Tensioned anchorage device and using method of tensioned anchorage device

An anchoring device and tensioning technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of difficult fixing and bonding of fiber boards, bending deformation and wear of tension rods, and achieve easy pasting and fixing. Tension uniformity, clear effect of overall force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

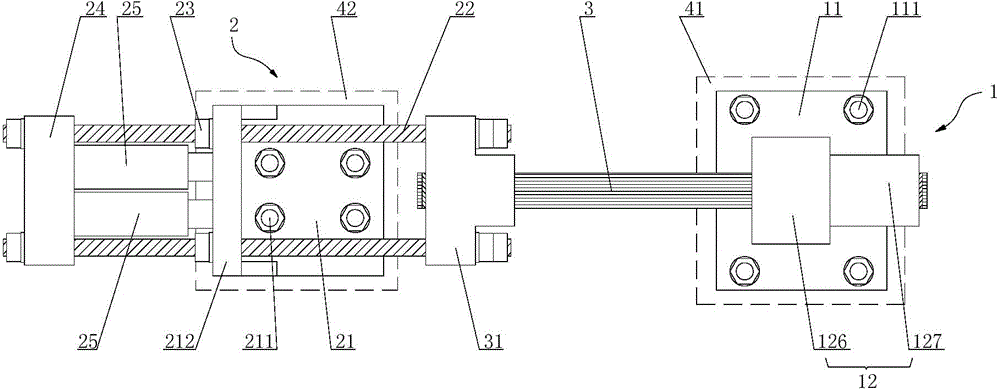

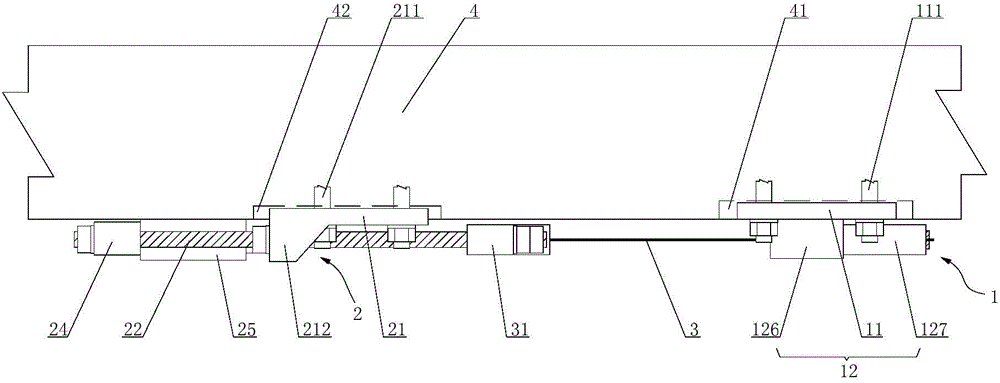

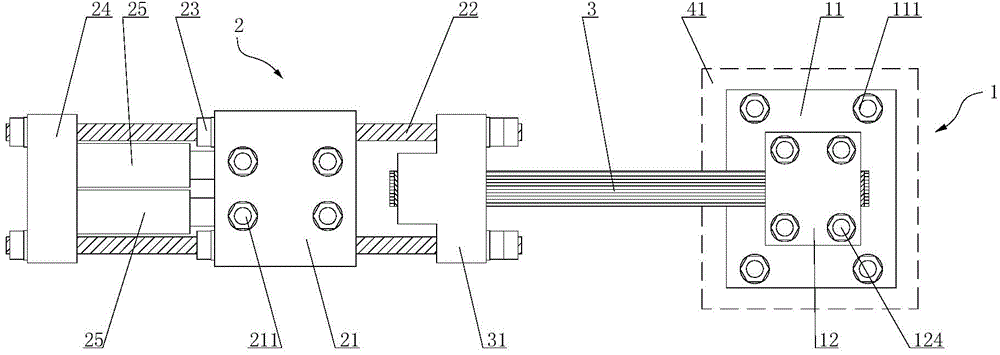

[0063] Such as Figure 1-6 As shown, the present invention provides a tension anchoring device, which includes a fixed end structure 1, a tension end structure 2 and a fiberboard 3, wherein: the fixed end structure 1 has a fixed end anchor seat 11, and the fixed end anchor seat 11 A fixed end clamp 12 is connected to it; the tension end structure 2 has a tension end anchor seat 21, and two tension rods 22 are pierced on the tension end anchor seat 21, and the two tension rods 22 are far away from the fixed One end of the end structure 1 is connected with a lock nut 23 and a rear reaction force plate 24, the lock nut 23 abuts against the anchor seat 21 of the tension end, and the rear reaction force plate 24 is connected with the tension end A plurality of jacks 25 are arranged side by side between the anchoring seats 21; one end of the fiberboard 3 is connected with a tension end clamp 31, and the other end is connected with the fixed end clamp 12, and the tension end clamp 31...

Embodiment approach 2

[0087] Such as Figure 1-18 As shown, the present invention also provides a method for using the tension anchor device as described in Embodiment 1. The structure, working principle and beneficial effects of the tension anchor device are the same as those in Embodiment 1, and will not be repeated here. . The method of using the tension anchoring device comprises the following steps:

[0088] Step 1): Grinding, cleaning and drying the surface of the structure 4, and then applying a primer layer on the surface of the structure 4;

[0089] Step 2): Install the tensioning anchor device on the surface of the structure 4 through the fixed-end anchoring seat 11 and the tensioning-end anchoring seat 21, and install the fixed-end clamp 12 connected to one end of the fiberboard 3 on the fixed-end anchoring seat 11, the tension end clamp 31 connected to the other end of the fiberboard 3 is connected to the two tension rods 22 of the tension anchor device;

[0090] Step 3): expand the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com