Patents

Literature

504results about How to "Power transmission is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

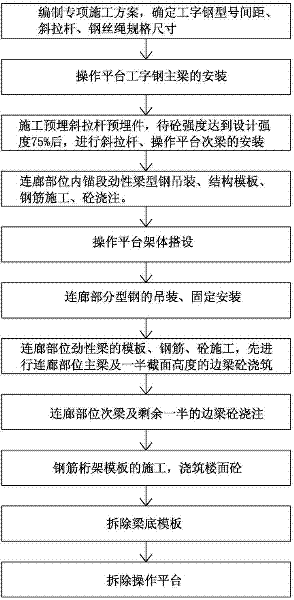

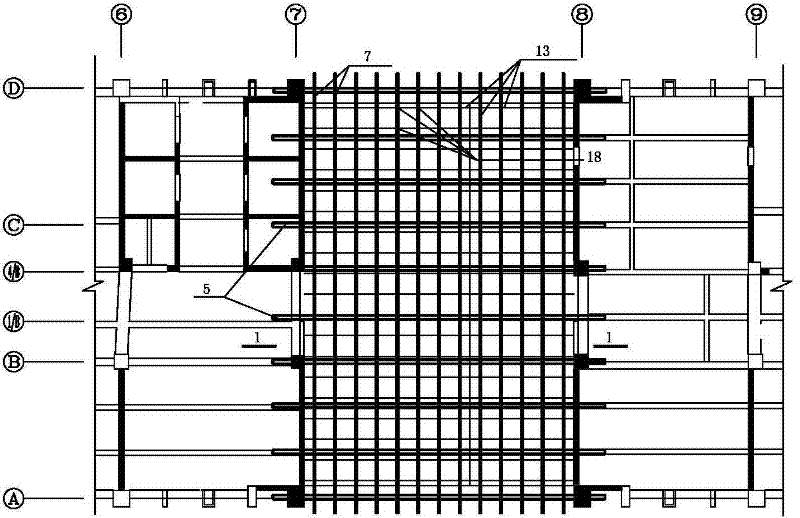

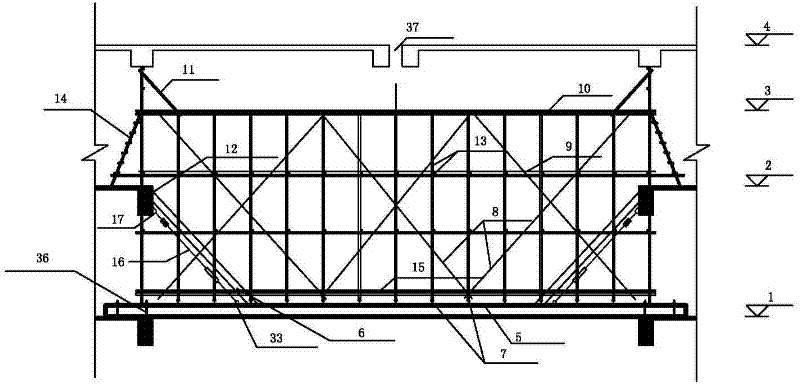

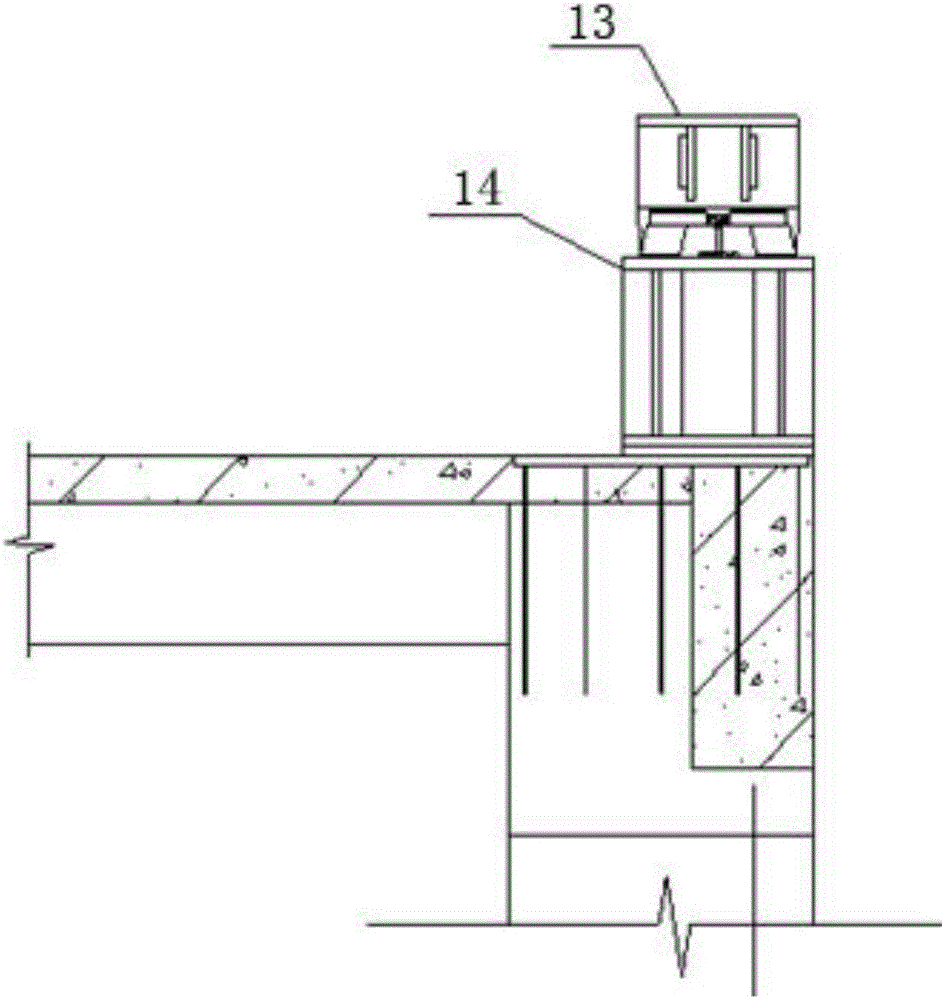

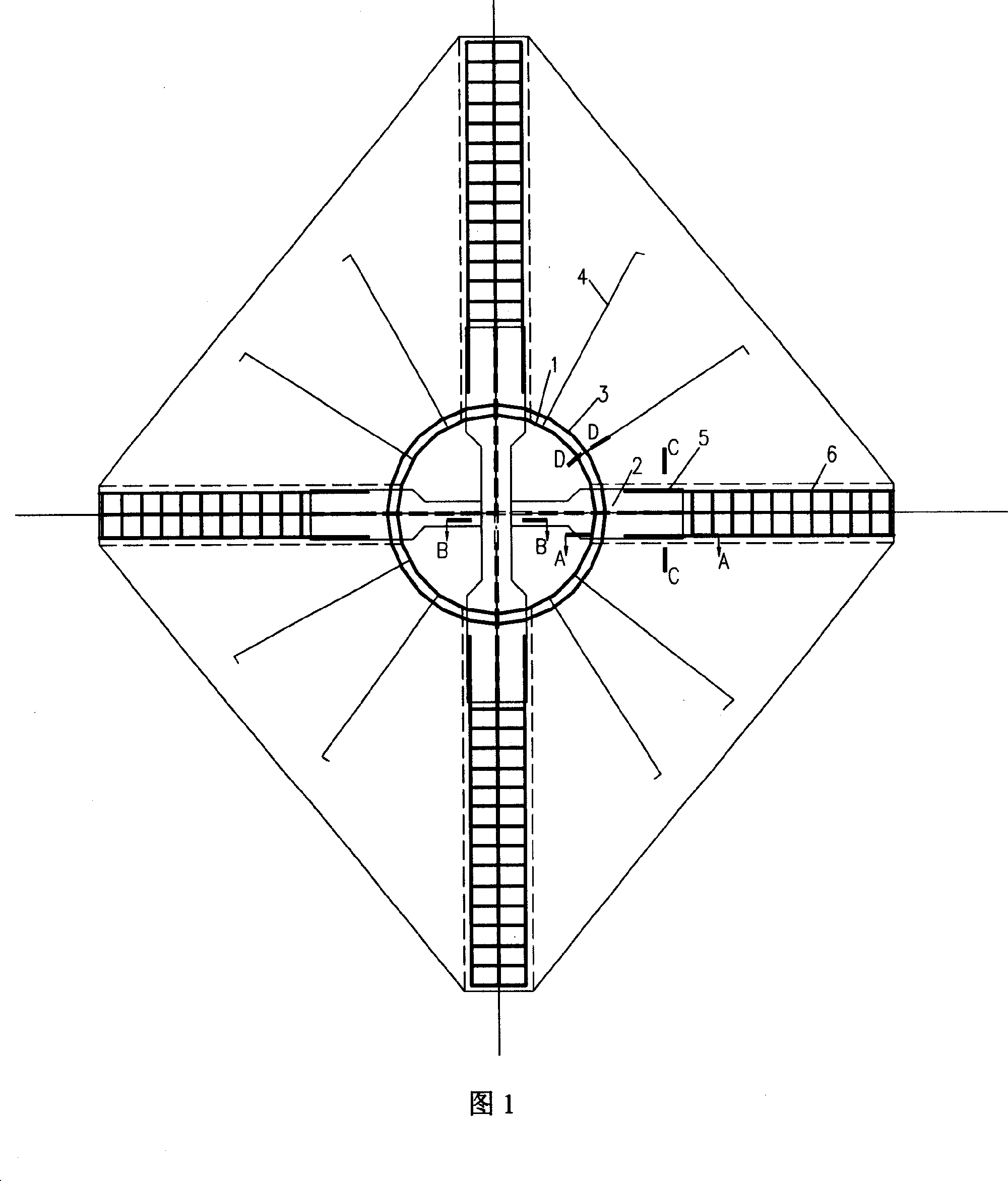

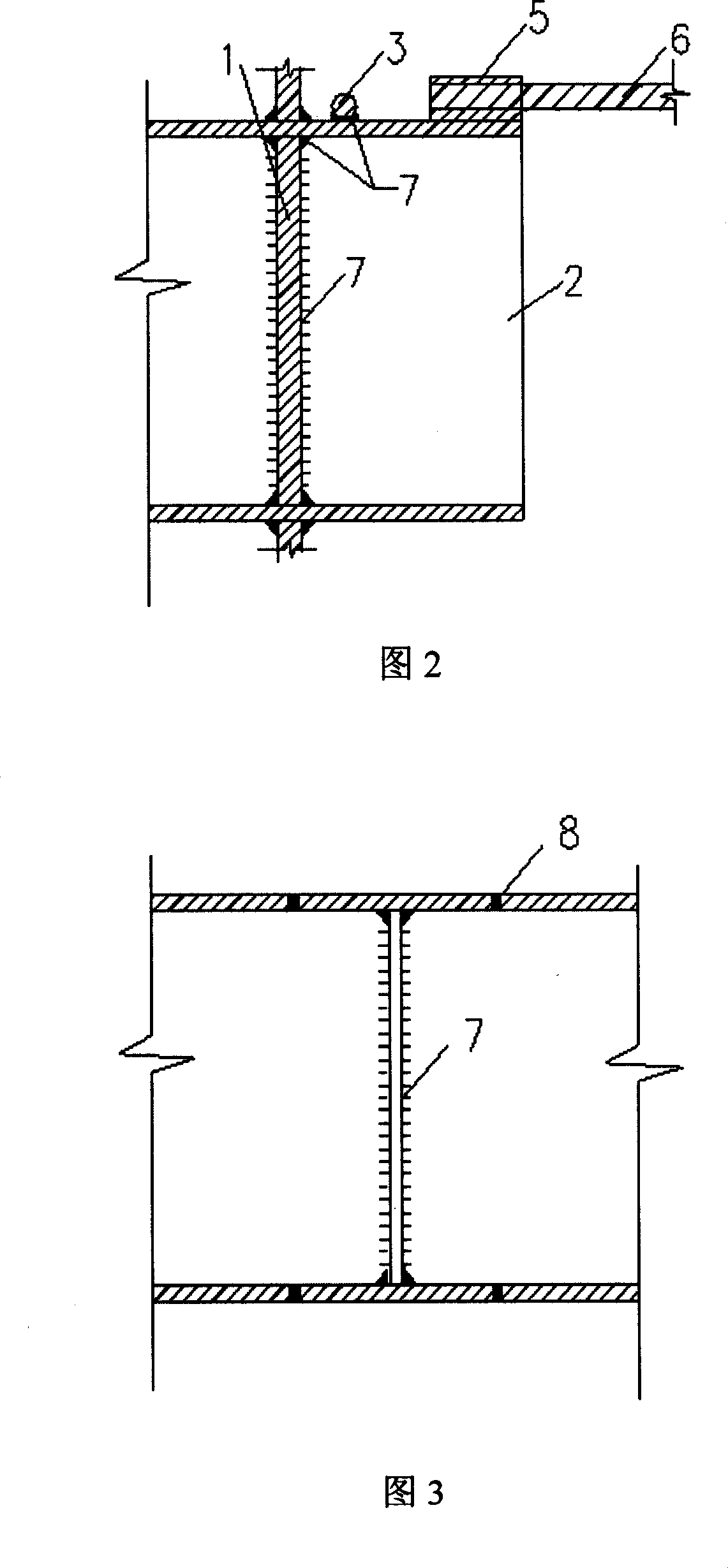

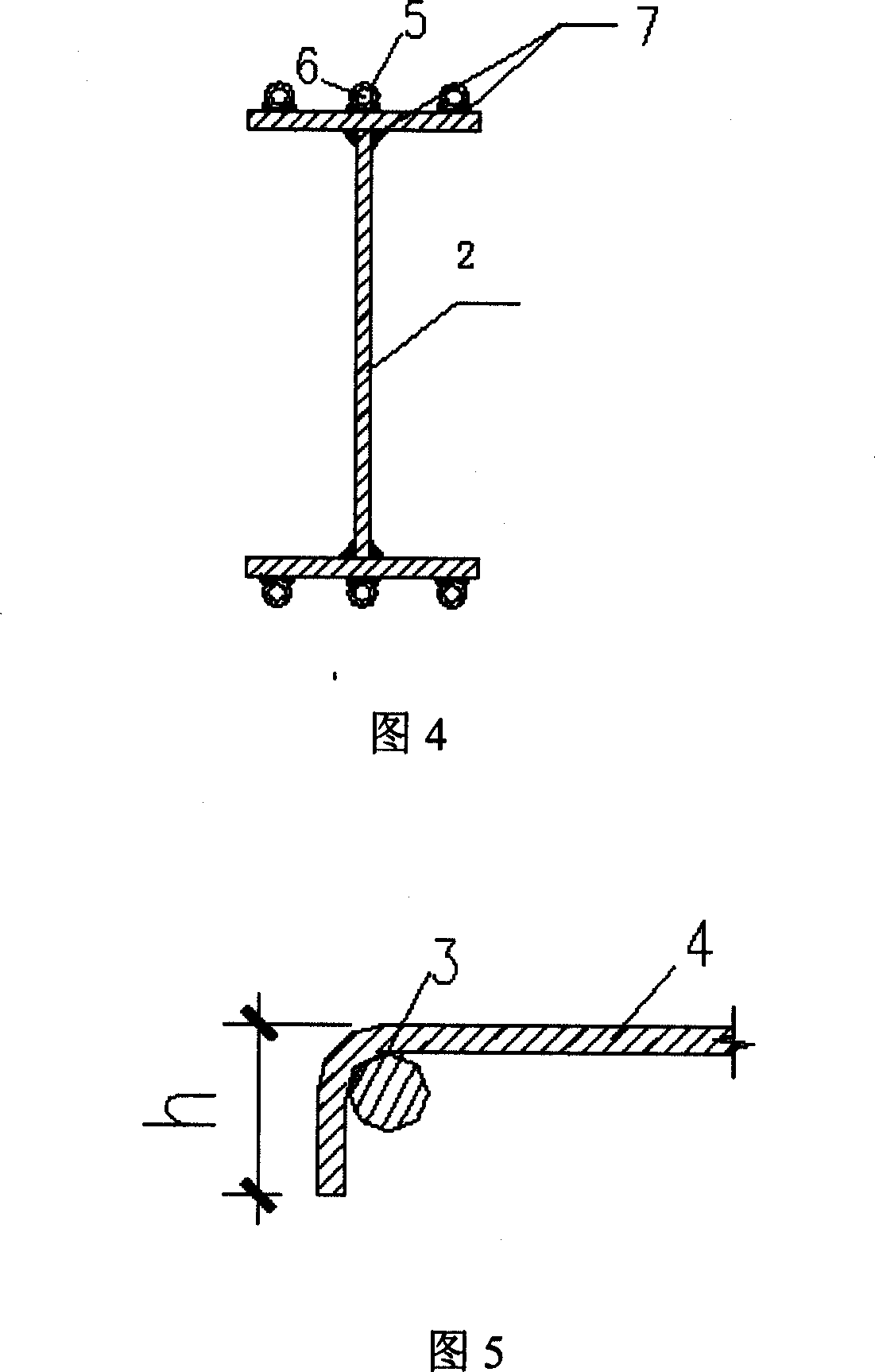

High-altitude long-span overhanging corridor type reinforced concrete structure and construction method

InactiveCN102444203ASave turnover materialsReduce construction costsBuilding material handlingSteel platesReinforced concrete

The invention relates to a high-altitude long-span overhanging corridor type reinforced concrete structure and a construction method, wherein the corridor part is a stiff beam structure; with own bearing capacity of a profile steel, a beam template supporting system is a hung template supporting system in such a manner of fixing a square steel by means of a U-shaped screw and a nut; a floorslab is a self-supporting steel bar truss template which is welded to a pre-embedded steel plate on the stiff beam by means of a pin; and a steel platform is arranged on a corresponding floor at the lower part of the corridor as an operating and safety protection platform for template support construction. The high-altitude long-span overhanging corridor type reinforced concrete structure and the construction method have the advantages that: the template supporting construction method, according to which the operating platform is built from H-steel or profile steel beams, the stiff beam is hung and is self-supported and the floorslab is self-supported, is employed, so that the problem of difficult template supporting of the high-altitude long-span overhanging corridor structure, the revolving materials are greatly saved, the construction cost is reduced, the construction progress is accelerated and the safety is ensured; and the steel plate is pre-embedded on the stiff beam, so that the floor bearing plate is effectively connected with the stiff beam and the floor bearing plate and the stiff beam are capable of acting together to ensure the safety of the structure.

Owner:浙江城建建设集团有限公司

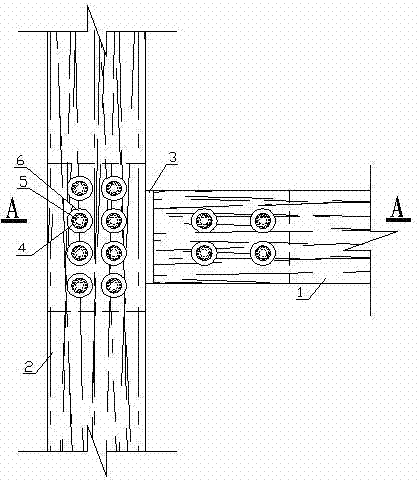

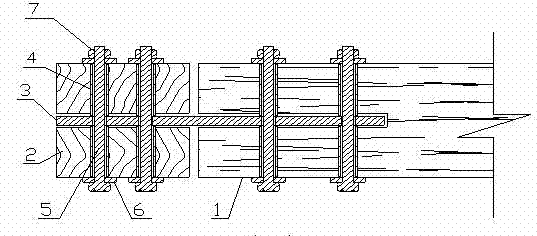

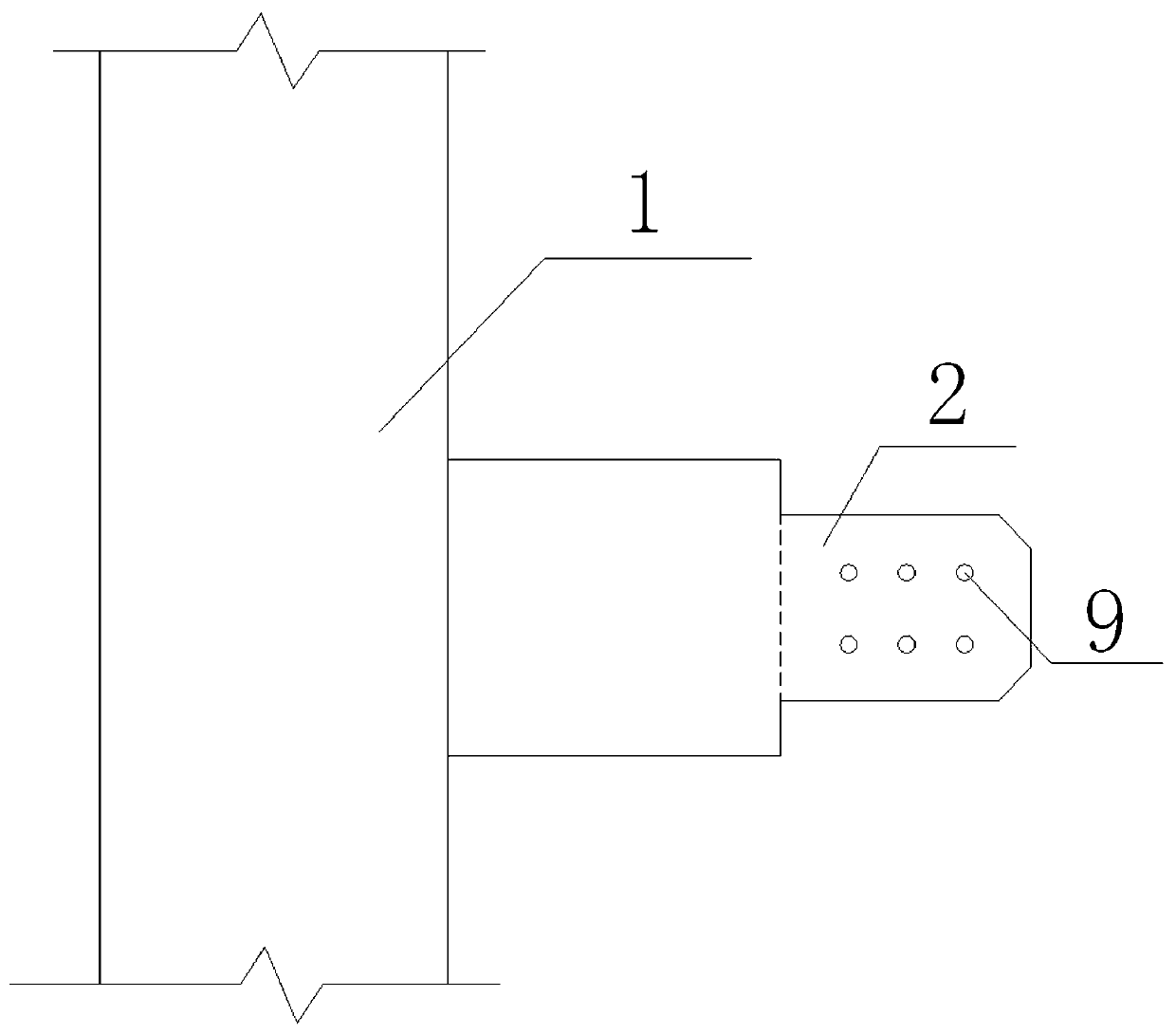

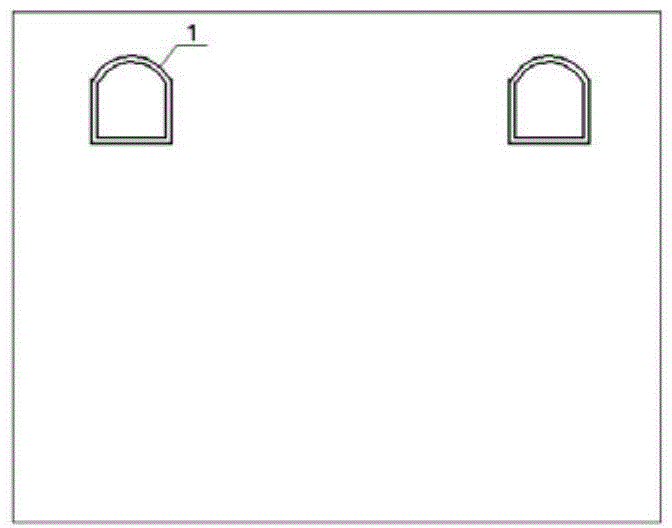

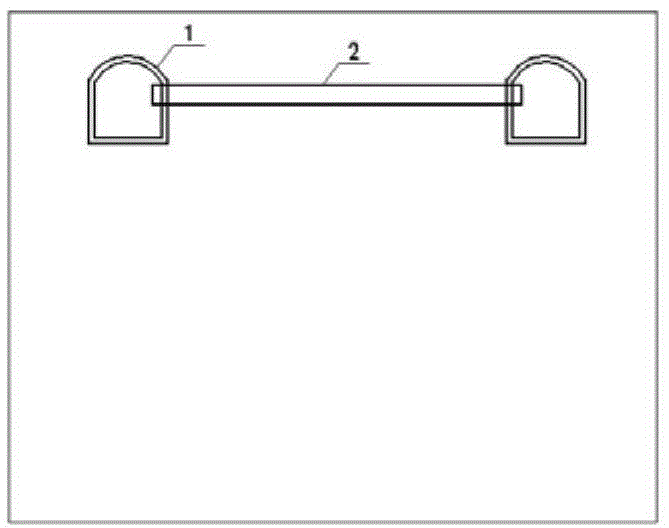

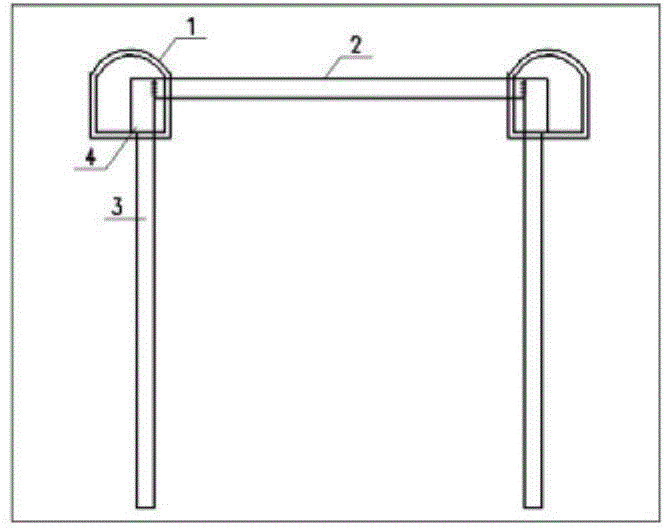

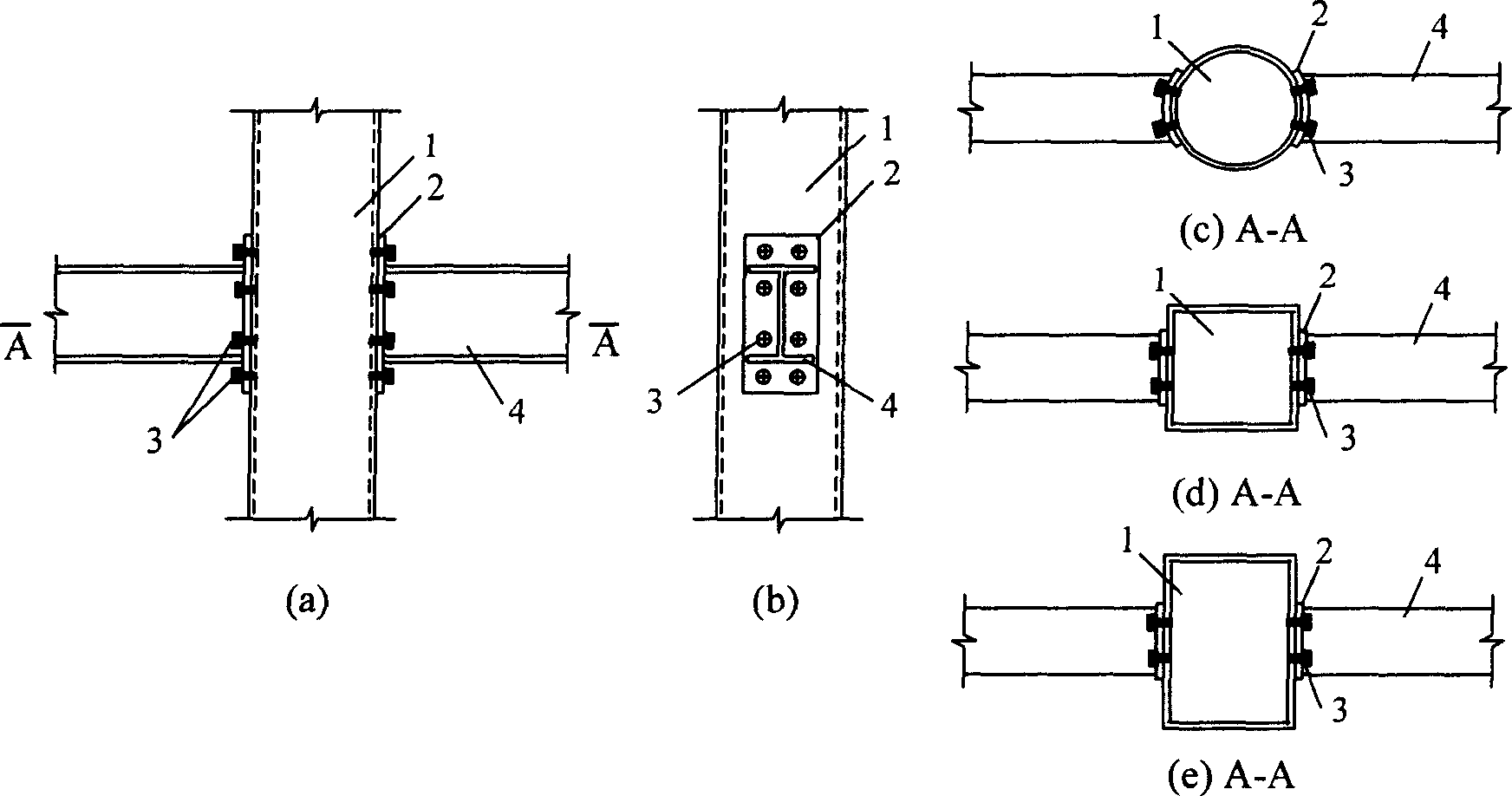

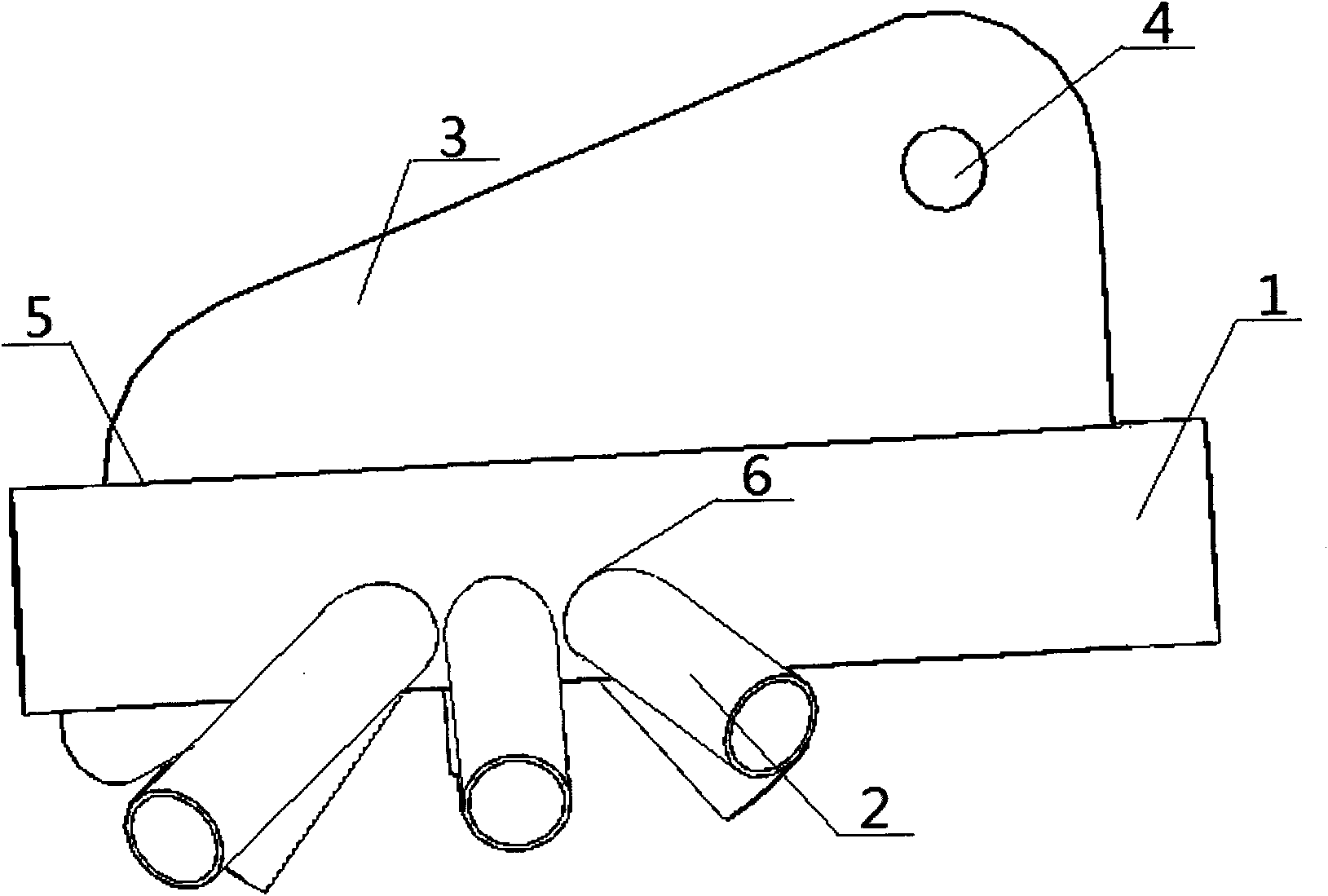

Bolted steel filling plate-sleeve connection node for beam-post wood structure

The invention belongs to the field of civil engineering technology, and particularly relates to a bolted steel filling plate-sleeve connection node for a beam-post wood structure. The connection node comprises a wood beam, a wood post, a steel filling plate, a sleeve, a bolt, a gasket and a nut. The the beam-post connection node is formed by inserting steel filling plates in grooves of the wood beam and the wood post, the sleeve is embedded in the bolt hole on the beam-post connection node; after the bolt passes through the sleeve, the sleeve is pressed by the gasket through a stretch-draw bolt, so that the sleeve pushes against the steel filling plates to generate larger pressure, friction generated by pressure is utilized for shear resistance and the increasing and decreasing of pressure stress is utilized for bending resistance. The connection node is definite in force transfer and convenient for construction, and gaps at the nodes almost have no influence on the load-carrying property and rigidity of the structure; in addition, the introduction of the sleeve can also prevent the local bearing damage of the wood below the gasket and reduce the contact pressure stress at the bolt of the wood beam (post), thus being beneficial to the exertion of strength of the wood. Compared with the existing connection mode, the connection node of the beam-post wood frame has large and stable bending-resistant rigidity.

Owner:何敏娟 +1

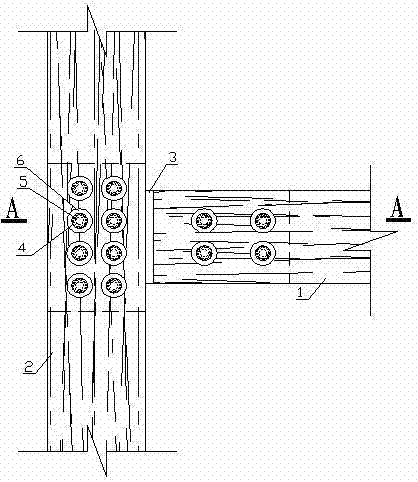

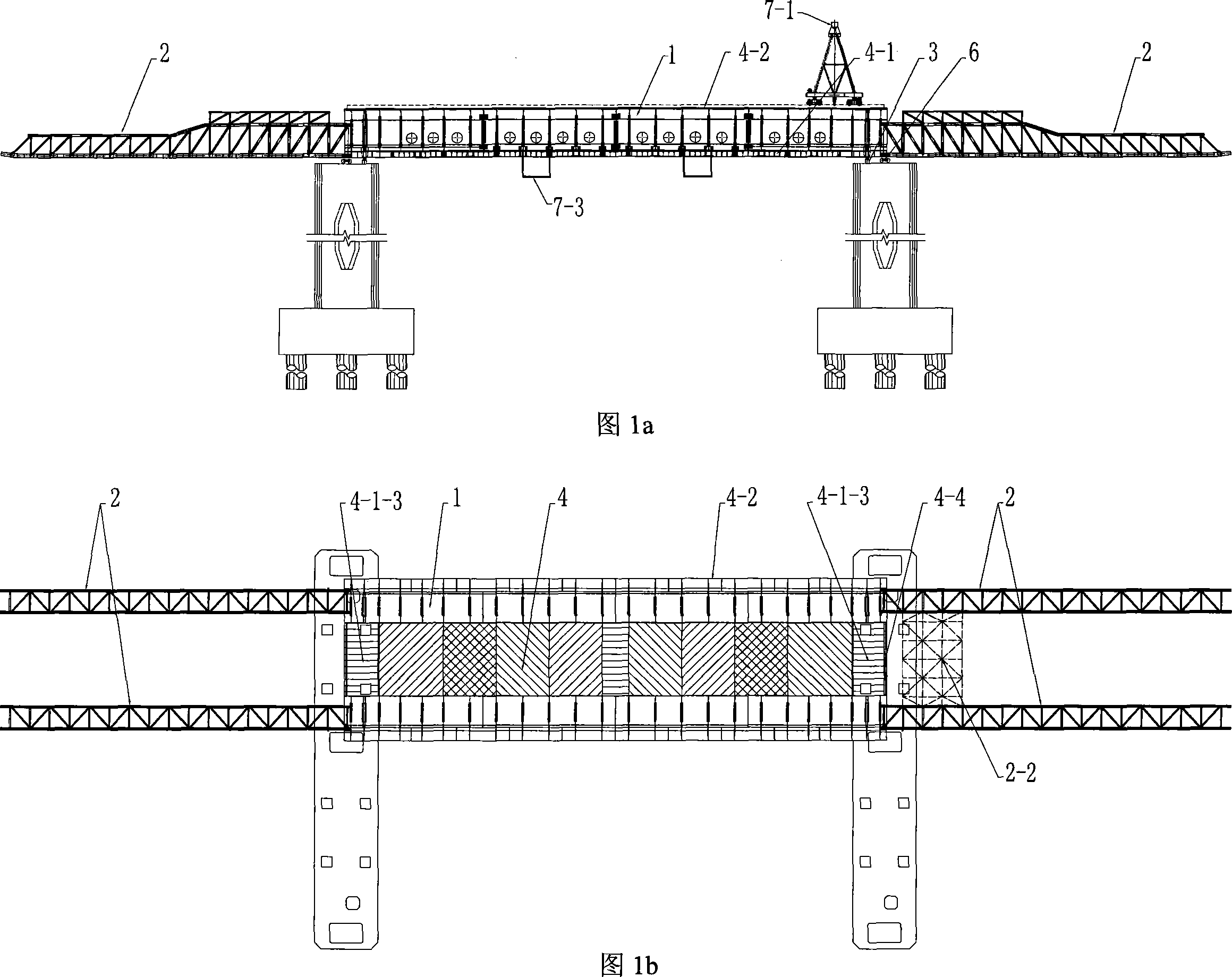

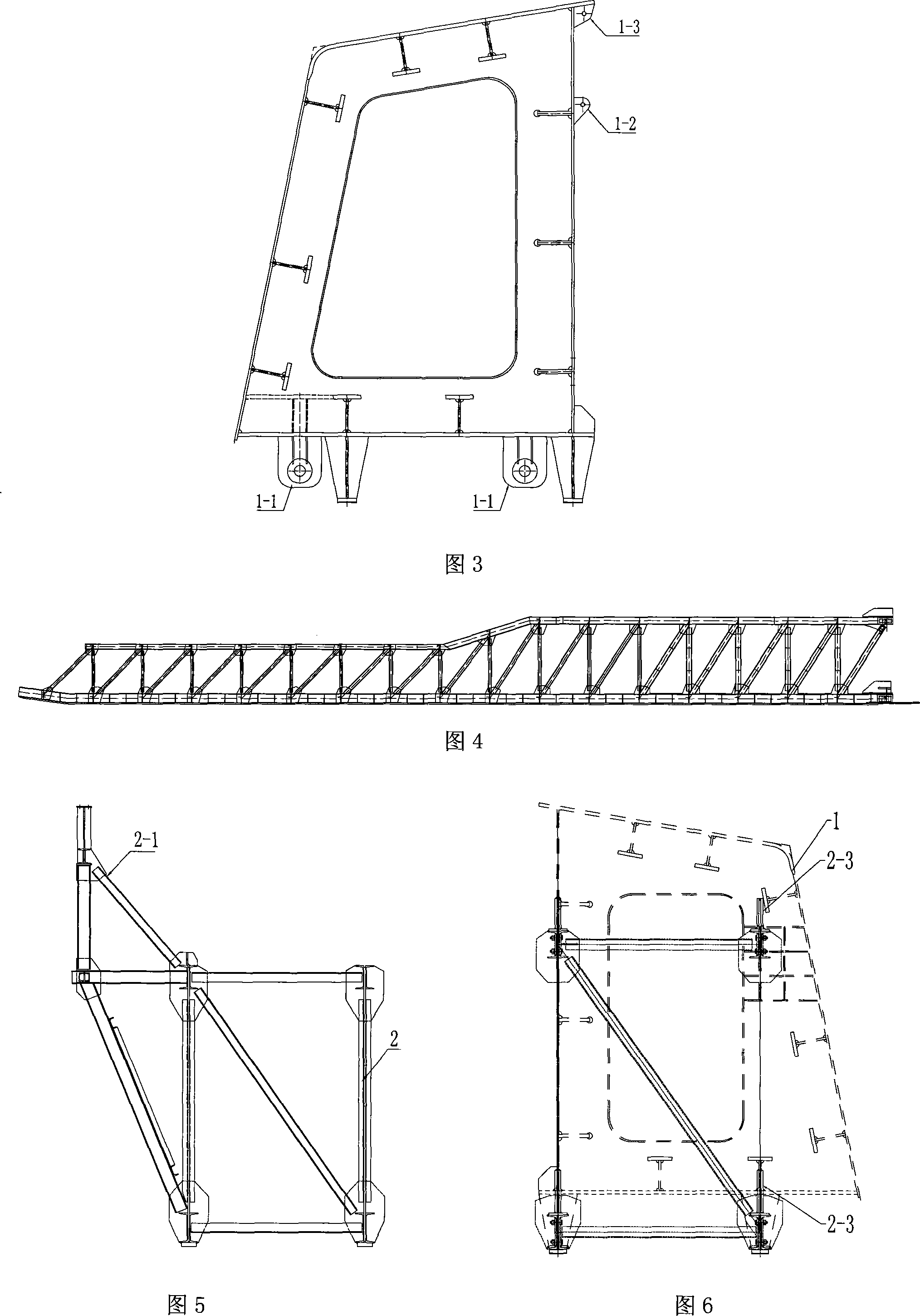

Abnormal shape steel case and orthotropic plate bottom formwork combined type moving die carrier framework and construction method thereof

ActiveCN101117791ALower the altitudeSolve the problem of running through holesBridge erection/assemblyBridge materialsPush and pullSelf locking

A heterotype steel box and an orthogonal heterology plate bottom mold combined moving mould base and a construction method are provided, the load bearing beam of the moving mould base is the beam of the heterotype steel box, and a top plate and an inner web plate are the outer mould of a concrete box beam; the bottom mold employs orthogonal heterology structure, high toughness and low height, through opening and closing by flat pushing at one side, and line feed is performed in the space between the concrete box beam and a pier shaft. The main beam of the moving mold base is directly supported at the pier top, with the self-locking hydraulic jacket to transmit the load and adjust the height, the transverse moving of the moving mold base is finished at the pier top, and therefore, a steel structure landing leg is not required. The longitudinal moving of the moving mold employs a steel strand and a continuous hydraulic jacket for pushing and pulling, power for the longitudinal moving is located at the front pier top, and removes the difficulty of the application of a bridge fabrication machine for a railway and a road bridge, is the construction equipment for the concrete box beam of the railway passenger line and used in the road bridge.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

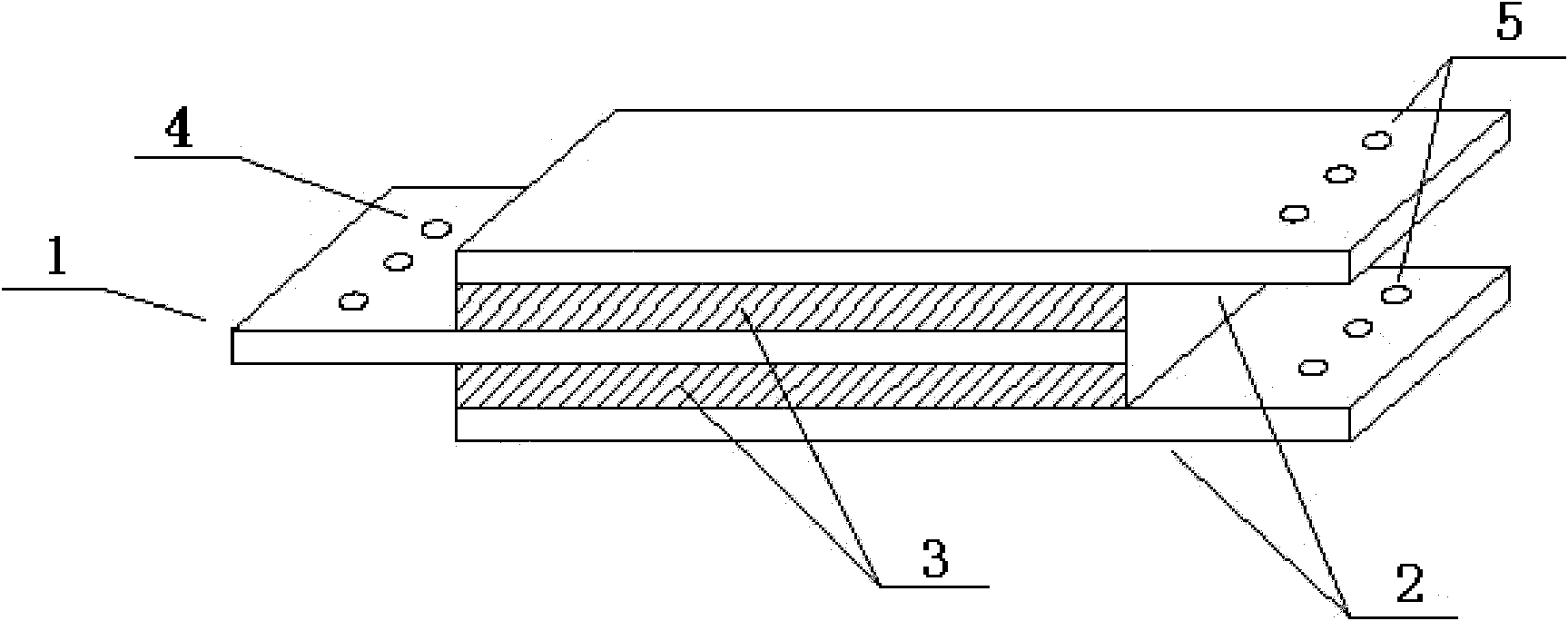

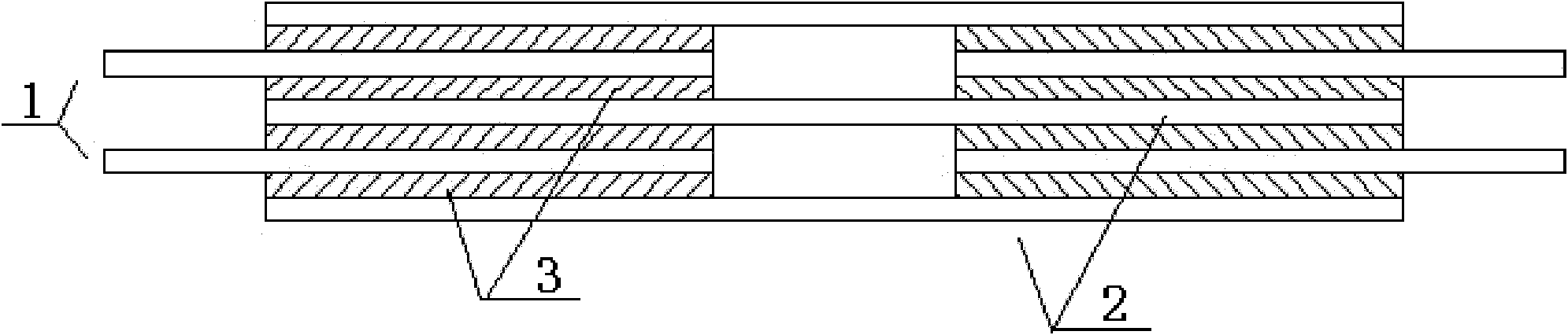

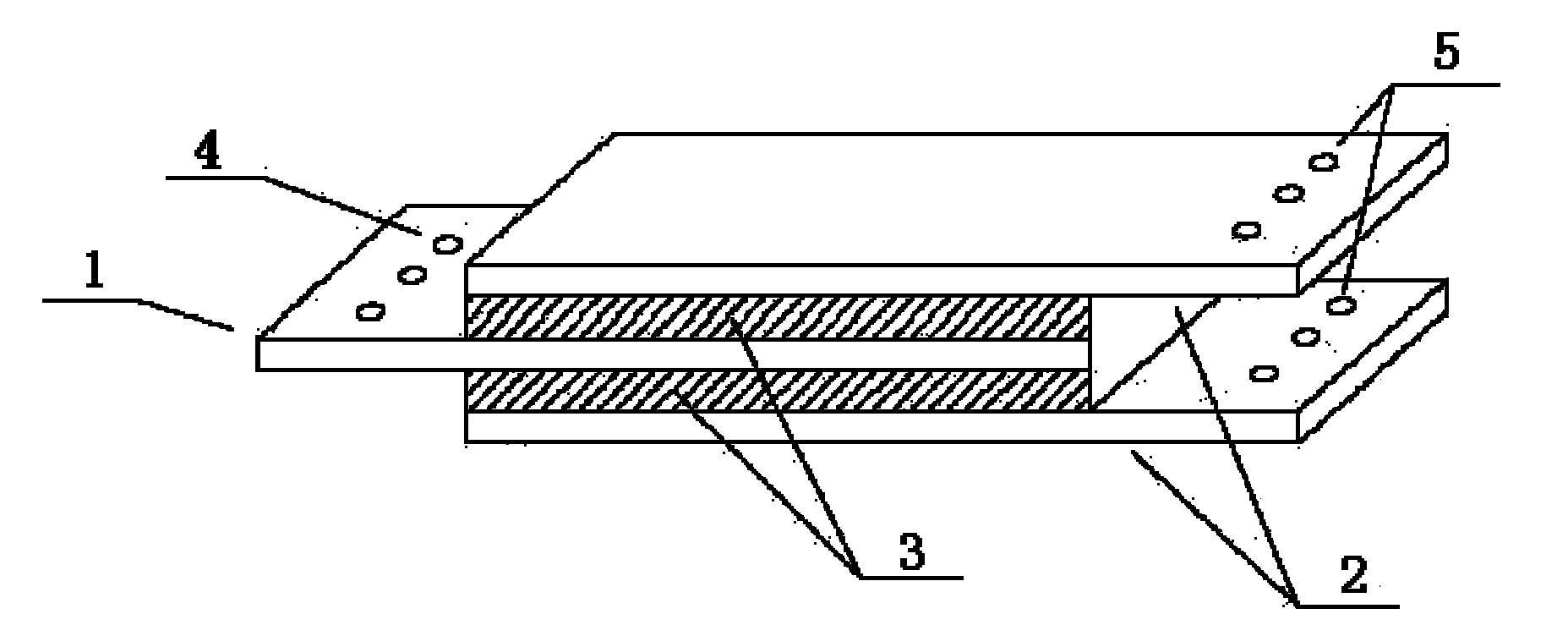

High-damping rubber fluid viscoelastic damper and manufacturing method thereof

ActiveCN102182256AReduce wind vibrationReduced responseBridge structural detailsBridge erection/assemblyHysteresisViscoelastic damping

The invention relates to the technical field of civil engineering, in particular to a damper and a manufacturing method thereof. A high-damping rubber fluid viscoelastic damper comprises a steel plate layer and a fluid viscoelastic material layer, wherein the steel plate layer comprises a middle steel plate and side steel plates arranged at two sides of the middle steel plate, the fluid viscoelastic material layer is arranged between the steel plate layer and the side steel plates, and the fluid viscoelastic material layer is the high-damping rubber fluid viscoelastic material layer made of high-damping rubber fluid viscoelastic material. Due to the adoption of the technical scheme, the invention has the following advantages: the vibration energy can be absorbed effectively by the deformation of the high-damping rubber fluid viscoelastic material, a hysteresis ring is full, and the fatigue resistance is good; and compared with the traditional fluid viscoelastic damper, the energy consumption property has stronger nonlinearity, and the energy consumption property is good under the condition of extremely small displacement and extremely low speed.

Owner:SHANGHAI EAGLE BRIDGE TECH

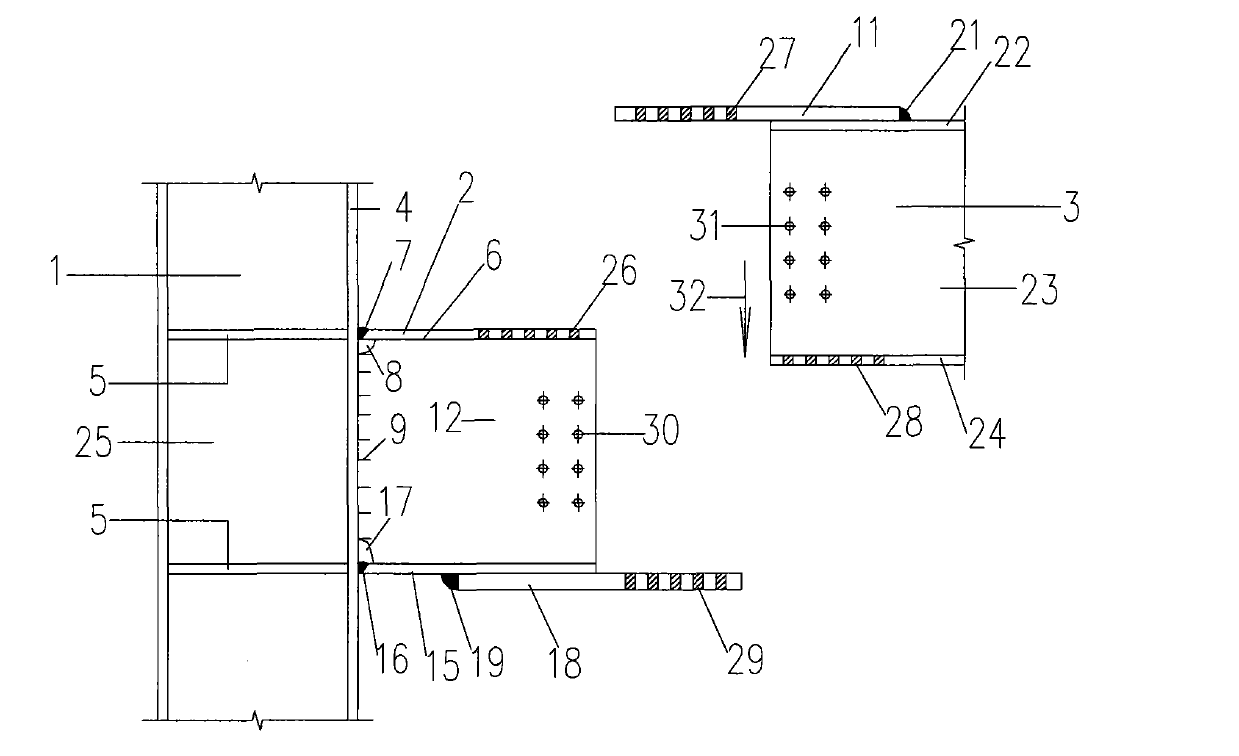

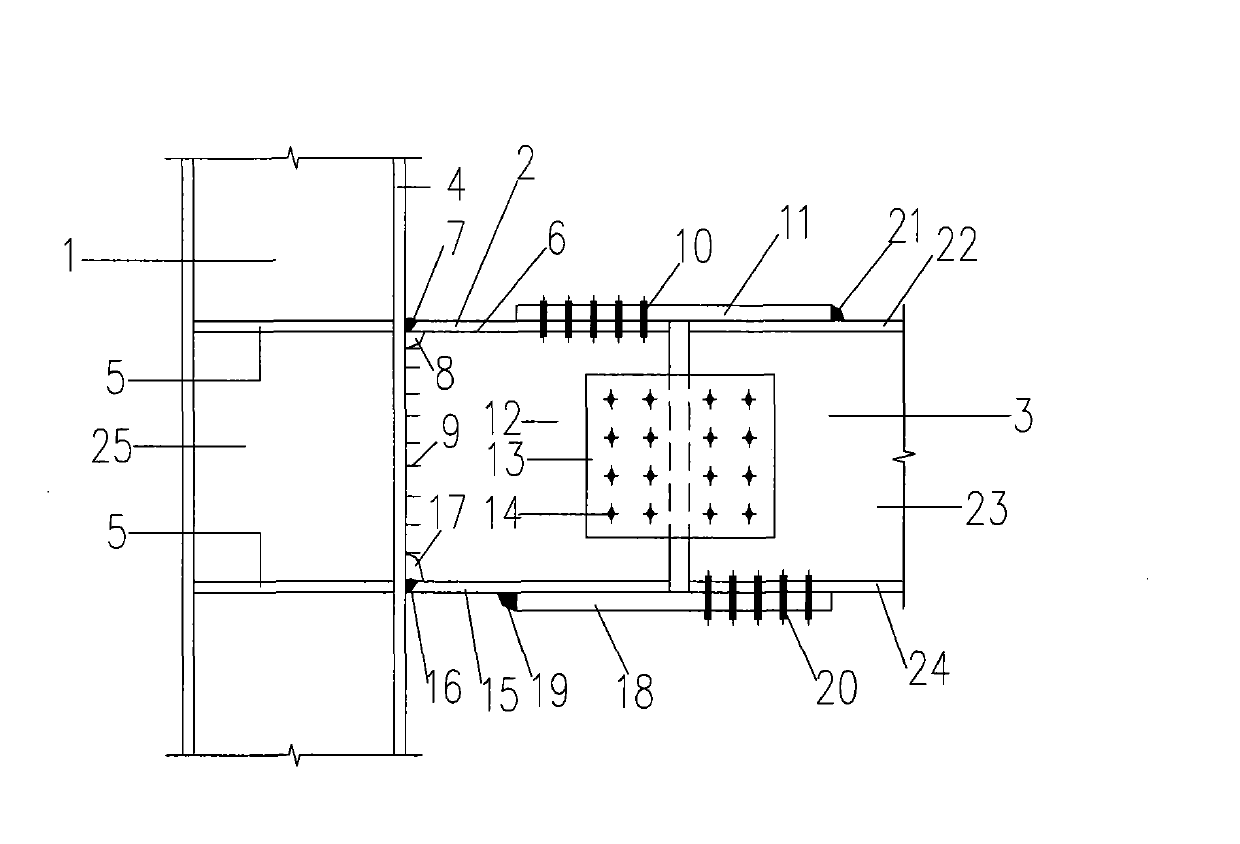

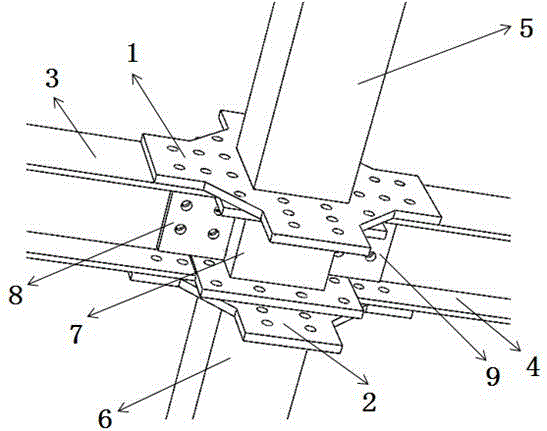

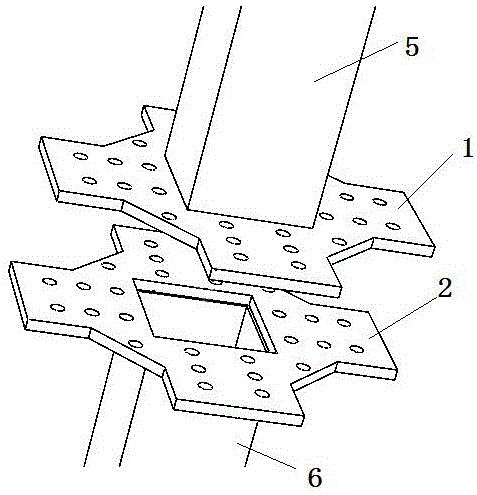

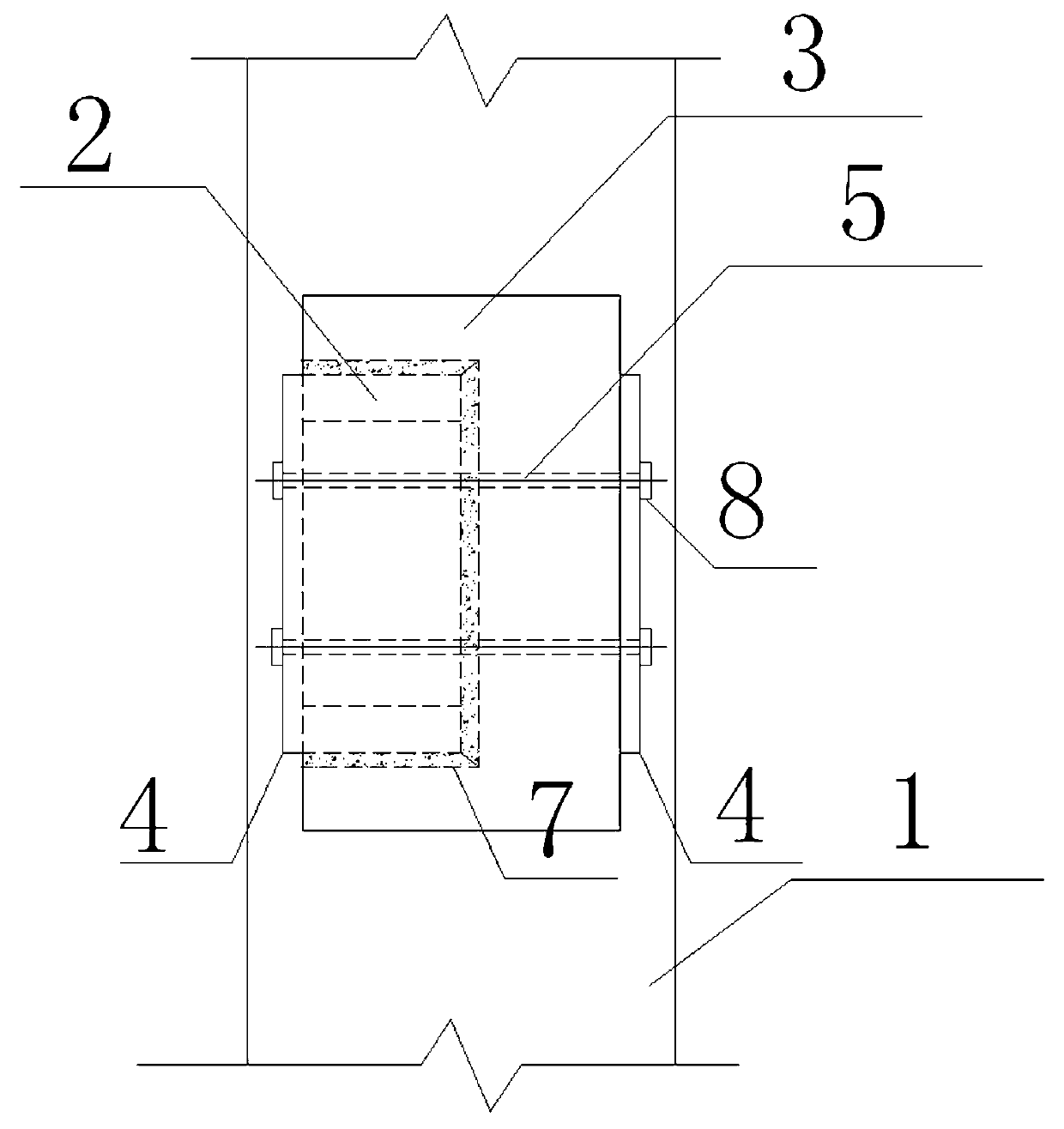

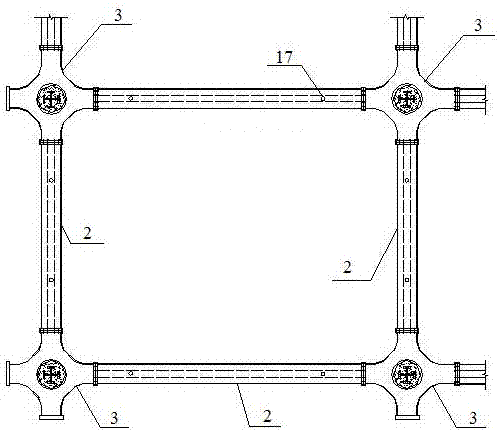

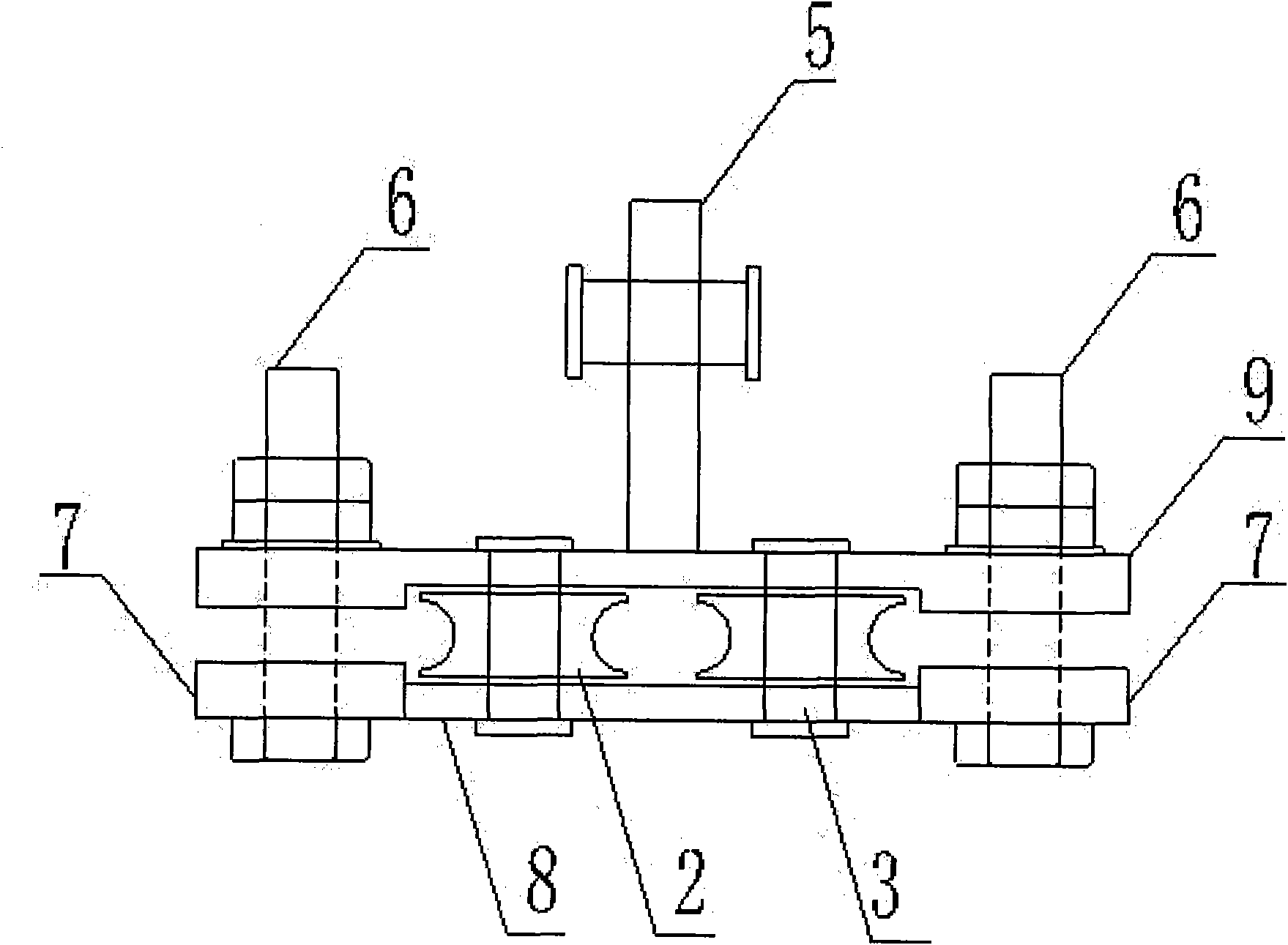

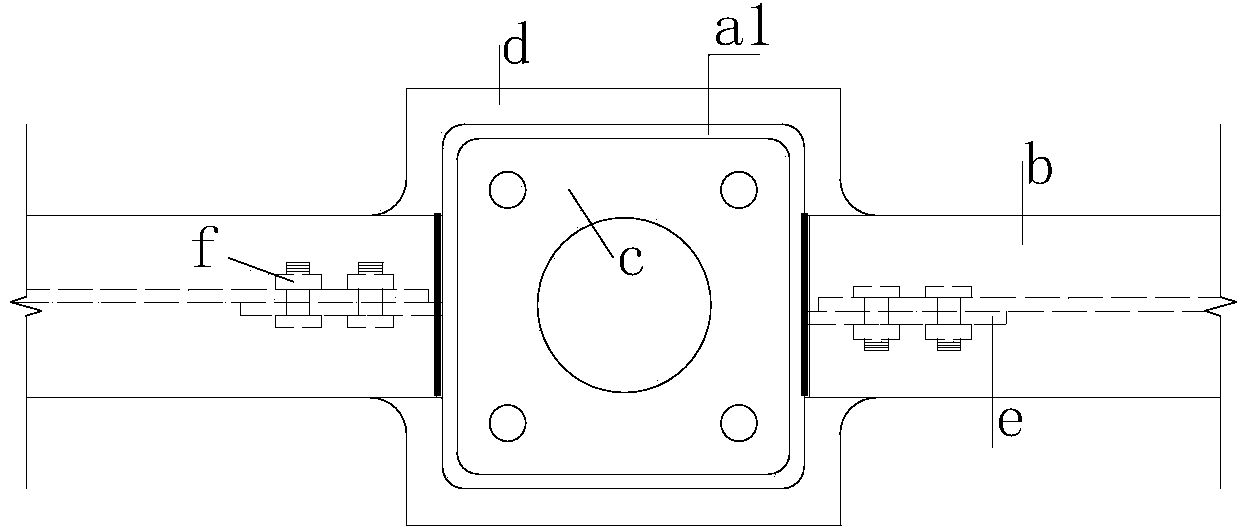

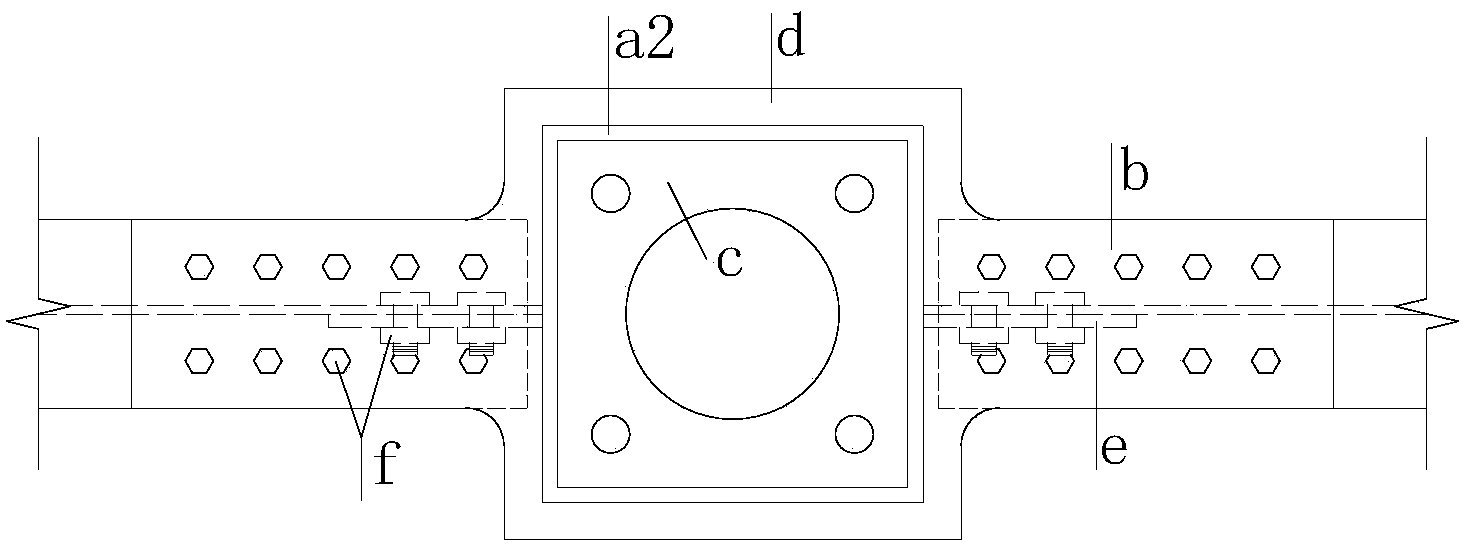

Steel structure beam column assembly type rigid joint

InactiveCN103290928APromote the standardization processReasonable structureBuilding constructionsCantilevered beamField conditions

The invention relates to a building steel structure beam column assembly type rigid joint which is characterized in that splicing plates are interactively arranged on upper flanges and lower flanges of a cantilever beam and a frame beam, and the splicing plates on the two sides are connected with the beams by welding seams in a steel structure processing factory previously. During field mounting of the joint, the splicing plates firmly welded on the two sides serve as ear plates to allow a mounting beam section to be in place quickly; after being in place, the splicing plates are connected with the upper flange and the lower flange of the beam on the other side and spliced with a web plate by bolts; and the mounting of the beam column rigid joint is accomplished. The beam column joint is wholly spliced by the bolts in a mounting field, and is reasonable in structure, definite in force transmission, high in construction efficiency and good in safety; the field mounting is in place quickly; no welding is adopted; the mounting efficiency can be improved; the risk of a fire caused by the welding is avoided; and the joint is wholly assembled by the bolts in a construction field, so that a great convenience is brought to a construction site where the construction field condition is poor and the welding cannot be carried out conveniently.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

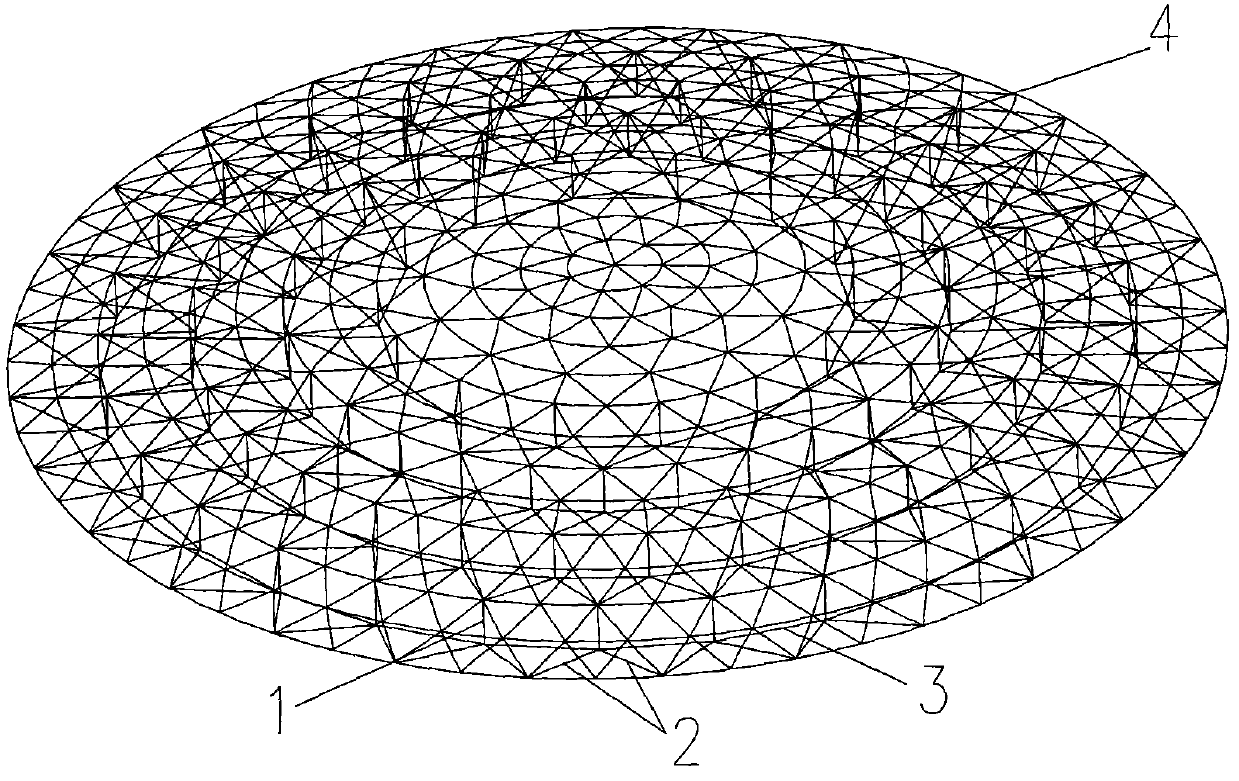

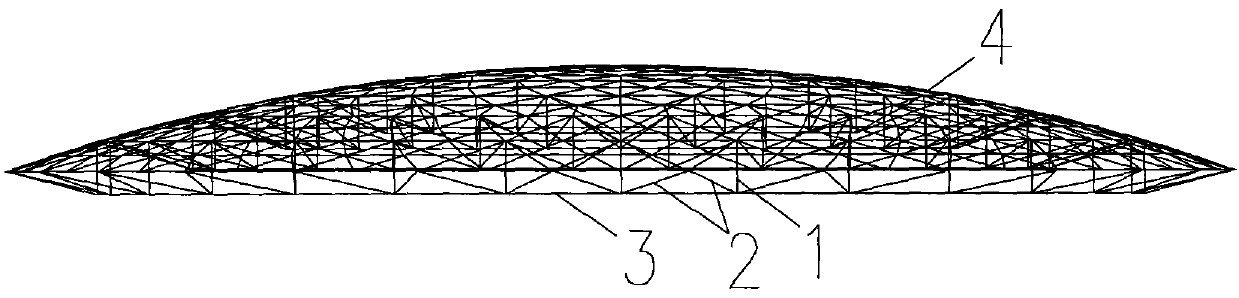

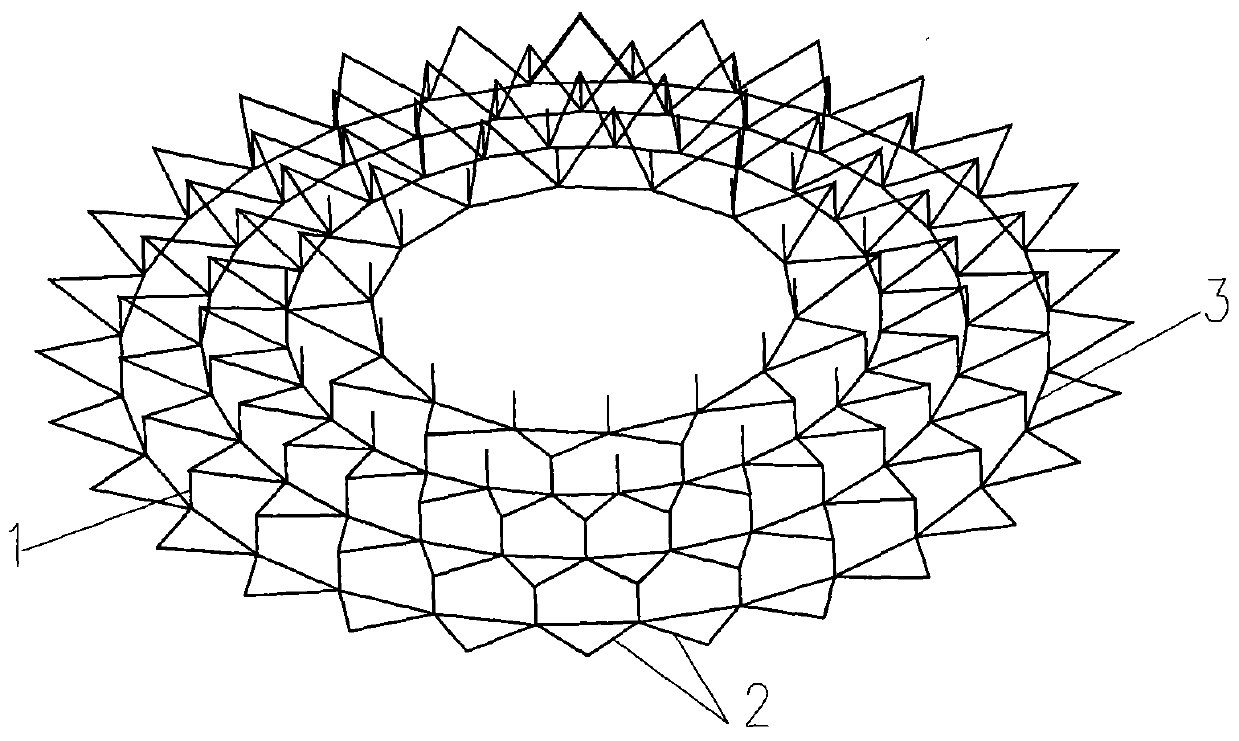

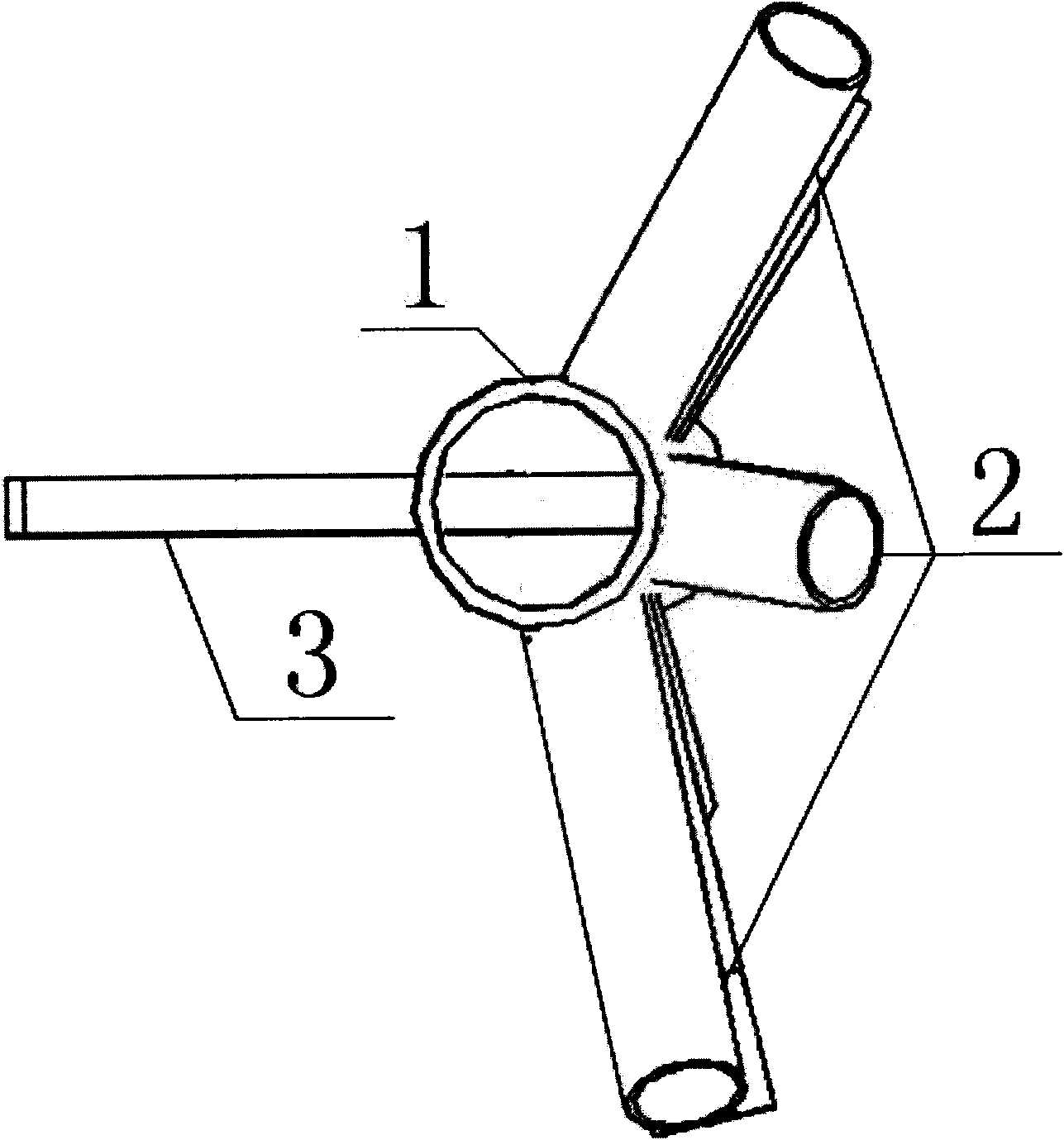

V-shaped radial string branch mesh dome

InactiveCN101029521AImprove integrityImprove carrying capacityBuilding roofsEngineeringUltimate tensile strength

A net dome with V shape radial sling includes stay bar, radial sling, hoop stress sling, upper net structure and steel tube. The top end of the stay bar is connected to the node of the upper net structure; the bottom end is connected to the steel tube. Radial slings cross along the loop stress sling in a V shape, with the crossing point connected to the bottom end of the stay bar, the other two ends connected to different nodes of the upper net structure. The loop stress sling threads through the steel tube and flexible connect to the stay bar.

Owner:BEIJING UNIV OF TECH

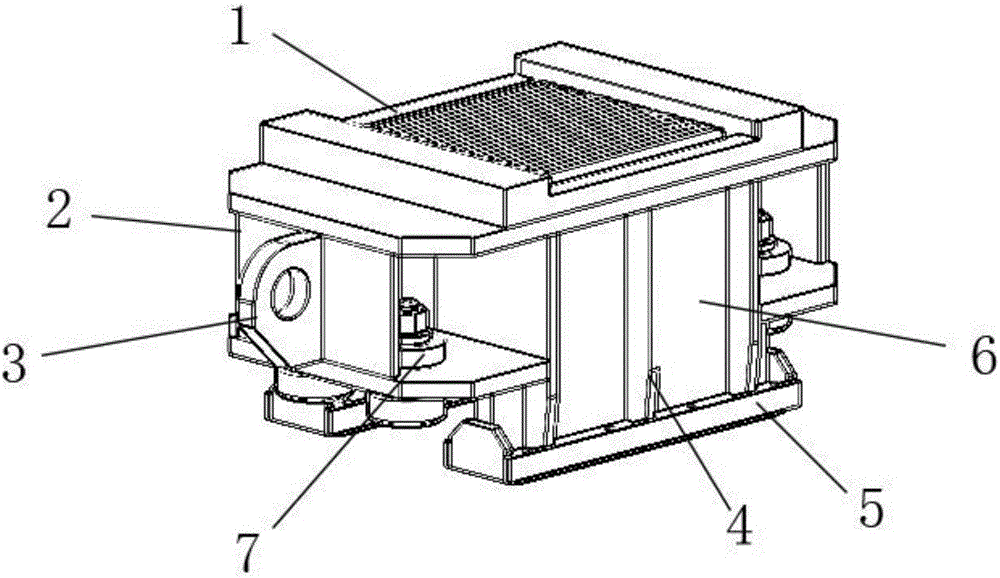

Sliding construction device and method for large-span arc-shaped roof

ActiveCN104989114ASimple structureStable structureBuilding material handlingReinforced concreteAngular velocity

The invention relates to the technical field of construction, in particular to a sliding construction device and method for a large-span arc-shaped roof. Finite element structural analysis software is adopted, the stress change of each rod piece is analyzed according to the actual condition of each installation stage, the stress change is compared with the stress limit value requirement of the design state to ensure structural safety in the construction stage, adverse additional stress can not be caused, and a temporary supporting jig frame, sliding shoes, an arc-shaped sliding steel box girder and a hydraulic pushing system are designed according to the reaction of each support, the reaction of the supporting jig frame and the column beam stress limit value of a reinforced concrete structure which are analyzed by the software. A pushing device controlled by a PLC works stably, the angular velocities of all pushing points are consistent, and the roof slides to the right position according to a predetermined movement path at an ideal sliding speed. Through the cooperation of various types of mechanical equipment, movement and hoisting are basically conducted within a small range, working efficiency is improved, and intersection construction with other professional construction sites is avoided.

Owner:SHANGHAI GREENLAND CONSTR GRP

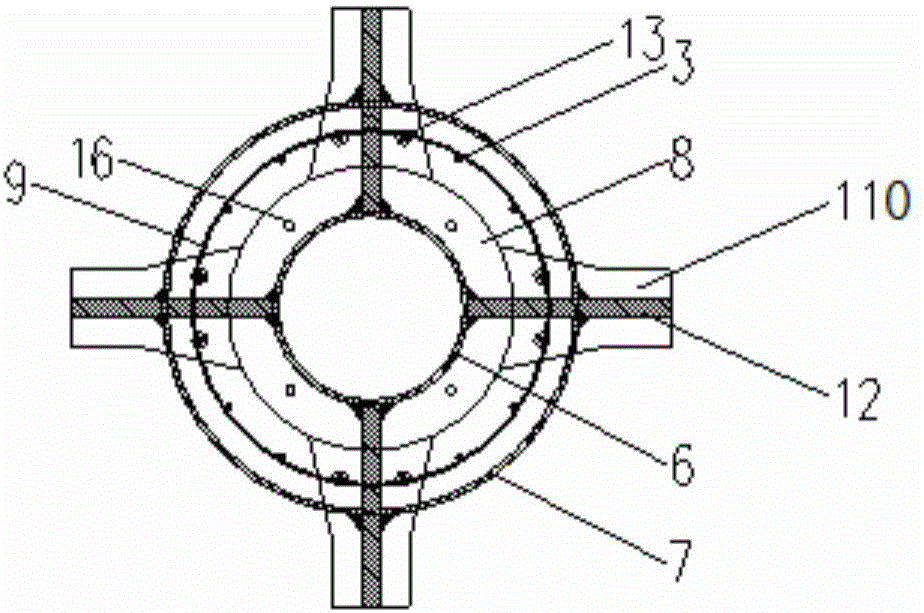

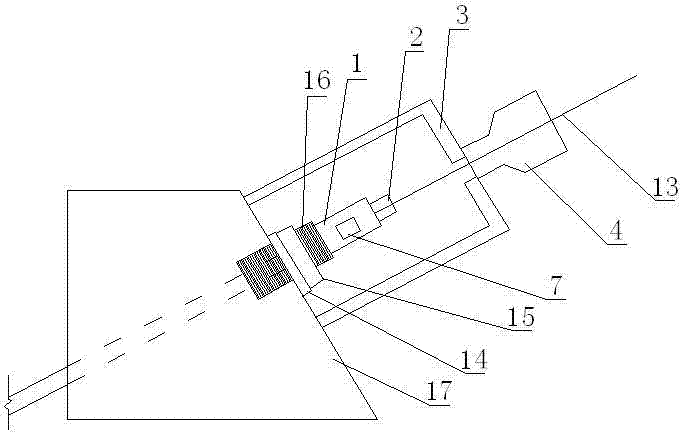

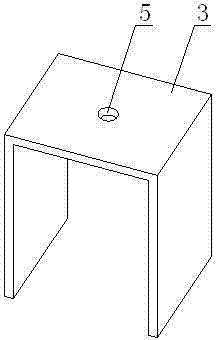

Fabricated steel structure type reinforced ring plate type flange beam column joint and using method thereof

InactiveCN107435377AEasy constructionFlexible structureBuilding constructionsUltimate tensile strengthEnergy consumption

The invention relates to a fabricated steel structure type reinforced ring plate type flange beam column joint and a using method thereof and belongs to the technical field of building structure members. The fabricated steel structure type reinforced ring plate type flange beam column joint comprises reinforced ring plates, a column seat, flitches and lapping plates. Columns are in high-strength bolted connection through the reinforced ring plates provided with prefabricated bolt holes at the column ends, and flange plates at the ends of the column seat. The columns and beam flanges are in high-strength bolted connection through the prefabricated bolt holes in the reinforced ring plates, and beam flange bolt holes. The lapping plates are arranged at the two ends of the column seat. A beam web and the column seat are connected through the flitches, specifically, bolt holes in the flitches are in high-strength bolted connection with bolt holes in the beam web and bolt holes in the lapping plates of the column seat simultaneously. The fabricated steel structure type reinforced ring plate type flange beam column joint can be uniformly machined and produced in a factory, productization and modulization can be achieved, and member standardization of a fabricated steel structure is facilitated; and the fabricated steel structure type reinforced ring plate type flange beam column joint is high in bearing capacity and strength, good in energy consumption capacity and beneficial for structural safety and anti-seismic capacity.

Owner:KUNMING UNIV OF SCI & TECH

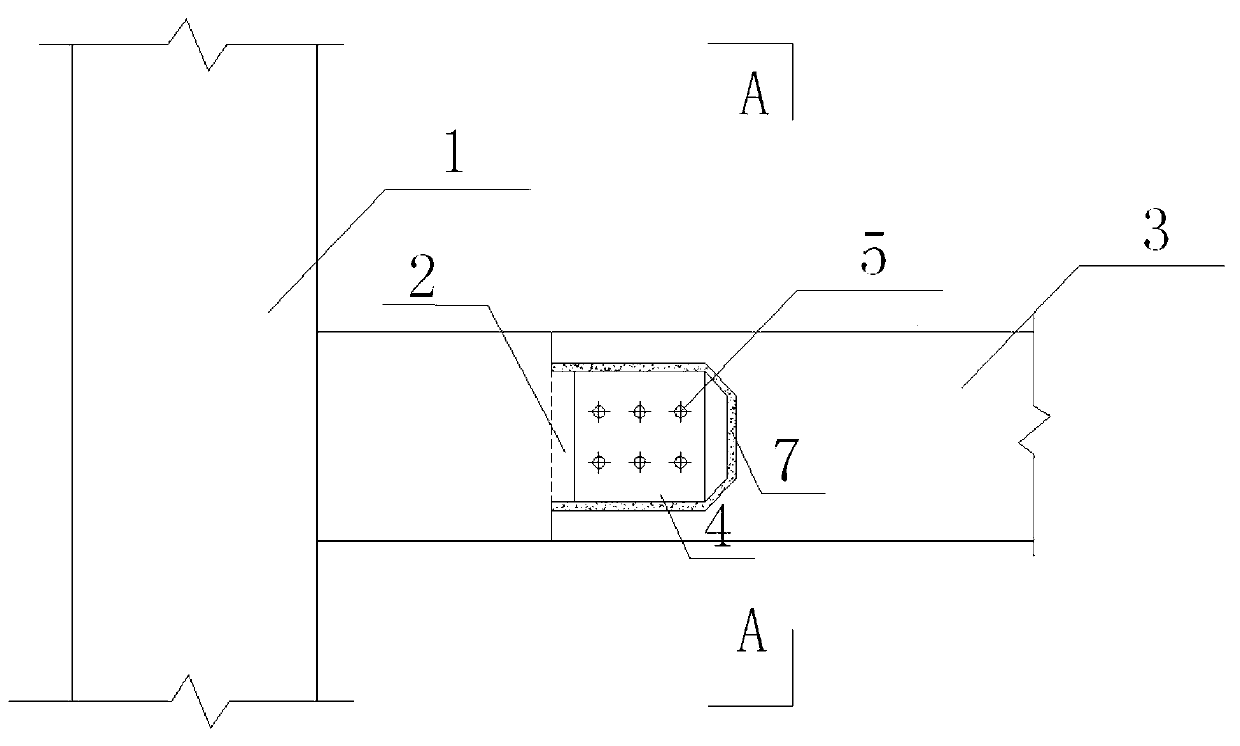

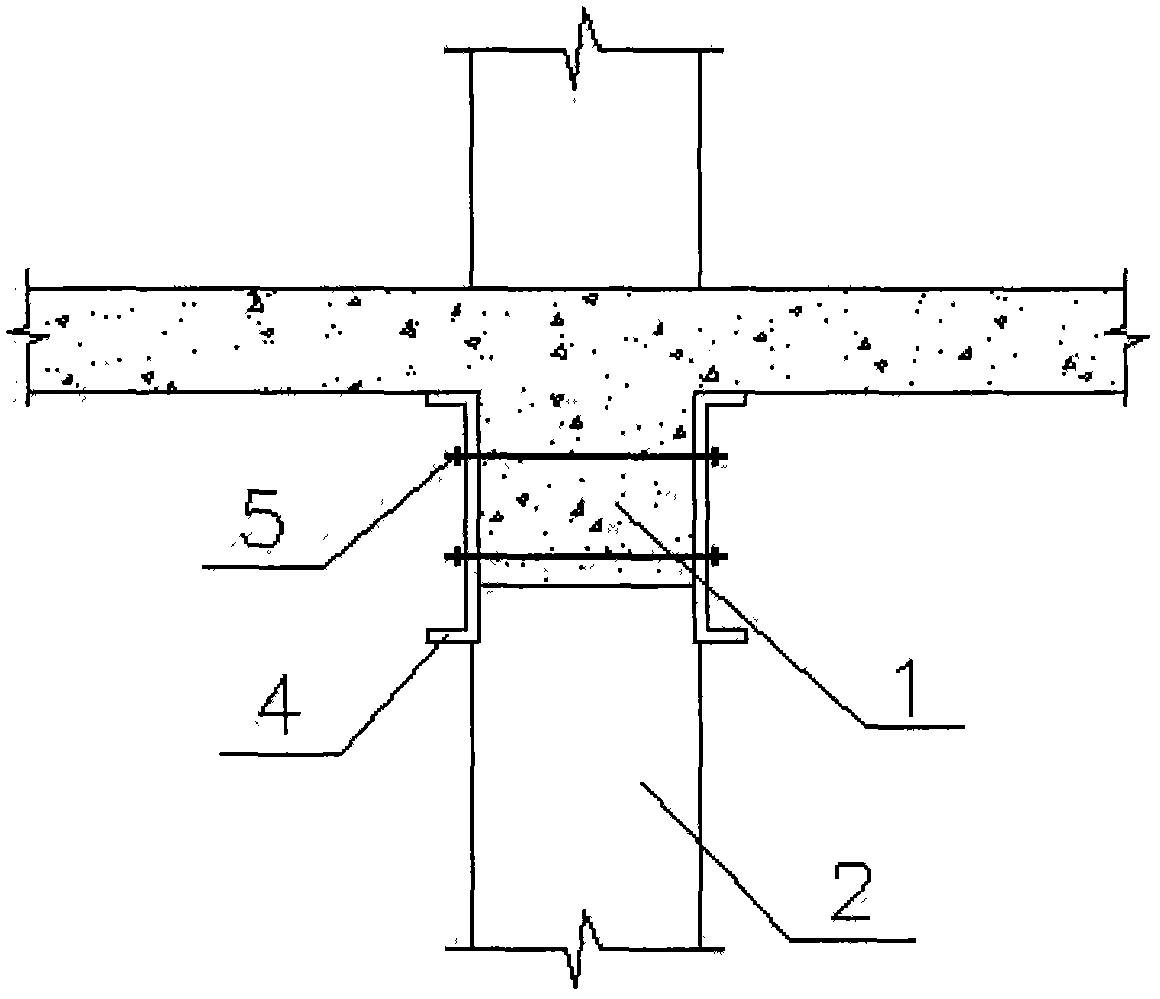

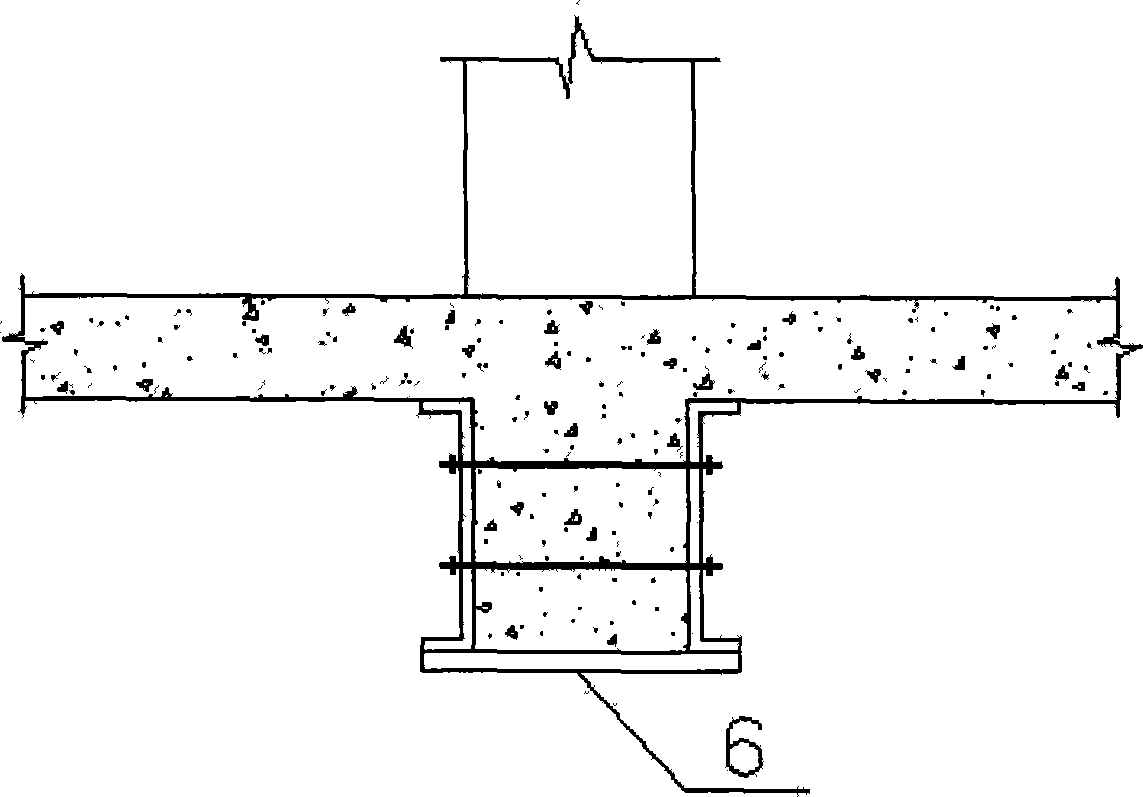

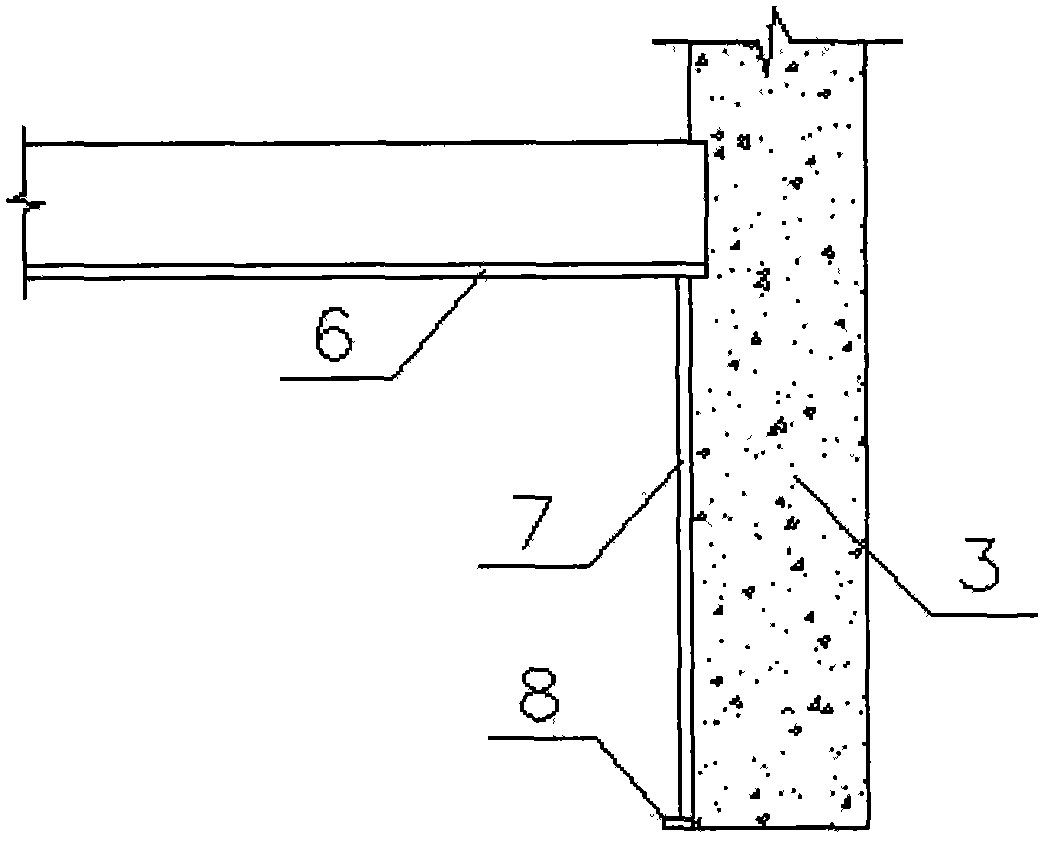

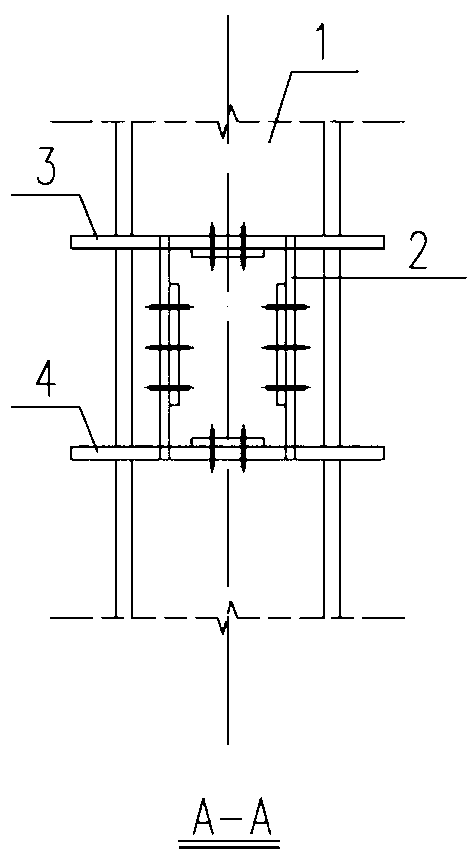

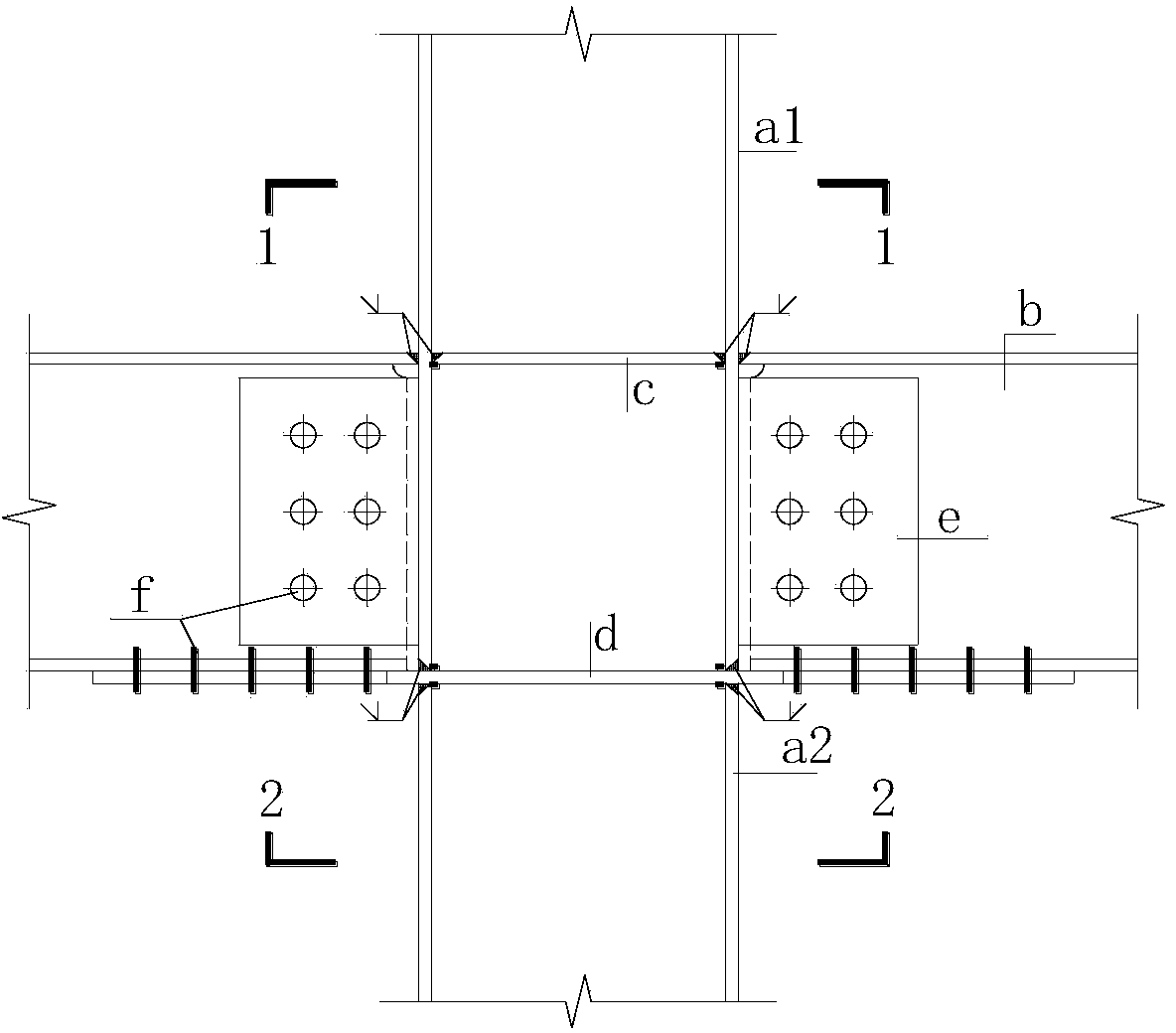

Assembled framework beam-column joint adopting transverse connection and construction method thereof

InactiveCN103104041AReliable strengthGuaranteed integrityBuilding material handlingReinforced concreteRebar

The invention relates to an assembled reinforced-concrete framework beam-column joint adopting transverse bolt connection. The joint comprises a hidden corbel arranged on a beam of a precast column, wherein hidden corbel bolt holes are transversely reserved in the hidden corbel; a notched groove matched with the hidden corbel is formed in the front / rear side face of an end-part connection part of a precast beam and is formed in a manner that the precast beam is notched towards one side of the precast beam from the vertical axis of the precast beam, the notched groove and the hidden corbel are the same in cross-section shape, and precast beam bolt holes are transversely reserved in corresponding positions of the bottom of the notched groove; and the transverse width of the hidden corbel is half that of the precast beam, the hidden corbel is embedded in the notched groove of the precast beam along the transverse direction, bolt cushion plates are arranged at the front and rear sides of an assembly which is formed after the hidden corbel is embedded in the notched groove of the precast beam, and bolts transversely penetrate through the bolt cushion plates, the hidden corbel bolt holes and the precast beam bolt holes so as to carry out fixing. A corresponding construction method comprises the steps of precasting, mounting and filling mortar in gaps. The joint and the corresponding construction method have the advantages that the internal force transmission between the precast beam and the precast column is clear, the joint is reliable in connection, the construction operation is simple, and the construction progress is accelerated.

Owner:ZHENGZHOU UNIV

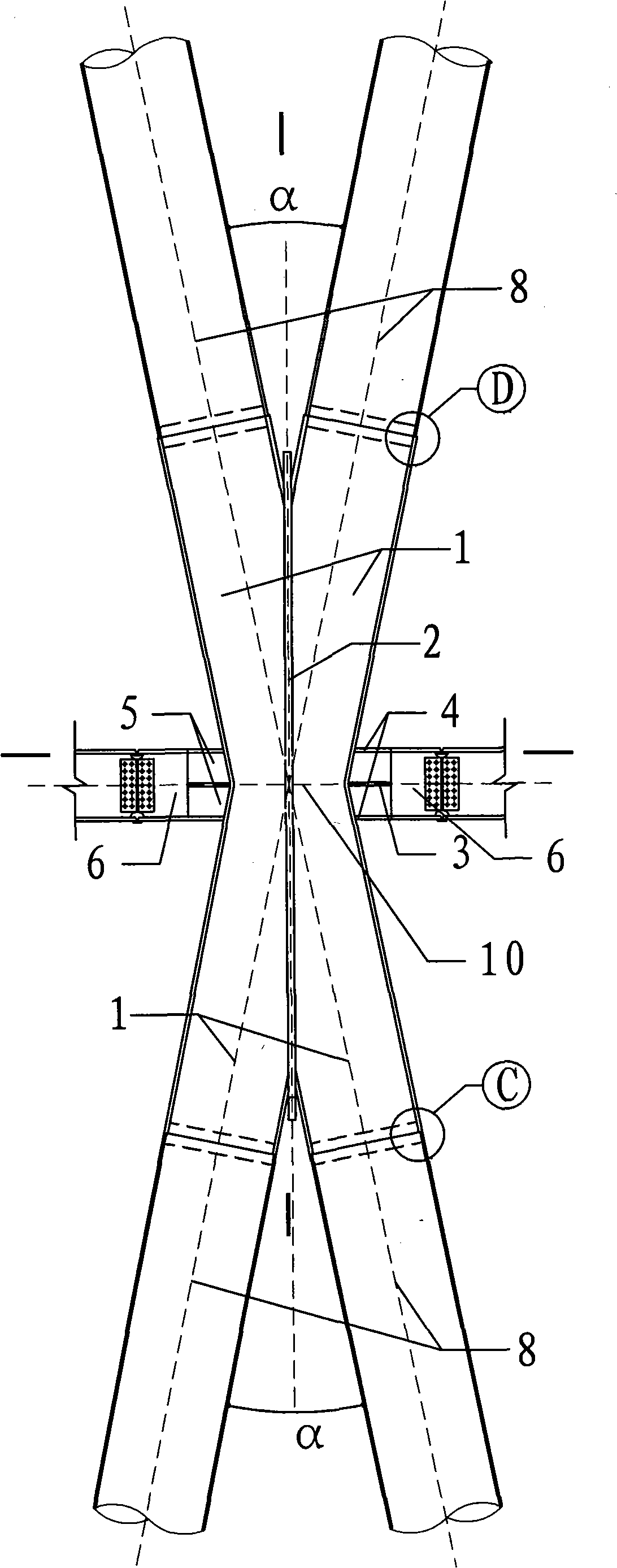

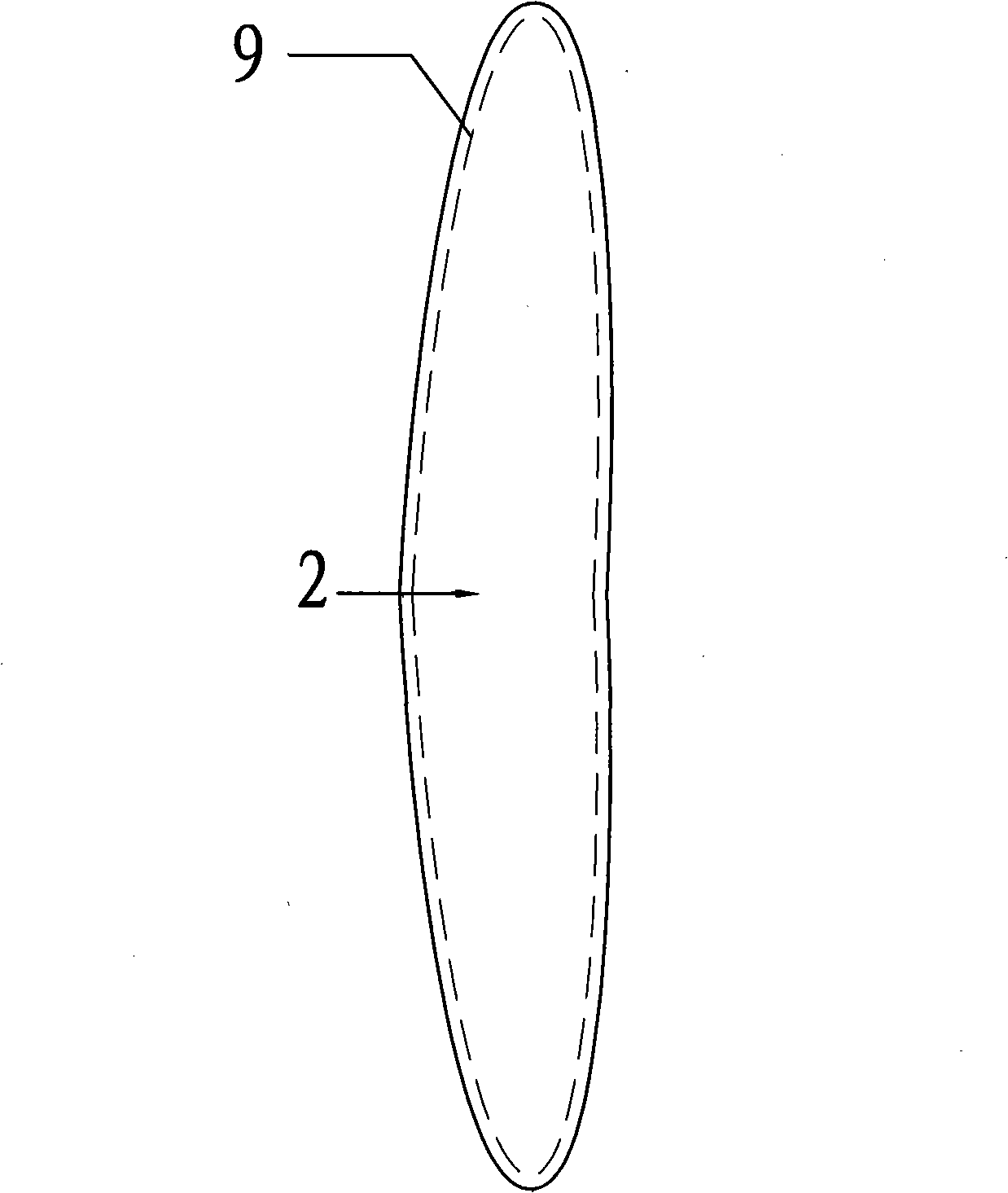

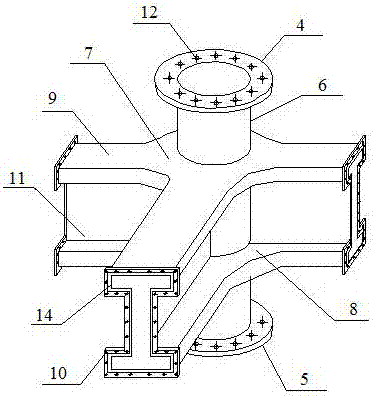

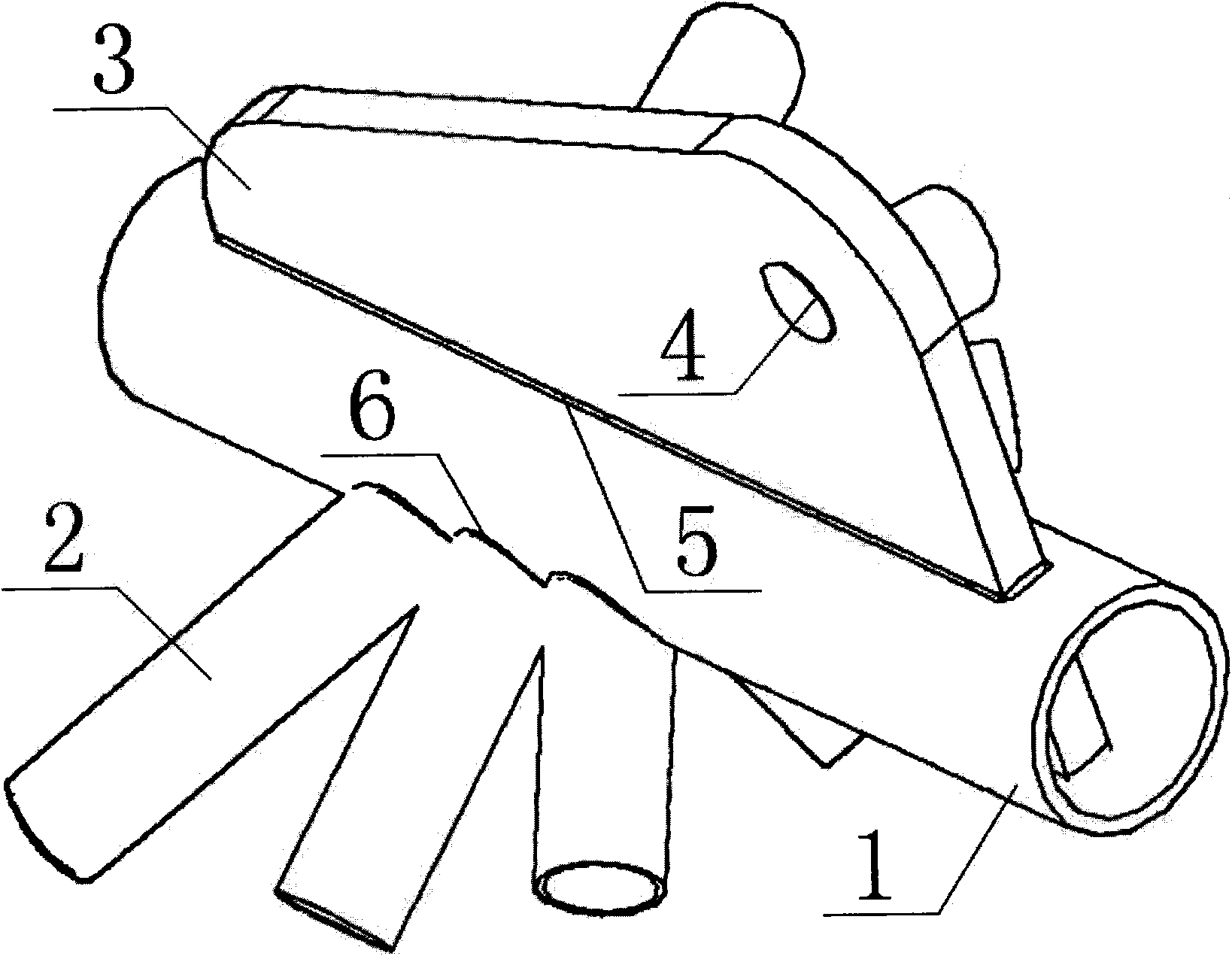

Steel tube concrete diagonal frame column spatial tubular joint and its manufacture method

InactiveCN101260689APower transmission is clearActive connectionBuilding constructionsSteel tubeMaterials science

The invention provides an oblique grid column spatial joint for a concrete-filled steel tube and a manufacture method thereof, wherein, four round steel tubes of the joint are crossed at the position of an oval connecting plate, and welding connections are adopted among the four round steel tubes and between the round steel tubes and the oval connecting plate; a circumferential reinforcing plate consists of at least two annular steel plates, is welded on the four round steel tubes on the welded joint of a central plane; two annular plates parallel to the circumferential reinforcing plate are respectively welded on round steel tubes above and under the circumferential reinforcing plate; stiffener plates are welded between the circumferential reinforcing plate and the annular plates in uniform distribution; and joint extending brackets are welded on the annular plates. The manufacture method of the joint comprises the welding among the round steel tubes and the connecting plate, and the welding of the circumferential reinforcing plate, the annular plates and the stiffener plates. The joint has the advantages of clear force transfer, high bearing capacity, light weight, good performance and convenient construction, can effectively connect an upper oblique grid column and a lower oblique grid column so as to realize the spatial intersection of the joint of the concrete-filled steel tube column, and have excellent engineering application foreground.

Owner:SOUTH CHINA UNIV OF TECH

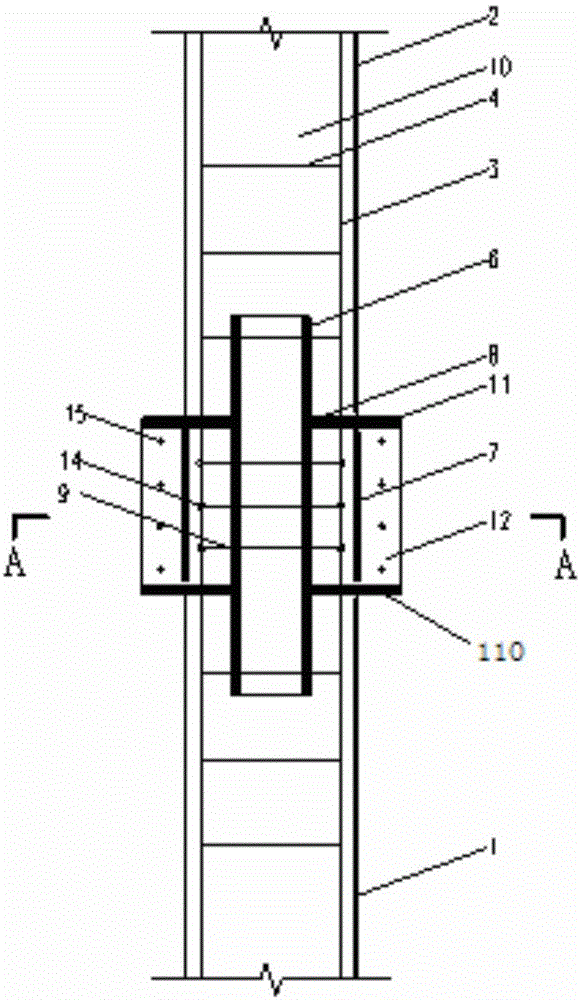

Circular steel tube constraining reinforced concrete-steel beam framework node for nodal-region composite steel tube

InactiveCN105672491AImprove bearing capacityImprove ductilityBuilding constructionsReinforced concrete columnShear capacity

The invention provides a circular steel tube constraining reinforced concrete-steel beam framework node for a nodal-region composite steel tube. The node comprises a first columnar circular steel tube, a second columnar circular steel tube, columnar longitudinal bars, columnar stirrups, a steel beam, a nodal-region inner-layer circular steel tube, a nodal-region outer-layer circular steel tube, outer reinforcing rings, nodal-region stirrups and concrete. The second columnar circular steel tube and the first columnar circular steel tube are located on the upper side and the lower side of the steel beam respectively. The steel beam directly transmits the shear force and the bending moment to the nodal-region inner-layer circular steel tube and then transmits the shear force and the bending moment to the core-region concrete, the condition that the nodal-region outer-layer steel tube directly bears the shear force is avoided to prevent the steel tube from being bent, and therefore the steel tube can fully play an annular constraining role to ensure the bearing capacity and the ductility of the node; the two ends of the nodal-region inner-layer circular steel tube stretch into an upper steel tube constraining reinforced concrete column and a lower steel tube constraining reinforced concrete column by a certain distance respectively, the integrity of the node is guaranteed, and the shear capacity and anti-seismic performance of the node are improved. The node is safe, reliable, good in integrity, clear in force transmission and convenient to construct and has the advantage on force bearing and the economic performance.

Owner:CHONGQING UNIV

Old house reinforcing structure and reinforcing method thereof

ActiveCN103924793ALarge deformationImprove internal space utilizationBuilding repairsFloor slabSheet steel

The invention relates to an old house reinforcing structure and a reinforcing method of the old house reinforcing structure, and belongs to the technical field of seismic hardening. The old house reinforcing structure comprises an original ring beam, an original floor and an original structure column, and further comprises newly-added channel steel, anchored bars, a newly-added rectangular steel plate, a newly-added long flat steel plate support and a steel base plate. The newly-added channel steel is arranged on the two sides of the original ring beam, drilled holes are formed in the original ring beam, the anchored bars are arranged in the drilled holes in a penetrating mode, two ends of the anchored bars are connected with the newly-added channel steel on the two sides respectively, the newly-added rectangular steel plate is arranged at the bottom of the original ring beam, and the contact portion of the newly-added steel plate and the lower edge of the newly-added channel steel is welded. The steel base plate is buried in the position, close to the original structure column, of the ground or the floor, the newly-added long flat steel plate support is welded between the steel base plate and the upper newly-added rectangular steel plate, and the newly-added long flat steel plate support is firmly bonded with the original structure column. The stability and safety of old house wall reconstruction engineering are guaranteed, and the problem that in old factory reconstruction, the original house is not reasonable in layout and poor in seismic resisting performance is solved.

Owner:凯盛建设有限公司

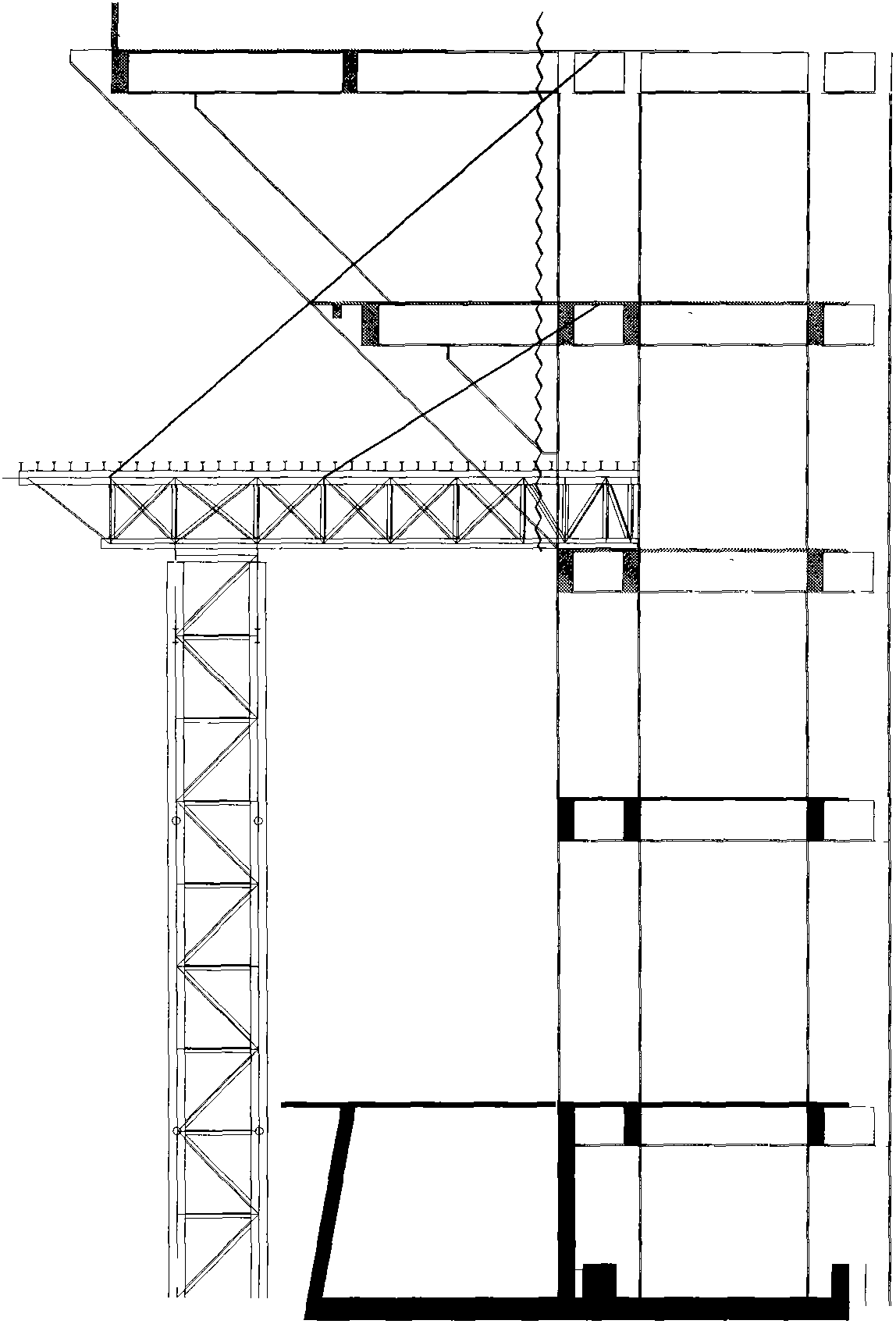

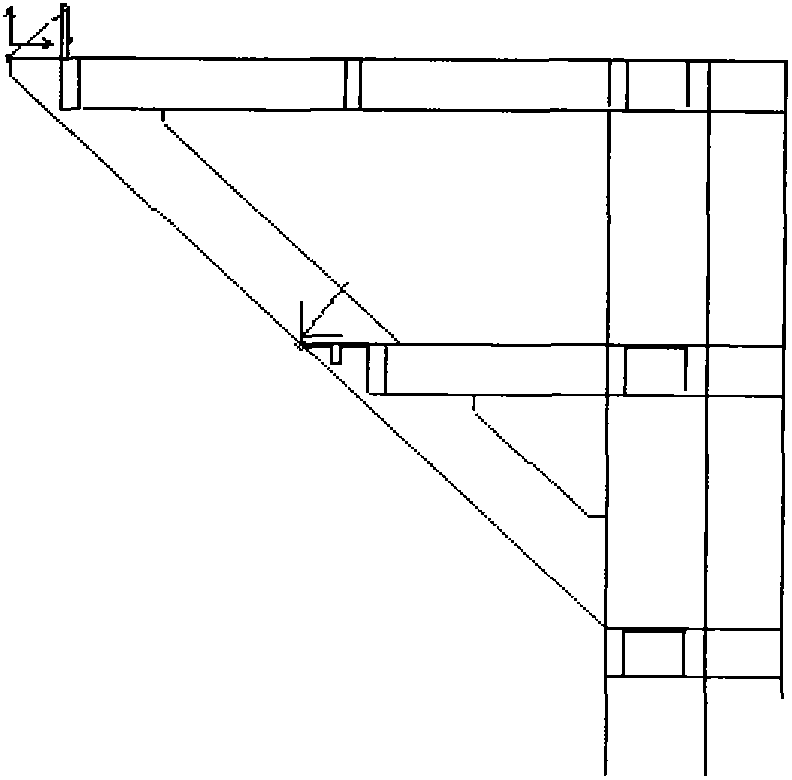

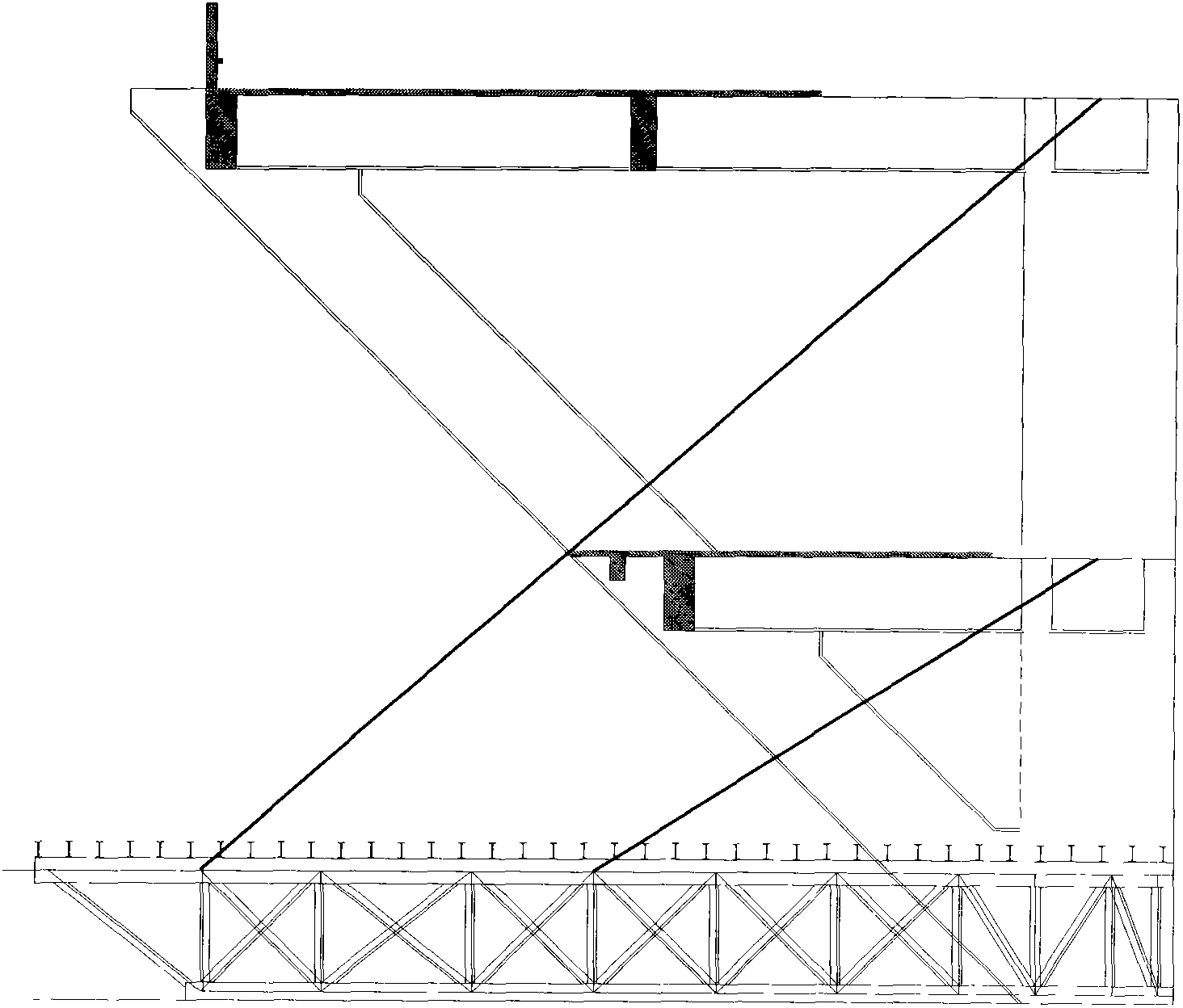

Construction method for 45-DEG-inclined long-overhanging reinforced concrete structure project

ActiveCN102322142AReasonable constructionReasonable forceBuilding material handlingFalseworkReinforced concrete

The invention relates to a construction method for a 45-DEG-inclined long-overhanging reinforced concrete structure project. When the project is constructed, a cable-stayed steel tube tower is combined with a scaffold; for a steel-structure support tower, hanging bars are adopted to resist an overturning force; for an upper-part scaffold, inclined braces are adopted to resist an overturning force; for a steel-structure support tower or an inclined-hauled steel truss with a grounded lower part, the upper part of the steel-structure support tower or the upper part of the inclined-hauled steel truss is assisted by a high support formwork with local full fastener steel tubes. The weak links or the dangerous links in a construction process are sufficiently acknowledged, the stress mechanism in the construction process of the 45-DEG-inclined long-overhanging reinforced concrete structure project is disclosed, and the requirements of economy and rationality and safety and reliability are satisfied through technical analysis, so that the construction method for the 45-DEG-inclined long-overhanging reinforced concrete structure project has the advantages of high technological content, stable structure, safety and reliability, explicit force transmission, rational stress, convenience and fastness for construction, shortened construction period for implementation, capability of prefabricating parts in factories and splicing and assembling in field, low cost and good economical efficiency.

Owner:YONGSHENG CONSTR GRP

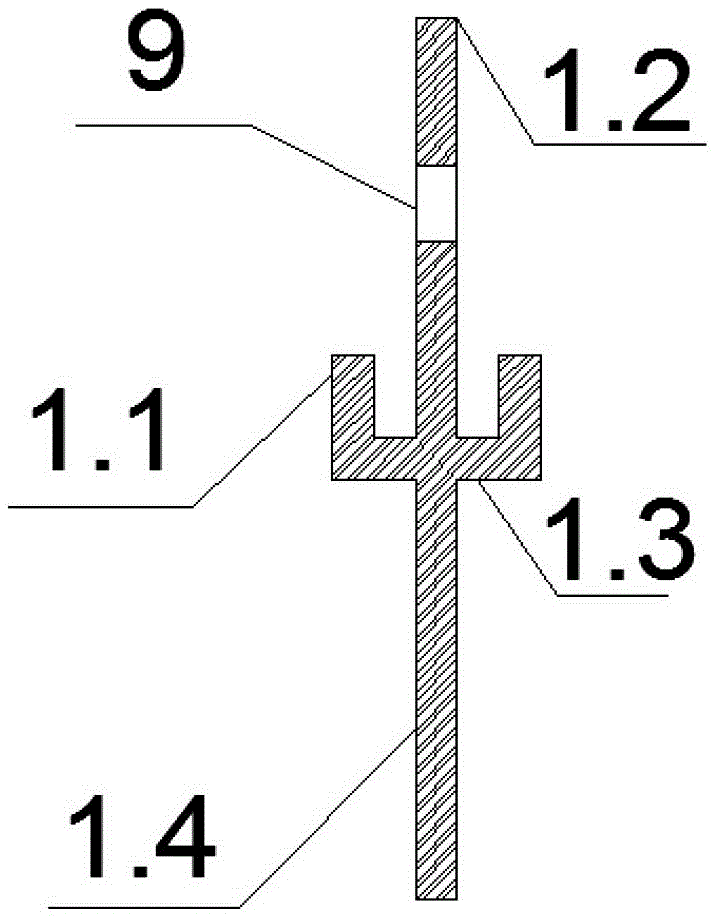

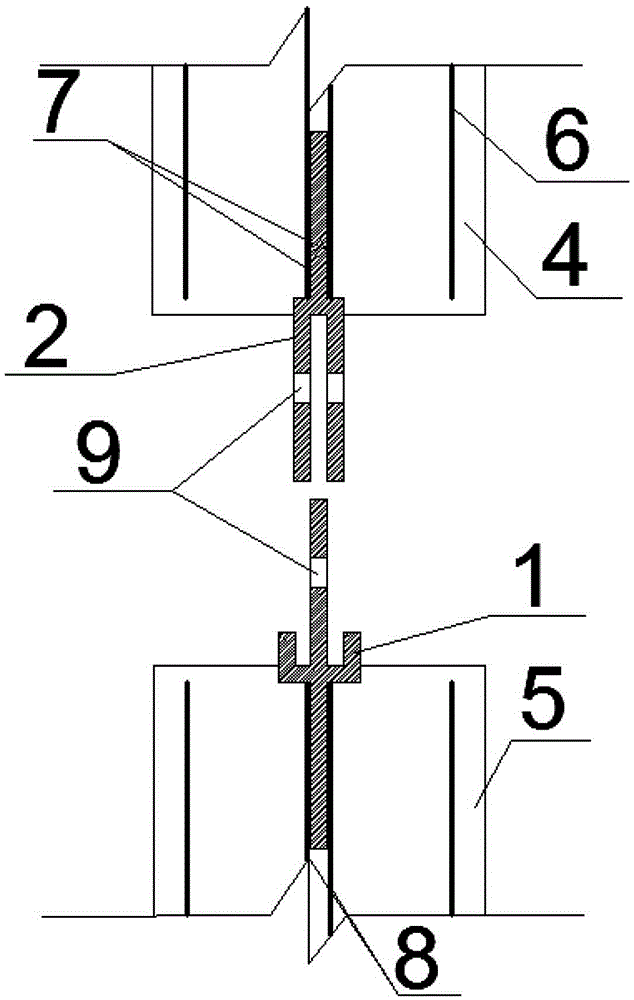

Inserting type steel plate connection structure of prefabricated shearing walls and construction method thereof

ActiveCN106836548AEasy to operateConstruction quality is easy to controlWallsUltimate tensile strengthIndustrial engineering

The invention discloses an inserting type steel plate connection structure of prefabricated shearing walls. The inserting type steel plate connection structure is characterized in that an upper prefabricated shearing wall and a lower prefabricated shearing wall are assembled and connected by connecting components, and concrete is cast behind the joint positions of the upper prefabricated shearing wall and the lower prefabricated shearing wall; the connecting components comprise an epsilon type steel plate part and a Y-shaped steel plate part which are matched in a pairing manner, and the epsilon type steel plate part and the Y-shaped steel plate part are connected in a clamping manner and fastened by fasteners. The inserting type steel plate connection structure disclosed by the invention has the advantages that the two prefabricated shearing walls are assembled on a site by adopting the inserting type steel plate connecting components, and by utilization of a fixing mode with matching of the steel plates and the fasteners, the operation for workers is convenient, the construction quality can be controlled, the installation and the construction are more convenient and faster, and the efficiency is high; by adoption of the epsilon type steel plate part and the Y-shaped steel plate part, not only is steel saved, but also the rigidity and strength of node connection are improved, and the earthquake-proof requirement of strong nodes and weak members is realized; and the connection method adopts matching of clamping connection of special steel plates and fastening connection of high-strength bolts, so that double safety is achieved, the reliable connection and definite force transmission are ensured, and the connecting strength and the connecting effect are guaranteed.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Transverse tunnel cover method for shallow-buried underground excavation large underground space construction

ActiveCN104863597AReduce spanMany working surfacesUnderground chambersTunnel liningSpatial structureGround settlement

The invention discloses a transverse tunnel cover method for shallow-buried underground excavation large underground space construction. Foundation pits or pilot tunnels are formed, in the longitudinal direction of underground space, of the tops of side walls of the underground space to be constructed, temporary transverse stress structures are formed inside the foundation pits or the pilot tunnels at a time and located above a top plate of the underground space to be constructed and are controllable in rigidity, the temporary transverse stress structures are connected with piles inside the foundation pits or the pilot tunnels to form a temporary transverse top cover-pile bearing system, and under protection of the transverse top cover-pile bearing system, a single-span or multi-span and a single-layer or multi-layer underground space structure can be constructed in a sequential construction mode or in an inverse construction mode. In shallow-buried underground excavation large underground space structure construction, ground settlement is effectively controlled, constructed building deformation is reduced, the construction risks are reduced, the construction period is shortened, and the construction cost is lowered.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST +1

End plate type steel pipe concrete column-steel beam connection node

The invention relates to an end plate steel tube concrete post-steel beam connecting node, wherein said node is new beam post connecting node, whose cylinder section shape comprises round, square and rectangle; the section shape of steel beam comprises H and I shapes; the end part of steel beam is mounted on the end plate; when constructing the node, directly inserting one-way locking bolt into the steel tube post wall and end plate hole; the head of bolt has self support function; forming rivet head at the inner side of steel tube; at last, pouring concrete into steel tube post, to form said inventive node. The inventive node has better bearing function and anti-vibration property, with simple structure, simple operation, and easy installment.

Owner:华北建设集团有限公司

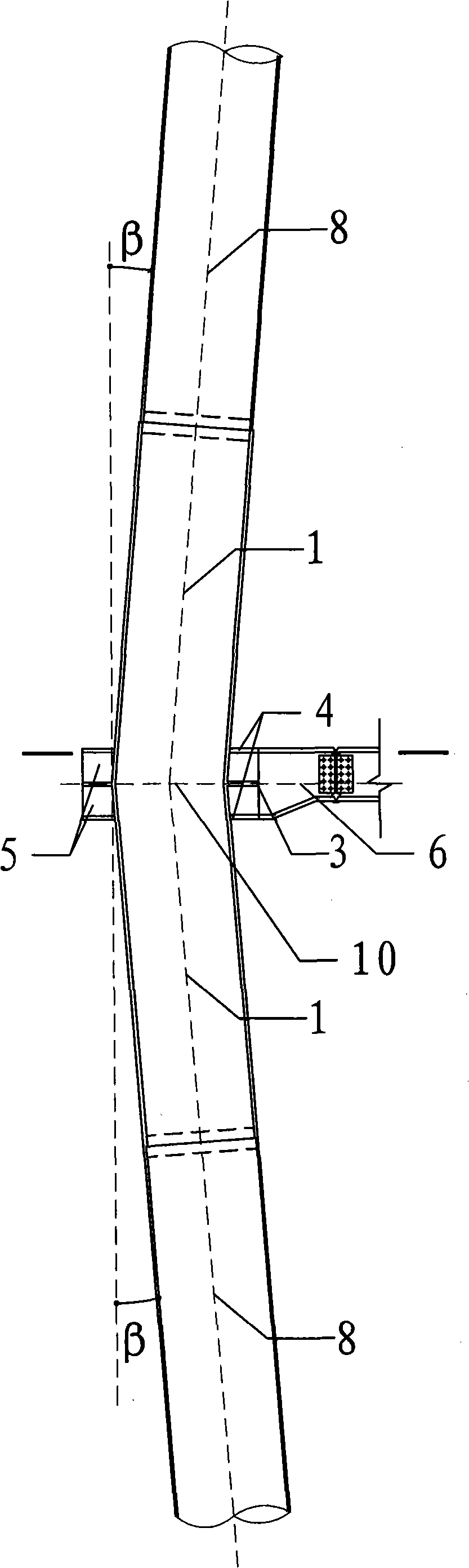

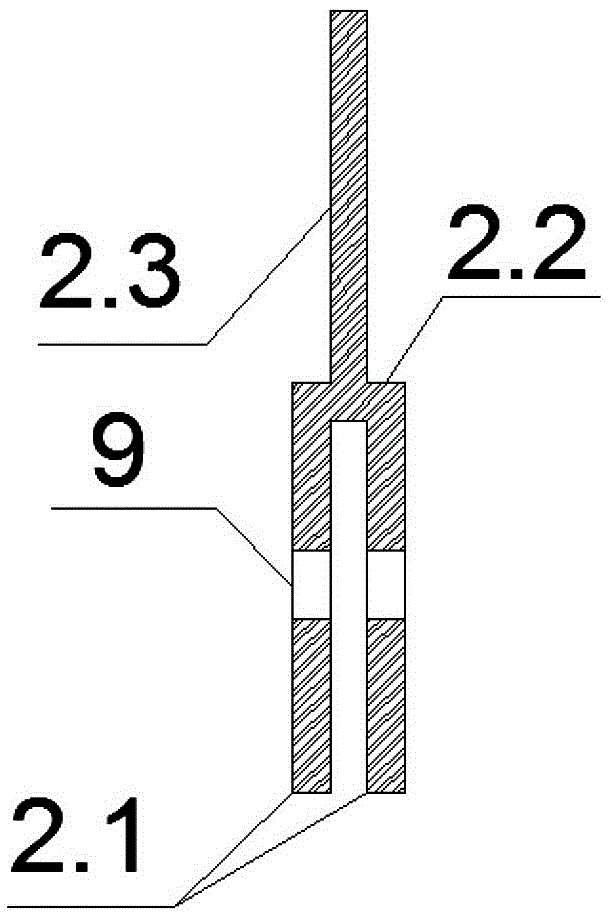

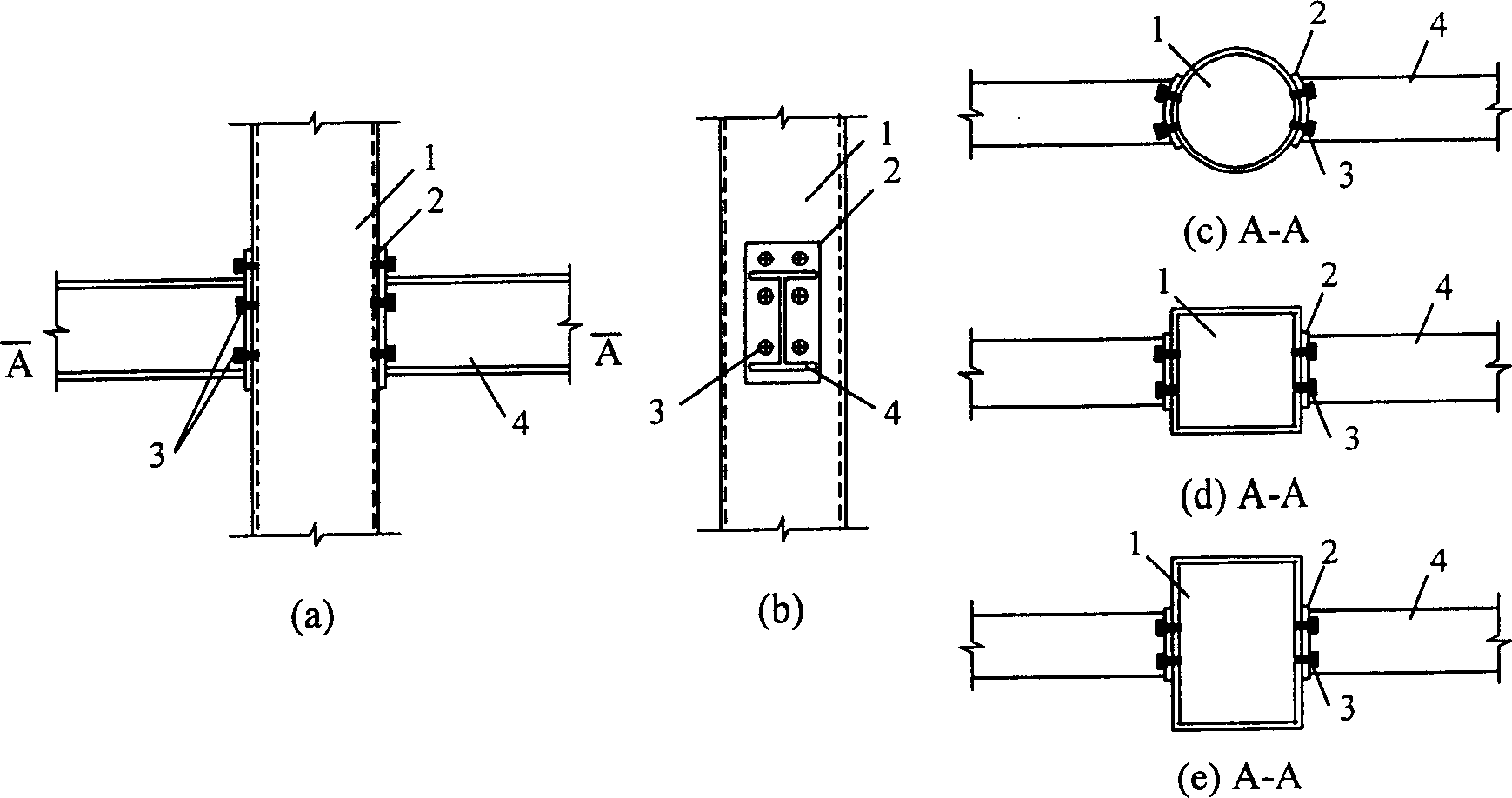

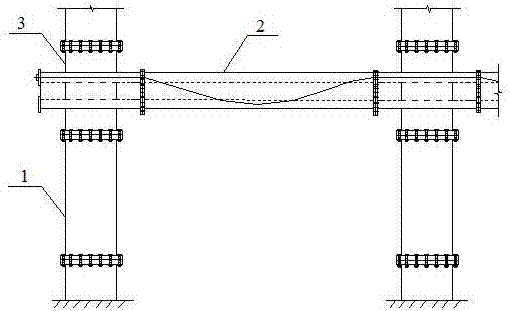

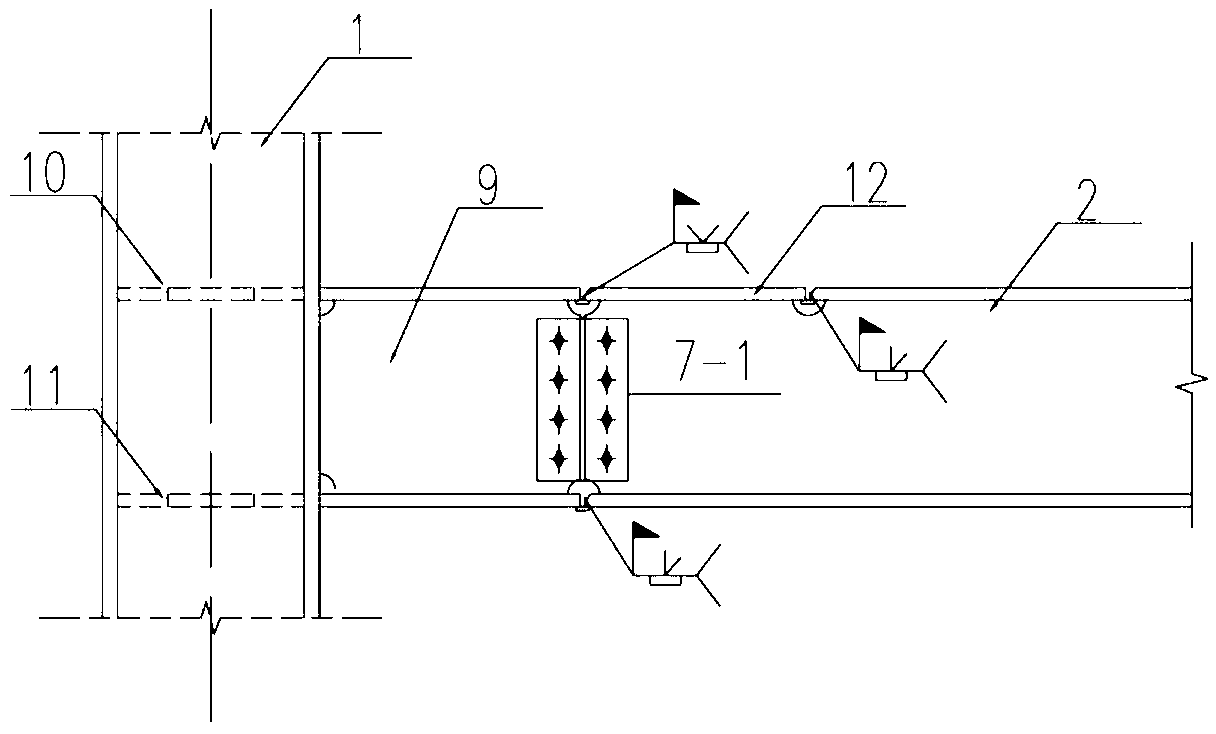

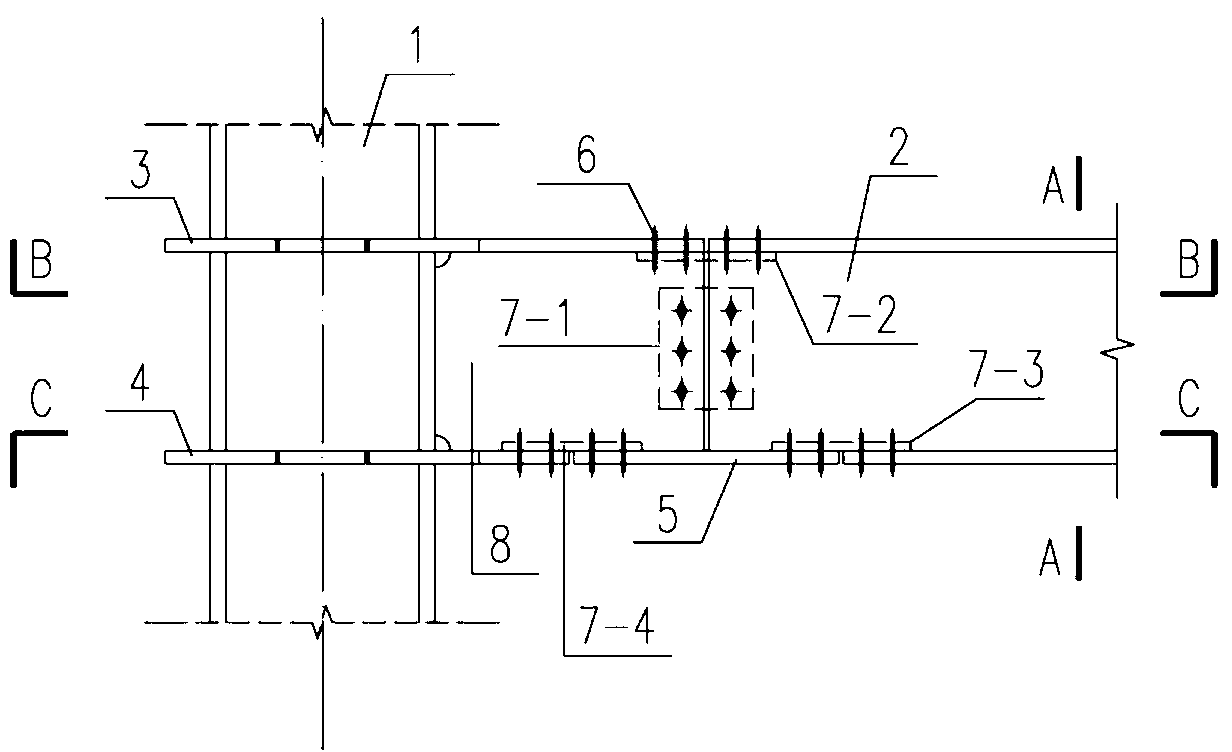

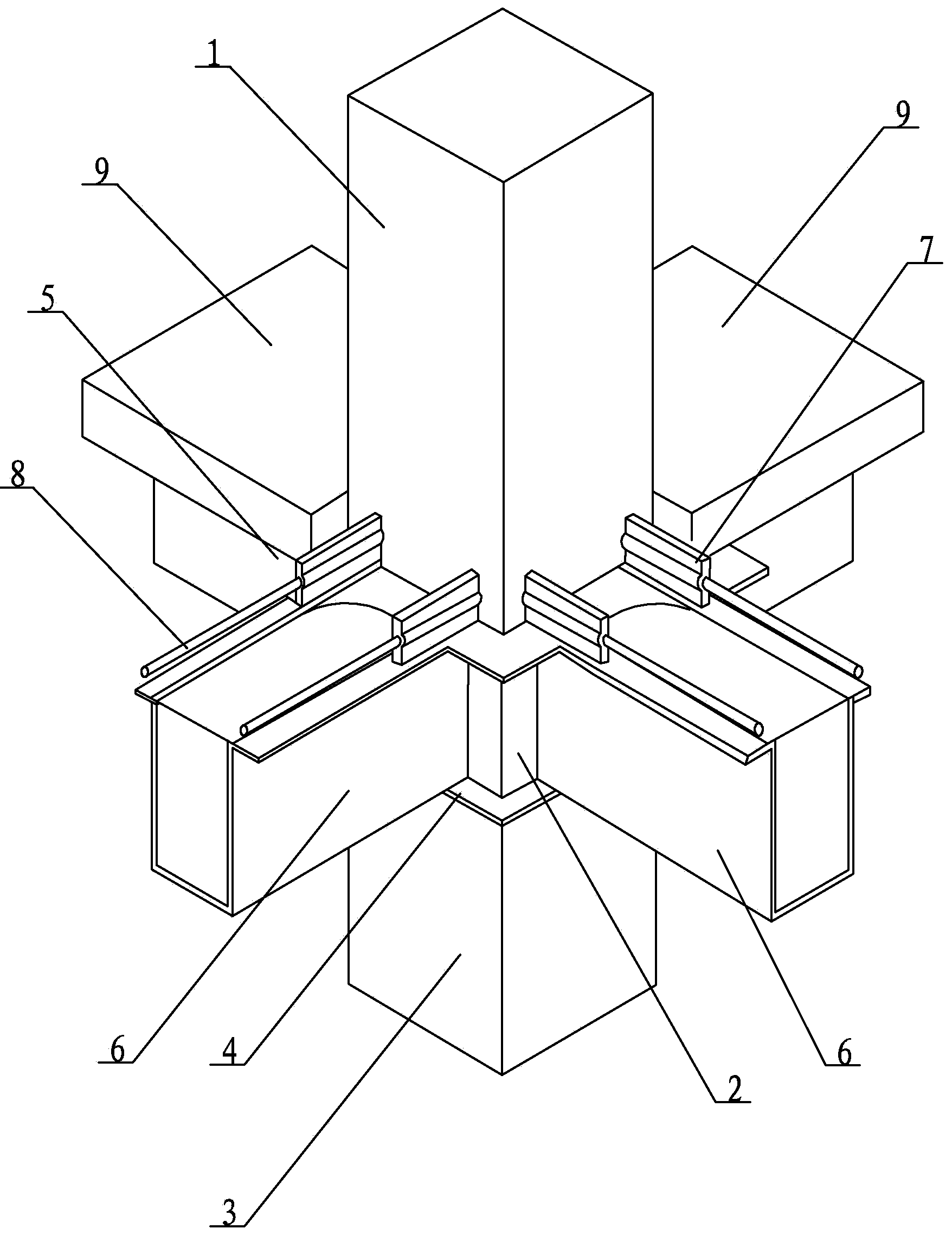

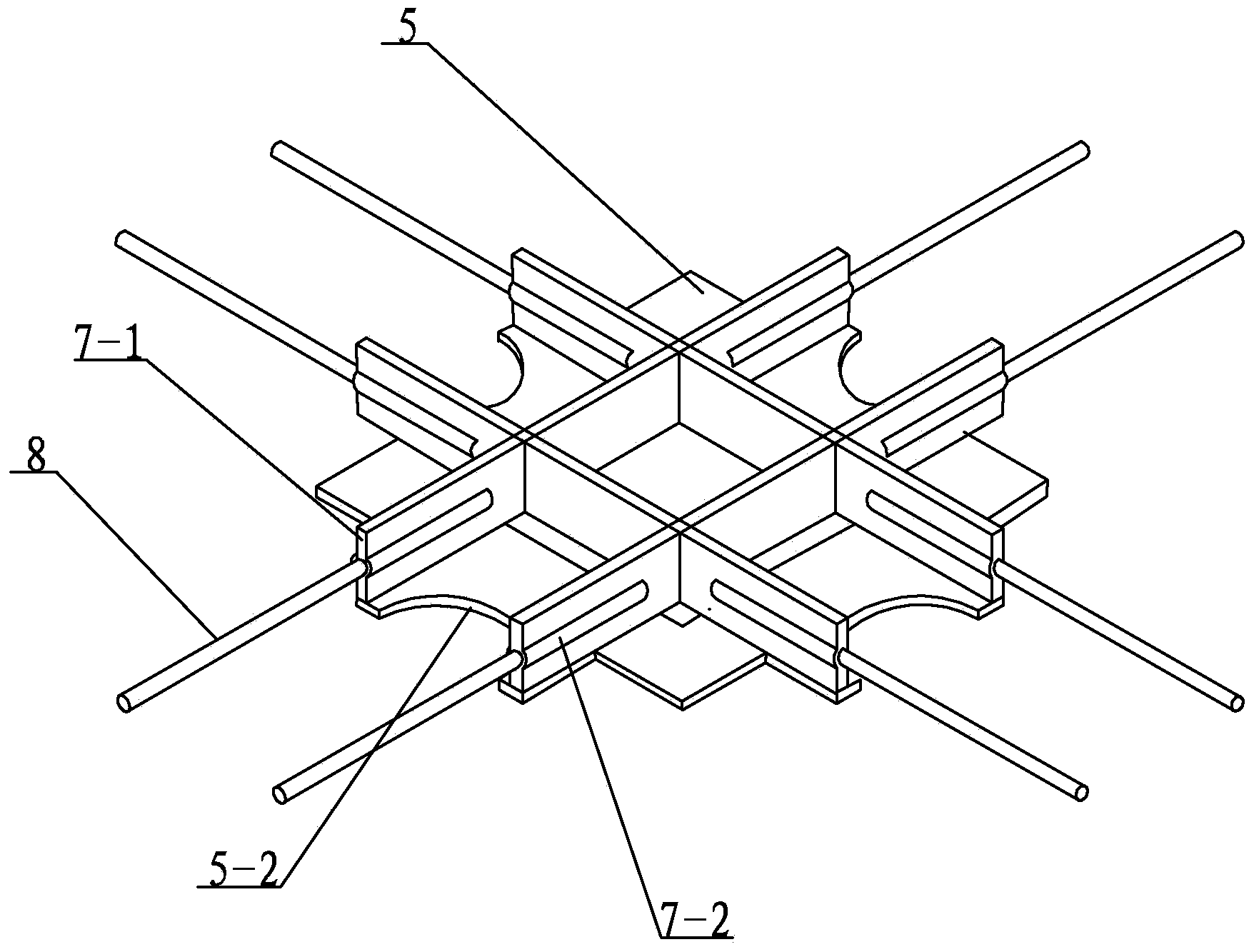

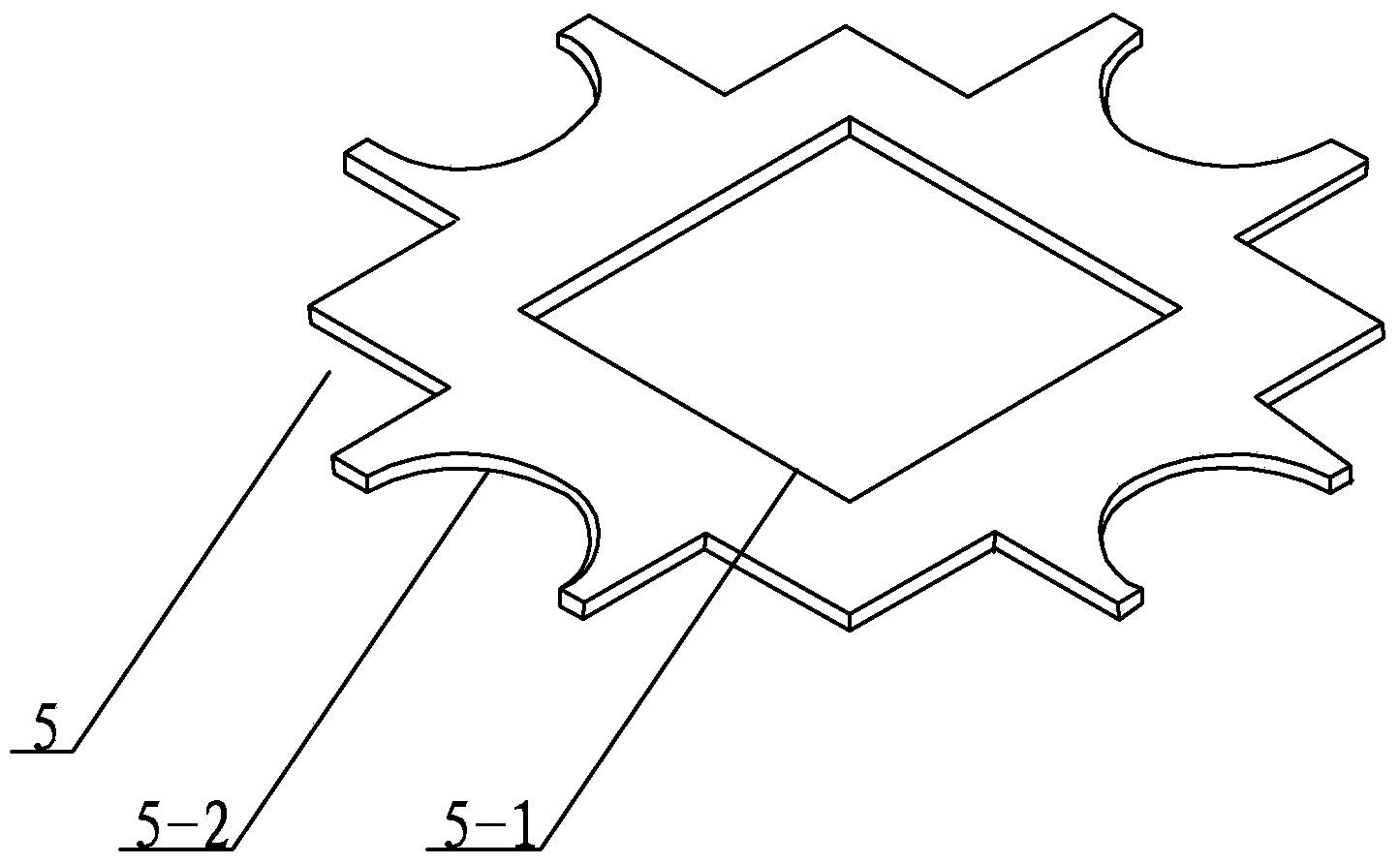

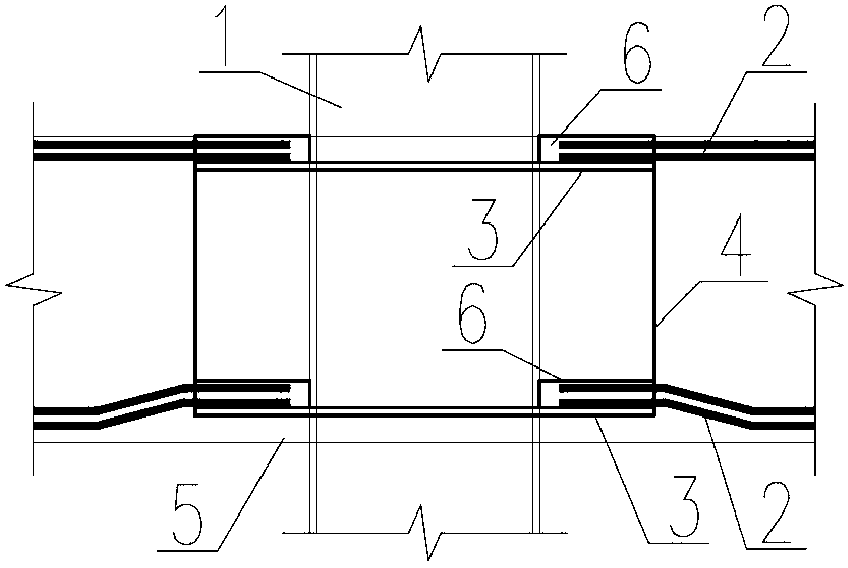

Steel pipe concrete frame with prestressing tendons and construction method thereof

ActiveCN106869315APower transmission is clearAccurate connectionLoad-supporting elementsCurve shapePre stress

The invention relates to a steel pipe concrete frame with prestressing tendons and a construction method thereof. The steel pipe concrete frame with the prestressing tendons is formed by connecting composite columns with composite beams through joints. The composite beams are horizontally arranged among the composite columns. The joints are outer sleeving integral type joints internally filled with self-compacting concrete. The composite columns are sectional-type steel pipe concrete composite columns with built-in profile steel. The composite beams are internal-prestress I-shaped steel pipe concrete composite beams. The prestressing tendons arranged in the composite beams bypass joint outer pipes from upper strengthening annular plates with cavities. The prestressing tendons are positioned through single-hole positioning plates and hole-formed double-hole main positioning plates, form symmetrical curve shapes and achieve tensioning and anchoring at joint end beams. The self-compacting fine stone concrete of the composite beams and self-compacting fine stone concrete of the joint end beams are through and form a whole with the joint outer pipes after curing. The problem that beam-column connecting joints of a novel steel pipe concrete frame with prestressing tendons are complex and liable to damage is solved.

Owner:广西万纵建设工程有限公司

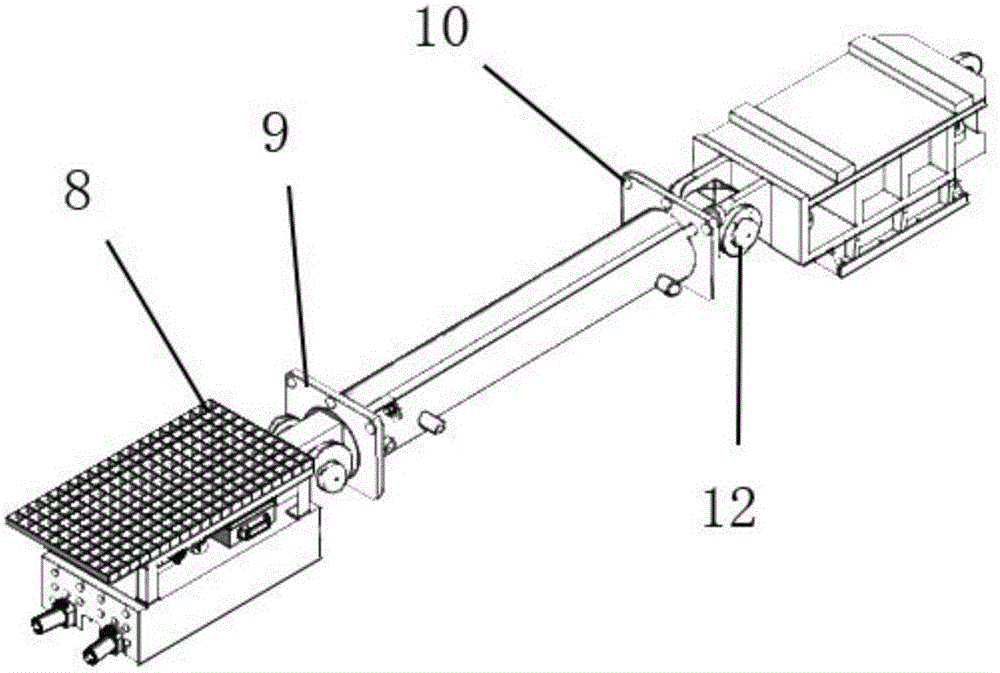

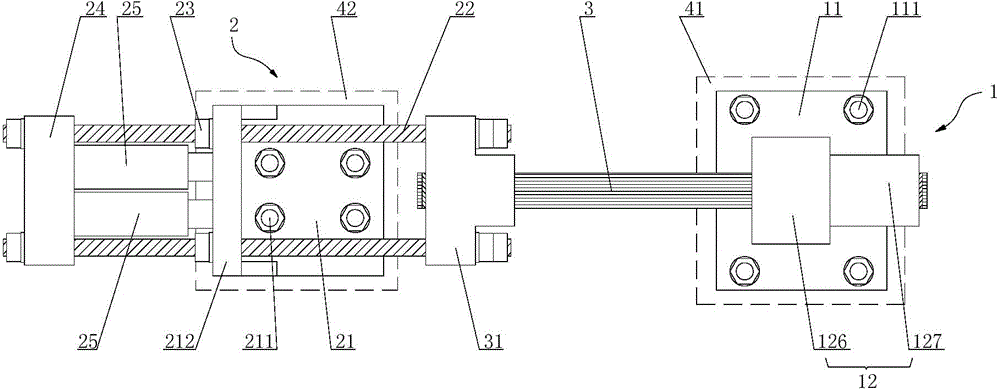

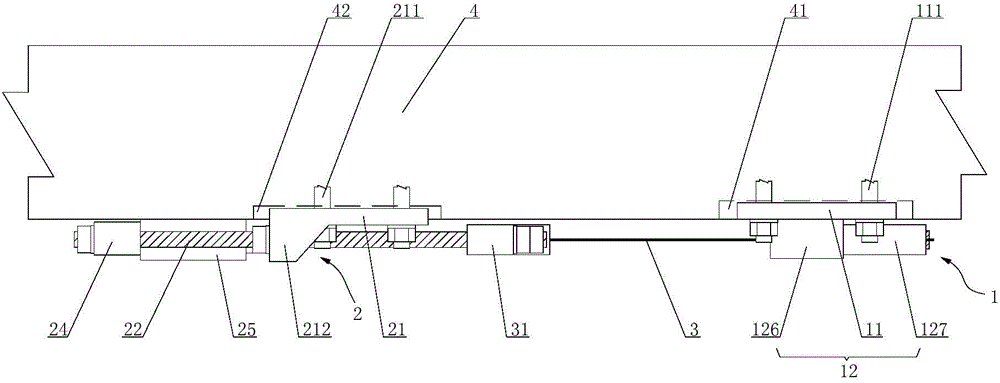

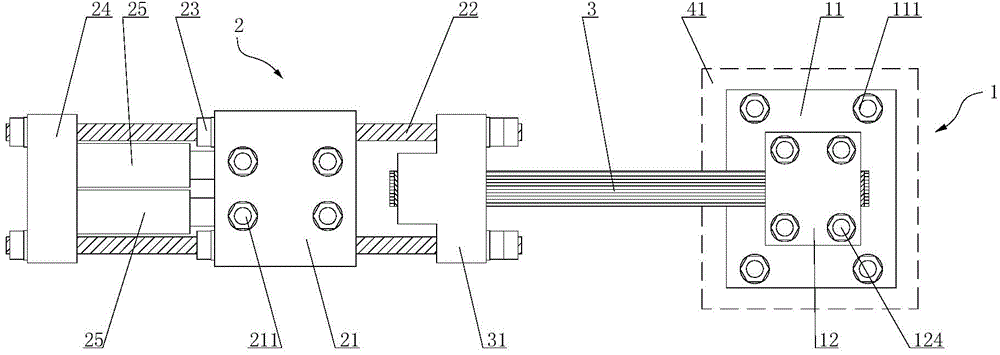

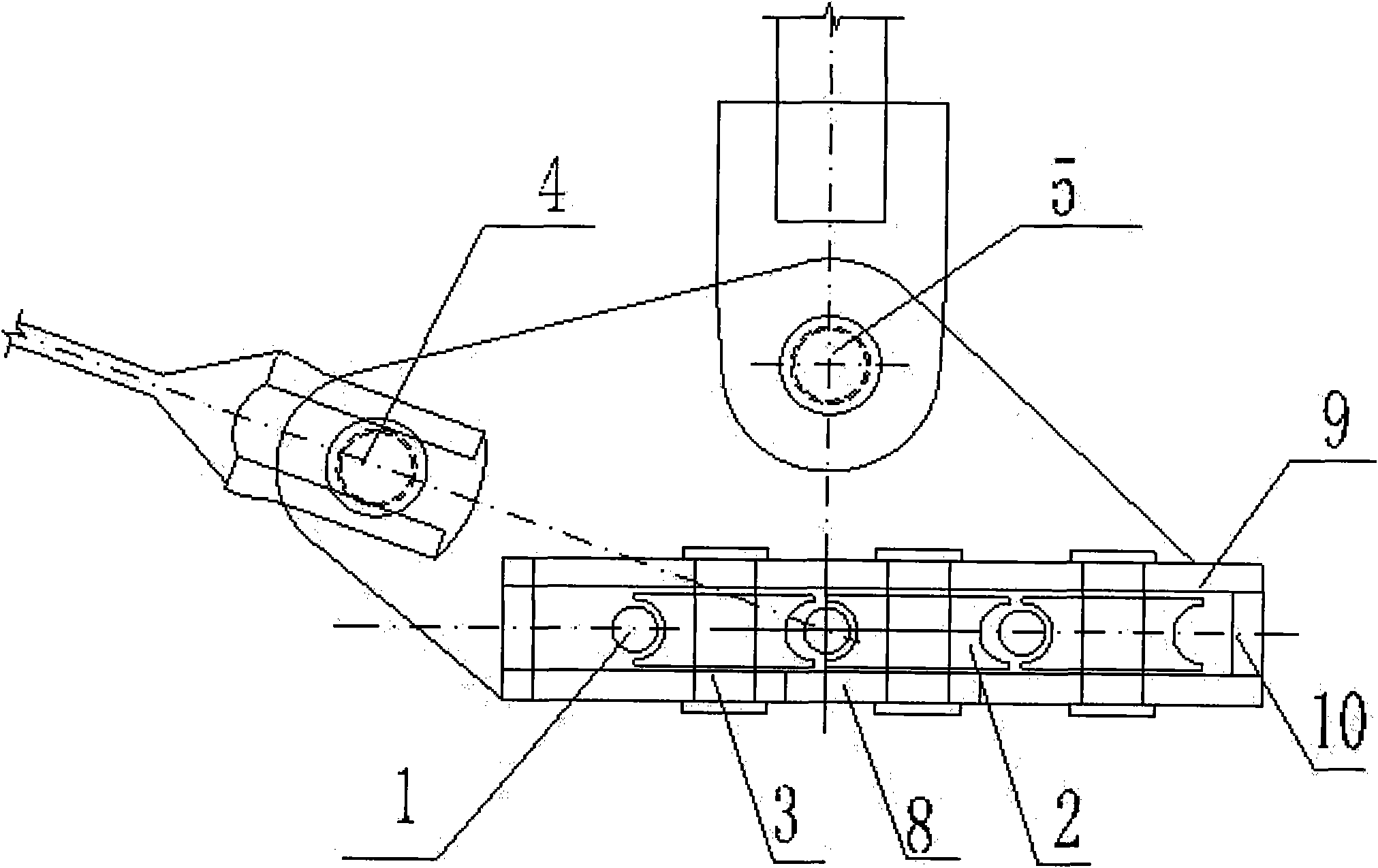

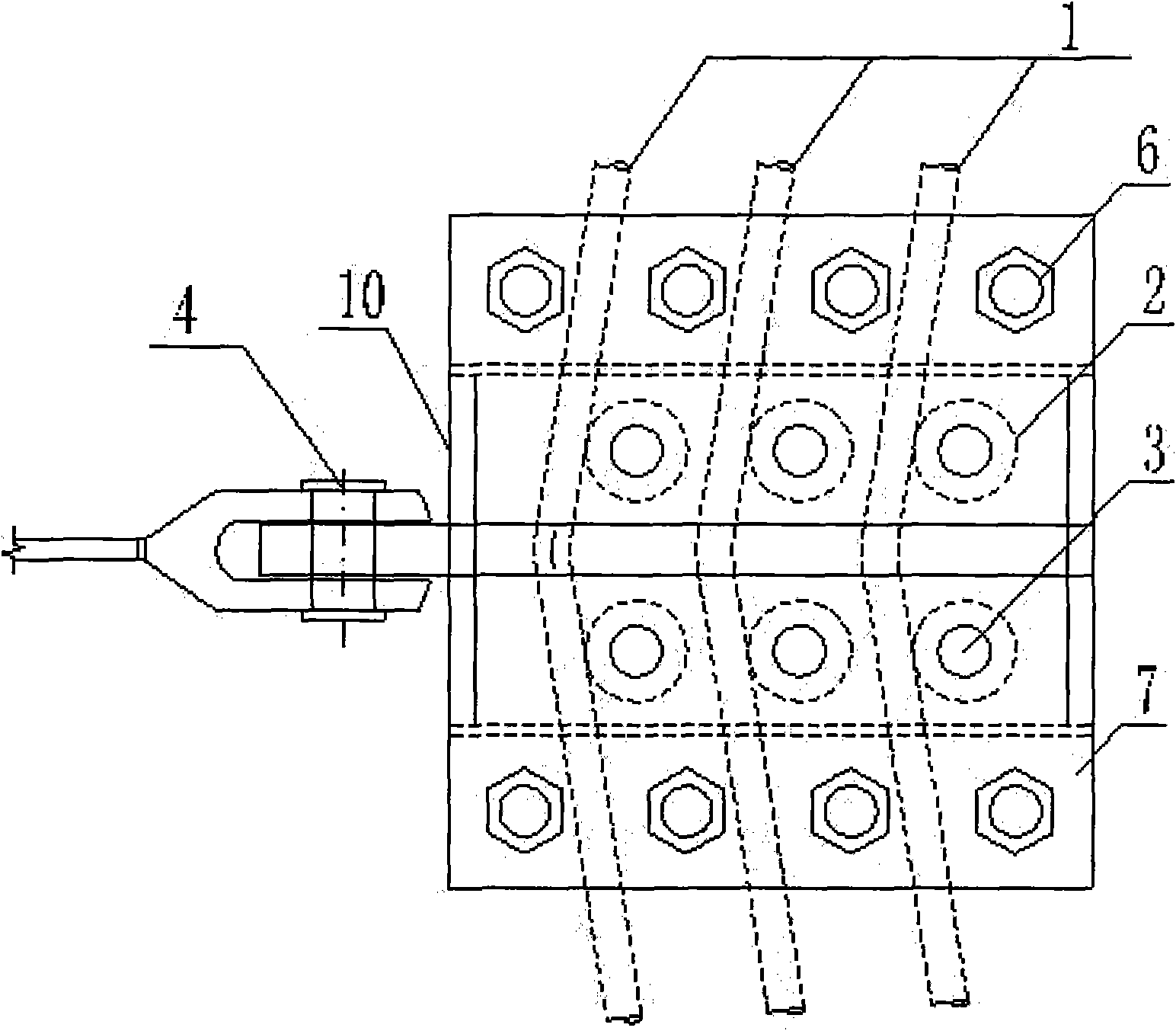

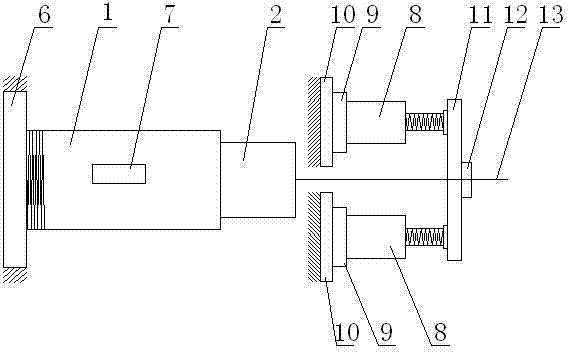

Tensioned anchorage device and using method of tensioned anchorage device

InactiveCN104153584AReduce distanceEasy to paste and fixBuilding reinforcementsBuilding material handlingEngineeringFiber

The invention provides a tensioned anchorage device and a using method of the tensioned anchorage device. The tensioned anchorage device comprises a fixed end structure, a tensioned end structure and a fiber plate, wherein the fixed end structure is provided with a fixed end anchorage base, and a fixed end fixture is connected to the fixed end anchorage base; the tensioned end structure is provided with a tensioned end anchorage base, two tensioned rods are arranged on the tensioned end anchorage base in a penetrated mode, the ends, far away from the fixed end structure, of the two tensioned rods are connected with a locking nut and a rear counter-force plate, the locking nut abuts against the tensioned end anchorage base, and a plurality of jacks are arranged between the rear counter-force plate and the tensioned end anchorage base side by side; one end of the fiber plate is connected with a tensioned end fixture, the other end of the fiber plate is connected with the fixed end fixture, and the tensioned end fixture is connected with the ends, close to the fixed end structure, of the two tensioned rods. By means of the tensioned anchorage device and the using method of the tensioned anchorage device, reliable connection between the fiber plate and a structural object can be achieved, the tensioned uniformity of the fiber plate is guaranteed, the tensioned anchorage device is small in size, flexible in arrangement and rapid and convenient to construct.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Node of steel tube concrete pole and steel reinforced concrete beam and processing method thereof

InactiveCN100999913AMeet buildingFulfil requirementsBuilding constructionsReinforced concreteSteel bar

The present invention discloses one kind of node structure for steel core concrete column and reinforced concrete beam and its forming process. The node structure includes feed-through bracket penetrating through and welded to steel pipe, ring rib welded to steel bracket outside the steel pipe, plate radial rib bent and hooked to the ring rib and main spiral rib sleeve welded to the end of the steel bracket. The forming process of the node structure includes calculating size of steel bracket, determining radial rib number and diameter and ring rib diameter, welding in plant, in-site tying of steel bars, and pouring concrete. The node structure has determined force transfer, capacity of controlling the crack development effectively, convenient construction and excellent engineering application foreground.

Owner:SOUTH CHINA UNIV OF TECH

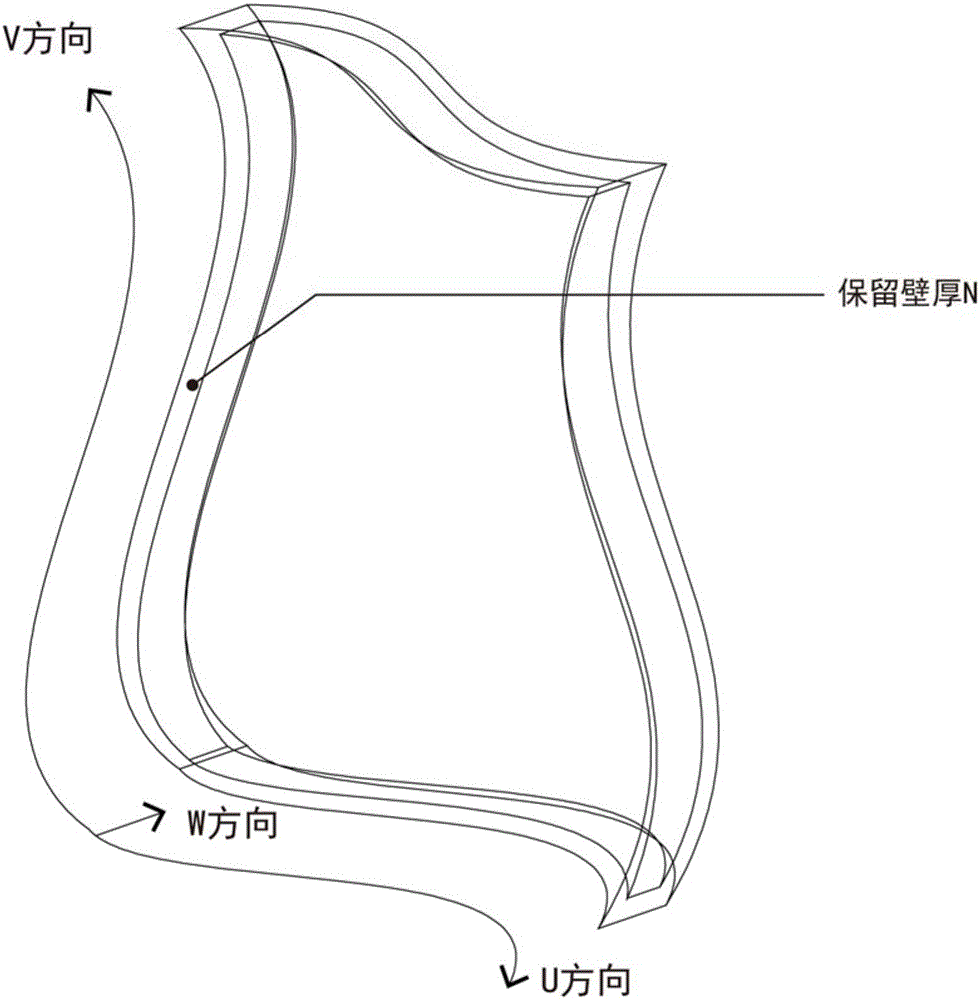

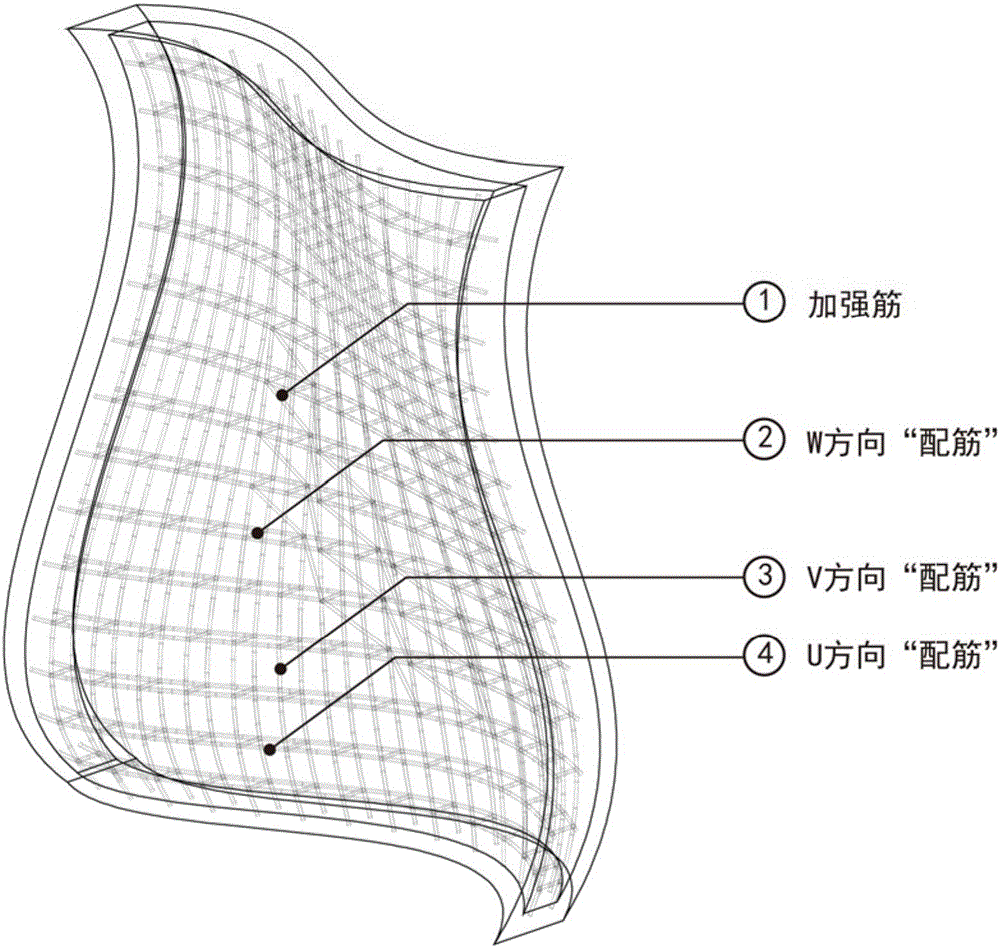

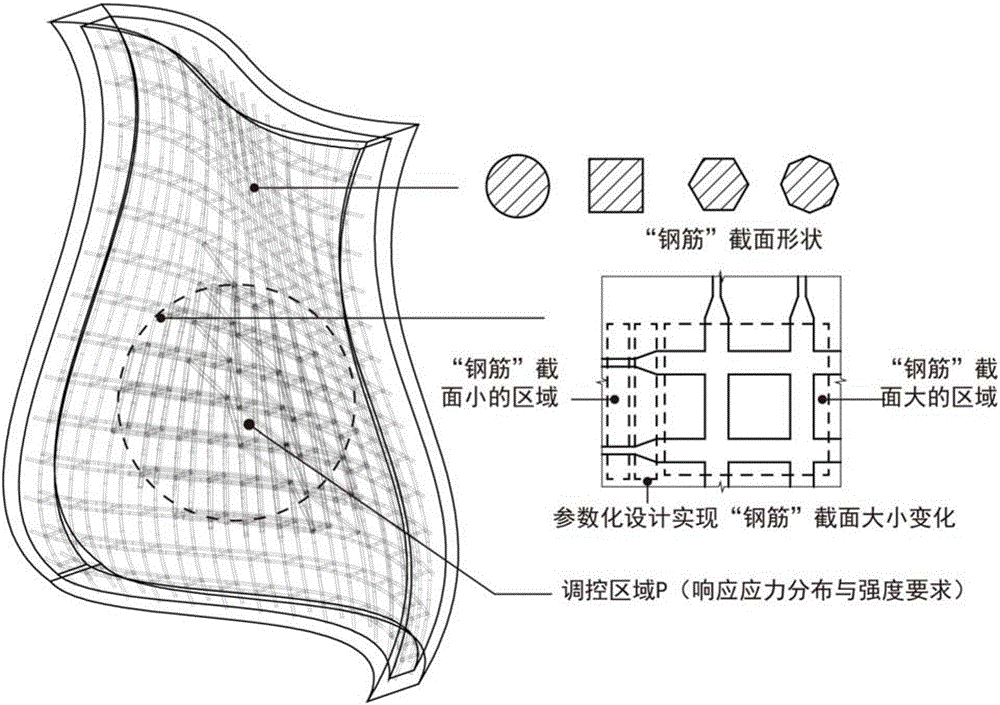

3d printing process and concrete combined building structure and construction method

The invention discloses a 3d (three-dimensional) printing process and concrete combined building structure and a construction method. The construction method comprises the following steps: 1) constructing a digital model of a shell and an internal structure of a building component; 2) performing 3d printing operation on the digital model; 3) pouring concrete to form an integrated structural component with the model which is printed in the step 2), and performing cooperative work; 4) after the building component in the step 3) is formed integrally, deciding whether to remove the shell of the 3d printing model according to engineering requirement, wherein the bare material of the concrete can be used as a model element. According to the 3d printing process and concrete combined building structure and the construction method, the problem that reinforcing steel bars are difficult to manufacture in special-shaped curved surface reinforced concrete construction can be effectively solved; force is transferred explicitly; construction components are reduced; construction processes are simplified; construction cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

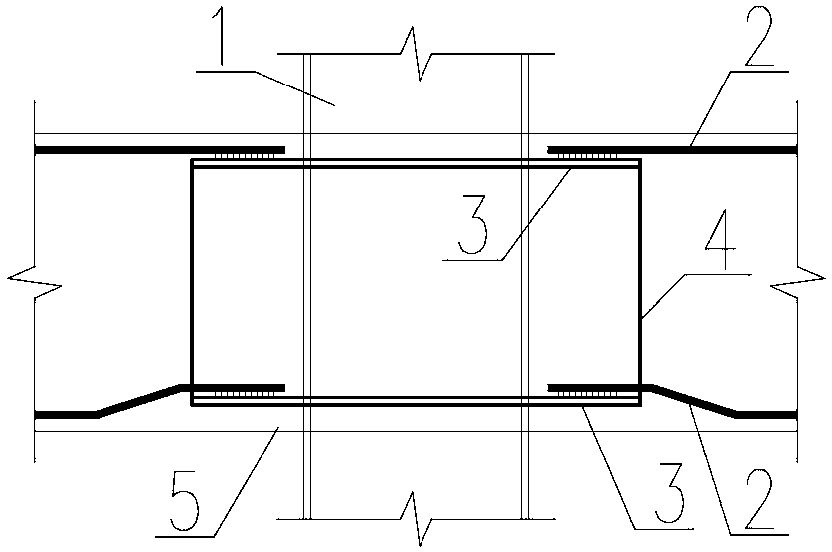

Concrete-filled rectangular steel tube column-box girder full-bolt connection node and construction method

ActiveCN102995756AAvoid weakeningMeet the seismic requirementsBuilding constructionsBox girderSteel tube

The invention belongs to the technical field of building structure engineering, and relates to a concrete-filled rectangular steel tube column-box girder full-bolt connection node. The concrete-filled rectangular steel tube column-box girder full-bolt connection node comprises a concrete-filled rectangular steel tube column, a box girder, an upper run-through clapboard, a lower run-through clapboard, a lower cover plate, a plurality of high-strength bolts, a plurality of connection plates and two shear plates. The upper run-through clapboard and the lower run-through clapboard penetrate through a concrete-filled rectangular steel tube column wall and are welded with the surrounding of the steel tube column wall of the concrete-filled rectangular steel tube column; the two webs of the box girder are welded together with the groove of the concrete-filled rectangular steel tube column via one shear plate respectively; the upper flange of the box girder is connected with the upper run-through clapboard by the high-strength bolts via the connection plates arranged in the box girder; the two webs of the box girder and the two shear plates are connected by the high-strength bolts via the connection plates arranged in the box girder respectively; and one end of the lower cover plate is connected with the lower flange of the box girder via the connection plate, and the other end of the lower cover plate is connected with the lower flange of the lower run-through clapboard via the connection plate. The invention provides a construction method for the node aforementioned simultaneously. The node and the construction method disclosed by the invention have the advantages of being convenient, fast, and easy to realize.

Owner:TIANJIN UNIV

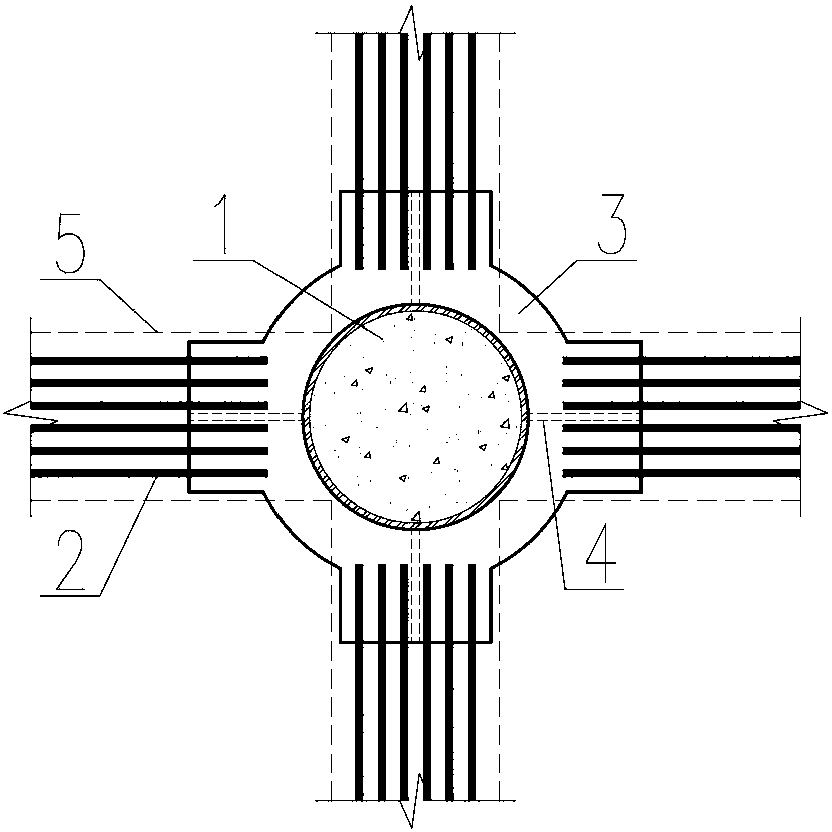

Node assembly of U-shaped steel-concrete composite beam and rectangular steel tube concrete column

ActiveCN103821235APower transmission is clearGuarantee the pouring qualityBuilding constructionsChinese charactersSteel bar

The invention provides a node assembly of a U-shaped steel-concrete composite beam and a rectangular steel tube concrete column, and relates to a node assembly of a steel tube concrete column. The node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column solves the problem that an existing node connection mode is unreasonable, the bearing capability of a node is too low, the ductility and energy-dissipating capacity of the core region of the node is insufficient, and therefore the node is damaged before other component. According to the node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column, a first rectangular steel tube, a second rectangular steel tube and a third rectangular steel tube are sequentially arranged from top to bottom, a node region inside partition plate is fixedly arranged between the second rectangular steel tube and the third rectangular steel tube, a node region reinforcing ring is fixedly arranged between the first rectangular steel tube and the second rectangular steel tube, four U-shaped steel beams are evenly distributed on four outer end faces of the second rectangular steel tube, a plurality of node region inserting plates are arranged on the node region reinforcing ring in the shape like a Chinese character 'jing', a steel bar is inserted in each node region inserting plate, and concrete is poured into the interior and the upper portion of each U-shaped steel beam. The node assembly of the U-shaped steel-concrete composite beam and the rectangular steel tube concrete column is used in constructional engineering.

Owner:JIANGSU ZHONGBAO STEEL STRUCTURE

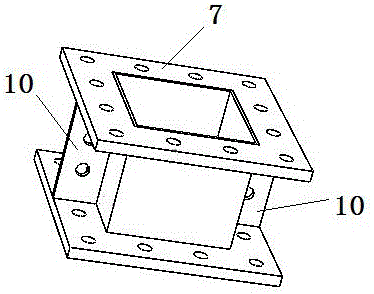

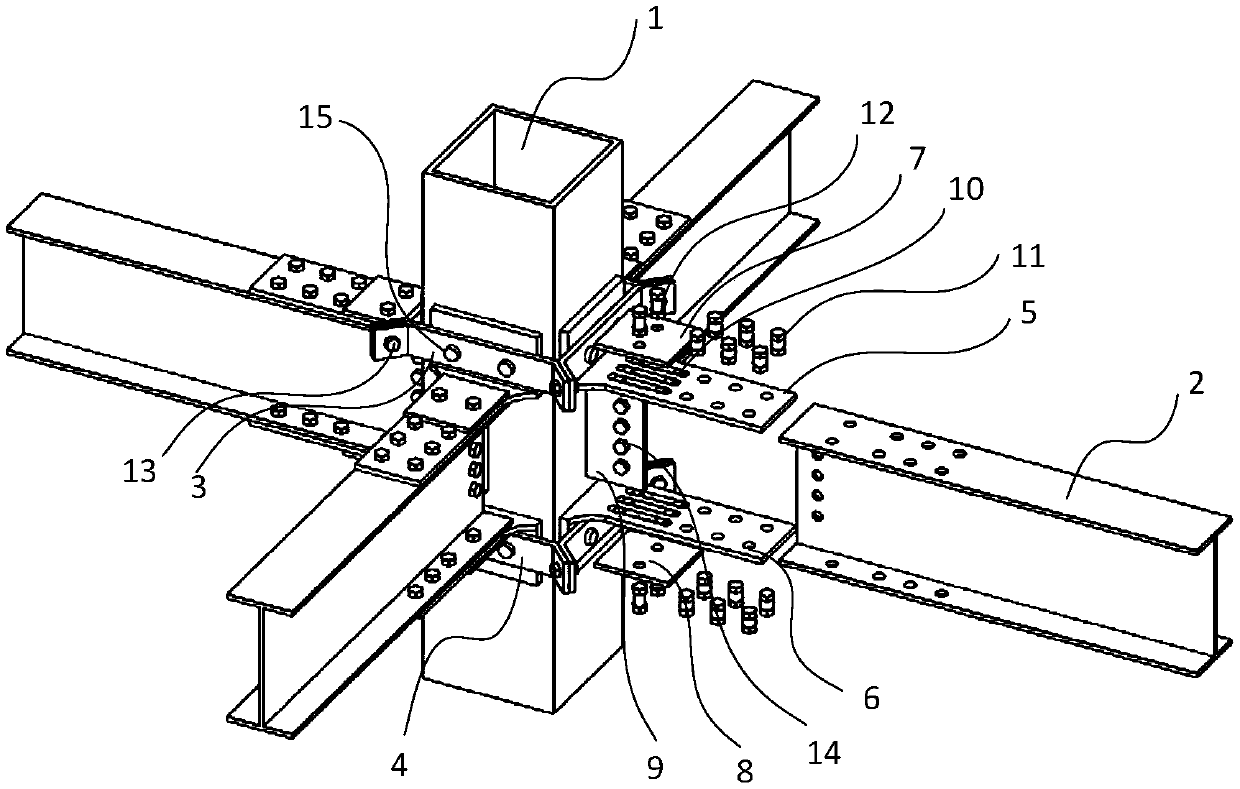

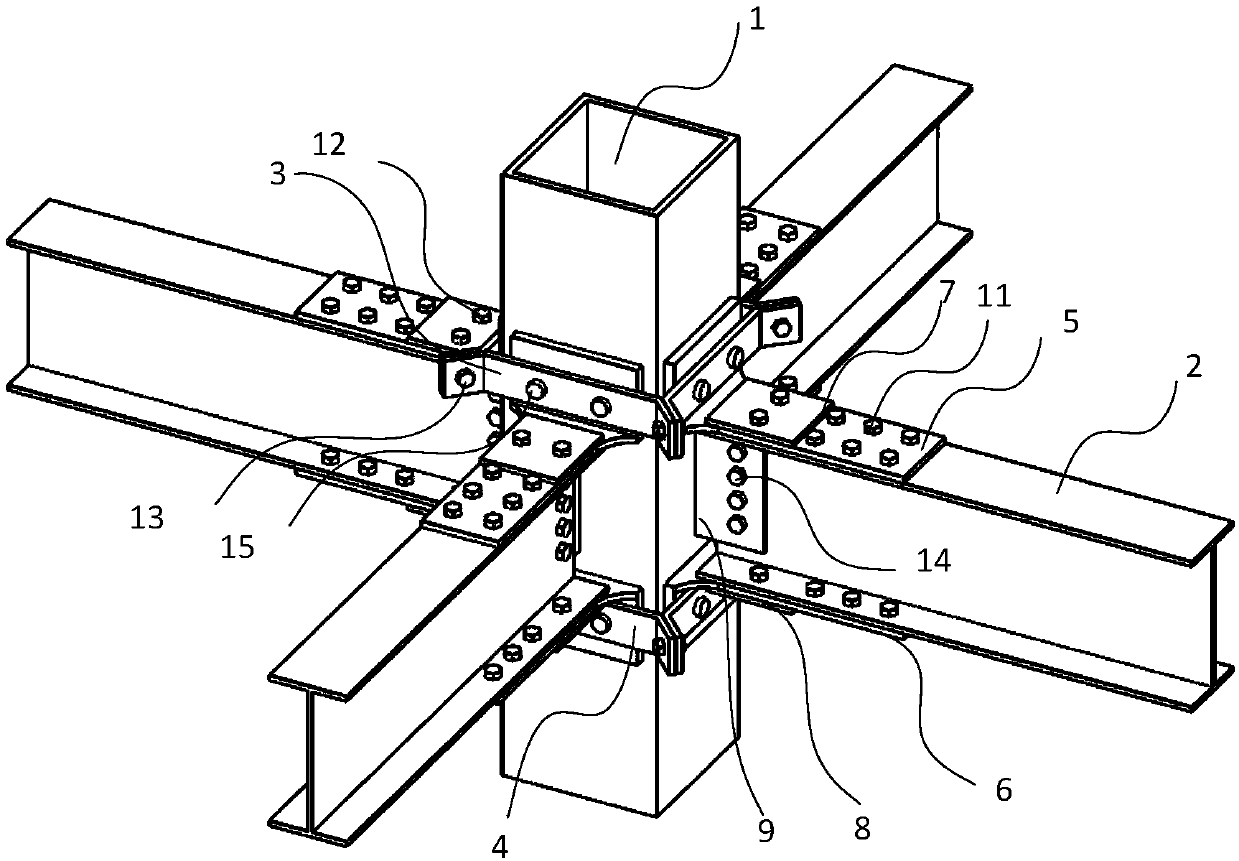

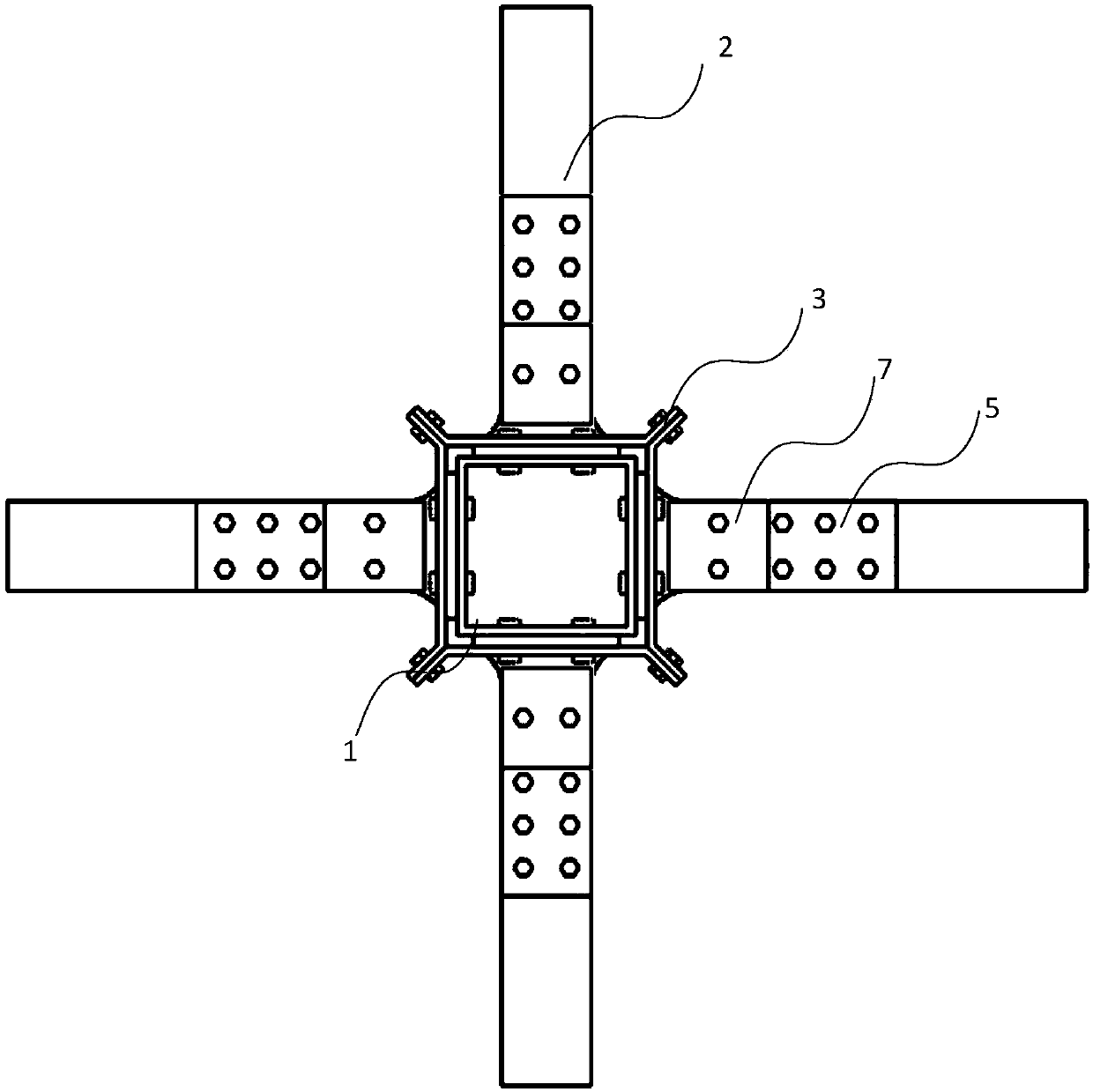

Replaceable energy consumption connecting node of assembly-type rectangular steel pipe column-H-type steel beam

PendingCN109537725AVarious formsImprove construction efficiencyProtective buildings/sheltersShock proofingArchitectural engineeringEngineering

The invention discloses a replaceable energy consumption connecting node of an assembly-type rectangular steel pipe column-H-type steel beam. A rectangular steel tubular column, an H-type steel beam and a replaceable energy consumption connecting force transmitting component are included, the replaceable energy consumption connecting force transmitting component comprises an unequal limb angle steel energy consumption connecting member, a rectangular sleeve tube, a buckling preventing constraint cover plate and a vertical web plate connecting plate; the unequal limb angle steel energy consumption connecting member is connected with the rectangular steel tubular column and a wing plate of the H-shaped steel beam; the buckling preventing constraint cover plate is connected with a weakening area of the unequal limb angle steel energy consumption connecting member; the rectangular sleeve tube sleeves the outer side of the short limb of the unequal limb angle steel energy consumption connecting member and is connected with the rectangular steel tubular column through a bolt; the vertical web plate connecting plate is connected with the rectangular tubular column and the web plate of theH-shaped steel beam. The replaceable energy consumption connecting node has the advantages that the node force transmission is reasonable and reliable, the advantages of building industrialization can be achieved, the replaceable energy consumption connecting force transmitting component is adopted by a node position, the expandability and energy consumption capability of the node are improved, the steel tubular column is not damaged after vibration, and the steel tubular column can be used again by replacing connecting components.

Owner:TIANJIN UNIV

Cable support node connecting device

InactiveCN101881050ASmall turning angleReduce the adverse effects of bending stiffnessBuilding reinforcementsUltimate tensile strengthMotherboard

The invention relates to a cable support node connecting device. The device comprises a cable body and a connecting device, wherein the connecting device comprises a node main plate, node upper plates, a vertical connecting plate, a node lower cover plate, clamping plates and a lug plate; the node upper plates, the vertical connecting plate and the node lower cover plate are connected into a cavity through a centre shaft; a bearing is sleeved on the centre shaft; both ends of the node main plate are provided with the node upper plates; both sides of the node lower cover plate are provided with the clamping plates; the cable body passes through the internal space of the connecting device and is tangent to the bearing; the centre shaft fixes the bearing and the cable body inside the connecting device through pre-tightening force of bolts; and the clamping plates are fixedly connected with the node upper plates through the bolts and are used for clamping or fixing the cable body passing through from the middle part. The node connecting device has the characteristics of simple structure, clear force transmission, reasonable stress, strong bearing capacity and the like. The device can fully exert material strength, effectively transmit steel cable force, reduce stress amplitudes, reduce prestress loss caused by friction and improve integral bearing capacity and stability of the structure.

Owner:BEIJING UNIV OF TECH

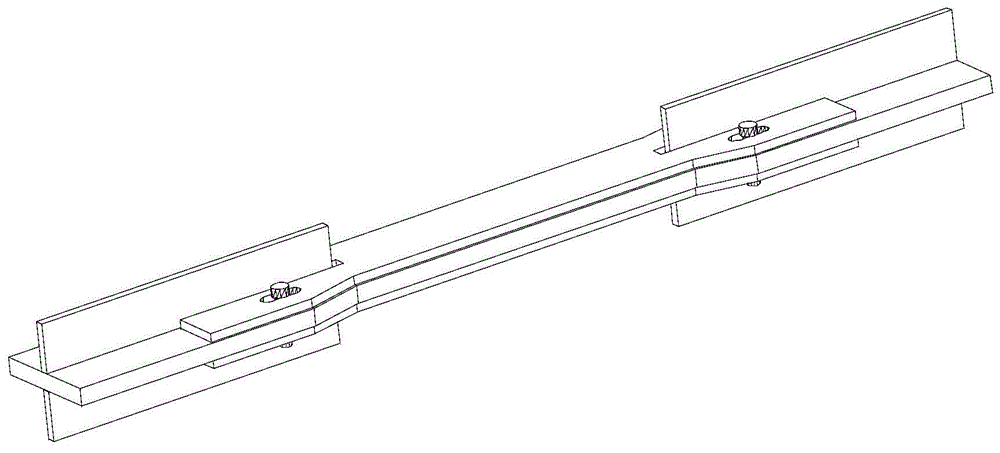

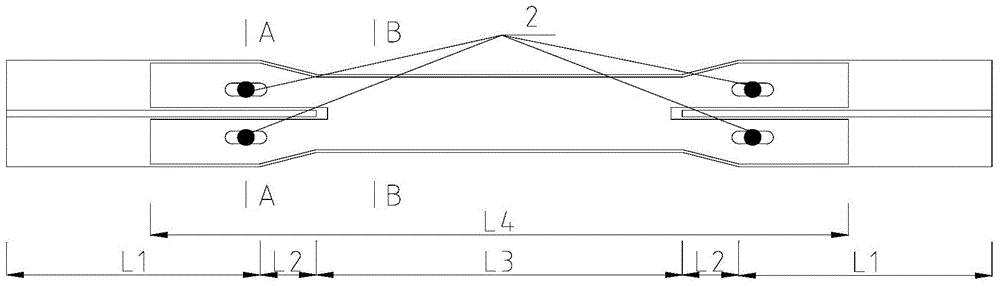

Anti-buckling limit support member for reinforcing post-yield stiffness

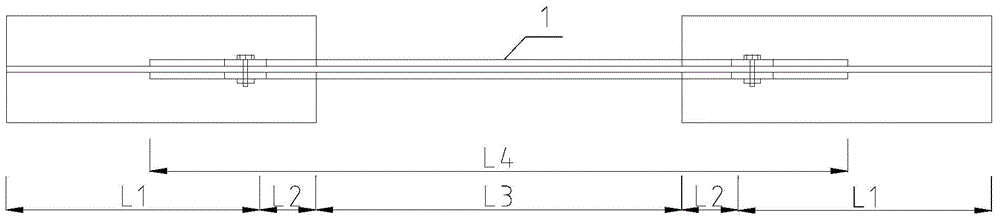

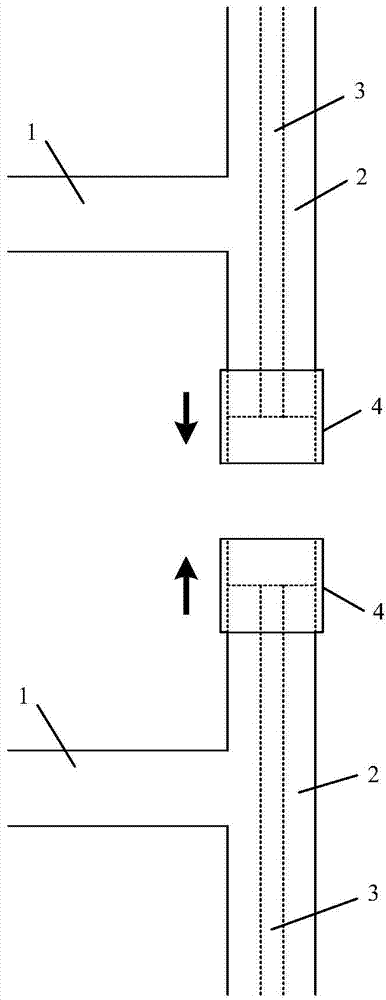

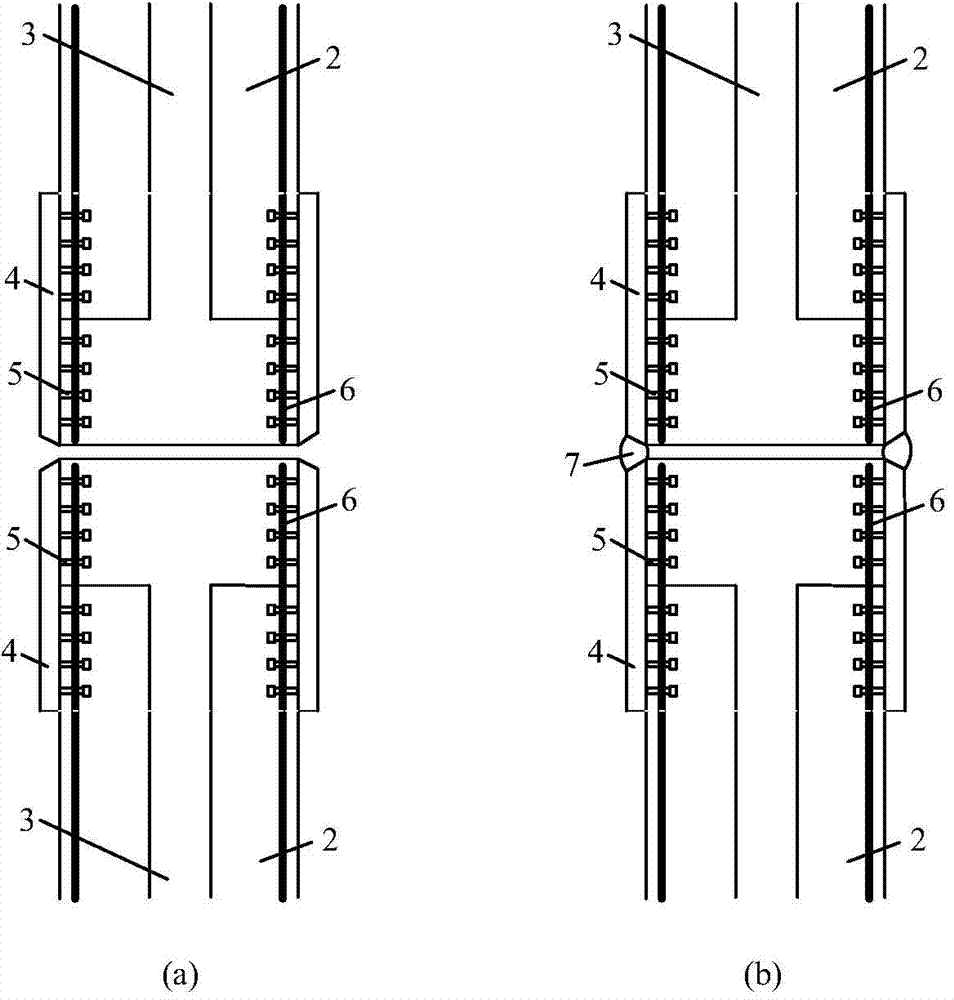

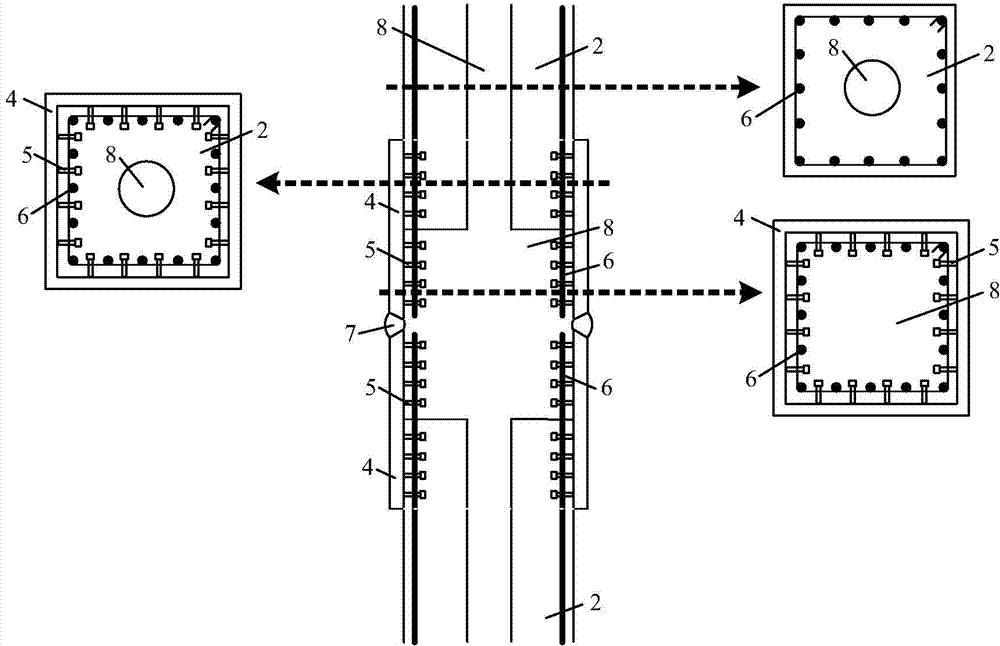

The invention discloses an anti-buckling limit support member for reinforcing a post-yield stiffness, which belongs to the technical field of building construction. The anti-buckling limit support member comprises a two-order yield steel core and an outer constraint steel tube, wherein the two-order yield steel core comprises a first-level yield steel core and a vertically-covering steel plate; the first-level yield steel sequentially comprises a connection section L1, transition sections L2 and a yield working section L3 from the both ends to the middle, the connection section L1 and the transition sections L2 are cross sections, the yield working section L3 is an inline section, and the yield working section L3 is located between the two transition sections L2; bolts are arranged on connection sections at the both sides of the first-level yield steel core; the lengths of the first-level yield steel core and the vertically-covering steel plate are L4, the steel plate is connected to the upper surface and the lower surface of the first-level yield steel core by the bolts at the both ends, grooves are opened in thee both ends of the steel plate, the cross sections of the first-level yield steel core stretch into the grooves, and the two-order yield steel core is located in the outer constraint steel tube. The anti-buckling limit support member disclosed by the invention is convenient to take materials, definite in force transfer, and capable of being widely applied to energy dissipation and seismic mitigation, and limit control for buildings.

Owner:BEIJING UNIV OF TECH

Field connecting method among prefabricated reinforced concrete columns

ActiveCN104775516AGuarantee construction quality and seismic performanceSimple structureBuilding constructionsRebarReinforced concrete column

The invention relates to a field connecting method among prefabricated reinforced concrete columns, facilitates to realize a novel prefabricated assembly technology mode of node factory prefabrication-beam column field connection, prevents the scene casting of concrete in a beam column node area, and belongs to the technical field of structural engineering. The method comprises the following steps: through long round hole ways are reserved in the prefabricated reinforced concrete columns; the ends are coated with steel sleeves; beam column nodes serve as a whole prefabricated unit for lifting on the scene; the steel sleeves at the ends of the upper and lower layers of columns are connected through butt welding joints after being aligned; and finally, concrete is cast in the round hole ways and cavities of the steel sleeves. The method has the advantages of simple configuration, convenience for construction, high field installation speed, low concrete wet operation load, little influence on surrounding environments, excellent stress performance, reliable force transfer, prevention of exposure of concrete cracks in connection areas by means of the steel sleeves, provision of restraint effect, convenience for material taking and processing, low use level of steels and good economical efficiency.

Owner:TSINGHUA UNIV

Project beam-column joint for reverse building method

InactiveCN103628572AEnable connectivityRealize power transmissionBuilding constructionsExcavationsEngineeringRebar

The invention belongs to the constructional engineering field and relates to a project beam-column joint for a reverse building method. The technical scheme of the project beam-column jpint for the reverse building method is as follows: after a foundation pit is excavated below the bottom elevation of a structural beam, a steel ring plate is welded in an elevation position opposite to the position of the main reinforcement of the structural beam at the outer side of a concrete filled steel tubular column; the width of the steel ring plate meets the welding requirement of the main reinforcement of the structural beam; the thickness of the steel ring plate meets the force transfer requirement of the main reinforcement of the structural beam. The main reinforcement of the structural beam transfers force to the main reinforcement of the structural beam of the adjacent span through the steel ring plate. The joint has the advantages that the connection of the reinforcements of the structural beam and force transfer among the reinforcements of the structural beam in the position of the beam-column joint in a reverse building foundation pit project are realized successfully, and the trouble of different traversing through the reinforcements of the beam-column joint to technicians in a field for a long time is solved.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST

Stud welding mixed connection node of rectangular concrete filled steel tubular column and H-shaped steel girder

InactiveCN103967133AAddress stressImprove prefabrication rateBuilding constructionsArchitectural engineeringEngineering

The invention discloses a stud welding mixed connection node of a rectangular concrete filled steel tubular column and an H-shaped steel girder. The H-shaped steel girder comprises an upper flange, a web and a lower flange, wherein the upper flange, the web and the lower flange are formed together. The rectangular concrete filled steel tubular column comprises an upper steel tube and a lower steel tube which are vertically arranged adjacently. The node comprises an inner separating board welded to the bottom in the upper steel tube, a through separating board welded to the bottom end of the upper steel tube and a vertical connecting board welded to the side of the bottom of the upper steel tube. The top end of the lower steel tube is welded to the lower surface of the through separating board. The upper flange is opposite to the inner separating board and welded to the upper steel tube. The web is connected with the vertical connecting board through high strength bolts. The lower flange is fixedly connected with the through separating board. According to the node, stud welding mixed connection is adopted, the node can be fast installed in the position in a field, a construction period can be obviously shortened, and the assembly process is facilitated. Meanwhile, due to the arrangement of the through separating board, a girder-end plastic hinge is moved outwards, the steel girder is damaged before the node, and safety of the node is guaranteed.

Owner:TIANJIN UNIV

Prestress steel structure tension construction method capable of accurately setting up tension force

ActiveCN103089018APower transmission is clearTensile and reliableBuilding material handlingStrain gaugePull force

The invention discloses a prestress steel structure tension construction method capable of accurately setting up tension force. The prestress steel structure tension construction method capable of accurately setting up the tension force includes the following steps. Firstly, a tension device is checked. Secondly, tension construction is performed by the tension device. A steel strand used by prestress concrete penetrates through a steel rod, a steel strand connection device and a counterforce frame. An opening end of the counterforce frame is arranged on the top of a support. A center hole hydraulic jack is installed at the other end of the counterforce frame and the steel strand is clamped. Two strain pieces are symmetrically adhered onto the middle of the steel rod. In time of tensioning, the strains pieces are used for recording in real time and detecting deformation. Tension force can be accurately worked out according to a conversion relationship between deformation and the tension force. The prestress steel structure tension construction method capable of accurately setting up the tension force uses the tension device to tension and is clear in force transmission, reliable in tension, simple and clear as a tension force level can be directly reflected by numerical reading of a strain gauge and beneficial to control of tension quality.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

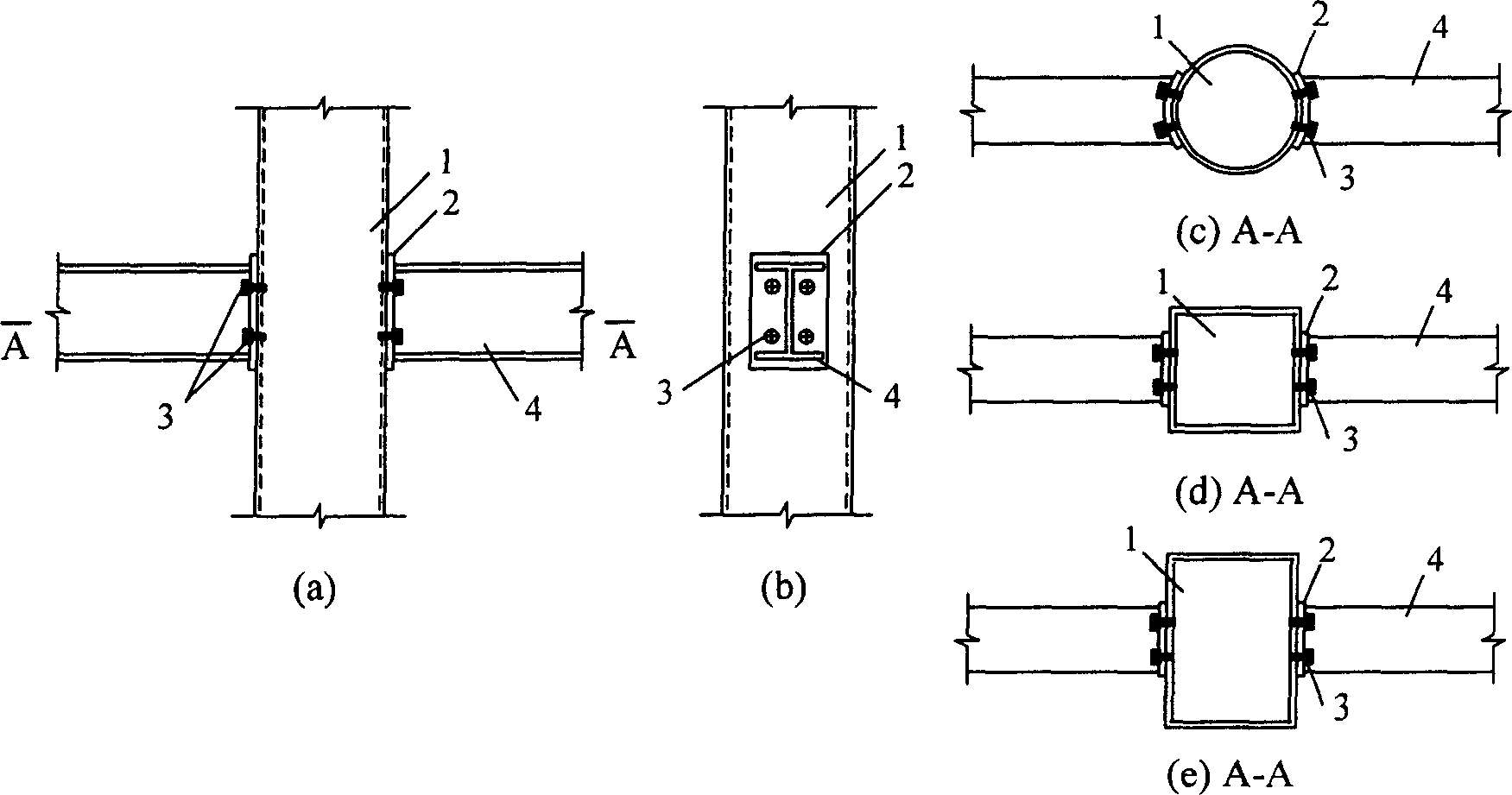

Inserting plate type welding through node

The invention relates to an inserting plate type welding through node, comprising a main pipe, a branch pipe and an ear plate. The main pipe can consist of a circular steel pipe or a square steel pipe and can be provided with a sleeve pipe for strengthening when bearing large force. The upper and lower parts of the main pipe are provided with two grooves. The branch pipe can consist of a circular steel pipe or a square steel pipe. The ear plate is provided with a circular hole or an elliptical hole. The ear plate is inserted into a main pipe groove and is and welded on the main pipe. The through line end of the branch pipe is cut by the machine, and the branch pipe is welded on the main pipe. Therefore, the inserting plate type through node is formed. The invention has the advantages of attractive structure appearance, direct and specific force transmission and convenient and simple construction, avoids the problem of increased manufacture cost caused by adopting the casting steel nodes, can sufficiently satisfy the requirement of structure stress, and is especially suitable for the connecting nodes of the pull cable and the main structure in the prestress space structures such as the stayed structures, chord bracing structures and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com