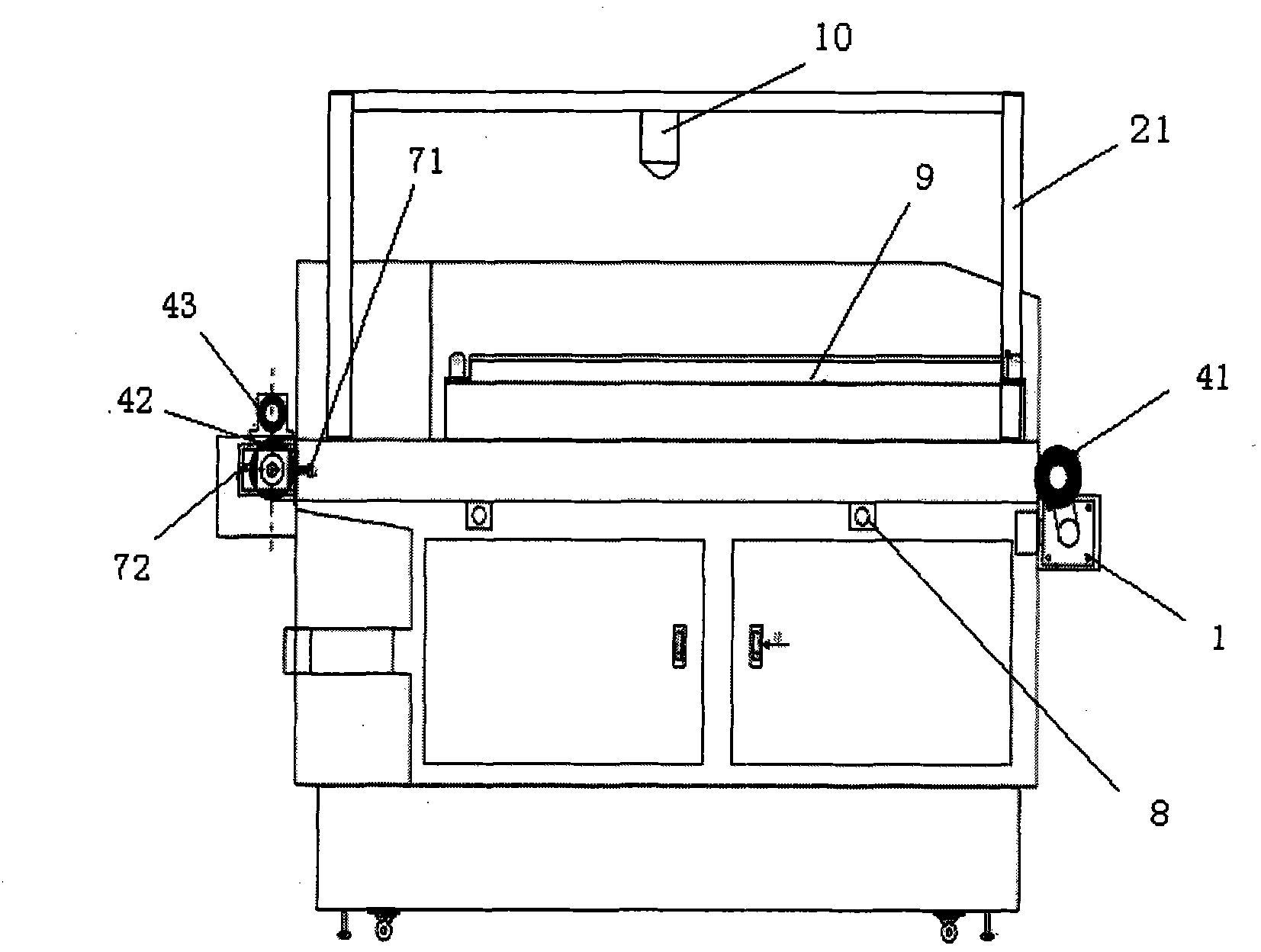

[0016] A kind of panorama laser cutting bed of the present invention, see image 3 with Figure 4 , the panoramic laser cutting machine includes a motor 1, a frame 2, a discharge rubber roller 41, a feed rubber roller 42, a mesh belt 6 and a tension adjustment device 7, and the motor 1 passes through the gear of the belt 3 and the discharge rubber roller 41. Connection; the mesh belt 6 is set on the frame 2 through the mesh belt bracket 8 and can move along the guide rail 9; the guide rail 9 is set on the frame 2; the motor 1 is set on the outer front of the frame 2, and the discharge rubber roller 41 is located The outer front part of the frame 2 and one end of the discharge rubber roller 41 are connected with the motor 1, and the other end is arranged on the frame 2 through the fixed frame 20; the feeding rubber roller 42 is positioned at the rear of the frame 2, and the feeding rubber One end of the roller 42 is arranged on the frame 2 through the rubber roller bracket 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com