Single-layer multiple-span bent column crane beam positioning method

A technology of multi-span bent frame and positioning method, which is applied in the field of positioning and configuration of crane girders, can solve the problems of inconsistent eccentricity, unsatisfactory use effect, difference in section size, foundation size and reinforcement area of side columns and middle columns, etc., and achieve The effects of uniform force, reasonable reinforcement, and reduced overhang length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

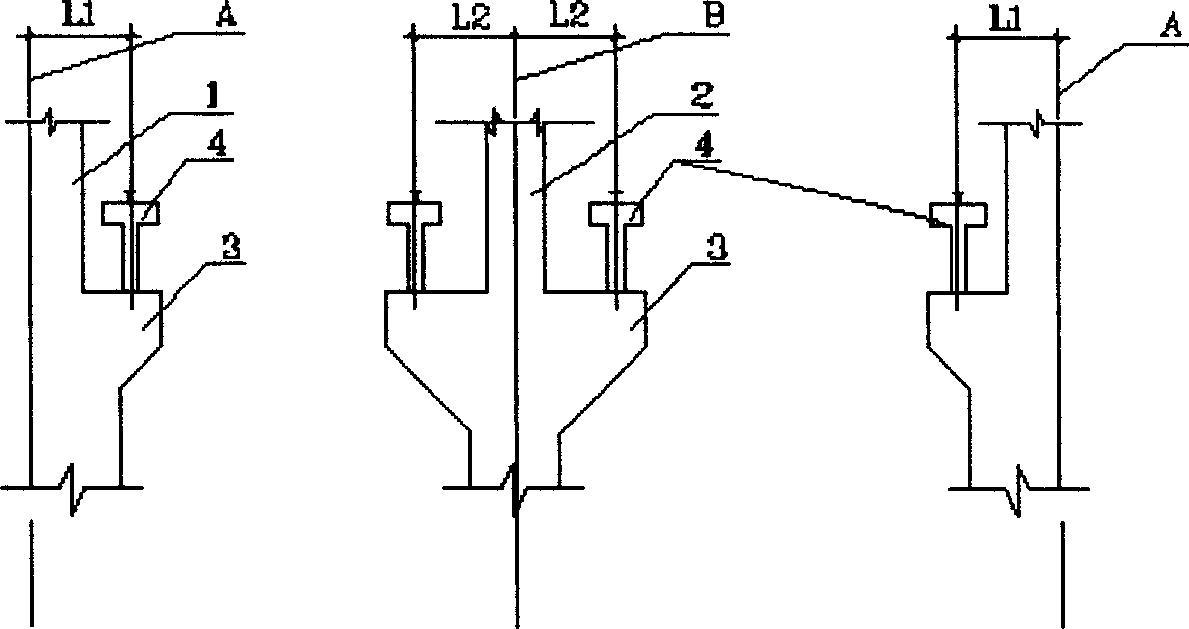

[0010] Implementation example of the present invention: when the crane beam (4) is installed on the bracket (3) of the bent frame side column (1) of the single-layer multi-span bent frame column and the bent frame center column (2), the The distance from the center line of the crane beam (4) on the corbel (3) of the side column of the bent frame (1) to the span marking line (A) of the side column of the bent frame (1) is L1, so that the The distance from the center line of the crane beam (4) on the corbel (3) of (2) to the span marking line (B) of the bent column (2) is L2, and L1 is greater than L2; the length of L1 and L2 It can be determined according to the specific construction situation. Generally, the length of L1 is longer than the length of L2 within the range of 50-500 mm or within the range of 100-300 mm; The length is set at 850 mm, and the length of L2 is set at 650 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com