Patents

Literature

97results about How to "Guaranteed specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

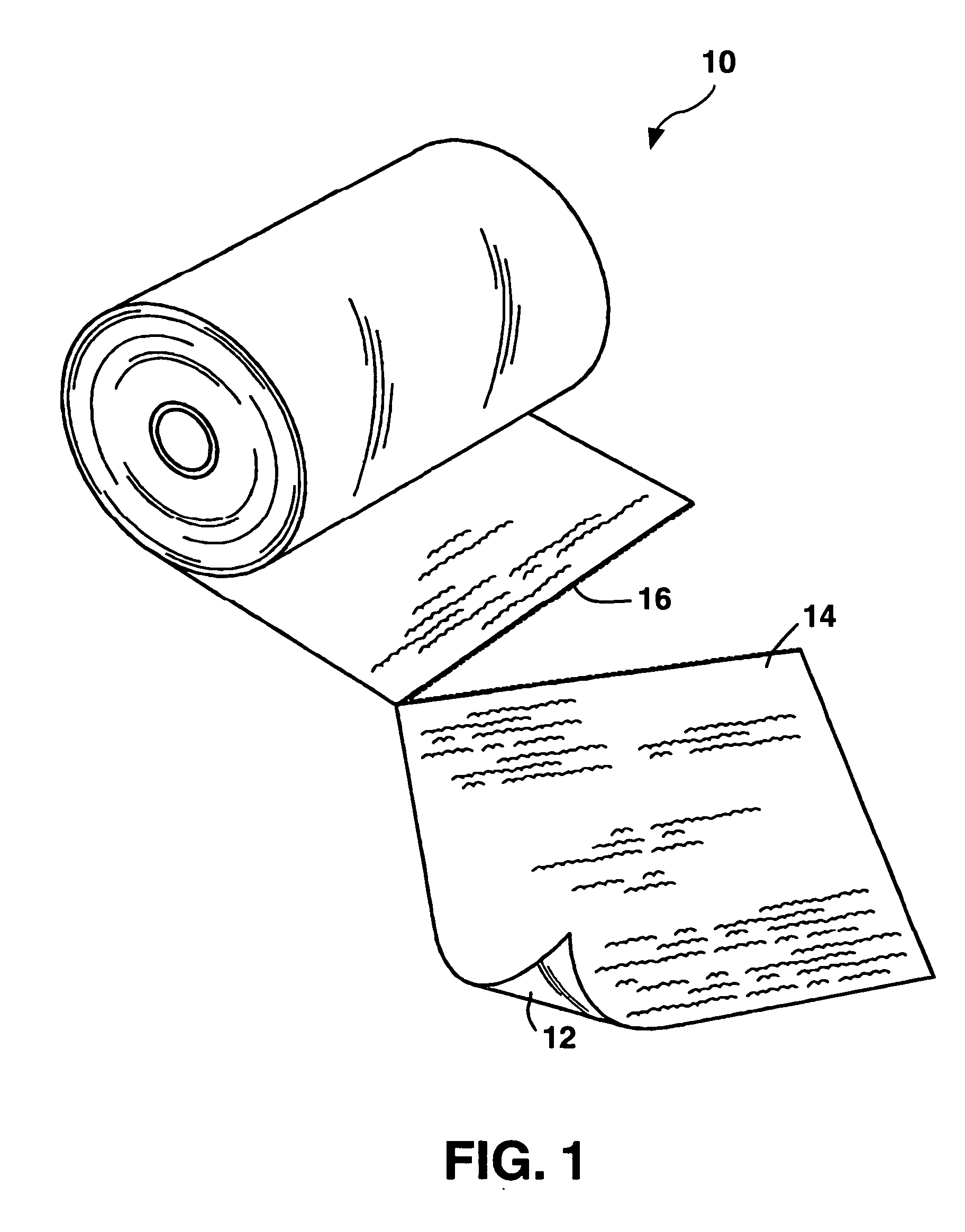

Disposable food preparation mats, cutting sheets, placemats, and the like

InactiveUS20060093788A1Decrease liquid permeable propertyGood bulkSynthetic resin layered productsCooking vesselsEngineeringFiber

Disposable liquid absorbent mats are described. The mats generally include at least a liquid absorbent layer and a liquid impervious layer. The liquid absorbent layer may be made from a tissue web, a hydroentangled web, an airlaid web, a coform web, and the like. The liquid impervious layer, on the other hand, may comprise a meltspun web, a film, a hydroentangled web, or even a tissue web that has been treated with a sizing agent that renders the web resistant to fluid flow. In one embodiment, the mats can be made so as to have a relatively low caliper so that the mats can be spirally wound into a roll. In other embodiments, however, the mats may be packaged in a stacked arrangement. The mats have various uses and applications. For instance, the mats are well suited for use during food preparation. The mats are well suited to absorbing fluids while preventing the fluids from striking through the product. In some embodiments, the mats are also well suited to serve as an absorbent and cut resistant surface. An added benefit is the addition of a layer of polymer to the bottom side of the film to achieve non-slip feature to an absorbent and cut resistant food prep mat.

Owner:KIMBERLY-CLARK WORLDWIDE INC

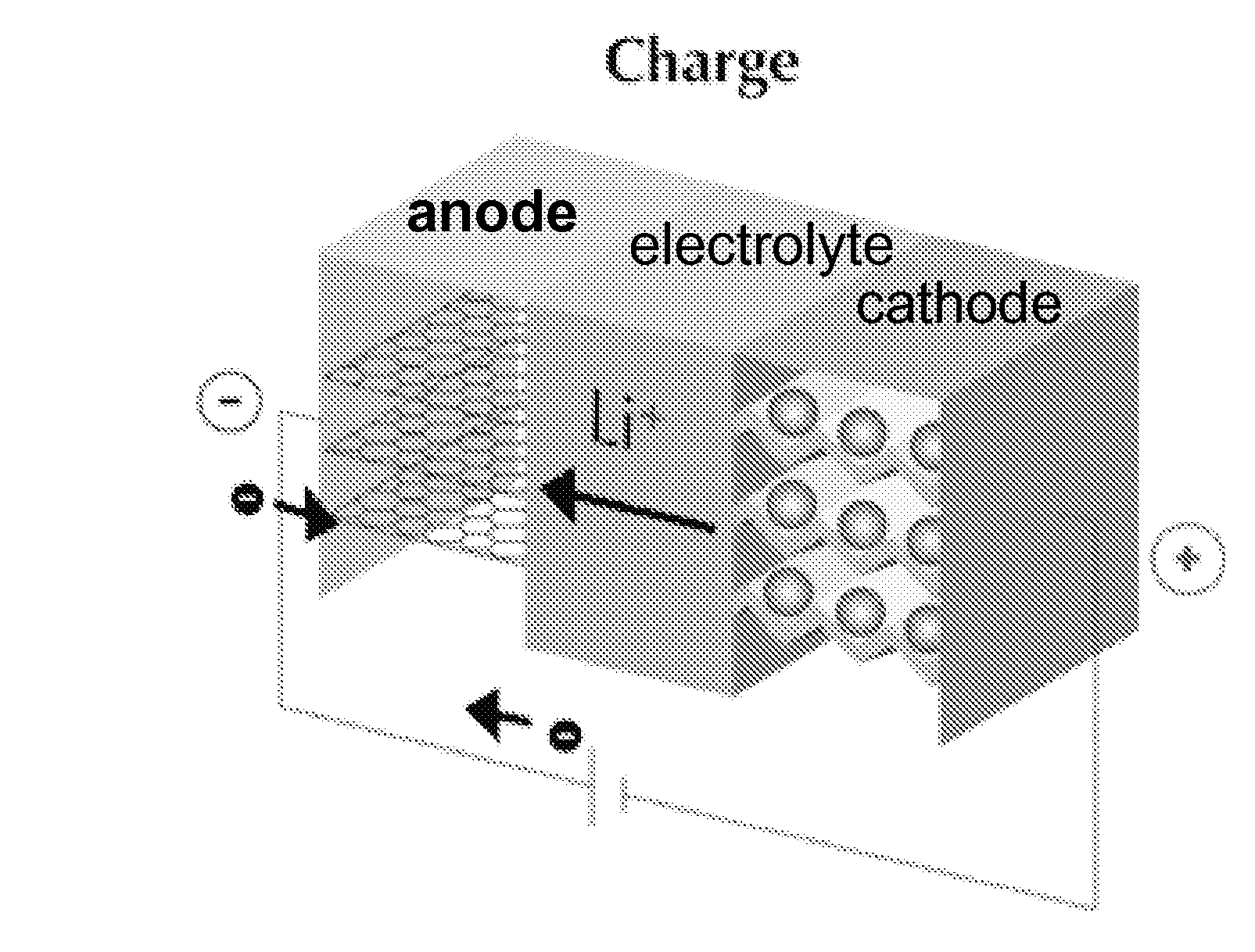

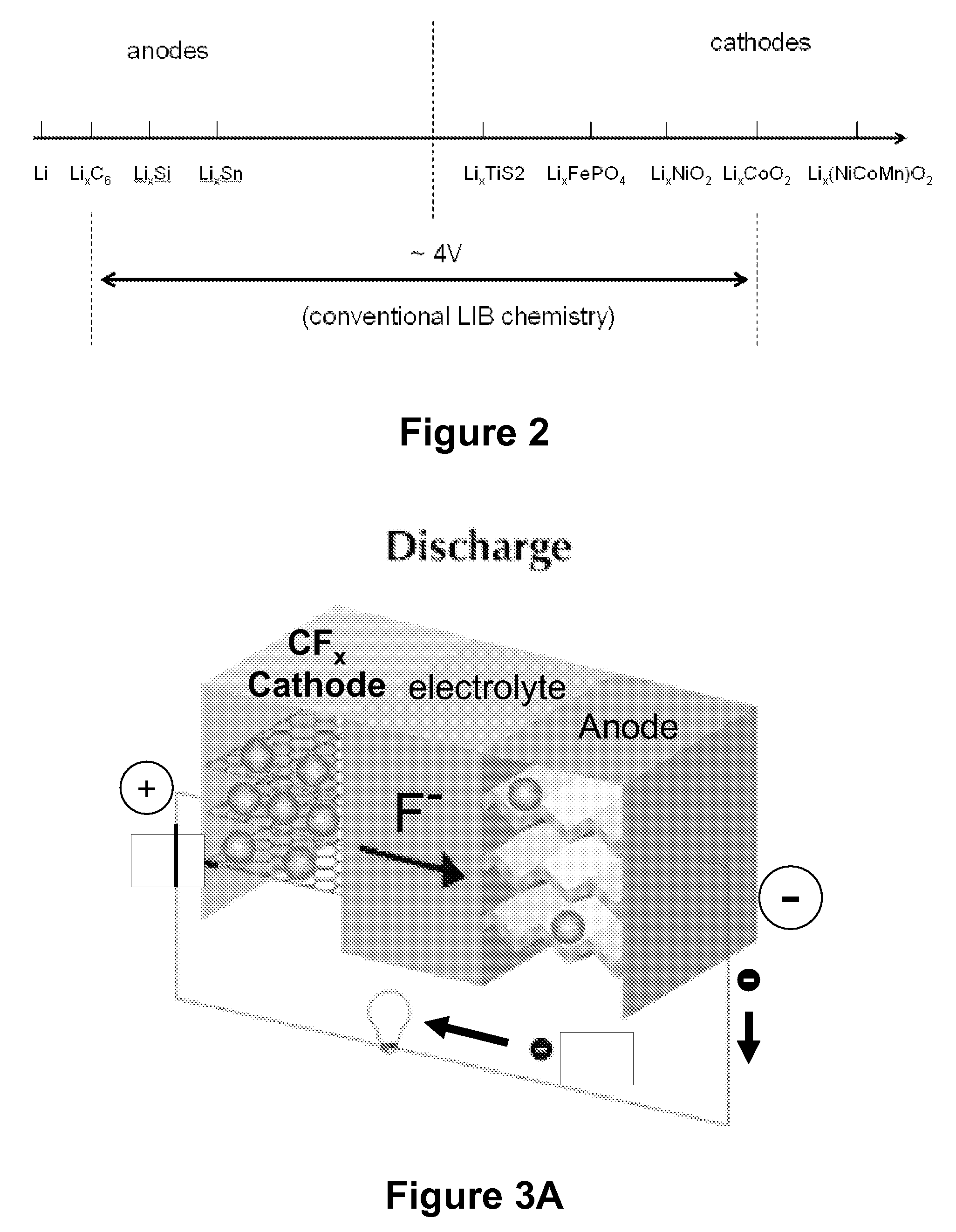

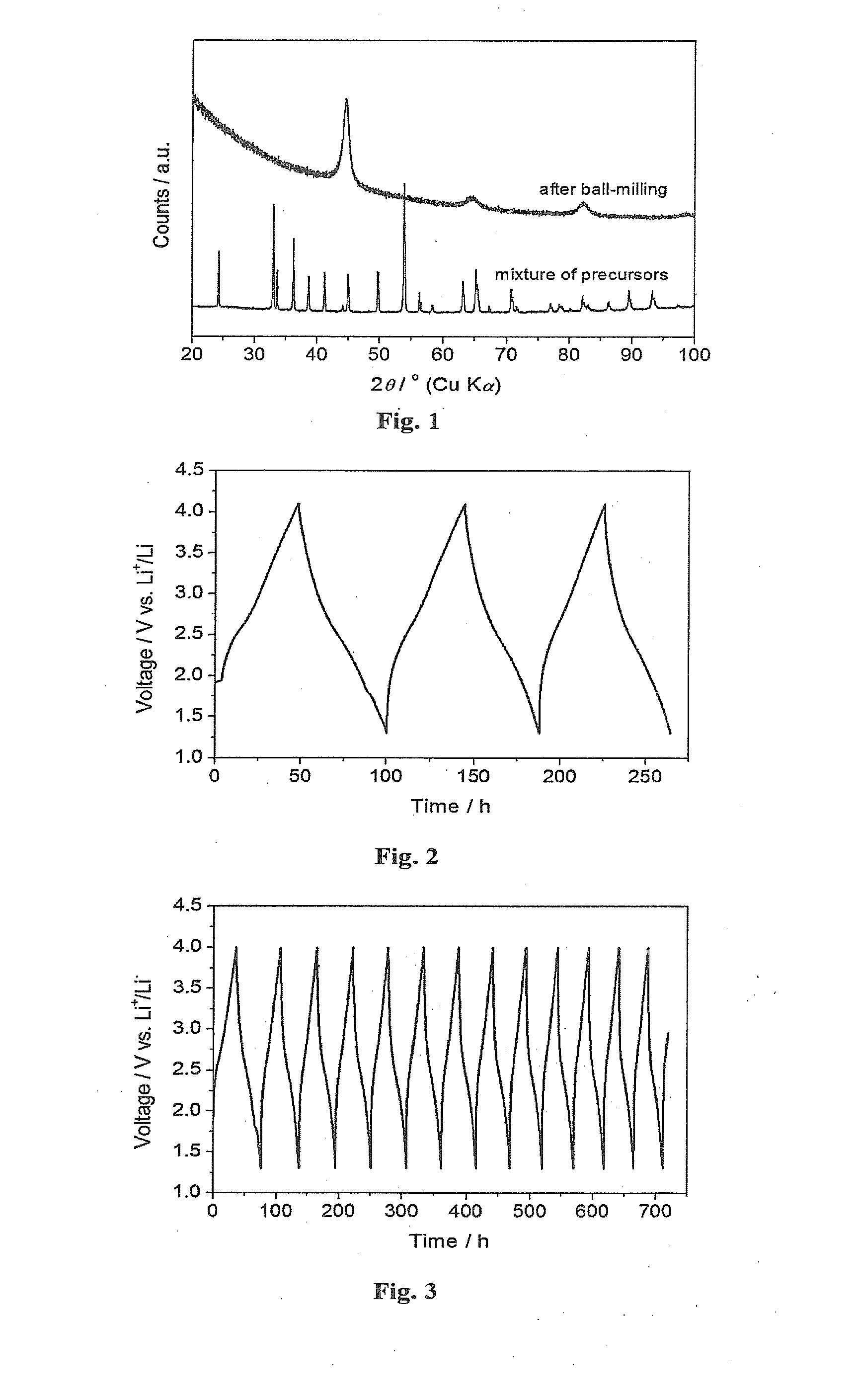

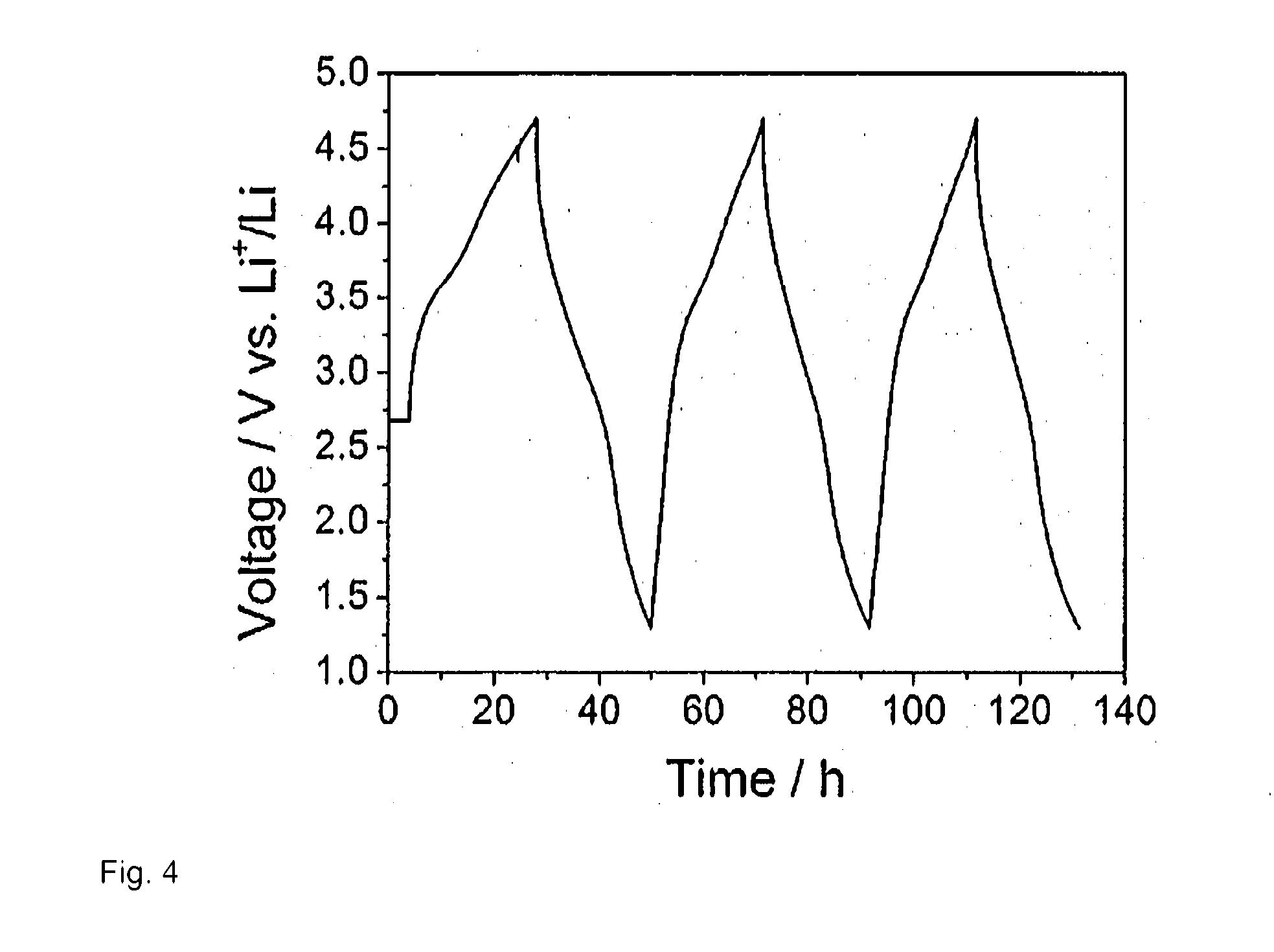

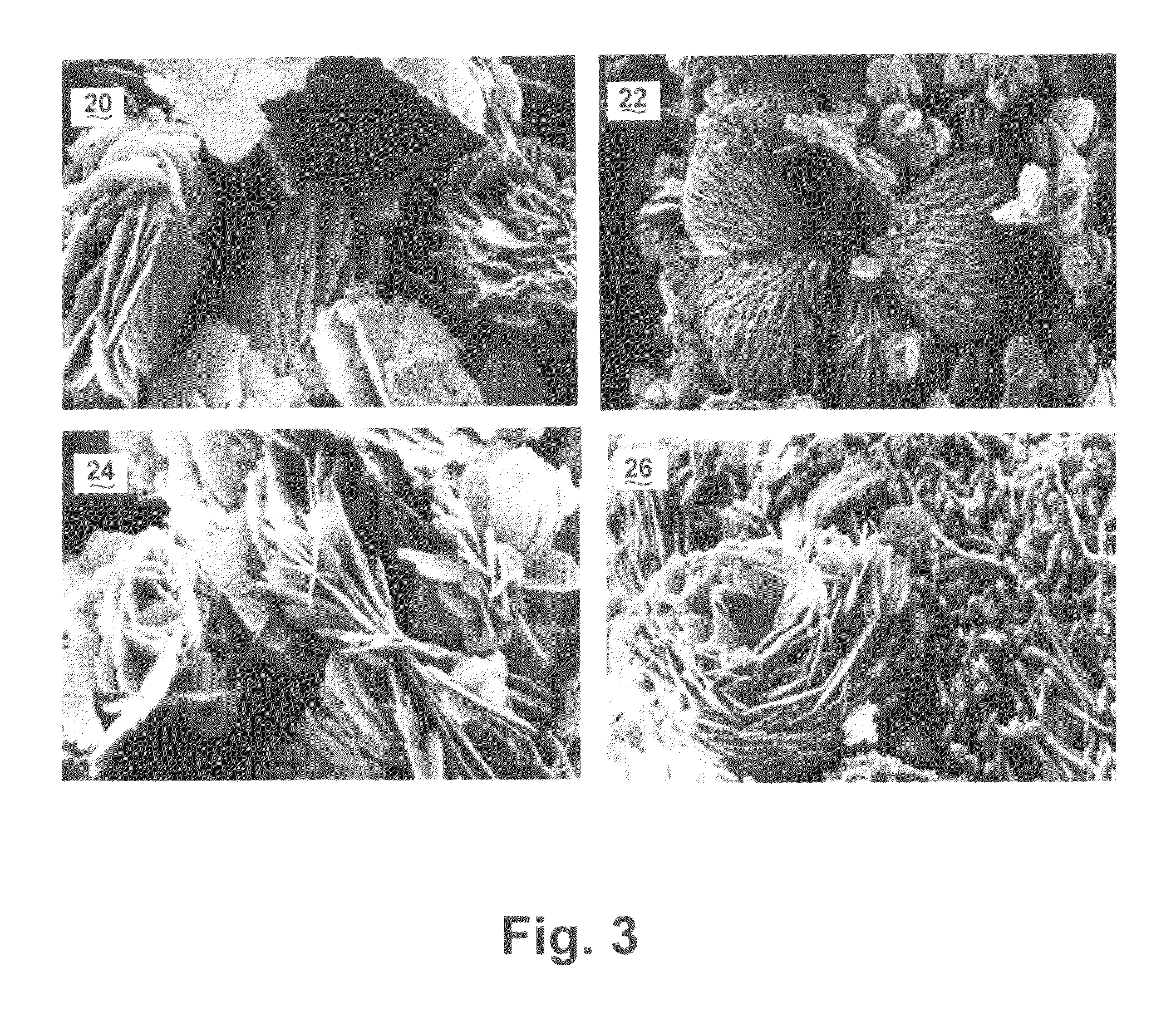

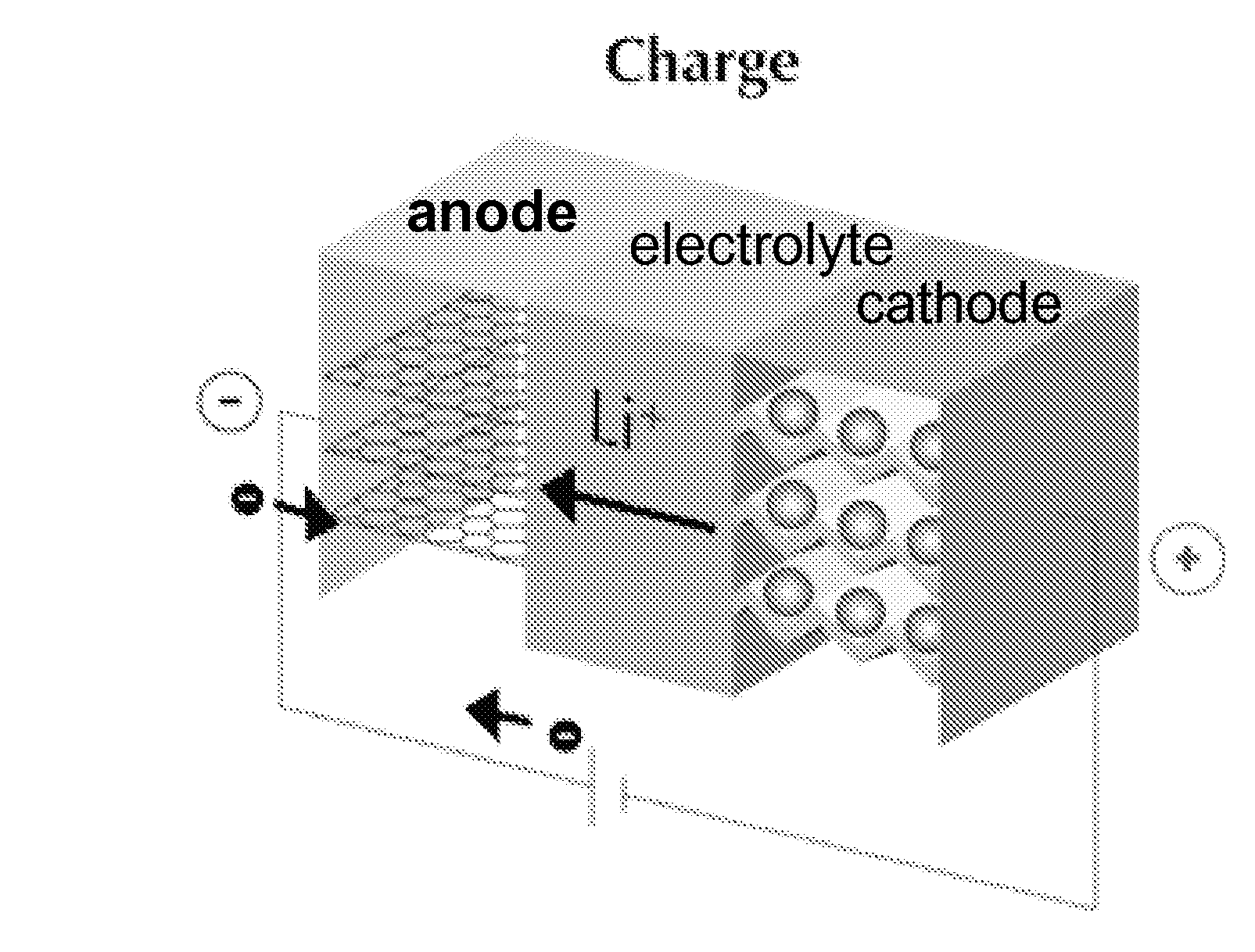

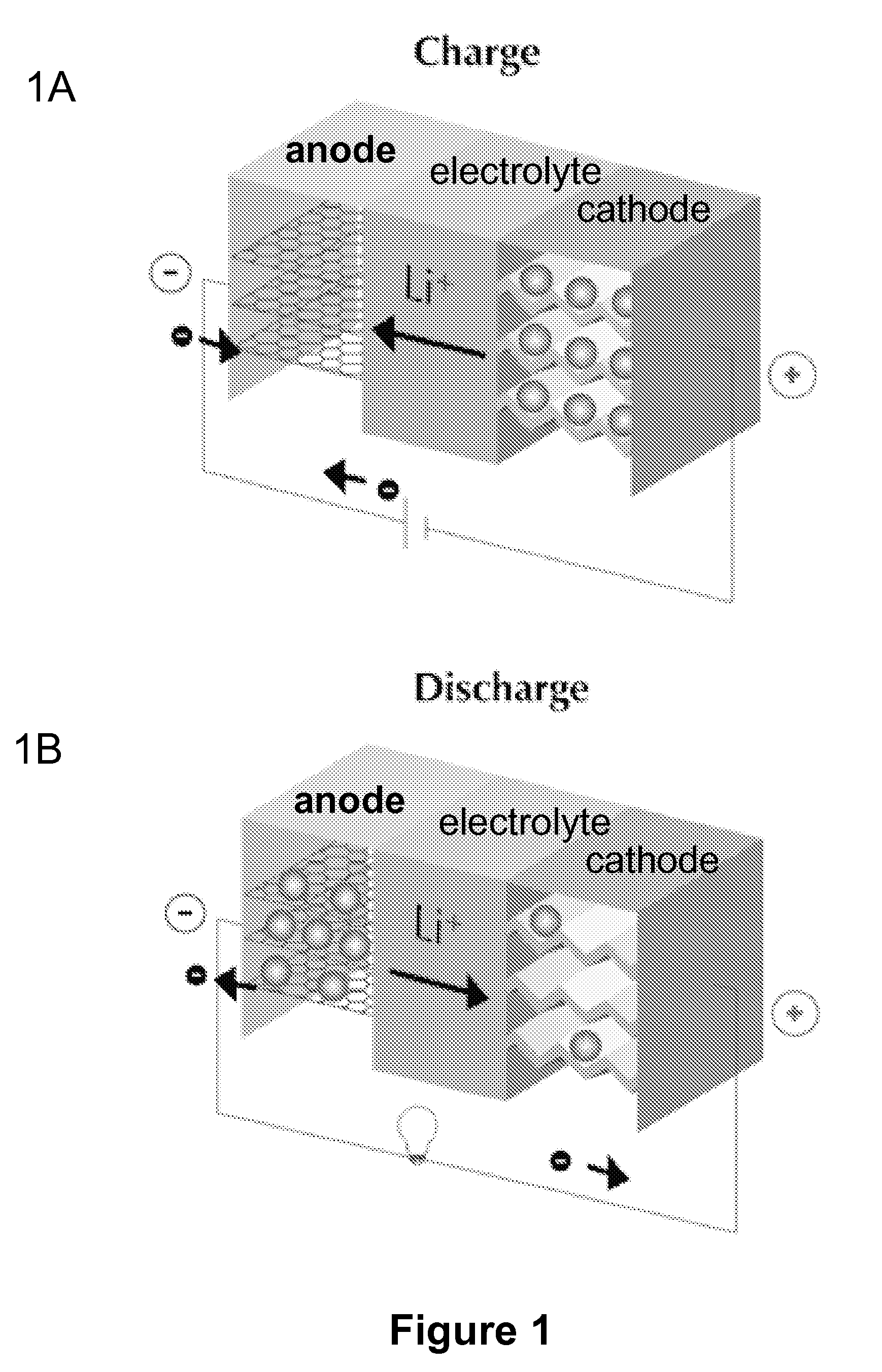

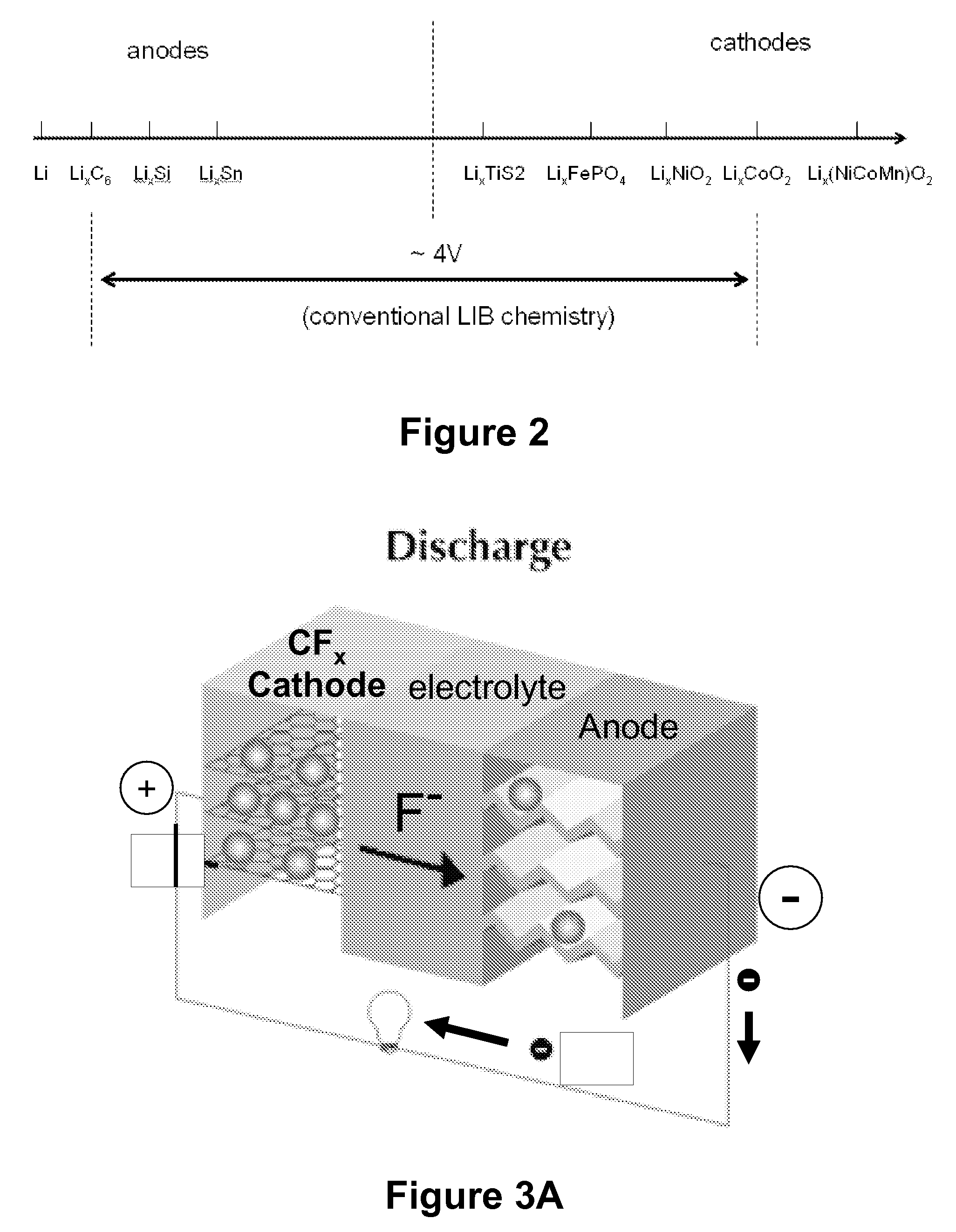

Fluoride ion electrochemical cell

ActiveUS20090029237A1Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

The present invention provides electrochemical cells capable of good electronic performance, particularly high specific energies, useful discharge rate capabilities and good cycle life. Electrochemical cells of the present invention are versatile and include primary and secondary cells useful for a range of important applications including use in portable electronic devices. Electrochemical cells of the present invention also exhibit enhanced safety and stability relative to conventional state of the art primary lithium batteries and lithium ion secondary batteries. For example, electrochemical cells of the present invention include secondary electrochemical cells using anion charge carriers capable of accommodation by positive and negative electrodes comprising anion host materials, which entirely eliminate the need for metallic lithium or dissolved lithium ion in these systems.

Owner:CALIFORNIA INST OF TECH +1

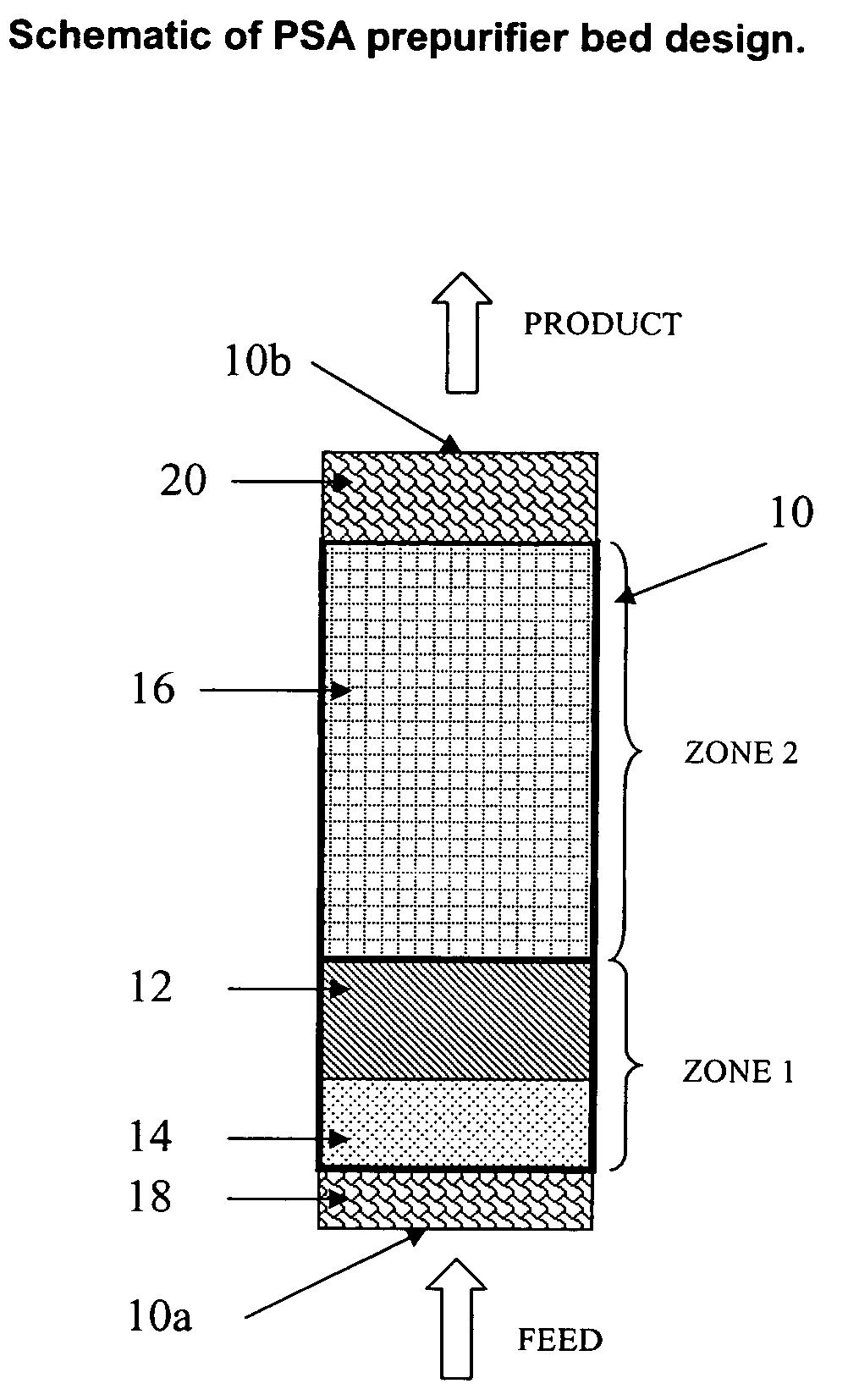

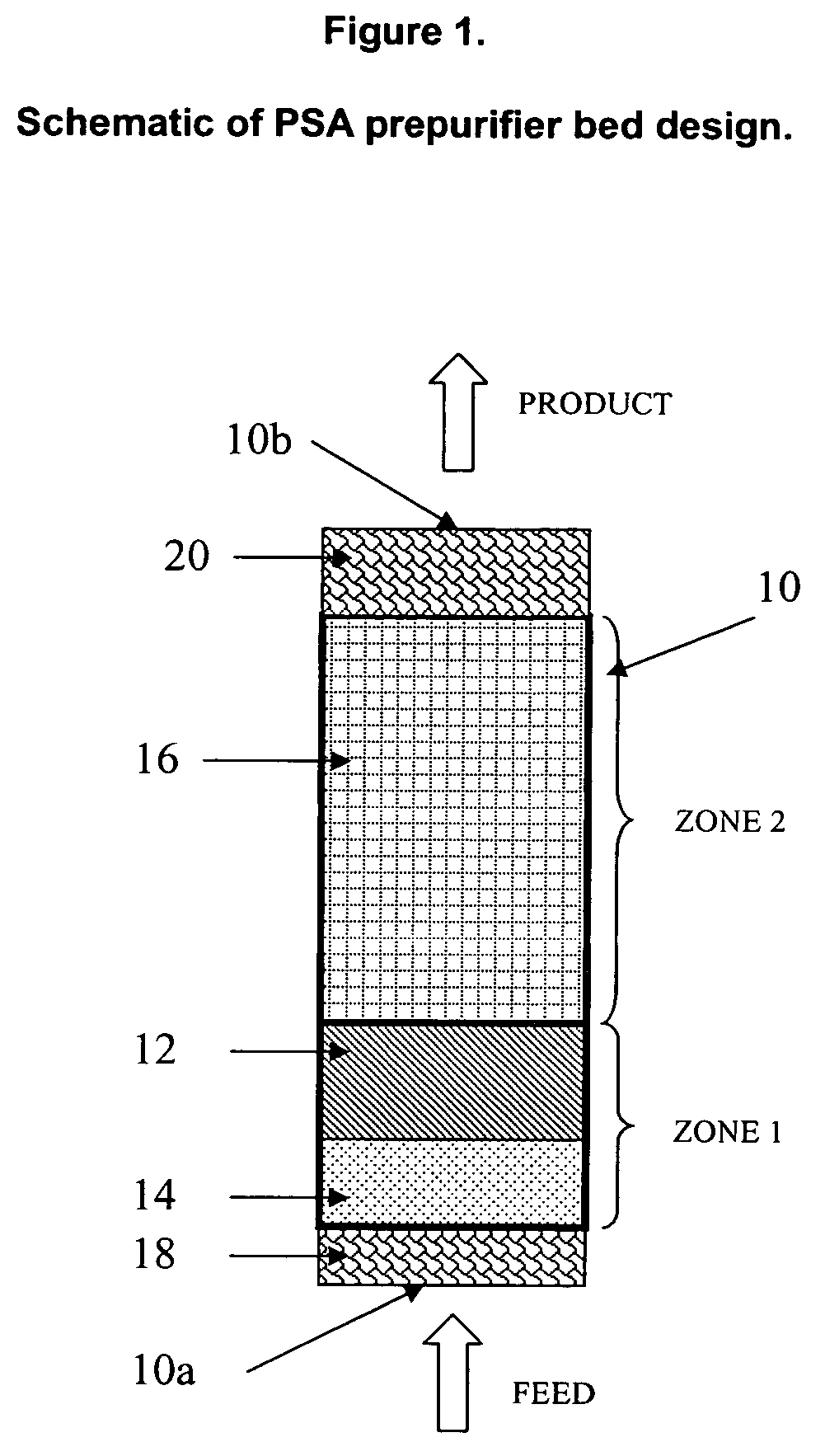

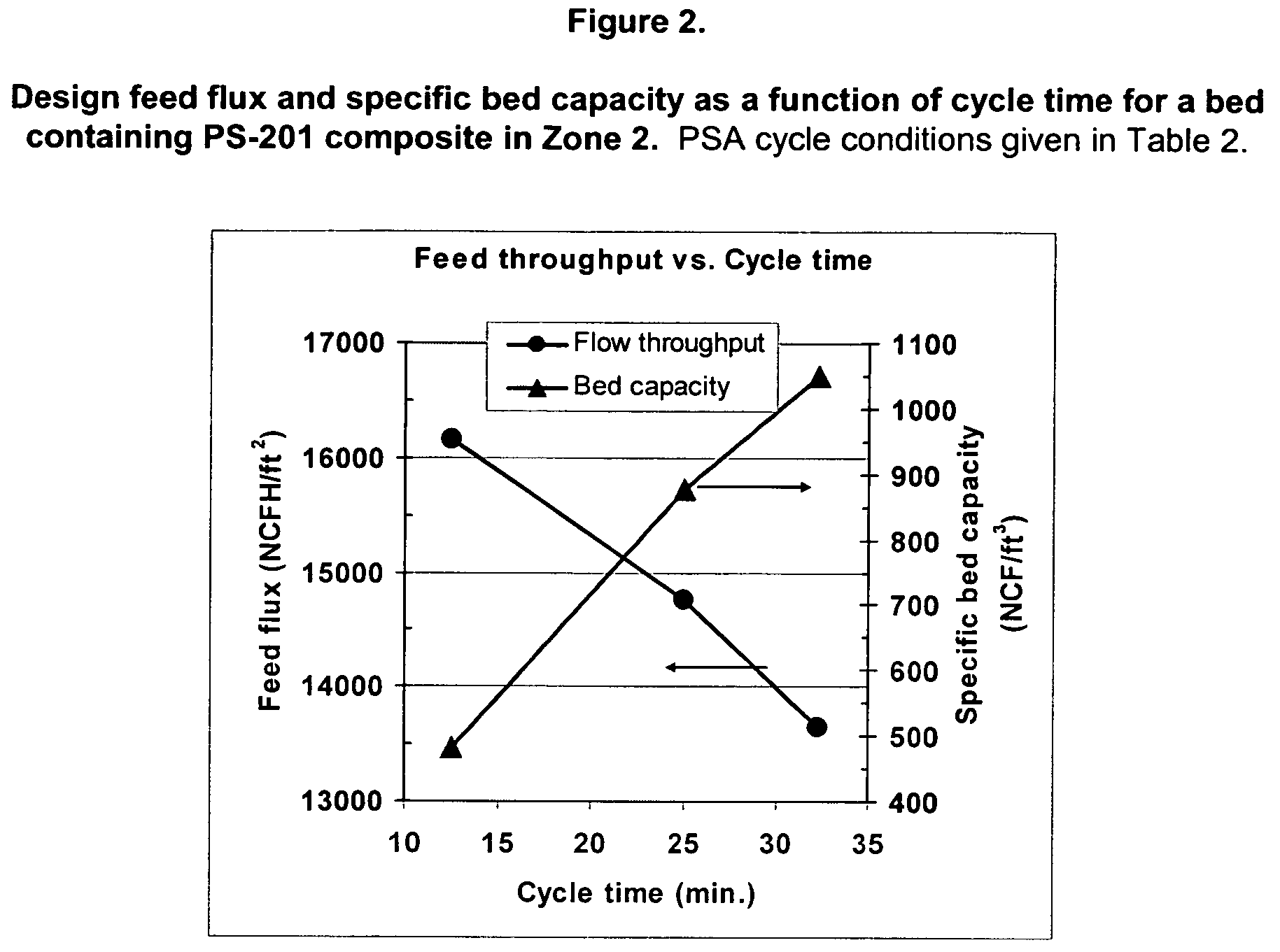

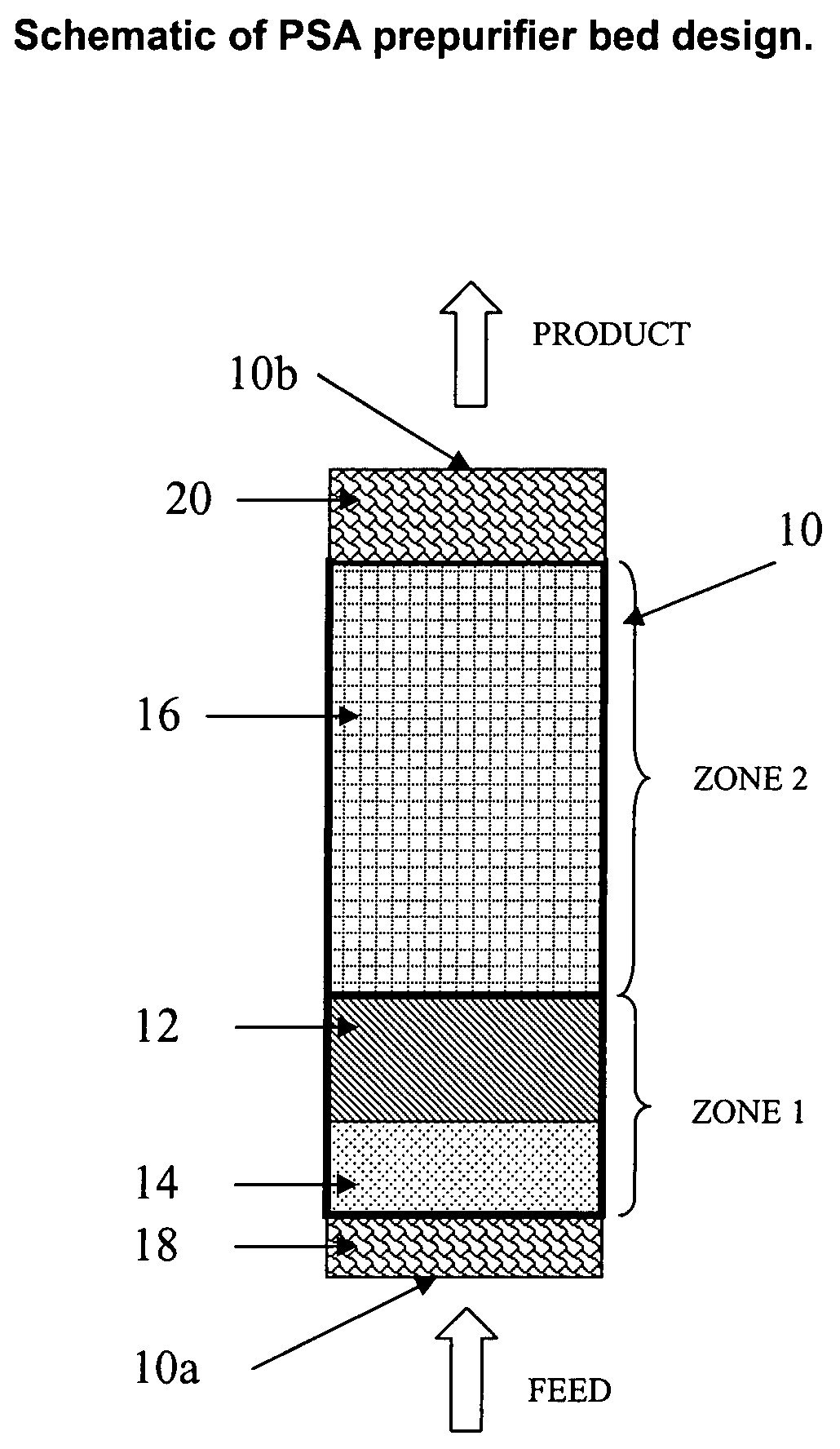

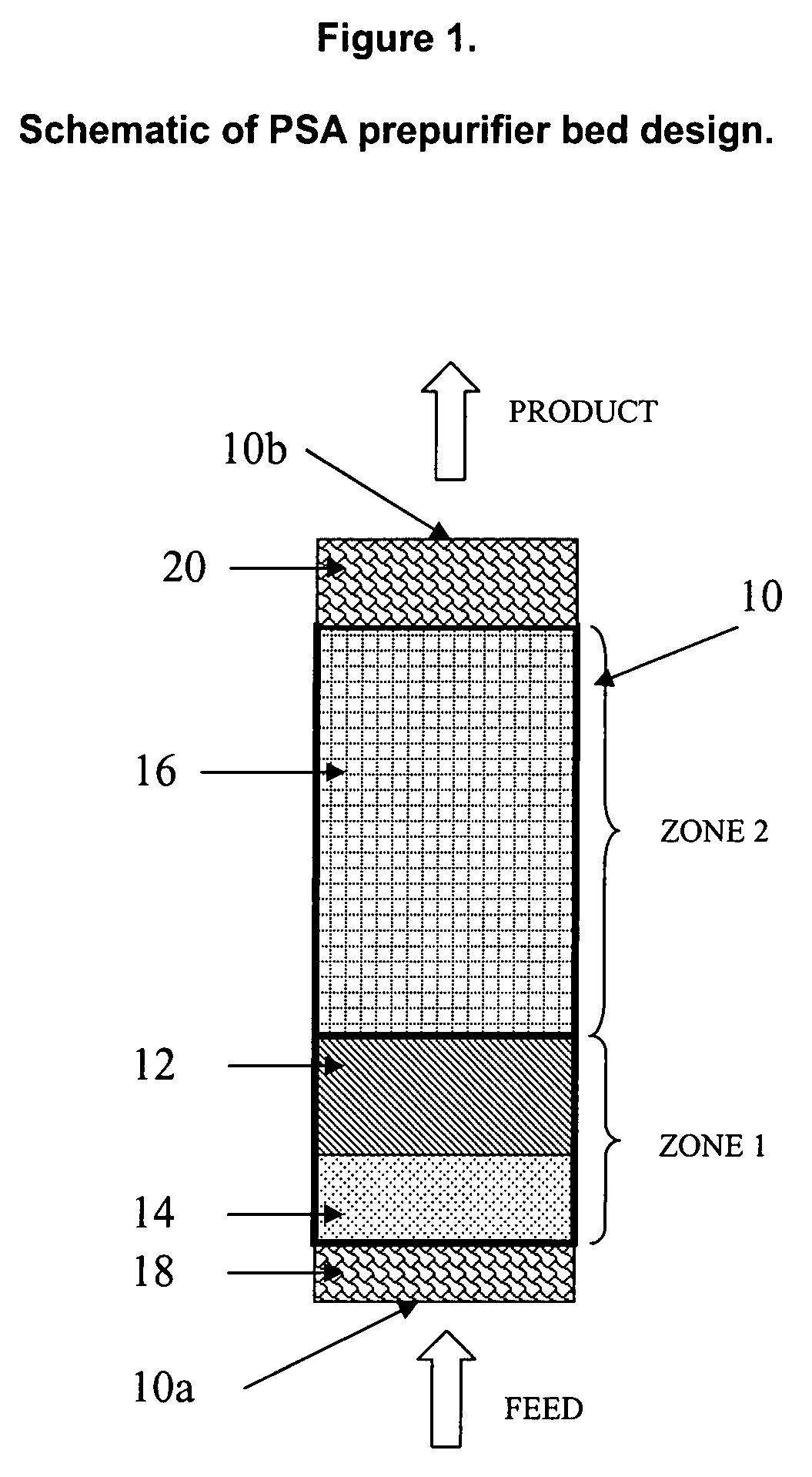

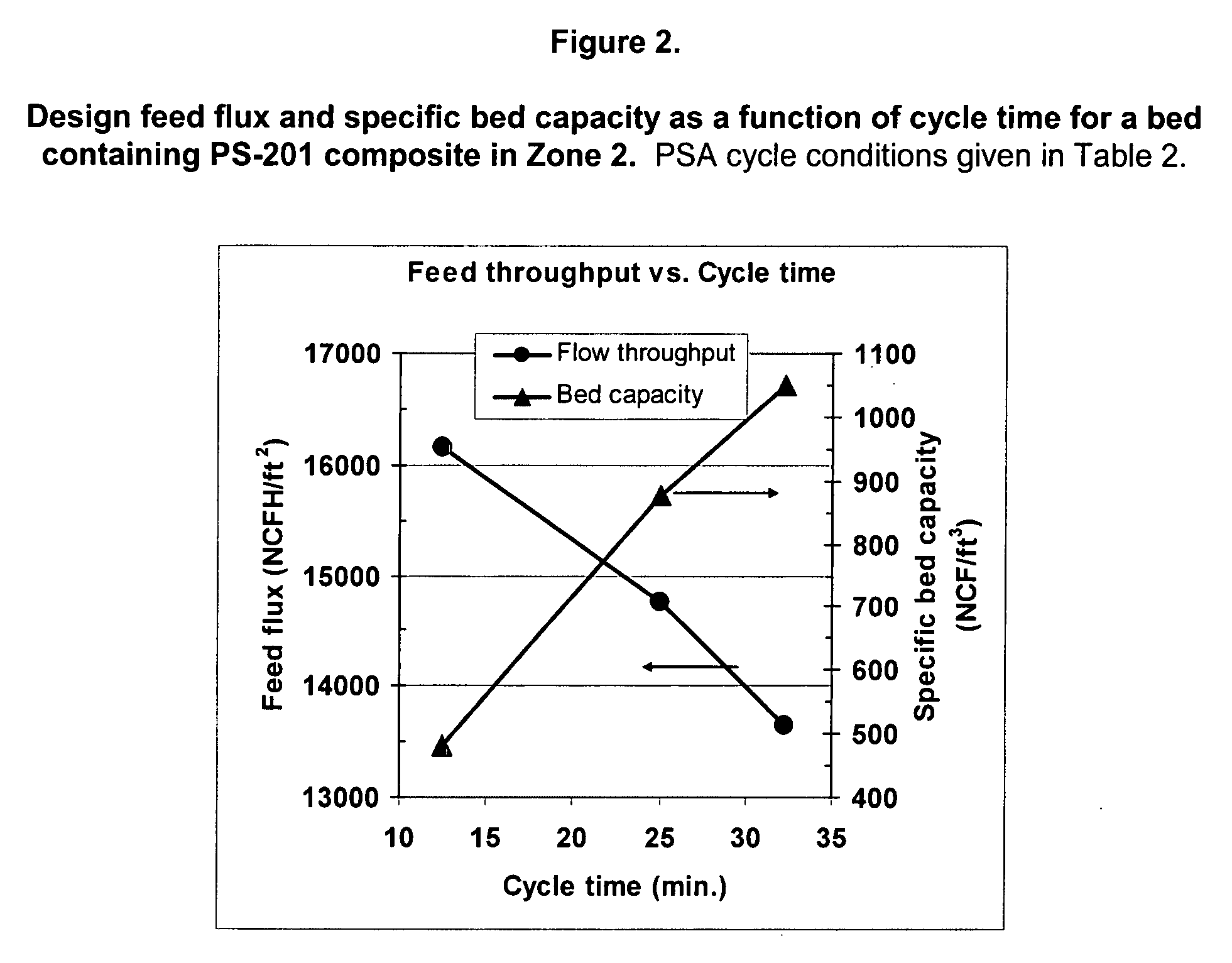

Adsorbents for pressure swing adsorption systems and methods of use therefor

InactiveUS7713333B2Reduce frequencyMaintain purityGas treatmentIsotope separationPurification methodsSorbent

The present invention relates generally to adsorbents for use in pressure swing adsorption (PSA) prepurification processes. The invention more particularly relates to the design of adsorbent zones to be used in PSA prepurification processes that are expected to provide for extensions in PSA cycle time, thereby reducing blowdown loss and operating costs associated with the process. One particular embodiment of the present invention includes a first adsorption zone containing activated alumina and a second adsorption zone of an alumina-zeolite mixture or composite adsorbent in which the volume of the first zone does not exceed 50% of the total volume of the first and second zone.

Owner:PRAXAIR TECH INC

Molecularly imprinted phosphate binders for therapeutic use

InactiveUS20050276781A1Increase surface areaSpecific binding capacityOrganic dyesSynthetic polymeric active ingredientsPhosphateCalcium Binder

Methods for synthesizing molecularly imprinted polymers (MIP) having an affinity for dietary phosphates, resulting polymers, pharmaceutical compositions and modes of administration are disclosed. The MIP compounds are useful for binding excess dietary phosphates in a patient in need thereof.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Lithium-ion battery positive electrode material and preparation method thereof

InactiveUS20150079471A1Good stretchabilityGood ductibilitySilver accumulatorsPositive electrodesLithium-ion batteryDiffusion layer

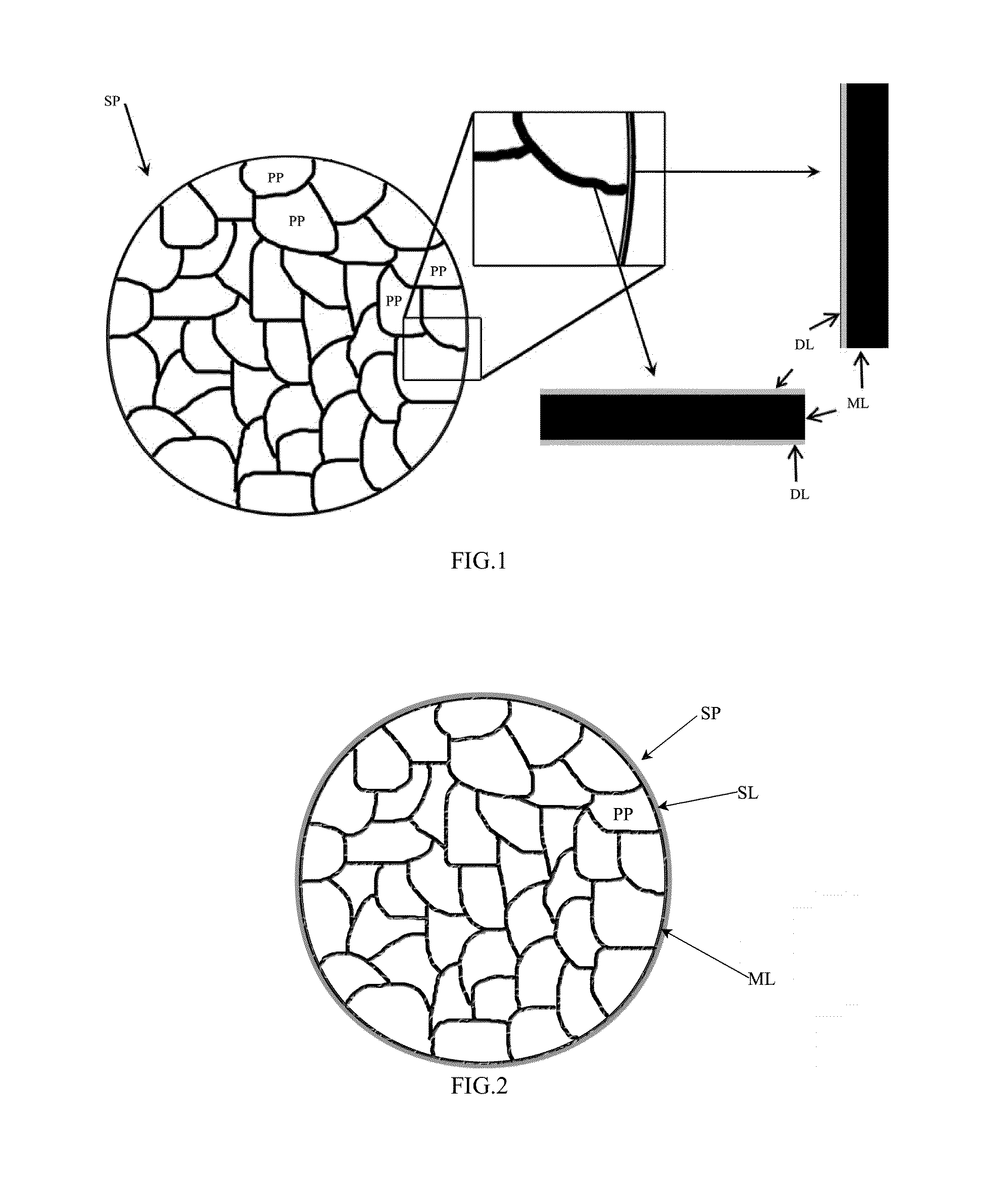

The present disclosure provides a lithium-ion battery positive electrode material and a preparation method thereof. In the lithium-ion battery positive electrode material, a secondary particle comprises lithium-containing multi-element transition metal oxide primary particles and a second phase material, a second phase material forms a second phase material layer distributed on a surface of the primary particle and forms a diffusion layer together with the lithium-containing multi-element transition metal oxide by means of atoms mutual diffusion to make the second phase material layer combined with the primary particle during formation of the secondary particle from the primary particles, thereby effectively suppressing chalking of the secondary particle along boundary among the primary particles, and effectively controlling size of the primary particles and the secondary particles, and improving specific capacity, cycling performance and safety performance of a lithium-ion battery to which the lithium-ion battery positive electrode material is applied.

Owner:NINGDE AMPEREX TECH +1

Pre-sulfurized cathode for alkali metal-sulfur secondary battery and production process

ActiveUS20160240841A1High storing/releasing rateImprove cycle lifeElectrode manufacturing processesFinal product manufacturePorous grapheneSulfur

A method of producing a pre-sulfurized active cathode layer for a rechargeable alkali metal-sulfur cell; the method comprising: (a) Preparing an integral layer of porous graphene structure having a specific surface area greater than 100 m2 / g; (b) Preparing an electrolyte comprising a solvent and a sulfur source; (c) Preparing an anode; and (d) Bringing the integral layer and the anode in ionic contact with the electrolyte and imposing an electric current between the anode and the integral layer (serving as a cathode) to electrochemically deposit nano-scaled sulfur particles or coating on the graphene surfaces. The sulfur particles or coating have a thickness or diameter smaller than 20 nm (preferably <10 nm, more preferably <5 nm or even <3 nm) and occupy a weight fraction of at least 70% (preferably >90% or even >95%).

Owner:GLOBAL GRAPHENE GRP INC

Novel glycolipid and use thereof

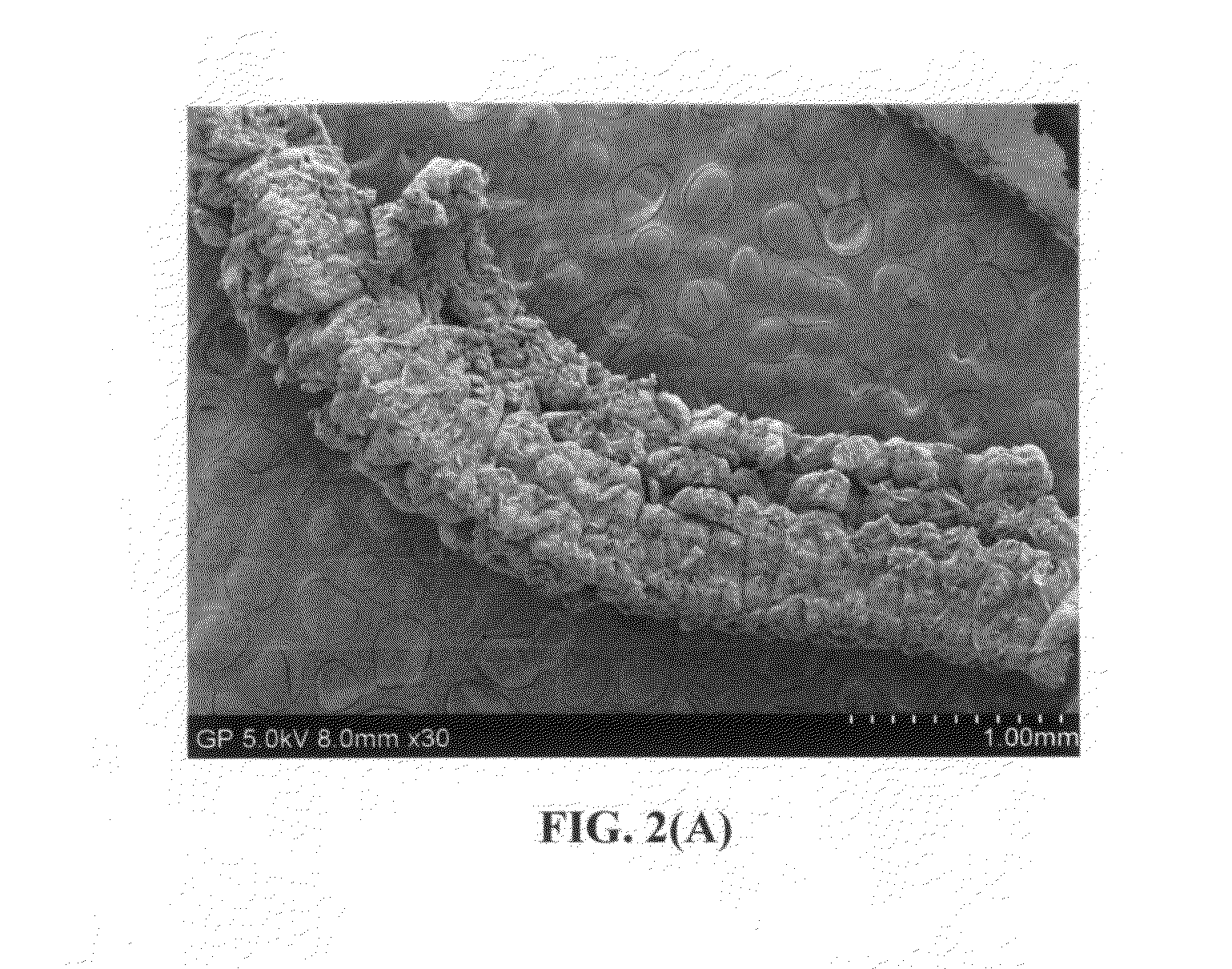

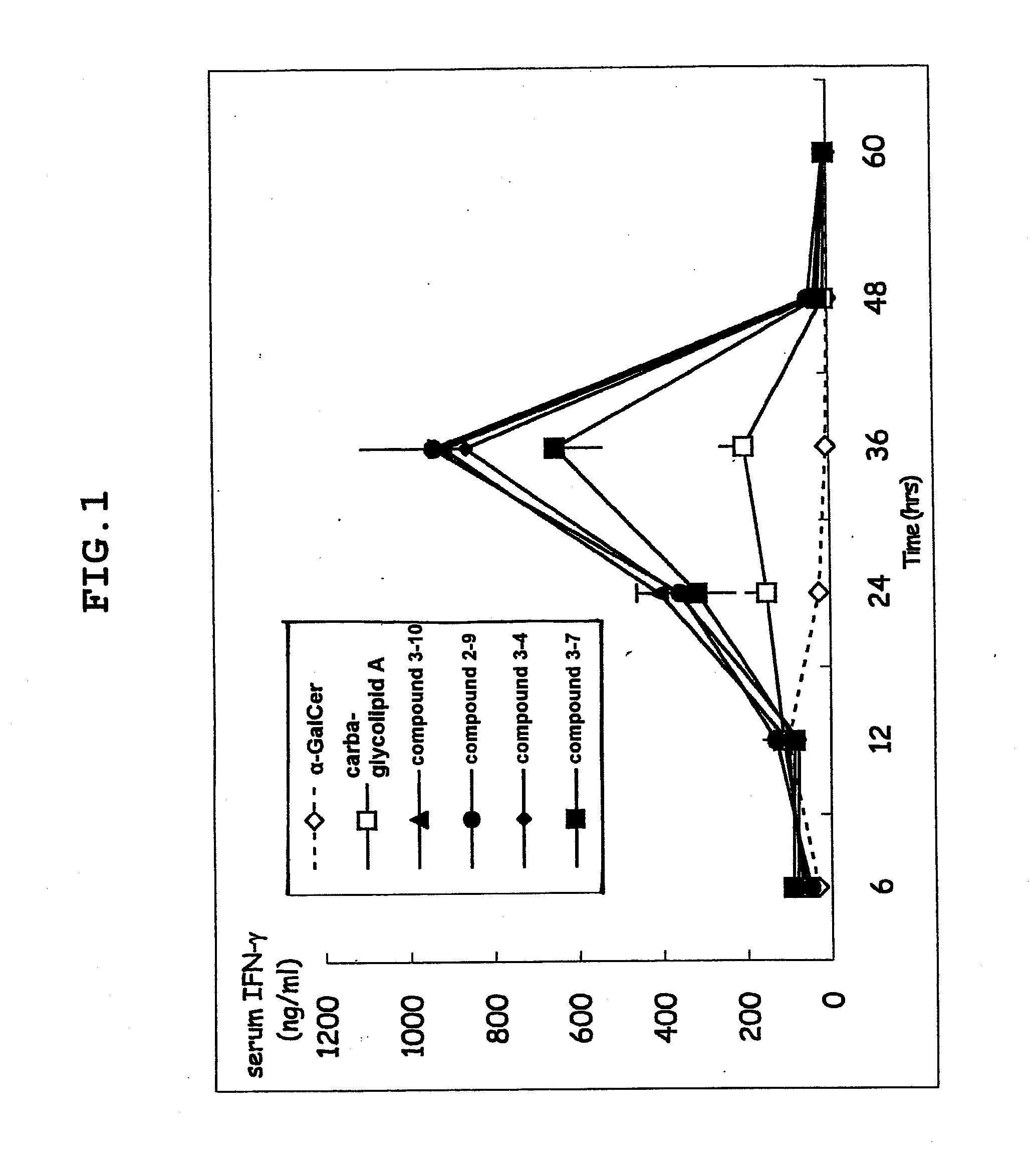

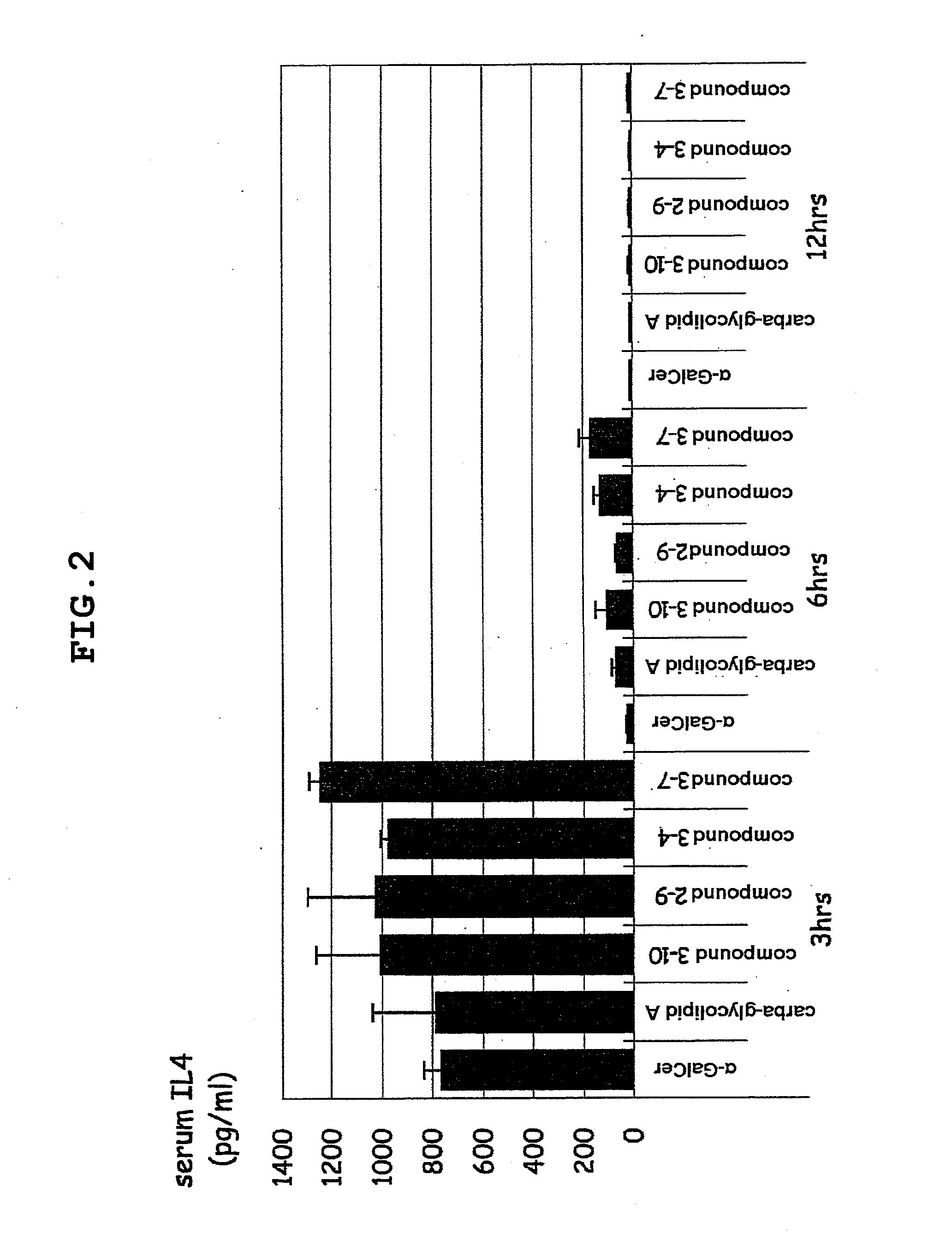

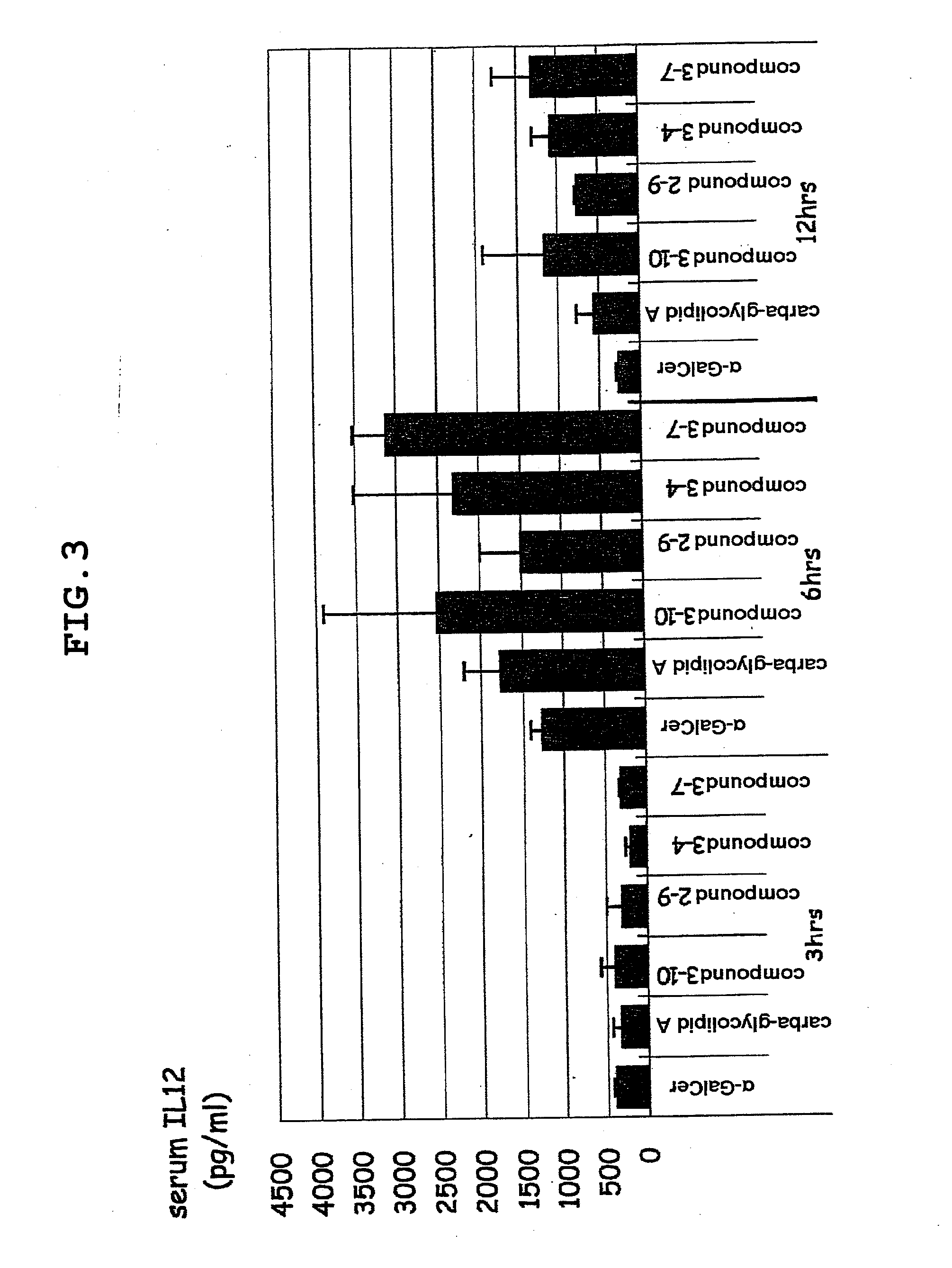

ActiveUS20110104188A1Guaranteed specific capacityEffective treatmentBiocideSkeletal disorderCancer treatmentGlycolipid

The invention provides a glycolipid effective for cancer treatment and the like and a synthetic intermediate therefor, as well as a medicament containing the glycolipid and the like. The glycolipid is represented by the formula (1) or a salt thereof

Owner:RIKEN

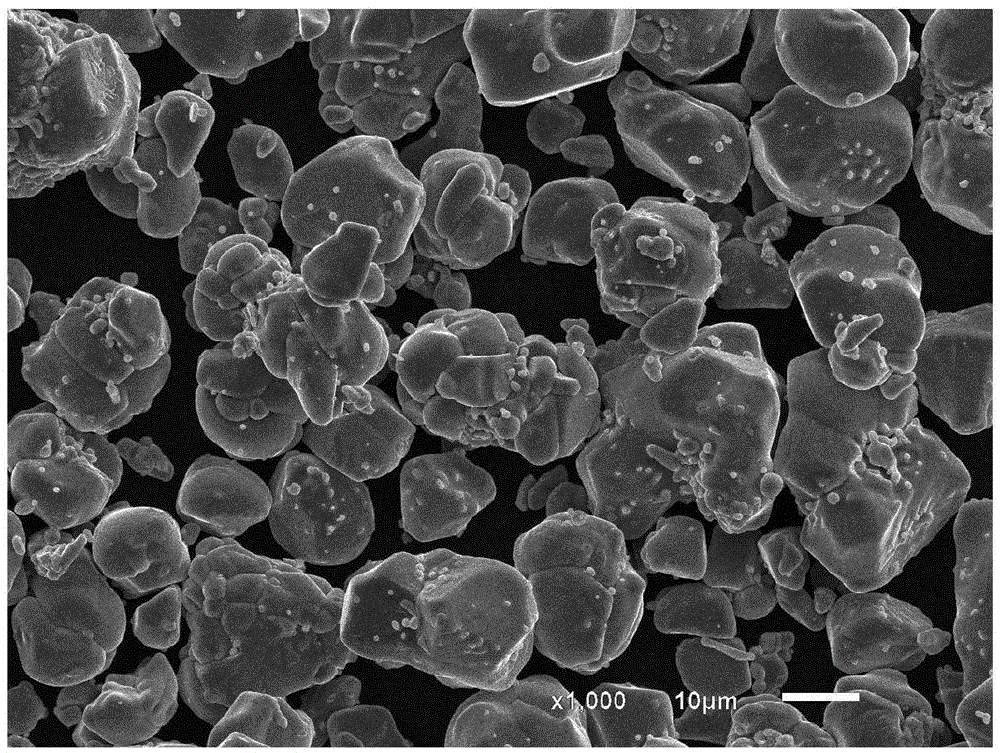

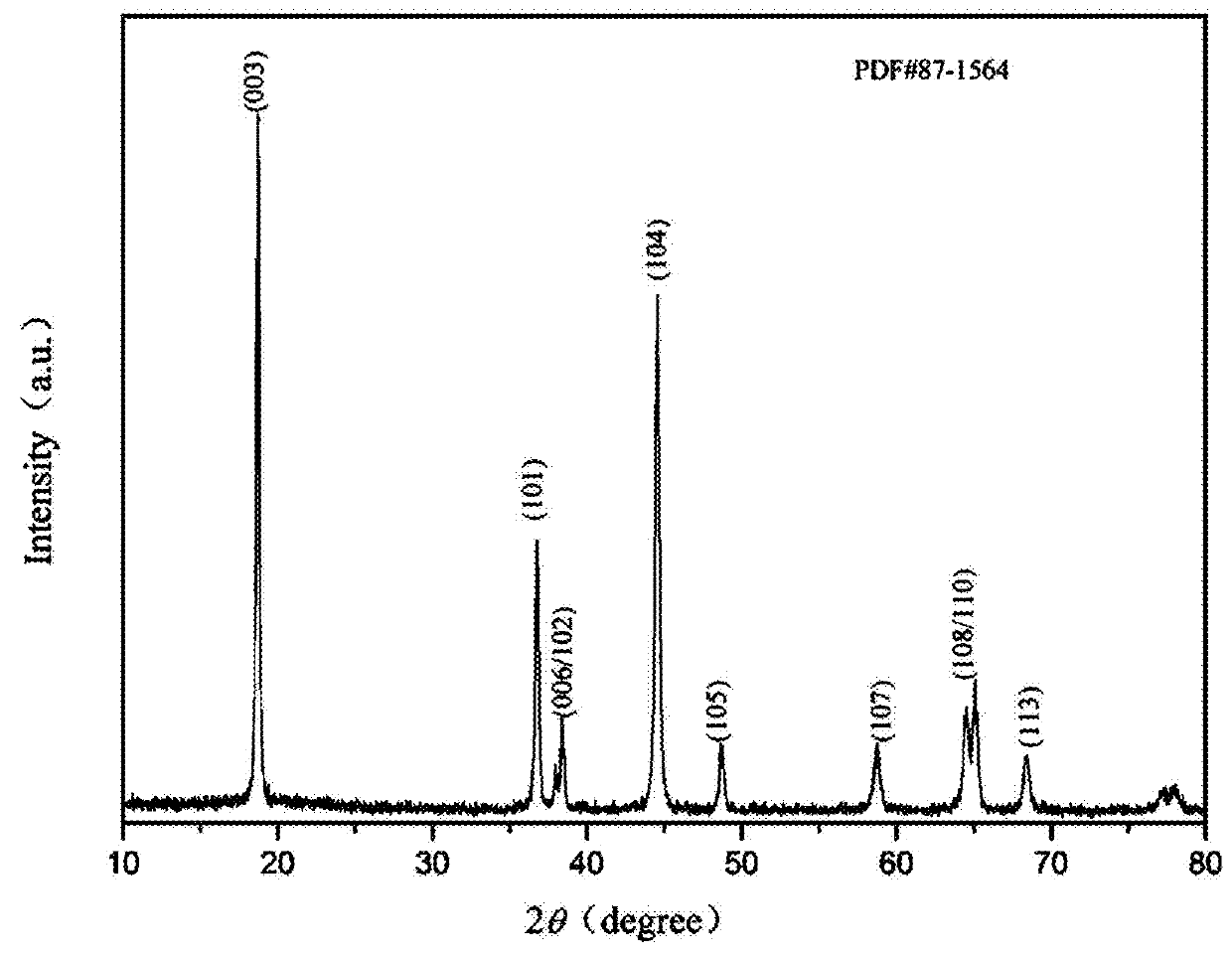

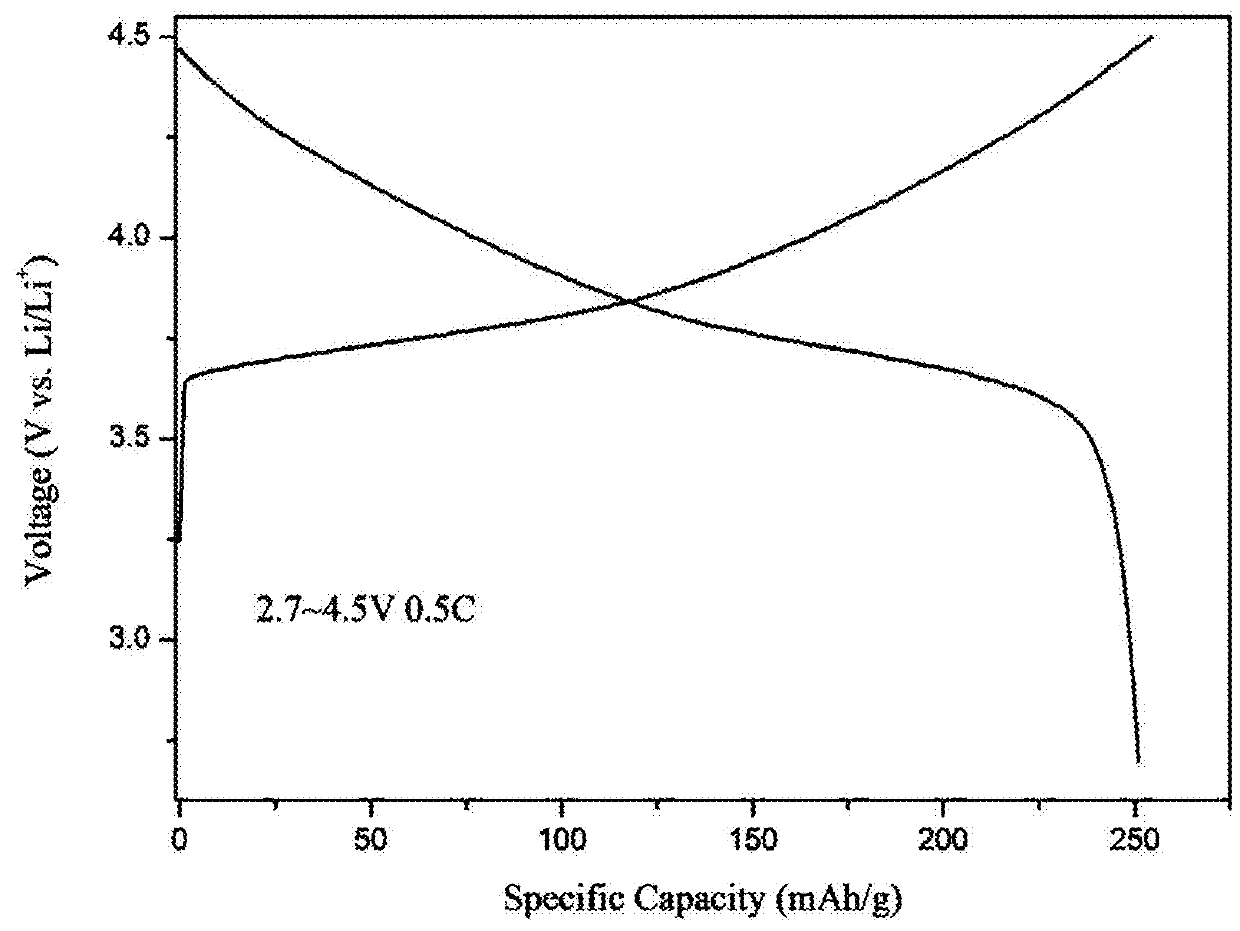

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

High-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof

ActiveUS20180183045A1Improve cycle stabilityGood chemical uniformityCell electrodesSecondary cellsAir atmosphereHigh energy

The present invention discloses a high-voltage ternary positive electrode material for lithium-ion battery and preparation method thereof. The chemical formula of the material is LiNi0.6-xMgxCo0.2-yAlyMn0.2-zTizO2-dFd, wherein 0<x,y,z,d≤0.05. The precursor of the positive electrode material is synthesized by gradient co-precipitation method and the positive electrode material is prepared by solid phase method. The content of nickel in the synthesized precursor particles has a gradient distribution from the inside to the outside. The obtained precursor is mixed and grinded evenly with the lithium source and the fluorine source at a certain ratio and put into the tube furnace. The obtained precursor is then pre-sintered in the oxygen-enriched air atmosphere and then heated up to be sintered, to obtain the target product. The positive electrode material for lithium-ion battery prepared by the method is free from impurity phase and has a good crystallinity, which is a high energy density positive electrode material.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Positive elctrode materials for lithium ion batteries and process for preparing the same

InactiveUS20120015250A1Improve overcharge performanceReduce usageNon-metal conductorsFinal product manufactureLithium-ion batteryMaterials science

Provided are a positive electrode material for lithium ion batteries and a process for preparing the same. The positive electrode material for lithium ion batteries comprises a composite positive electrode material consists of LiCoO2 and an auxiliary positive electrode material, the general formula of the auxiliary positive electrode material is LiCo1−x−yNixMnyO2, wherein 0<x<0.9, 0<y<0.9, 0<x+y<0.9, and the LiCoO2 is a modified LiCoO2 coated with an Al2O3 film. The overcharge performance of the batteries can be significantly increased and the use amount of the overcharge additive can be reduced by using the positive electrode material so as to its improve the cycle performance of the batteries and improve the anti-overcharge safety in the special applications and the charging conditions.

Owner:SHENZHEN BAK BATTERY CO LTD

Oxyfluoride compounds for lithium-cells and batteries

InactiveUS20170005332A1Easy accessImprove featuresMolybdeum compoundsPositive electrodesMedicinal chemistryCathode material

The present invention concerns specific new compounds of formula Li(2−x)Na(x)MO(2−y / 2)F(1+y) (where 0≦x≦0.2 and −0.6≦y≦0,8 and M is a transition metal), cathode material comprising the new compounds, batteries and lithium-cells comprising said new compound or cathode material, a process for the production of the new compound and their use.

Owner:KARLSRUHER INST FUR TECH

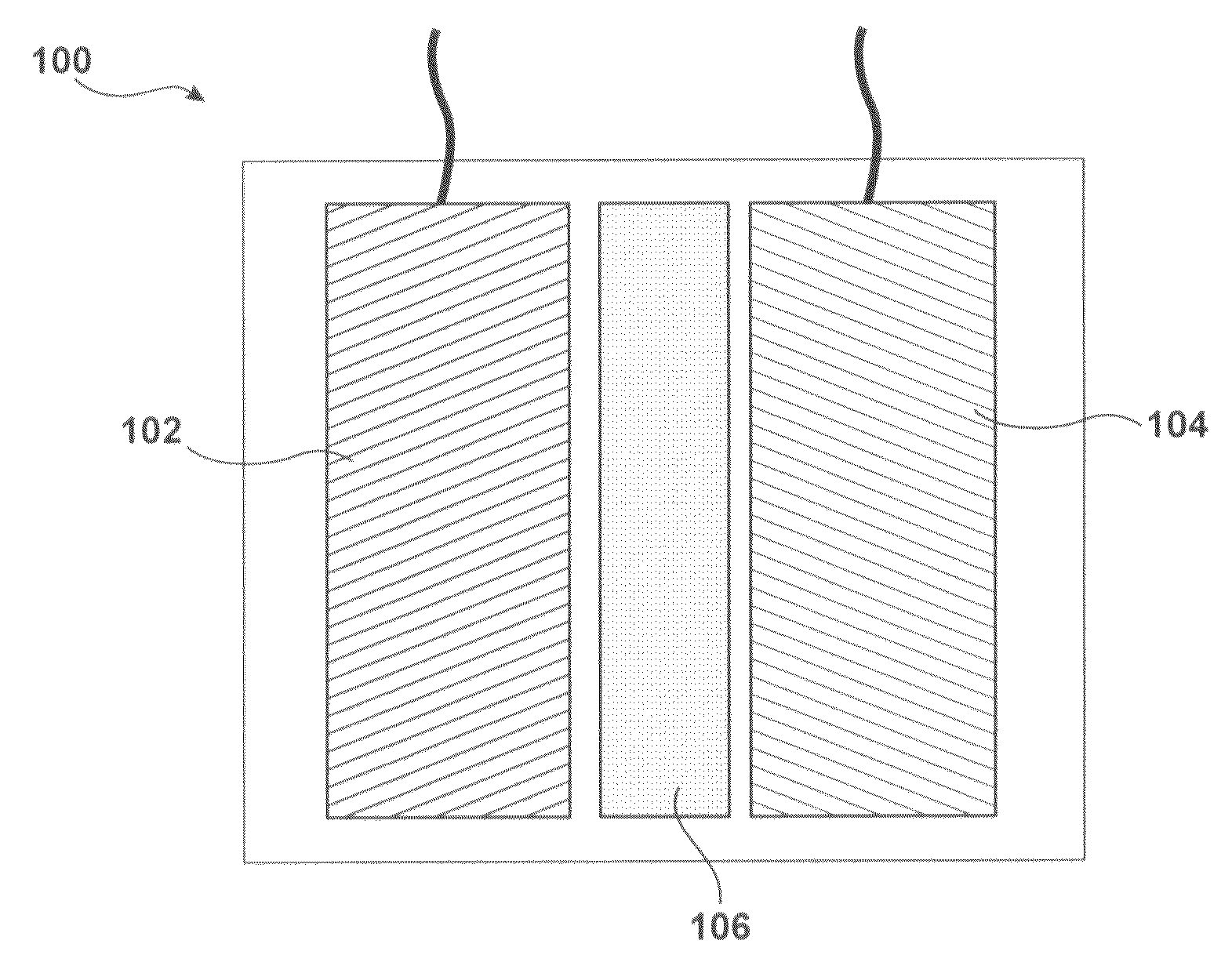

Lithium battery with silicon-based anode and silicate-based cathode

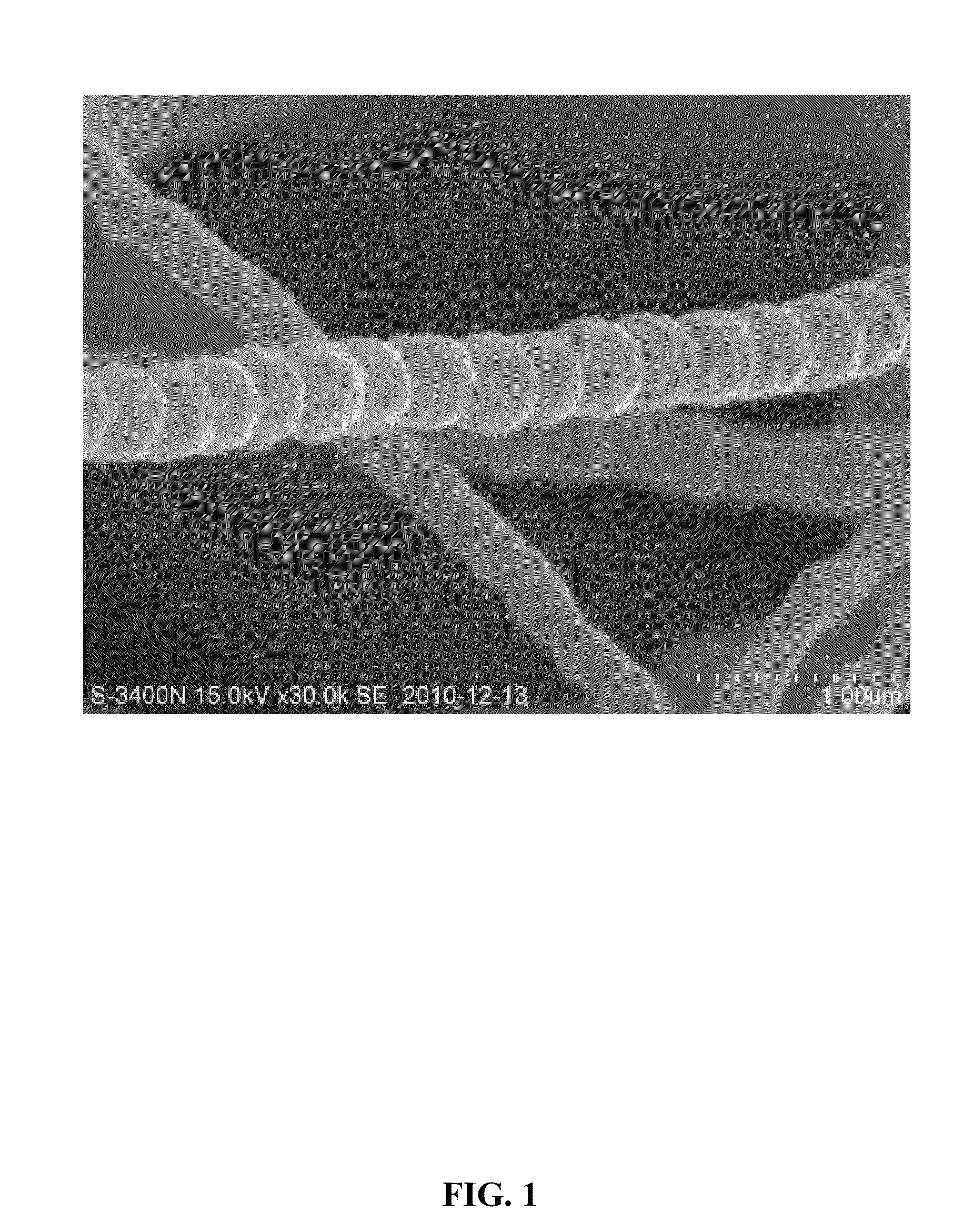

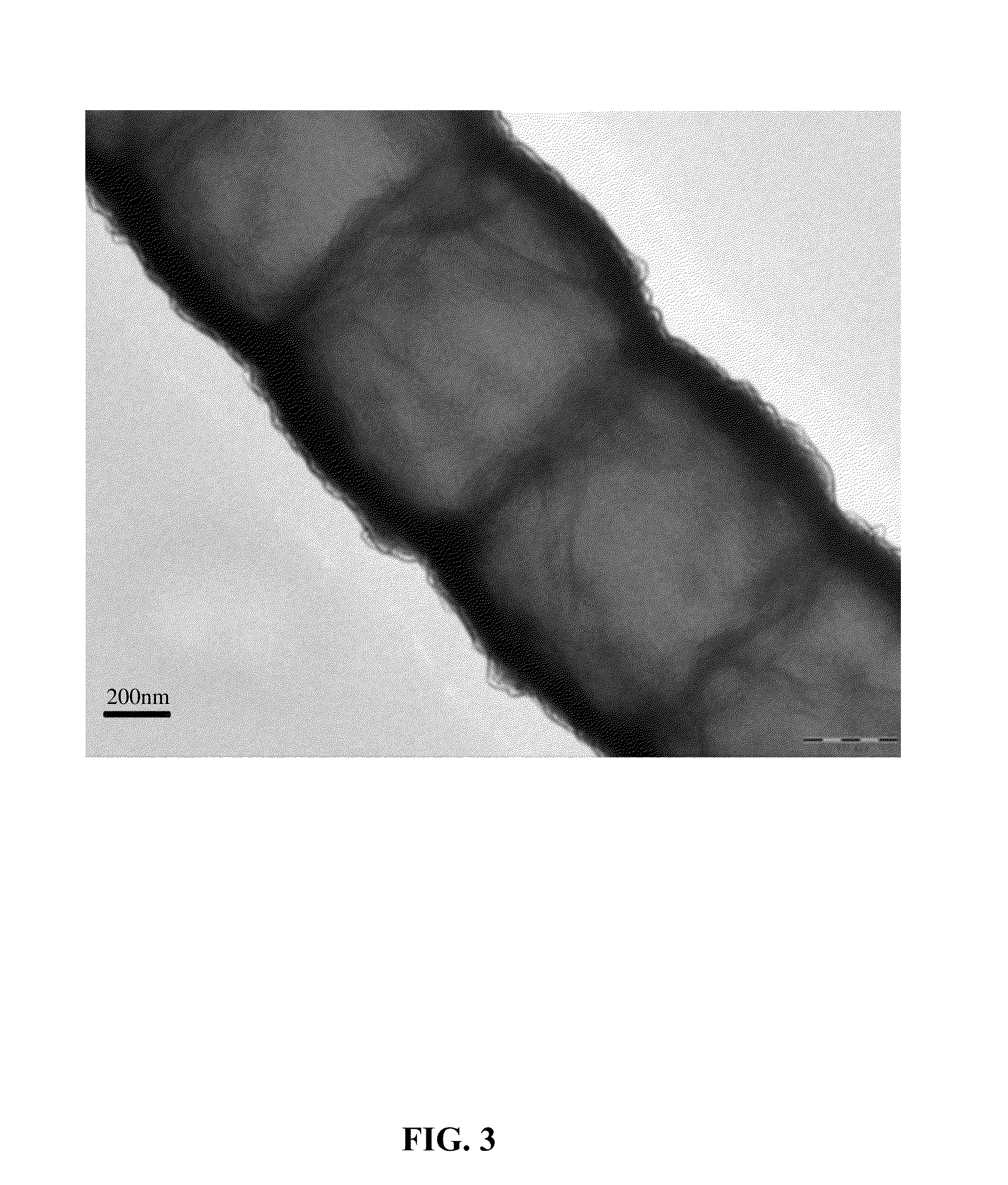

ActiveUS20130234674A1High energy capacityImprove cycle efficiencyMaterial nanotechnologyBatteries circuit arrangementsNickel–lithium batteryCarbon nanofiber

A lithium-ion battery is provided and related methods. The lithium-ion battery includes an electrode comprising an Olivine flake-like structure and an electrode comprising a plurality of coated carbon nanofibers. The Olivine flake-like structures form clusters through which the lithium ions are transported while reducing initial cycle irreversibility. The electrode comprising the coated carbon nanofibers additionally reduce initial cycle irreversibility by controlling expansion of the substrate forming the electrode comprising the coated carbon nanofibers.

Owner:GENERAL MOTORS COMPANY

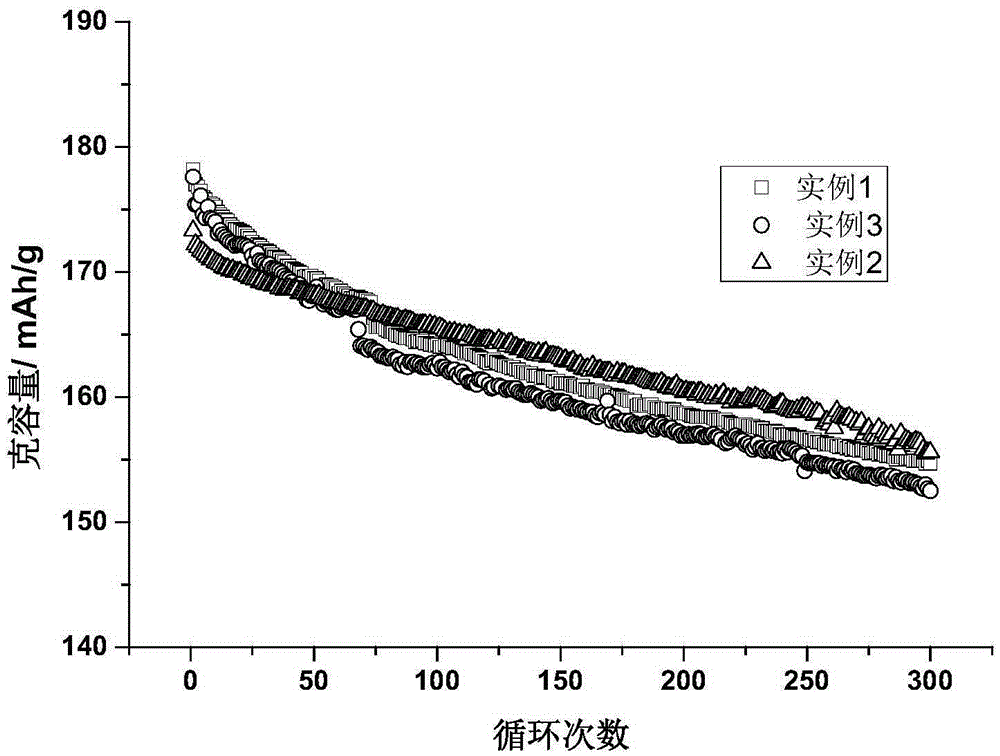

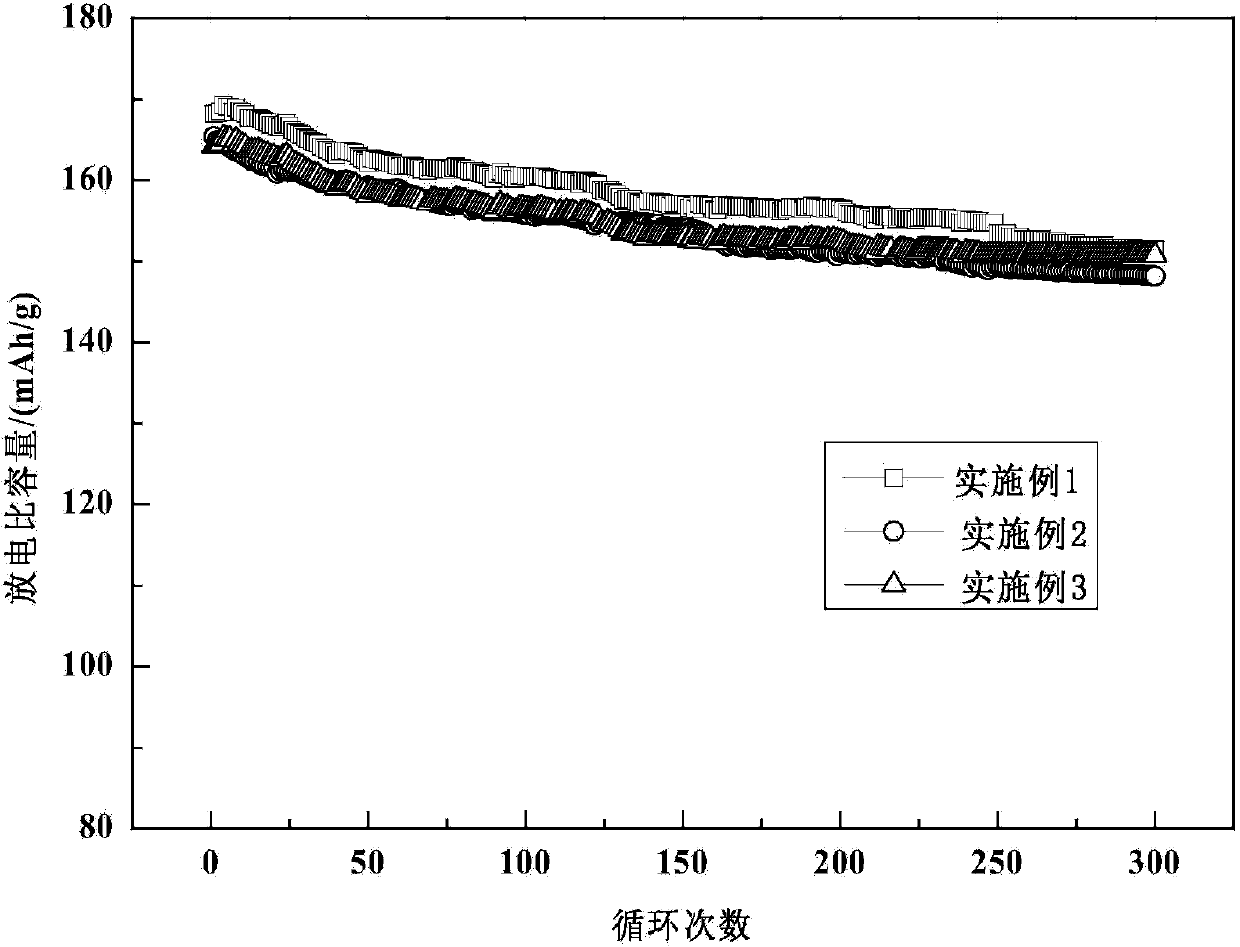

Pretreatment method of cobaltosic oxide for preparing high-voltage lithium cobalt oxide, high-voltage lithium cobalt oxides anode material and preparation method of high-voltage lithium cobalt oxide

The invention discloses a pretreatment method of cobaltosic oxide. The method comprises the steps of mixing a titanium-containing organic matter with an organic solvent so as to obtain a mixed liquid; adding cobaltosic oxide powder into the mixed liquid under a stirring condition so as to form a turbid liquid, adding deionized water into the turbid liquid, adequately stirring the turbid liquid and the deionized water until a uniform pulp-shaped fluid material is formed, and drying the uniform pulp-shaped fluid material so as to obtain a cobaltosic oxide compound. The high-voltage lithium cobalt oxide can be obtained by adequately mixing the obtained cobaltosic oxide compound, a lithium source and a dopant to obtain a mixture, and performing solid sintering and covering on the mixture at a high temperature. The tap density of the prepared high-voltage lithium cobalt oxide is more than 3.0g / cm<3>, the compaction density is more than 4.2g / cm<3>, the primary discharge gram capacity in the range of 2.8V to 4.34V can reach more than 164mAh / g, and the circulating capacity retention rate in 300 weeks is more than 89 percent. The prepared high-voltage lithium cobalt oxide has the advantages of good processing performance, high tap density, good circulating performance, high specific capacity and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

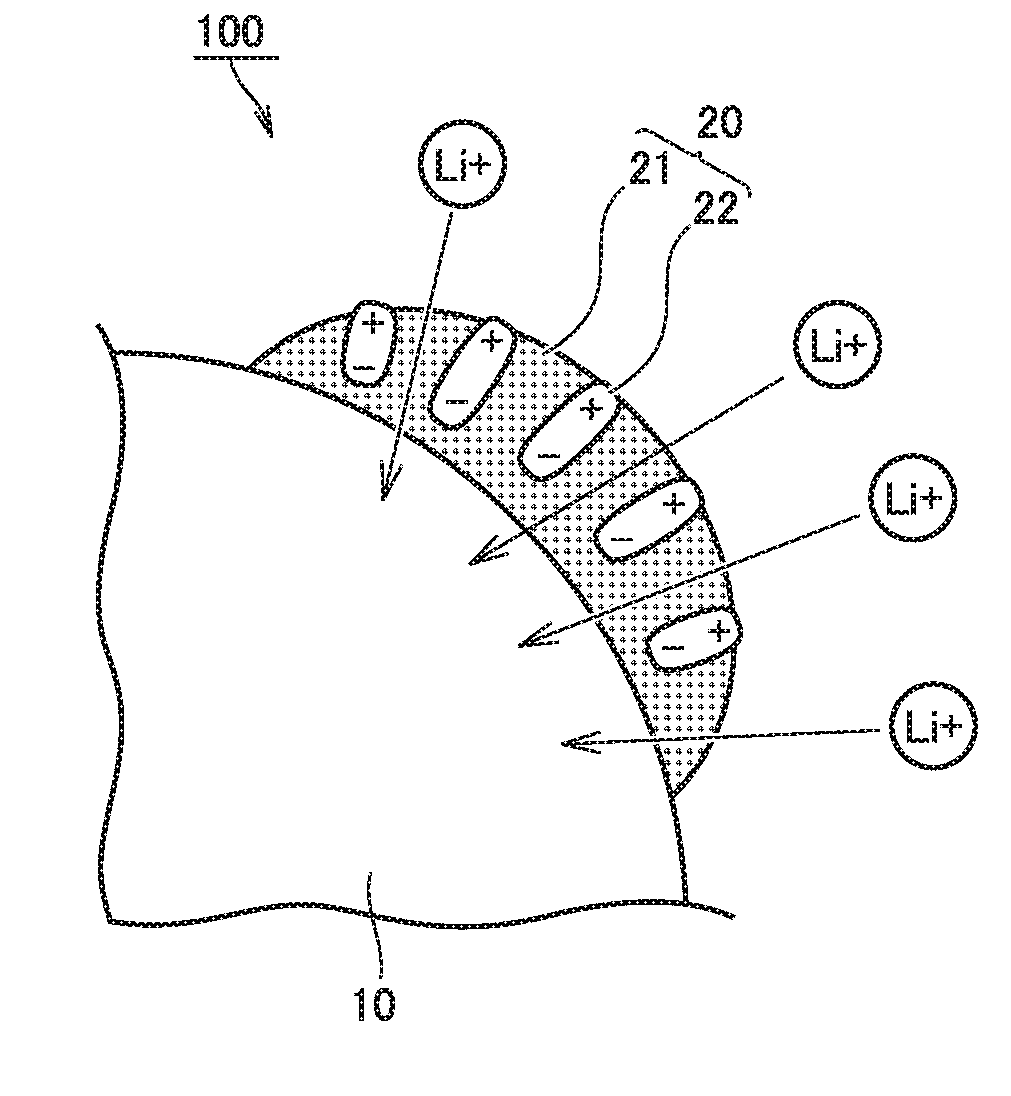

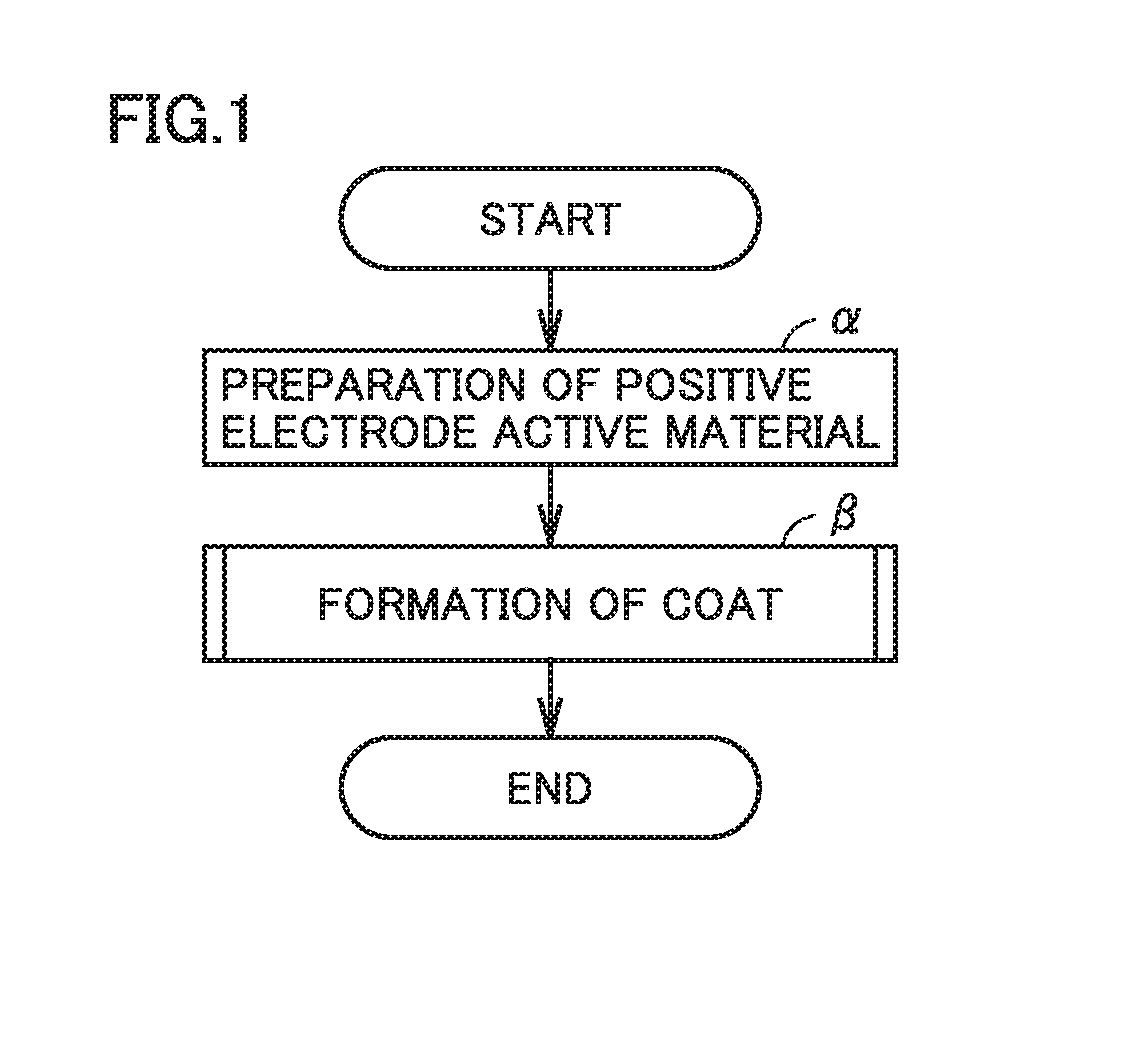

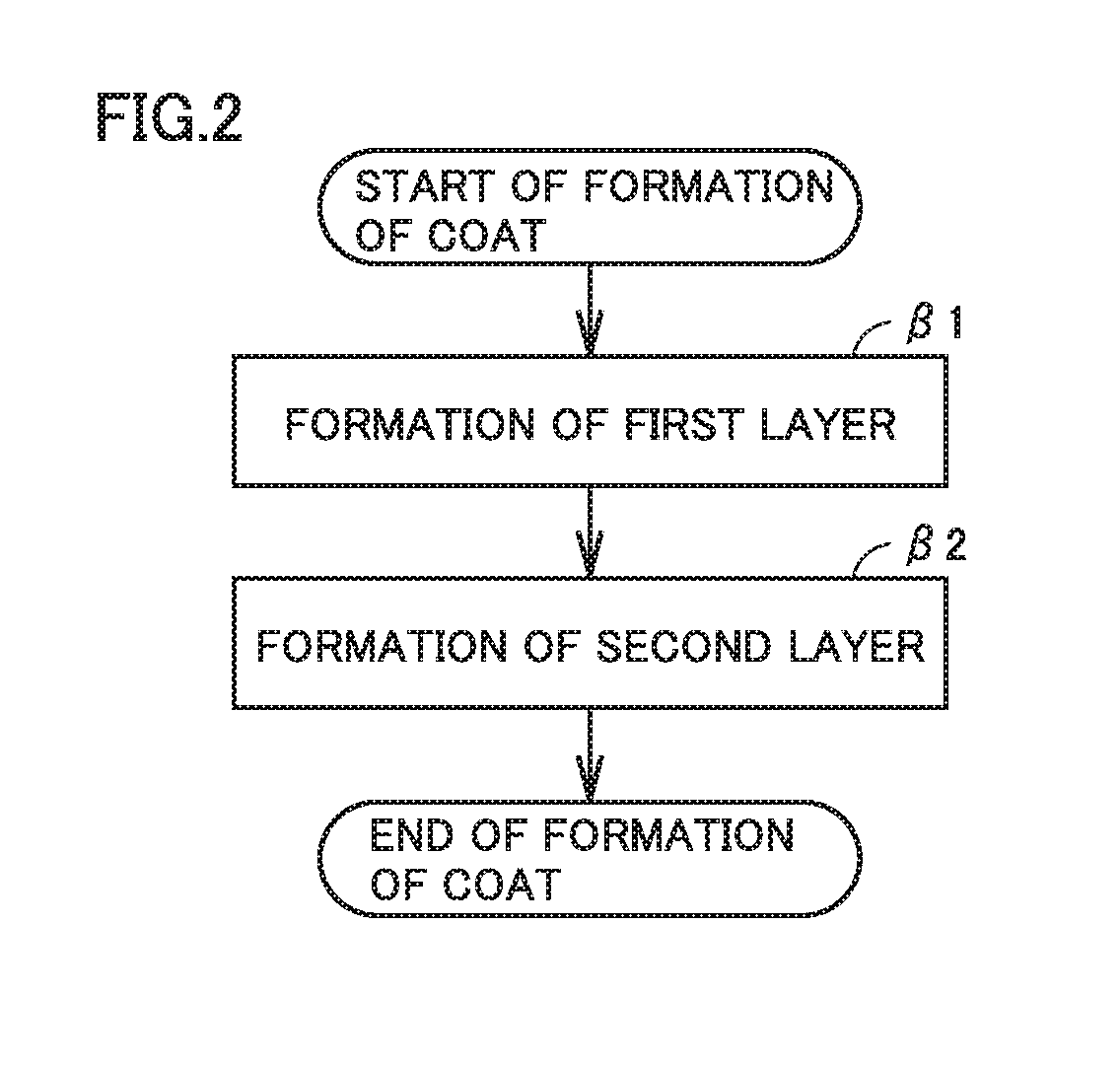

Method of manufacturing positive electrode material for lithium ion secondary battery and positive electrode material for lithium ion secondary battery

ActiveUS20180254477A1Decreasing resistance of batteryPoor in lithium (Li) ion conductivitySecondary cellsPositive electrodesLithiumElectrical conductor

A method of manufacturing a positive electrode material for lithium ion secondary battery includes the following (α) and (β): (α) a positive electrode active material is prepared; and (β) the positive electrode material for lithium ion secondary battery is manufactured by forming a coat on at least a portion of a surface of the positive electrode active material. The coat is formed to satisfy the following (1) to (3): (1) the coat includes a lithium ion conductor and a ferroelectric substance; (2) the ferroelectric substance is dispersed in the lithium ion conductor; and (3) the lithium ion conductor is interposed at least partially between the positive electrode active material and the ferroelectric substance.

Owner:TOYOTA JIDOSHA KK

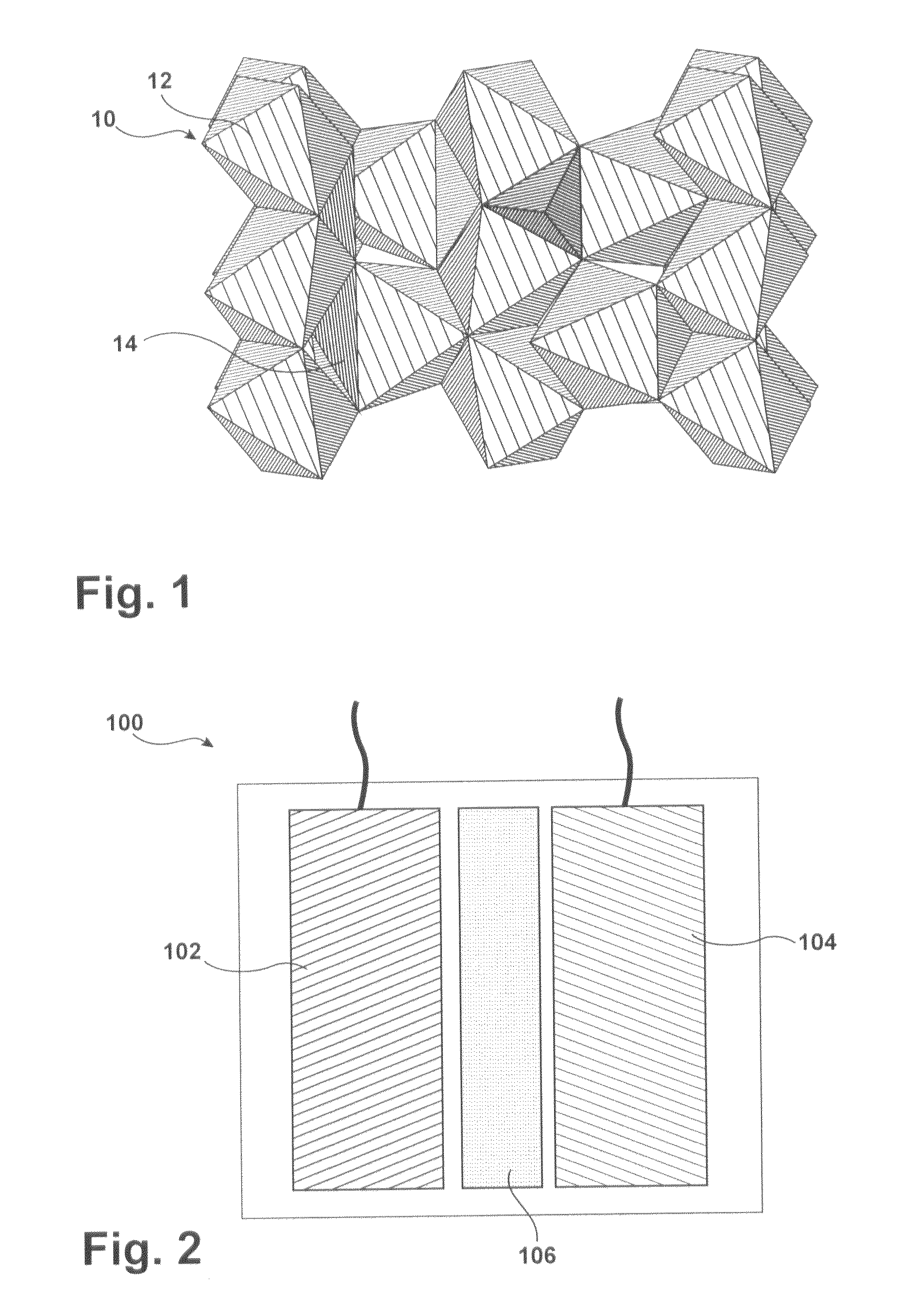

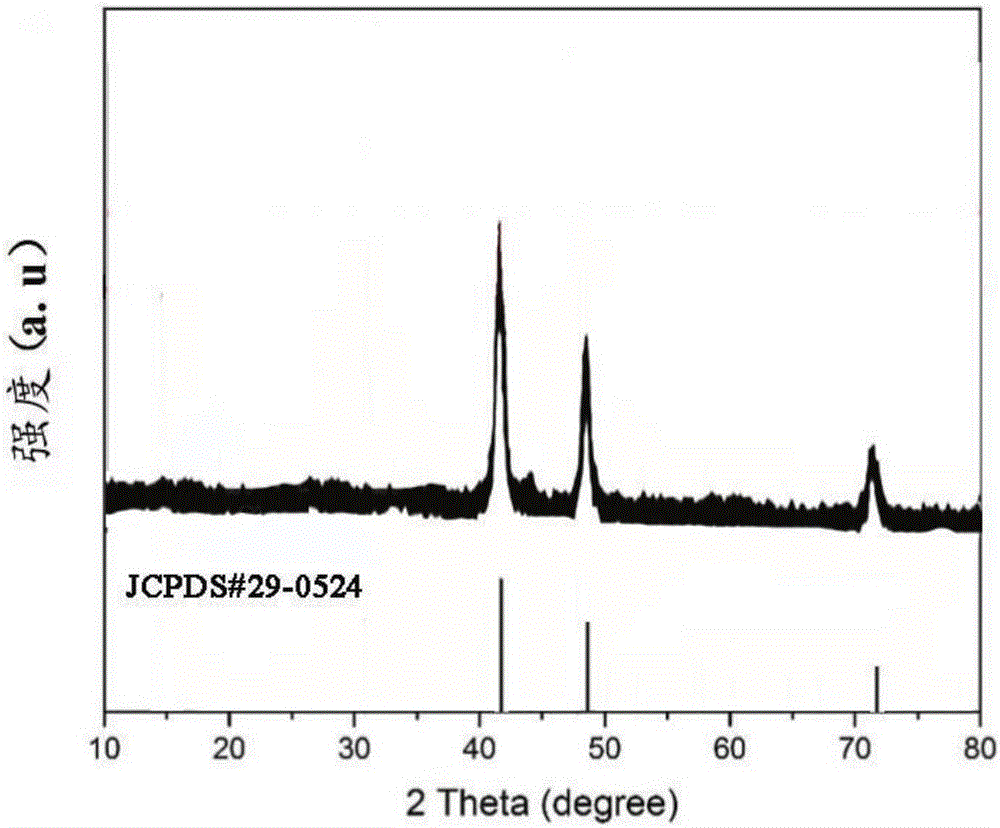

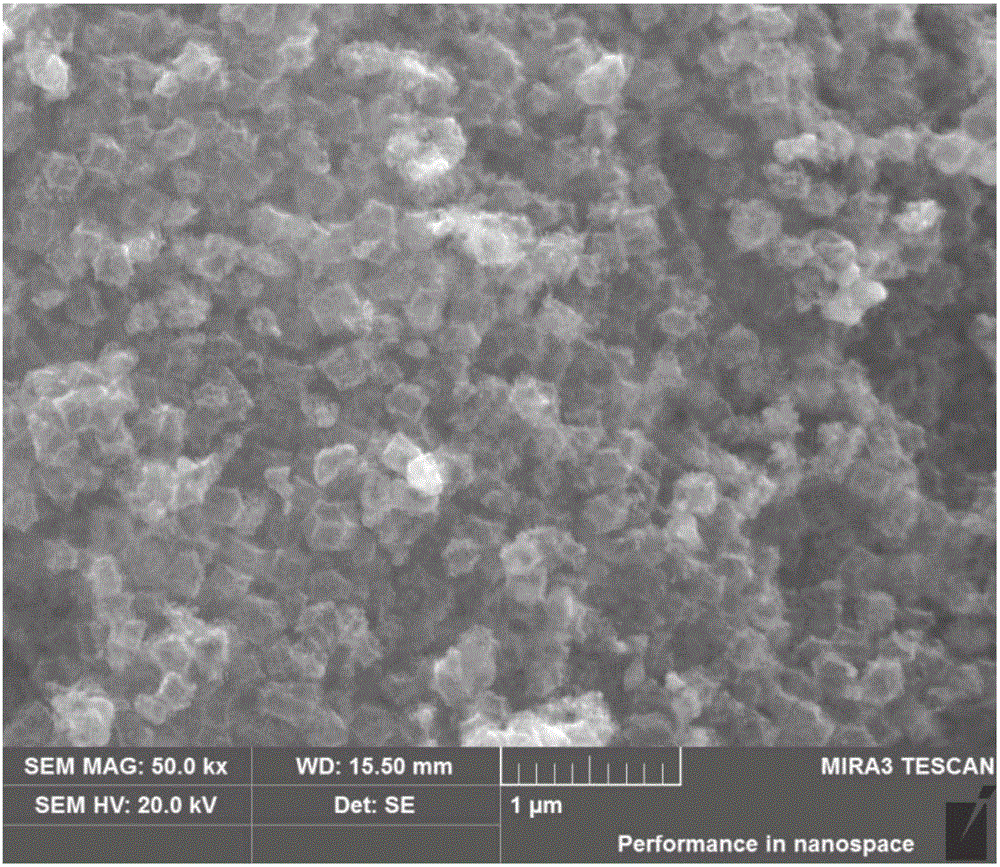

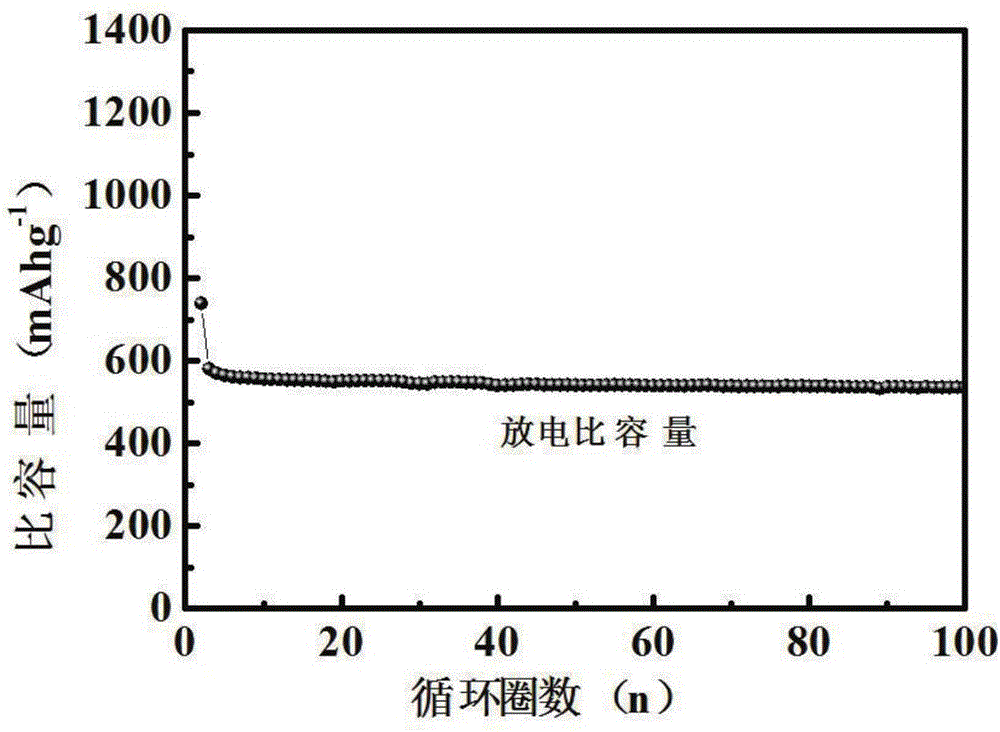

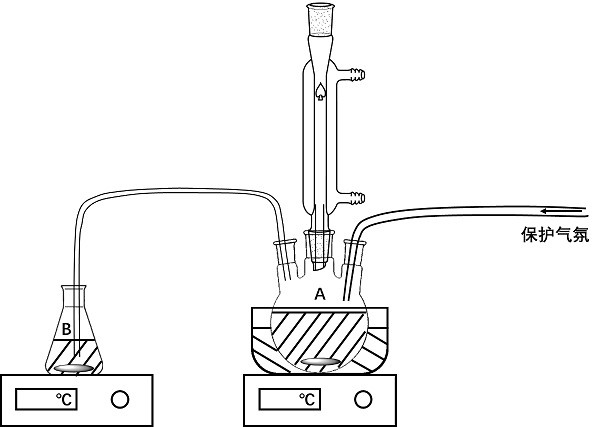

Dodecahedral porous Co3ZnC/C composite material preparation method and use of dodecahedral porous Co3ZnC/C composite material in lithium ion battery

ActiveCN106058215AUniform shapeImprove stabilityCell electrodesSecondary cellsElectrical batteryPyrrolidinones

The invention discloses a preparation method of a dodecahedral porous Co3ZnC / C composite material. The preparation method comprises dispersing polyvinylpyrrolidone, a cobalt salt and a zinc salt in alcohol to obtain a dispersion liquid, adding 2-methylimidazole into the dispersion liquid, carrying out a stirring reaction process, standing purification and washing to obtain a precursor compound and carrying out heat treatment on the precursor compound at a temperature of 500-700 DEG C in a protective atmosphere to obtain the Co3ZnC / C composite material. The dodecahedral porous Co3ZnC / C composite material has uniform morphology, good stability and porous characteristics. The invention also discloses a use of the dodecahedral porous Co3ZnC / C composite material in a lithium ion battery. The dodecahedral porous Co3ZnC / C composite material as a negative electrode material can be used in a lithium ion battery. The dodecahedral porous Co3ZnC / C composite material guarantees a specific capacity and improves an electrode material rate capability and cycling stability. The preparation method has simple processes, realizes a low cost and has a good research prospect.

Owner:CENT SOUTH UNIV

Method for preparing a positive active material for a lithium secondary battery

ActiveUS20160351898A1Improve specific capacity and cycling performance and safety performanceHigh specific capacityCell electrodesSecondary cellsHigh ratePhosphate

The present invention provides a method for preparing a positive active material for a secondary lithium battery. The method includes the steps of: synthesizing an intermediate product of a core represented by formula LixMyN1-yO2-αAβ; adding P source into the intermediate product to obtain a phosphate which does not contain lithium; and adding lithium source into the mixture of the phosphate and LixMyN1-yO2-αAβ and sintering to obtain the positive active material for secondary lithium battery. The method for preparing a positive active material for a secondary lithium battery of the present invention has the following advantages: 1) the P source can be dispersed on the surface of the core more uniformly; 2) the coating layer can be bonded to the core more tightly; and 3) the positive active material has higher rate discharge performance.

Owner:NINGDE AMPEREX TECH

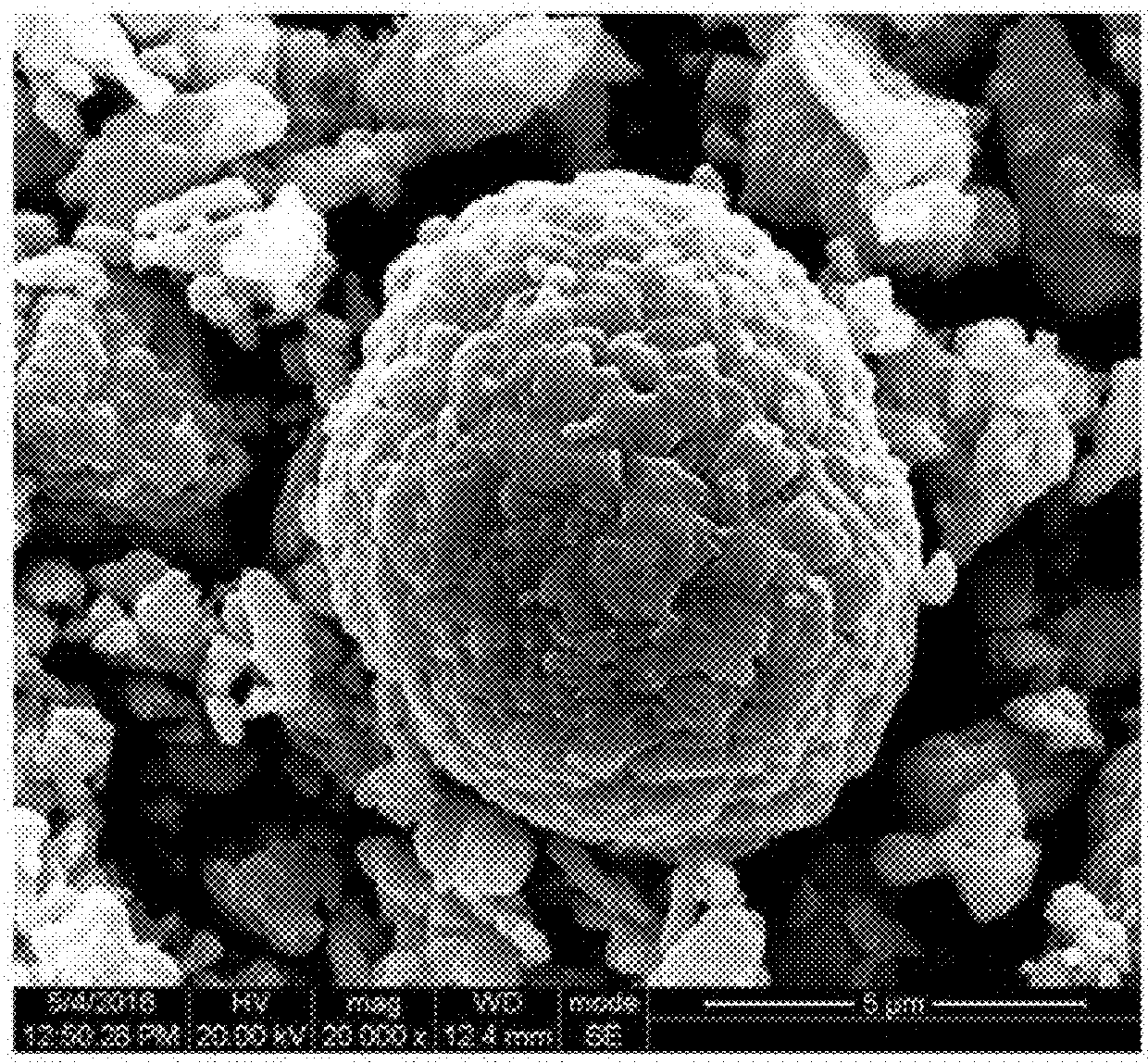

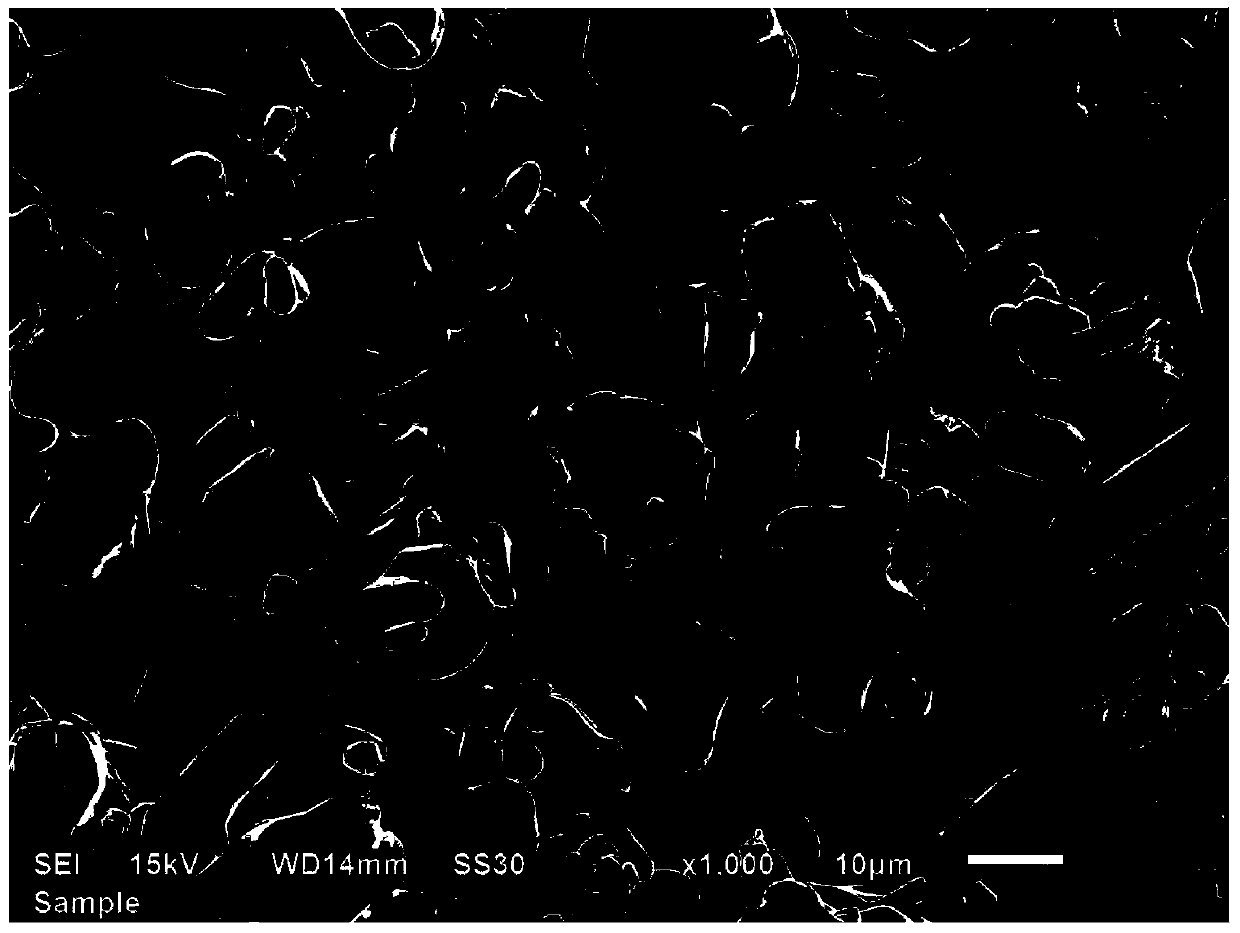

Nickel hydroxide, method for producing positive electrode active material for non-aqueous electrolyte secondary battery, electrode for non-aqueous electrolyte secondary battery, and non-aqueous electrolyte secondary battery

ActiveUS20100068624A1Guaranteed specific capacityLarge capacityFinal product manufactureActive material electrodesHigh rateNickel oxide hydroxide

A positive electrode active material for a non-aqueous electrolyte secondary battery, including a lithium nickel composite oxide, is produced by baking a nickel hydroxide having a mean primary particle size of 1 to 5 μm and a DBP absorption amount of 10 to 30 mL / 100 g and a lithium compound in an oxidizing atmosphere. This lithium nickel composite oxide is excellent in packing characteristics and power characteristics (particularly high-rate characteristics), and useful as a positive electrode active material of a non-aqueous electrolyte secondary battery.

Owner:PANASONIC CORP

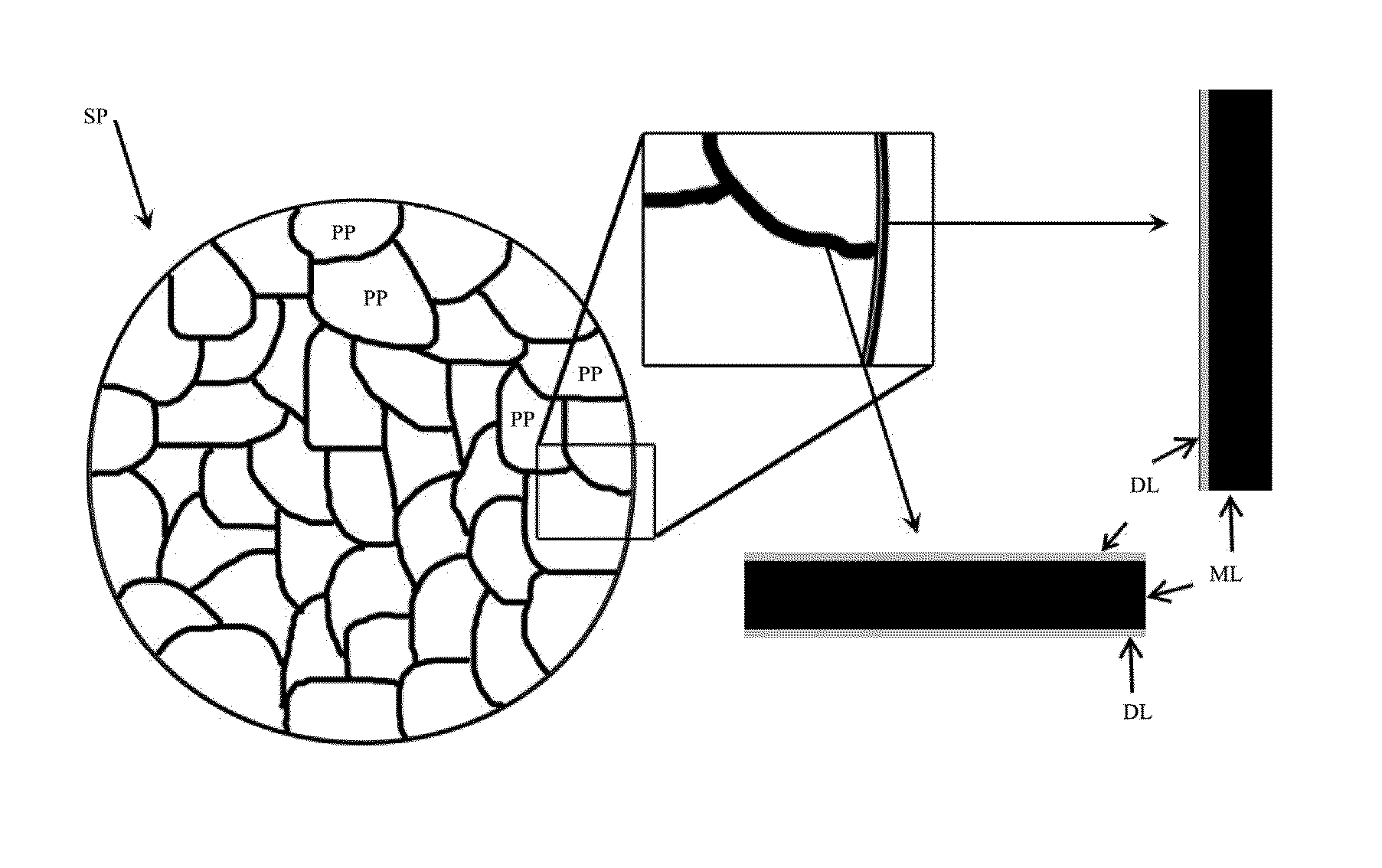

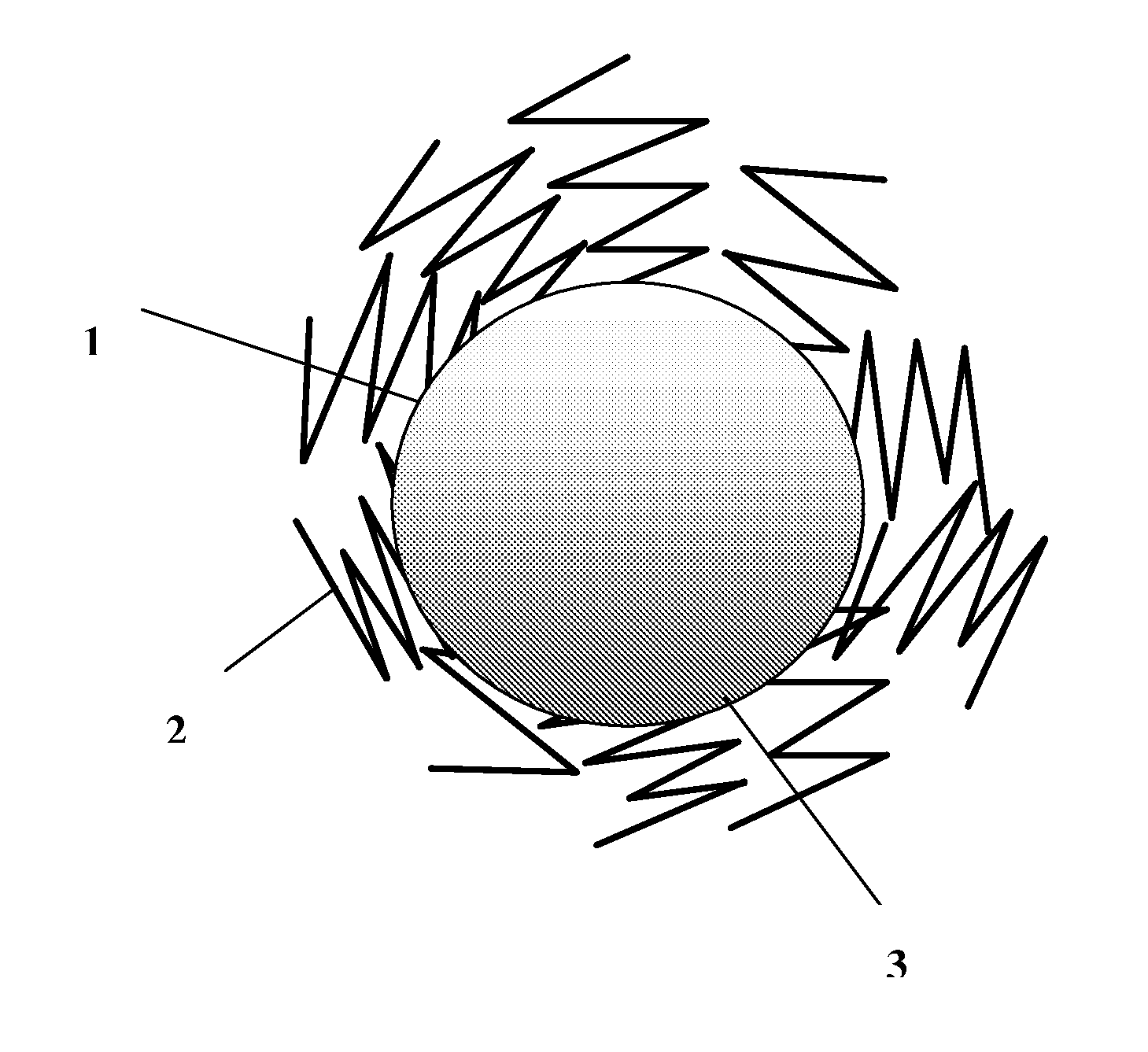

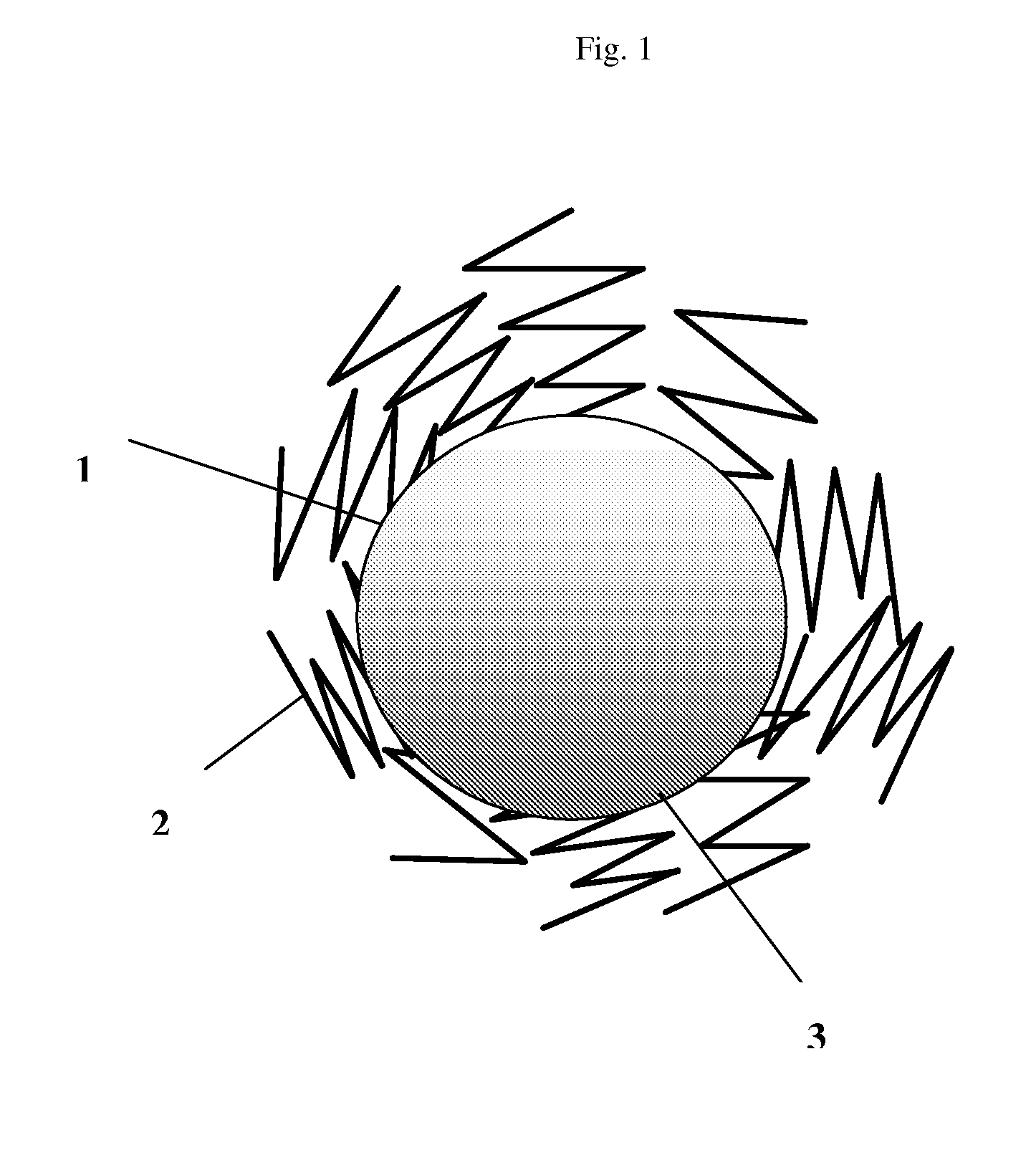

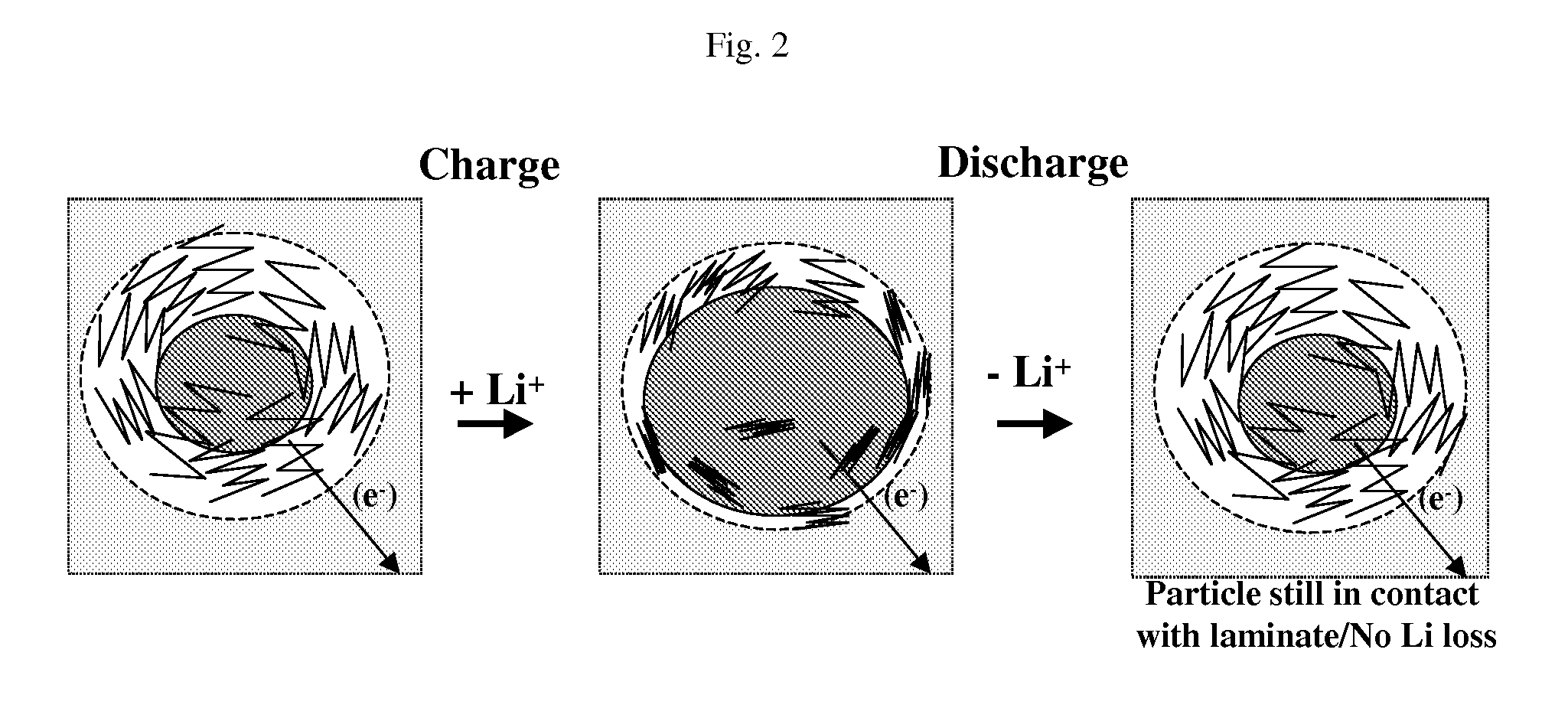

Composite for li-ion cells and the preparation process thereof

ActiveUS20100308278A1Prevent oxidationEfficiency and reversible capacityNon-metal conductorsConductive materialEngineeringElectron

Disclosed herein is a composite for Li-ion cells, comprising an active material particle for Li-ion cells and an electronically conductive elastic material bound or attached to the active material particle. According to the present invention, the electronically conductive elastic material bound or attached to the active material particle allows the particle to maintain electronic contact with the electrode laminate matrix despite ongoing movement or expansion and contraction of the active material particles, such that the cycling efficiency and reversible capacity of the Li-ion cells prepared from the composite of the present invention is improved.

Owner:FARASIS TECH (GANZHOU) CO LTD

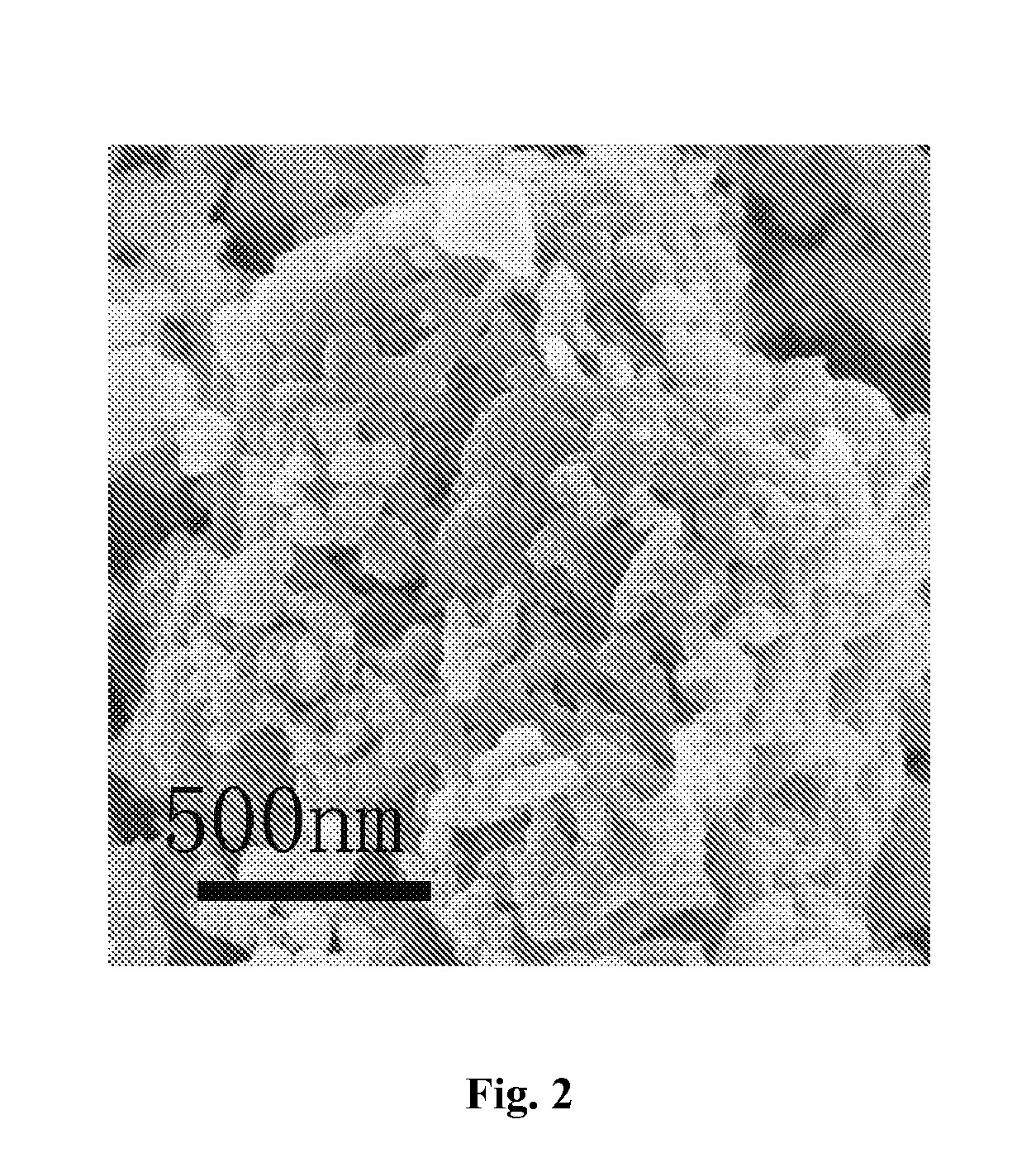

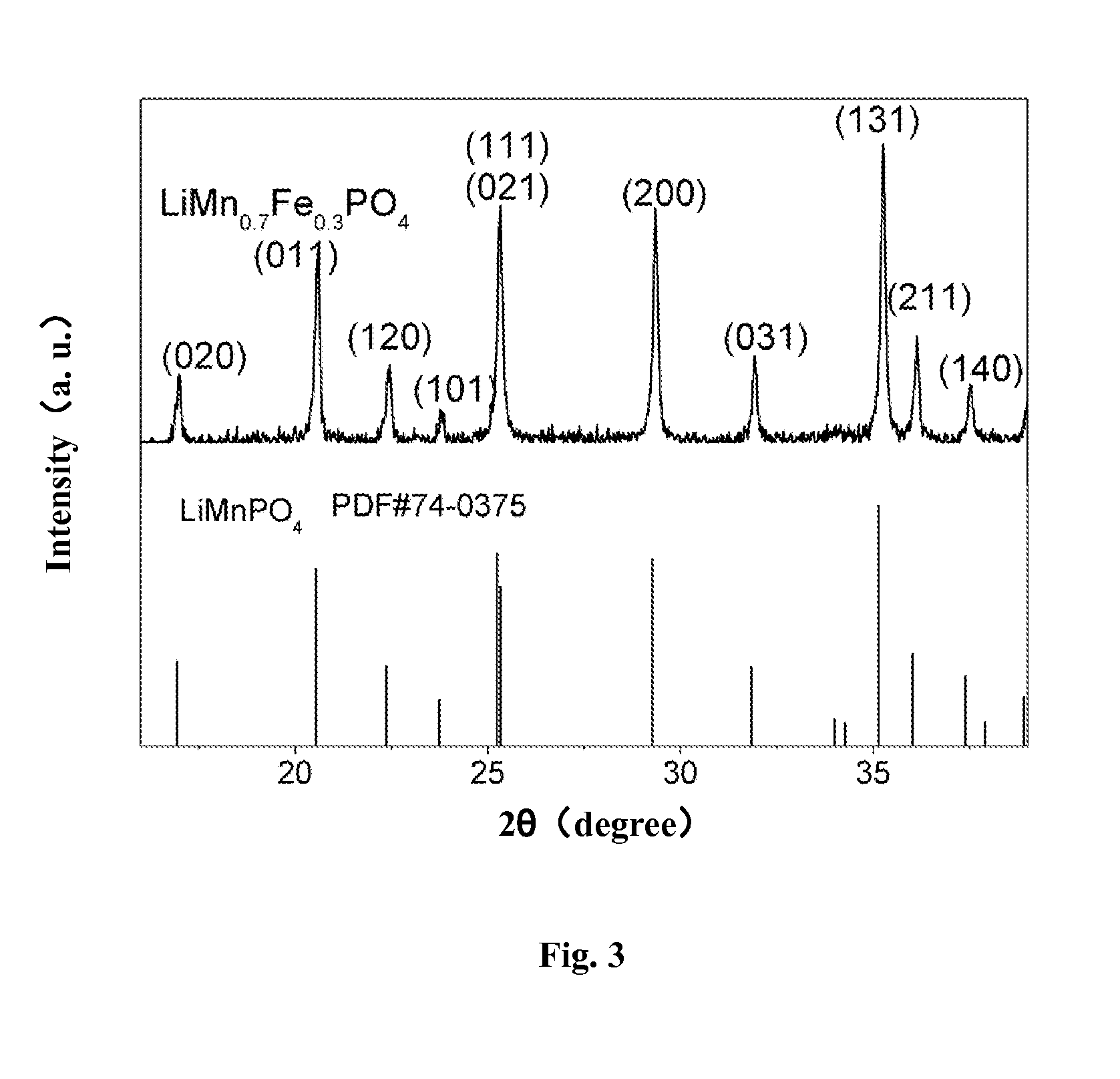

Porous Lithium Mangaense Phosphate-Carbon Composite Material, Preparation Method and Application Thereof

InactiveUS20160013474A1Improve Capacitive PerformanceExcellent rate performanceMaterial nanotechnologyNon-metal conductorsCarbon compositesPhosphate

A porous lithium manganese phosphate-carbon composite material, and a preparation and application thereof. Multiple nano-pores are distributed in the composite material, and the composite material includes a lithium manganese phosphate material and carbon. The method for preparing the porous lithium manganese phosphate-carbon composite material includes the steps of: mixing a porous pyrophosphate material with a doped metal source, a lithium source, phosphate and a carbon source and then drying them to obtain a reaction precursor, and calcining the reaction precursor at a constant temperature under a protective atmosphere to obtain the composite material. The lithium manganese phosphate material contains compounds in a general formula of LiMnxM1−xPO4, and the porous pyrophosphate material contains compounds in a general formula of (MnxM1−x)2P2O7 and 0 wt % to 50 wt % of carbon, where M comprises a transition metal, and 0.6≦x≦1.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

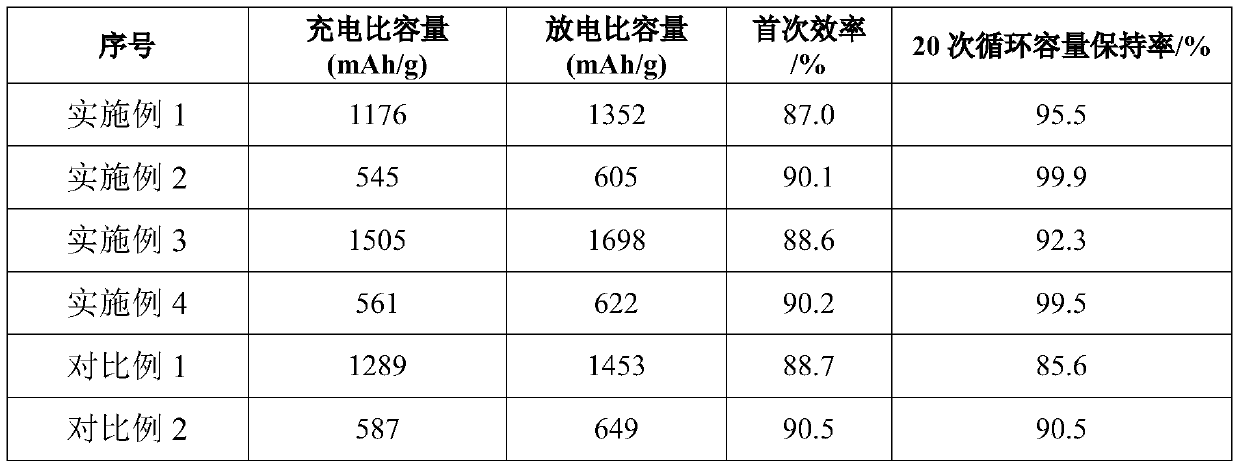

Lithium-ion battery silicon carbon negative electrode material and preparation method thereof

InactiveCN110504430AImprove cycle stabilityAchieving Controlled OxidationMaterial nanotechnologyNegative electrodesCyclic processCarbon coating

The invention provides a lithium-ion battery silicon carbon negative electrode material and a preparation method thereof. The preparation method of the lithium-ion battery silicon carbon negative electrode material comprises the following steps: S1, after mixing a silicon source and a solvent, wet grinding is performed under an oxidizing condition to form an oxide layer on the surface of the silicon source, wherein the mass of oxygen element accounts for 9.8% to 14% of the mass of the silicon source, and a slurry is obtained; S2, the slurry obtained in step S1 is compounded with a carbon material and dried to obtain a silicon carbon core material; S3, the silicon carbon core material obtained in step S2 is subjected to a fusion process treatment, and then mixed with a carbon coating material uniformly, and then calcined at a high temperature to be shaped; and S4, the material obtained in step S3 is crushed and sieved to obtain the silicon carbon negative electrode material. According to the invention, controlled oxidation of nano-silicon is realized during the wet grinding process, so that an oxide layer is formed on the surface of the silicon source; and the presence of the oxidelayer avoids side reactions between the silicon source and the electrolyte, and reduces the phenomenon of electrochemical agglomeration during the cyclic process at the same time; therefore, the cyclestability of the silicon carbon negative electrode material is significantly increased.

Owner:SHAANXI COAL & CHEM TECH INST

Adsorbents for pressure swing adsorption systems and methods of use therefor

InactiveUS20080148937A1Reduce frequencyMaintain purityGas treatmentIsotope separationPurification methodsSorbent

The present invention relates generally to adsorbents for use in pressure swing adsorption (PSA) prepurification processes. The invention more particularly relates to the design of adsorbent zones to be used in PSA prepurification processes that are expected to provide for extensions in PSA cycle time, thereby reducing blowdown loss and operating costs associated with the process. One particular embodiment of the present invention includes a first adsorption zone containing activated alumina and a second adsorption zone of an alumina-zeolite mixture or composite adsorbent in which the volume of the first zone does not exceed 50% of the total volume of the first and second zone.

Owner:PRAXAIR TECH INC

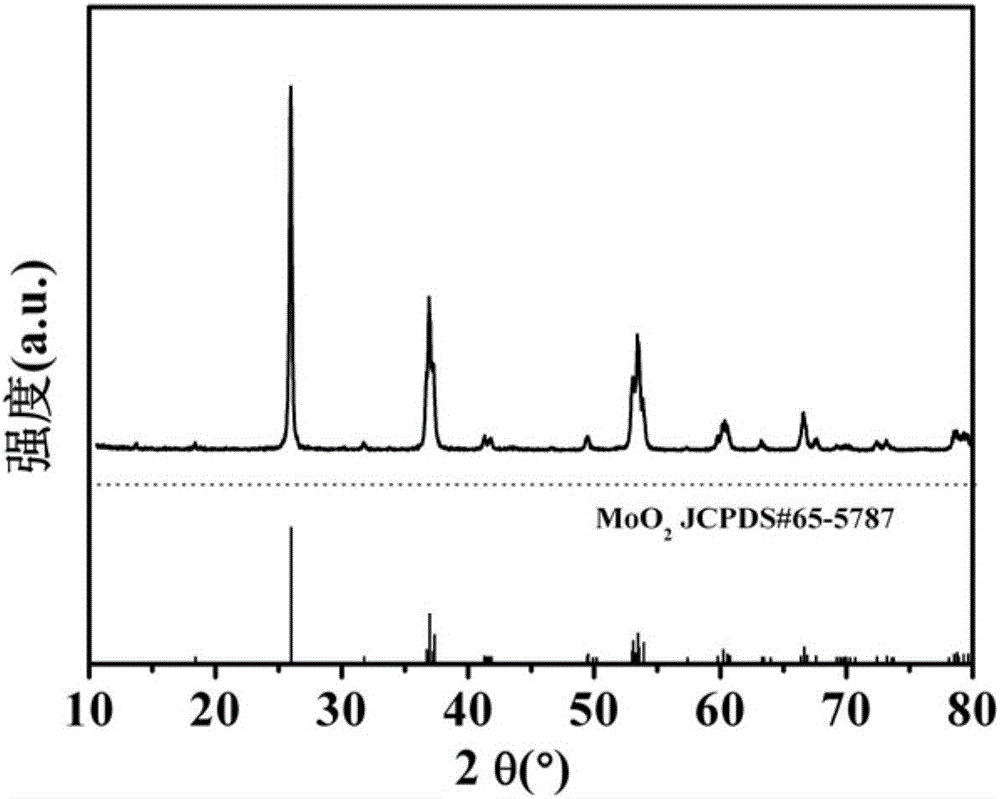

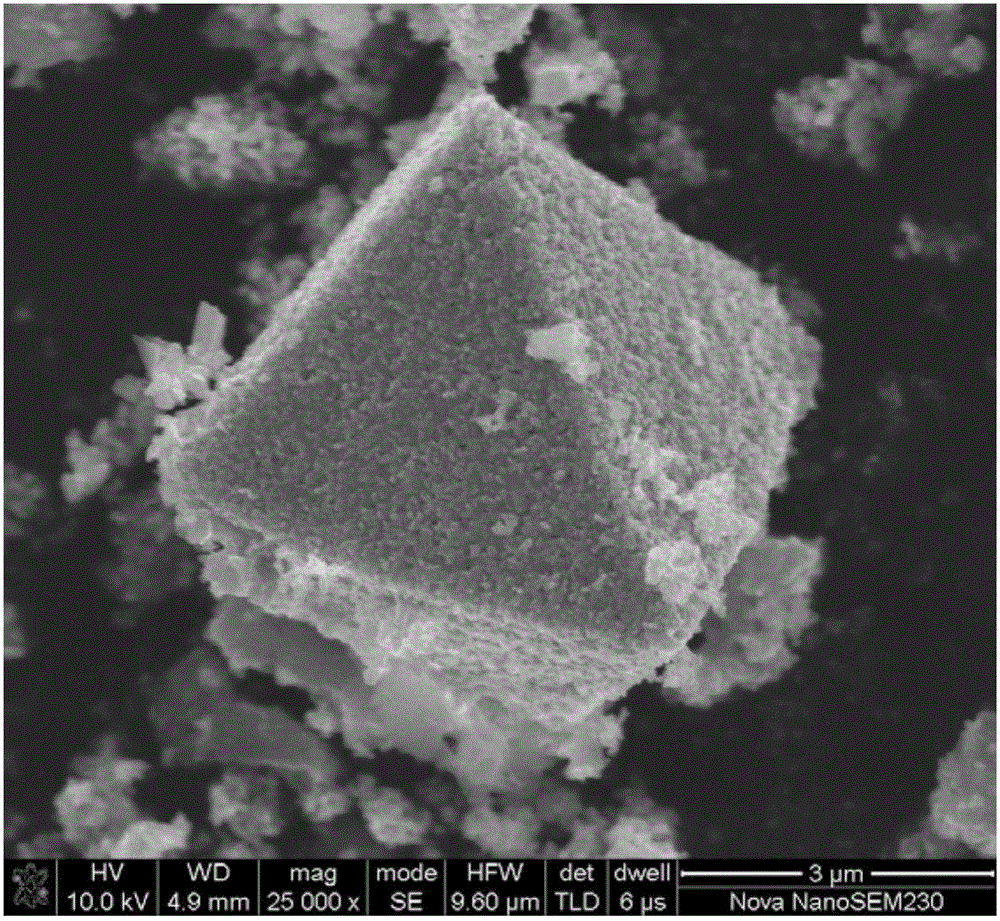

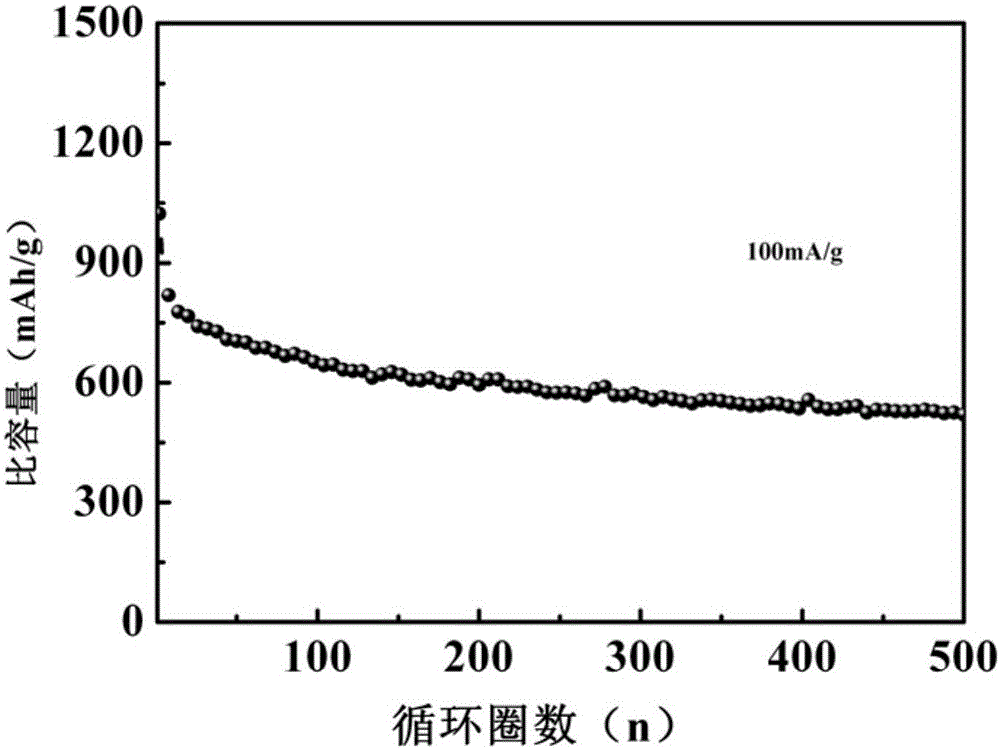

Preparation method of octahedral porous molybdenum dioxide and application of octahedral porous molybdenum dioxide in lithium-ion battery

InactiveCN105977479AUniform shapeGood stabilityCell electrodesSecondary cellsAmmonium hydroxideEmulsion

The invention discloses a preparation method of octahedral porous molybdenum dioxide and an application of the octahedral porous molybdenum dioxide in a lithium-ion battery. The preparation method comprises the steps of: adding trimesic acid and tetramethyl ammonium hydroxide to a solution containing a copper salt and a phosphomolybdic acid and / or phosphomolybdate for stirring to form an emulsion; transferring the emulsion into a hydrothermal reaction kettle for hydrothermal reaction to obtain a precursor compound; and putting the precursor compound into a protective atmosphere, carrying out thermal treatment at a high temperature and then washing the product to obtain a porous octahedral molybdenum dioxide material which is formed by stacking and assembling ultrafine nanoparticles, is uniform in shape and form and good in stability and has a porous characteristic. The molybdenum dioxide material is applied to the lithium-ion battery as a negative electrode material, so that the rate capability and the cycling stability of the electrode material are improved under the premise of ensuring the specific capacity; the preparation technology of the molybdenum dioxide material is simple; the cost is low; and the molybdenum dioxide material has a relatively good research prospect.

Owner:CENT SOUTH UNIV

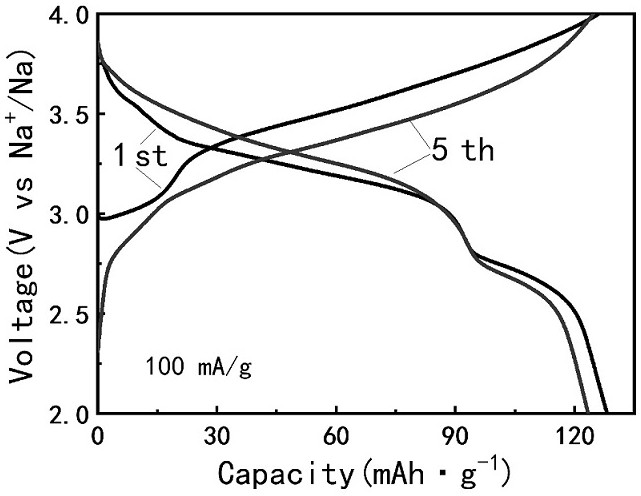

High-entropy Prussian blue material and preparation method thereof

ActiveCN113690433AHigh crystallinityImprove cycle stabilityIron cyanidesCell electrodesElectrical batterySource material

The invention discloses a high-entropy Prussian blue material, and the molecular formula of the high-entropy Prussian blue material is NaxMIN[Fe(CN)6]zwH2O, wherein M is n different transition metal elements, n is greater than or equal to 5, yn is greater than or equal to 0.01 and less than or equal to 0.90, y1 + y2 + y3 + y4 + y5+... + yn = 1, w is less than or equal to 4.0, x is greater than or equal to 1.40 and less than or equal to 1.95, and z is greater than or equal to 0.90 and less than or equal to 0.98. The high-entropy Prussian blue material is of a monoclinic phase structure, the microstructure of the high-entropy Prussian blue material is large-size crystal particles, and the crystal particles are uniform in size, single in shape and regular in polyhedral morphology. The invention also provides application of the high-entropy Prussian blue material as a positive electrode material in a sodium-ion battery and a preparation method of the high-entropy Prussian blue material. A coprecipitation method is adopted, and the high-entropy Prussian blue material with high specific capacity, good rate capability and excellent cycle performance is obtained through selection of source materials, technological process design and selection and control of technological parameters in preparation.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

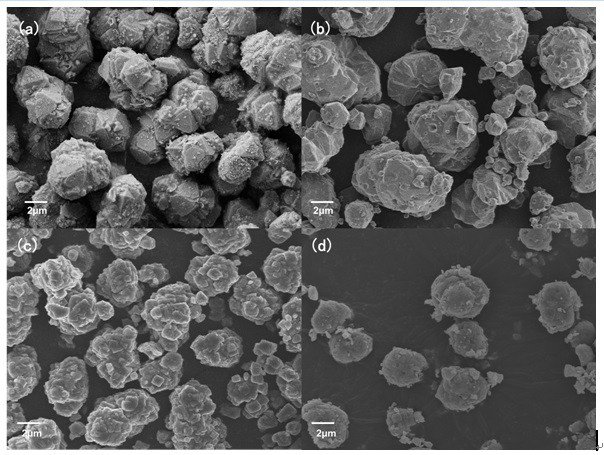

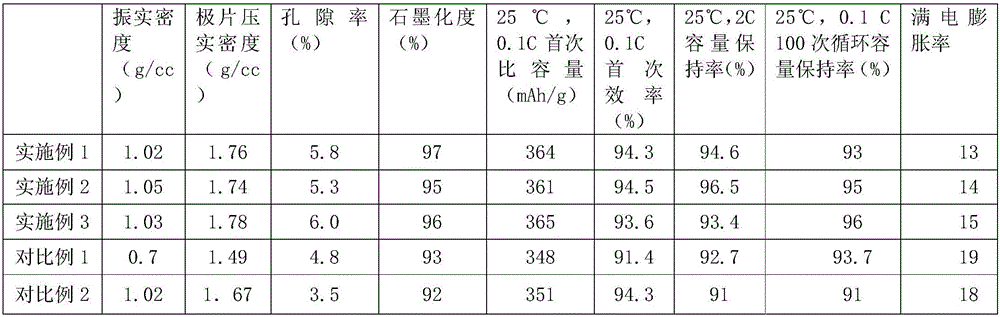

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

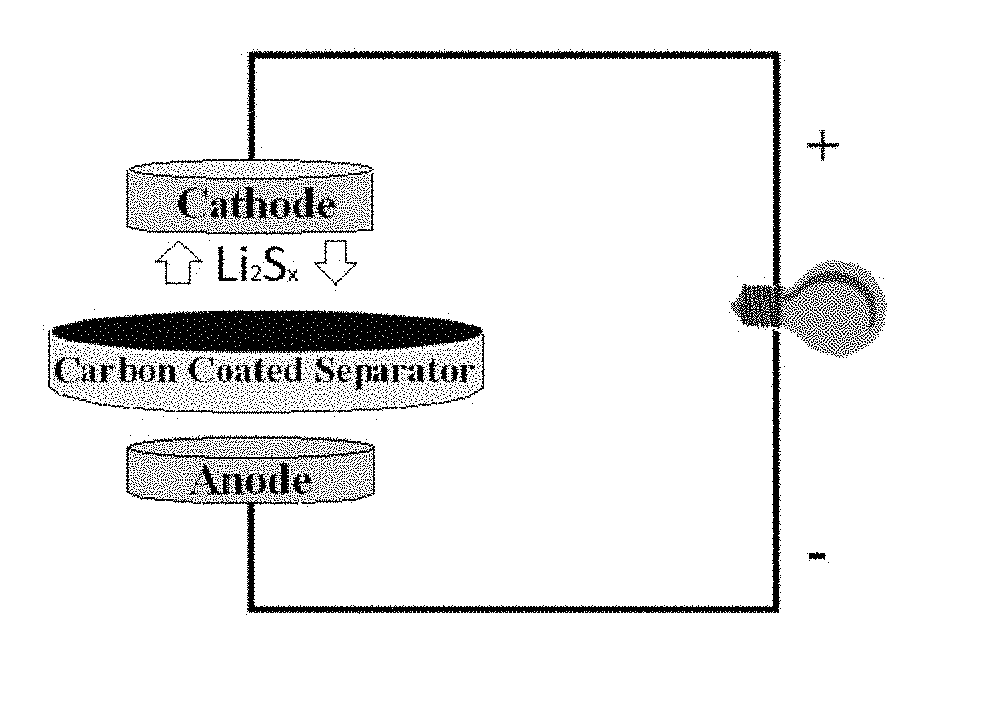

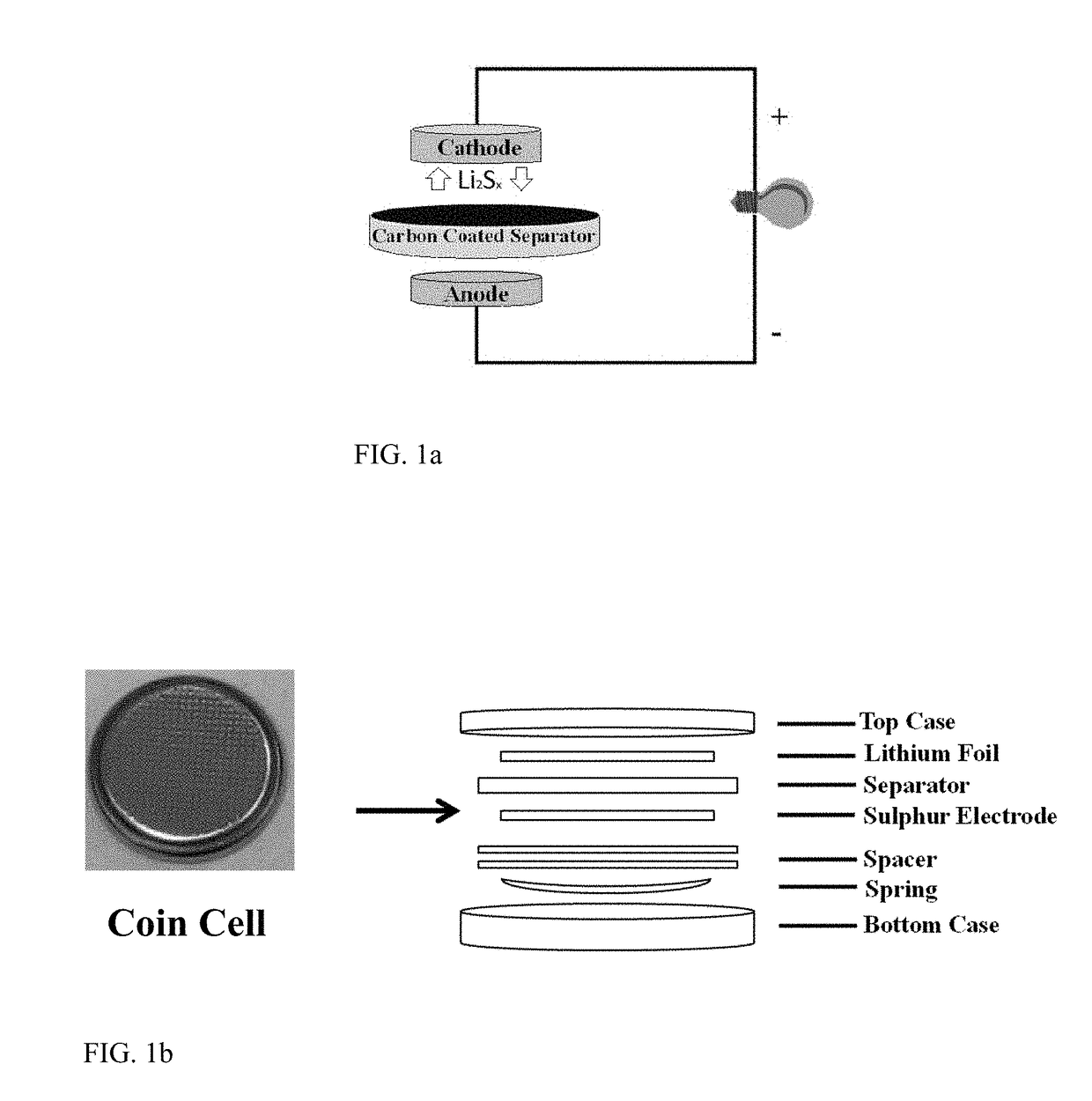

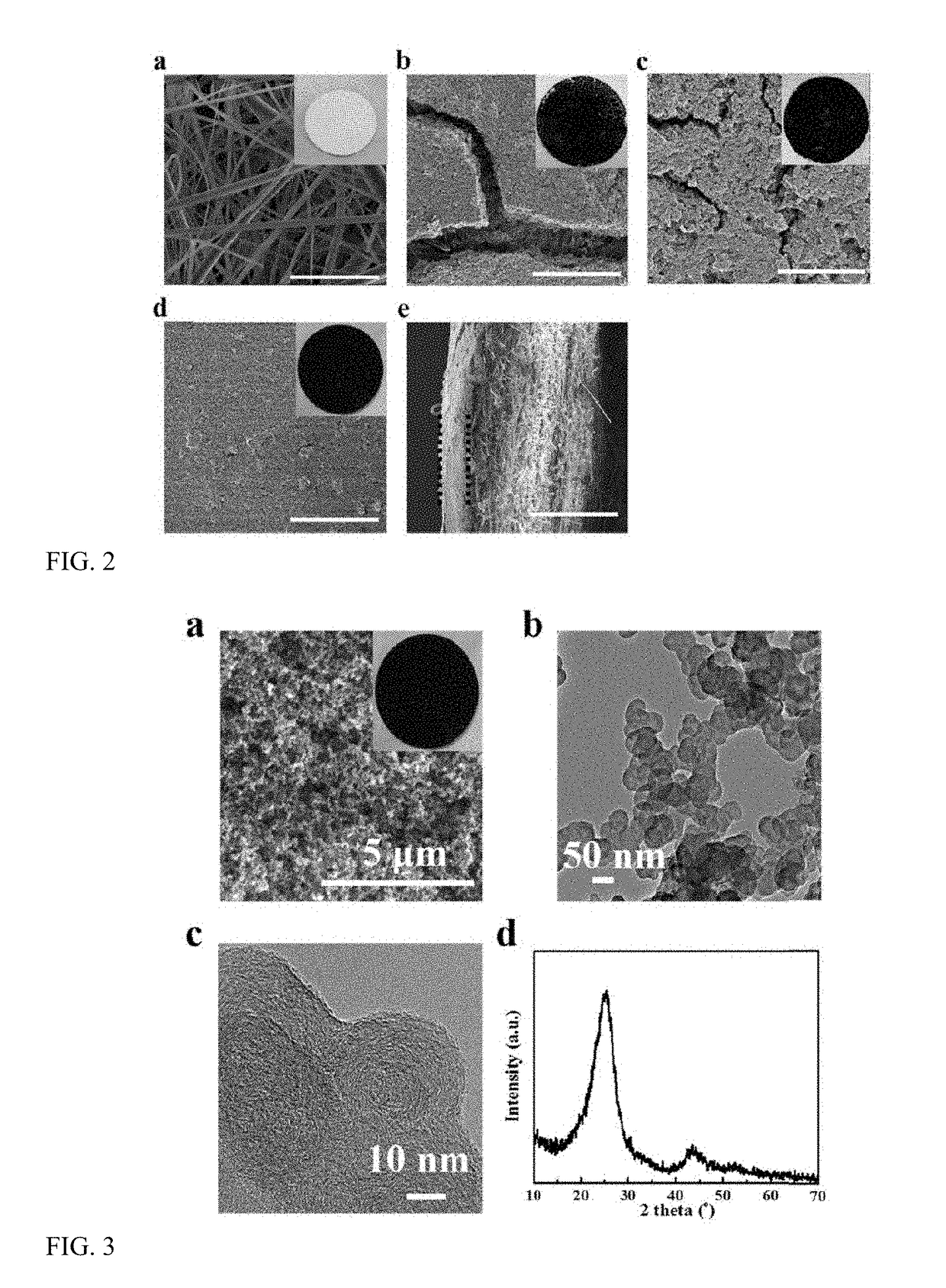

Li-S Battery with Carbon Coated Separator

ActiveUS20180287121A1Inhibit migrationHigh porosityCell electrodesFinal product manufactureCarbon coatedBattery cell

A Li—S battery cell comprising a Sulphur-containing cathode, a Lithium-containing anode, a separator in between the cathode and anode with an electrolyte on both sides of the separator filling interspaces between the anode and the cathode. The separator contains electrically conducting carbon and prevents polysulphide intermediates from migrating from the Sulphur-containing cathode to the Lithium anode.

Owner:NORTH CAROLINA STATE UNIV +1

Mesoporous Composite Titanium Oxide and a Preparation Method

ActiveUS20120184433A1Simple processLow costElectric discharge heatingCell electrodesPore distributionHydrodesulfurization

The invention discloses a mesoporous composite titanium oxide and a preparation method thereof, wherein the mesoporous composite titanium oxide material is composed of a mesoporous titanium oxide and an inorganic matter is composite on the outside surface and the wall of pores of the mesoporous titanium oxide; said inorganic matter contains at least one element selected from carbon, silicon, sulphur, phosphorus and selenium in an amount of 0.01%-25%, on amount of the element mass, of the mass of said mesoporous composite titanium oxide material; at least one most probable pore diameter of pore distribution of the mesoporous compound titanium oxide material is 3-15 nm, the specific surface area is 50-250 m2 / g, and the pore volume is 0.05-0.4 m3 / g. As a catalyst carrier, the rate of conversion of the hydrodesulfurization reaction of the material reaches as high as 98 percent, and as a lithium ion battery cathode material, the specific capacity of the lithium ion battery cathode material reaches as high as 220 mAh / g. Moreover, the preparation method of the material is simple, has low cost and is suitable for industrial bulk production.

Owner:NANJING UNIV OF TECH +1

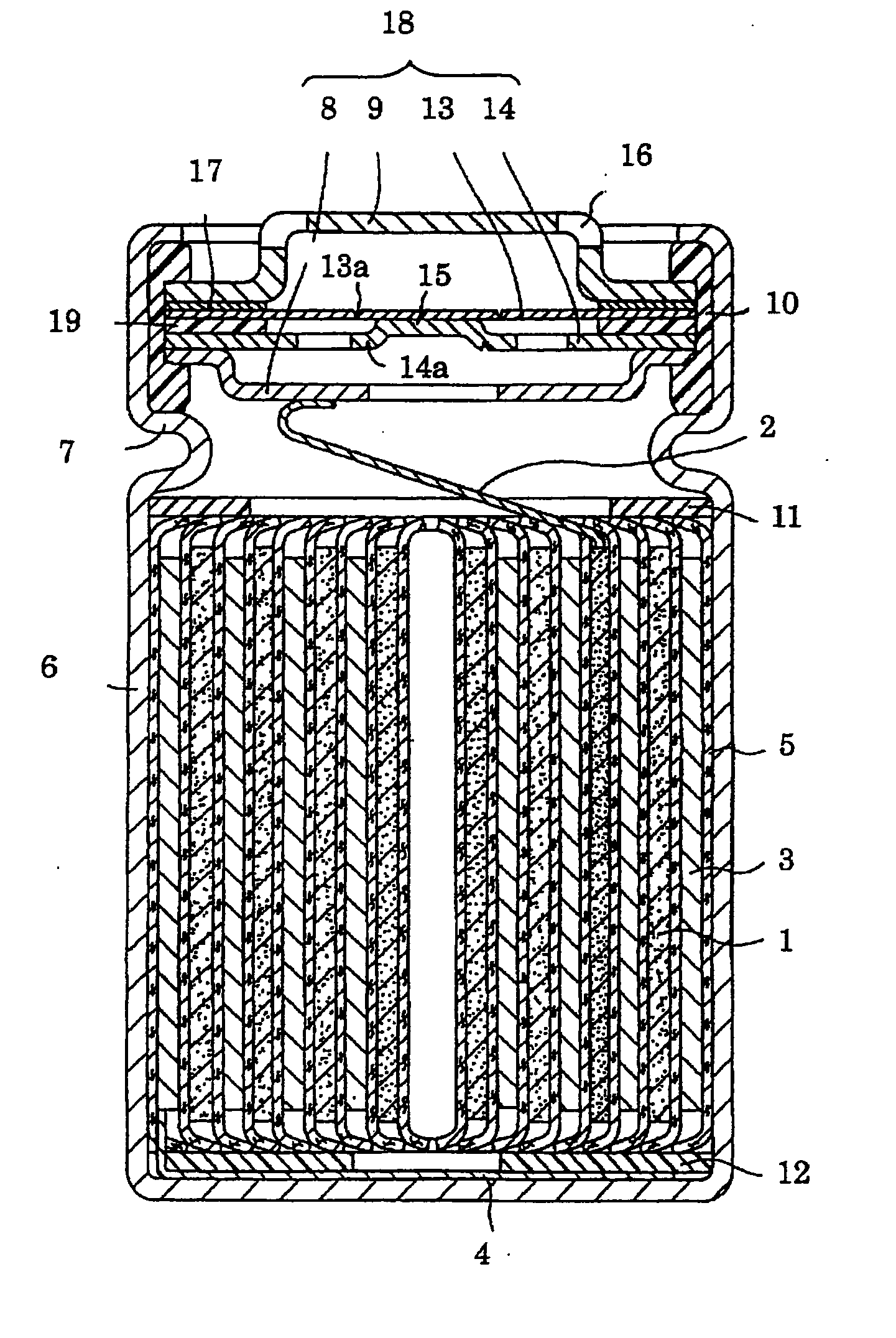

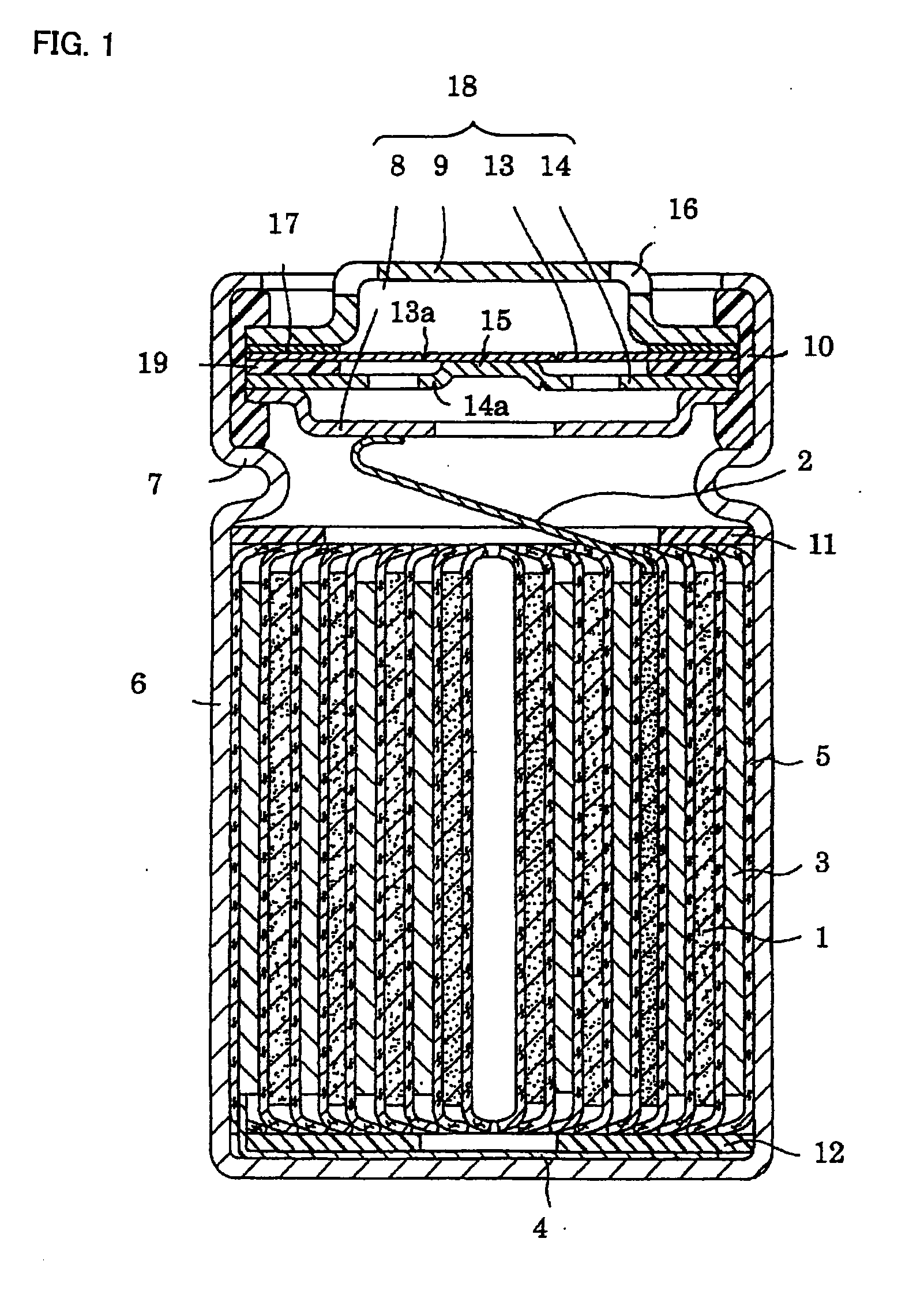

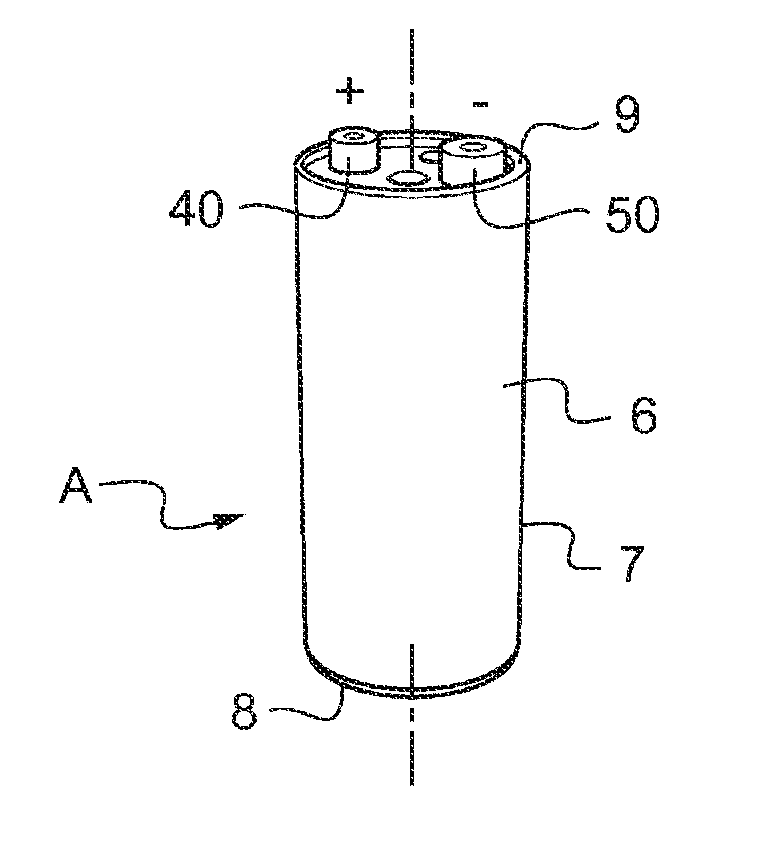

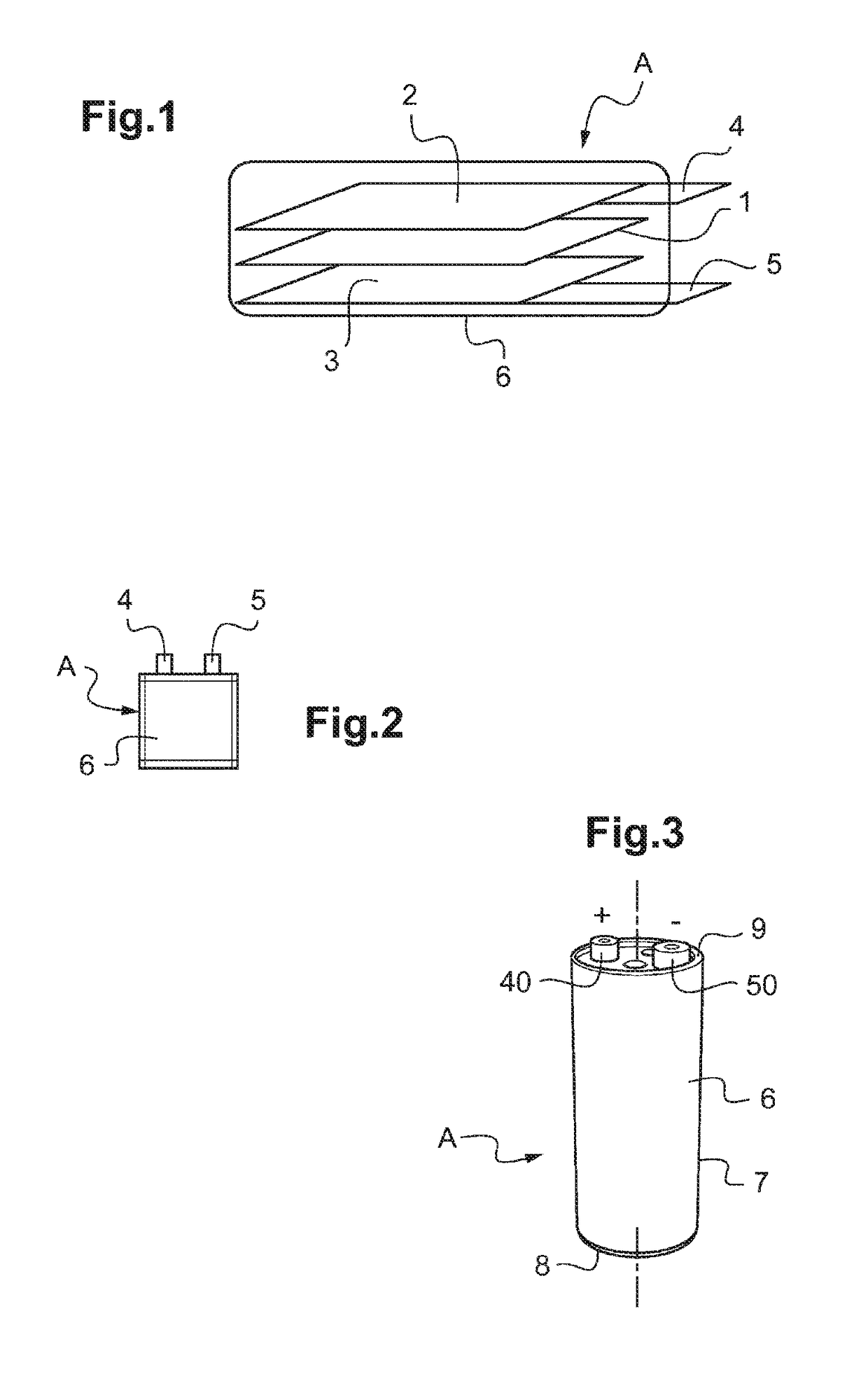

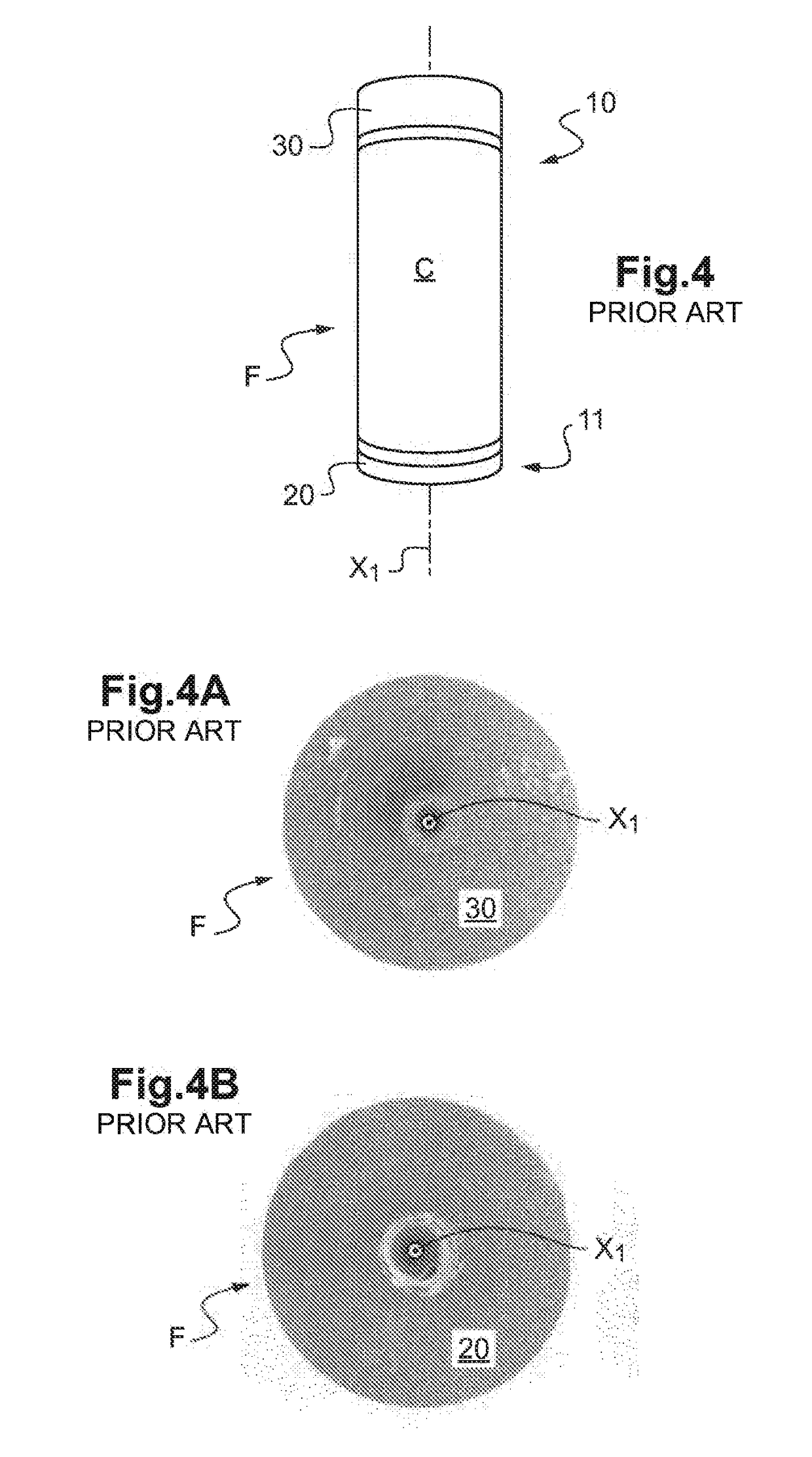

Method for producing an electrochemical bundle for a metal-ion accumulator comprising folding or coiling the foil ends around themselves

ActiveUS20180190962A1High densityRemove heatCell electrodesFinal product manufactureElectrical batteryElectrical connection

The invention relates to a method for producing an electromechanical bundle for a metal-ion battery, for electrical connection thereof to the output terminals of the battery, characterised by coiling or folding the sides of at least one of the two electrodes on itself, then compacting by packing in order to further increase the density of the coiled sides in order to weld the electrode to a current collector.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Fluoride ion electrochemical cell

ActiveUS20120270076A9Improve performanceHigh energyAlkaline accumulatorsLead-acid accumulatorsMetallic lithiumState of art

Owner:CALIFORNIA INST OF TECH +1

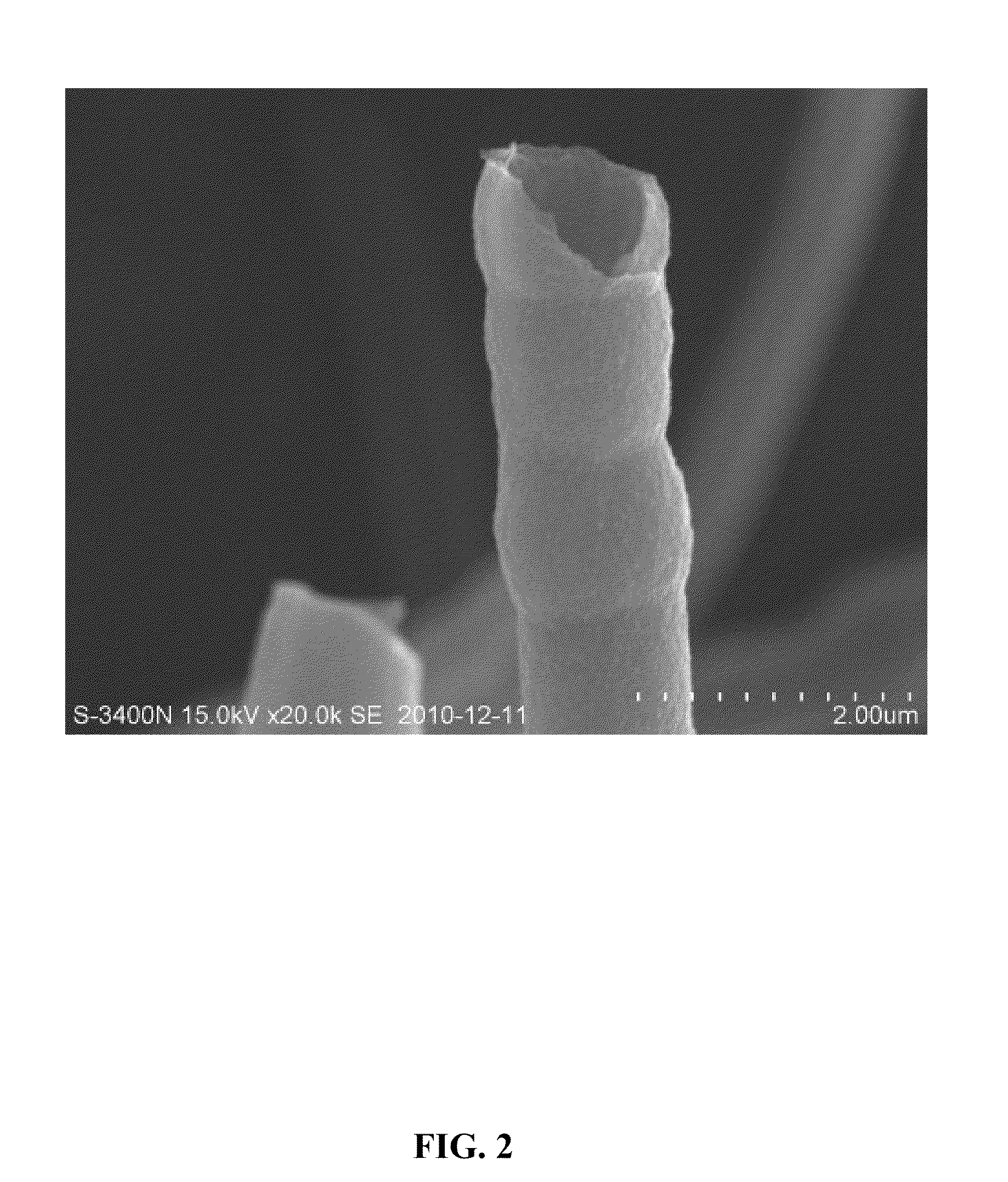

Method for preparing carbon nanotube or carbon microtube

ActiveUS20140027678A1Low yieldHigh production costNon-metal conductorsMaterial nanotechnologyCarbon nanotubeRoom temperature

A method for preparing a carbon nanotube, including: a) preparing an LPAN solution, stirring the LPAN solution at between 100 and 200° C. for between 100 and 200 hours to yield a cyclized LPAN solution; b) heating the cyclized LPAN solution at between 200 and 300° C. for between 1 and 10 hours to yield an OPAN; c) grinding, screening, and drying at room temperature the OPAN to yield a thermal oxidative precursor; d) calcining the thermal oxidative precursor at between 400 and 1000° C. for between 1 and 24 h in the presence of inert gas having a flow rate of between 10 and 500 mL / min to yield a carbonated precursor; and e) calcining the carbonated precursor at between 1000 and 1500° C. for between 1 and 10 hours in the presence of the inert gas having a flow rate of between 10 and 500 mL / min to yield a carbon nanotube material.

Owner:LIU JIANHONG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com