Patents

Literature

41results about How to "Efficient milling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

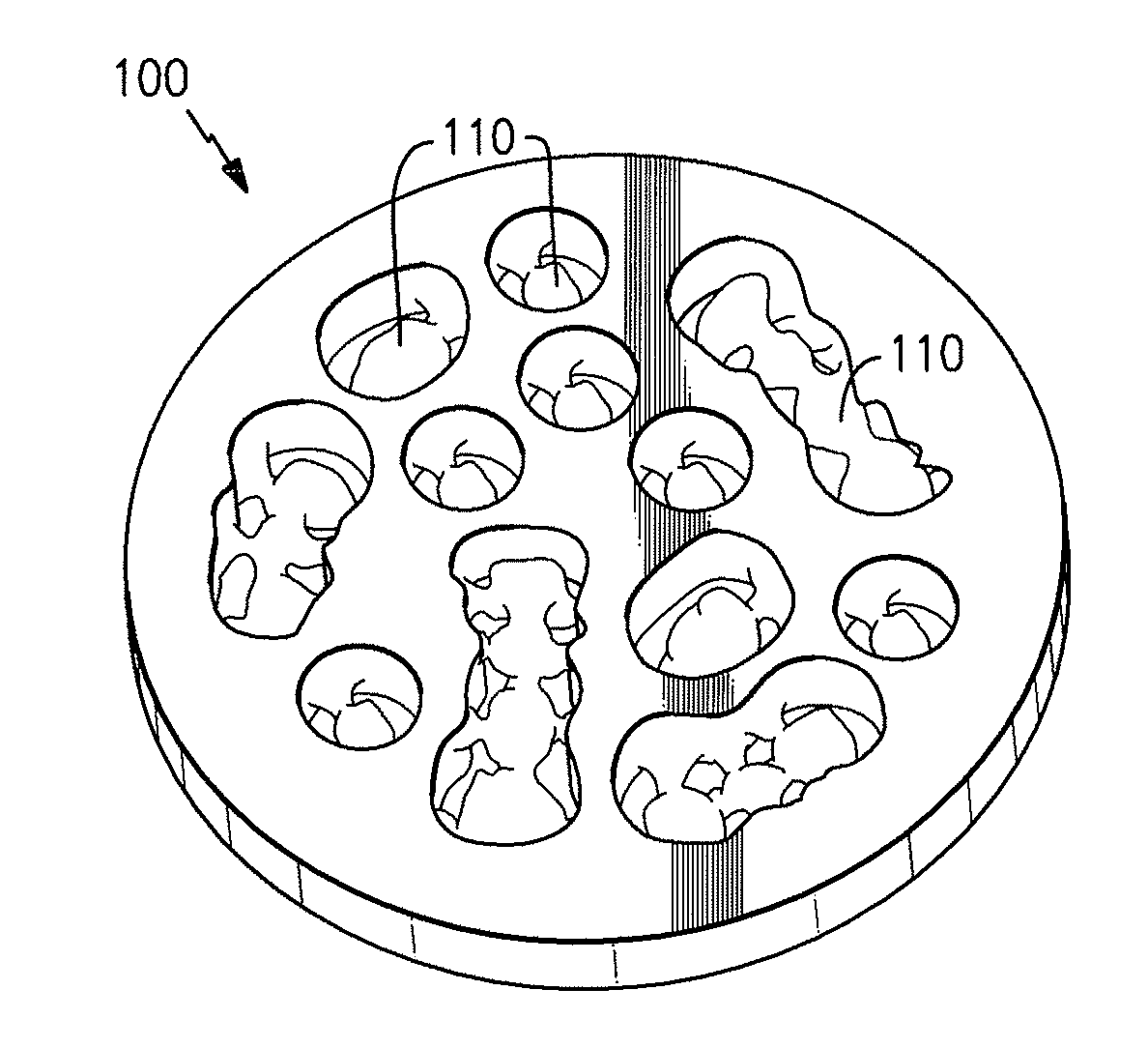

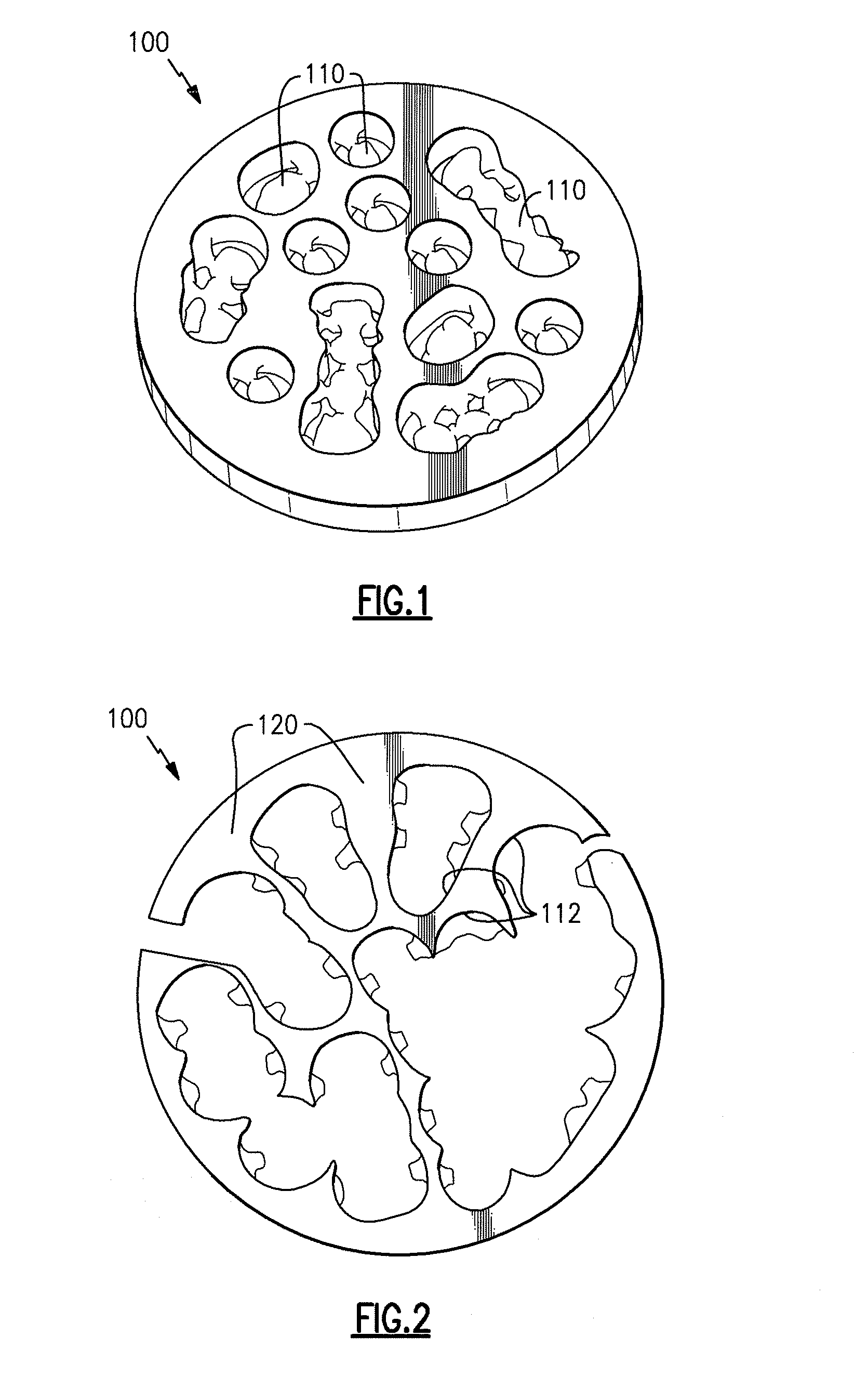

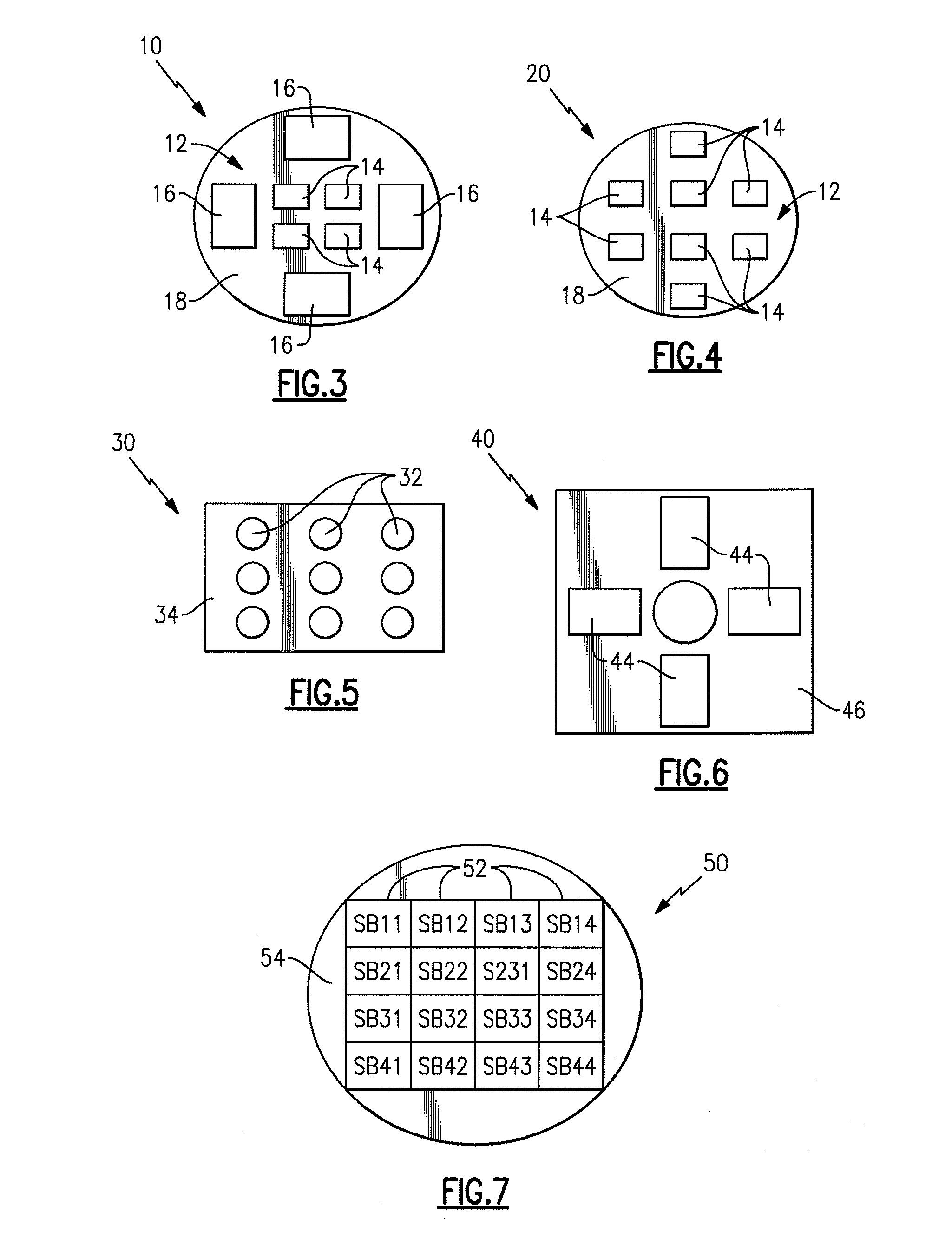

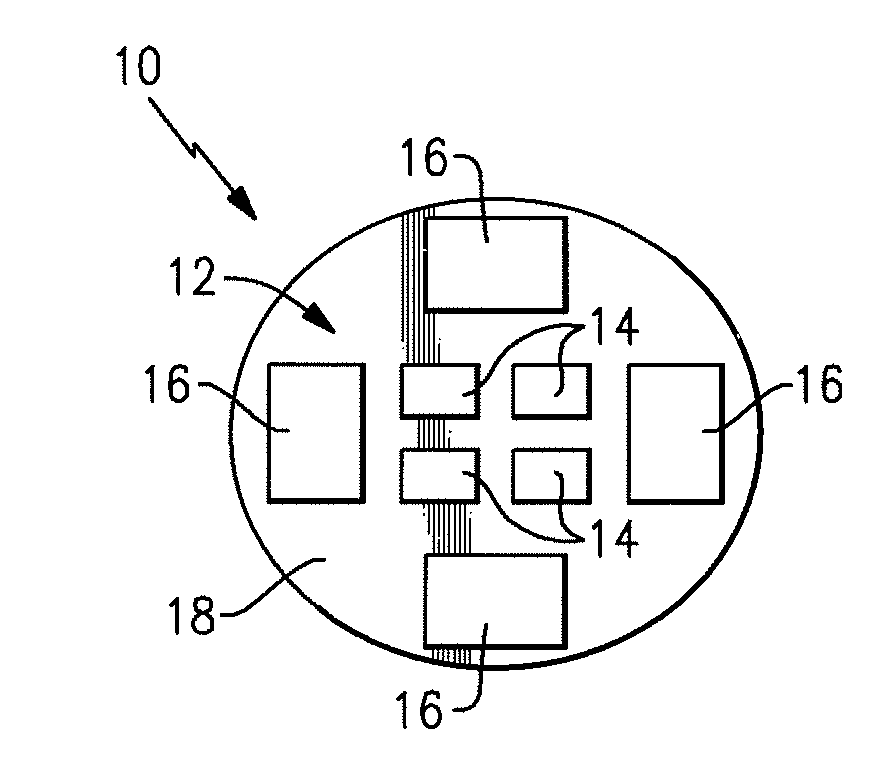

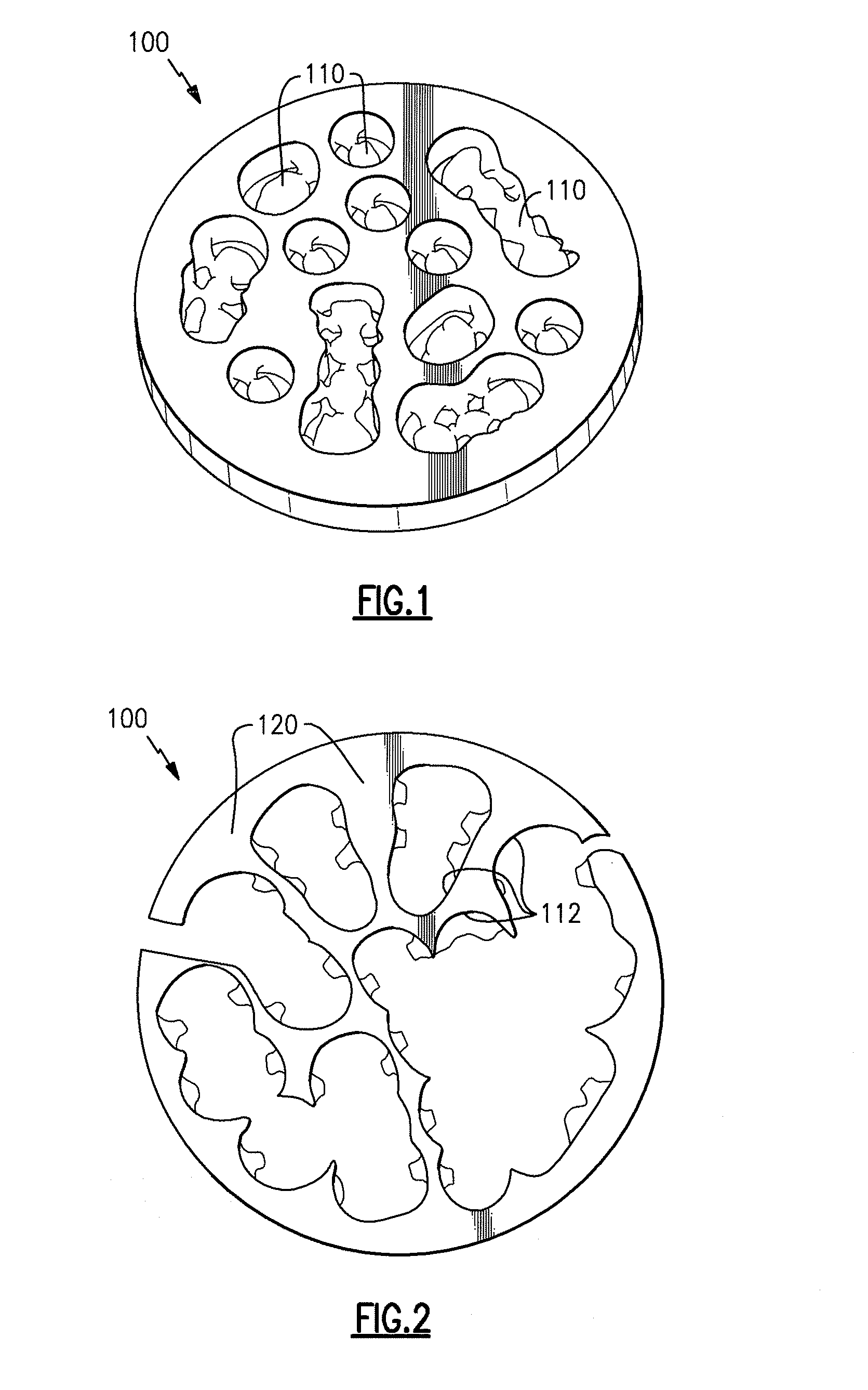

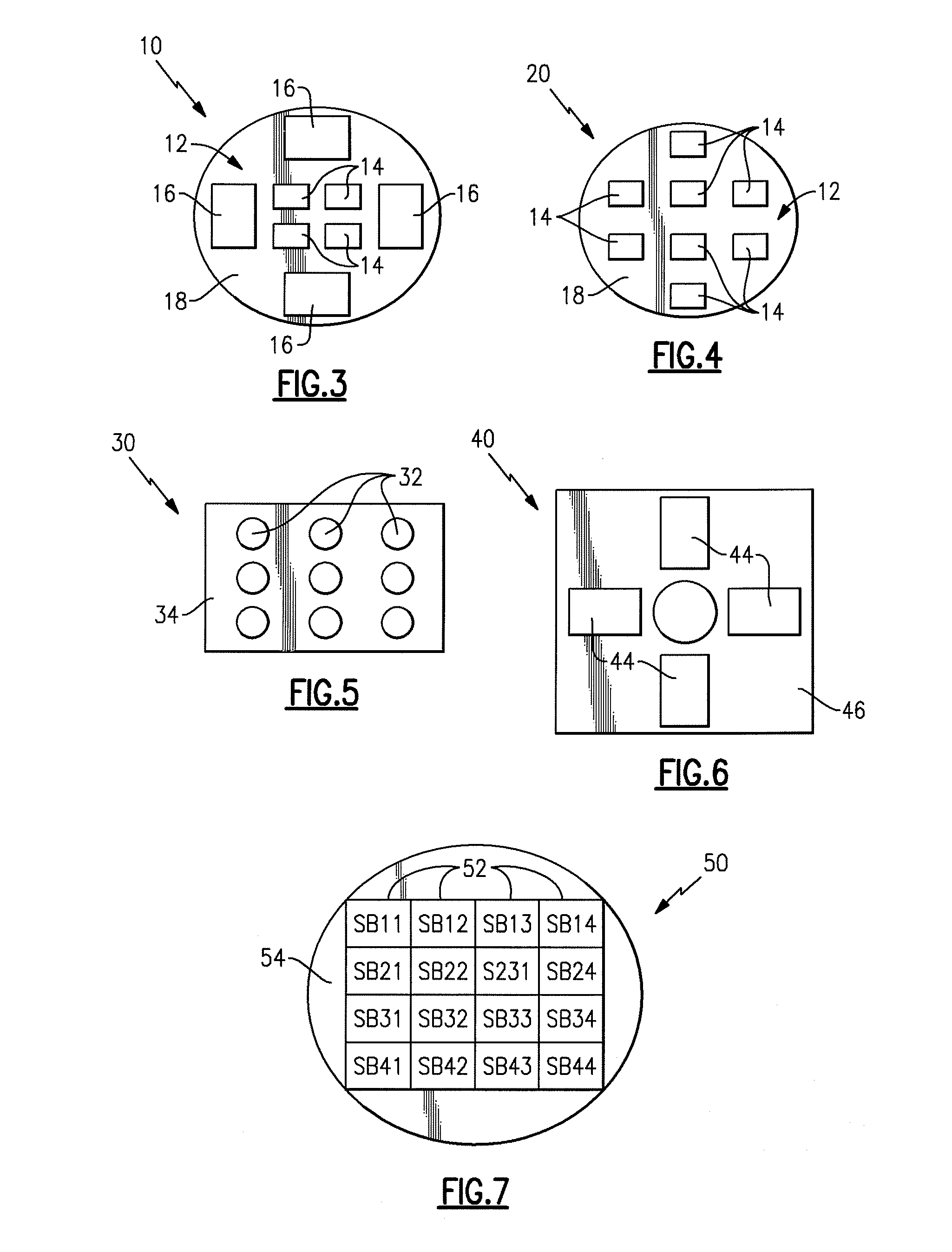

Addressable Matrices/Cluster Blanks for Dental CAD/CAM Systems and Optimization Thereof

ActiveUS20090023112A1Maximum interchangabilityMaximum flexibilityDwelling equipmentDental toolsEngineeringCam

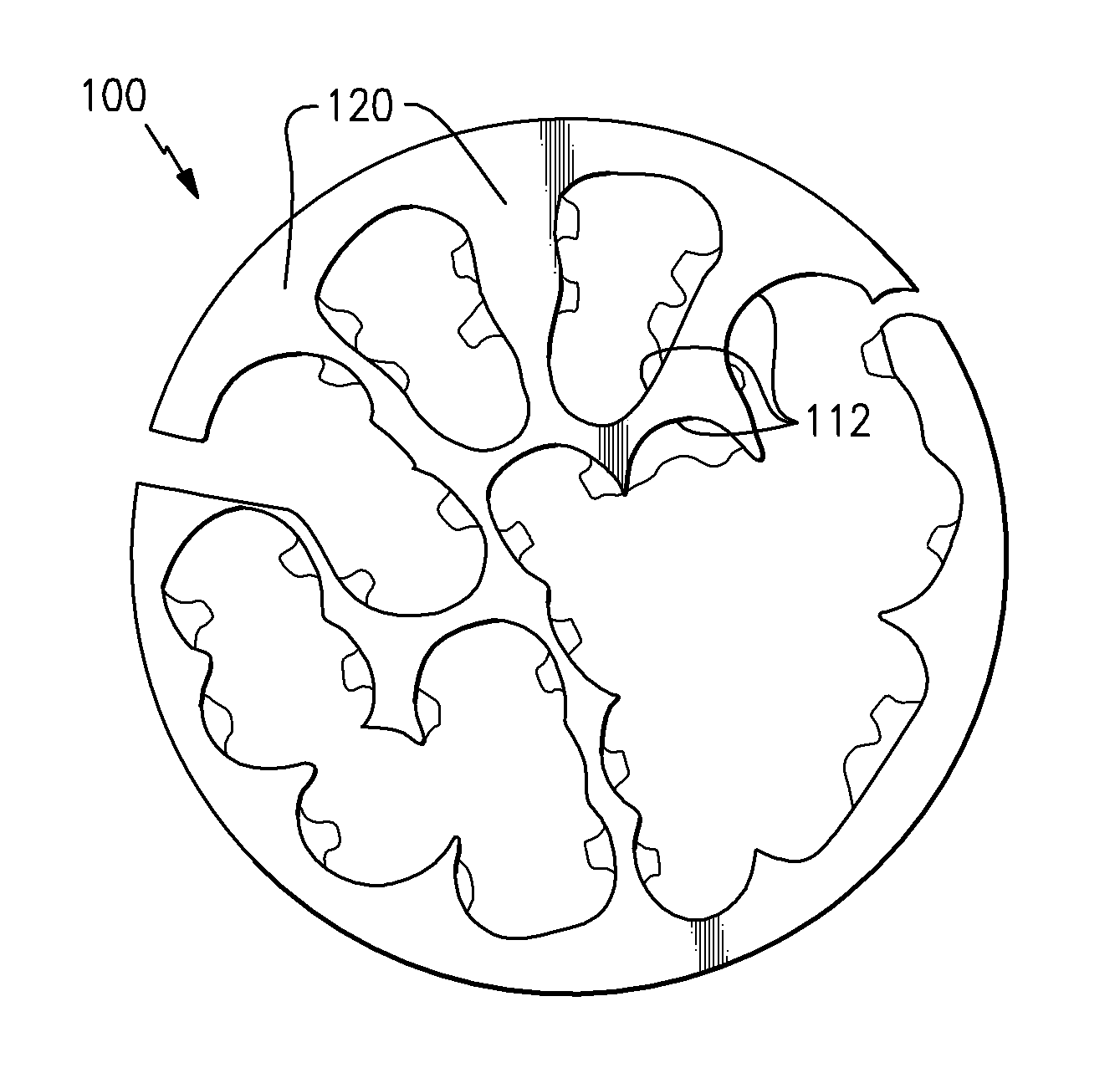

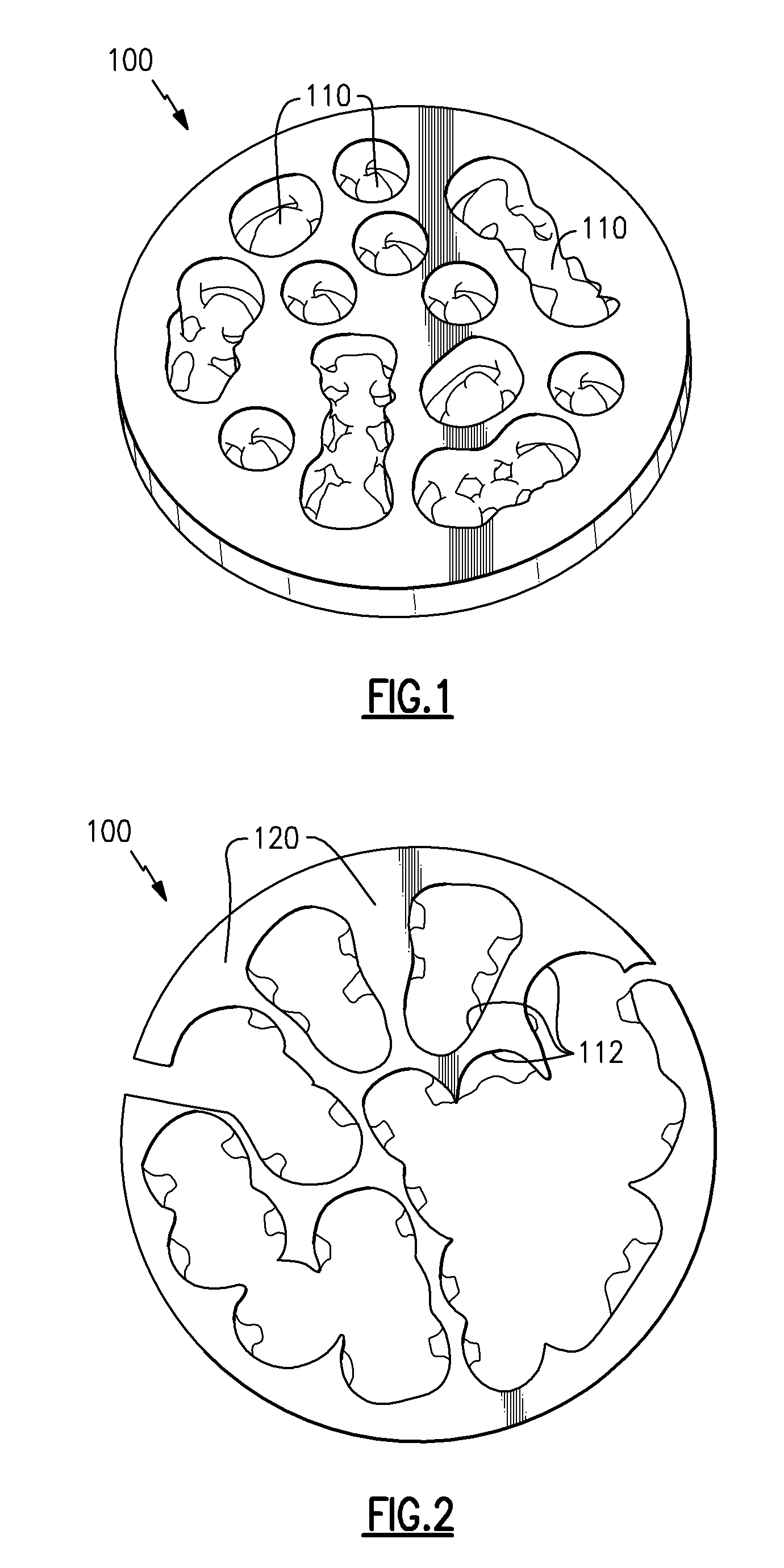

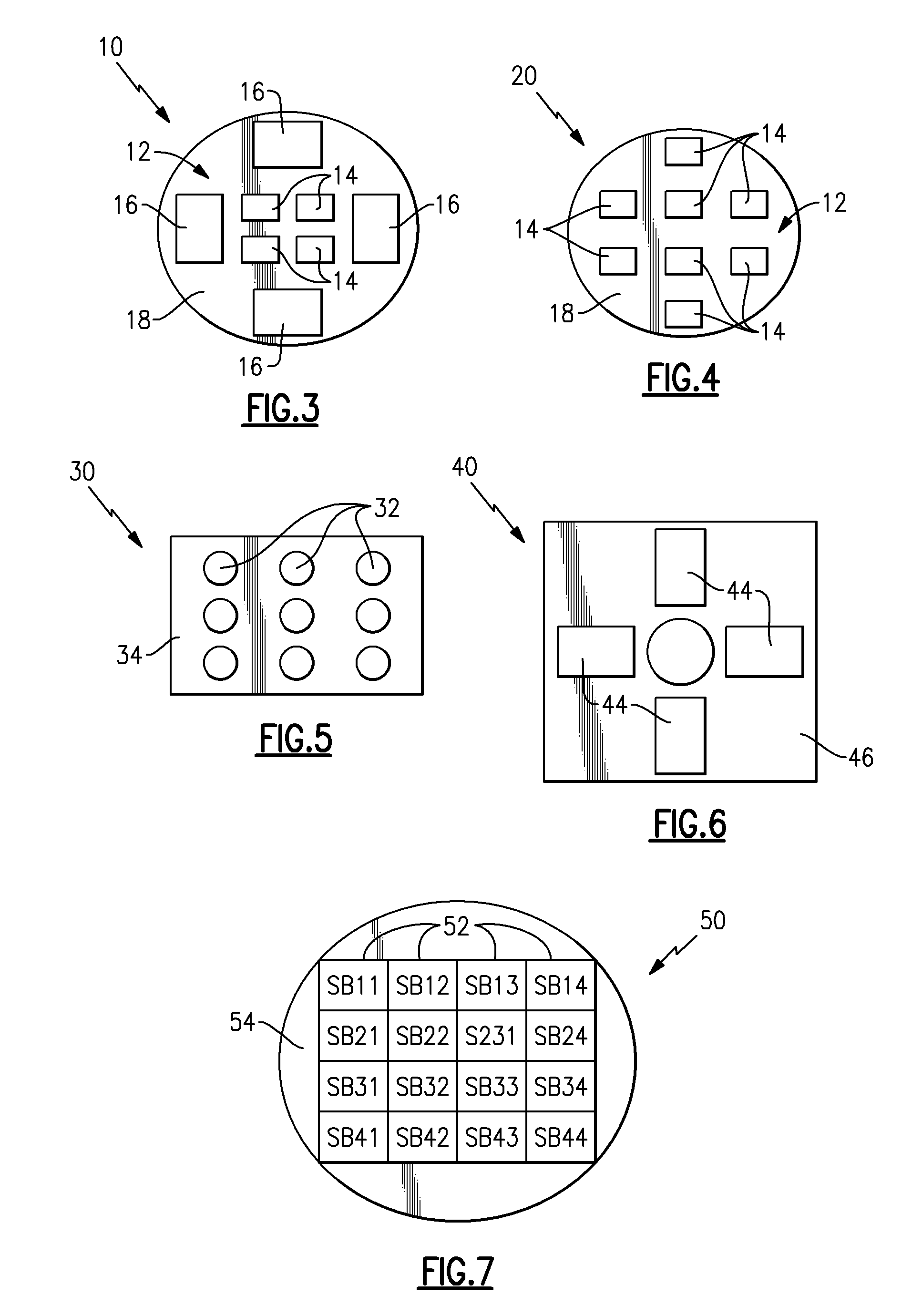

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

Addressable matrices/cluster blanks for dental CAD/CAM systems and optimization thereof

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

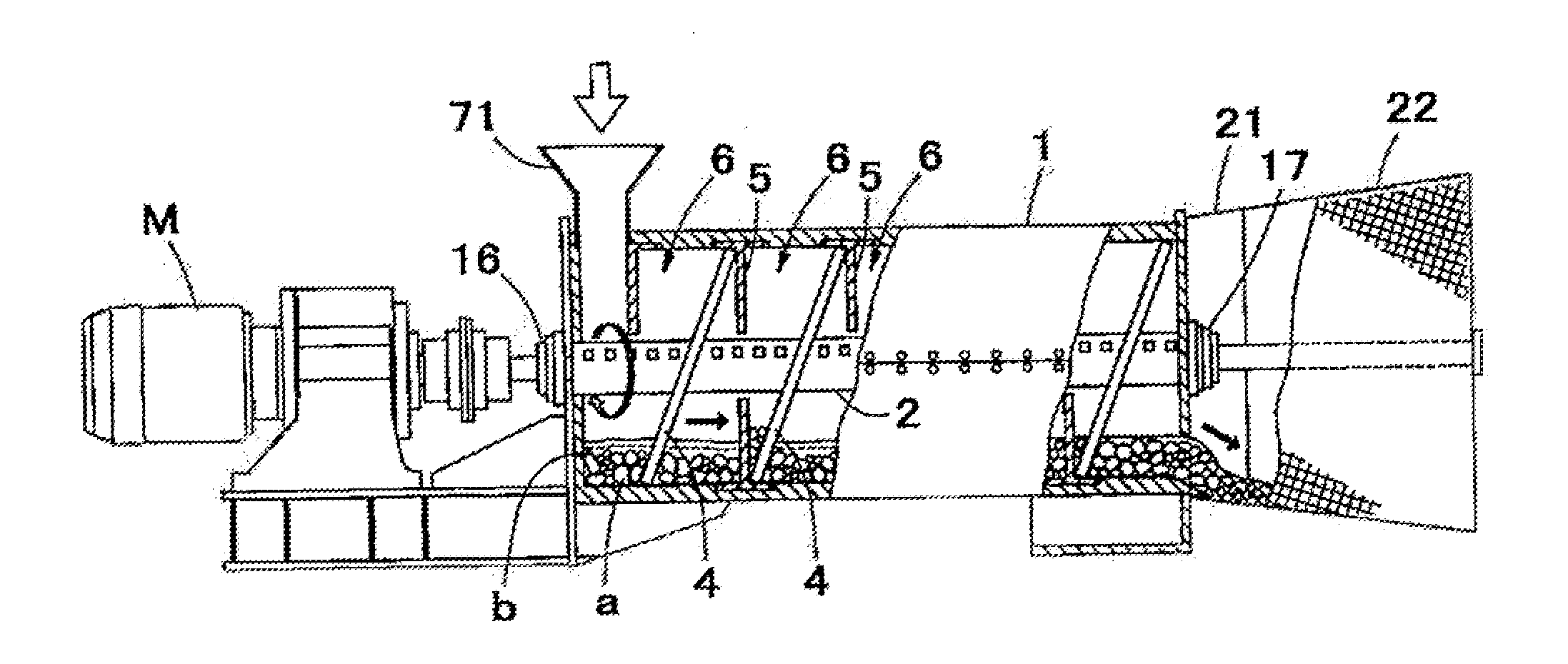

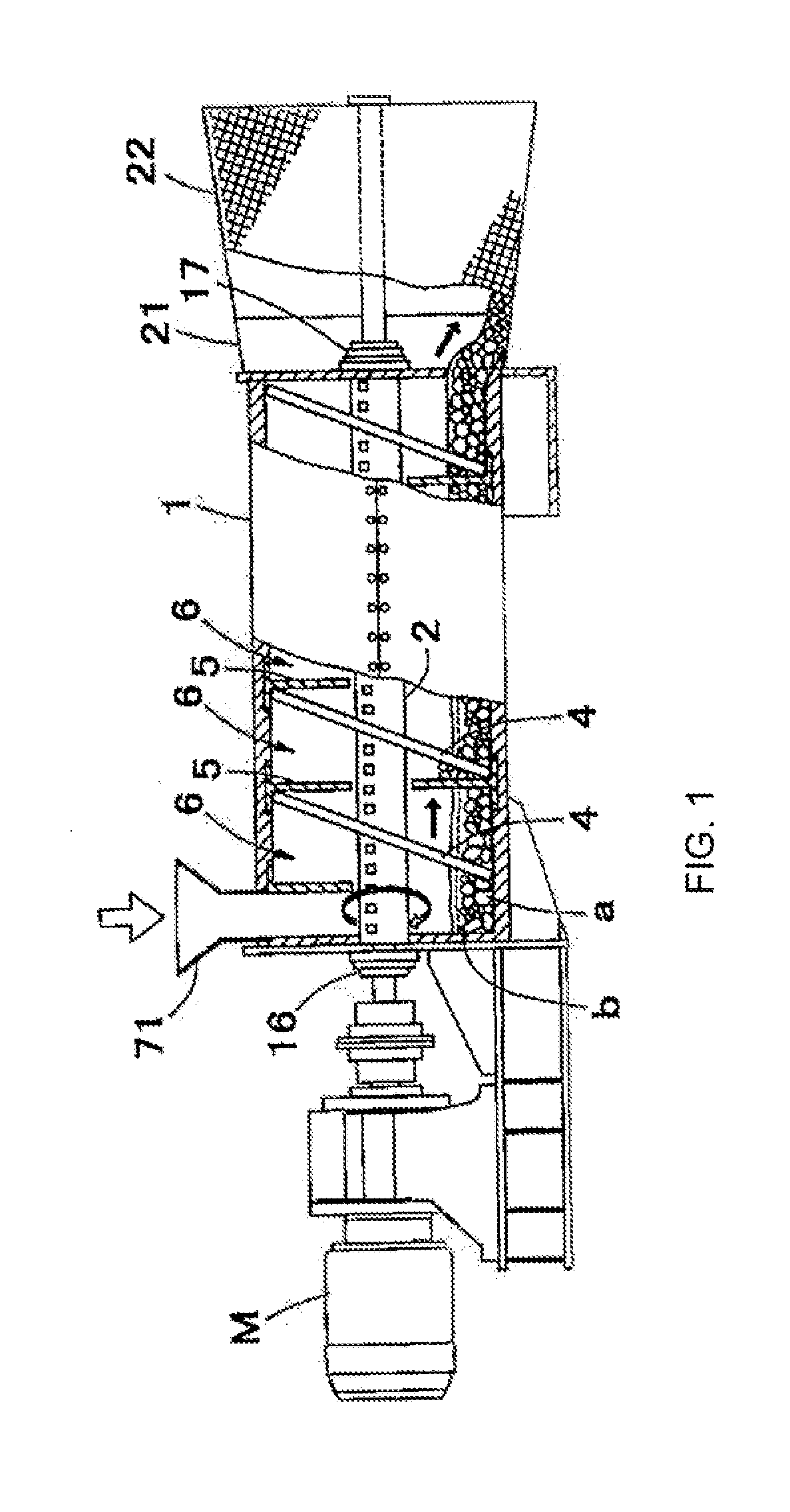

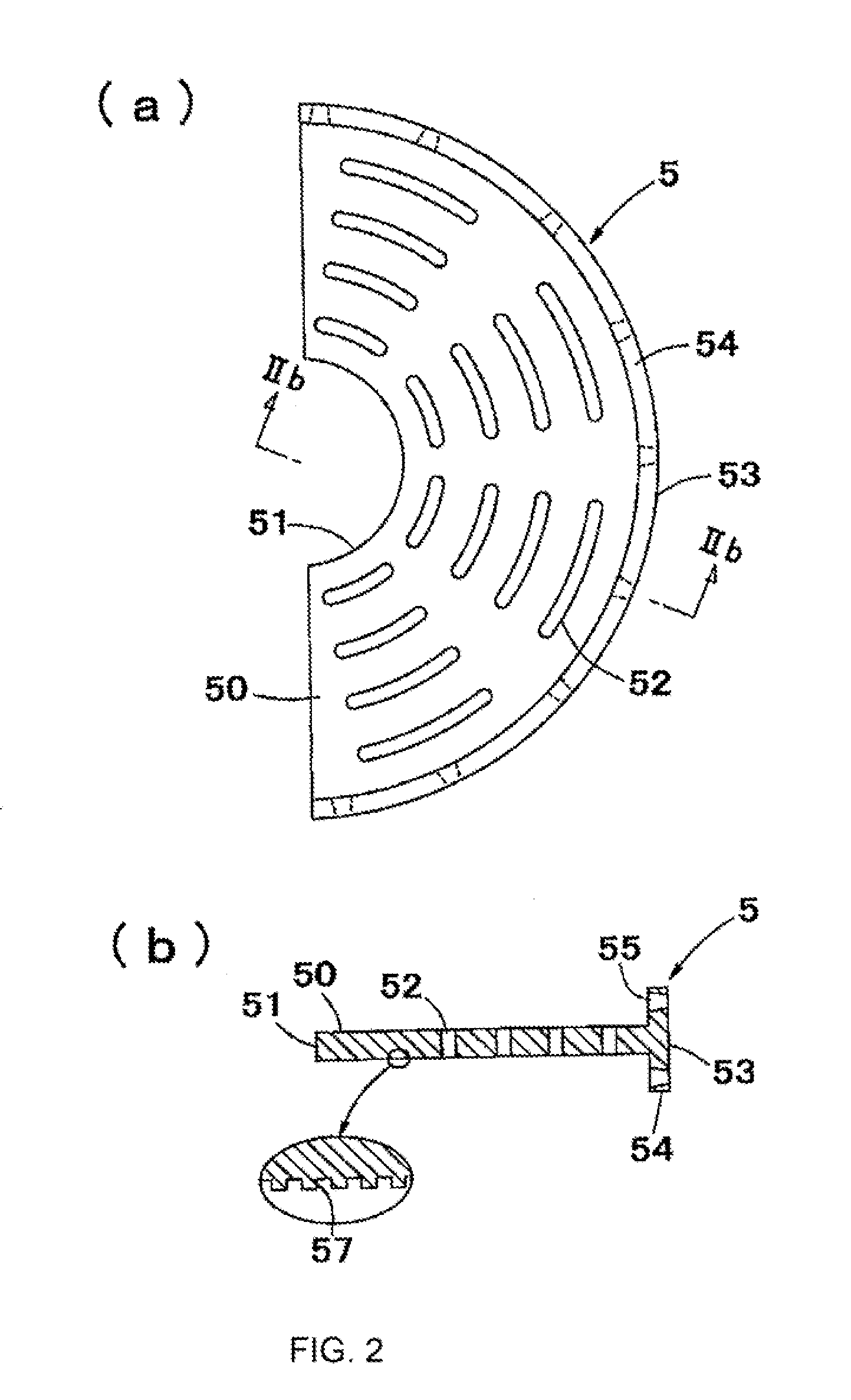

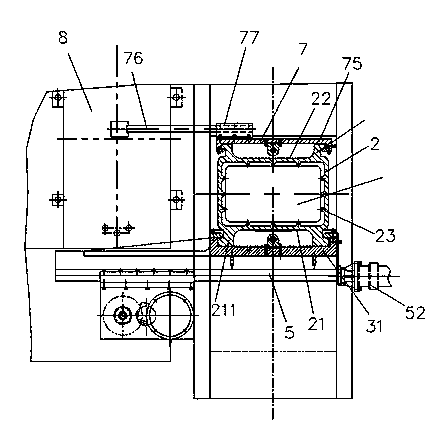

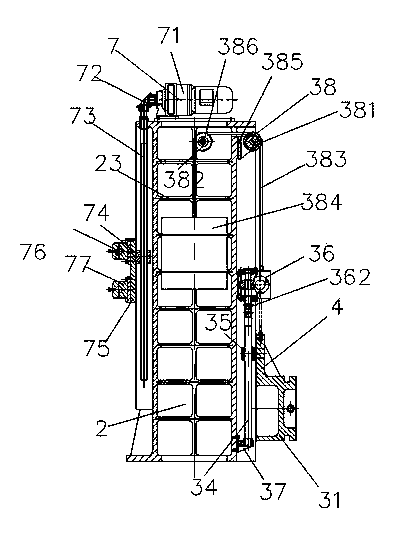

Mill

ActiveUS20140008473A1Reduce amount of noiseDecrease in volumeCocoaRoads maintainenceInterior spaceEngineering

To provide a mill that can greatly reduce noise during operation and can also contribute to greater device compactness. The mill is provided with: a tubular drum body configured in a manner so that a material to be milled introduced from one section can be discharged from another section; a central shaft that penetrates within the drum body in the direction of tube length thereof; and a plurality of milling plates that are attached at a predetermined interval in the axial direction of the central shaft, and that compartmentalize the interior space of the drum body in to a plurality of milling chambers. The drum body and / or the milling plates rotate, and the mill does not have a milling medium that mills the material to be milled by contacting the material to be milled while rolling within the drum body.

Owner:KK KINKIDOROSHIZAI

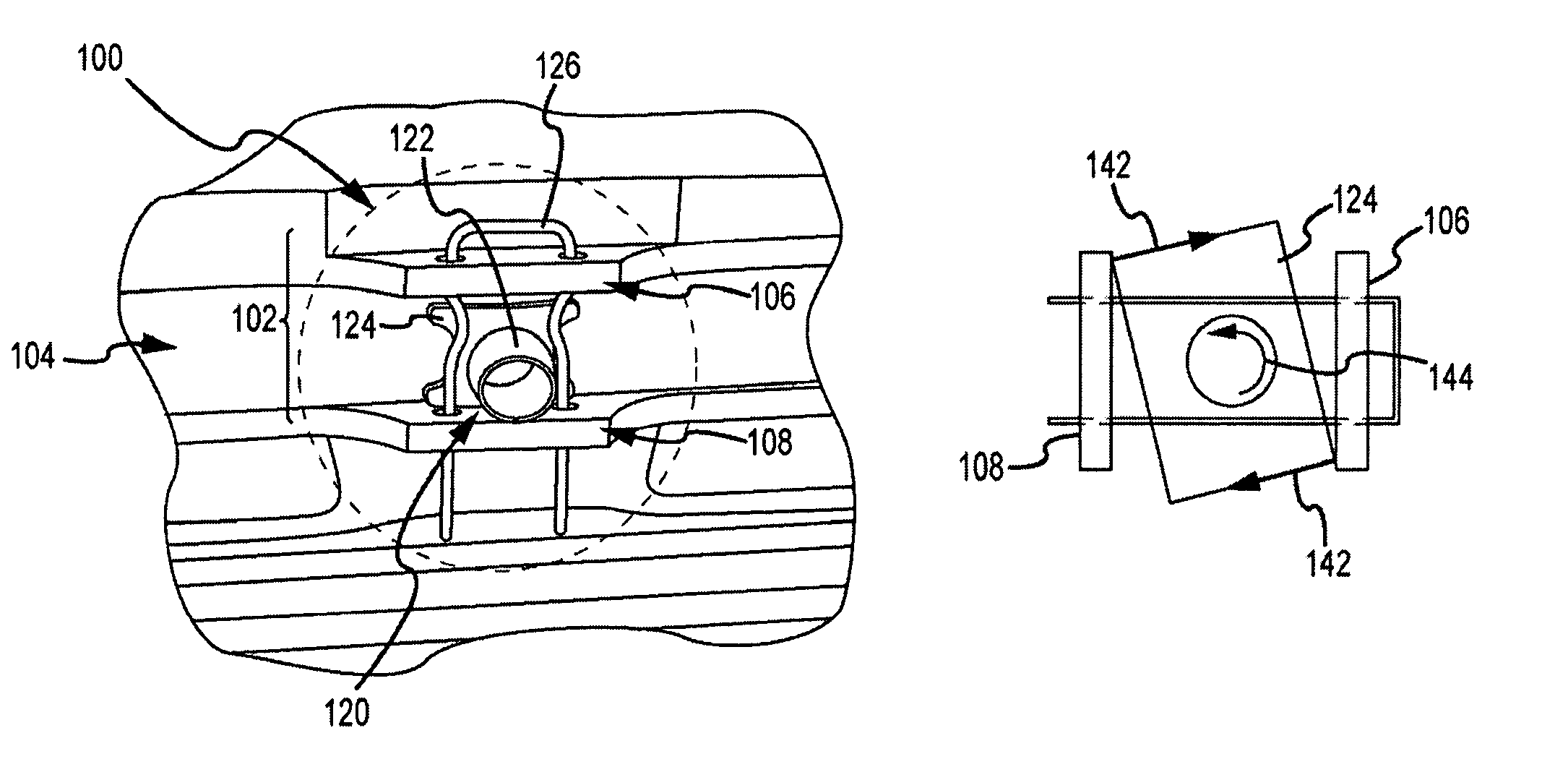

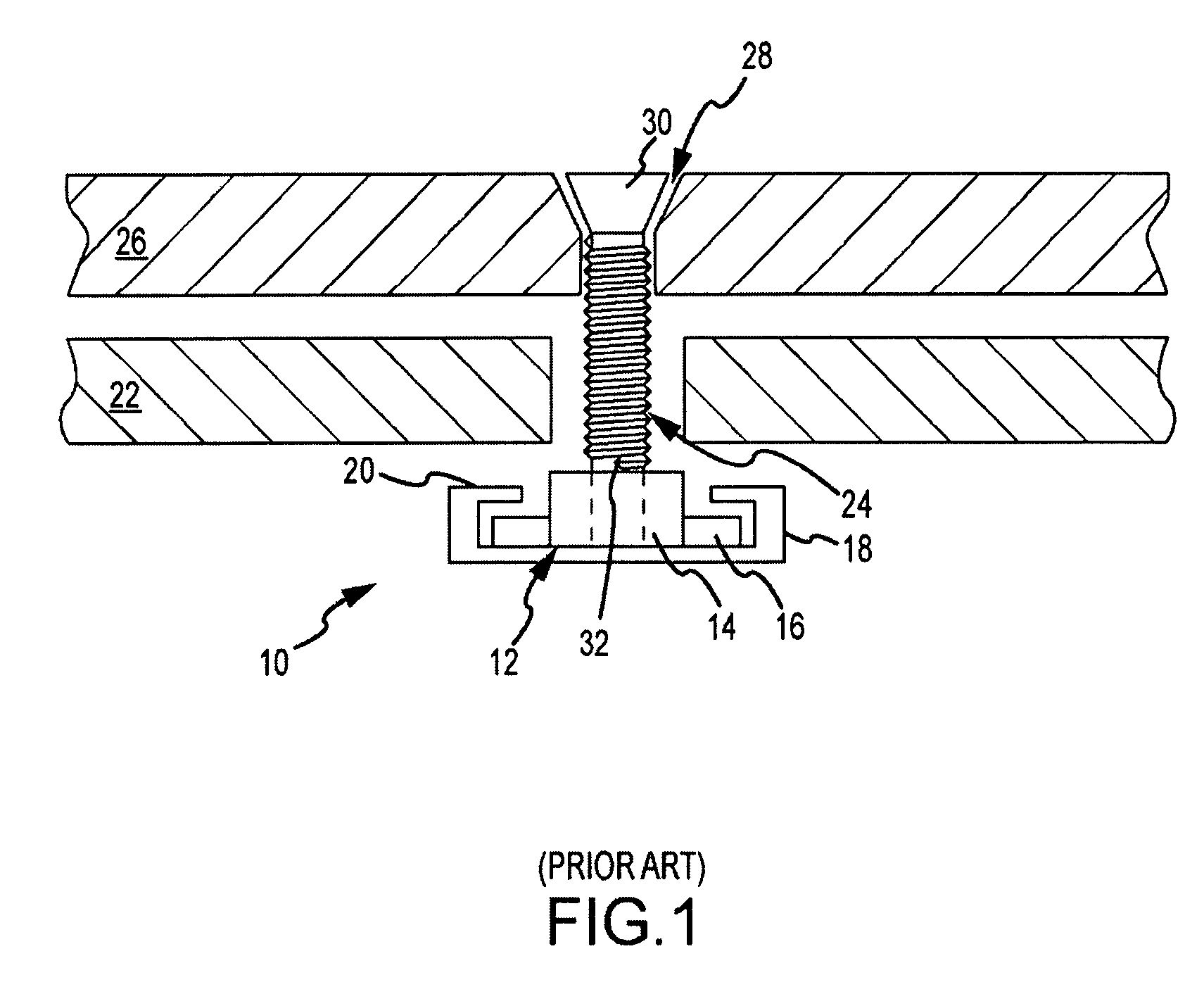

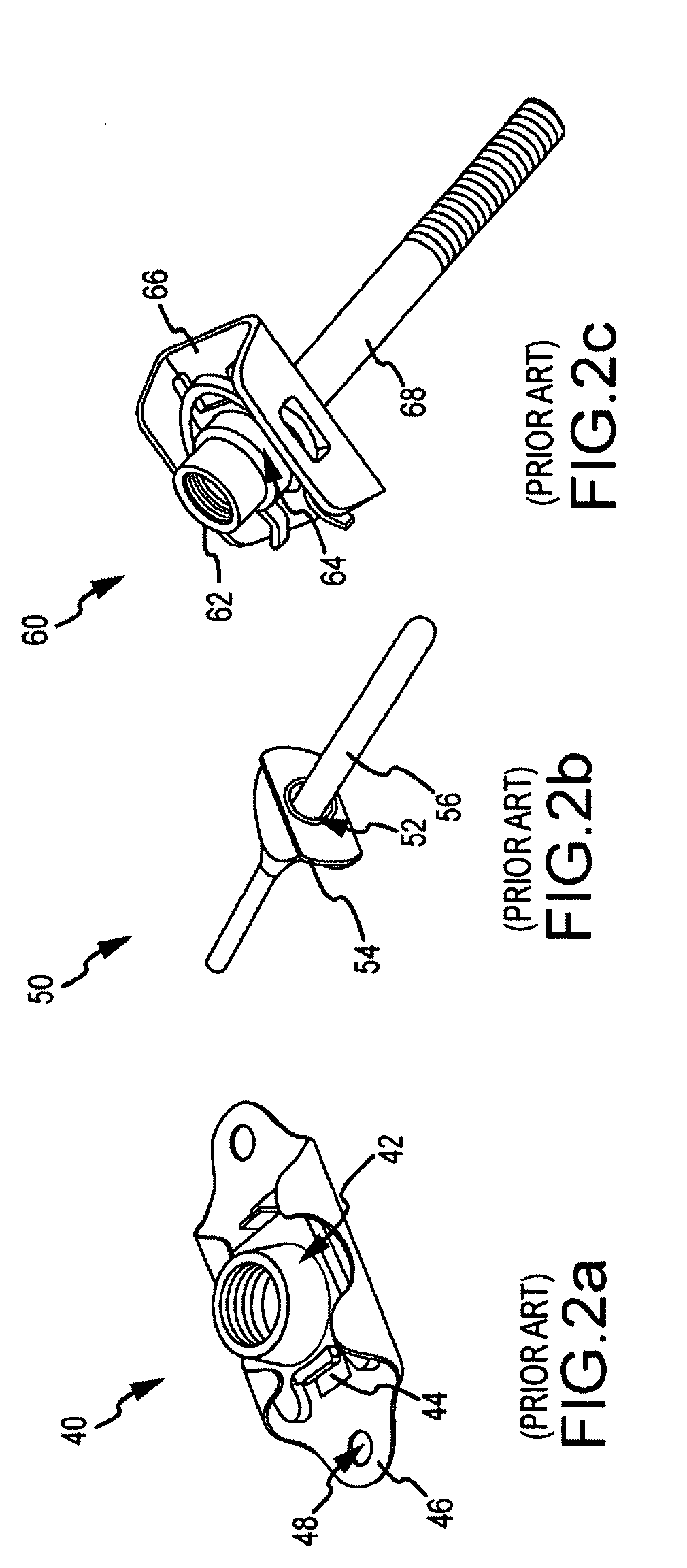

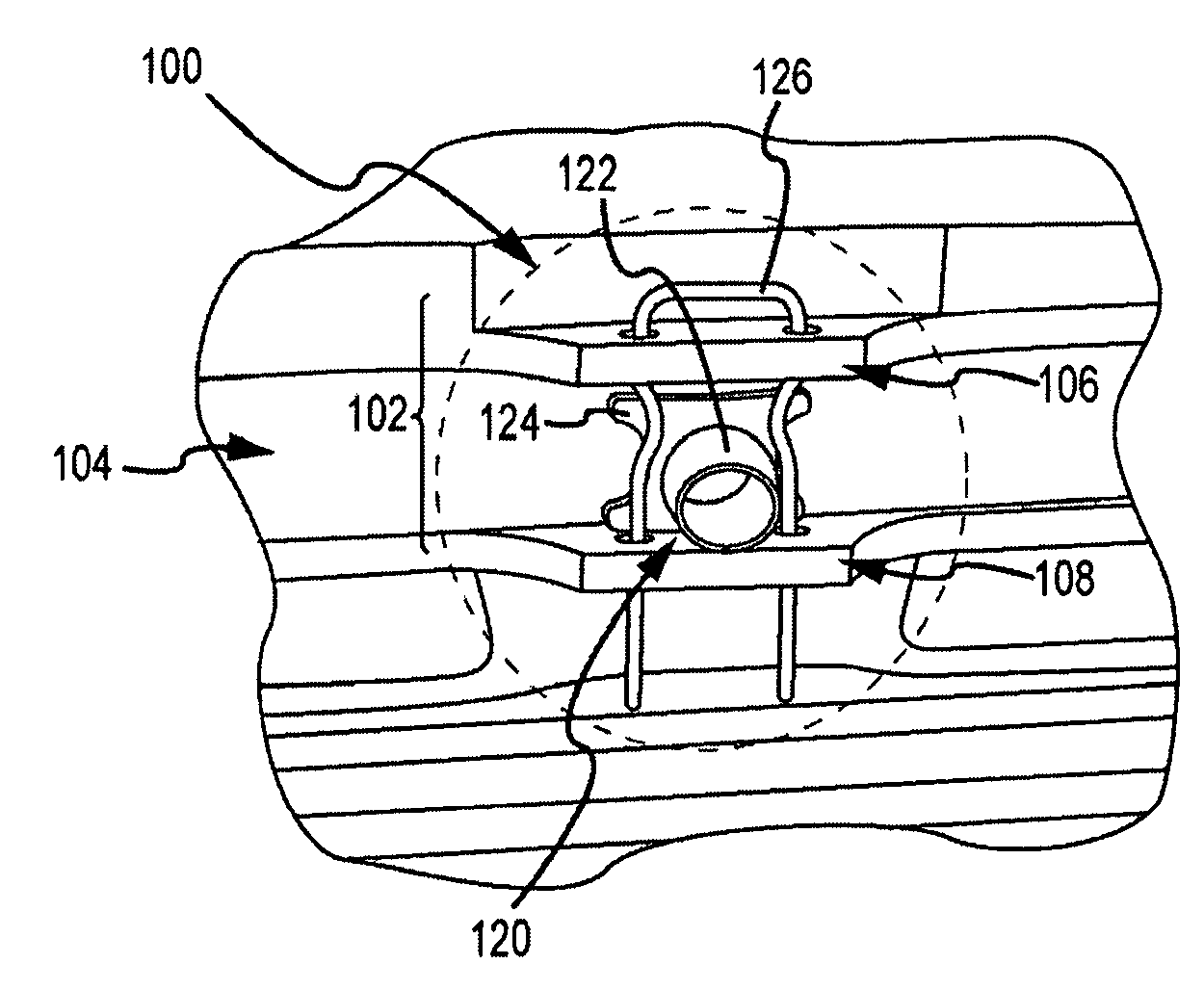

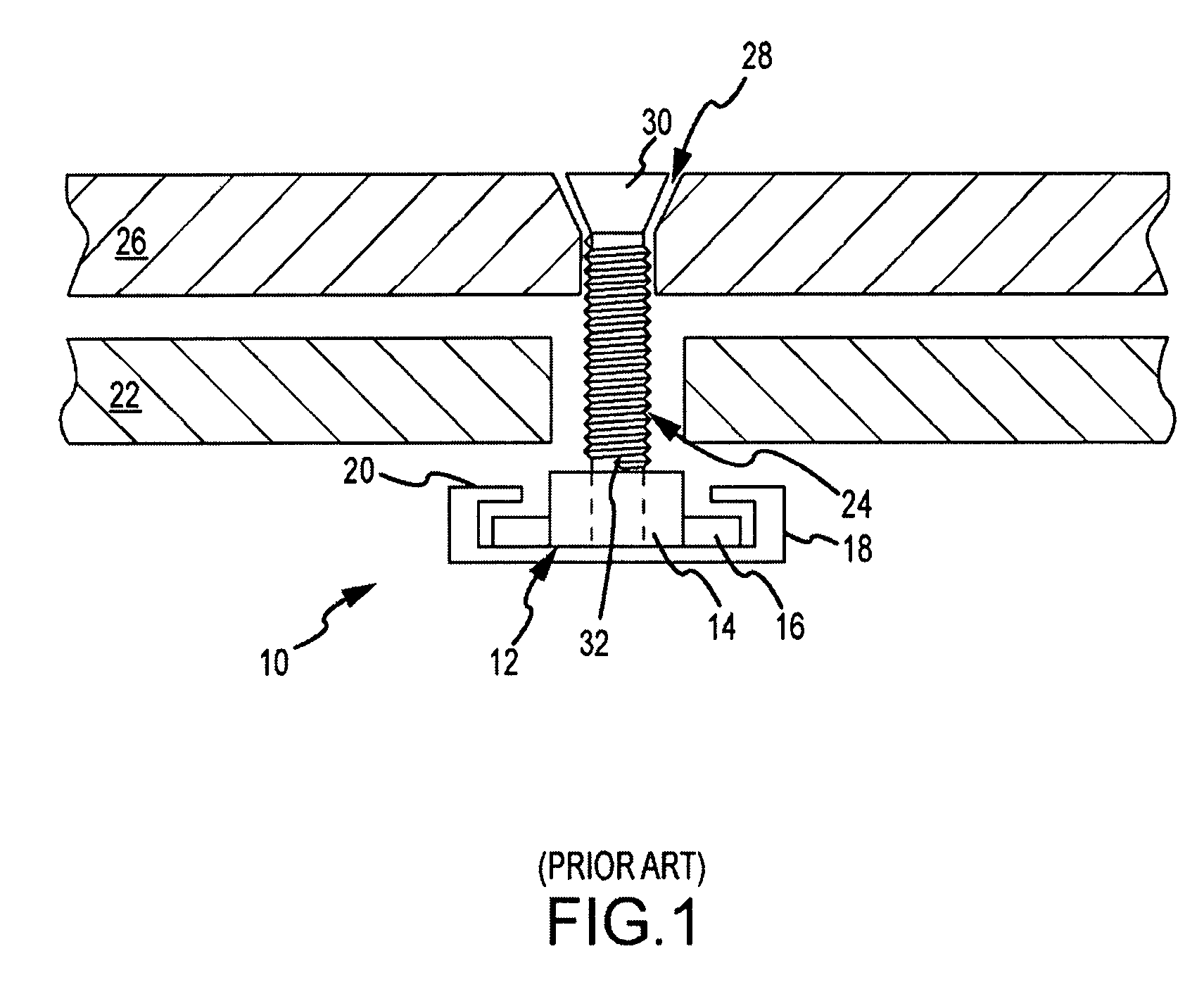

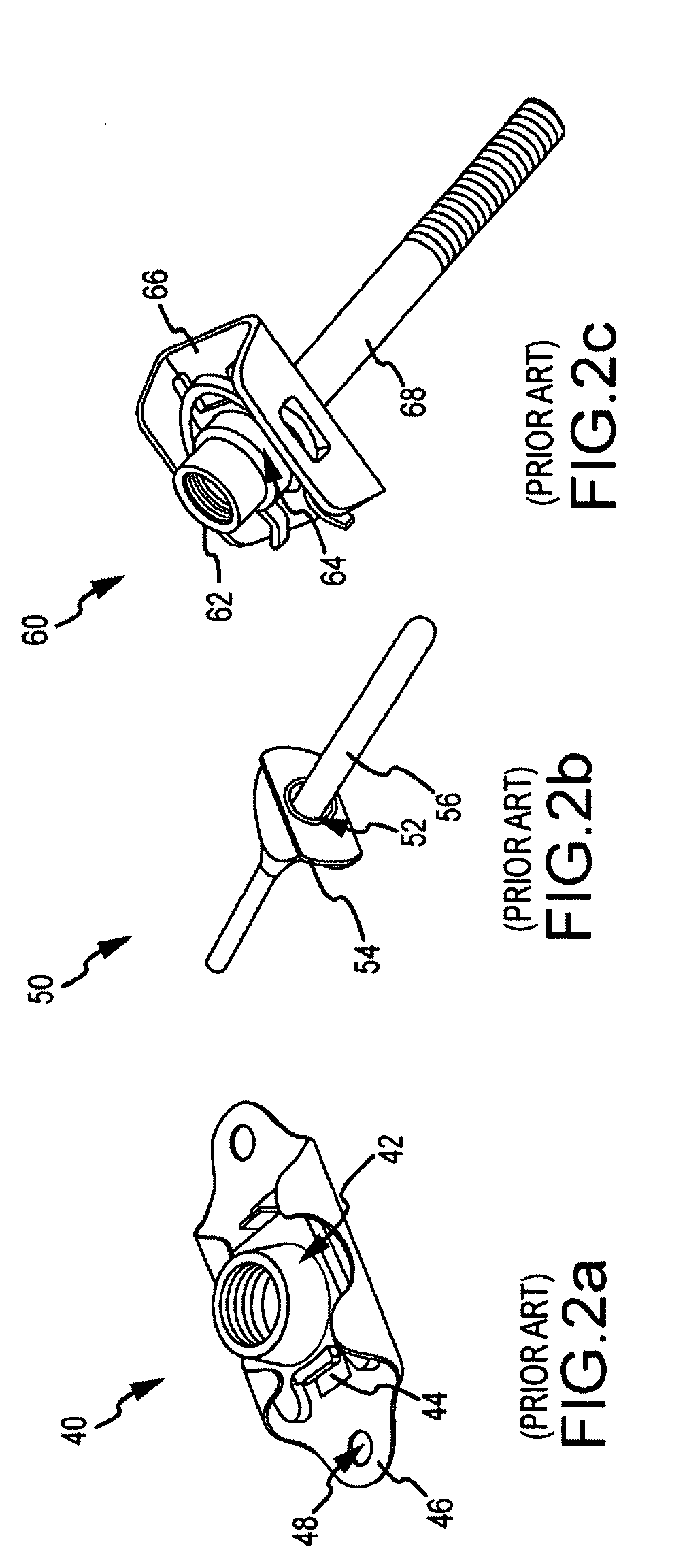

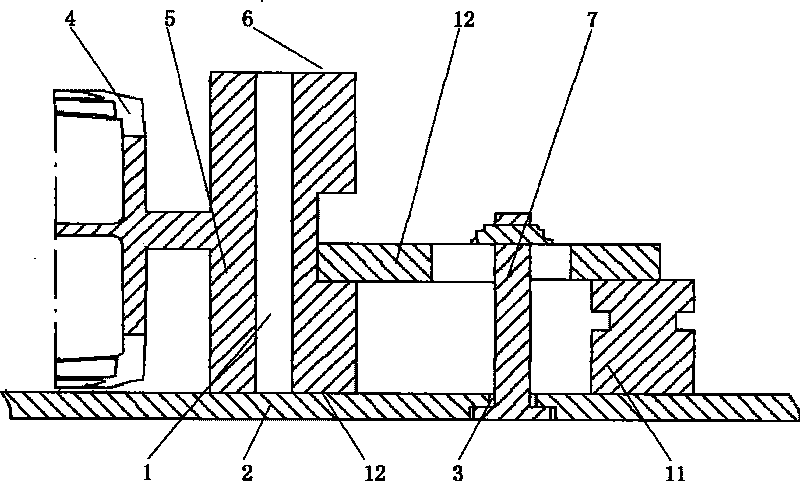

Integrated nutplate and clip for a floating fastener and method of manufacture and assembly

An inexpensive and reliable floating fastener is provided by manufacturing an integrated nutplate into the backside of the interior structural member. A retention clip engages the nutplate to capture the nut while allowing the nut to float. The integrated nutplate roughly aligns the floating nut to the axial through-hole in the structural member and provides the torque resistance required to drive the screw into the nut. The retention clip holds the nut in place and provides the axial resistance required for the lead chamfer of the screw to engage the nut and resist the axial loading on the screw during installation. The nutplate is designed to facilitate cost-effective manufacturing. The per hole cost of the integrated floating-fastener is approximately 30% of the cost of the industry standard riveted floating fastener.

Owner:RAYTHEON CO

Addressable matrices/cluster blanks for dental cad/cam systems and optimization thereof

A cluster mill blank includes a framework constructed to cooperate with a blank holder of an existing CAD / CAM system, and a plurality of sub-blanks attached to the framework forming an addressable matrix or cluster blank. CAD / CAM systems including such a framework, as well as associated methods are described.

Owner:IVOCLAR VIVADENT AG

Efficient milling process method of split type receiver

InactiveCN107717029AOptimize cutting parametersEfficient millingMilling equipment detailsFeed processingEngineering

The invention relates to a high-efficiency milling process method for split casings, which adopts cycloidal milling tool path, large depth of cut, small width of cut, and fast feed process parameters. The steps are: high-efficiency milling tool path planning; using large depth of cut , small cutting width, high feed speed mode, and optimize cutting parameters; high-efficiency milling tool path planning includes: select the tool path of helical feed and cycloid opening pre-processing groove; select the cycloid reciprocating tool path; pendulum Arc transitions are used between lines to avoid right-angle turns. The method of the present invention is applied in the face milling process of the outer shape of the aircraft engine opening case. The processing method adopts the cycloidal tool path, large depth of cut, small cutting width, and fast feed, and utilizes the advantage of the long edge of the tool to cut the surface of the opening case. It can be used in profile milling to improve the utilization rate of tools. In terms of reducing costs and improving processing efficiency, it realizes high-efficiency milling of open casings and improves processing efficiency.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

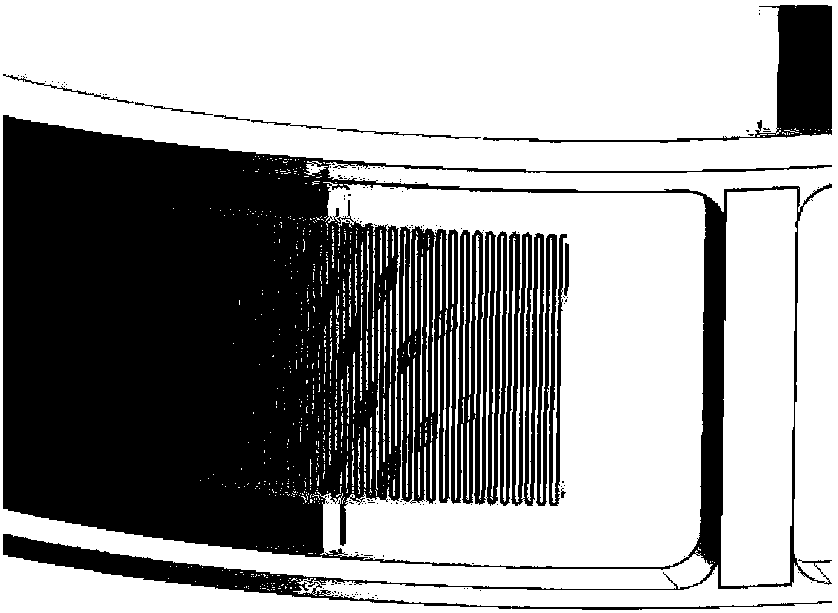

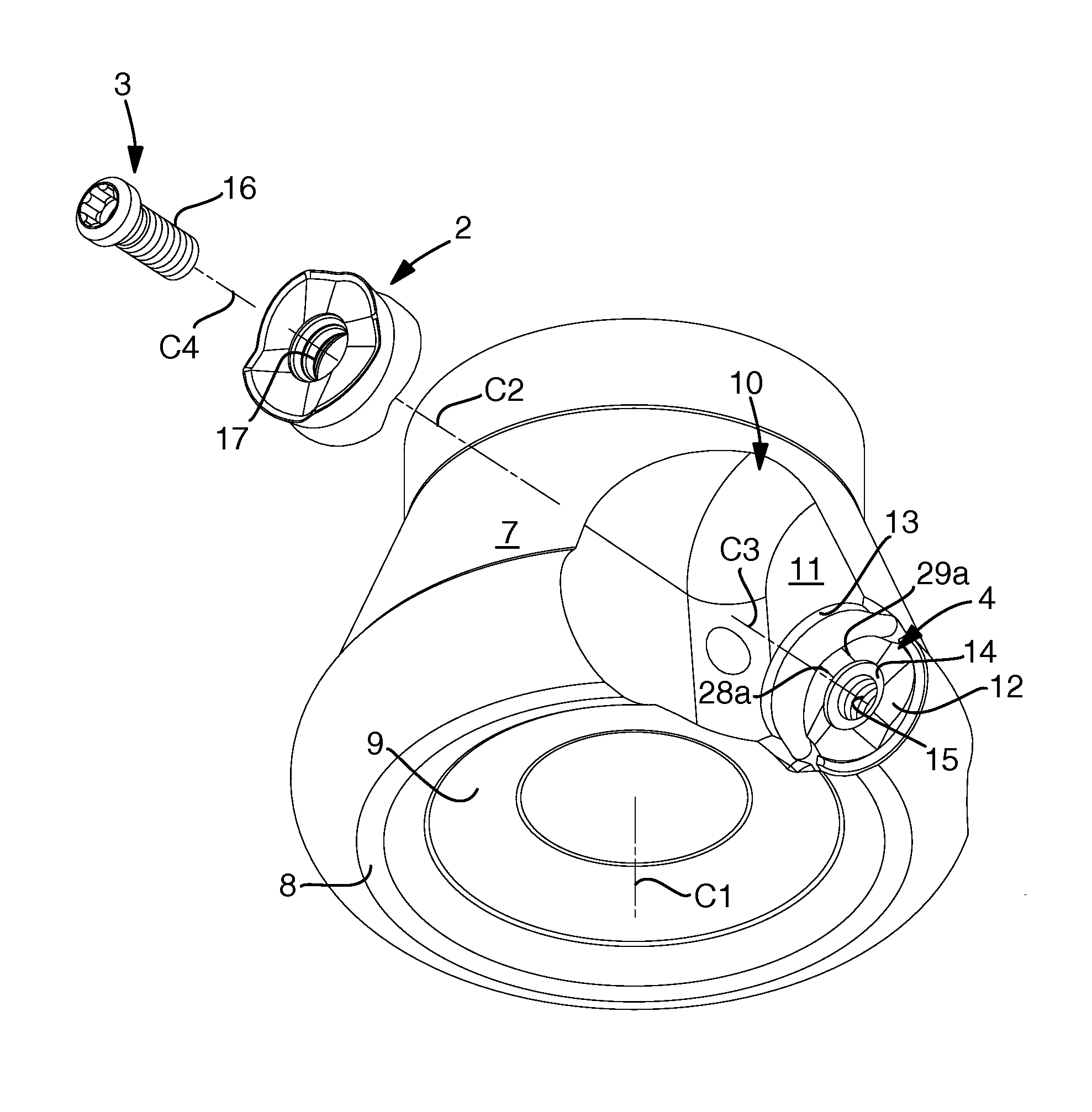

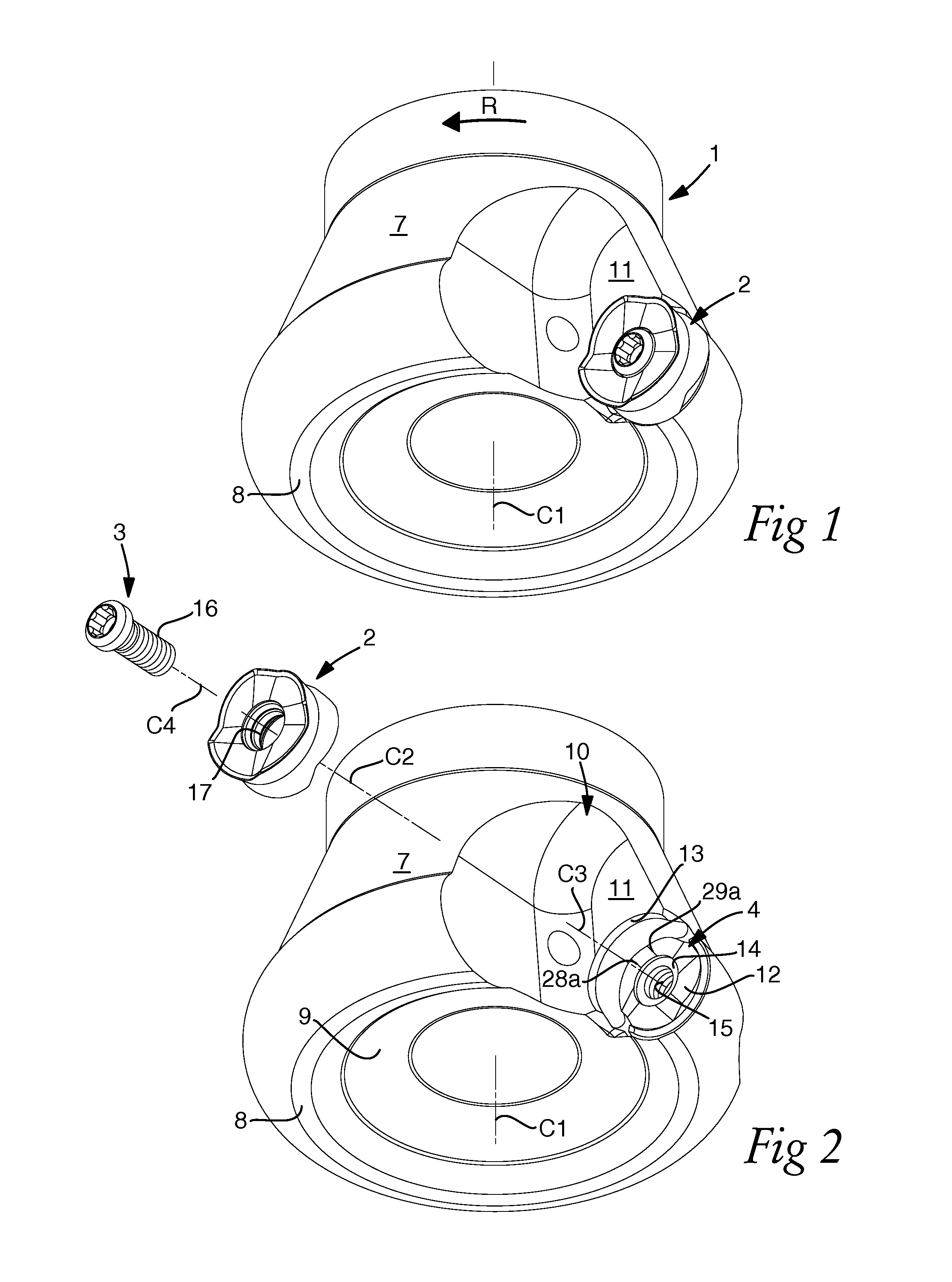

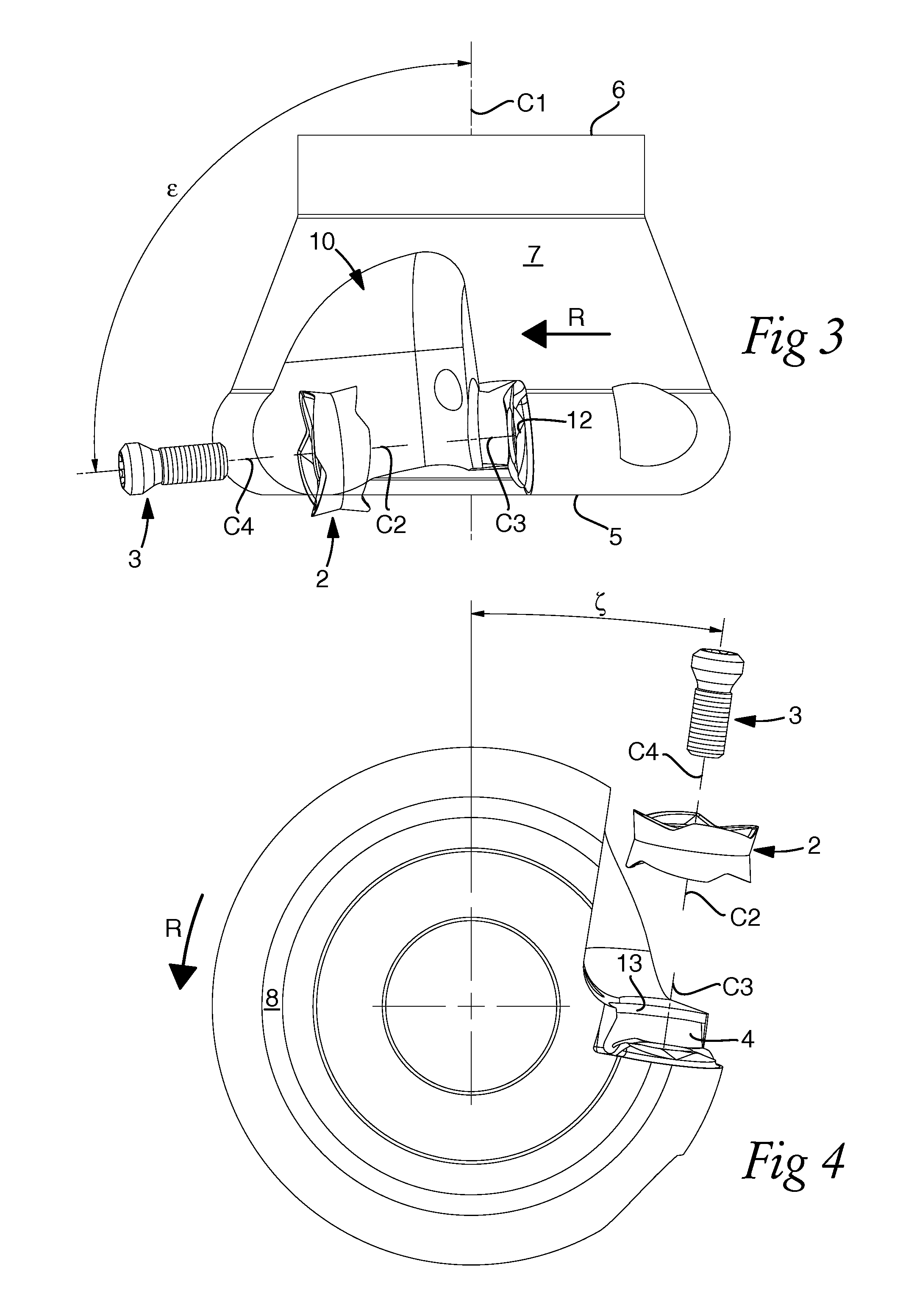

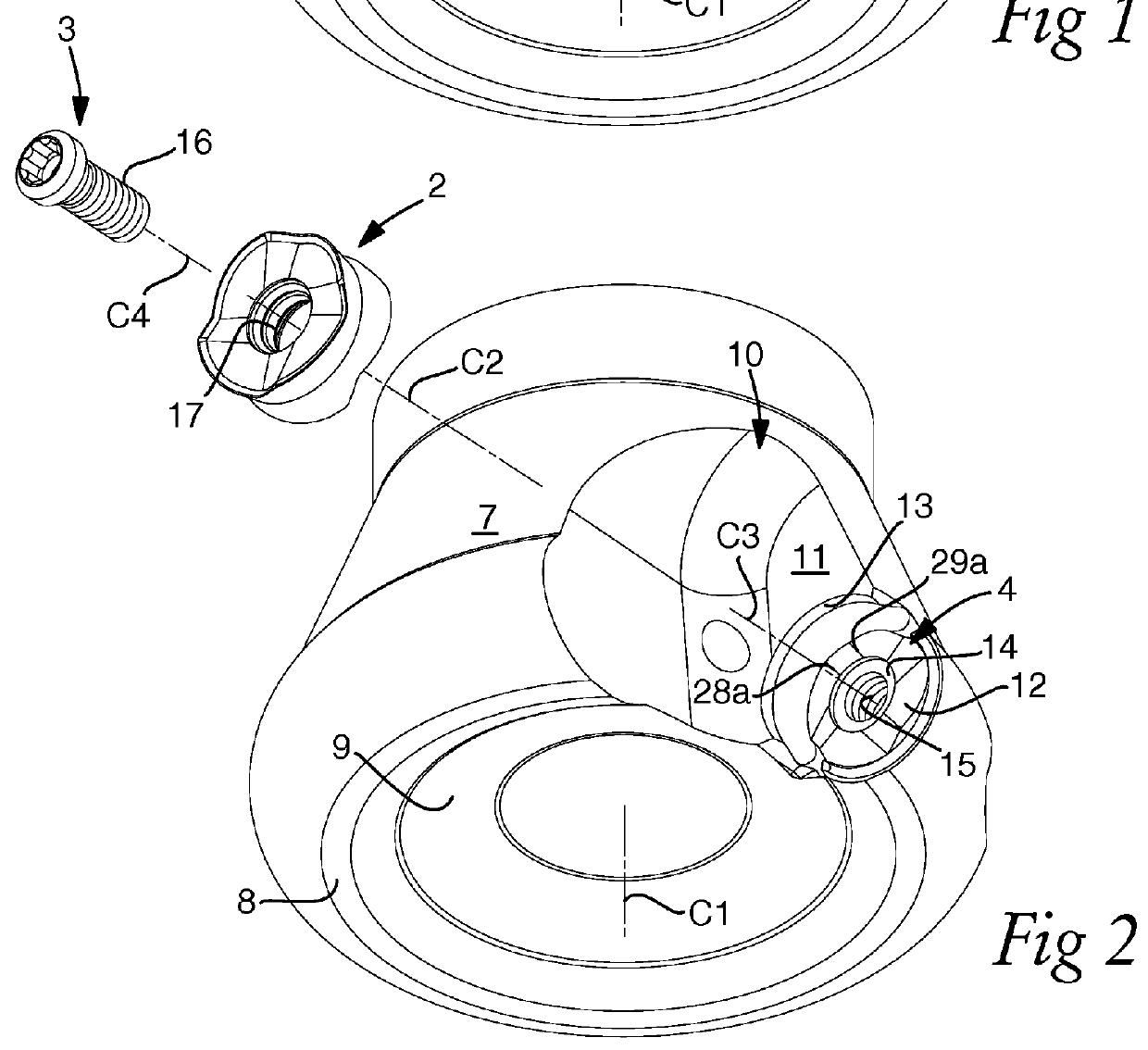

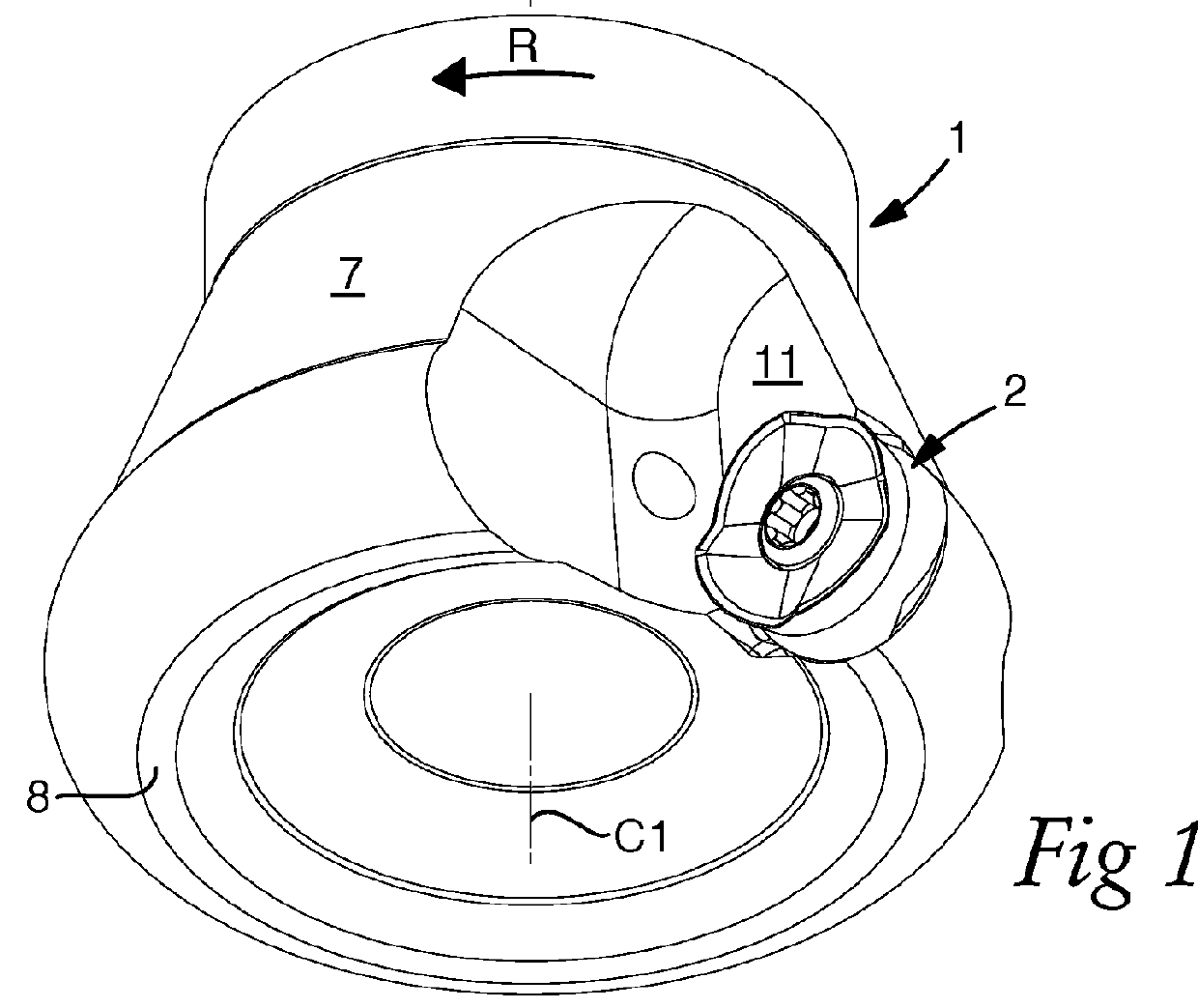

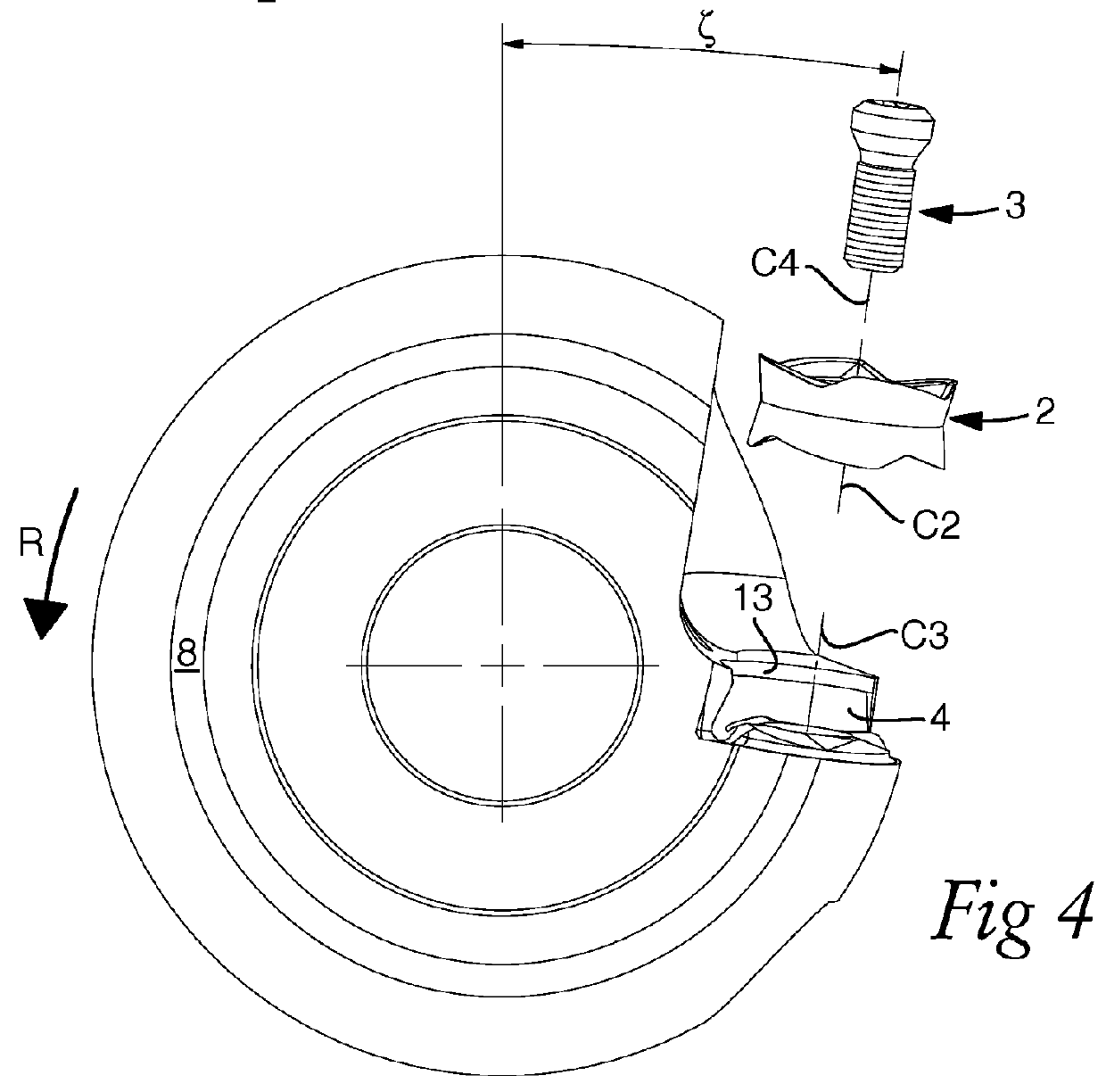

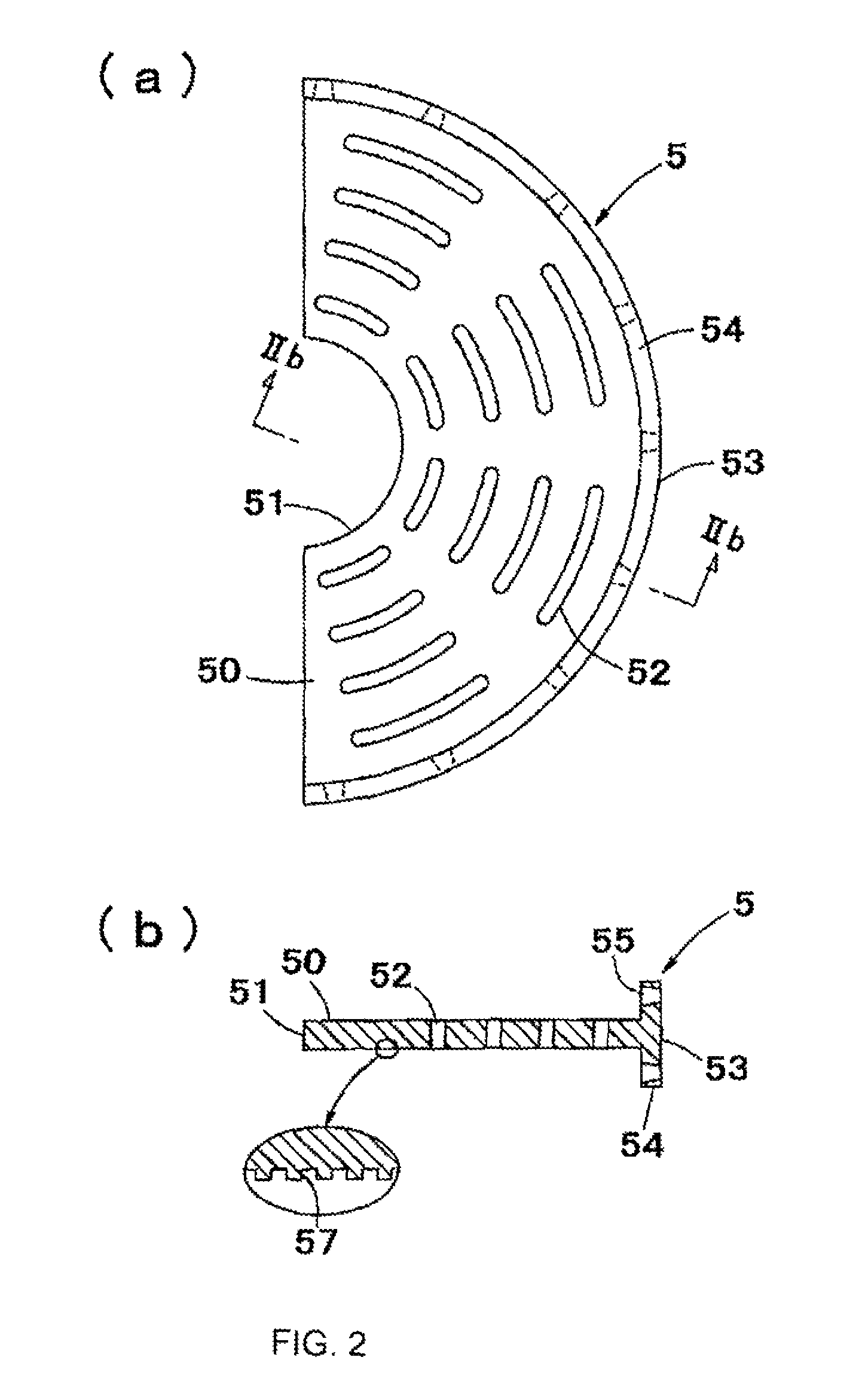

Milling tool as well as a milling insert

ActiveUS20140030034A1Ample ramping angleSimple and cost-effective wayTransportation and packagingMilling cuttersEdge segmentNeutral plane

A double-sided, indexable milling insert has a round basic shape defined by an imaginary cylinder, which is concentric with a center axis and extends between two reference planes that extend perpendicular to the center axis and are equidistantly separated from a neutral plane. The milling insert includes a pair of opposite chip faces located in the reference planes between which an envelope surface concentric with the center axis extends, a plurality of identical and alternately usable cutting edges along the peripheries of the chip faces, and lock means for rotationally securing the milling insert in one of several predetermined index positions. The individual cutting edge has the shape of a wave trough and includes two edge segments that meet at a bottom point.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

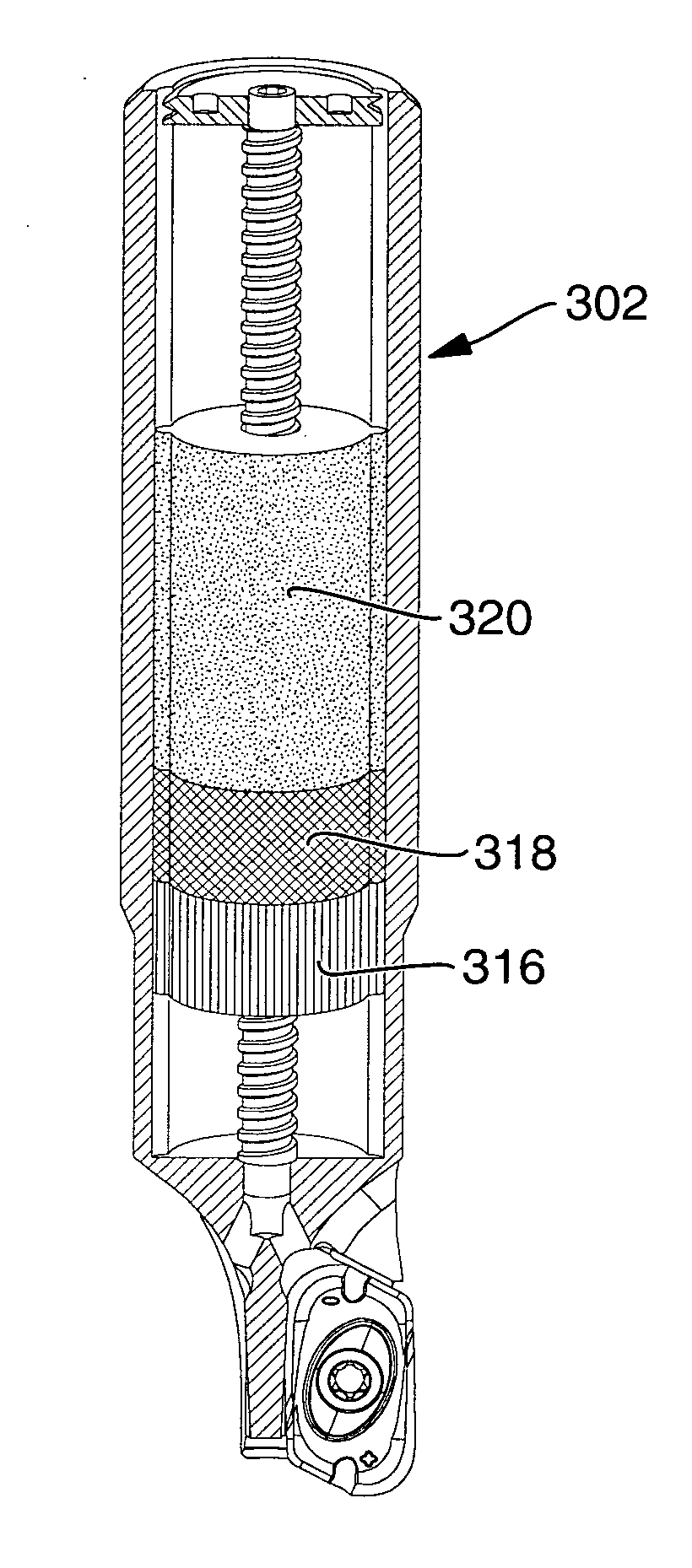

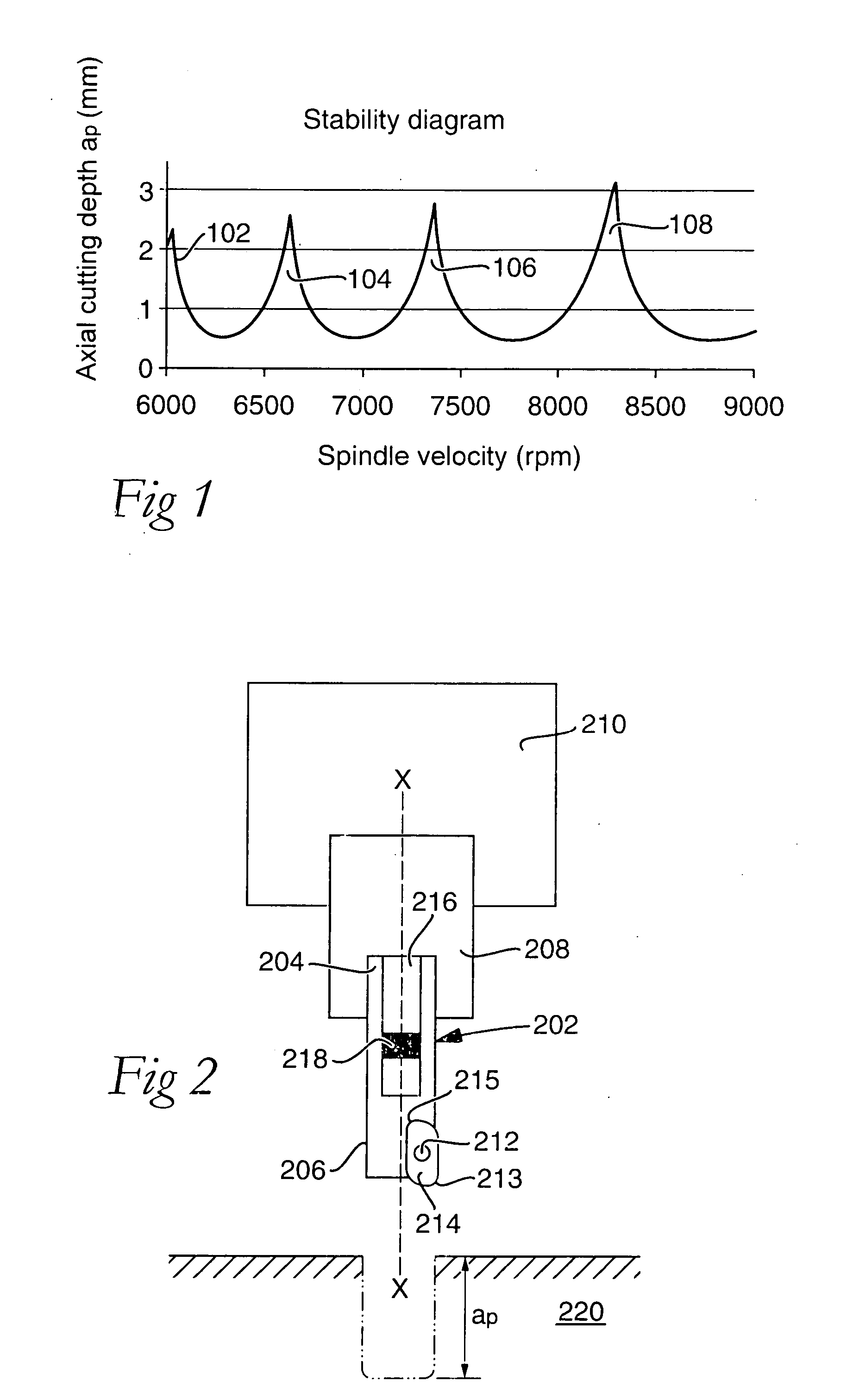

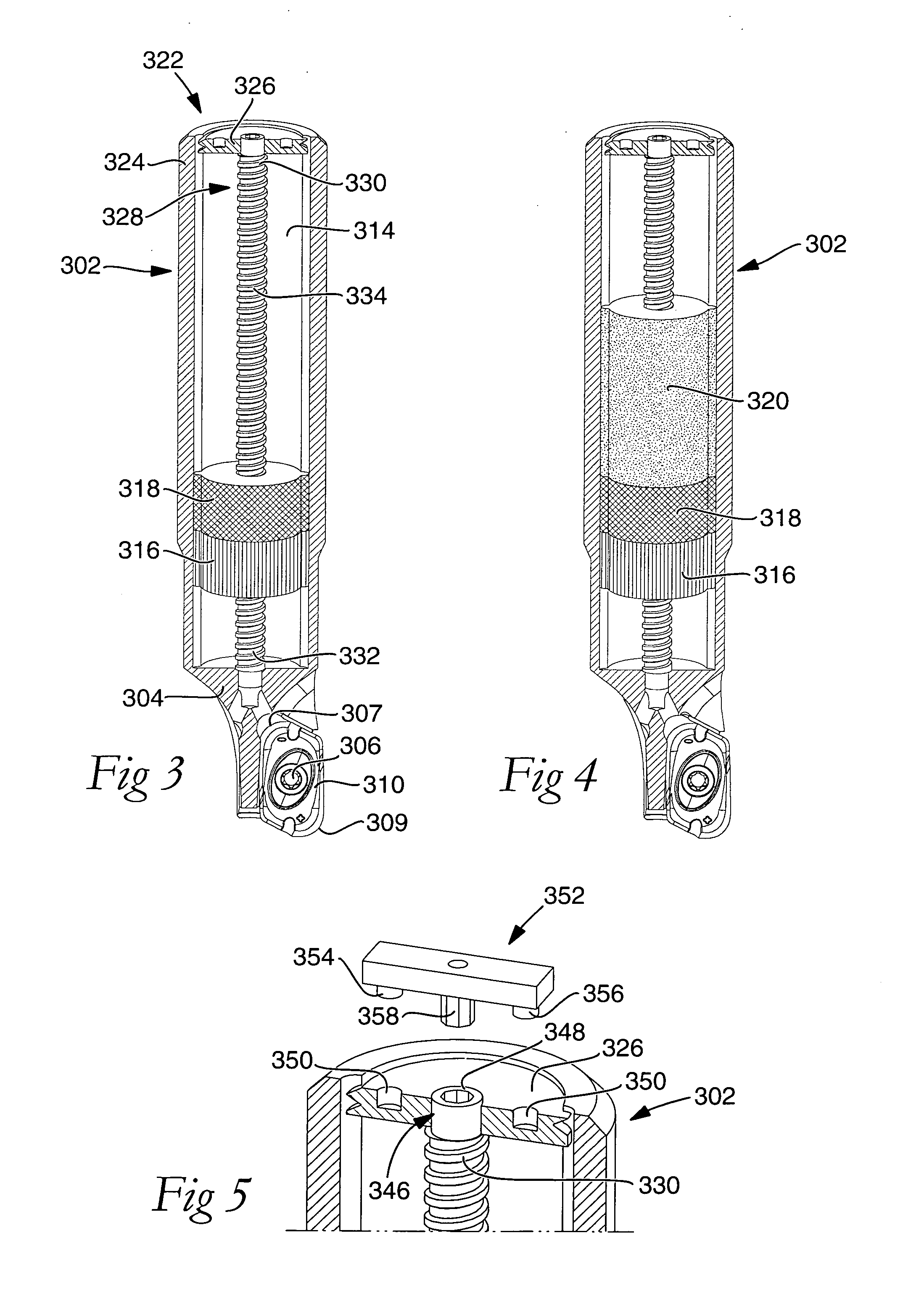

Device and method for milling of materials

ActiveUS20100296889A1Easy to getEfficient millingTurning machine accessoriesMilling cuttersMilling cutterEngineering

Device and method for milling of materials including a milling cutter body including a first end portion and an opposite second end portion. The first end portion is connected to a rotatable spindle and the second end portion is provided with at least one cutting edge. The milling cutter body defines a longitudinal axis and is provided with an axial recess, wherein at least one mass element is arranged in the recess. The axial position of the mass element in relation to the milling cutter body is tuned by use of tuning members included in the device for the tuning of the natural frequency of the device. The mass element is axially locked in relation to the milling cutter body by use of lock members included in the device, in order to optimize the natural frequency of the device for the milling operation in question.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Integrated nutplate and clip for a floating fastener and method of manufacture and assembly

ActiveUS20090129889A1Inexpensive and reliableInexpensive and reliable floatingNutsBoltsAxial LoadingsEngineering

An inexpensive and reliable floating fastener is provided by manufacturing an integrated nutplate into the backside of the interior structural member. A retention clip engages the nutplate to capture the nut while allowing the nut to float. The integrated nutplate roughly aligns the floating nut to the axial through-hole in the structural member and provides the torque resistance required to drive the screw into the nut. The retention clip holds the nut in place and provides the axial resistance required for the lead chamfer of the screw to engage the nut and resist the axial loading on the screw during installation. The nutplate is designed to facilitate cost-effective manufacturing. The per hole cost of the integrated floating-fastener is approximately 30% of the cost of the industry standard riveted floating fastener.

Owner:RAYTHEON CO

Use of polycarboxylate ethers in combination with other additives for milling cement

InactiveUS20160024307A1Improve early strengthReducing floating of rustInksCement productionIron sulfateAlkaline earth metal

Use of an aqueous composition containing at least one polycarboxylate ether as cement grinding aid, wherein the aqueous composition contains one or more additives, or the aqueous composition is used in combination with one or more additives, and wherein the additive is selected from 1,3-propanediol, a carboxylic acid, a sulfonated amino alcohol, boric acid, a salt of boric acid, a salt of phosphoric acid, sorbitol, a saccharide, a gluconate, iron sulfate, tin sulfate, an antimony salt, an alkali salt, an alkaline earth salt, lignin sulfonate, glycerol, melamine, melamine sulfonate and mixtures thereof.

Owner:SIKA TECH AG

Increasing starch extraction rate in cereals

InactiveUS20080009615A1Enhanced grain production and storage and digestibility and palatabilityPromote weight gainSugar derivativesSugar derivatives preparationBiotechnologyHardness

The present invention provides for control of seed grain hardness resulting in improved cereals for both agricultural feed and commercial food products for human consumption.

Owner:MONTANA STATE UNIVERSITY +1

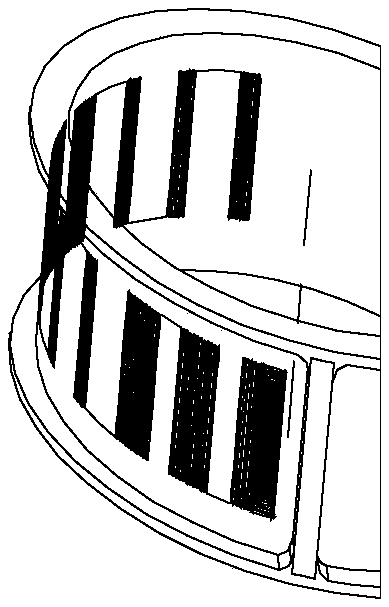

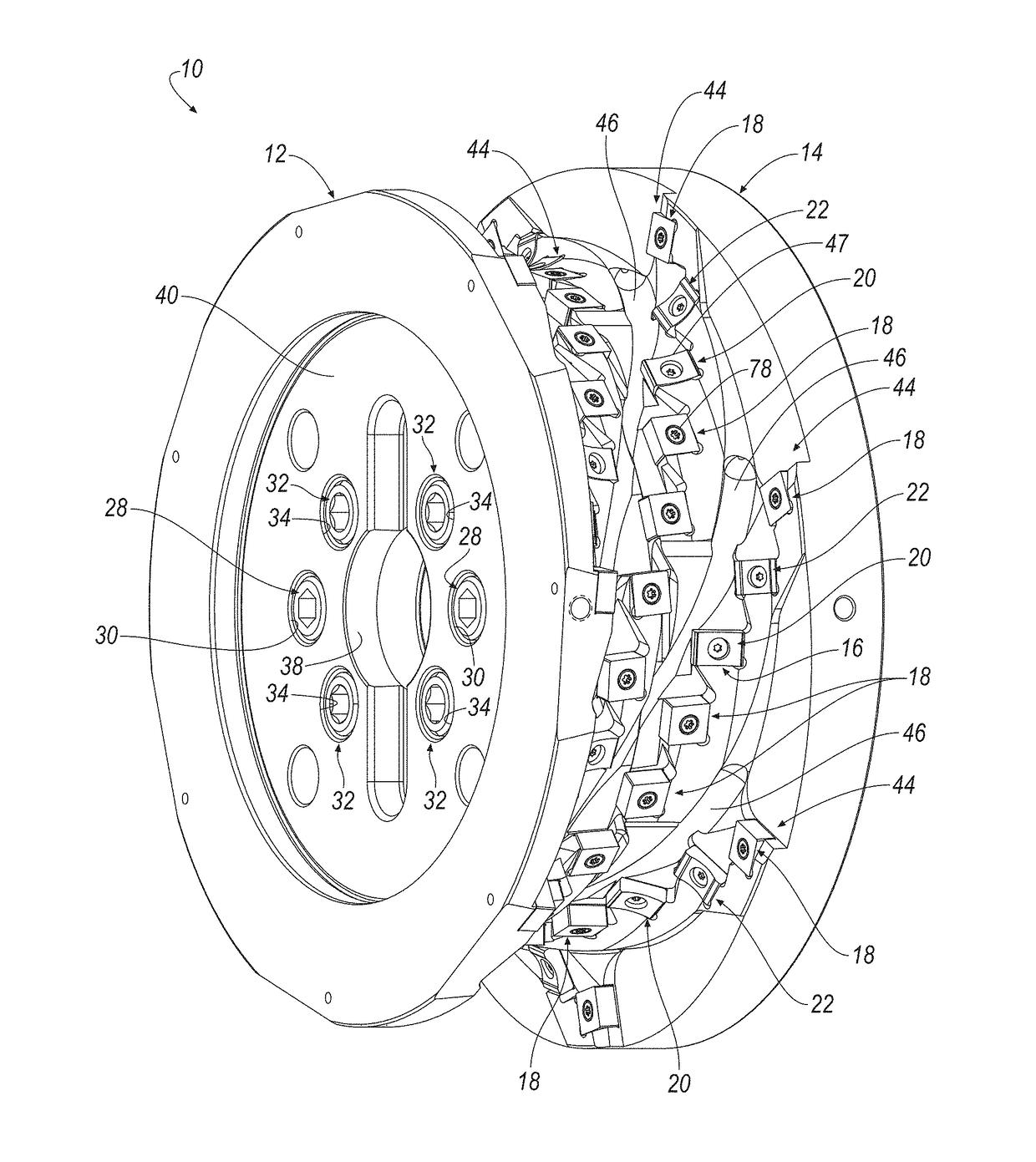

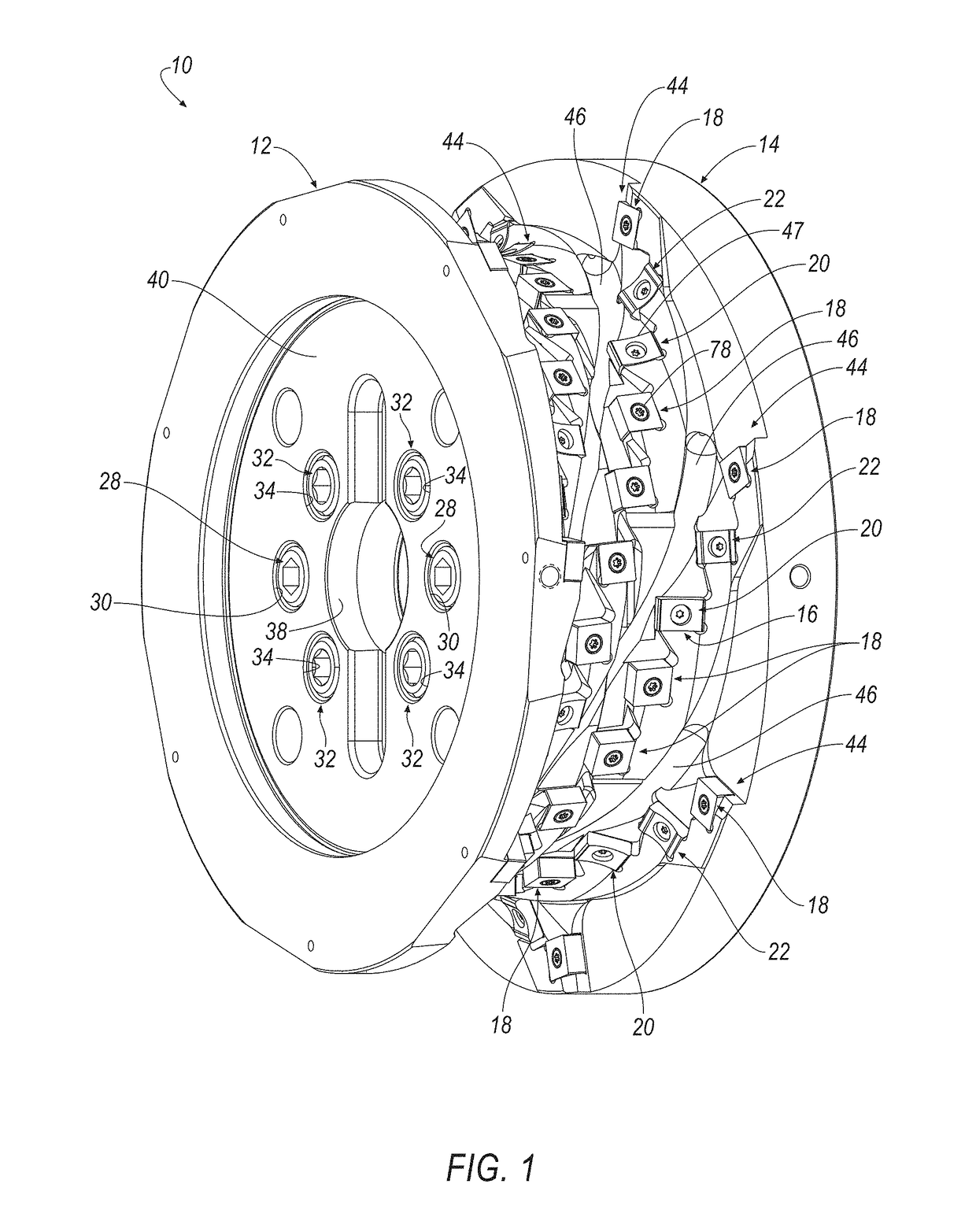

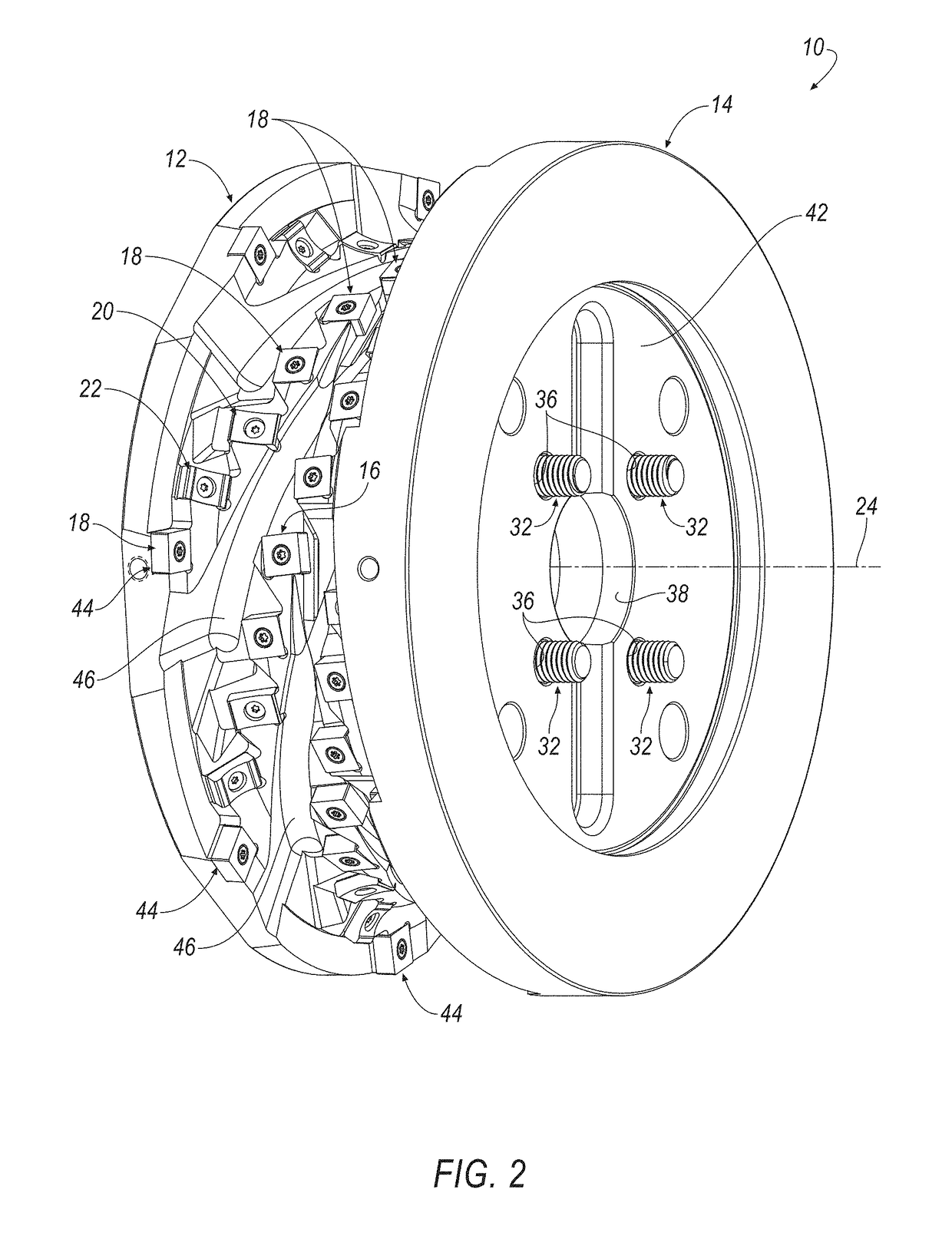

Cutting tool assembly for milling a rail top

A cutting tool assembly for milling a rail top, includes a first section and a second section mounted to the first section. Each section includes a plurality of insert-receiving pockets for receiving a plurality of different types of cutting inserts. The plurality of different types of cutting inserts are arranged in a plurality of helical teeth that may be separated by a helical chip flute. In one embodiment, a first type of cutting insert is formed with a radius, R, a second type of cutting insert is formed with a radius, R1, and a third type of cutting insert is formed with a radius, R2, to perform a milling operation on three different areas of the rail top.

Owner:KENNAMETAL INC

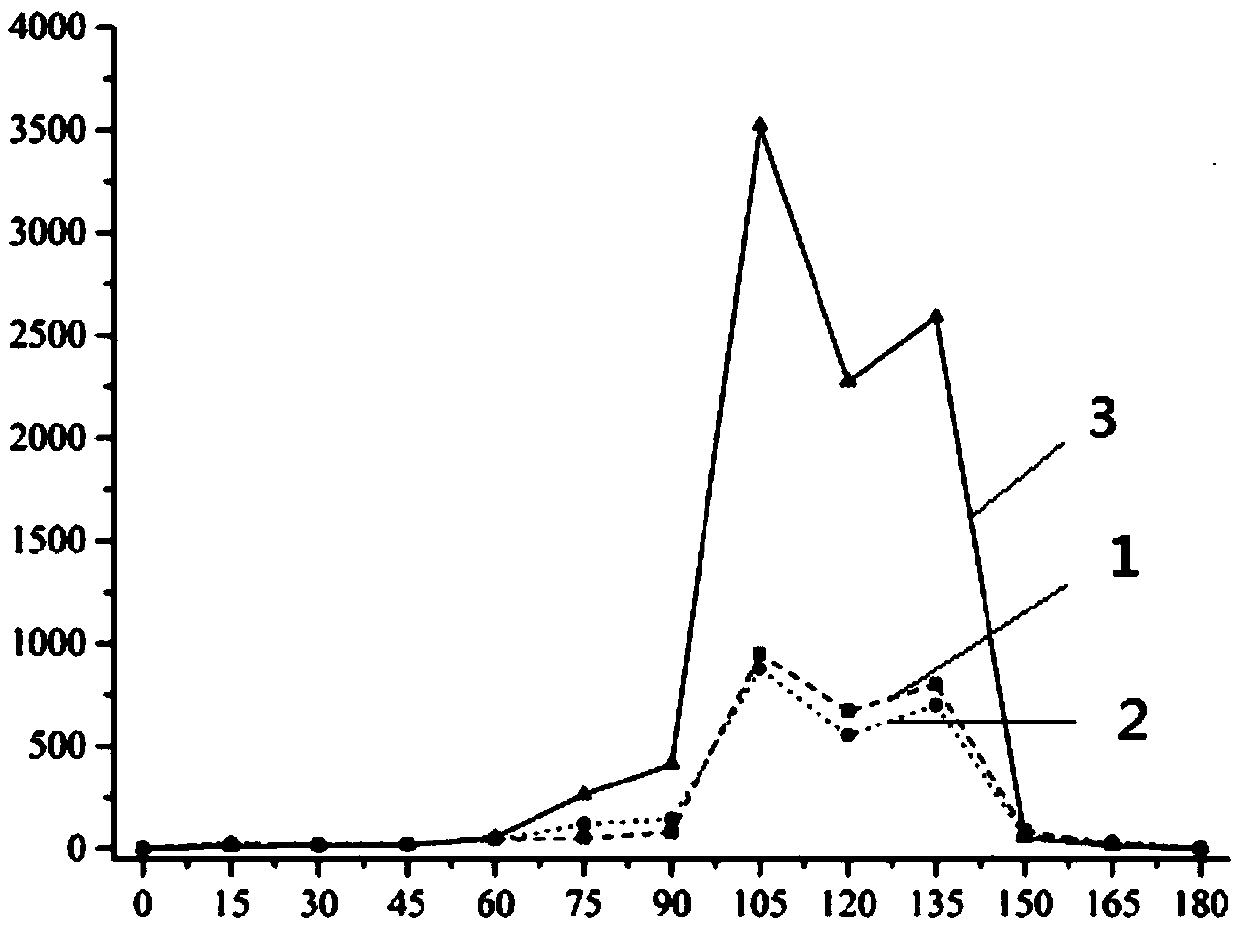

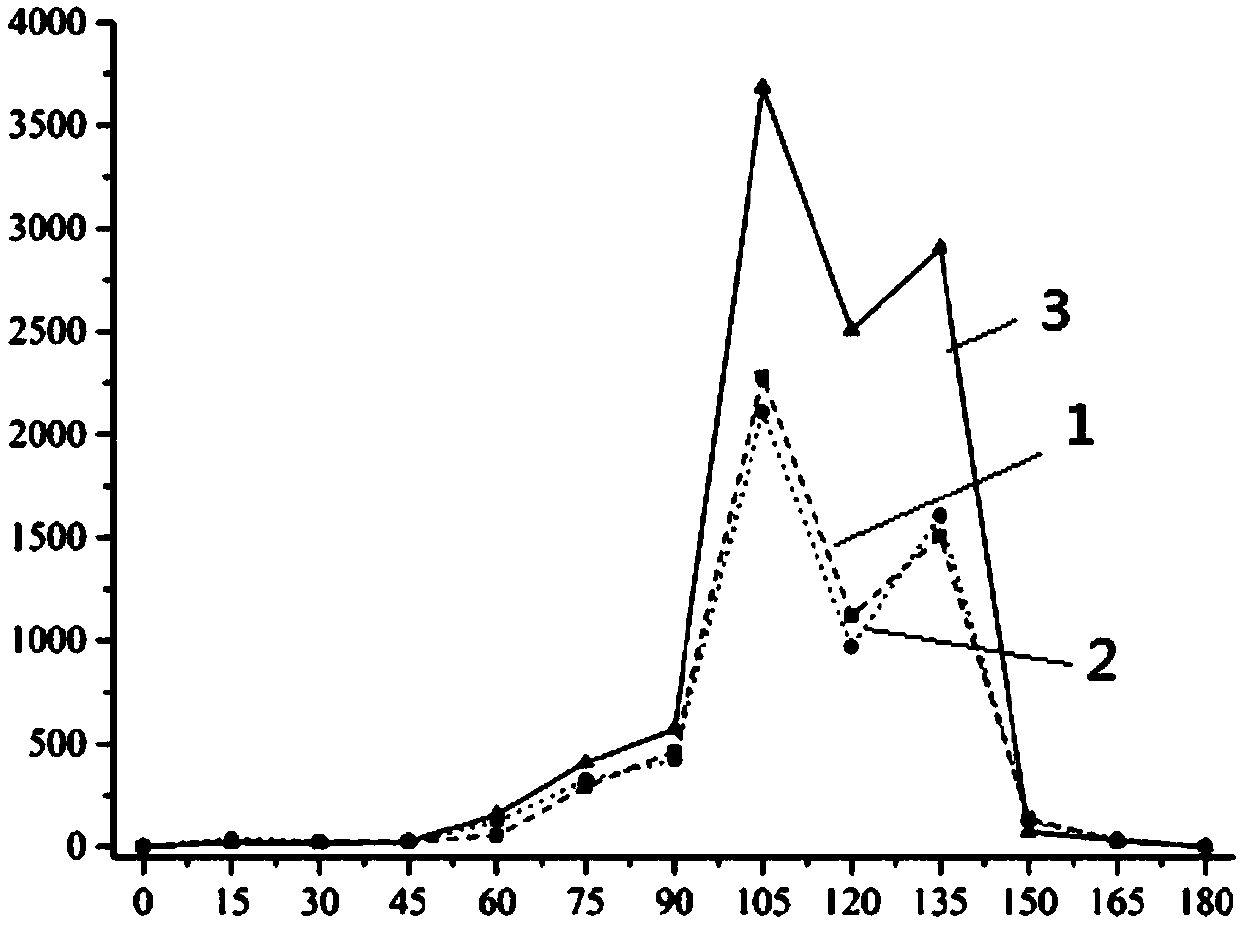

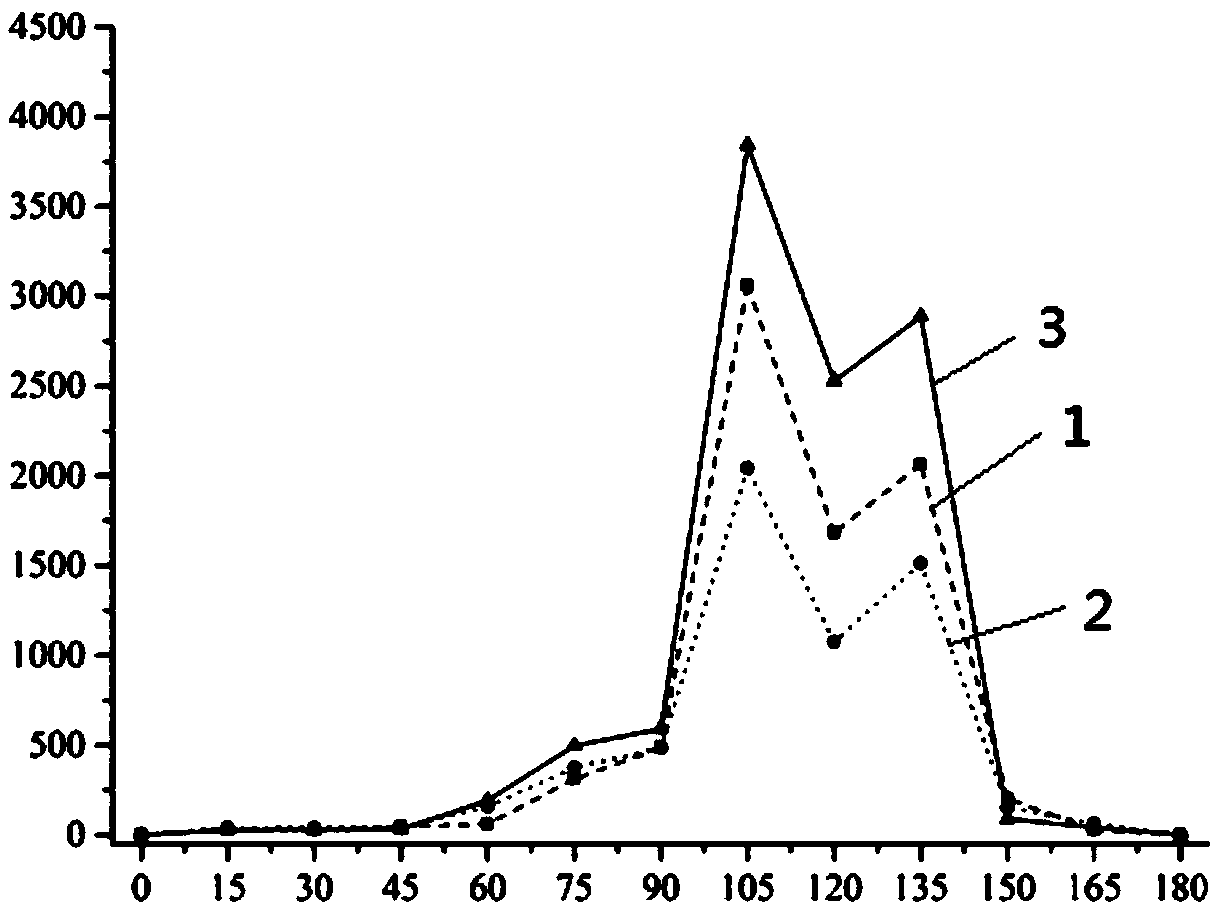

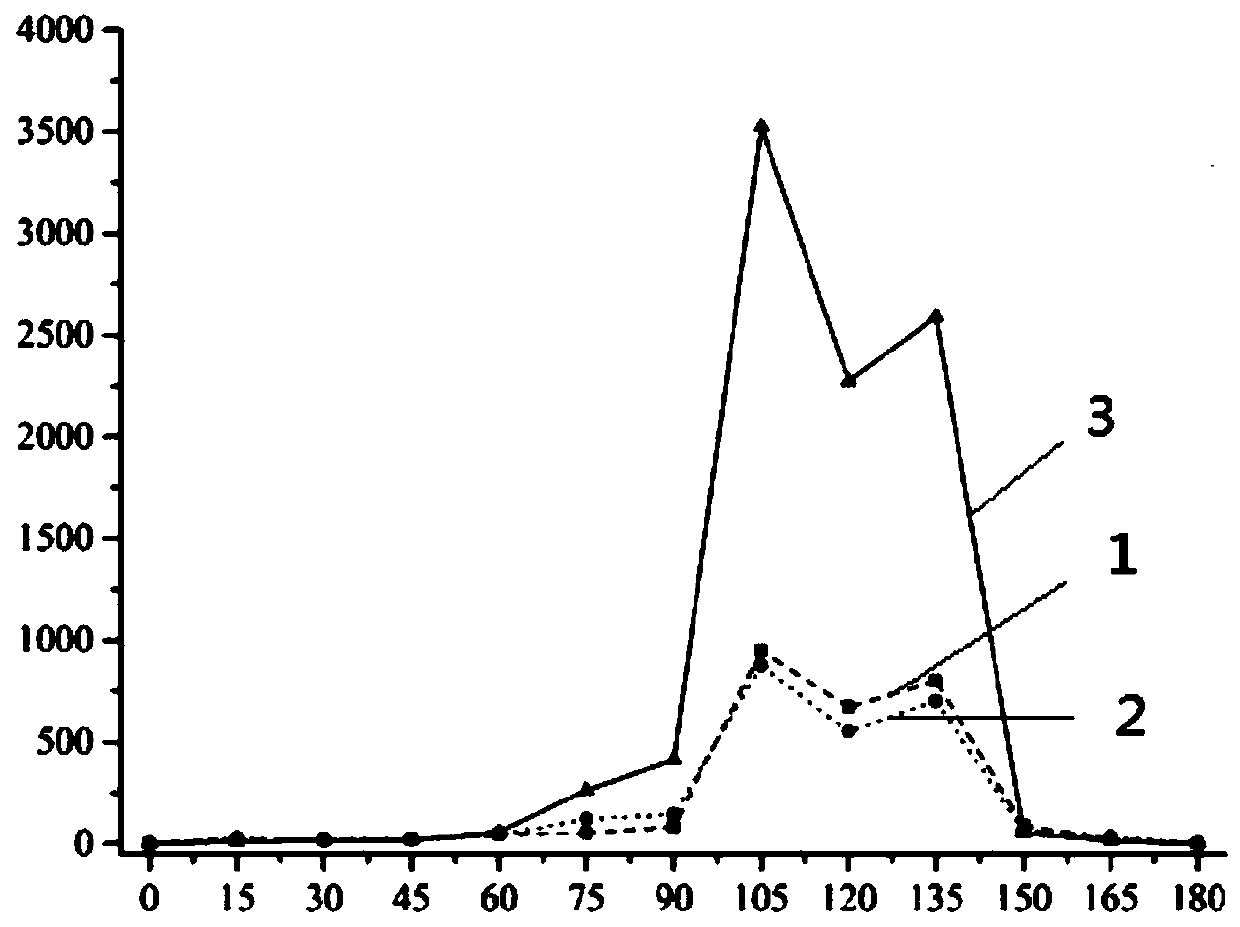

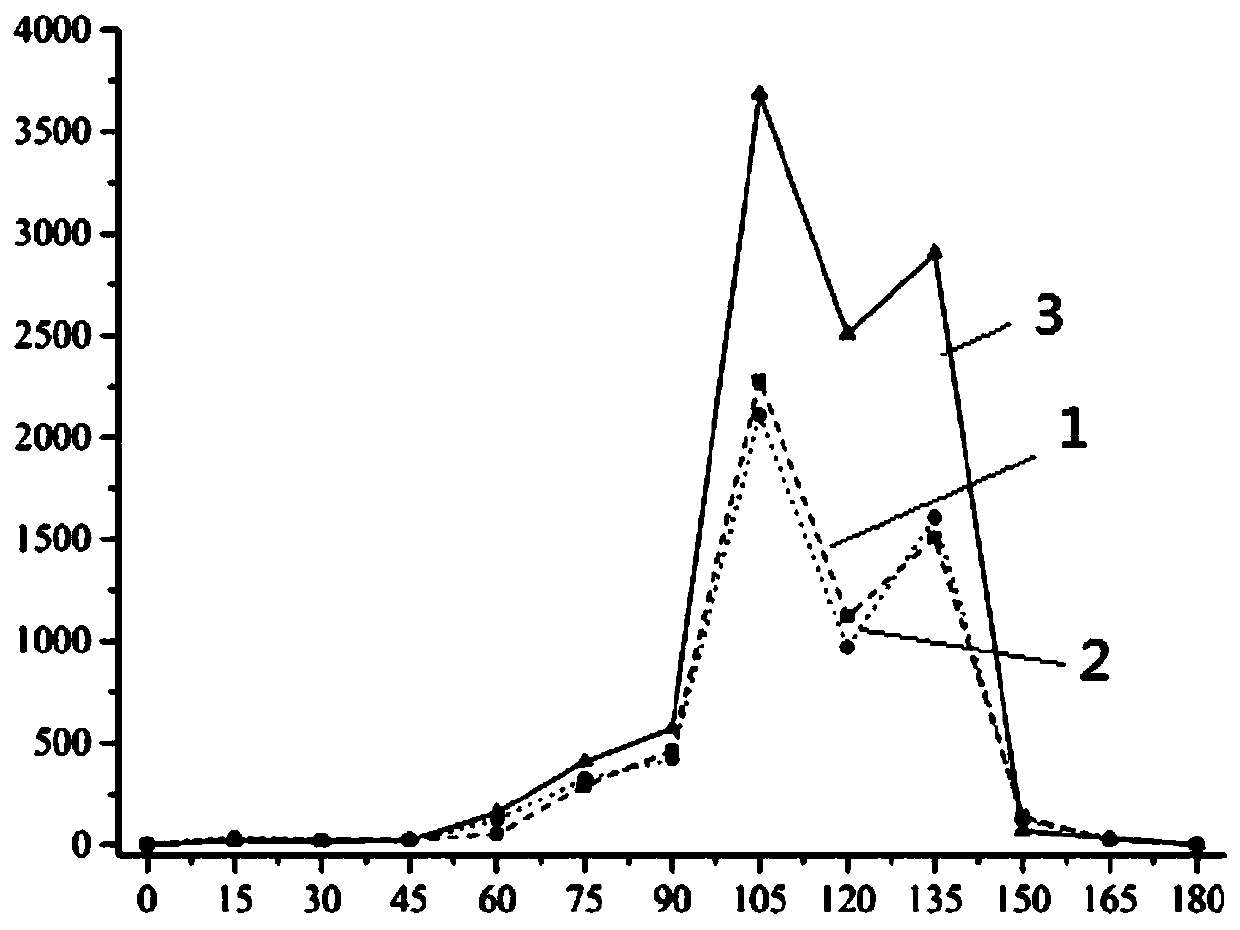

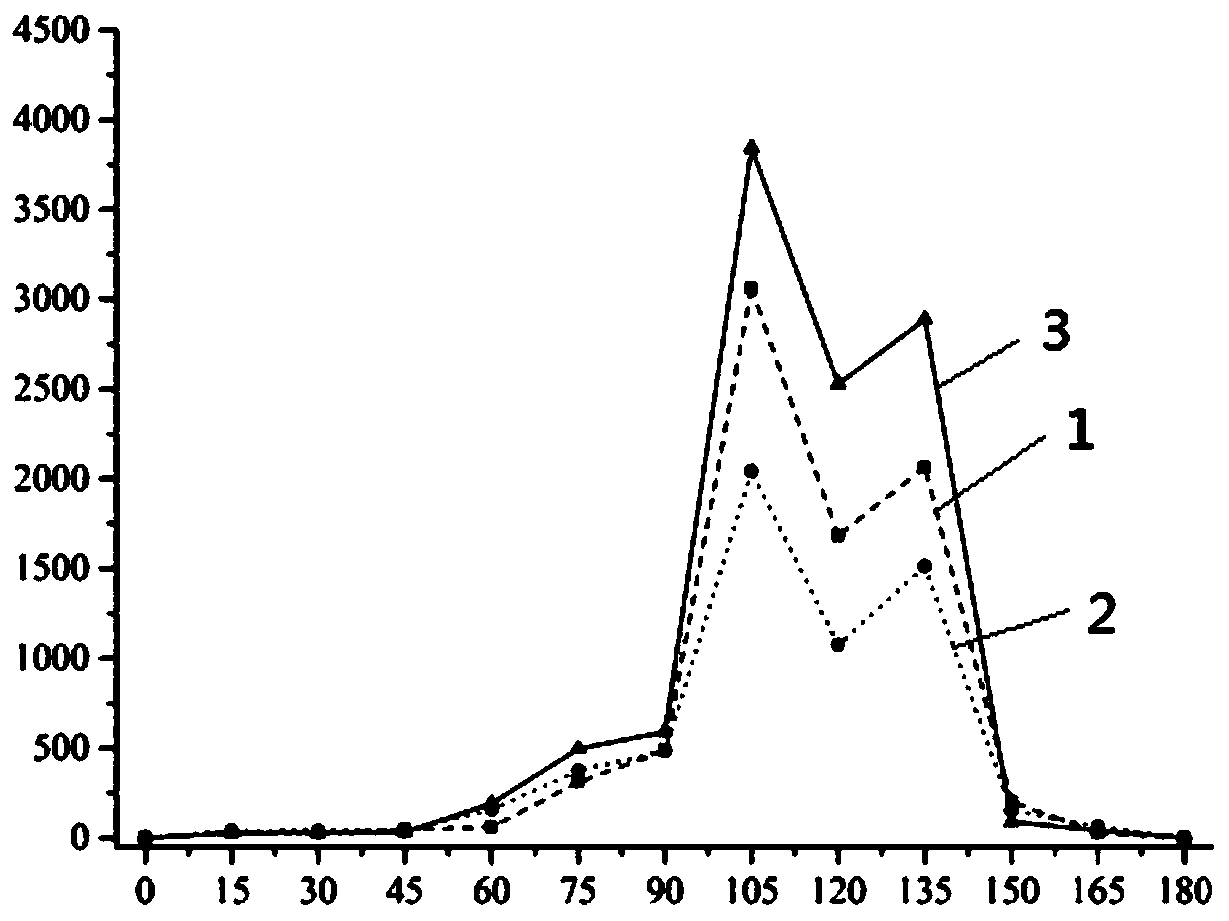

Optimizing selection method of carbon fiber composite down milling and upmilling machining manners

ActiveCN108393521AHigh-quality millingEfficient millingWorkpiecesMilling equipment detailsFibrous compositesMachining

The invention relates to an optimizing selection method of carbon fiber composite down milling and up milling machining manners and belongs to the technical field of machining. According to the optimizing selection method of the carbon fiber composite down milling and up milling machining manners, based on milling machining parameters, the actual change ranges of the fiber cutting angles in the milling process are correspondingly worked out, according to the properties of a utilized material and the utilized cutter structure, in an experiment or finite element calculation manner, the fiber cutting angle range enabling the machining quality to be the best is determined, the proportions of the condition that the actual ranges of the fiber cutting angles during down milling and up milling arewithin the optimal range are calculated finally, and the milling manner with the larger proportion is selected as the optimal milling manner under the working condition. By the adoption of the optimizing selection method, a new method can be provided for achievement of high-quality high-efficiency high-precision milling of a carbon fiber composite component, optimizing selection of the milling manners is achieved, the calculation steps are simple and convenient, and the optimizing selection method has good engineering application prospect.

Owner:DALIAN UNIV OF TECH

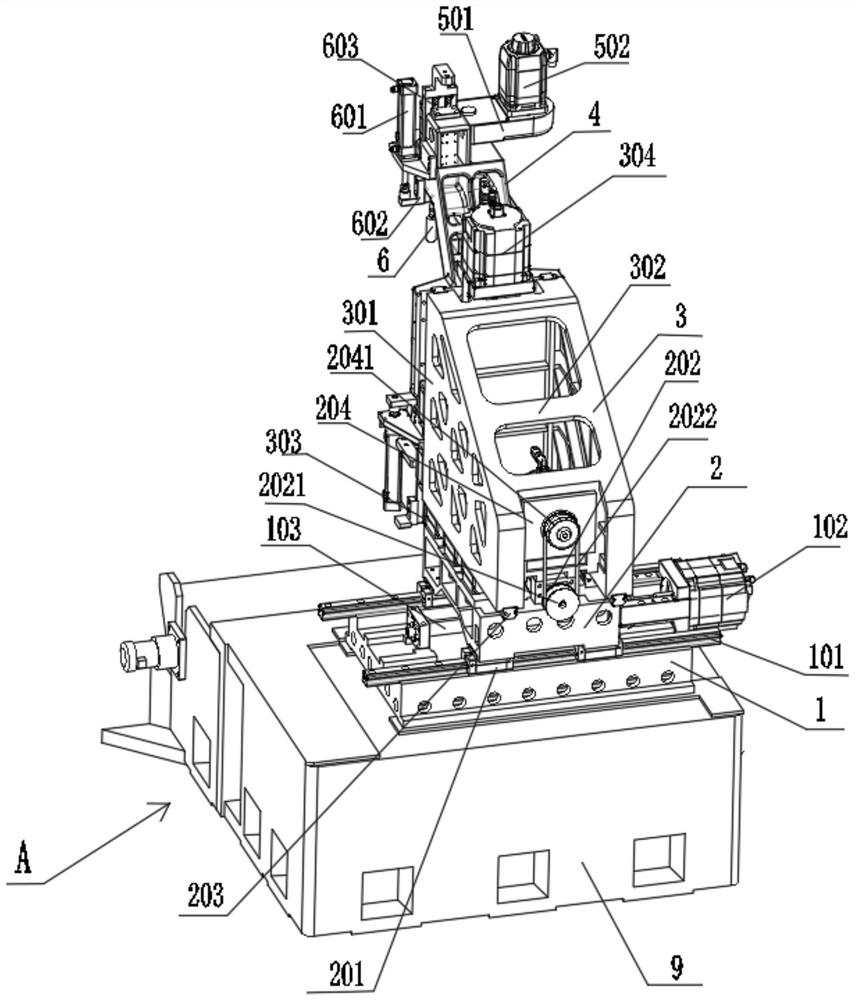

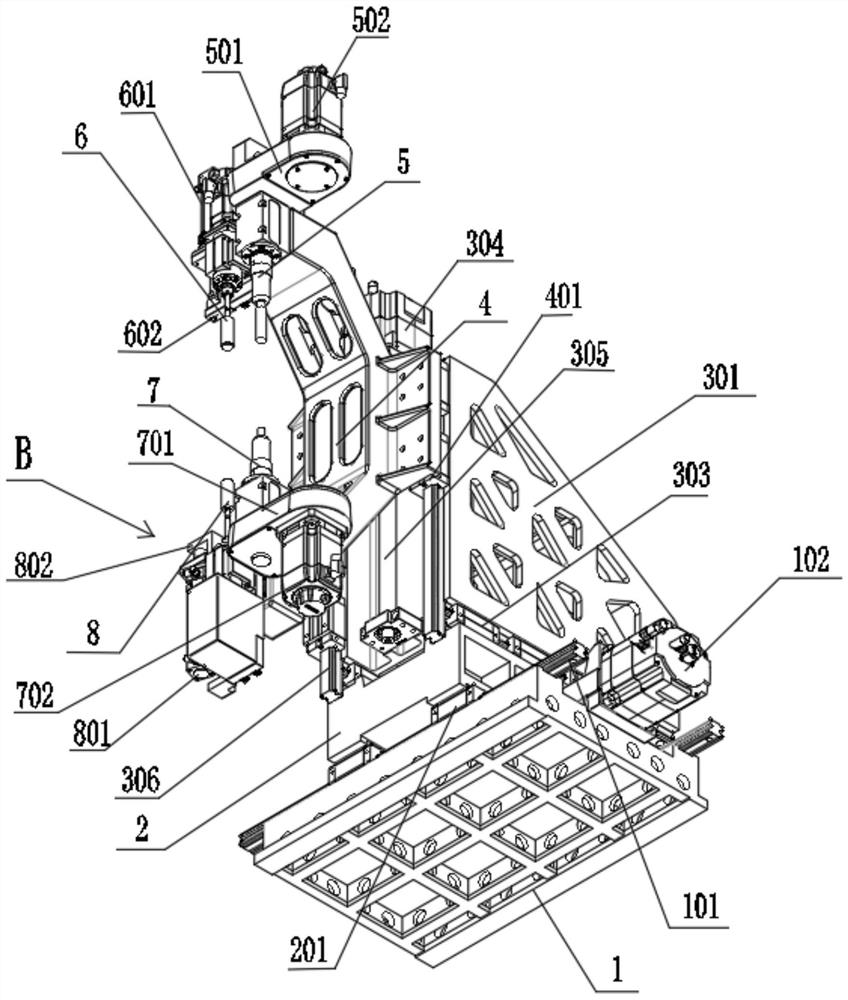

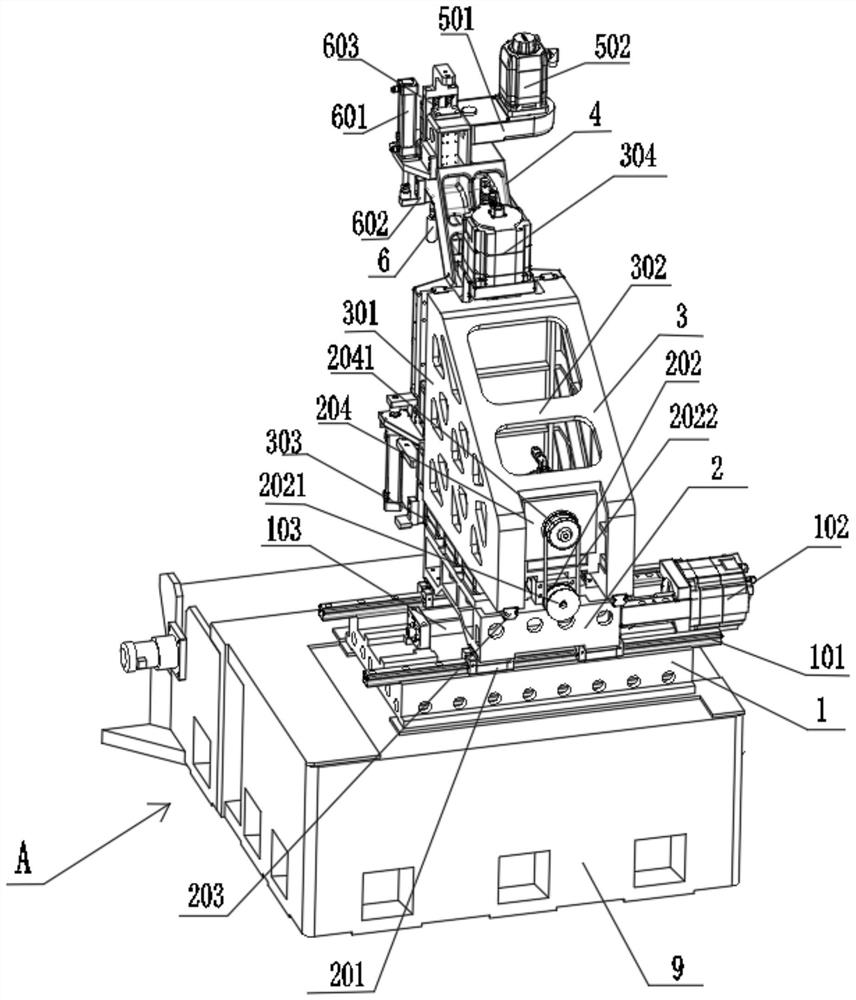

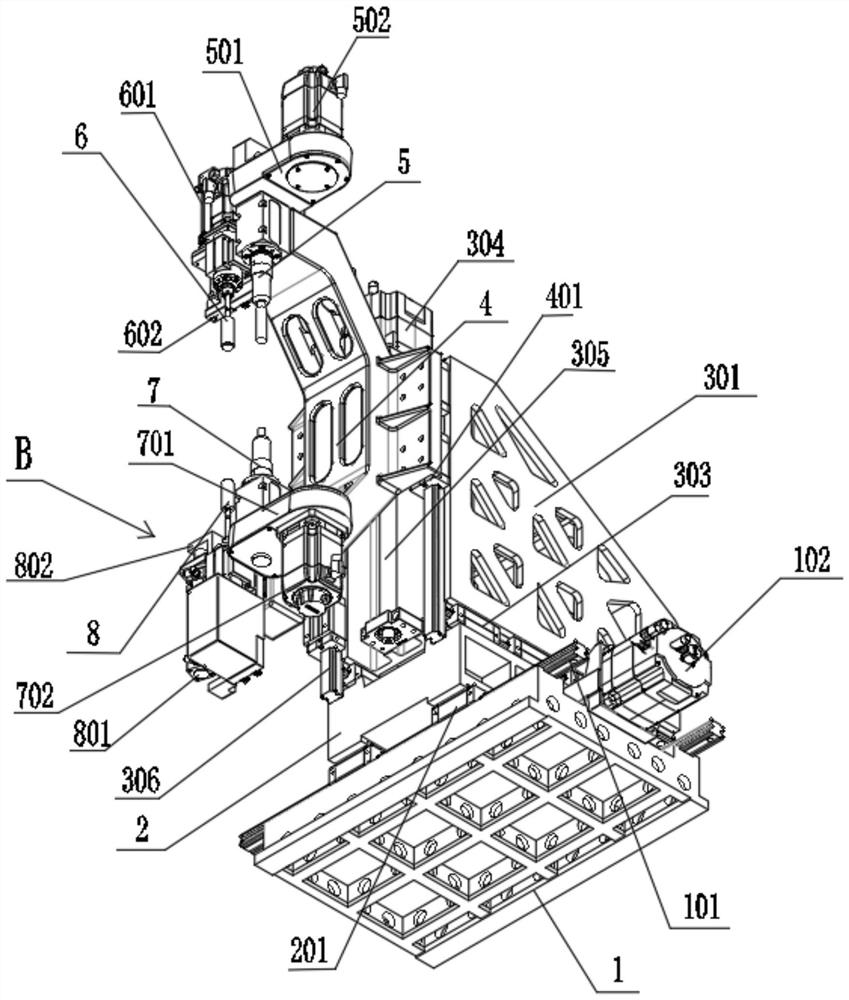

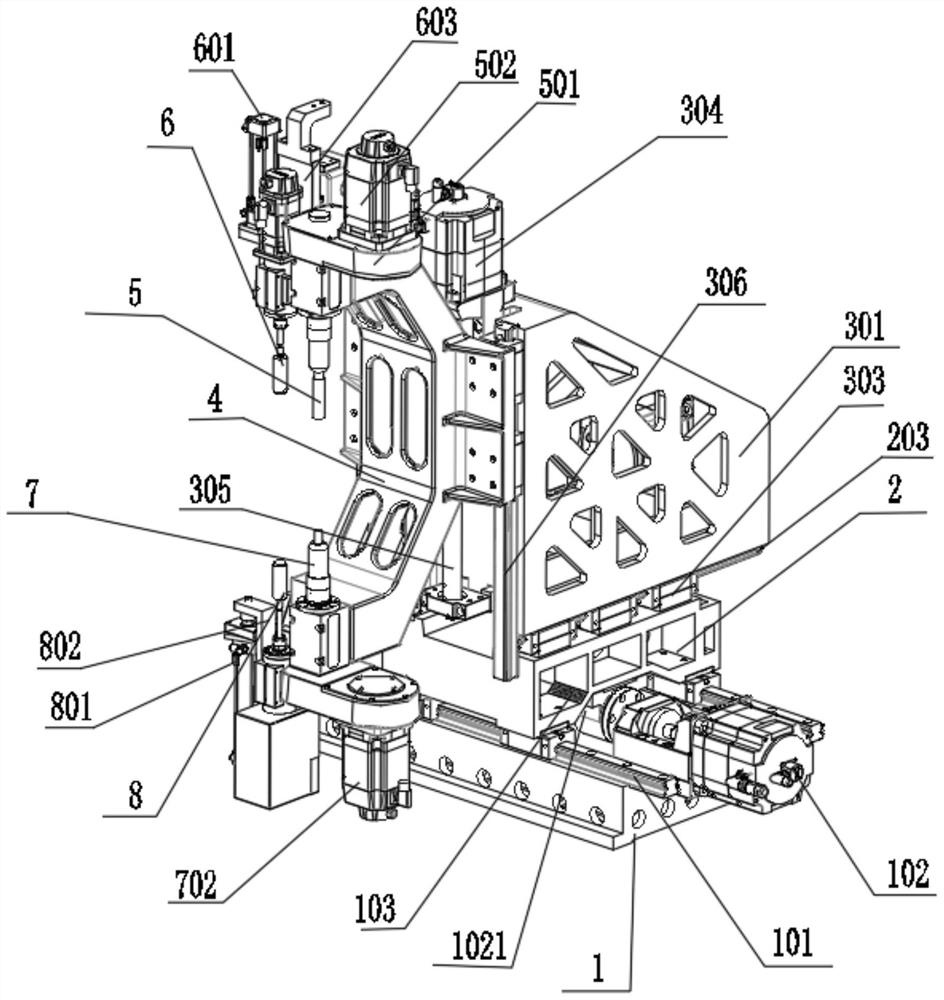

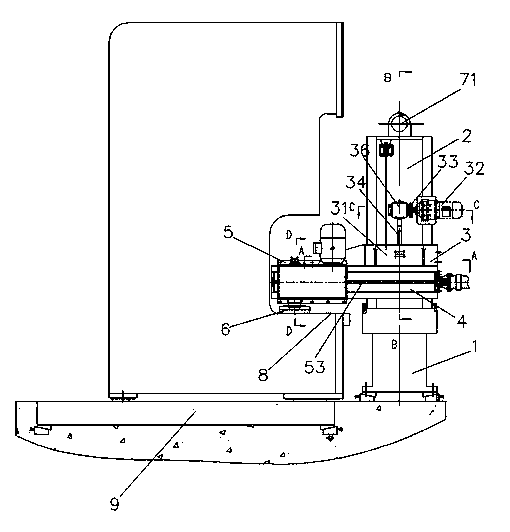

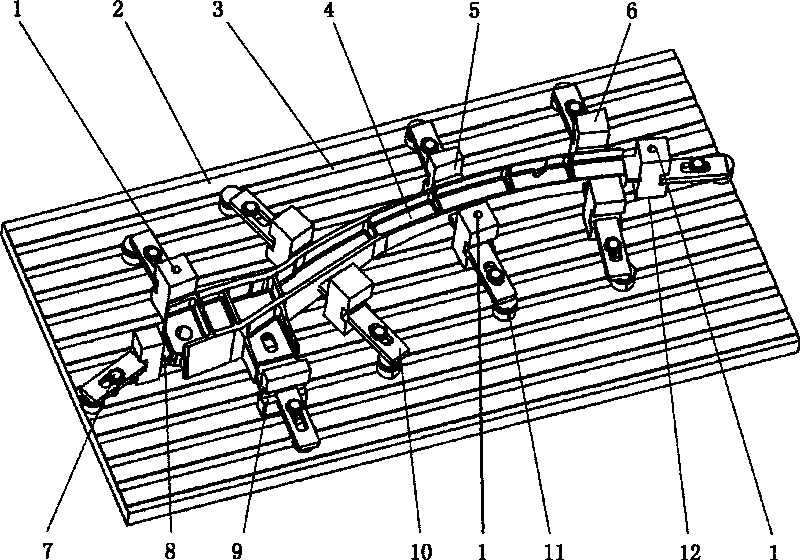

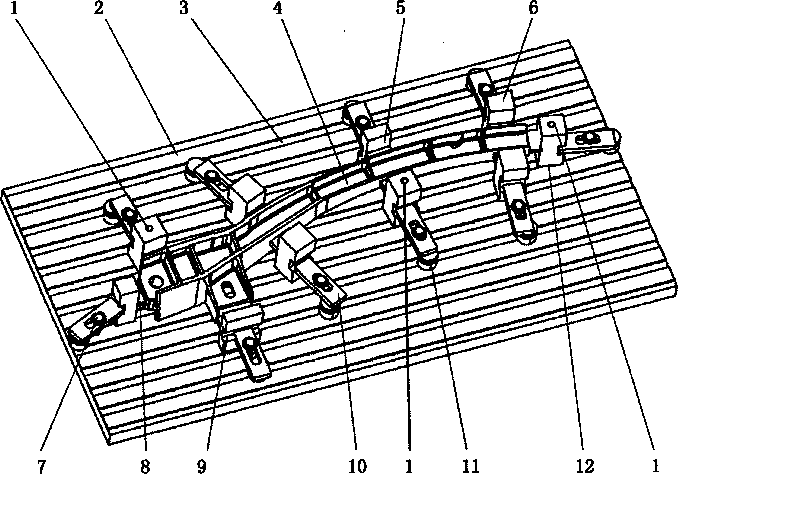

Three-axis linkage mechanism for processing battery box body tray frame assembly

InactiveCN114310429AImprove control efficiencyEfficient millingFeeding apparatusOther manufacturing equipments/toolsMilling cutterElectrical battery

The invention discloses a three-axis linkage mechanism for battery box body tray frame assembly machining, and relates to the technical field of battery box body tray machining. The deburring device comprises an X-axis translation structure, a Y-axis translation structure, a Z-axis translation structure and a C-shaped mounting frame, the upper end and the lower end of the C-shaped mounting frame are symmetrically arranged, a first milling cutter mechanism and a first deburring mechanism capable of conducting lifting motion are mounted on the side portion of the upper end of the C-shaped mounting frame, and a second milling cutter mechanism and a second deburring mechanism capable of conducting lifting motion are mounted on the lower end portion of the C-shaped mounting frame; the first milling cutter mechanism and the second milling cutter mechanism are symmetrically and oppositely arranged, and the first deburring mechanism and the second deburring mechanism are symmetrically and oppositely arranged. According to the full-automatic milling and deburring mechanism, efficient milling and deburring actions can be performed on the upper surface and the lower surface of the automobile battery box body tray frame assembly workpiece in a full-automatic manner, the machining rhythm is efficient and accurate, the control efficiency is high, the occupied space is small, the structure is compact and efficient, the weight is light, and the material cost of the mechanism is low.

Owner:驭孚智能科技(上海)有限公司

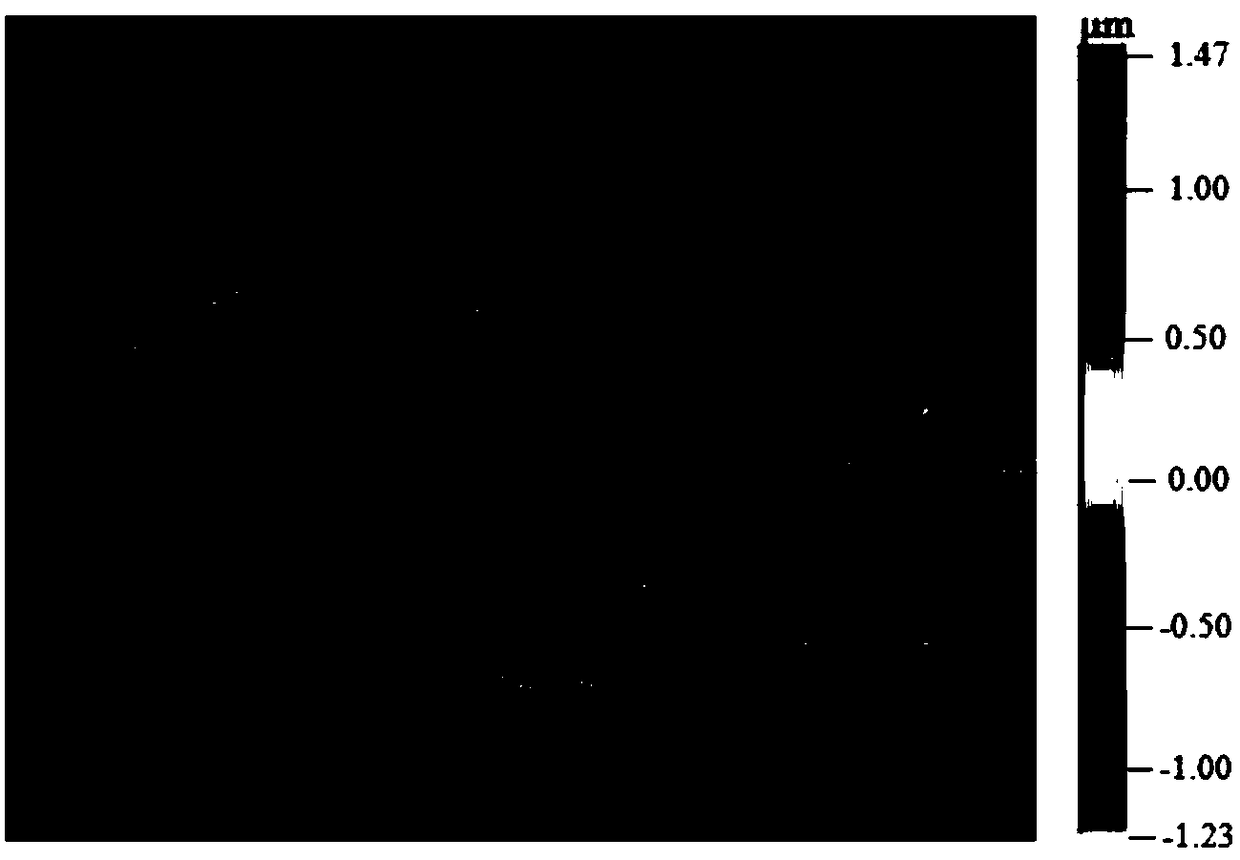

Anti-fatigue efficient milling parameter optimization control method for titanium alloy thin-wall component

InactiveCN108563849AEfficient Surface IntegrityImprove surface integrityGeometric CADConstraint-based CADMaterial removalMATLAB

The invention discloses an anti-fatigue efficient milling parameter optimization control method for a titanium alloy thin-wall component. The method comprises the following steps that: establishing the primary election technological parameter domain of a titanium alloy thin-wall component; carrying out an orthogonal test; testing the surface integrity parameter of a test component; establishing acharacteristic relational expression of a titanium alloy thin-wall component milling technological parameter and surface integrity; according to the relational expression of the titanium alloy thin-wall component milling technological parameter and the surface integrity, a target function and a milling technological parameter constraint condition, establishing an optimization model for the anti-fatigue efficient milling parameter of the titanium alloy thin-wall component; and through an optimization tool in MATLAB, solving the optimization model for the anti-fatigue efficient milling parameterof the titanium alloy thin-wall component to obtain the anti-fatigue efficient milling parameter of the titanium alloy thin-wall component. By use of the method, the problems of poor surface integrity characteristic and low material removal rate in a milling process of the titanium alloy thin-wall component are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

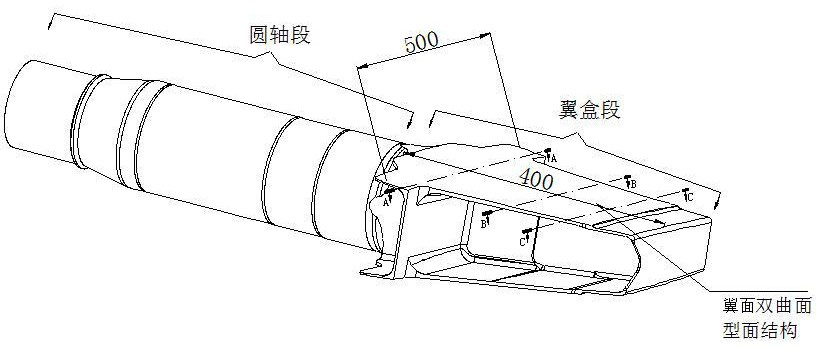

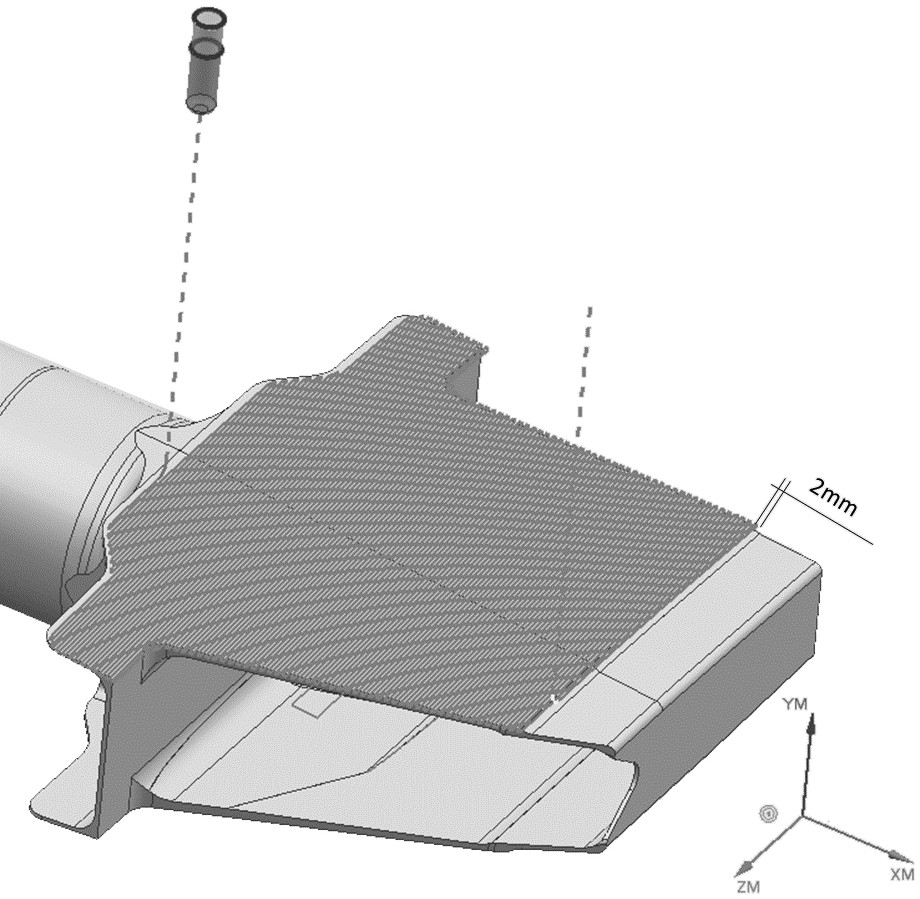

End mill and rotating shaft beam airfoil hyperboloid milling method based on end mill

InactiveCN113369551AIncrease arcSolve the problem of small line spacingMilling cuttersMilling equipment detailsMilling cutterPolishing

The invention discloses an end mill and a rotating shaft beam airfoil hyperboloid milling method based on the end mill, the end mill is suitable for efficient machining and forming of small-curvature hyperboloids, and the radian of a contact point of a cutter and a material is increased in cutter bottom edge machining, so that the cutting line spacing can be increased; the problem that the row spacing is small when a large-R bull-nose milling cutter is used for machining a curved surface through a fixed shaft is effectively solved, the part machining efficiency is improved by times, and meanwhile, a large amount of manual polishing by bench workers is eliminated. When the curved surface of the wing surface of the rotating shaft beam is milled, under the condition that the cutting linear speed, the feeding amount per tooth and the cutting residual height are not changed, the cutting efficiency is improved by about 5 times compared with that of a five-tooth integral hard alloy milling cutter used in an original process, so that the part surface line cutting time is about 40 min; and meanwhile, the cutting surface quality is improved, the surface texture is uniform, smooth and free of sticky chips; and the size precision of the machined curved surface completely meets the inspection requirements, a large amount of manual polishing of bench workers is eliminated, and the practicability is good.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Milling tool as well as a milling insert

ActiveUS9333568B2Ample ramping angleSimple and cost-effective wayTransportation and packagingMilling cuttersEdge segmentEngineering

A double-sided, indexable milling insert has a round basic shape defined by an imaginary cylinder, which is concentric with a center axis and extends between two reference planes that extend perpendicular to the center axis and are equidistantly separated from a neutral plane. The milling insert includes a pair of opposite chip faces located in the reference planes between which an envelope surface concentric with the center axis extends, a plurality of identical and alternately usable cutting edges along the peripheries of the chip faces, and lock means for rotationally securing the milling insert in one of several predetermined index positions. The individual cutting edge has the shape of a wave trough and includes two edge segments that meet at a bottom point.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Three-axis linking mechanism for processing battery box body tray frame assembly

InactiveCN111604696AEfficient and precise processing rhythmImprove control efficiencyOther manufacturing equipments/toolsLarge fixed membersStructural engineeringAutomotive battery

The invention discloses a three-axis linking mechanism for processing a battery box body tray frame assembly and relates to the technical field of processing a battery box body tray. The three-axis linking mechanism comprises an X-axis direction translation structure, a Y-axis direction translation structure, a Z-axis direction translation structure and a C shaped mounting rack; the C shaped mounting rack is arranged with the upper and lower ends being symmetrical; a first milling cutter mechanism and a first deburring mechanism capable of doing lifting motion are mounted on the side part of the upper end; a second milling cutter mechanism and a second deburring mechanism capable of doing lifting motion are mounted at the lower end part; the first milling cutter mechanism and the second milling cutter mechanism are symmetrically and oppositely arranged; and the first deburring mechanism and the second deburring mechanism are symmetrically and oppositely arranged. The three-axis linkingmechanism can efficiently carry out milling and deburring operation on the upper and lower surfaces of a workpiece of the automobile battery box body tray frame assembly in a full-automatic manner, is efficient and precise in processing pace, high in control efficiency, small in occupied area, compact and efficient in structure, light in self weight and low in material cost.

Owner:驭孚智能科技(上海)有限公司

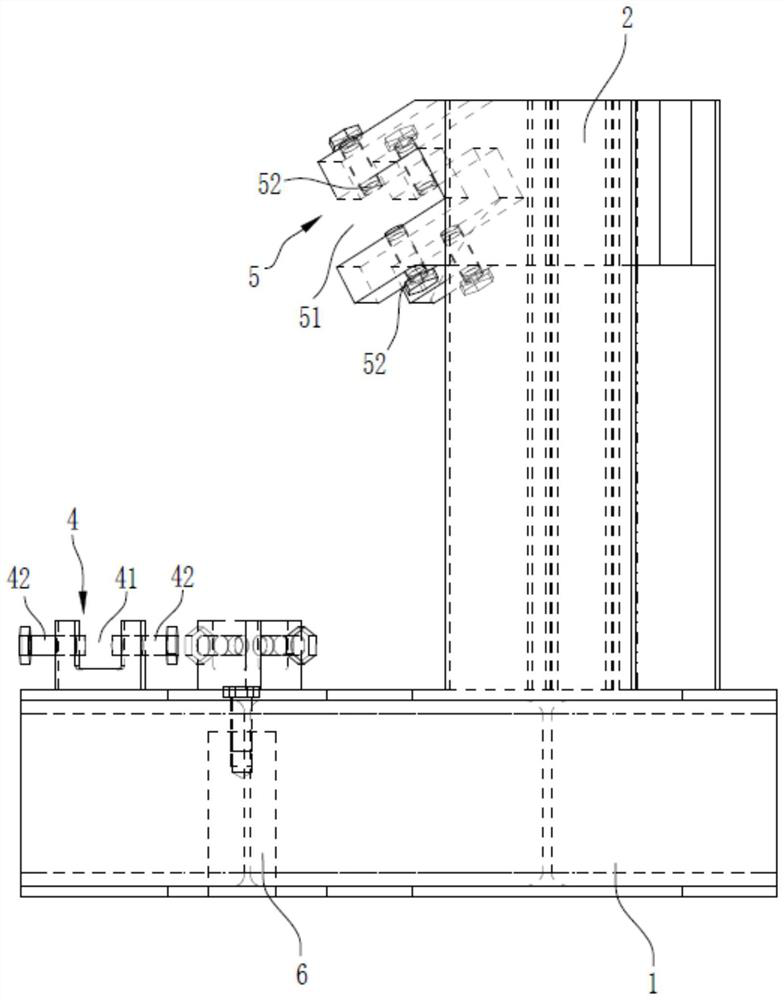

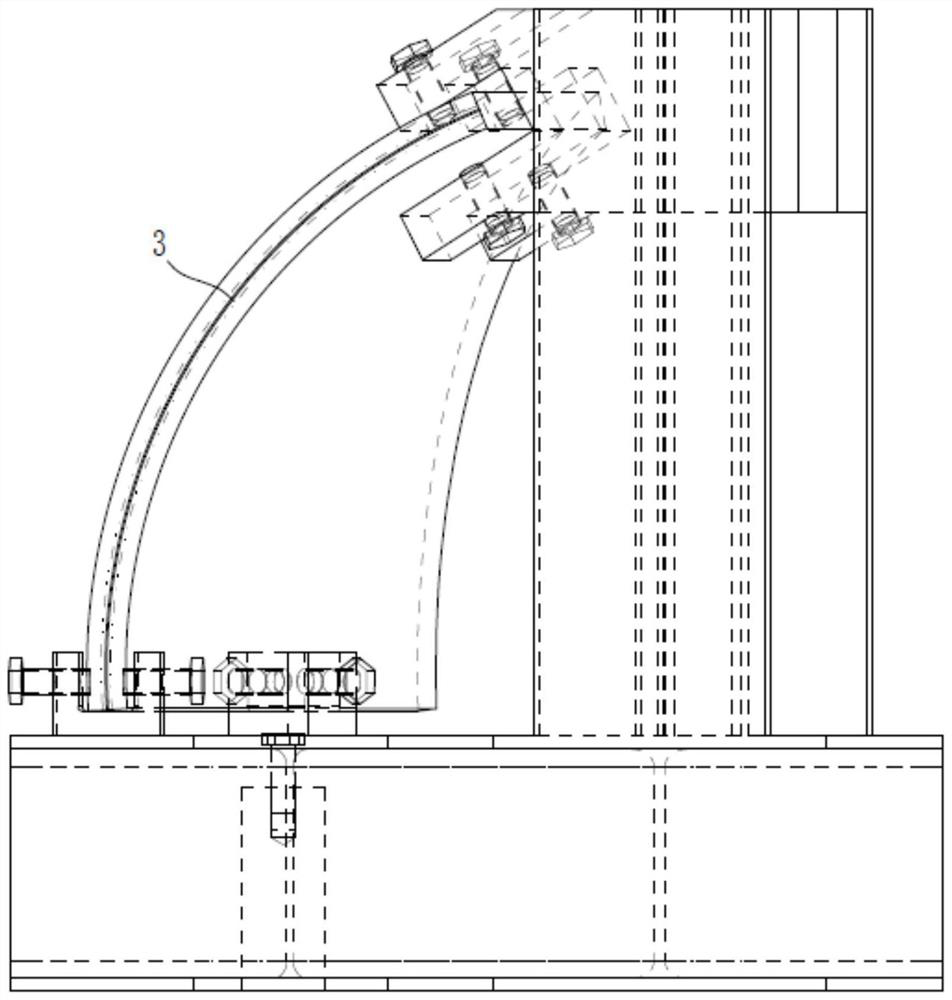

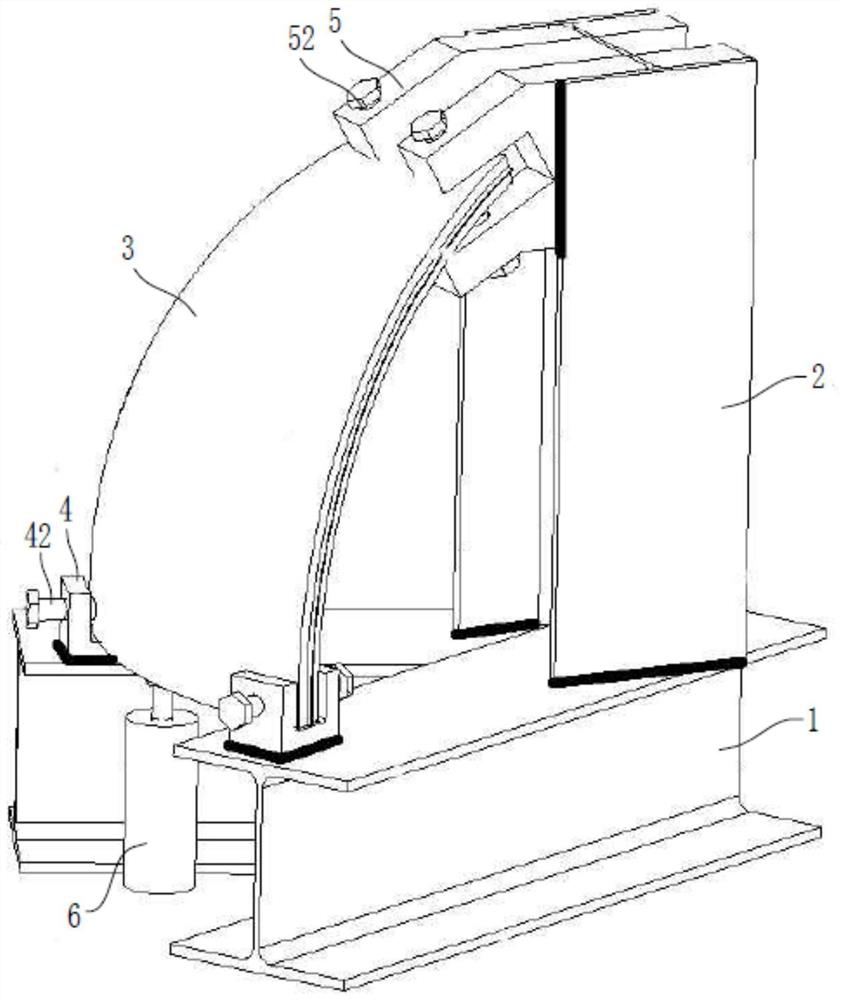

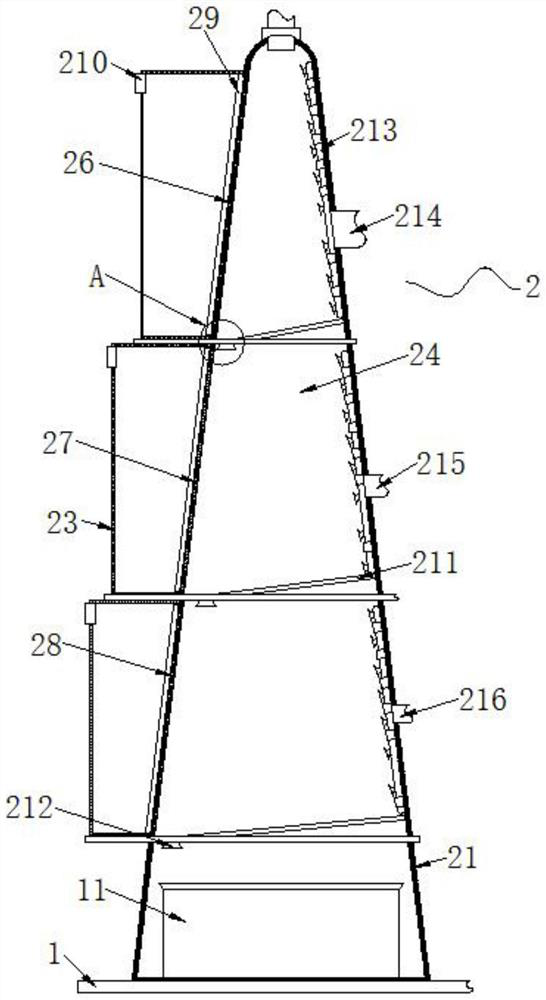

Titanium alloy thick-wall spherical head scalloped petal longitudinal seam groove milling and fixing device and machining method

PendingCN114193191AEasy to installPrecise positioningLarge fixed membersPositioning apparatusTitanium alloyMachining

The invention belongs to the field of titanium alloy thick-wall spherical head scalloped petal longitudinal seam groove milling, and particularly relates to a titanium alloy thick-wall spherical head scalloped petal longitudinal seam groove milling fixing device and a machining method. The fixing device comprises a bottom supporting base and a vertical supporting frame, at least two sets of bottom clamping bases capable of fixedly clamping the large end of the scalloped segment part are installed on the bottom supporting base, and the bottom clamping bases are provided with bottom adjusting mechanisms. The vertical supporting frame is provided with at least two sets of top clamping bases capable of fixedly clamping the small ends of the scalloped segment parts, and the top clamping bases are provided with top adjusting mechanisms. And the height adjusting mechanism is used for adjusting the height of the scalloped segment part. According to the device, the scalloped segment parts are easy to install, position and fix, and positioning is accurate; batched scalloped segment parts of the same specification are convenient to machine and position, the machining efficiency is obviously improved, and efficient and high-precision milling machining of longitudinal seam grooves of the titanium alloy thick-wall spherical end socket scalloped segment parts is facilitated.

Owner:NANJING BAOSE

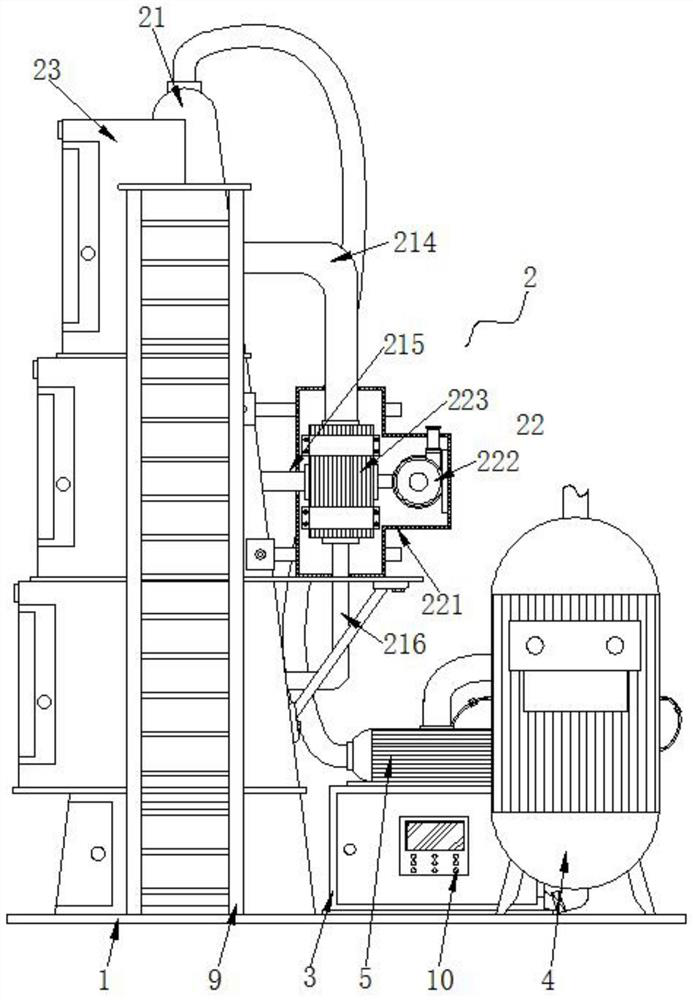

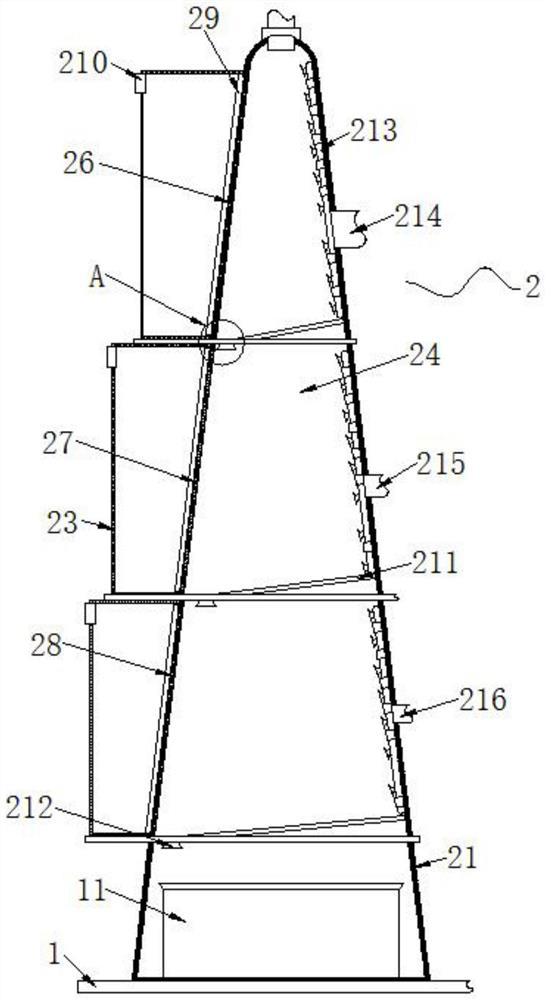

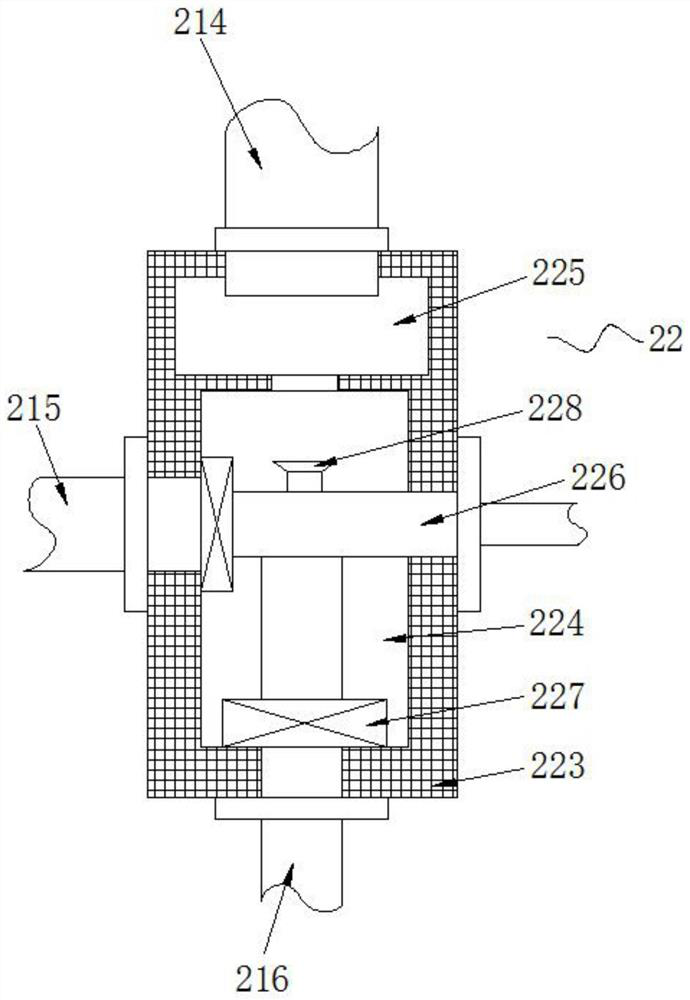

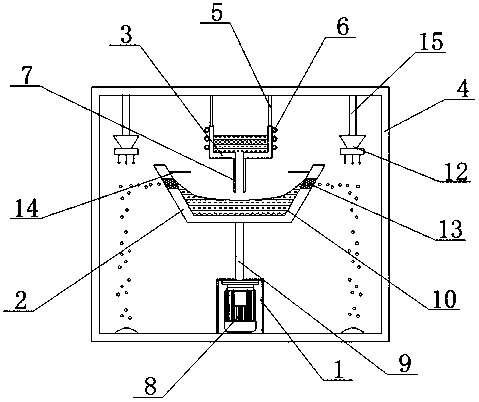

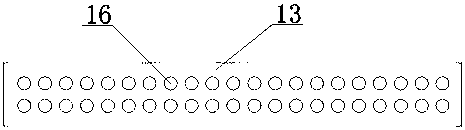

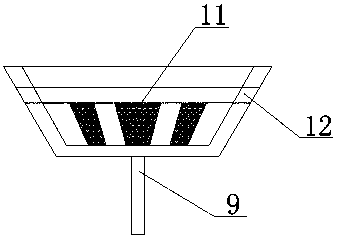

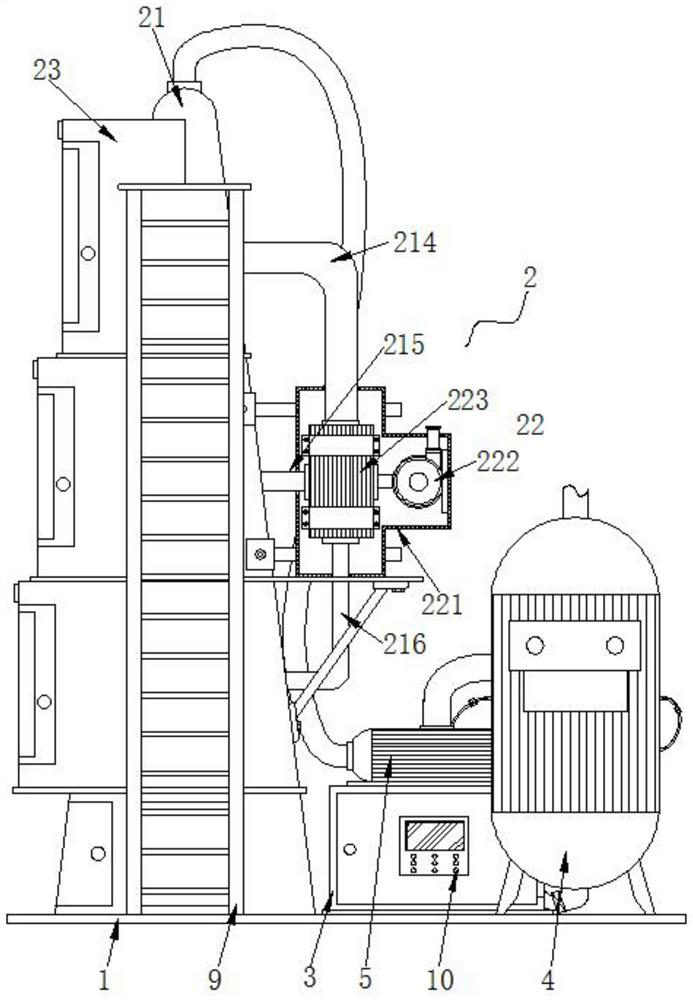

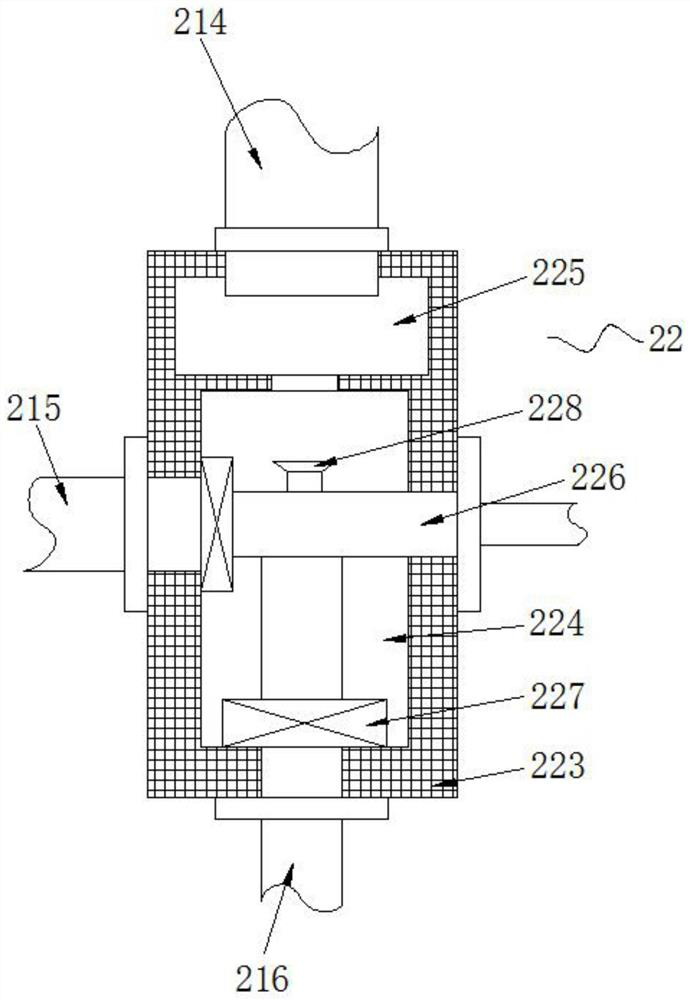

Pelleting and screening system used for producing high polymer material

ActiveCN111632705AReduce screening costsImprove screening efficiencyGas current separationGrain treatmentsProcess engineeringIndustrial engineering

The invention discloses a pelleting and screening system used for producing a high polymer material. The system comprises a base, and further comprises a winnowing mechanism, a control box and a smashing mechanism which are fixedly installed on the base in sequence from left to right. A material drawing pump is fixedly installed on the top of the control box through a connecting plate. A discharging opening of the material drawing pump communicates with a feeding opening in the top of the winnowing mechanism through a material guide pipe. The invention relates to the technical field of high polymer material production. According to the pelleting and screening system used for producing the high polymer material, by the adoption of the winnowing mechanism, the situation a large area of powder is piled up on a screen, and the screen is blocked is avoided, and the screening cost of the high polymer material is saved greatly. Multi-level screening can be completed at a time, the screening efficiency is improved greatly, a crushing mechanism and grinding equipment are combined into one, free switching work between crushing and grinding can be completed by controlling the extruding interval in crushing and grinding mechanisms, the equipment is simple in structure and low in cost, and the production efficiency is improved greatly.

Owner:苏州路熙智能科技有限公司

Metal powder manufacturing device capable of controlling grain size of metal powder

The invention provides a metal powder manufacturing device capable of controlling the grain size of metal powder. The metal powder manufacturing device comprises a powder manufacturing device body. The powder manufacturing device body comprises a motor base, a rotating ring, a heating crucible and a housing. A first fixed rod is arranged at the top of the heating crucible. One end of the first fixed rod is welded on the inside wall at the top of the housing. A heating coil sleeves the heating crucible. A draft tube is arranged at the bottom of the heating crucible. A motor is arranged in the motor base. A rotating shaft is arranged at the bottom of the rotating ring. A through hole is formed in the top of the motor base. One end of the rotating shaft penetrates through the through hole tobe mounted on the output shaft of the motor. A rotating groove is formed in the top of the rotating ring. A diversion trench is formed in the inside wall of the rotating groove. A leakage net is arranged at the top of the diversion trench. An overflowing-preventing plate is arranged at the top of the leakage net. The metal powder manufacturing device is reasonable in design, high in powder manufacturing efficiency, and high in finished product ratio.

Owner:王若渔

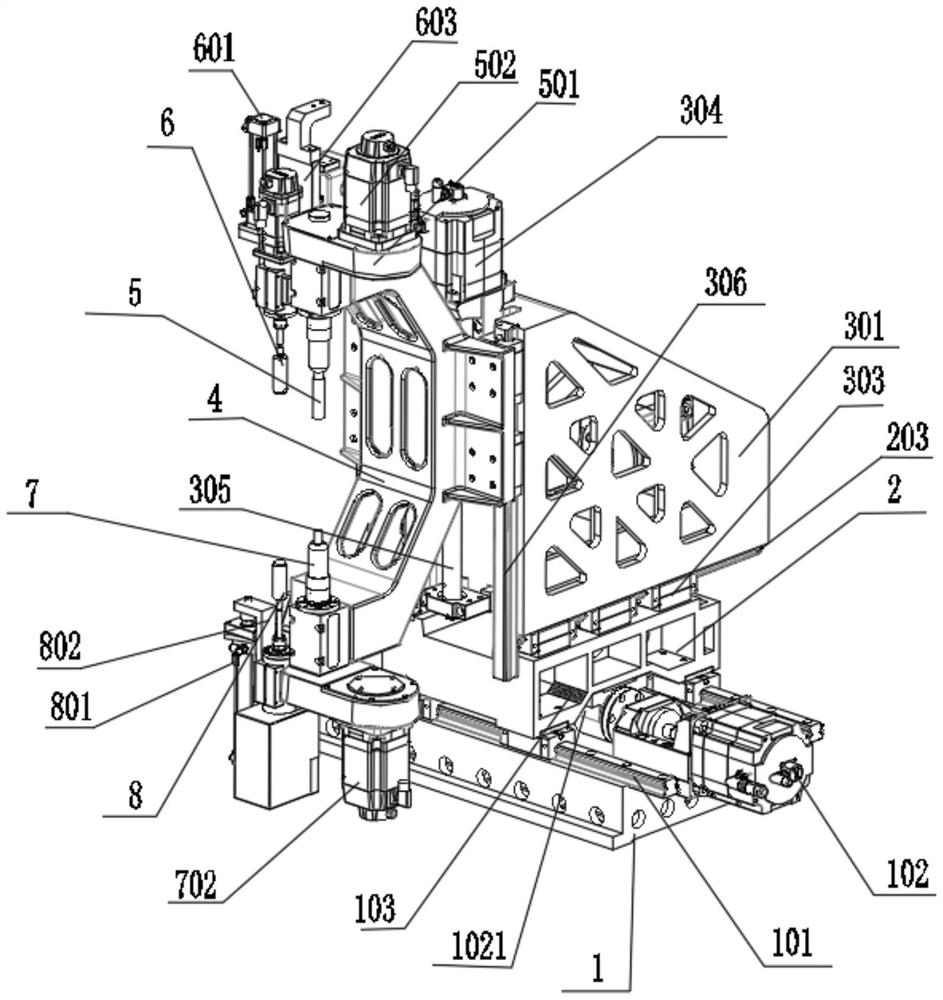

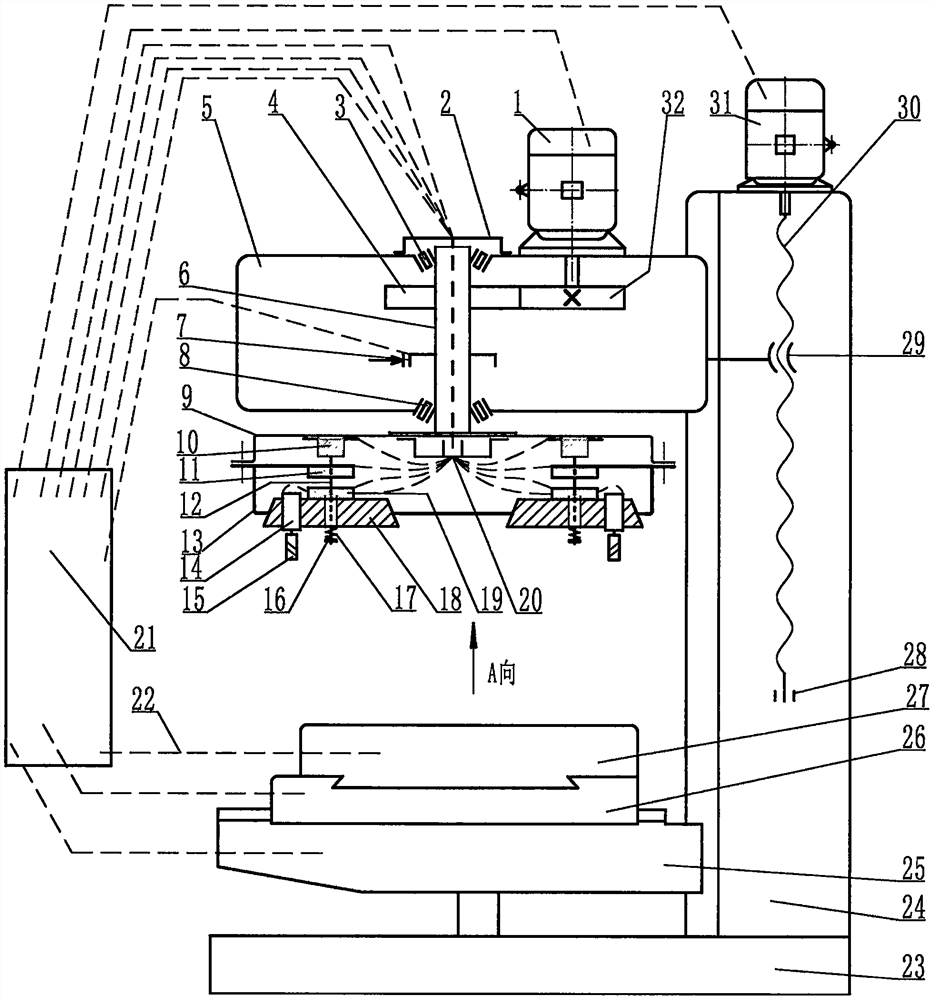

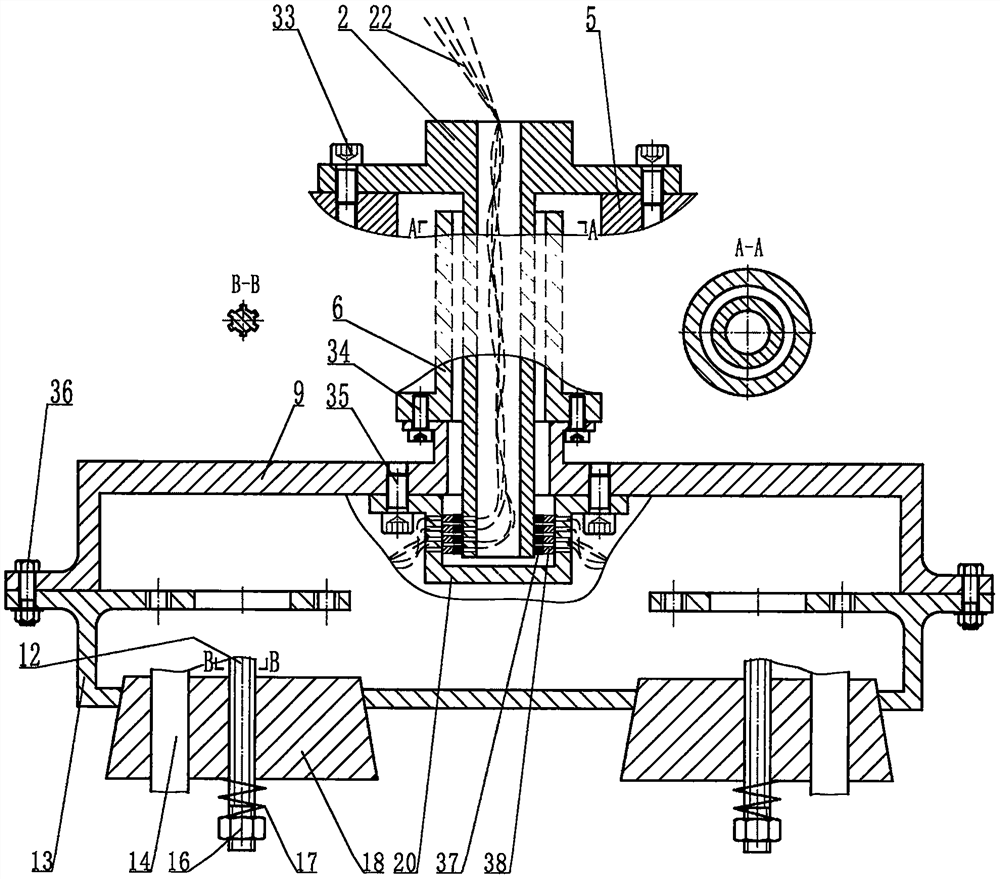

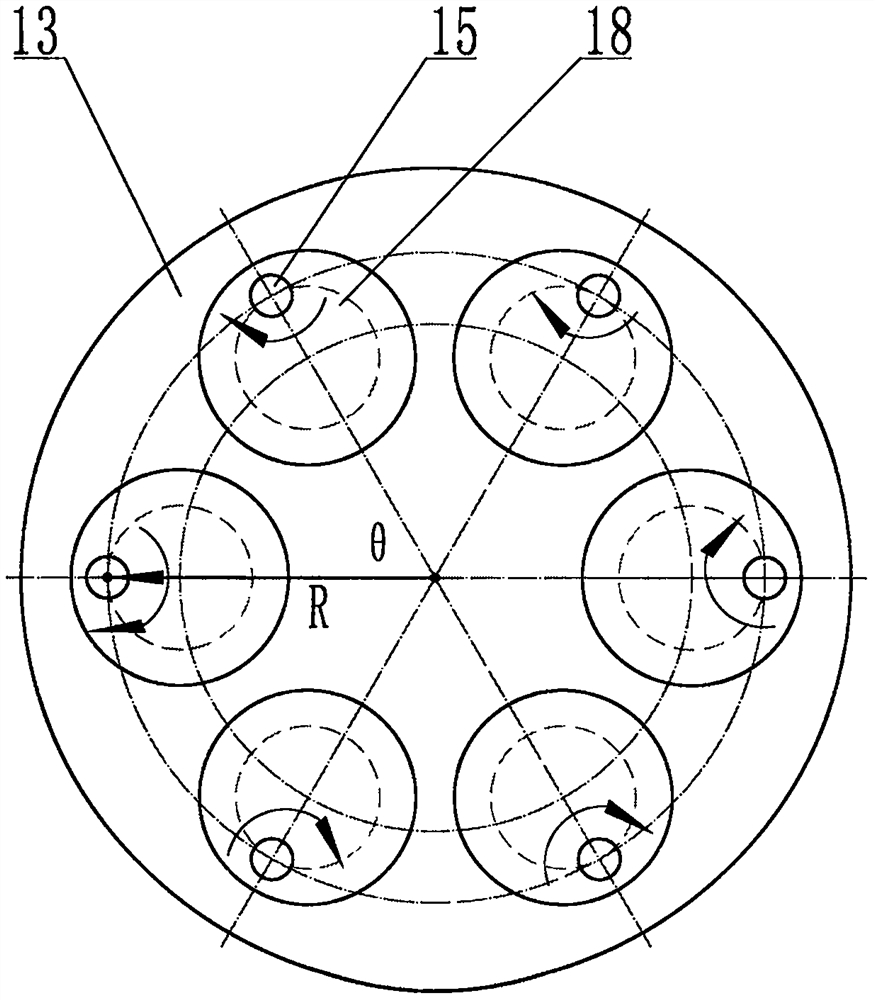

Open presser workbench surface processing special machine tool

InactiveCN102717131BImprove processing qualityEfficient millingMeasurement/indication equipmentsLarge fixed membersHigh volume manufacturingSurface level

The invention discloses an open presser workbench surface processing special machine tool, which comprises a power slipway, a column, a vertical carriage mobile apparatus, a crossbeam, a horizontal carriage feeding device, a milling power head and a press workbench surface leveling measurement apparatus, the power slipway is arranged at the front part of the press workbench in a parallel mode, the lower part of the column is fixed on the power slipway, the vertical carriage mobile apparatus is connected to a first side surface of the column in a vertical and slidable mode, and one end of a crossbeam is fixed on the vertical carriage mobile apparatus. The horizontal carriage feeding device is connected with the crossbeam in a horizontal and slidable mode, the milling power head fixed on the horizontal carriage feeding device, and the press workbench surface measurement apparatus is connected with a second side surface of the column in the vertical and slidable mode. The machine tool enables milling treatment with high efficiency on the press workbench surface, and is capable of substantially reducing the treatment cost, increasing the work efficiency and the treatment quality of the press workbench surface, and is suitable for large batch production.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

Mill

ActiveUS9427742B2Lower the volumeReduce the amount of noiseRoads maintainenceGrain treatmentsInterior spaceEngineering

Owner:KK KINKIDOROSHIZAI

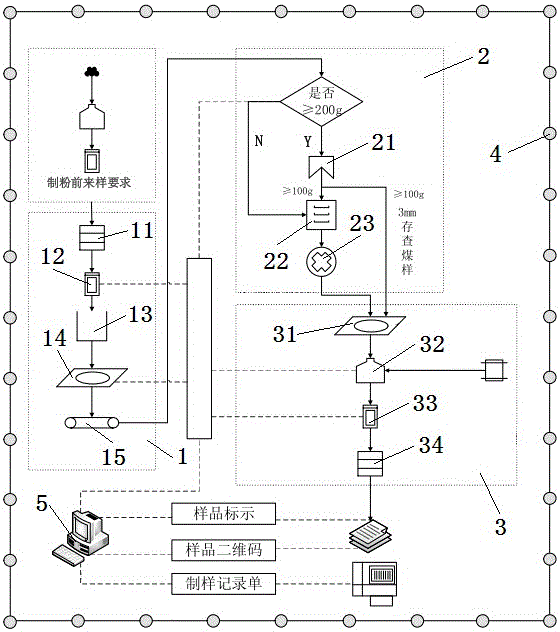

3mm coal sample milling and packaging integrated equipment and method thereof

PendingCN106840798AImprove the technical level of quality inspectionReasonable structural designPreparing sample for investigationCo-operative working arrangementsBiochemical engineeringCoal

The invention relates to 3mm coal sample milling and packaging integrated equipment and a method thereof. Current scientific research institutions, coal quality testing units, etc. commonly face the difficulty in large-scale milling work of 3mm coal samples. The invention is characterized in that the equipment comprises a disassembling sampling system, a coal sample milling system, a packaging encoding system and dust removal systems. The disassembling sampling system and the coal sample milling system are connected. The coal sample milling system and the packaging encoding system are connected. The dust removal systems are arranged around disassembling sampling system, around the coal sample milling system and around the packaging encoding system. After milling and packaging, a packaged and encoded 0.2mm general analytical testing coal sample and a packaged and encoded 3mm coal sample for back-check can be obtained, and corresponding sample marks, sample QR codes and sample preparation record lists are printed.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

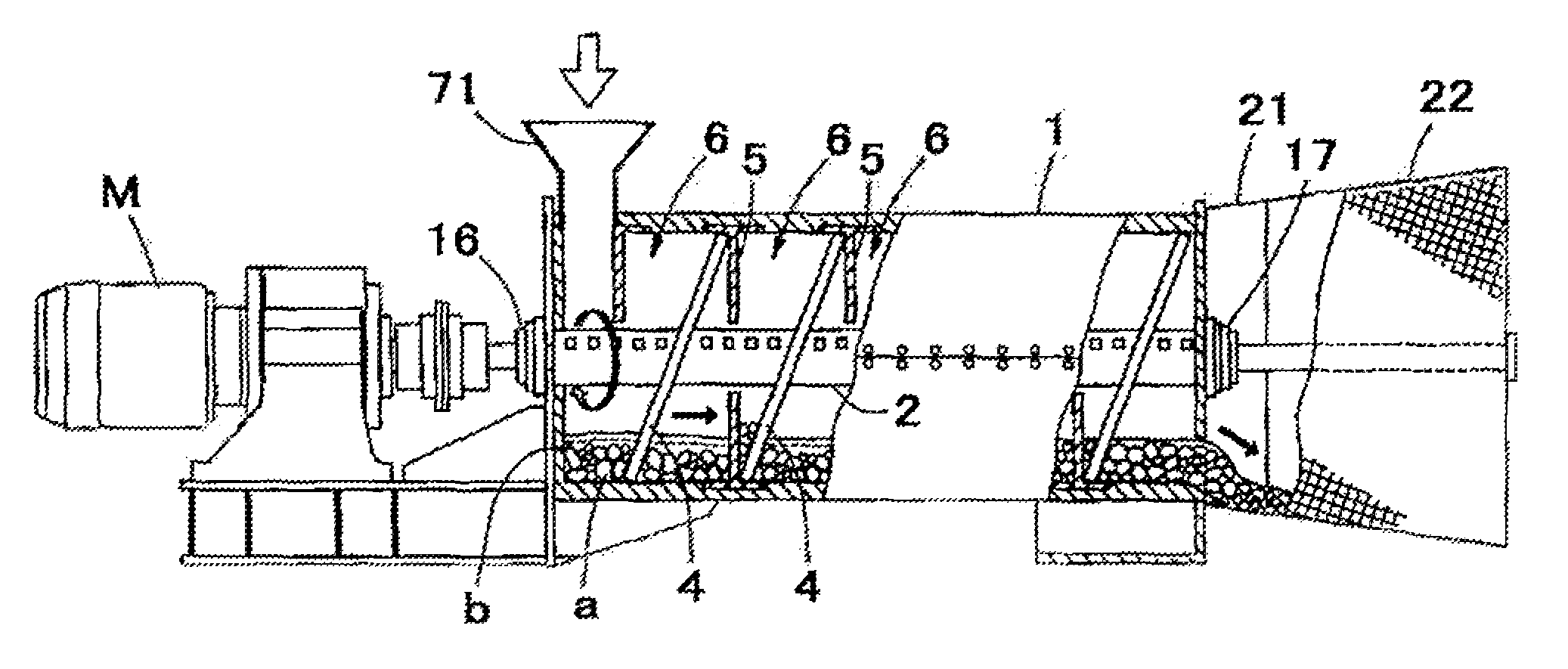

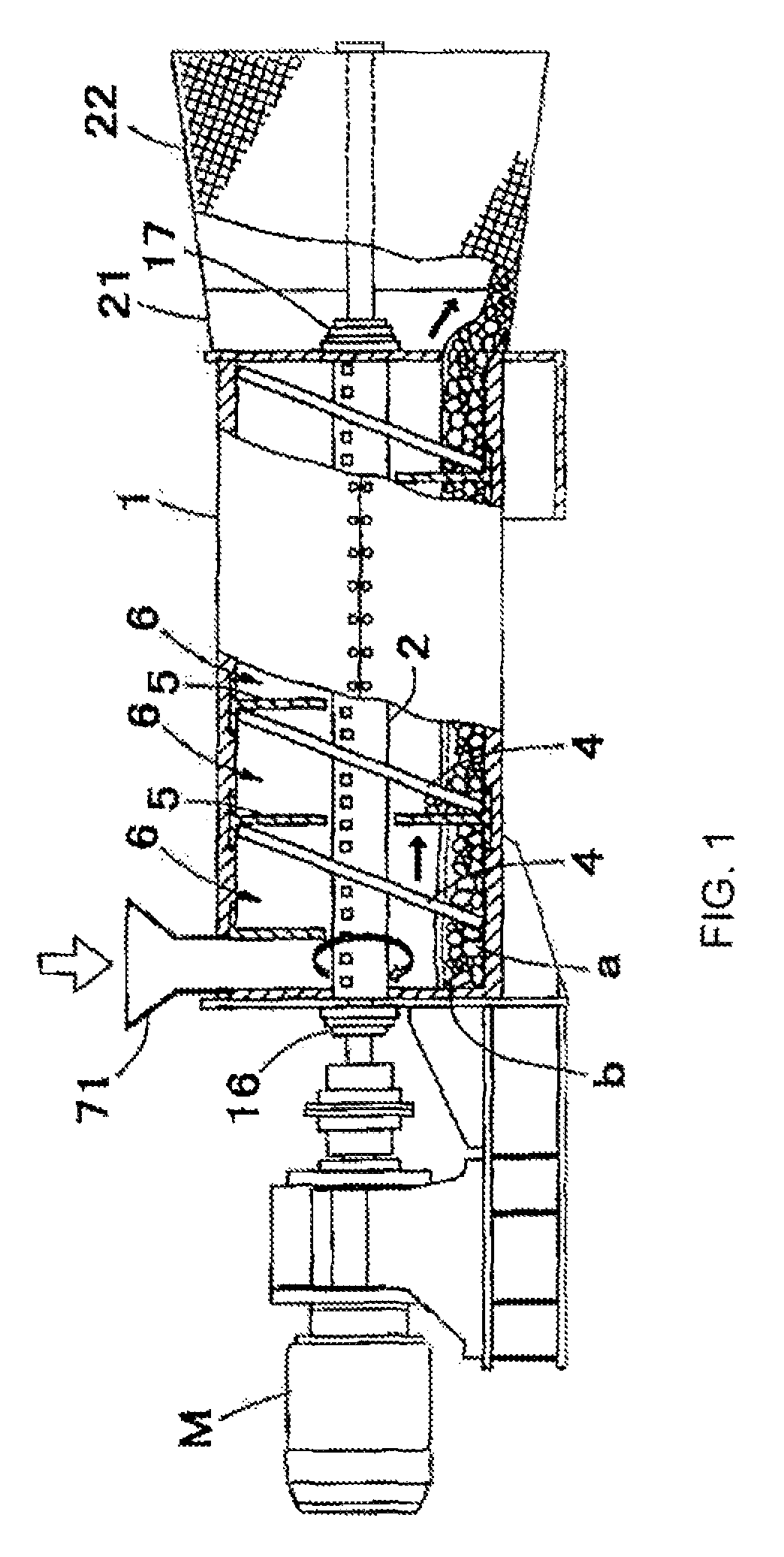

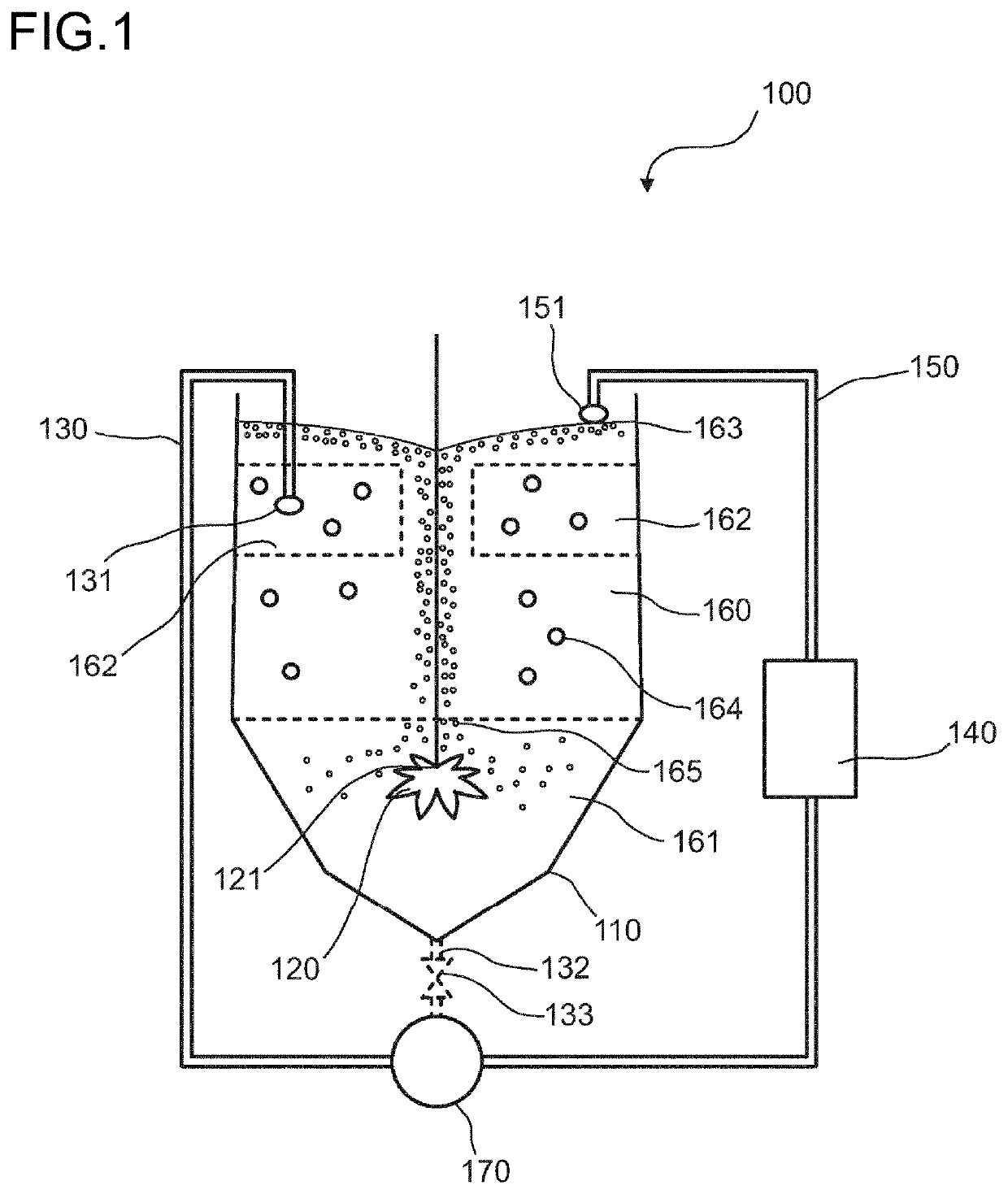

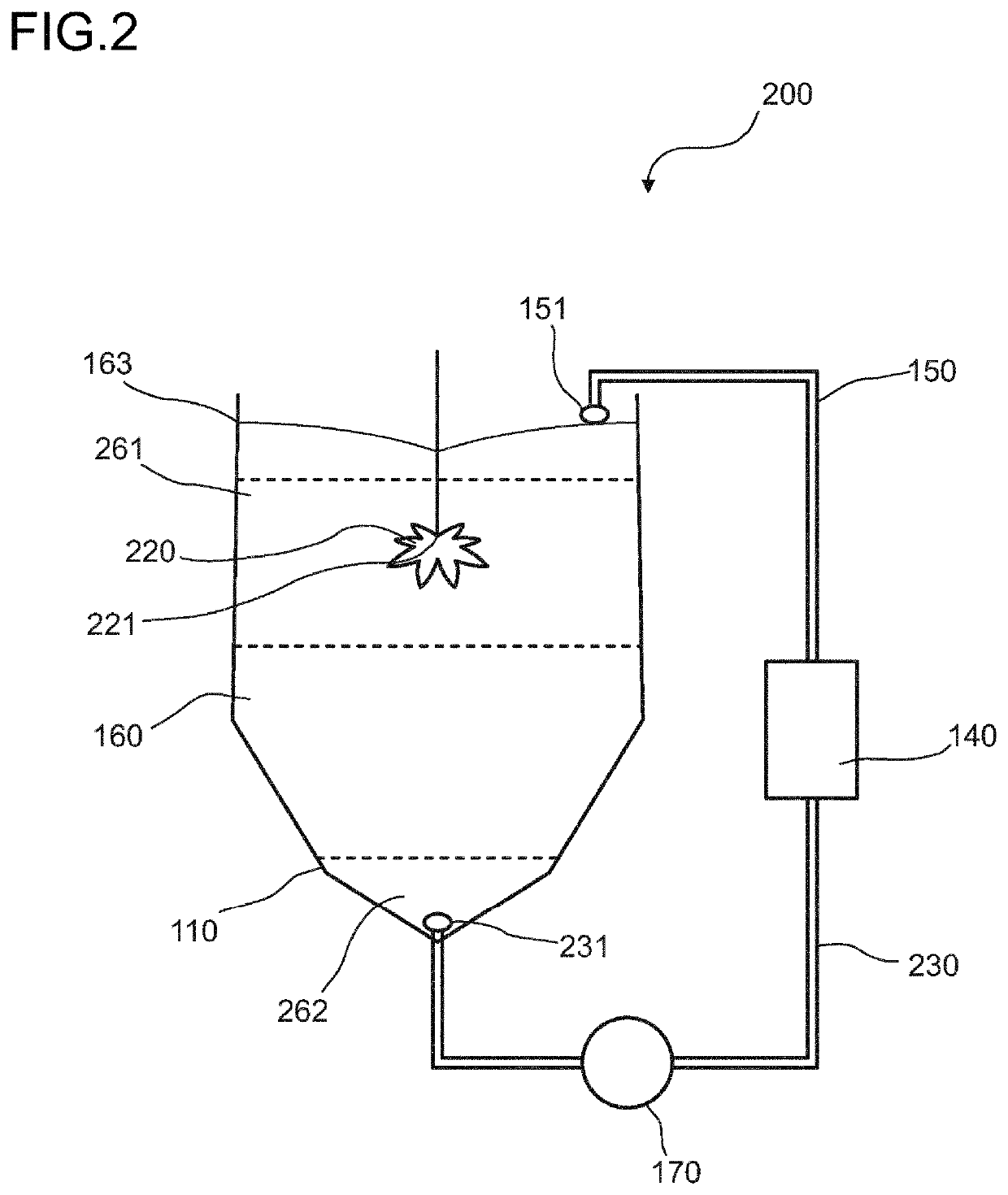

Method for dispersing and milling particles in a fluid

PendingUS20220362726A1Weaken energyShorten the timeFlow mixersRotary stirring mixersEngineeringMechanical engineering

Described herein is a method and a system for dispersing particles in a fluid. The method includes stirring a fluid including particles in a stirring container using stirring means. During stirring the fluid is recirculated by continuously retrieving an amount of fluid from a retrieving position. Further, the particles are milled, where during each pass through the milling means a size of particles in the retrieved fluid is reduced. The retrieved fluid having passed through the milling means is continuously reintroduced into the stirring container at a reintroduction position. The reintroduced fluid is mixed with the fluid in the stirring container in a mixing region defined by the stirring means, and the retrieving position is determined such that the retrieved fluid includes particles with an average particle size differing from the average particle size of particles in the mixing region.

Owner:BASF COATINGS GMBH

Multi-spindle electromechanical fully automatic adjustable wheelbase milling and drilling compound processing machine tool

ActiveCN110814757BEfficient millingImprove drilling efficiencyFeeding apparatusOther manufacturing equipments/toolsElectric machineControl engineering

Owner:秦皇岛市国阳钢铁有限公司

An Optimum Method for Up-and-Up Milling of Carbon Fiber Composite Materials

ActiveCN108393521BSmall damage depthHigh-quality millingWorkpiecesMilling equipment detailsFibrous compositesMachining

The invention relates to an optimizing selection method of carbon fiber composite down milling and up milling machining manners and belongs to the technical field of machining. According to the optimizing selection method of the carbon fiber composite down milling and up milling machining manners, based on milling machining parameters, the actual change ranges of the fiber cutting angles in the milling process are correspondingly worked out, according to the properties of a utilized material and the utilized cutter structure, in an experiment or finite element calculation manner, the fiber cutting angle range enabling the machining quality to be the best is determined, the proportions of the condition that the actual ranges of the fiber cutting angles during down milling and up milling arewithin the optimal range are calculated finally, and the milling manner with the larger proportion is selected as the optimal milling manner under the working condition. By the adoption of the optimizing selection method, a new method can be provided for achievement of high-quality high-efficiency high-precision milling of a carbon fiber composite component, optimizing selection of the milling manners is achieved, the calculation steps are simple and convenient, and the optimizing selection method has good engineering application prospect.

Owner:DALIAN UNIV OF TECH

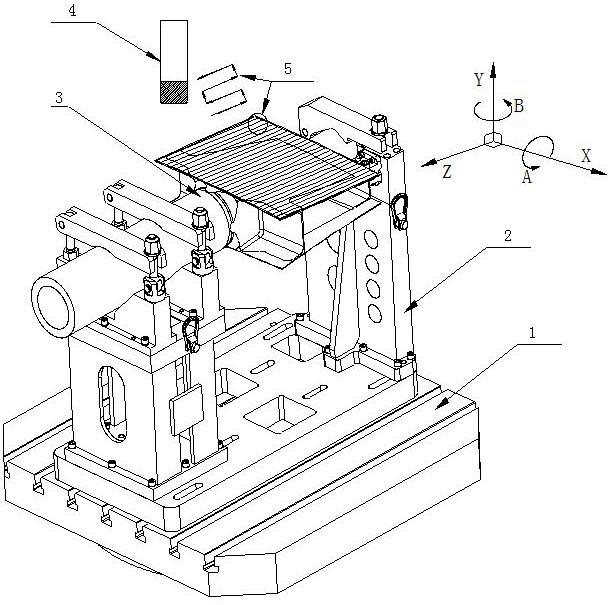

Numerical control machining method based on rigid construction parts and clamping fixture for numerical control machining

ActiveCN101412120BReduce deformationMeet assembly requirementsMilling equipment detailsPositioning apparatusNumerical controlDigital control

The invention aims to provide a method for processing rigid structure parts through digital control and a clamp structure for processing the rigid structure parts through the digital control. The method mainly comprises the following steps: performing rough machining on part blanks, processing a plurality of process lug bosses with the equal height on the periphery of the contour surface of the parts in the process of the rough machining, and processing a rigid connecting bridge between the process lug bosses and the contour surface of the parts to make the process lug bosses connected with the contour surface of the parts continuously. The process lug bosses are evenly distributed on the periphery of the contour of the parts according to the differences of the part structures, and the weaker parts of the part structures are provided with more process lug bosses properly. One of the advantages of the method is to use the process lug bosses combined with the parts to replace special fixtures so as to save the manufacturing cost.

Owner:XIAN AIRCRAFT IND GROUP

A granulation screening system for polymer material production

ActiveCN111632705BReduce screening costsImprove screening efficiencyGas current separationGrain treatmentsMolecular materialsProcess engineering

The invention discloses a granulation and screening system for polymer material production. It comprises a base, and also includes an air-selecting mechanism, a control box and a crushing mechanism which are fixedly installed on the base in sequence from left to right. The top of the control box passes through the A pumping pump is fixedly installed on the connecting plate, and the discharge port of the pumping pump is communicated with the feeding port on the top of the air-selecting mechanism through a material guide pipe. The invention relates to the technical field of polymer material production. The granulation and screening system for the production of polymer materials, using the air separation mechanism, will not cause the powder to accumulate on the screen in a large area, resulting in blockage of the screen, which greatly saves the screening cost of polymer materials, and can complete multi-stage screening at one time. , the screening efficiency is greatly improved, and it can be realized that by combining the crushing mechanism and the grinding equipment, and controlling the extrusion distance in the crushing and grinding mechanism, the free switching of crushing and grinding can be completed. The equipment has a simple structure, low cost, and Production efficiency is greatly improved.

Owner:苏州路熙智能科技有限公司

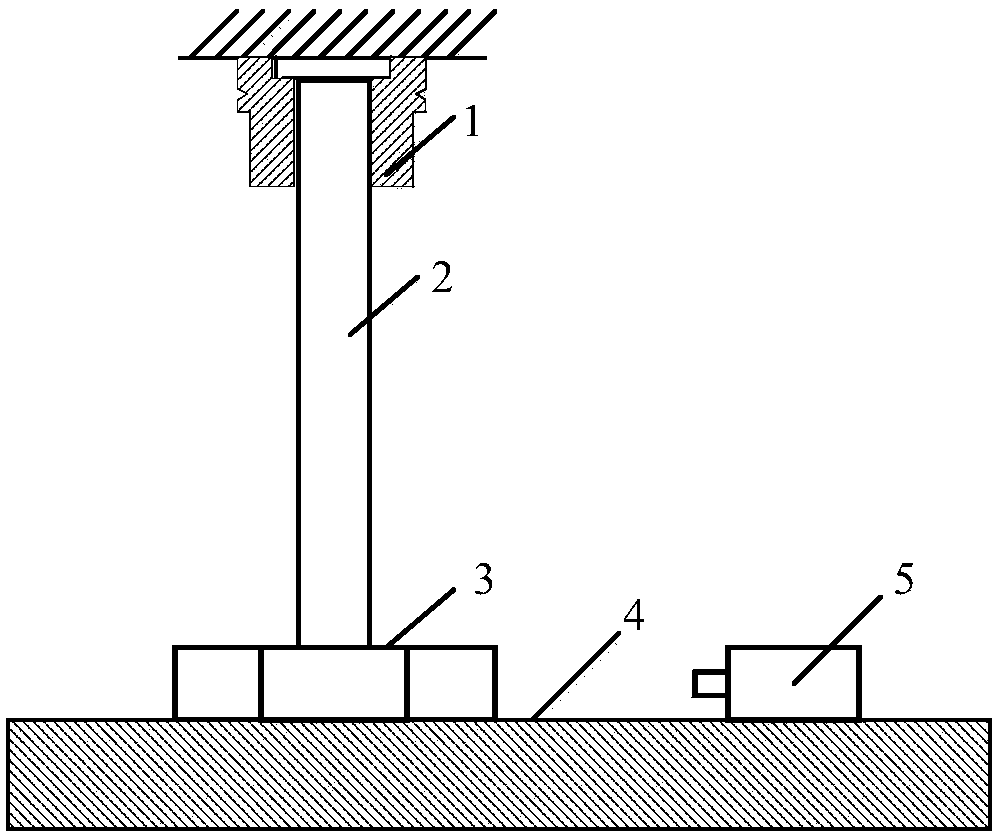

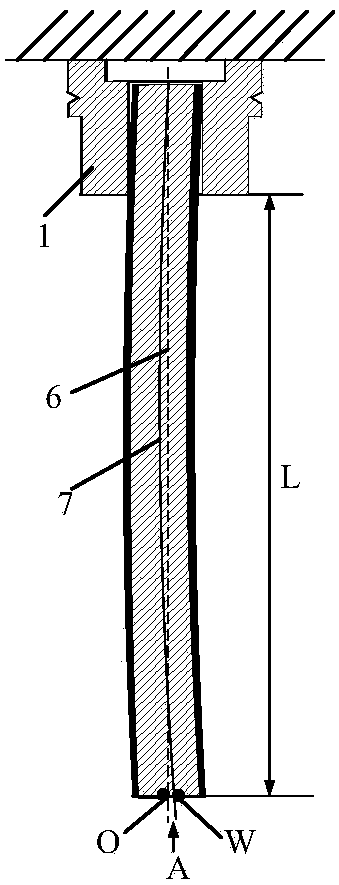

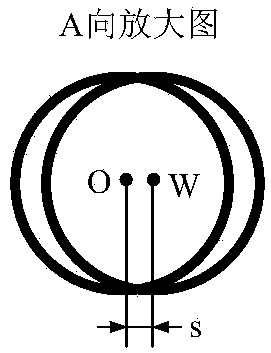

Milling cutter spindle with large draw ratio and capable of automatic dynamic balance during super-speed rotation through material compensation

ActiveCN108480733AReduce residual unbalanceImprove balanceMilling cuttersMeasurement/indication equipmentsUltra high speedMeasuring instrument

The invention discloses a milling cutter spindle with a large draw ratio and capable of automatic dynamic balance during super-speed rotation through material compensation, and provides the milling cutter spindle with a special hollow dynamic balance cavity. By accommodating compensation material ultra-fine copper powder in the cavity, in short acceleration time, the compensation material is redistributed by means of centrifugal force generated by rotation, and a rotating axis around the milling cutter spindle is banded, so that the residual unbalance degree of the milling cutter spindle is reduced, fast automatic dynamic balance of the milling cutter spindle in a high-speed rotation process is effectively achieved, axis deviation of the milling cutter spindle is effectively avoided, the eccentric amplitude of the milling cutter spindle is reduced, and the dynamic balance performance of the milling cutter spindle is improved. The detection part mainly refers to a bearing balance protection and detection device which comprises a bearing, a measuring instrument, a collector, a clamp and the like, and optimization design can be conducted on the compensation material and the special cavity structure, so that the automatic dynamic balance performance of the milling cutter spindle is improved.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com