Patents

Literature

52results about How to "High energy capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

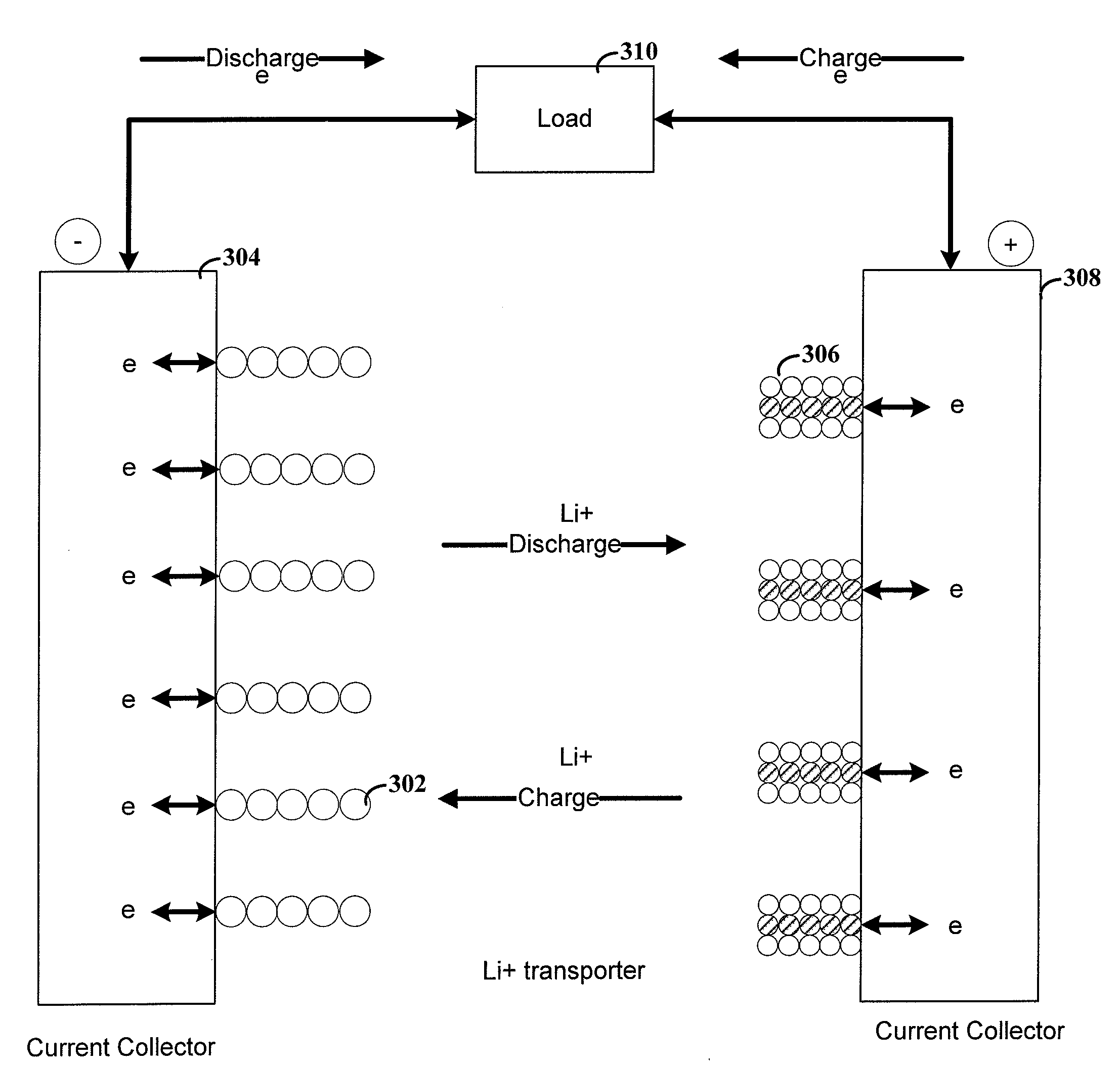

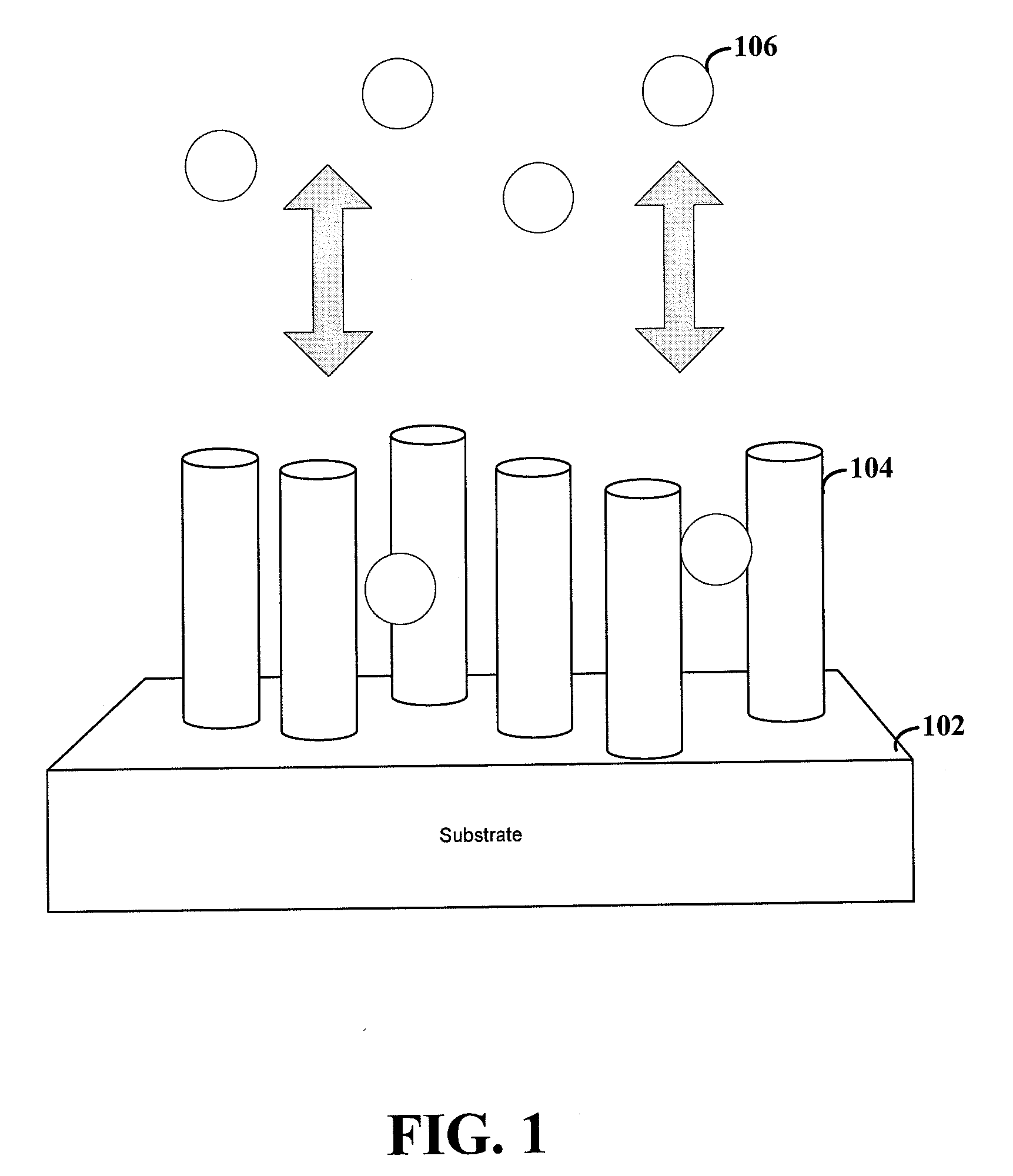

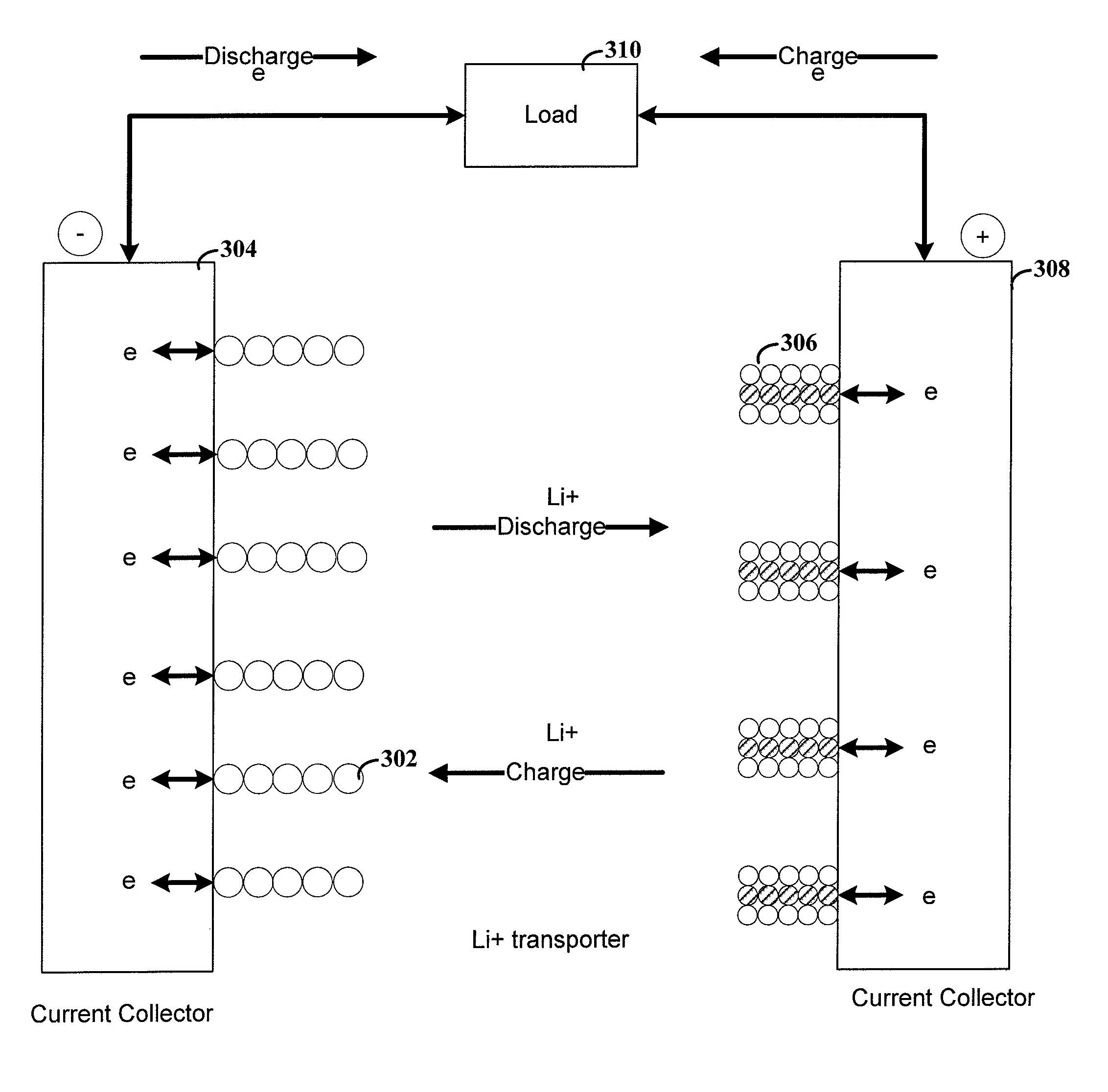

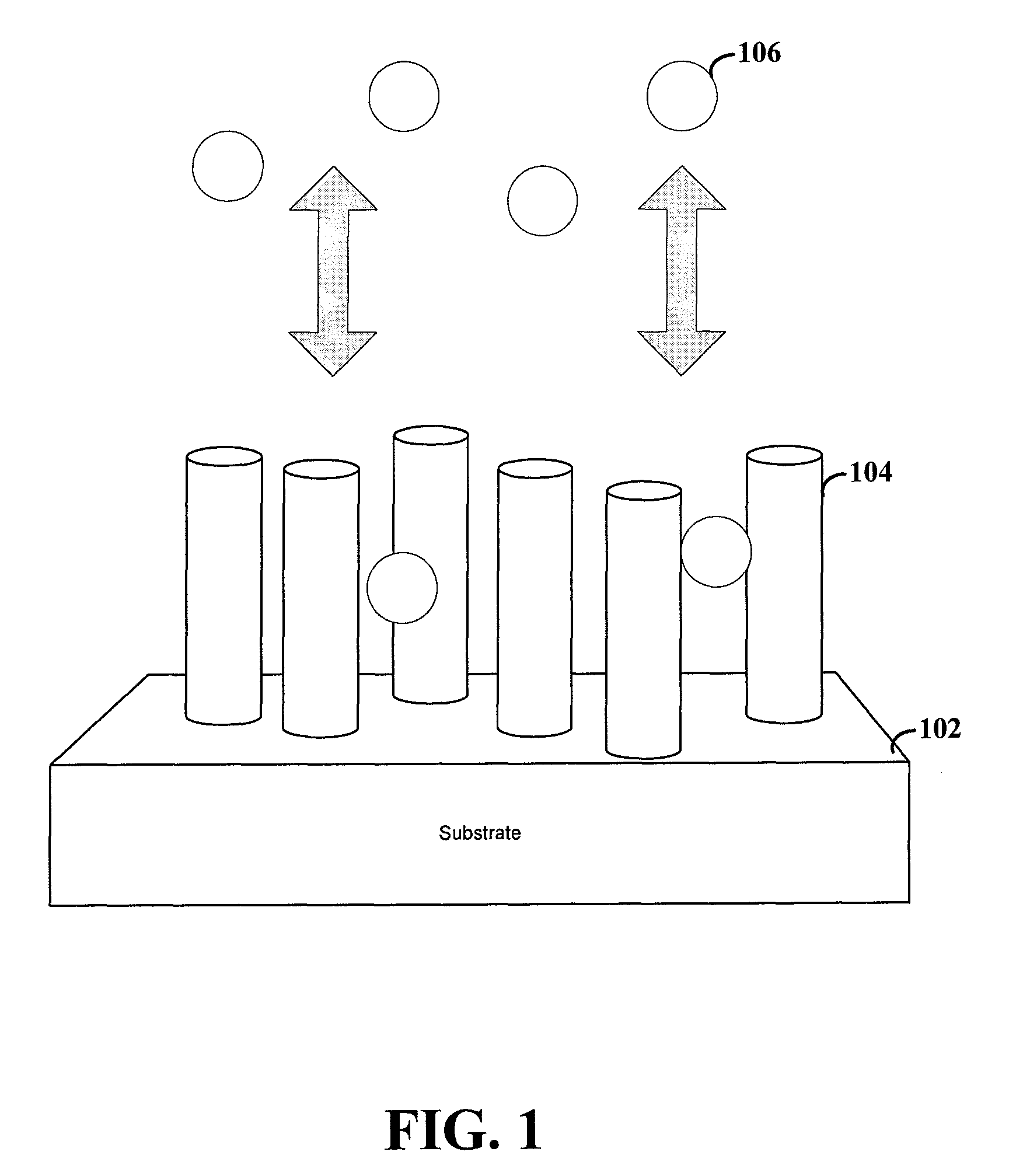

Nanowire Battery Methods and Arrangements

ActiveUS20090042102A1High energy capacityNanostructure manufactureFinal product manufactureNanowireNanowire battery

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Nanowire battery methods and arrangements

ActiveUS7816031B2High energy capacityNanostructure manufactureFinal product manufactureNanowireNanowire battery

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

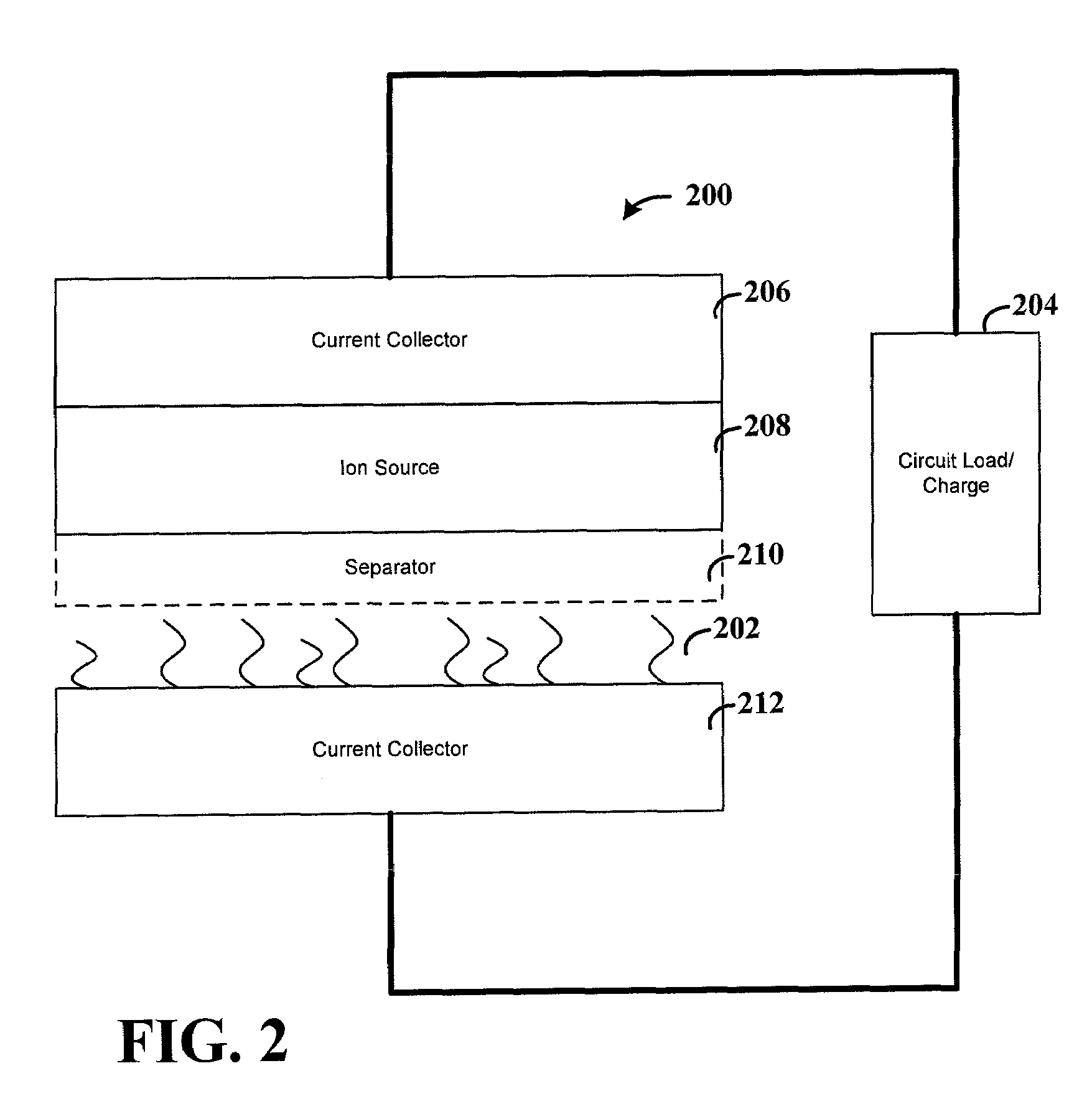

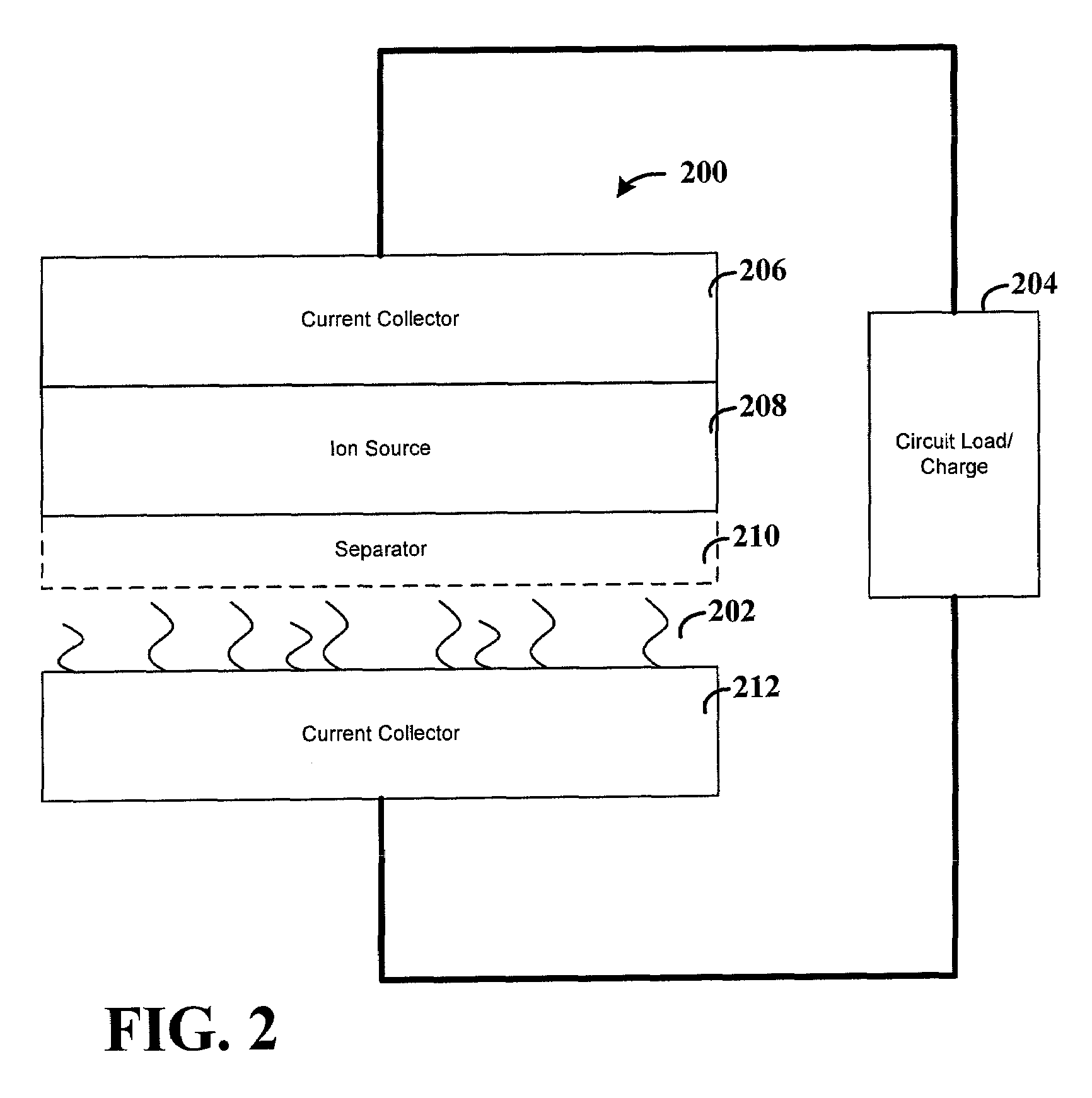

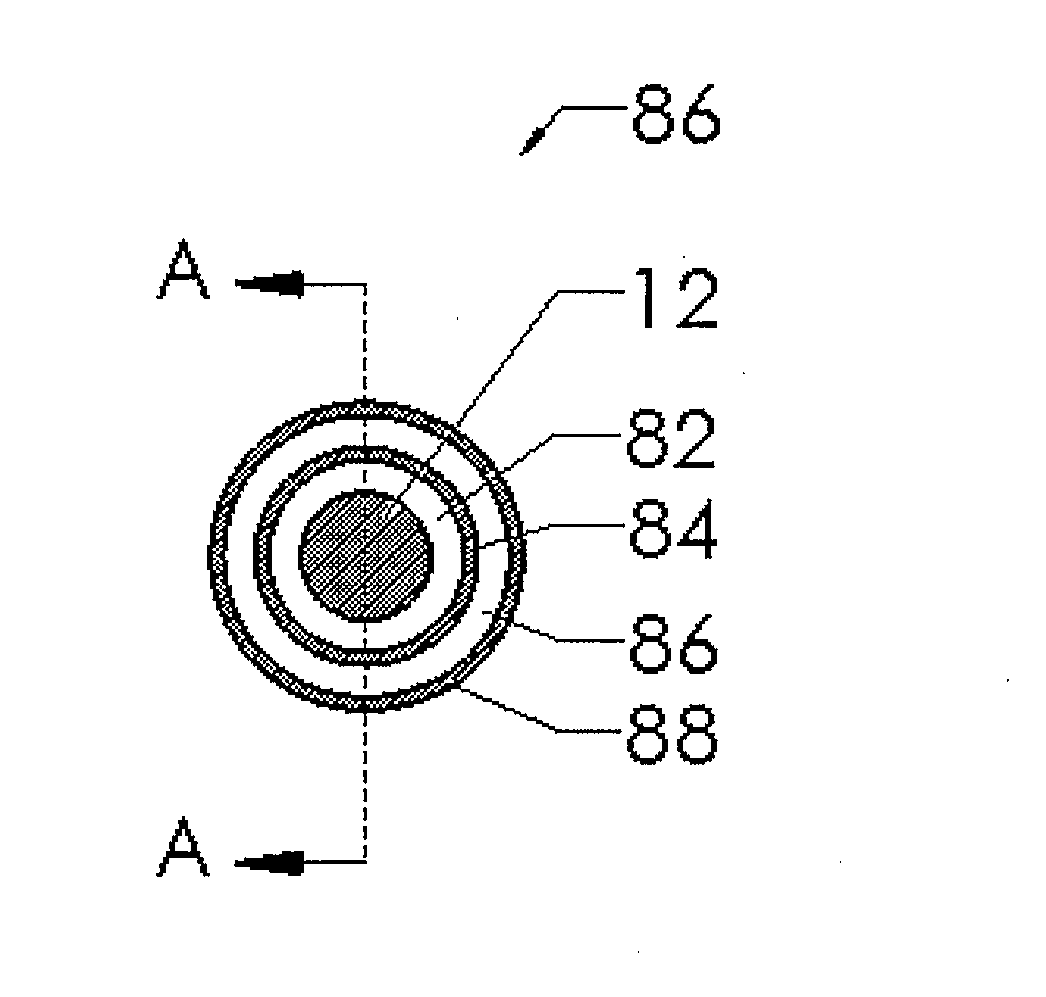

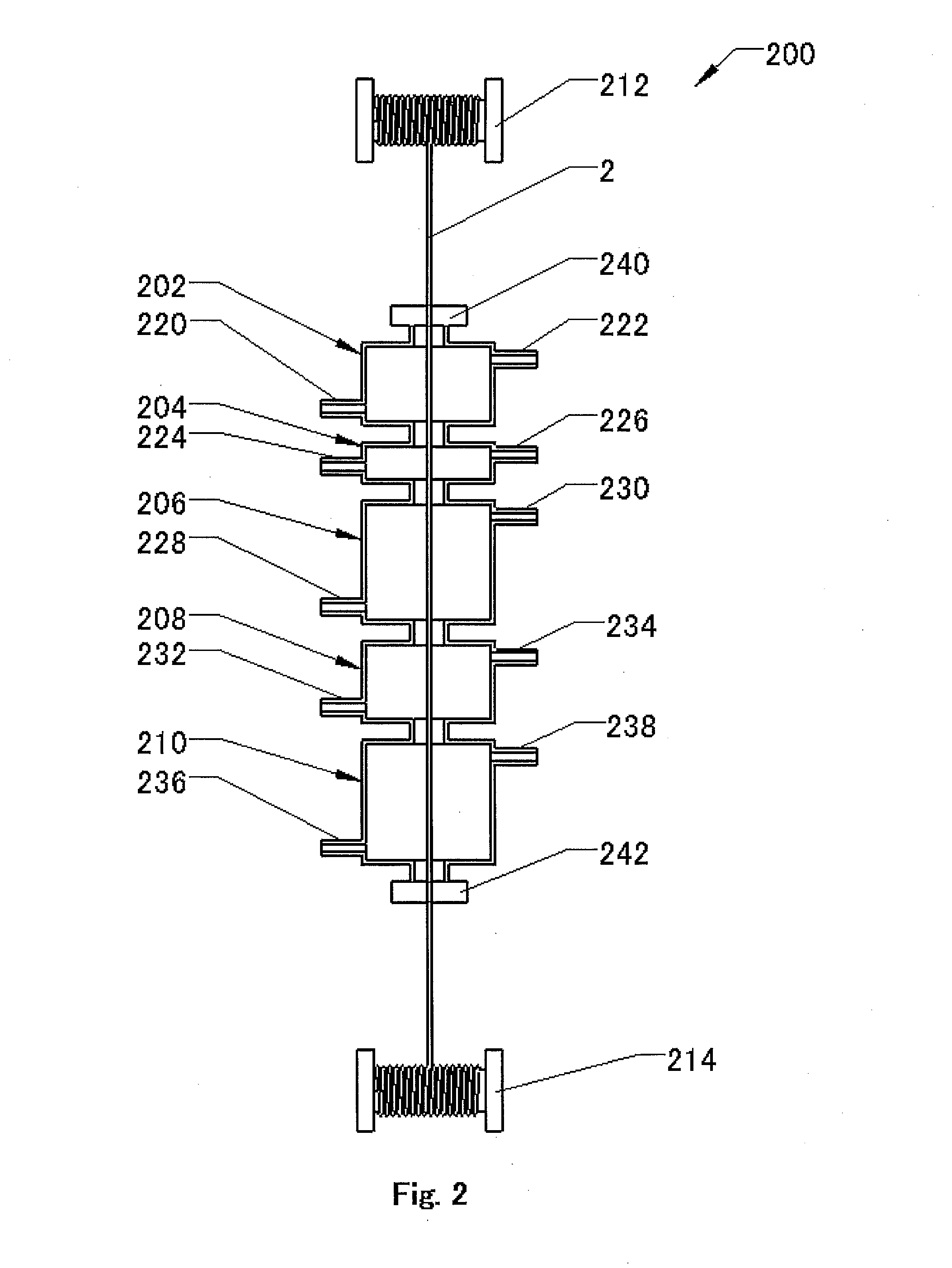

Li-ion battery and battery active components on metal wire

InactiveUS20130344363A1Improve performanceFast charging rateElectrode thermal treatmentFinal product manufactureIon exchangeMaterials science

A battery on a conductive metal wire and components of a battery on a conductive metal wire of circular cross section diameter of 5-500 micrometers and methods of making the battery and battery components are disclosed. In one embodiment, the battery features a porous anode or cathode layer which assist with ion exchange in batteries. Methods of forming the porous anode or cathode layer include deposition of an inert gas or hydrogen enriched carbon or silicon layer on a heated metal wire followed by annealing of the inert gas or hydrogen enriched carbon silicon layer. Energy storage devices having bundles of batteries on wires are also disclosed as are other energy storage devices.

Owner:KALPTREE ENERGY

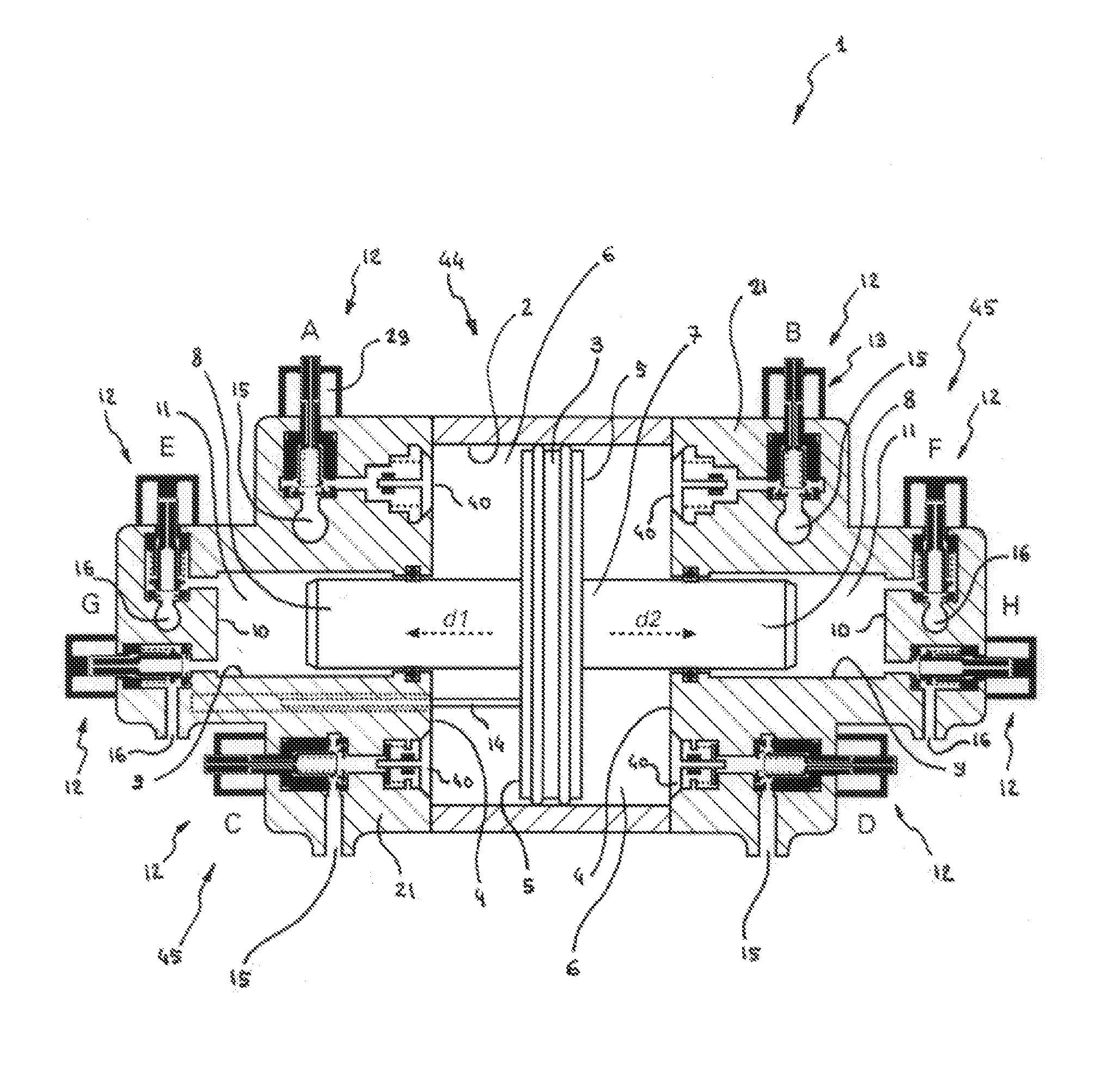

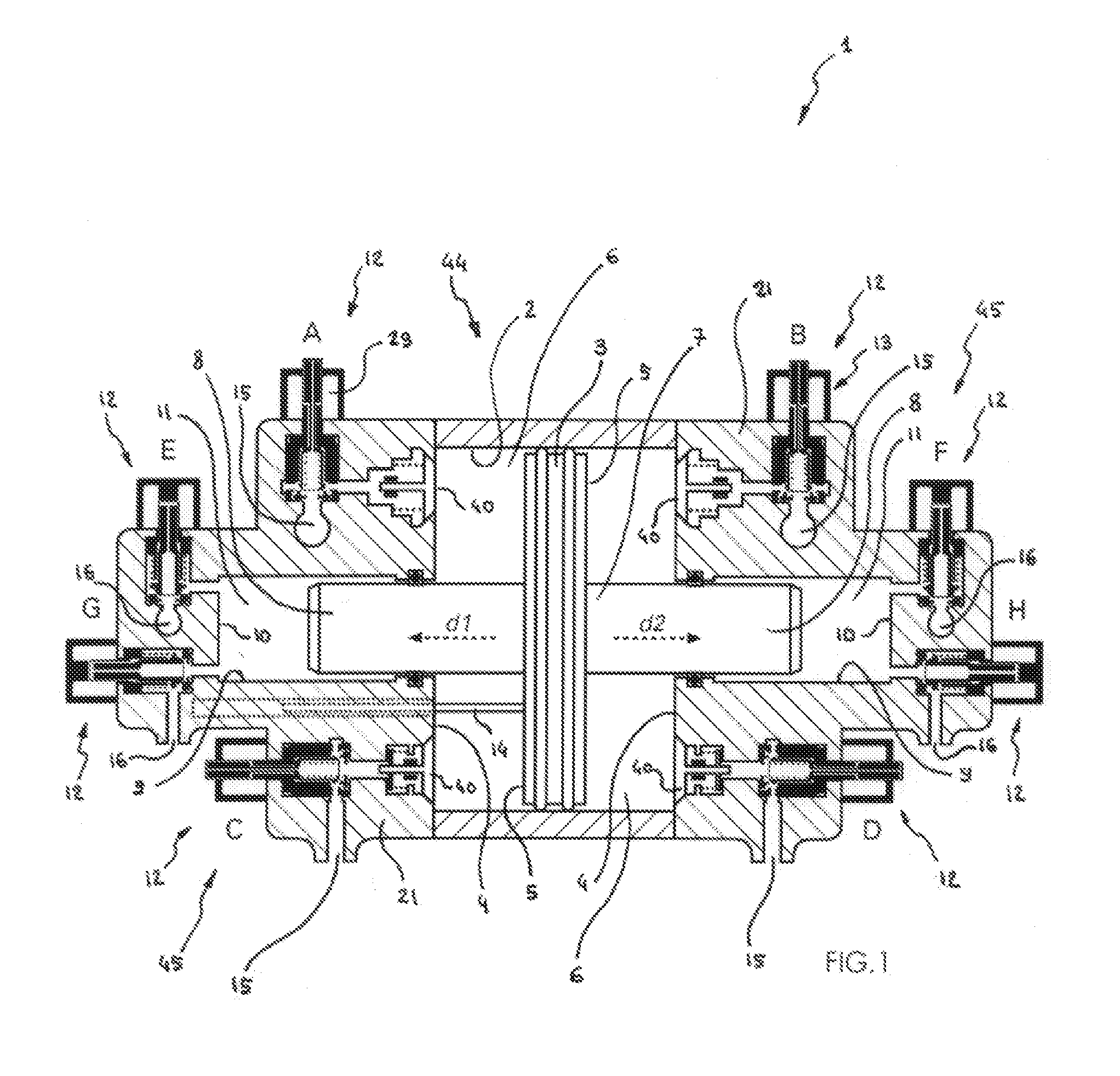

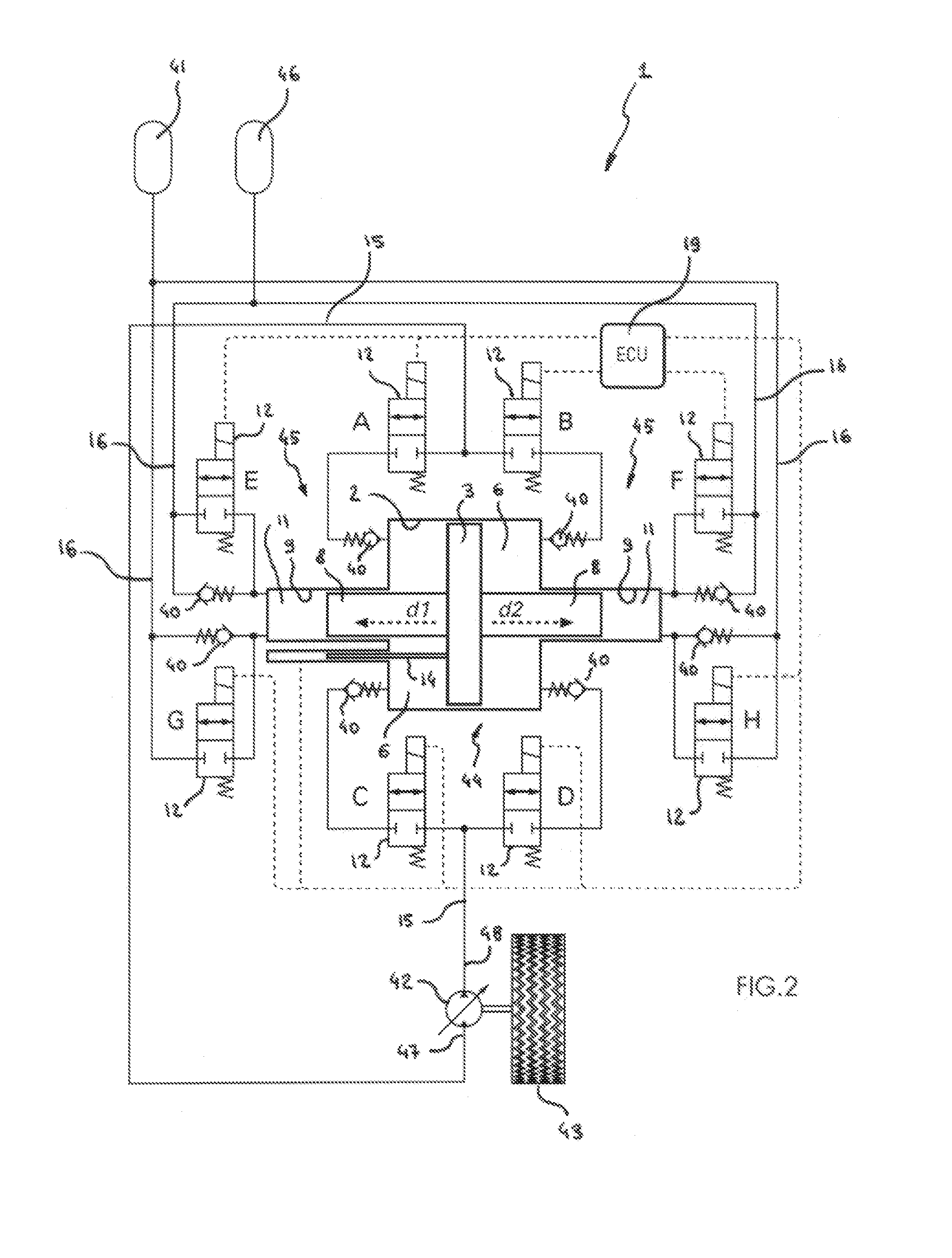

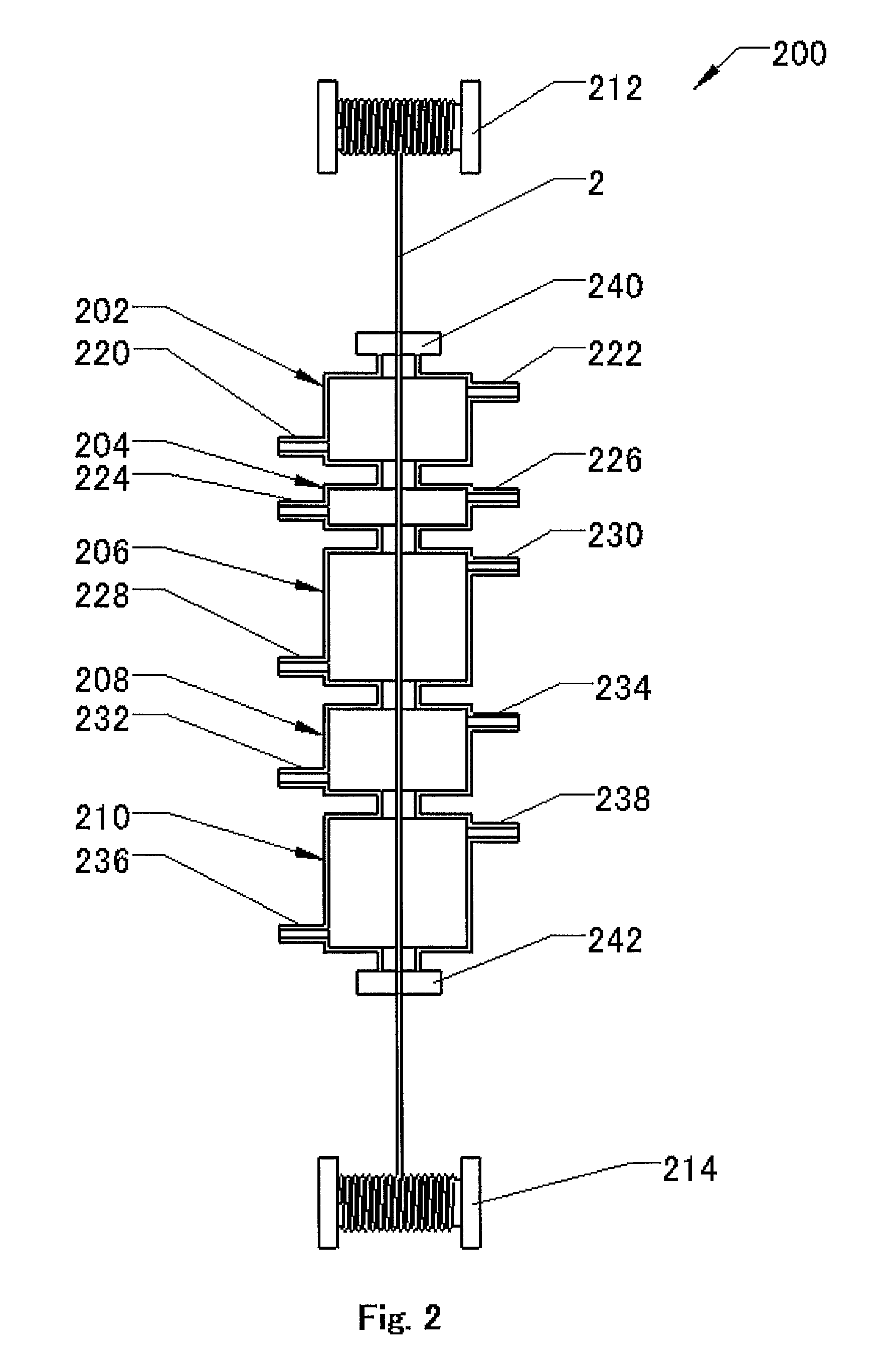

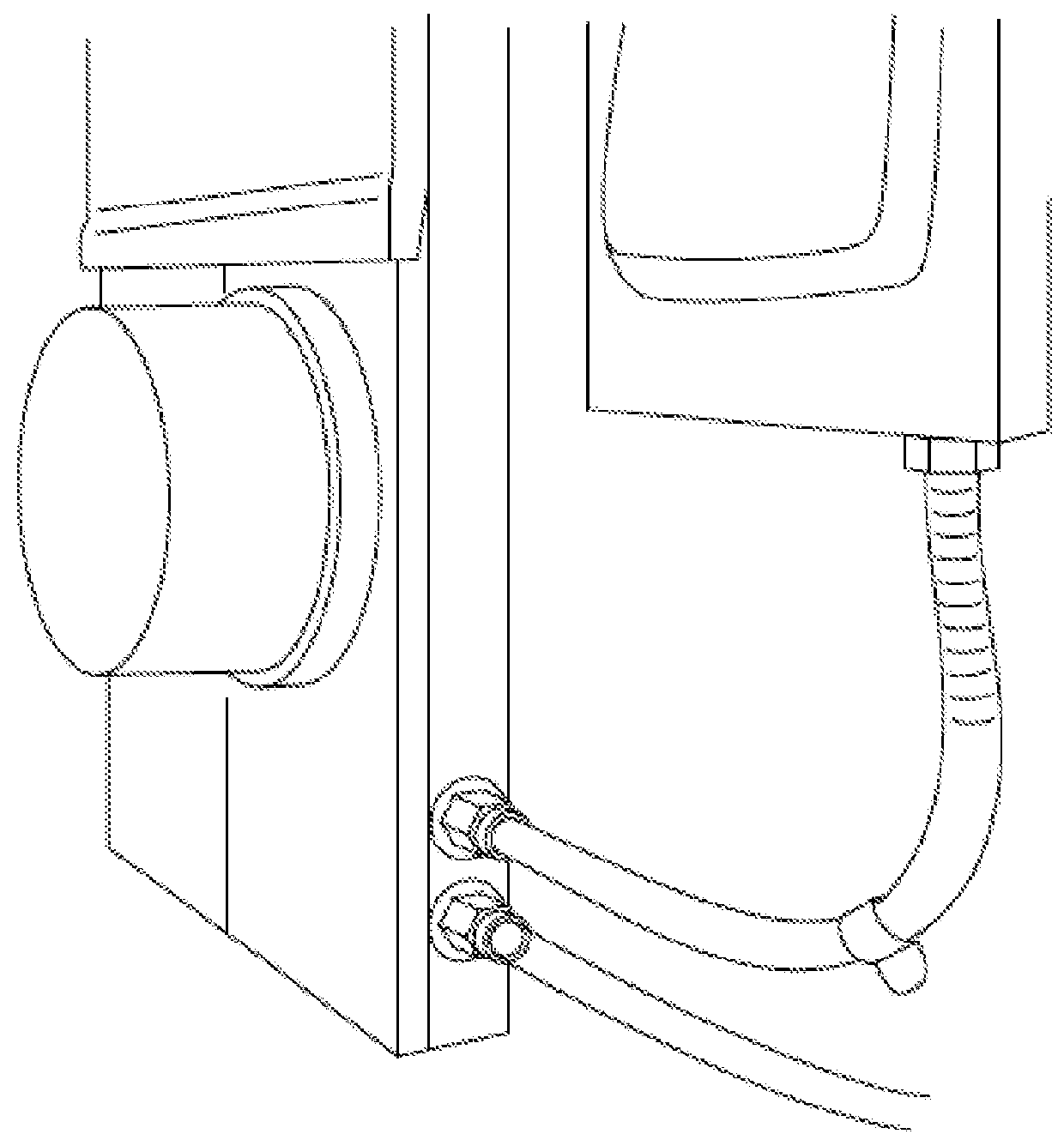

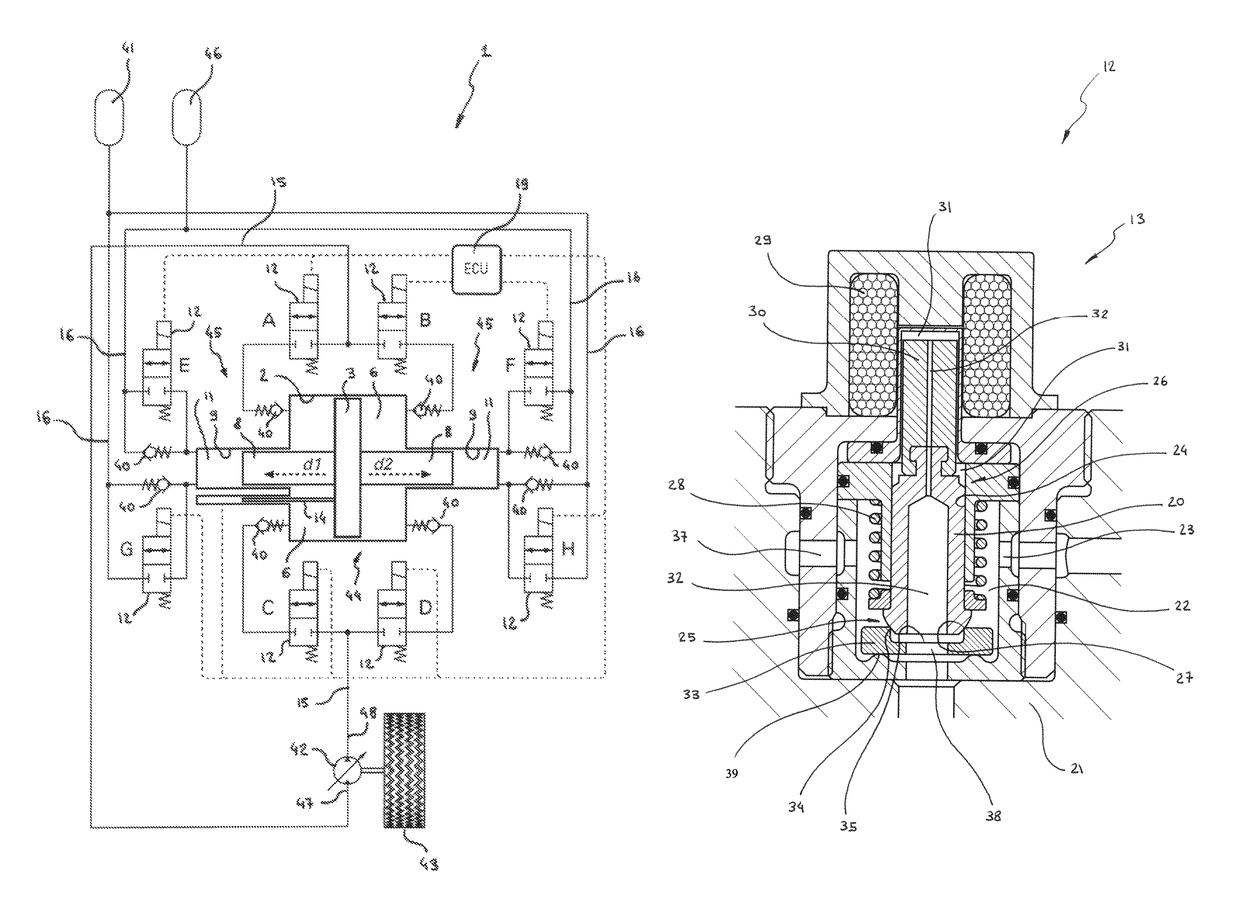

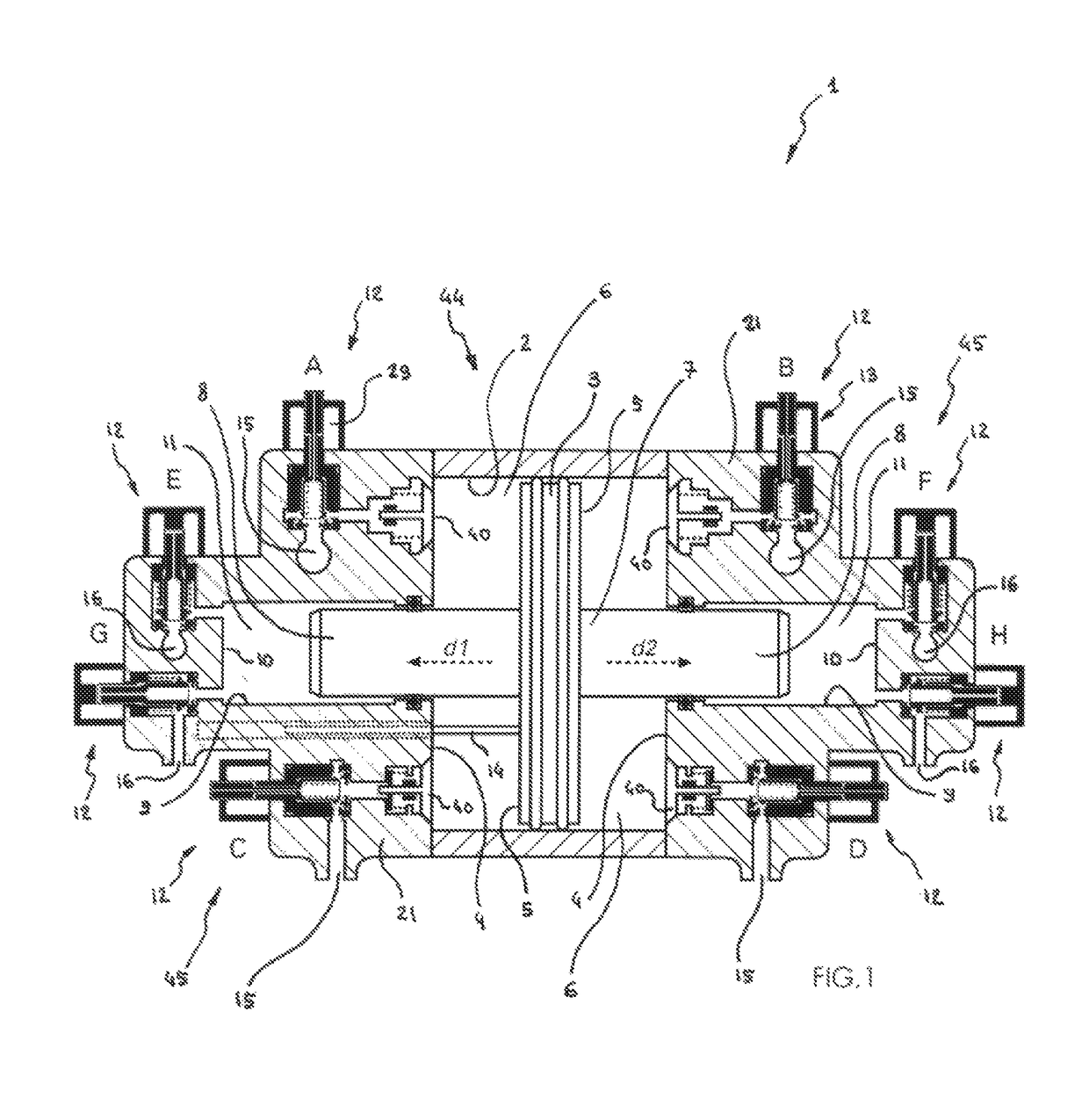

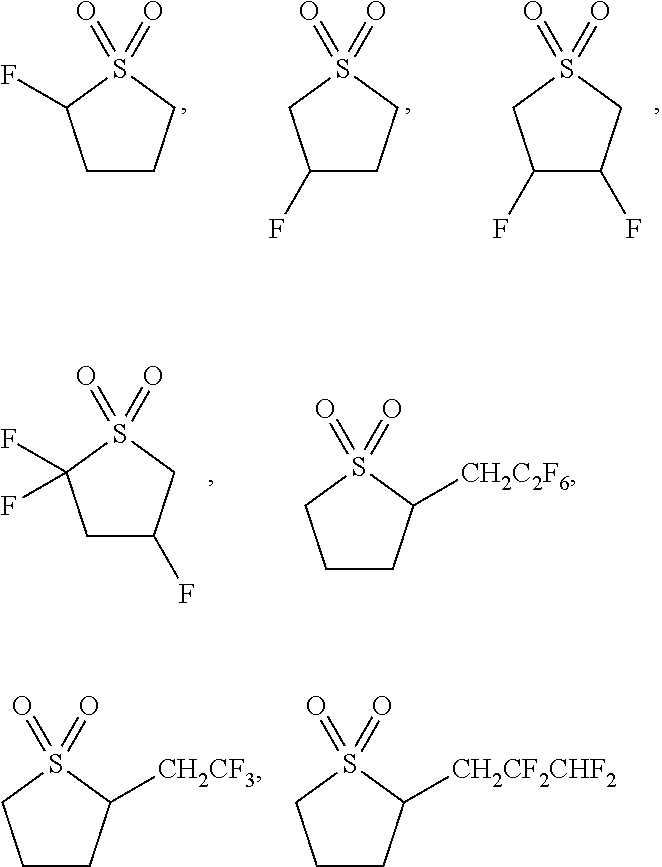

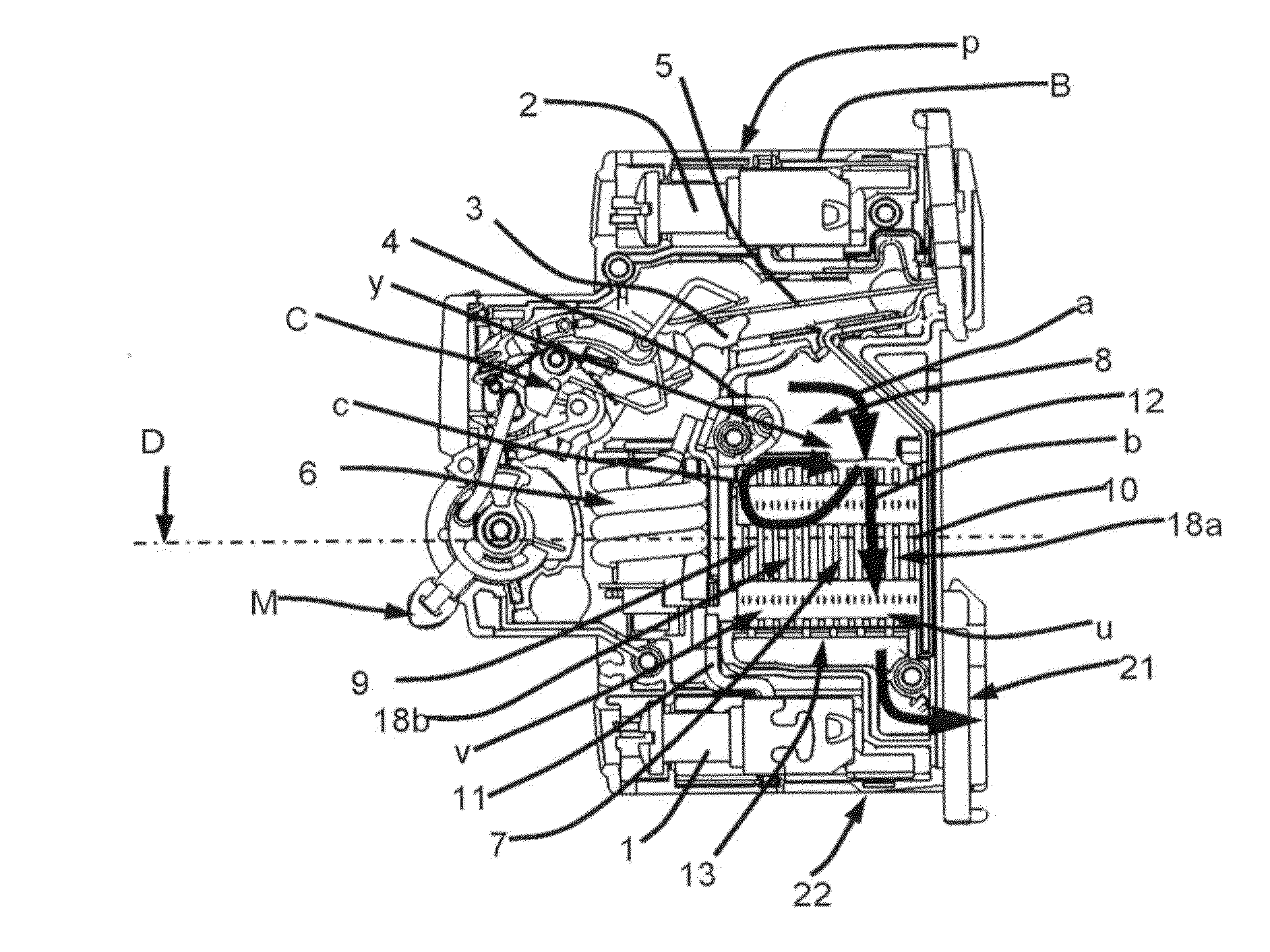

Reversible hydraulic pressure converter employing tubular valves

ActiveUS20150053075A1Improve efficiencyImprove hydraulic efficiencyPropulsion power plantsAccumulator installationsValve actuatorEngineering

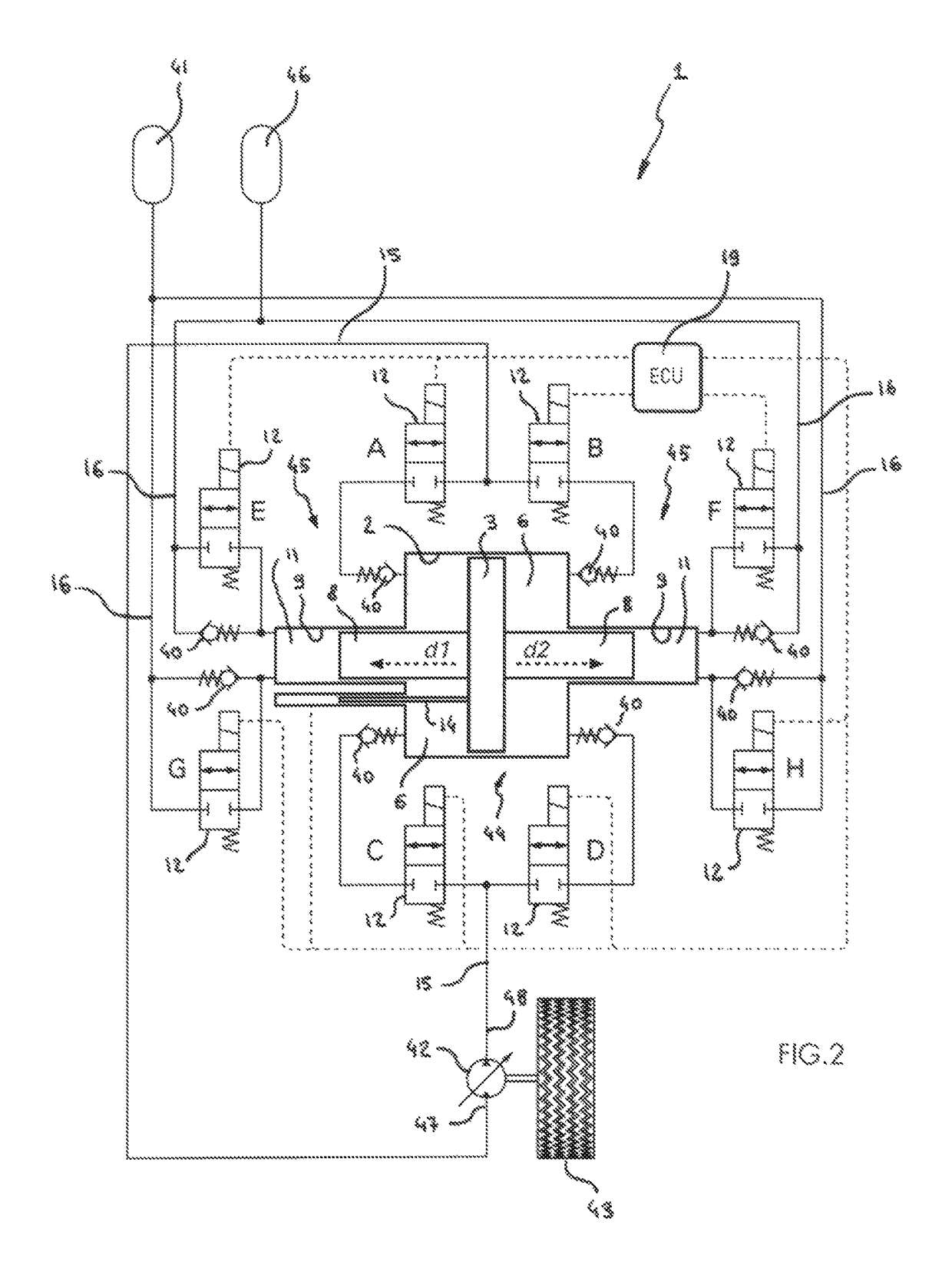

The reversible hydraulic pressure converter (1) employing tubular valves includes a medium-pressure stage (44) consisting of a medium-pressure cylinder (2) and a double-acting medium-pressure piston (3) the position of which is sent to a control computer of the converter (19) by a piston position sensor (14), the cylinder (2) and the piston (3) forming two medium-pressure chambers (5) that can be placed in communication with a medium-pressure inlet-outlet circuit (15) by at least one tubular valve (12), the converter (1) also including two high-pressure cylinders (9) each cooperating with a high-pressure piston (8) of smaller diameter and defining two high-pressure chambers (11) that can be placed in communication with a high-pressure inlet-outlet circuit (16) by at least one tubular valve (12), each of the various tubular valves (12) cooperating with an independent valve actuator (13).

Owner:RABHI VIANNEY

Lithium battery with silicon-based anode and silicate-based cathode

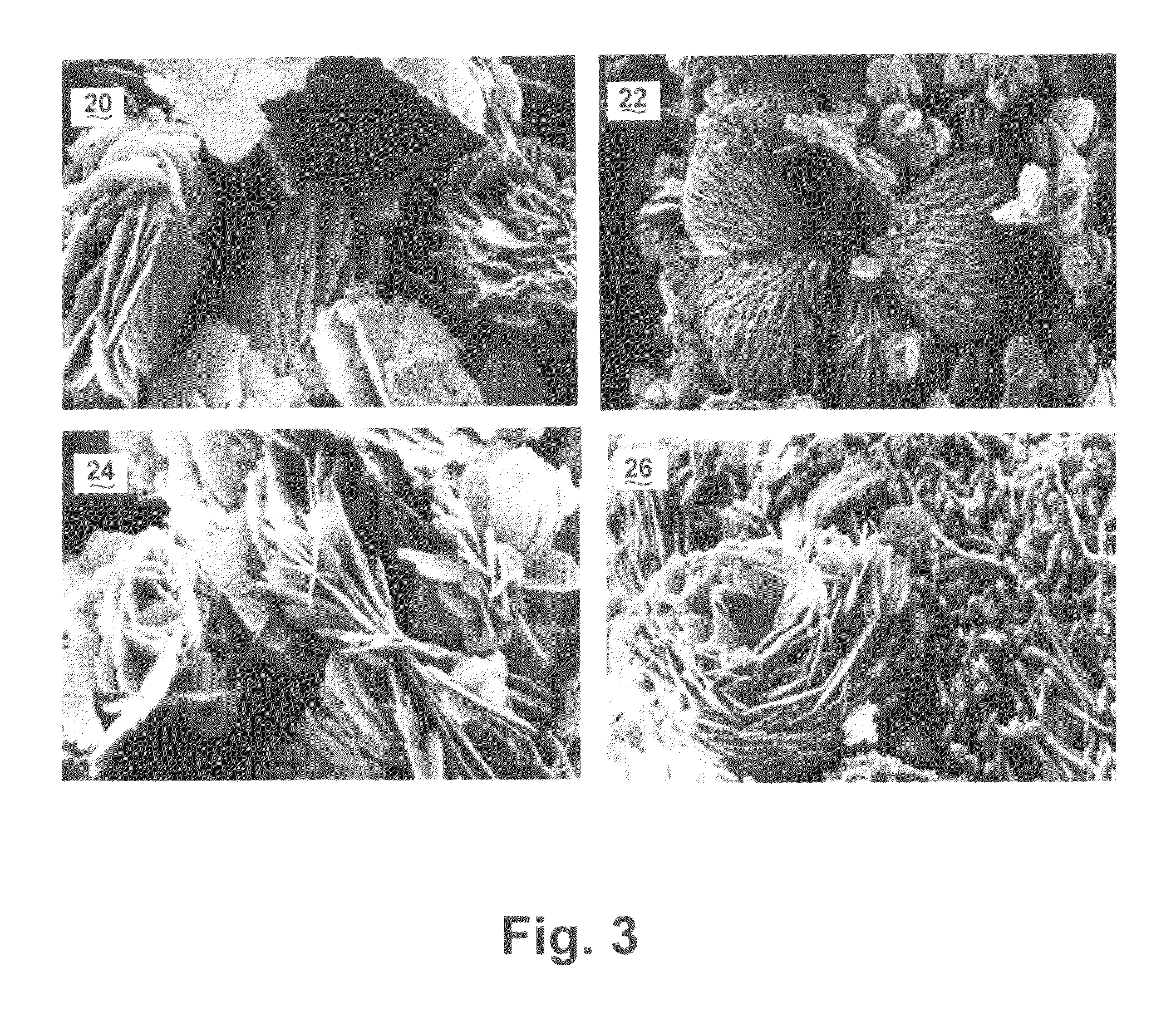

ActiveUS20130234674A1High energy capacityImprove cycle efficiencyMaterial nanotechnologyBatteries circuit arrangementsNickel–lithium batteryCarbon nanofiber

A lithium-ion battery is provided and related methods. The lithium-ion battery includes an electrode comprising an Olivine flake-like structure and an electrode comprising a plurality of coated carbon nanofibers. The Olivine flake-like structures form clusters through which the lithium ions are transported while reducing initial cycle irreversibility. The electrode comprising the coated carbon nanofibers additionally reduce initial cycle irreversibility by controlling expansion of the substrate forming the electrode comprising the coated carbon nanofibers.

Owner:GENERAL MOTORS COMPANY

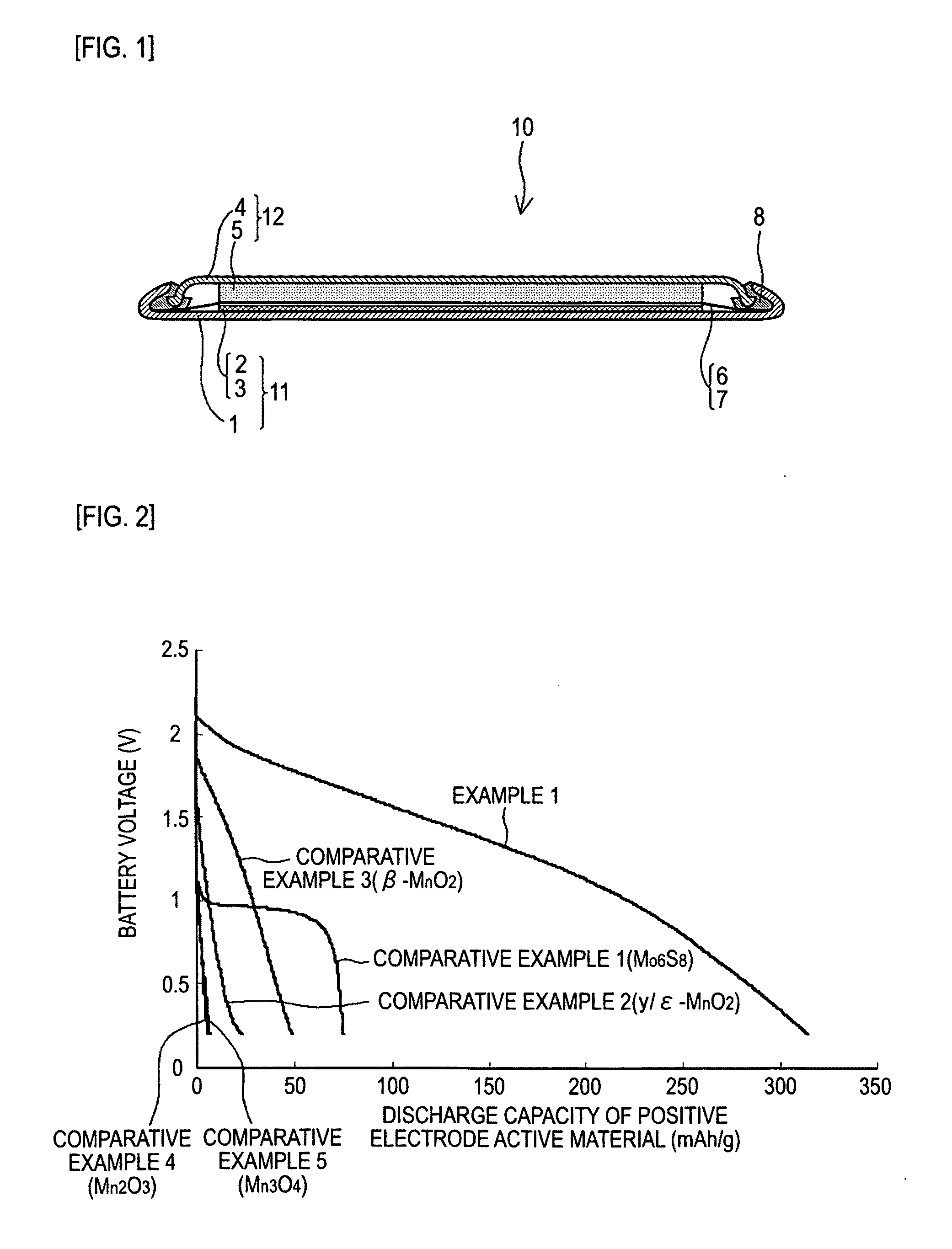

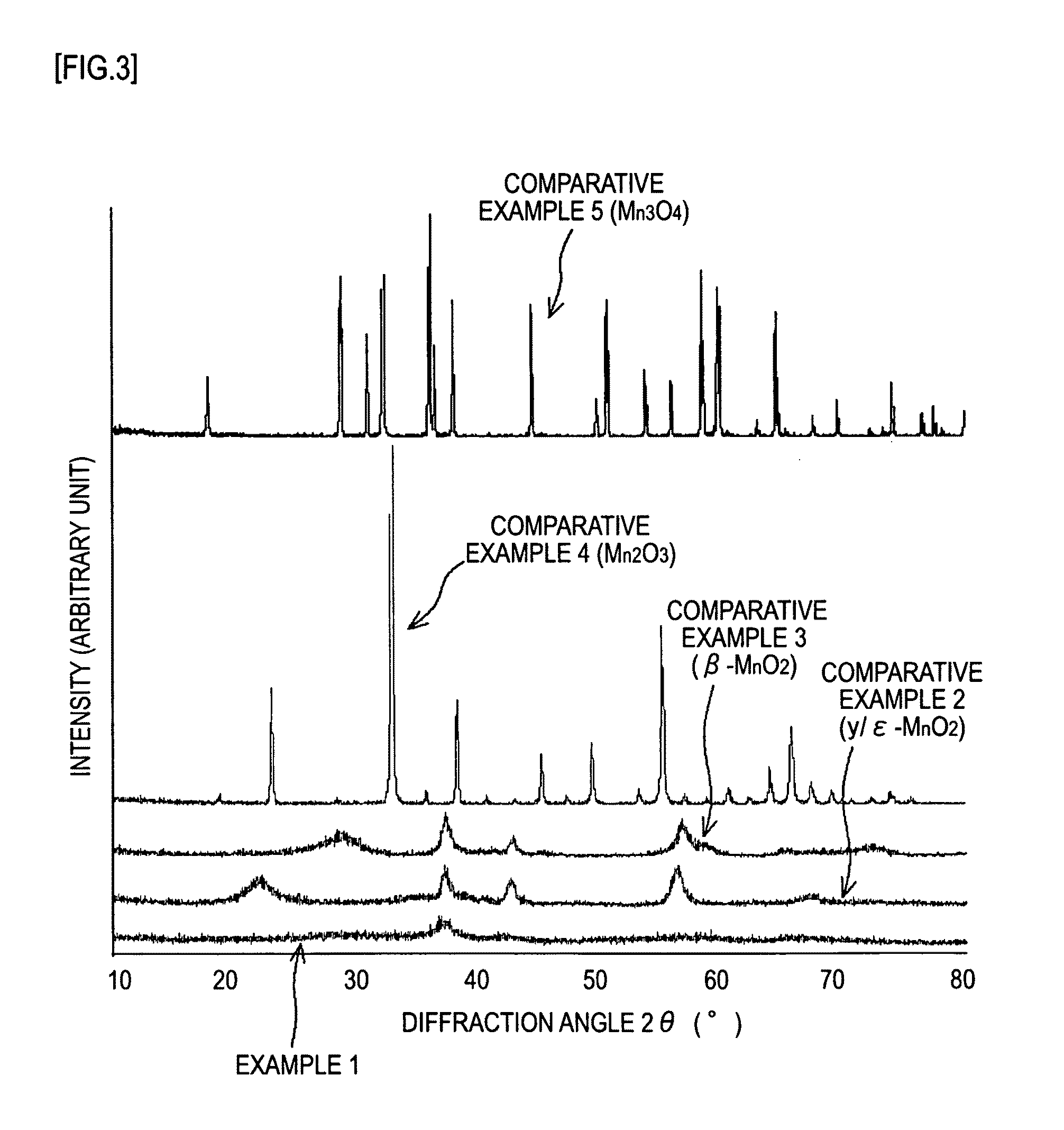

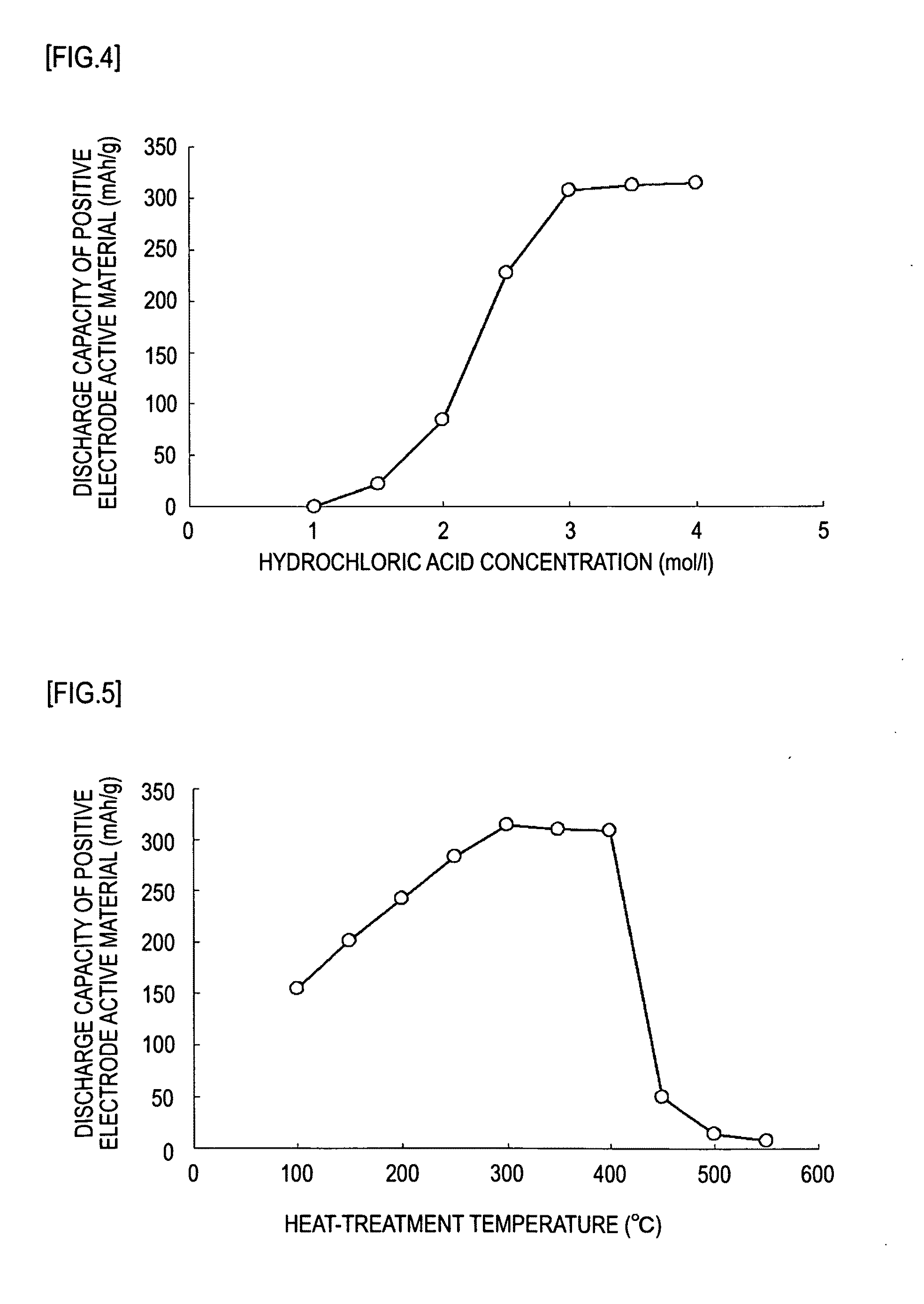

Positive electrode active material, method for producing the same, and electrochemical device

ActiveUS20100196762A1High electromotive forceHigh energy capacityFinal product manufactureOrganic electrolyte cellsHigh energyPERMANGANATE ION

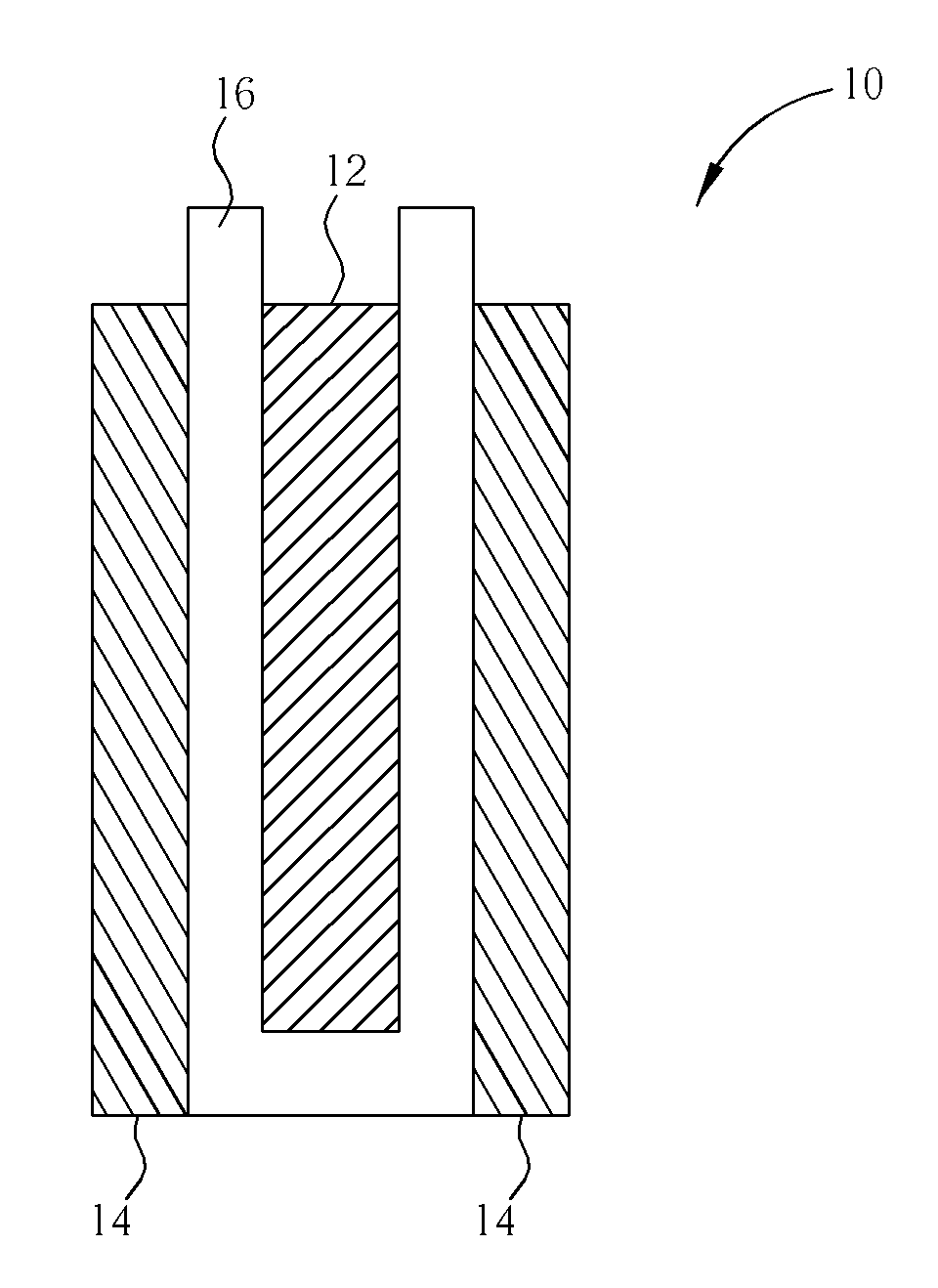

The invention provides a high-capacity positive electrode active material capable of sufficiently exploiting the excellent characteristics of magnesium metal or the like as a negative electrode active material, such as high energy capacity; a method for producing the same; and an electrochemical device using the positive electrode active material. A positive electrode 11 includes a positive electrode can 1, a positive pole pellet 2 having a positive electrode active material and the like, and a metal mesh support 3. A negative electrode 12 includes a negative electrode cap 4 and a negative electrode active material 5 such as magnesium metal. The positive electrode pellet 2 and the negative electrode active material 5 are disposed so as to sandwich a separator 6, and an electrolyte 7 is injected into the separator 6. The positive electrode active material, which provides the feature of the invention, is synthesized by a step of reacting a permanganate, such as potassium permanganate, with hydrochloric acid preferably having a concentration of 3 to 4 mol / l to produce a precipitate, and a step of filtering the precipitate, thoroughly washing the filtered precipitate with water, and then subjecting the washed precipitate to heat treatment preferably at a temperature of 300 to 400° C. for not less than 2 hours, thereby giving a manganese oxide.

Owner:MURATA MFG CO LTD

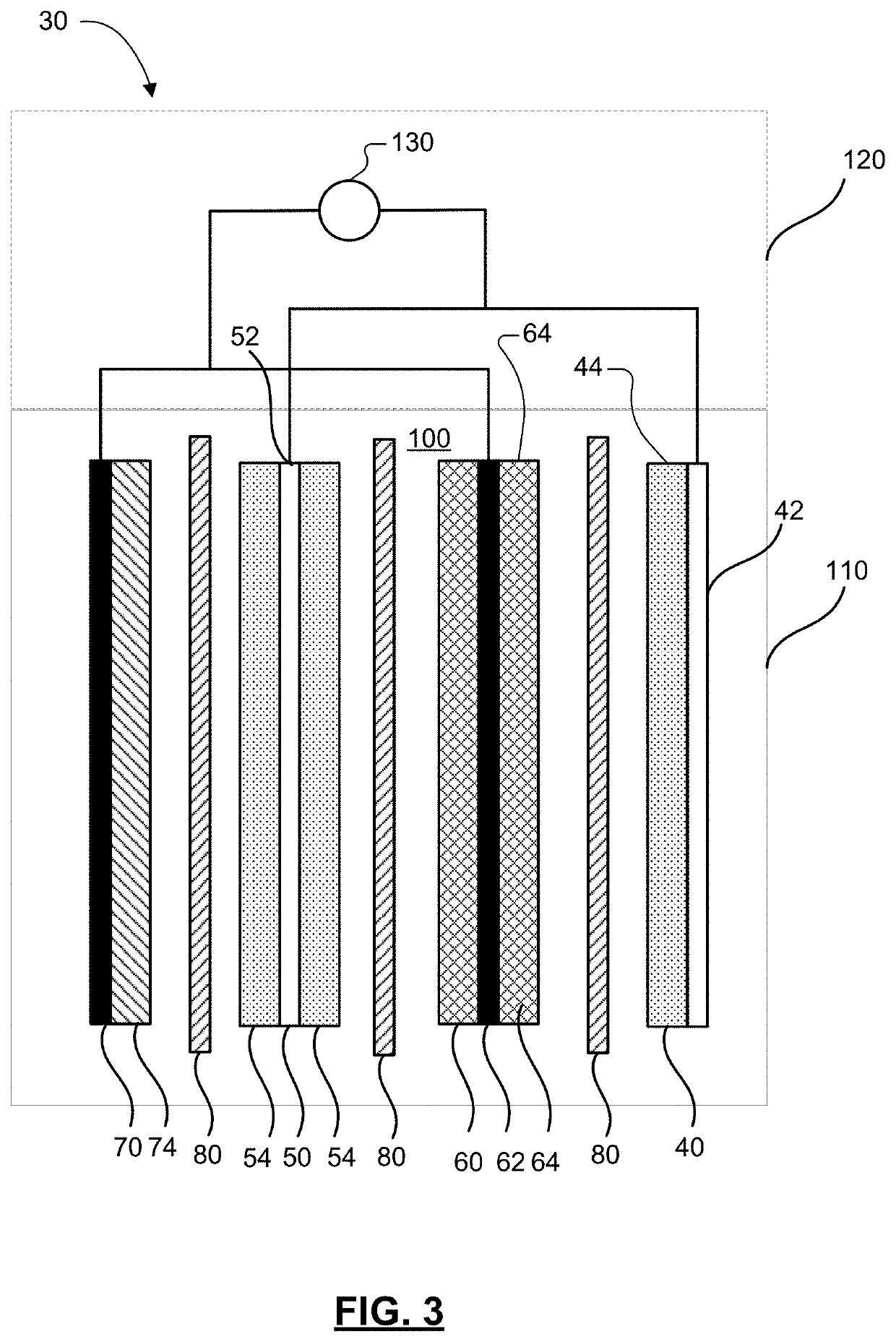

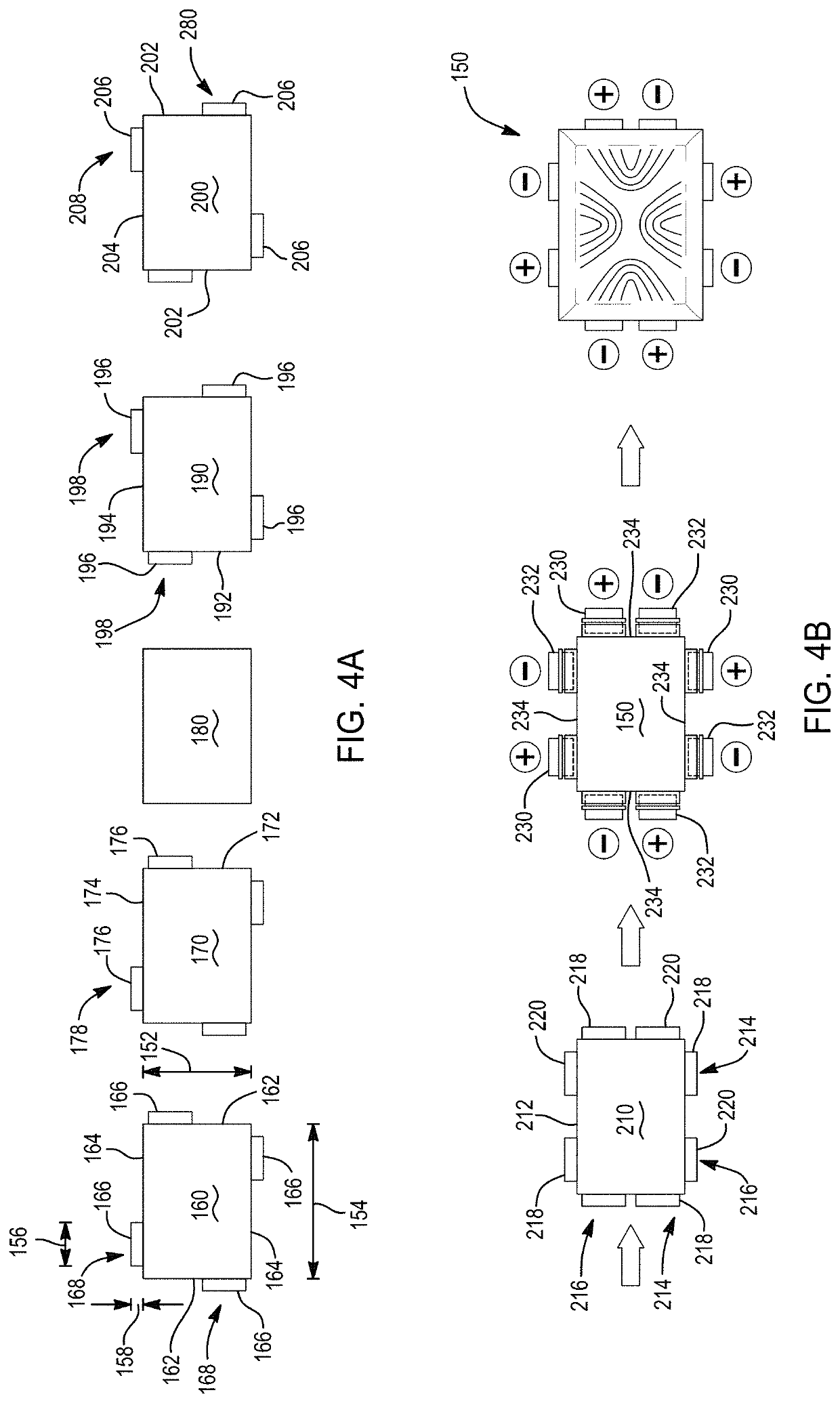

Ultra-high power hybrid cell design with uniform thermal distribution

PendingUS20210110979A1High energy capacityIncreased power capacityHybrid cell detailsHybrid capacitor electrodesElectrical batteryEngineering

A capacitor-assisted hybrid lithium-ion electrochemical cell assembly includes two positive electrodes having a first polarity, each having at least two electrically conductive tabs disposed on at least one first edge and at least one second edge. Further, two negative electrodes having a second polarity each having at least two electrically conductive tabs disposed on at least one first edge and at least one second edge. At least one of the two positive electrodes or negative electrodes are distinct from one another. The electrically conductive tabs are substantially aligned in the electrochemical cell to respectively define a plurality of positive electrical connectors and a plurality of negative electrical connectors to reduce current density during high power charging and discharging.

Owner:GM GLOBAL TECH OPERATIONS LLC

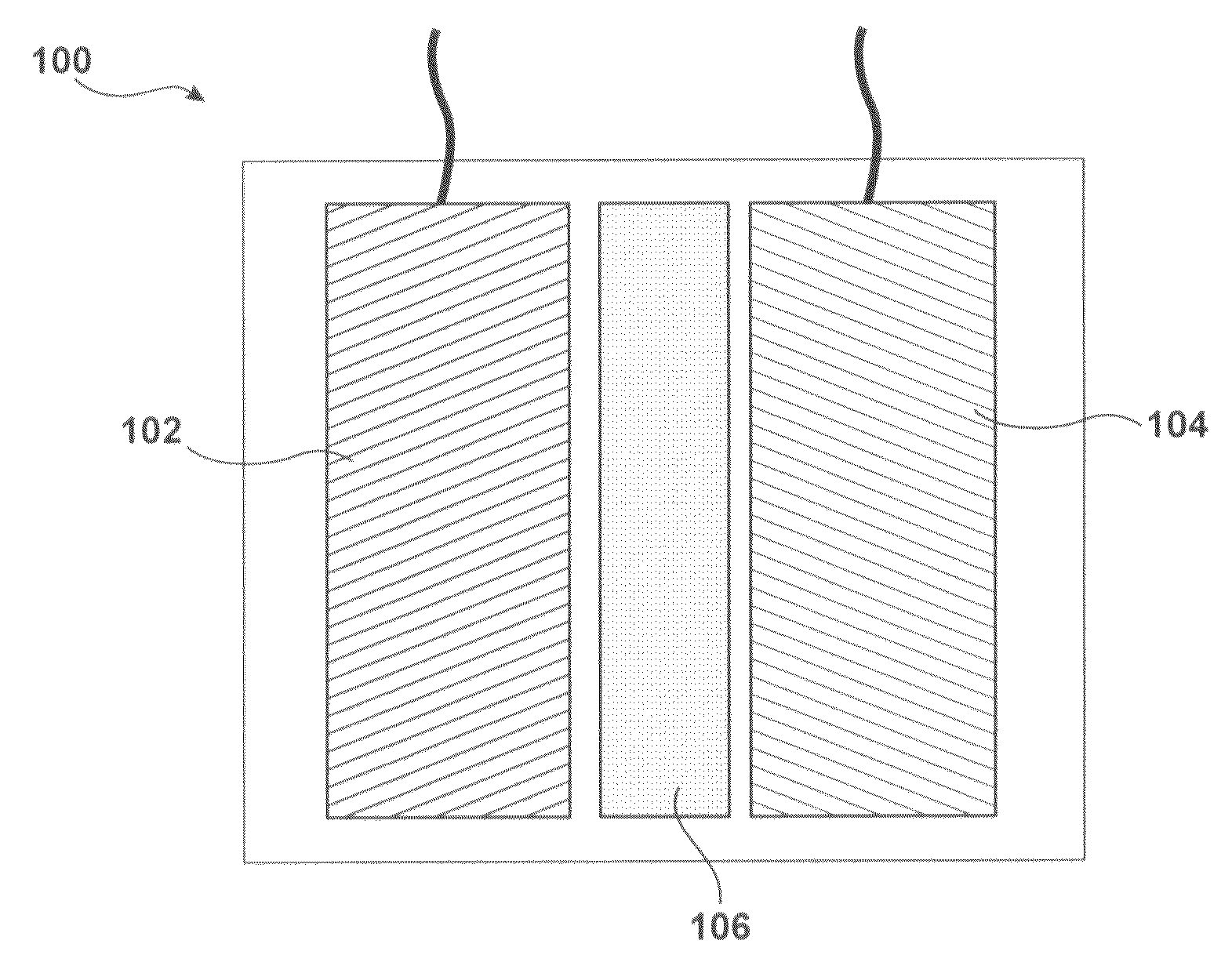

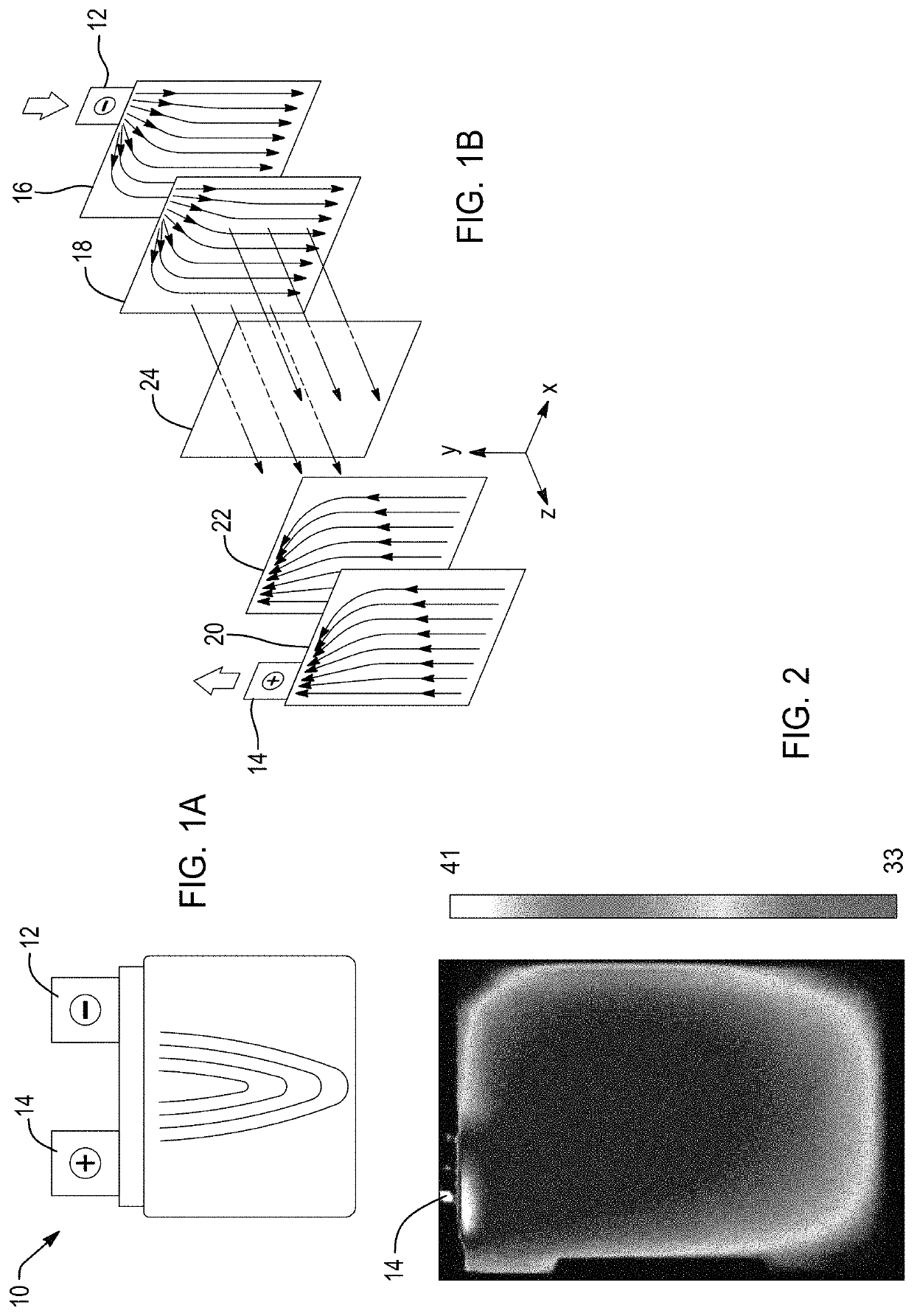

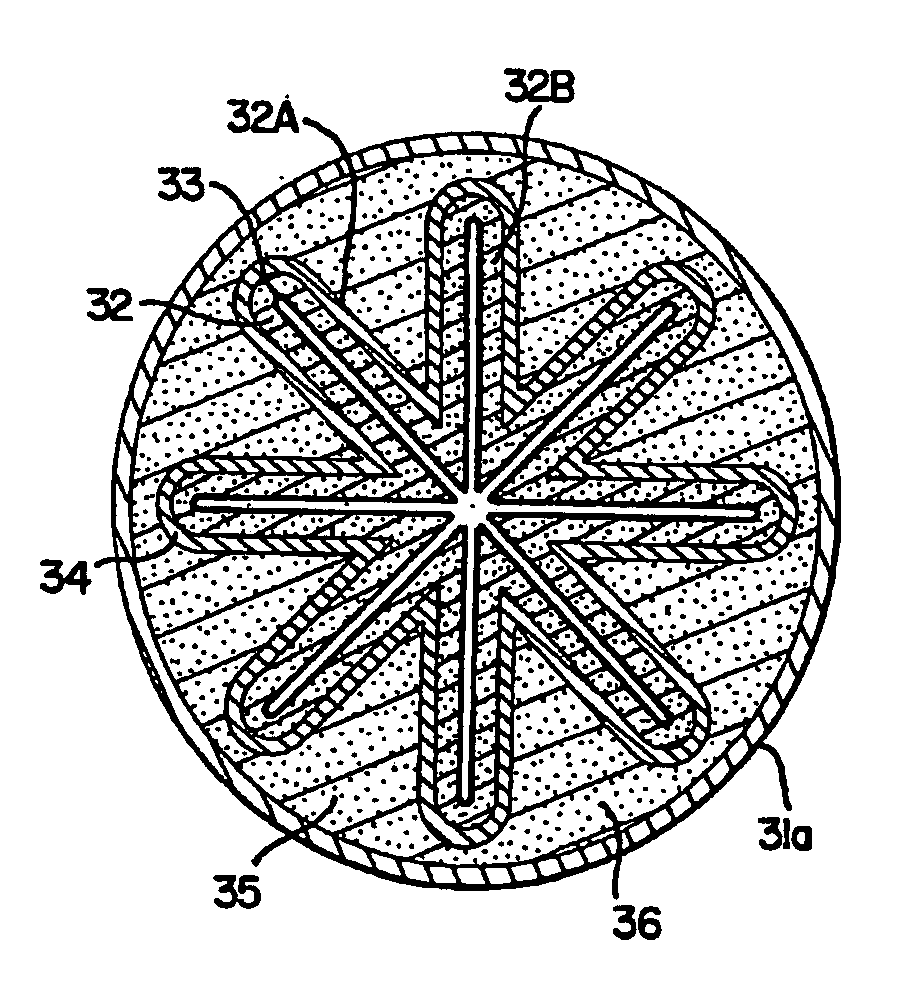

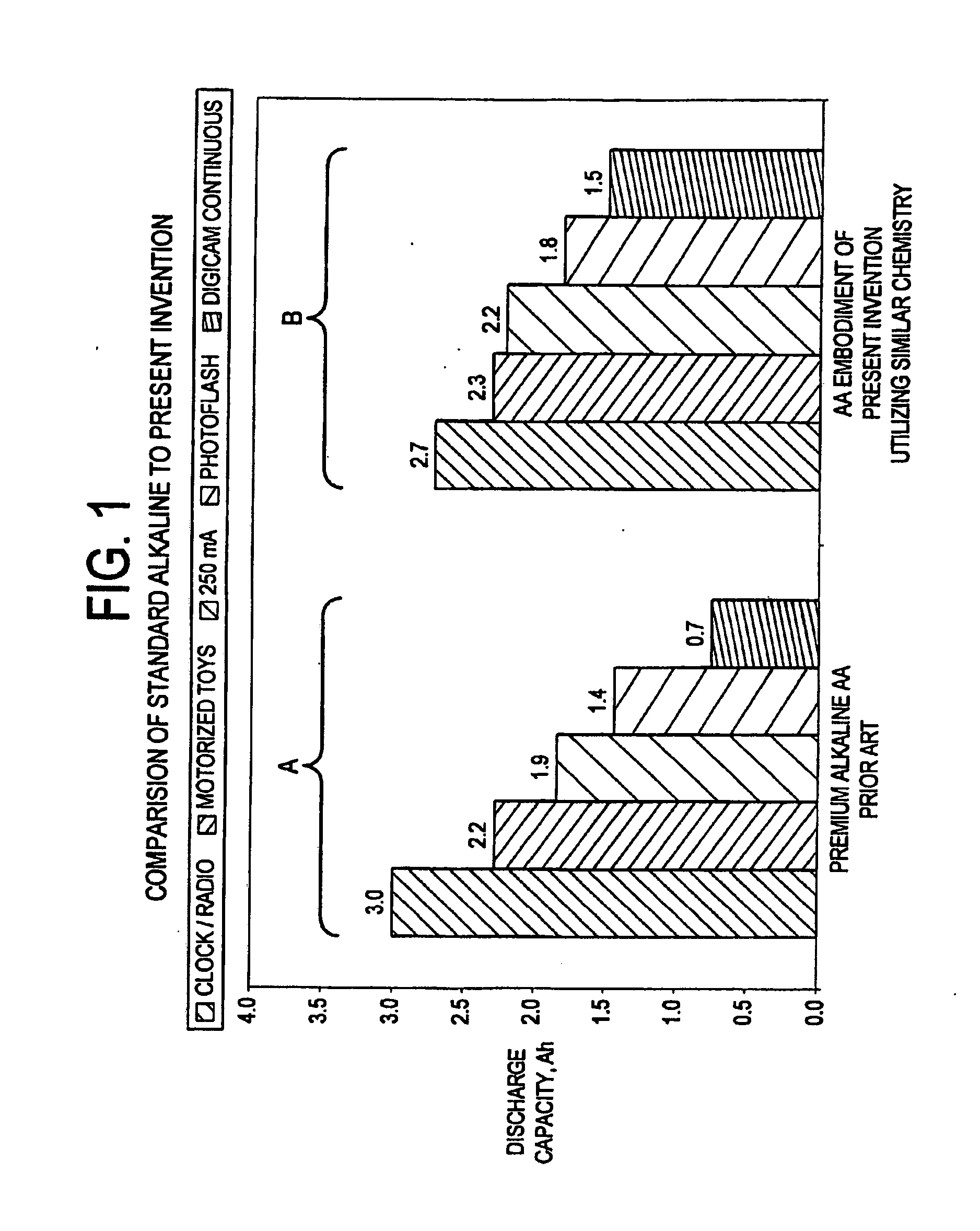

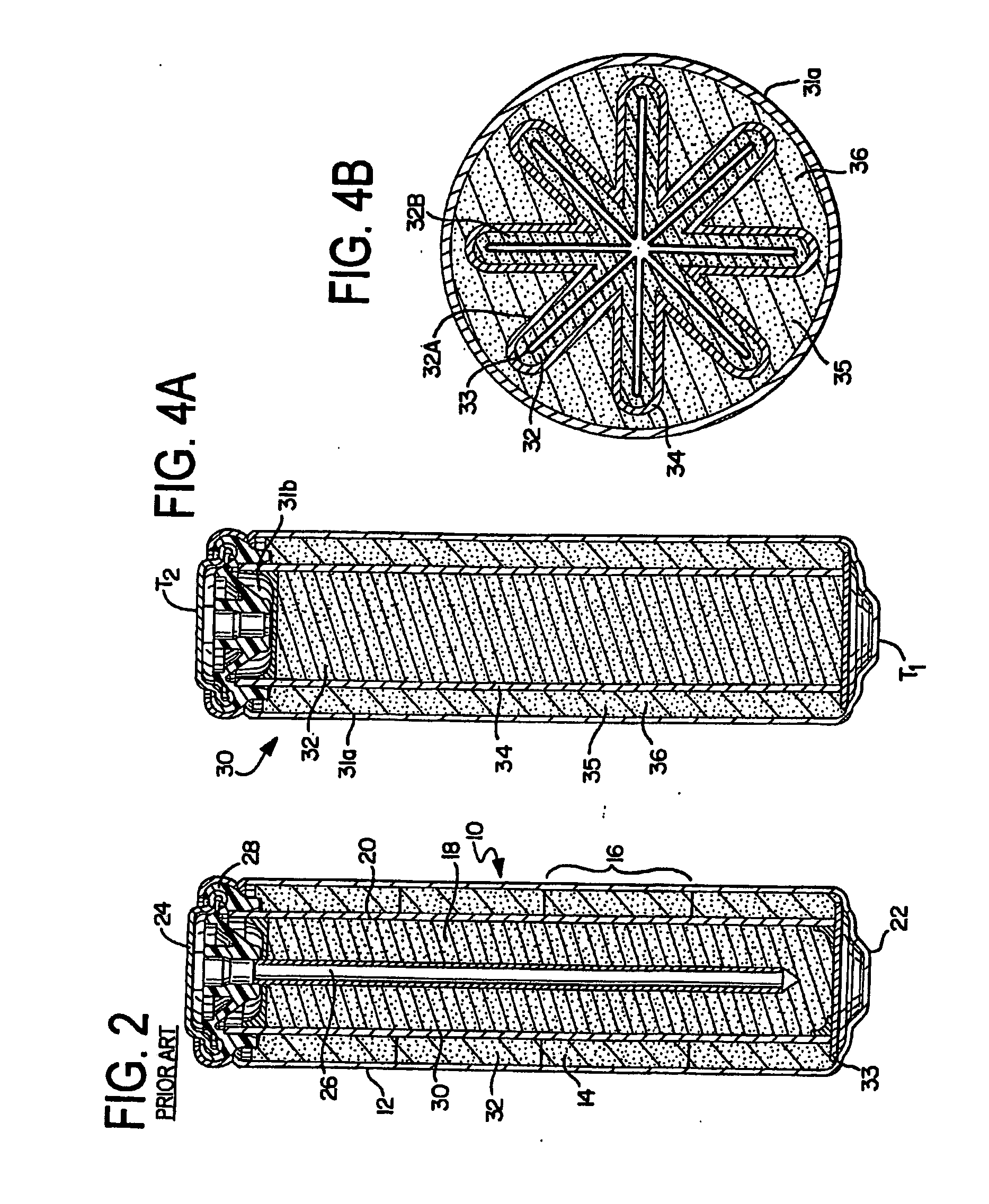

Embedded electrode conformations for balanced energy, power, and cost in an alkaline cell

InactiveUS20070092794A1Equivalent throughputratesHigh speed productionFinal product manufactureElectrode carriers/collectorsHypochloriteEngineering

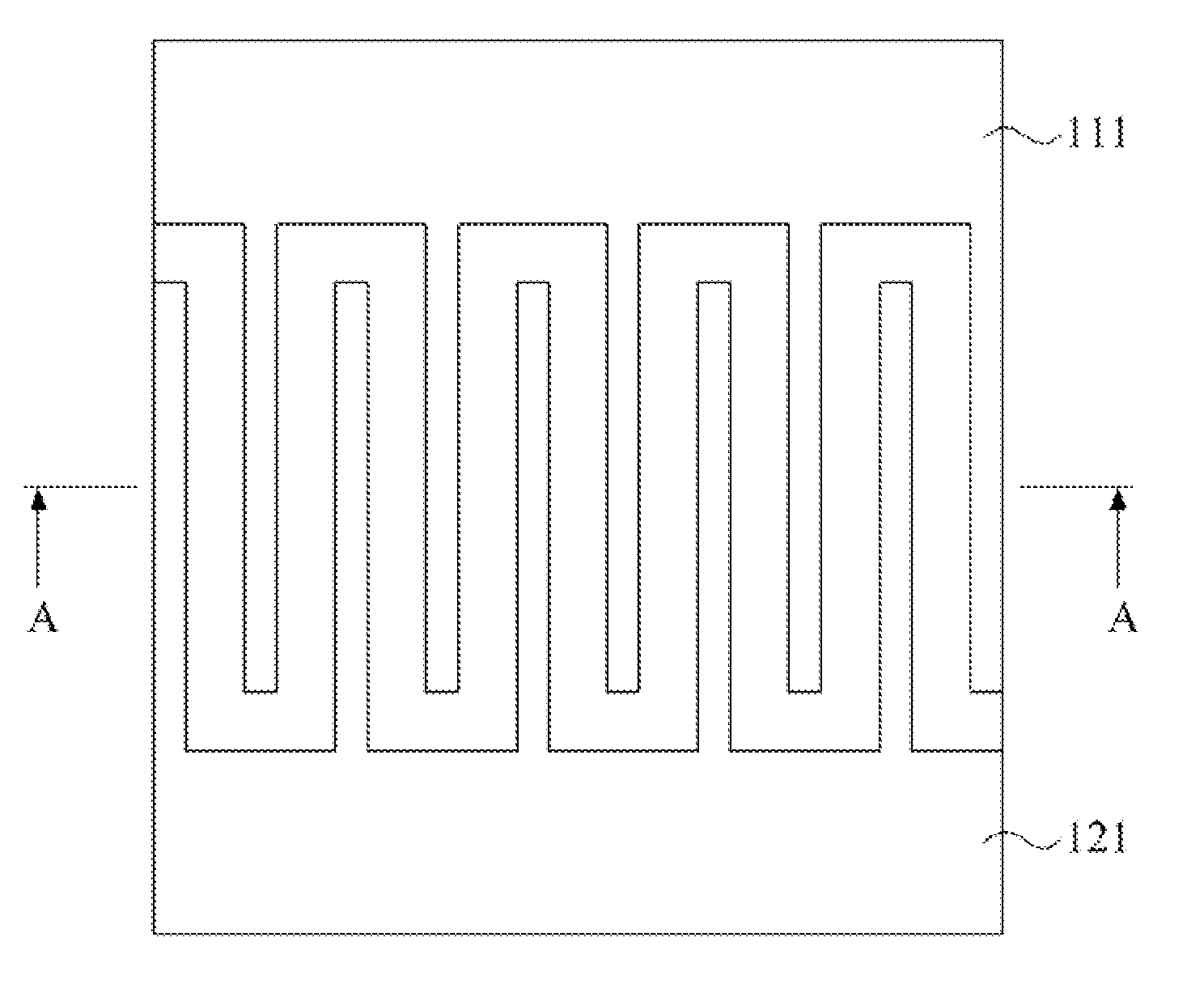

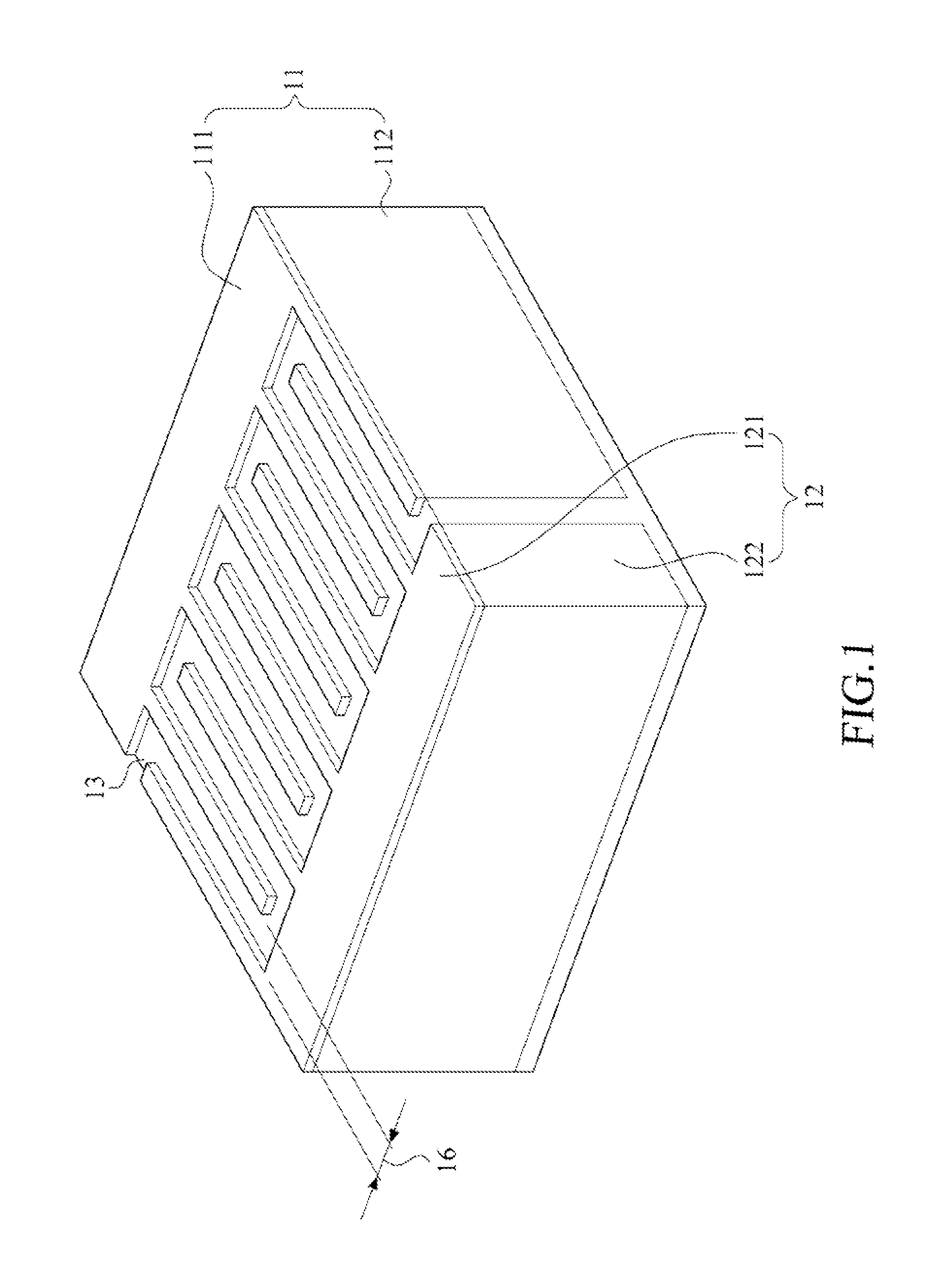

A battery cell, such as a cylindrical or prismatic alkaline cell, is disclosed having significantly improved capacity utilization at mid-range power levels of discharge by implementing a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and outer electrodes as compared to high-power discharge applications utilizing a densely corrugated geometry for the inner electrode. A battery cell, such as a cylindrical or prismatic alkaline cell, having a curvilinear-like inner electrode configuration that provides moderated surface area between the inner and an NiOOH outer electrodes. The NiOOH material made from a nickel hydroxide reacted with a hypochlorite in the absence of an alkaline hydroxide

Owner:RECHARGEABLE BATTERY CORP

Li-ion battery and battery active components on metal wire

InactiveUS8993172B2Improve performanceProlong lifeElectrode thermal treatmentFinal product manufactureElectrical batteryIon exchange

A battery on a conductive metal wire and components of a battery on a conductive metal wire of circular cross section diameter of 5-500 micrometers and methods of making the battery and battery components are disclosed. In one embodiment, the battery features a porous anode or cathode layer which assist with ion exchange in batteries. Methods of forming the porous anode or cathode layer include deposition of an inert gas or hydrogen enriched carbon or silicon layer on a heated metal wire followed by annealing of the inert gas or hydrogen enriched carbon silicon layer. Energy storage devices having bundles of batteries on wires are also disclosed as are other energy storage devices.

Owner:KALPTREE ENERGY

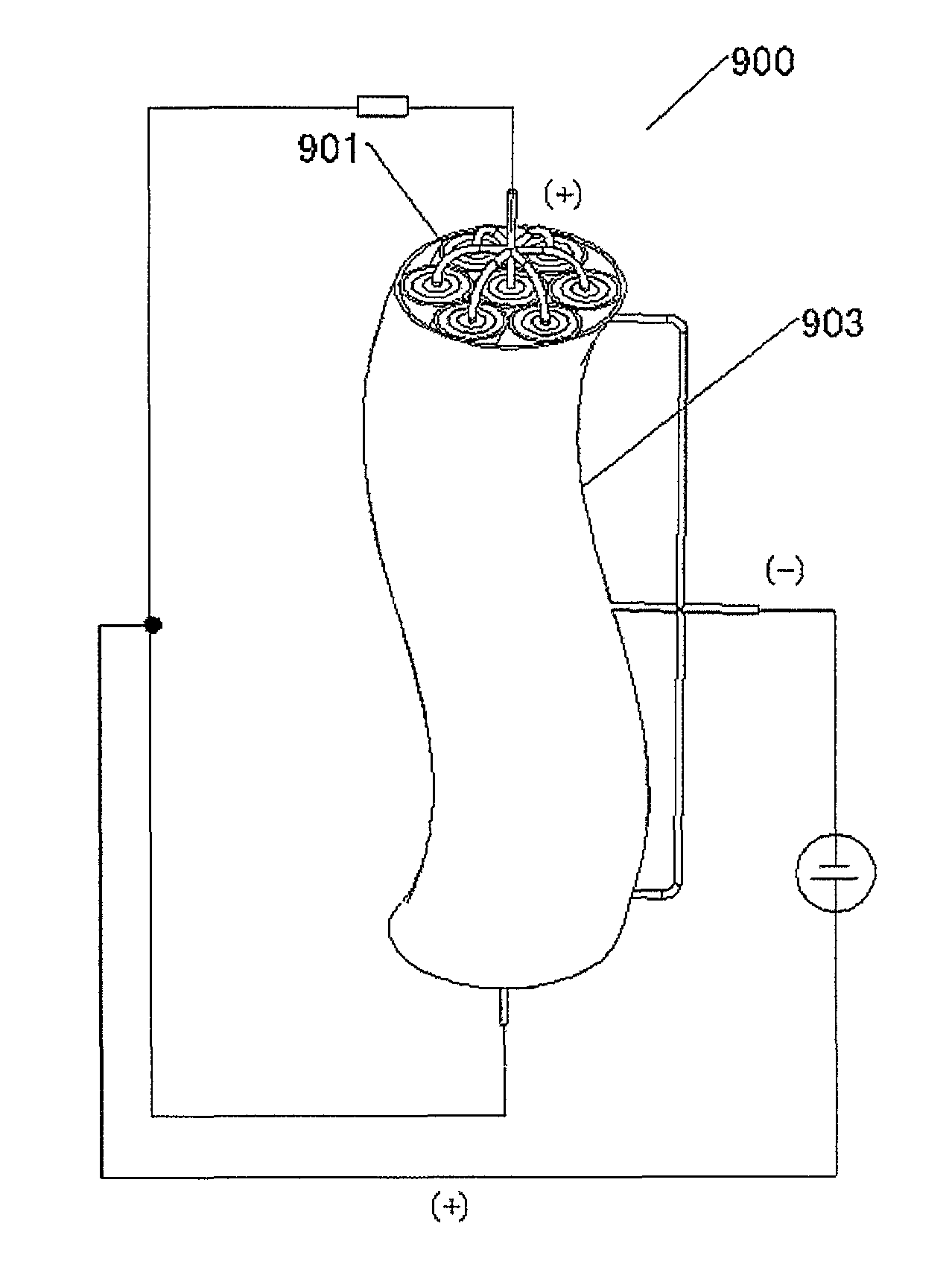

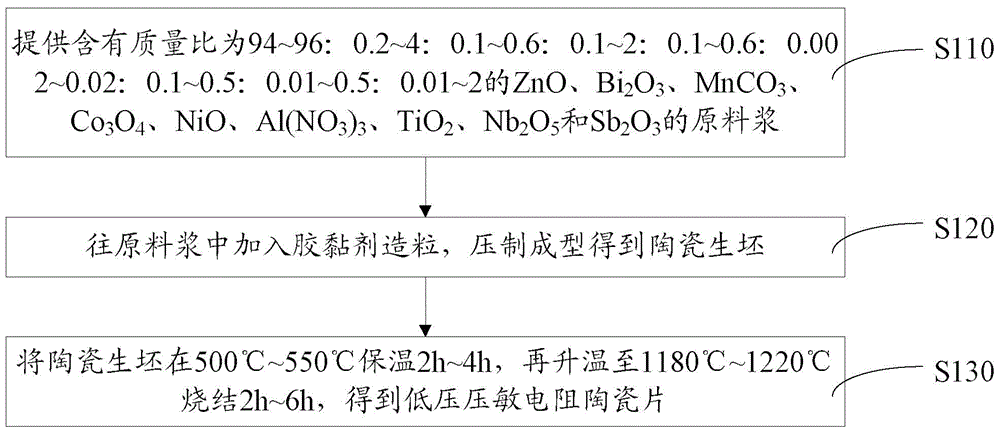

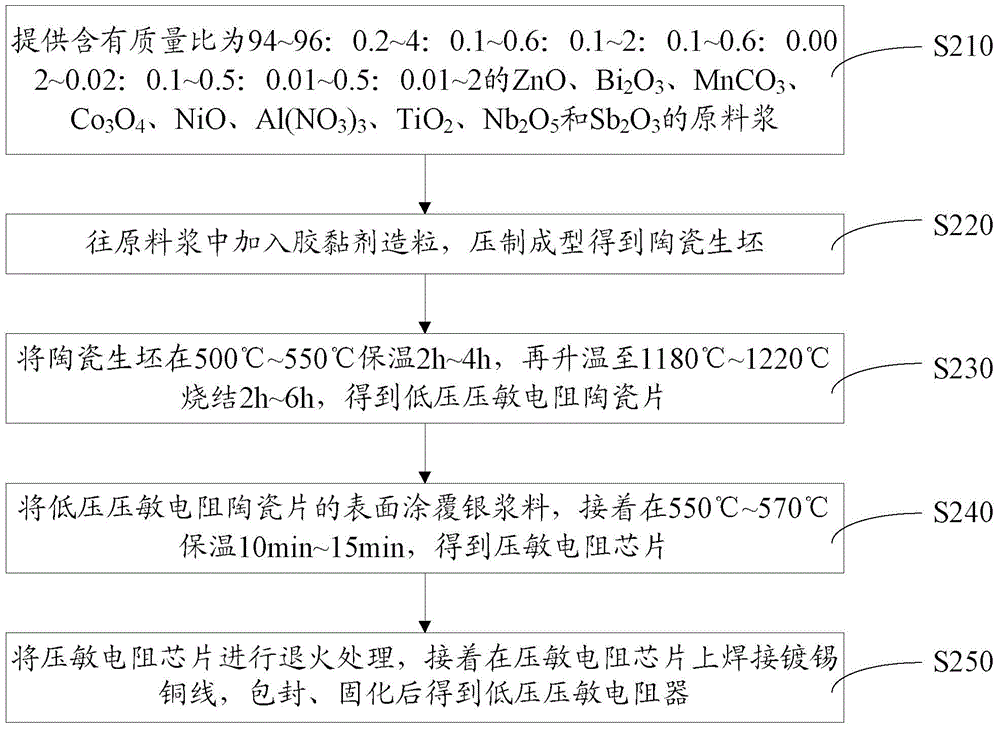

Low-voltage varistor ceramic chip and preparation method thereof, and preparation method of low-voltage varistor

ActiveCN104086170AImprove flow capacityHigh energy capacityResistor manufactureOvervoltage protection resistorsHigh energyLow voltage

The invention discloses a low-voltage varistor ceramic chip which is formed by sintering mixed powder. The mixed powder comprises, by mass, 94-96% of ZnO, 0.2-4% of Bi2O3, 0.1-0.6% of MnCO3, 0.1-2% of Co3O4, 0.1-0.6% of NiO, 0.002-0.02% of Al(NO3)3, 0.1-0.5% of TiO2, 0.01-0.5% of Nb2O5, and 0.01-2% of Sb2O3. With the low-voltage varistor, low-voltage varistor 8 / 20 [mu]s waveform through-flow performance can be well improved, and low-voltage varistor energy-bearing capacity can be improved. The high-energy low-voltage varistor has good lightening resistance. Also, the invention provides a preparation method of the low-voltage varistor ceramic chip and a preparation method of the low-voltage varistor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

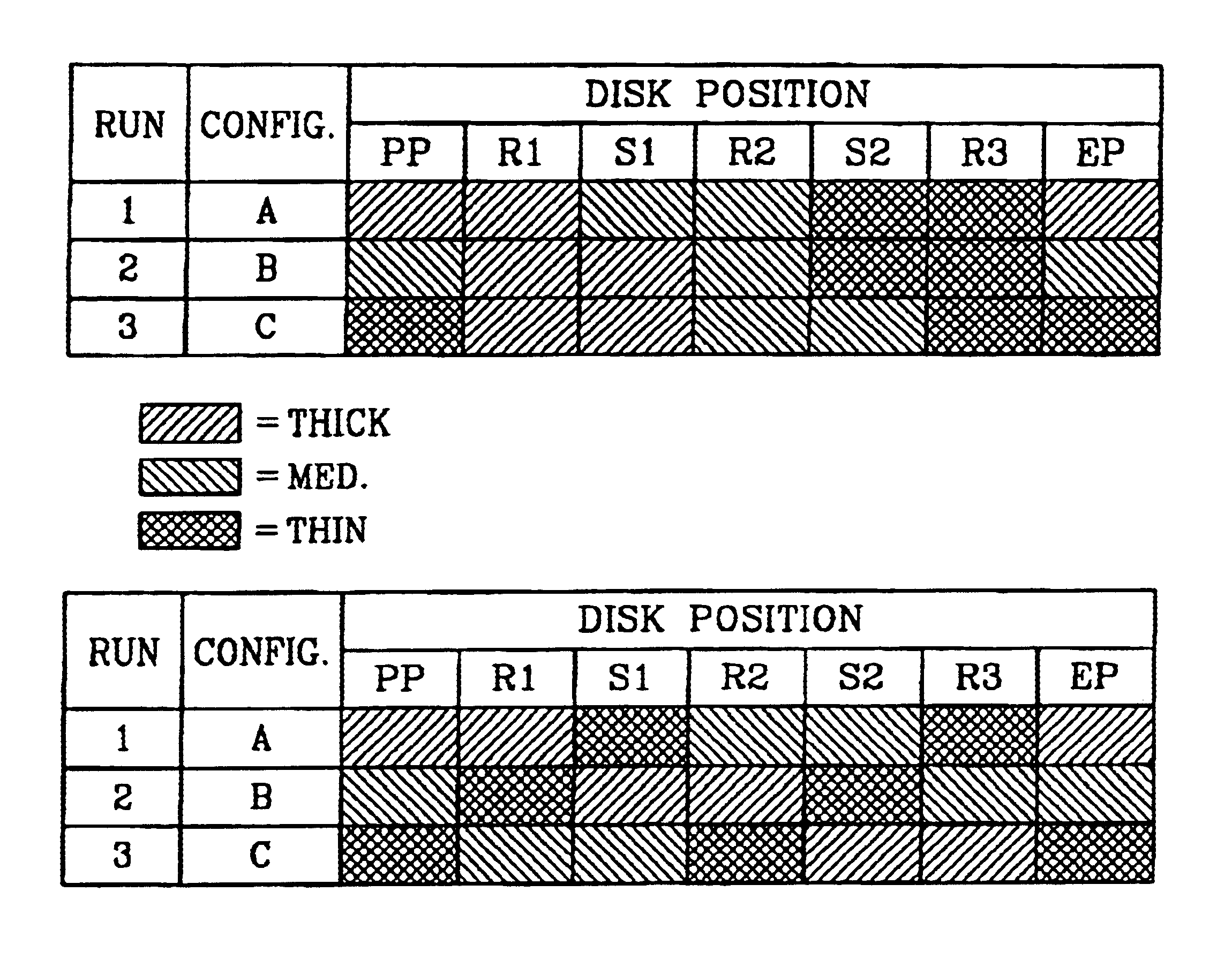

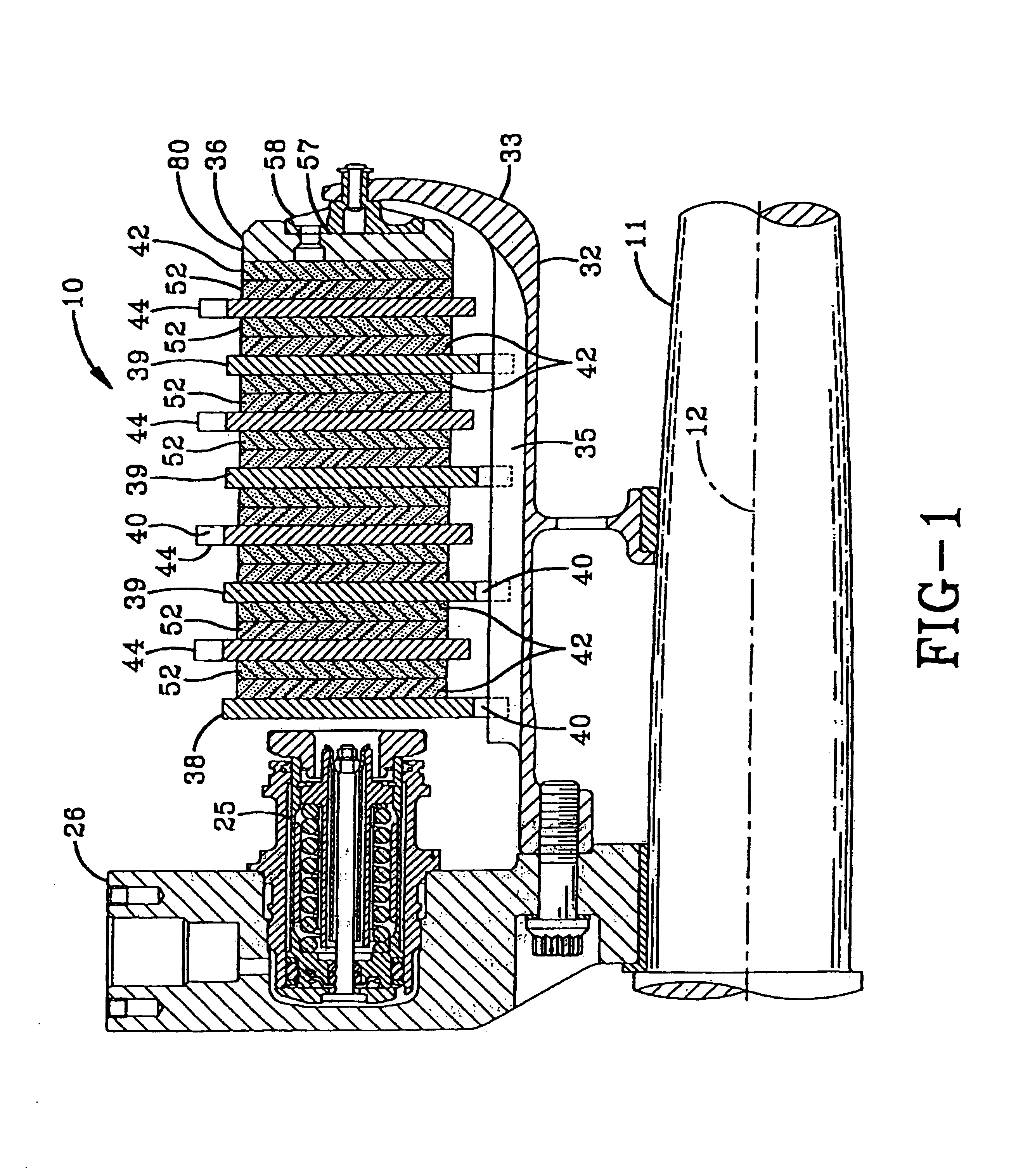

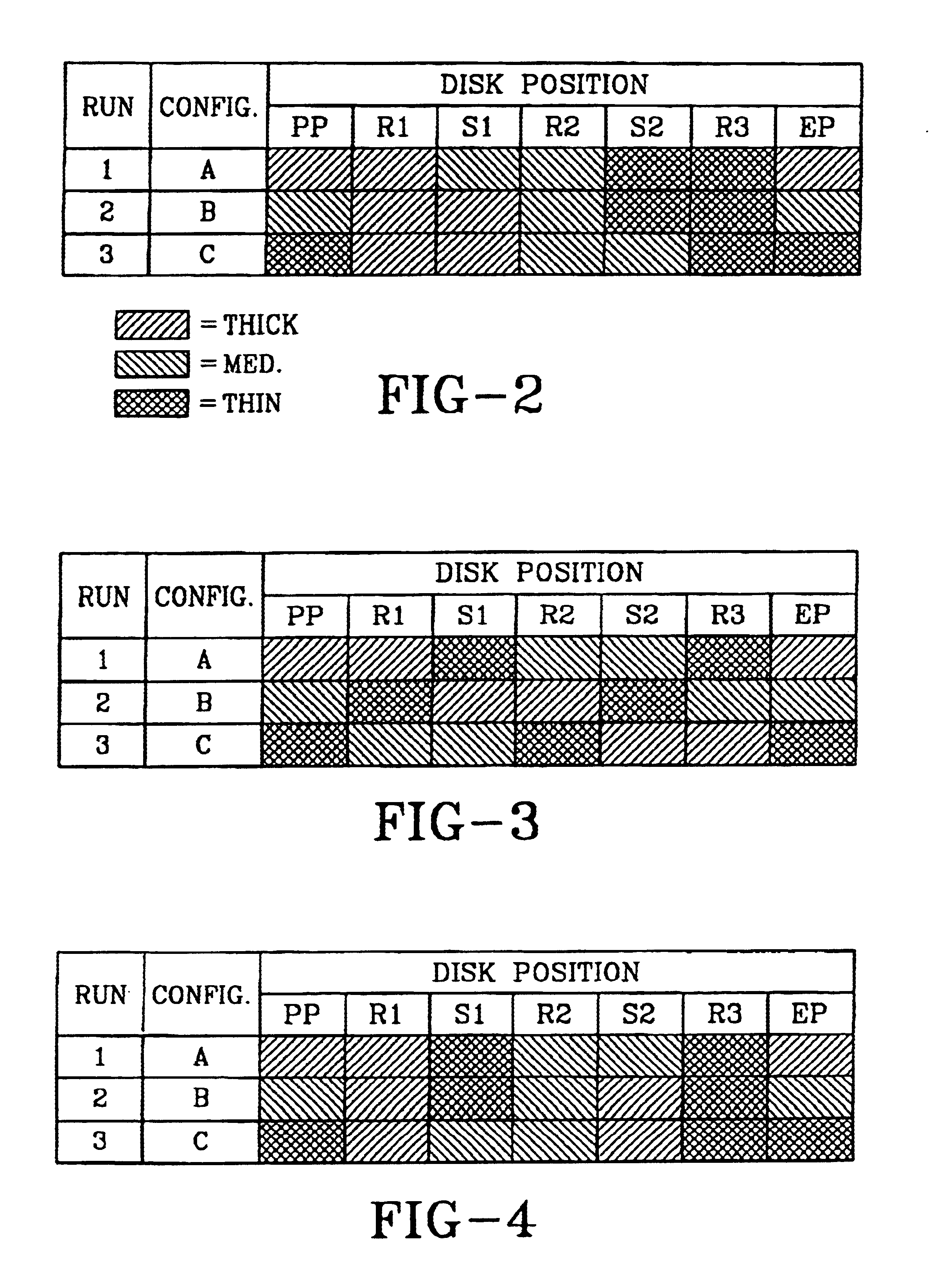

Three run disk brake stack and method of assembly

InactiveUS7168528B1Extend your lifeLow costAxially engaging brakesBraking elementsEngineeringMechanical engineering

In the invention there is provided a disk brake stack having disks with available wear portions of a first thickness, a second thickness and a third thickness. The disk(s) having an initial available wear portion of a first thickness are of a thickness so that at the first overhaul, the available wear portion of such disks are only partly worn away and disks are about equal to disks having an initial available wear portion of a second thickness. The disks having an initial available wear portion of a second thickness at the first overhaul are only partly worn away and such disks are about equal to the disks having an initial available wear portion of a third thickness. The disks initially having an available wear portion of a third thickness at the first overhaul are substantially fully worn and are replaced by new or refurbished disks having an available wear portion of a first, second or third thickness. Also, the invention comprises a method of assembly and overhaul of a disk brake stack, utilizing disks having available wear portion of a first thickness, a second thickness, and a third thickness.

Owner:THE BF GOODRICH CO

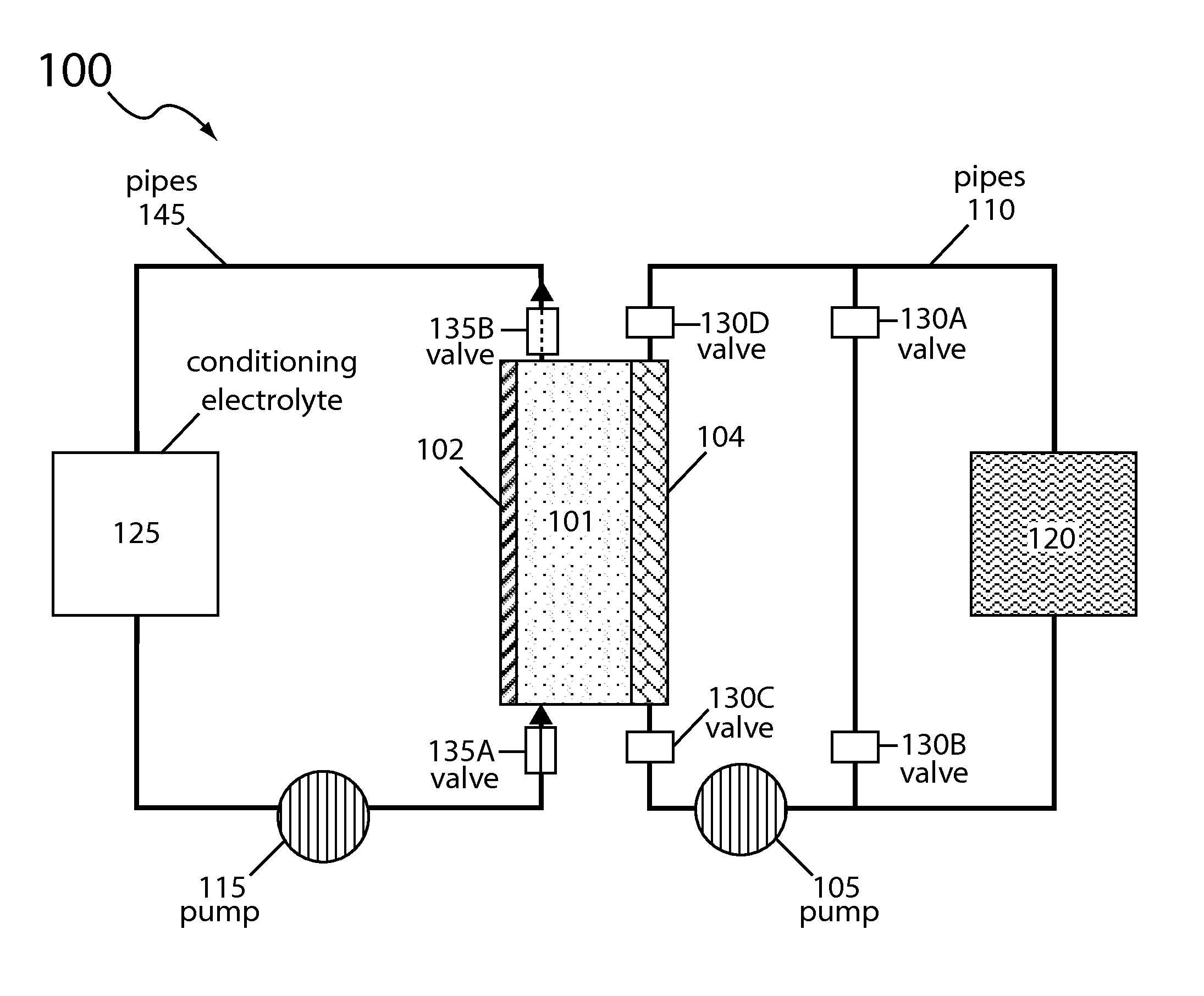

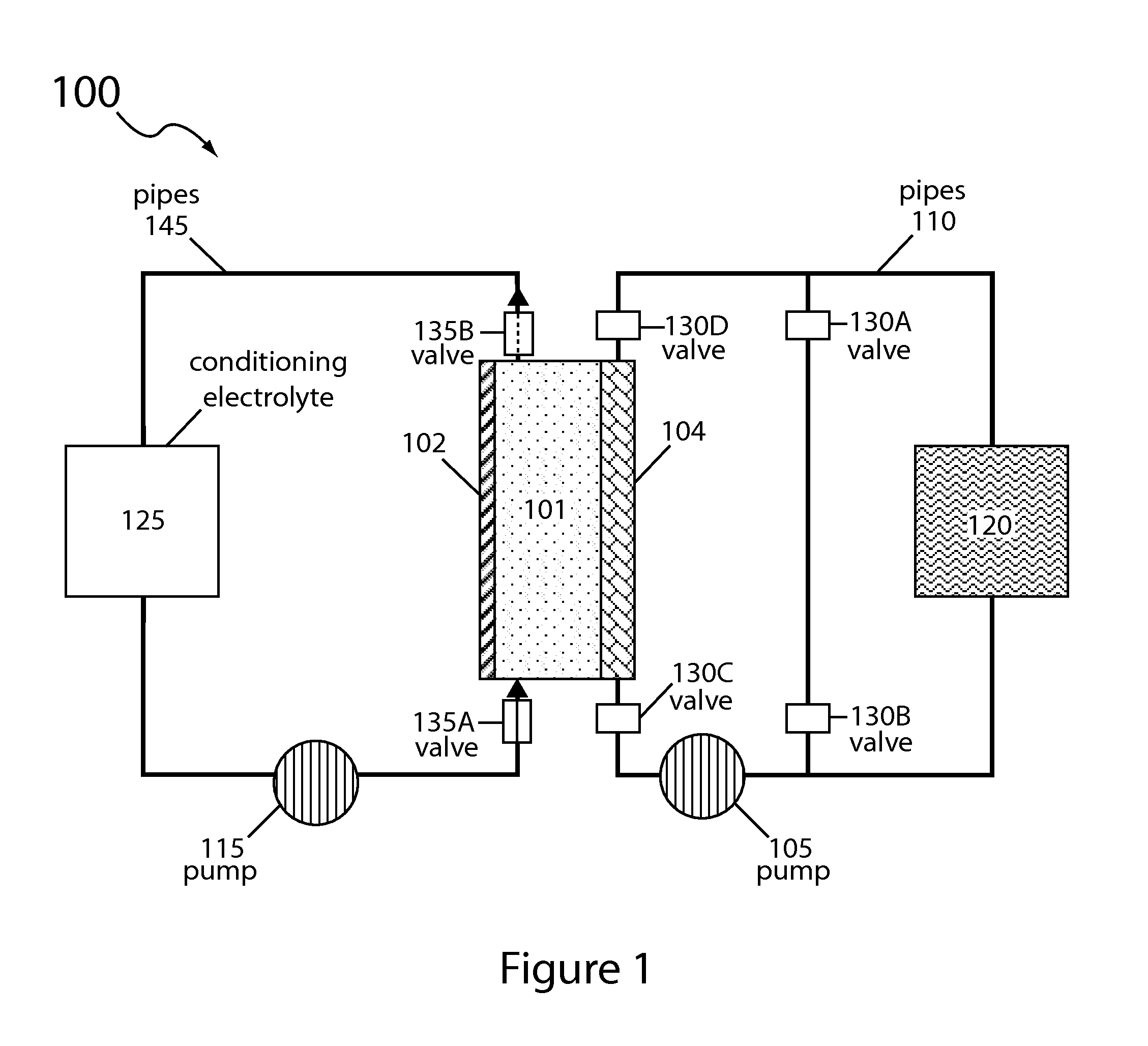

Li-ion/polysulfide flow battery

InactiveUS20130059177A1Extended service lifeCorrosion minimizationElectrolyte moving arrangementsCell electrodesElectrochemical responseHigh energy

Li-Ion / Polysulfide flow battery systems are provided to achieve high energy density and long service life. The system is configured to minimize corrosion of the lithium electrode by providing an electrochemical reactor comprising a first and a second electrode configured in spaced apart relation defining an inter-electrode channel through which the sulfur electrolyte is caused to flow.

Owner:POLYPLUS BATTERY CO INC

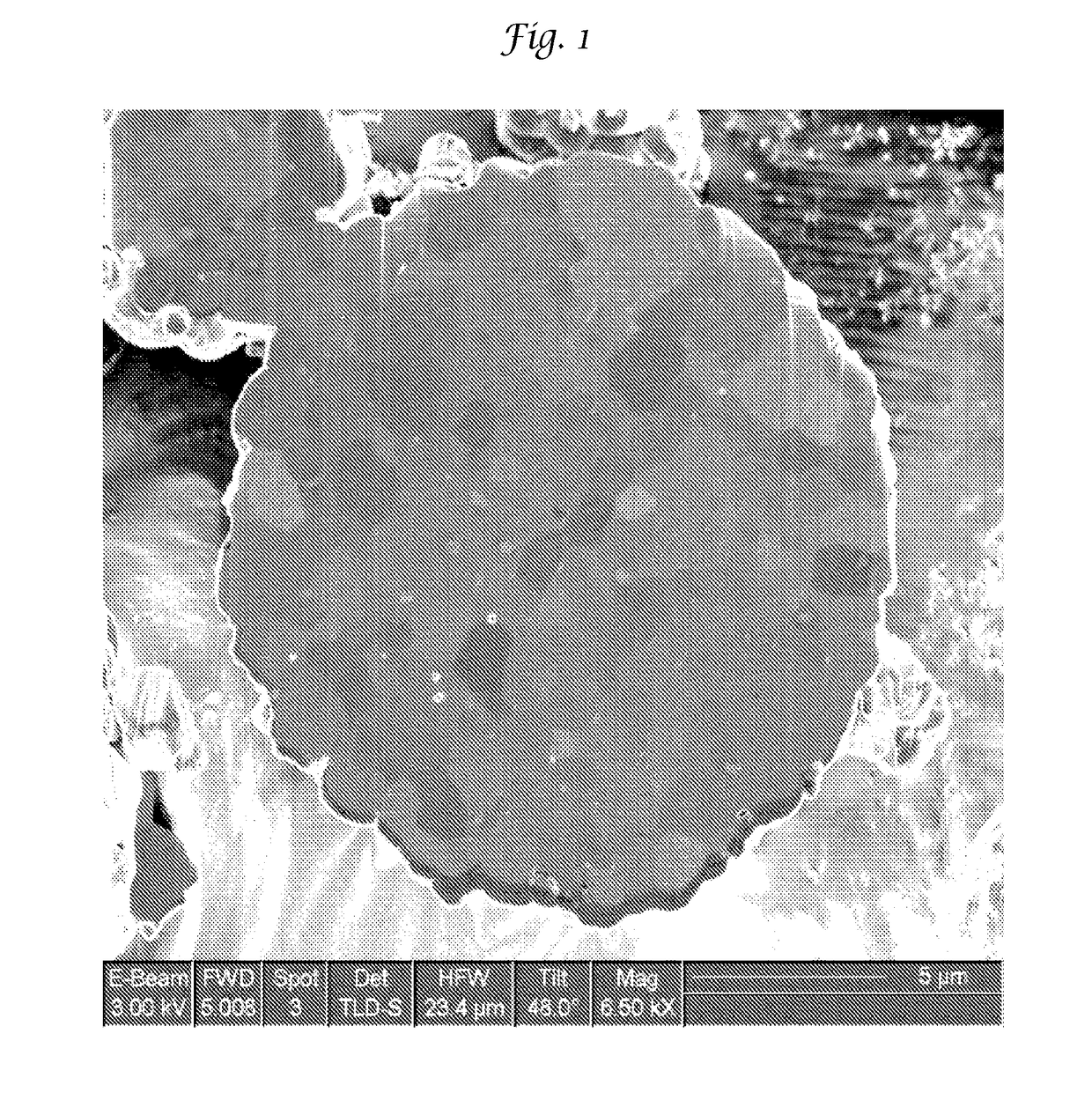

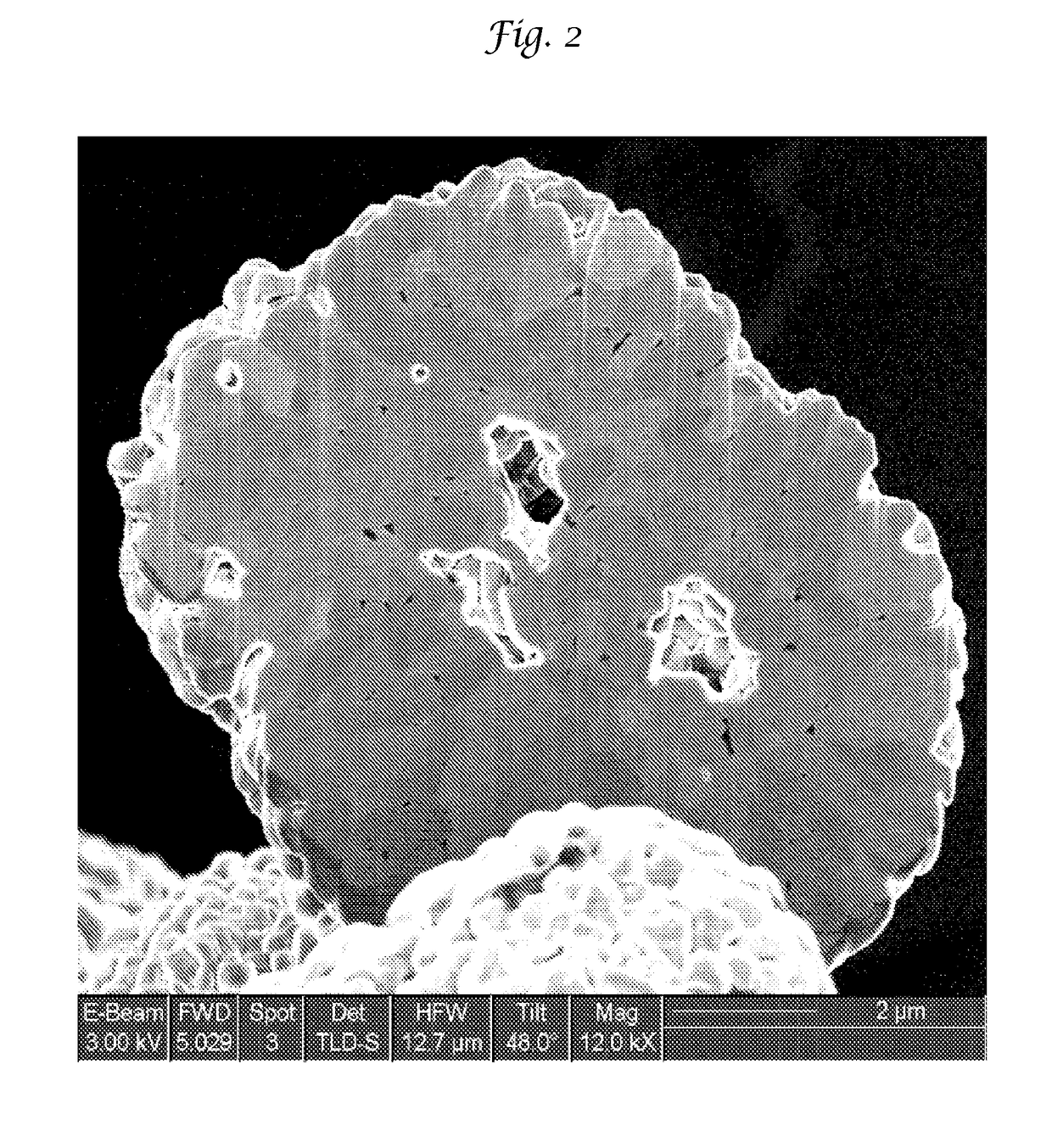

Improved lithium metal oxide cathode materials and method to make them

ActiveUS20170084919A1Improve securityImprove cycle performancePositive electrodesLi-accumulatorsParticulatesHigh density

A method for forming lithium metal oxides comprised of Ni, Mn and Co useful for making lithium ion batteries comprises providing precursor particulates of Ni and Co that are of a particular size that allows the formation of improved lithium metal oxides. The method allows the formation of lithium metal oxides having improved safety while retaining good capacity and rate capability. In particular, the method allows for the formation of lithium metal oxide where the primary particle surface Mn / Ni ratio is greater than the bulk Mn / Ni. Likewise the method allows the formation of lithium metal oxides with secondary particles having much higher densities allowing for higher cathode densities and battery capacities while retaining good capacity and rate performance.

Owner:JIANGSU HENGTRON NANOTECH CO LTD

Lead acid battery having lightly gelled electrolyte

InactiveUS20100304210A1Improve electrical performanceLower internal resistanceLead-acid accumulatorsCell component detailsSilica particlePhysical chemistry

A lead acid battery having lightly gelled electrolyte is provided. The lead acid battery includes a plurality of alternating positive plates and negative plates, a plurality of separators sandwiched in between the positive plates and the negative plates, and a lightly gelled electrolyte including dilute sulfuric acid and silica particles substantially in the range of 0.1% to 3% of the electrolyte by weight. The silica particles are fumed silica particles.

Owner:LIN YI MING

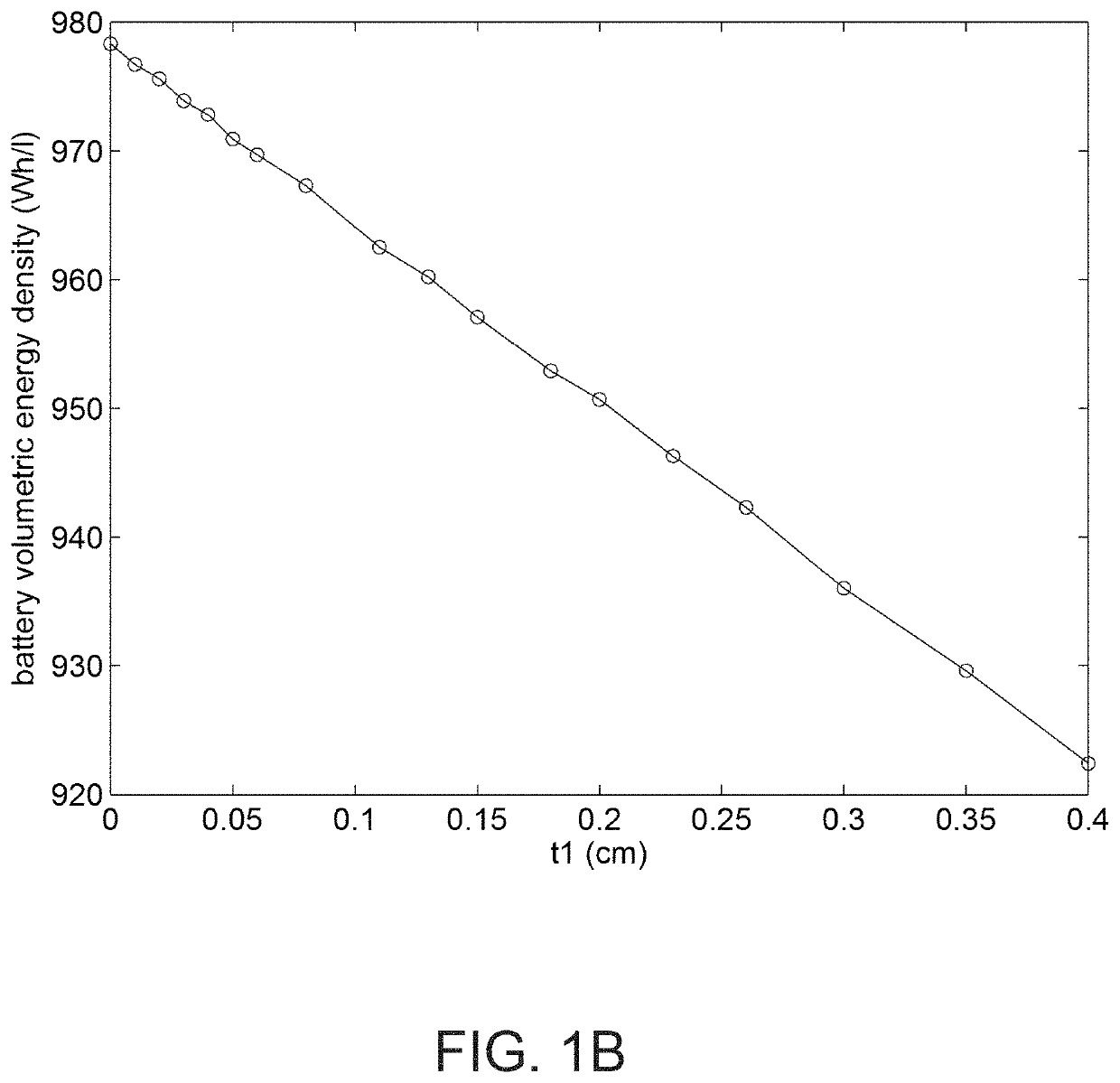

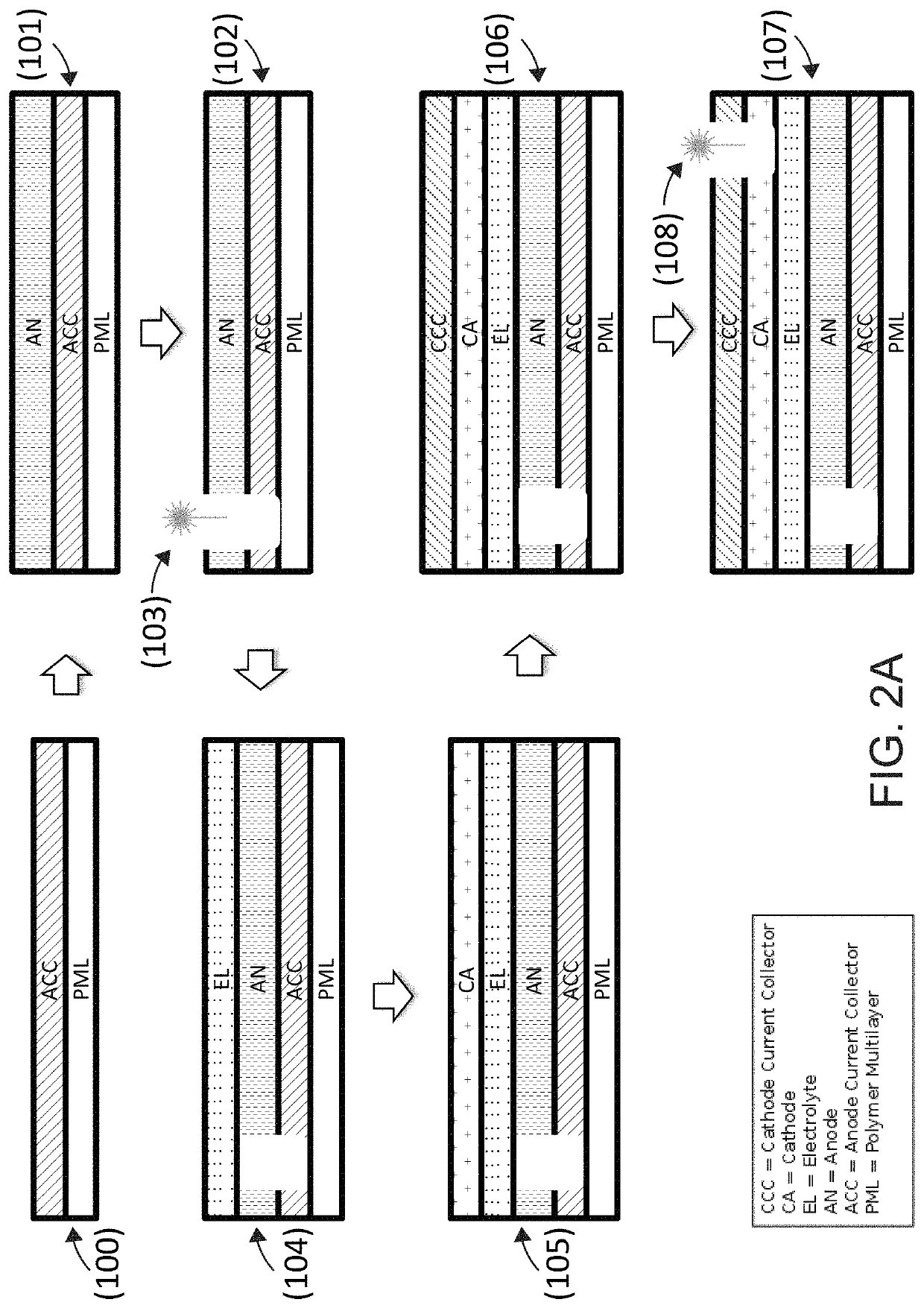

High energy density multilayer battery cell with thermally processed components and method for making same

ActiveUS10707477B2Eliminate generationPrevent oxidationFinal product manufacturePrinted batteriesElectrical batteryHigh energy

A method of producing a monolithically integrated high energy density solid-state battery device. The method can include positioning a substrate and depositing one or more stacked monolithically integrated high energy density solid-state electrochemical cells in series or in parallel configurations sequentially or individually. Each of these cells can have a first barrier layer, a cathode current collector deposited overlying the first barrier layer, a cathode overlying the electrically conductive layer, an anode, an anode current collector deposited overlying the solid state layer of negative electrode material, and a second barrier layer. The method can also include rapidly heating the one or more stacked cells to a target temperature for at least 60 minutes, and connecting and terminating the one or more stacked monolithically integrated high energy density solid-state electrochemical cells electrically in series or in parallel, to from a monolithically integrated high energy density solid-state battery device.

Owner:DYSON TECH LTD

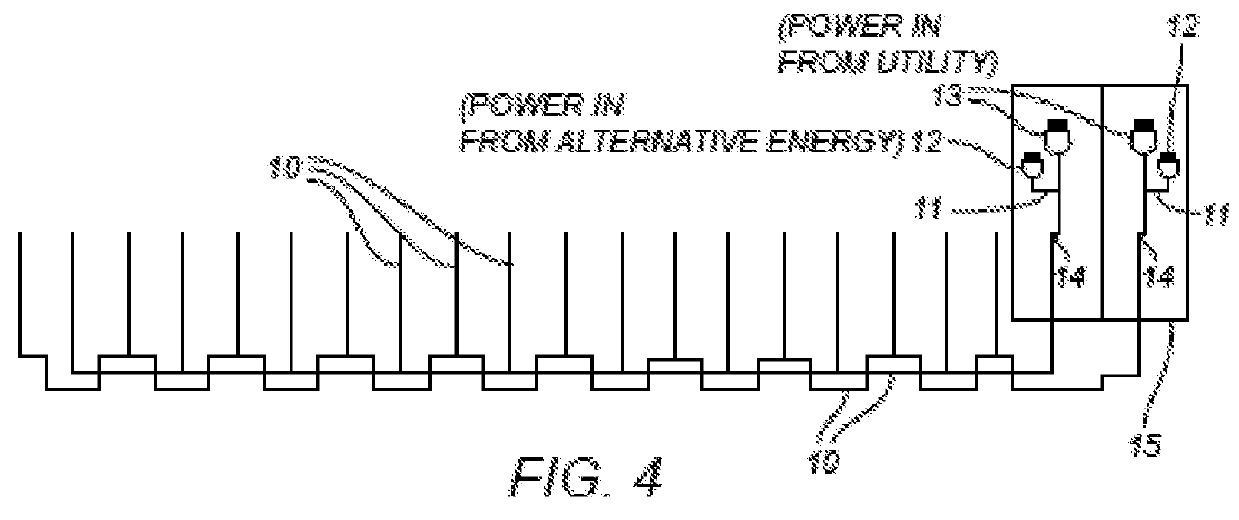

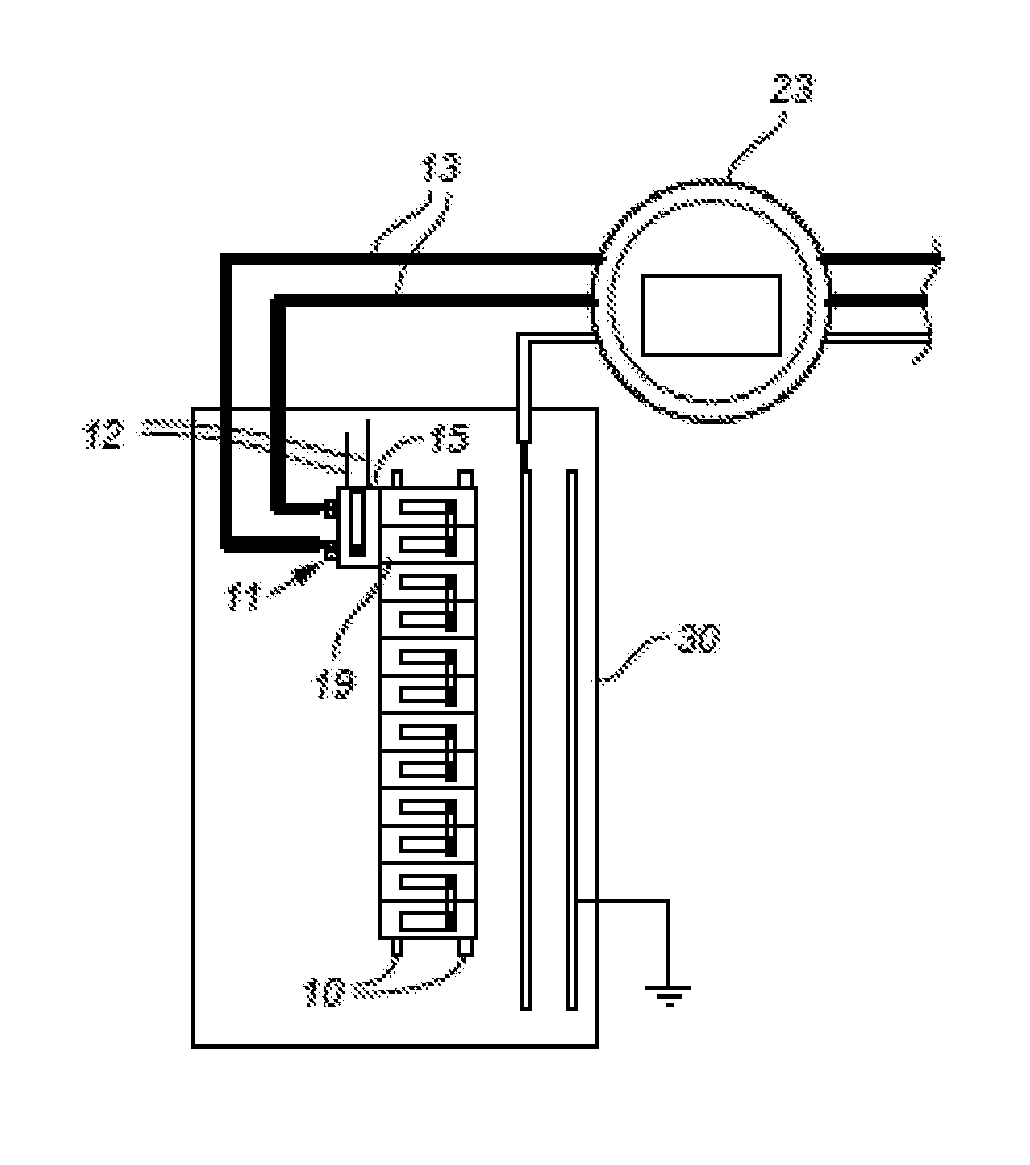

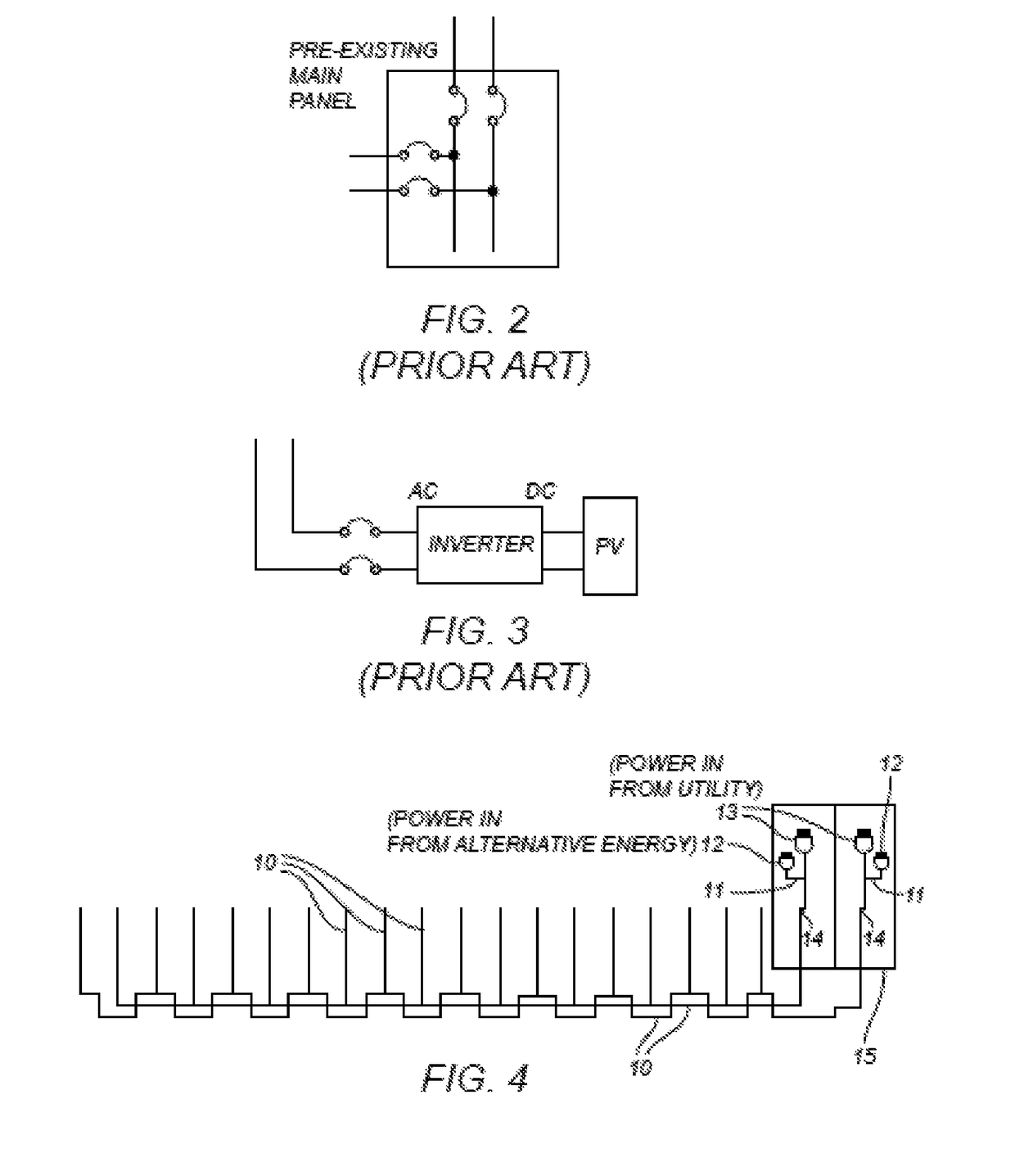

Alternative energy bus bar by pass breaker, methods of use and installation

InactiveUS20160056617A1High energy capacityEliminating carbon build up and corrosionLine/current collector detailsSingle network parallel feeding arrangementsFuel cellsPower grid

The present invention is directed, in part, to electrical components and methods of use associated with such components. In particular, the invention relates to an electrical device and improved method of back feeding energy generated from alternative energy devices such as solar panels, wind turbines, fuel cells, electrical generators and other alternative energy sources, to the utility without the necessity of installing a sub panel or replacing an existing panel, resulting in significant cost savings for the user and increased electrical energy available to the power grid. The invention further discloses installation of a back feed circuit breaker into an existing main panel and main circuit breaker thus, eliminating the need of a home owner to completely reinstall a new electrical system in order to install alternative energy sources such as for example, solar panels and the like.

Owner:QFE 002 LLC

Method for reducing the dendritic metal deposition on an electrode and lithium-ion rechargeable battery which uses this method

InactiveUS20150147604A1Reducing dendritic metal depositionAvoid dendrite formationBatteries circuit arrangementsFinal product manufactureLithiumElectrical battery

In a method for reducing the dendritic metal deposition on an electrode, a non-dendritic state of the metal deposition is ascertained, and a magnetic or electric field is generated at the electrode and is modulated in such a way that it stabilizes the non-dendritic state of the metal deposition. The method is applied, e.g., to a lithium-ion rechargeable battery including an anode having an anode arrester, a cathode having a cathode arrester, and a separator, which are situated in a housing, in which a dendritic metal deposition at the anode is reduced with the aid of the method.

Owner:ROBERT BOSCH GMBH

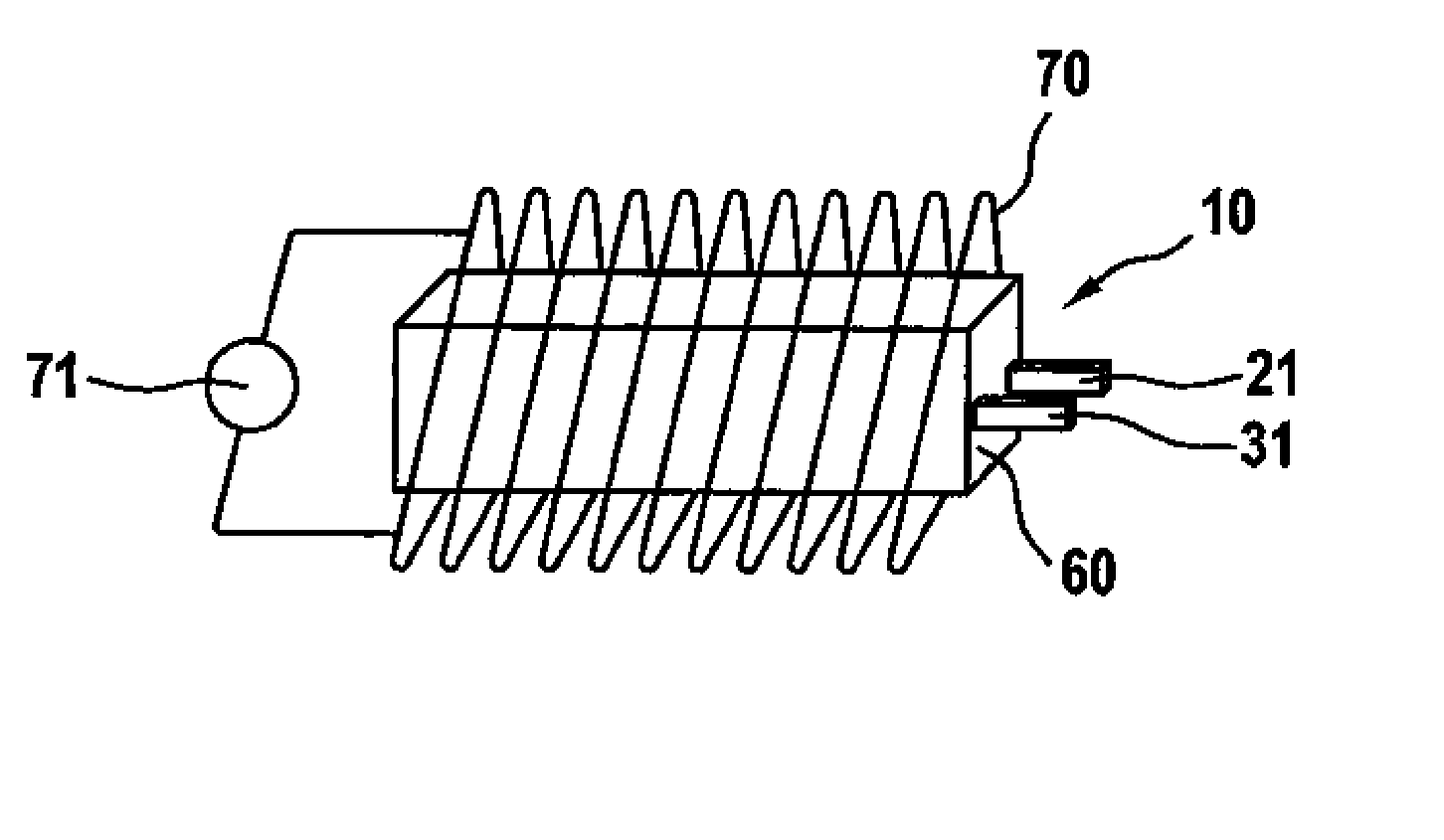

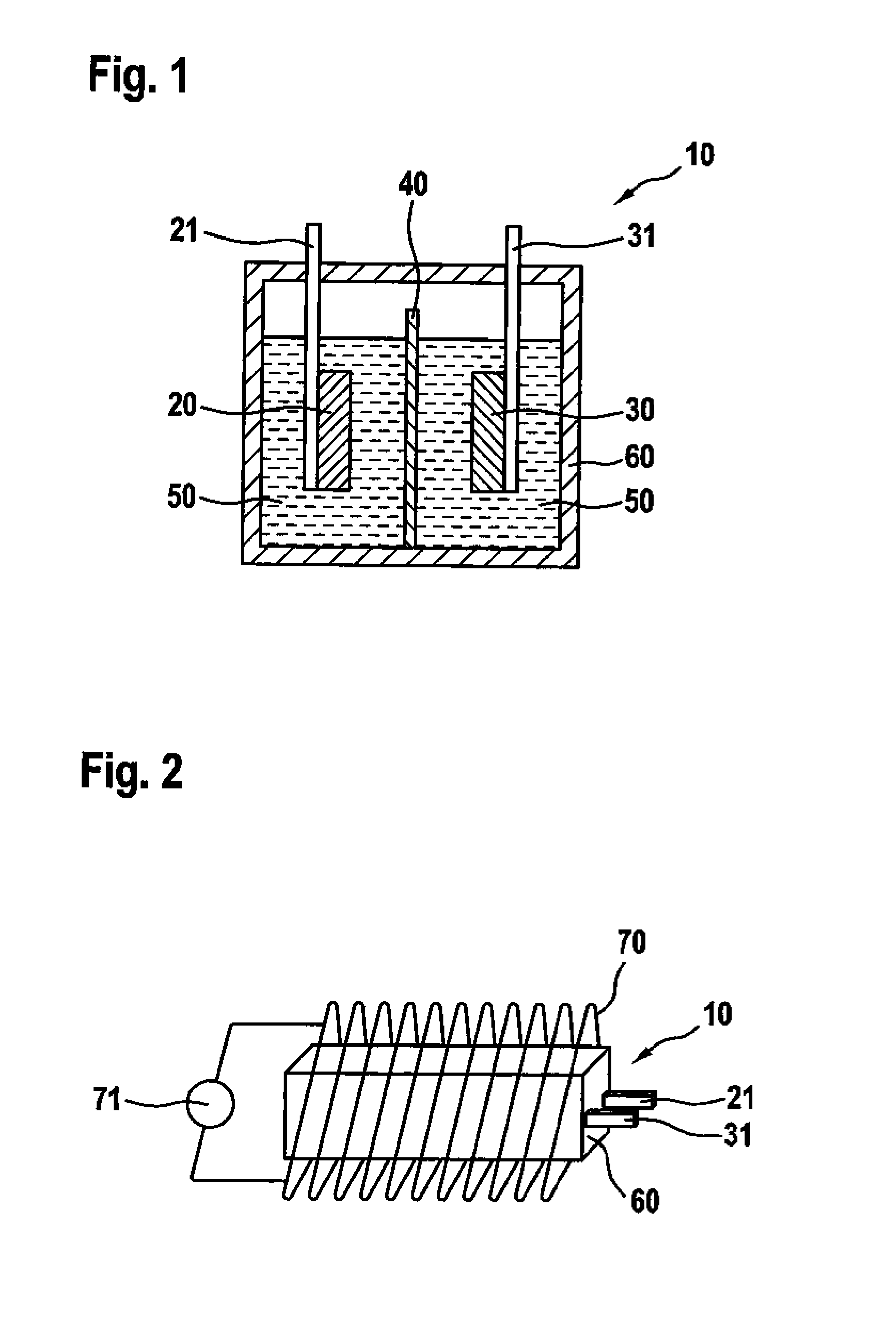

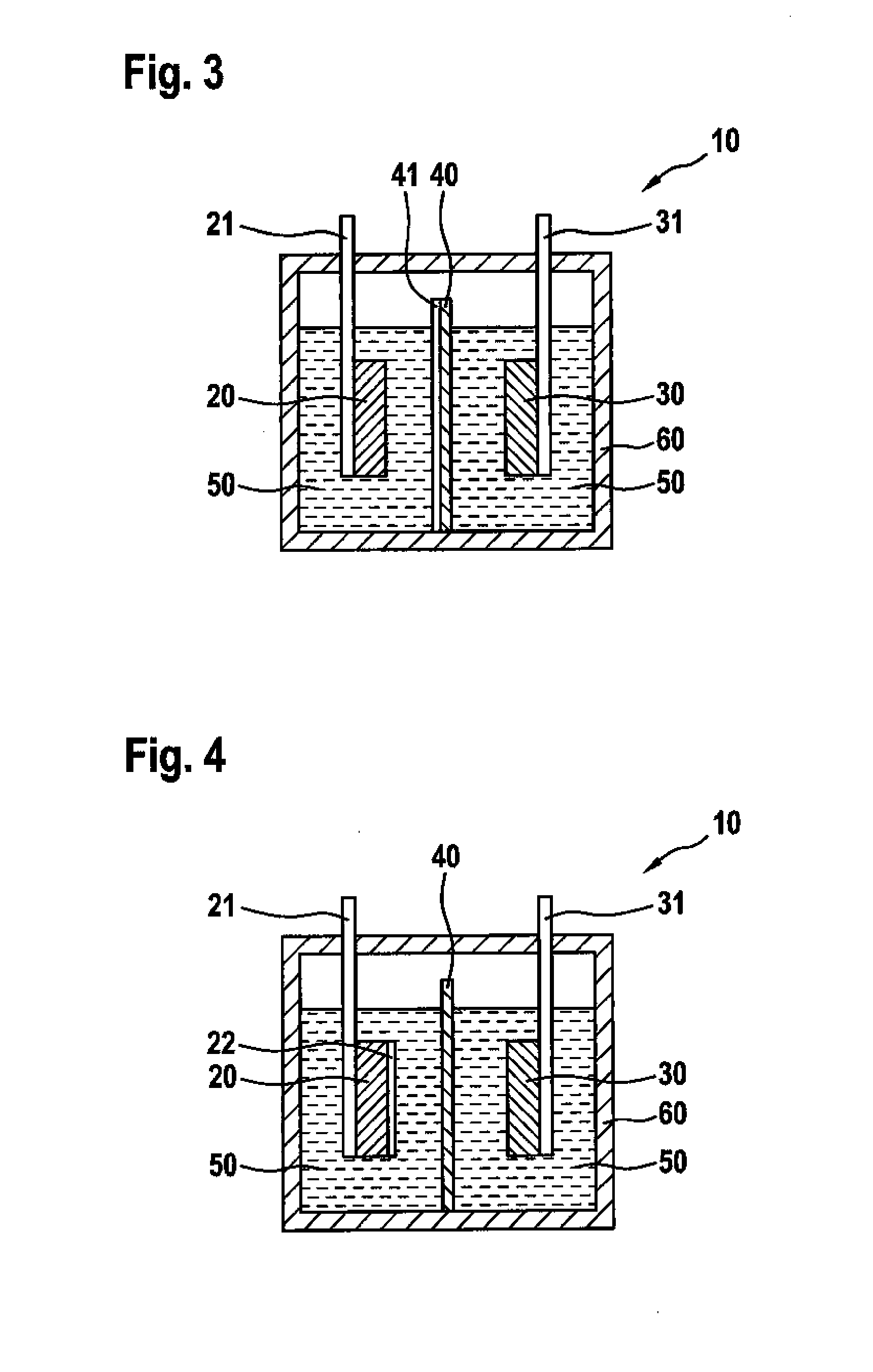

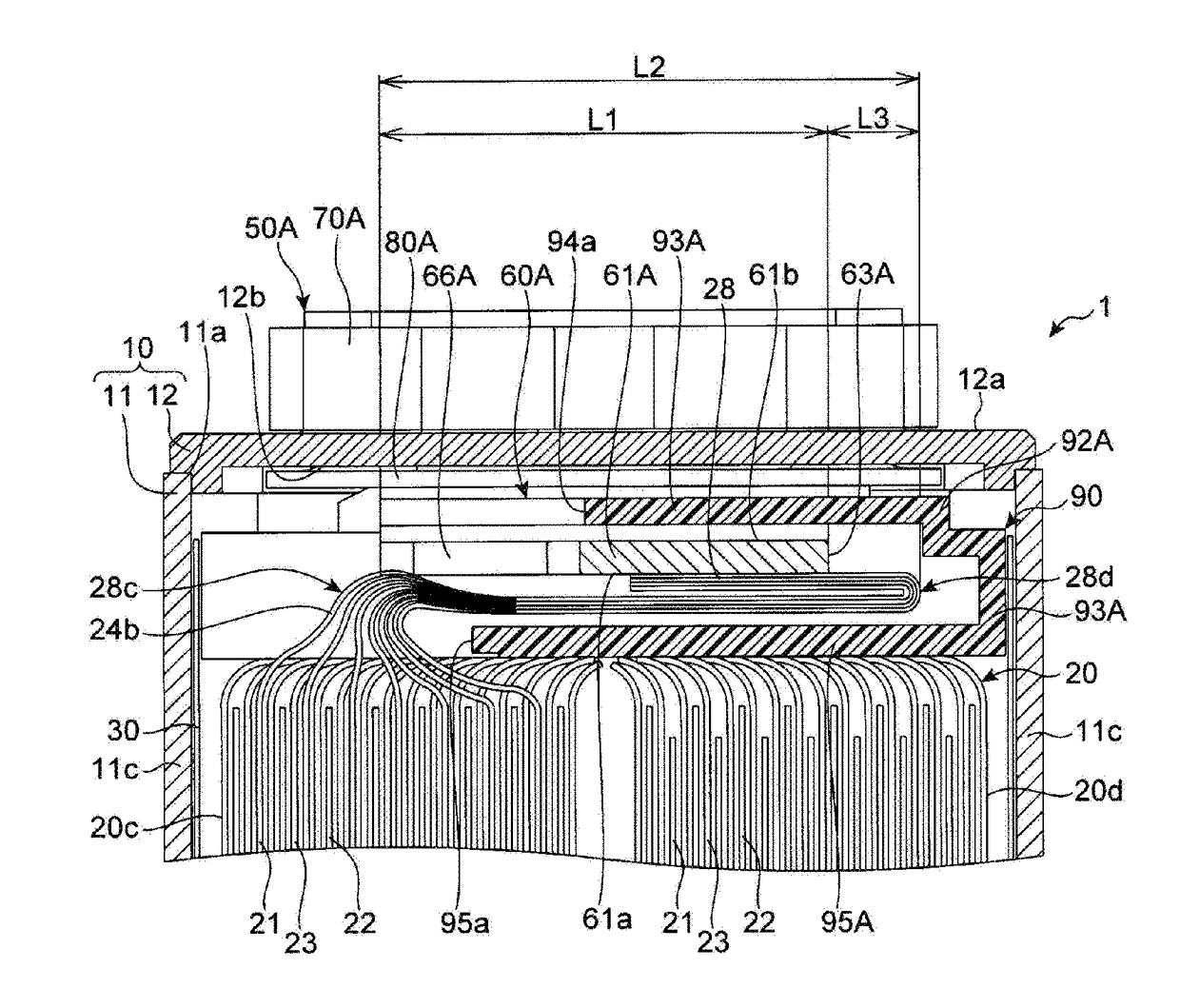

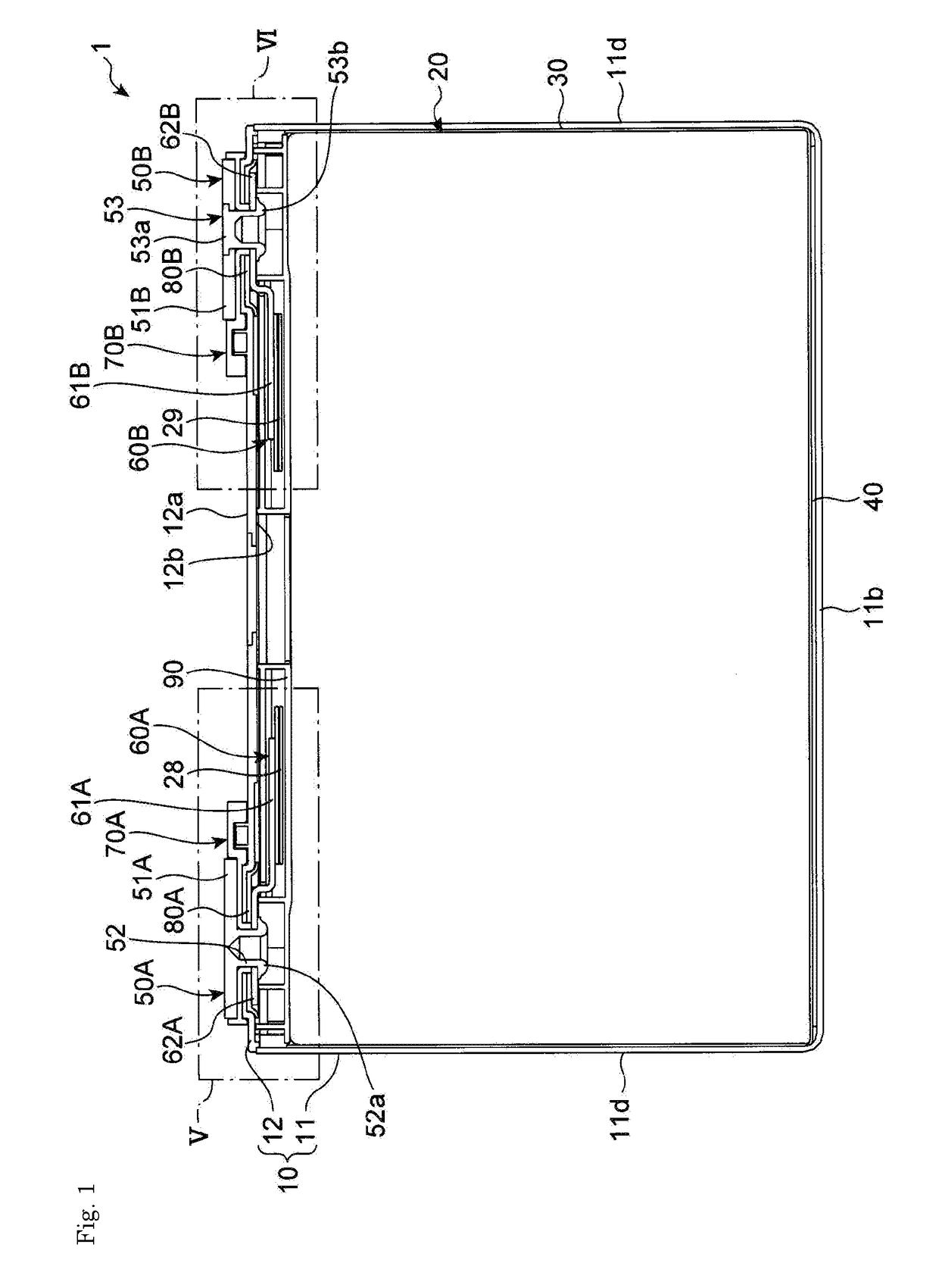

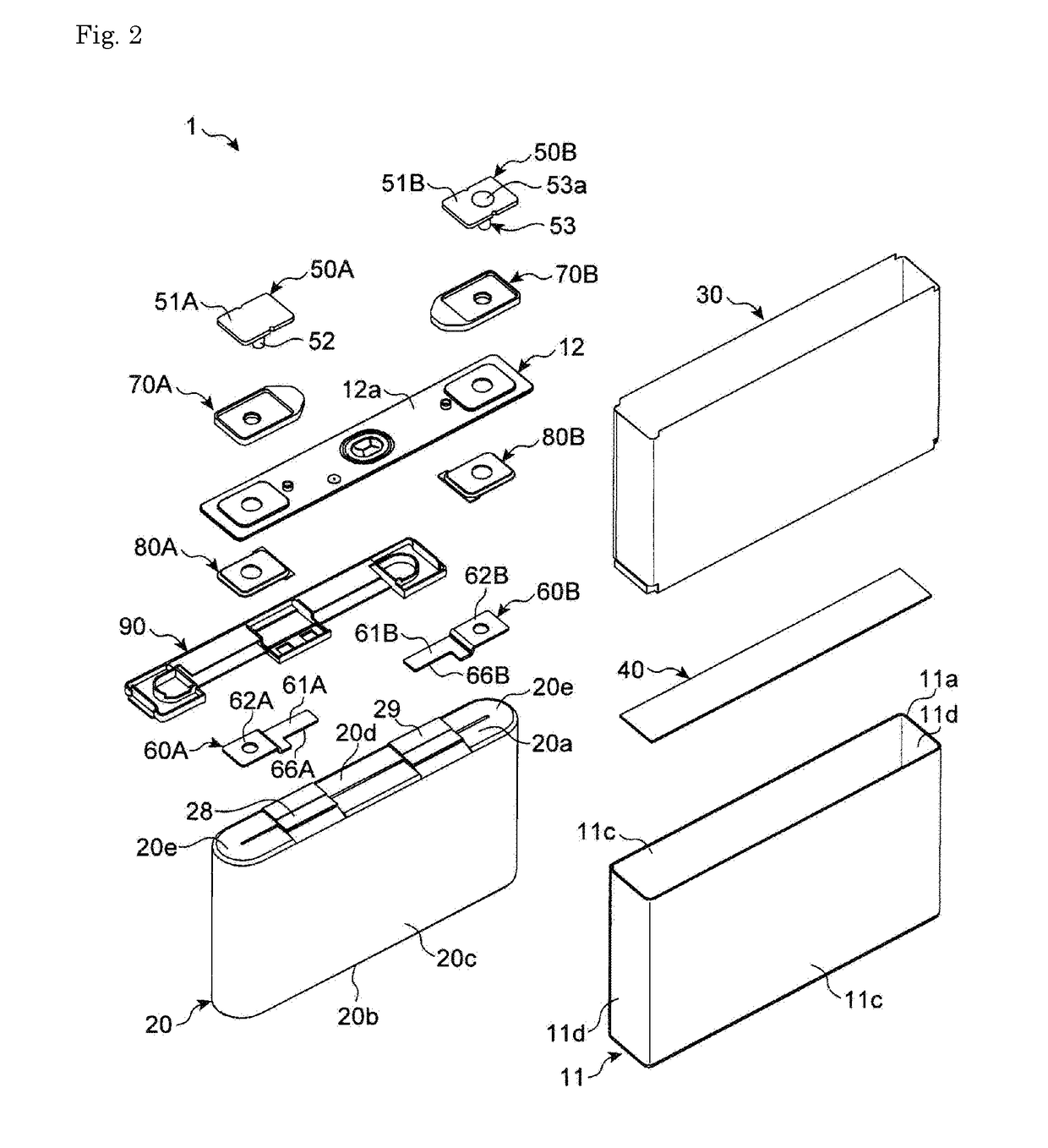

Energy storage device

InactiveUS20170365839A1High energy capacityIncrease capacityCell seperators/membranes/diaphragms/spacersFinal product manufactureElectricityEngineering

An energy storage device (battery) includes an electrode assembly having current collecting tabs, each of which is formed of a plurality of projecting portions, projecting from a first straight line portion on one side in a stacking direction of electrode sheets. The electrode assembly is housed in a case (exterior body). The energy storage device further includes current collectors, which are electrically connected to the external terminals, disposed on the case. The current collectors, are connected to the current collecting tabs, arranged in a stacking direction of the electrode sheets, on a second straight line portion side where the projecting portions, are not formed.

Owner:GS YUASA INT LTD

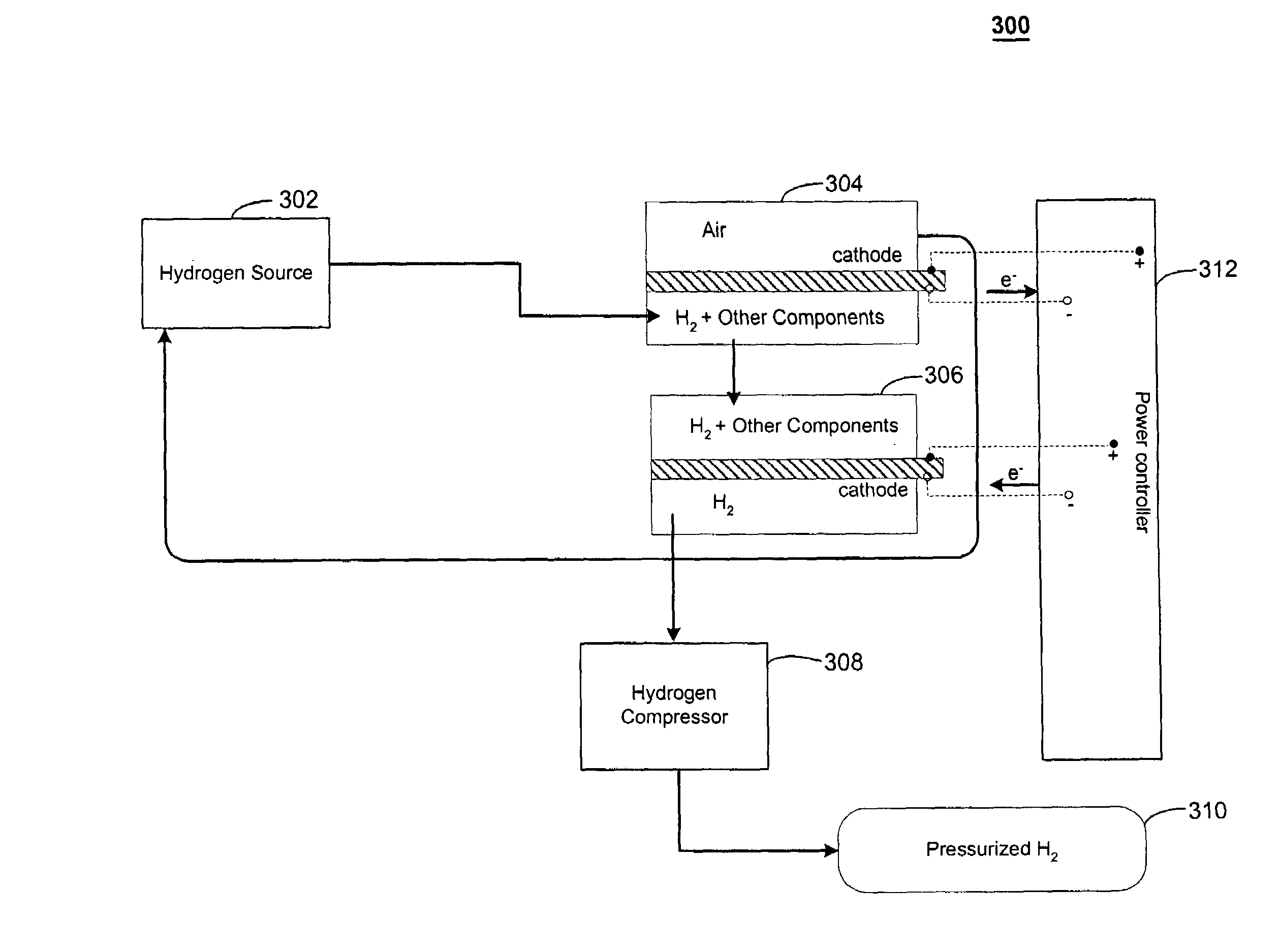

Systems and methods to generate hydrogen and electrical power in a reversible compound fuel cell

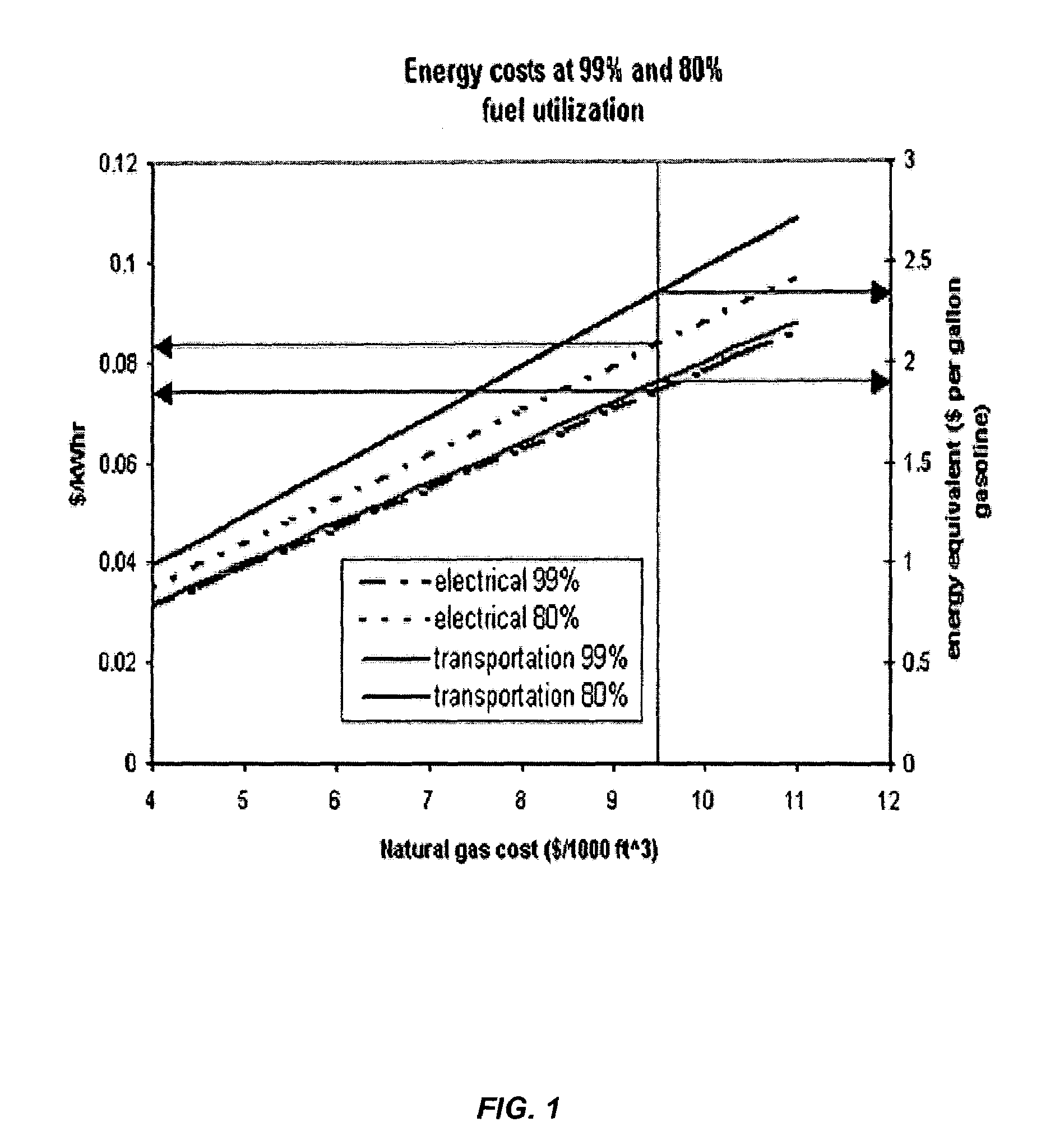

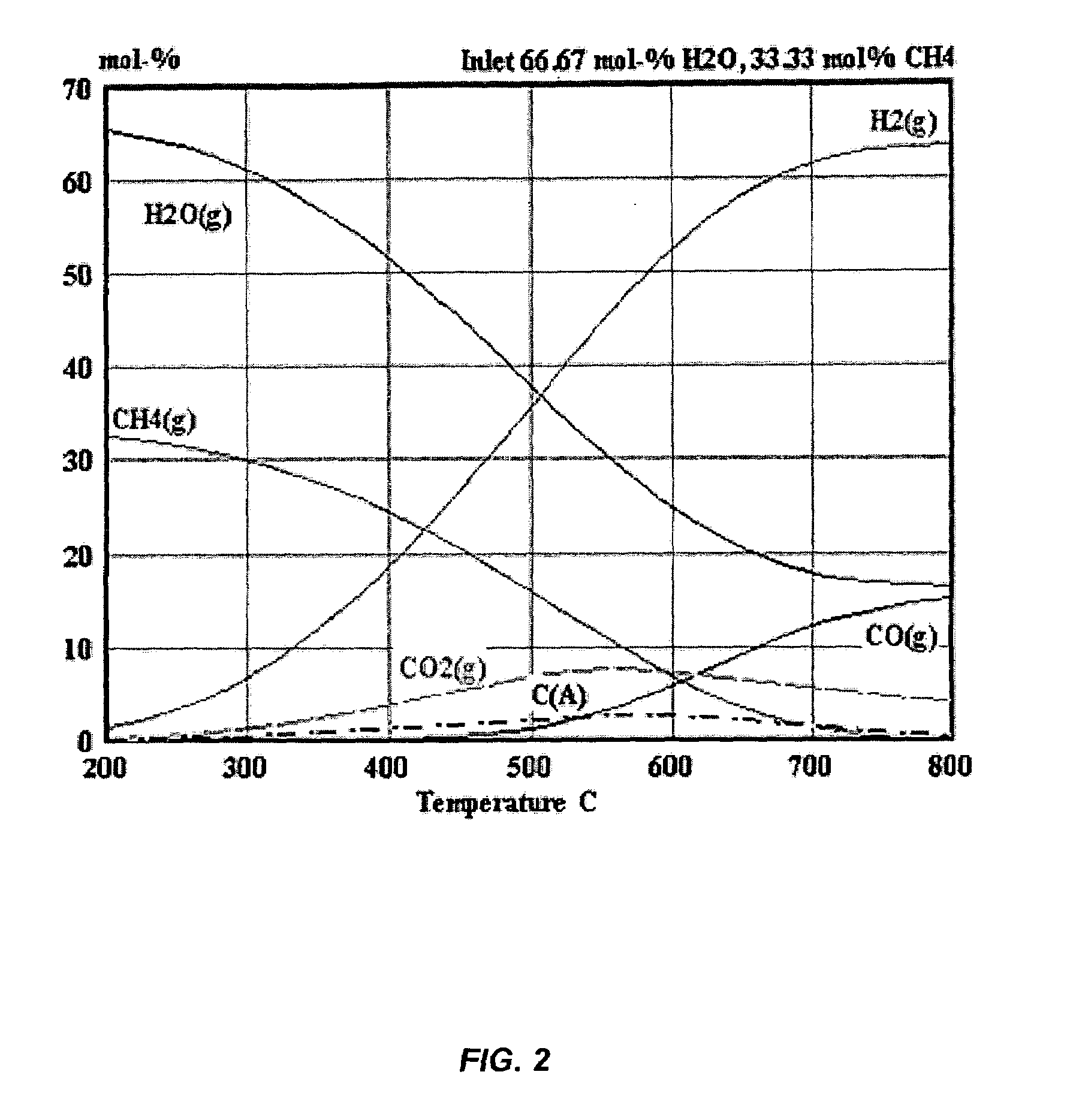

ActiveUS7255949B2Increase pressurizationHigh purityFuel cell auxillariesRegenerative fuel cellsElectricityHydrogen

Owner:PROTONETICS INT

Reversible hydraulic pressure converter employing tubular valves

ActiveUS9695840B2High energy capacitySmall sizeServomotor componentsAccumulator installationsValve actuatorHigh pressure chamber

The reversible hydraulic pressure converter (1) employing tubular valves includes a medium-pressure stage (44) consisting of a medium-pressure cylinder (2) and a double-acting medium-pressure piston (3) the position of which is sent to a control computer of the converter (19) by a piston position sensor (14), the cylinder (2) and the piston (3) forming two medium-pressure chambers (5) that can be placed in communication with a medium-pressure inlet-outlet circuit (15) by at least one tubular valve (12), the converter (1) also including two high-pressure cylinders (9) each cooperating with a high-pressure piston (8) of smaller diameter and defining two high-pressure chambers (11) that can be placed in communication with a high-pressure inlet-outlet circuit (16) by at least one tubular valve (12), each of the various tubular valves (12) cooperating with an independent valve actuator (13).

Owner:RABHI VIANNEY

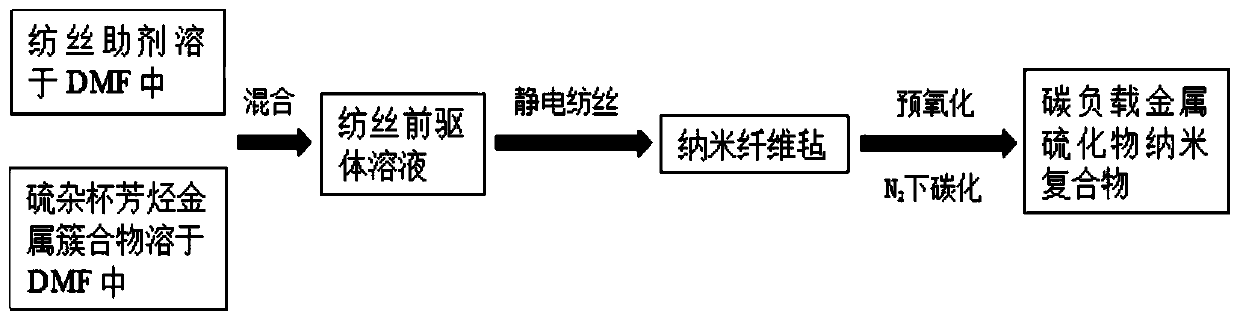

Method for preparing carbon-loaded metal sulfide nanocomposite through electrostatic spinning

ActiveCN109817936AImprove electrochemical performanceGood capacitance characteristicsCell electrodesCapacitanceFiber

The invention belongs to the field of metal sulfide nano-materials, and particularly relates to a method for preparing a carbon-loaded metal sulfide nanocomposite through electrostatic spinning, whichcomprises the following steps: (1) preparing a spinning precursor solution: respectively dissolving a thiacalixarene metal cluster compound and a spinning aid in DMF (Dimethyl Formamide), and mixing;(2) preparing nano-fibers by electrostatic spinning: sucking the obtained spinning precursor solution into an injector, adjusting the pump flow rate and voltage of the injector and the distance between a spinning needle and a receiving plate, spinning, and receiving a nano-fiber felt by the receiving plate; (3) pre-oxidizing the nano-fiber felt: pre-oxidizing the collected nano-fiber felt; and (4) carbonizing in an N2 atmosphere: carbonizing the pre-oxidized nano-fiber felt, and naturally cooling to obtain the target product. The target product is ideal in electrochemical performance and goodin capacitance characteristic, the flaky carbon material is directly used as an electrode, additives or impurities such as a binding agent can be eliminated, and the energy capacity and performance are improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Lead acid battery having lightly gelled electrolyte

InactiveUS7799466B2Improve electrical performanceLower internal resistanceLead-acid accumulatorsNon-aqueous electrolyte cellsSilica particlePhysical chemistry

A lead acid battery having lightly gelled electrolyte is provided. The lead acid battery includes a plurality of alternating positive plates and negative plates, a plurality of separators sandwiched in between the positive plates and the negative plates, and a lightly gelled electrolyte including dilute sulfuric acid and silica particles substantially in the range of 0.1% to 3% of the electrolyte by weight. The silica particles are fumed silica particles.

Owner:HIRATE ENERGY TECH LTD

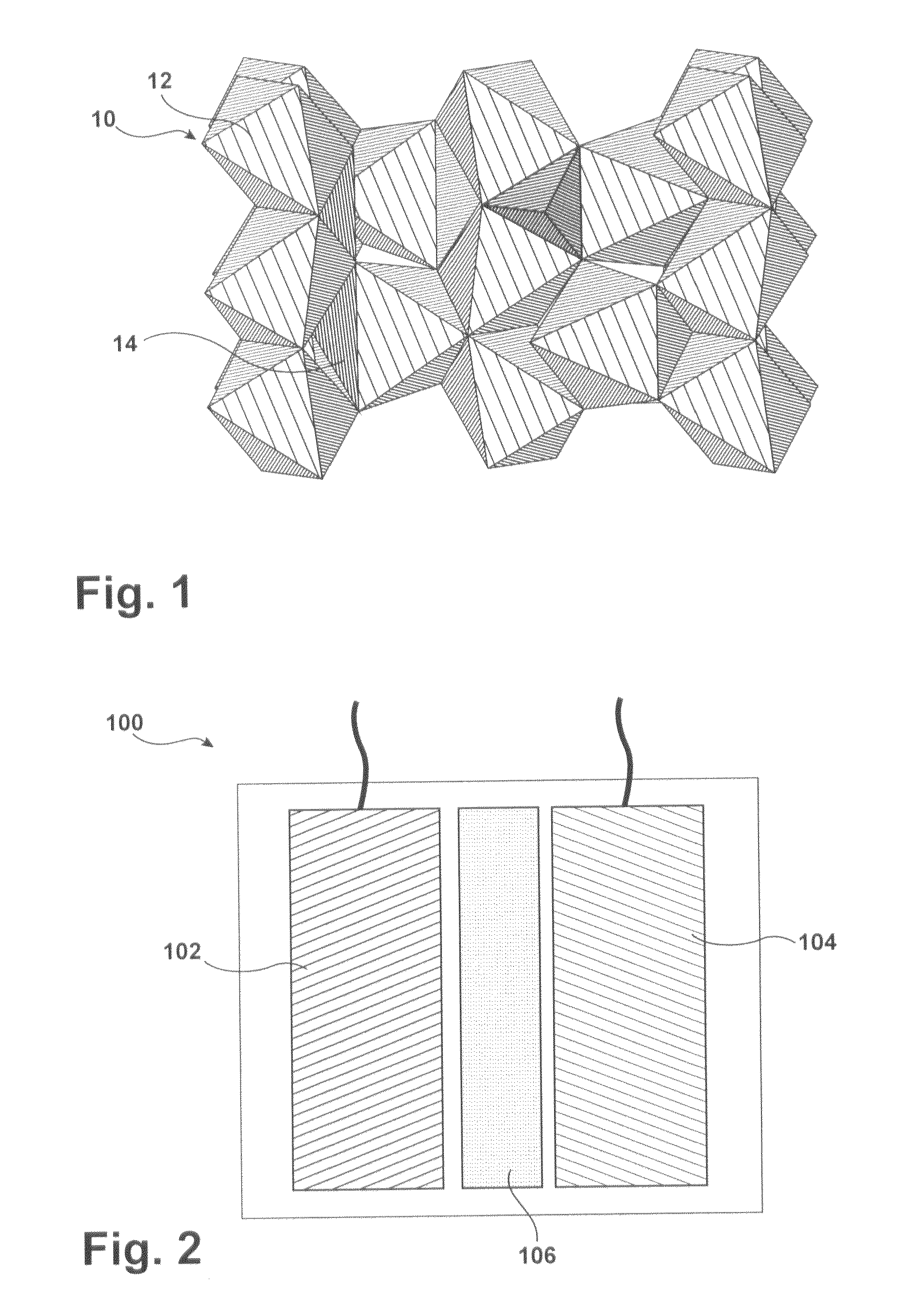

Solid State Supercapacitor and Method for Manufacturing the Same

InactiveUS20120127630A1High purityImprove compactnessMaterial nanotechnologyFixed capacitor electrodesElectricityNanowire

A solid state supercapacitor and a method for manufacturing the same is provided, the solid state supercapacitor including two nanowire electrodes with their surface full of nanowire bundle and a dielectric material filled in a space between the two nanowire bundle electrodes and the nanowire bundle, wherein the nanowire bundle includes many nanowires to increase the surface area of electrodes; since the two nanowire bundle electrodes include the nanowire bundle, the surface area thereof is large; a dielectric layer is the original material of the dielectric material, directly reacted, deposited and cured in the space between the two nanowire bundle electrodes without causing pollutions due to additional processing; therefore, the dielectric layer is of high purity and density and has high permittivity to achieve the greatest permittivity of the dielectric material. As a result, the energy capacity of unit volume of the capacitor is effectively increased.

Owner:DELIJIOU IND & SYST

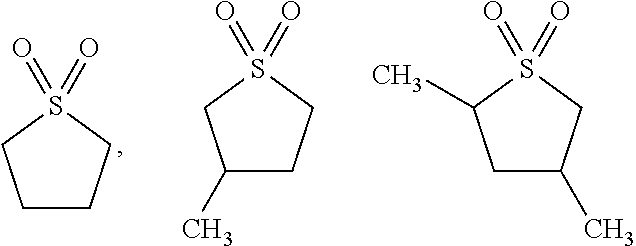

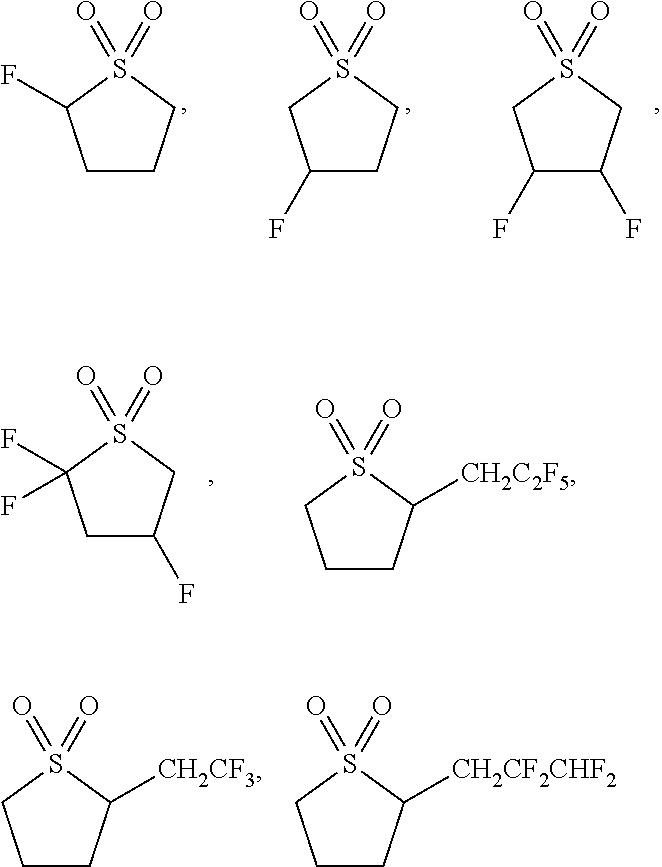

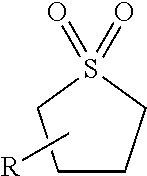

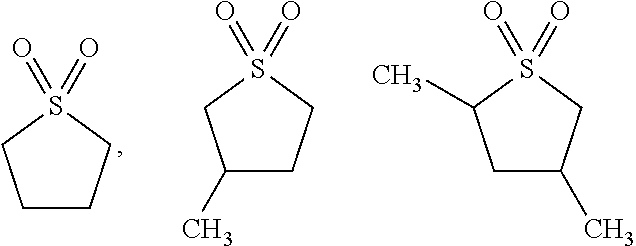

Electric double layer capacitor

InactiveUS8767376B2Improve pressure resistanceImprove long-term reliabilityHybrid capacitor electrolytesElectrolytic capacitorsEtherSolvent

An object of the present invention is to provide an electric double layer capacitor which has a high withstand voltage, and is resistant to degradation and excellent in long term reliability. Disclosed is an electrolytic solution for an electric double layer capacitor including a solvent (I) for dissolving an electrolyte salt and an electrolyte salt (II), wherein the solvent (I) for dissolving an electrolyte salt includes a sulfolane compound and a fluorine-containing chain ether. Also disclosed is an electric double layer capacitor using the electrolytic solution.

Owner:DAIKIN IND LTD

Alternative energy bus bar by pass breaker, methods of use and installation

InactiveUS9728972B2High energy capacityEliminating carbon build up and corrosionSingle network parallel feeding arrangementsWind energy generationFuel cellsPower grid

The present invention is directed, in part, to electrical components and methods of use associated with such components. In particular, the invention relates to an electrical device and improved method of back feeding energy generated from alternative energy devices such as solar panels, wind turbines, fuel cells, electrical generators and other alternative energy sources, to the utility without the necessity of installing a sub panel or replacing an existing panel, resulting in significant cost savings for the user and increased electrical energy available to the power grid. The invention further discloses installation of a back feed circuit breaker into an existing main panel and main circuit breaker thus, eliminating the need of a home owner to completely reinstall a new electrical system in order to install alternative energy sources such as for example, solar panels and the like.

Owner:QFE 002 LLC

Electric double layer capacitor

InactiveUS20120243145A1Improve pressure resistanceImprove long-term reliabilityHybrid capacitor electrolytesElectrolytic capacitorsEtherSolvent

An object of the present invention is to provide an electric double layer capacitor which has a high withstand voltage, and is resistant to degradation and excellent in long term reliability. Disclosed is an electrolytic solution for an electric double layer capacitor including a solvent (I) for dissolving an electrolyte salt and an electrolyte salt (II), wherein the solvent (I) for dissolving an electrolyte salt includes a sulfolane compound and a fluorine-containing chain ether. Also disclosed is an electric double layer capacitor using the electrolytic solution.

Owner:DAIKIN IND LTD

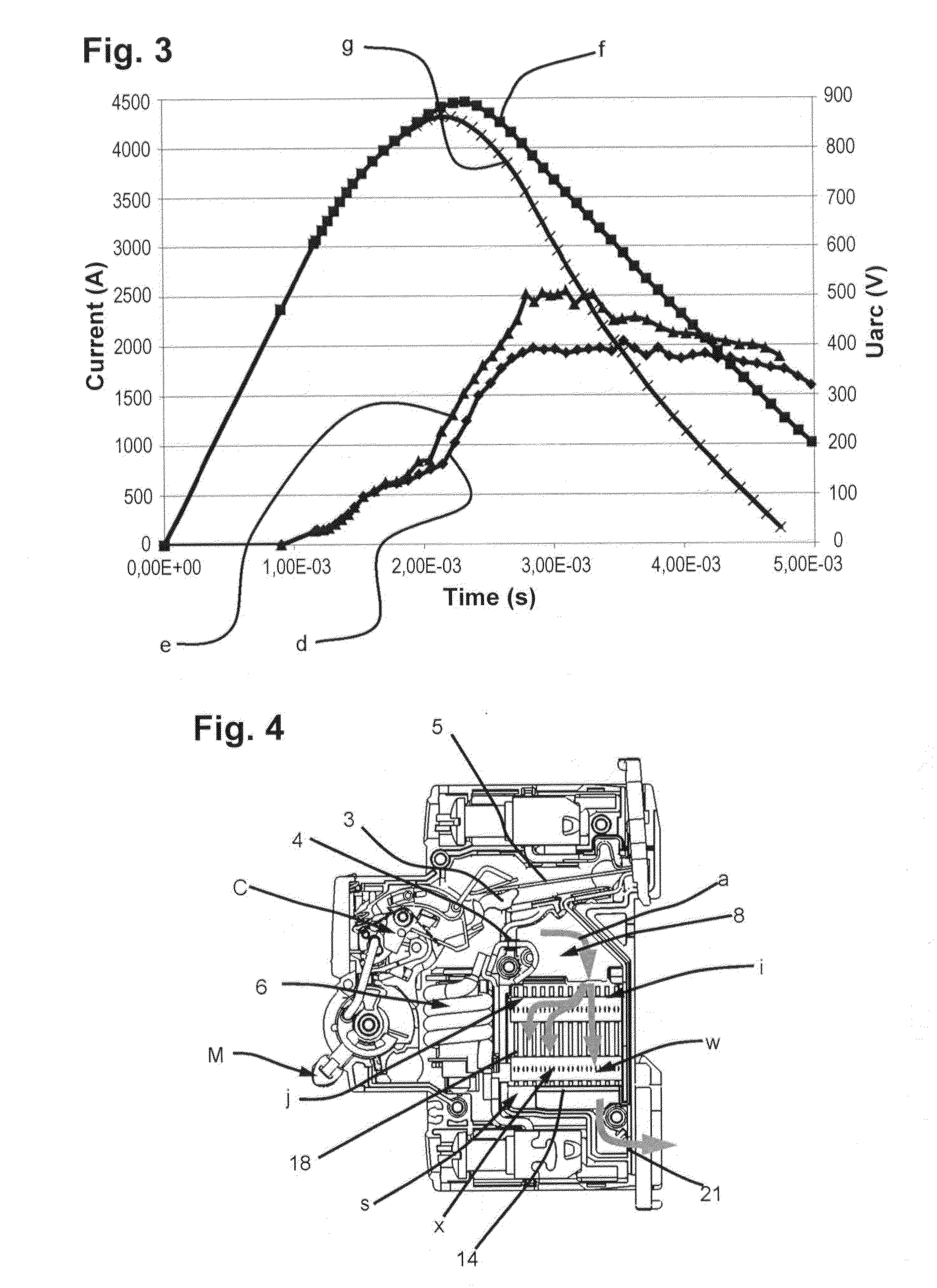

Arc extinguishing chamber for an electric protection apparatus and electric protection apparatus comprising same

ActiveUS20140339197A1Increase capacityHigh energy capacityHigh-tension/heavy-dress switchesAir-break switchesInterrupter TechniqueExhaust gas

The present invention relates to an arc extinguishing chamber of an electric protection apparatus comprising an arc formation chamber containing a stationary contact and a movable contact which, when they separate, form an arc between them, said arc formation chamber communicating with the inlet of a second chamber, called arc extinguishing chamber. This chamber comprises a wall called balancing wall, substantially solid at least on its central part, said wall being located downstream from the arc extinguishing chamber and being formed and arranged with respect to the arc extinguishing chamber in such a way as to slow down the exhaust flow of the breaking gases on the side of the arc extinguishing chamber where the gases go first, and enhancing flow of the exhaust gases on the opposite side, the exhaust gases being stopped by the central part of the wall and escaping via the edges of the wall.

Owner:SCHNEIDER ELECTRIC IND SAS

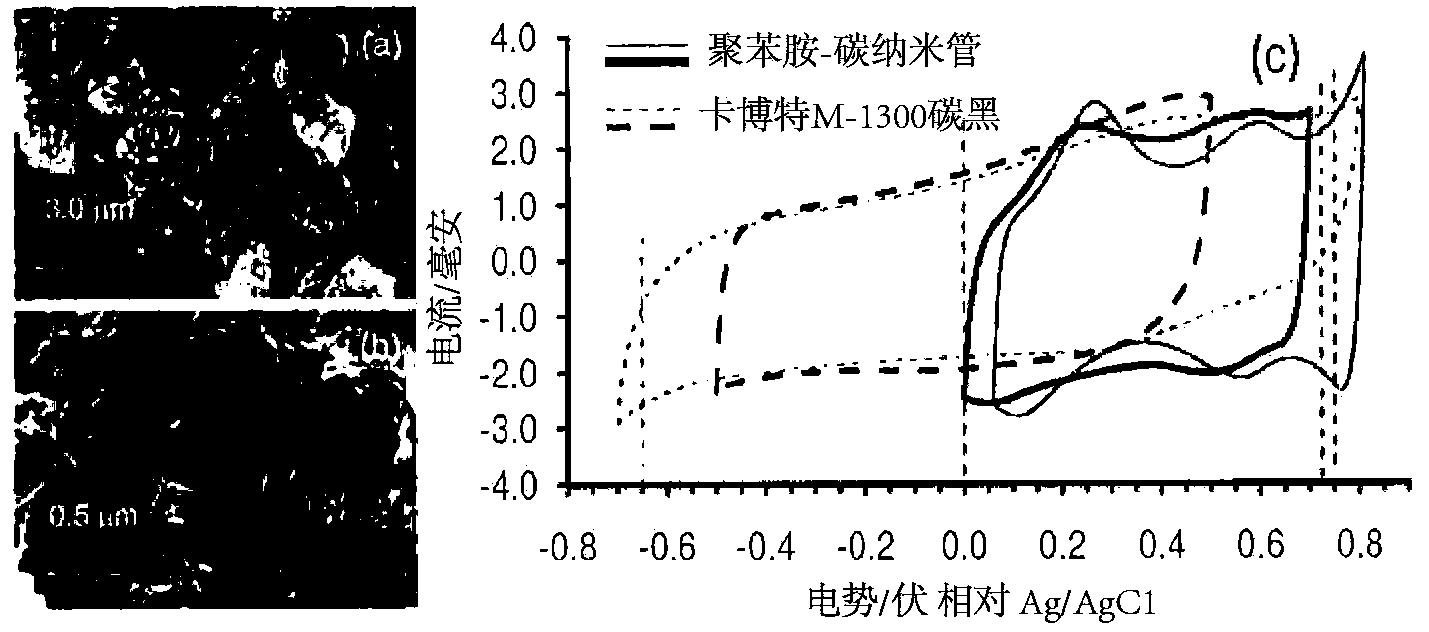

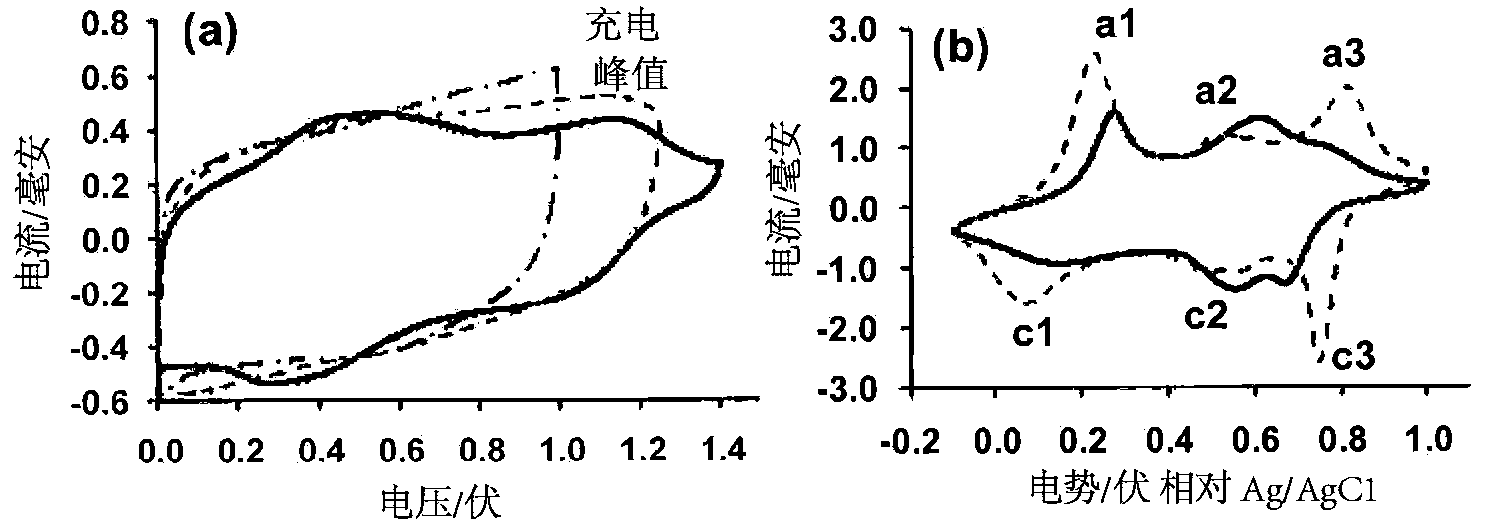

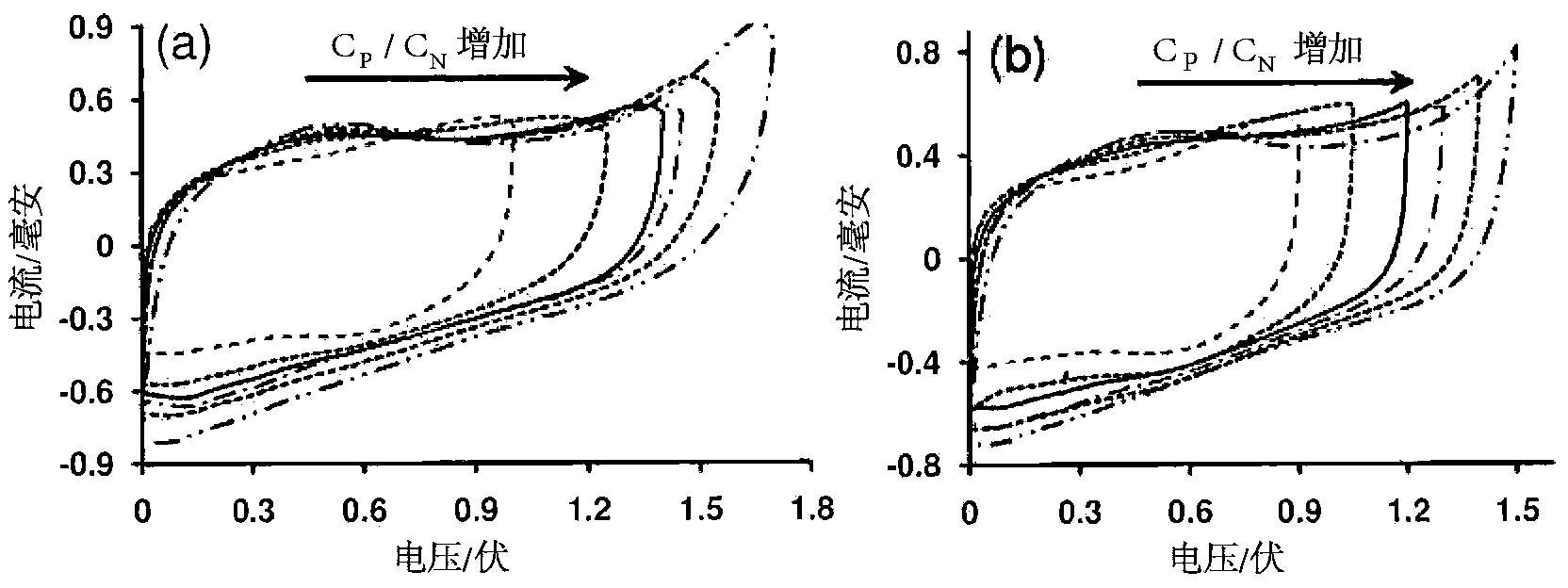

Charge storage device and method of manufacturing it

InactiveCN103384905AIncrease battery voltageHigh energy capacityHybrid capacitor electrodesDouble layer capacitorsCapacitancePower capability

The present invention provides a charge storage device, comprising a pair of electrodes, each electrode being operable to store electric charge and having a respective capacitance Cp, CN that is different to the other, with the ratio of the capacitances CP / CN being greater than 1. In exemplary embodiments, the charge storage device may be an asymmetrical supercapacitor, which is operable to provide an enhanced energy capacity by increasing the cell voltage through unequalising the electrode capacitance. Hence, by increasing the CP / CN ratio an improved power capability can be achieved over conventional devices, while offering a simple and low cost manufacturing strategy. The present invention has particular application with cameras, electric vehicles, elevators, renewable energy stores, fuel cells, batteries and many forms of electronic devices.

Owner:UNIVERSITY OF NOTTINGHAM

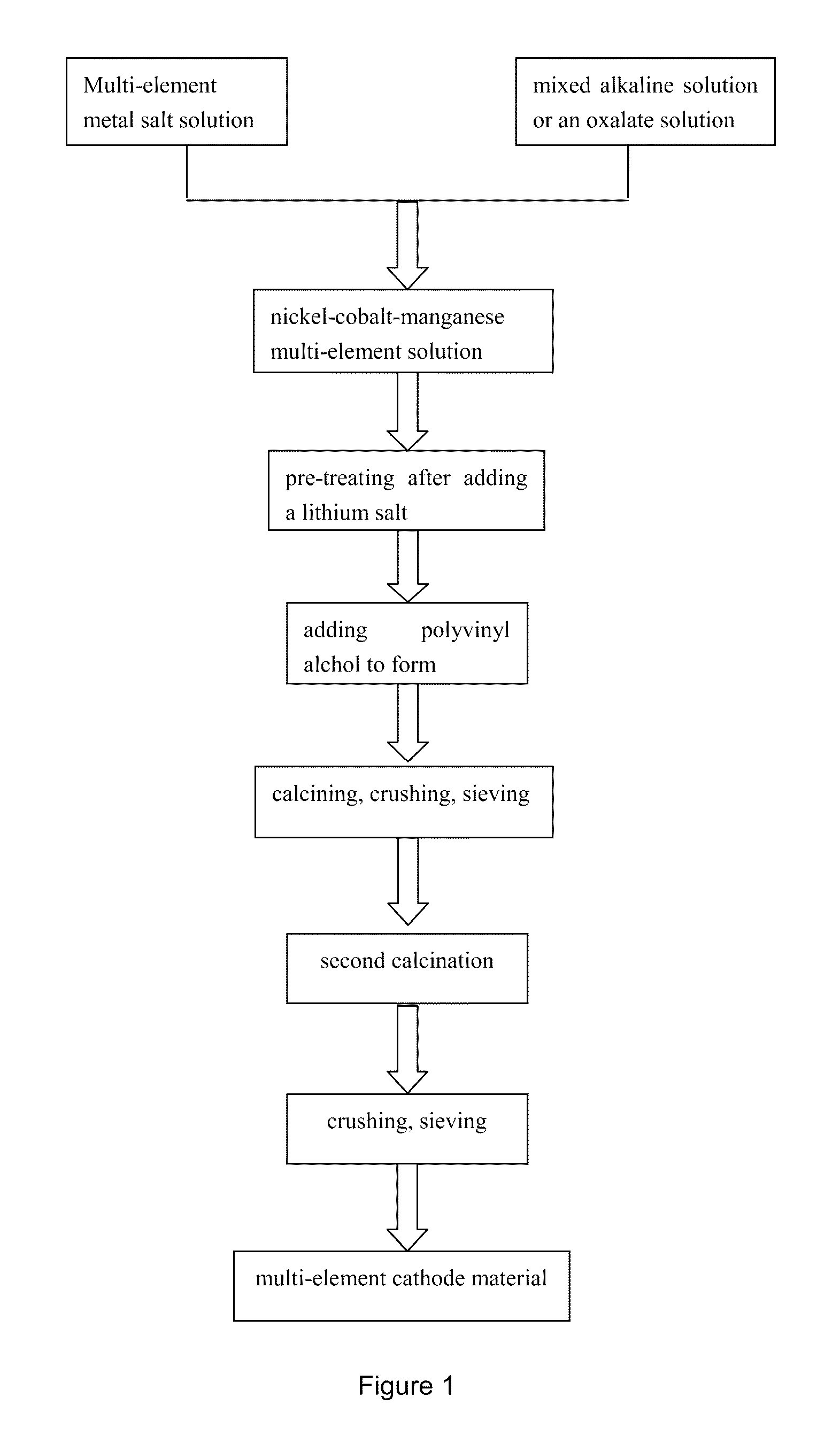

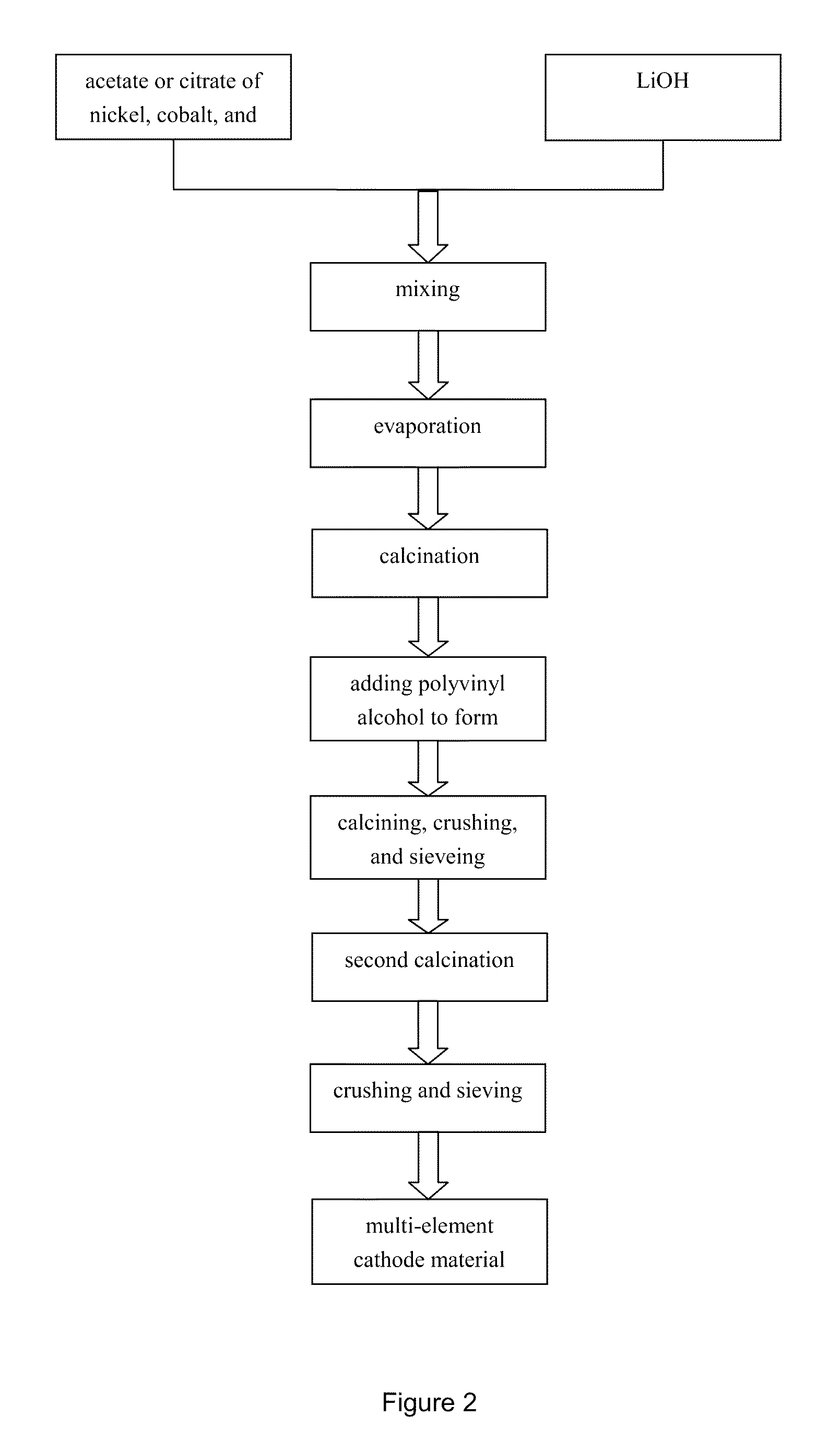

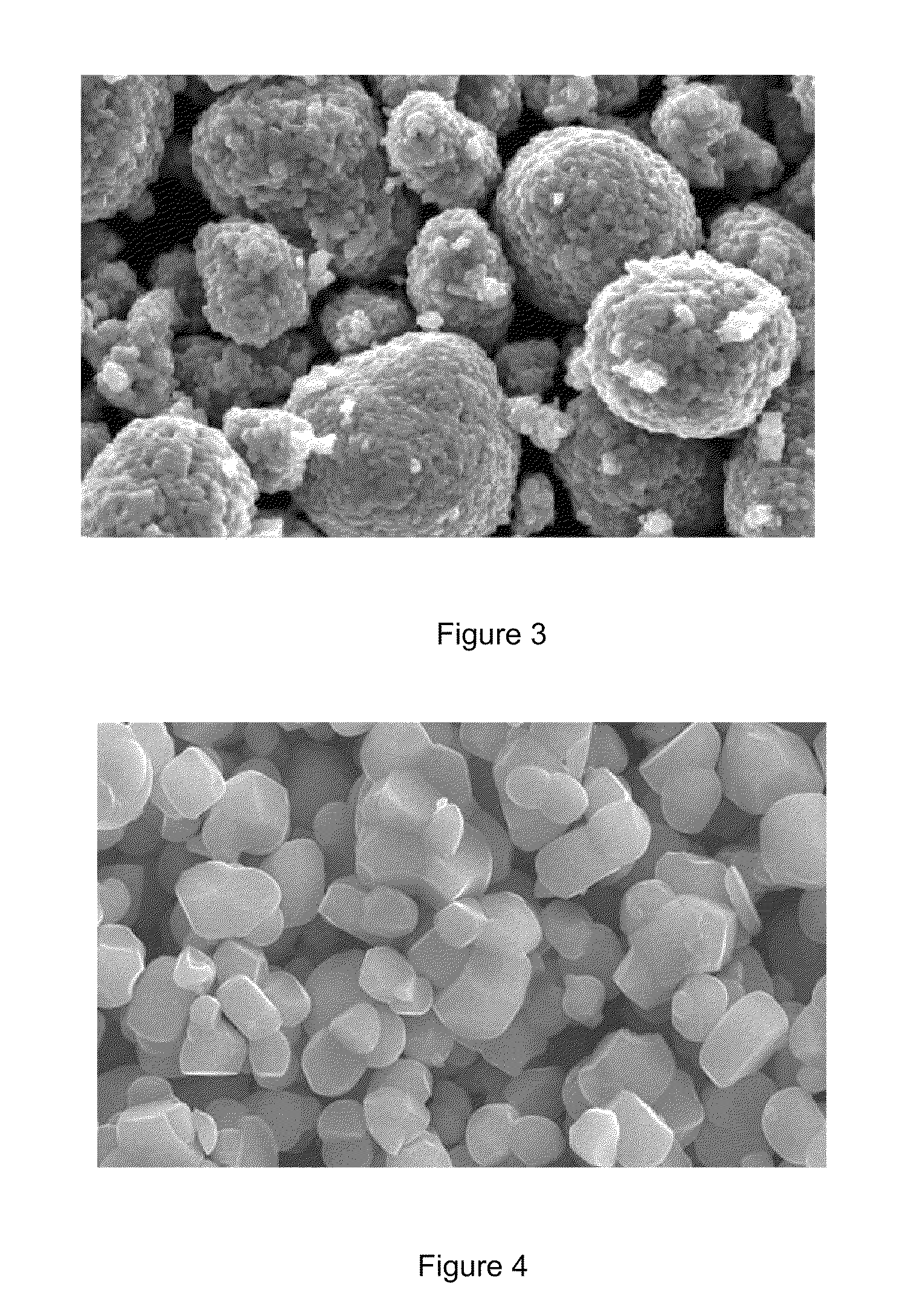

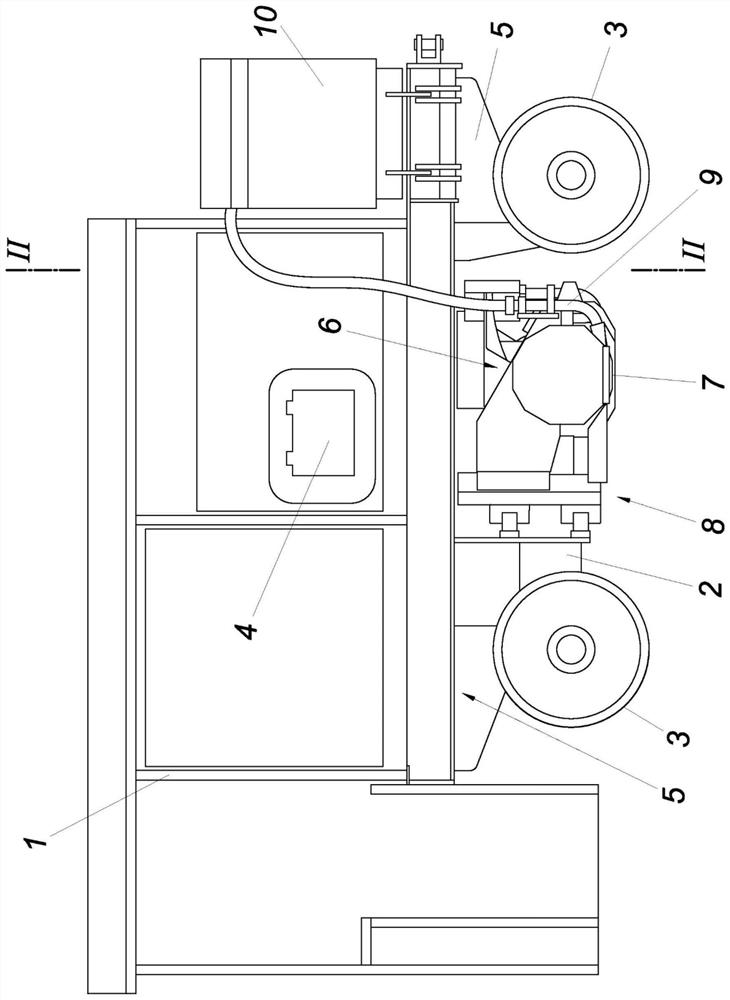

Nickel-cobalt-manganese multi-element lithium ion battery cathode material with dopants and its methods of preparation

InactiveUS8709302B2Increase compaction densityReduce absorptionConductive materialSecondary cellsChemical synthesisDopant

The present invention discloses a high compact density nickel-cobalt-manganese multi-element lithium ion battery cathode material with dopants and methods of its preparation. A preparation method of this battery cathode material is as follows: (A) preparing a nickel-cobalt-manganese multi-element intermediate with dopants by co-precipitation or chemical synthesis; (B) preparing a mixture by mixing said multi-element intermediate with a lithium salt; (C) pre-treating the said mixture, then adding into it polyvinyl alcohol and mixing uniformly; (D) pressing the resulting material into lumps, calcining the lumps at 800˜950° C., cooling after its removal from the furnace, crushing, passing through a 400 mesh sieve; (E) calcining the resulting power at 700˜800° C., cooling after its removal from the furnace, crushing and sieving to obtain a product. The lithium battery cathode material obtained using the above-described method has the formula LiNixCoyMnzM(1-x-y-z)O2. The cathode material has non-agglomerated single crystal particles. The material has a particle size ranging from 0.6˜30 μm, a compact density of 3.5˜3.7 g / cm3, and an initial discharge capacity of 150˜165 mAh / g, with excellent cycling and safety performance.

Owner:CHENGDU JINGYUAN NEW MATERIALS TECH

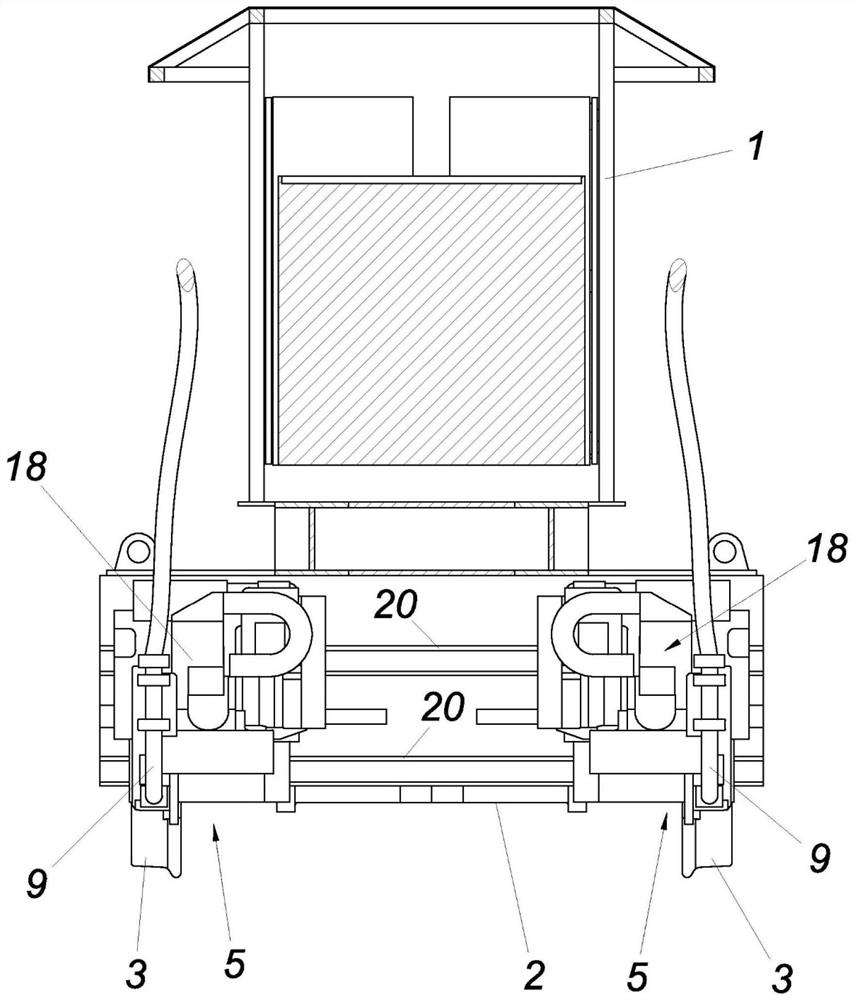

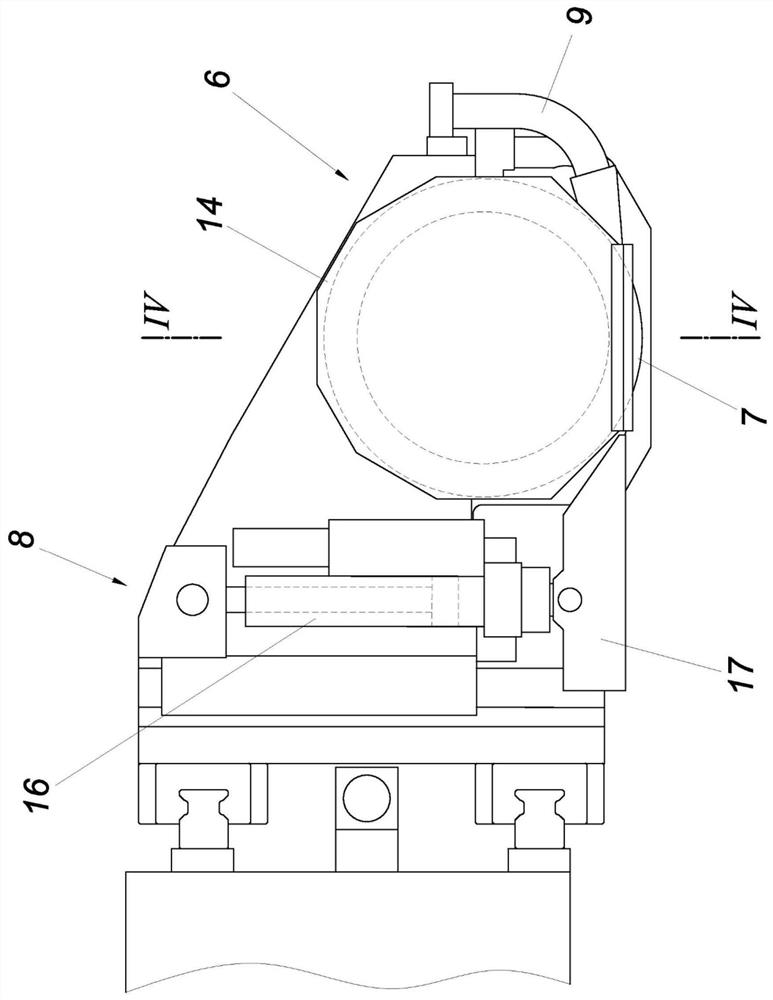

Processing device for rail systems in urban areas

InactiveCN111684133AReliable deliveryIncrease coefficient of frictionGrinding wheel securing apparatusGrinding machinesAbove groundFeed drive

The invention describes a processing device for rail systems in urban areas, having a travel drive (5), a processing drive (6) and a contour-defining, rotationally driven processing tool (7) mounted in a floating manner on a shaft (10) arranged in a housing (11), wherein the processing tool (7), the housing (11) and the shaft (10) are arranged on a chassis (2) having wheels (3) and can be placed by a feed drive (8) against a rail head (13) to be processed. In order to configure a device of the type described at the outset in such a way that it has a compact design such that it can be used forprocessing rail systems in urban areas both above ground and below ground, it is proposed that the processing tool (7) is of pot-shaped design and attached end-side by its base to the shaft (10), wherein the circumferential surface of the cutting edge-bearing flank of the processing tool (7) at least partially circumferentially encloses the shaft (10) and the closer-situated shaft bearing (12).

Owner:林辛格工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com