Numerical control machining method based on rigid construction parts and clamping fixture for numerical control machining

A technology of rigid structure and processing method, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as the inability to meet the development cycle of parts and the poor deformation effect of parts, so as to shorten the development cycle and improve the processing efficiency. and quality, good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

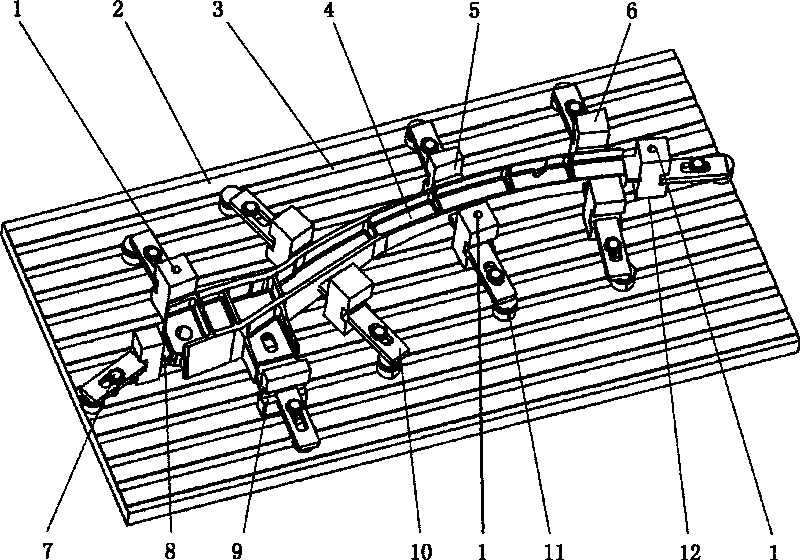

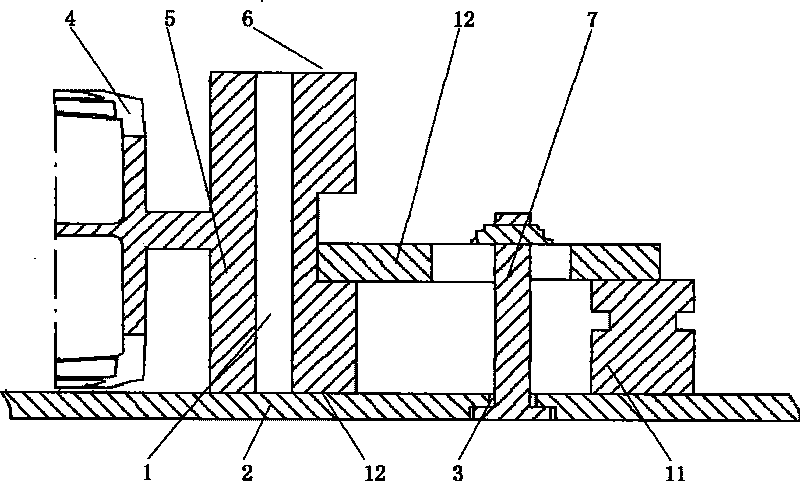

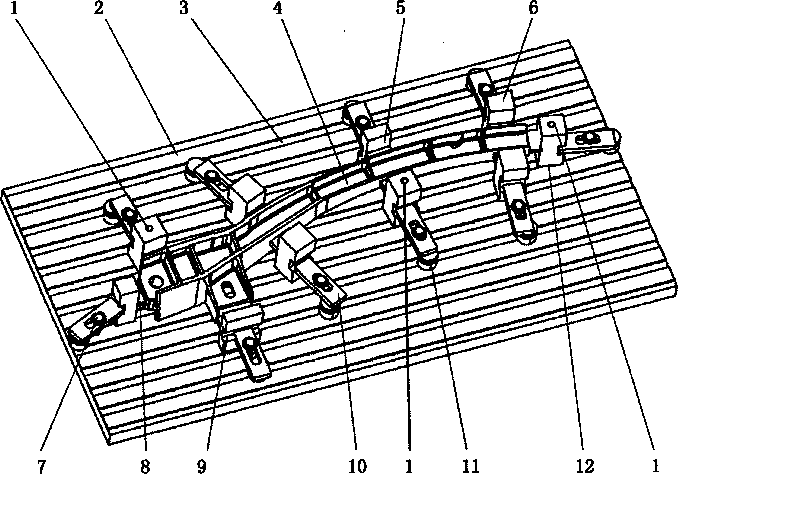

[0016] refer to figure 1 , figure 2 A positioning and clamping view and a partial cross-sectional view of an embodiment of the present invention are shown. Now describe this invention in conjunction with accompanying drawing.

[0017] The part body 4 to be processed in the figure is the main load-bearing frame part of the aircraft fuselage. This part has the characteristics of high rigidity and complex structure. The process plan of CNC machining of such parts is arranged according to the rough machining, semi-finishing, and finishing procedures of the blank first, and the auxiliary process and inspection process are properly arranged. Especially for frame parts with large deformation, the flatness is not guaranteed. The aging process should also be properly arranged.

[0018] When implementing the rough machining of the part blank, a plurality of process bosses 5 are reserved around the part body 4 through rough machining, and there is an uninterrupted connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com