Patents

Literature

48results about How to "Reduce overhang length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

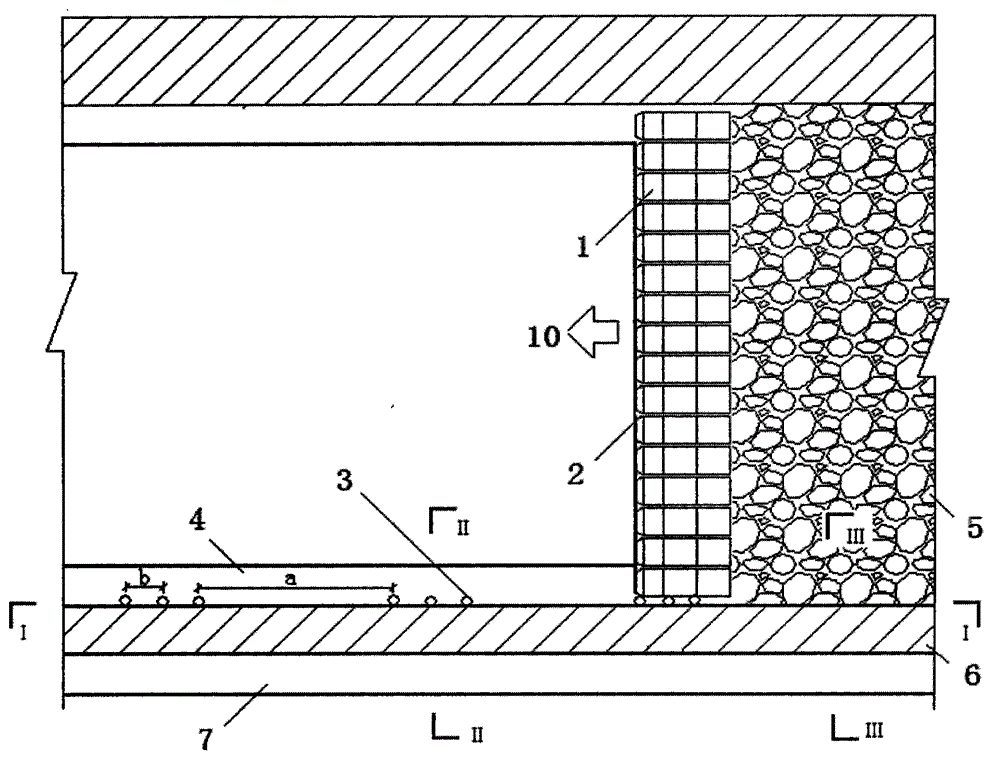

Gob-side entry driving surrounding rock control method using remaining small pillars

InactiveCN103244180AReduce overhang lengthBreach of integrityMining devicesBlastingEngineeringDeep hole

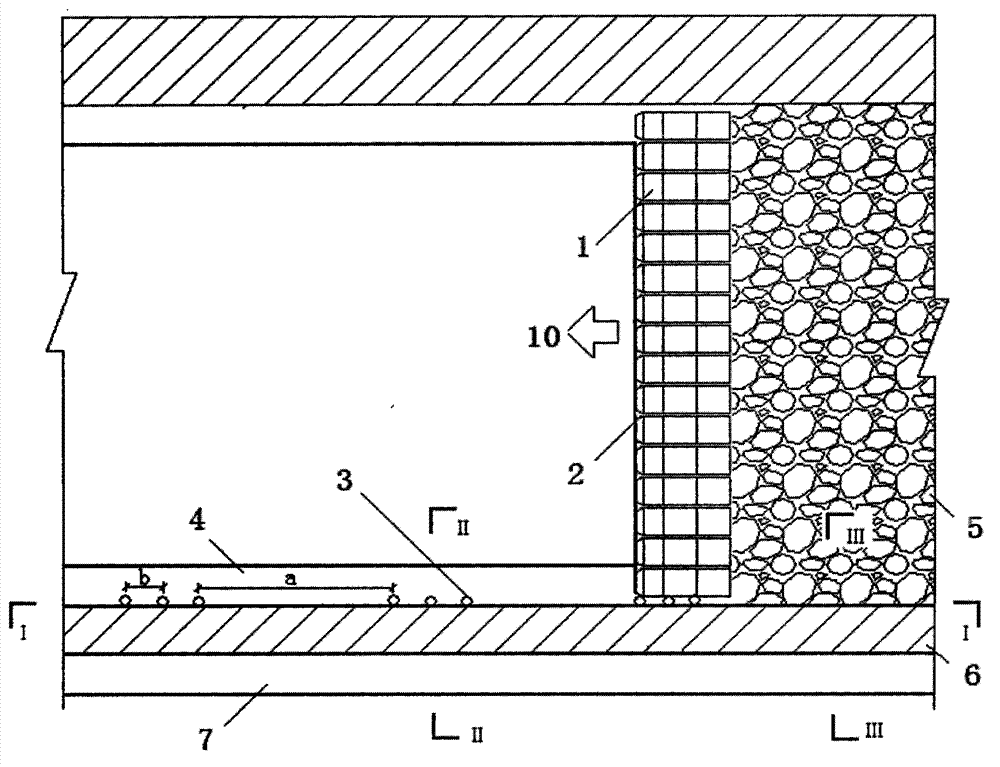

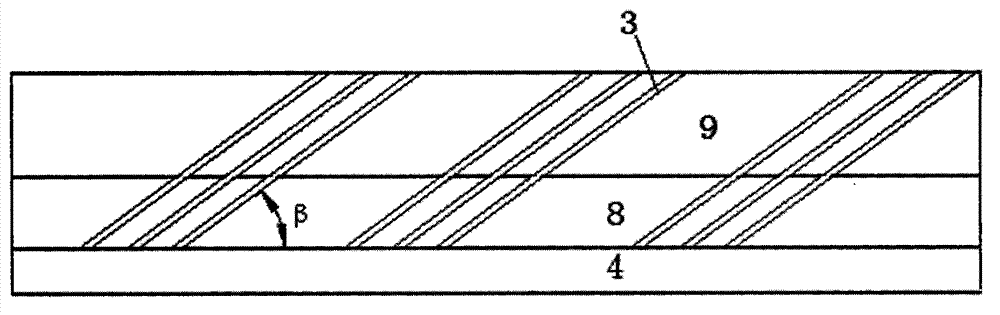

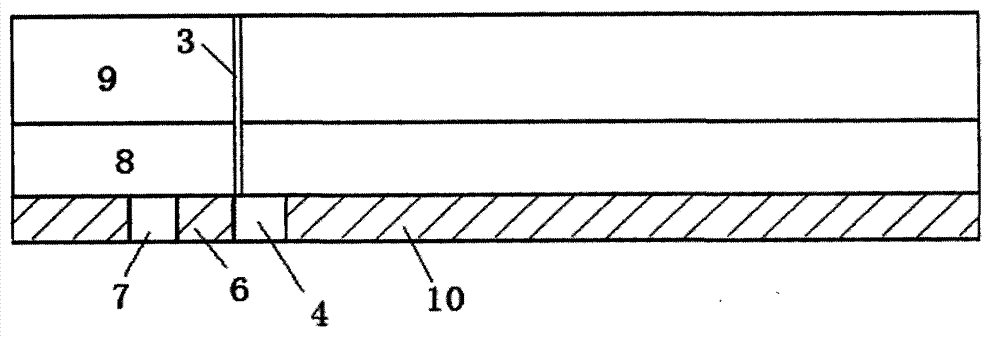

The invention discloses a gob-side entry driving surrounding rock control method using remaining small pillars. The method includes: distributing blast holes of different angles and depths in a working face conveying chute during extraction on an upper region working face, preforming a weak face in a certain area of a basic roof to damage completeness of a basic roof rock stratum by deep hole presplitting, and allowing a suspension arch of the basic roof to break at predetermined positions under the action of roof pressure after extraction of the working face. Therefore, the length of the hanging arch of the lateral basic roof of a gob is shortened, gob lateral abutment pressure is reduced, roadway pressure is relieved during gob-side entry driving in a lower region using remaining small pillars, and maintenance of a roadway is facilitated.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

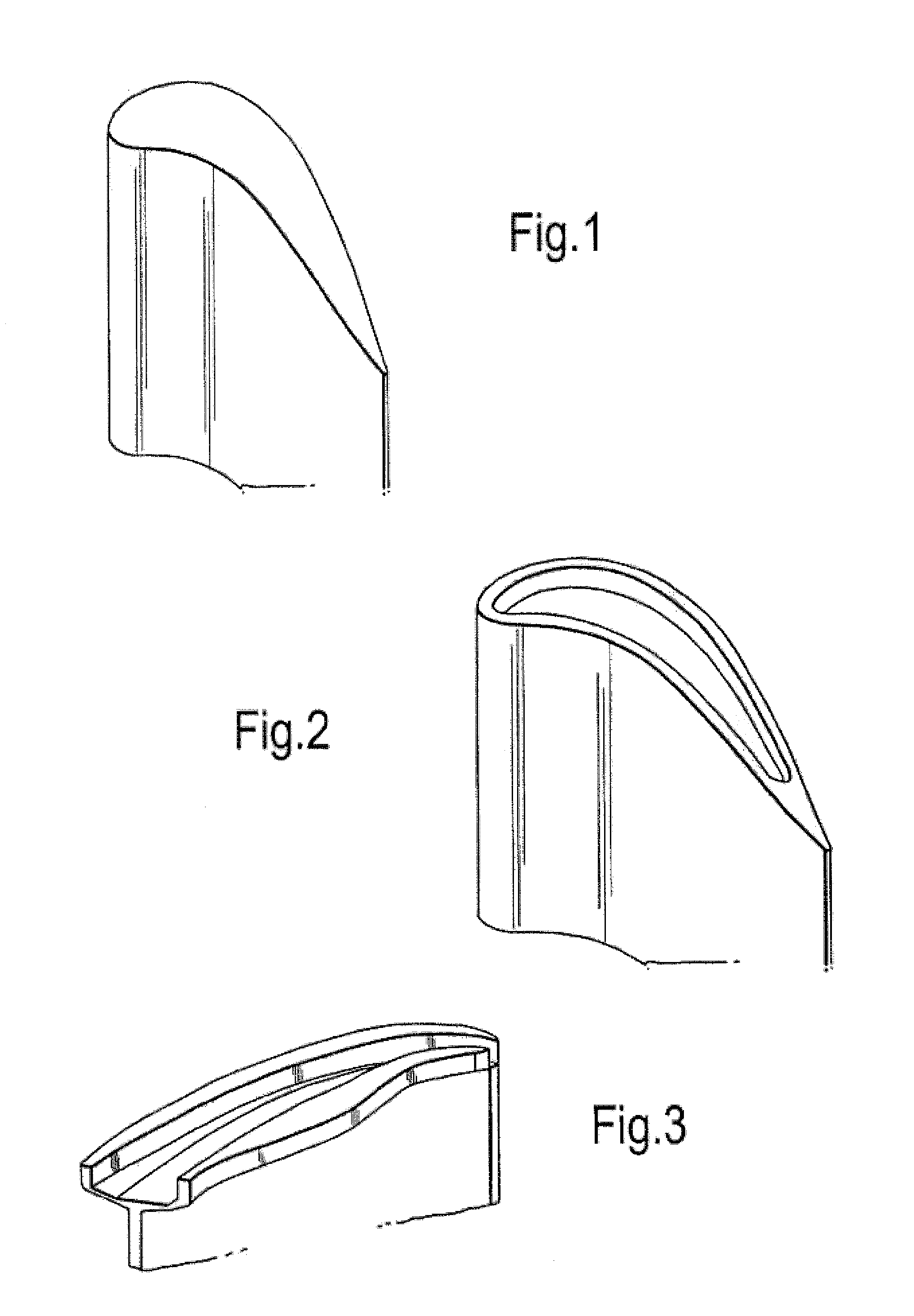

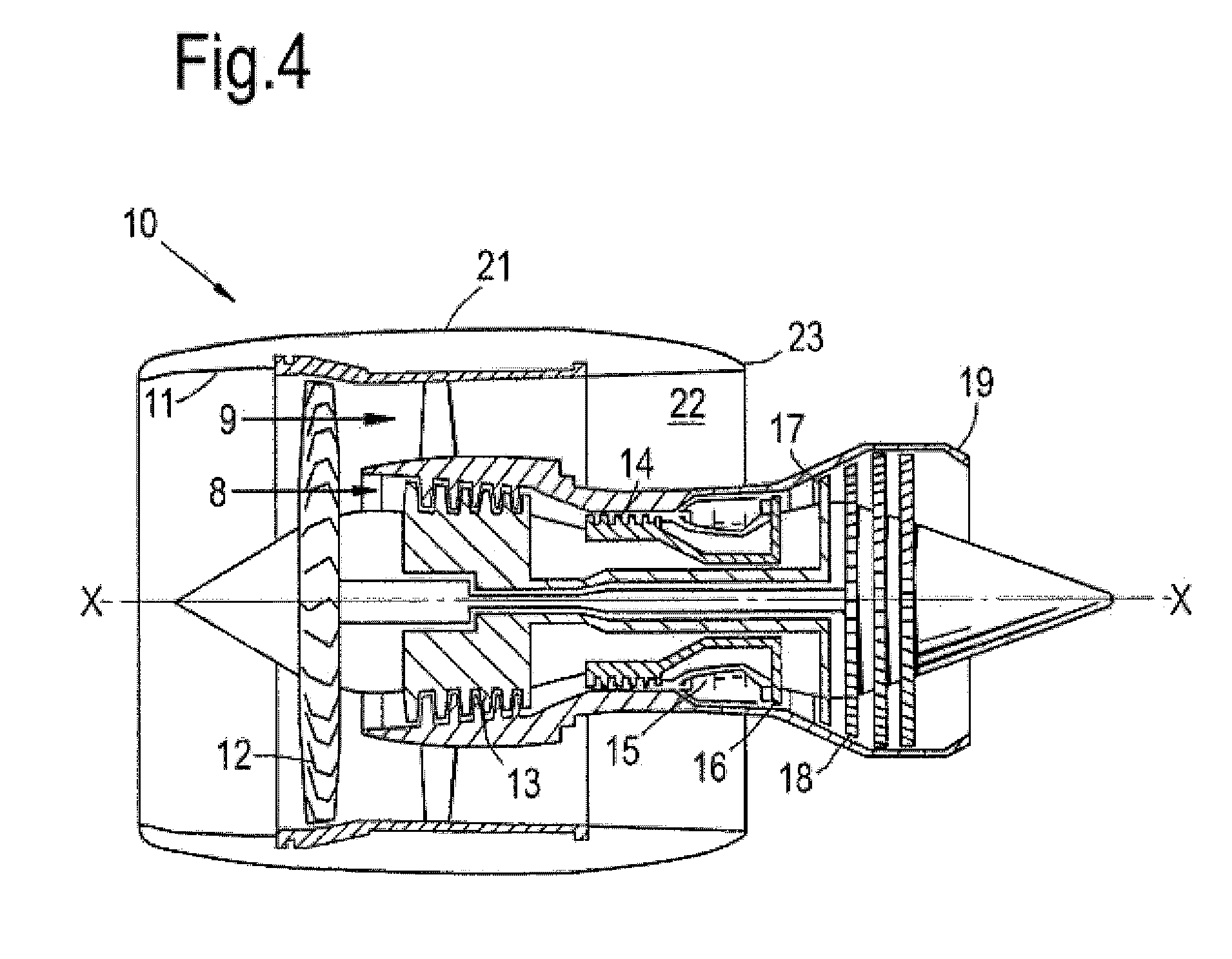

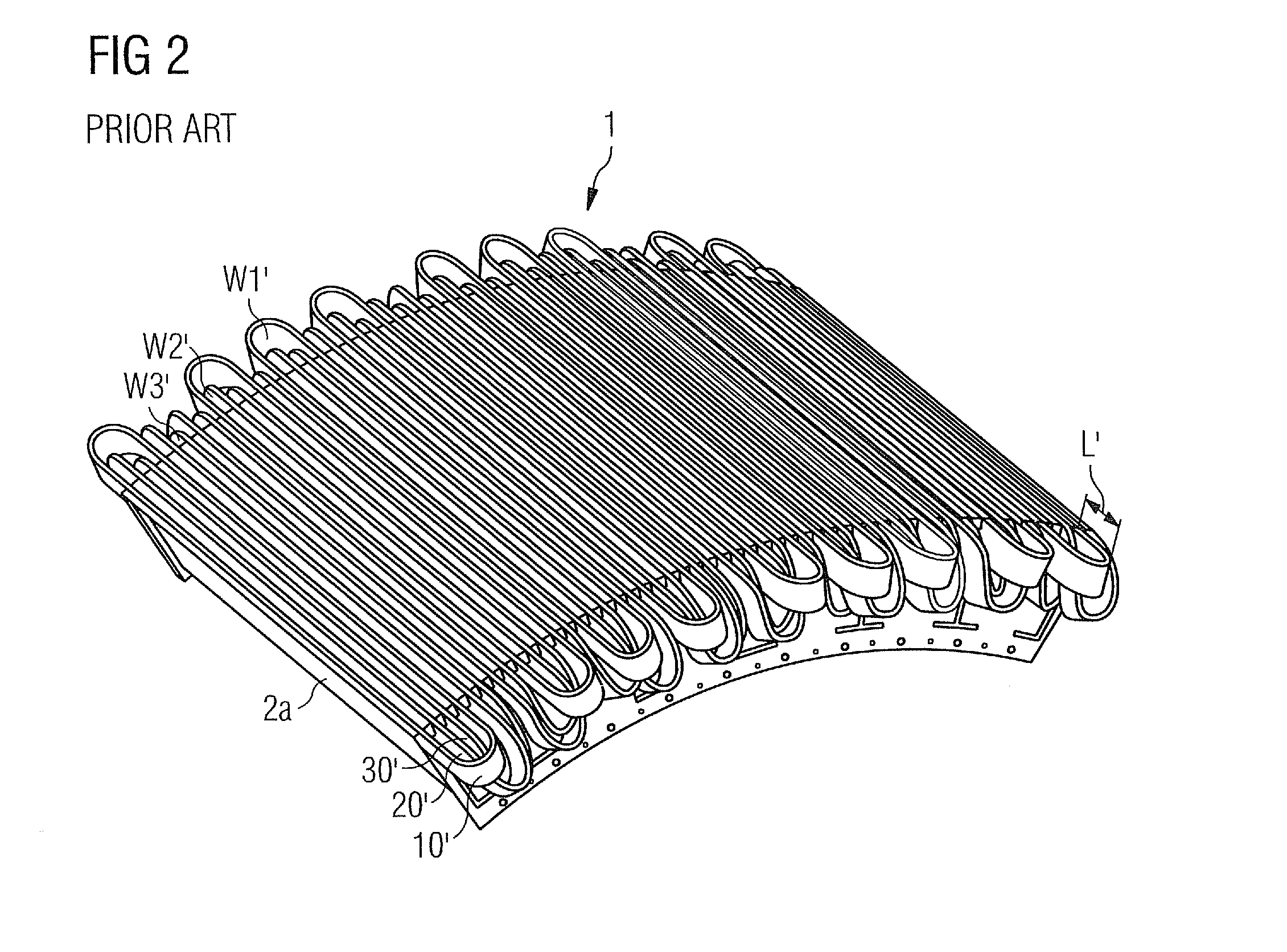

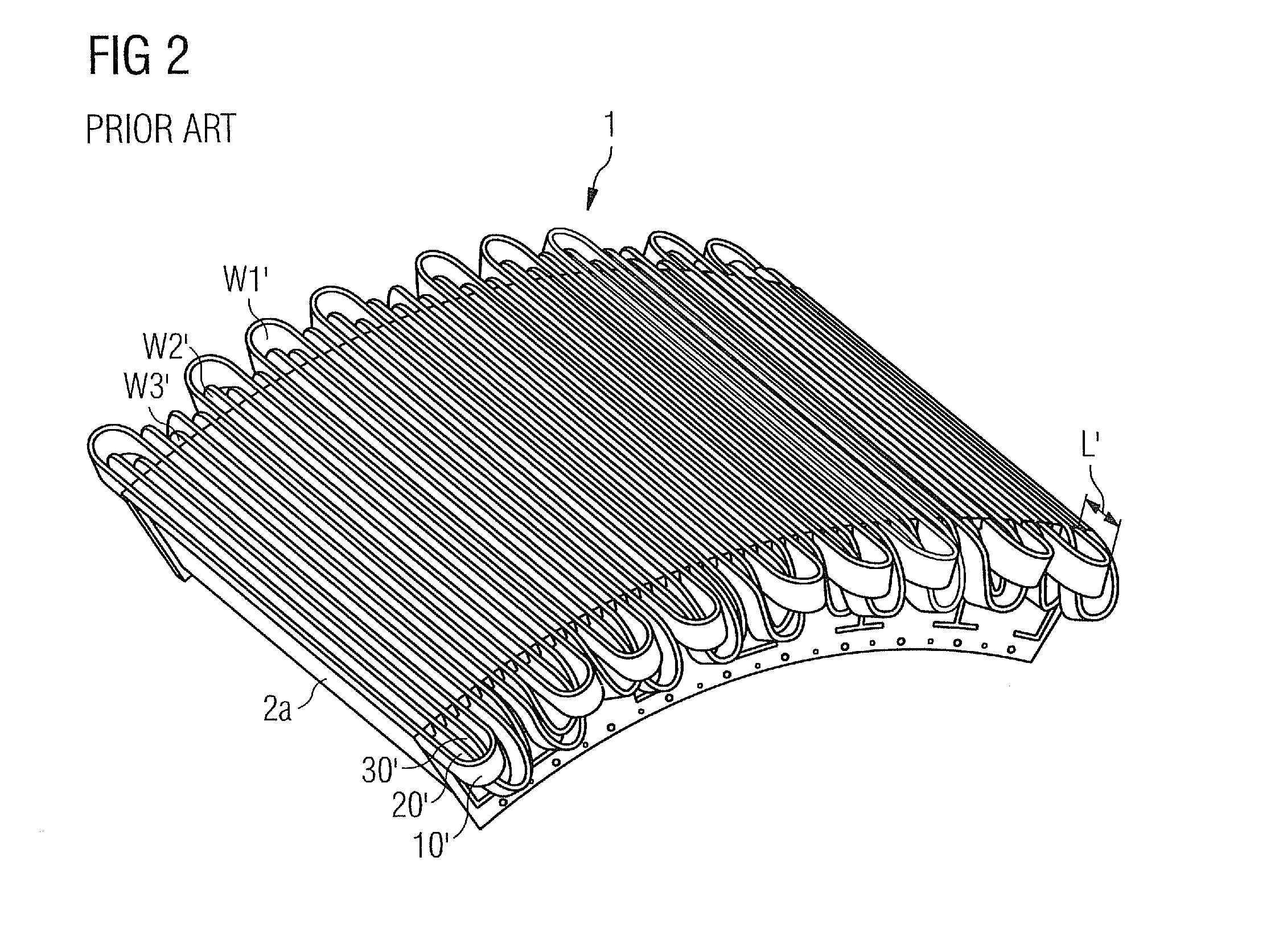

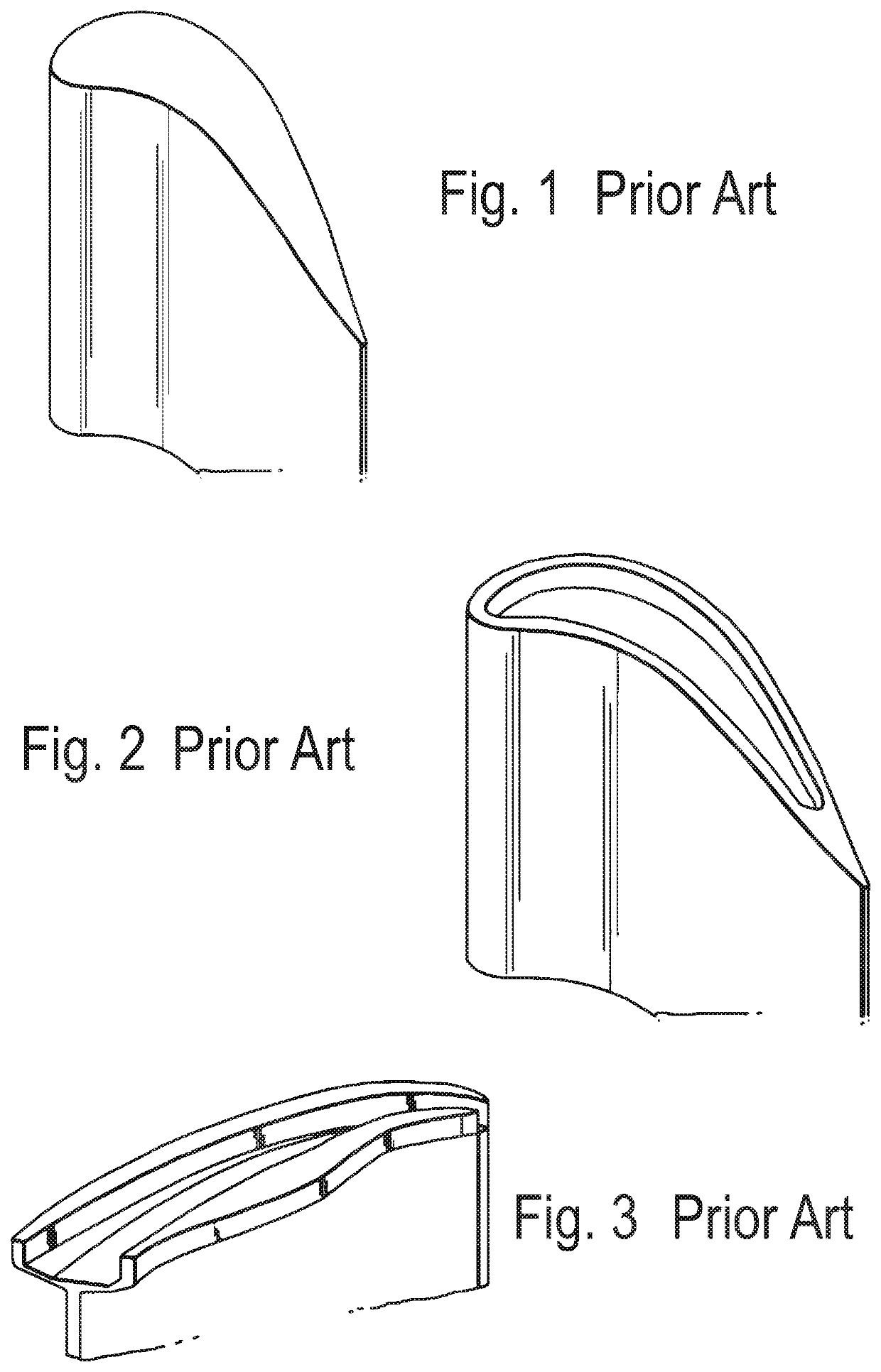

Turbine blade

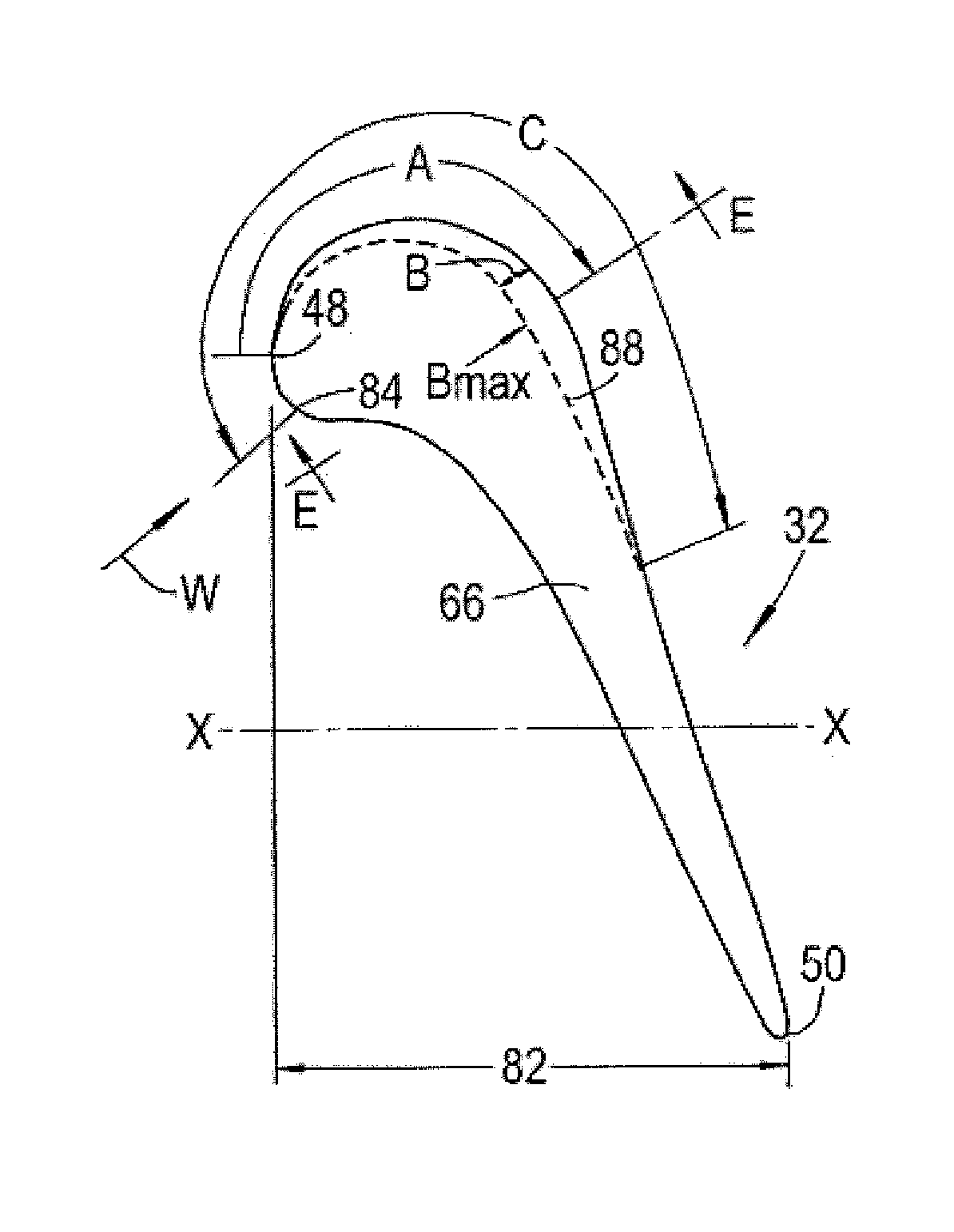

A turbine blade has a root portion, a platform and an aerofoil, the aerofoil is mounted on the platform and is formed by a pressure side wall and a suction side wall and has an outer surface, the pressure side wall and the suction side wall meet at a leading edge and a trailing edge, the aerofoil has an axial chord length, the suction side wall defines part of the radially outward surface of the aerofoil, the suction side wall defines art overhang, the overhang has a maximum overhang length that is between 5% and 20% of the axial chord length of the blade and is located between 5% and 50% of the suction surface length from the leading edge.

Owner:ROLLS ROYCE PLC +1

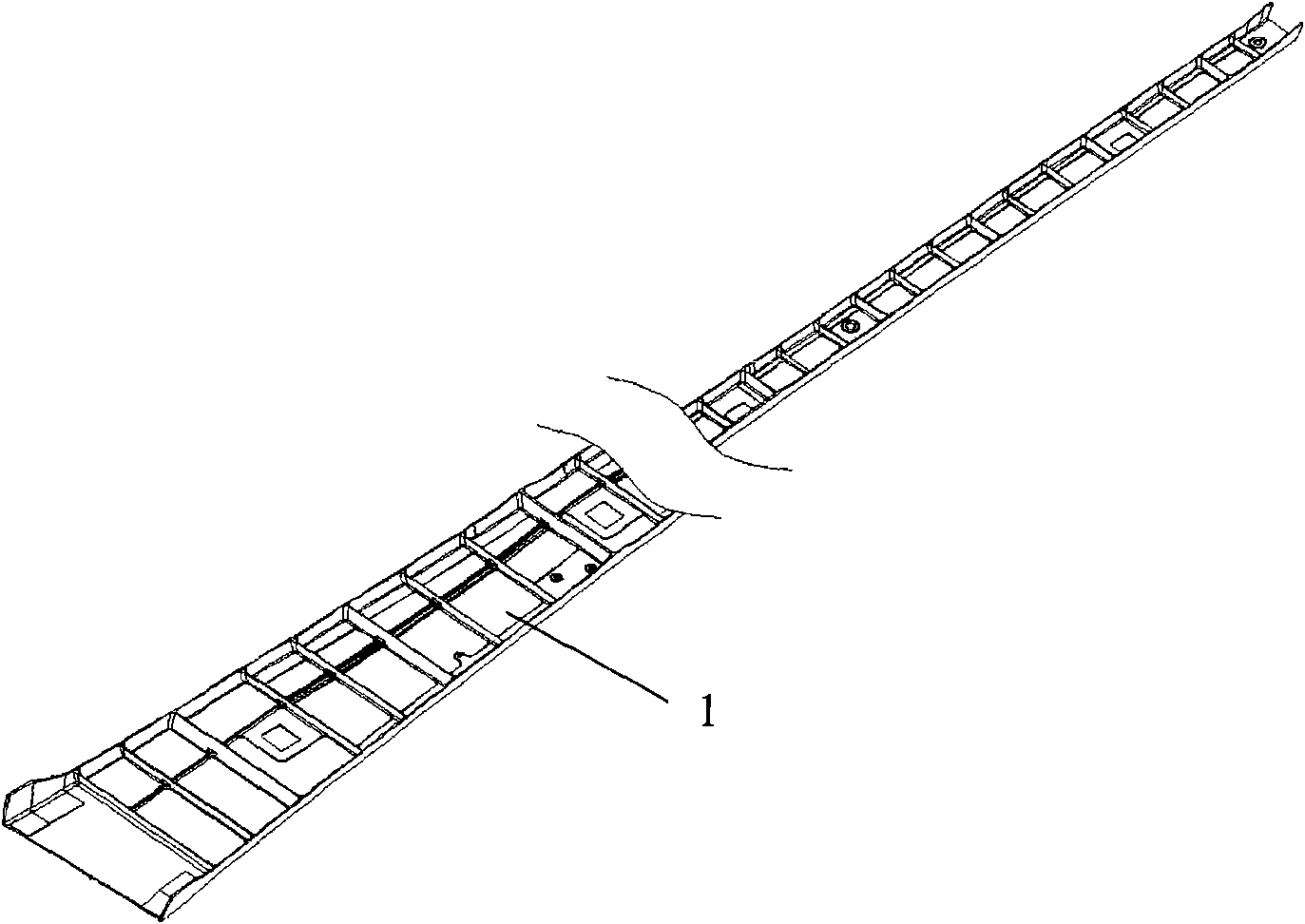

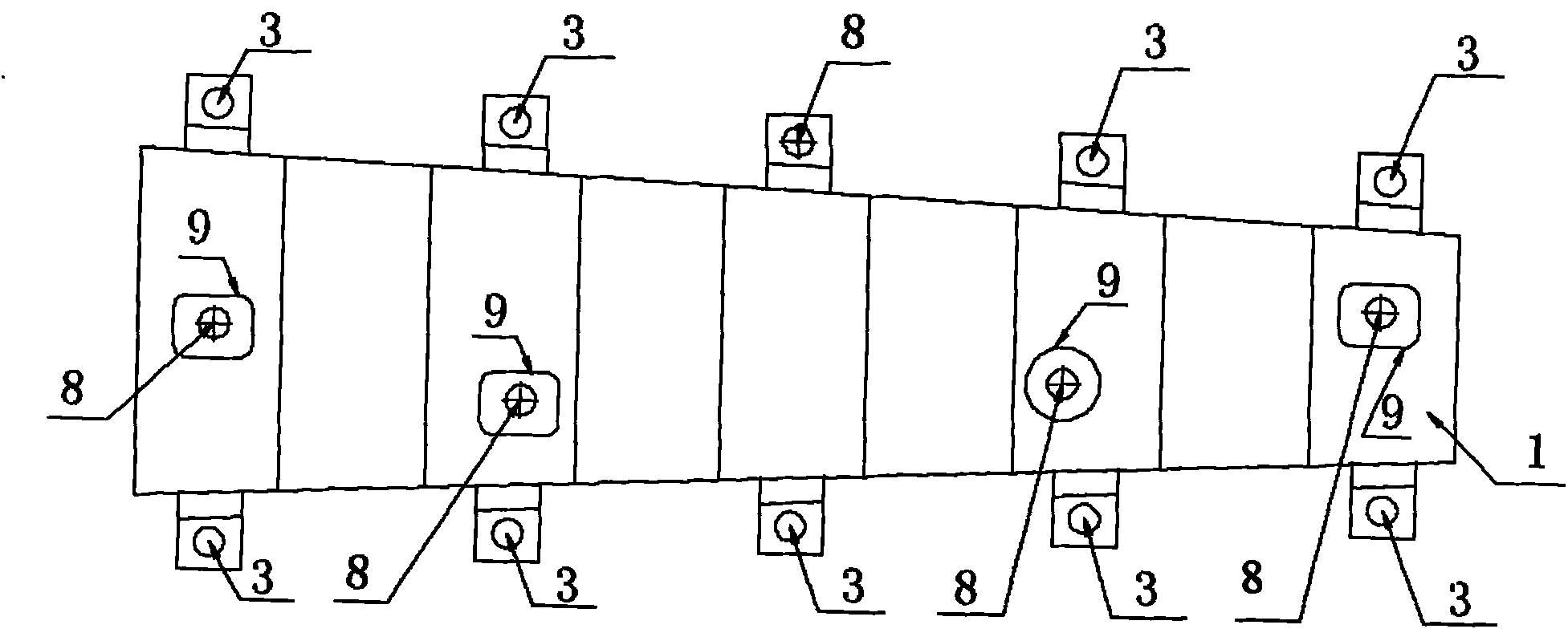

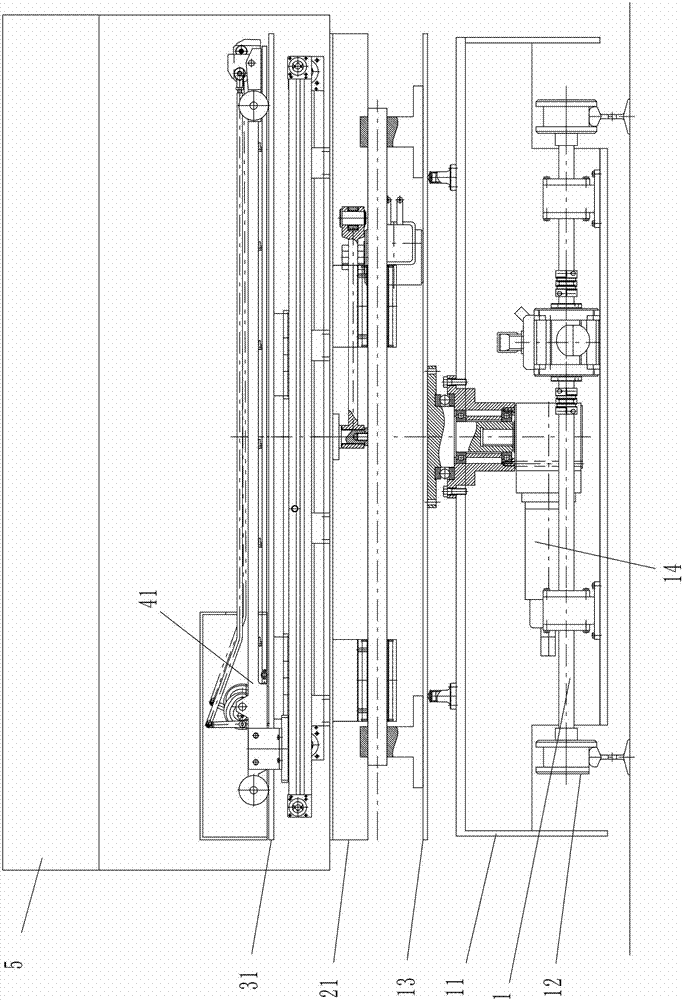

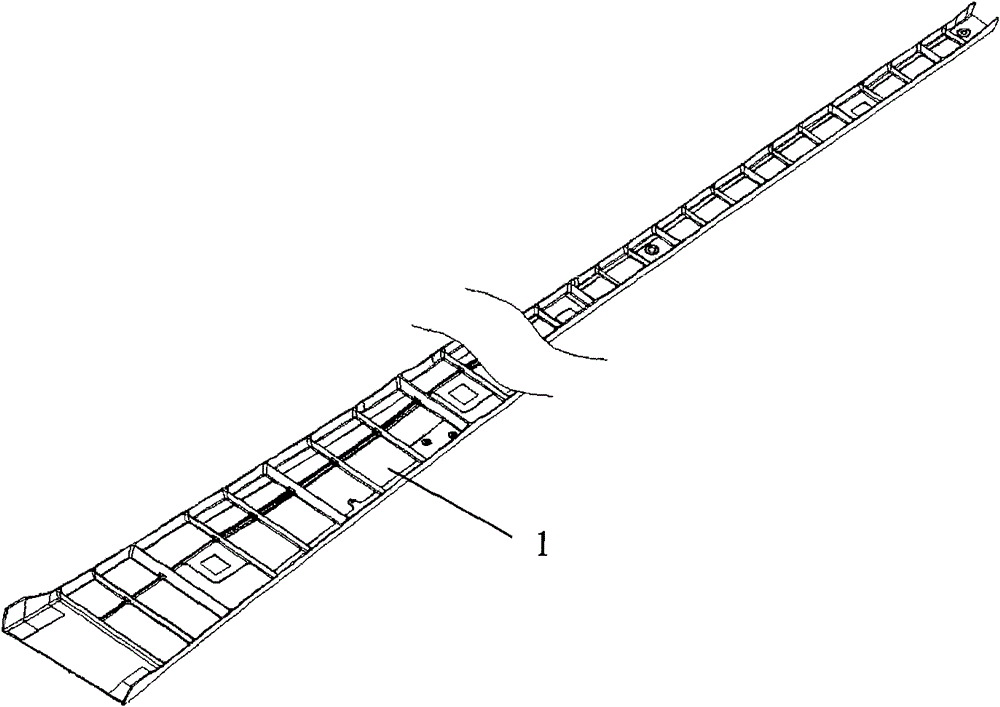

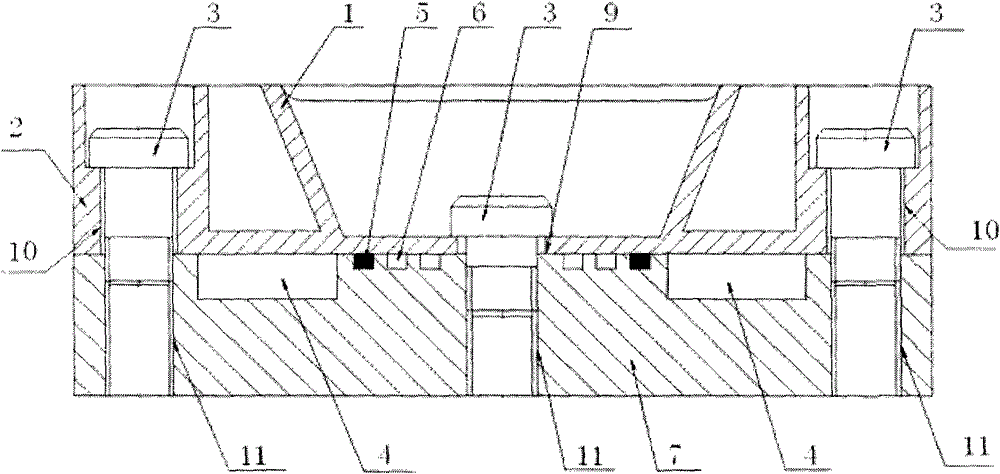

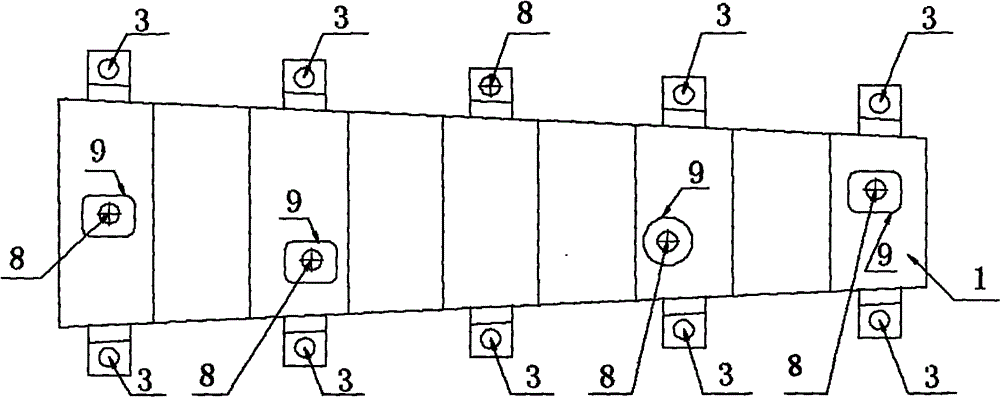

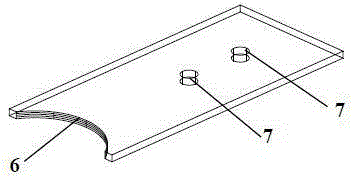

Numerical control machining clamping method for aircraft wing beam parts

ActiveCN102069395AImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsPositioning apparatusMechanical engineeringNumerical control system

The invention discloses a numerical control machining clamping method for large-scale beam parts. The method comprises the following steps of: on the basis of theoretical appearances of parts, machining a plurality of positioning process platforms and compression process platforms on a blank; machining positioning holes and compression holes on a milling tool correspondingly; reserving a tool withdraw groove on the milling tool; and positioning the part blank in the positioning holes on the milling tool through the positioning process platforms and compressing and fixing in the compression holes of the milling tool through the compression process platforms. The overall appearance is machined in place by a tool through one-time clamping; the preparation time is saved; a secondary alignment error is avoided; therefore, the numerical control machining efficiency and the quality are improved; and the milling tool is simple to design and manufacture.

Owner:XIAN AIRCRAFT IND GROUP

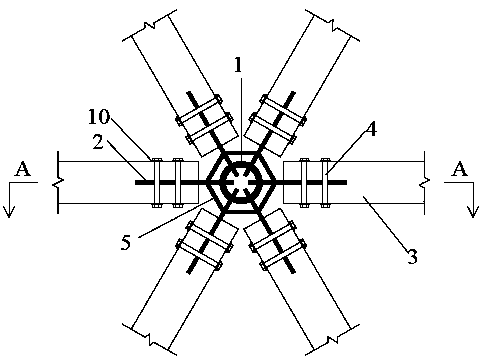

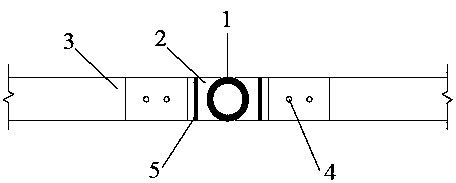

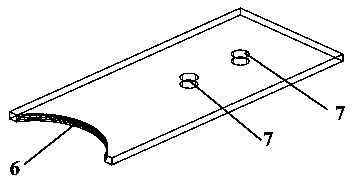

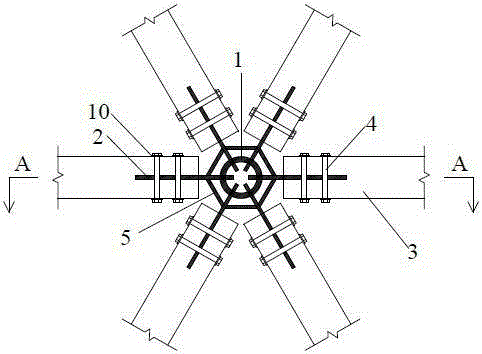

Bamboo latticed shell hollow sphere connecting joint welded with steel insertion sheets and installing method

InactiveCN103469901ASimple structureClosely connectedBuilding material handlingHigh integrityRenewable resource

The invention provides a bamboo latticed shell hollow sphere connecting joint welded with steel insertion sheets and an installing method. The bamboo latticed shell hollow sphere connecting joint comprises M steel insertion sheets, M bamboo rod pieces, M or M-1 reinforced steel sheets, a hollow sphere and 2M bolts, wherein a circular-arc gap is reserved in one end of each steel insertion sheet; a bolt hole A is reserved in the other end of each steel insertion sheet; one end of the circular-arc gap reserved in each steel insertion sheet is fixed together with the hollow sphere by welding; a groove and a bolt hole B are reserved in the end part of the each rod bamboo rod piece; one end, where the bolt hole is reserved, of each steel insertion sheet is inserted into the groove reserved in each bamboo rod piece; the bolt hole A reserved in each steel insertion sheet is aligned with the bolt hole B reserved in each bamboo rod piece; each bolt hole A and bolt hole B are fixed by using two bolts; the reinforced steel sheets are welded on the steel insertion sheets between the bamboo rod pieces and the hollow sphere. The bamboo latticed shell hollow sphere connecting joint has the advantages of simple structure, easiness in positioning and installing, clear force transmission, high integrity, easiness in maintaining and environmental friendliness; bamboo belonging to an environment-friendly renewable resource is taken as the rod piece material of the latticed shell connecting joint, so that an outstanding environmental protection advantage is achieved.

Owner:NANJING FORESTRY UNIV

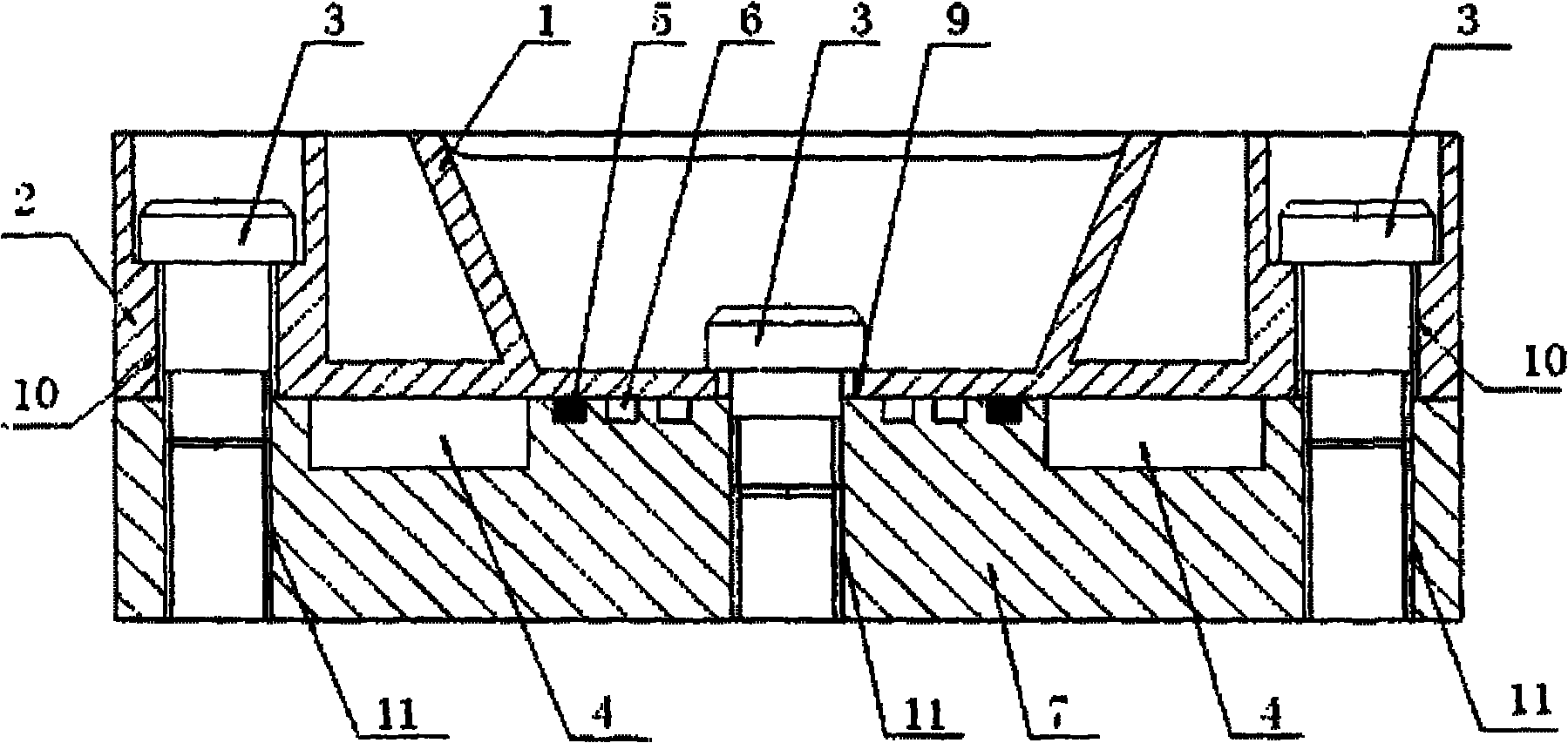

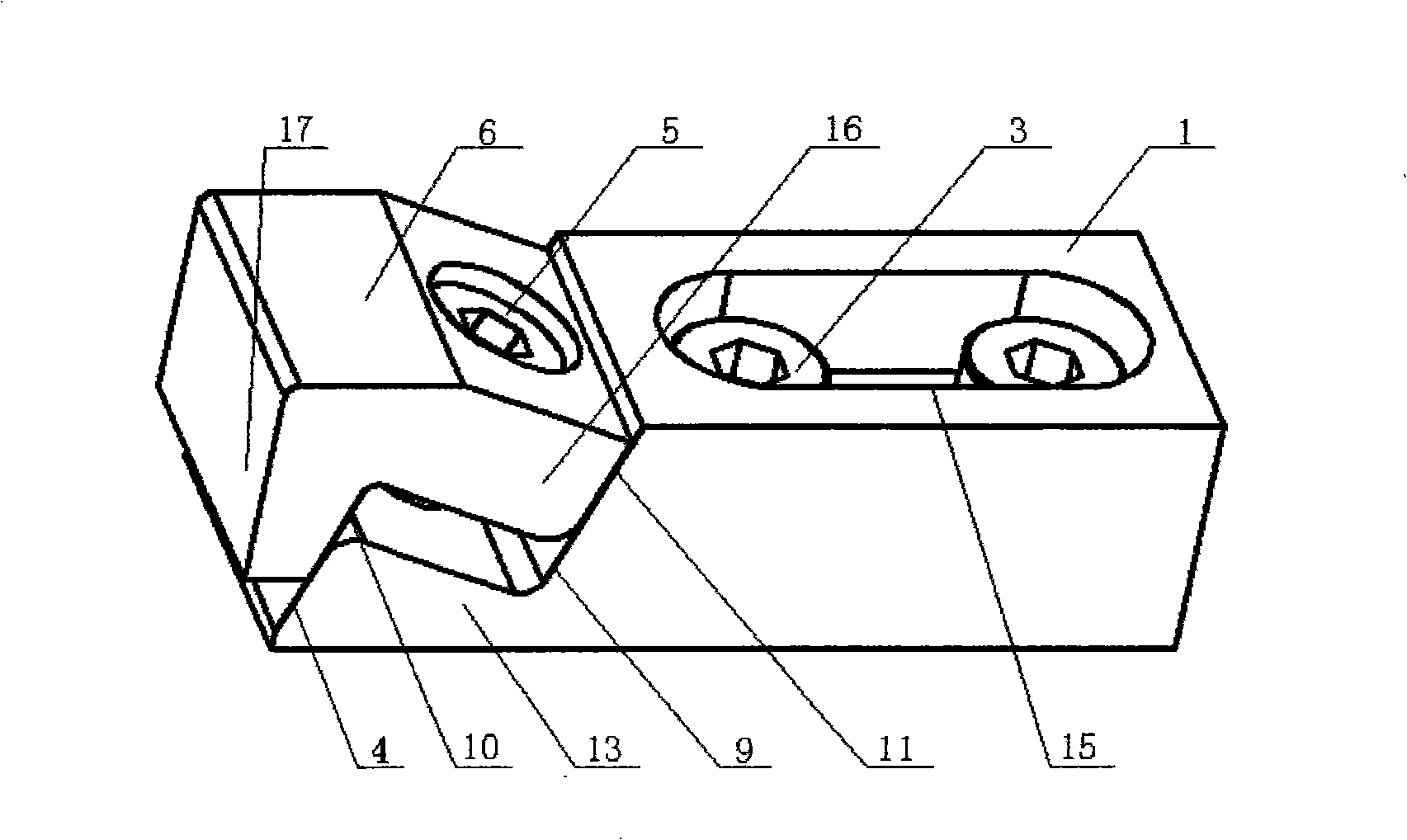

Method and device for compressing numerical control machining parts

InactiveCN101347906AImprove processing efficiencyReduced risk of collision with hold-downsPositioning apparatusMetal-working holdersNumerical controlKinematic pair

The invention provides a compressing method which is suitable for high-efficiency numerical control machining and can clamp a part effectively, quickly and safely and a compressing apparatus. A compressing clamp is arranged at two sides of a part to be processed by a T-shaped groove of a numerical controlled working table, a fixed lock block and a movable lock block of the compressing clamp form a kinematic pair, thus the movable lock block can move along a constant inclined surface of the fixed lock block; the compressing clamp adopts sidewise compressing, so that the total height of the compressing apparatus can be reduced, not only can the overhanging length of a tool be effectively shortened, clamping speed and numerical control machining efficiency can be enhanced, but also the risk that a machine tool collides with the compressing apparatus in numerical control machining can be reduced.

Owner:XIAN AIRCRAFT IND GROUP

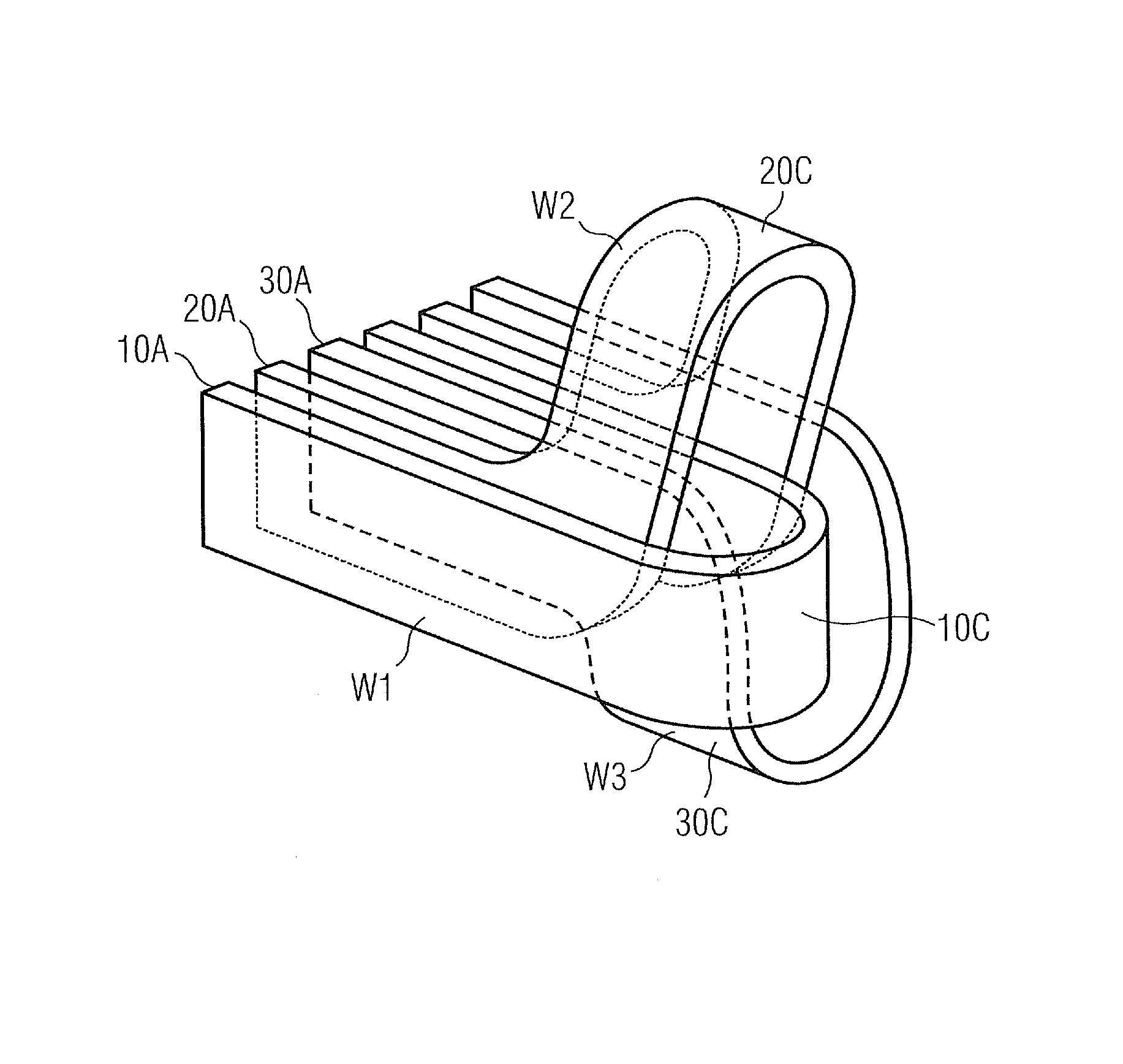

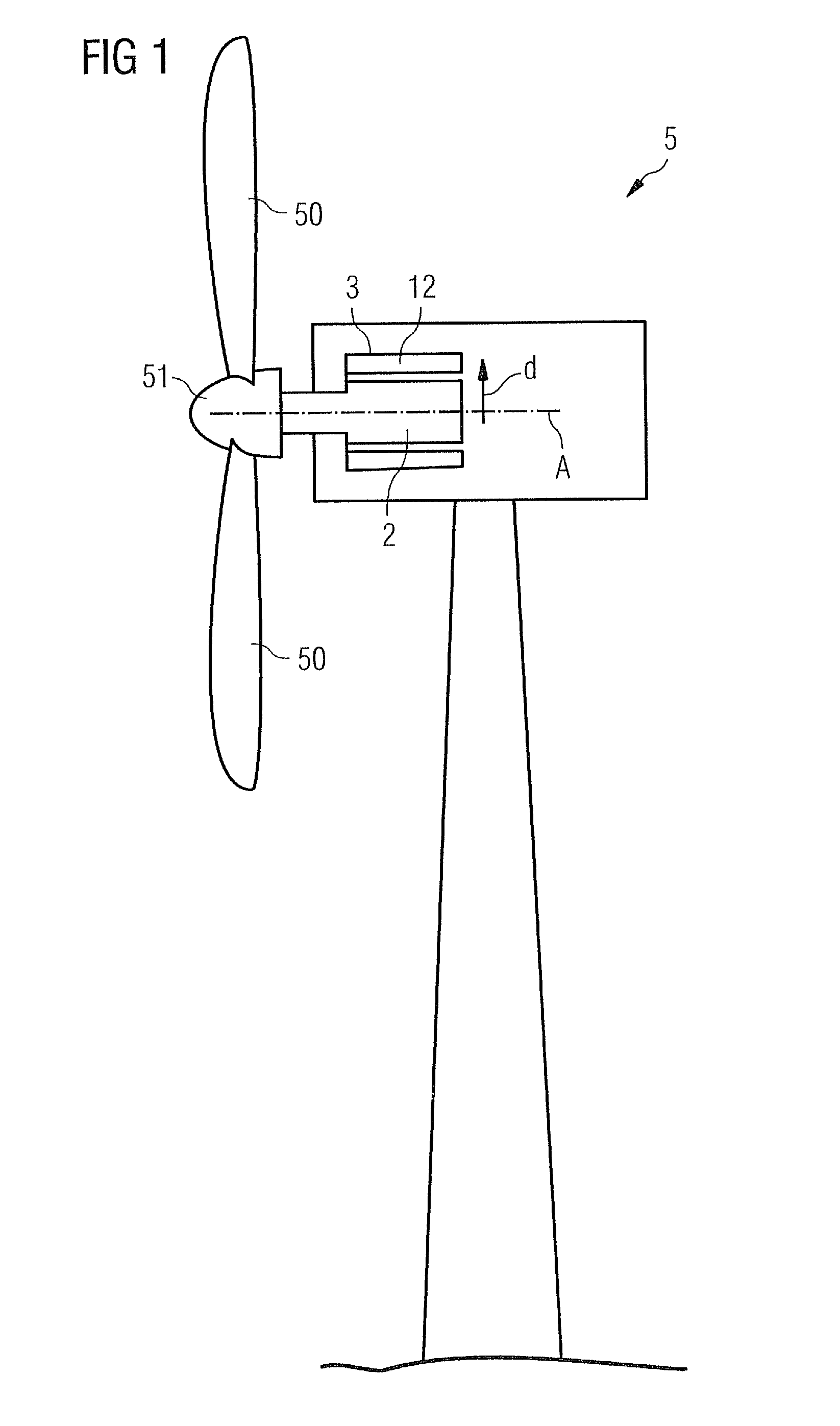

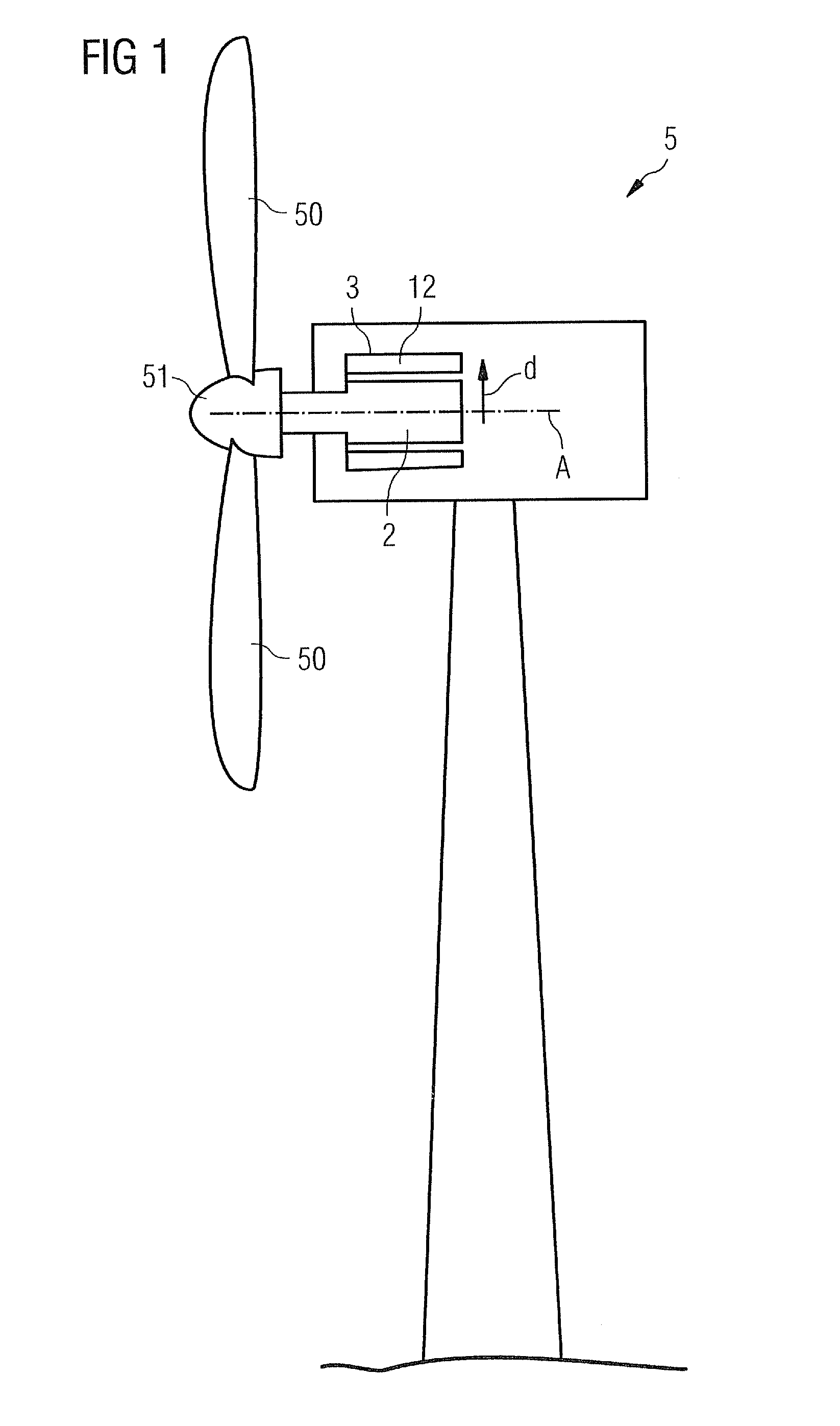

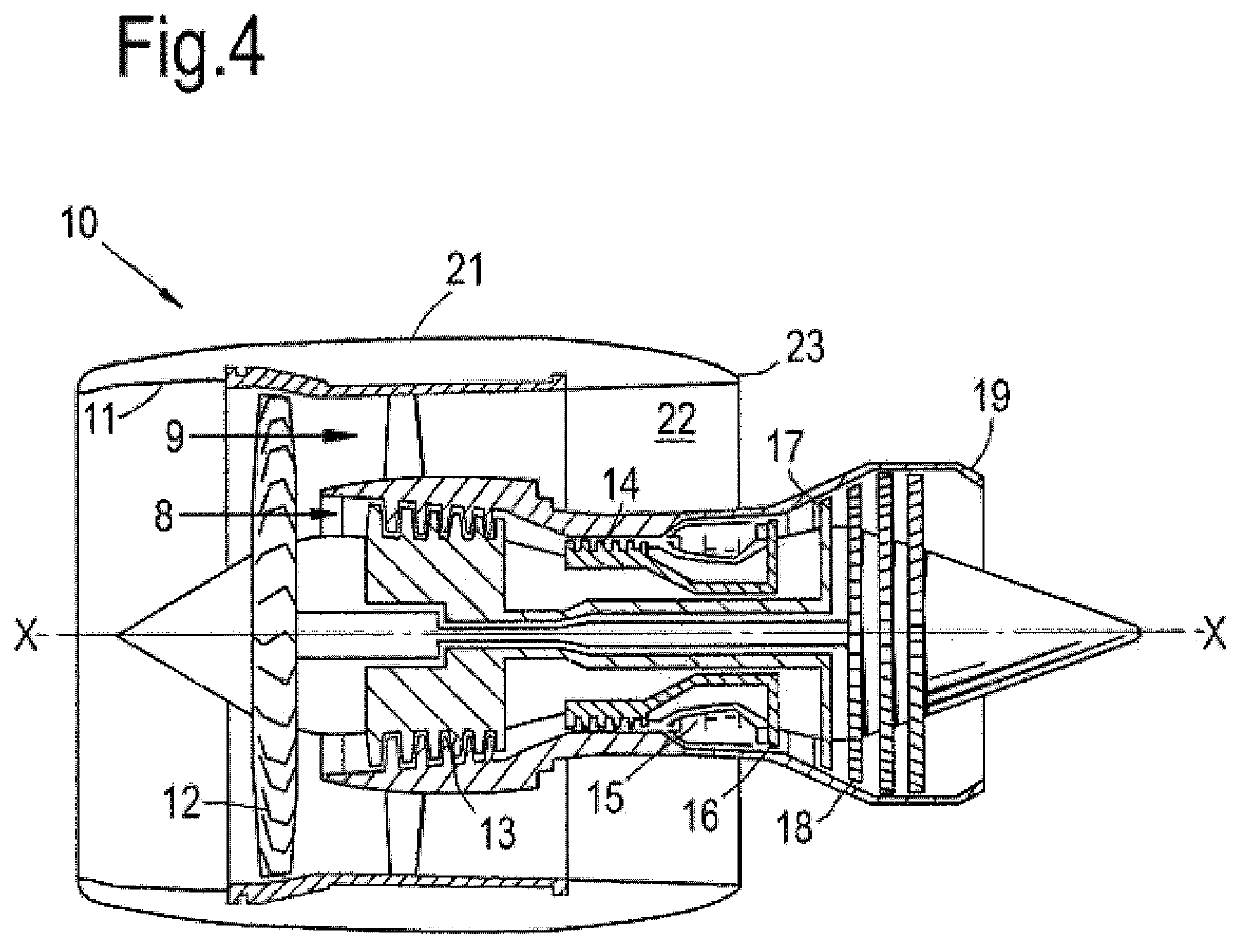

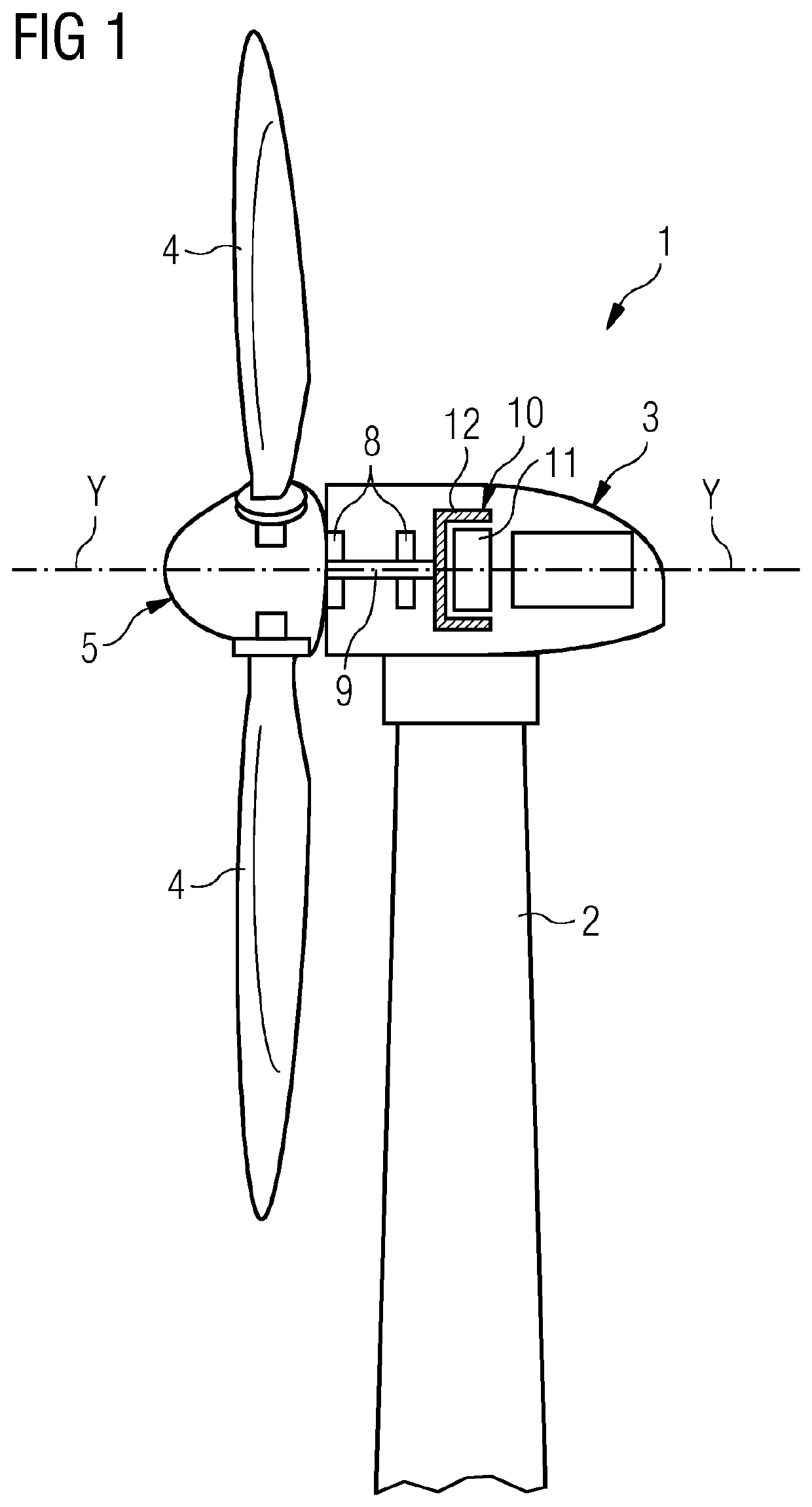

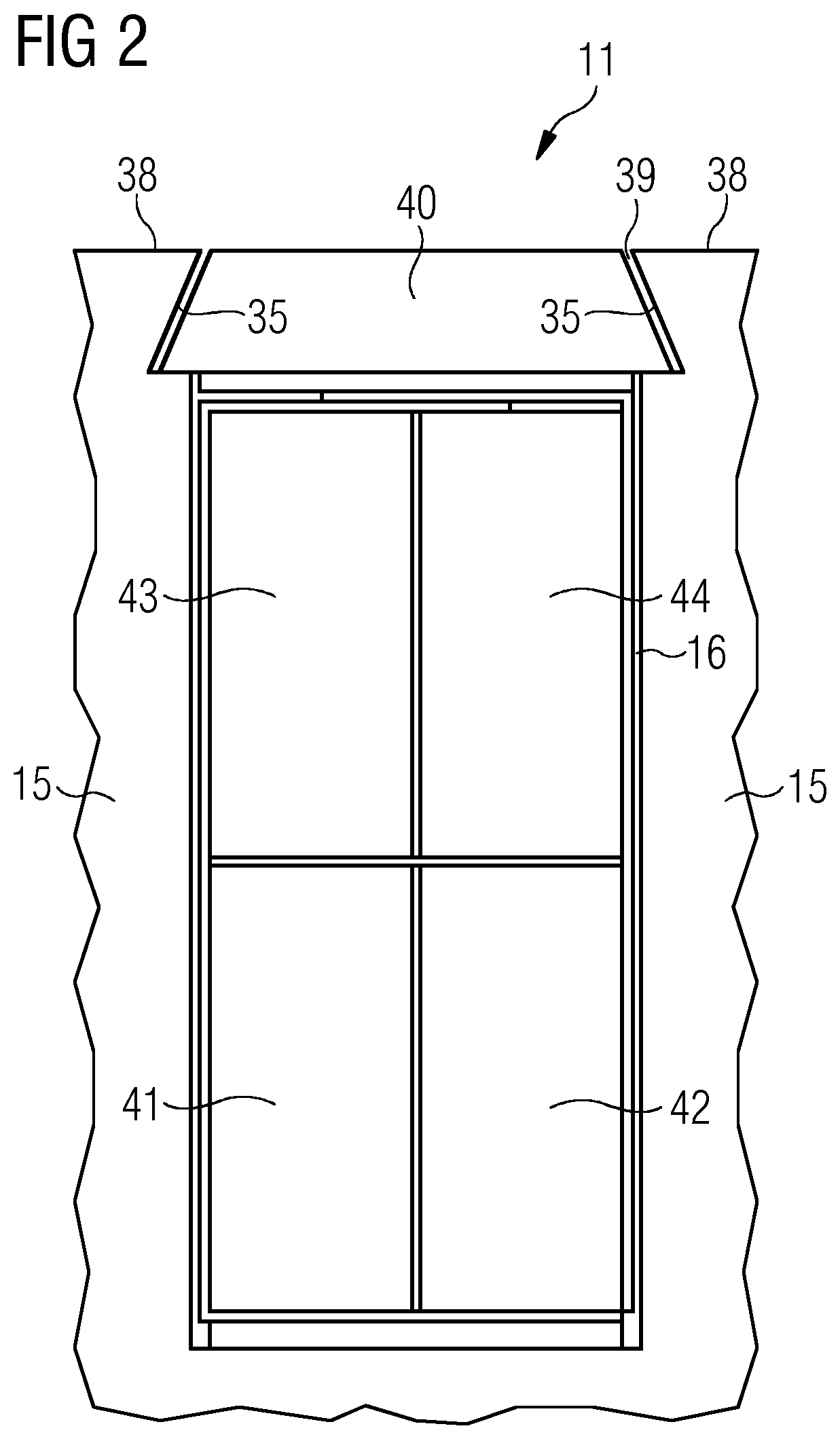

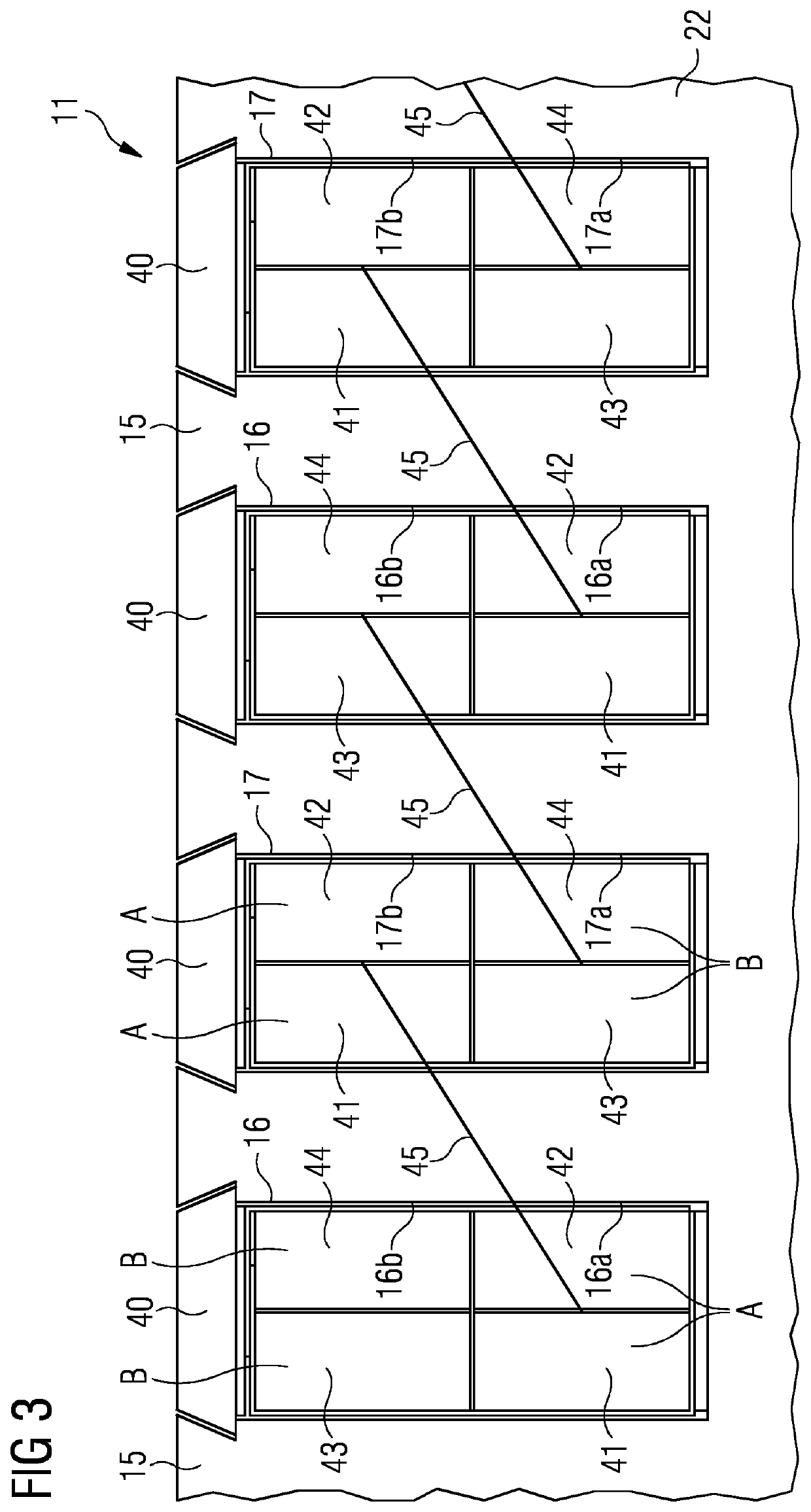

Electrical machine, in particular an electrical generator

InactiveUS8847458B2Reduce overhang lengthImprove electricity efficiencySynchronous machinesAsynchronous induction motorsElectricityElectric machine

An electrical machine includes an armature and at least one field magnet arrangement separated by a gap from each other. The armature and / or the field magnet arrangement include a plurality of coils. Each coil includes conductive body sections. The body sections of the coils are joined electrically by conductive end sections. At least one of the end sections of at least one coil of the armature is tilted in a direction away from the armature towards the field magnet arrangement and / or at least one of the end sections of at least one coil of the field magnet arrangement is tilted in a direction away from the field magnet arrangement towards the armature. The electrical machine may be used in a wind turbine to generate electrical power.

Owner:FLENDER GMBH

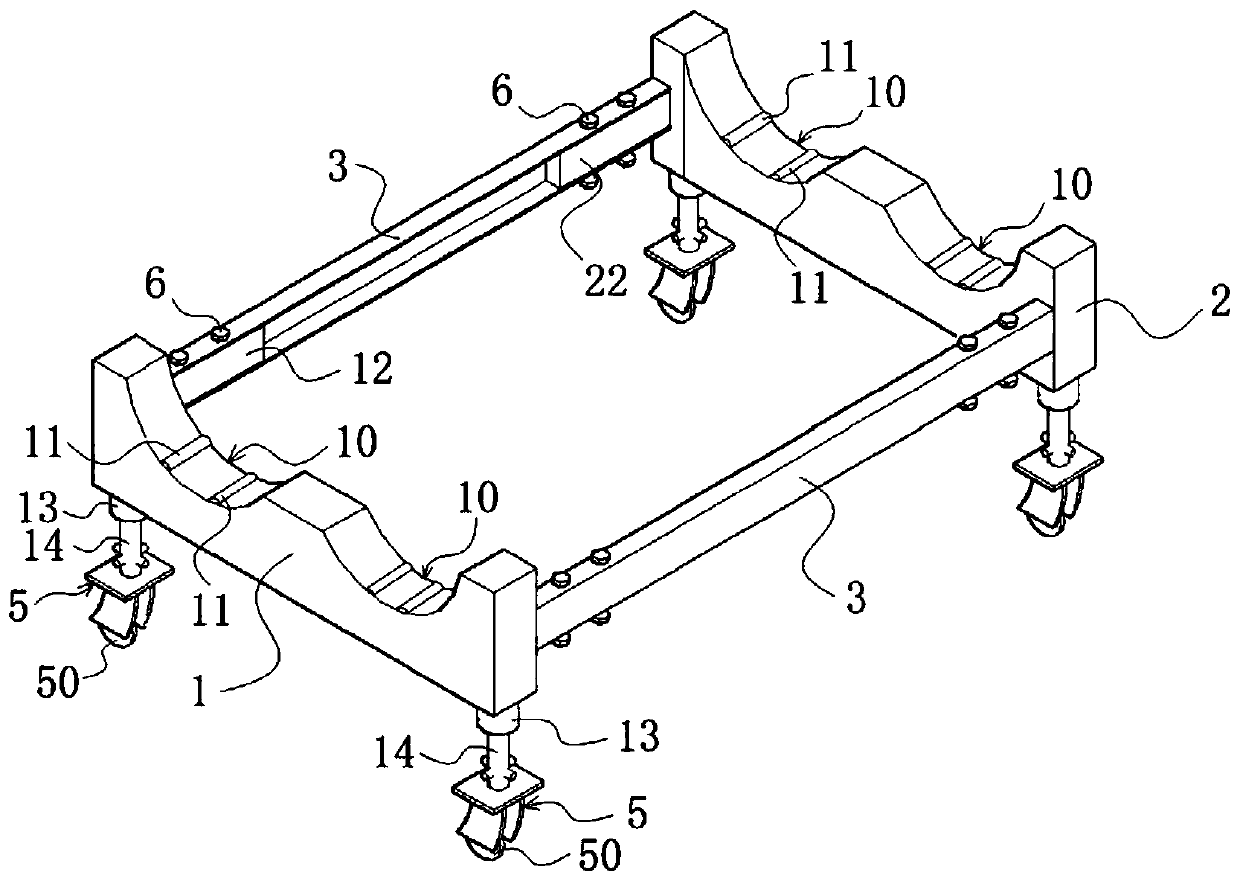

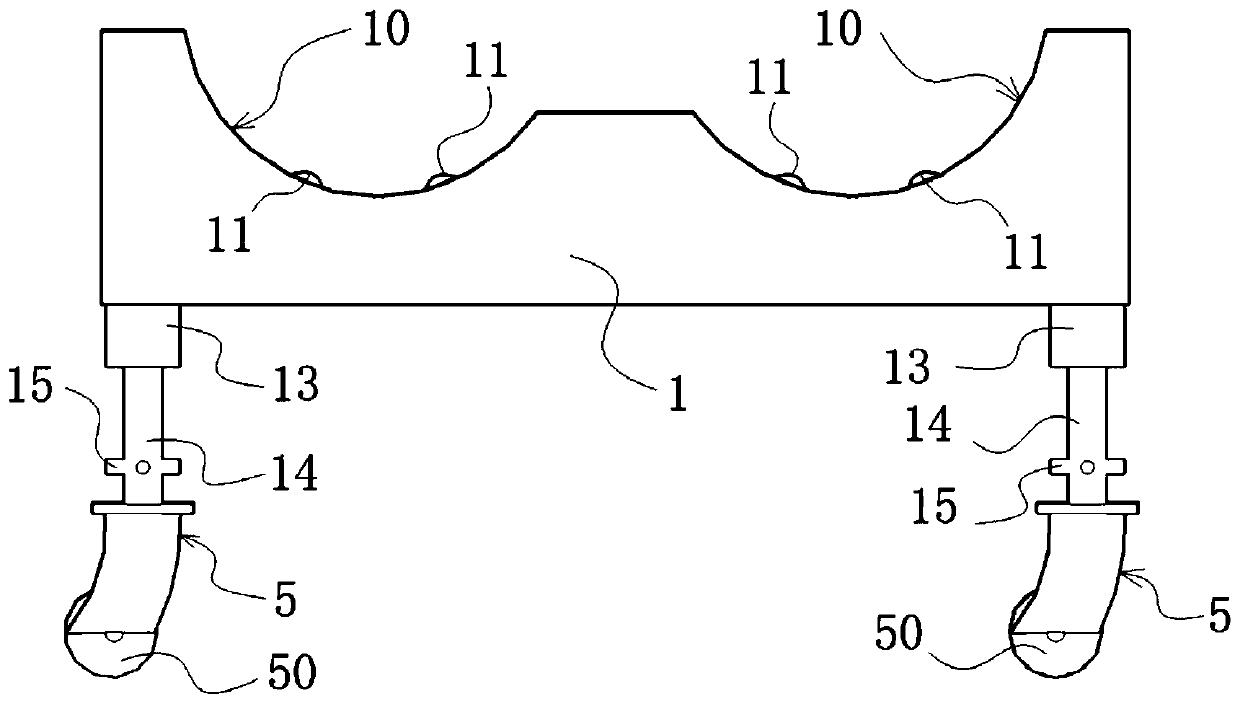

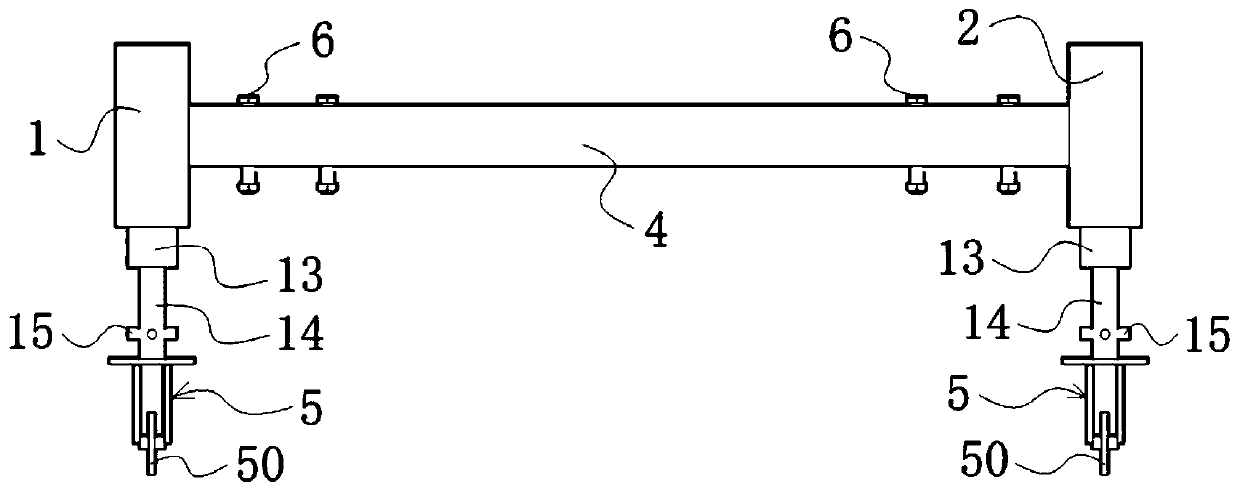

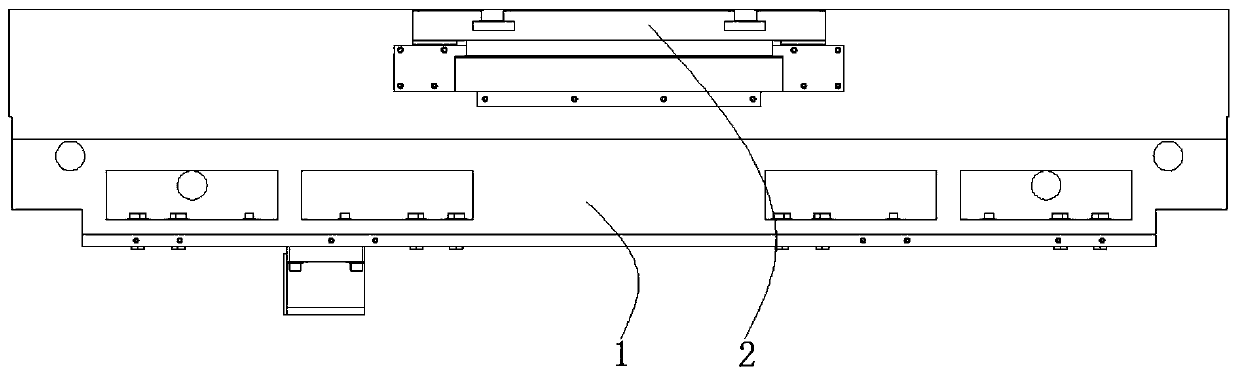

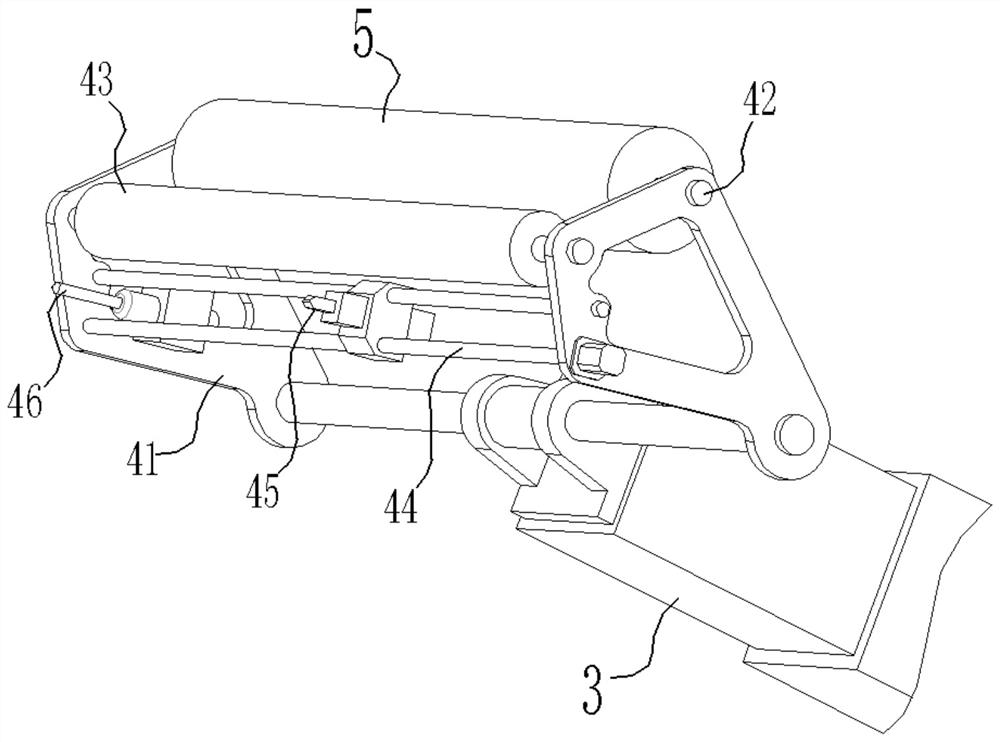

Multifunctional transfer device

InactiveCN110294005AFix stability issuesImprove versatilityHand carts with multiple axesSize differencePipe fitting

The invention provides a multifunctional transfer device, and relates to the technical field of transfer devices. The multifunctional transfer device comprises a support, a wheel frame and rolling wheels, wherein the support comprises two supporting plates which are oppositely arranged and a telescopic structure which is connected between the two supporting plates, corresponding notches are formedin the upper edges of the two supporting plates respectively, and the notches are used for positioning a pipe fitting transversely erected on the two supporting plates; at least two ribs which protrude out of the wall surface and extend in the axial direction of the notches are arranged on the notches, and the ribs are arranged at the bottoms of the notches at intervals; and the support is further provided with fastening bolts for locking the relative positions of the two supporting plates when the two supporting plates are adjusted to a set distance. The distance between the two supporting plates can be adjusted according to the pipe fittings with different lengths, and the overhanging lengths of the front end and the rear end of the pipe fittings which are transversely erected on the two supporting plates is shortened as far as possible, so that the stability of the center of gravity of the pipe fitting is ensured; and the size difference between the pipe fitting and the notches canbe counteracted through the two spaced ribs, and the transportation stability is better, and the universality is better.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

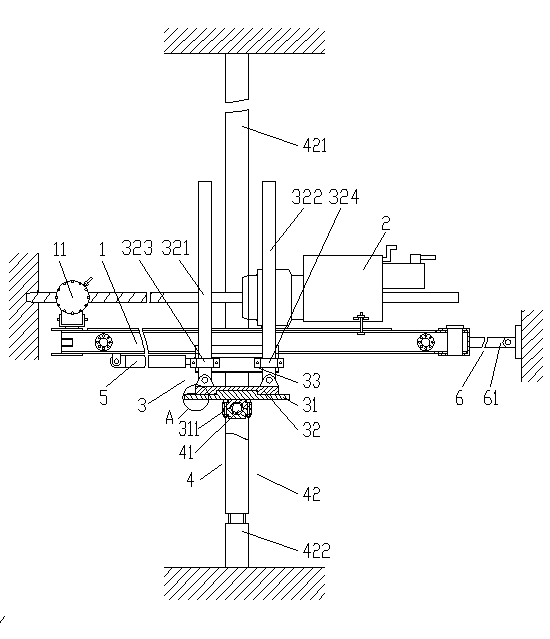

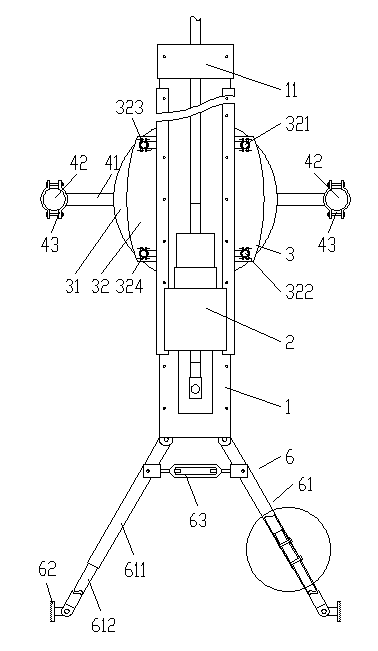

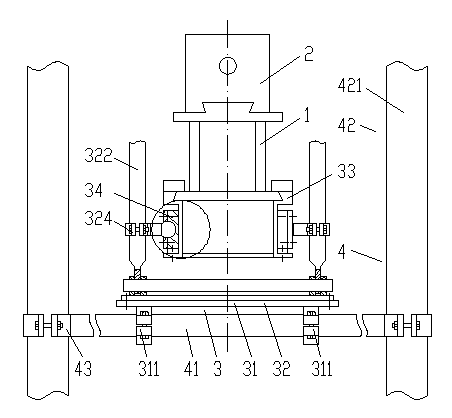

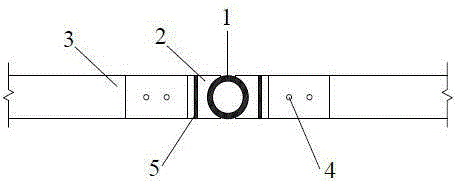

Skid-mounted positioning drilling machine underground coal mine

The invention discloses a skid-mounted positioning drilling machine underground a coal mine, which comprises a runway, a power head, a runway mounting component, a mounting bracket hydraulic system and a control device, wherein the power head is fixed on the runway; the runway is arranged on the runway mounting component; the runway mounting component is arranged on a mounting bracket, and comprises a bottom board which is fixed on a transverse beam of the mounting bracket, and arranged horizontally; the bottom board is provided with a turnplate which is connected with the runway, and can rotate horizontally; angle scale marks and scale values are arranged on the upper plane of the bottom board; the turnplate is provided with an angle pointer; a runway rotating device used for allowing the runway to rotate in a vertical direction is arranged on the turnplate; a slide rail pair is arranged between the runway rotating device and the runway; and a hydraulic cylinder is connected between the runway and the runway rotating device. Preferably, an inverted-V-shaped auxiliary support for fixing the drilling machine is arranged at the tail end of the runway. The skid-mounted positioning drilling machine has the benefits that angular separation of a drilling hole is accurate in positioning, and the skid-mounted positioning drilling machine is small in size, light in weight, convenient to move and mount, and firm and reliable to mount.

Owner:重庆市能源投资集团科技有限责任公司 +1

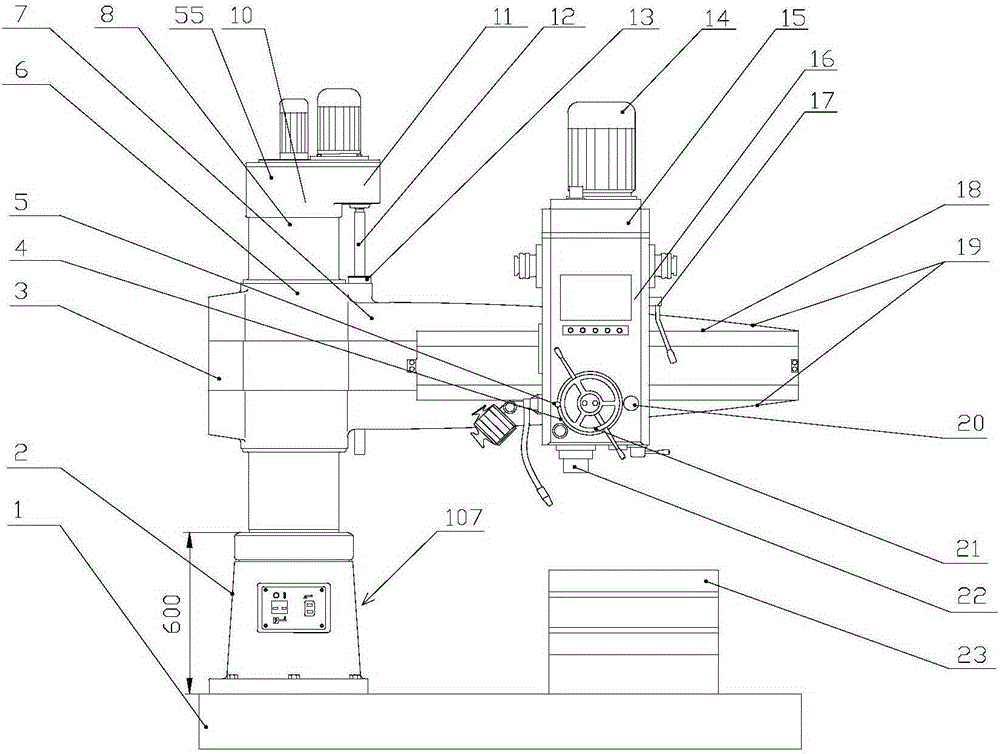

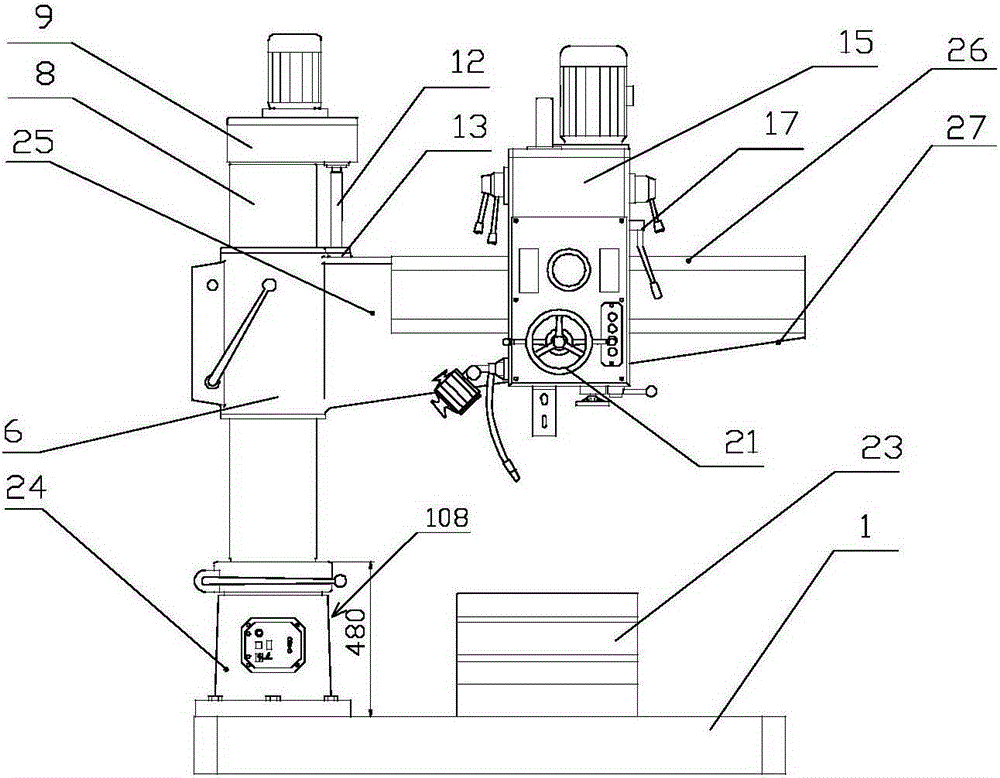

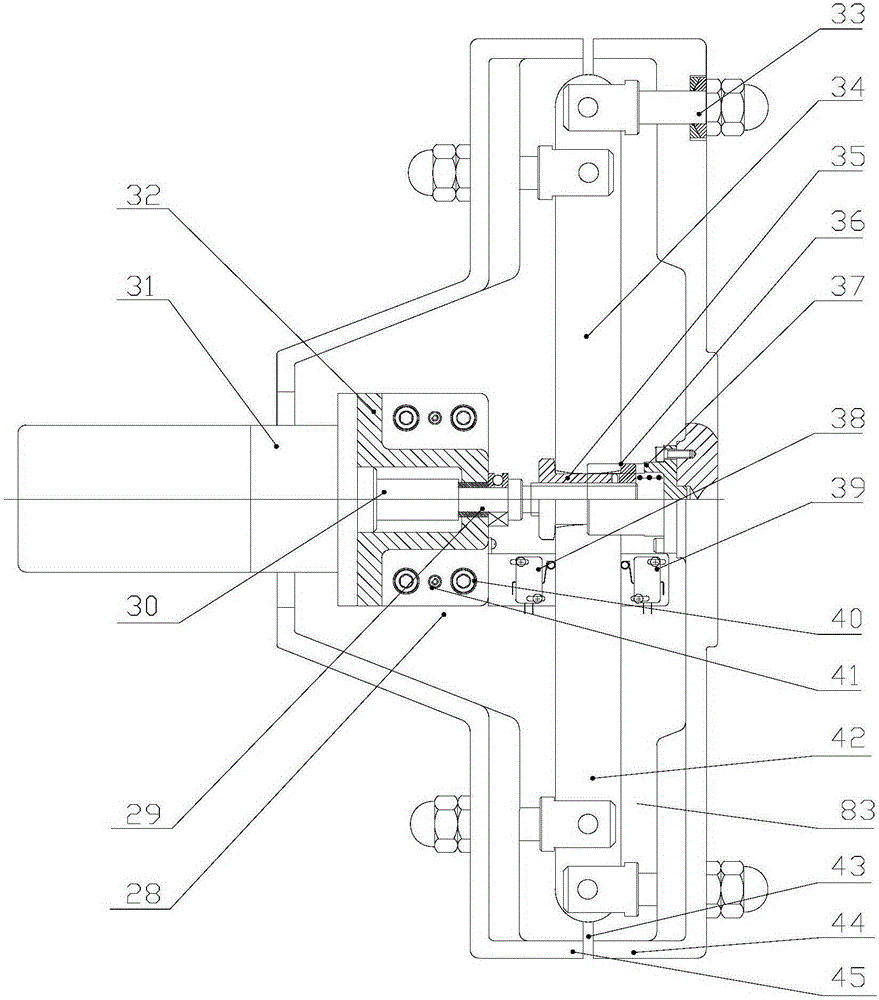

A radial drilling machine

InactiveCN103624294BImprove performanceSimple structureFeeding apparatusLarge fixed membersElectromagnetic clutchBusbar

The invention belongs to the drilling machine field, and in particular relates to a radial drilling machine. A workbench of the radial drilling machine is fixedly arranged at one end of a base, an internal column is fixedly arranged at the other end of the base, an external column is sleeved on the internal column, a rocker arm sleeve is arranged on one end of a rocker arm, the rocker arm sleeve is sleeved on the outer side of the external column, the rocker arm sleeve and the external column form a lead-screw-and-screw-nut fit structure through a rocker arm lifting lead screw and a lifting screw nut, which are used in a matched manner; a column clamping device and a rocker arm lifting safety device are driven by a gearbox body arranged on top of the external column; an opening is formed in the outer end part of the rocker arm sleeve on one end of the rocker arm, a rocker arm clamping device is arranged at the end part, busbars are respectively arranged on the upper and lower sides of the rocker arm, and the busbars adopt the form of hyperbolic curve; a spindle gearbox is mounted on a rocker arm guide rail of the rocker arm, and a main transmission electromagnetic clutch is arranged in the spindle gearbox. With the adoption of the radial drilling machine, the purposes of increasing performance, simplifying structure, facilitating manufacturing, usability, saving energy and facilitating operation are realized.

Owner:SHENYANG JINSHAN MACHINE TOOL

Electrical machine, in particular an electrical generator

InactiveUS20120217750A1Compact overhang designReduce material usageSynchronous machinesAsynchronous induction motorsElectricityElectric machine

An electrical machine includes an armature and at least one field magnet arrangement separated by a gap from each other. The armature and / or the filed magnet arrangement include a plurality of coils. Each coil includes conductive body sections. The body sections of the coils are joined electrically by conductive end sections. At least one of the end sections of at least one coil of the armature is tilted in a direction away from the armature towards the field magnet arrangement and / or at least one of the end sections of at least one coil of the field magnet arrangement is tilted in a direction away from the field magnet arrangement towards the armature. The electrical machine may be used in a wind turbine to generate electrical power.

Owner:FLENDER GMBH

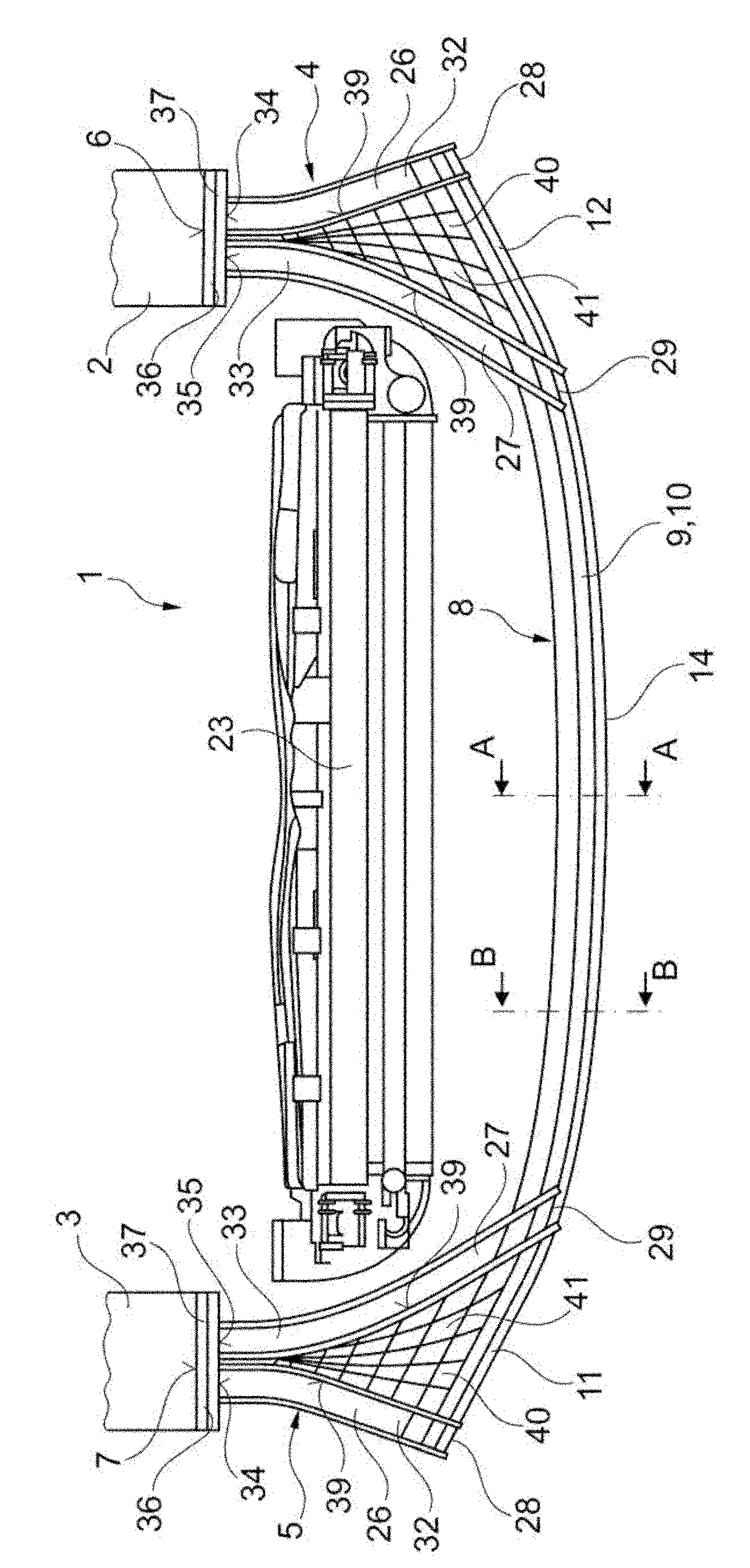

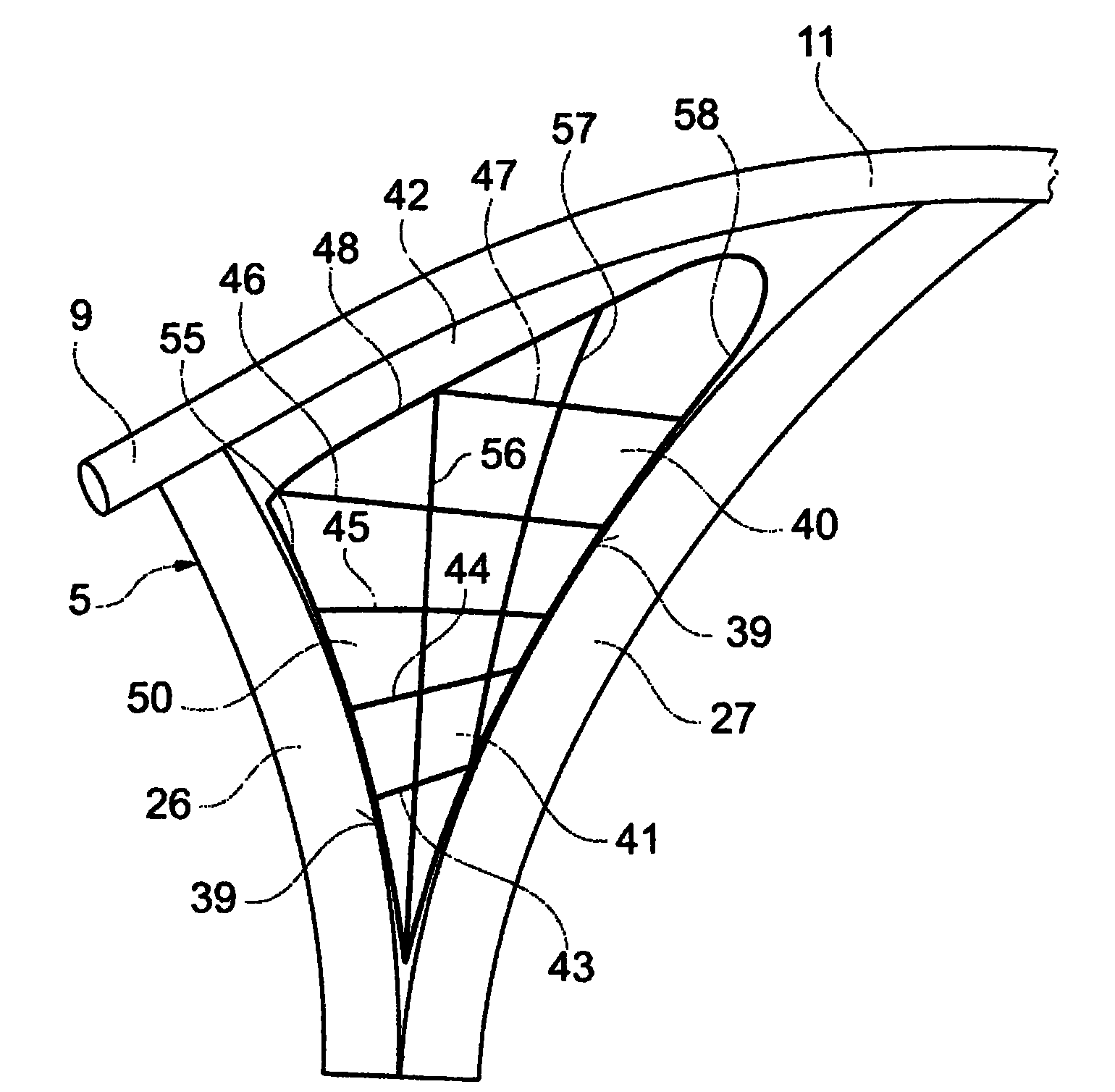

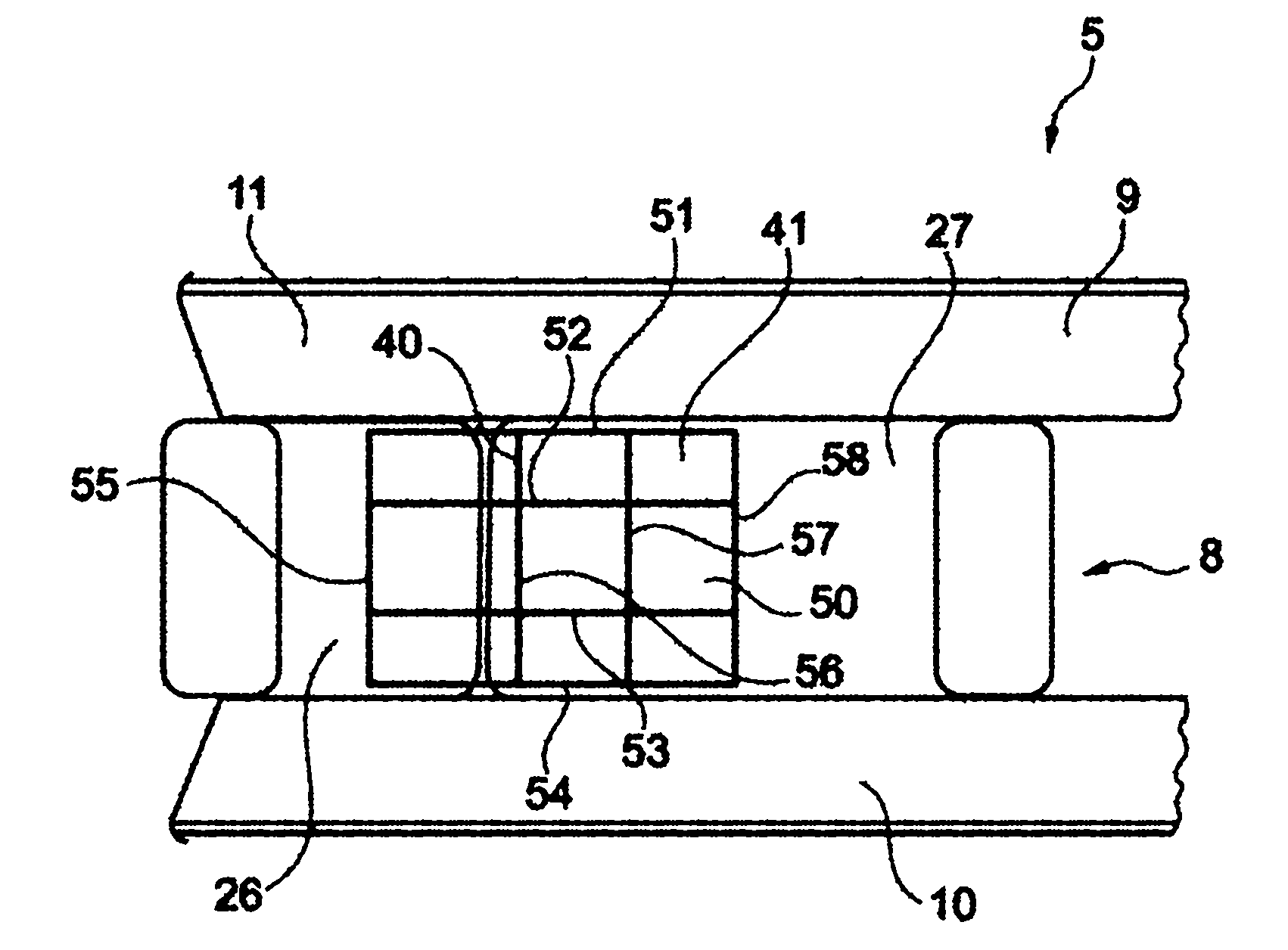

Motor vehicle front structure

InactiveCN102145676ASpeed up the flowReduce distanceBumpersPropulsion coolingHoneycombMechanical engineering

A motor vehicle front structure (1) is provided with at least one front frame (31) having two side members (2, 3) and an impact cross-member structure (8). Two crash boxes (4, 5) are fixed between the respective front end (6, 7) of the side members (2, 3) and the impact cross-member structure (8). Each of the crash boxes (4, 5) comprises a first and a second leg (26, 27) which are jointly fixed to the front end (6, 7) of each side member (2, 3). The first and second legs (26, 27) formed in a V merge shape with ends (28, 29) spread from each other in the direction of the impact cross-member structure (8). The spread ends (28, 29) are fixed on end regions (11, 12) of the impact cross member structure (8). Between the legs (26, 27) a connecting structure (40) with a honeycomb construction (41) is arranged.

Owner:GM GLOBAL TECH OPERATIONS LLC

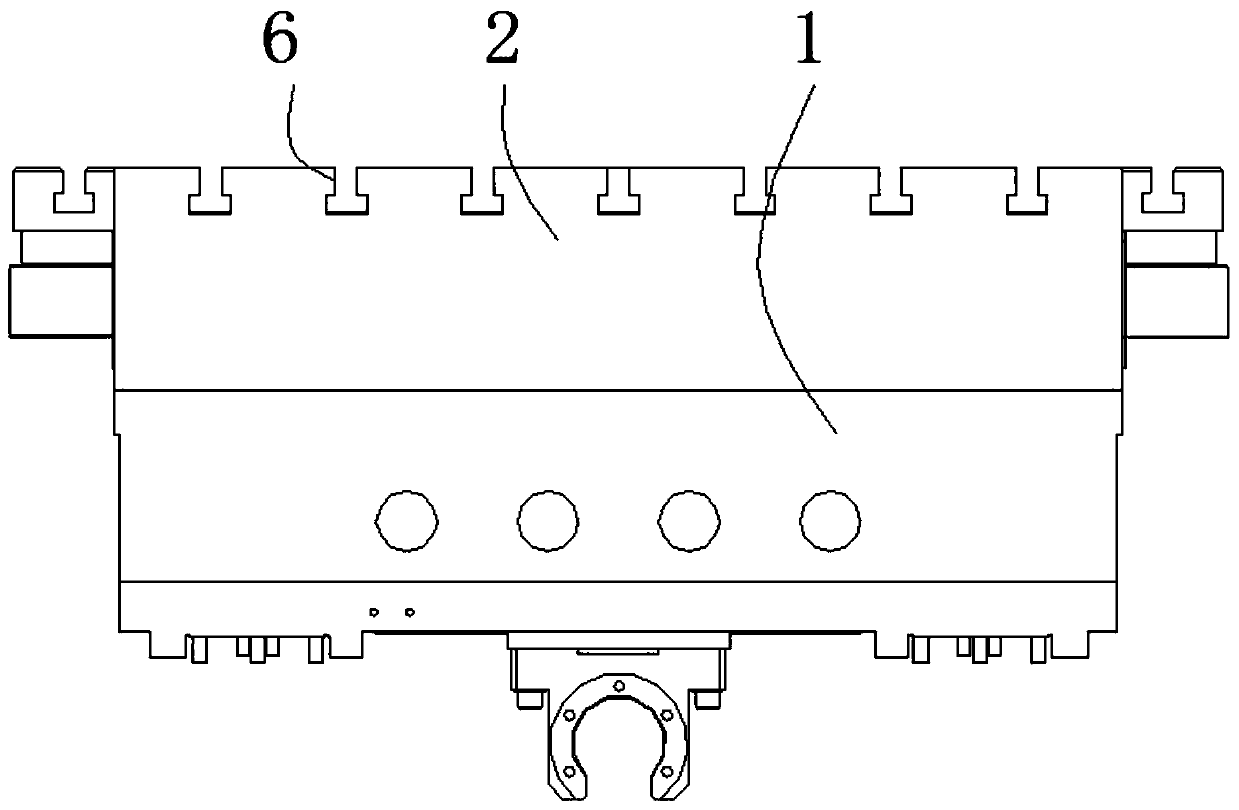

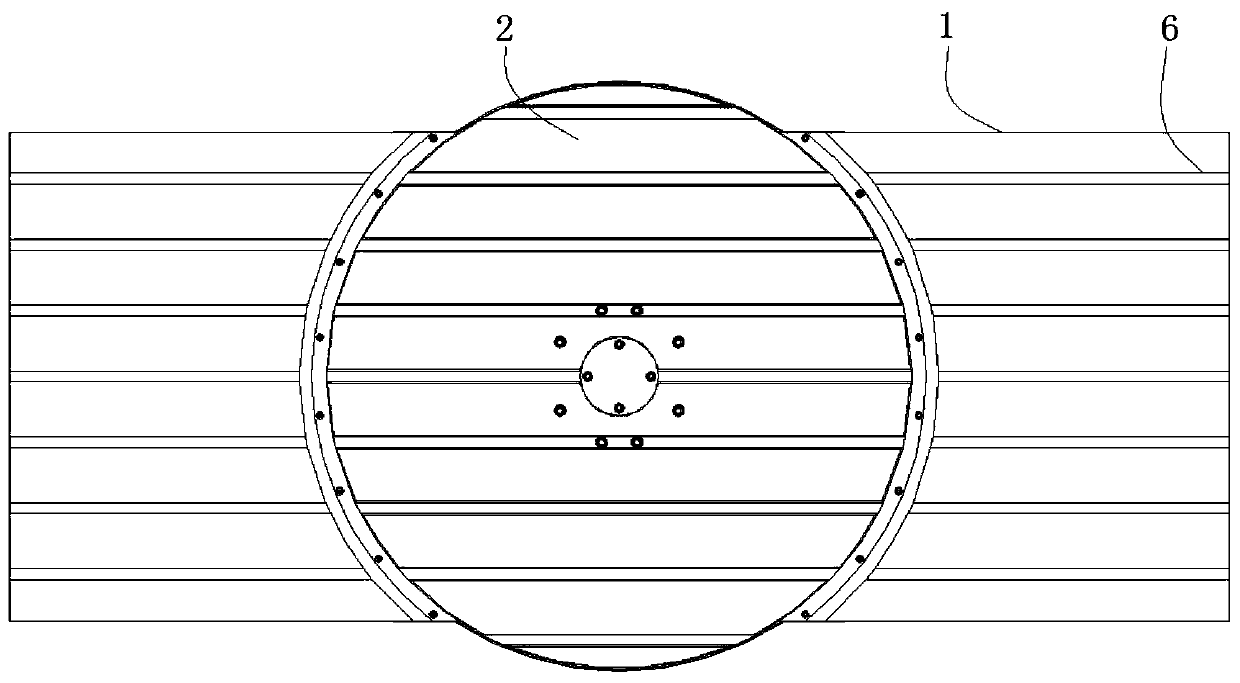

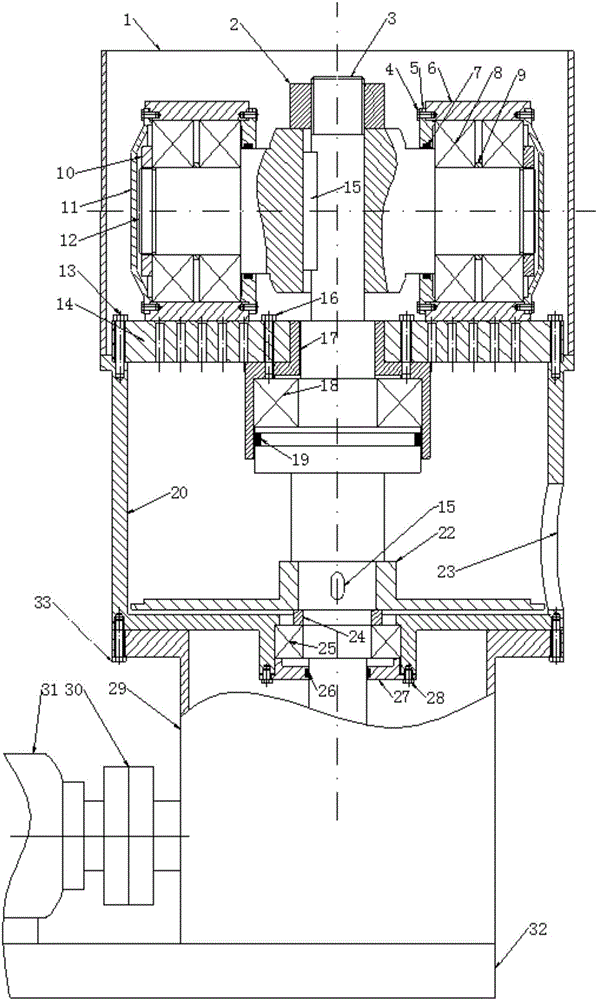

Embedded type direct-driven rotating table supported by surface bearing

InactiveCN111496553AImprove versatilityIncrease flexibilityPrecision positioning equipmentLarge fixed membersNumerical controlNeedle roller bearing

The invention discloses an embedded type direct-driven rotating table supported by a surface bearing and relates to the technical field of numerical control machine tools. The embedded type direct-driven rotating table supported by the surface bearing comprises a basic workbench. The top of the basic workbench is provided with the rotating table body through a surface needle bearing. A rotating table body base is fixedly arranged at the center position of the basic workbench through a bolt. According to the embedded type direct-driven rotating table supported by the surface bearing, due to thefact that the rotating table body which can rotate is arranged on the basic workbench, the rotating table body and the basic workbench are coplanar, the rotating table body can machine small workpieces, a T-shaped groove in the rotating table body is adjusted to be consistent with a T-shaped groove in the basic workbench in direction so that large workpieces can be machined, two workbench workingmanners are achieved on one machine tool, and the universality and flexibility of the machine tool are improved.

Owner:SHANDONG PULUTE MACHINE TOOL

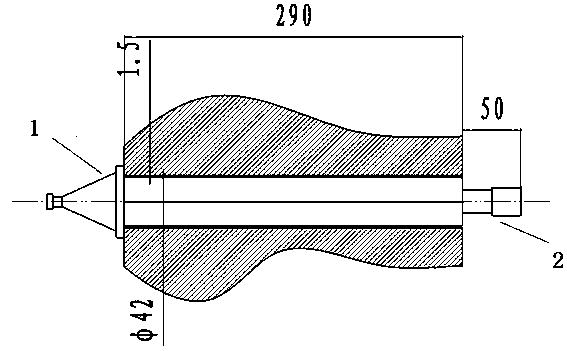

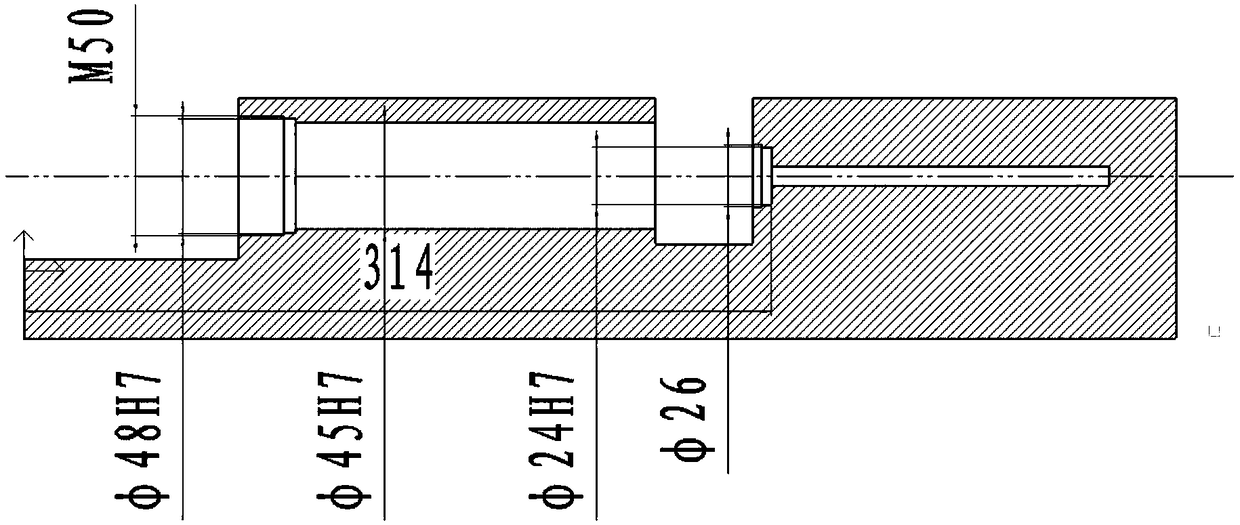

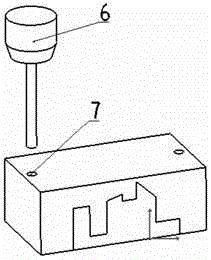

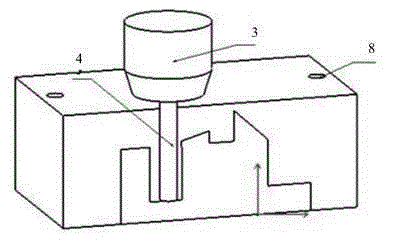

High-precision deep hole machining tool with inner wing type structure and machining method

InactiveCN109482950AHigh hardnessReduce overhang lengthMilling cuttersReaming toolsStructural engineeringMachine tool

The invention discloses a high-precision deep hole machining tool with an inner wing type structure and a machining method, and belongs to the technical field of high-precision deep hole machining. According to a machined deep hole structure, a hole with the diameter of 24 mm is formed in a position with the depth of more than 300 meters, and a slot hole with the diameter of 45 mm is formed in a deep range with the depth of more than 300 meters. A suitable cutting parameter tool is selected in the tool and the machining method. The machining method comprises the steps that tool feeding and discharging modes are arc modes during finish machining, and helical milling layered machining is carried out. High-precision deep holes of the type structure can be machined, and the machining success rate of the high-precision deep holes can be improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

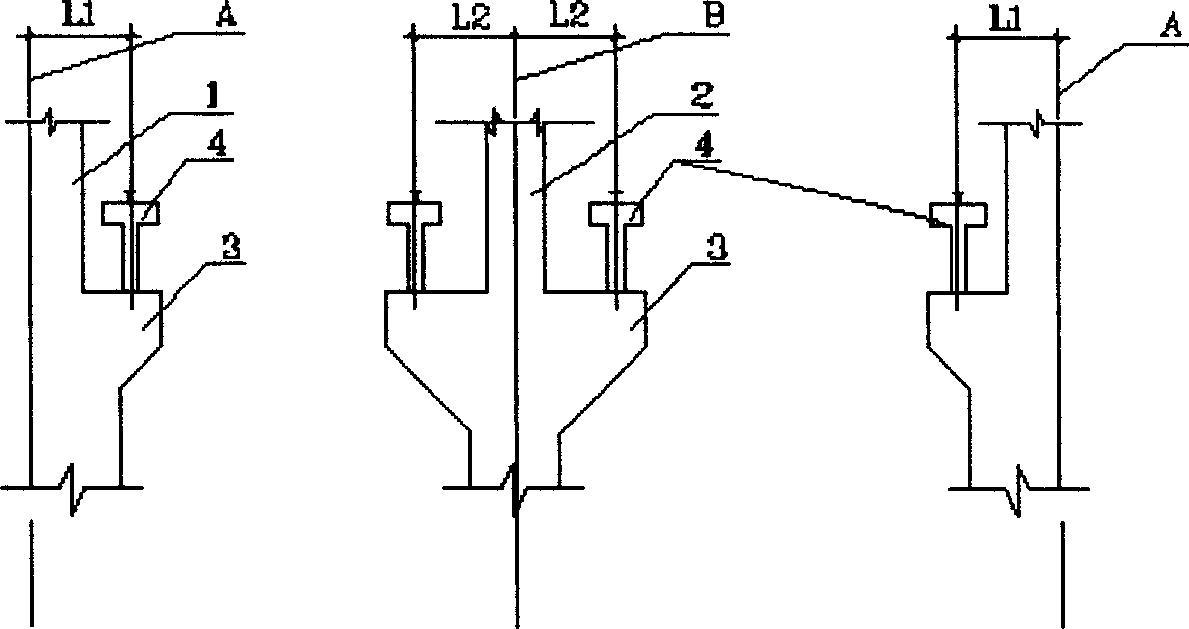

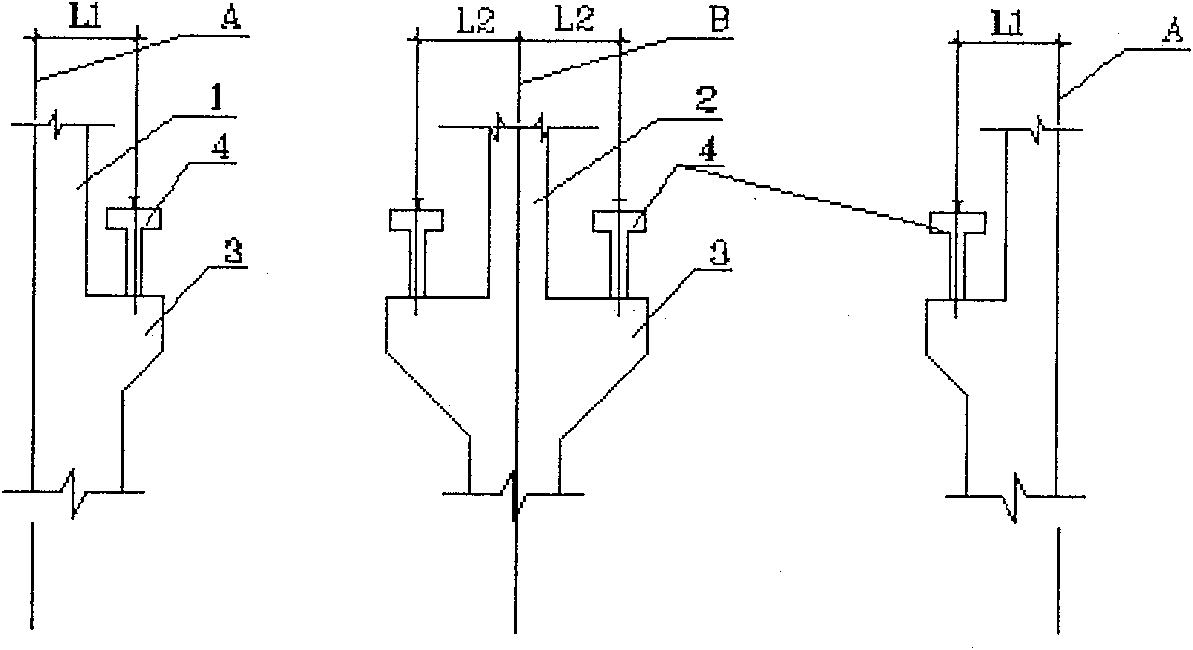

Single-layer multiple-span bent column crane beam positioning method

The invention discloses the single-layer multiple-bay bent crane beam localization. When the crane beam is installed on the bracket of bent side column and bent central column, the distance between central line of crane beam on bracket and scale line of bent side pillar is L1, the distance between central line of crane beam on bracket and scale line of bent central pillar is L2, and the L1 is bigger than L2. The invention adjusts the location dimension between the central lines of crane beam on bent side column and bent central column and span scale line, and the effect of side column caused by single crane load is the same with the effect of central column caused by single crane load. The method has the advantages of homogeneous forcing and low cost.

Owner:GUIYANG AL-MG DESIGN & RES INST

Simply-supported beam method cantilever connecting corridor formwork support system construction technology

InactiveCN106088313AReduce overhang lengthReduce torqueBuilding constructionsSupporting systemEngineering

The invention discloses a simply-supported beam method cantilever connecting corridor formwork support system construction technology. The technology comprises the following steps of cantilever I-shaped steel compression ring embedding, simply-supported I-shaped steel selecting and welding, simply-supported I-shaped steel hoisting, cantilever I-shaped steel hoisting, formwork support system building, rebar installing, concrete pouring and simply-supported beam formwork support system dismantling. According to the simply-supported beam method cantilever connecting corridor formwork support system construction technology, the support system cantilever length is reduced, the torque is reduced, and therefore the frame cantilever length is reduced to support the loaded formwork support system.

Owner:QINGDAO HAICHUAN CONSTR GROUP

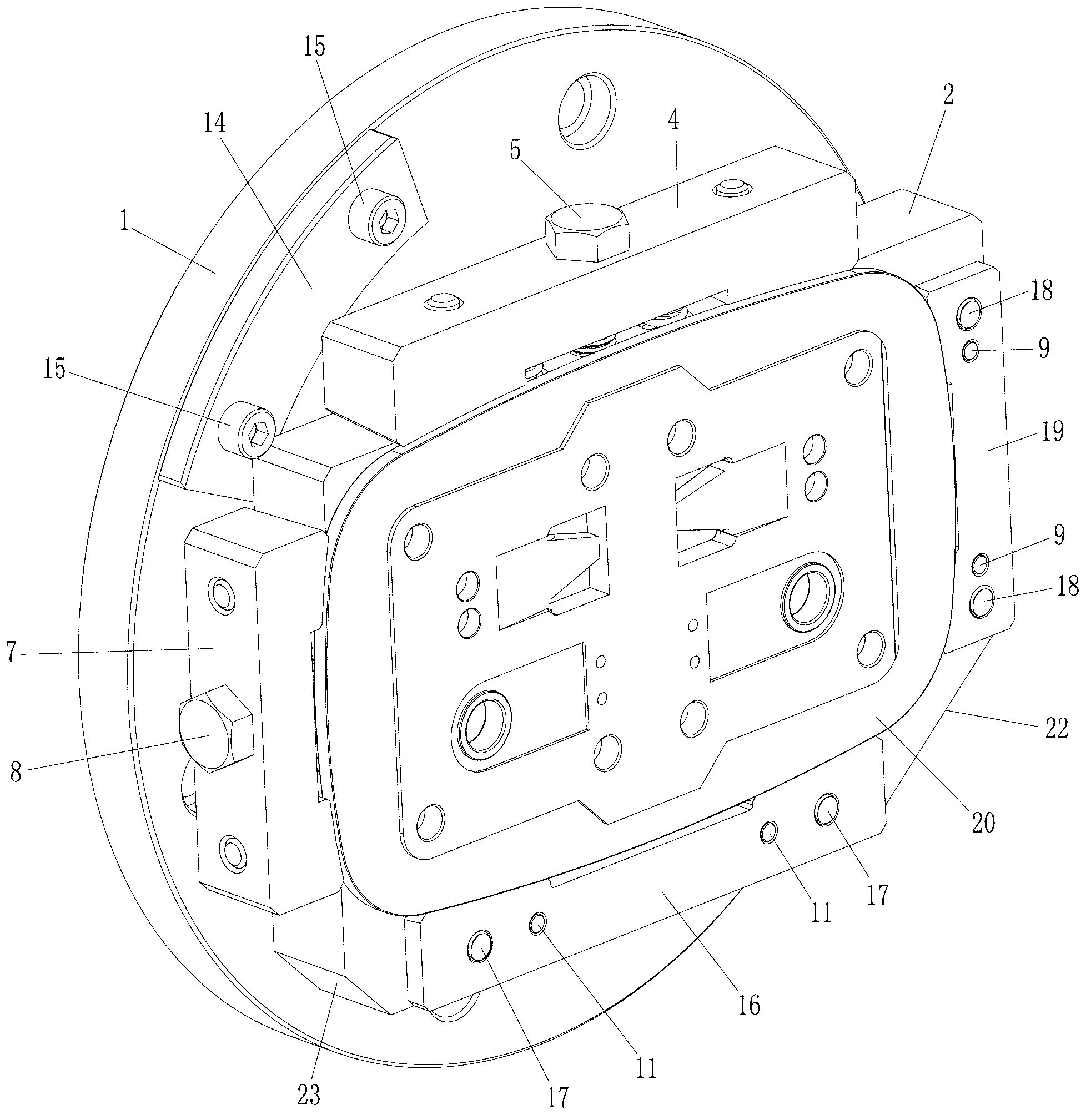

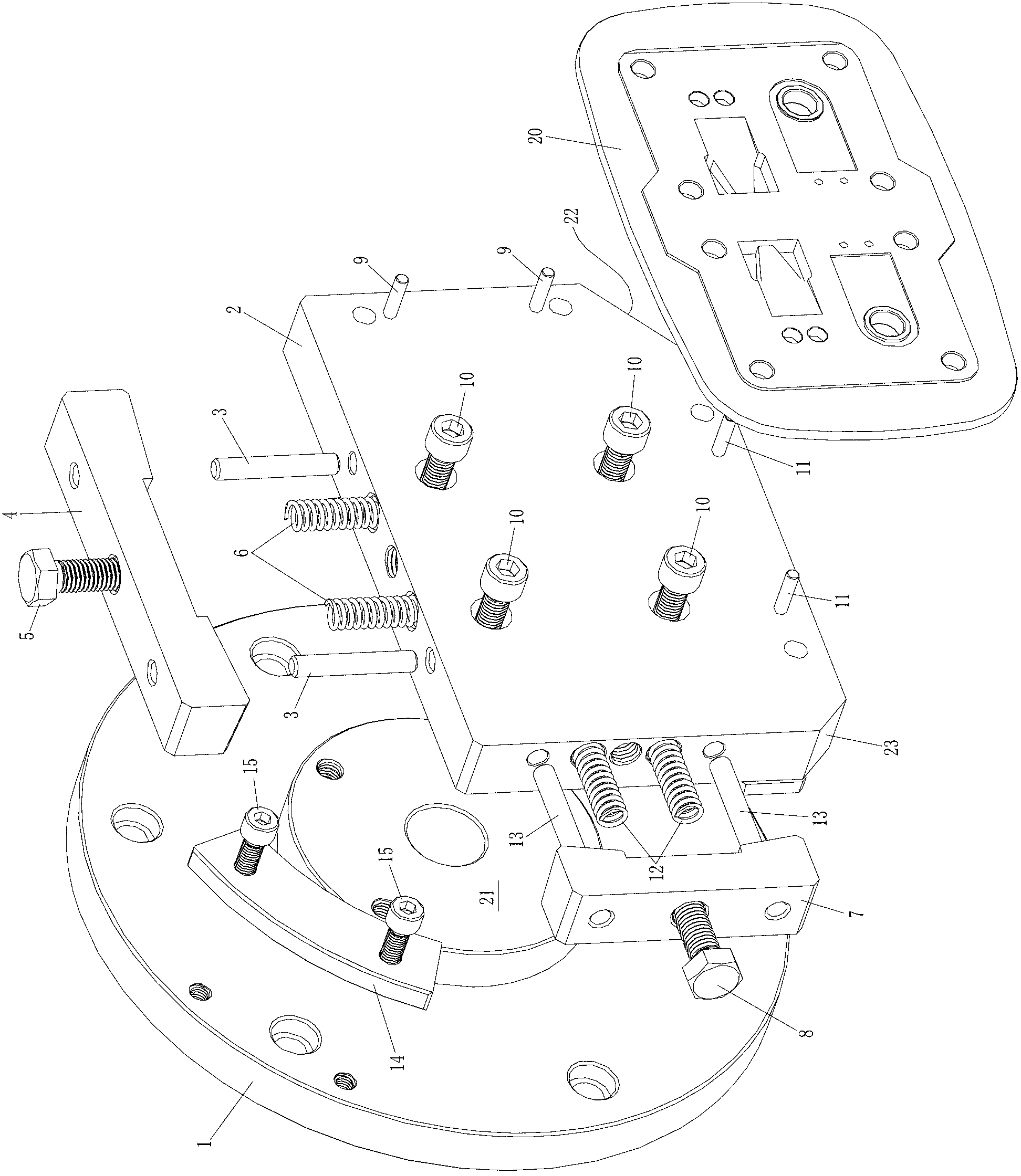

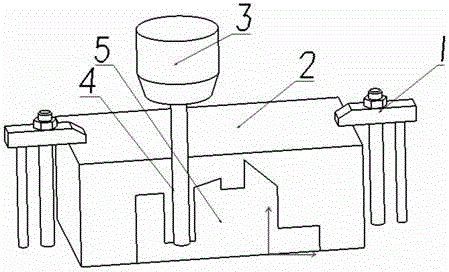

Fixture for turning thin aluminum valve plate

InactiveCN103286603ACompact designReduce overhang lengthPositioning apparatusMetal-working holdersEngineeringDigital control

A fixture for turning a thin aluminum valve plate comprises a flange bottom connected with a spindle of a digital controlled lathe. A rectangular main positioning plate of the valve plate is fixedly connected to a positioning spigot tire of the flange bottom, and is arranged deviating the center of the flange bottom right-off and downwards. The left lower corner of the main positioning plate of the valve plate is provided with a small chamfer, and the right lower corner of the main positioning plate of the valve plate is provided with a large chamfer. A longitude fixed clamping plate is arranged on the upper right edge of the outer side of the main positioning plate of the valve plate, and a transverse fixed clamping plate is arranged on the upper lower edge of the outer side of the main positioning plate of the valve plate. A longitude movable clamping plate is arranged on the left end face of the main positioning plate of the valve plate, and a transverse movable clamping plate is arranged on the upper side end face of the main positioning plate of the valve plate. The outer side faces of the longitude movable clamping plate and the transverse movable clamping plate are flush and are slightly lower than the plane to be machined of the thin aluminum valve plate. The thin aluminum valve plate is clamped radially, the fixture is safe and reliable, products have well flatness after machining, and the requirement of processing technology of the products can be guaranteed.

Owner:ZHEJIANG SHANHAI MACHINERY

Turbine blade with tip overhang along suction side

ActiveUS10641107B2Reduce overhang lengthBlade accessoriesLeakage preventionLeading edgeSuction force

A turbine blade has a root portion, a platform and an aerofoil, the aerofoil is mounted on the platform and is formed by a pressure side wall and a suction side wall and has an outer surface, the pressure side wall and the suction side wall meet at a leading edge and a trailing edge, the aerofoil has an axial chord length, the suction side wall defines part of the radially outward surface of the aerofoil, the suction side wall defines an overhang, the overhang has a maximum overhang length that is between 5% and 20% of the axial chord length of the blade and is located between 5% and 50% of the suction surface length from the leading edge.

Owner:ROLLS ROYCE PLC +1

Automatic feeding and discharging vehicle for freeze-dried line

InactiveCN104512717AReduce overhang lengthAvoid bending deformationConveyor partsFreeze-dryingEngineering

The invention discloses an automatic feeding and discharging vehicle for a freeze-dried line. The automatic feeding and discharging vehicle comprises a travelling assembly, a bottle collection bedplate and a horizontal movement unit; the horizontal movement unit can be horizontally connected onto the travelling assembly in a mobile mode; the bottle collection bedplate is connected onto the horizontal movement unit and can move along the movement direction of the horizontal movement unit in a linear mode. The automatic feeding and discharging vehicle for the freeze-dried line has the advantages of being simple and compact in structure, low in cost, high in efficiency and the like.

Owner:TRUKING TECH LTD

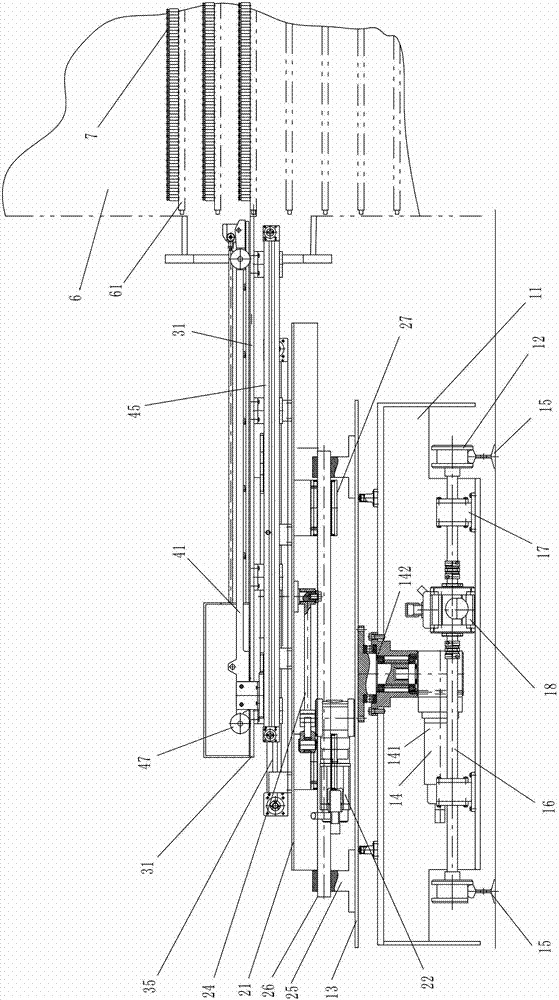

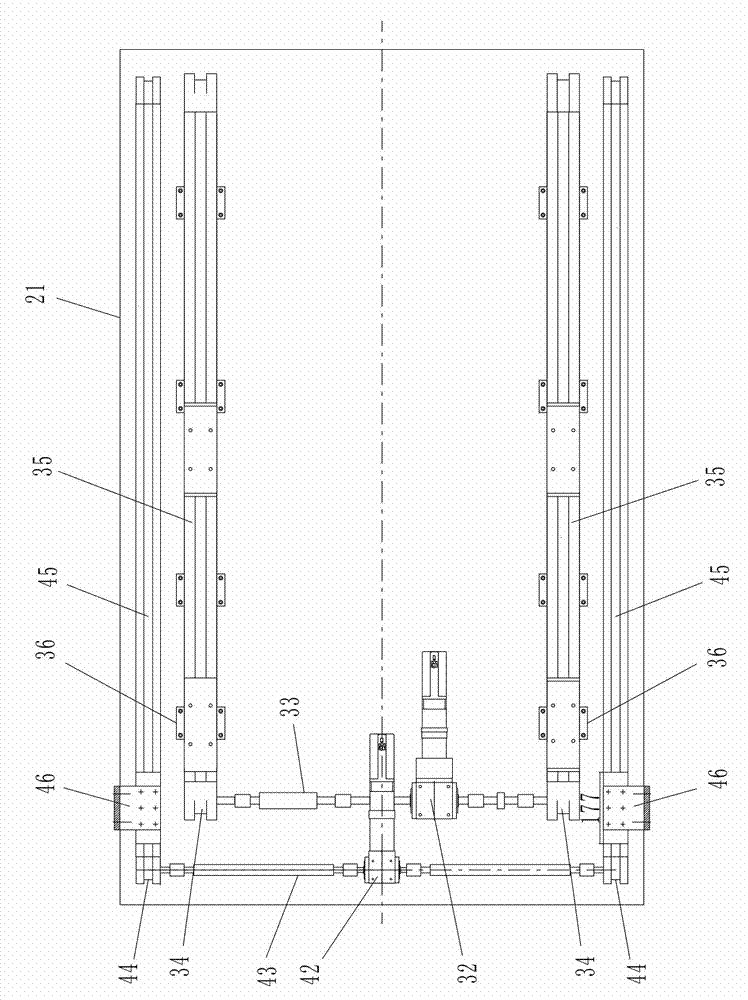

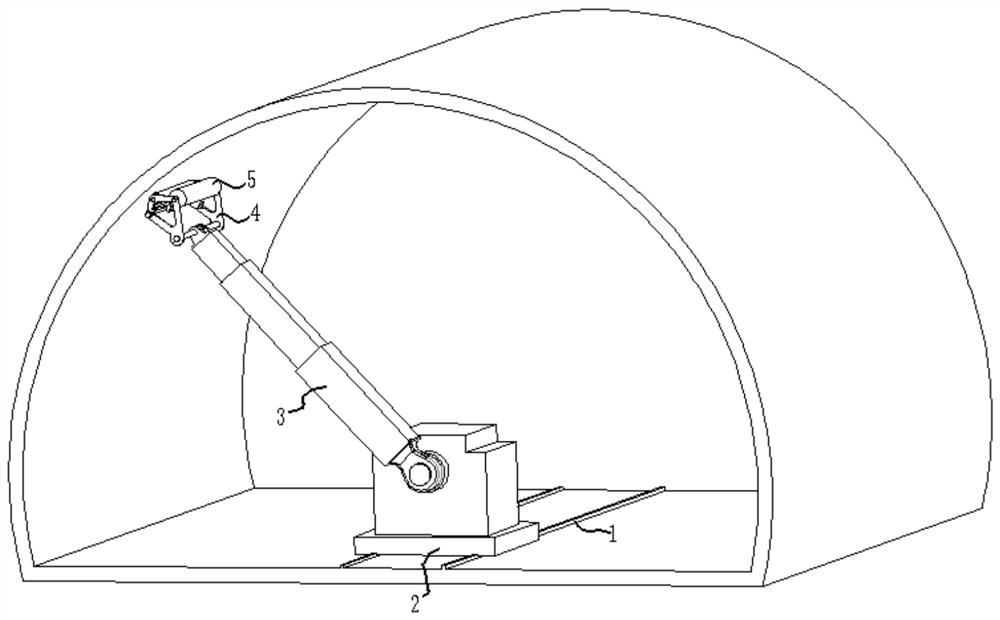

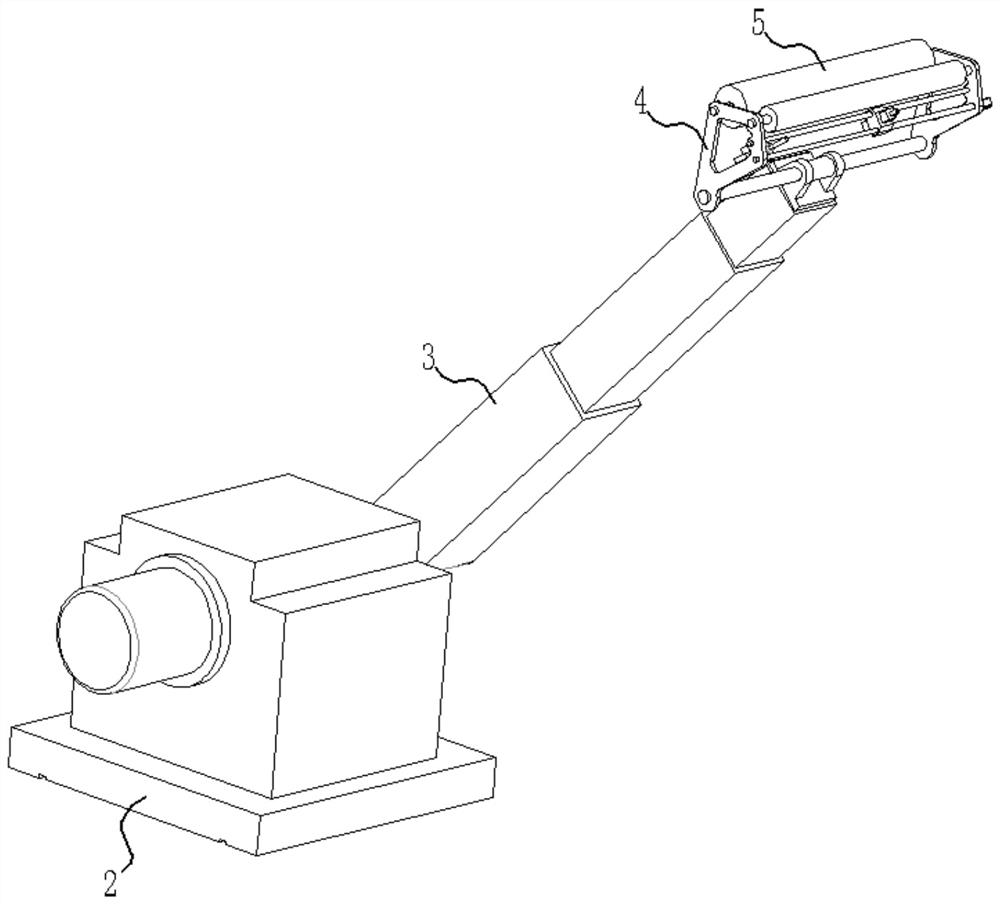

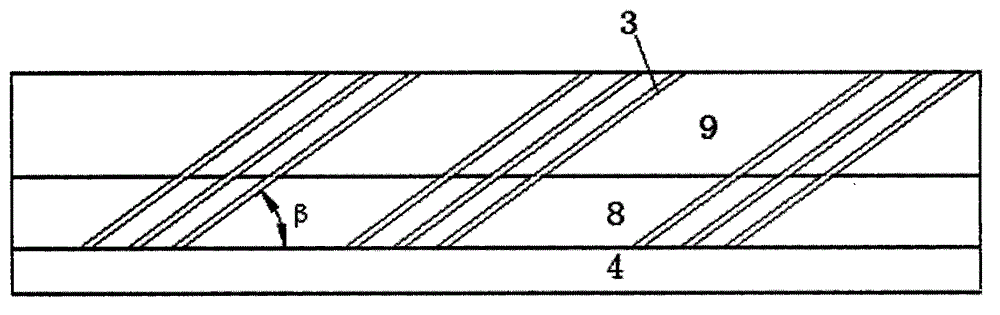

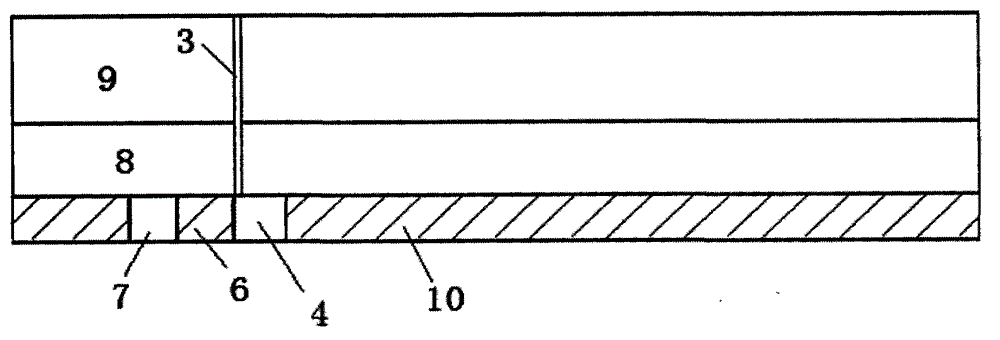

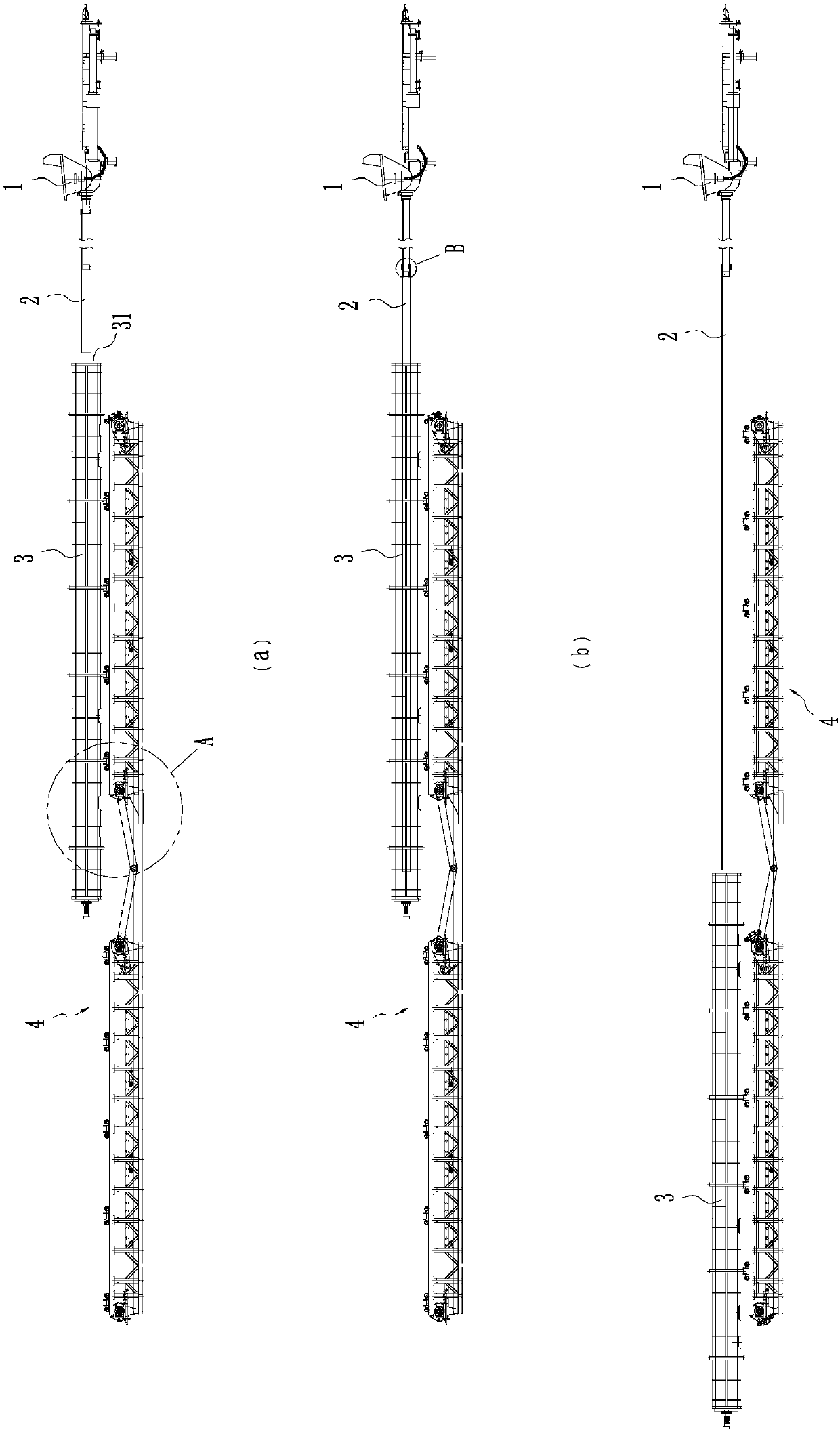

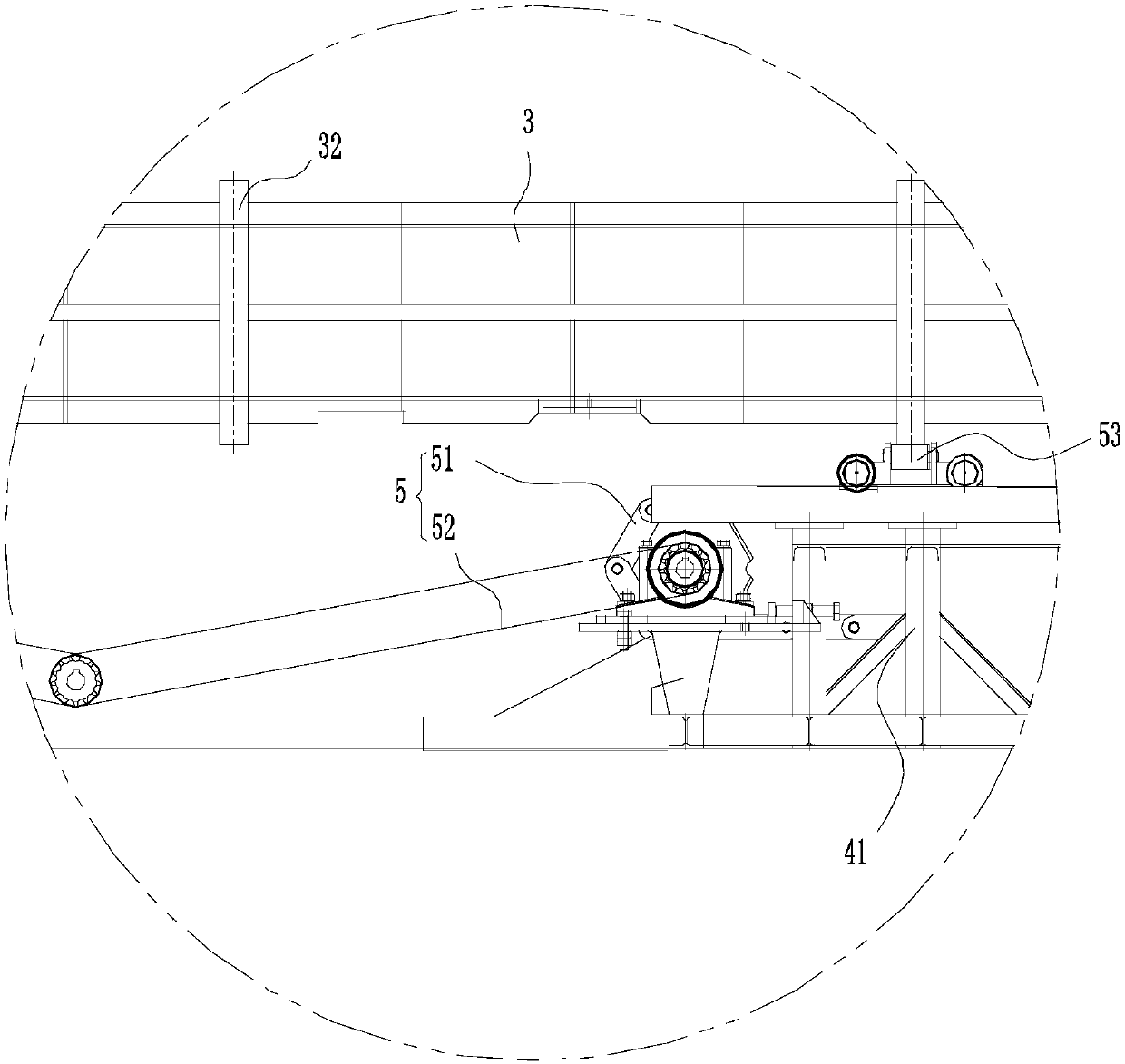

Telescopic cloth hanging trolley and cloth hanging control method

PendingCN114183176AReduce the difficulty of transitionReduce overhang lengthUnderground chambersTunnel liningControl systemControl theory

A telescopic cloth hanging trolley comprises a chassis used for walking in a tunnel, a base is hinged to a telescopic arm, and the telescopic arm is connected with a cloth hanging frame. The telescopic arm can be driven by the control system to rotate and stretch out and draw back so that the cloth hanging frame can move in the circumferential direction of the tunnel arch face. The cloth hanging frame is used for hanging cloth and comprises a reel used for installing a waterproof cloth roll, a pressing roller used for pressing the waterproof cloth on the inner wall of a tunnel, a gluer and a movable nail gun, and the nail gun is used for nailing the waterproof cloth on the inner wall of the tunnel. Automatic cloth paving, nailing and gluing are achieved, the mechanical degree is high, the efficiency is high, and the labor cost is reduced. In addition, the trafficability is greatly improved, and the transition difficulty of the cloth hanging trolley is reduced. According to the cloth hanging control method, the rotation angle of the servo motor and the telescopic length of the servo oil cylinder are controlled by establishing a polar coordinate equation of a tunnel arch surface curve, so that the cloth hanging frame moves according to the curve determined by the polar coordinate equation. The control method has the advantages of high adaptability and high efficiency.

Owner:洛阳中天建工机械有限公司

Gob-side entry driving surrounding rock control method using remaining small pillars

InactiveCN103244180BReduce overhang lengthBreach of integrityMining devicesBlastingEngineeringDeep hole

The invention discloses a gob-side entry driving surrounding rock control method using remaining small pillars. The method includes: distributing blast holes of different angles and depths in a working face conveying chute during extraction on an upper region working face, preforming a weak face in a certain area of a basic roof to damage completeness of a basic roof rock stratum by deep hole presplitting, and allowing a suspension arch of the basic roof to break at predetermined positions under the action of roof pressure after extraction of the working face. Therefore, the length of the hanging arch of the lateral basic roof of a gob is shortened, gob lateral abutment pressure is reduced, roadway pressure is relieved during gob-side entry driving in a lower region using remaining small pillars, and maintenance of a roadway is facilitated.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

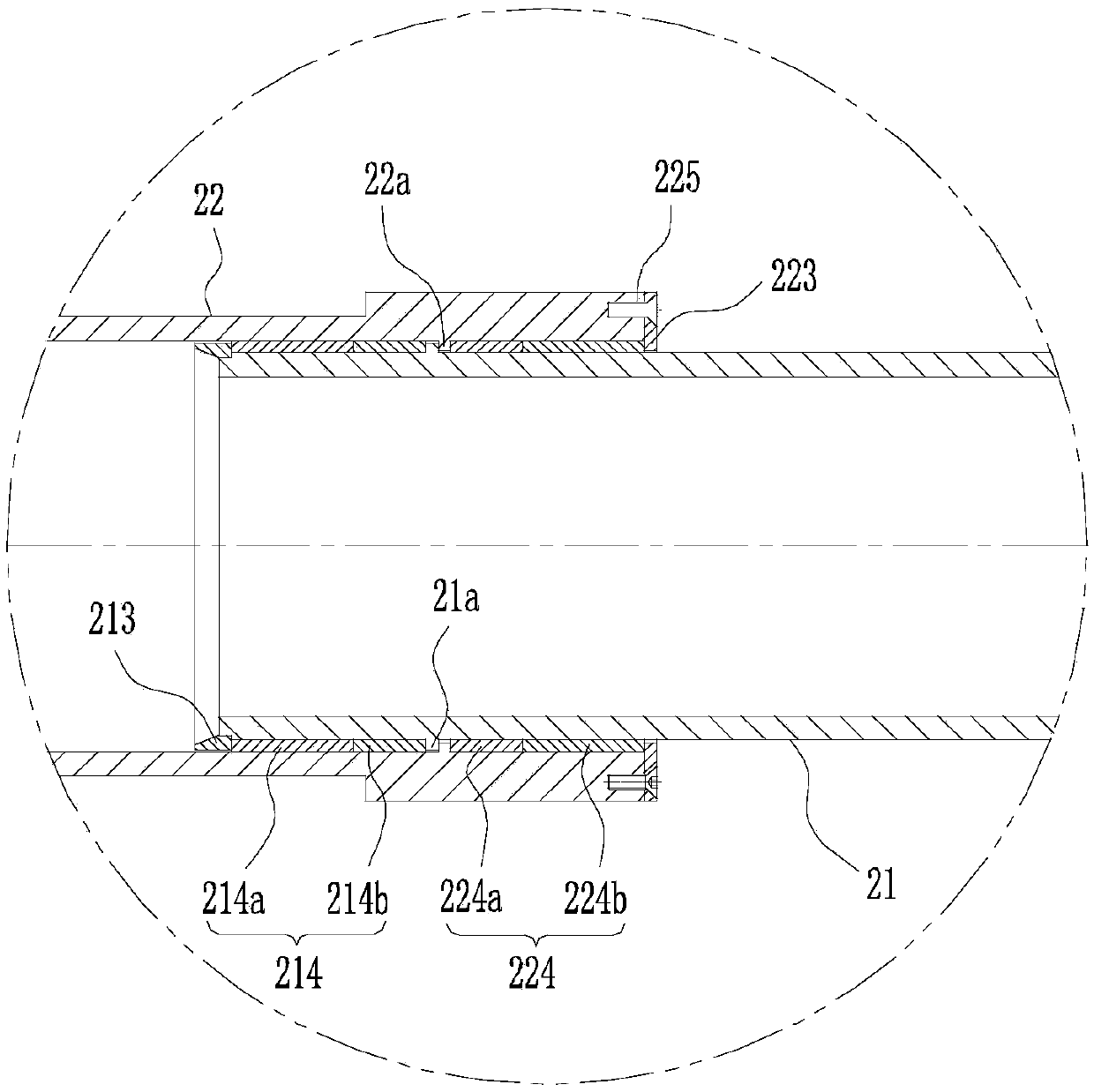

Telescopic pumping pipe

InactiveCN110230401ALow overall costReduce disturbance distortionFeeding arrangmentsBuilding material handlingDistortionPipe support

The invention discloses a telescopic pumping pipe. The telescopic pumping pipe comprises at least two rigid pipes of different pipe diameters, and the rigid pipes are axially installed in a sleeved mode in sequence in the order of small to large pipe diameters, wherein the outer rigid pipes can axially and freely slide relative to the sleeved inner rigid pipes, and anti-off sealing structures aredisposed between the inner rigid pipes and the sleeving outer rigid pipes. When pumping starts, the outer rigid pipes can be extended forward into a pipe pile mold, that is, the overhanging telescopicpumping pipe is supported by the pipe pile mold; and when pumping is completed, the pipe pile mold is separated from the telescopic pumping pipe, and the outer rigid pipes can be retracted toward a pump machine to reduce the overall overhanging length, so that the deflection distortion of the pumping pipe is reduced. Therefore, the overall cost of pipe pile material pumping and distribution equipment is reduced by eliminating existing pumping pipe support structures by the telescopic pumping pipe.

Owner:周兆弟

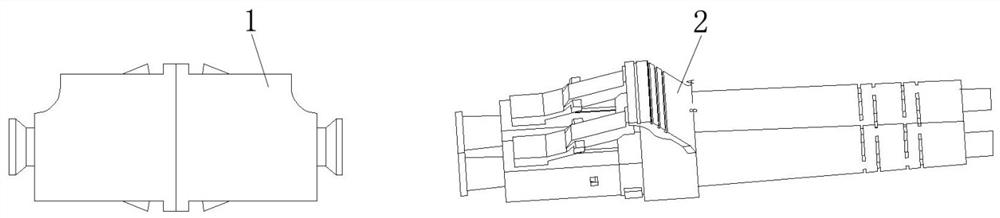

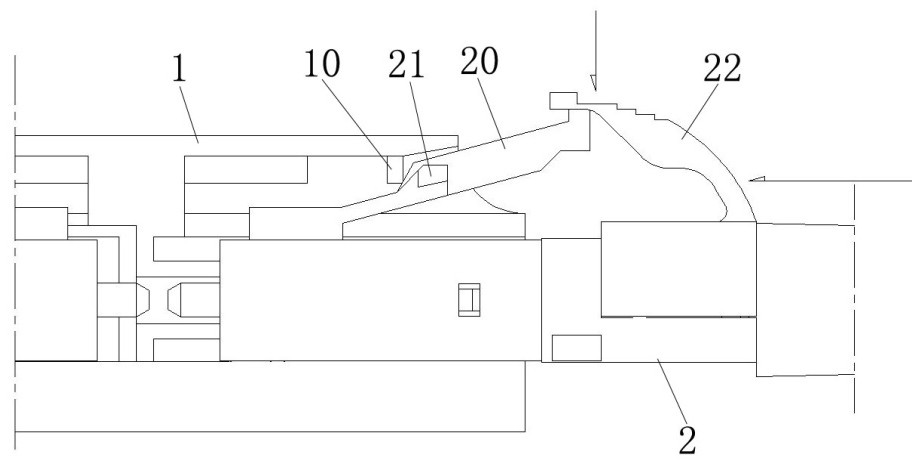

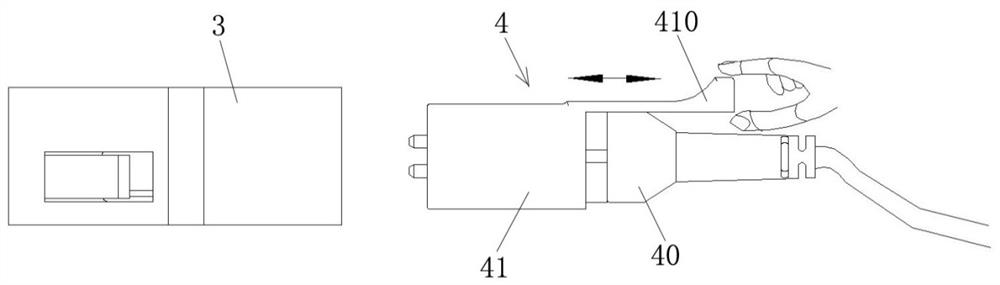

Double-core plug shell assembly and double-core plug

ActiveCN112859252AReduce overhang lengthMiniaturizationCoupling light guidesEngineeringMechanical engineering

The invention relates to a double-core plug shell assembly and a double-core plug. The double-core plug comprises an inner shell and an outer shell, and the inner shell and the outer shell are detachably connected. A locking elastic claw is located on the outer side surface of the inner shell and overhangs from front to back; a bidirectional stop structure is arranged on the inner shell and is used for being in stop fit with the outer shell in the front direction and the rear direction; a hollow long groove is formed in the outer shell and corresponds to the locking elastic claw so that at least parts of the locking elastic claw is exposed out of the outer shell to be matched with a resisting boss of an adapter in a stopping manner; and a pressing structure is arranged on the outer shell and presses the locking elastic claw downwards in the process that the outer shell slides backwards relative to the inner shell so that the locking elastic claw is unlocked from the resisting boss of the adapter. According to the double-core plug, if the polarity of the double-core plug needs to be replaced, only the inner shell needs to be taken out of the outer shell, the posture of the inner shell is replaced, then the inner shell is installed into the outer shell again, polarity replacement is completed, operation is convenient, and installation is accurate.

Owner:中航光电(上海)有限公司

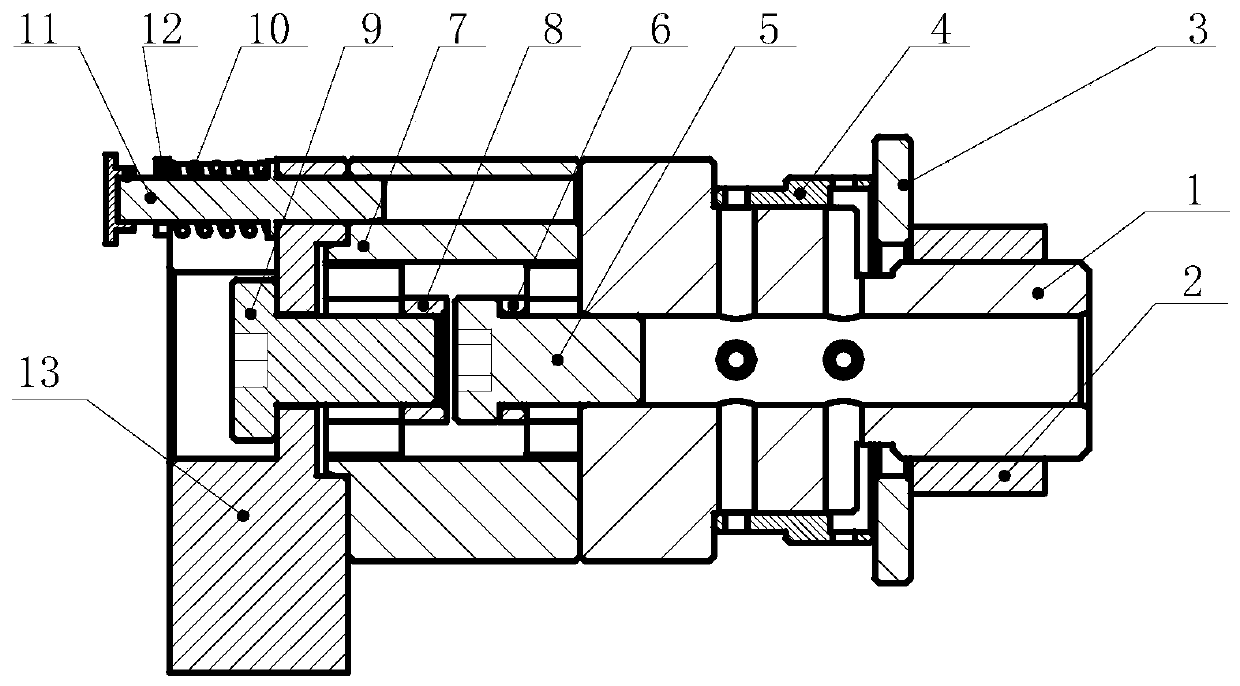

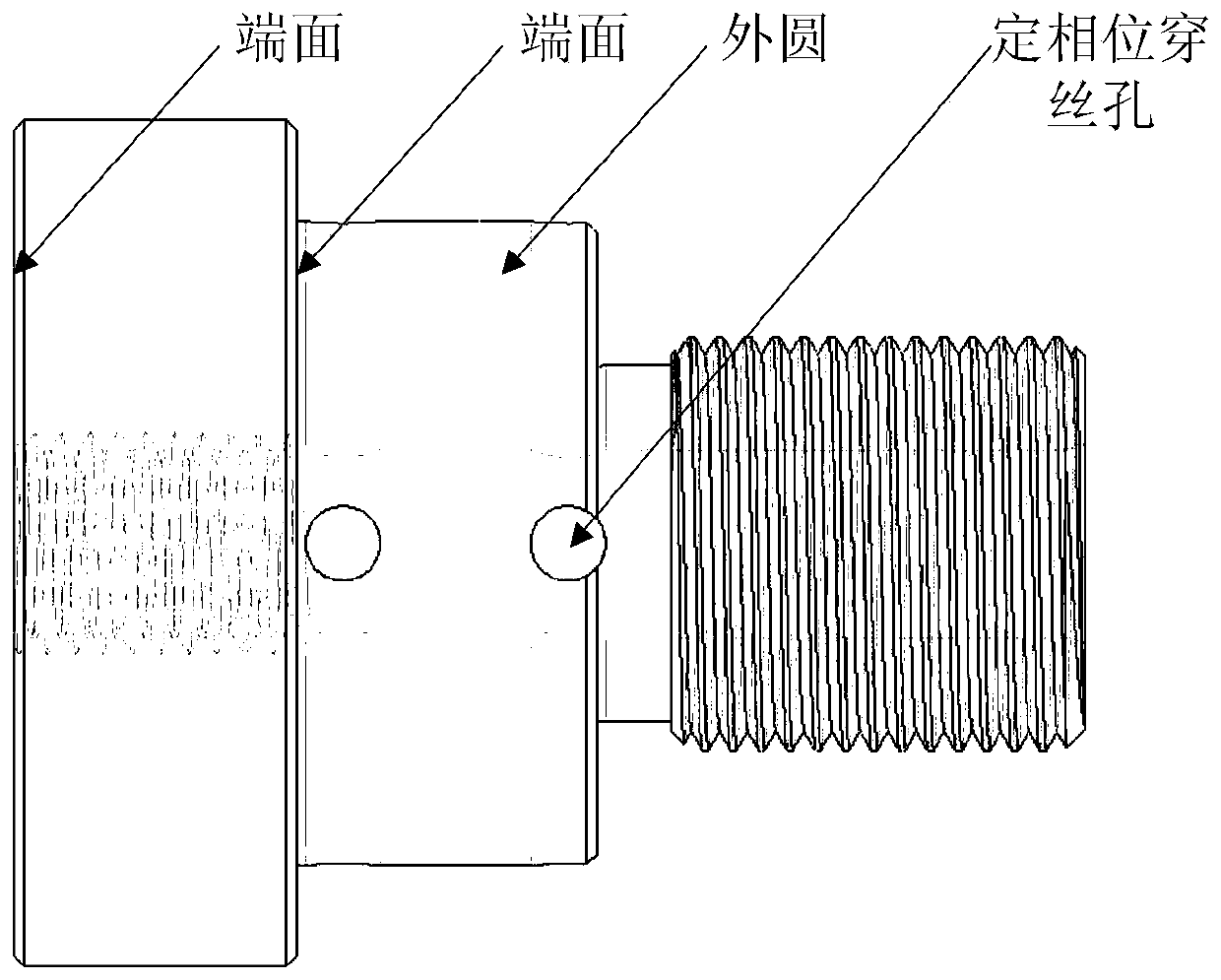

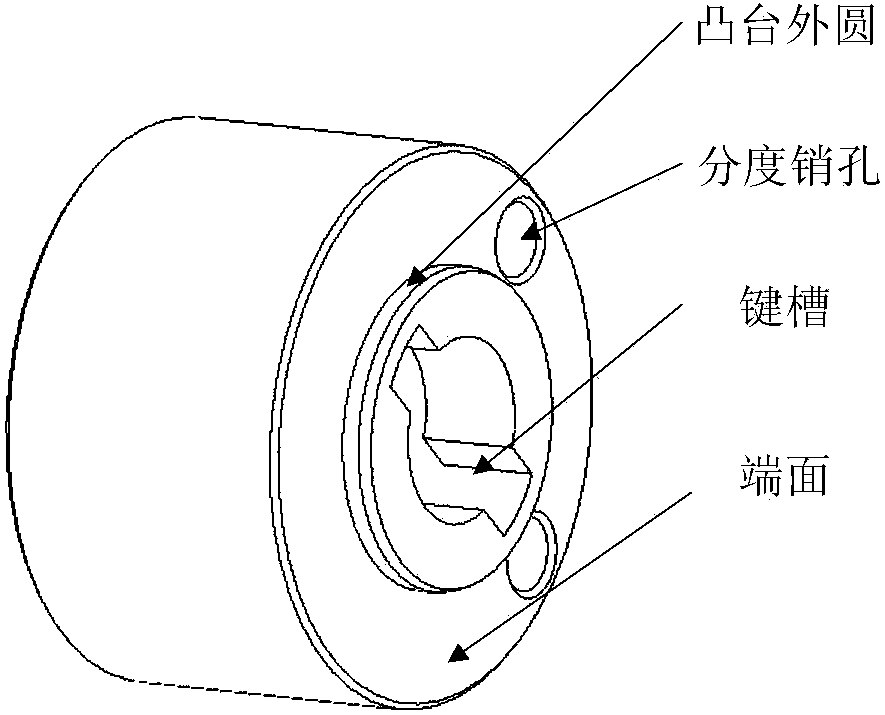

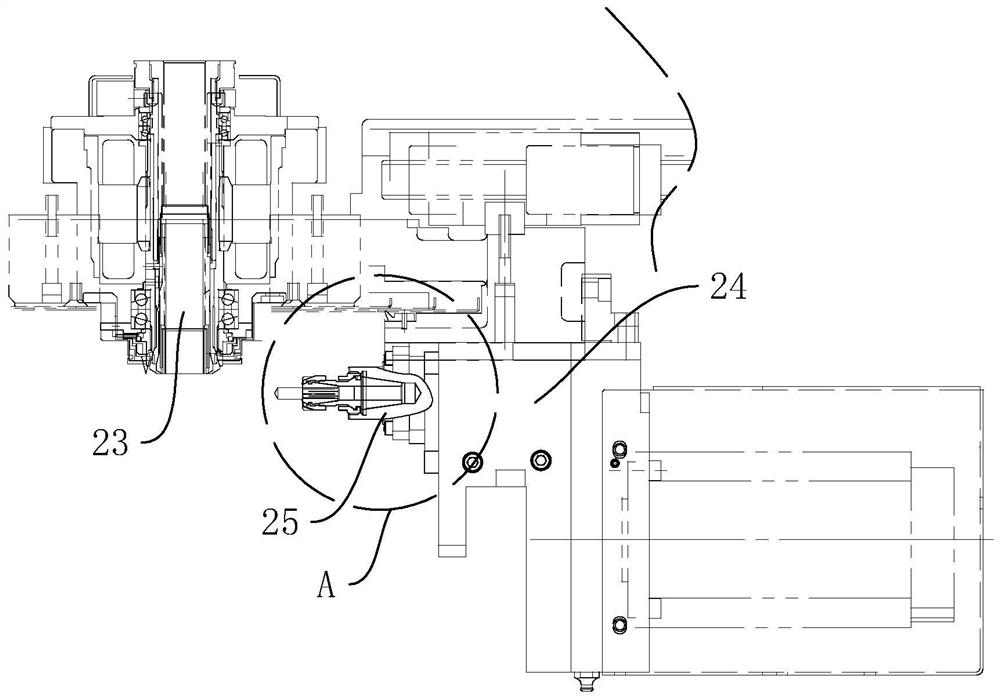

Cylindrical surface fixed-phase pin hole wire cutting tool and method for planetary lead screw

ActiveCN110340474AQuick clampingEasy to replaceMetal sawing devicesPrecision positioning equipmentFixed frameThree stage

The invention discloses a cylindrical surface fixed-phase pin hole wire cutting tool for a planetary lead screw. The tool comprises a workpiece fixing frame, a transition dividing plate and a fixing support, wherein the workpiece fixing frame is of a three-stage step shaft structure, a fixed phase wire penetrating hole is machined in a middle cylindrical section, the position of the wire penetrating hole is consistent with the position of the workpiece fixed phase pin hole, the workpiece is arranged on the outer side of the middle cylindrical section of the step shaft structure in a sleeving mode and is locked through a limiting gasket and a workpiece fixing nut, the workpiece fixing frame is fixedly connected with the transition dividing plate, the transition dividing plate is fixed on the fixing support, and dividing phase positioning is carried out on a fixed pin. The invention further discloses a cylindrical surface fixed-phase pin hole wire cutting method for the planetary lead screw. According to the tool and the method, the required phase rotation (such as 90 degrees) is realized through the dividing pin holes of the transition dividing plate, the locking mode is convenient,the alignment time can be shortened, and the processing efficiency is greatly improved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

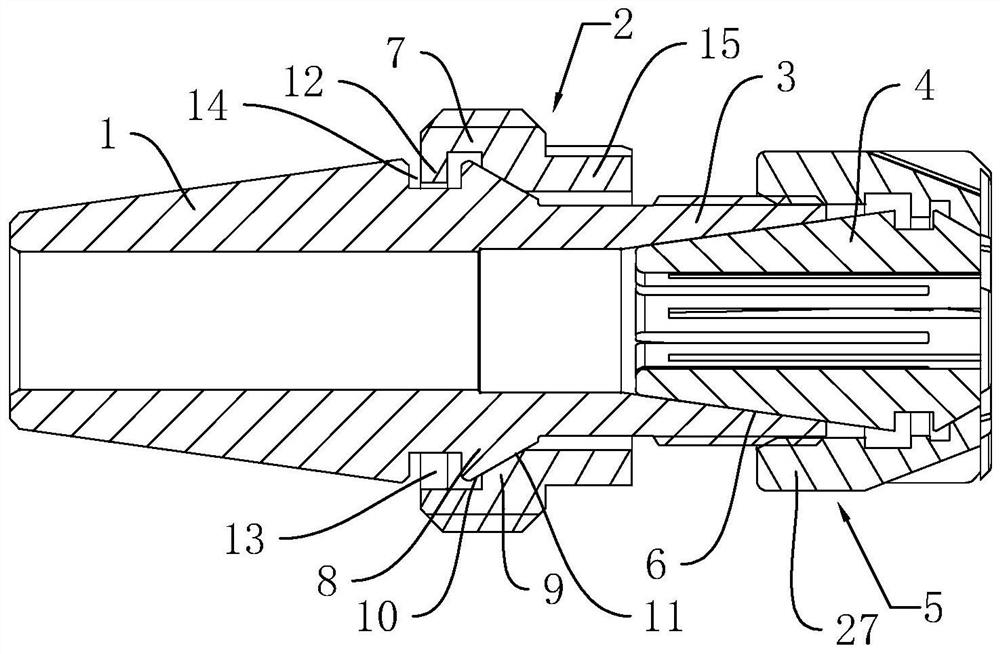

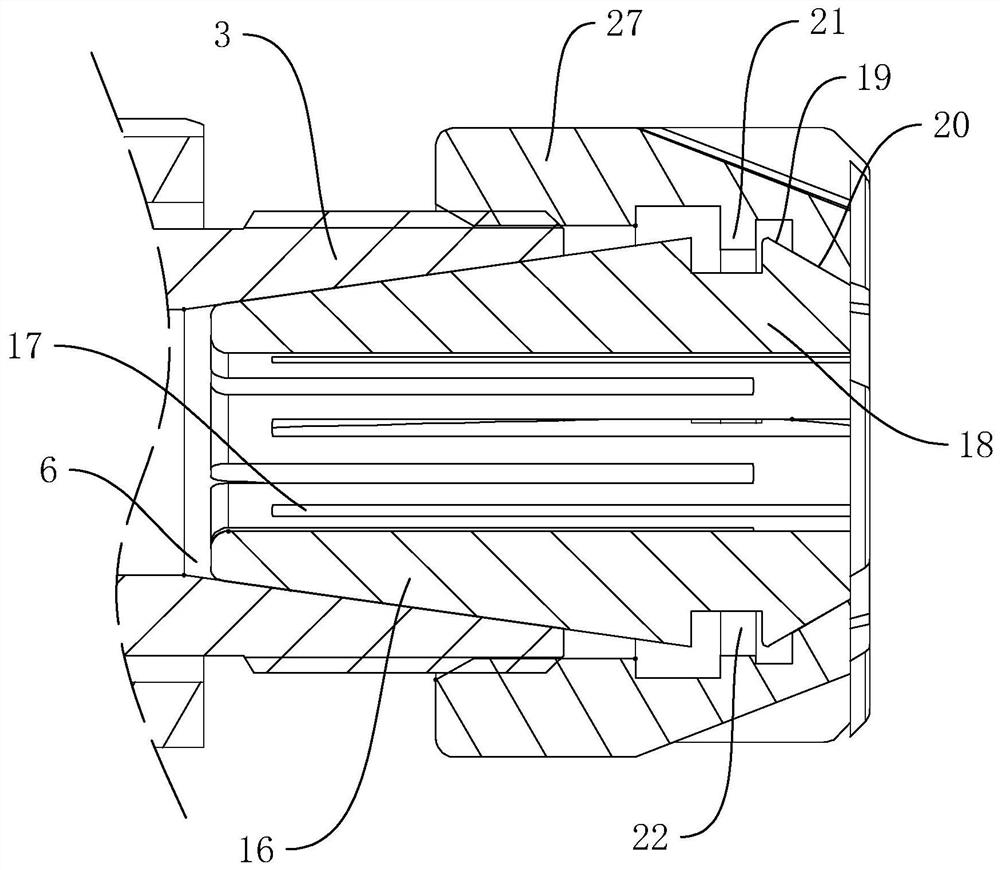

Stable collet chuck structure and machine tool applying same

PendingCN113211115AIncrease the clamping lengthImprove stabilityPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention relates to a stable collet chuck structure and a machine tool applying the same, and belongs to the field of machine tool clamps. The stable collet chuck structure comprises a taper shank, a connecting piece, a connecting rod, a chuck and a locking piece, wherein the connecting piece is rotationally connected to the end part of the taper shank in a sleeving mode and is used for being connected with a power head, the connecting rod is connected to one end, close to the connecting piece, of the taper shank, moreover, a mounting groove is formed in the connecting rod, the chuck is arranged in the mounting groove in a penetrating mode, and the locking piece is connected to the connecting rod and is used for tightening the chuck. The stable collet chuck structure has the effects that the overhanging length of a cutter can be reduced, the vibration of the cutter during machining is reduced, and then the machining precision is improved.

Owner:津上精密机床(浙江)有限公司

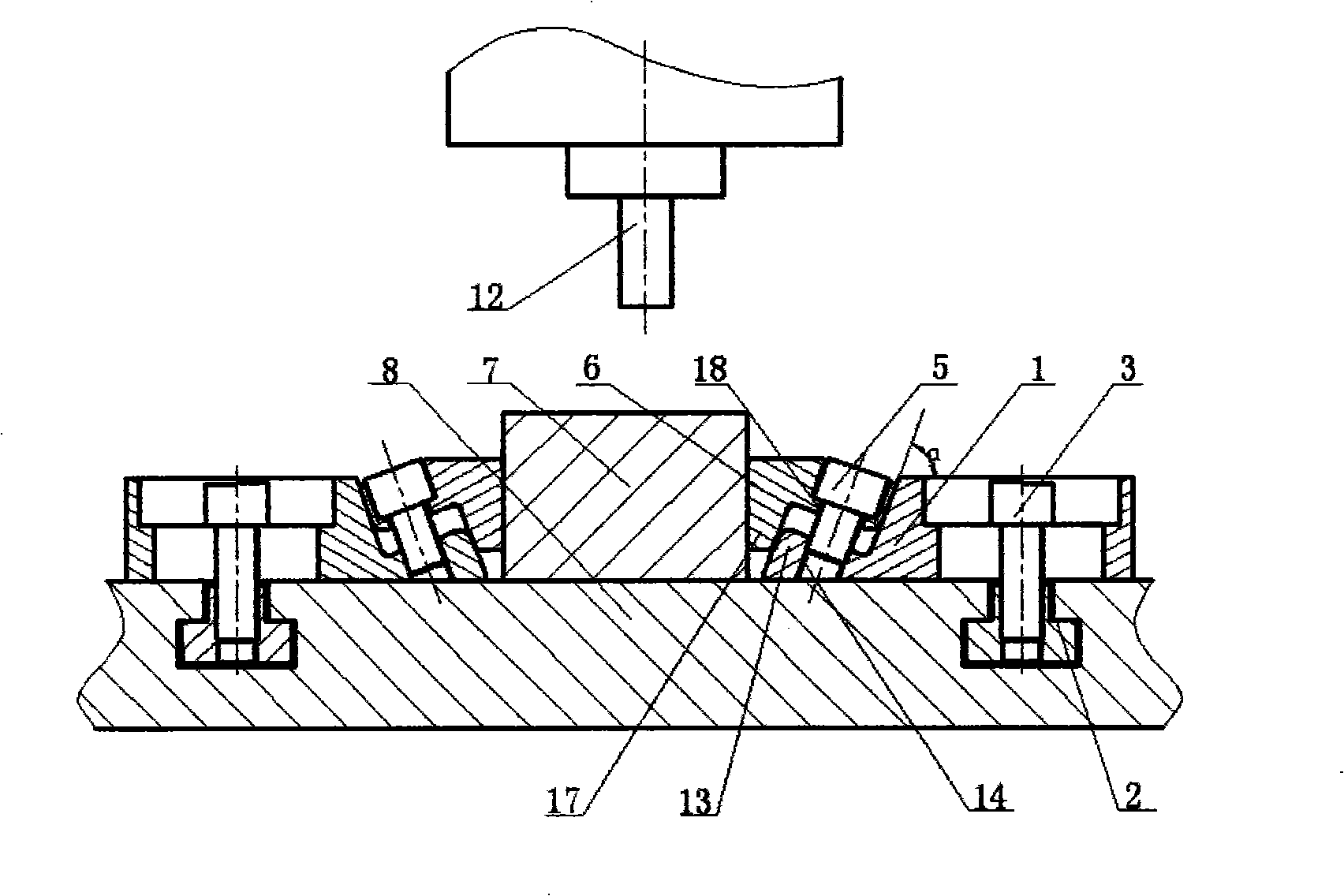

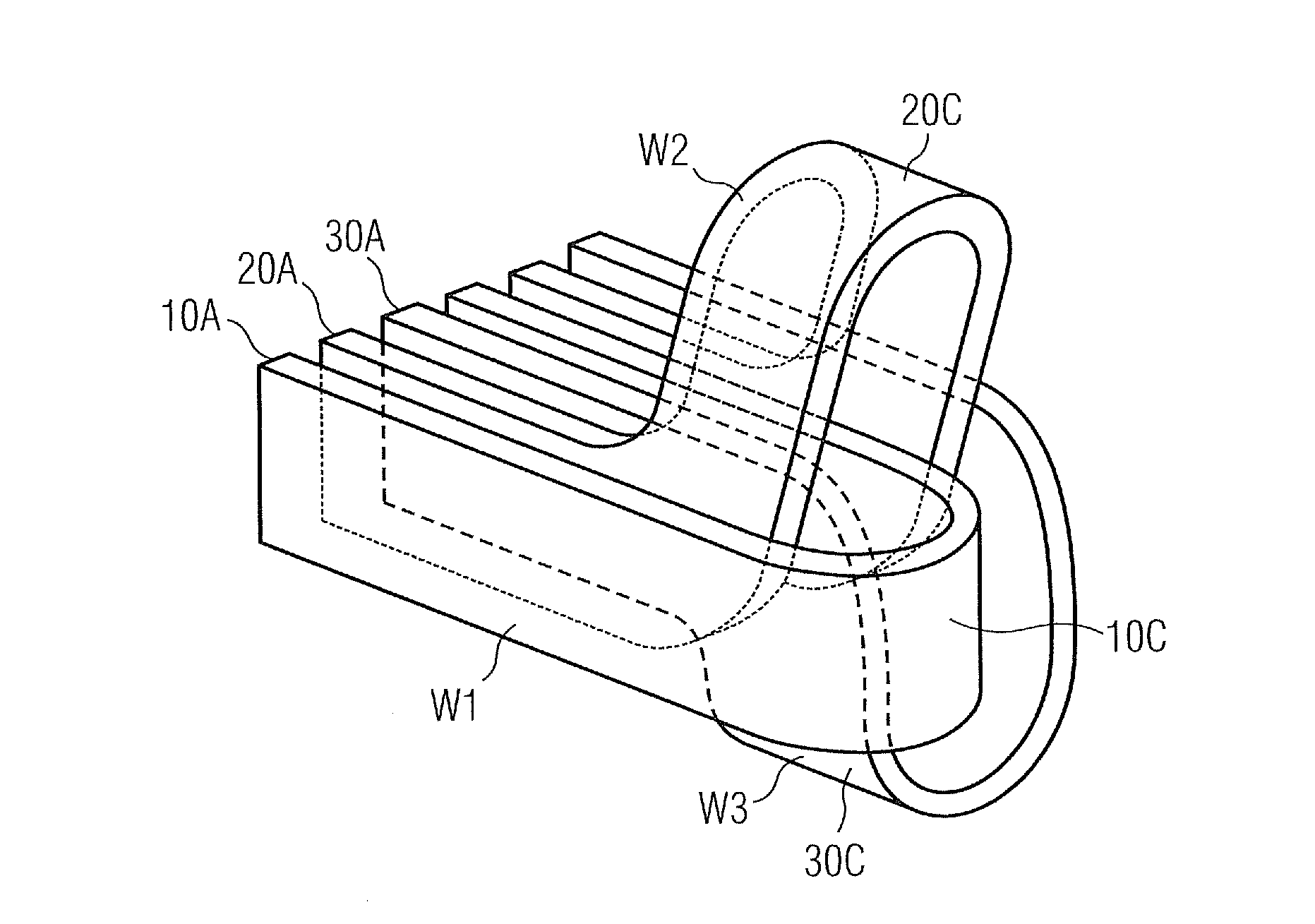

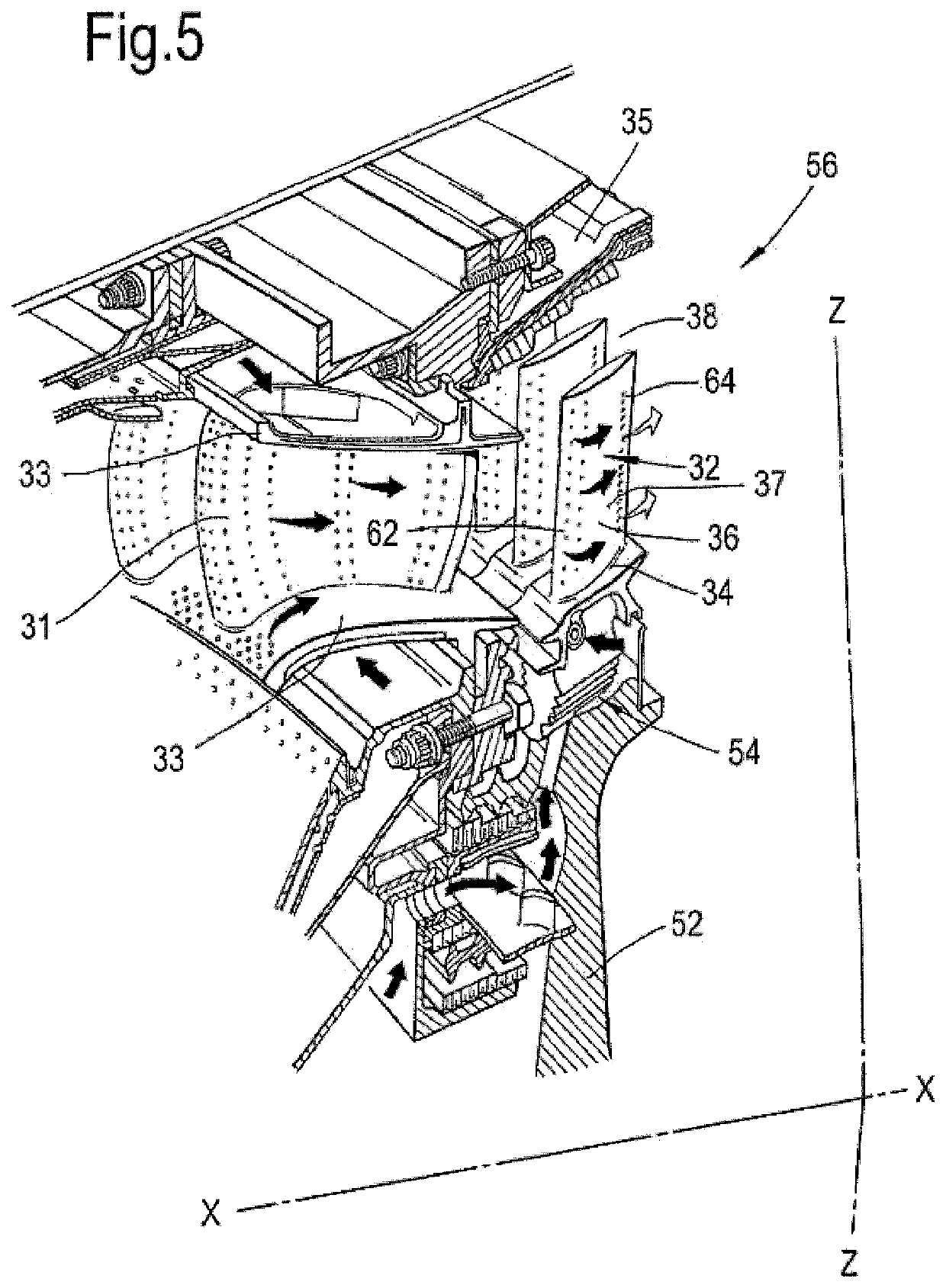

Coil formation in an electric machine with concentrated windings

PendingUS20210083533A1Performance is not affectedReduce overhang lengthMagnetic circuit stationary partsManufacturing stator/rotor bodiesCoils (formation)Electric machine

Provided is an electric generator including a stator including:a stator yokea plurality of teeth,a plurality of slots extending radially from the stator yoke to respective radial slot ends, the plurality of slots being circumferentially interposed between the teeth of the stator, each slot including a bottom portion adjacent to the stator yoke and a top portion adjacent to the respective radial slot end. The stator further includes a plurality of coils housed in the plurality of slots, each slot housing at least one coil in the bottom portion and at least another coil in the top portion, each coil housed in the bottom portion of a first slot of the plurality of slots being connected to another respective coil housed in the top portion of a second slot of the plurality of slots.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Single-layer multiple-span bent column crane beam positioning method

The invention discloses a positioning method for a crane beam of a single-layer multi-span bent column. The distance from the center line of the crane beam installed on the corbel of the side column of the bent frame to the span marking line of the side column of the bent frame is L1, so that the center line of the crane beam installed on the corbel of the middle column of the bent frame to the span line of the bent frame The distance between the span markings of the center column is L2, and L1 is greater than L2. The invention adjusts the positioning dimension between the center line of the crane beam on the corbel of the traditional bent frame side column and the center column and the span marking line of the column, so that the effect of a single crane load on the side column and the center column is basically the same. The invention has the advantages of making the single-layer multi-span bent frame column and the foundation evenly stressed, and has the advantages of saving engineering investment and the like.

Owner:GUIYANG AL-MG DESIGN & RES INST

Numerical control machining clamping method for aircraft wing beam parts

ActiveCN102069395BImprove quality and efficiencyImprove processing efficiencyMilling equipment detailsPositioning apparatusNumerical controlEngineering

The invention discloses a numerical control machining clamping method for large-scale beam parts. The method comprises the following steps of: on the basis of theoretical appearances of parts, machining a plurality of positioning process platforms and compression process platforms on a blank; machining positioning holes and compression holes on a milling tool correspondingly; reserving a tool withdraw groove on the milling tool; and positioning the part blank in the positioning holes on the milling tool through the positioning process platforms and compressing and fixing in the compression holes of the milling tool through the compression process platforms. The overall appearance is machined in place by a tool through one-time clamping; the preparation time is saved; a secondary alignmenterror is avoided; therefore, the numerical control machining efficiency and the quality are improved; and the milling tool is simple to design and manufacture.

Owner:XIAN AIRCRAFT IND GROUP

A connection node and installation method of hollow spheres of bamboo reticulated shell with welded steel inserts

InactiveCN103469901BSimple structureClosely connectedBuilding material handlingHigh integrityRenewable resource

The invention provides a bamboo latticed shell hollow sphere connecting joint welded with steel insertion sheets and an installing method. The bamboo latticed shell hollow sphere connecting joint comprises M steel insertion sheets, M bamboo rod pieces, M or M-1 reinforced steel sheets, a hollow sphere and 2M bolts, wherein a circular-arc gap is reserved in one end of each steel insertion sheet; a bolt hole A is reserved in the other end of each steel insertion sheet; one end of the circular-arc gap reserved in each steel insertion sheet is fixed together with the hollow sphere by welding; a groove and a bolt hole B are reserved in the end part of the each rod bamboo rod piece; one end, where the bolt hole is reserved, of each steel insertion sheet is inserted into the groove reserved in each bamboo rod piece; the bolt hole A reserved in each steel insertion sheet is aligned with the bolt hole B reserved in each bamboo rod piece; each bolt hole A and bolt hole B are fixed by using two bolts; the reinforced steel sheets are welded on the steel insertion sheets between the bamboo rod pieces and the hollow sphere. The bamboo latticed shell hollow sphere connecting joint has the advantages of simple structure, easiness in positioning and installing, clear force transmission, high integrity, easiness in maintaining and environmental friendliness; bamboo belonging to an environment-friendly renewable resource is taken as the rod piece material of the latticed shell connecting joint, so that an outstanding environmental protection advantage is achieved.

Owner:NANJING FORESTRY UNIV

A flat die pellet machine

InactiveCN103721635BLower the altitudeReduce wall thicknessGranulation by pressingShaping pressThrust bearingMetallic materials

The invention discloses a flat-mold granulator which consists of a material bucket, a case, a working assembly, a main shaft assembly and a transmission assembly. According to the flat-mold granulator, working pressing force is directly transferred to a mold plate through a thrust bearing, and the case does not suffer from the pressing force, so that the wall thickness of the case can be reduced; moreover, a centripetal thrust bearing is directly arranged below the mold plate, so that the suspension length of the upper part of the main shaft is reduced, the working stability is facilitated, two bearings are not needed to be arranged below the case, and the height of the case can be reduced, therefore, the wall thickness of the case is reduced, the height is reduced, the overall height of the granulator is reduced, the mounting space is reduced, the amount of a metal material is reduced, and the production cost of the overall machine is lowered.

Owner:JIANGSU UNIV

Clamping and fixing method for part blank

InactiveCN105081819AReduce overhang lengthShorten production timePositioning apparatusMetal-working holdersMachine partsWorkload

The invention relates to a clamping and fixing method for a part blank. Firstly, a plurality of clamping points are selected on a work surface of the blank every 300-500 mm according to the shape of a part, and it is guaranteed that the positions of the clamping points are 30 mm away from the biggest outline of the horizontal plane of the part; secondly, the part blank is arranged on a worktable, threaded through holes are machined in the part blank with the clamping points as the benchmark, and the threaded through holes penetrate through the worktable; and thirdly, the part blank and the worktable are fastened together through bolts, so that the part blank is clamped and fixed. By means of the special clamping and fixing method, the extended length of a tool is reduced when the part blank is machined, the surface quality of the machined part is improved, the workload is lightened, and the production time for the part is shortened.

Owner:HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com