Bamboo latticed shell hollow sphere connecting joint welded with steel insertion sheets and installing method

A technology for connecting nodes and hollow spheres, which is applied in the processing of building materials, construction, and building construction. It can solve the problems of weakening the cross-section of bamboo connection ends, reducing the strength of nodes, and brittle failure, and achieves clear force transmission and good integrity. , The effect of reducing the bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

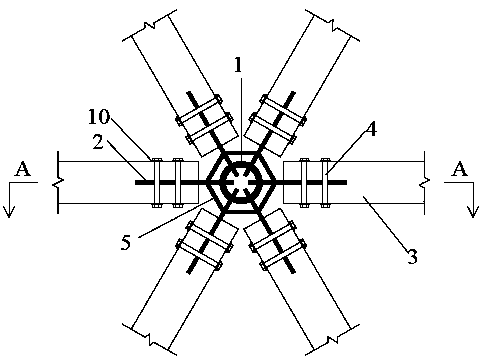

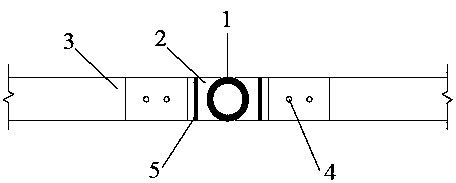

[0029] Such as figure 1 As shown, a method for installing the hollow ball connection node of the bamboo reticulated shell with welded steel inserts includes the following steps:

[0030] Its installation steps include:

[0031] 1) Number the hollow ball 1 as A1, and the 6 steel inserts 2 are respectively numbered as A1-a, A1-b, A1-c, A1-d, A1-e, A1-f, and the corresponding 6 bamboo rods 3 respectively numbered A1a-B1a, A1b-B2a, A1c-B3a, A1d-B4a, A1e-B5a, A1f-B6a;

[0032] 2) Place the hollow ball 1 numbered A1 on the welding equipment with positioning device;

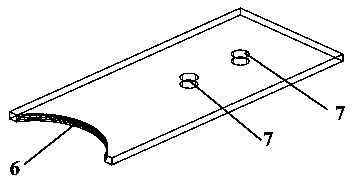

[0033] 3) Weld one end of the six steel inserts 2 numbered A1-a, A1-b, A1-c, A1-d, A1-e, and A1-f to the hollow ball 1 in order to reserve the arc-shaped notch 6 Above, the angle at which each steel insert 2 is welded on the hollow ball 1 is less than 90 degrees formed by the central axis of the rod after the meshing of the bamboo reticulated shell. The welding equipment is equipped with a positioning device, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com