Automatic production process for post production flow of concrete blocks

A technology for concrete blocks and production processes, which is applied in the stacking of objects, destacking of objects, and conveyor objects, etc., can solve the problems of high labor intensity of workers, unfavorable production efficiency, quality of concrete blocks, and easy damage to blocks. , to achieve a high degree of automation, reduce labor intensity, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

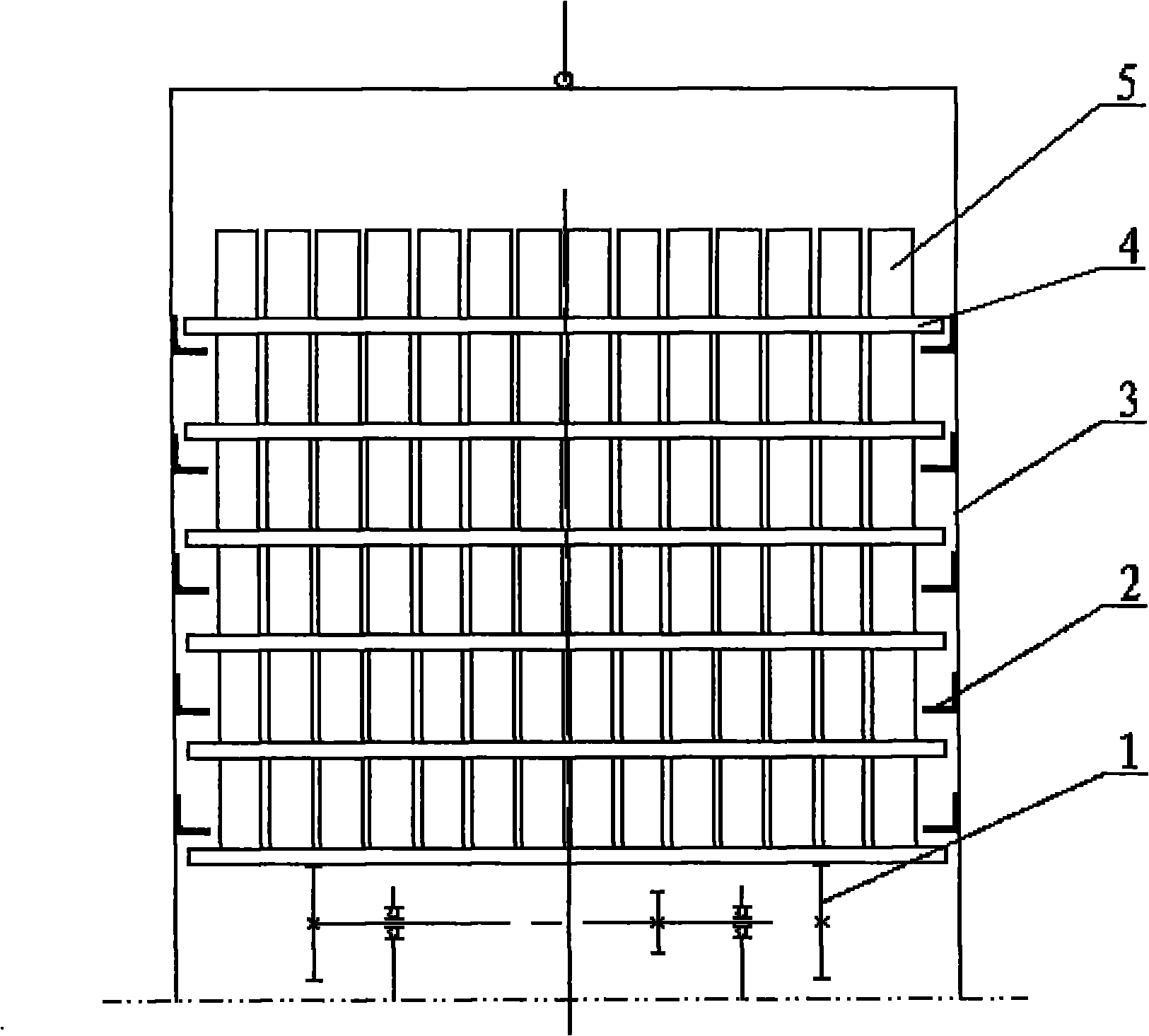

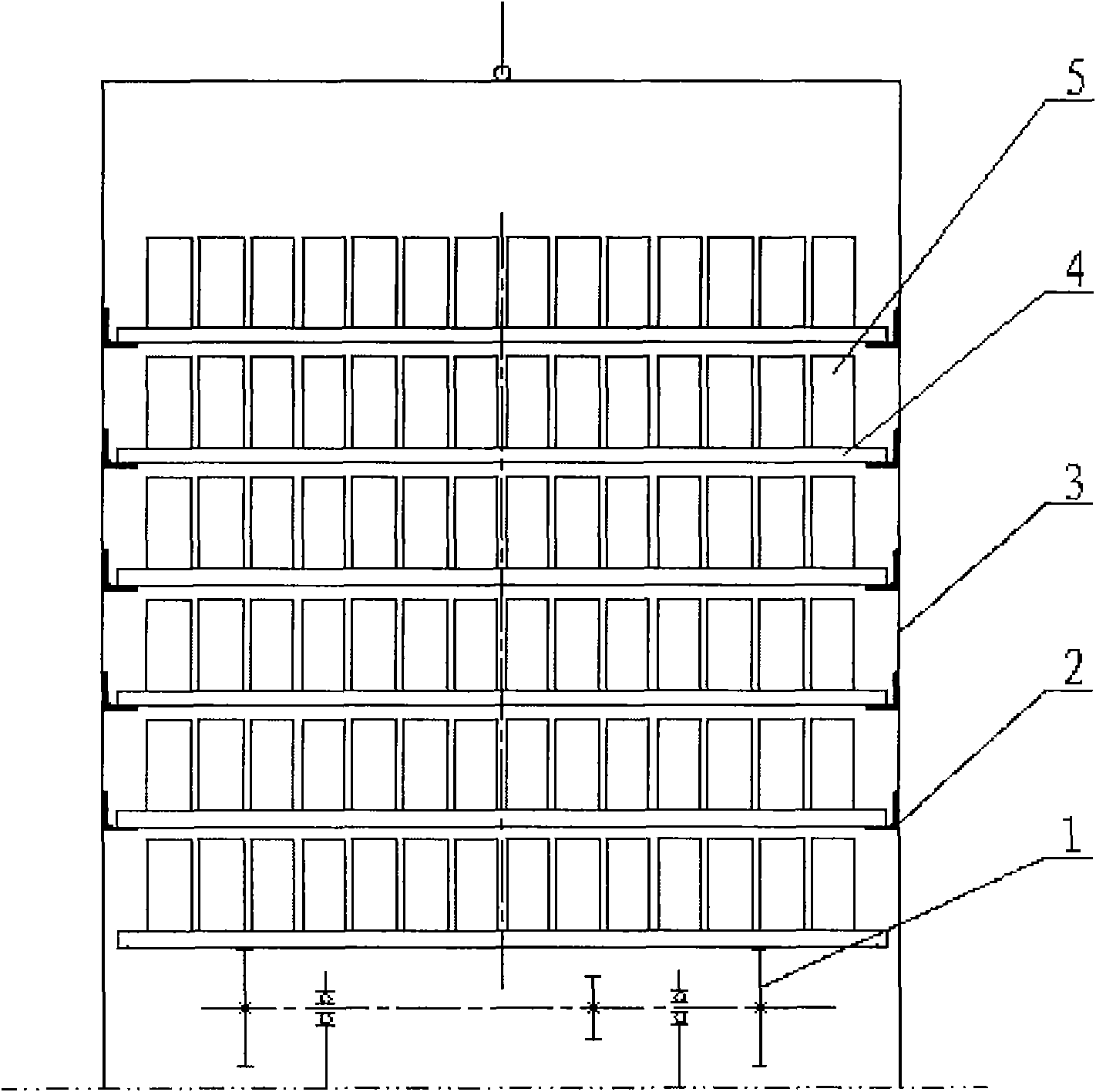

[0019]Specific embodiments of the present invention are described below with reference to the accompanying drawings.

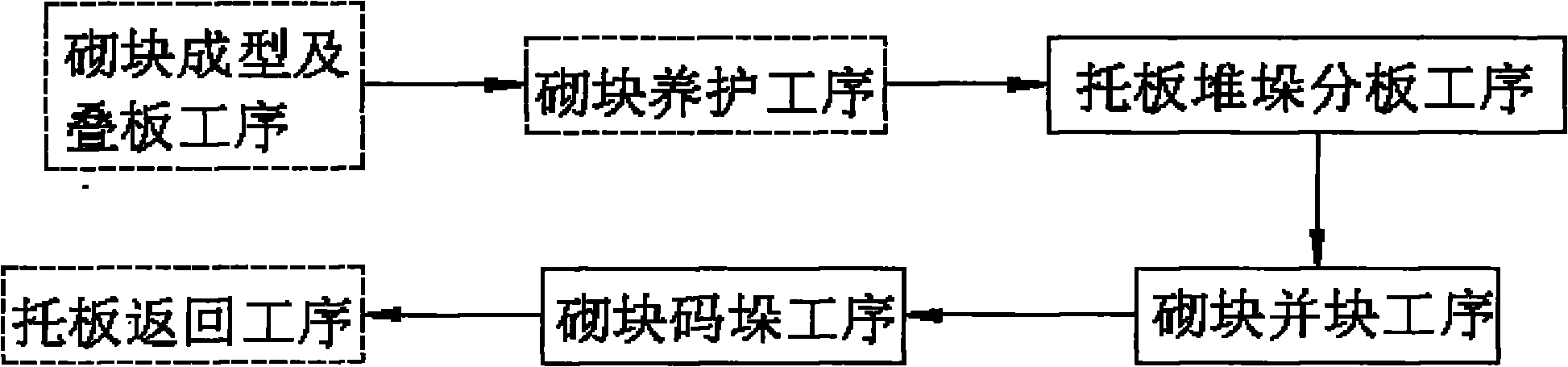

[0020] see figure 1 Generally speaking, the complete production process of concrete blocks mainly includes the front-end production process and the back-end production process. The front-end production process mainly refers to the preparation process of concrete, the forming and stacking process of concrete blocks, and the curing process of concrete blocks. The invented automatic production process of the concrete block production process mainly includes the following processes: the pallet stacking and separating process, the block combining process and the block stacking process. It should be noted that, in the following description of the automatic production process of the concrete block rear production process of the present invention, the "forward movement" involved refers to the flow direction of the pallet 4 according to each process in the entire autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com