Patents

Literature

45results about How to "High electromotive force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Redox flow battery

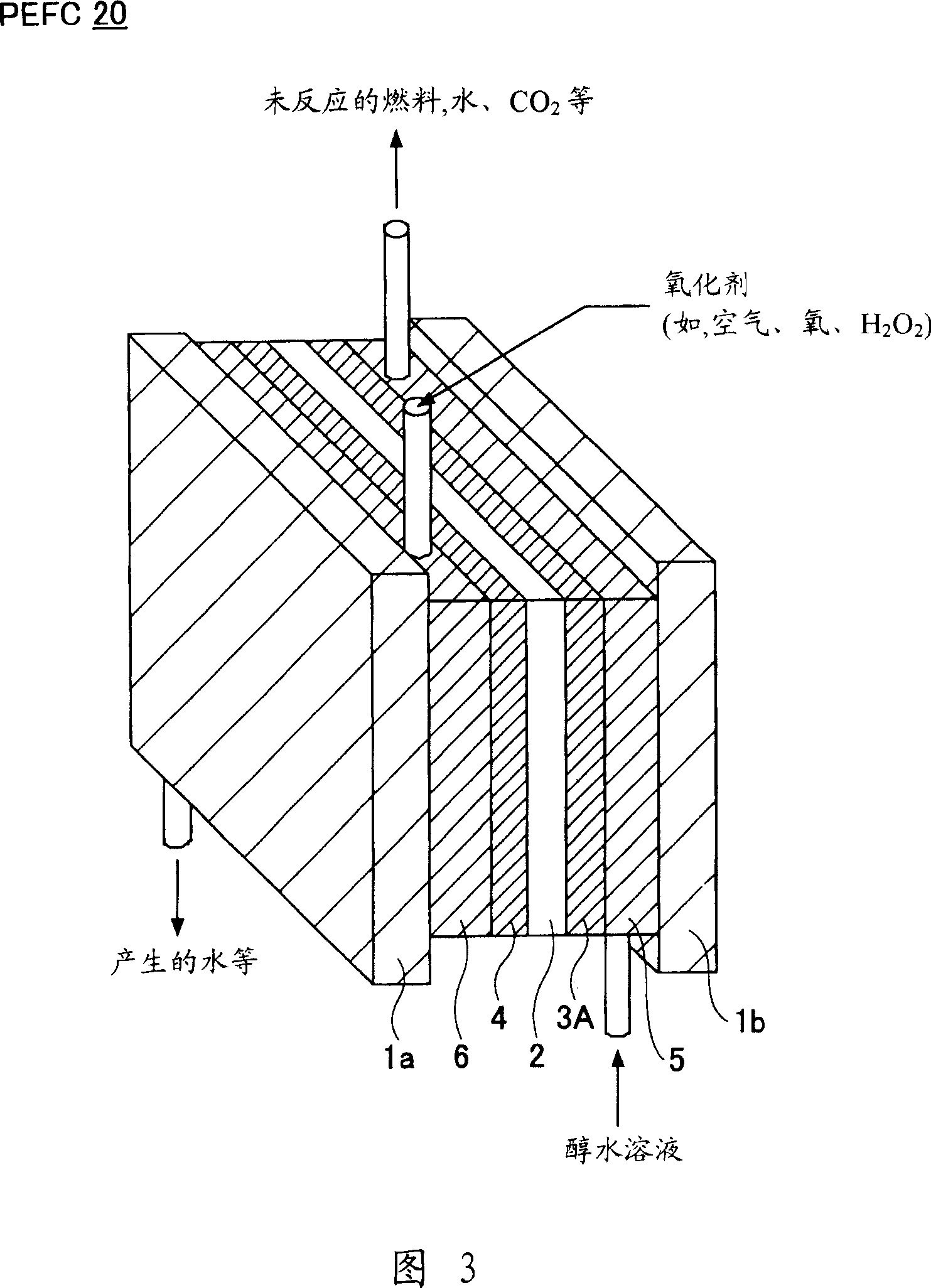

ActiveUS20120045680A1Suppress generationHigh electromotive forceElectrolyte moving arrangementsCell electrodesManganesePhysical chemistry

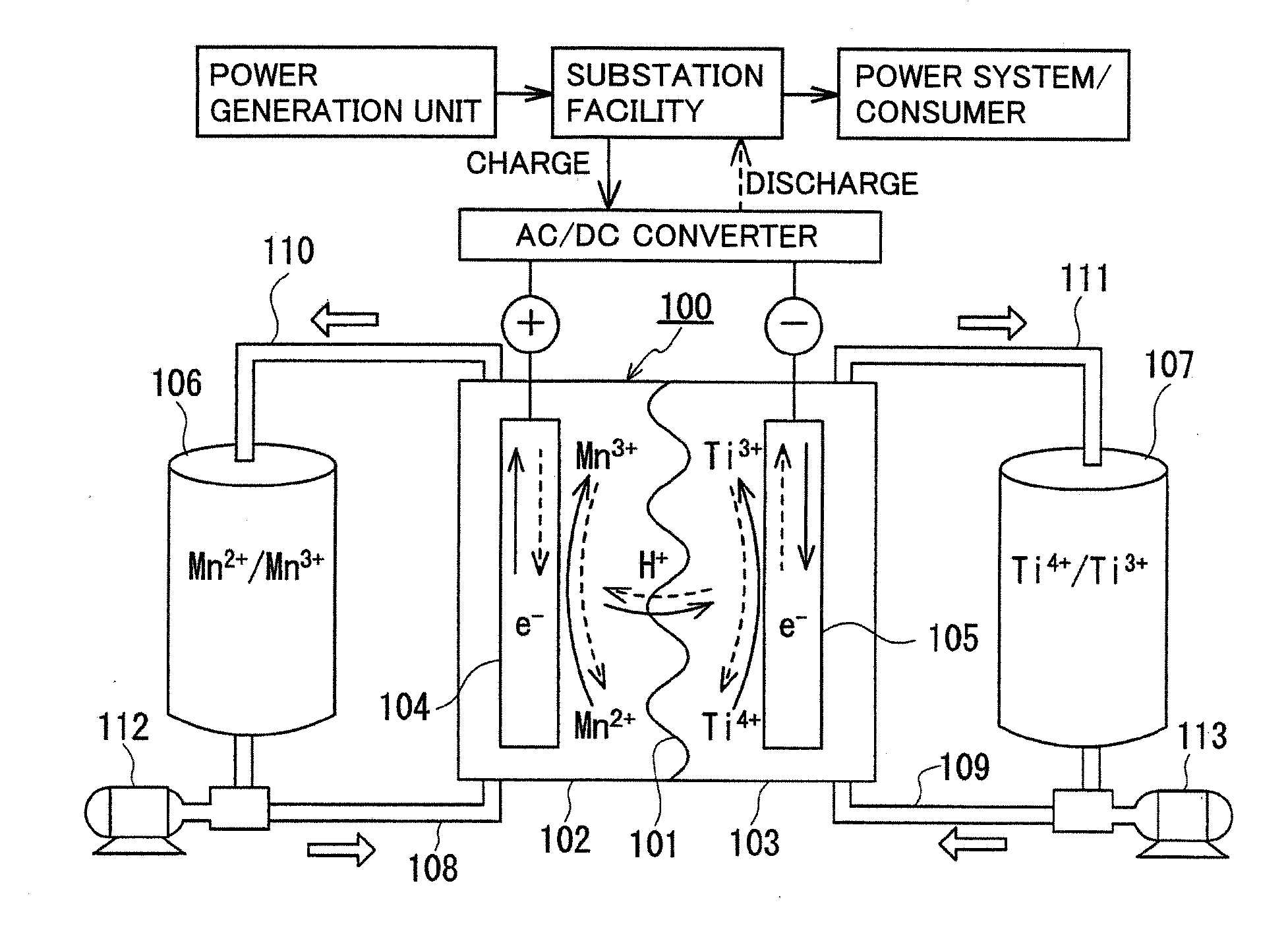

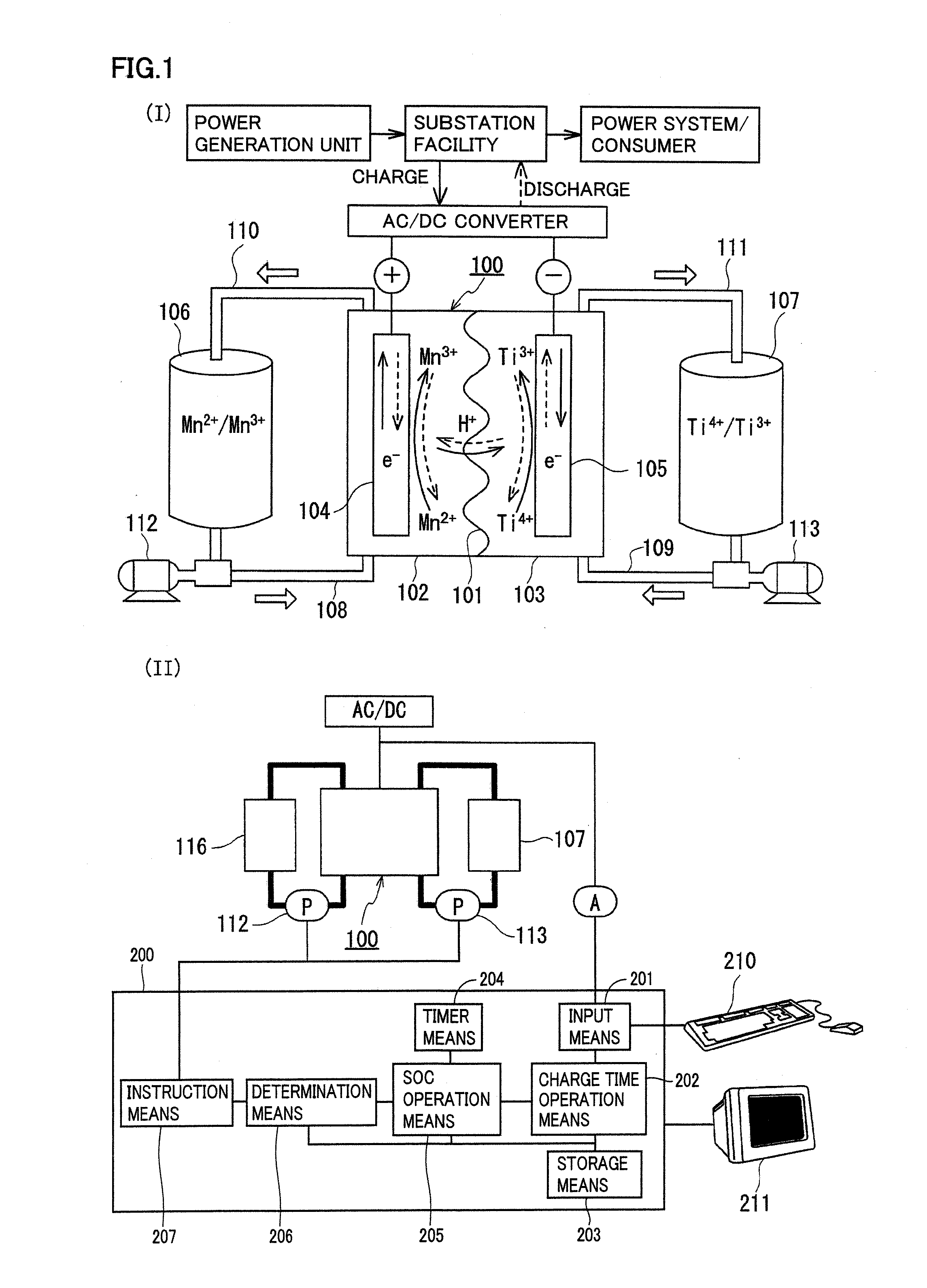

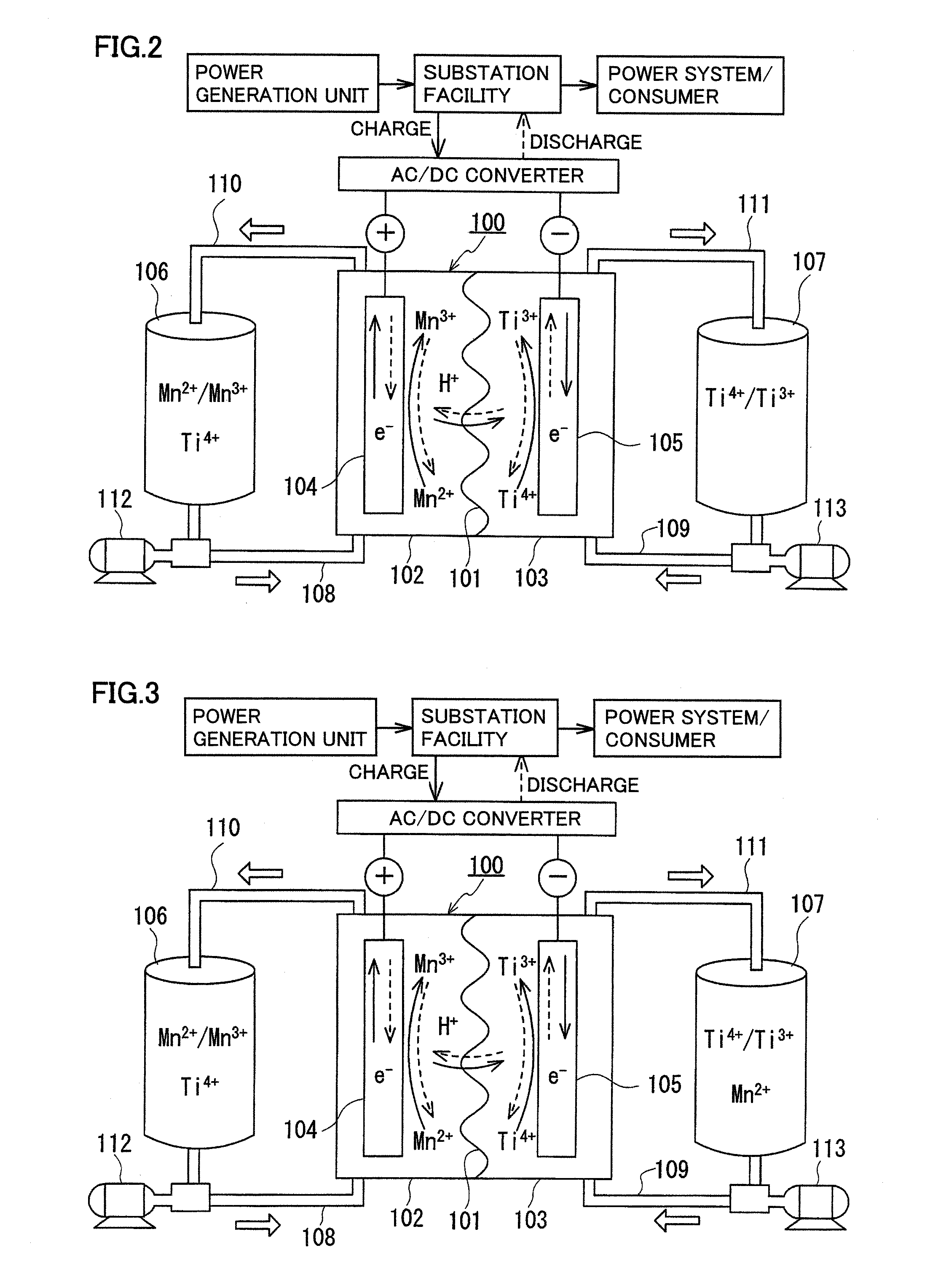

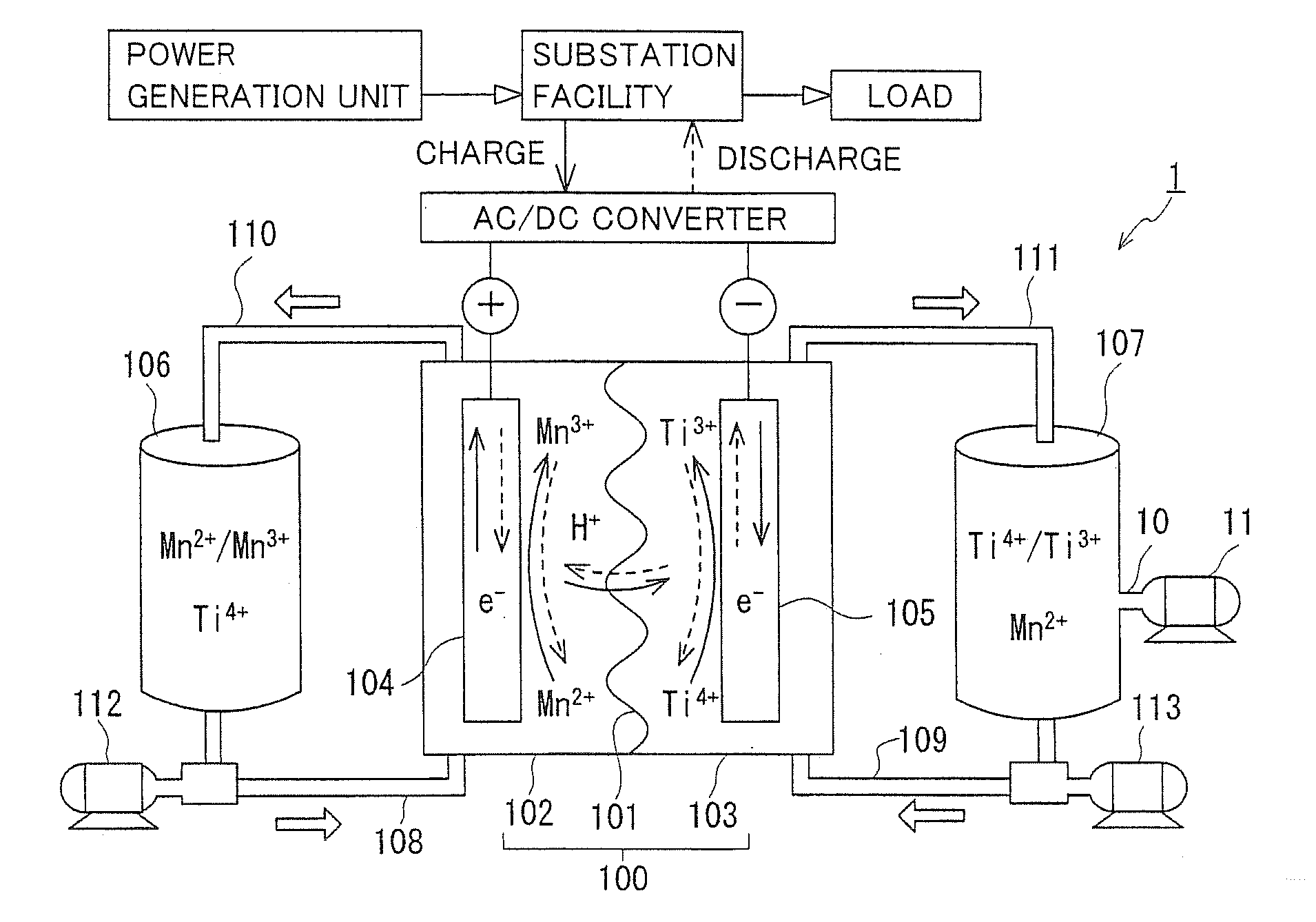

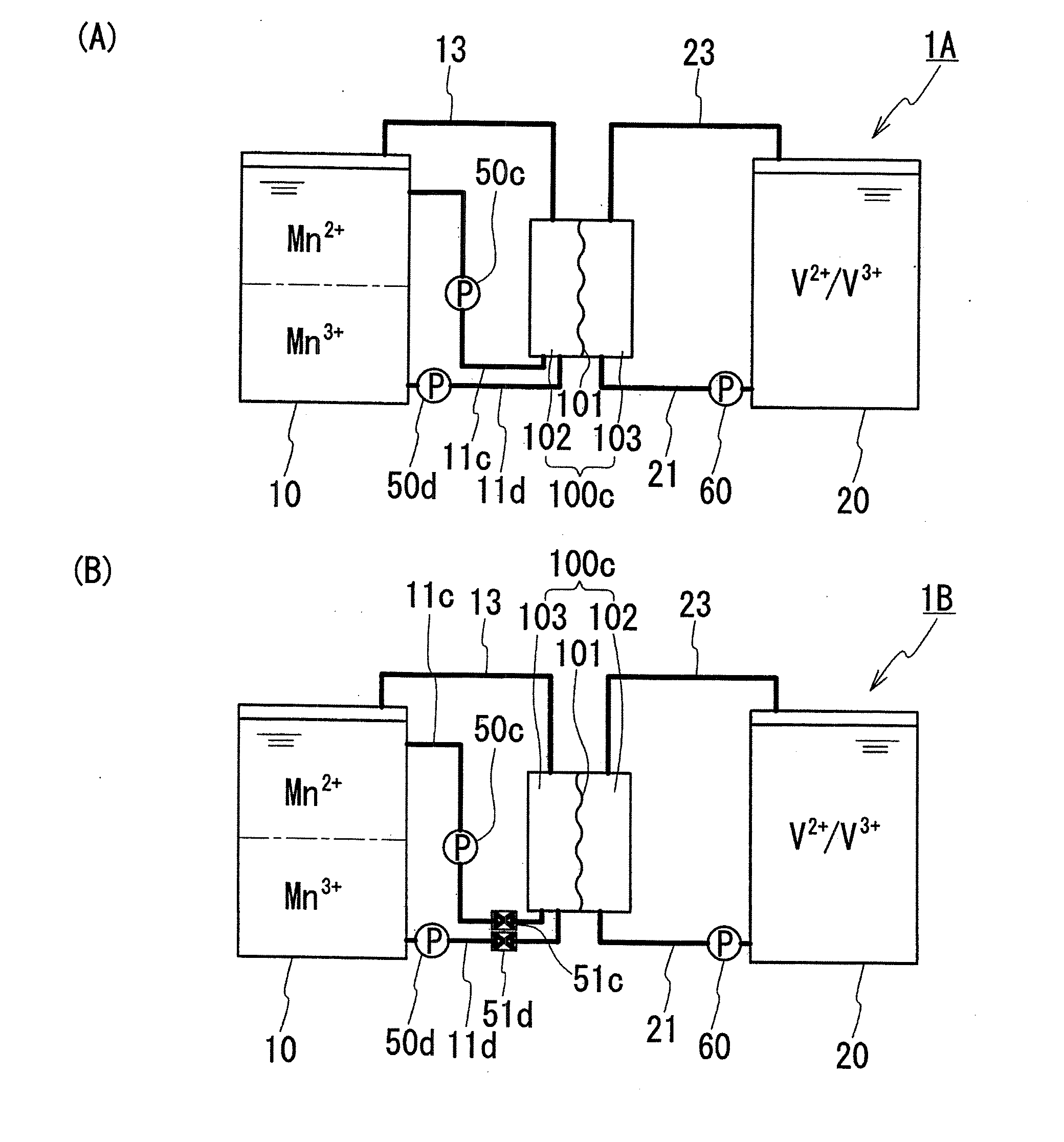

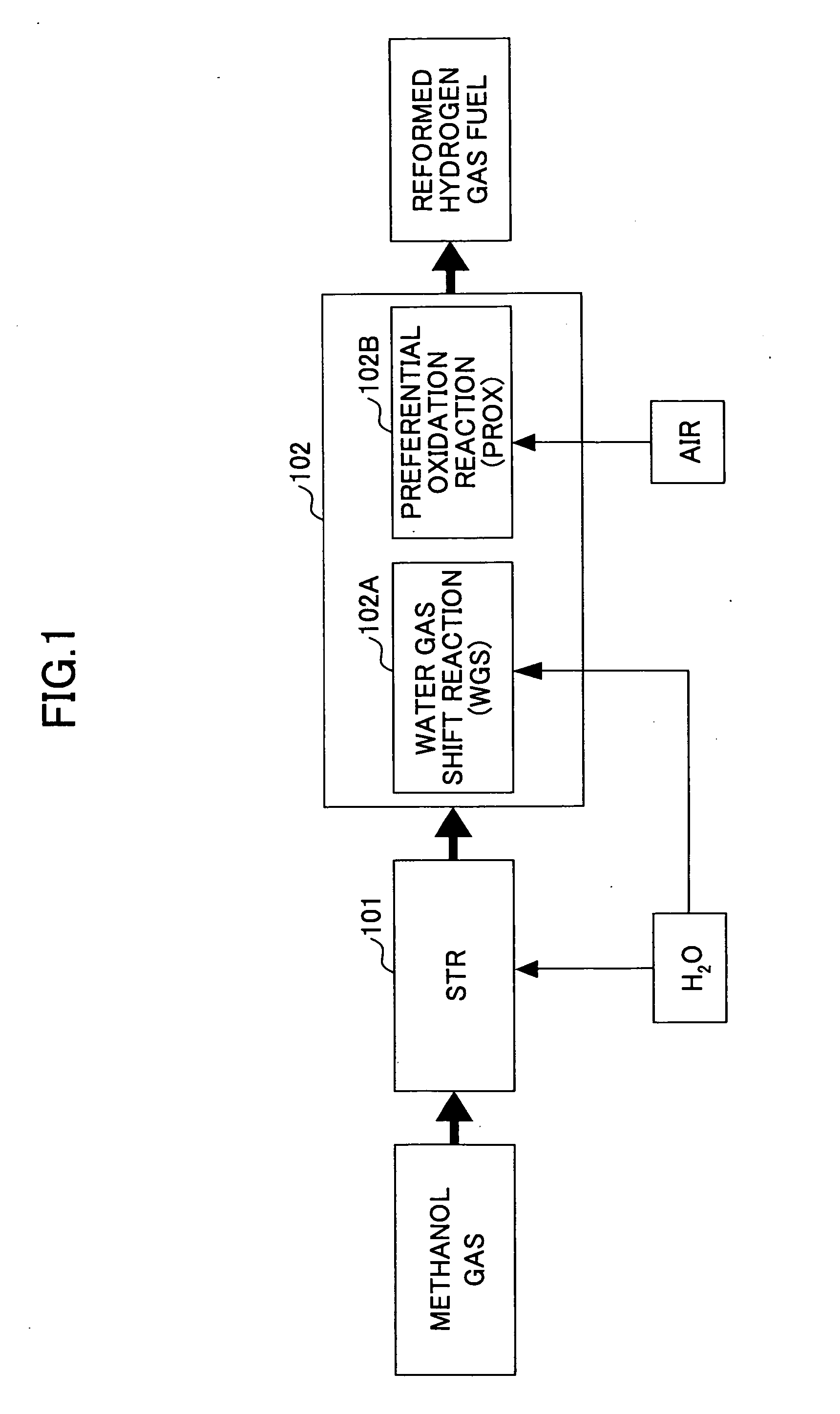

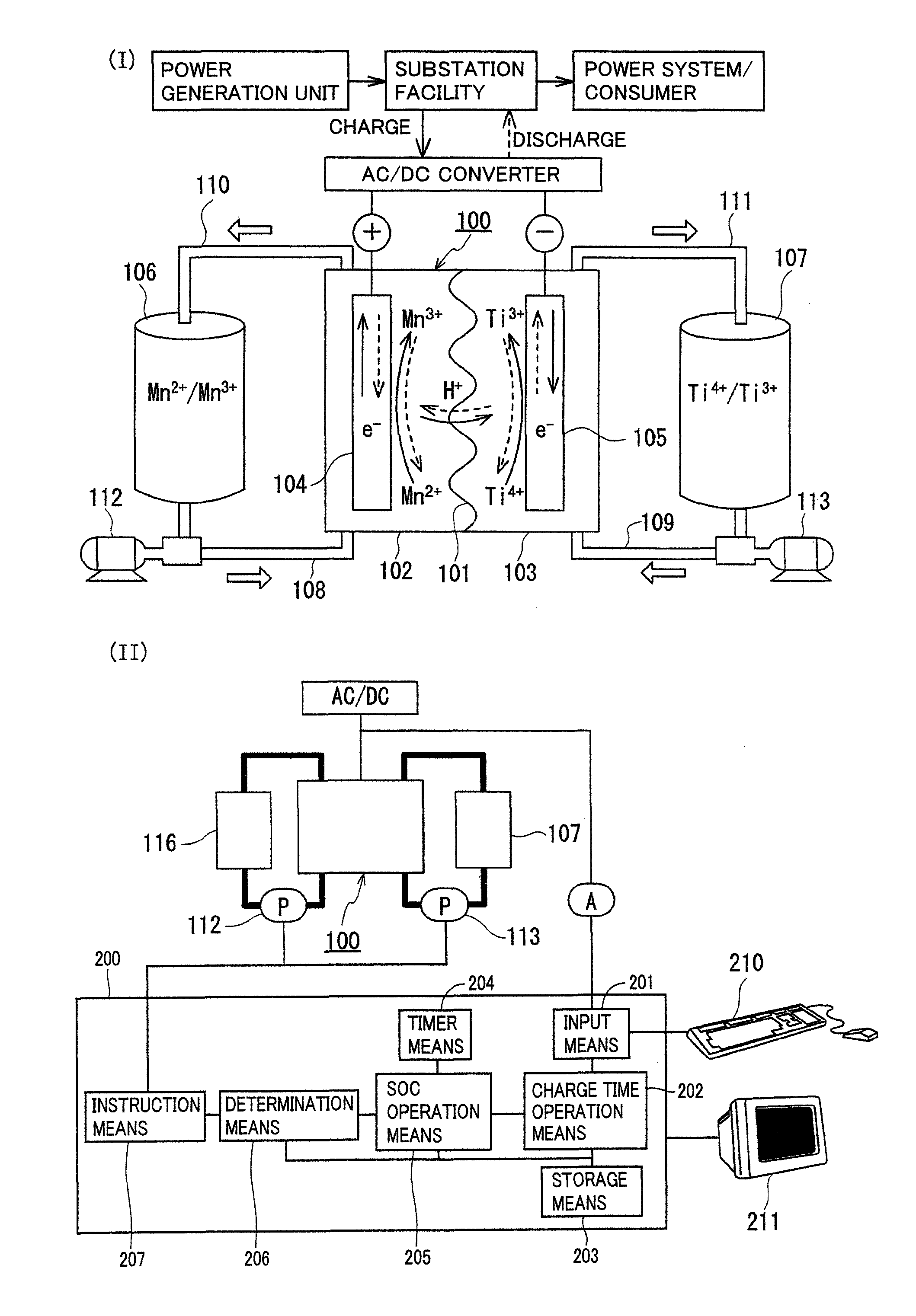

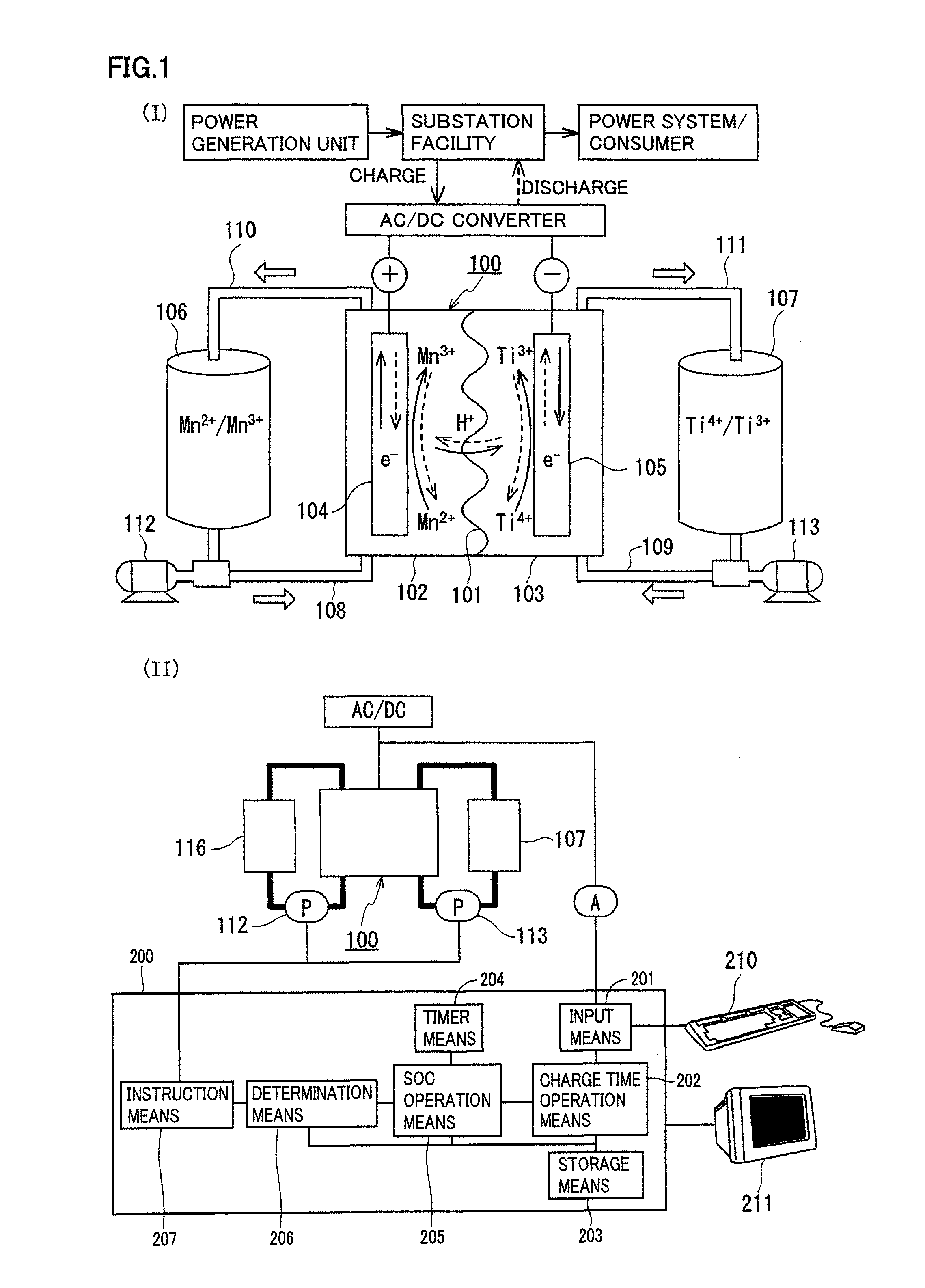

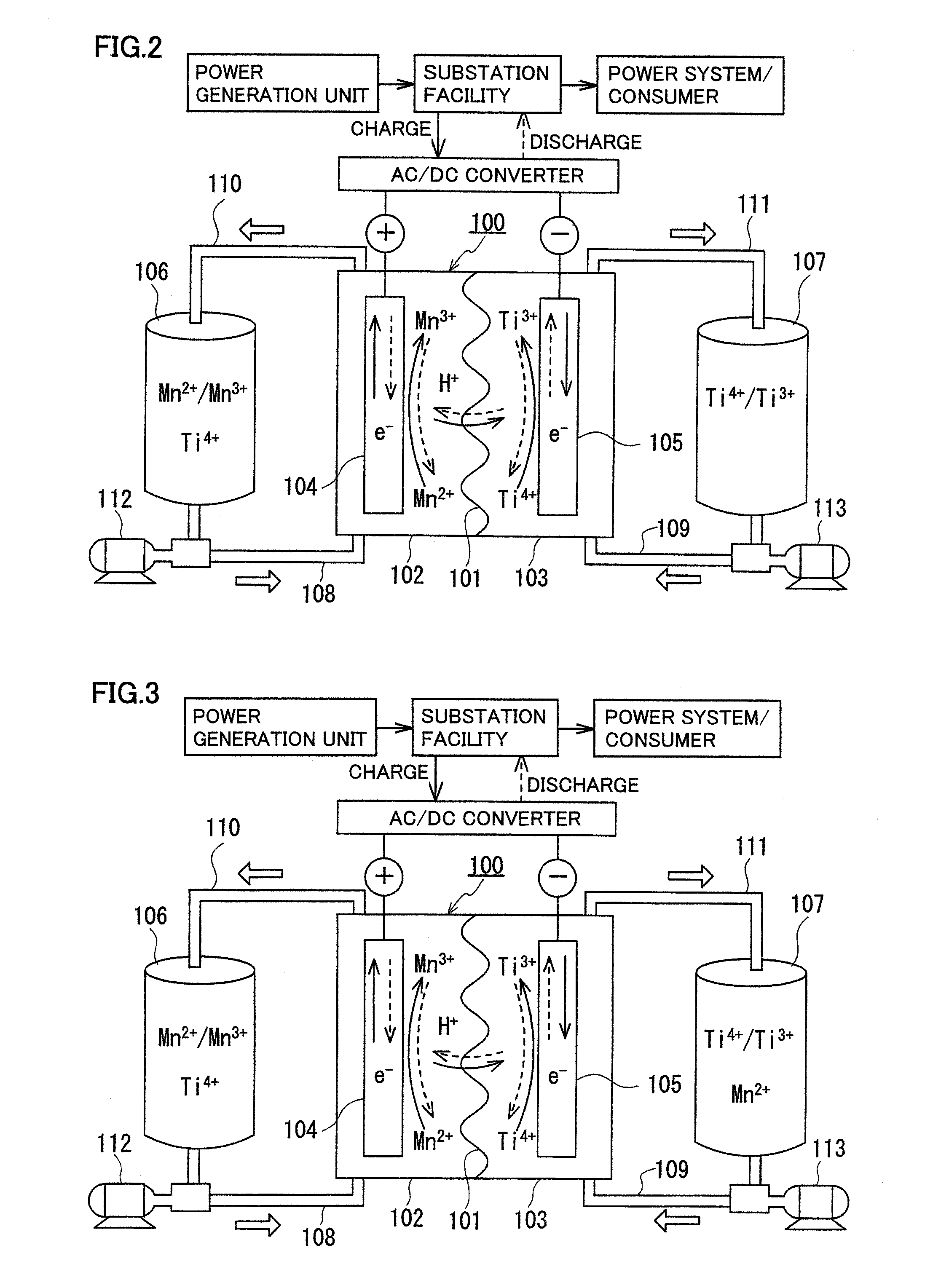

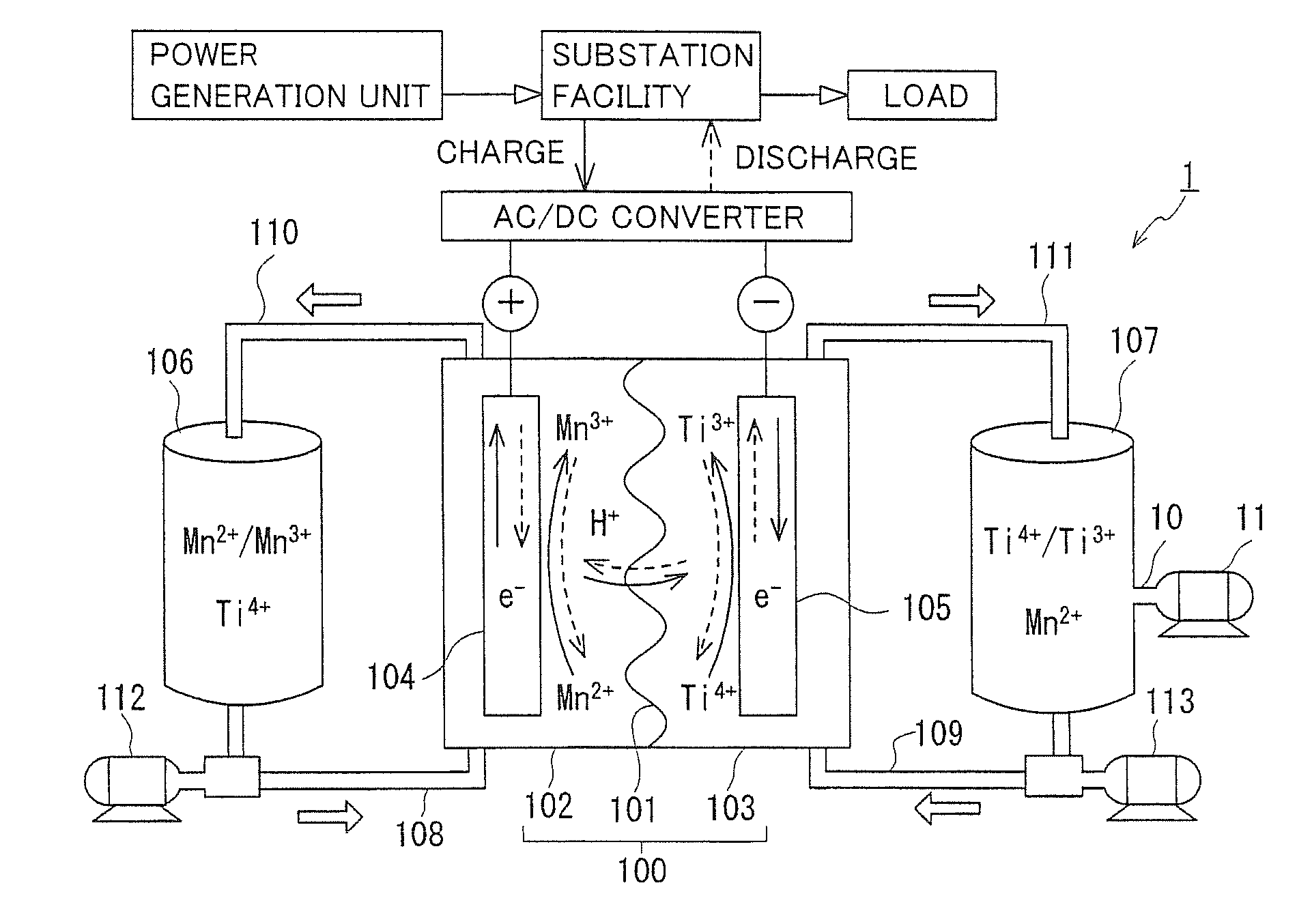

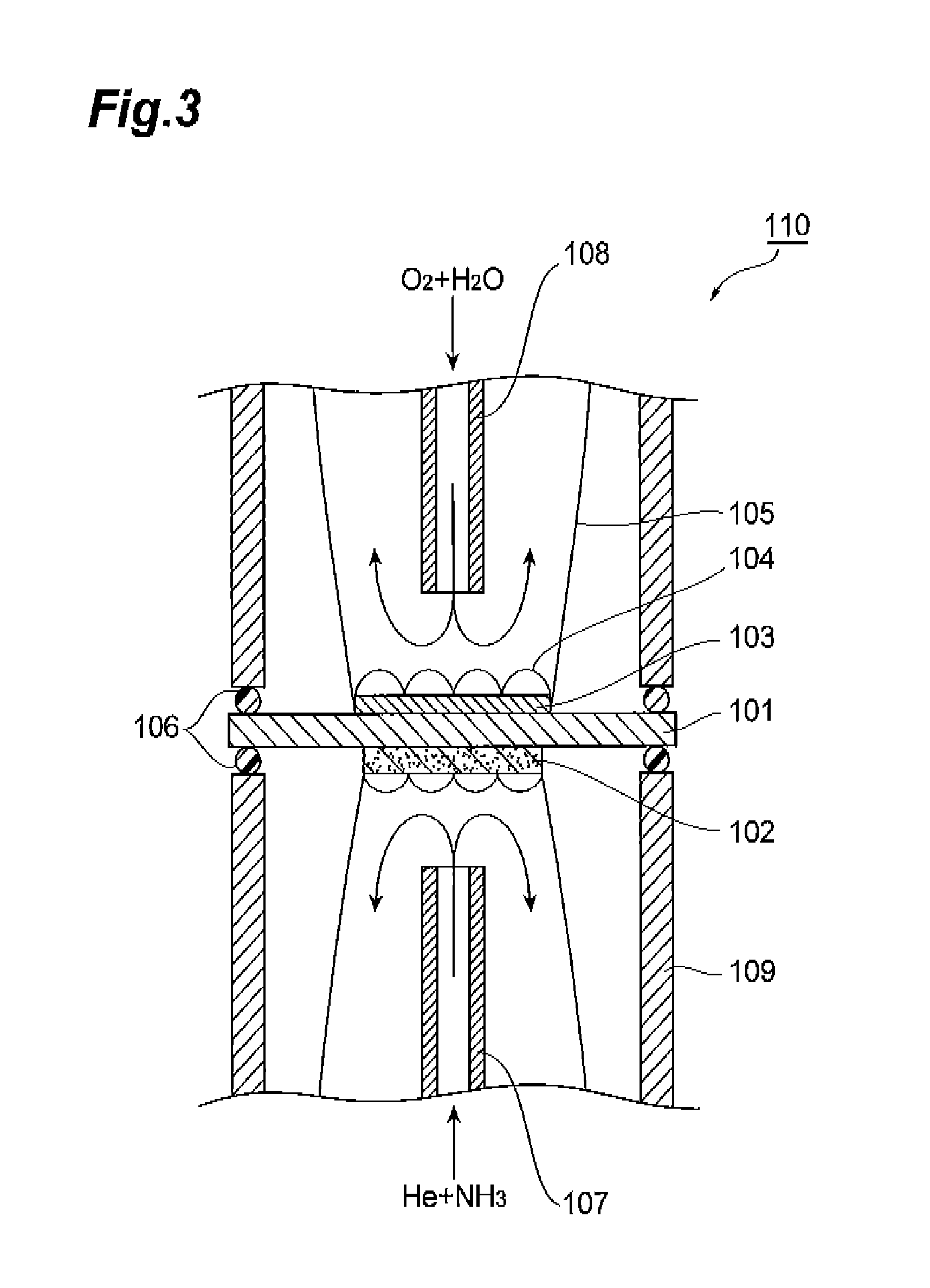

A redox flow battery having a high electromotive force and capable of suppressing generation of a precipitation is provided. In a redox flow battery 100, a positive electrode electrolyte and a negative electrode electrolyte are supplied to a battery cell including a positive electrode 104, a negative electrode 105, and a membrane 101 interposed between the electrodes 104 and 105, to charge and discharge the battery. The positive electrode electrolyte contains a manganese ion, or both of a manganese ion and a titanium ion. The negative electrode electrolyte contains at least one type of metal ion selected from a titanium ion, a vanadium ion, a chromium ion, a zinc ion, and a tin ion. The redox flow battery 100 can suppress generation of a precipitation of MnO2, and can be charged and discharged well by containing a titanium ion in the positive electrode electrolyte, or by being operated such that the positive electrode electrolyte has an SOC of not more than 90%. In addition, the redox flow battery 100 can have a high electromotive force equal to or higher than that of a conventional vanadium-based redox flow battery.

Owner:SUMITOMO ELECTRIC IND LTD

Photovoltaic cell

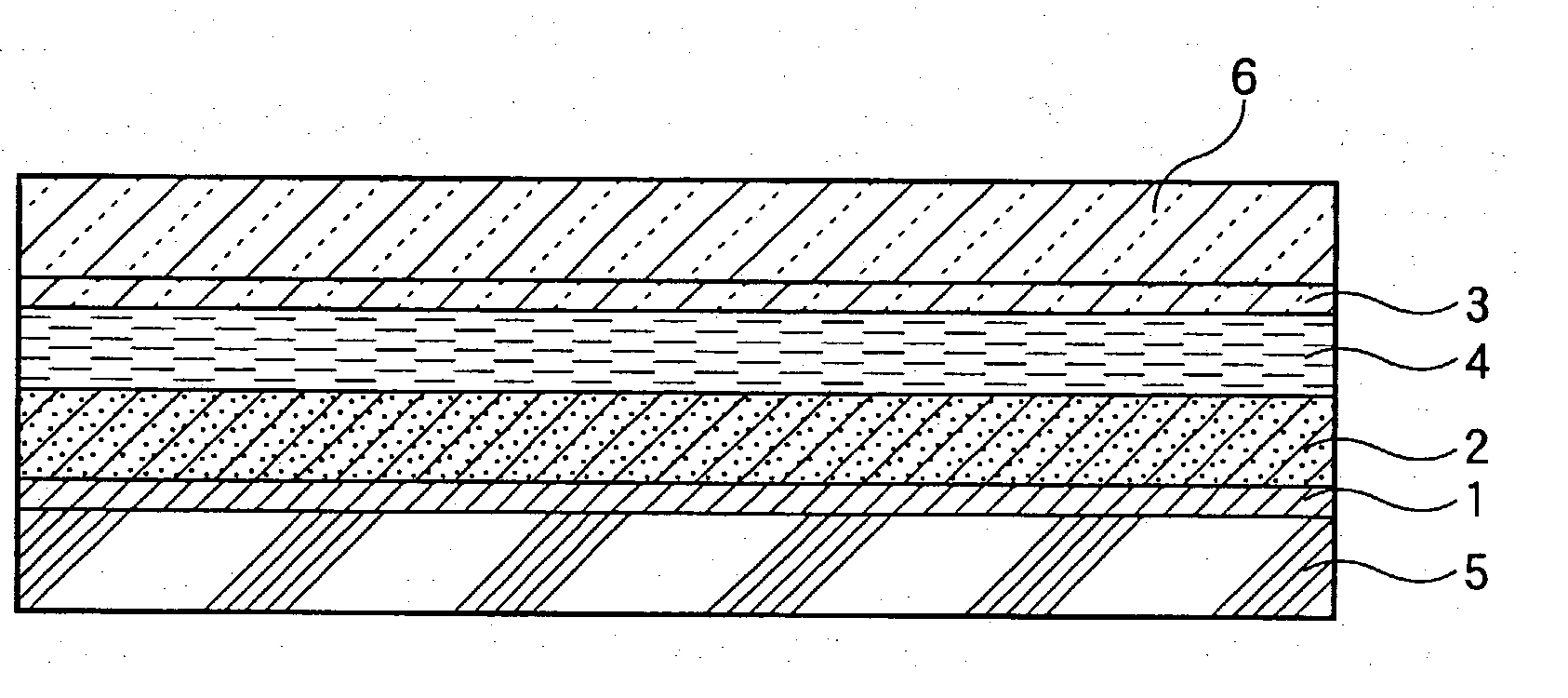

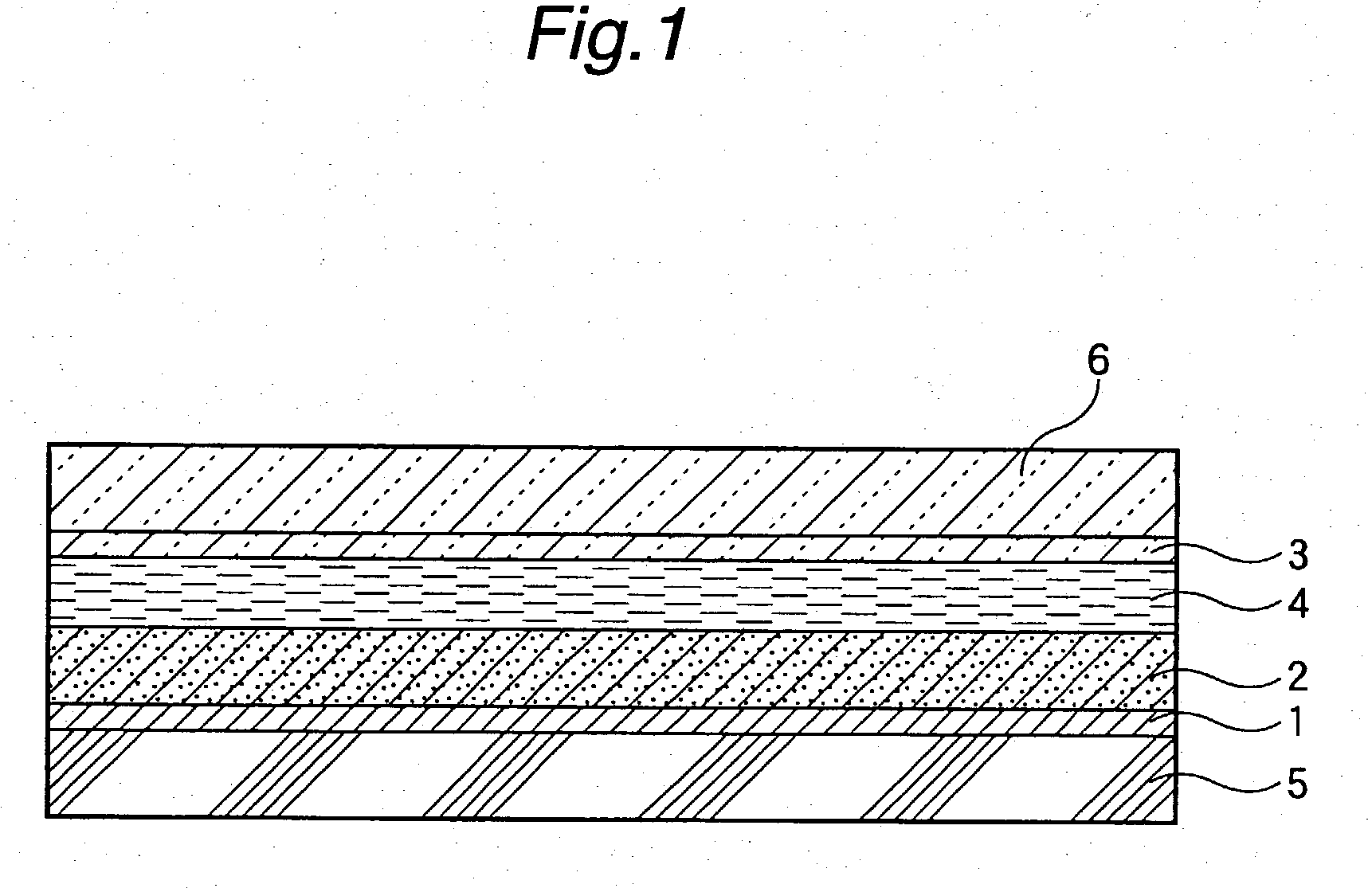

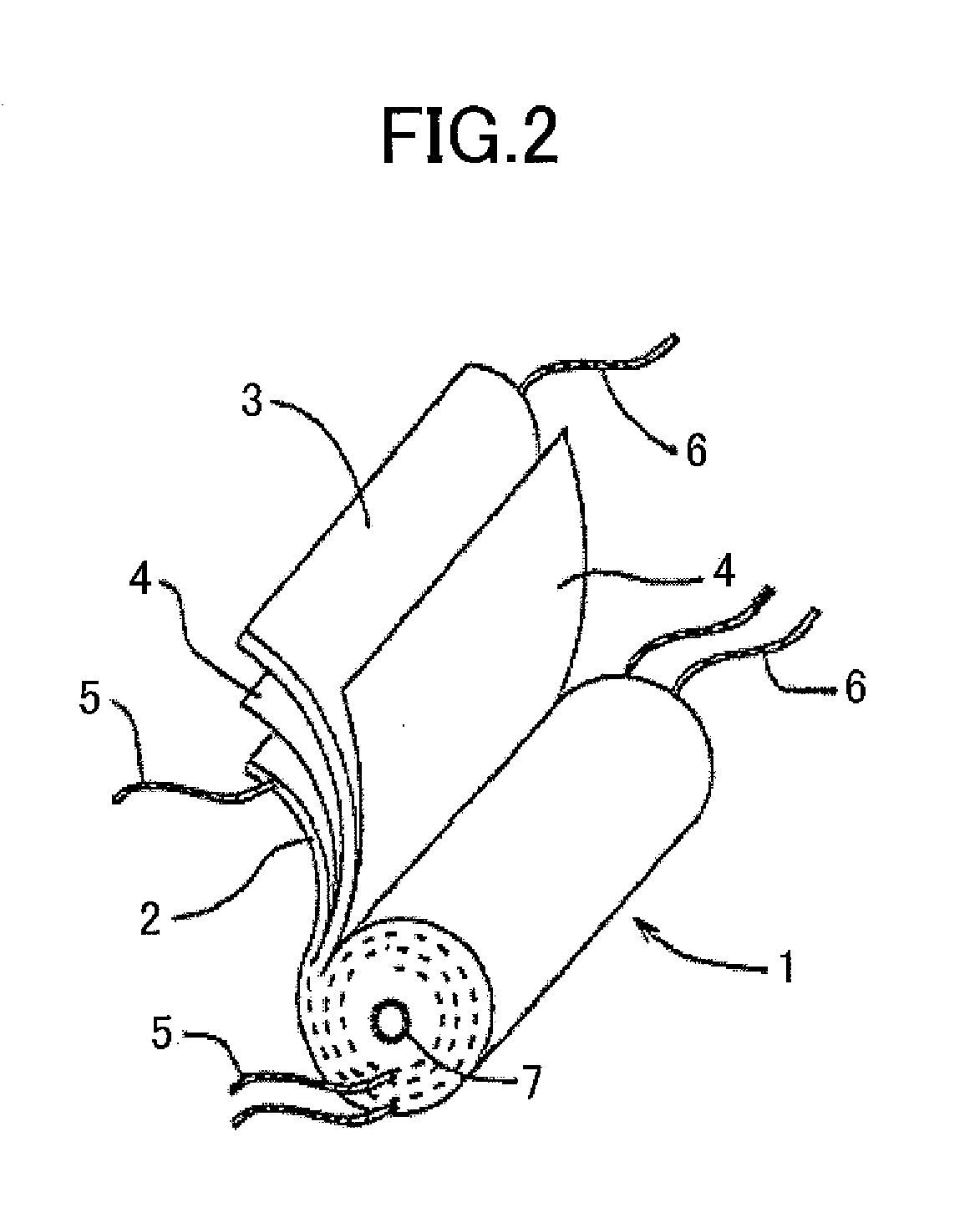

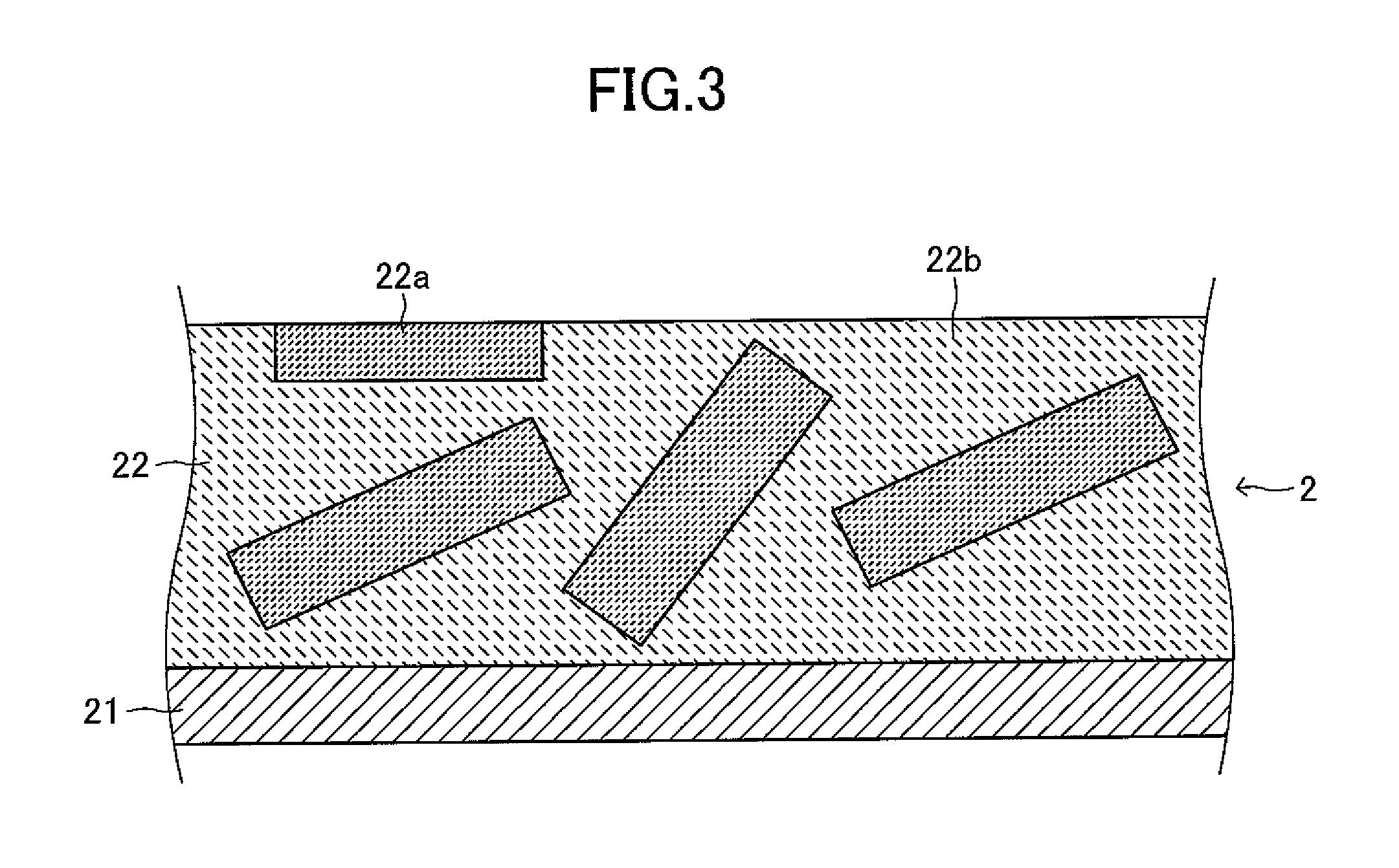

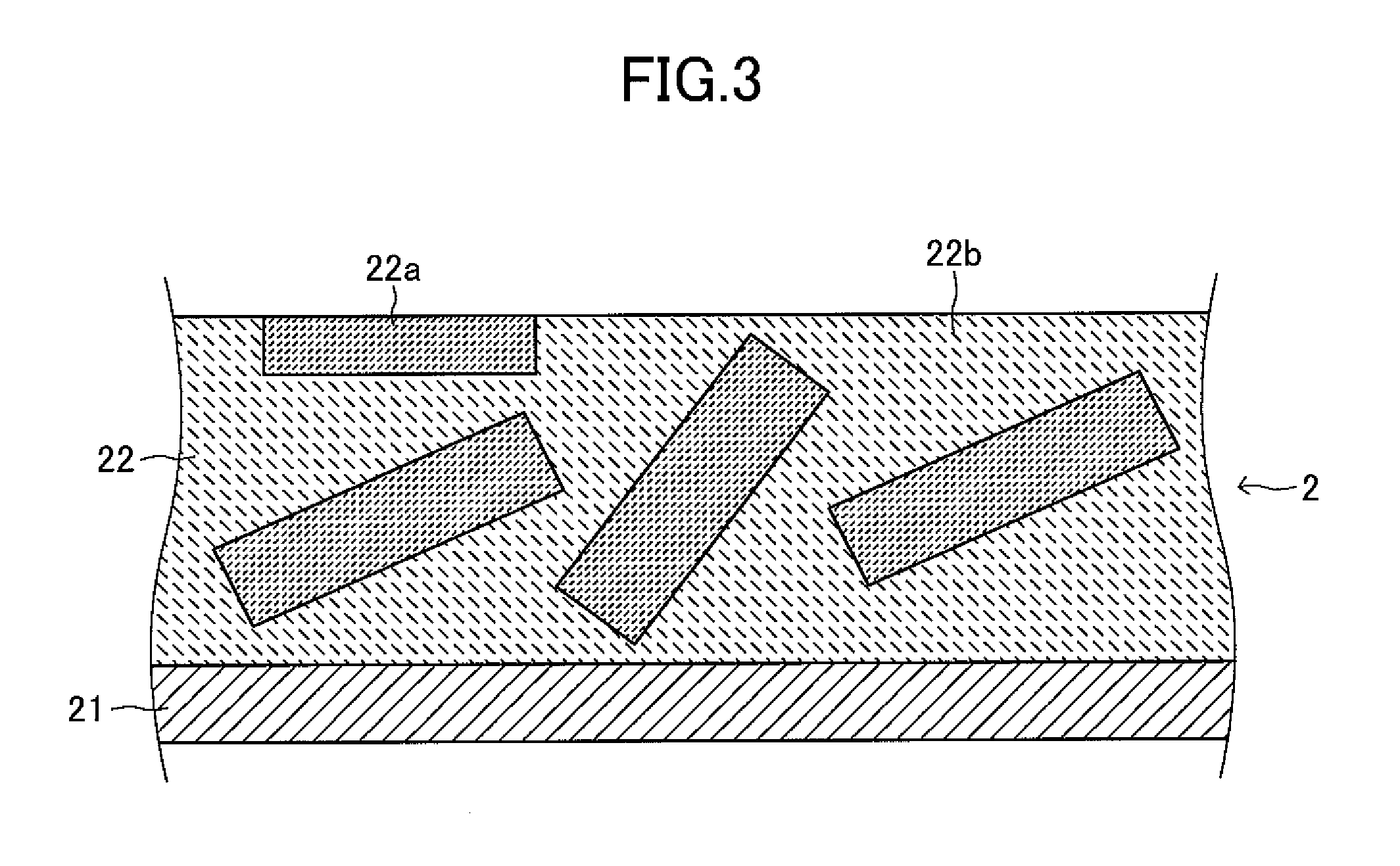

InactiveUS20030196692A1Smooth movementImprove photoelectric conversion efficiencyLight-sensitive devicesDeferred-action cellsPhotosensitizerDecomposition

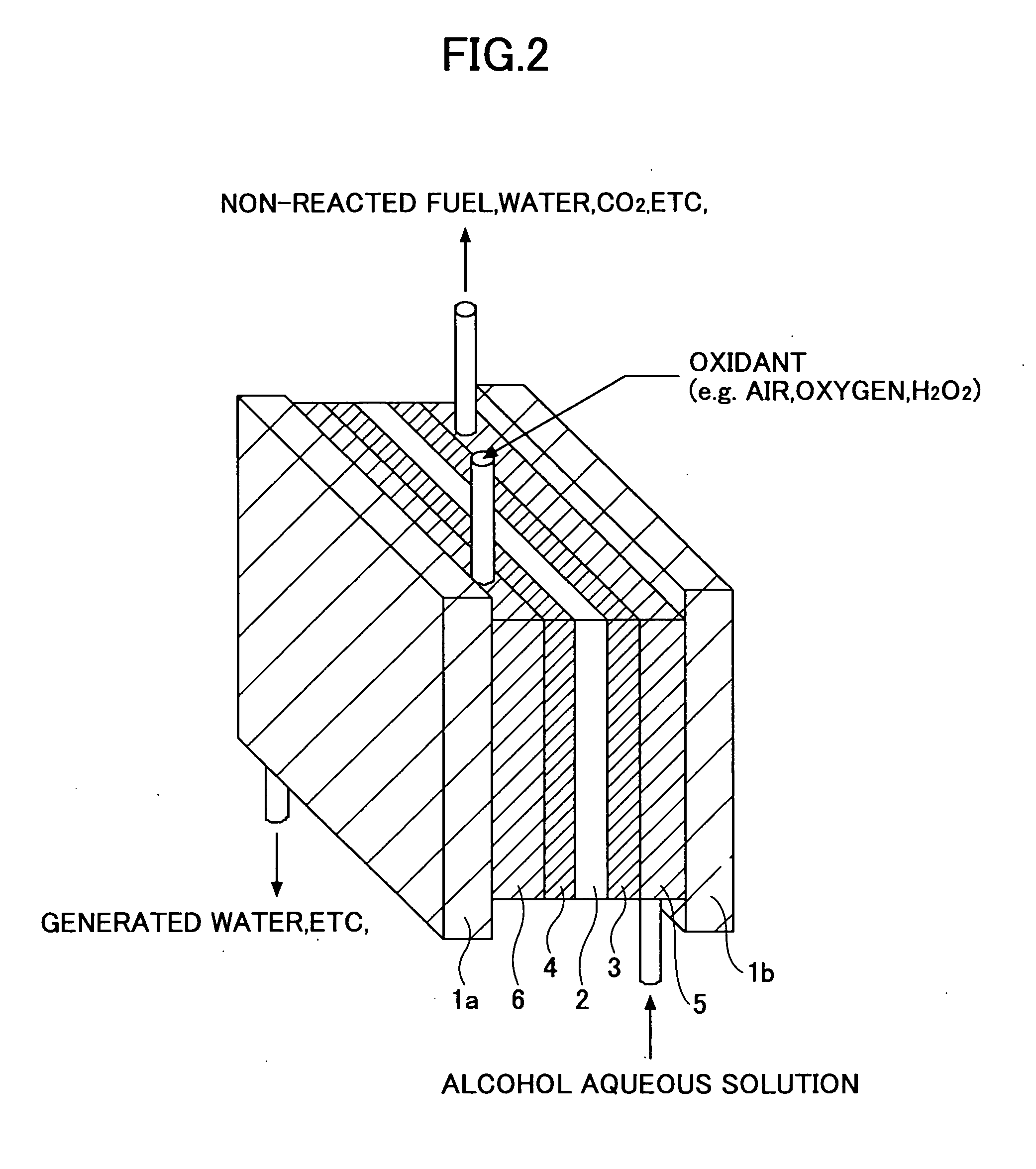

Disclosed is a photovoltaic cell comprising a substrate having an electrode layer (1) on the surface and having a porous metal oxide semiconductor film (2) which is formed on the electrode layer (1) and on which a photosensitizer is adsorbed, a substrate having an electrode layer (3) on the surface, both of said substrates being arranged in such a manner that the electrode layer (1) and the electrode layer (3) face each other, and an electrolyte layer provided between the semiconductor film (2) and the electrode layer (3), wherein the semiconductor film (2) contains an inhibitor of back current, and at least one pair of substrate and electrode layer thereon have transparency. The photovoltaic cell is capable of inhibiting back current and decomposition of a spectrosensitizing dye caused by the ultraviolet rays, has high photoelectric conversion efficiency and is capable of generating high electromotive force.

Owner:JGC CATALYSTS & CHEM LTD

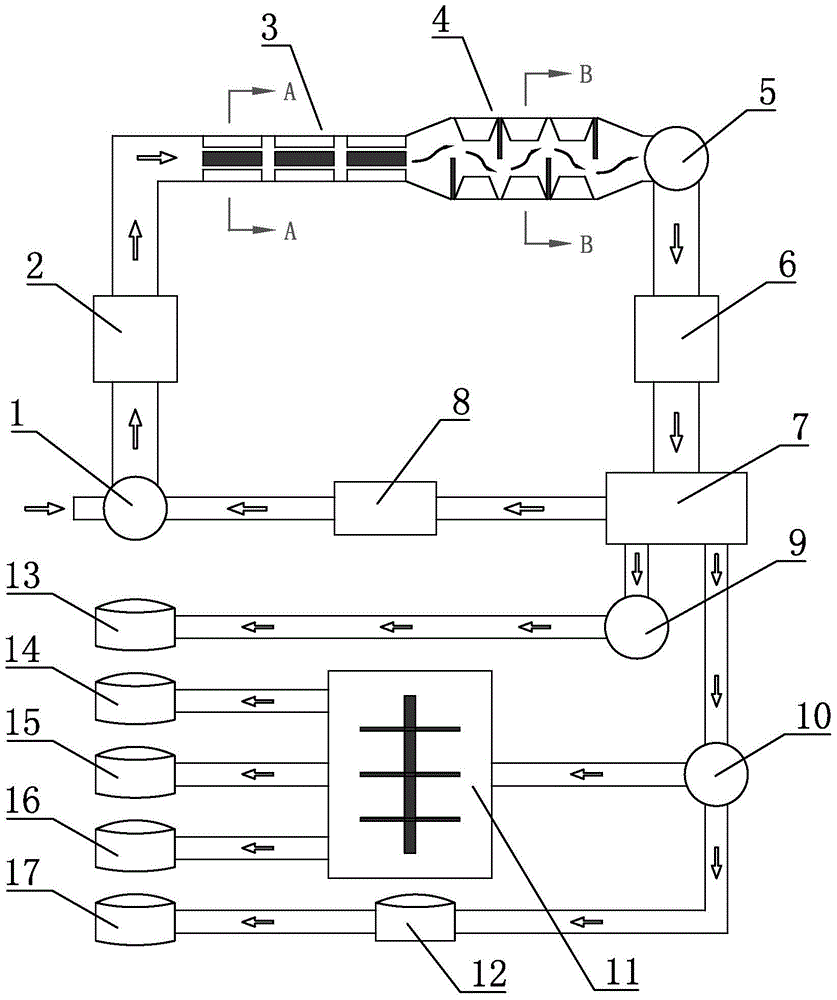

Redox flow battery and method of operating the same

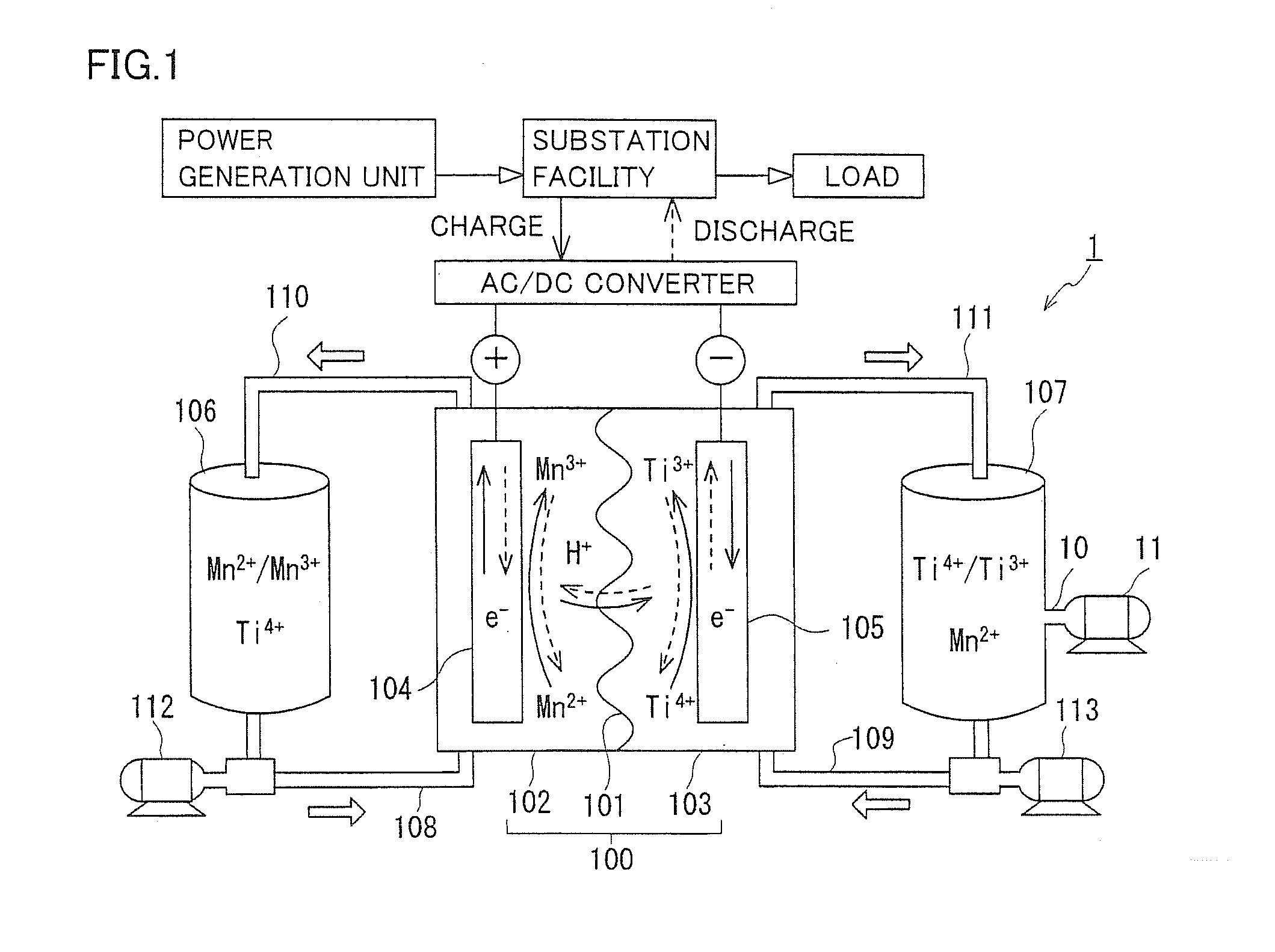

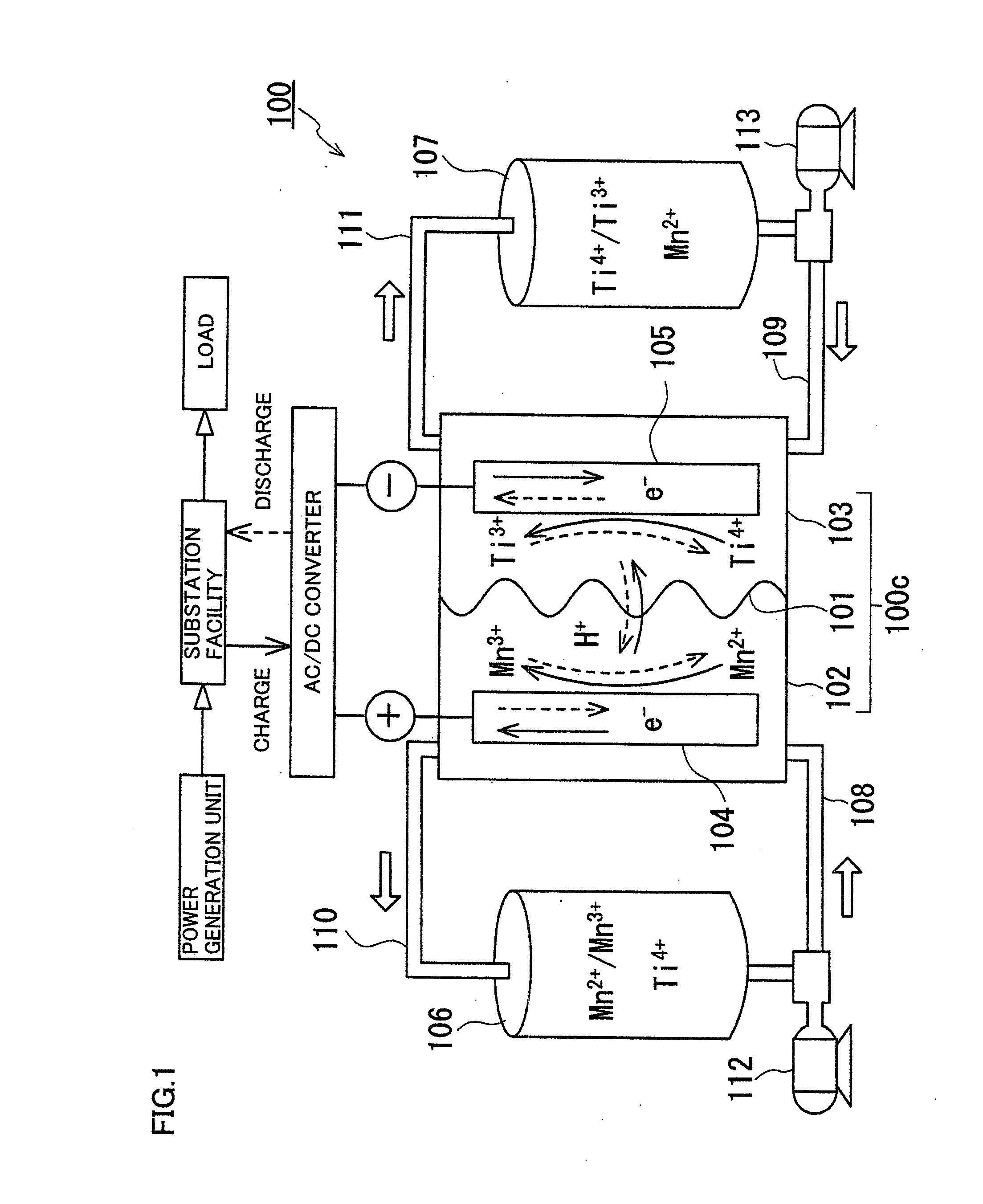

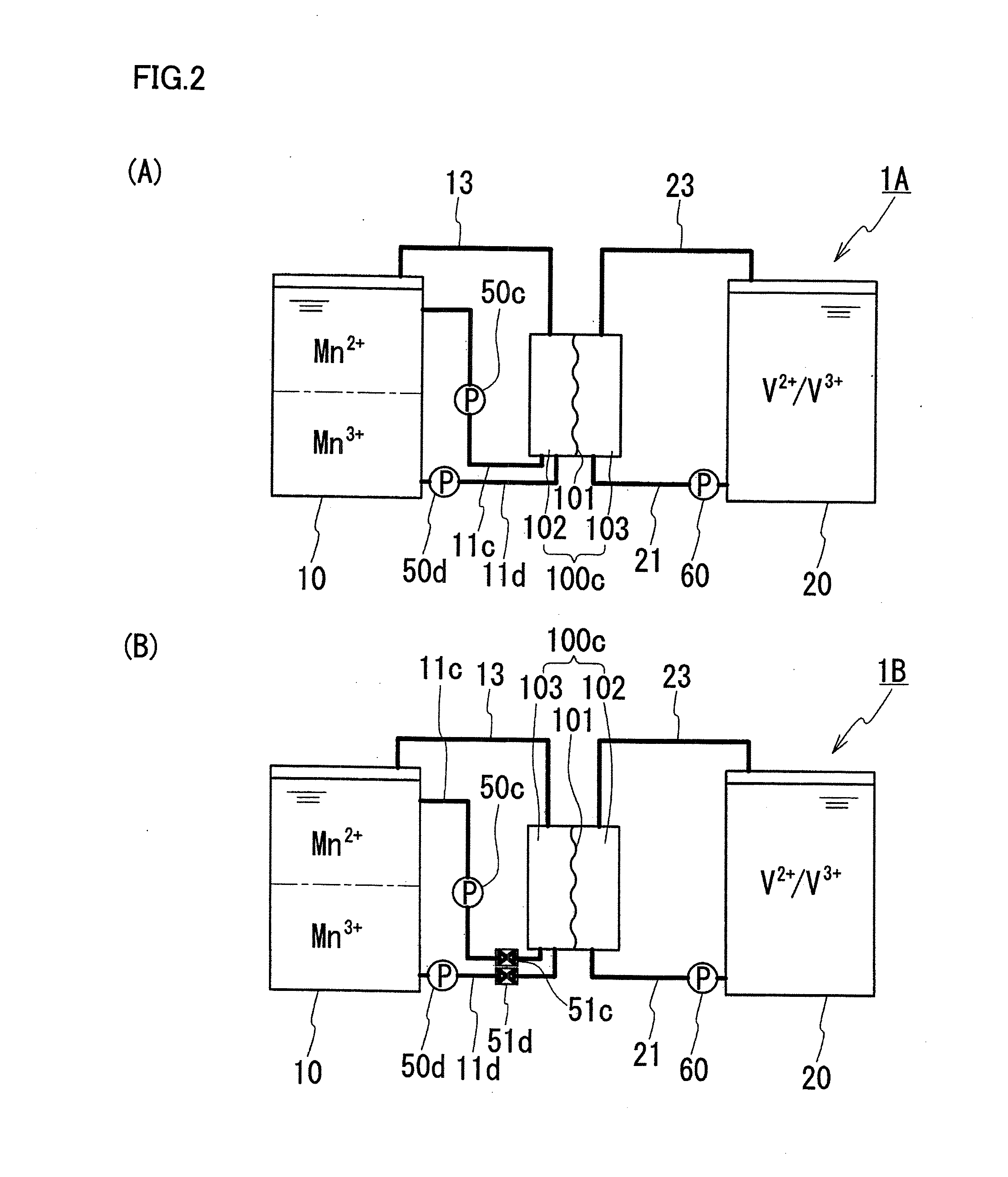

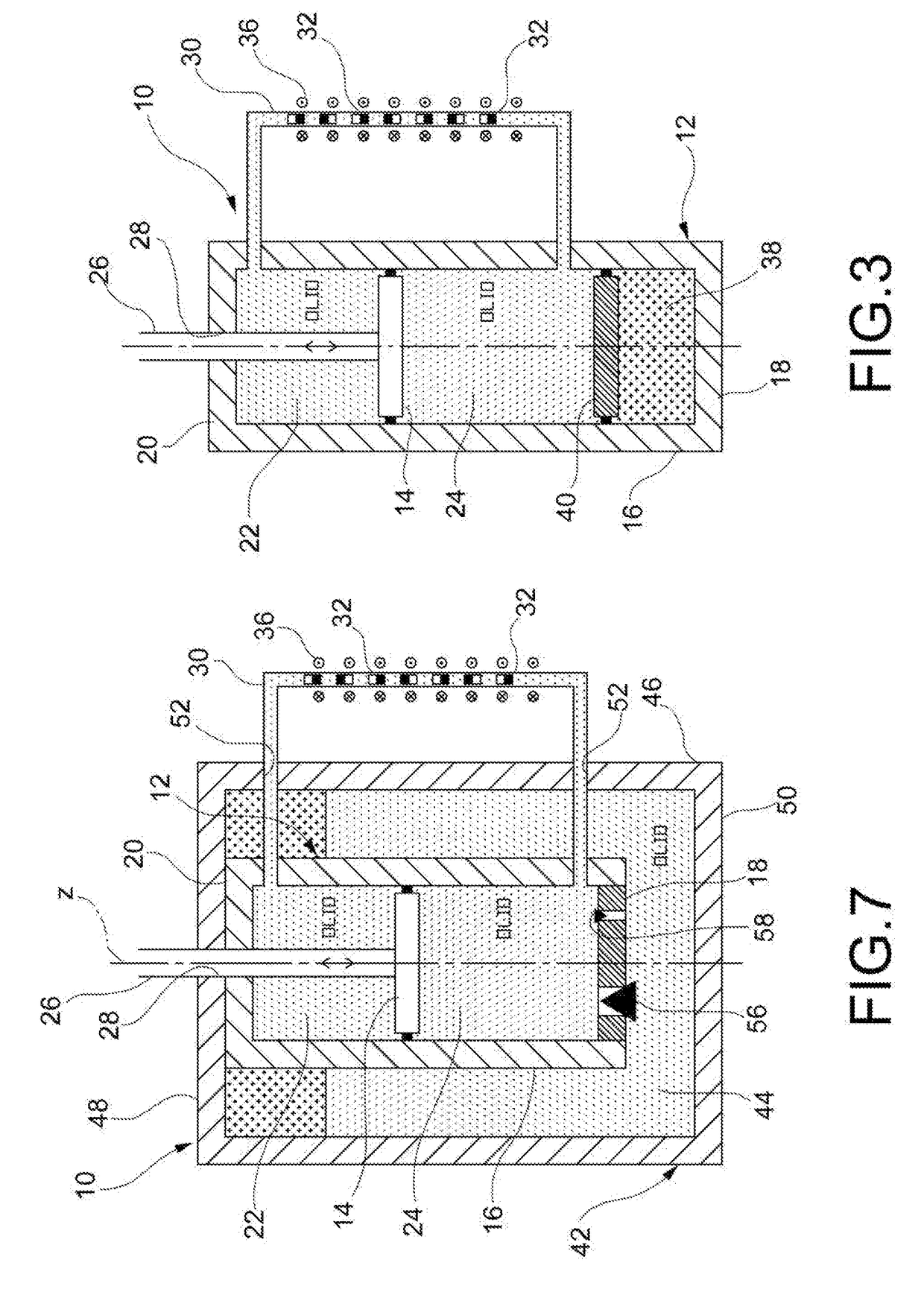

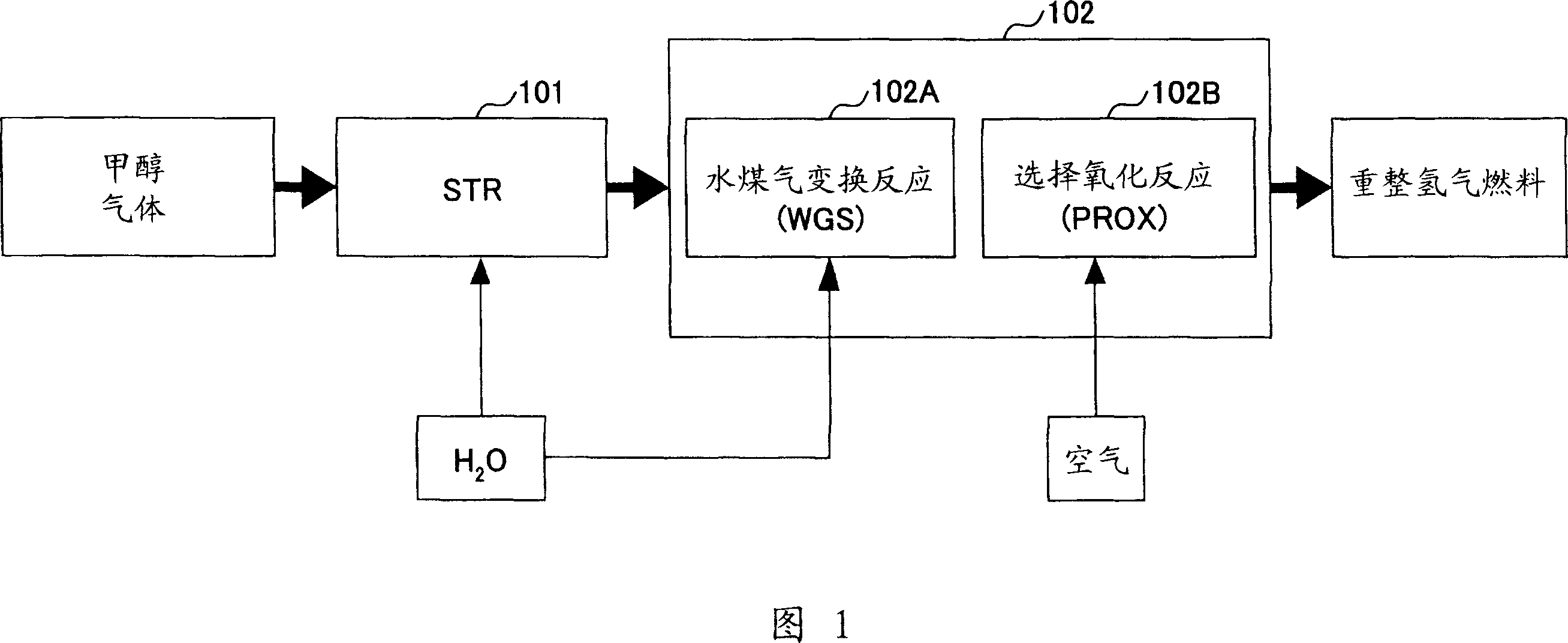

ActiveUS20130157162A1High electromotive forceInvention decreaseFuel cell auxillariesRegenerative fuel cellsRedoxEngineering

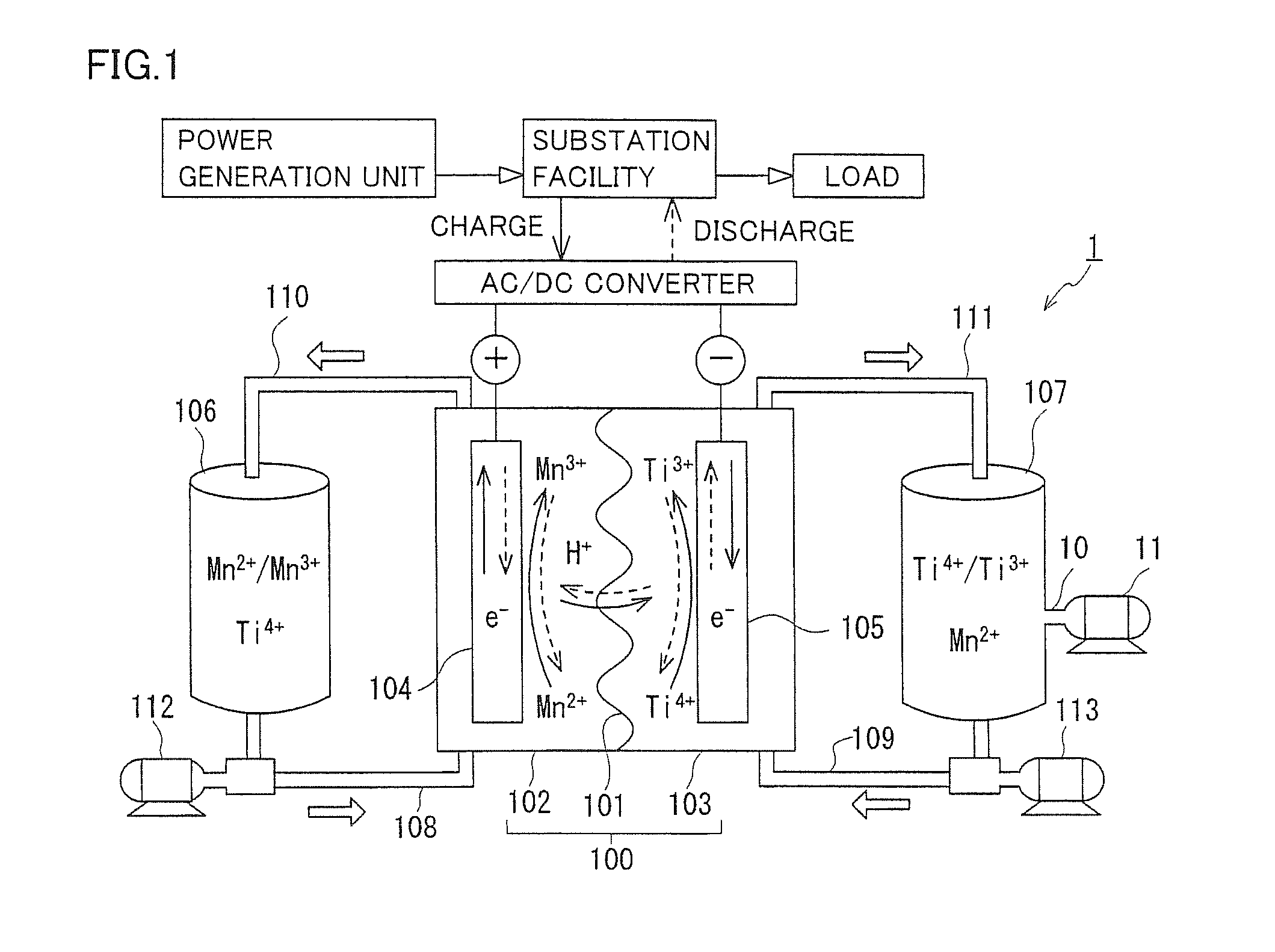

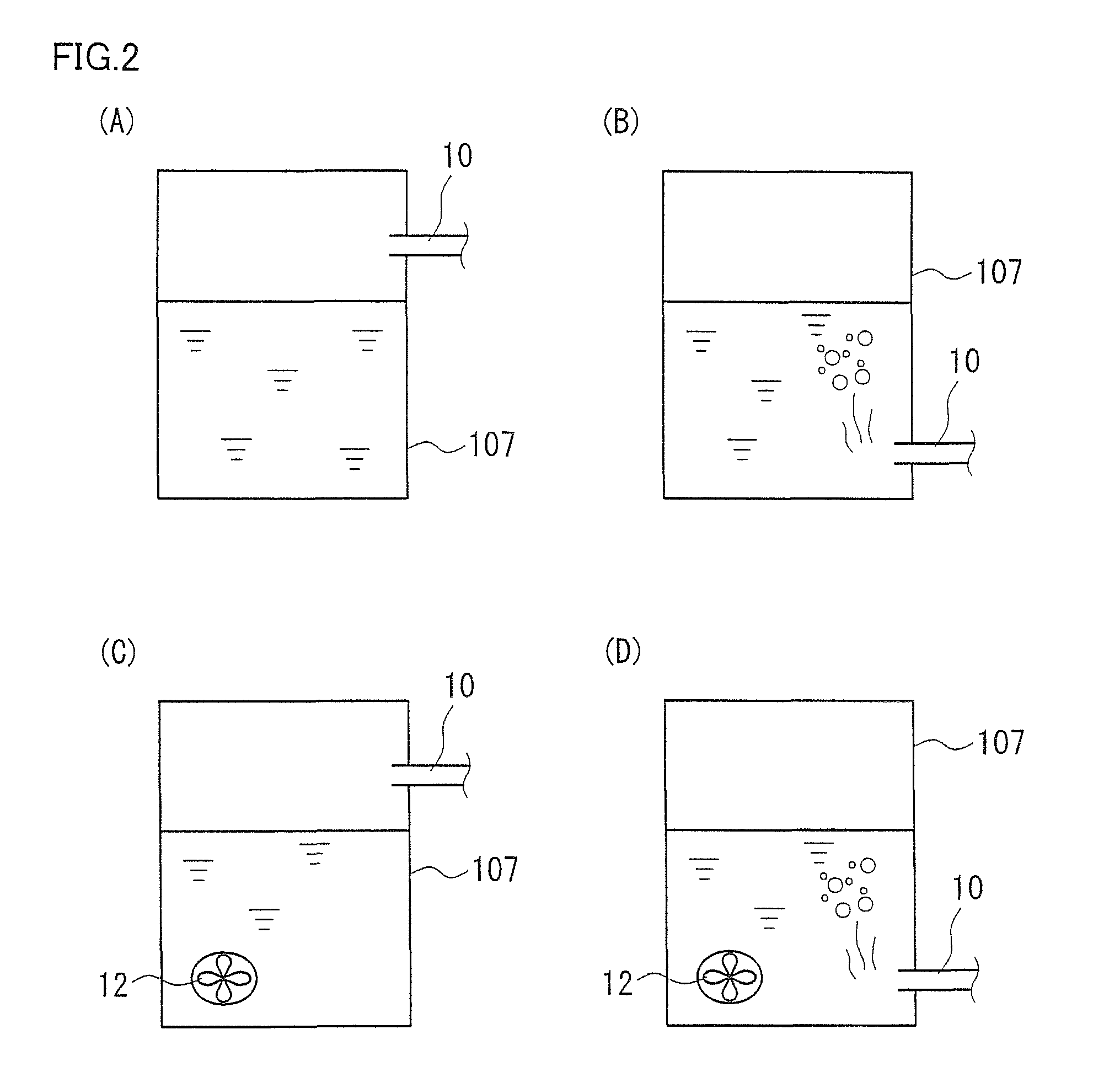

A redox flow battery in which a positive electrode electrolyte stored in a positive electrode tank and a negative electrode electrolyte stored in a negative electrode tank are supplied to a battery element to charge and discharge the battery is provided, the positive electrode electrolyte in the redox flow battery containing a Mn ion as a positive electrode active material, the negative electrode electrolyte containing at least one of a Ti ion, a V ion, and a Cr ion as a negative electrode active material, in which the redox flow battery includes a negative-electrode-side introduction duct in communication with inside of the negative electrode tank from outside thereof, for introducing oxidizing gas into the negative electrode tank, and a supply mechanism for supplying the oxidizing gas into the negative electrode tank via the negative-electrode-side introduction duct.

Owner:SUMITOMO ELECTRIC IND LTD

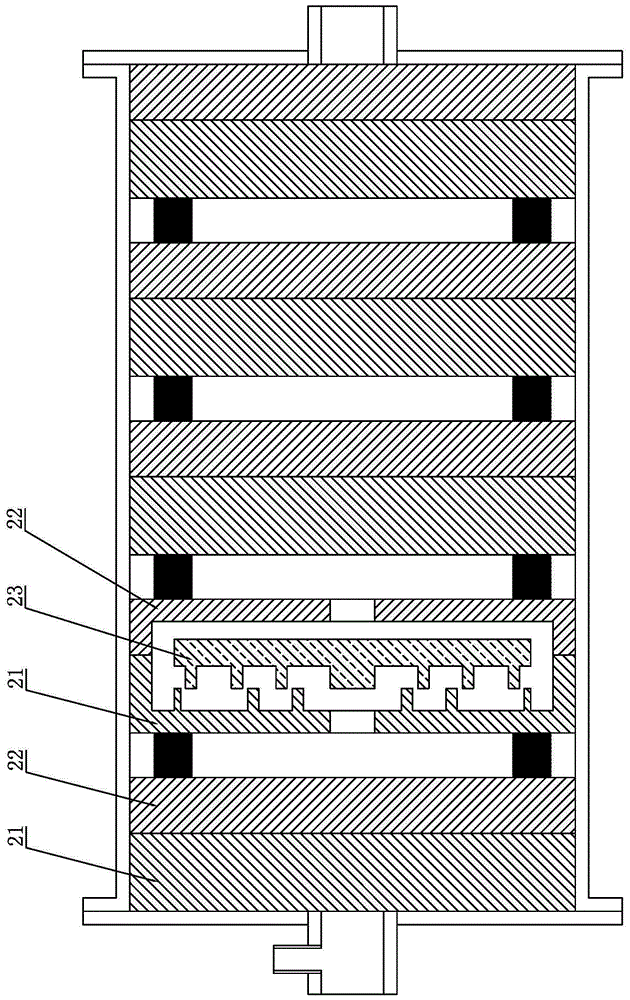

Redox flow battery

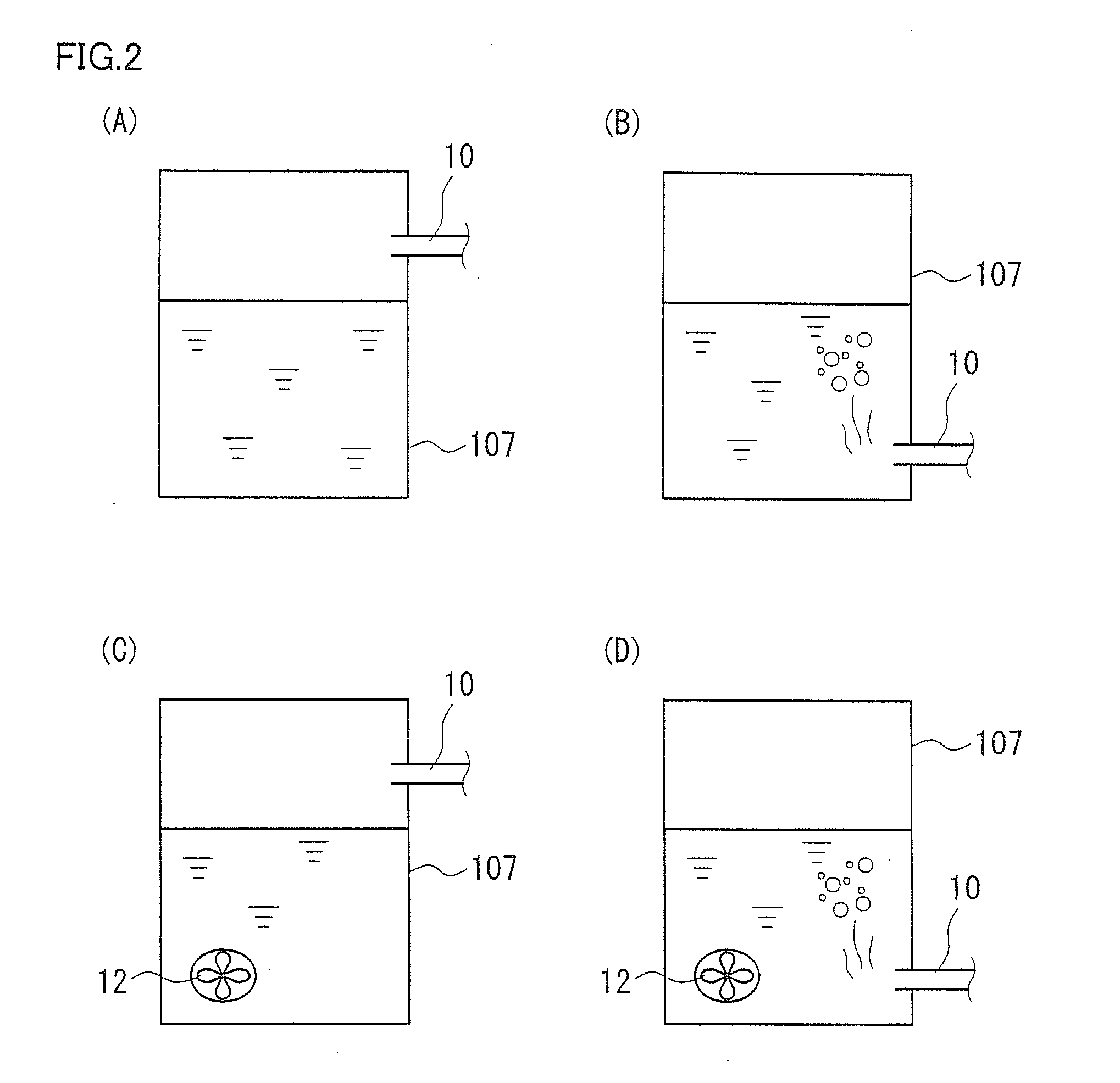

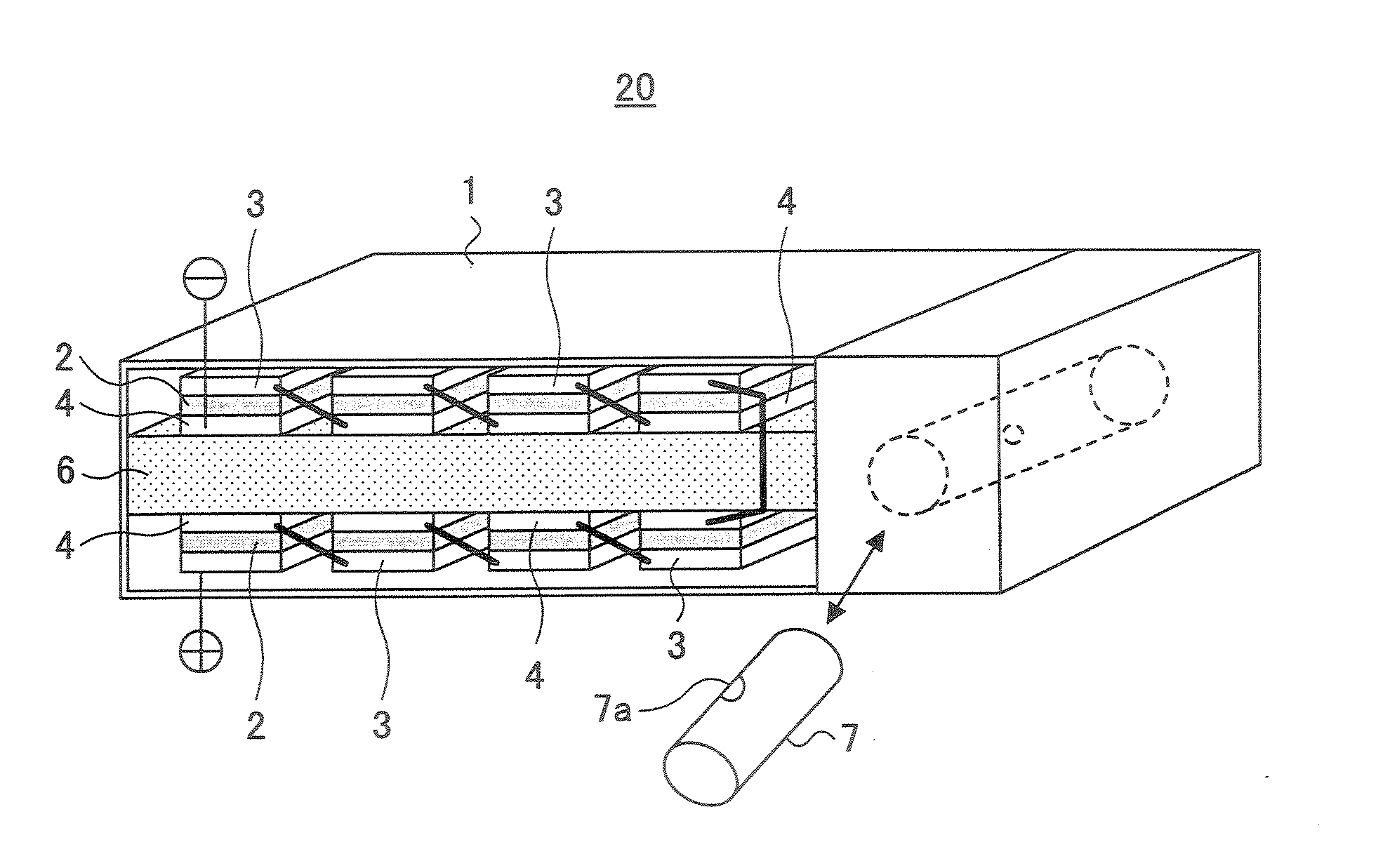

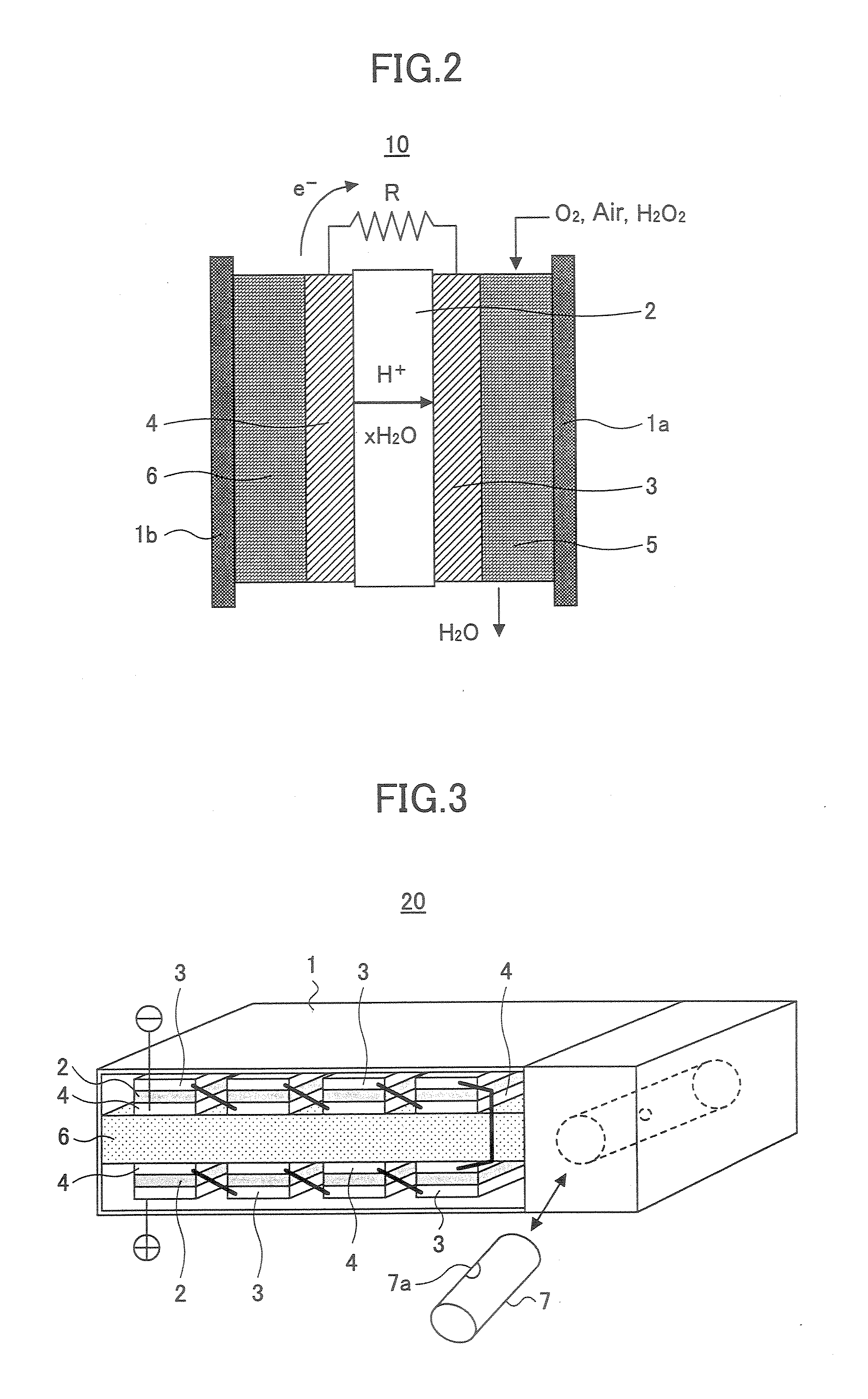

ActiveUS20140134465A1High electromotive forceStable discharge characteristicsCell electrodesRegenerative fuel cellsEngineeringCharge and discharge

A redox flow battery charged and discharged by supply of a positive electrode electrolyte stored in a positive electrode tank and a negative electrode electrolyte stored in a negative electrode tank to a battery element, in which the positive electrode electrolyte contains a Mn ion as a positive electrode active material, and the positive electrode tank includes a positive electrode charging pipe opening to a position close to a liquid level of the positive electrode electrolyte in the positive electrode tank, and a positive electrode discharging pipe opening to a position close to the bottom of the positive electrode tank. This redox flow battery can include a stirring mechanism for stirring the electrolytes in the tanks, and can include a connection pipe connecting the positive electrode tank to the negative electrode tank.

Owner:SUMITOMO ELECTRIC IND LTD

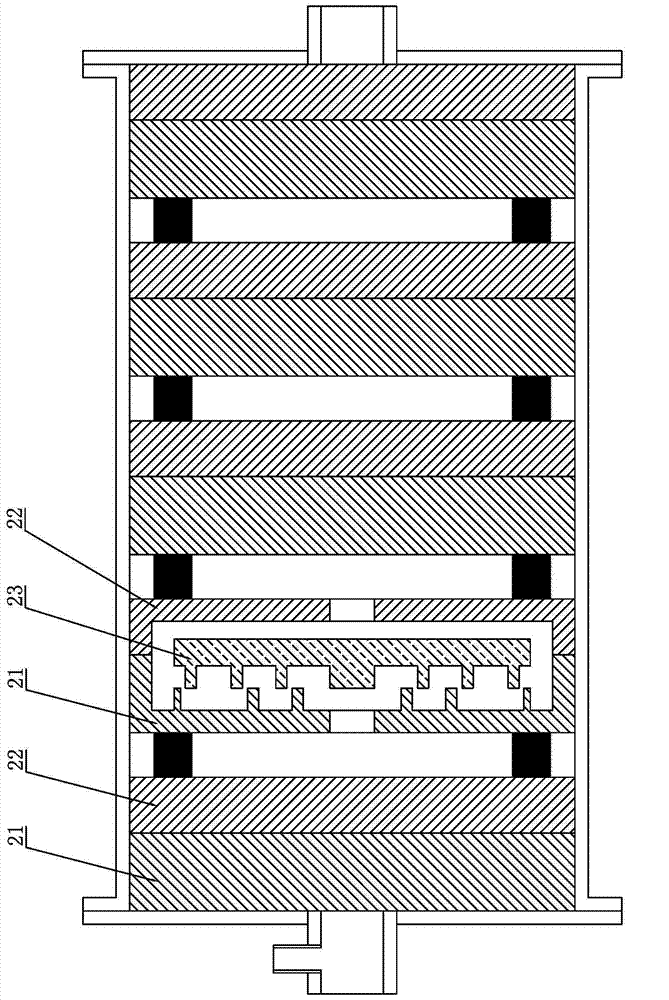

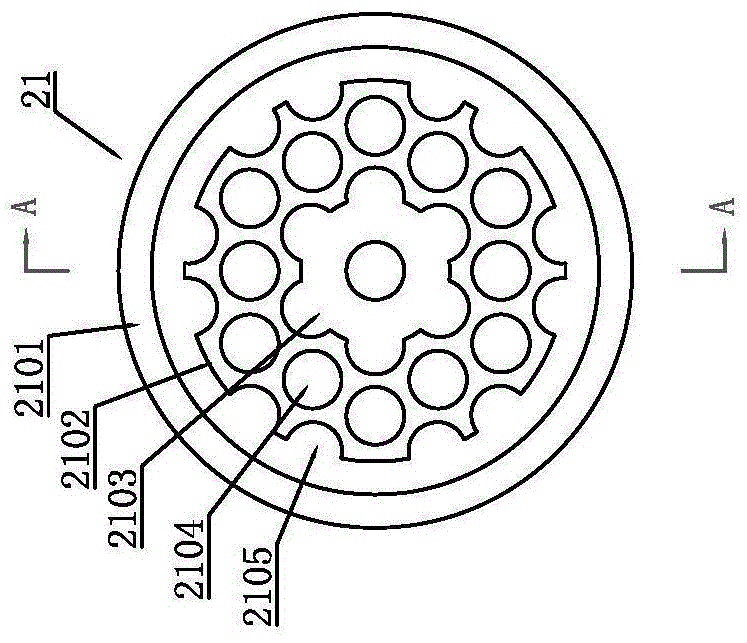

Qunatum carbon, and preparation method and implementation apparatus thereof

ActiveCN104261383AGood dispersionSynthetic size controllableMaterial nanotechnologyMixing methodsDouble bondElectromotive force

The invention relates to a qunatum carbon which comprises carbon particles with the particle size of 0.6-100nm, wherein the carbon particles are mono carbon and / or graphene particles; and the surface layer of the carbon particles contain carbon, hydrogen, oxygen and nitrogen compounds, which comprise condensed aromatics, compounds containing carbon-oxygen single bond, compounds containing carbon-oxygen double bond and compounds containing carbon-hydrogen bond. The invention also relates to a qunatum carbon solution which is a water solution containing qunatum carbon. The ORP of the qunatum carbon solution is 280-380mv, the electric conductivity sigma is 1-5ms / cm, the electromotive force is 280-380mv, the pH value is 1.5-3.2, and the concentration is 0.1-0.45%. The invention also relates to a device and method for preparing the qunatum carbon. The method has the advantages of simple technique, low cost, no generation of three wastes, uniform carbon particle size and stable product quality, is easy to control, and can easily implement large-scale production.

Owner:北京三昌宇恒科技发展有限公司

Ferrite core for RFID application, method of manufacturing the same, and ferrite coil using the same

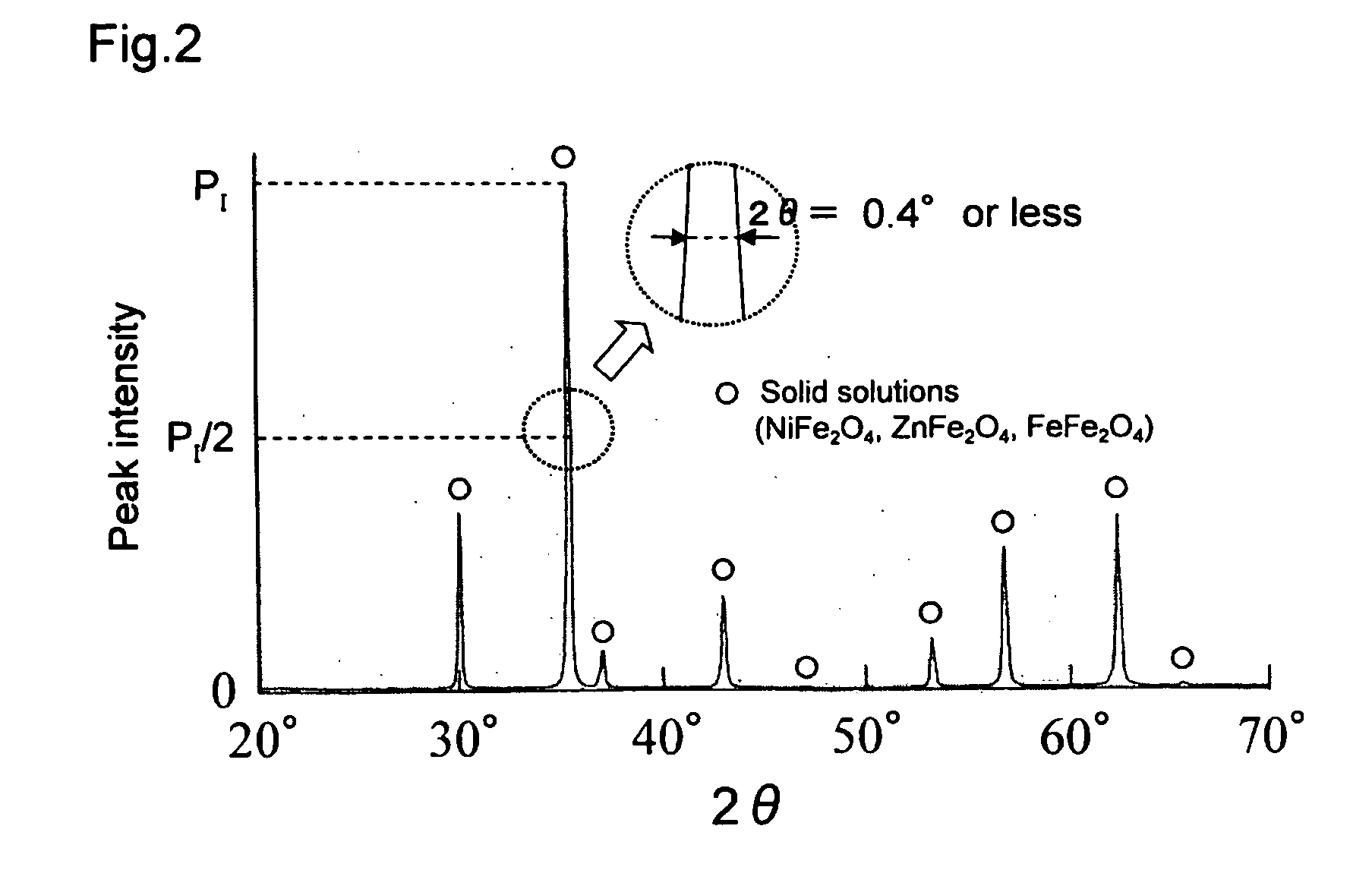

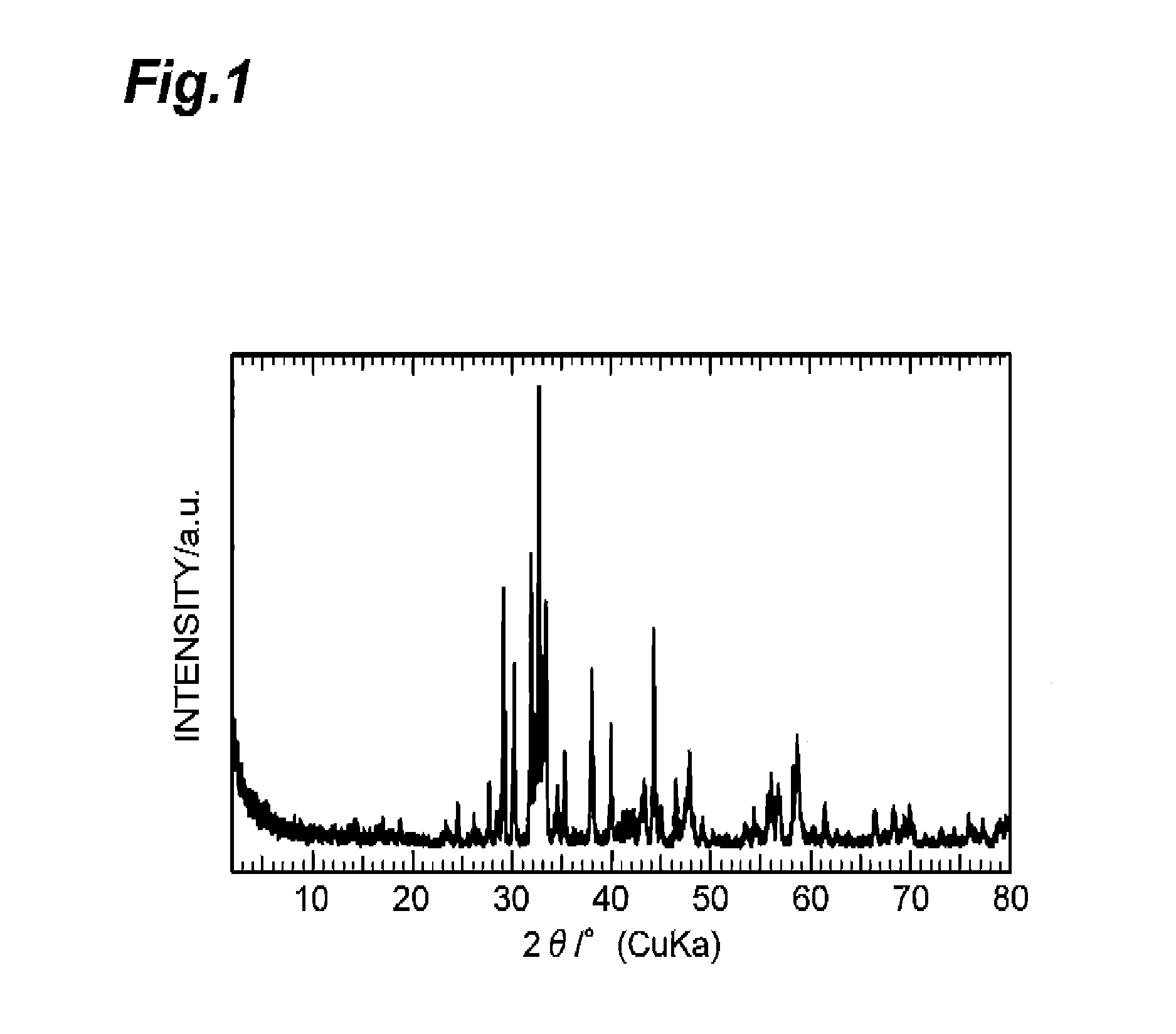

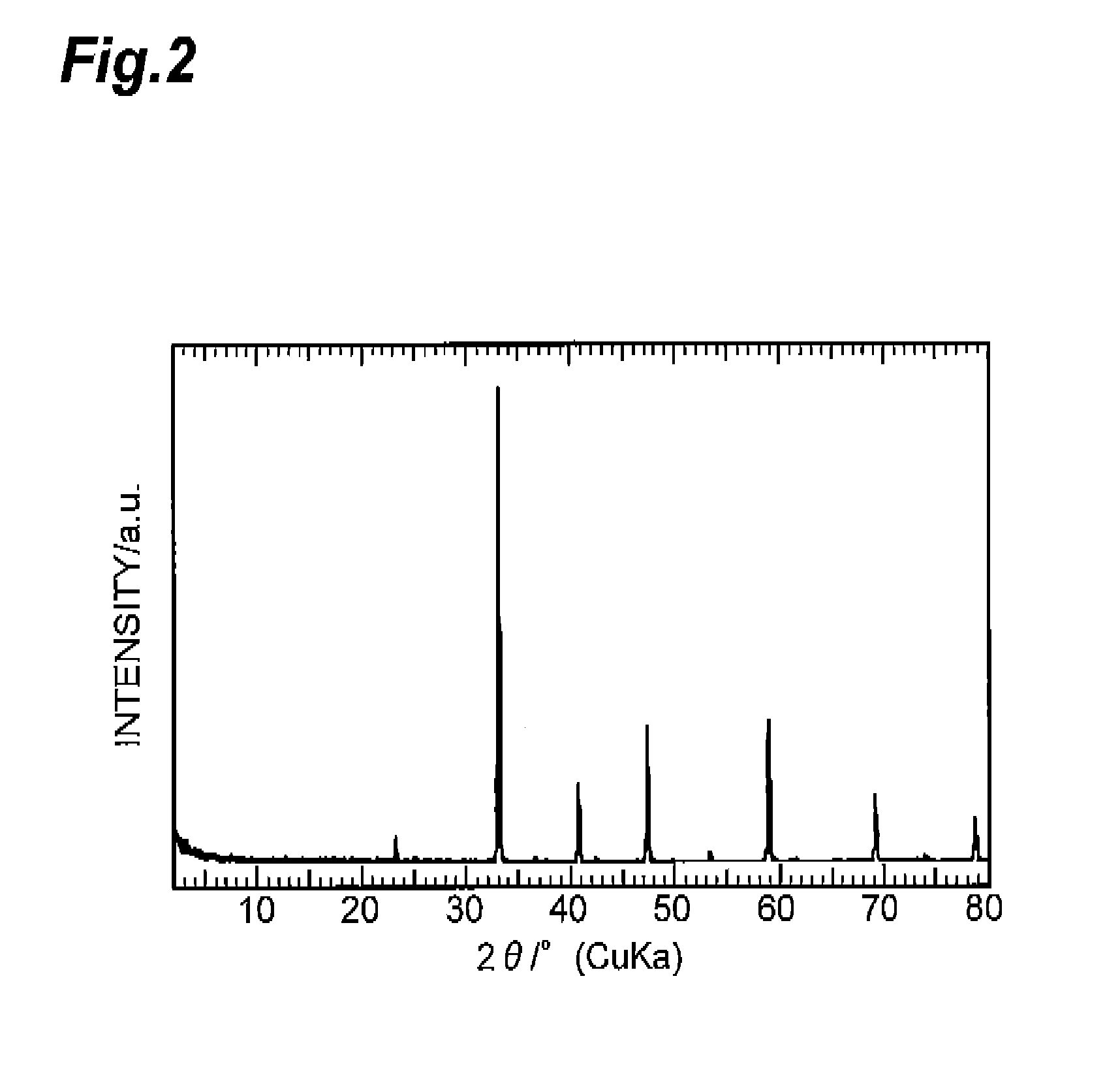

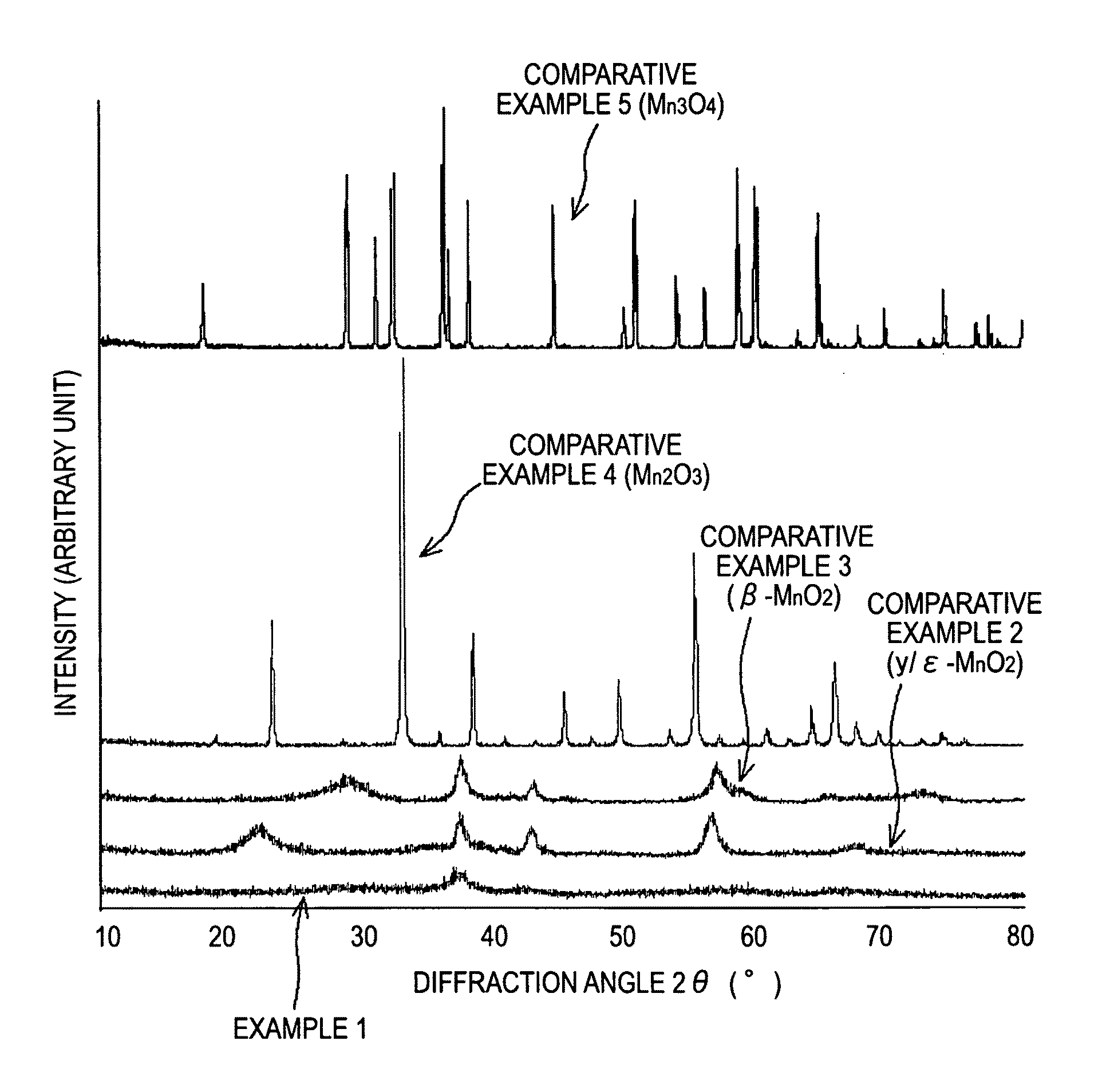

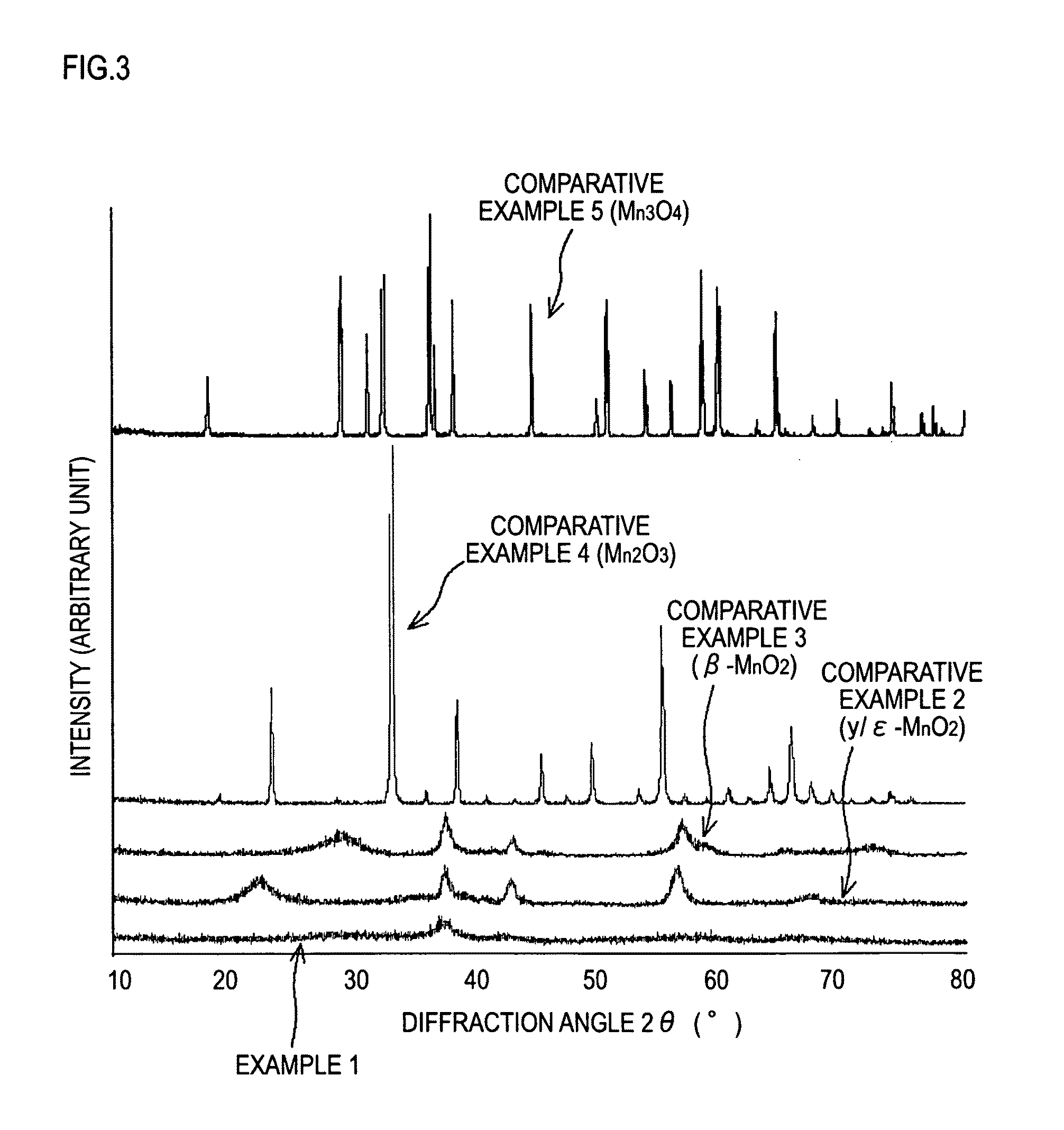

ActiveUS7195717B2Low core lossHigh curie temperatureFoundry mouldsInorganic material magnetismFull width at half maximumX-ray

Owner:KYOCERA CORP

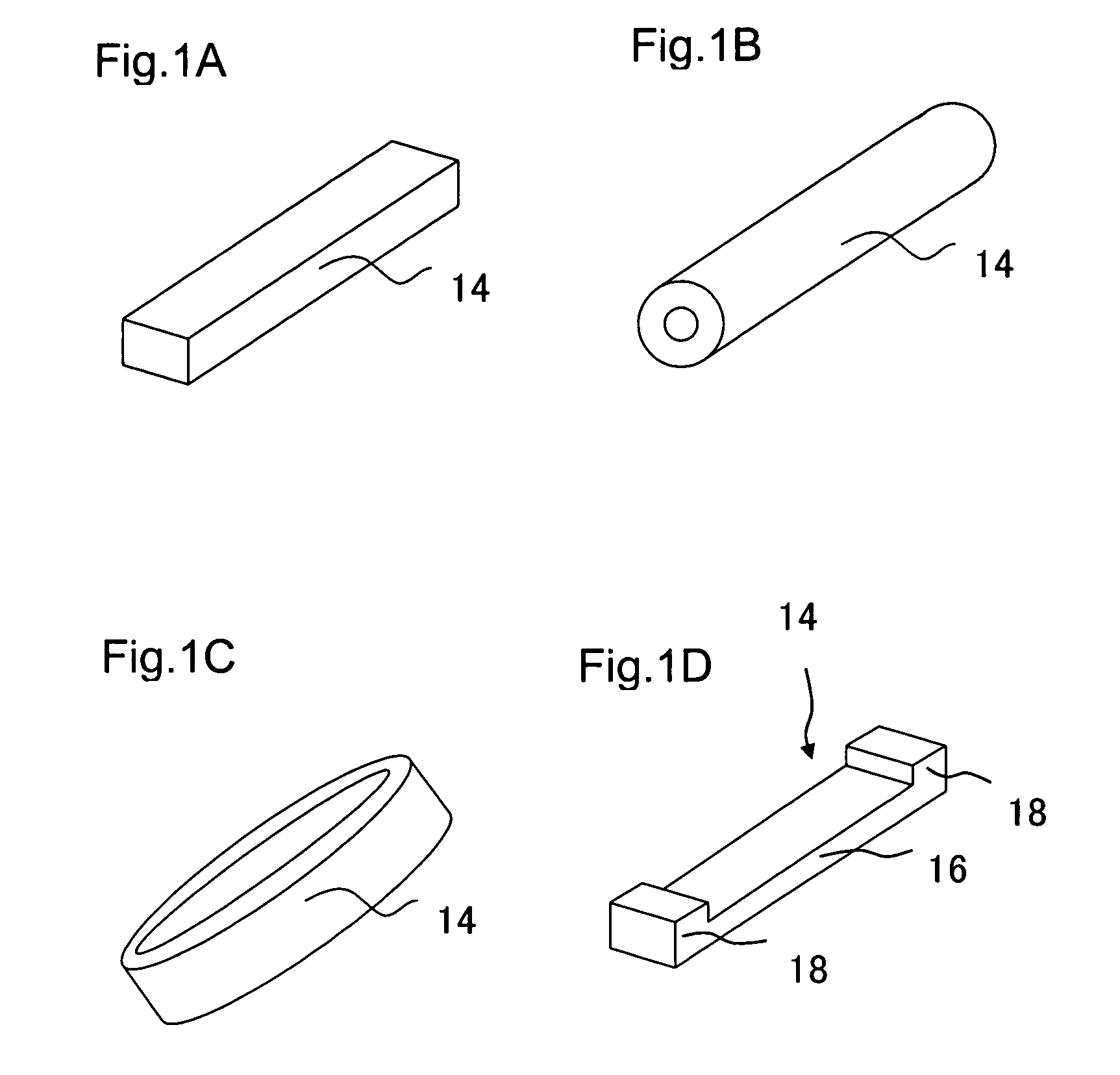

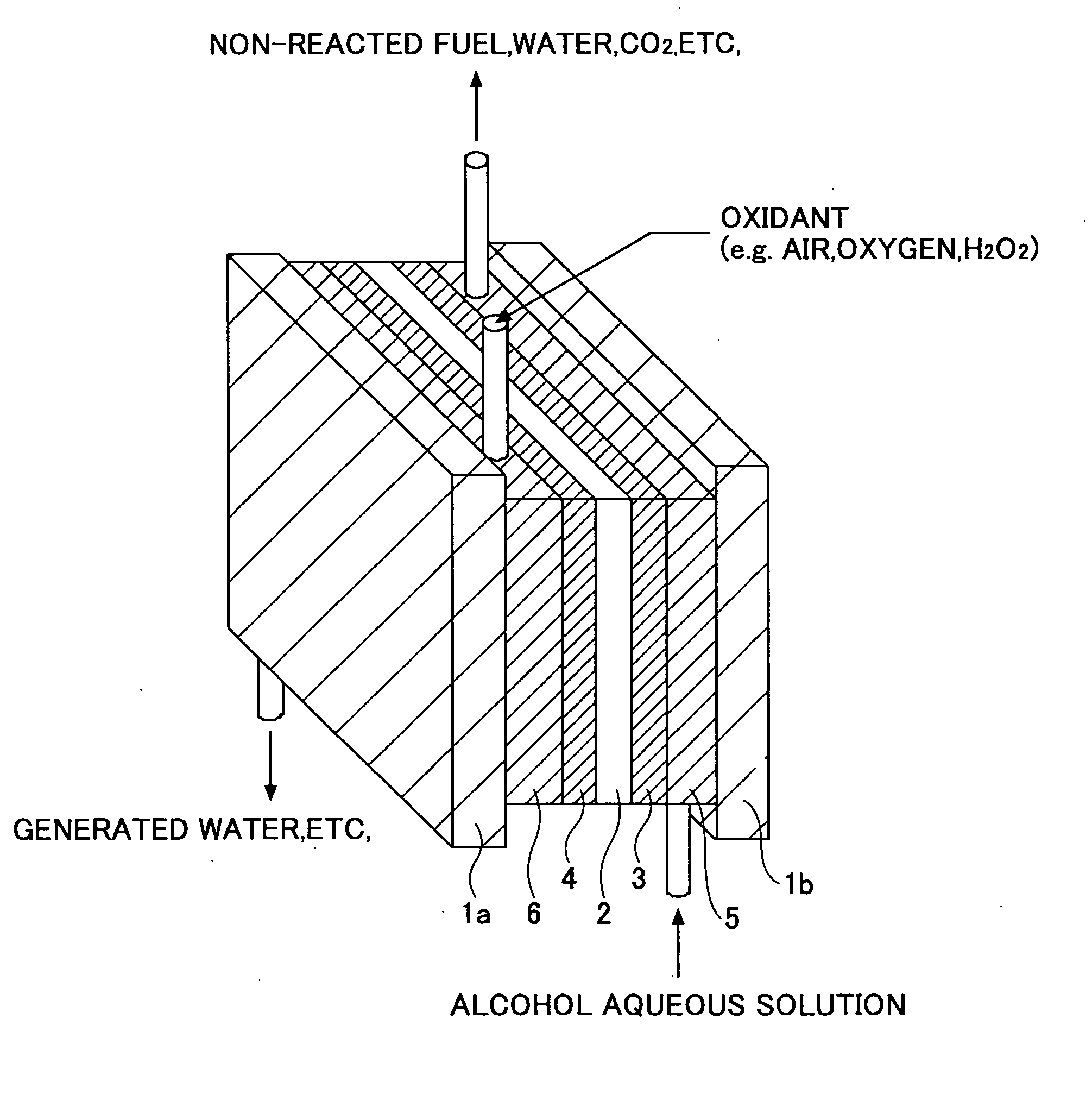

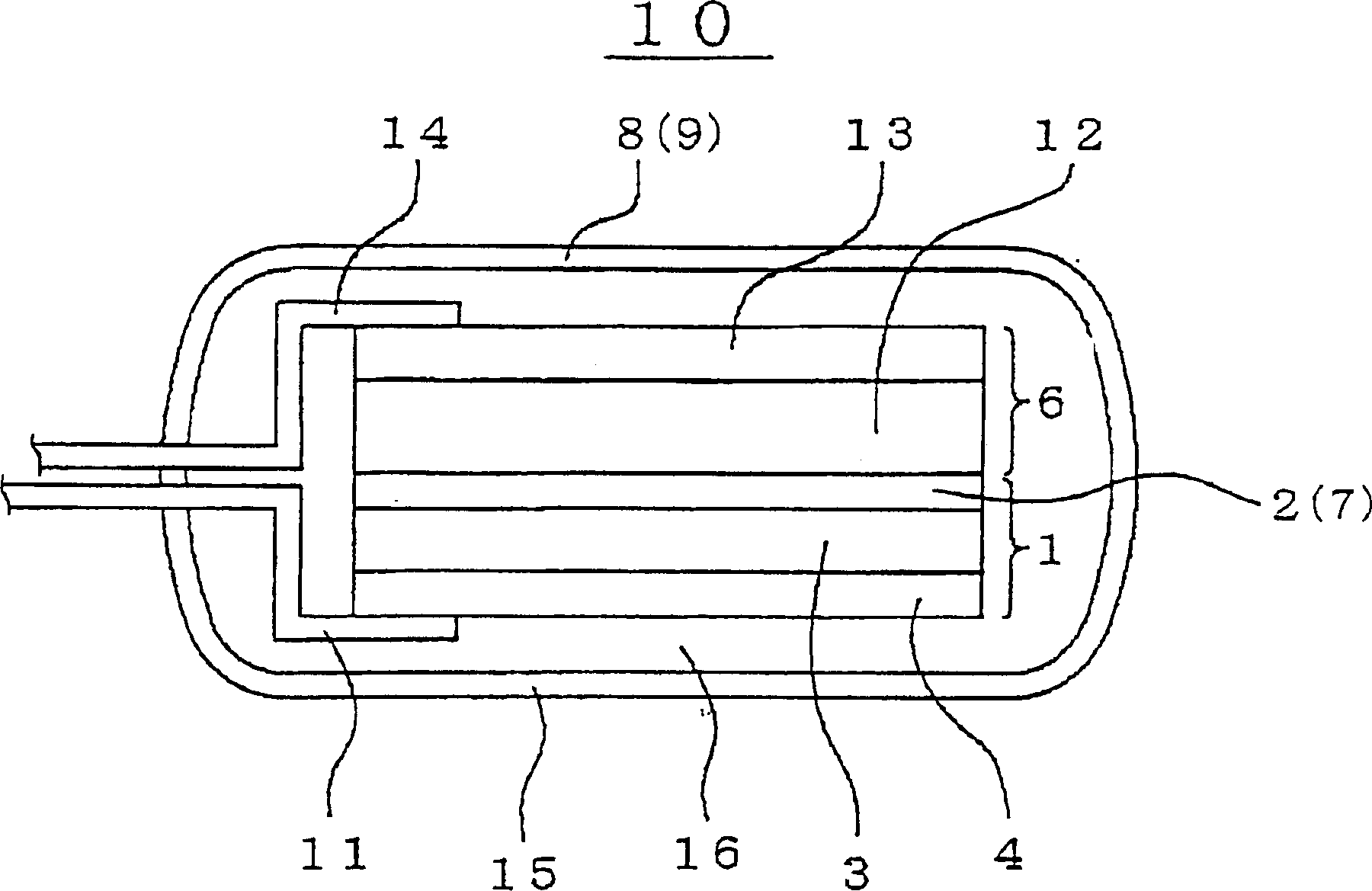

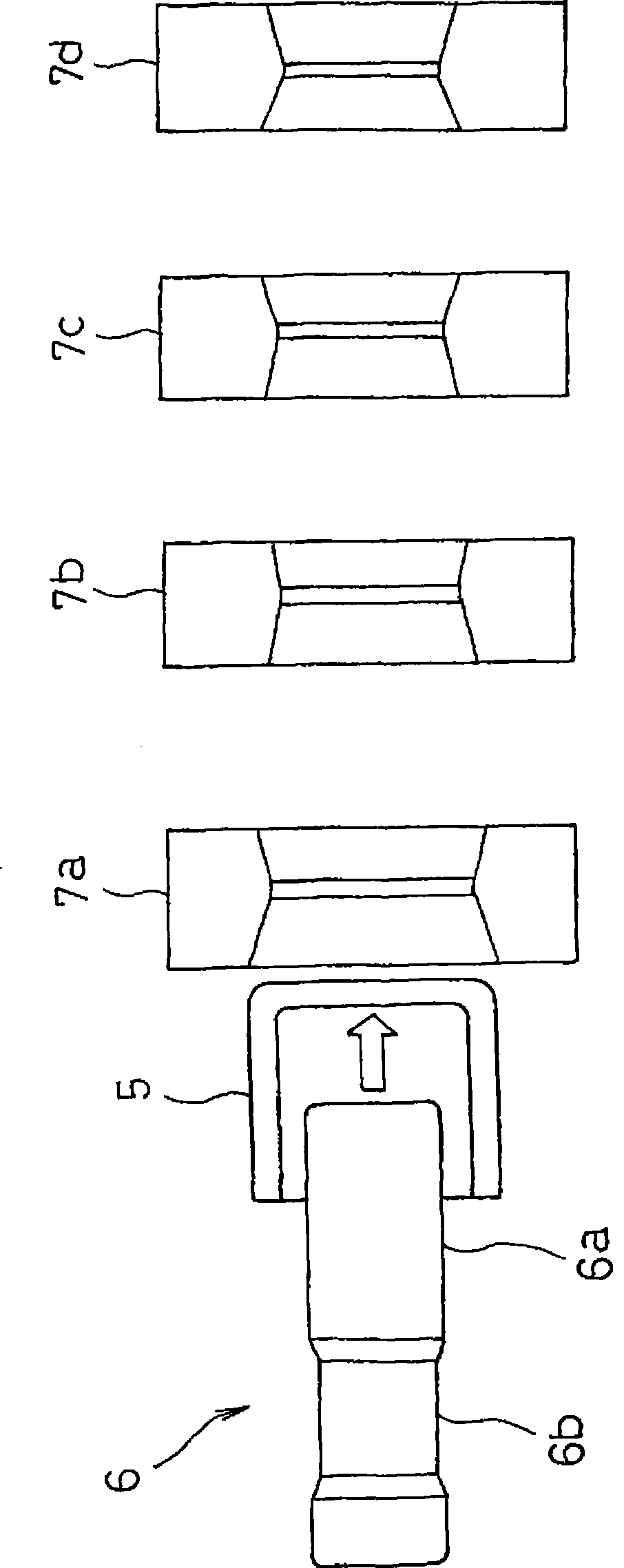

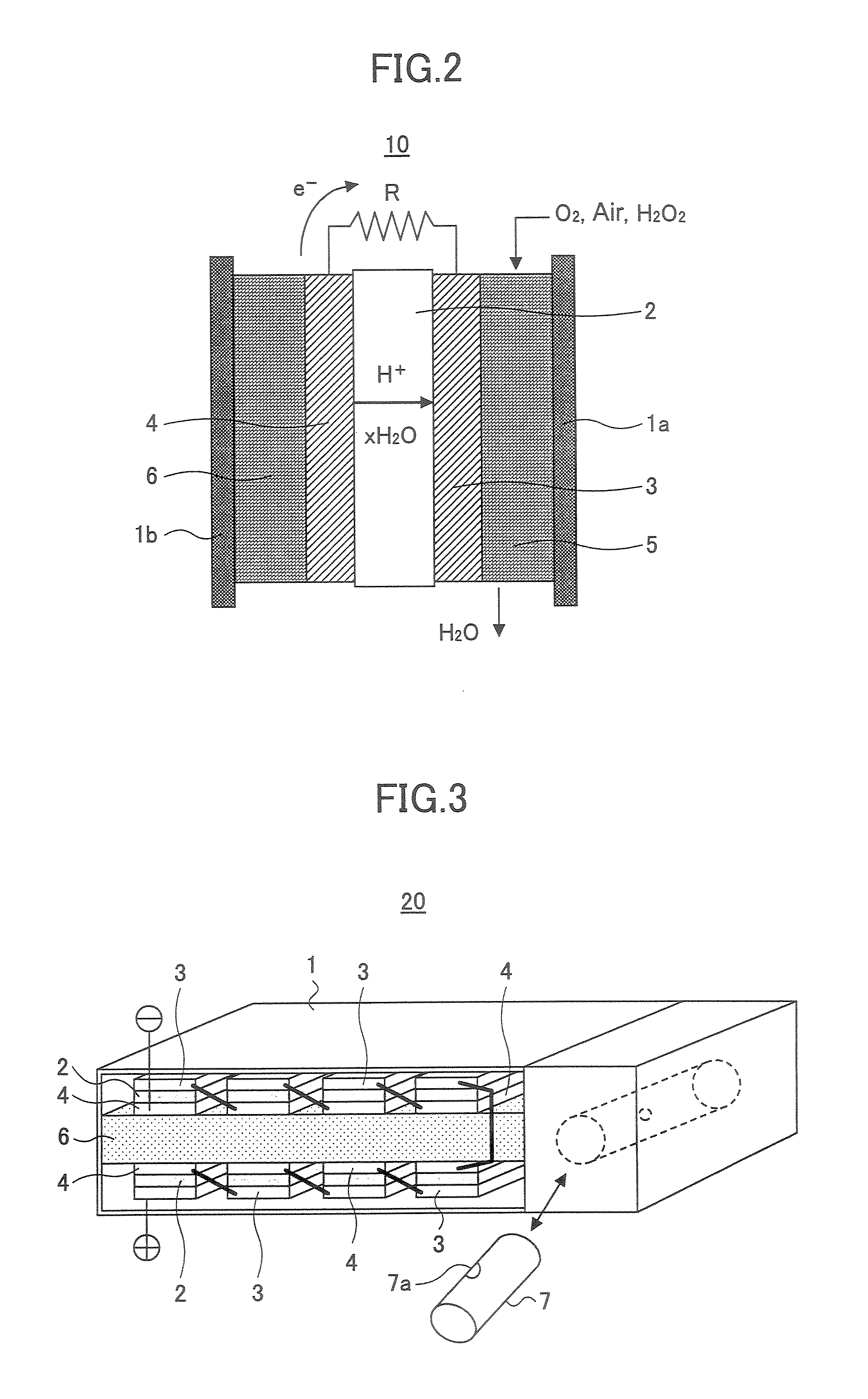

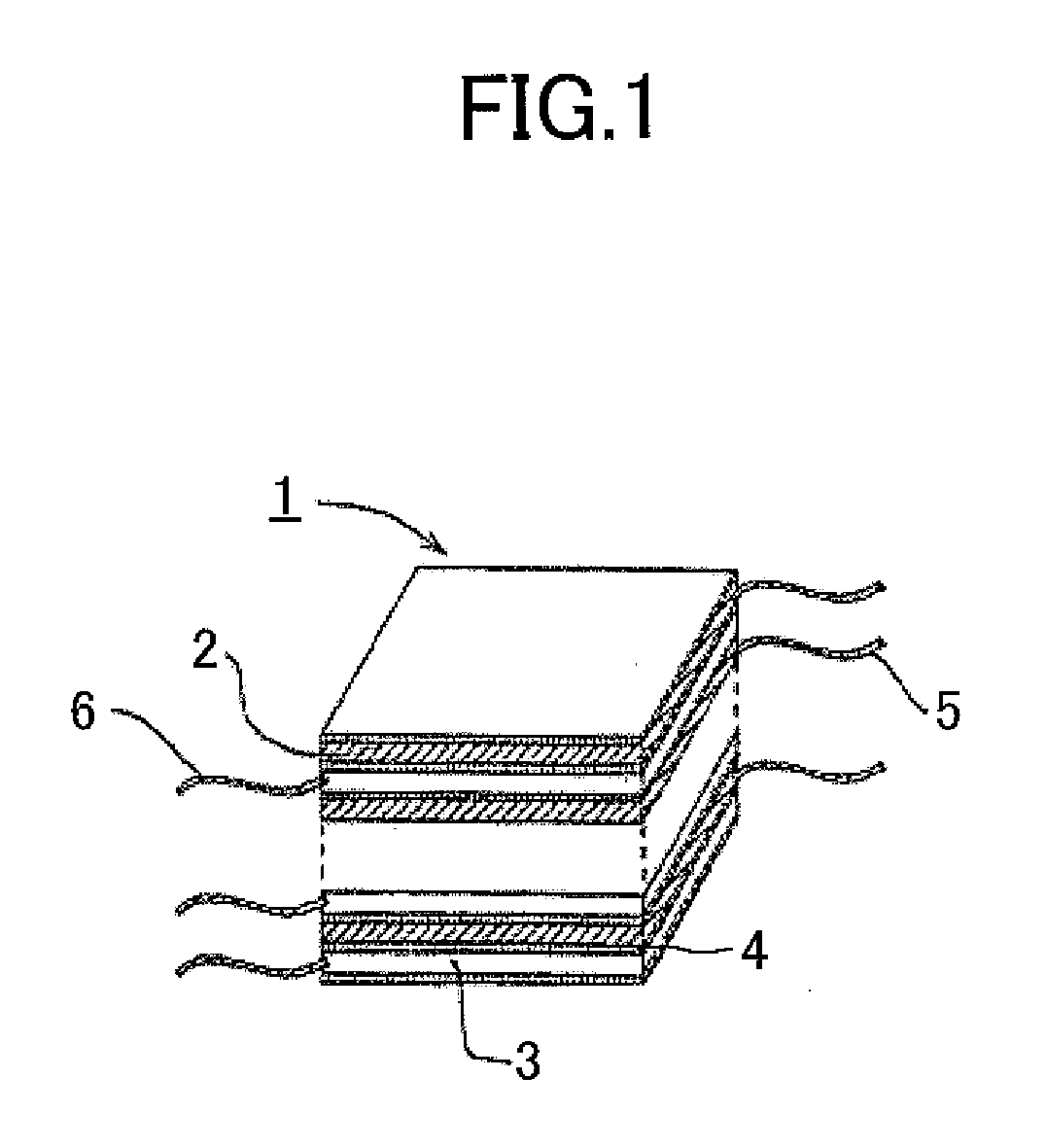

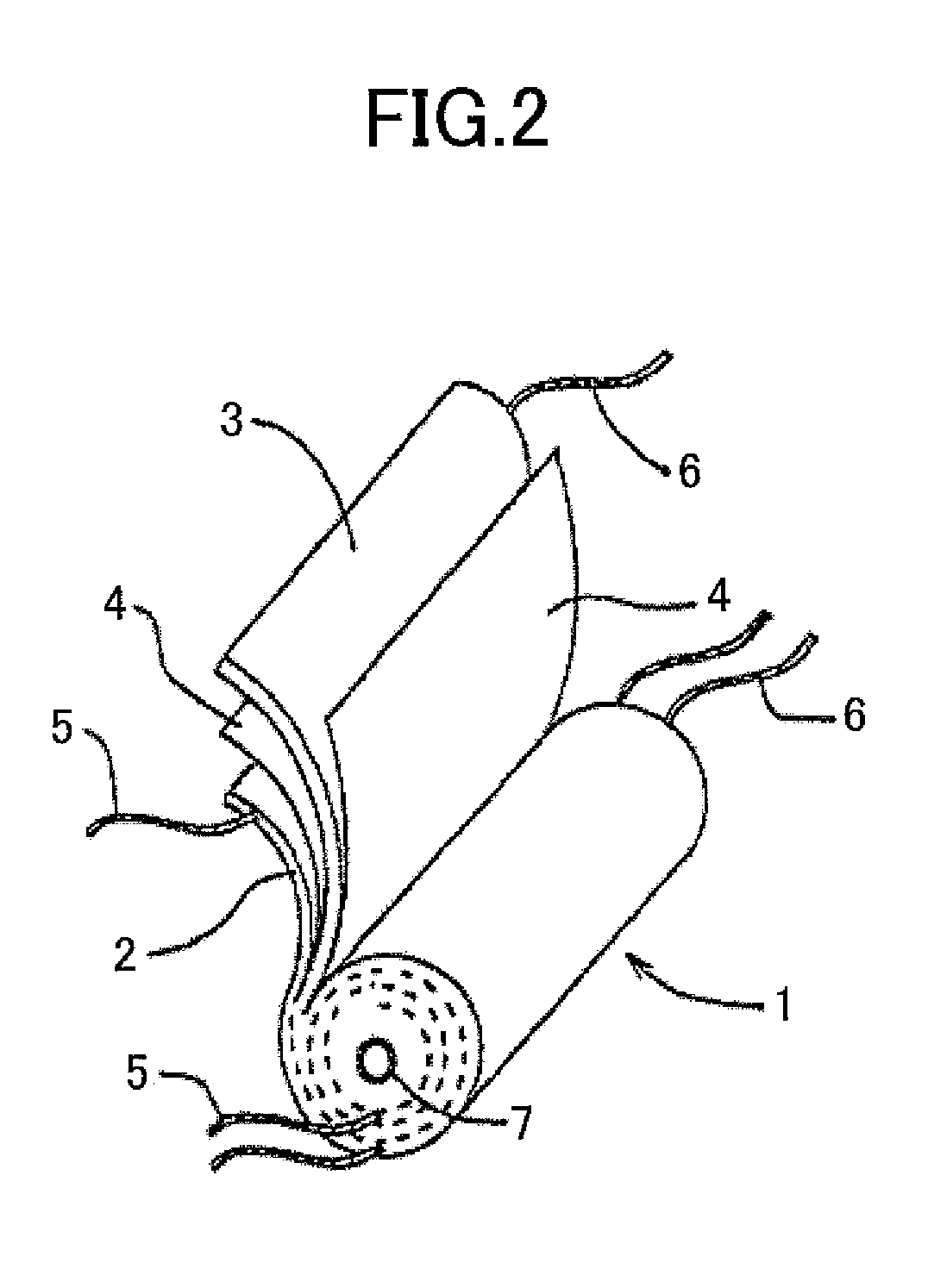

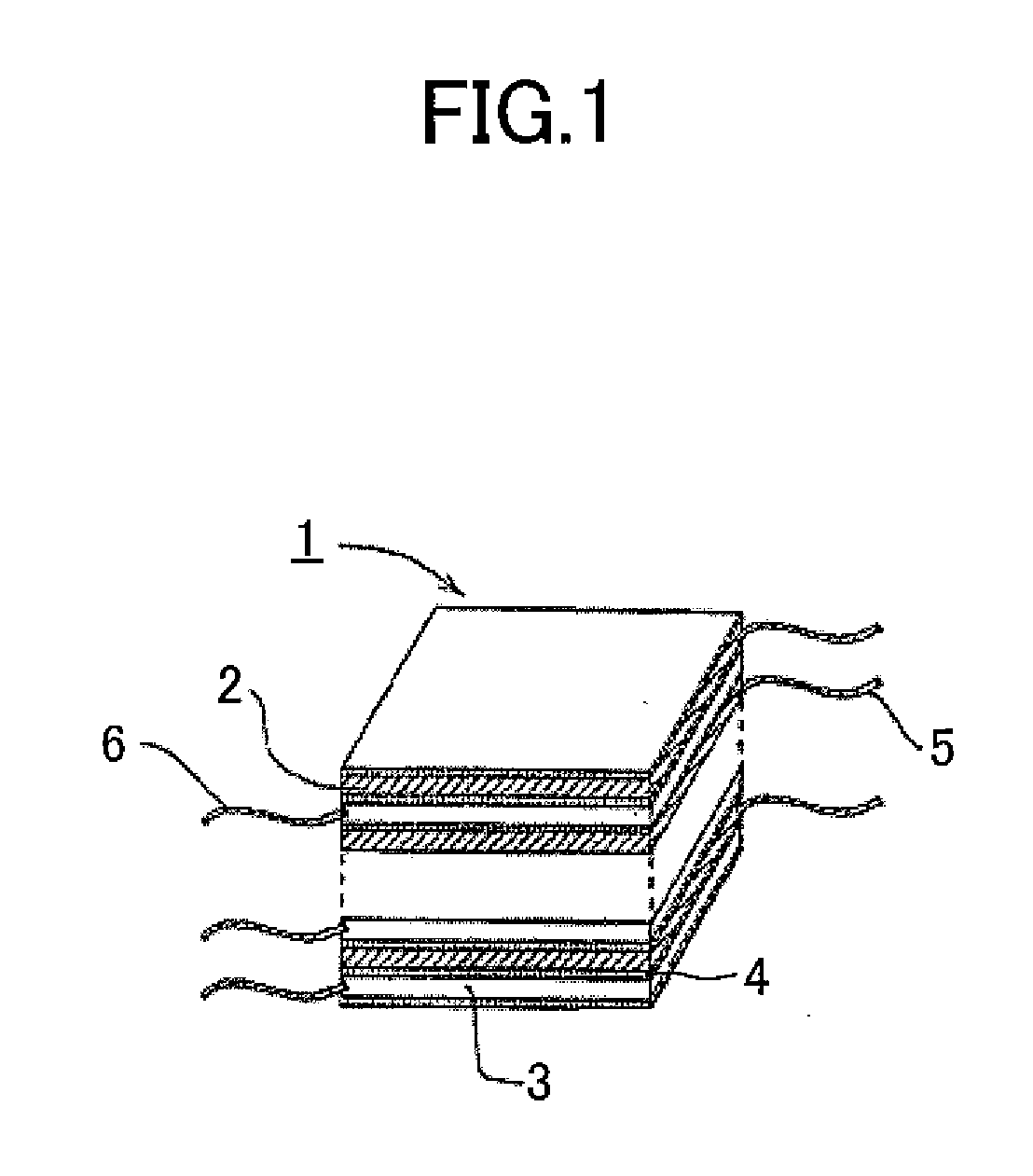

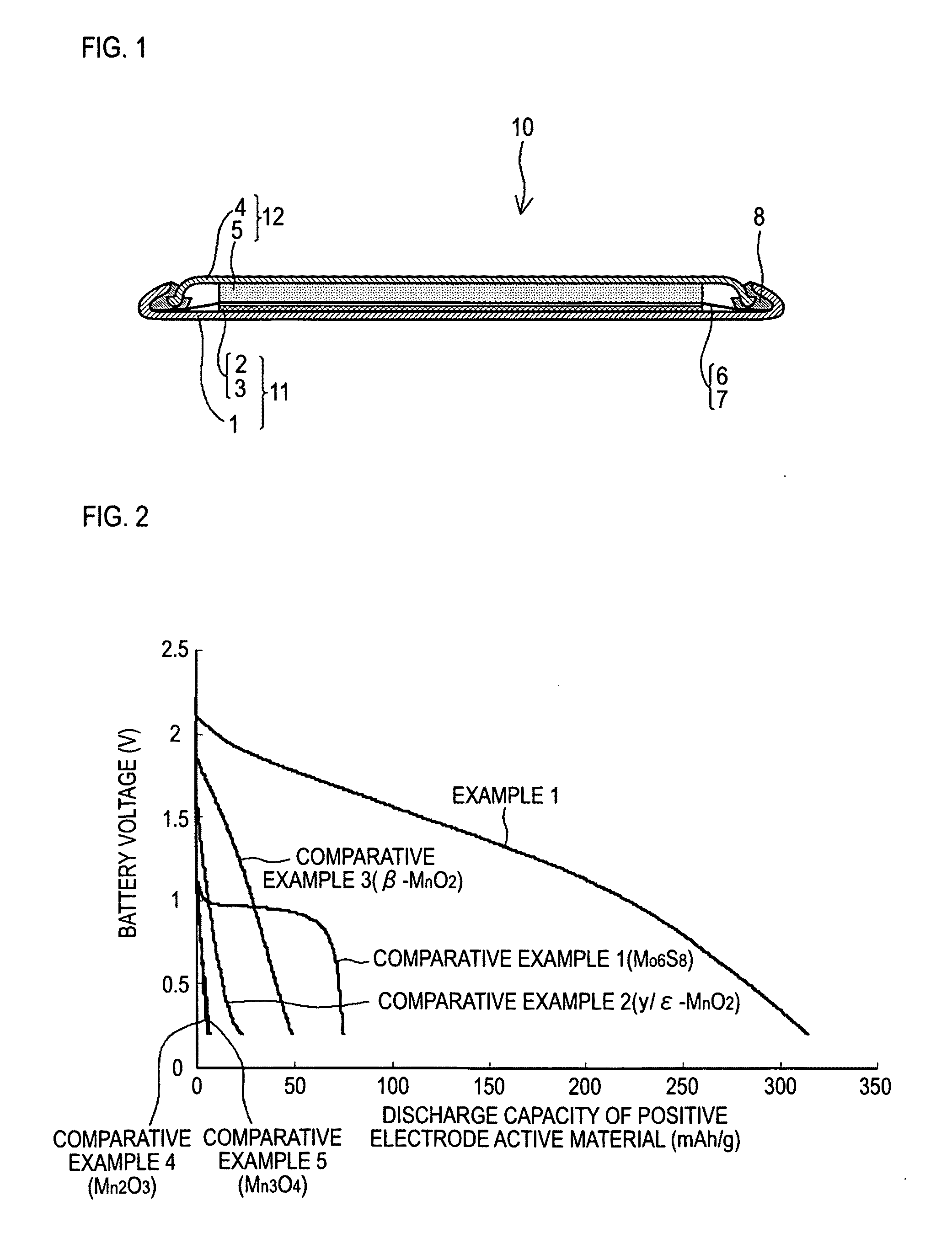

Positive electrode active material, method for producing the same, and electrochemical device

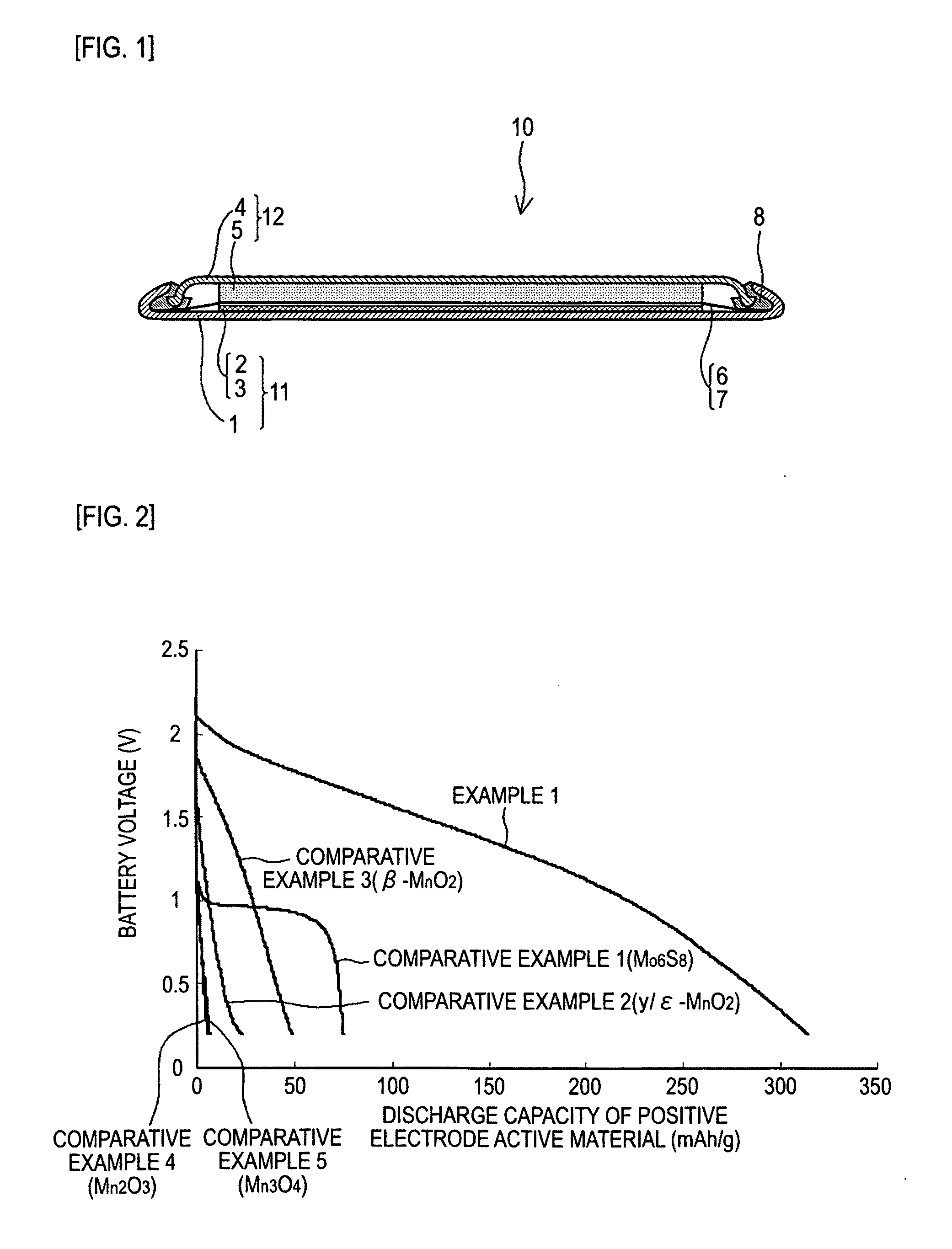

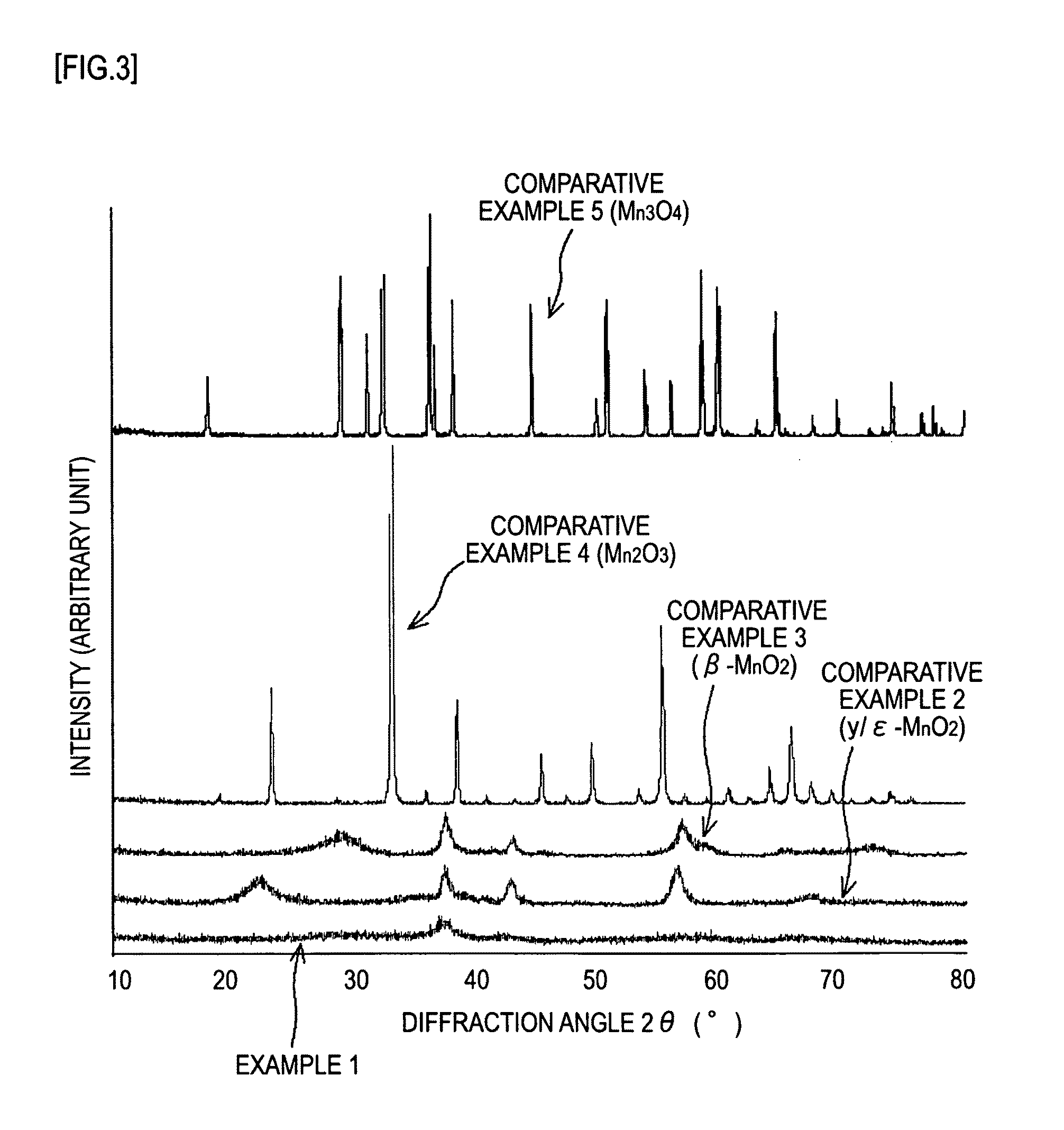

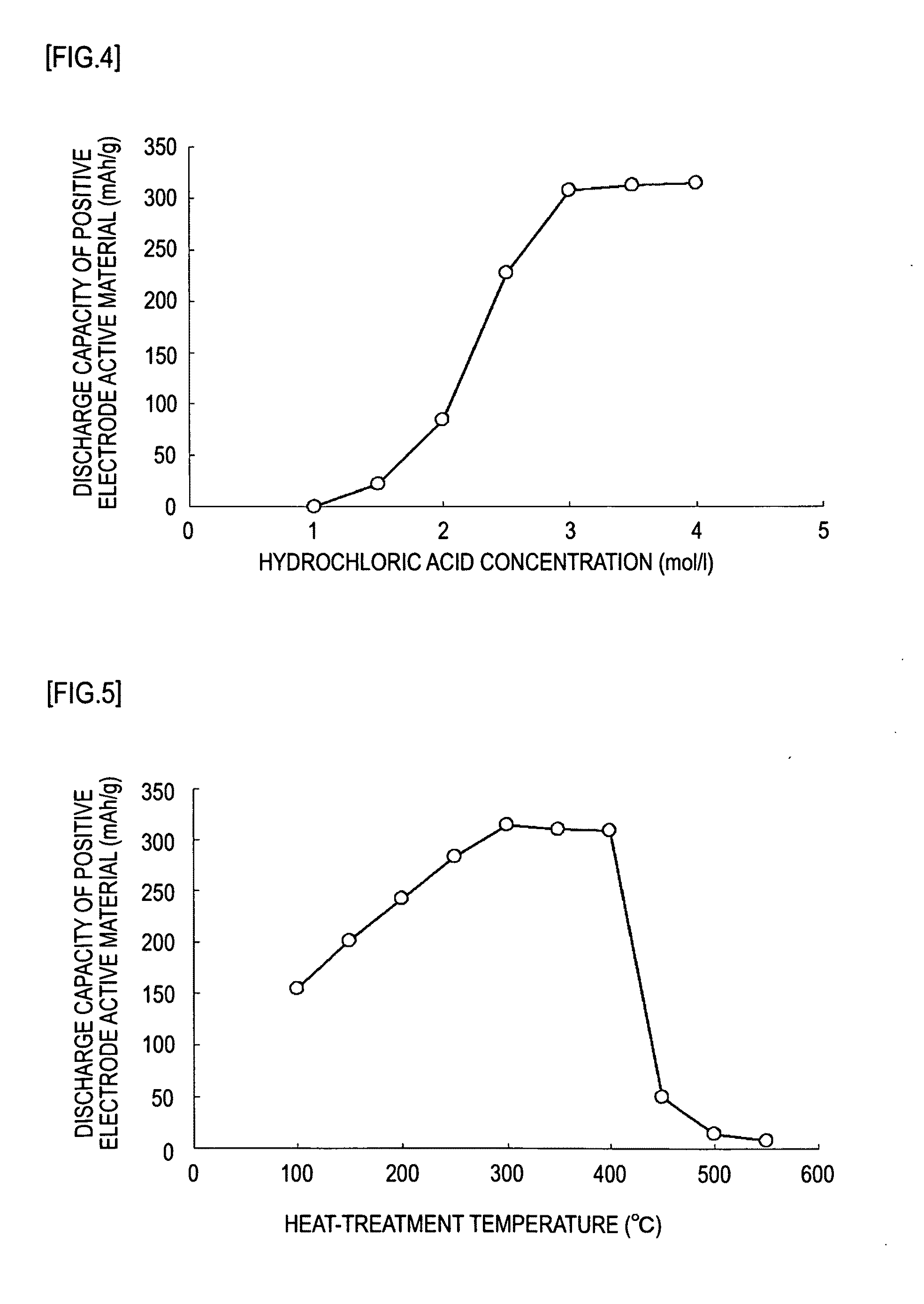

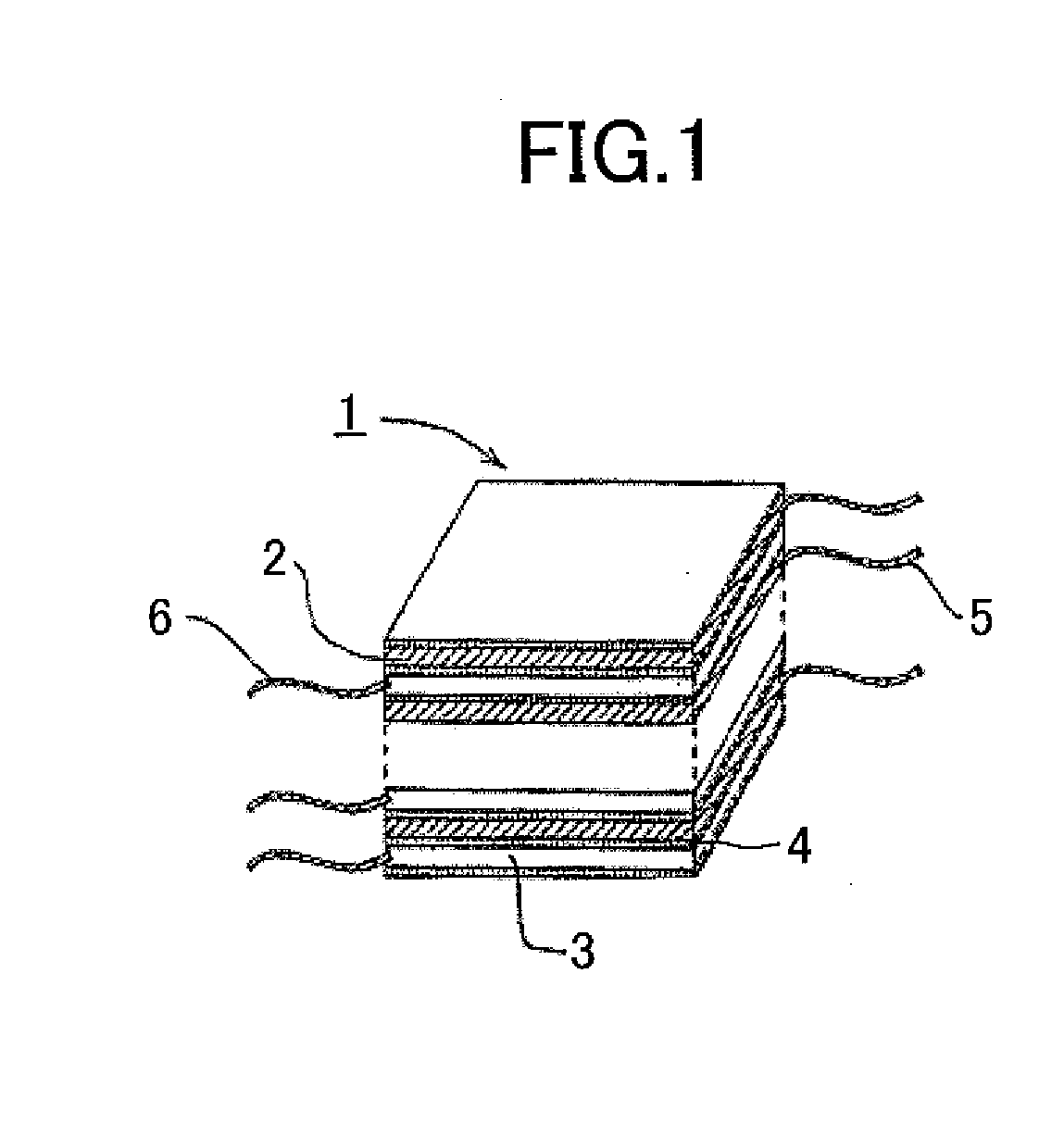

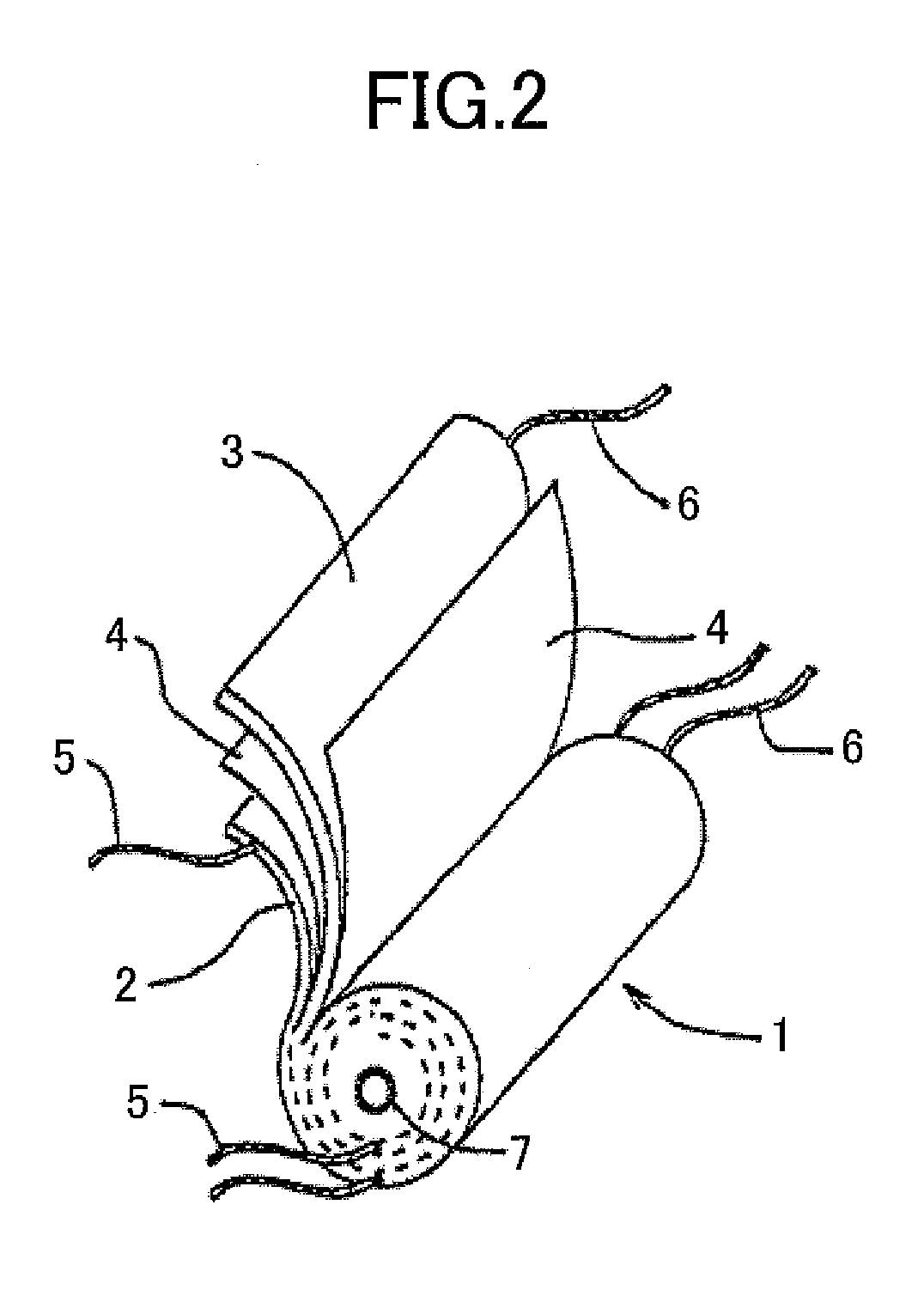

ActiveUS20100196762A1High electromotive forceHigh energy capacityFinal product manufactureOrganic electrolyte cellsHigh energyPERMANGANATE ION

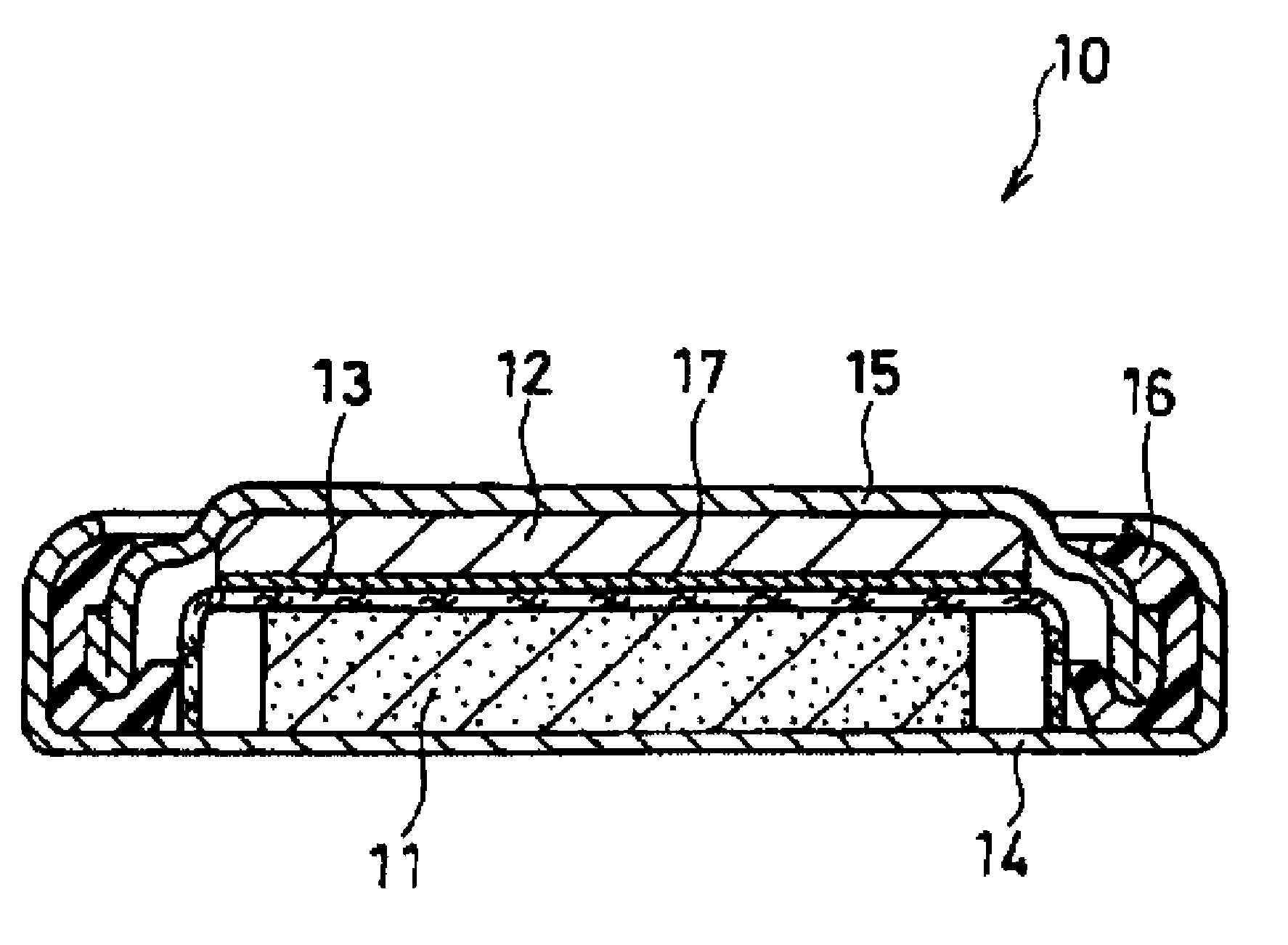

The invention provides a high-capacity positive electrode active material capable of sufficiently exploiting the excellent characteristics of magnesium metal or the like as a negative electrode active material, such as high energy capacity; a method for producing the same; and an electrochemical device using the positive electrode active material. A positive electrode 11 includes a positive electrode can 1, a positive pole pellet 2 having a positive electrode active material and the like, and a metal mesh support 3. A negative electrode 12 includes a negative electrode cap 4 and a negative electrode active material 5 such as magnesium metal. The positive electrode pellet 2 and the negative electrode active material 5 are disposed so as to sandwich a separator 6, and an electrolyte 7 is injected into the separator 6. The positive electrode active material, which provides the feature of the invention, is synthesized by a step of reacting a permanganate, such as potassium permanganate, with hydrochloric acid preferably having a concentration of 3 to 4 mol / l to produce a precipitate, and a step of filtering the precipitate, thoroughly washing the filtered precipitate with water, and then subjecting the washed precipitate to heat treatment preferably at a temperature of 300 to 400° C. for not less than 2 hours, thereby giving a manganese oxide.

Owner:MURATA MFG CO LTD

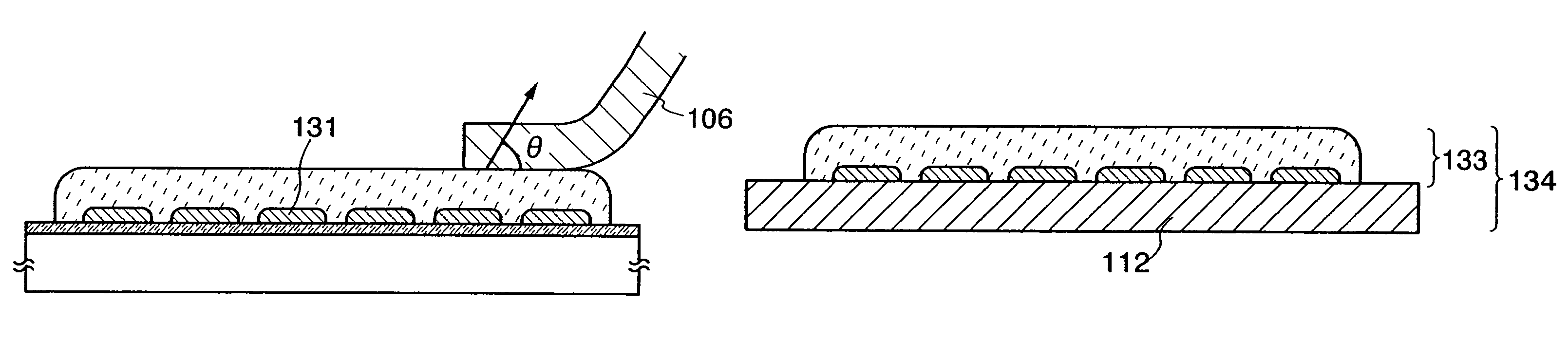

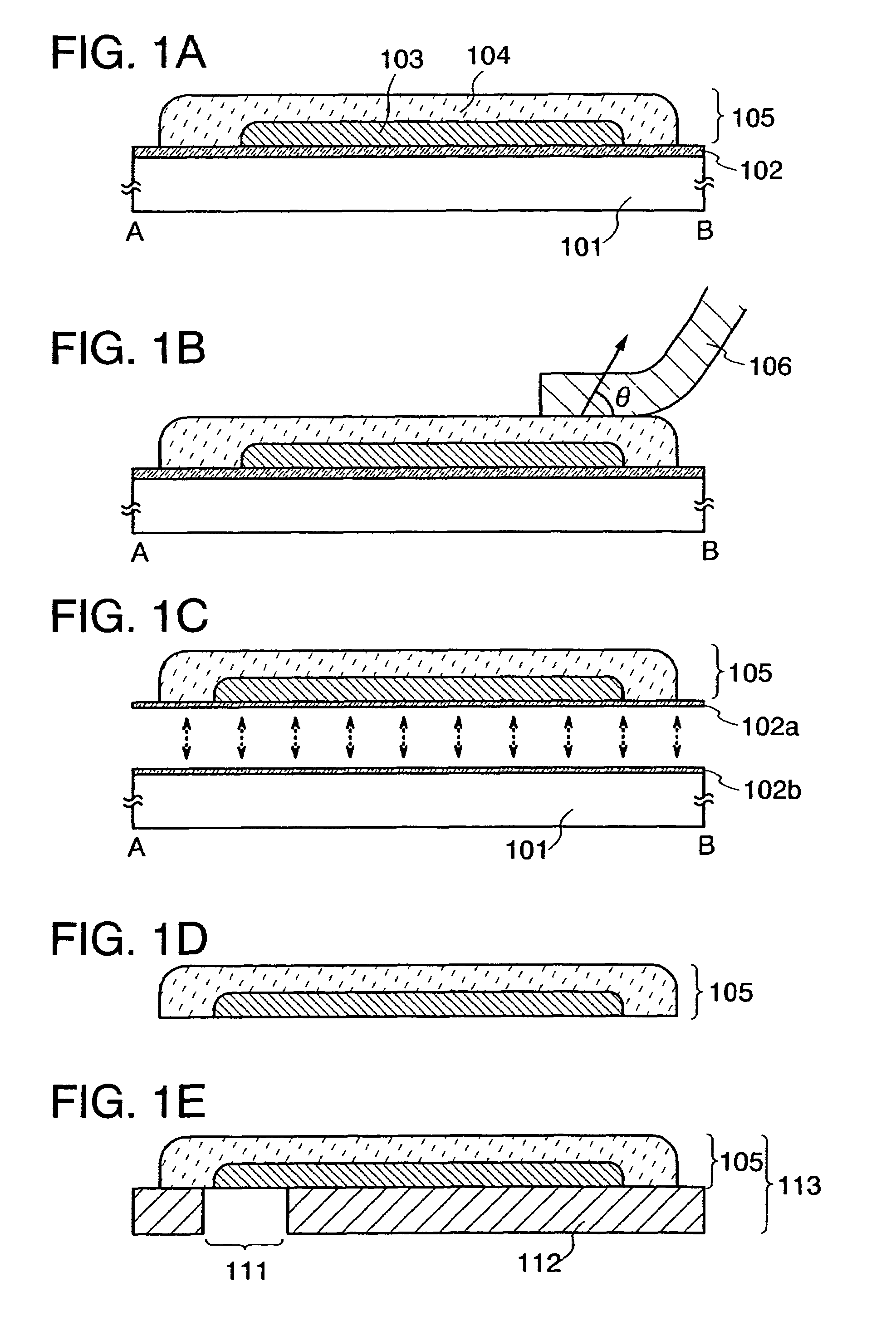

Layer having functionality, method for forming flexible substrate having the same, and method for manufacturing semiconductor device

It is an object of the present invention to provide a method for forming a layer having functionality including a conductive layer and a colored layer and a flexible substrate having a layer having functionality with a high yield. Further, it is an object of the present invention to provide a method for manufacturing a semiconductor device that is small-sized, thin, and lightweight. After coating a substrate having heat resistance with a silane coupling agent, a layer having functionality is formed. Then, after attaching an adhesive to the layer having functionality, the layer having functionality is peeled from the substrate. Further, after coating a substrate having heat resistance with a silane coupling agent, a layer having functionality is formed. Then, an adhesive is attached to the layer having functionality. Thereafter, the layer having functionality is peeled from the substrate, and a flexible substrate is attached to the layer having functionality.

Owner:SEMICON ENERGY LAB CO LTD

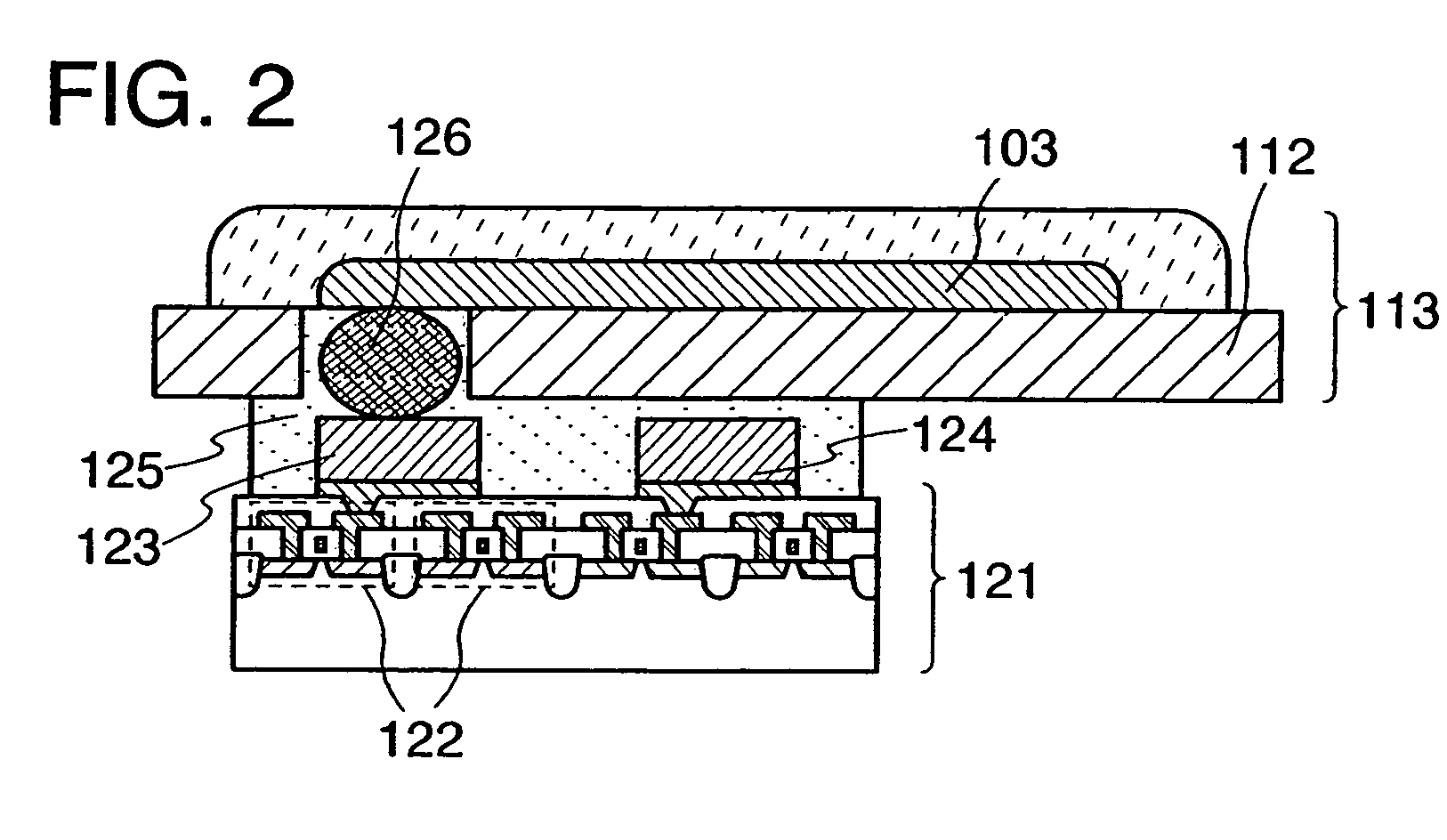

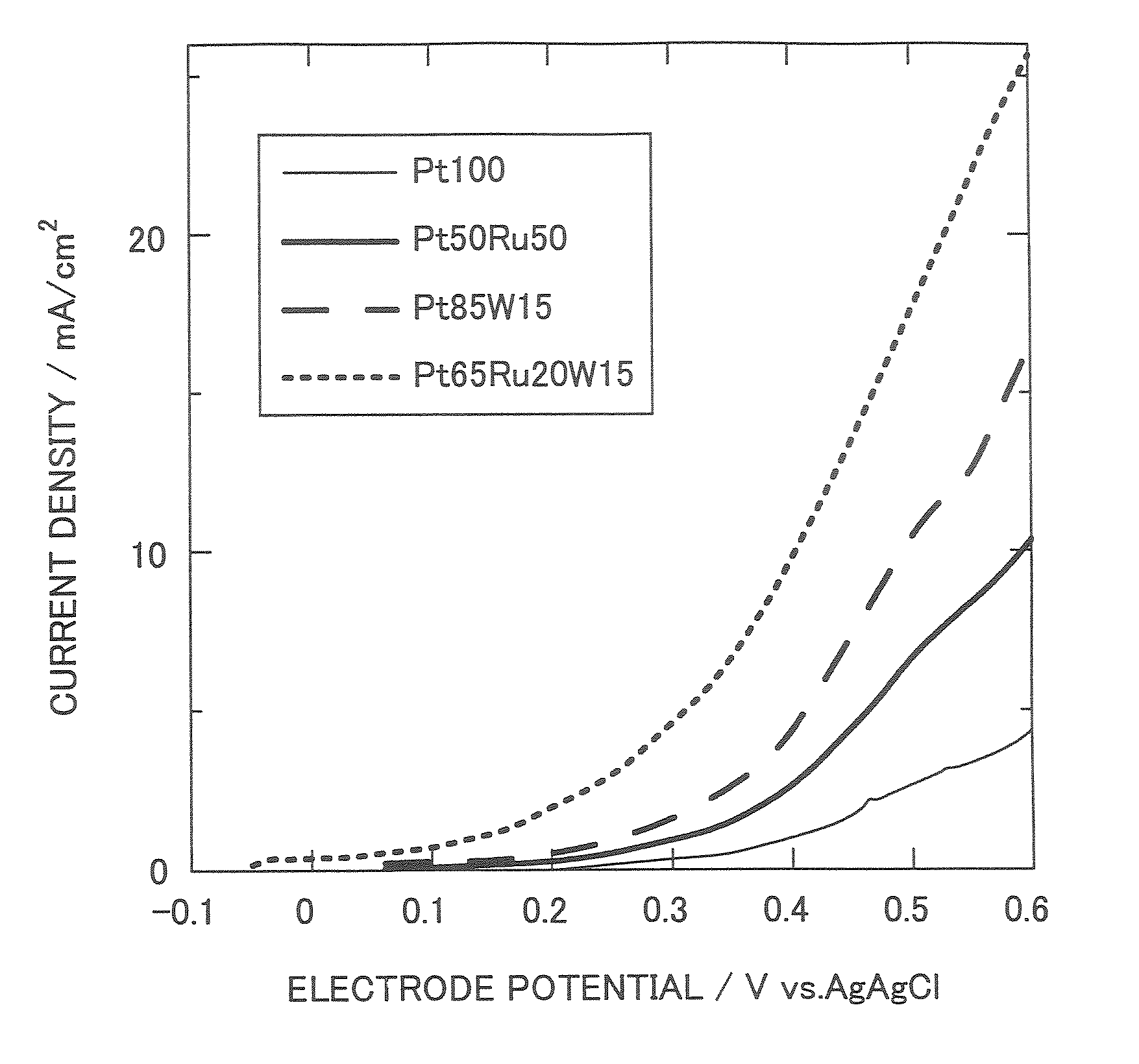

Electrode Catalyst, Method for Preparation Thereof, Direct Alcohol Fuel Cell

InactiveUS20070281200A1Increase current densityImprove the immunityFuel cells groupingFinal product manufacturePlatinumAlcohol

An anode is formed by a metal electrocatalyst including an element mixture made up of platinum and at least one of ruthenium and molybdenum as an active constituent which electrocatalyst is fabricated under vacuum using a vapor phase method, and in this way, the speed of electrode oxidation reaction of alcohol such as methanol, ethanol, and isopropyl alcohol may be substantially increased. Also, by using such an electrocatalyst as the anode, a direct alcohol fuel cell with a high output may be realized using alcohol that is not reformed as fuel.

Owner:RICOH KK

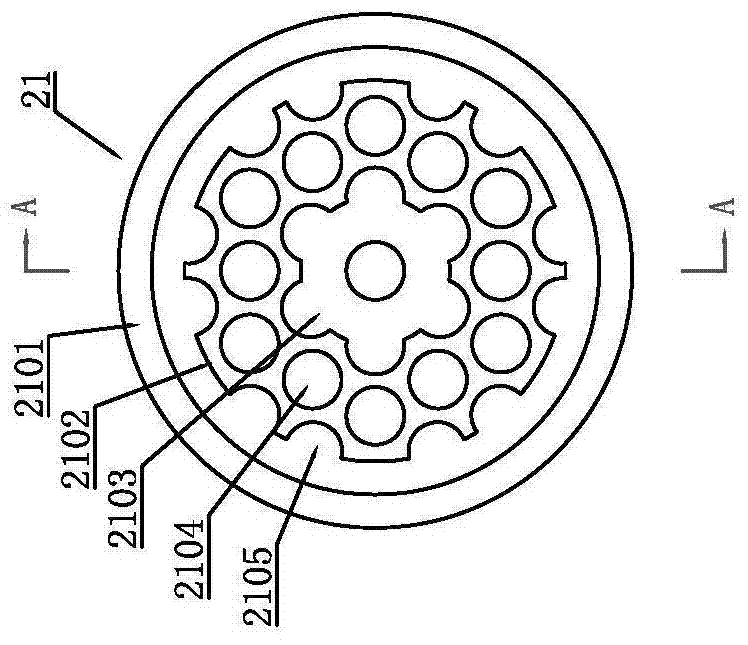

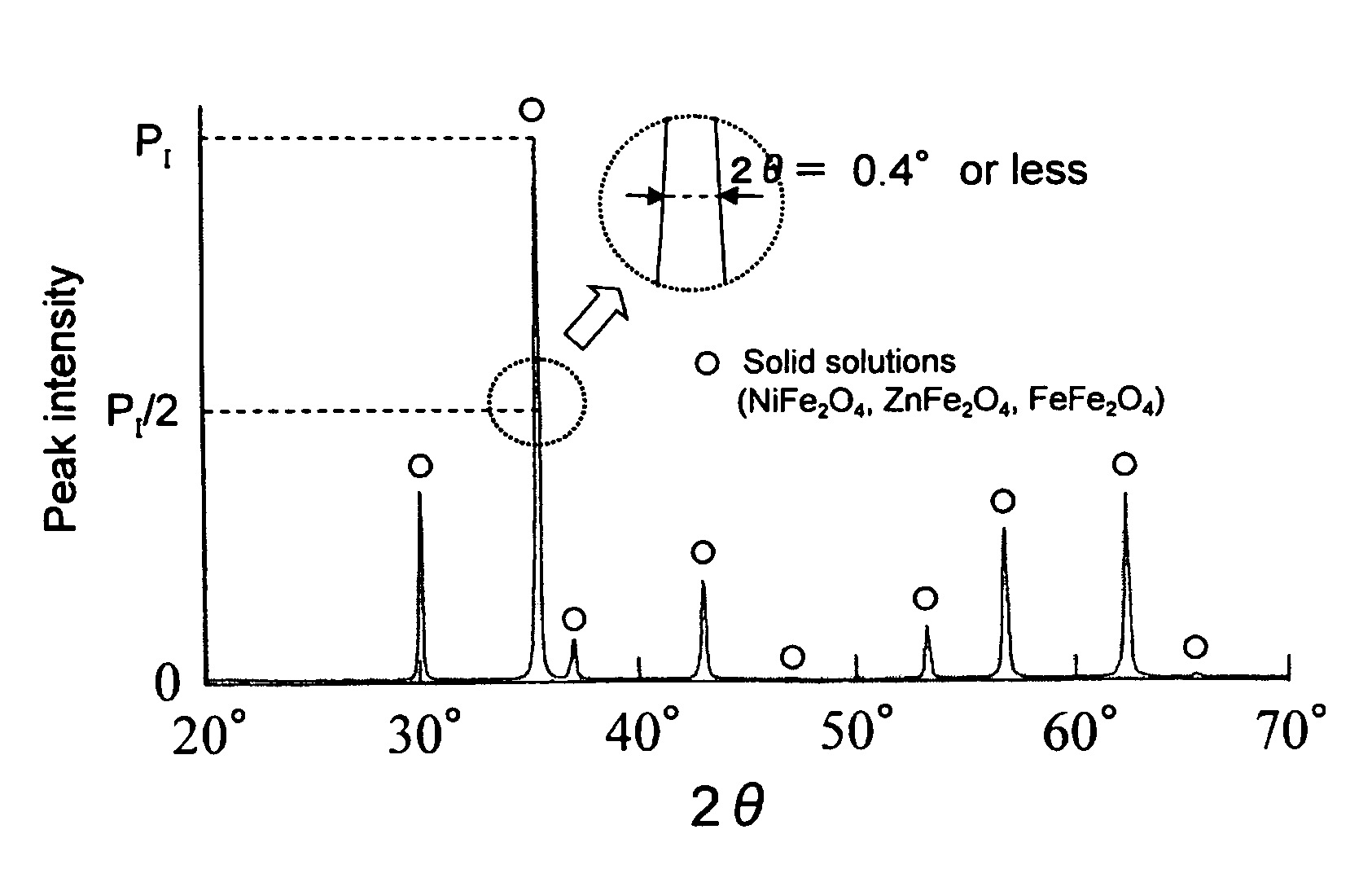

Ferrite core for RFID application, method of manufacturing the same, and ferrite coil using the same

ActiveUS20050023501A1Low core lossHigh curie temperatureInorganic material magnetismCeramic shaping apparatusFull width at half maximumX-ray

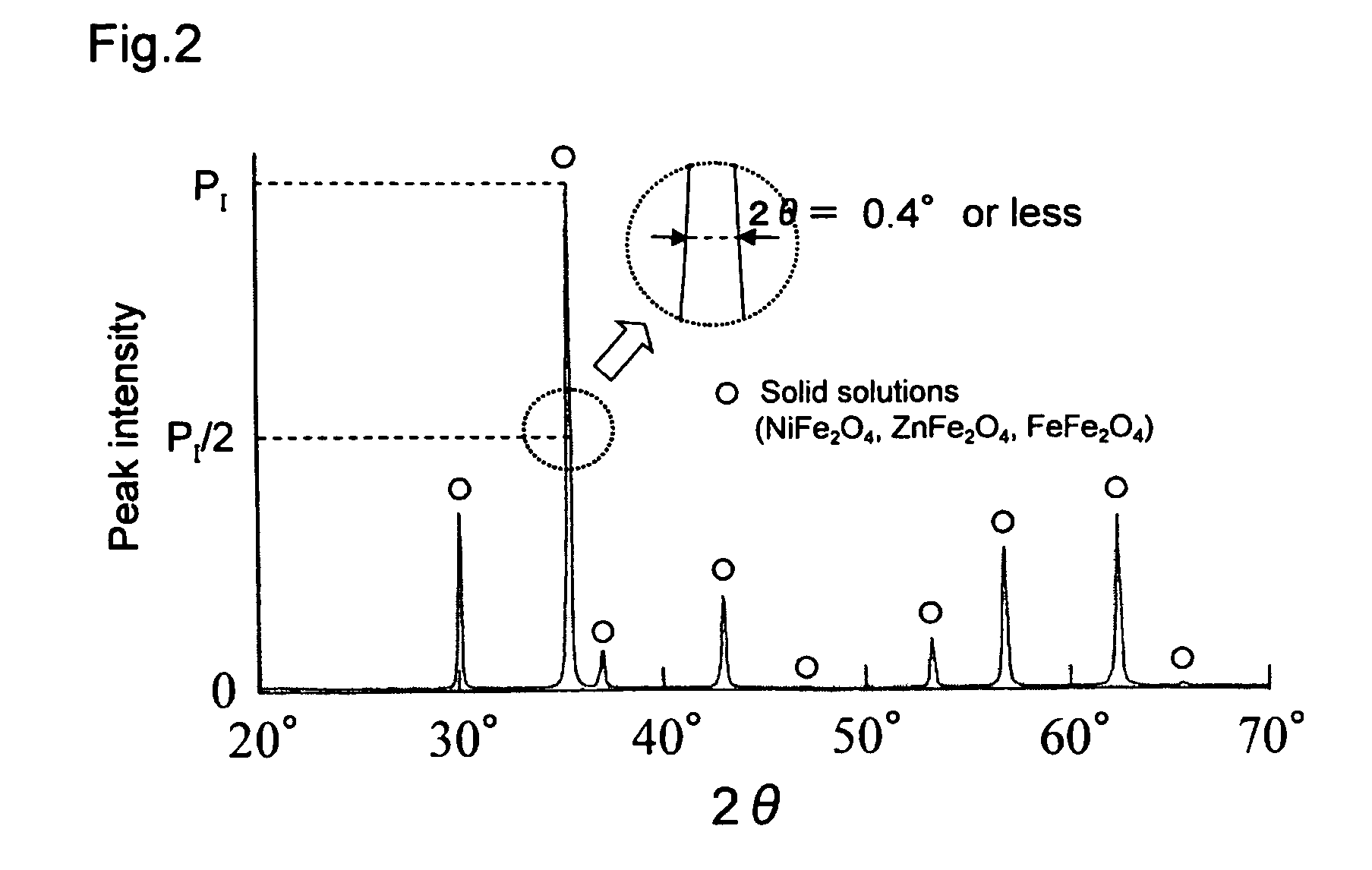

A ferrite core comprising a sintered oxide containing at least 48.6 to 53.9 mol% of Fe on Fe2O3 basis, 12.3 to 35.2 mol % of Ni on NiO basis and 16.4 to 37.0 mol % of Zn on ZnO basis as metal elements, and contains a crystal phase comprising two or more kinds of solid solutions selected from NiFe2O4, ZnFe2O4 and FeFe2O4, wherein full width at half maximum of a diffraction peak, of crystal phase of which diffraction angle 2θ is in a range from 34.6 to 36.4° as measured by X-ray diffraction analysis using Cu—Kα beam, is 0.4° or less.

Owner:KYOCERA CORP

Lithium accumulator with improved negative pole structure and its preparing method

InactiveCN1392624AImprove stabilityInhibition of basic growthElectrode rolling/calenderingLi-accumulatorsLithiumElectrode

A lithium secondary battery includes: a positive electrode; and a negative electrode, which further includes a lamination structure comprising: a lithium ion supporting layer capable of supporting lithium ions; and an amorphous-state lithium-based layer in contact directly with the lithium ion supporting layer.

Owner:NEC CORP

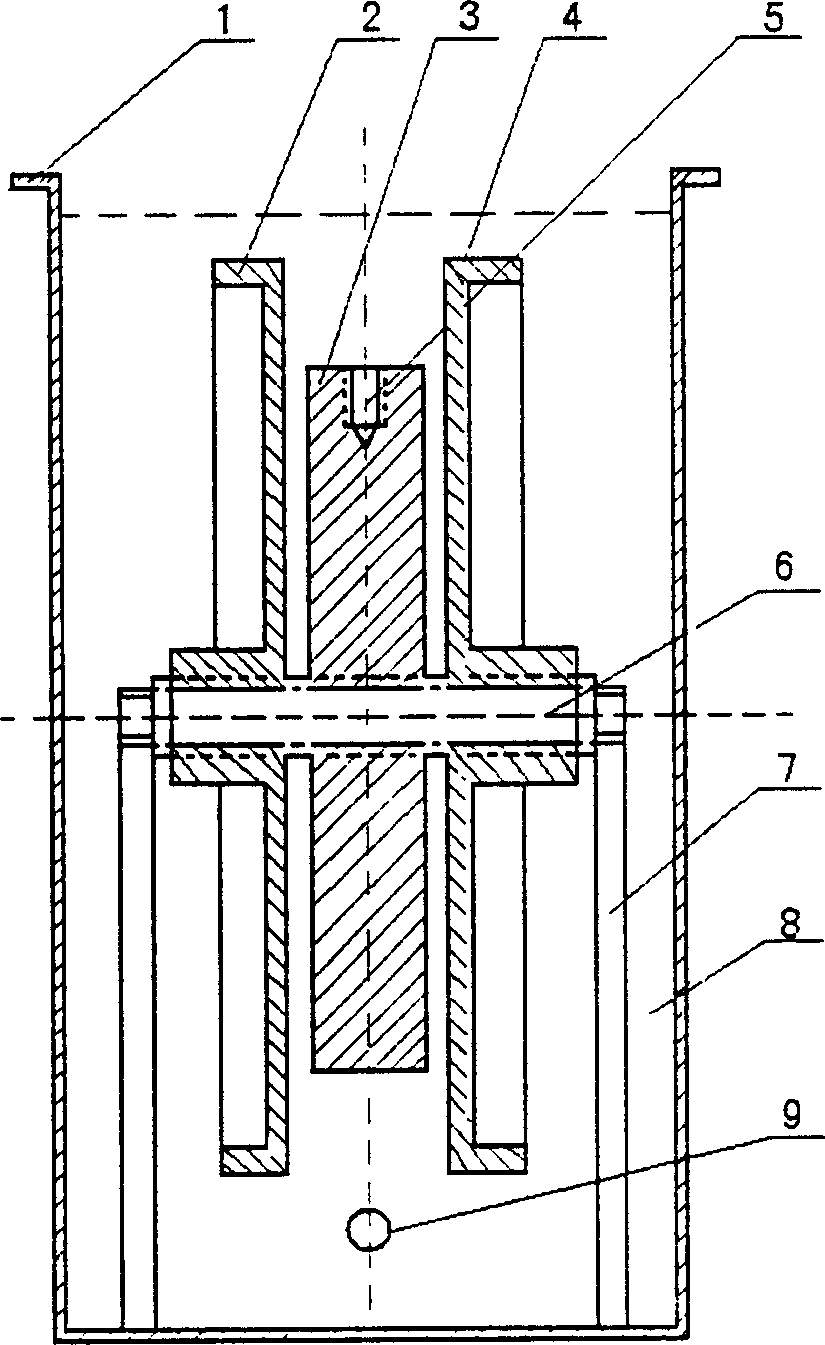

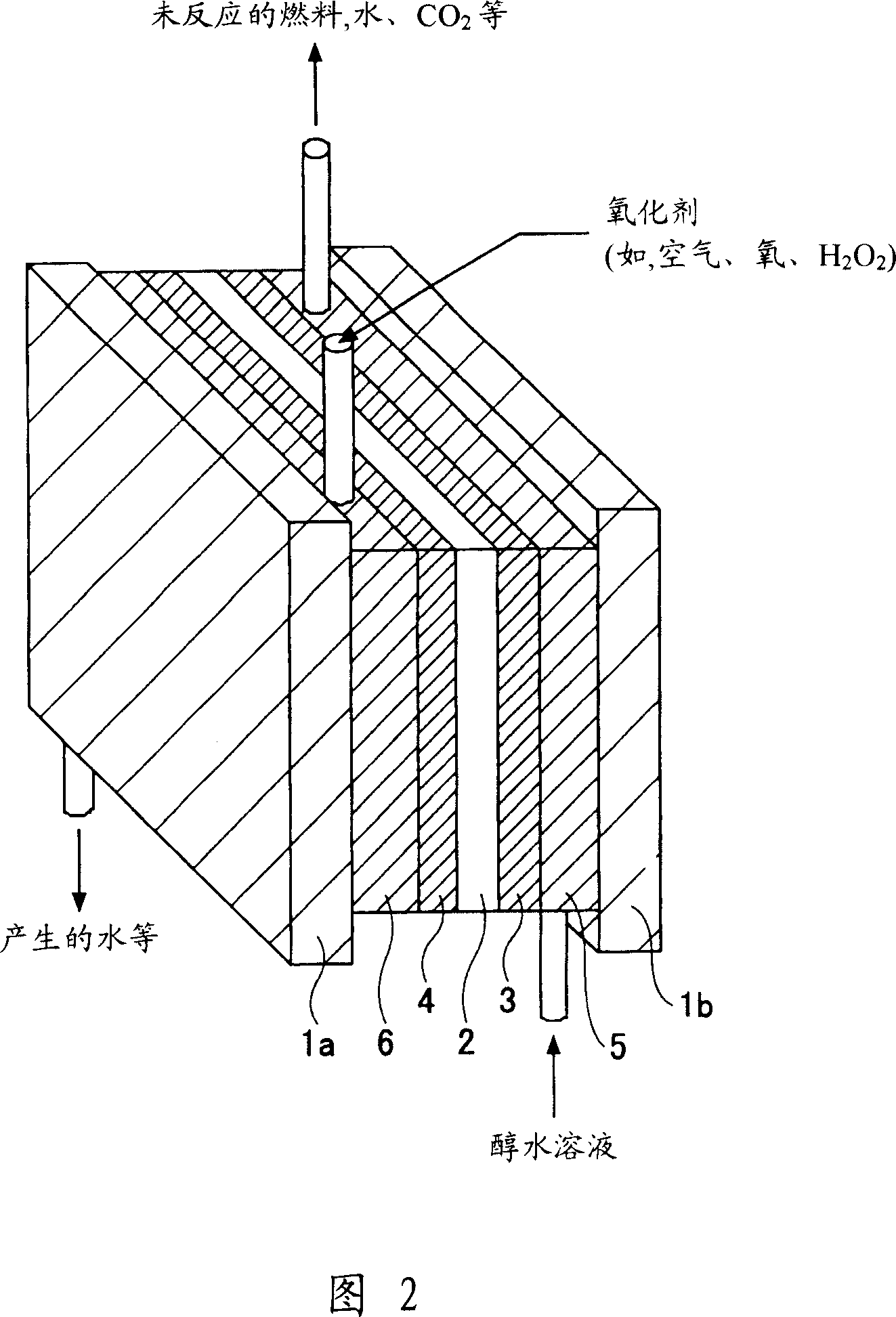

Production and producer for nanometer carbon liquid

InactiveCN1853764AUniform particle sizeEasy to prepareElectrolysis componentsMixing methodsGraphite carbonLow voltage

A process for preparing the liquid containing carbon nanoparticles includes such steps as preparing deionized water, preparing graphite carbon plate as positive electrode, arranging two metal plates as negative electrode at both sides of graphite carbon plate, immersing them in said deionized water for 24 hr, applying a low voltage (3-35 v) for 7-10 days to obtain said liquid, laying aside for 24 hr, and ultrasonic treating for 1-2 hr. Its apparatus is composed of casing, circulating pump, supporting frame, plate electrode connecting rods, and positive and negative plate electrodes.

Owner:北京天中树科技发展有限公司

Electrocatalyst for ethanol oxidation and direct ethanol fuel cell using the same

InactiveUS20080032885A1Reduce overvoltageReduce fuel costFuel cells groupingVacuum evaporation coatingTungstenDirect-ethanol fuel cell

An electrocatalyst for ethanol oxidization includes an elemental mixture containing platinum and ruthenium and at least one element, wherein the foregoing at least one element is selected from the group of tungsten, tin, molybdenum, copper, gold, manganese, and vanadium.

Owner:RICOH KK

Method for producing spinel-type lithium manganate

InactiveUS20110311436A1Excellent high-temperature cycle characteristic and rate characteristicIncrease energy densityCell electrodesLithium compoundsCrystal structureManganate

The production method of the present invention includes a raw material preparation step of preparing a raw material mixture; a firing step of firing the raw material mixture prepared through the raw material preparation step; and a crushing step of crushing the fired compact obtained through the firing step, wherein the raw material mixture contains a main raw material containing at least a manganese compound, and a seed crystal having a spinel-type crystal structure.

Owner:NGK INSULATORS LTD

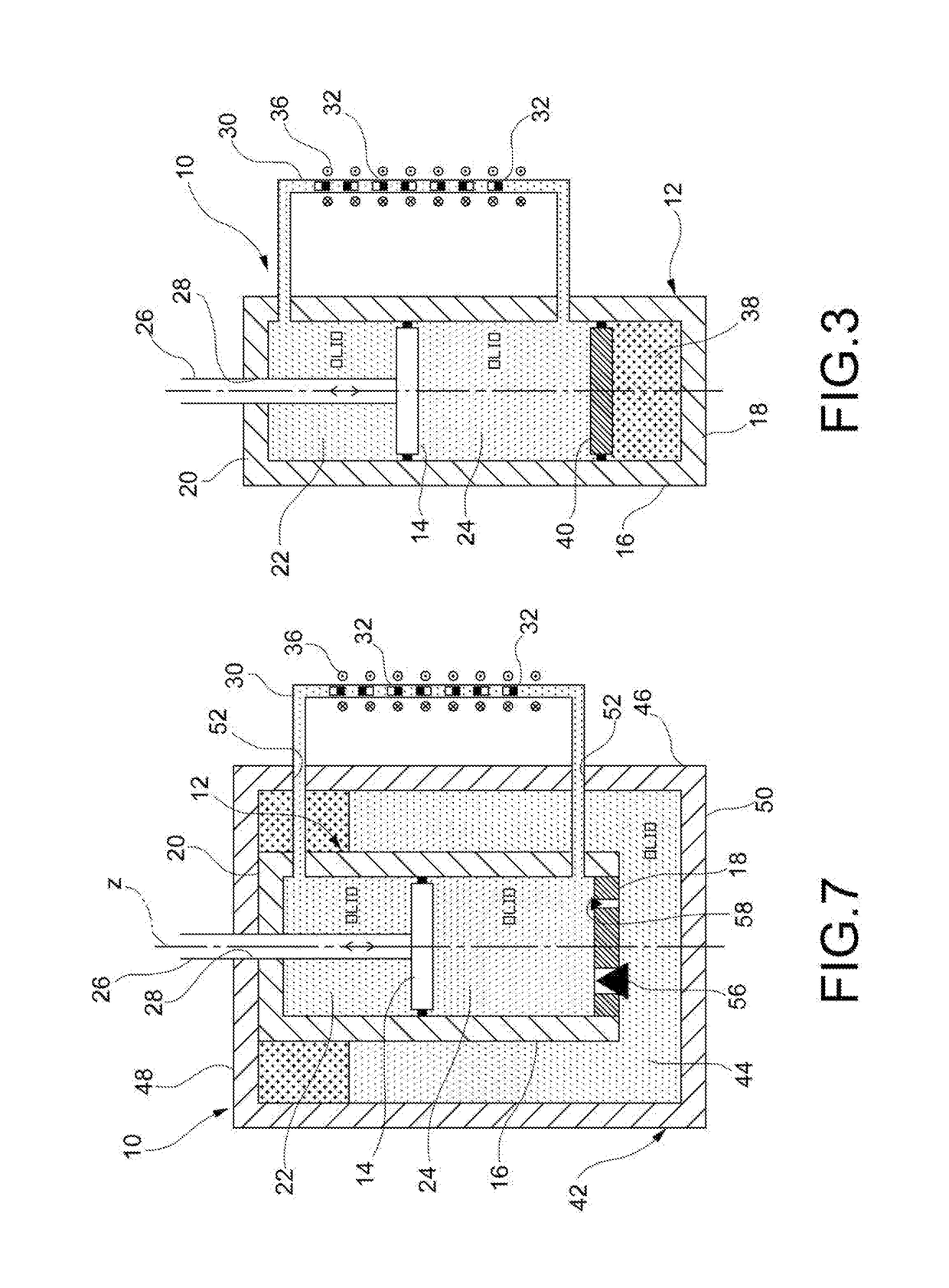

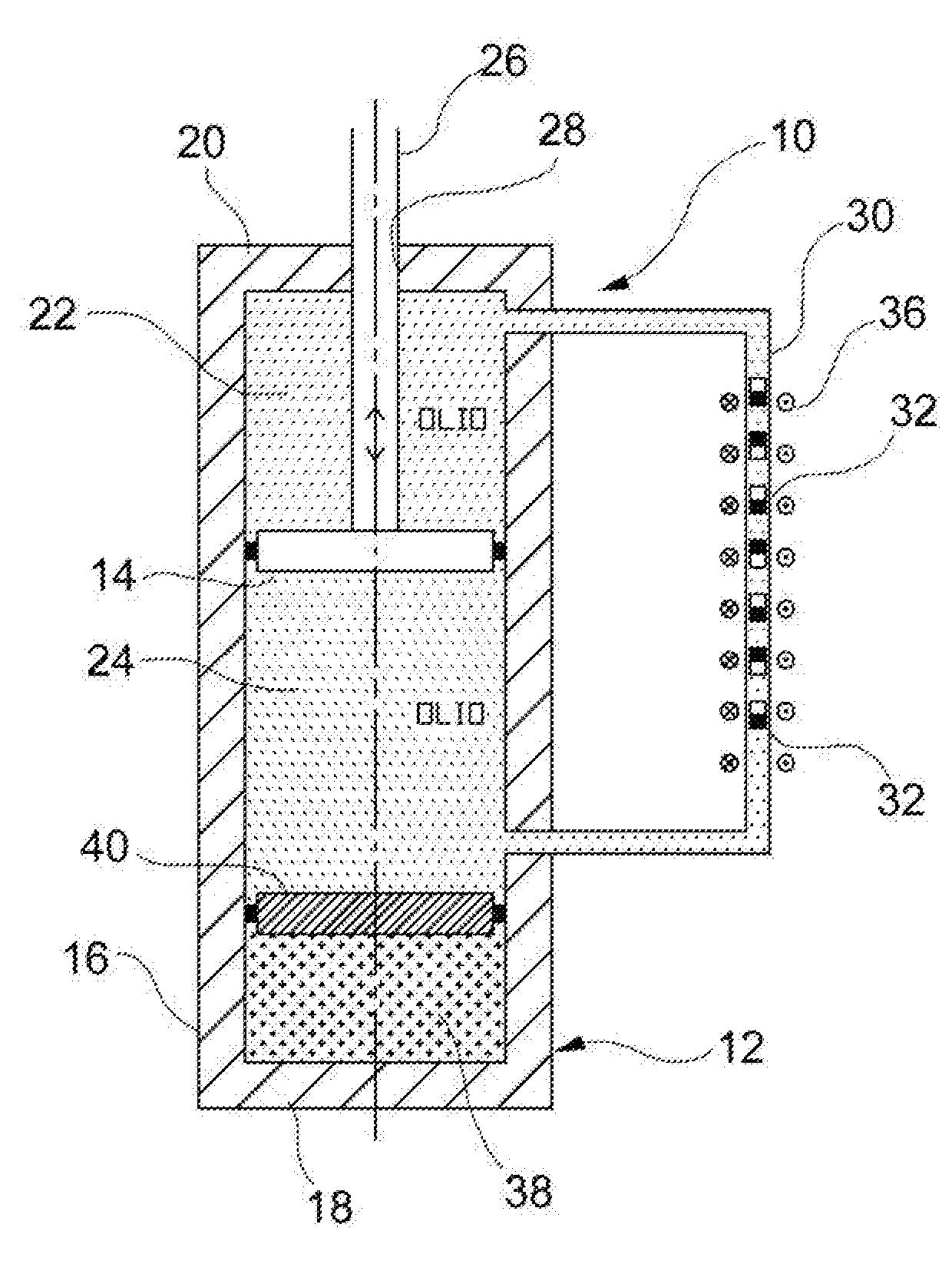

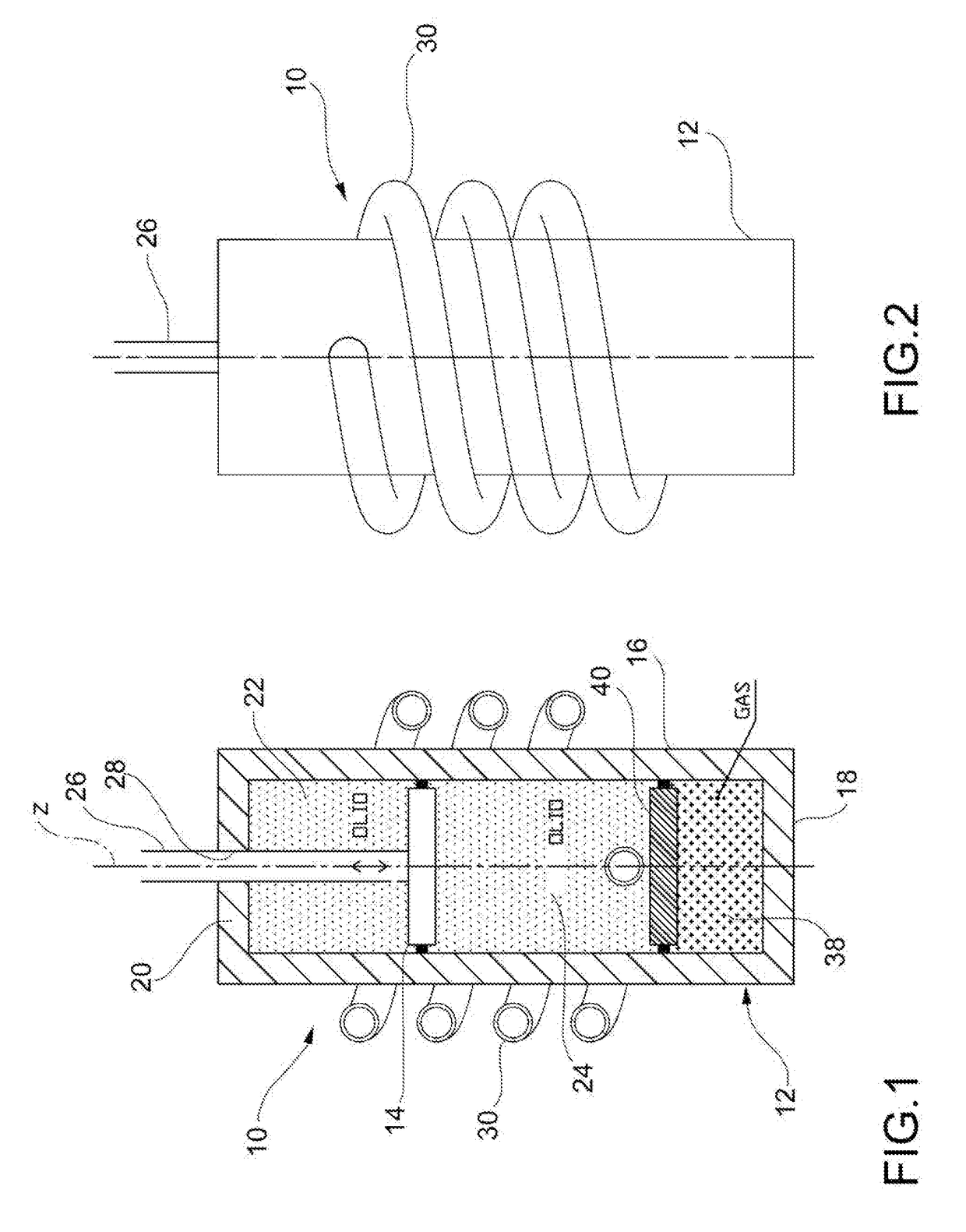

Regenerative hydraulic shock-absorber for vehicle suspension

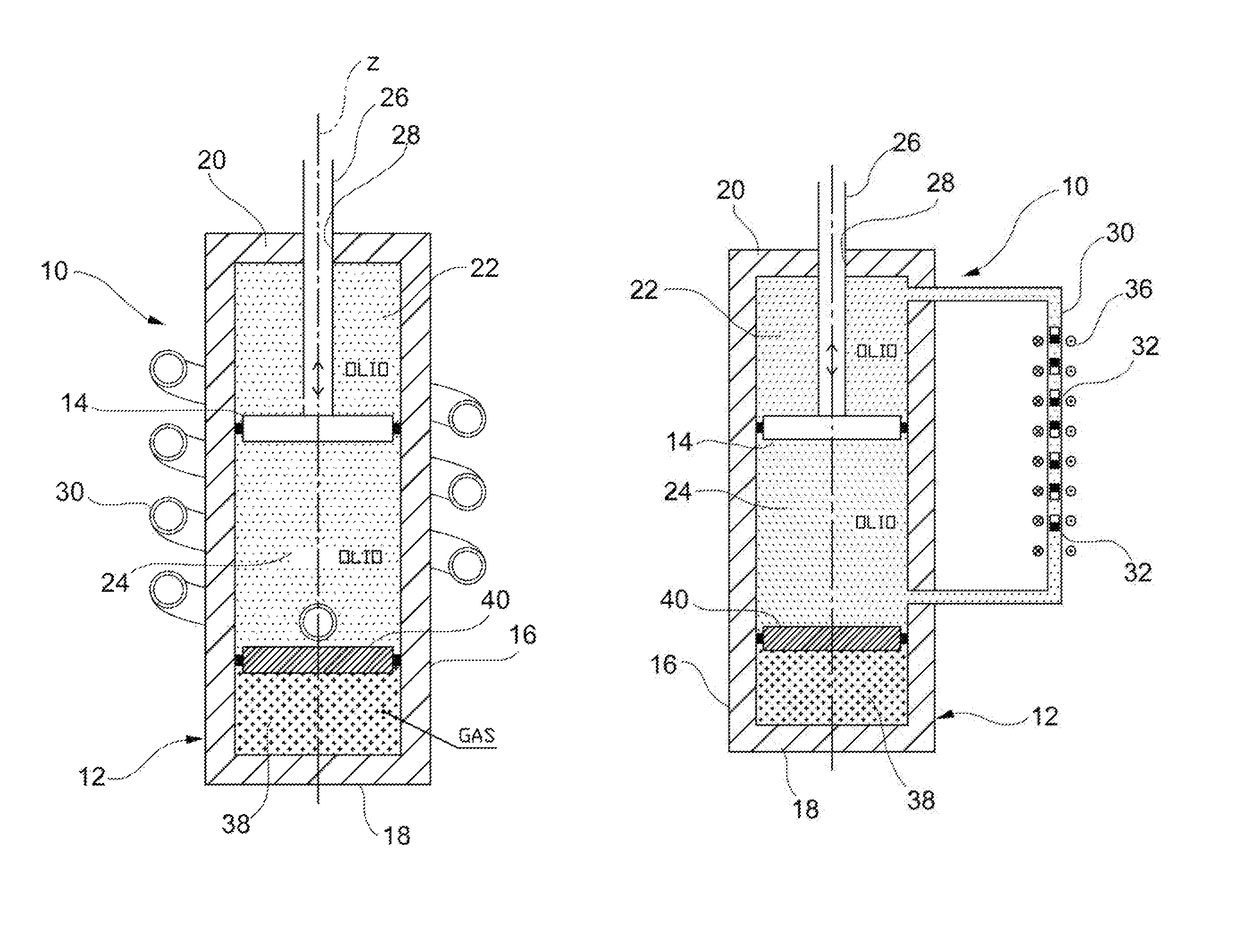

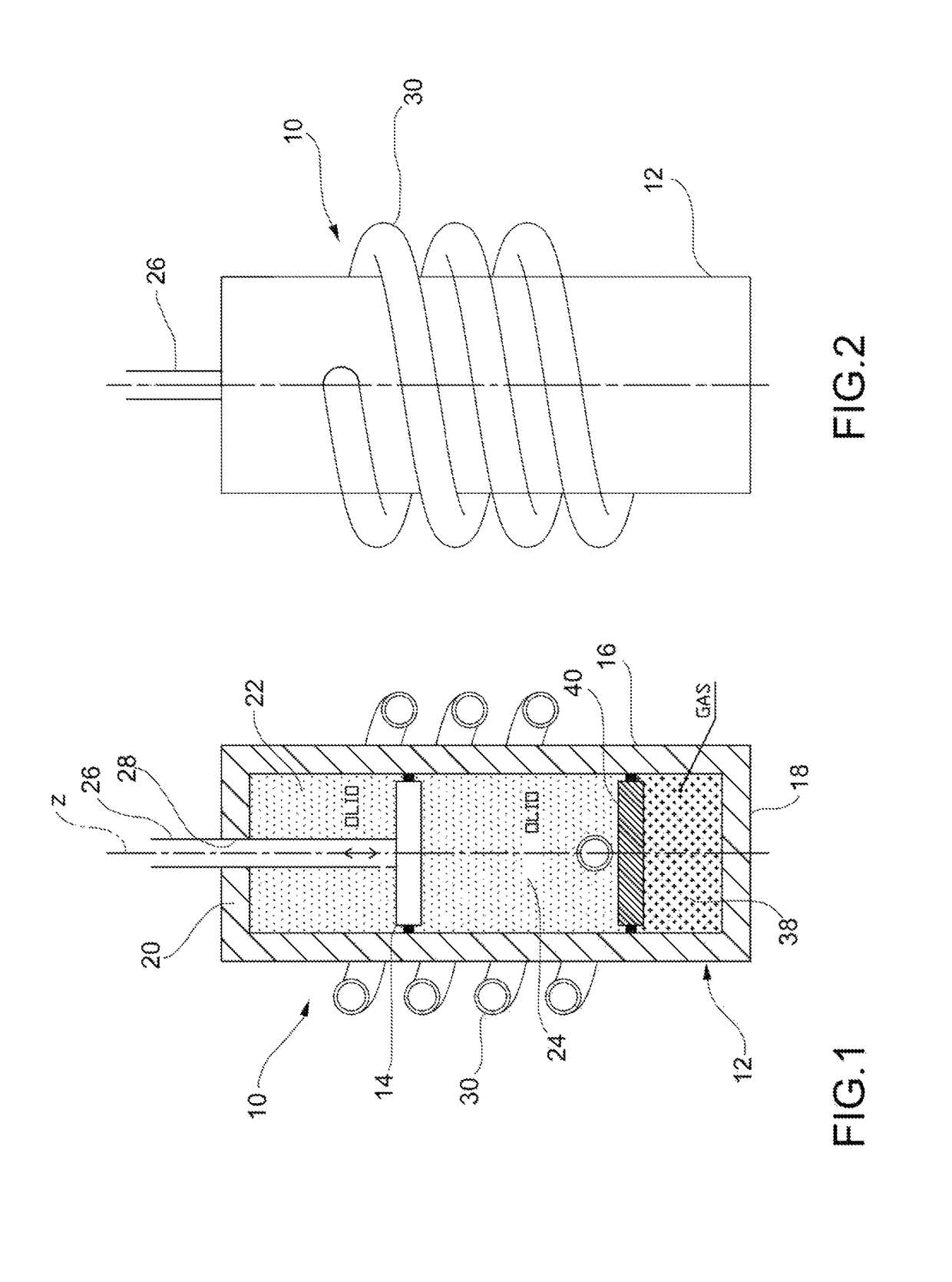

ActiveUS10052926B2Convenient lengthLarge effect speedAuxillary drivesSpringsWorking fluidReciprocating motion

The shock-absorber comprises: a cylinder containing a hydraulic working fluid; a piston slidably arranged in the cylinder so as to split the cylinder into two variable-volume working chambers, namely a first working chamber, or extension chamber, and a second working chamber, or compression chamber; an auxiliary conduit in fluid communication on one side with the first working chamber and on the other with the second working chamber; a train of permanent magnets slidably arranged in the auxiliary conduit so as to reciprocally move along the auxiliary conduit, dragged by the working fluid flowing between the first and second working chambers through the auxiliary conduit as a result of the reciprocating motion of the piston in the cylinder; and electric energy generating device for generating electric energy by exploiting the movement of the train of permanent magnets along the auxiliary conduit.

Owner:SISTEMI SOSPENSIONI SPA +1

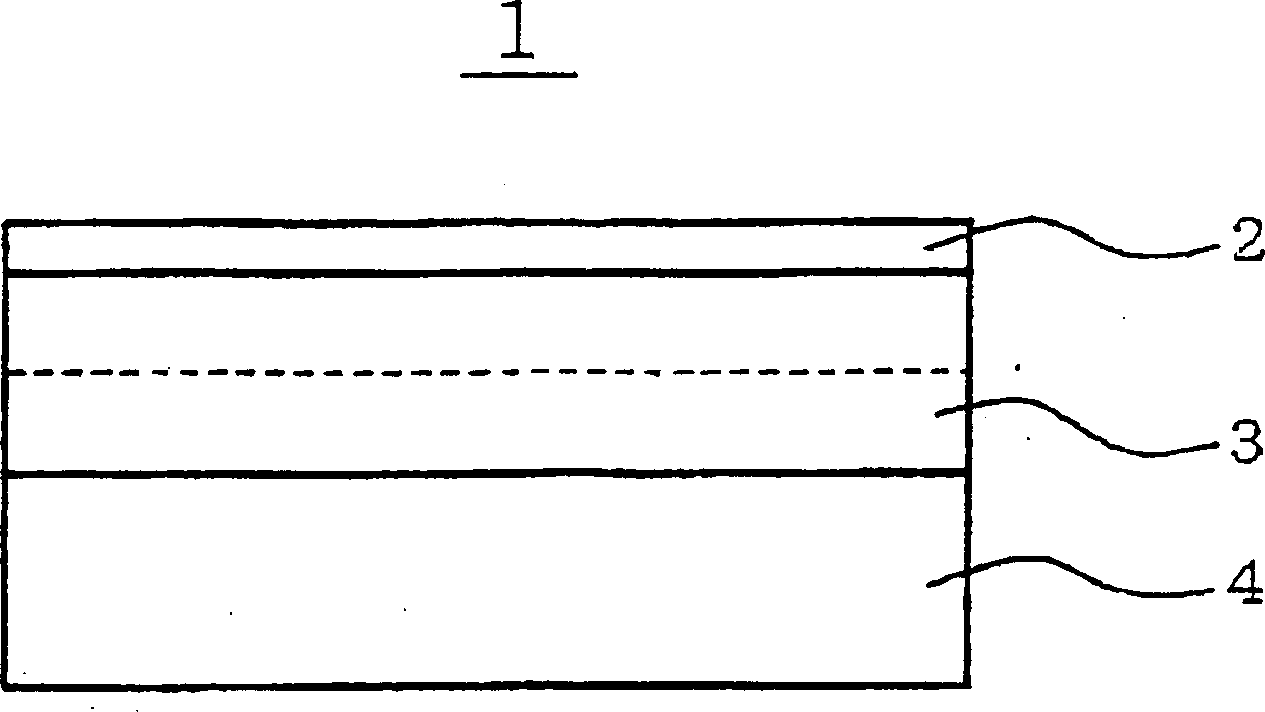

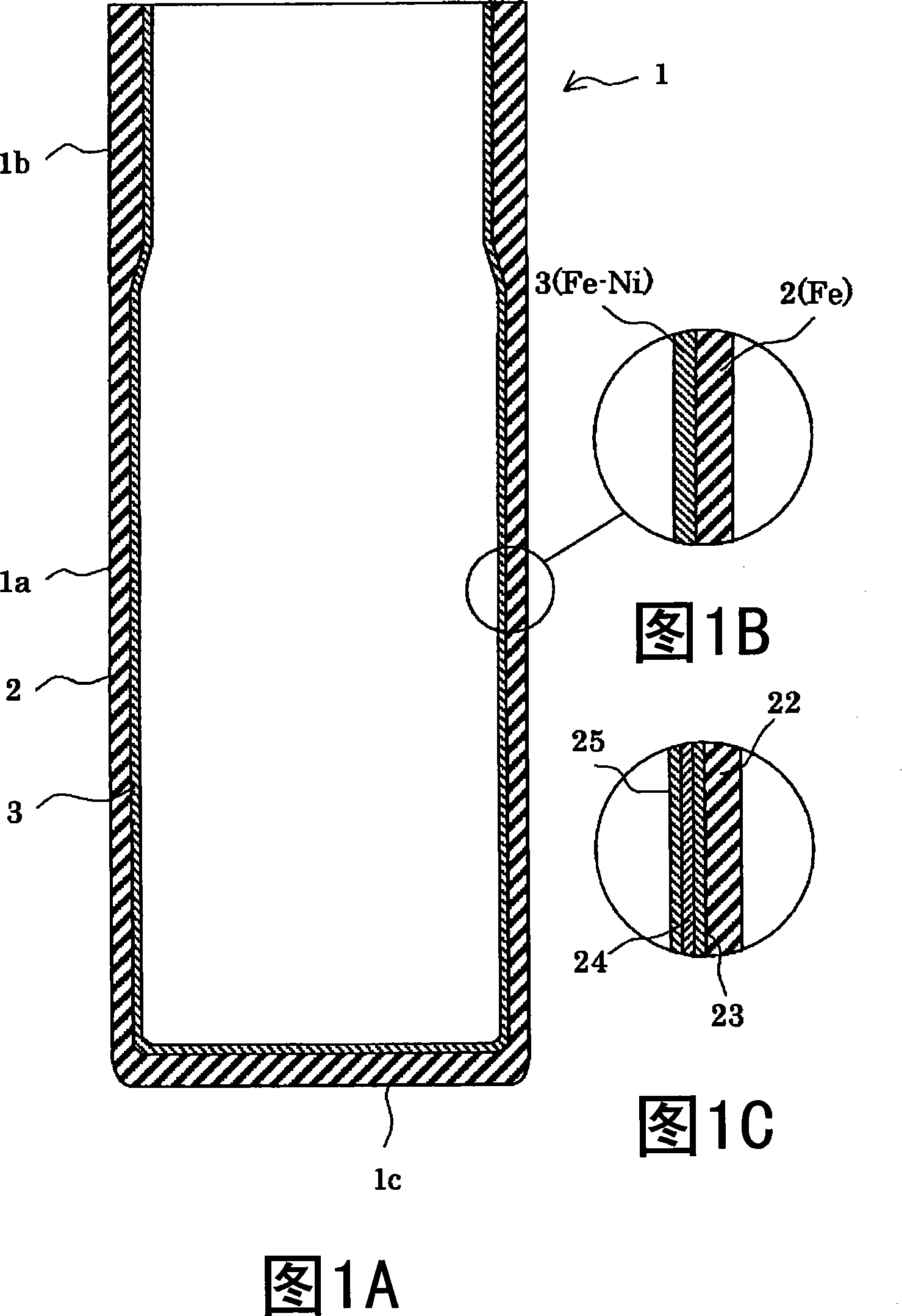

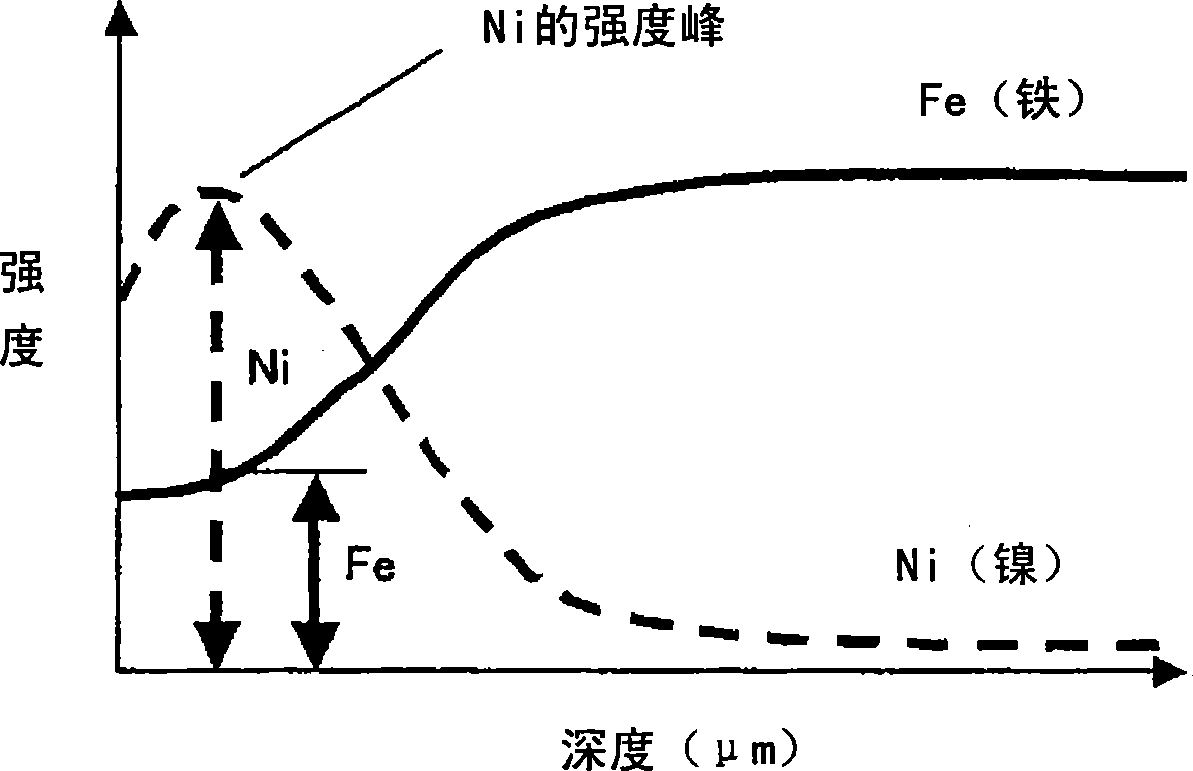

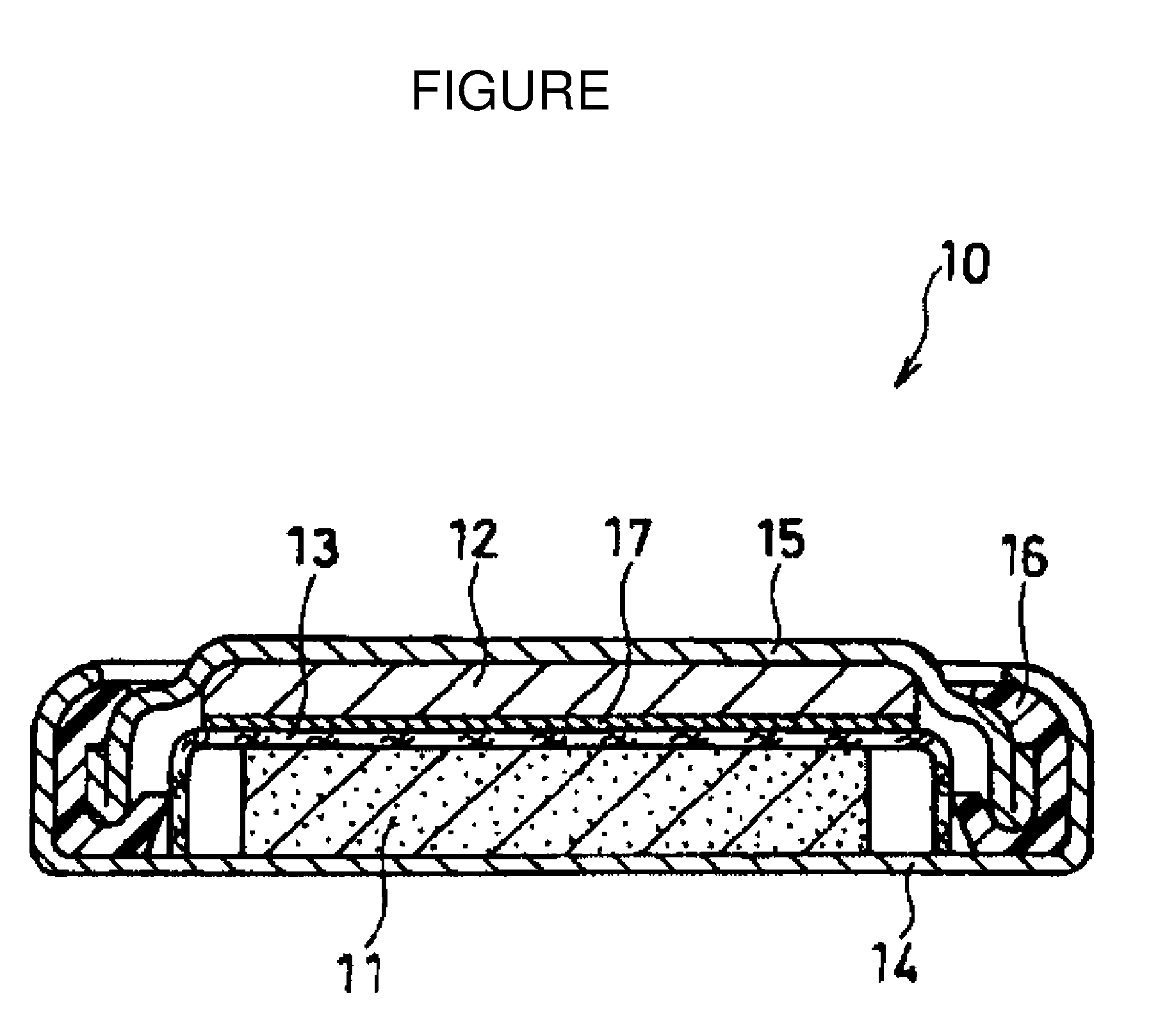

Battery can and battery using the same

InactiveCN101501884AHigh electromotive forceDissolution inhibitionFinal product manufactureJackets/cases materialsDiffusion layerErosion

An Fe-Ni diffusion layer (3) is formed on the surface of a steel sheet (2) having an Fe content of not less than 98% by weight, while regulating the Fe / Ni ratio of the Fe-Ni diffusion layer (3) within the range of 0.1-2.5; and the resulting is formed into a battery can (1) having predetermined dimensions so that the Fe-Ni diffusion layer (3) serves as the inner surface of the can. When a battery is produced by using this battery can (1), the battery has excellent liquid leakage resistance by suppressing overdischarge erosion even when only a small amount of Ni is used therein.

Owner:PANASONIC CORP

Redox flow battery

ActiveUS8288030B2Suppress generationHigh electromotive forceElectrolyte moving arrangementsRegenerative fuel cellsManganeseElectromotive force

A redox flow battery having a high electromotive force and capable of suppressing generation of a precipitation is provided. In a redox flow battery 100, a positive electrode electrolyte and a negative electrode electrolyte are supplied to a battery cell including a positive electrode 104, a negative electrode 105, and a membrane 101 interposed between the electrodes 104 and 105, to charge and discharge the battery. The positive electrode electrolyte contains a manganese ion, or both of a manganese ion and a titanium ion. The negative electrode electrolyte contains at least one type of metal ion selected from a titanium ion, a vanadium ion, a chromium ion, a zinc ion, and a tin ion. The redox flow battery 100 can suppress generation of a precipitation of MnO2, and can be charged and discharged well by containing a titanium ion in the positive electrode electrolyte, or by being operated such that the positive electrode electrolyte has an SOC of not more than 90%. In addition, the redox flow battery 100 can have a high electromotive force equal to or higher than that of a conventional vanadium-based redox flow battery.

Owner:SUMITOMO ELECTRIC IND LTD

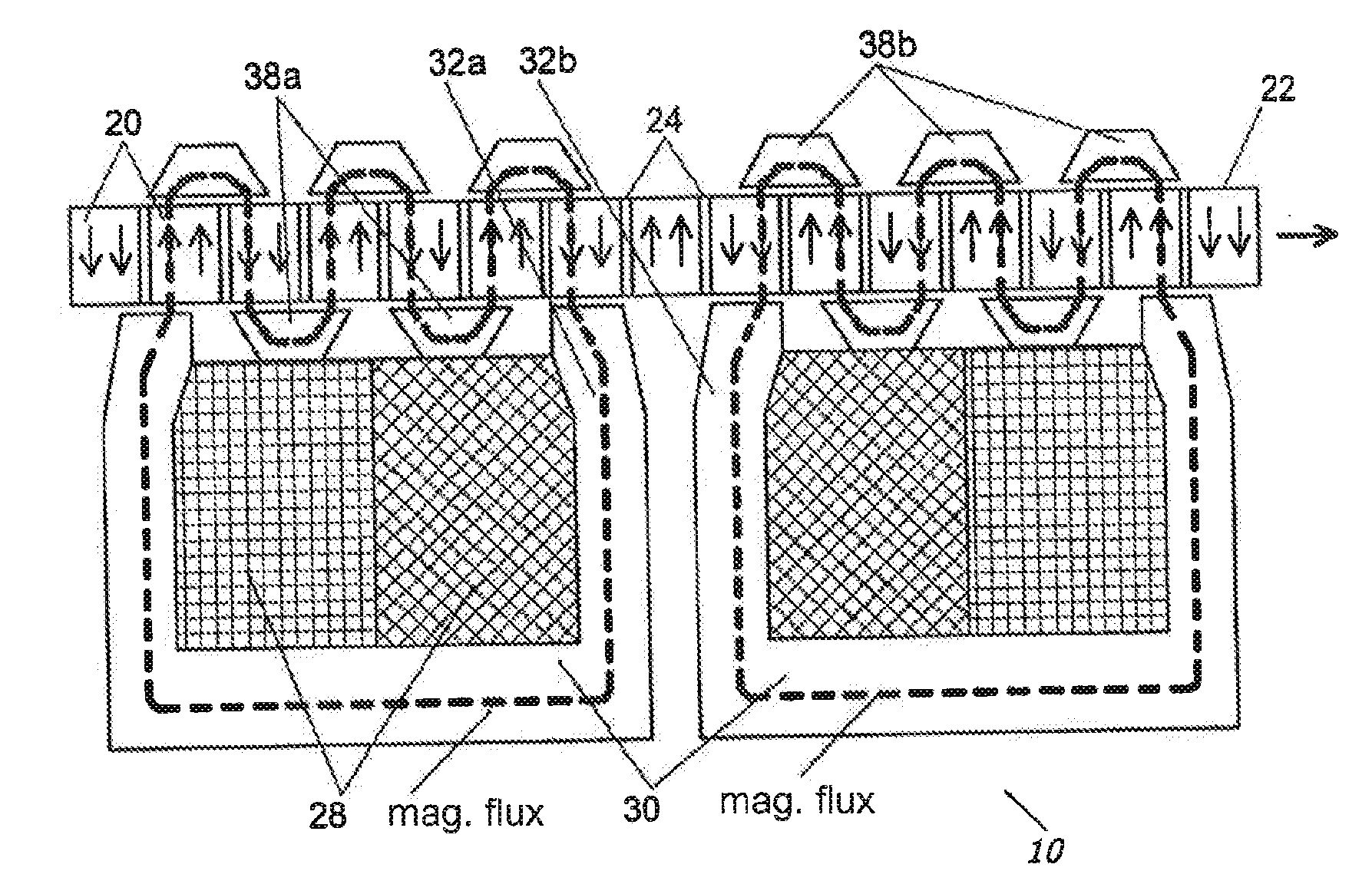

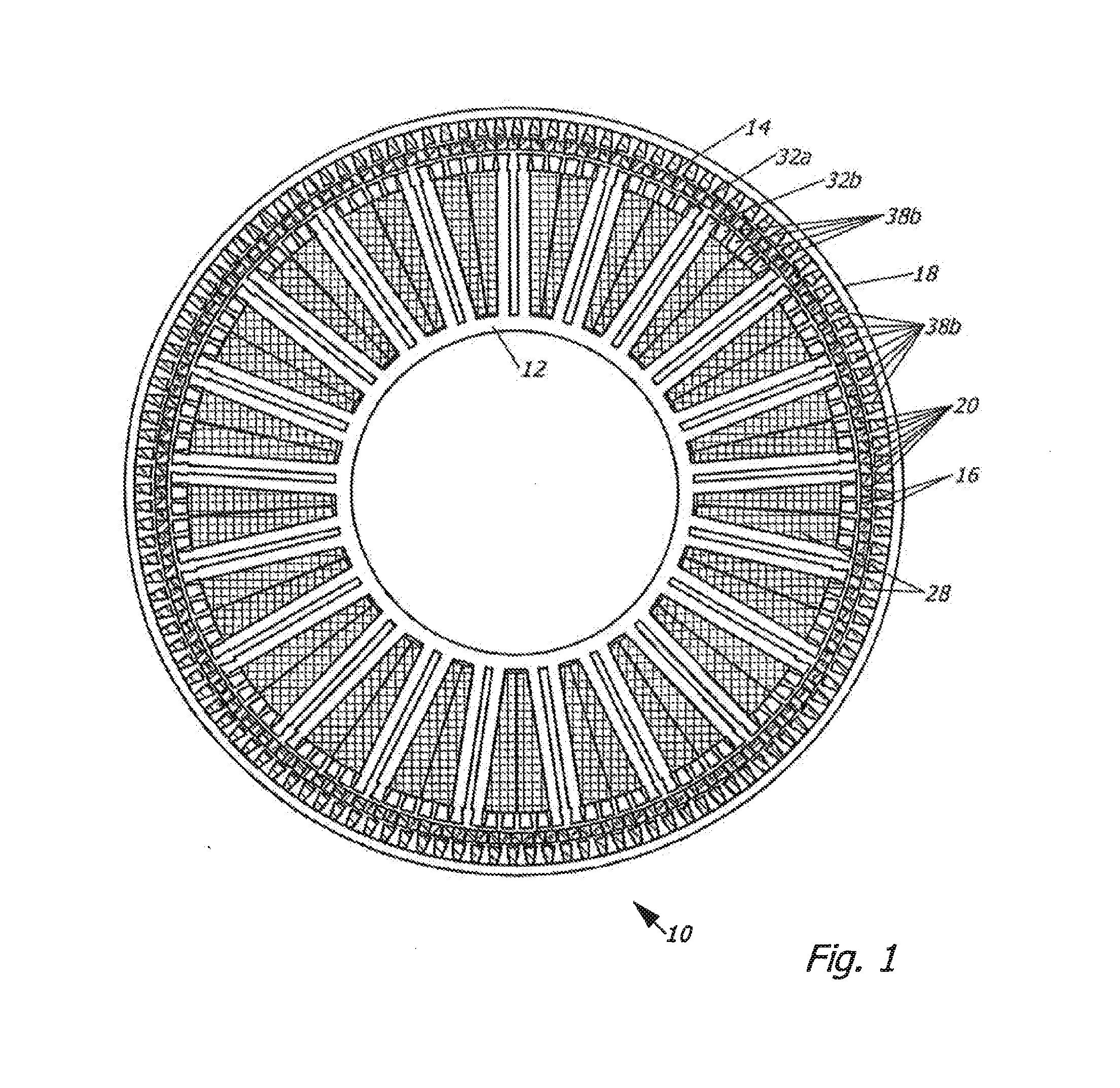

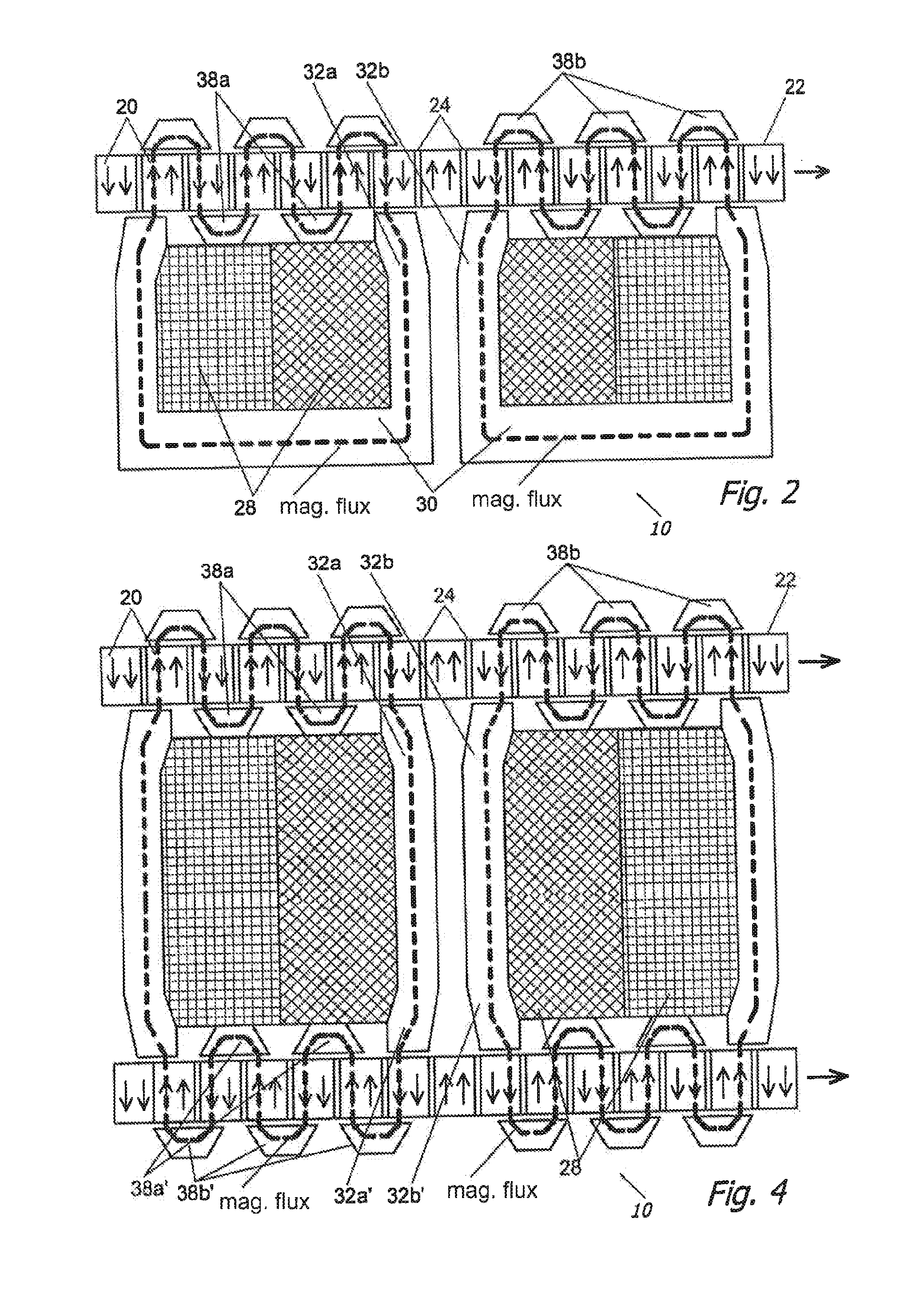

Electric machine excited by permanent magnets

InactiveUS20120242181A1Compact structureImprove efficiencySynchronous machine detailsMagnetic circuit stationary partsElectric machineHigh power density

In order to provide a compact and highly efficient electric machine having high power density, an electric machine excited by permanent magnets, comprising a stator and a rotor, is provided. The stator comprises a coil arrangement and the rotor has permanent magnet elements. The coil arrangement comprises a winding and surrounds a flux yoke. The flux yoke comprises at least one limb. Between every two limbs, flux guide parts are arranged that are spaced apart from each other and that are aligned with the ends of the limbs. Neighbouring permanent magnet elements have opposing magnetic orientations and are combined to form a magnet disc. On the side facing away from the limbs of the permanent magnet elements, flux guide parts are arranged. The limbs and the flux guide parts face the permanent magnet elements forming an air gap.

Owner:COMPACT DYNAMICS

Regenerative hydraulic shock-absorber for vehicle suspension

ActiveUS20180001728A1Maximize electromotive forceControl lengthAuxillary drivesSpringsElectric energyWorking fluid

The shock-absorber comprises: a cylinder containing a hydraulic working fluid; a piston slidably arranged in the cylinder so as to split the cylinder into two variable-volume working chambers, namely a first working chamber, or extension chamber, and a second working chamber, or compression chamber; an auxiliary conduit in fluid communication on one side with the first working chamber and on the other with the second working chamber; a train of permanent magnets slidably arranged in the auxiliary conduit so as to reciprocally move along the auxiliary conduit, dragged by the working fluid flowing between the first and second working chambers through the auxiliary conduit as a result of the reciprocating motion of the piston in the cylinder; and electric energy generating device for generating electric energy by exploiting the movement of the train of permanent magnets along the auxiliary conduit.

Owner:SISTEMI SOSPENSIONI SPA +1

Electrocatalyst for ethanol oxidation and direct ethanol fuel cell using the same

InactiveUS7960070B2High electromotive forceIncrease productionFuel cells groupingVacuum evaporation coatingPlatinumFuel cells

An electrocatalyst for ethanol oxidization includes an elemental mixture containing platinum and ruthenium and at least one element, wherein the foregoing at least one element is selected from the group of tungsten, tin, molybdenum, copper, gold, manganese, and vanadium.

Owner:RICOH KK

Redox flow battery and method of operating the same

ActiveUS8632903B2High electromotive forceReduce capacityCell electrodesFuel cell auxillariesEngineeringCharge and discharge

A redox flow battery in which a positive electrode electrolyte stored in a positive electrode tank and a negative electrode electrolyte stored in a negative electrode tank are supplied to a battery element to charge and discharge the battery is provided, the positive electrode electrolyte in the redox flow battery containing a Mn ion as a positive electrode active material, the negative electrode electrolyte containing at least one of a Ti ion, a V ion, and a Cr ion as a negative electrode active material, in which the redox flow battery includes a negative-electrode-side introduction duct in communication with inside of the negative electrode tank from outside thereof, for introducing oxidizing gas into the negative electrode tank, and a supply mechanism for supplying the oxidizing gas into the negative electrode tank via the negative-electrode-side introduction duct.

Owner:SUMITOMO ELECTRIC IND LTD

Lithium primary battery

InactiveUS20160344039A1High electromotive forceExcellent high-temperature storage characteristicOrganic electrolyte cellsPrimary cell electrodesAlloyLithium-ion battery

A lithium primary battery including a negative electrode including metal lithium and / or a lithium alloy, a positive electrode including a positive electrode active material, a separator interposed between the negative electrode and the positive electrode, and a nonaqueous electrolyte. The positive electrode active material includes Fe2(SO4)3. The negative electrode has a coating layer on a facing surface facing the positive electrode, and the coating layer includes a powder or fibrous material.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Method for producing spinel-type lithium manganate

InactiveUS20110311437A1Excellent high-temperature cycle characteristic and rate characteristicIncrease energy densityLithium oxides/hydroxidesManganates/permanganatesManganateManganese

The production method of the present invention includes (A) a forming step of forming into a sheet-like compact a raw material containing at least a manganese compound and not containing a lithium compound; (B) a first firing step of firing the sheet-like compact formed through the forming step; and (C) a second firing step of firing a mixture of the fired compact obtained through the first firing step and a lithium compound at a temperature lower than the firing temperature employed in the first firing step.

Owner:NGK INSULATORS LTD

Solid electrolyte including layered metal oxide, fuel cell including thereof, production method for solid electrolyte, and production method for electrode catalyst

ActiveUS8986894B2High electromotive forceSolve the lack of densityCell electrodesSolid electrolyte cellsRare-earth elementFuel cells

A solid electrolyte including a layered metal oxide represented by the formula (1),(La1-xAx)(Sr1-yBy)3(Co1-zCz)3O10-δ (1)[wherein A represents a rare earth element other than La; B represents Mg, Ca, or Ba; C represents Ti, V, Cr, or Mn; 0≦x<1, 0≦y<1, 0≦z<1; and δ represents an oxygen deficiency amount].

Owner:TOYOTA JIDOSHA KK +1

Method for producing spinel-type lithium manganate

InactiveUS20110311435A1High crystallinityEfficient millingManganates/permanganatesManganeseManganate

Owner:NGK INSULATORS LTD

Electrode catalyst, method for manufacturing the same, and direct alcohol fuel cell

InactiveCN1922746AReduce usageHigh electromotive forceFuel cells groupingCell electrodesPlatinumPtru catalyst

Owner:RICOH KK

Quantum carbon and its preparation method and implementation equipment

ActiveCN104261383BGood dispersionSynthetic size controllableMaterial nanotechnologyMixing methodsDouble bondOxygen compound

The invention relates to a quantum carbon, comprising carbon particles with a particle size of 0.6-100nm, the carbon particles are single carbon and / or graphene particles, and the surface layer of the carbon particles contains carbon, hydrogen, Oxygen and nitrogen compounds, the compounds containing carbon, hydrogen, oxygen and nitrogen include condensed aromatic hydrocarbons, compounds containing carbon-oxygen single bonds, compounds containing carbon-oxygen double bonds, and compounds containing carbon-hydrogen bonds. The invention also discloses a quantum carbon solution, the quantum carbon solution is an aqueous solution containing quantum carbon, the ORP of the quantum carbon solution is 280mv-380mv, the conductivity σ is 1-5ms / cm, and the electromotive force It is 280mv~380mv, the pH value is 1.5-3.2, and the concentration is 0.1%-0.45%. The invention also discloses a device and a method for preparing the quantum carbon. The invention has the advantages of simple process, low cost, easy control, easy realization of large-scale production, no generation of three wastes, uniform particle size of produced carbon particles, and stable product quality.

Owner:北京三昌宇恒科技发展有限公司

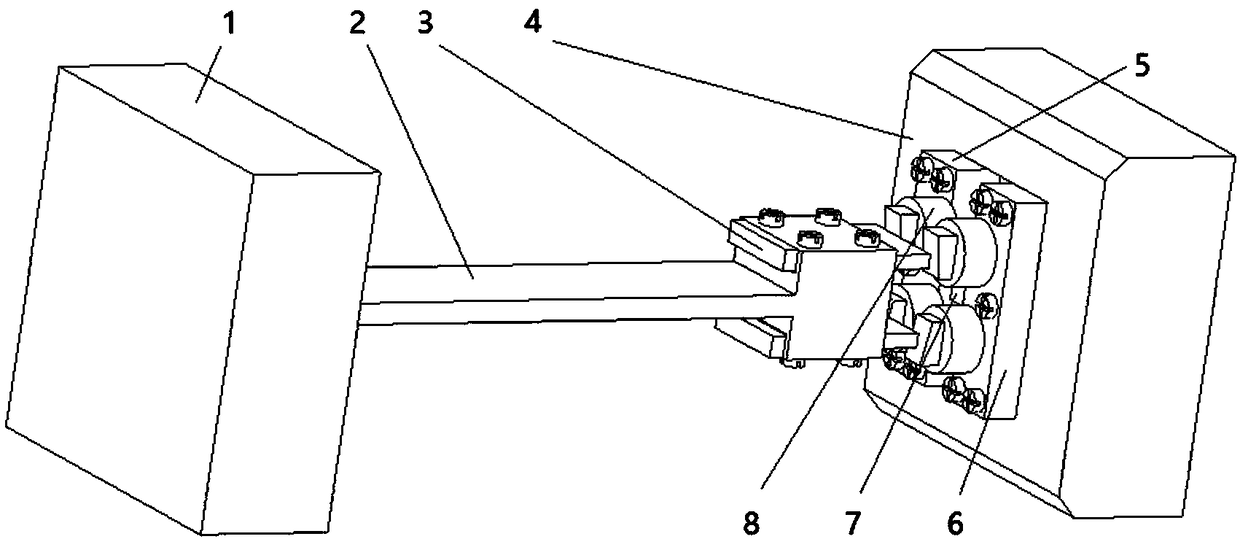

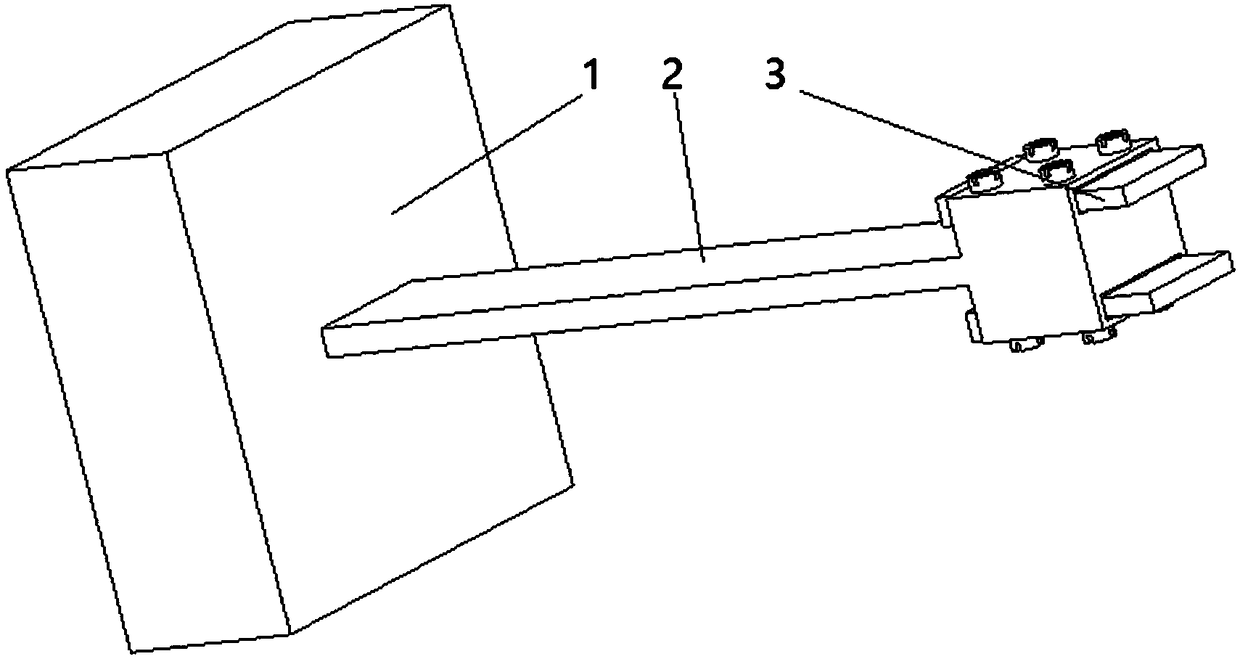

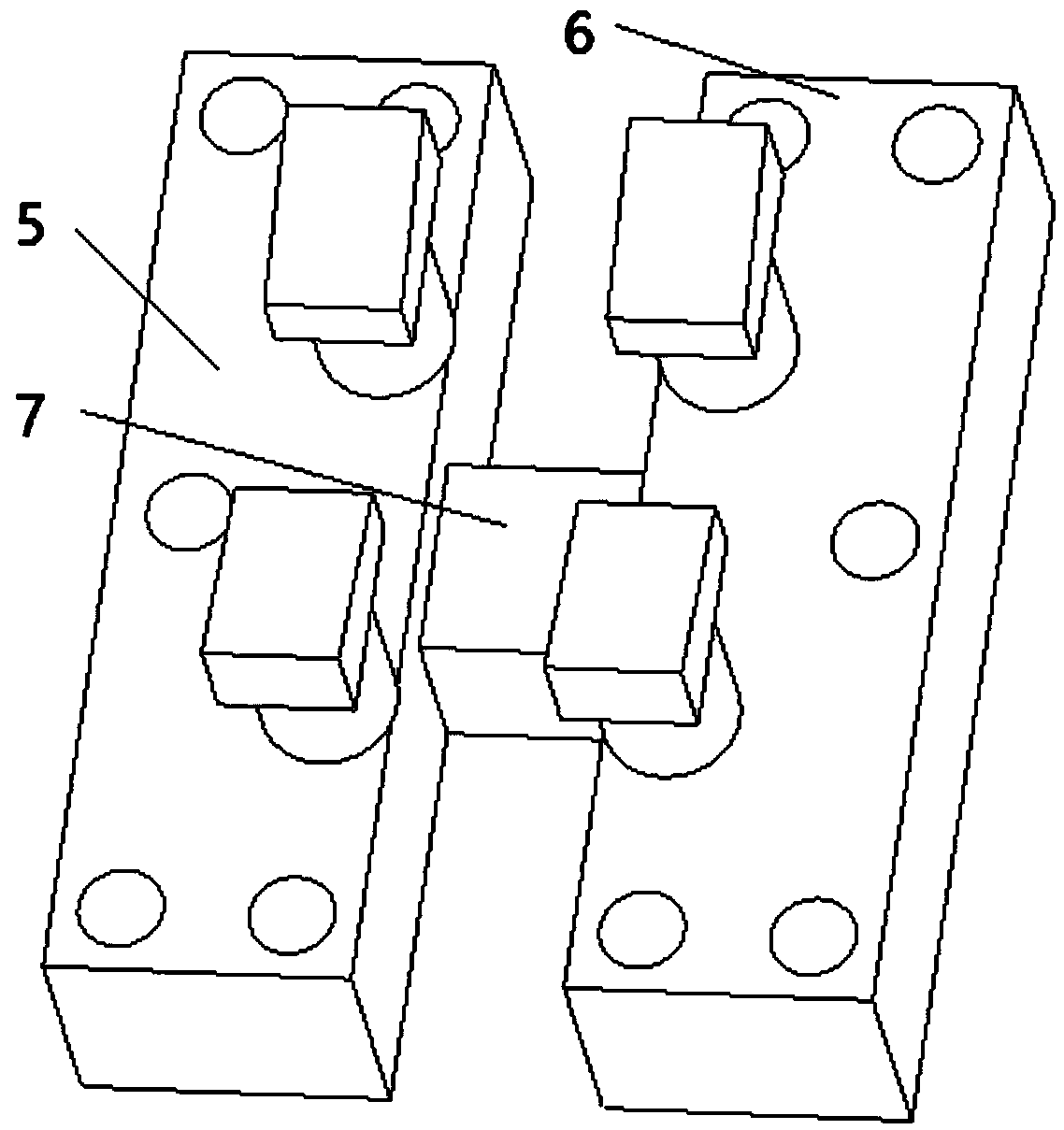

Free-end magnetic circuit adjusting cantilever beam vibration energy collecting device

PendingCN108631537AIncreased reluctanceReduce magnetic inductionDynamo-electric machinesCantilevered beamEnergy conversion efficiency

A free-end magnetic circuit adjusting cantilever beam vibration energy collecting device is disclosed. One end of a cantilever beam is inserted into and is fixedly arranged on the fixing end of the cantilever beam. The cross section of the cantilever beam is in a rectangular shape. The tail of the cantilever beam is provided with a counterweight. Two cantilever beam magnet yokes are installed andfixed on the counterweight. A permanent magnet fixing end is close to the free end of the cantilever beam. The fixing end of a permanent magnet is horizontally and symmetrically installed and fixed with a left permanent magnet yoke and a right permanent magnet yoke. A gap is arranged between the left permanent magnet yoke and the right permanent magnet yoke. One side of the left permanent magnet yoke and one side of the right permanent magnet yoke, which are close to the cantilever beam, are provided with two coil supports which are vertically distributed respectively. The left permanent magnet yoke and the right permanent magnet yoke are installed with the permanent magnets. An induction coil is wound on the installation shaft of the two coil supports in each of the left permanent magnetyoke and the right permanent magnet yoke. The two leading-out terminals of the induction coil are connected to an energy collecting circuit. In the invention, energy conversion efficiency is high andvibration damping is small.

Owner:ZHEJIANG UNIV OF TECH

Nanometer chitosan compound/fiber composite diaphragm for lithium battery and preparation method of diaphragm

InactiveCN104953069ASimple production processLess investmentCell component detailsFiberElectrolytic agent

The invention belongs to the field of manufacturing of lithium batteries, and in particular relates to a nanometer chitosan compound / fiber composite diaphragm for a lithium battery and a preparation method of the diaphragm. According to the invention, an ionic polymer membrane material is formed by loading and combining of nanometer chitosan compound particles and natural non-woven fiber; the natural non-woven fiber is adopted as a support, and the nanometer chitosan compound / fiber composite diaphragm is obtained through rolling and drying (at 40-50 EG C), wherein the thickness of the nanometer chitosan compound / fiber composite diaphragm is 5-60 micrometers. The nanometer chitosan compound / fiber composite diaphragm has excellent three-dimensional network conformation, and the porosity is 80% or above; the nanometer chitosan compound / fiber composite diaphragm has no stress effect or form memory effect. The nanometer chitosan compound / fiber composite diaphragm has chemical stability, form dimensional stability, thermal stability, insulativity and excellent physical mechanical strength: fracture length(Km):4.3, and annular pressure index (kgf / 152mm / Nm / g):11.92 in electrolyte and under -40 DEG C to 150 DEG C, and has excellent adsorption affinity with the electrolyte. The nanometer chitosan compound / fiber composite diaphragm has positive charge characteristics, and can provide a free channel for positive electric lithium ions.

Owner:SICHUAN XIDANFO LITHIUM BATTERY +1

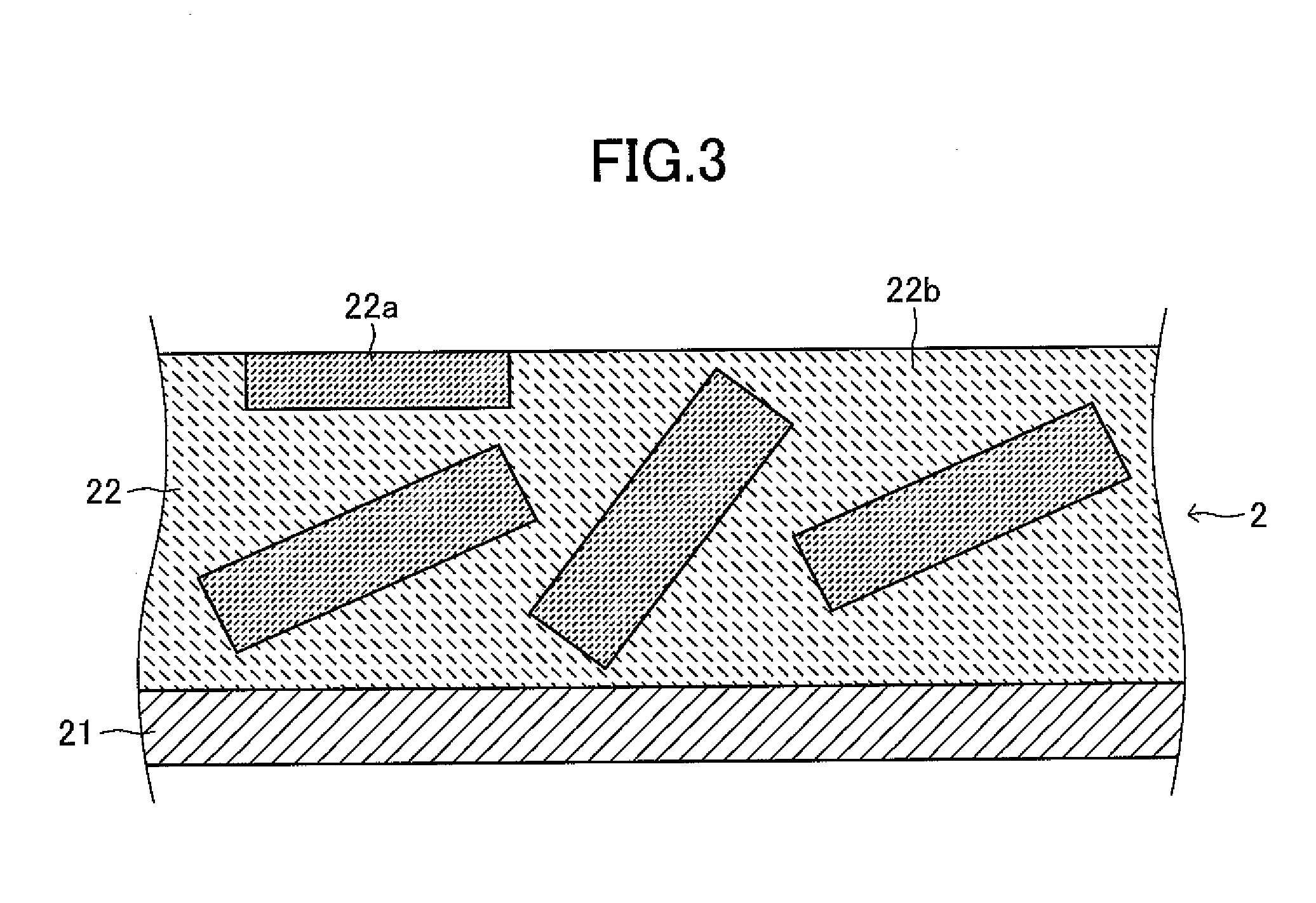

Positive electrode active material, method for producing the same, and electrochemical device

ActiveUS9413005B2High electromotive forceAbundant resourcesOrganic electrolyte cellsPositive electrodesHigh energyPERMANGANATE ION

The invention provides a high-capacity positive electrode active material capable of sufficiently exploiting the excellent characteristics of magnesium metal or the like as a negative electrode active material, such as high energy capacity; a method for producing the same; and an electrochemical device using the positive electrode active material. A positive electrode 11 includes a positive electrode can 1, a positive pole pellet 2 having a positive electrode active material and the like, and a metal mesh support 3. A negative electrode 12 includes a negative electrode cap 4 and a negative electrode active material 5 such as magnesium metal. The positive electrode pellet 2 and the negative electrode active material 5 are disposed so as to sandwich a separator 6, and an electrolyte 7 is injected into the separator 6. The positive electrode active material, which provides the feature of the invention, is synthesized by a step of reacting a permanganate, such as potassium permanganate, with hydrochloric acid preferably having a concentration of 3 to 4 mol / l to produce a precipitate, and a step of filtering the precipitate, thoroughly washing the filtered precipitate with water, and then subjecting the washed precipitate to heat treatment preferably at a temperature of 300 to 400° C. for not less than 2 hours, thereby giving a manganese oxide.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com