Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

A technology of cobalt tetroxide and positive electrode material, which is applied in battery electrodes, circuits, electrical components, etc., to achieve high automation, increase stability, and be suitable for industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

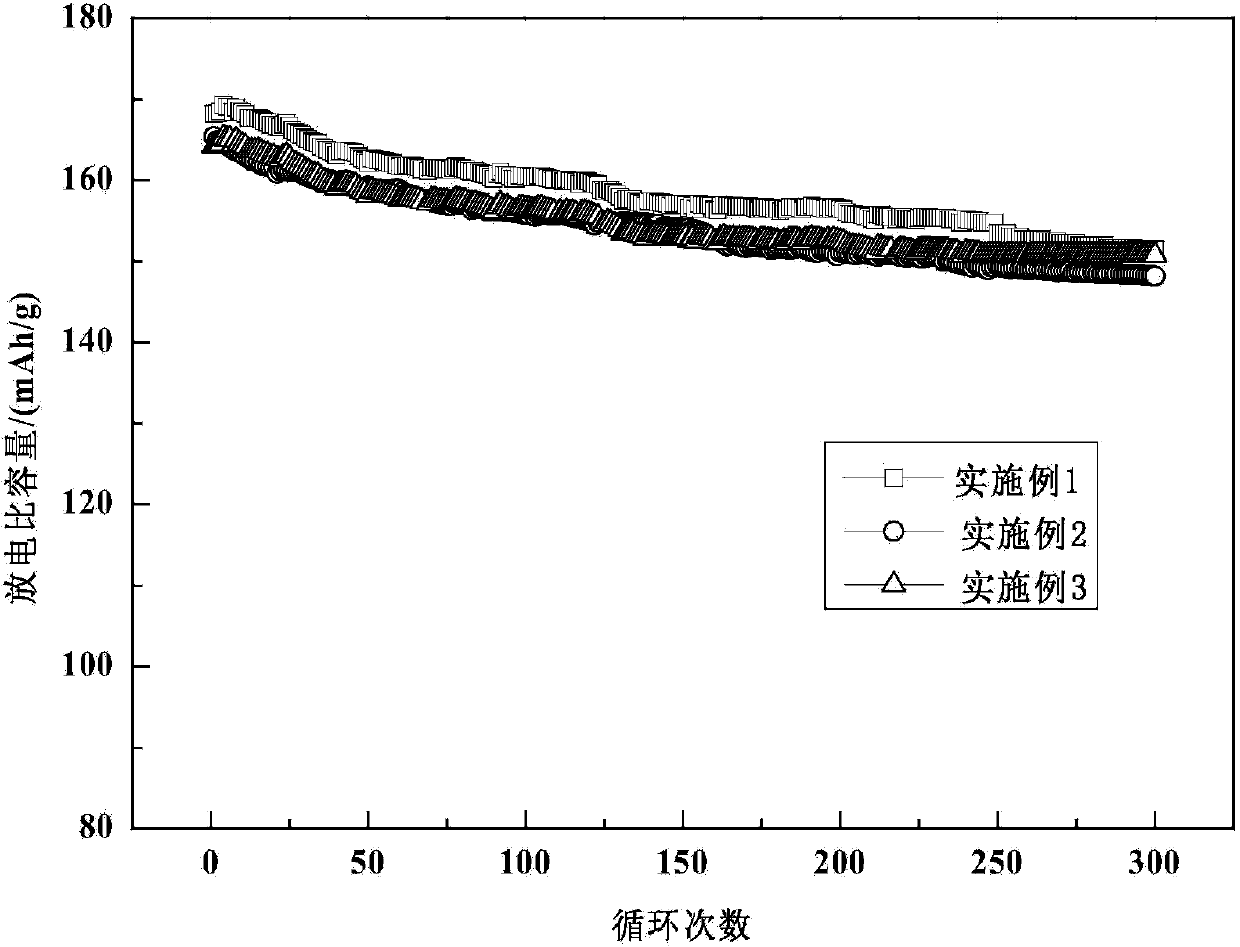

Embodiment 1

[0036] A preparation method of the high-voltage lithium cobaltate positive electrode material of the present invention, comprising the following steps:

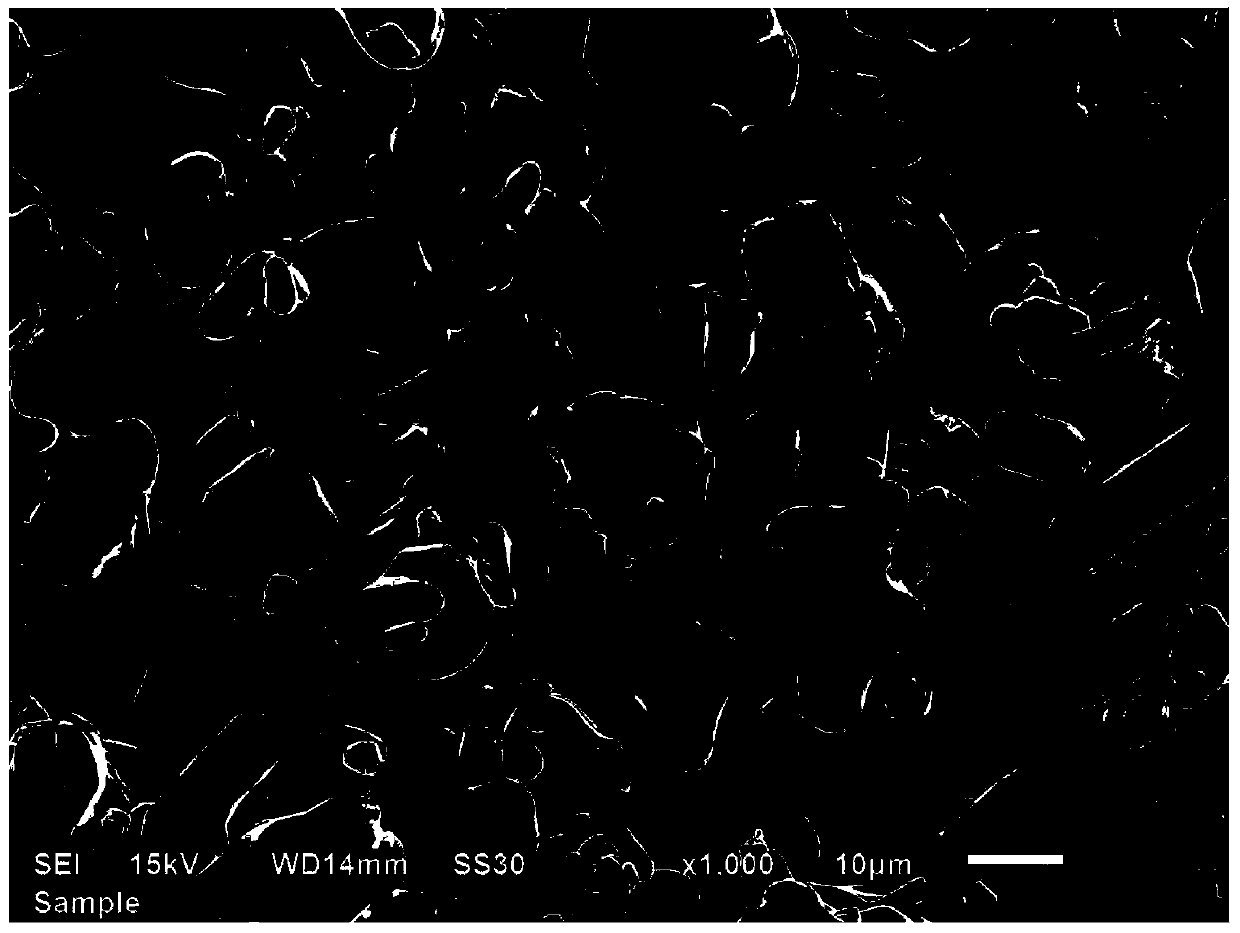

[0037] (1) Cobalt tetraoxide coating pretreatment: miscible tetraisopropyl titanate and absolute ethanol, the volume ratio of tetraisopropyl titanate and absolute ethanol is controlled at 1:10, forming clear tetraisopropyl titanate Ester mixed solution: Add the powder of tricobalt tetroxide into the tetraisopropyl titanate mixed solution under stirring to form a suspension, and keep stirring for 30 minutes until uniform. In the suspension, tetraisopropyl titanate accounts for three cobalt tetroxide and titanium The percentage of the total mass of tetraisopropyl titanate is 0.1wt%; then, deionized water is added dropwise to the mixed suspension, and the deionized water added dropwise is mixed with tetraisopropyl titanate mixed in the suspension. The volume ratio of the ester mixed solution is 1:1, until a uniform milky white s...

Embodiment 2

[0043] A preparation method of the high-voltage lithium cobaltate positive electrode material of the present invention, comprising the following steps:

[0044] (1) Cobalt tetraoxide coating pretreatment: miscible tetraisopropyl titanate and absolute ethanol, the volume ratio of tetraisopropyl titanate and absolute ethanol is controlled to 1:20, forming clear tetraisopropyl titanate Ester mixture; in the state of stirring, add the powder of tricobalt tetroxide into the tetraisopropyl titanate mixture to form a suspension, and keep stirring for 30 minutes until uniform; in the suspension, tetraisopropyl titanate accounts for three cobalt tetroxide and titanium The percentage of the total mass of tetraisopropyl titanate is 0.1wt%; then, deionized water is added dropwise to the mixed suspension, and the deionized water added dropwise is mixed with tetraisopropyl titanate mixed in the suspension. The volume ratio of the ester mixed solution is 1:1, until a uniform milky white susp...

Embodiment 3

[0050] A preparation method of the high-voltage lithium cobaltate positive electrode material of the present invention, comprising the following steps:

[0051] (1) Cobalt tetroxide coating pretreatment: miscible tetrabutyl titanate solution and absolute ethanol, the volume ratio of tetrabutyl titanate and absolute ethanol is controlled to 1:50, forming a clear mixture of tetrabutyl titanate solution; in the state of stirring, add the powder of tricobalt tetroxide into the tetrabutyl titanate mixture to form a suspension, and keep stirring for 30 minutes until uniform; in the suspension, tetrabutyl titanate accounts for three cobalt tetroxide and tetrabutyl titanate The percentage of the total mass of the solution is 10wt%; then, deionized water is added dropwise to the mixed suspension, and the volume ratio of the dropped deionized water to the tetrabutyl titanate mixed solution mixed in the suspension is 1:1, until a uniform milky white suspension is formed, then stir for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com