Patents

Literature

40results about How to "Lightweight components" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

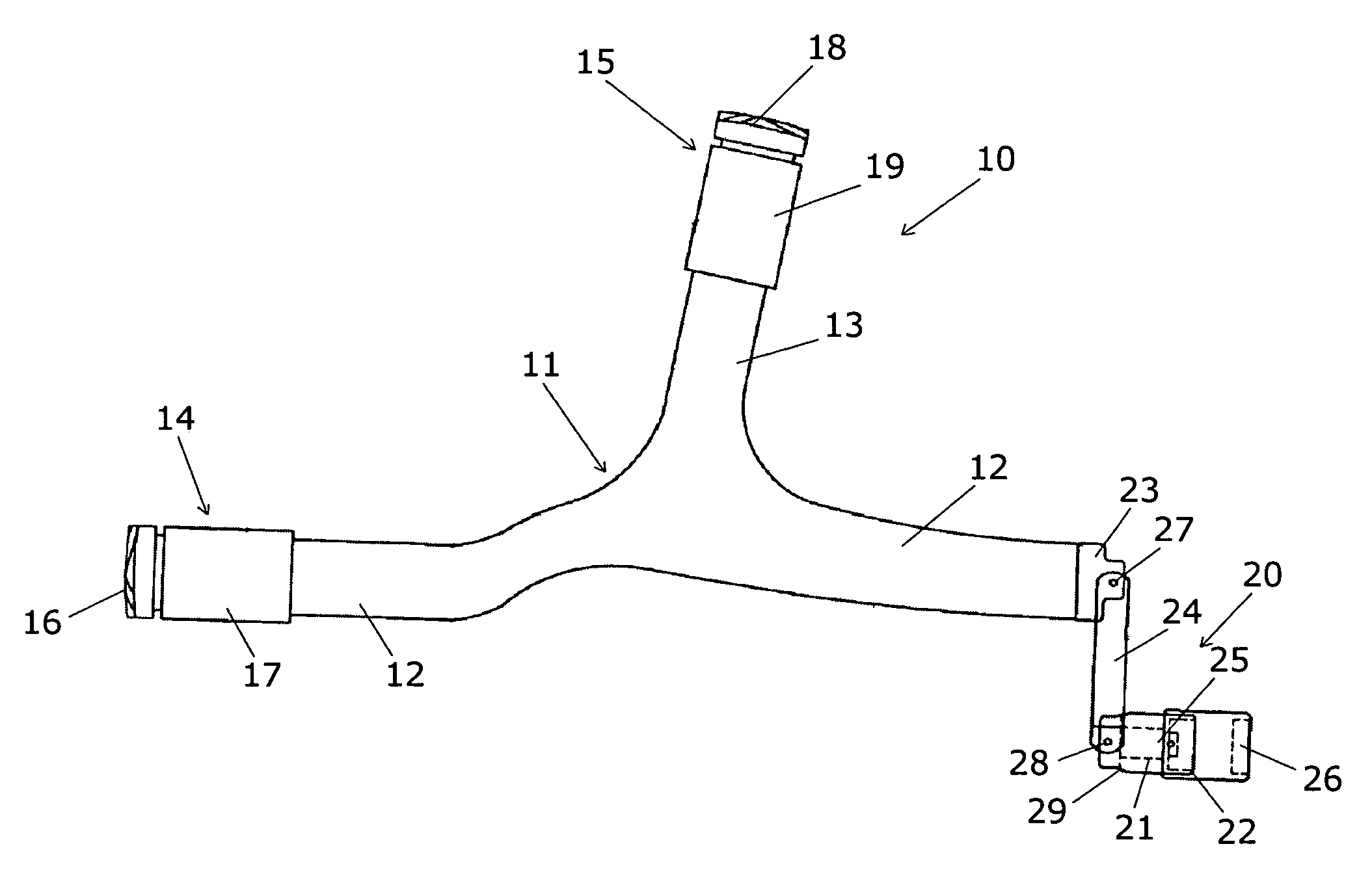

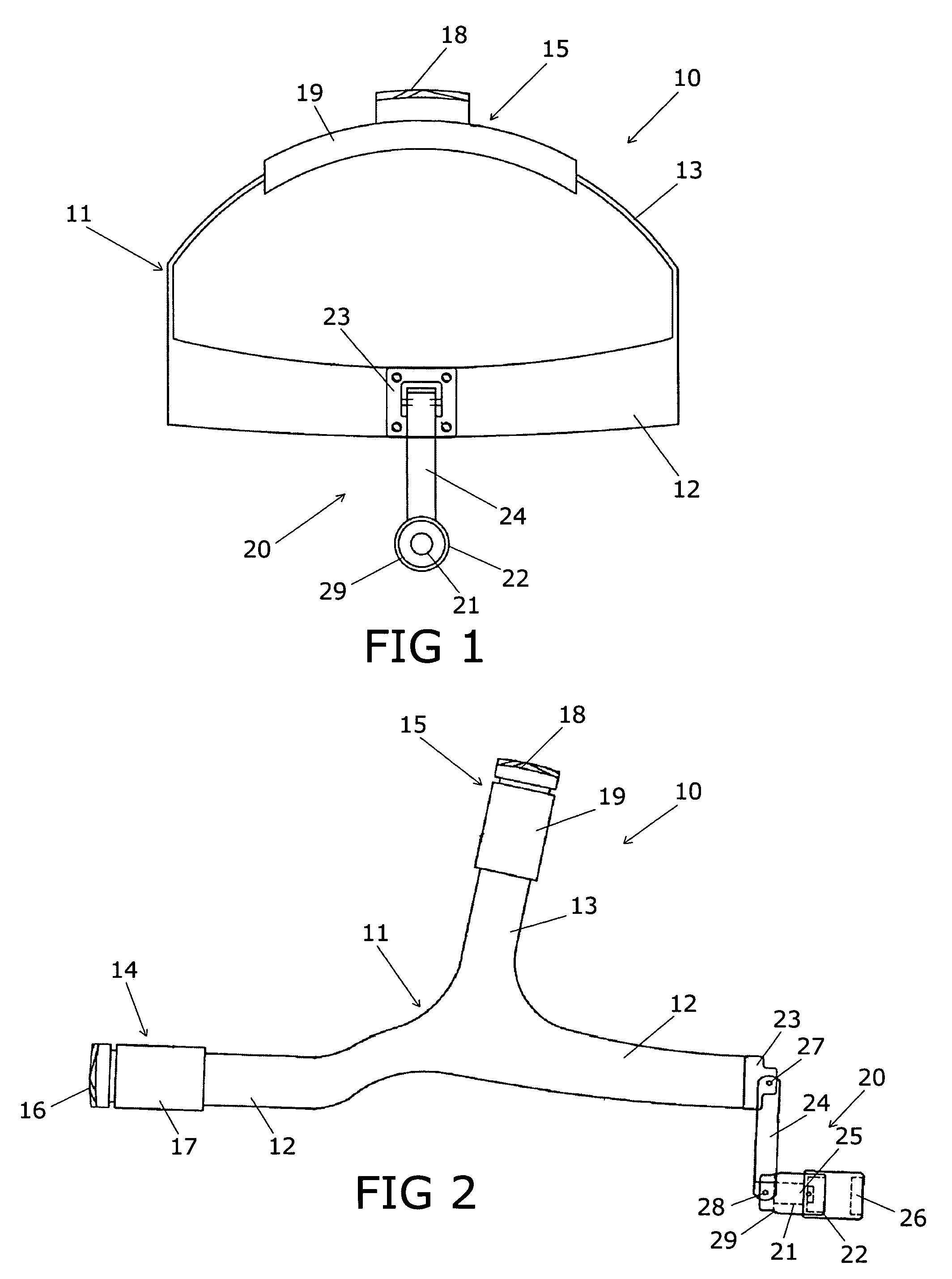

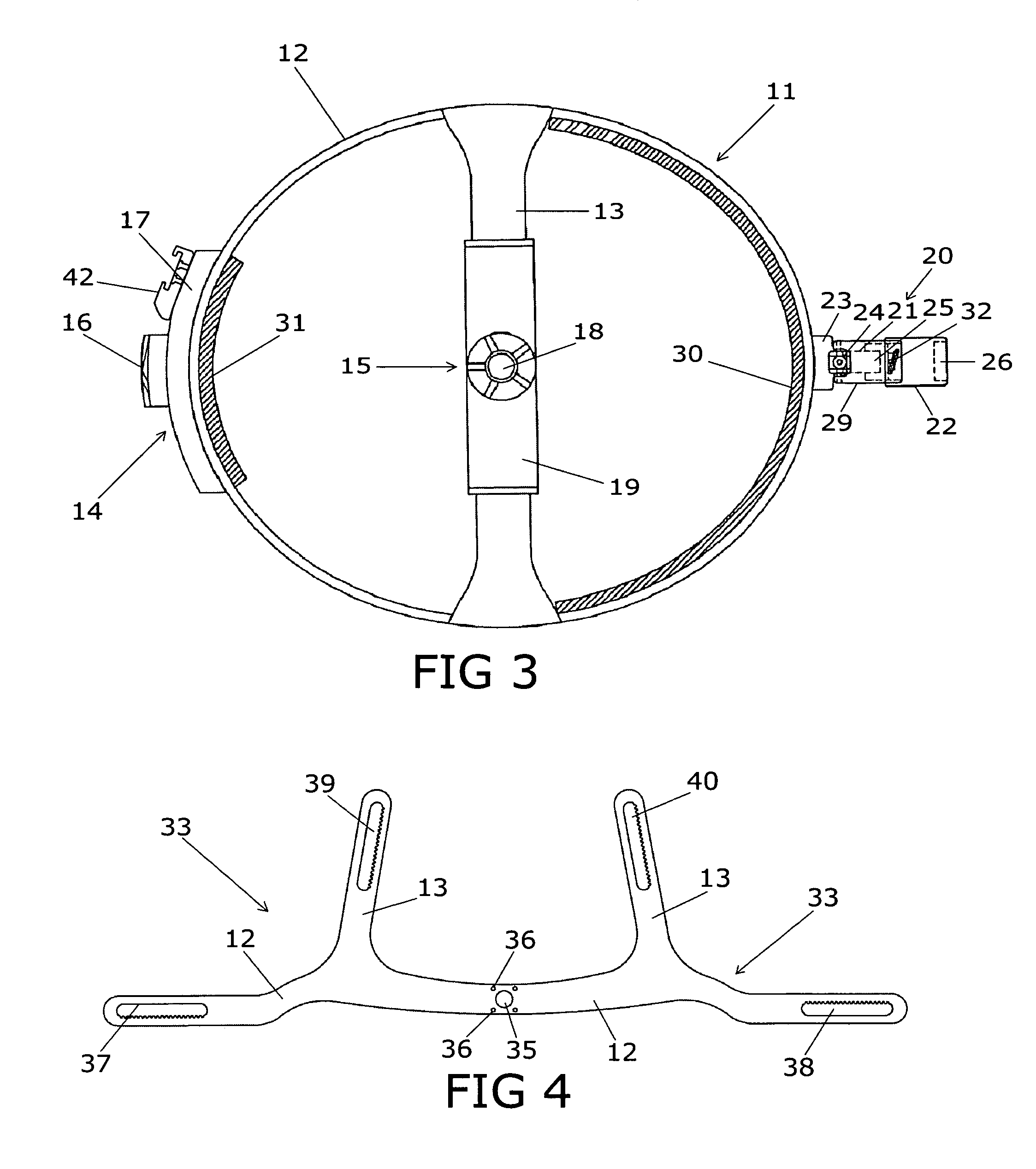

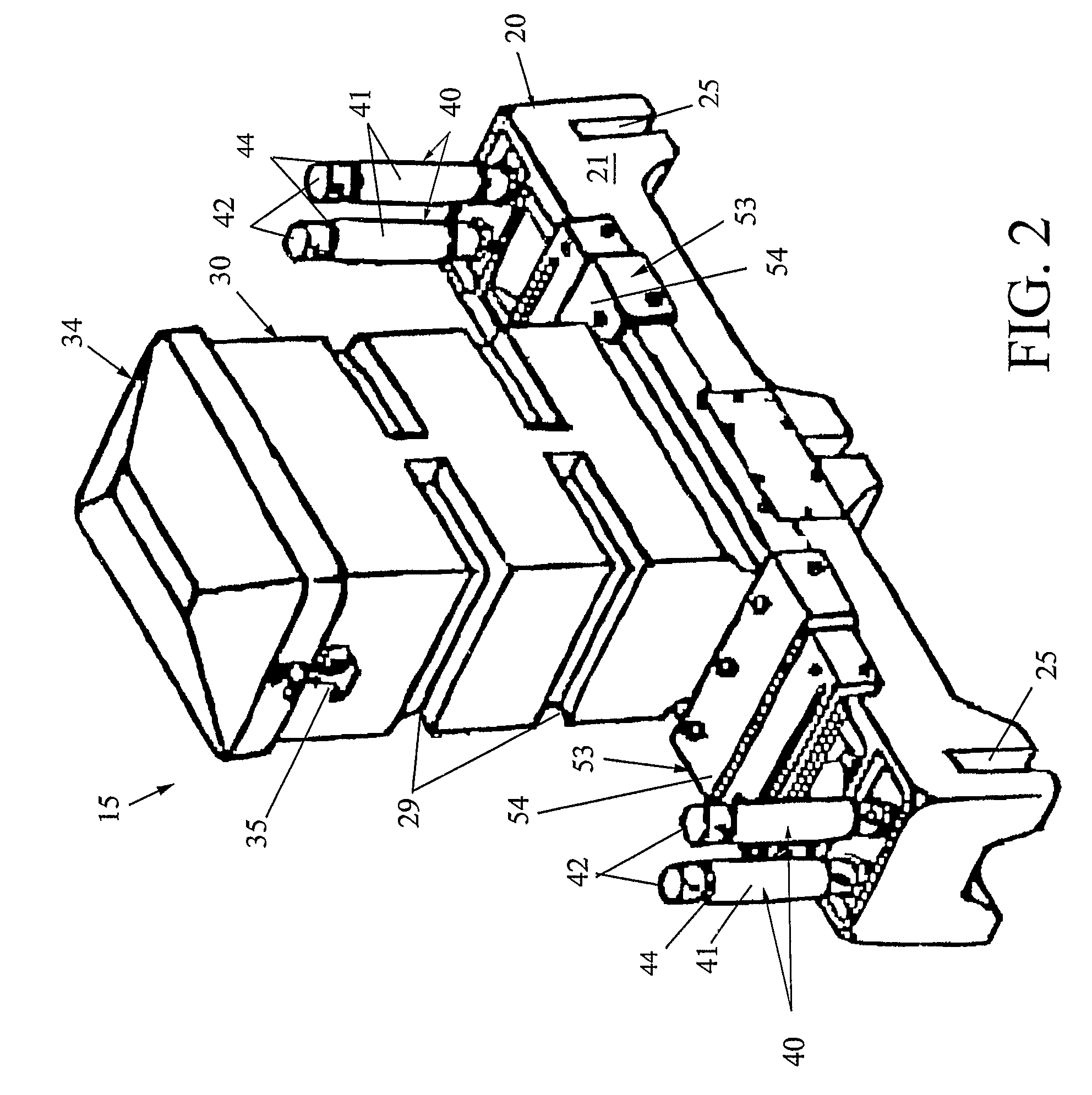

Surgical headlight assembly

InactiveUS7210810B1Easily switchable power sourceEasily adjustLighting support devicesPoint-like light sourceEngineeringHeadphones

A surgical headlight assembly having a headset structure constructed of lightweight components. The headset structure has adjustable head strap members comprising a generally circular lateral band and a top band. A removable liner is attached to the inside surface of the adjustable headset structure. A lighting assembly which is adjustable with respect to the headset and which uses an adjustable LED is also provided connected to the lateral band. A battery pack is utilized to power the LED.

Owner:PMT

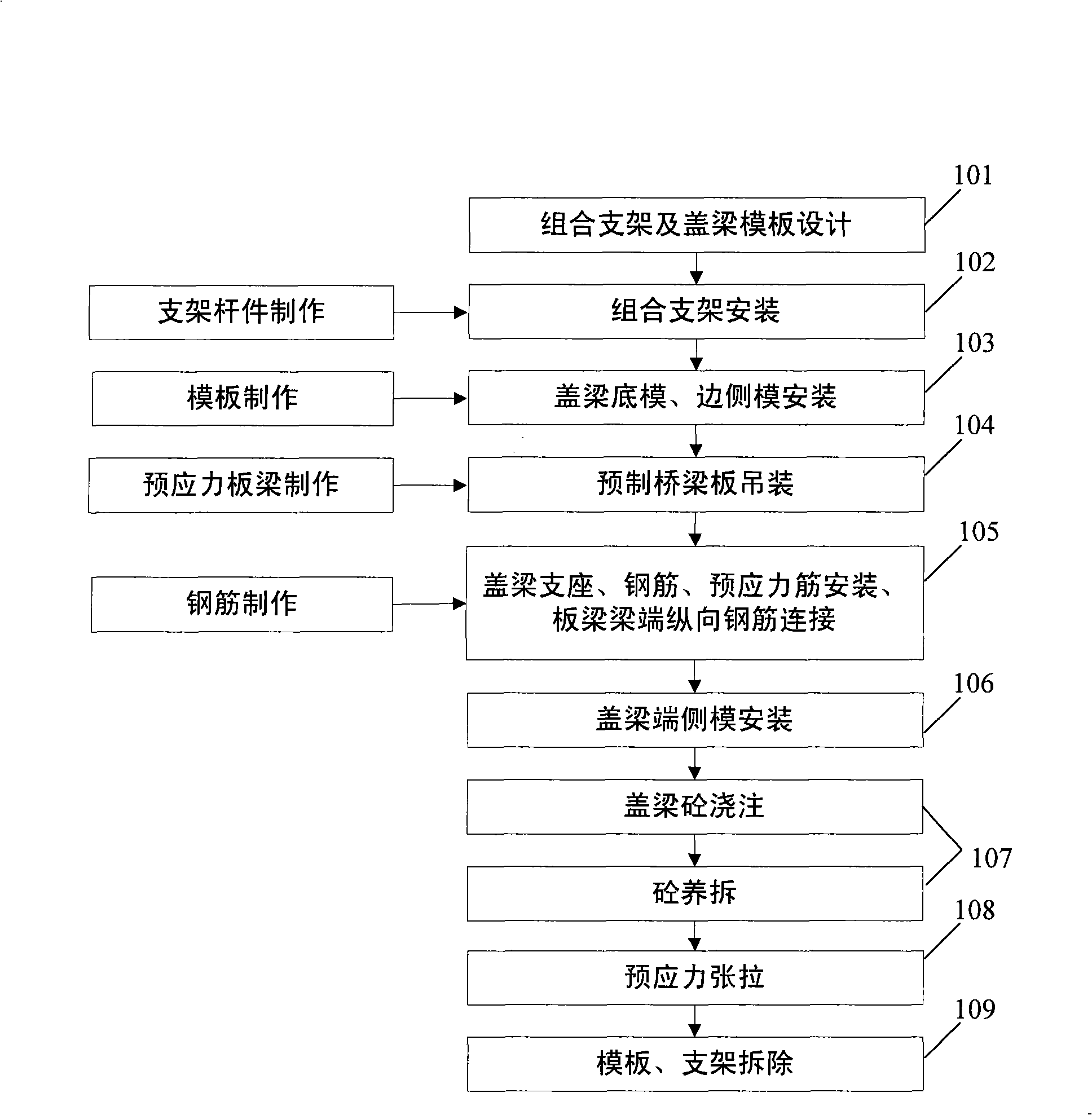

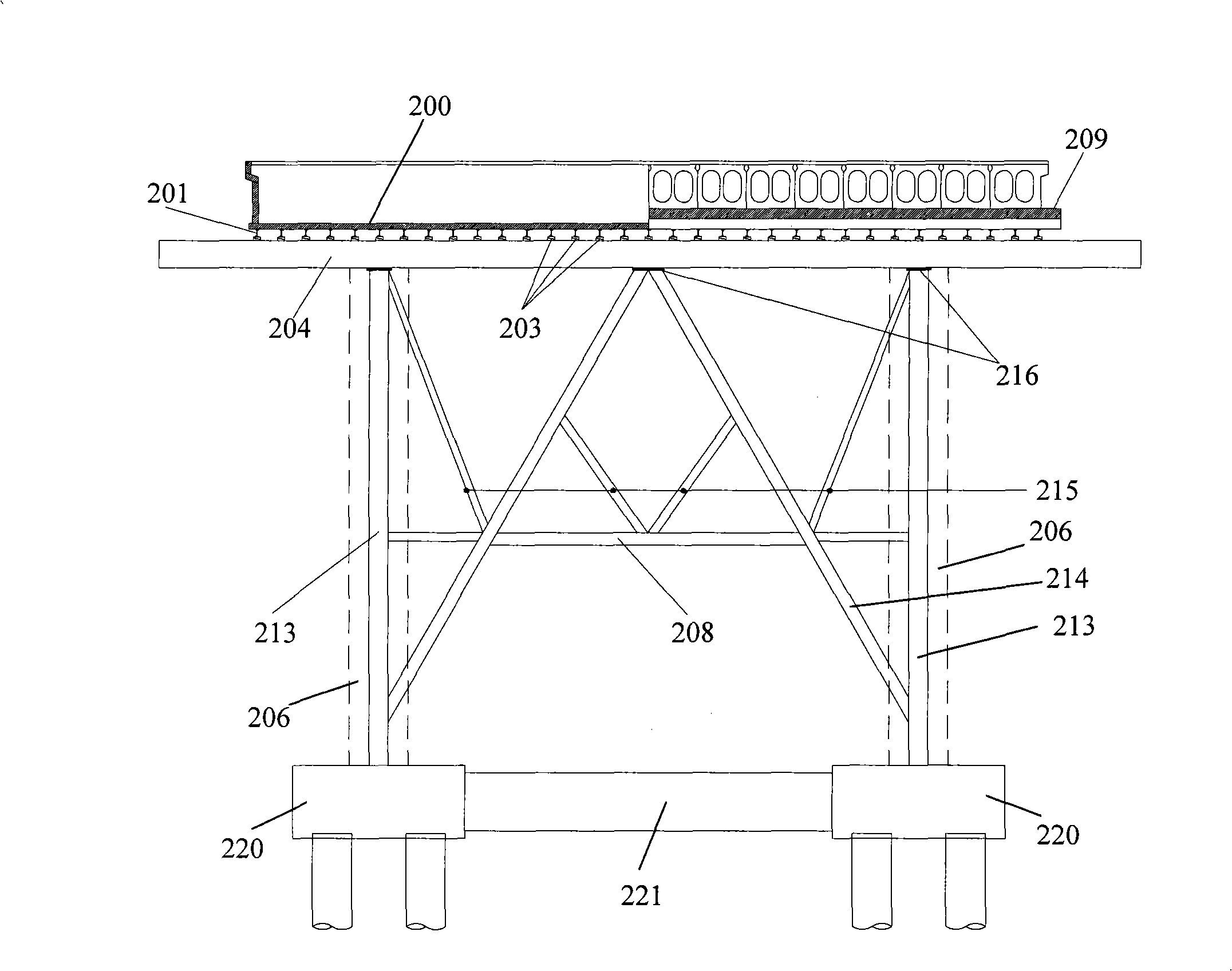

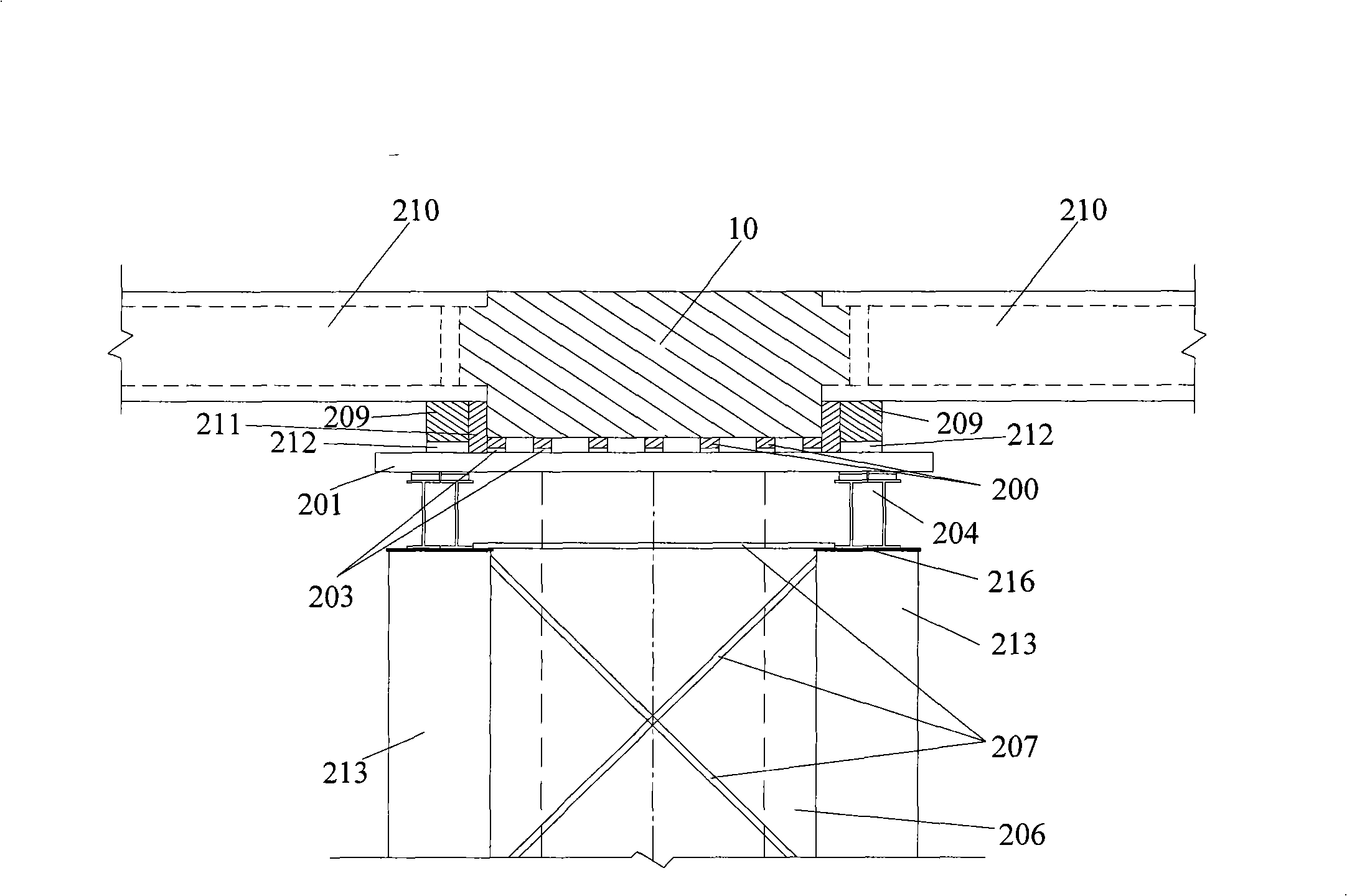

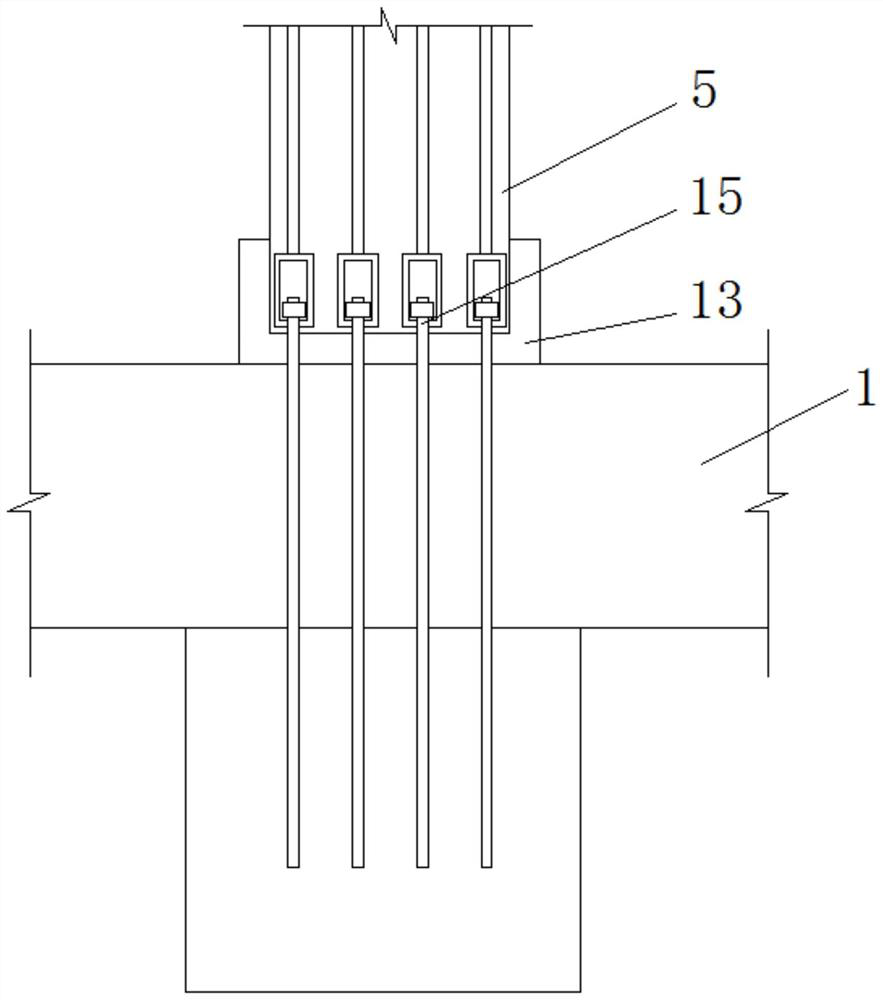

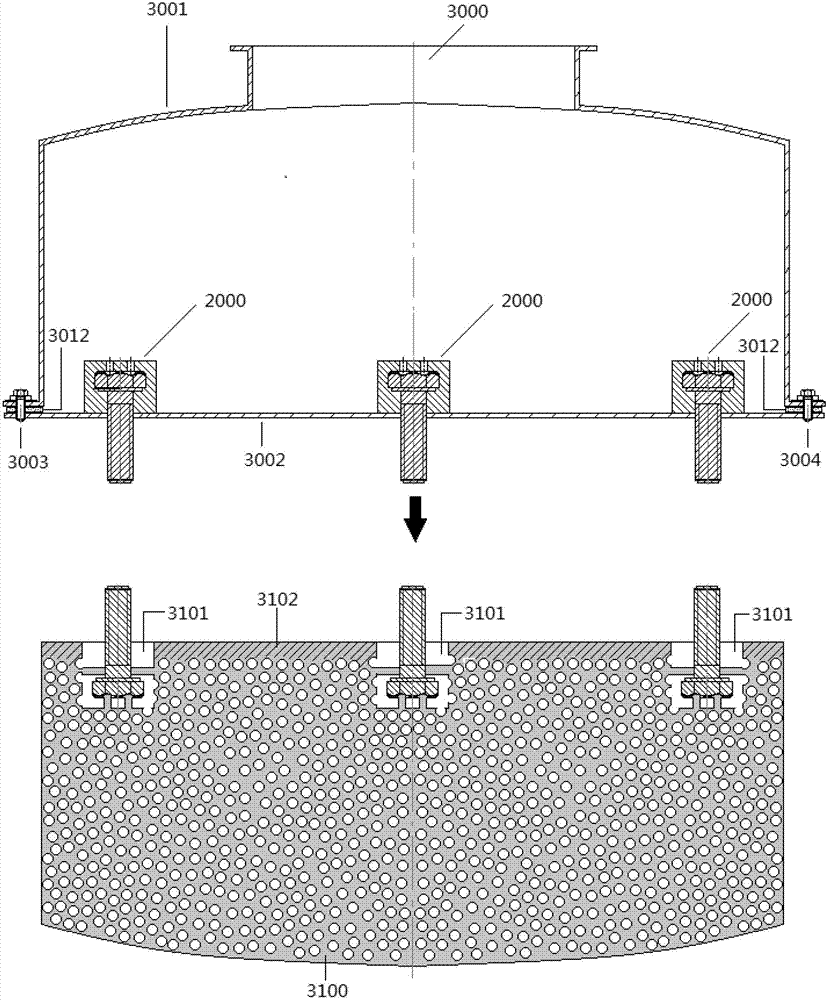

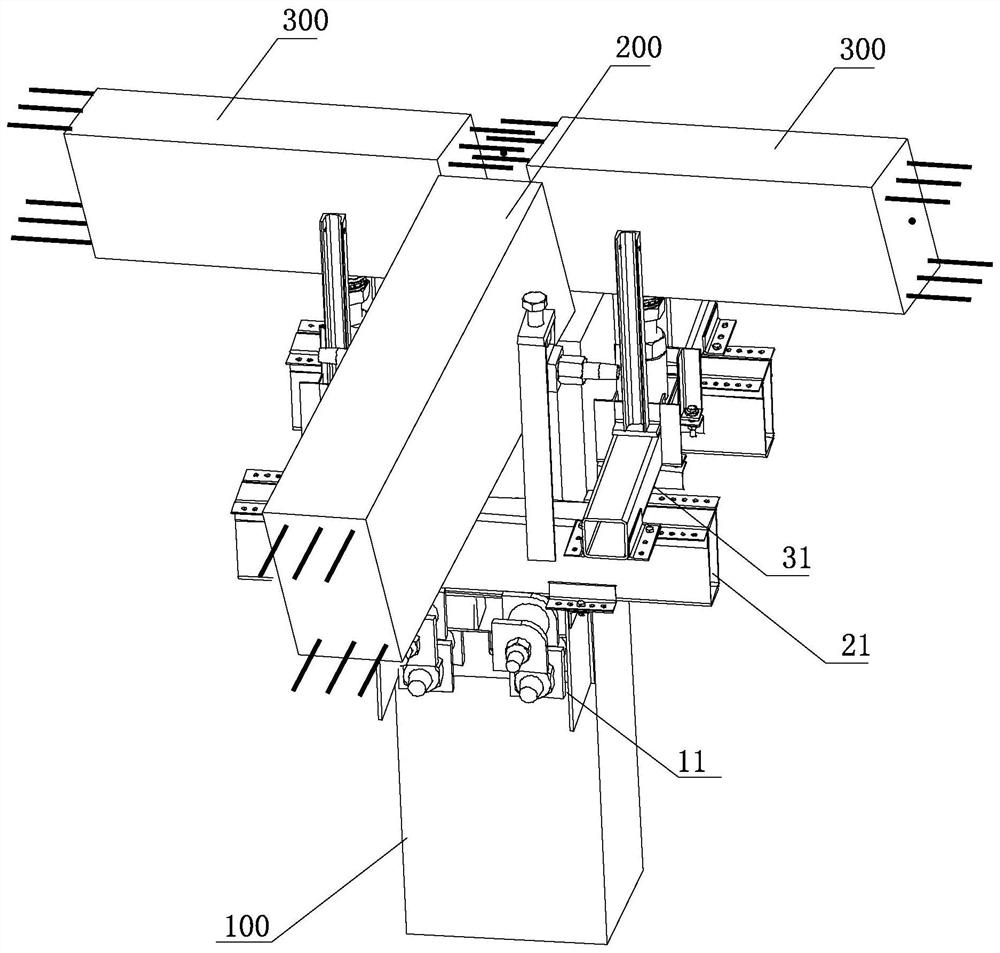

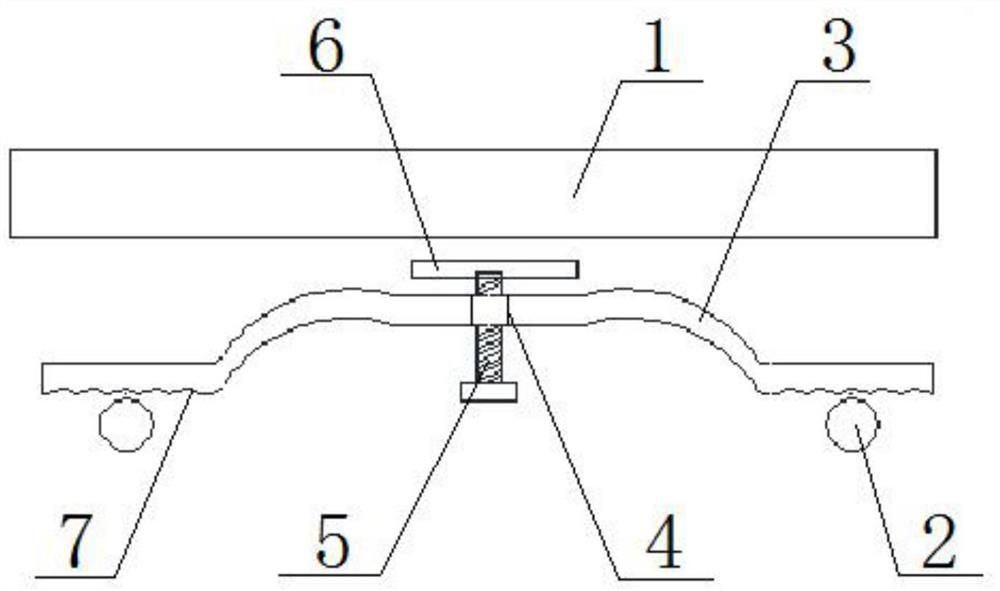

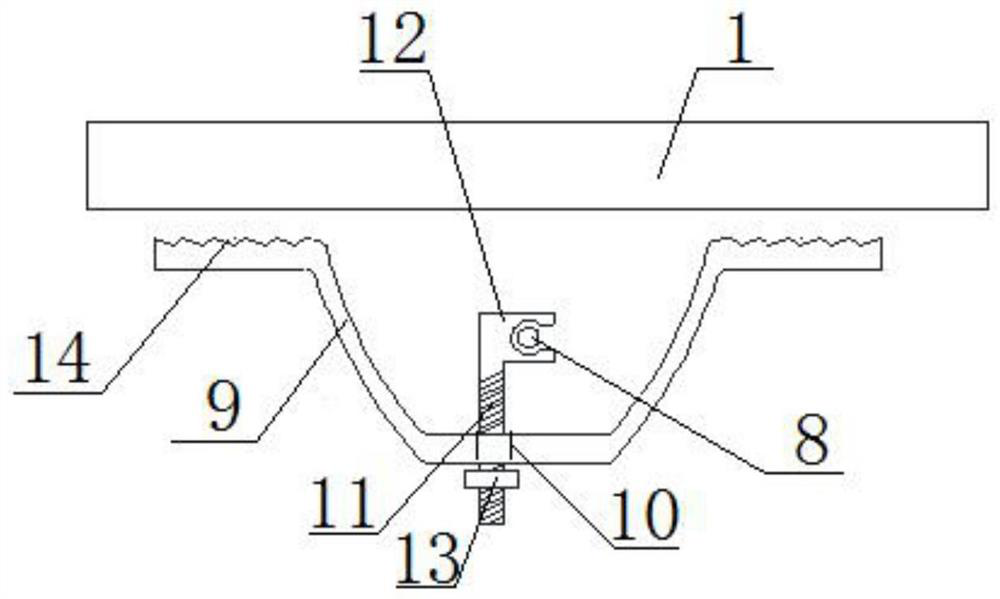

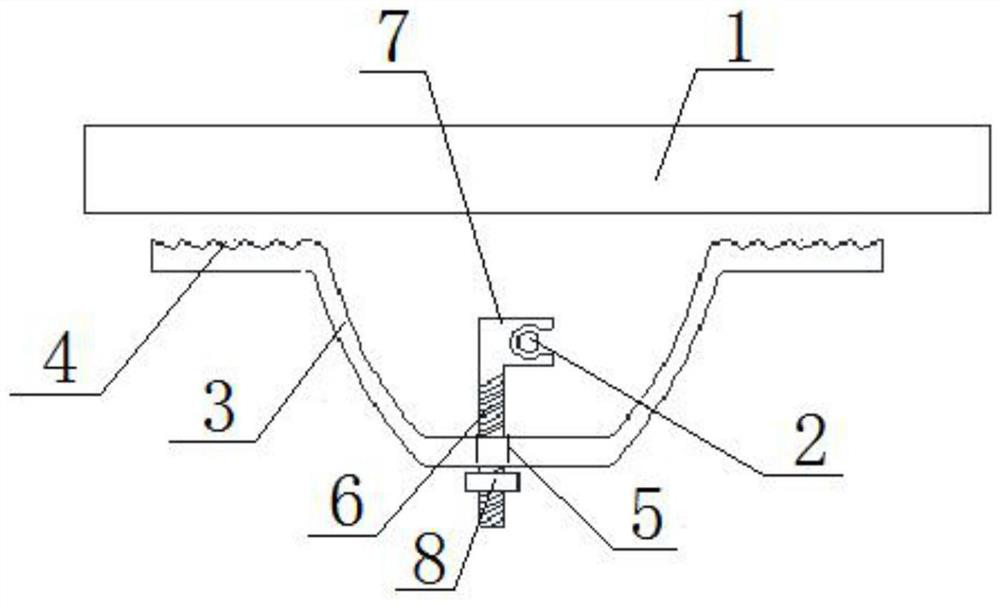

Post-poured hidden coping construction method for converting simply supported beams into continuous beams

ActiveCN101538831AAvoid harmLightweight componentsBridge erection/assemblyContinuous beamEngineering

The invention discloses a post-poured hidden coping construction method for converting simply supported beam into continuous beam. Plate girders are precast in a plant, are then connected with precast plate girders at two sides thereof via cast-in-situ copings so as to convert the precast plate girders into continuous beams, wherein the method of combining supports is adopted to carry out construction, in the method, a temporary support for installing the precast plate girders and a formwork support for installing the post-poured hidden copings are combined to be one, thus obtaining excellent effect.

Owner:HONGRUN CONSTR GROUP STOCK

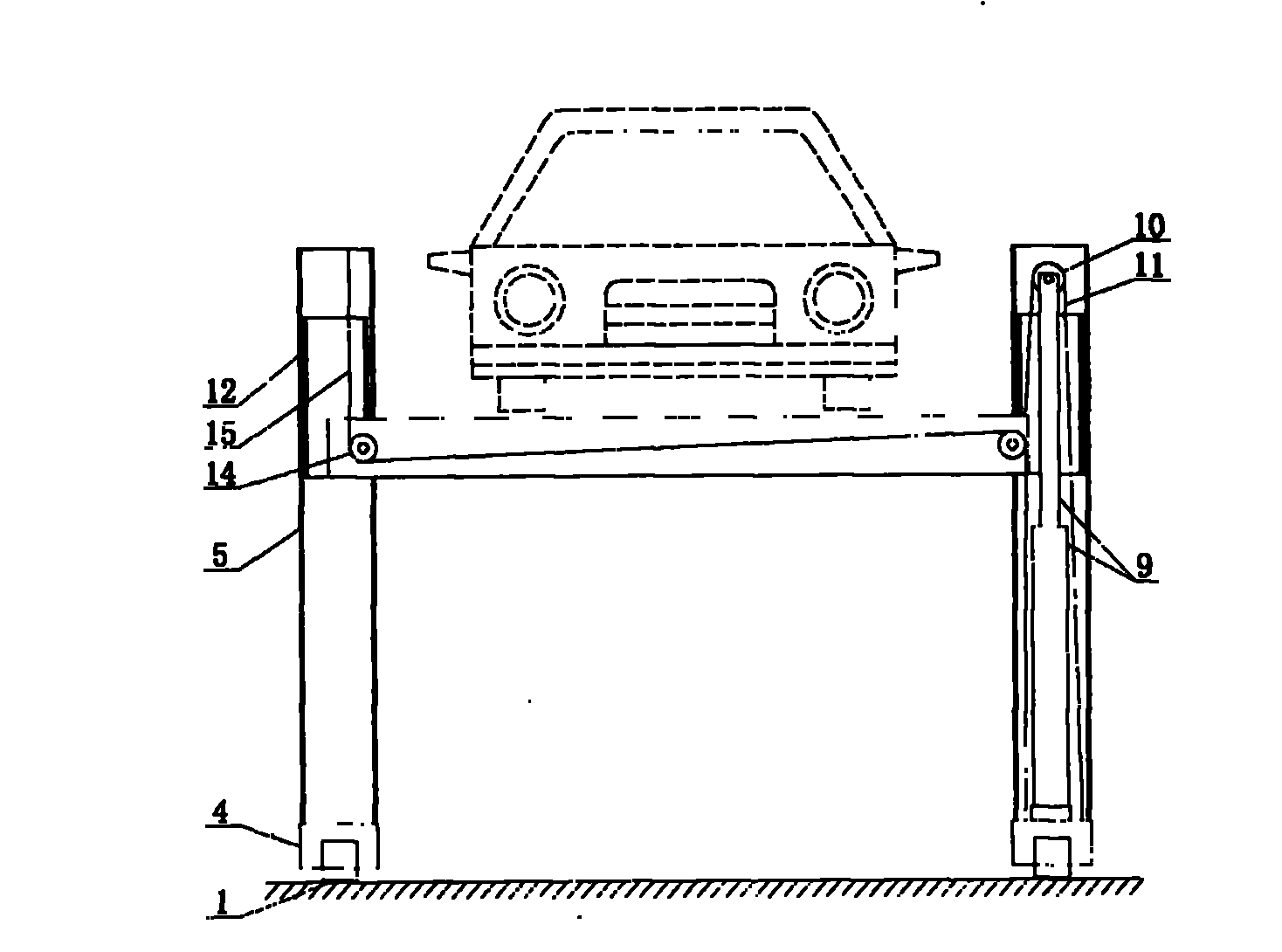

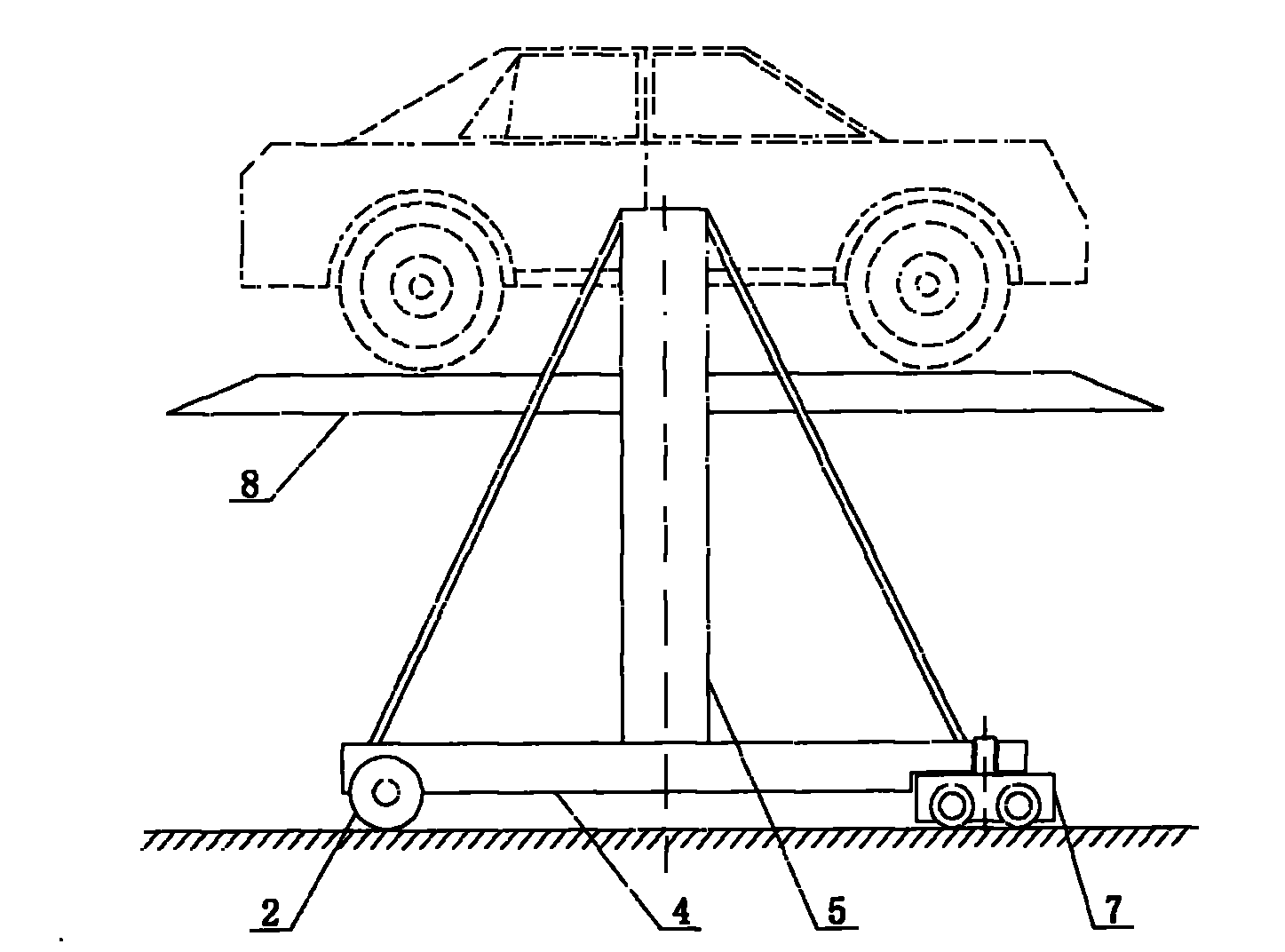

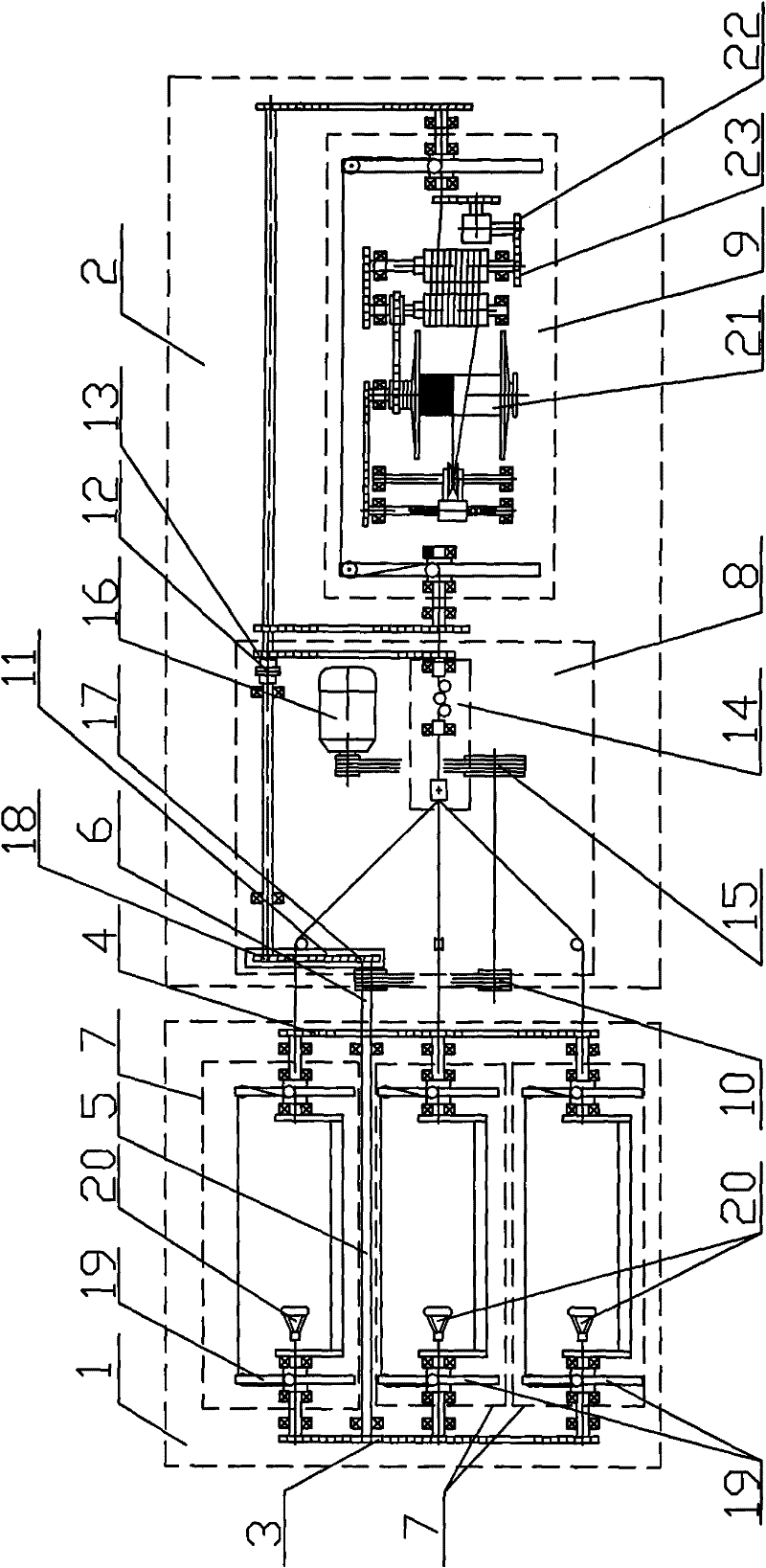

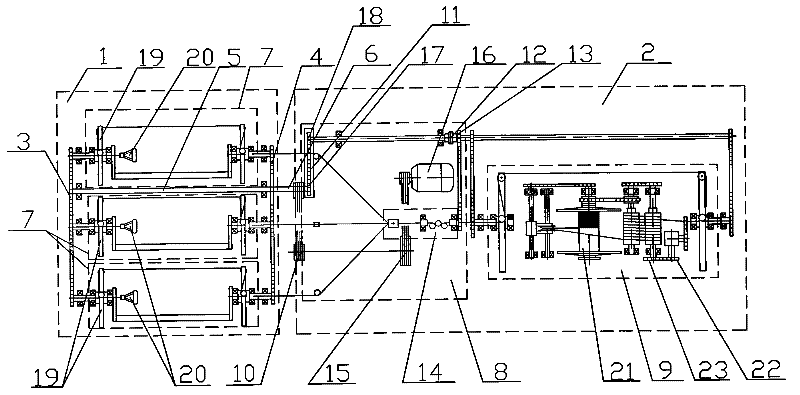

Mobile lifting avoidance-free upper parking deck

The invention provides a mobile lifting avoidance-free upper parking deck. The parking deck comprises a traveling system composed of a plurality of different forms of rollers, a car loading plate, as well as lifting columns and bases which are arranged at two sides of the car loading plate. The parking deck is characterized in that the lifting columns and the bases are respectively arranged at the two sides of the car loading plate; the lifting columns and the bases at different sides below the car loading plate are not connected with each other; and the traveling system is arranged on the bases and comprises an azimuth guide device. The mobile lifting avoidance-free upper parking deck is used for adding a parking layer on a parking space of a ground or underground garage; and by utilizing the upper parking deck, when the upper parked car is lifted up and down, the car in the original ground parking space does not need to be driven out for avoidance.

Owner:金华法

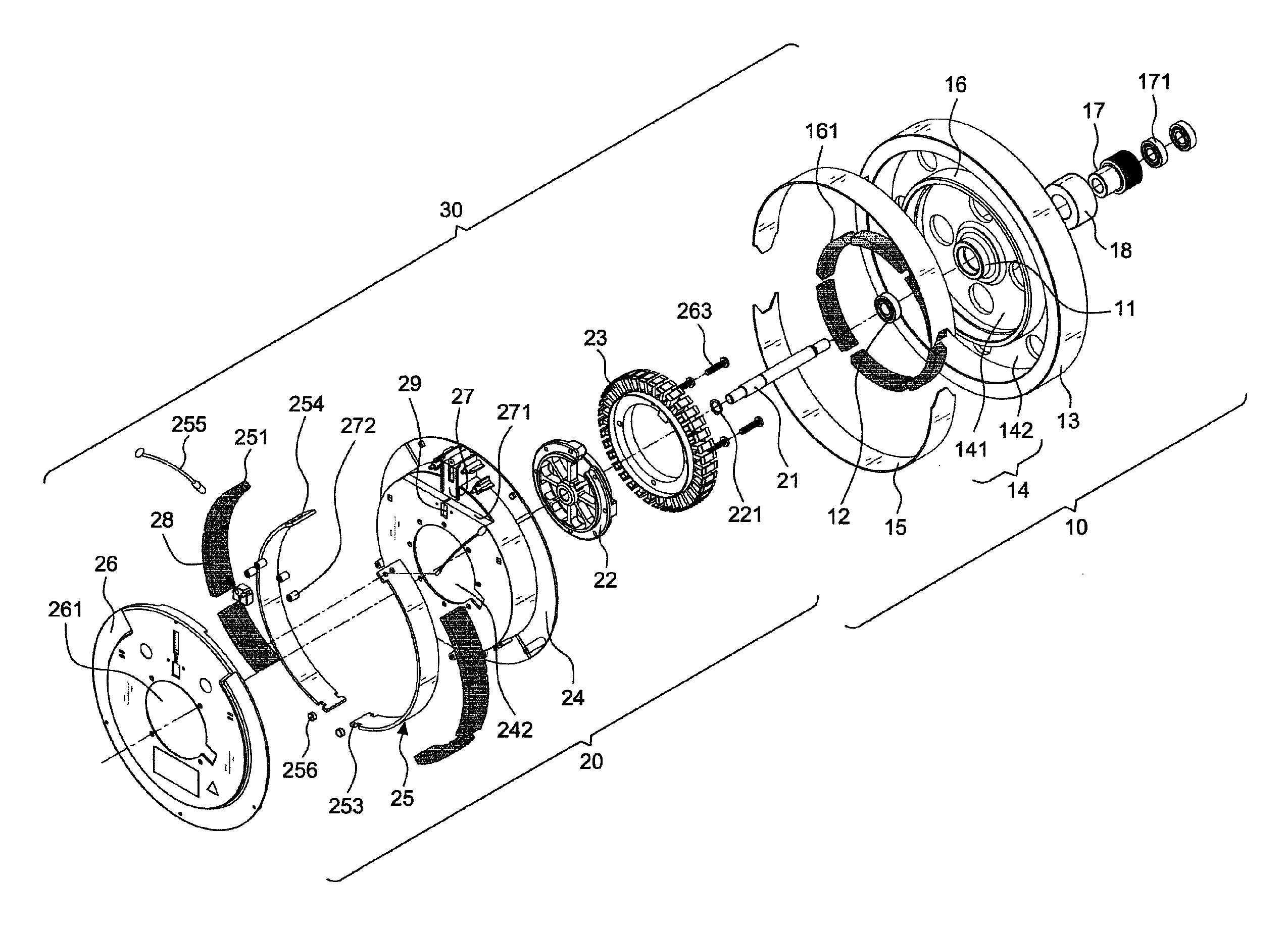

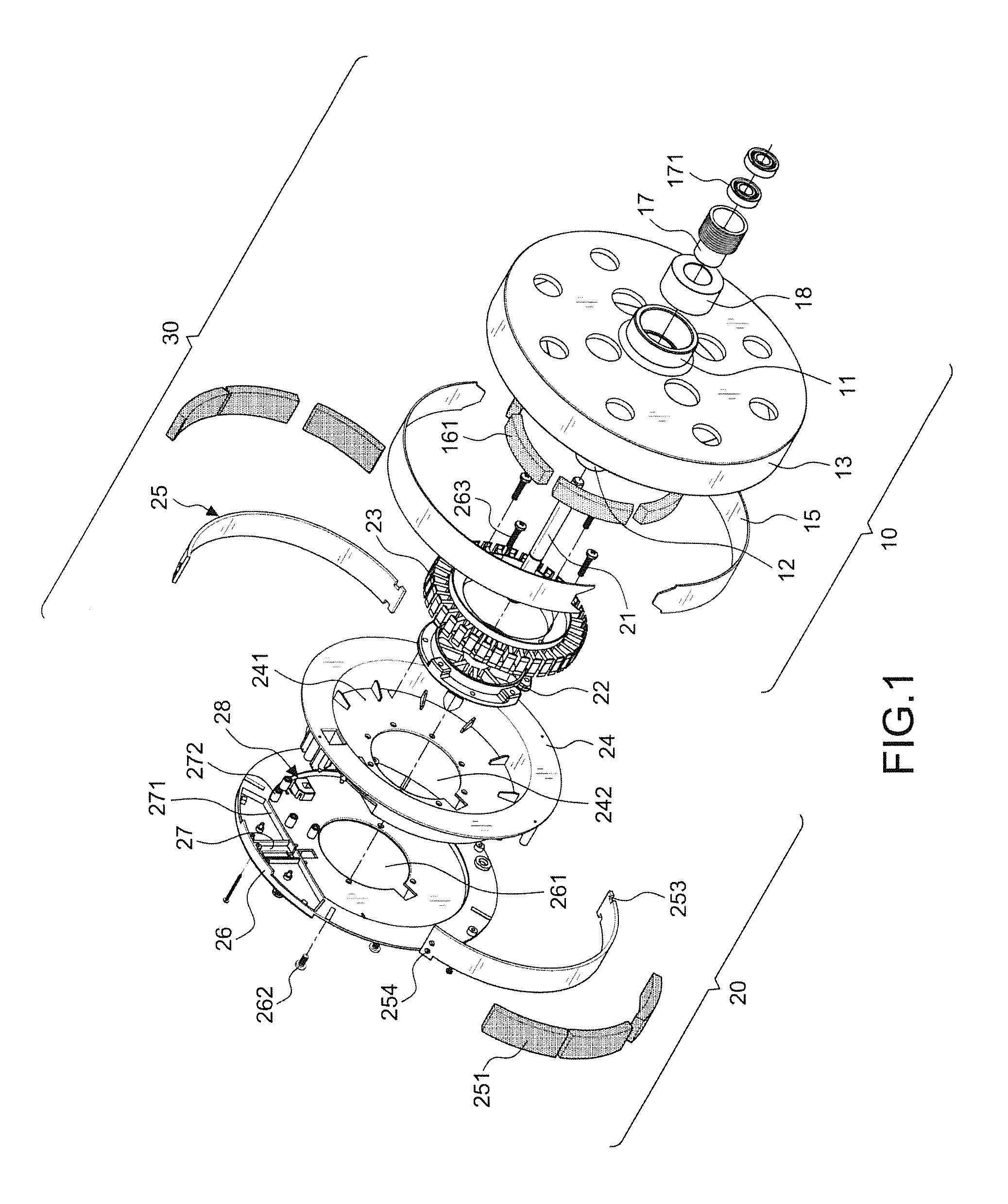

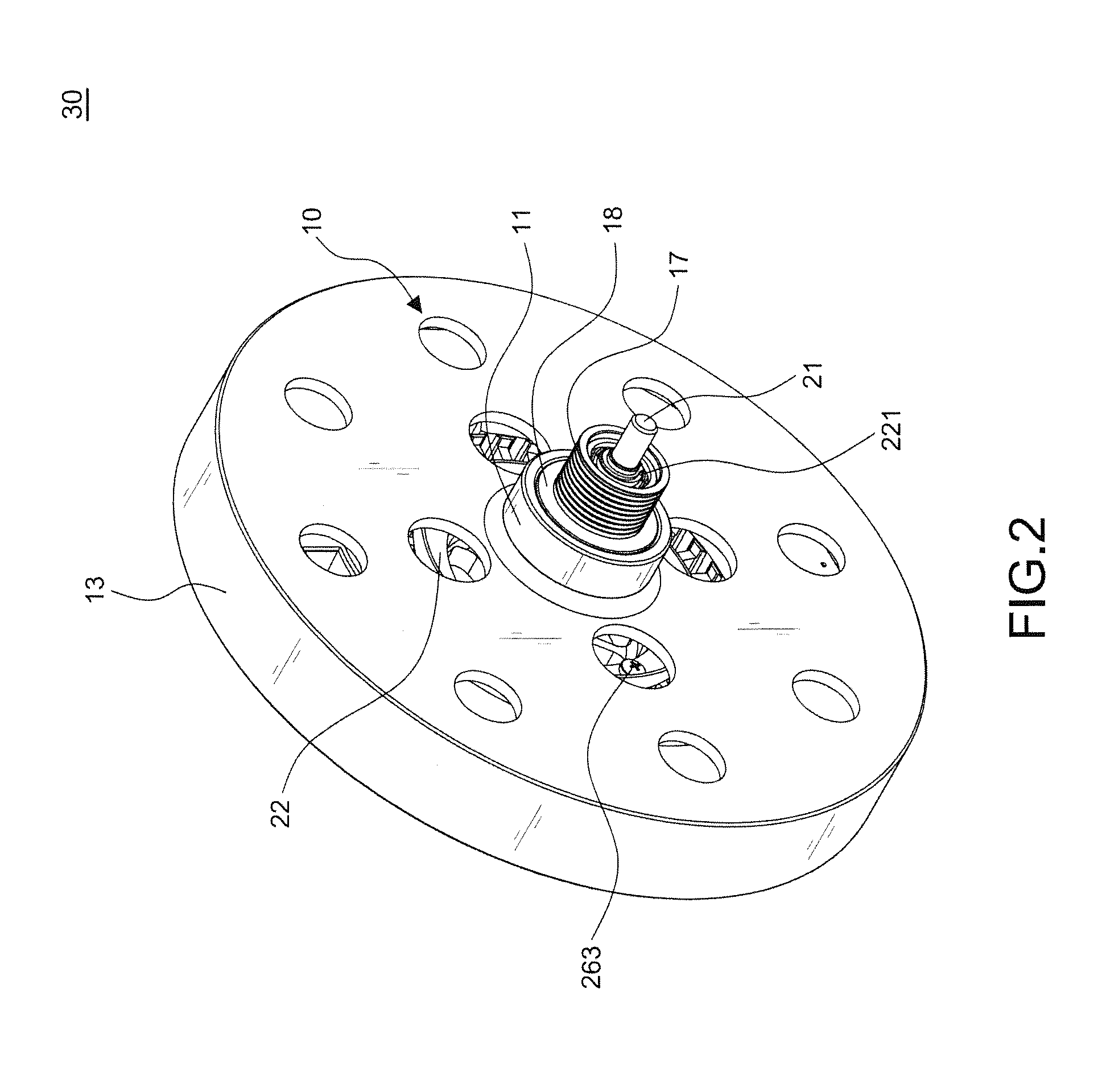

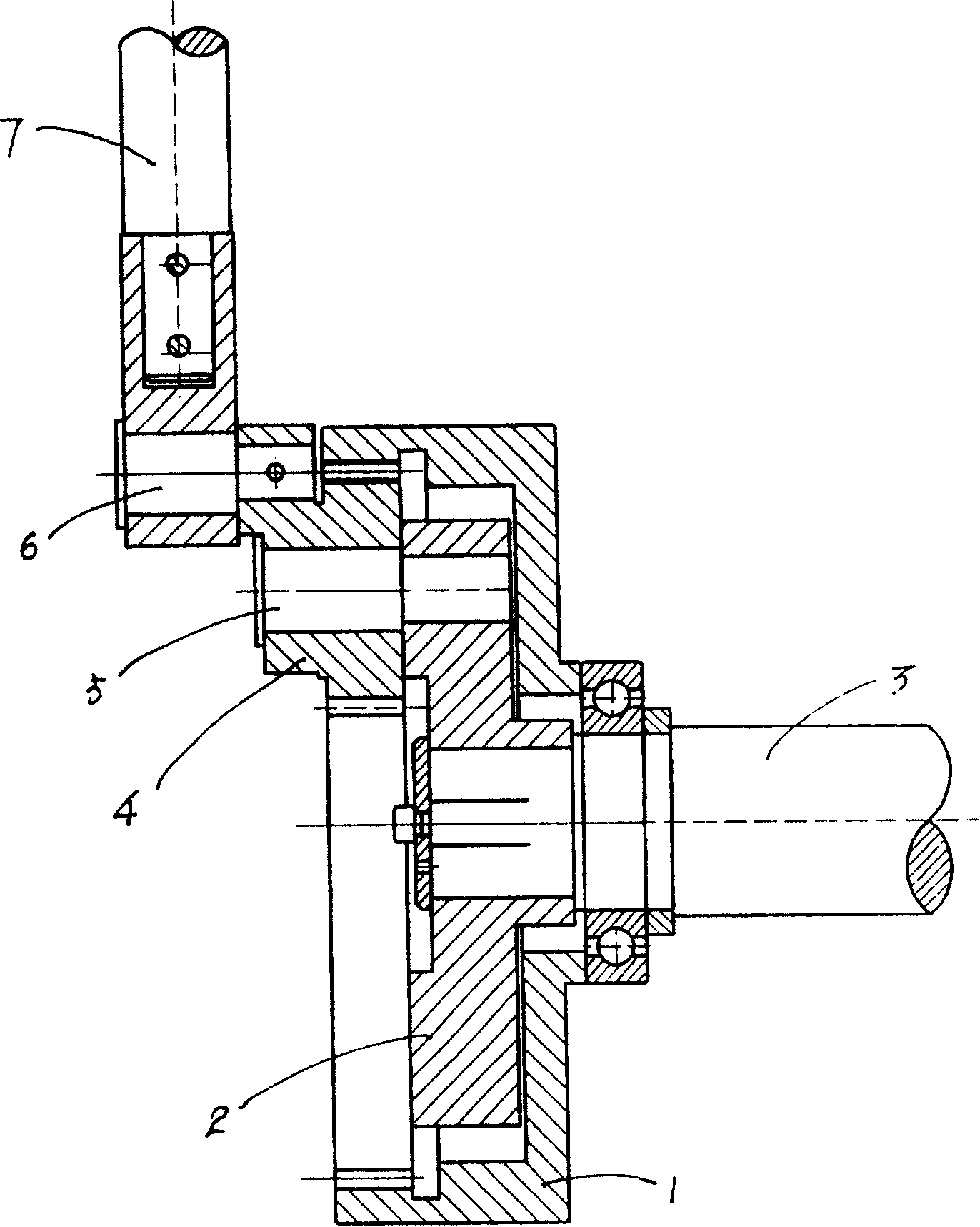

Magnetic controlled power generator

ActiveUS8957641B1Easy to disassembleEasy maintenanceMechanical energy handlingMuscle exercising devicesElectrical resistance and conductanceControl power

A magnetic controlled power generator provides a magnetic controlled loading device, power generator and flywheel device to form two independent modules which are easily assembled and disassembled for easy manufacture and maintenance. Besides, the magnetic controlled power generator has simple installation and lightweight components to generate a radial displacement for magnetic flux control, achieving continuous adjustment of the load resistance, thereby having the effect of reducing the cost and weight.

Owner:CHI HUA FITNESS

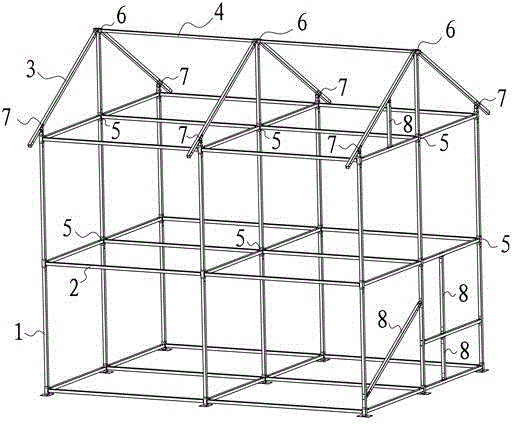

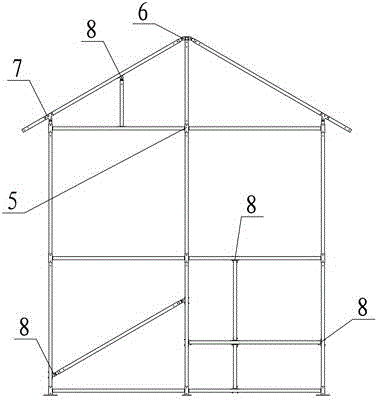

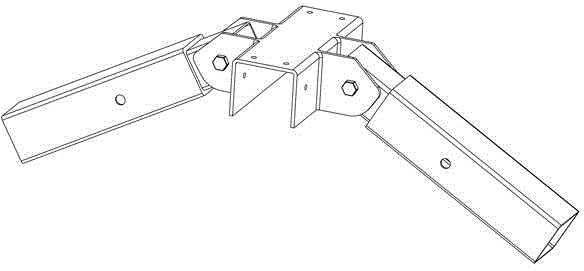

Novel integration house structure

The invention relates to a novel integration house structure. The novel integration house structure comprises a steel structure frame and a wall body and is characterized in that the steel structure frame comprises upright posts and cross beams which are mutually and vertically connected, rafters and purlines, wherein the upright posts and the cross beams adopt upright post and cross beam connecting pieces for connection and fixation; the two rafters are connected and fixed by adjustable purlin connecting pieces; the upright posts and the purlines are connected and fixed by adjustable eave connecting pieces; the steel frame structure is supported and reinforced by supporting and reinforcing connecting pieces. According to the novel integration house structure, the used steel amount is reduced, components are minimized, and the cost is low; industrialized production is realized, the assembly is rapid, and the transportation is convenient; no building garbage and building dust is generated, and the environment is not destroyed; the thermal insulation performance of a roof and the wall body is good, the building energy-saving effect is good, the mechanical structure is good, and the anti-seismic property is good.

Owner:湖南千盟园林工程有限公司

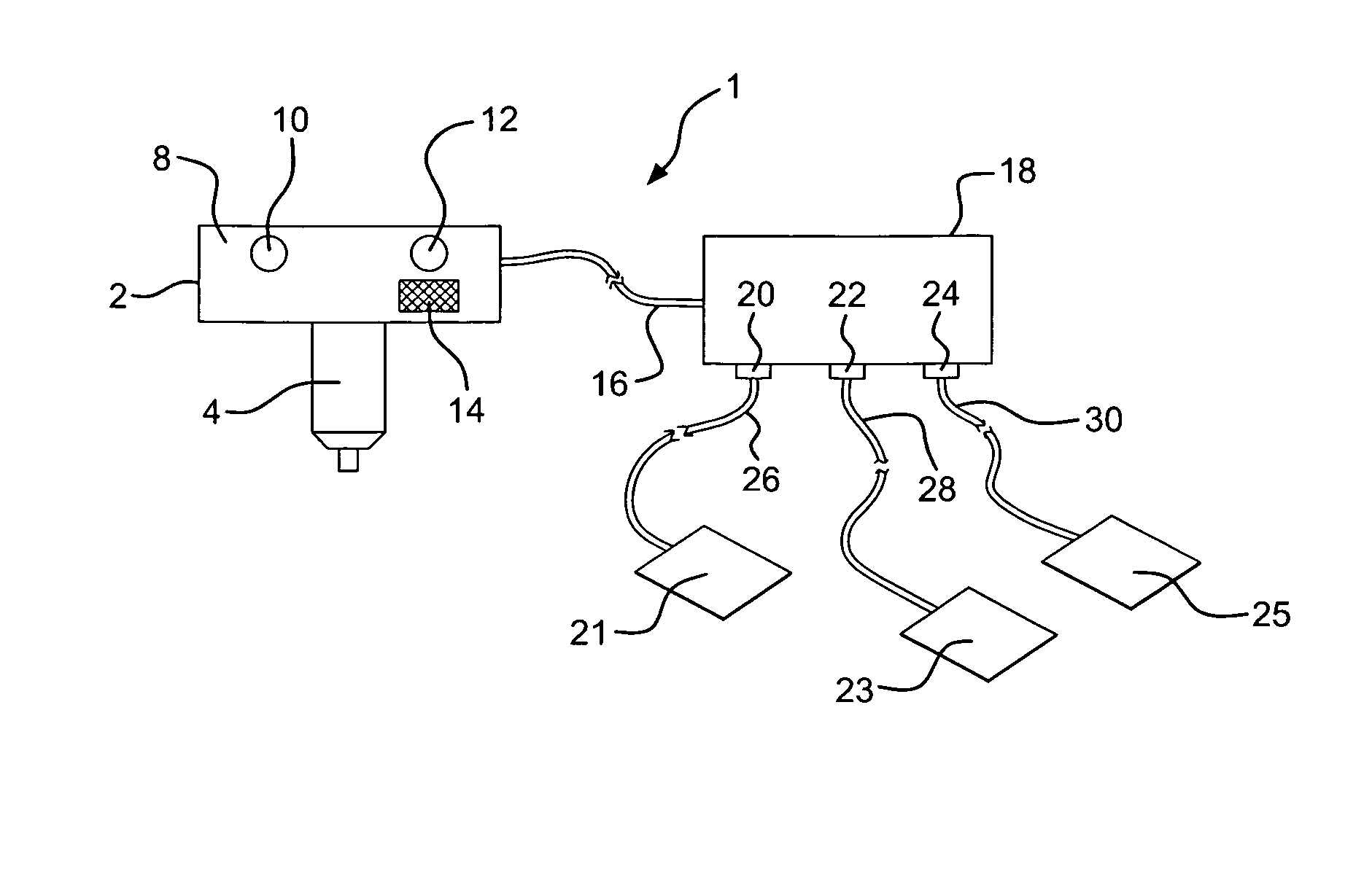

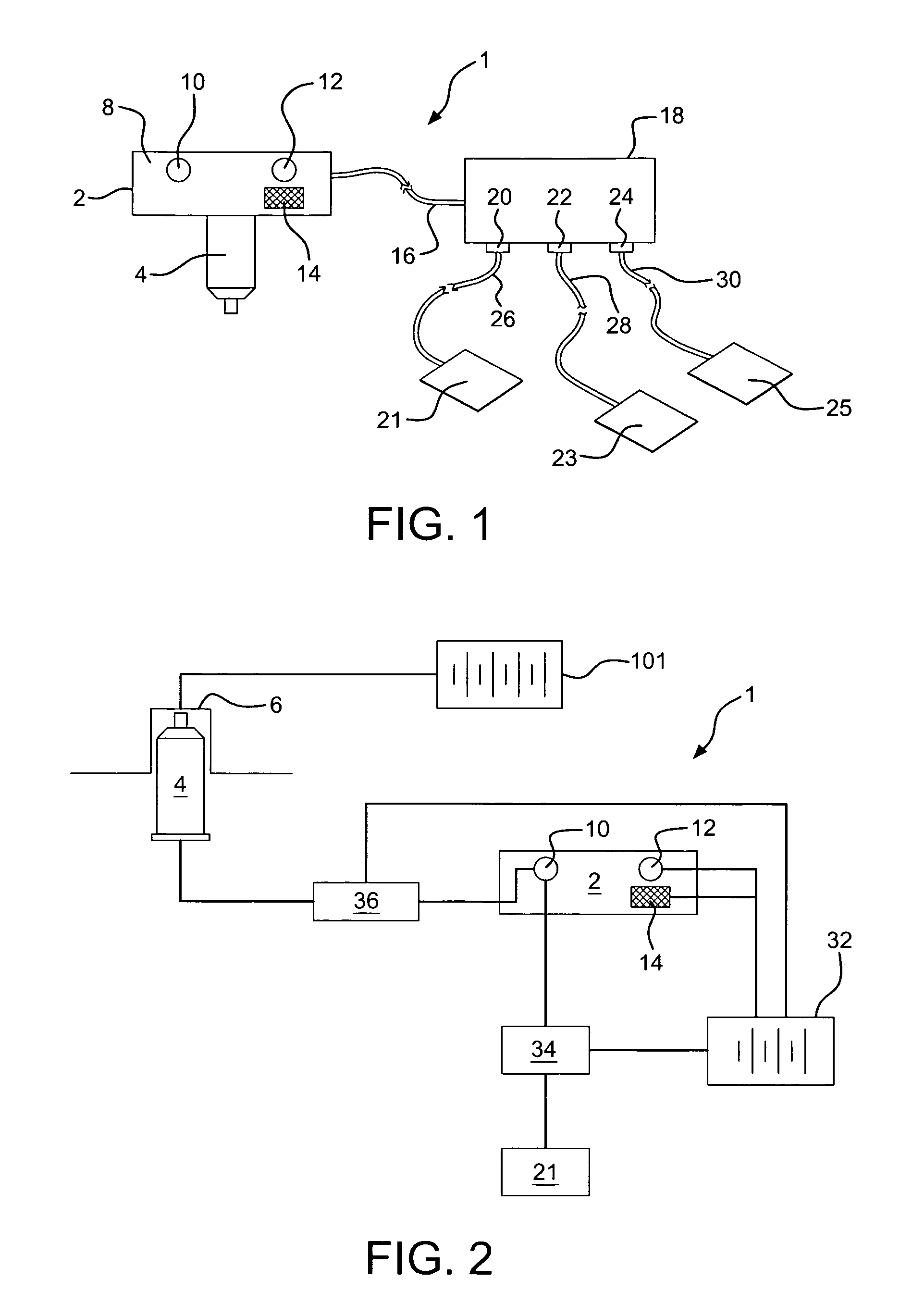

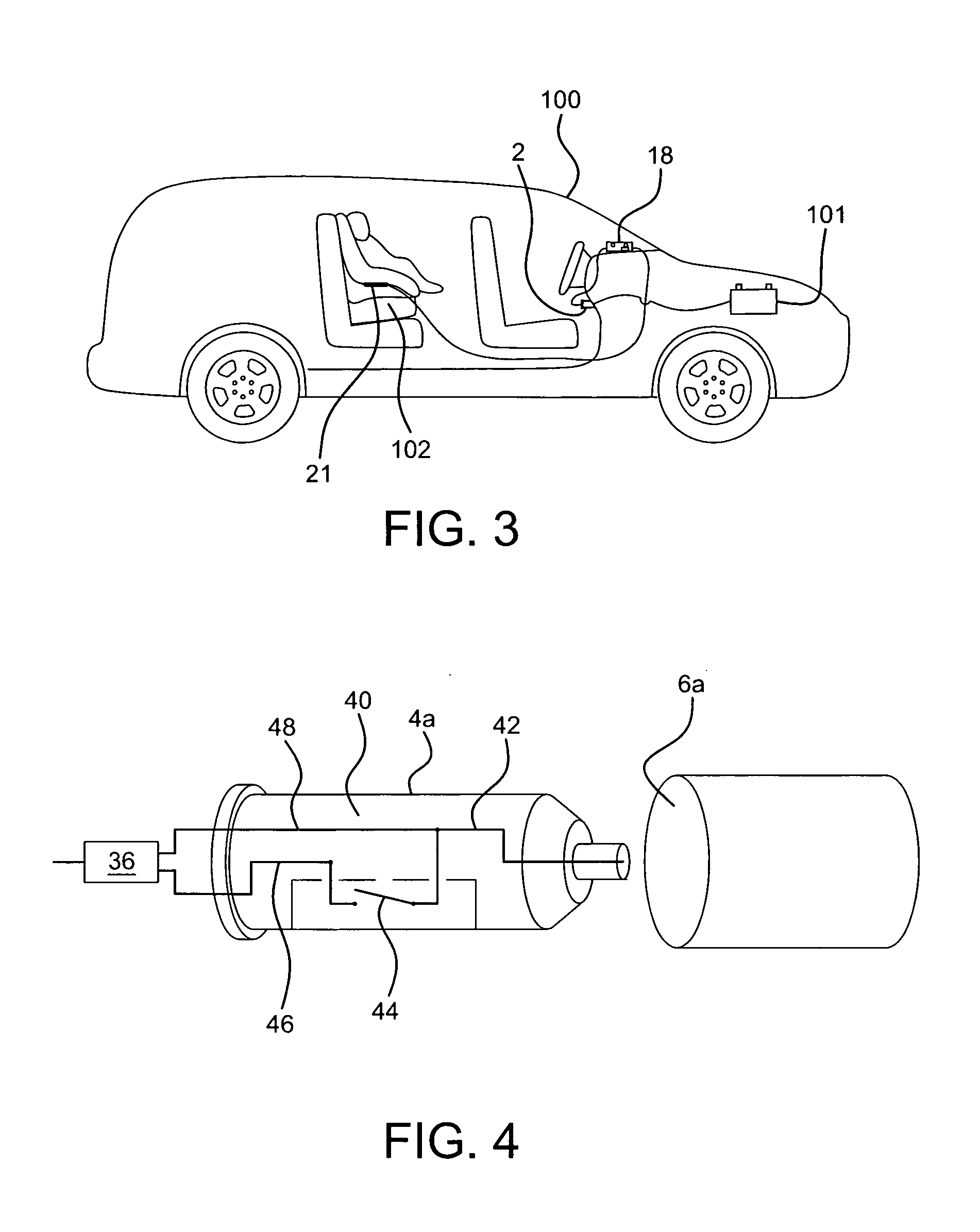

Child safety seat system

InactiveUS8154395B2Efficiently provideLightweight componentsElectric devicesAutomatic initiationsElectricityRechargeable cell

A portable child safety seat system has three lightweight, easily transferable modular components. The system utilizes one or more pressure sensor switches configured to be placed under the cushion of a vehicle's infant seat or cushions of multiple infant seats to detect the presence of a child in that seat. Electrical lines connect the pressure sensor switch to an interface unit which contains a back-up electrical power source, i.e. a rechargeable battery. The interface unit is in turn connected by electrical lines to a controller component which has a plug section for receiving electricity and a display section to indicate the presence of the child in the infant seat. When a child is in the infant seat and the vehicle's engine is running, the pressure sensing switch is closed and electricity is directed to light the display section of the controller. When the engine is not running, electricity is directed from the back-up battery to light the display section. An optional voltage sensing circuit is provided for use with certain types of vehicles.

Owner:TAYLOR MARC

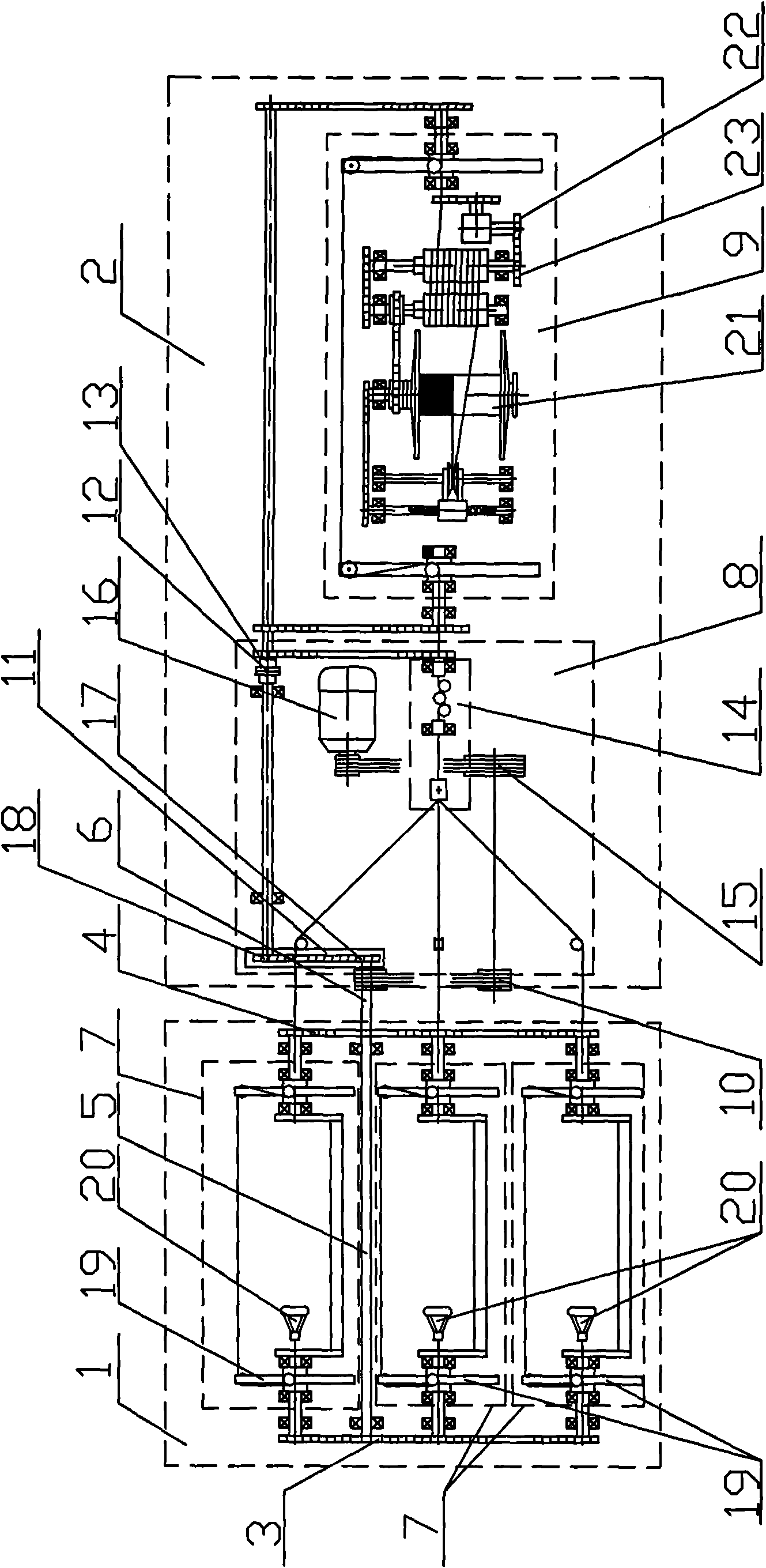

Two-in-one rope machine and rope manufacturing method thereof

InactiveCN101654880ALarge adjustment rangeLightweight componentsRope making machinesSmall footprintSprocket

The invention discloses a two-in-one rope machine, comprising a stranding device and a rope twisting device. The stranding device and the rope twisting device are connected by a second shaft, whereinthe stranding device is internally provided with a first chain wheel group, a main spool, a first shaft and three parallel arranged strand manufacturing devices; the rope twisting device consists of an over-twisting limiter and a rope forming device, the over-twisting limiter is provided with a vee pulley, a second chain wheel group, a coupling device, a third chain wheel group, an overt-twistingdevice, a triangular adhesive tape and a motor, the second chain wheel group consists of a wheel A and a wheel B, the wheel A and the wheel B are connected by a chain. Each strand manufacturing deviceis provided with a spool and a strand spindle seat; and the over-twisting limiter is connected with the rope forming device by a shaft. The rope manufacturing method of the two-in-one rope machine comprises the steps of running threading, pre-twisting; rope manufacturing; rope forming and removing the spool before running the machine. The invention has the advantage of small occupation area, lower cost of device and labor and higher work efficiency.

Owner:JIANGSU JIAOLONG HEAVY IND GROUP

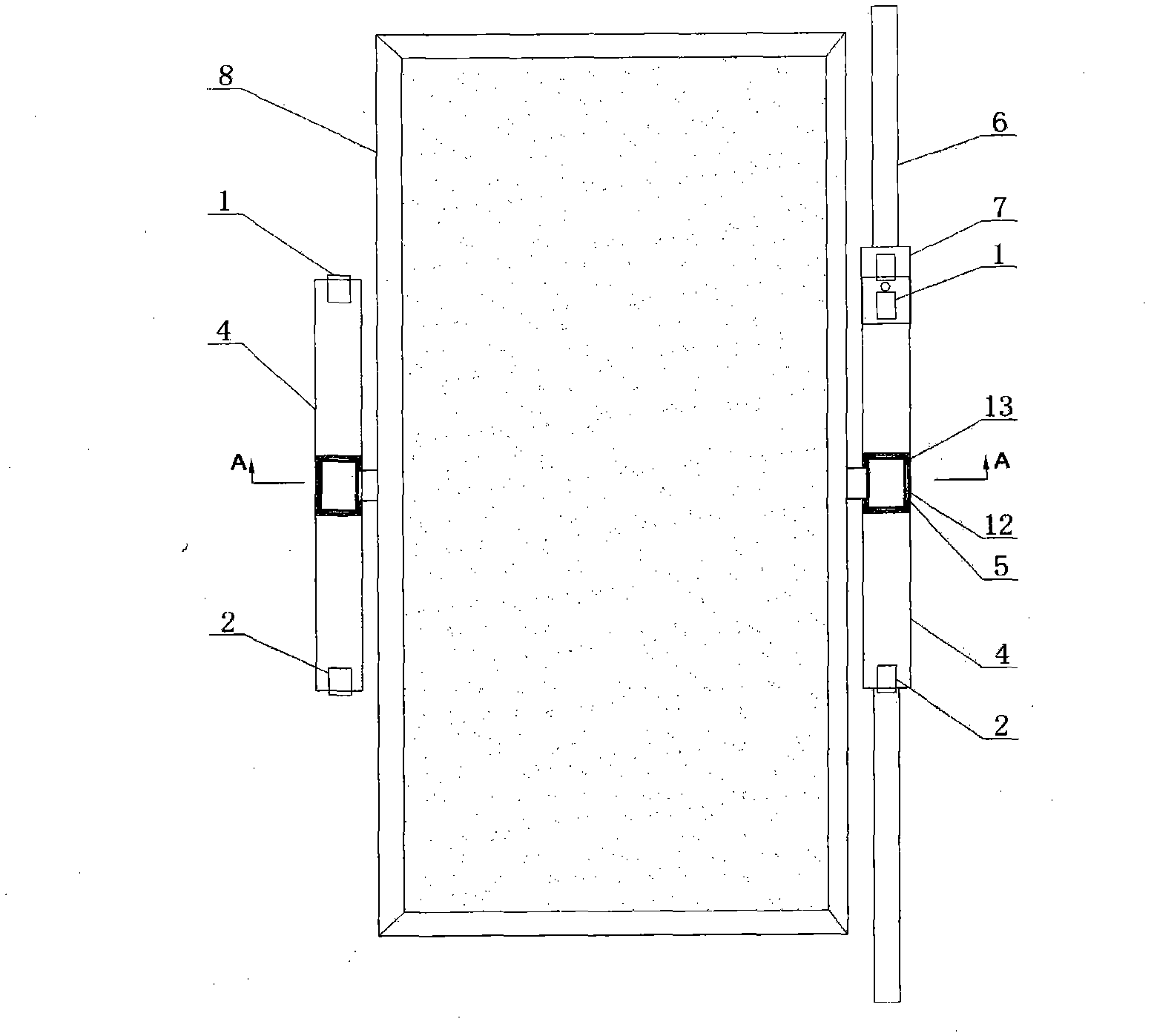

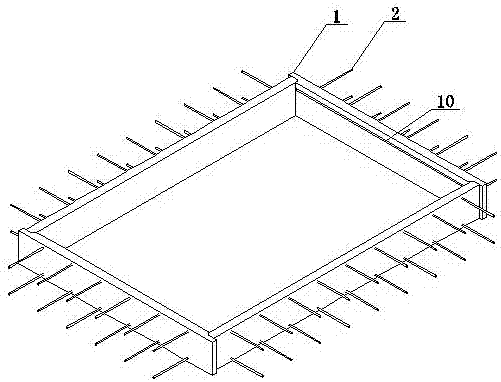

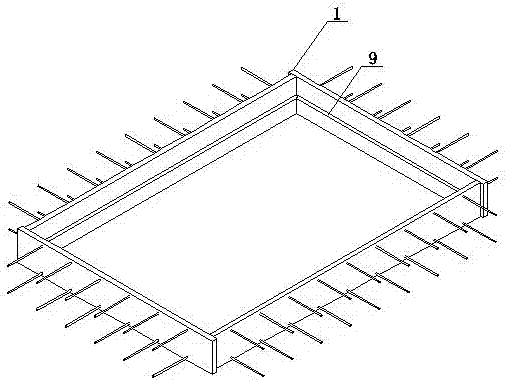

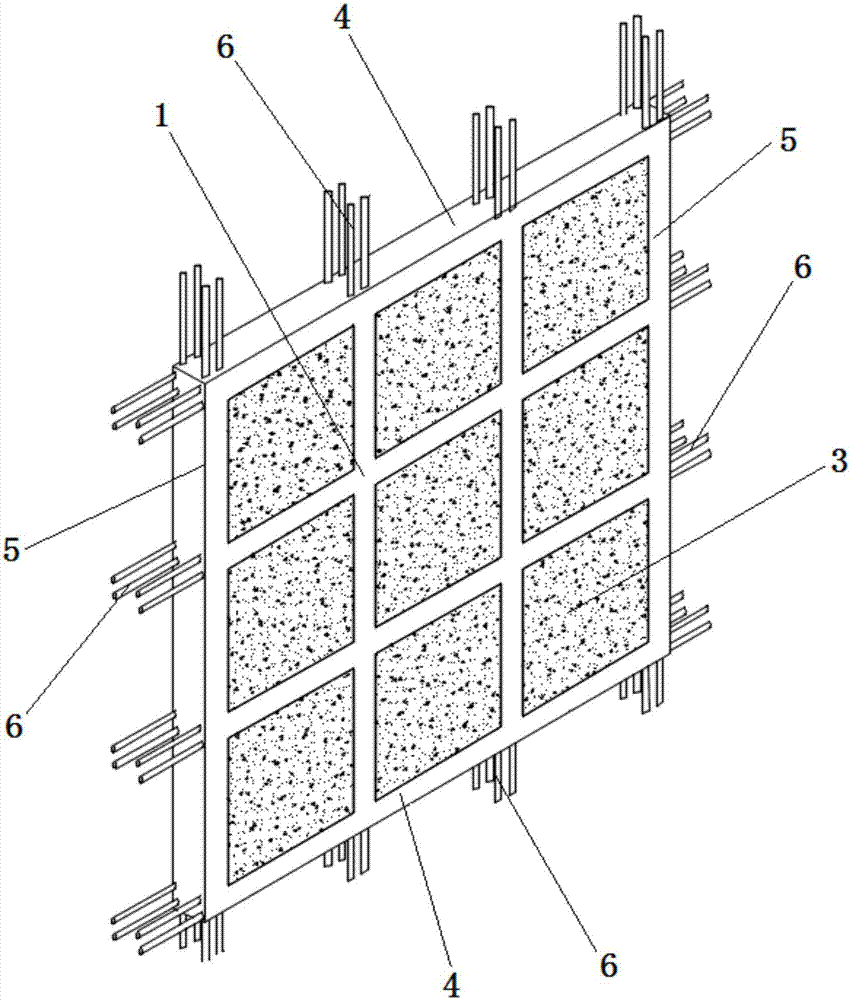

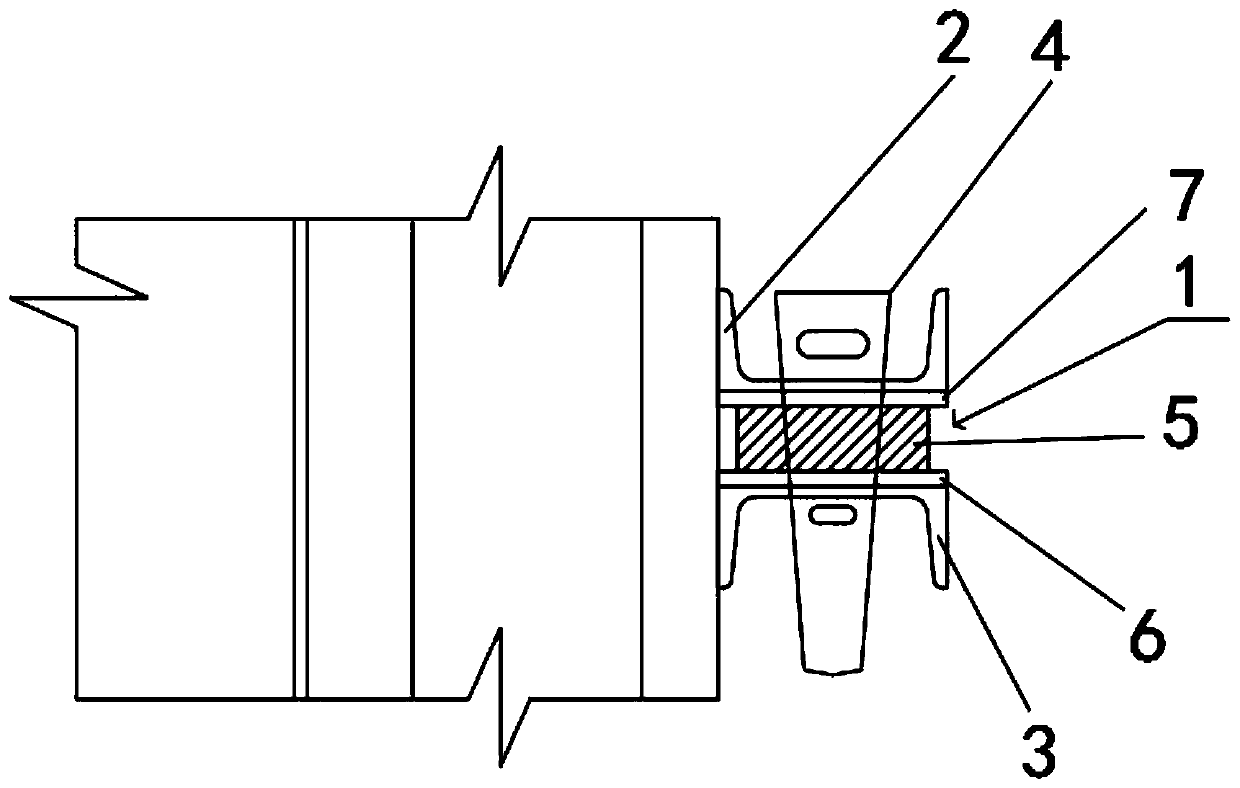

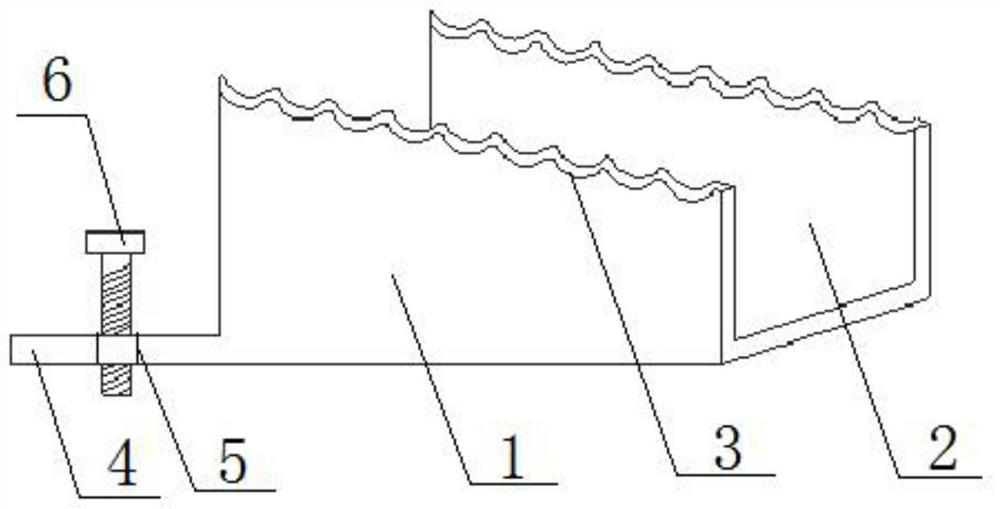

Prefabricated wall concrete door and window frame and construction method

PendingCN107299695ALow amortized costLow costWallsBase framesArchitectural engineeringPrecast concrete

The invention relates to a prefabricated wall concrete door and window frame and a construction method. In existing prefabricated concrete wall manufacturing, the template is large in amortizing amount, when a laminating plate type concrete wall is manufactured, the wall is poor in integrity, and the strength cannot meets transportation and hoisting requirements. The prefabricated wall concrete door and window frame comprises a prefabricated concrete door and window frame body (1), the prefabricated concrete door and window frame body is a straight strip plate spliced in a square box shape or an integral square box shape, an outward extending tie bar (2) is installed at the outer side of the straight strip plate or at the periphery of the integral square box, and the outward extending tie bar extends into wall bodies (3) of all sides of windows and doors. The construction method is used for the prefabricated wall concrete door and window frame.

Owner:湖北宇辉中工建筑产业化有限公司

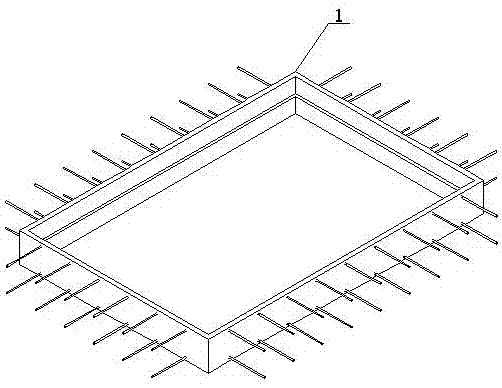

Method for reducing leakage in liquid conveying system

Inserting the in and out ports of the valve of the liquid delivery system into the in and out liquid channel, fastening them together, it can ensure the tightness of the connection between the pipe and the valve, reducing the leaking point of the valve and the contact point of the pipe. It is light, reduced in cost by saving the original flange disk, and easy for construction.

Owner:河南中轴集团有限公司

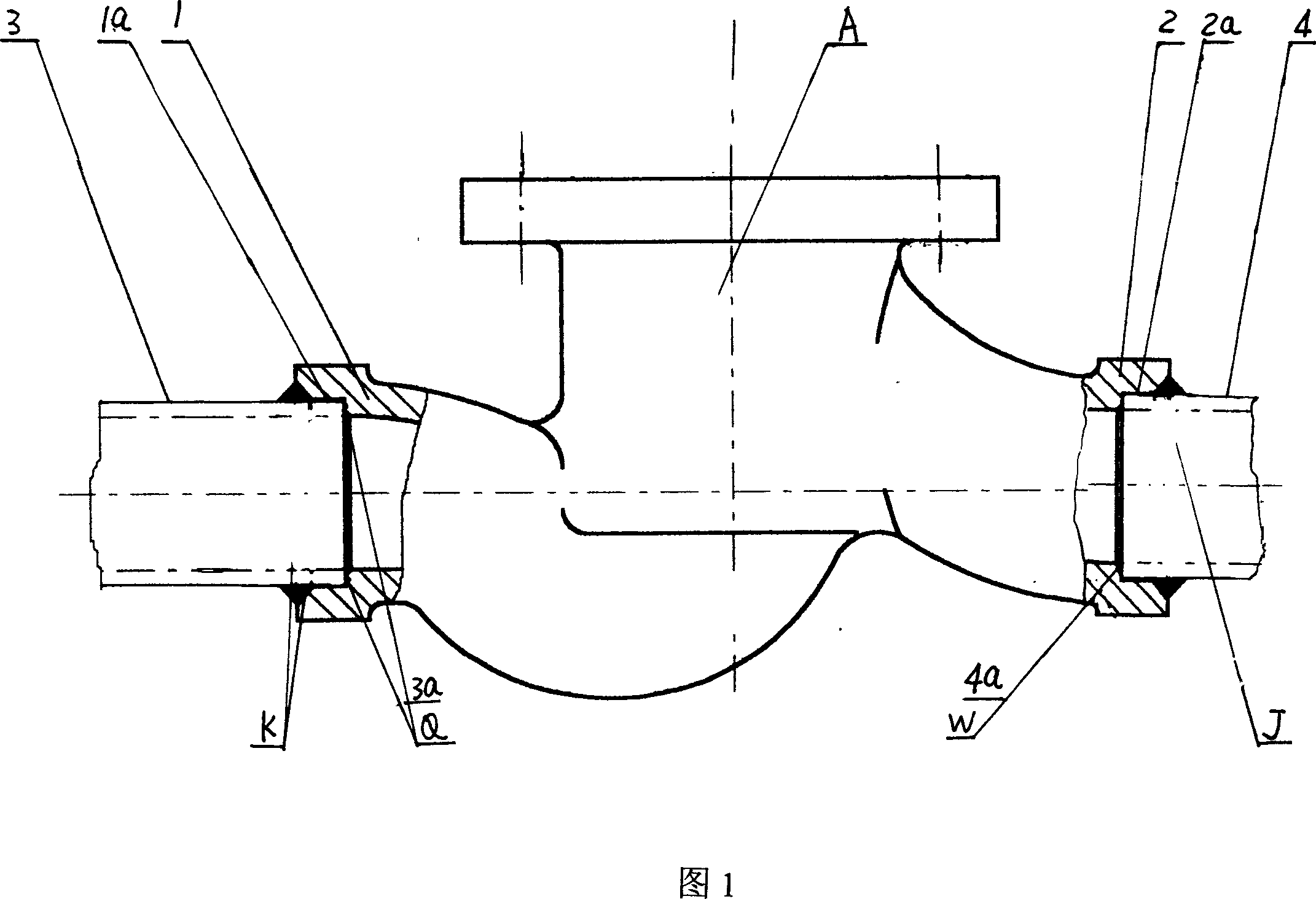

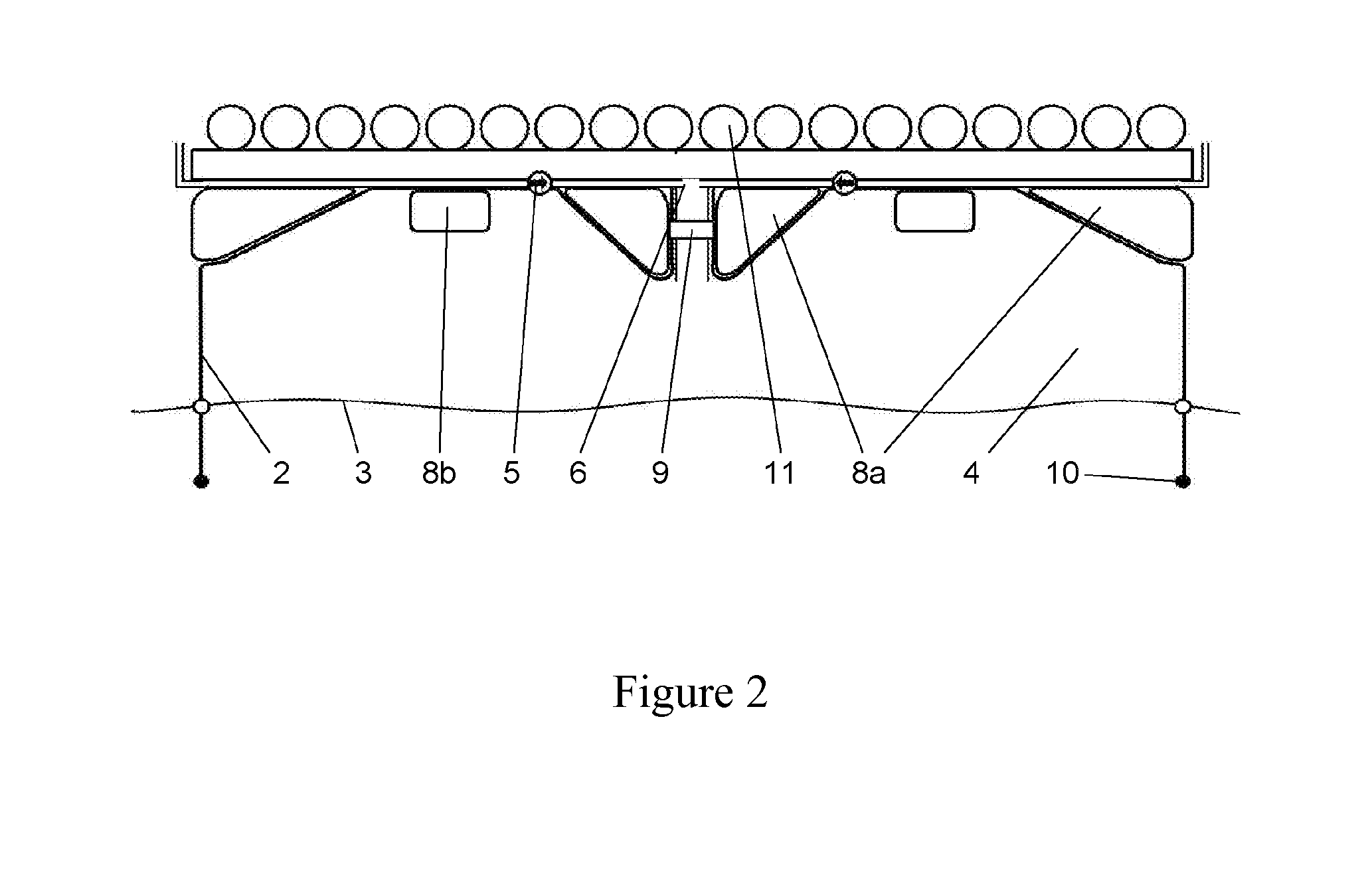

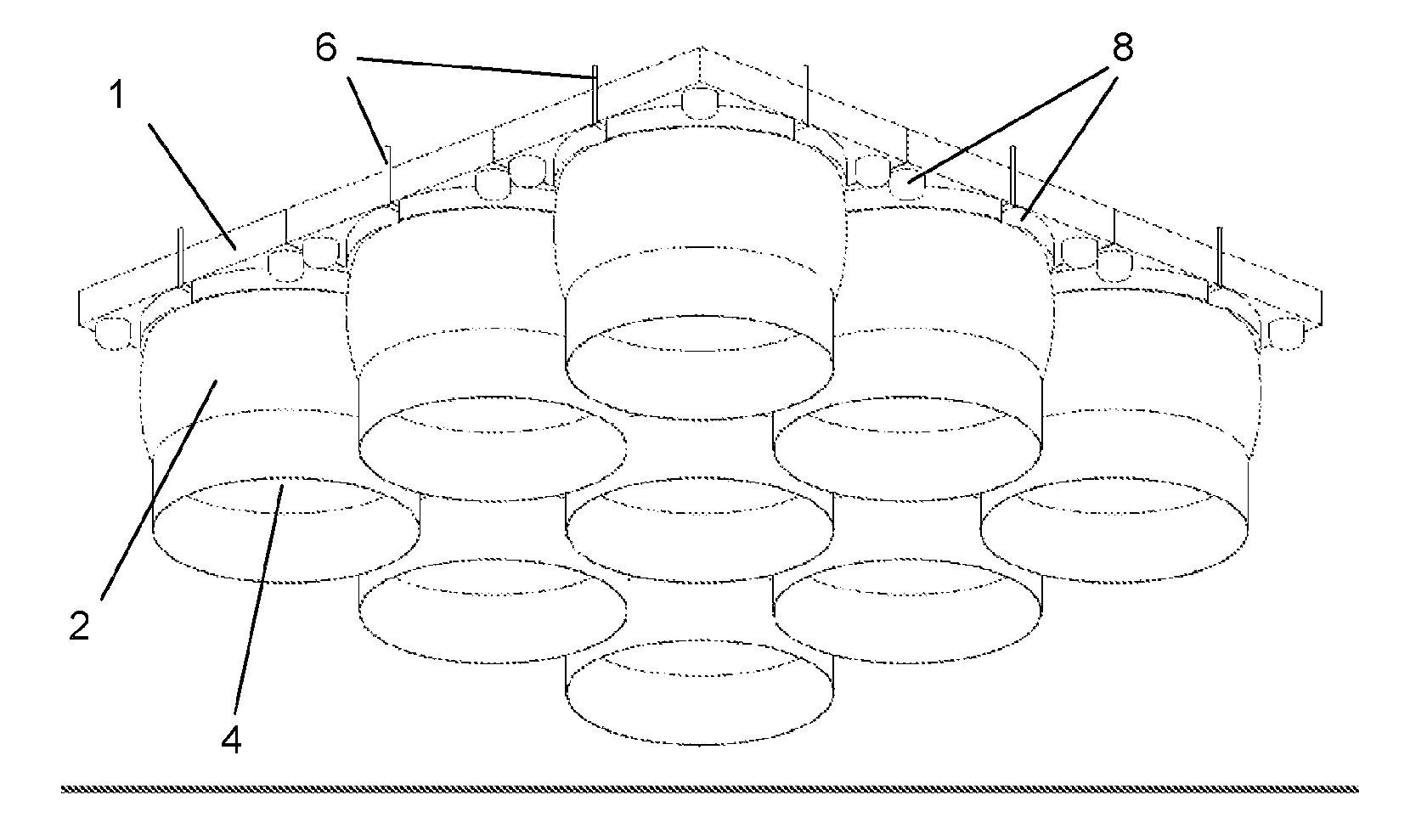

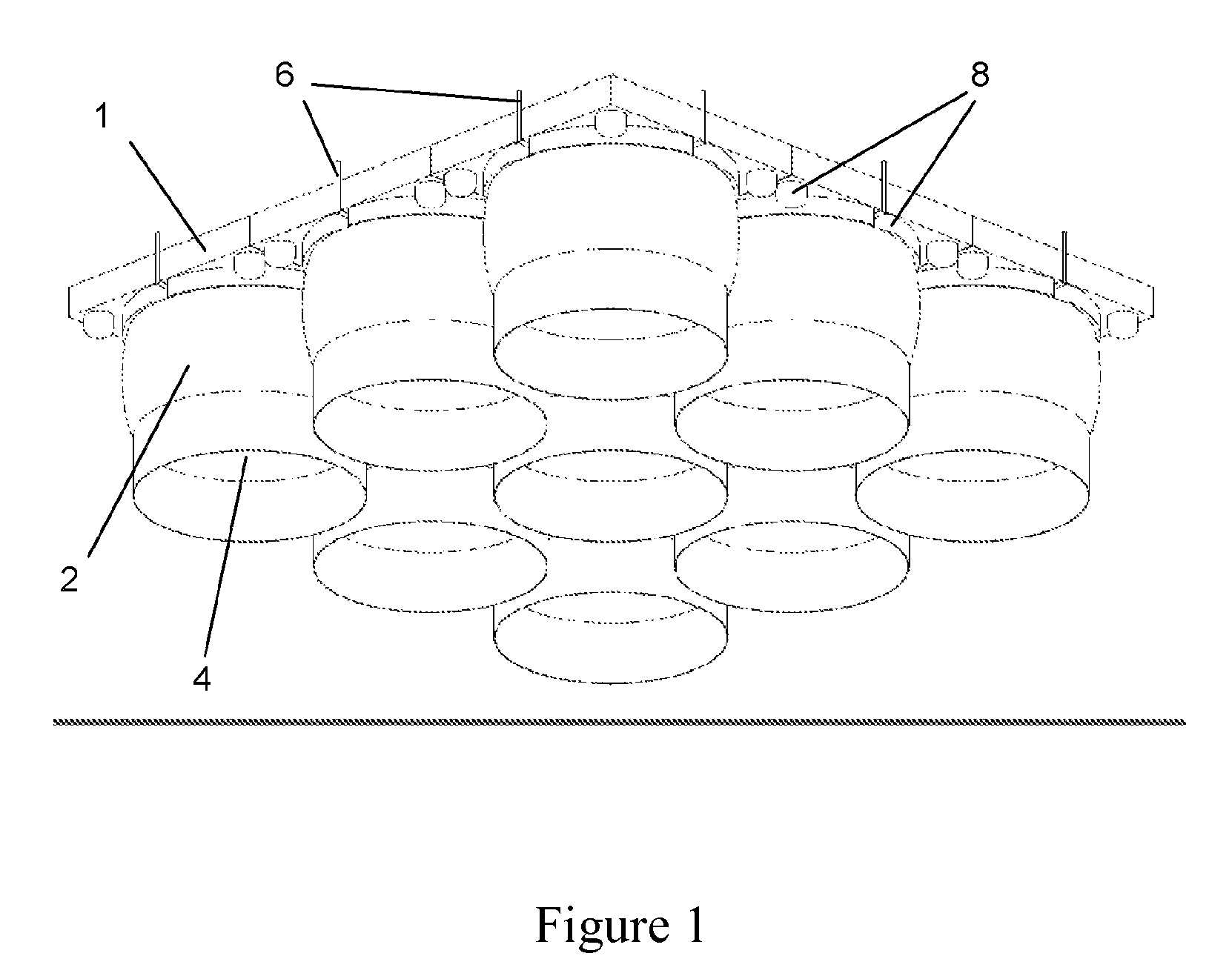

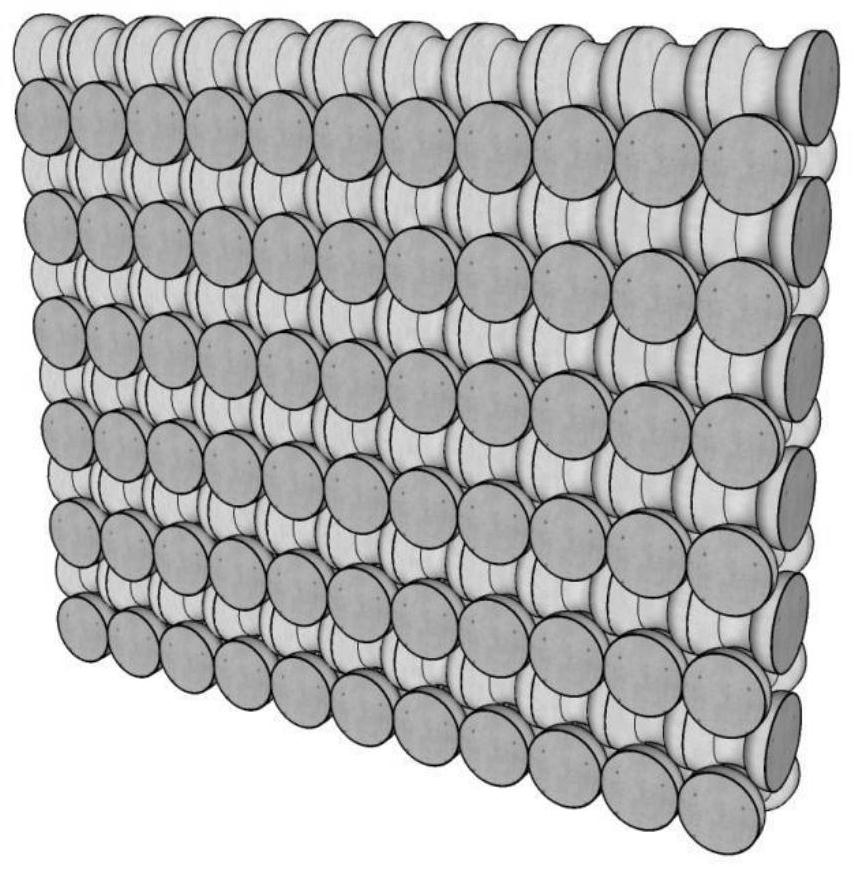

Floating platform

ActiveUS20150298774A1Increase volumeReduce air pressureSolar heating energySolar heat devicesEngineeringFloating platform

A floating platform is provided including the following: a covering element; at least three buoyant bodies, which are separated from each other, are fixedly mounted to the lower face of the covering element, are open toward the bottom, and are made of a gas-tight, pressure- and corrosion-resistant flexible material. The buoyant bodies enclose a closed hollow space when coming into contact with a liquid surface. At least one compressed-air generating device is also provided for generating an overpressure in the individual hollow spaces.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

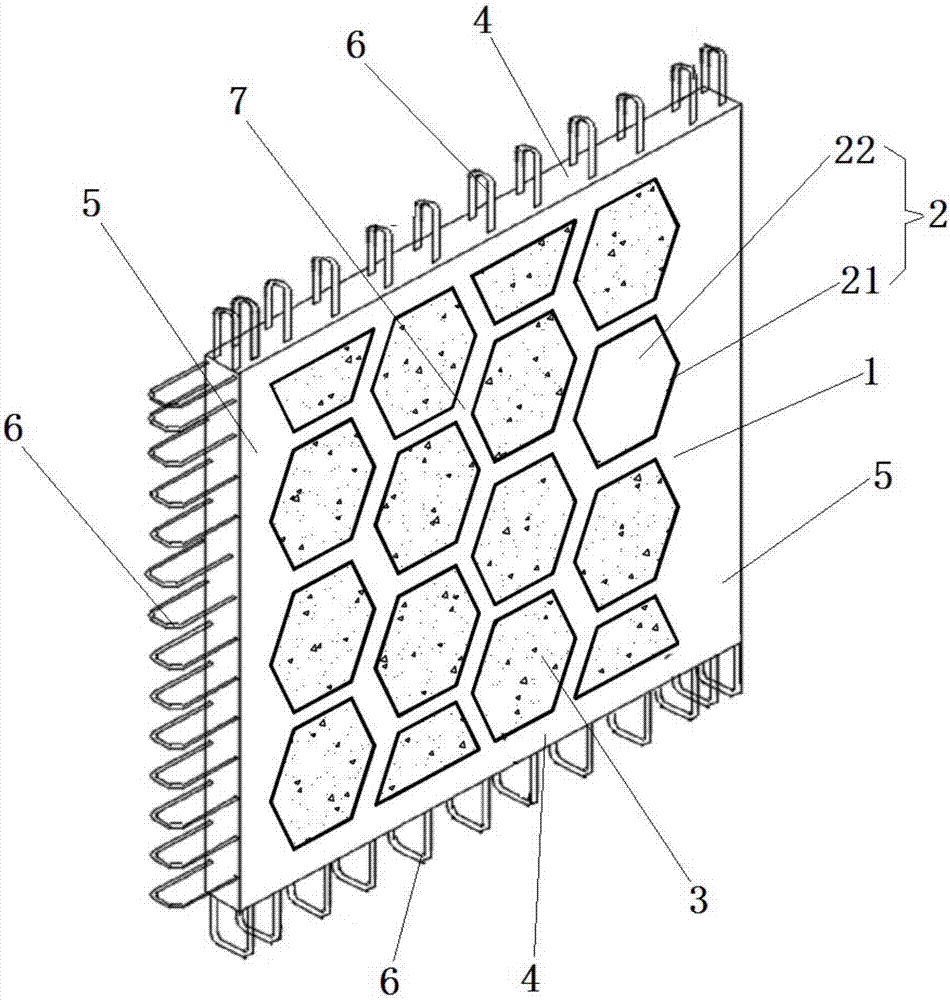

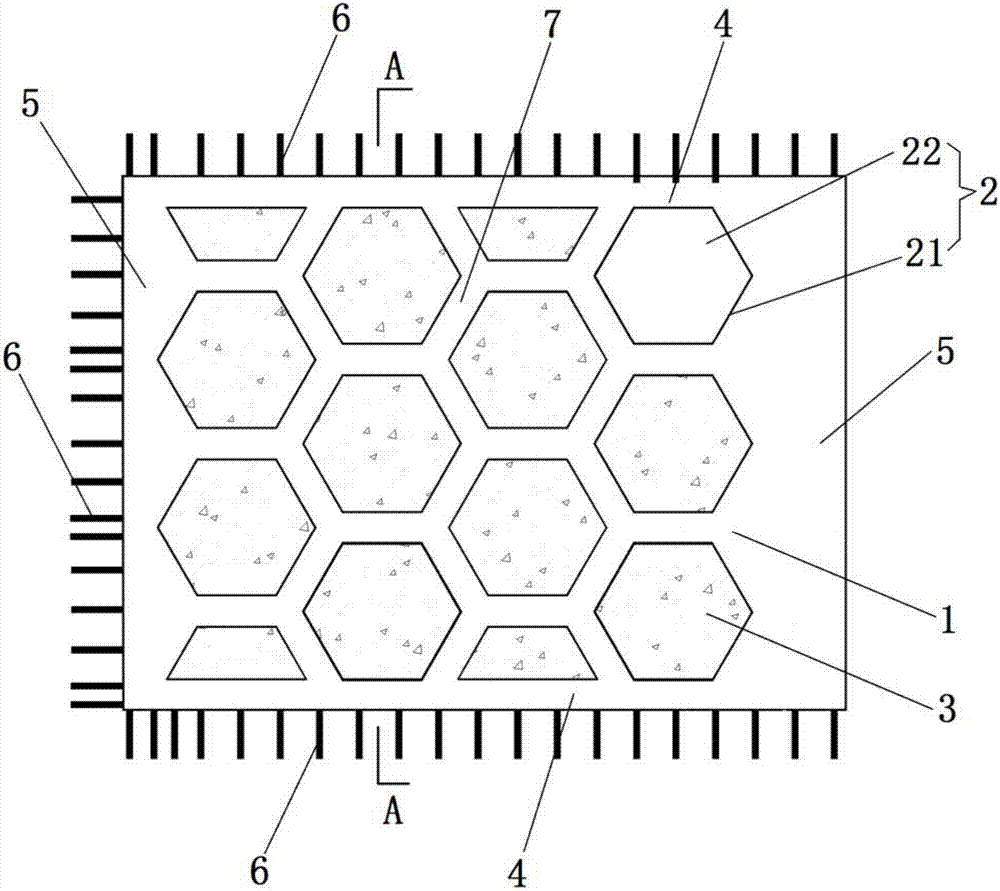

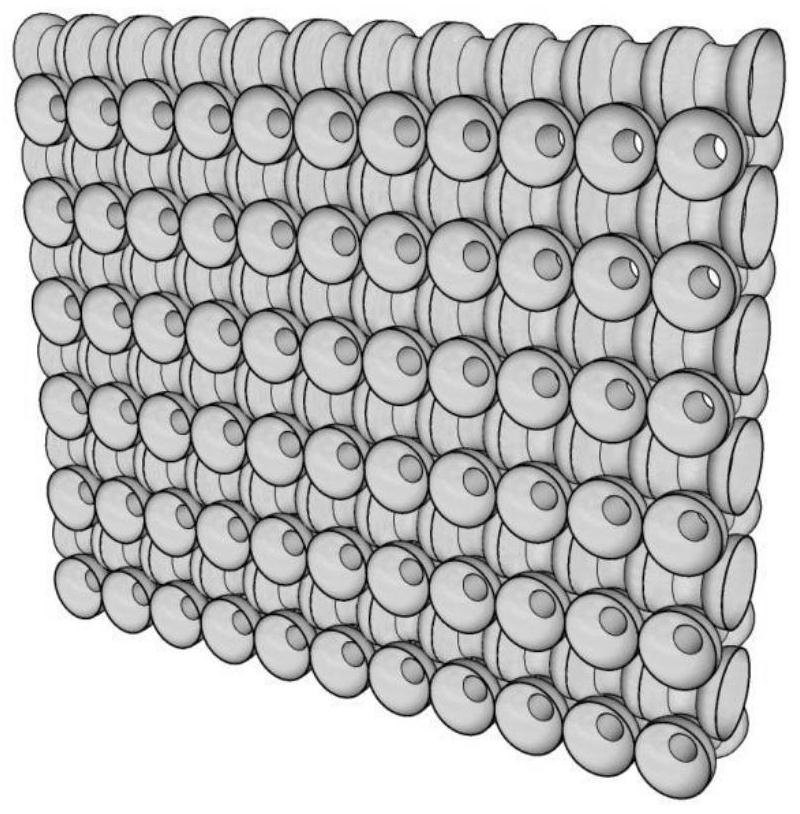

Prefabricated honeycomb composite structure wallboard

InactiveCN107083819AReasonable structureEasy to manufactureBuilding componentsHoneycomb structureMaterials science

The invention discloses a prefabricated honeycomb composite structural wallboard which comprises a platy cubic wallboard body provided with at least six surfaces. A plurality of honeycomb structure units distributed in a honeycomb shape are arranged in the wallboard body. Each honeycomb structure unit comprises a polygonal honeycomb wall which is formed by connecting at least six edges or a tubular honeycomb wall composed of arc edges, a honeycomb hole and filler, wherein the honeycomb hole is formed by the honeycomb wall, and the filler is arranged in the honeycomb hole. The periphery of the honeycomb structure unit located in the middle is adjacent to at least four additional honeycomb structure units. The prefabricated honeycomb composite structural wallboard is easy and convenient to manufacture, the polygonal or arc-shaped honeycomb structure units formed by at least six sides are adopted and distributed in the wallboard in the honeycomb shape so that the wallboard of a composite structure can be formed, the bearing capacity of the assembled wallboard is improved so that the stress of the wallboard can be more uniform and reasonable, the safety performance of the wallboard is improved, and the economical efficiency is remarkable.

Owner:刘祥锦

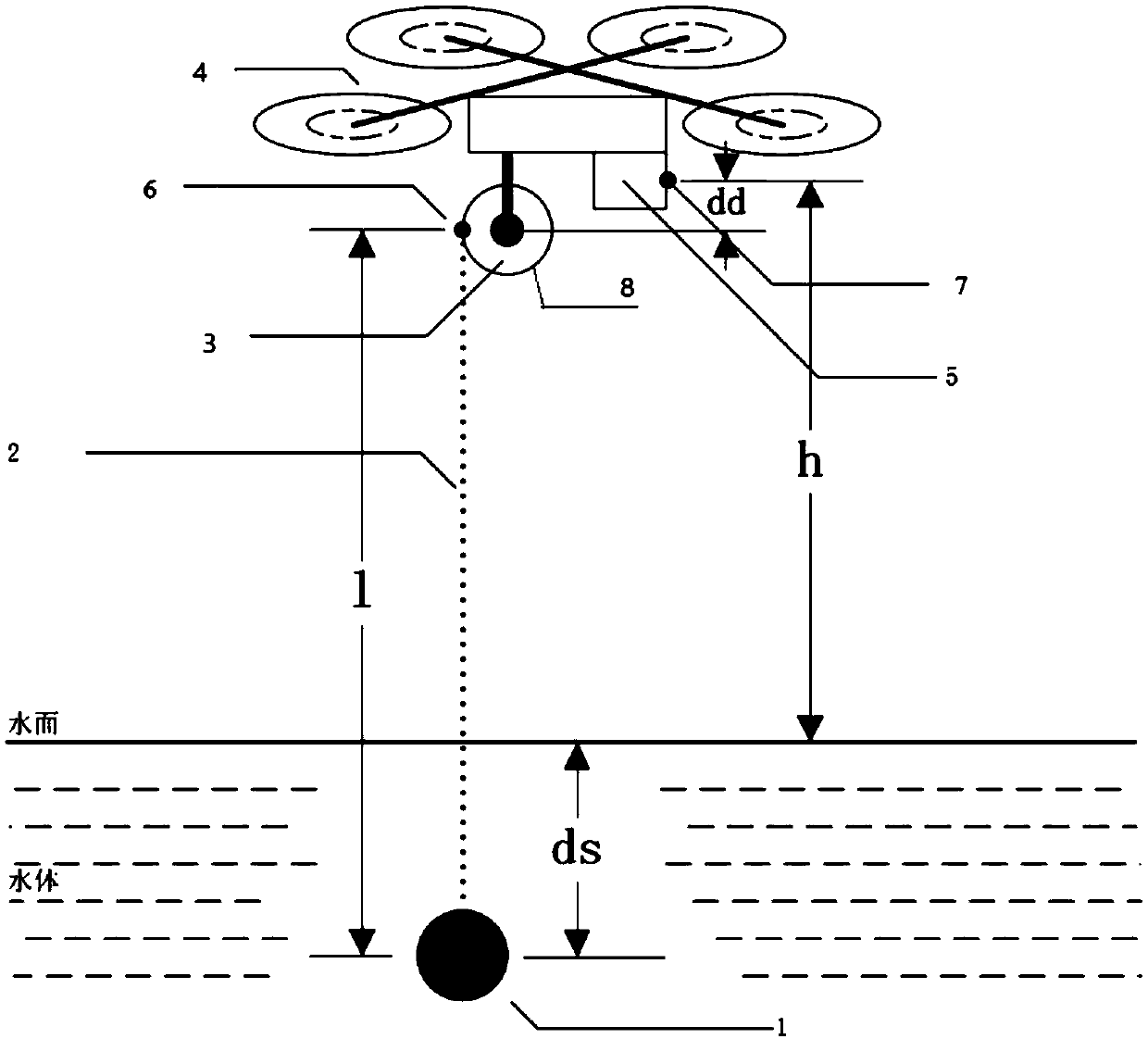

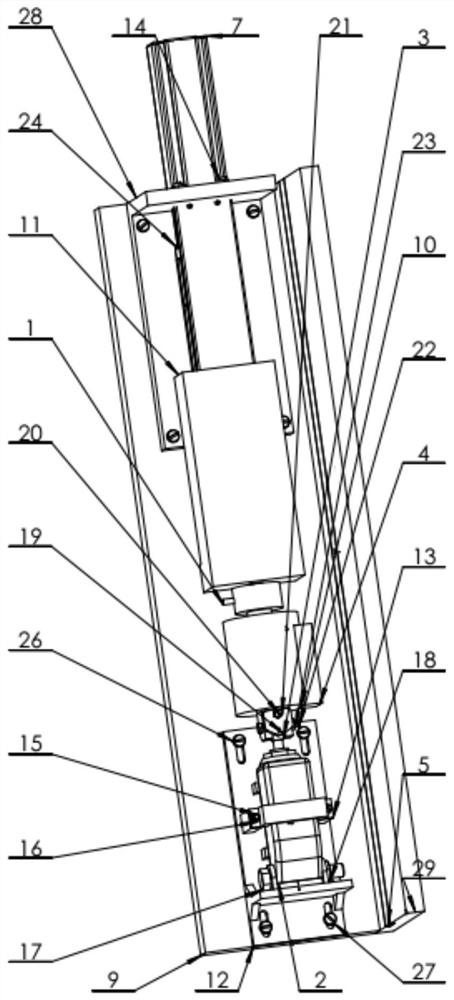

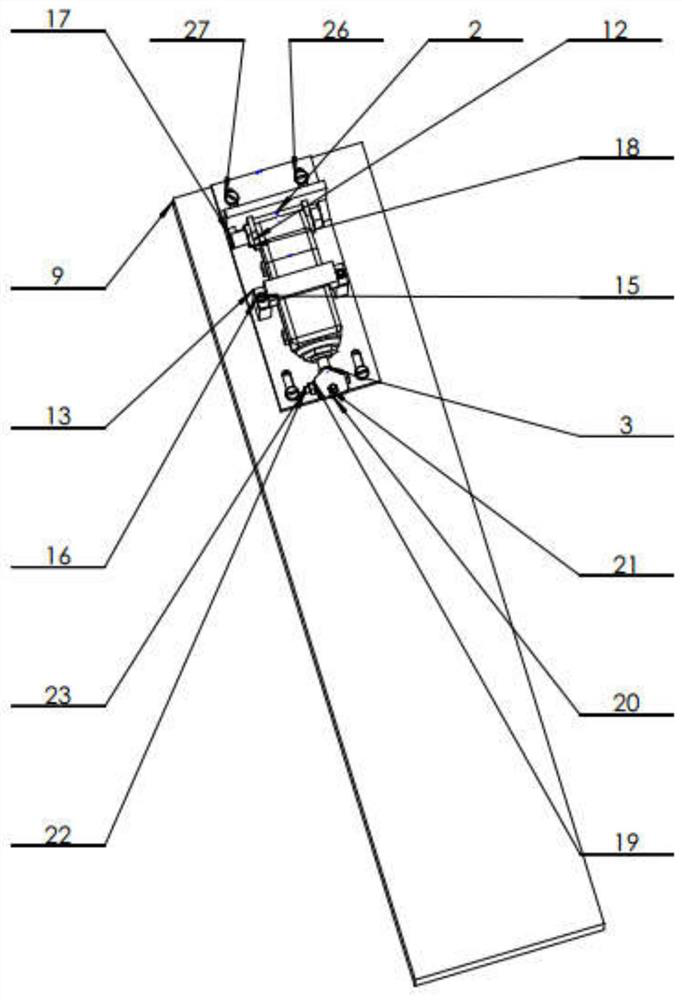

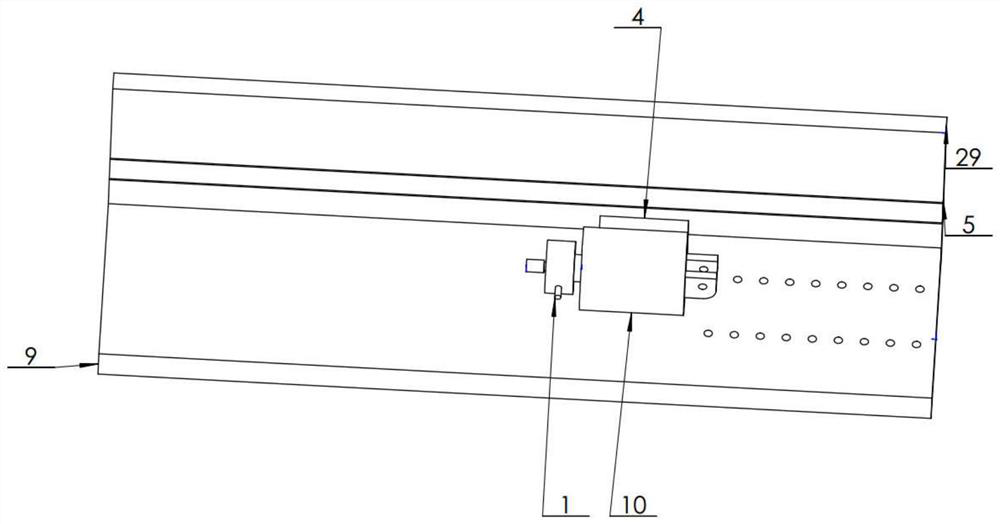

Water quality probe depth keeping system and method suitable for unmanned aerial vehicle

InactiveCN109655311ASolve the problem of setting depthWater entry depth controllableWithdrawing sample devicesAircraftsUncrewed vehicleWater quality

The invention belongs to the technical field of unmanned aerial vehicles and discloses a water quality probe depth keeping system and method suitable for an unmanned aerial vehicle. The water qualityprobe depth keeping system comprises a sling length sensing unit, a height detector and a sling retracting unit carried on an unmanned aerial vehicle load; the sling length sensing unit is used for detecting the length of a released sling, the height detector is used for detecting the flying height of the unmanned aerial vehicle; during working, the sling is attached to the sling retracting unit and used for suspending a water quality probe, the sling retracting unit determines the length of the sling required according to the detection results of the sling length sensing unit and the height detector and controls the retraction of the sling, so that the water quality probe is at the target underwater depth. By means of the water quality probe depth keeping system and method, the controllable and adjustable underwater depth of the water quality probe suspended by the unmanned aerial vehicle is achieved, the underwater depth can be dynamically and automatically adjusted during the operation, and depth keeping acquisition or detection is achieved.

Owner:武汉飞流智能技术有限公司

Floating platform

ActiveUS9365267B2Increase volumeReduce air pressureSolar heating energySolar heat devicesEngineeringFloating platform

A floating platform is provided including the following: a covering element; at least three buoyant bodies, which are separated from each other, are fixedly mounted to the lower face of the covering element, are open toward the bottom, and are made of a gas-tight, pressure- and corrosion-resistant flexible material. The buoyant bodies enclose a closed hollow space when coming into contact with a liquid surface. At least one compressed-air generating device is also provided for generating an overpressure in the individual hollow spaces.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

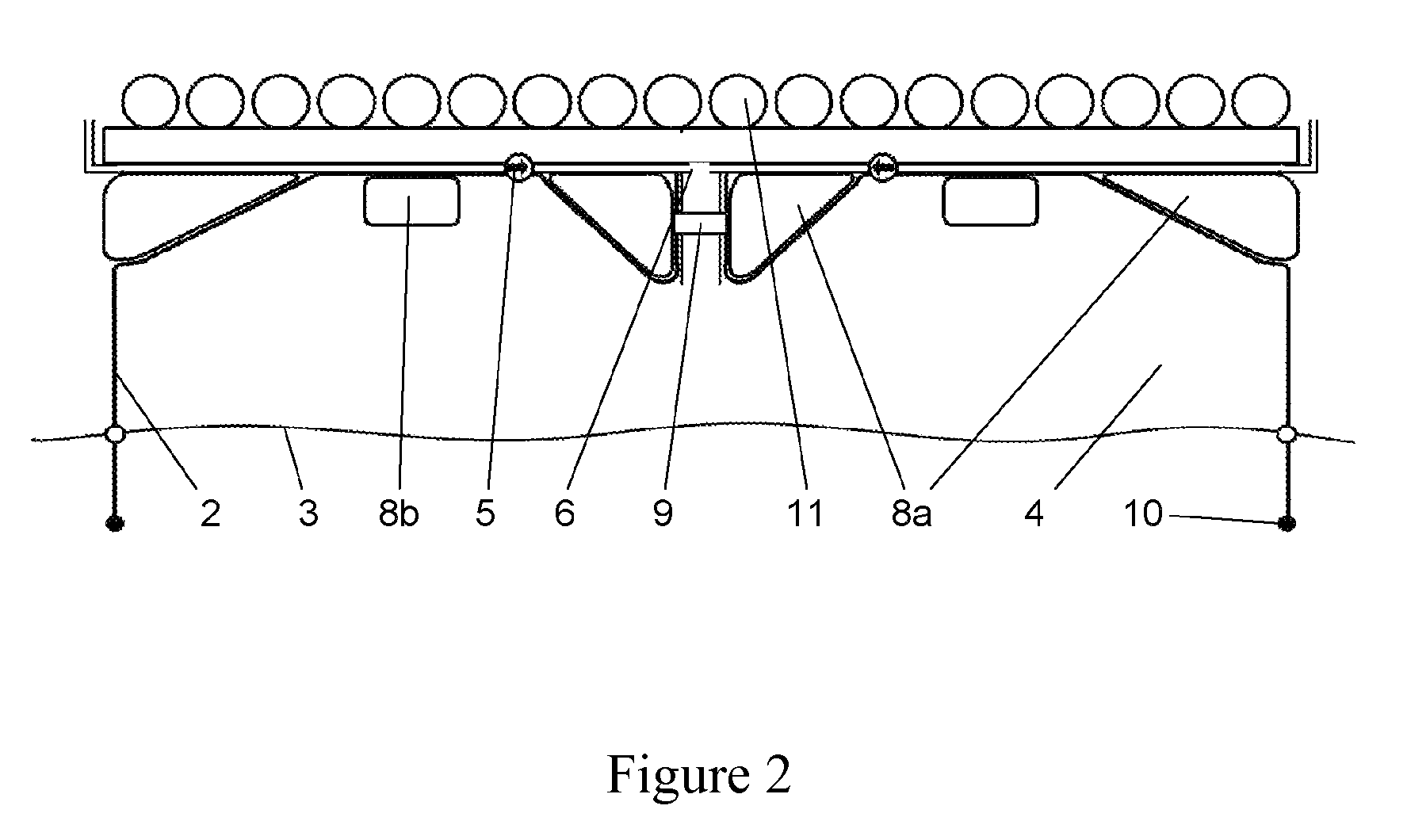

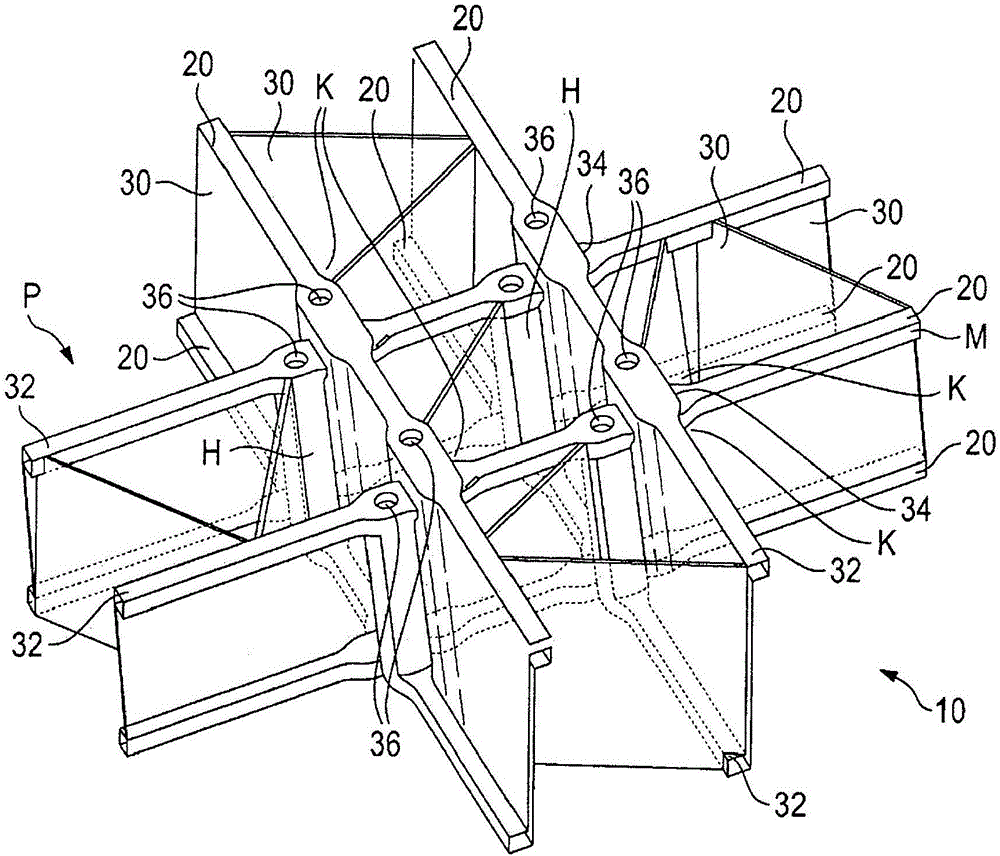

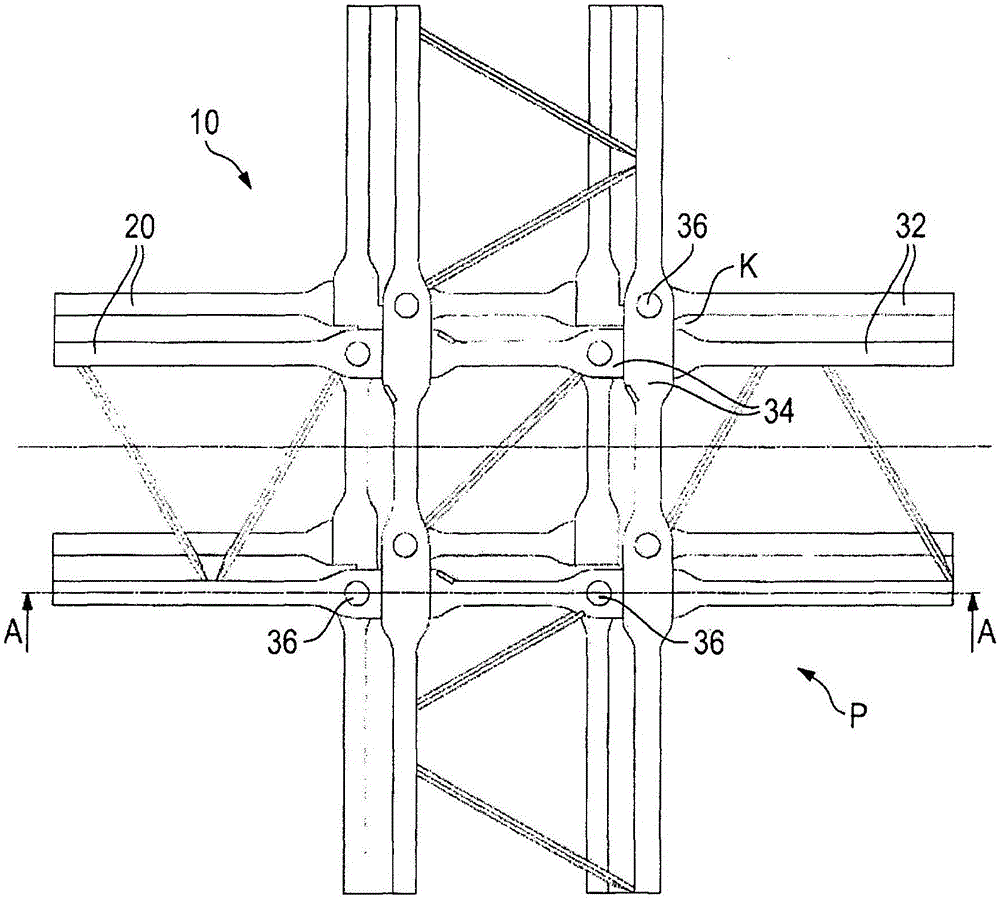

Fibre composite material component, and method for producing a fibre composite material component

ActiveCN106794609AReduce usageAvoid accumulationHollow wall articlesDomestic articlesFibrous compositesMaterials science

The present invention relates to a fibre composite material component (10) having fibre bundles (20) and having a matrix (M) of thermoplastic and / or thermosetting material, wherein the fibre bundles (20) are arranged such that they form a profile (P), wherein bracing means (30) are arranged between the fibre bundles (20), wherein at least two fibre bundles (20) are arranged in a skewed manner with respect to one another and wherein at least one cavity (H) is formed in the region of the intersection (K) of the skewed fibre bundles (20). Furthermore, the present invention relates to a method for producing a fibre composite material component (10) having fibre bundles (20) and having a matrix (M) of thermoplastic and / or thermosetting material.

Owner:BAYERISCHE MOTOREN WERKE AG

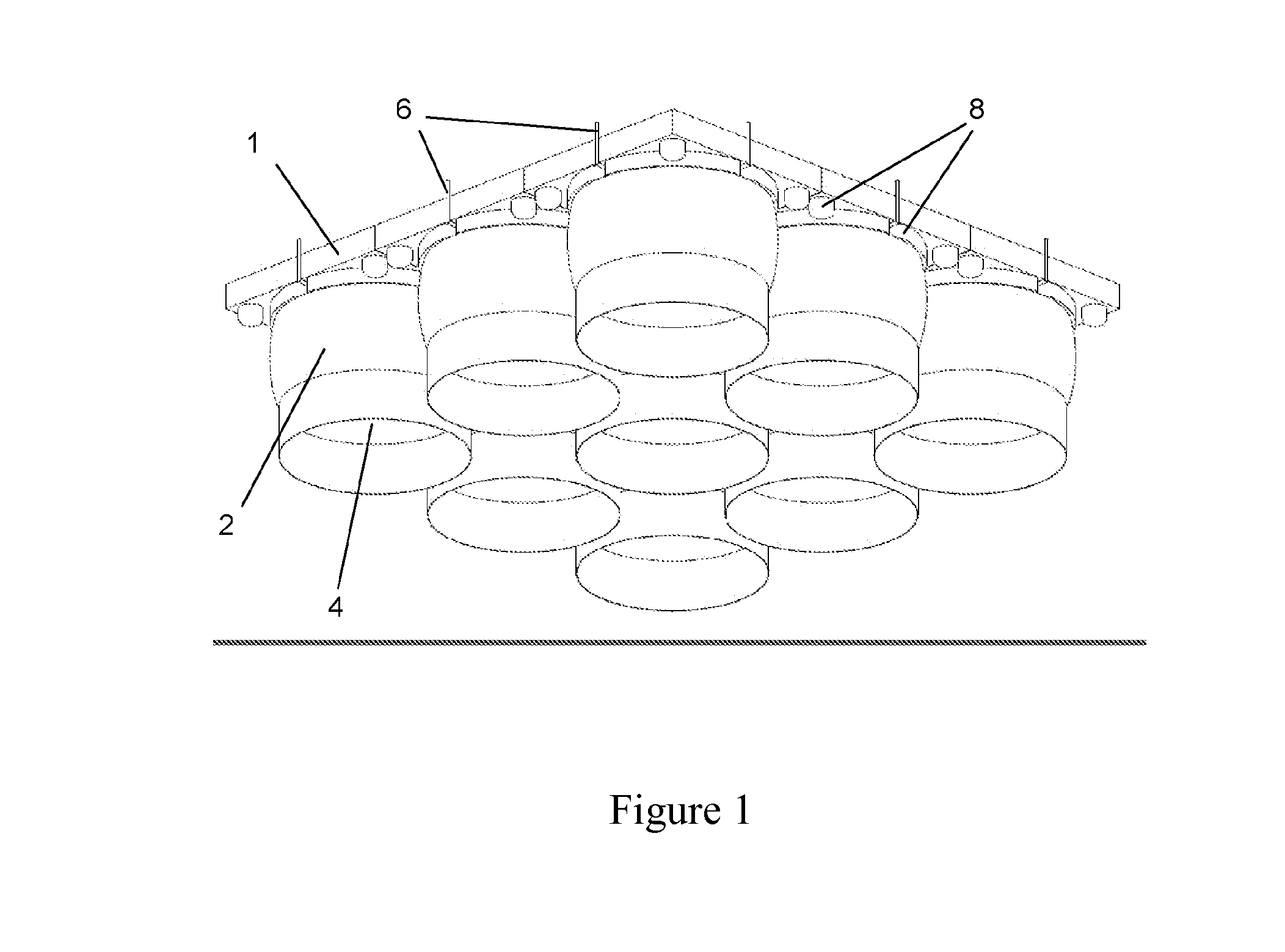

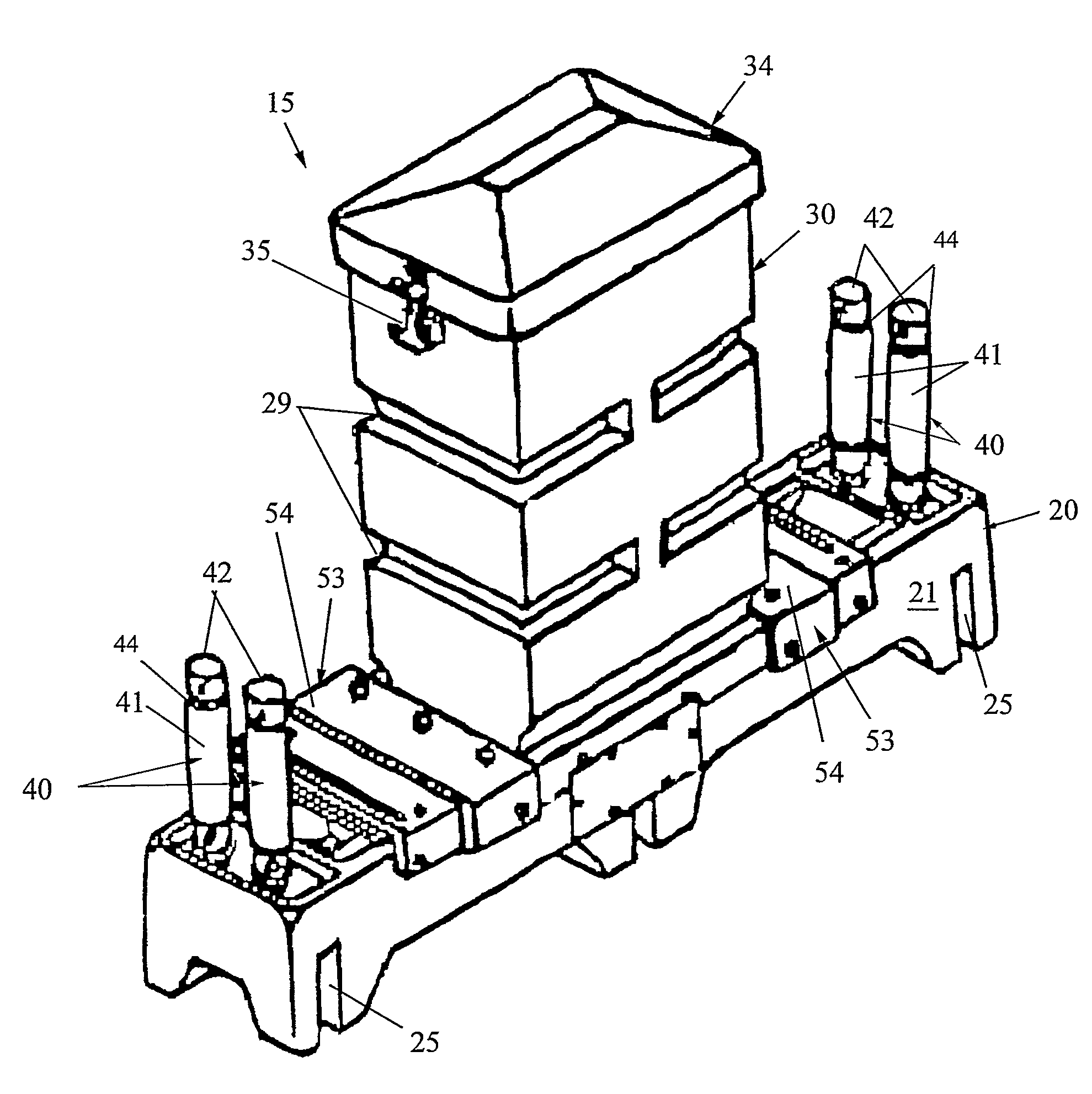

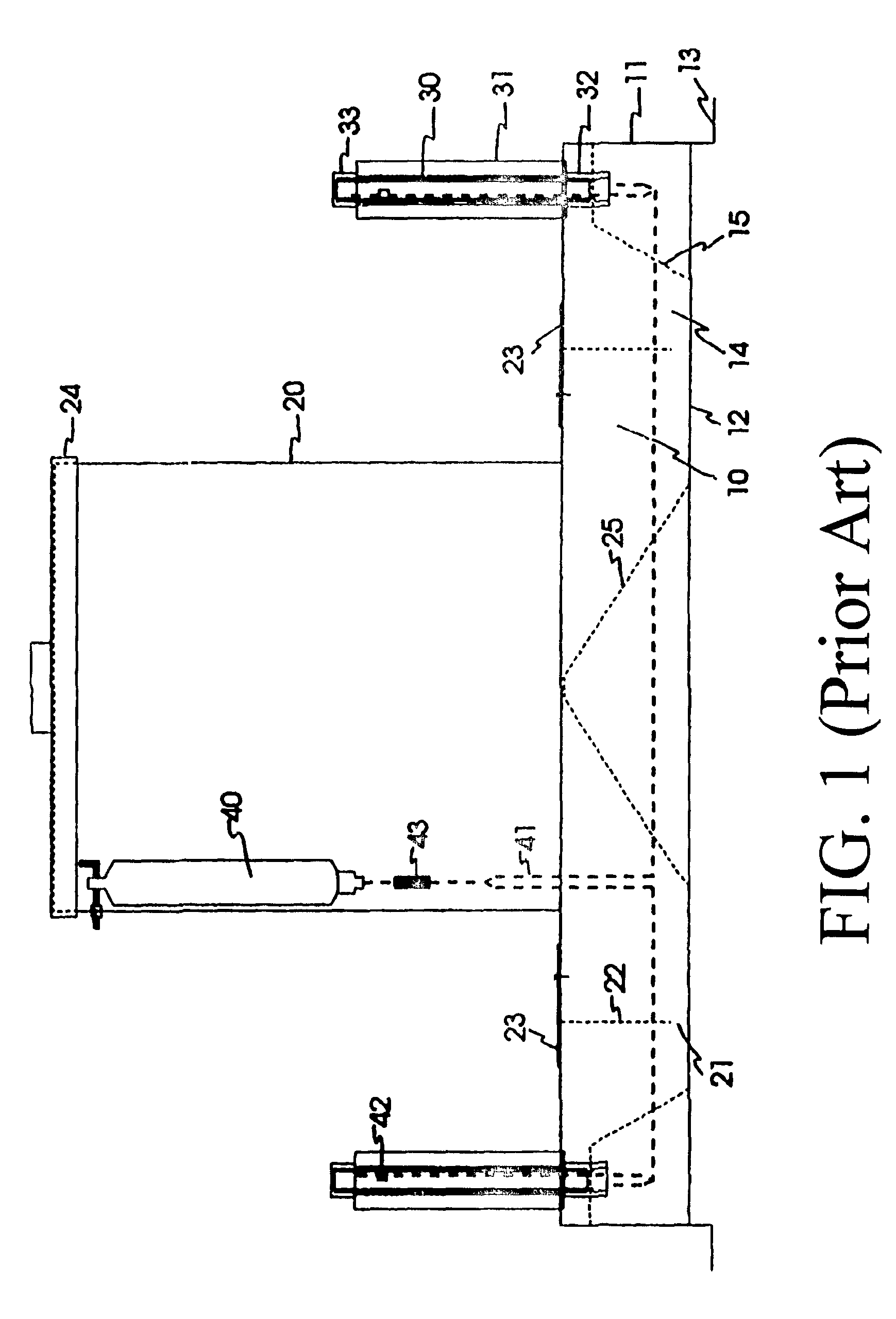

Apparatus for use in controlling the spread of ectoparasite-borne diseases

ActiveUS8056513B2Reduce manufacturing costEasy to assembleOther apparatusGrooming devicesWildlifeBiology

A device (15) for the application of pesticides to animals as they feed and that accommodates wildlife of all sizes, poses no threat of harm to the animals, and maximizes the per capita application of pesticide. Whole kernel corn (or other feed) placed in a feed bin (30) is dispensed into a trough / receptacle (20) through an opening at the bottom of the bin. The trough / receptacle (20) is surrounded by pesticide applicators (40) such that as an animal feeds, some part of its head, neck and / or ears will contact one or more of the applicators. The applicators (40) are flexible and rotatable, so that animals attracted to the apparatus to feed are subjected to the application of a pesticide upon their head, neck, ears, and / or, where applicable, antlers or horns, the flexible and rotatable applicators (40) maximizing pesticide application with minimal stress to both the animal and device. The device employs a modular molded polyethylene design that is durable, economical, mass-producible, lightweight, and can be shipped for user-assembly, thereby reducing shipping and manufacturing costs.

Owner:ABEL BRUCE ALAN +2

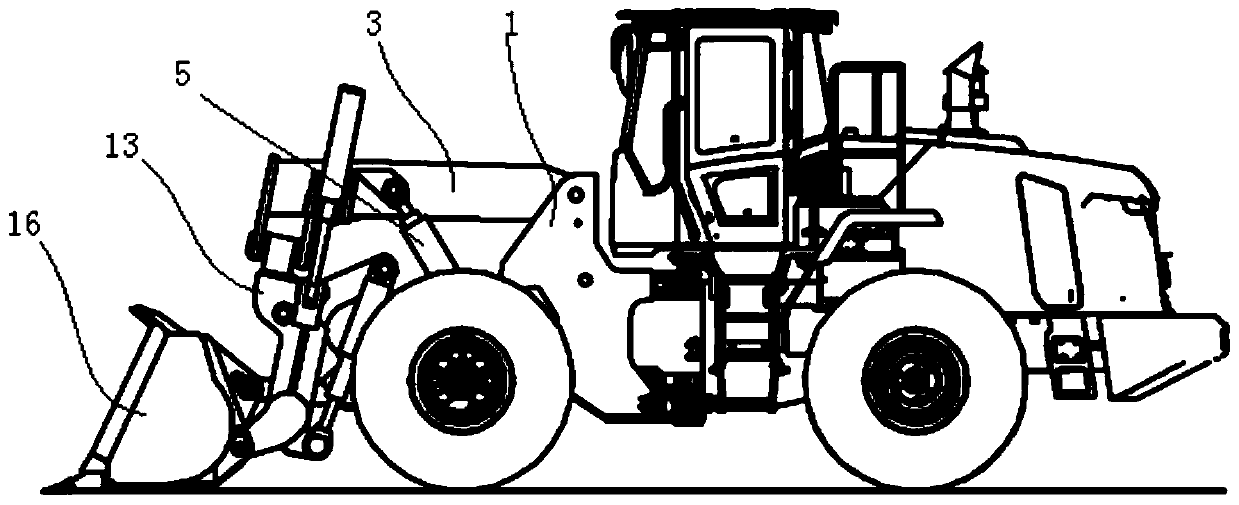

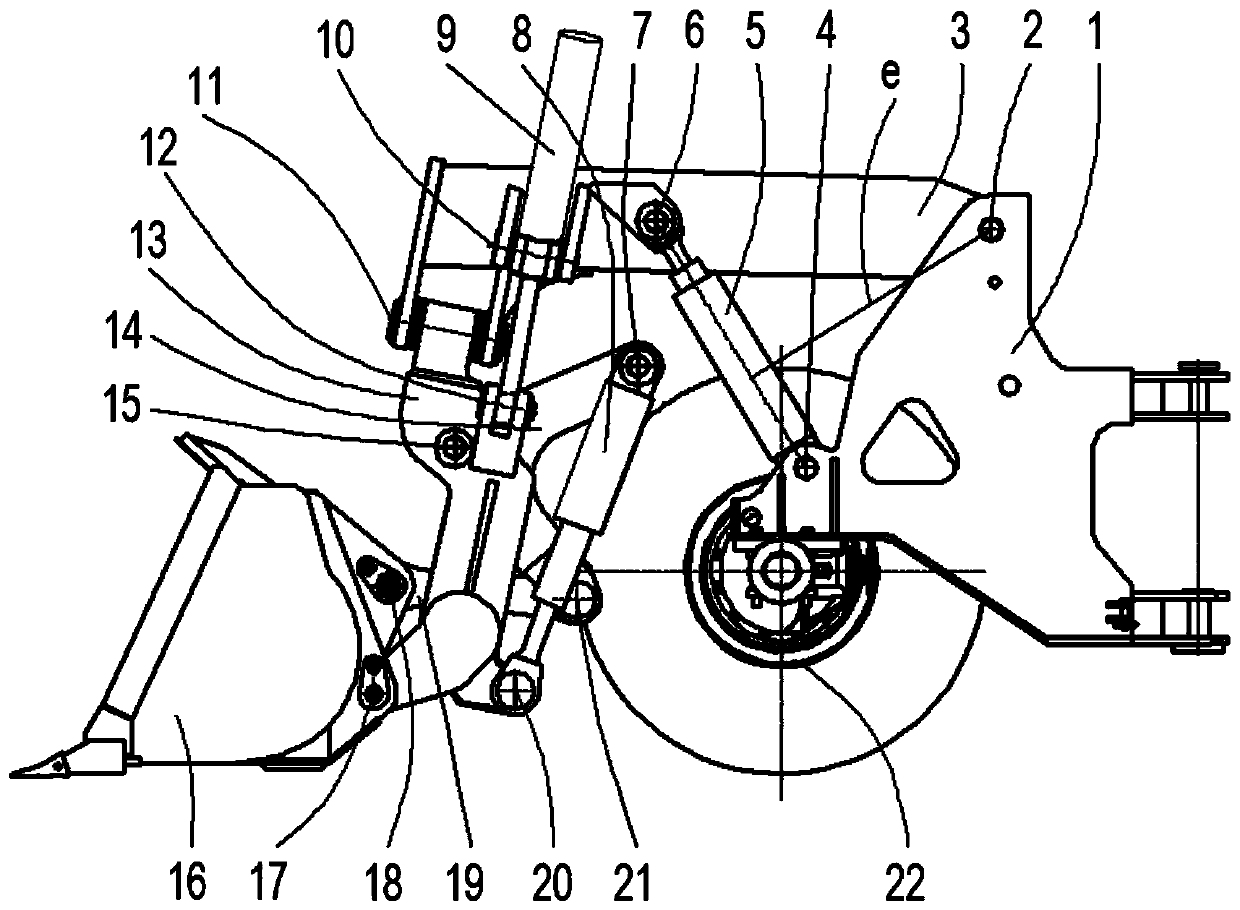

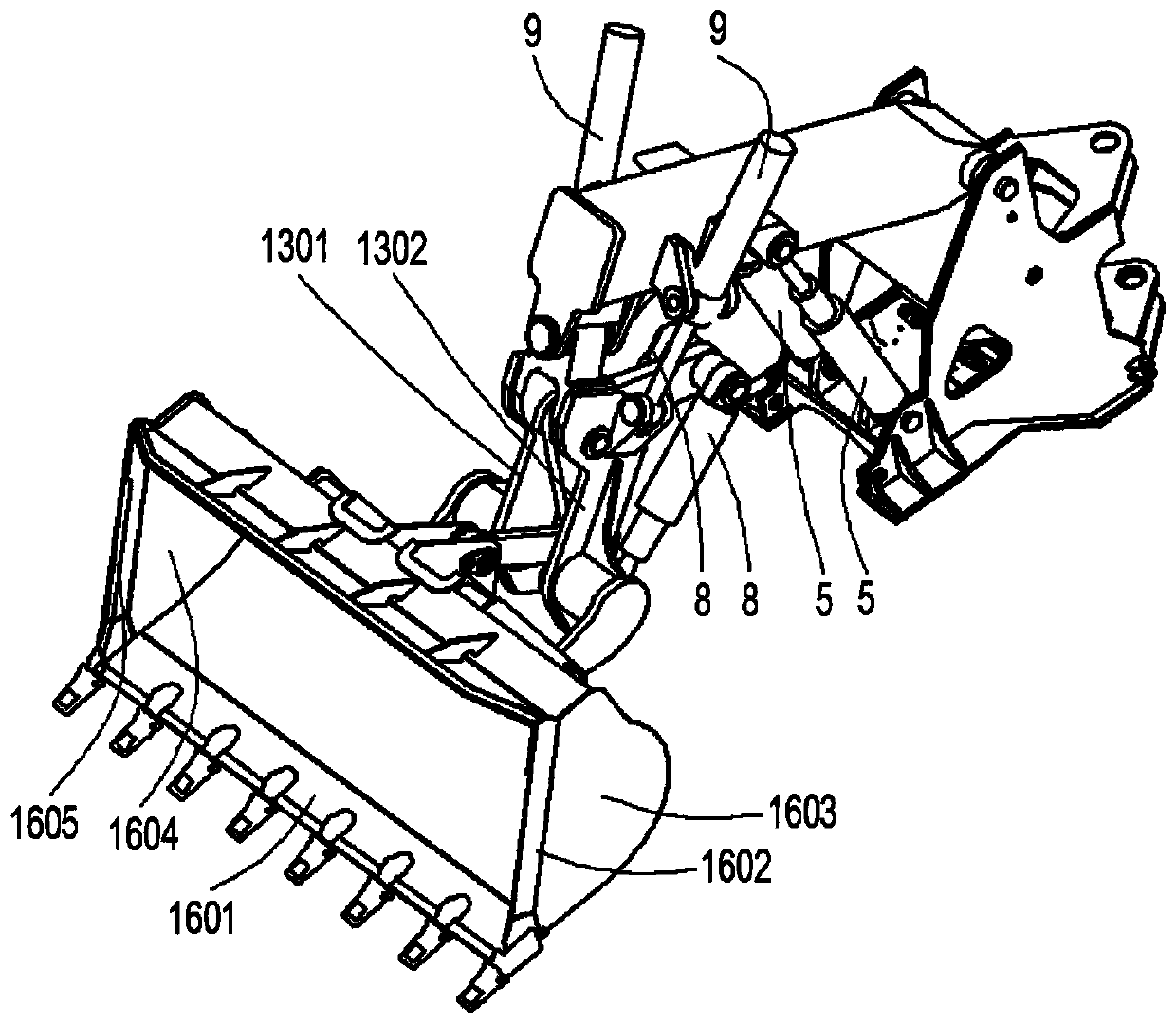

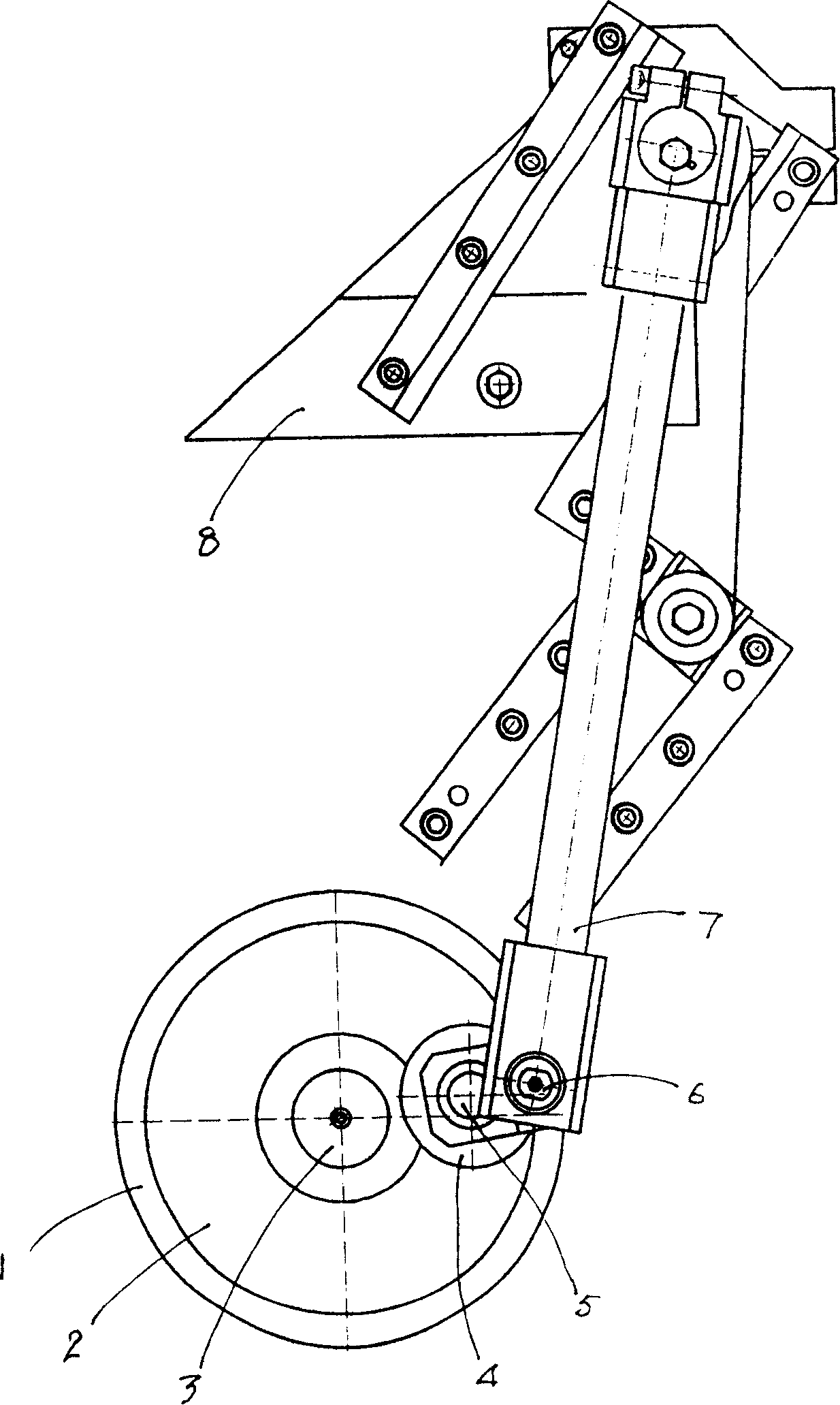

Loader

InactiveCN111236336ANot easy to spillEfficacy ratioMechanical machines/dredgersStructural engineeringShovel

The invention relates to a loader, and aims to solve the problem of low shovel loading operation efficiency of the existing loader. The loader is provided and comprises a connecting frame, the rear end of the connecting frame is hinged to the front end of a movable arm, a bucket rotating mechanism is arranged on the connecting frame, and a bucket is hinged to the front end of the connecting frameand the bucket rotating mechanism; and a rotating shaft axis of the rear end of the connecting frame rotating around the movable arm is perpendicular to the length direction of the bucket, and a rotation driving device for driving the connecting frame to rotate around the rotating shaft axis on the rear end of the connecting frame is arranged between the connecting frame and the movable arm. According to the loader, the fact that the standard bucket with the two closed ends performs operation by using a side dumping mode can be realized, the bucket filling rate is guaranteed, the operation advancing path is reduced, and the operation efficiency of the loader is improved.

Owner:莫华栋

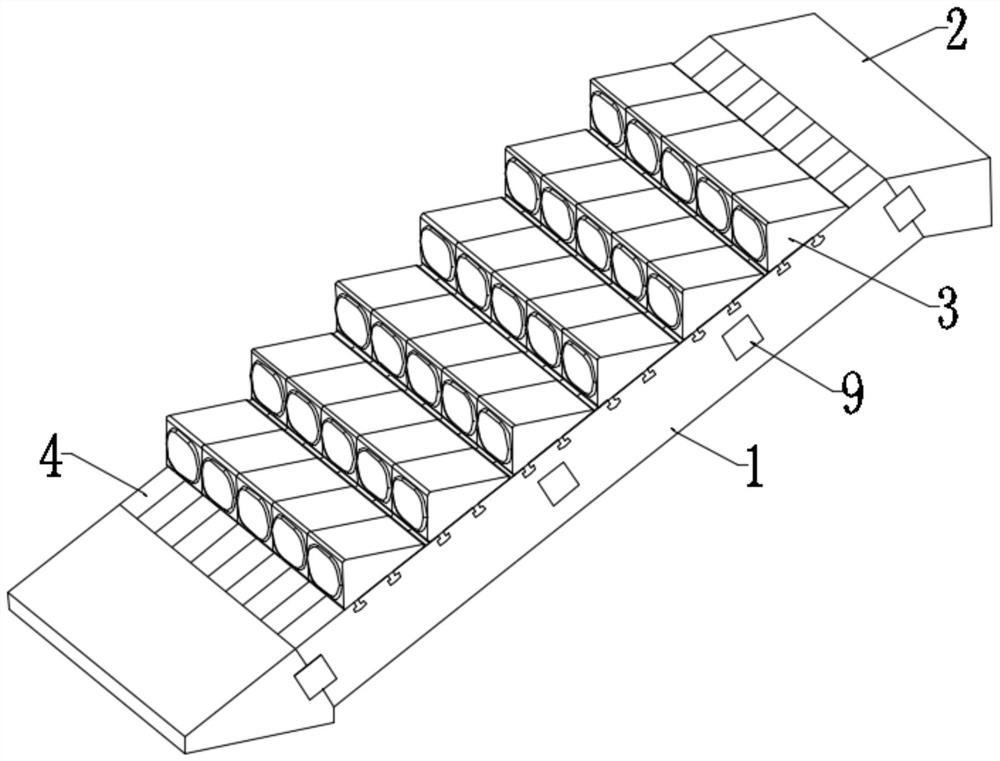

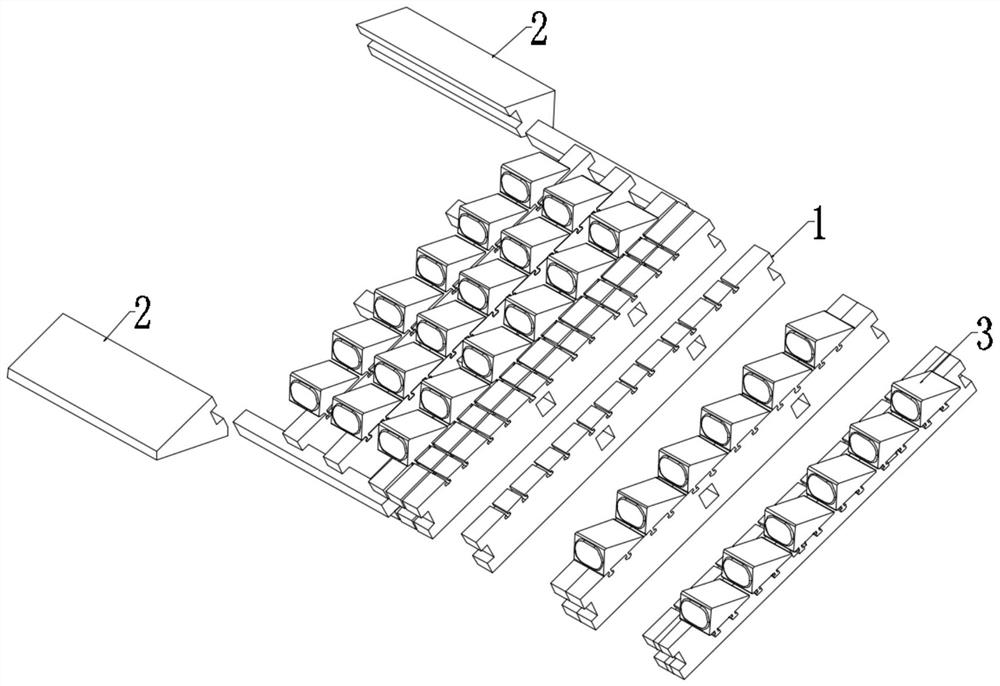

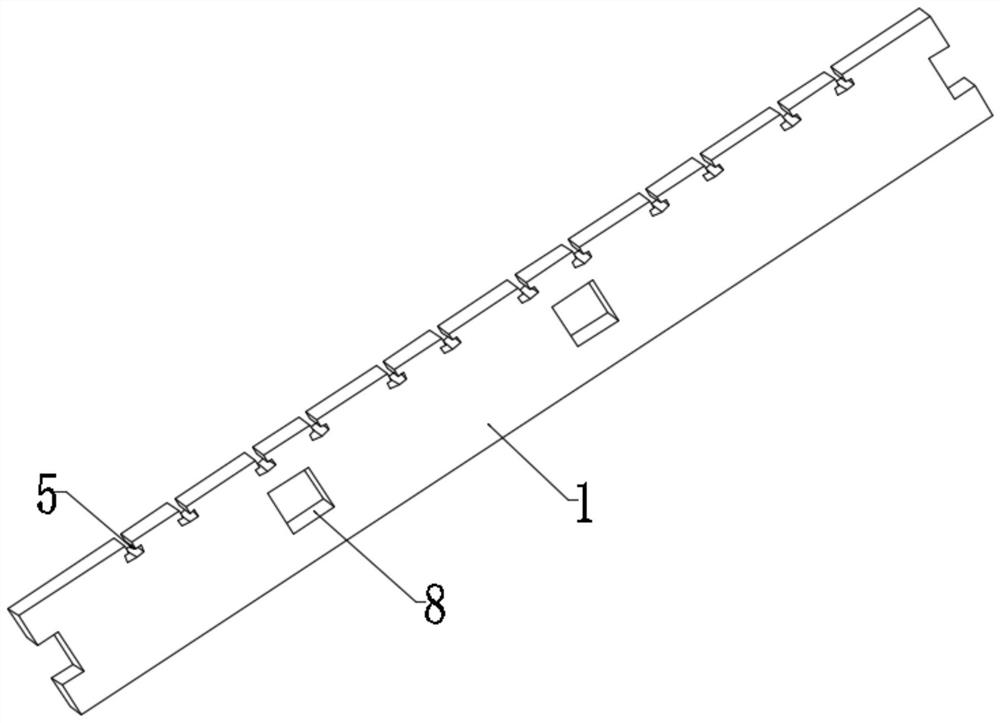

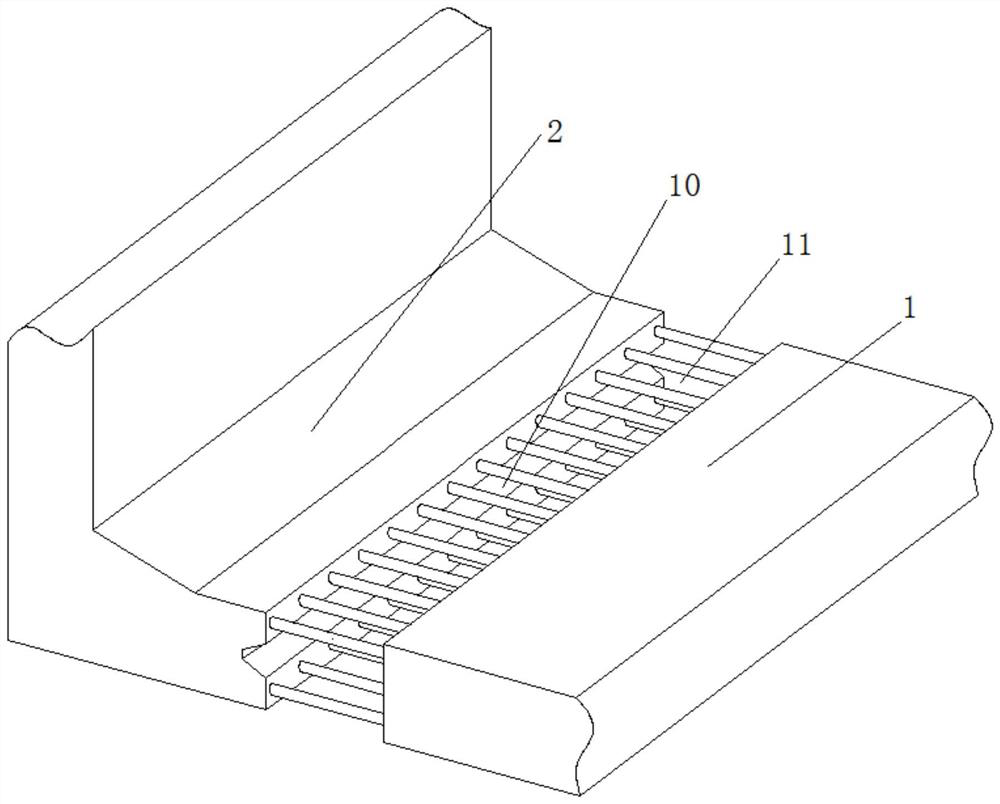

Assembly type stairway installation structure

PendingCN112282232AGuaranteed stabilityTo achieve reinforcementTread-and-riser unitsRight triangleArchitectural engineering

The invention provides an assembly type stairway installation structure. The assembly type stairway installation structure comprises foundation plates, prefabricated parts and step blocks; the two ends of each foundation plate are connected with the two prefabricated parts in a clamped mode correspondingly, the plurality of foundation plates are connected with the prefabricated parts in a clampedmode to form stairway plates, the end faces of every two adjacent foundation plates are attached, a plurality of mortises are formed in the surfaces of the foundation plates, each step block is a cylinder with a right-angled triangular section, a plurality of tenons are arranged on the inclined plane of each step block, the tenons are clamped in the mortises, and the inclined planes are attached to the surfaces of the stairway plates. According to the assembly type stairway installation structure, through the multi-module design of the stairway structure, the structure of the stairway is scattered, so that the stairway is convenient to transport, and the transportation cost is saved; through the structural design of the multi-module bottled assembly type stairway, components of the stairway are light, installation can be completed without the help of a special machine, the construction difficulty is lowered, and the stairway installation efficiency is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

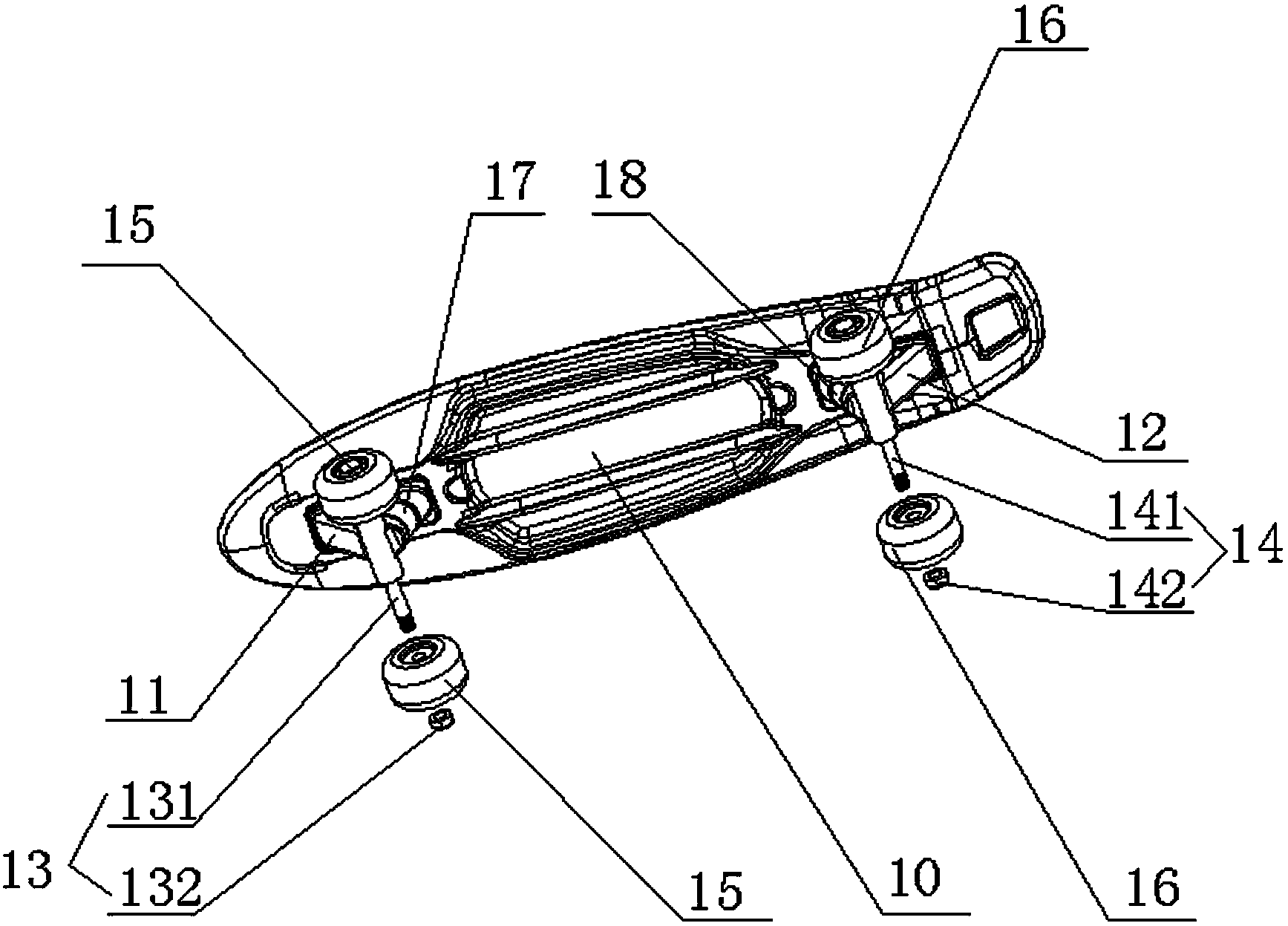

Slide with plastic supports

InactiveCN103768780AReduced risk of breakageStable structureSkate-boardsRoller skatesDamping functionSlide plate

The invention discloses a slide with plastic supports, the front bridge support and the rear bridge support of the slide are both made of plastic, and the front bridge support, the rear bridge support, and the pedal are integrated into a whole piece. The front bridge support is provided with a first projection and a second projection, the first projection and the second projection are both sleevedly arranged in a front damper, and the first projection is opposite to the second projection. The rear bridge support is provided with a third projection and a fourth projection, and the third projection and the fourth projection are both sleevedly arranged in a rear damper, and the third projection is opposite to the fourth projection. The front bridge support, the rear bridge support and the pedal are integrated into a whole piece, thus the structure is firm; moreover the front bridge support and the rear bridge support are both made of plastic, so the slide is light; two oppositely arranged projection-fixing dampers are provided so as to reduce the breakage risk of the front bridge support and the rear bridge support and provide a damping function at the same time.

Owner:伟旺有限公司

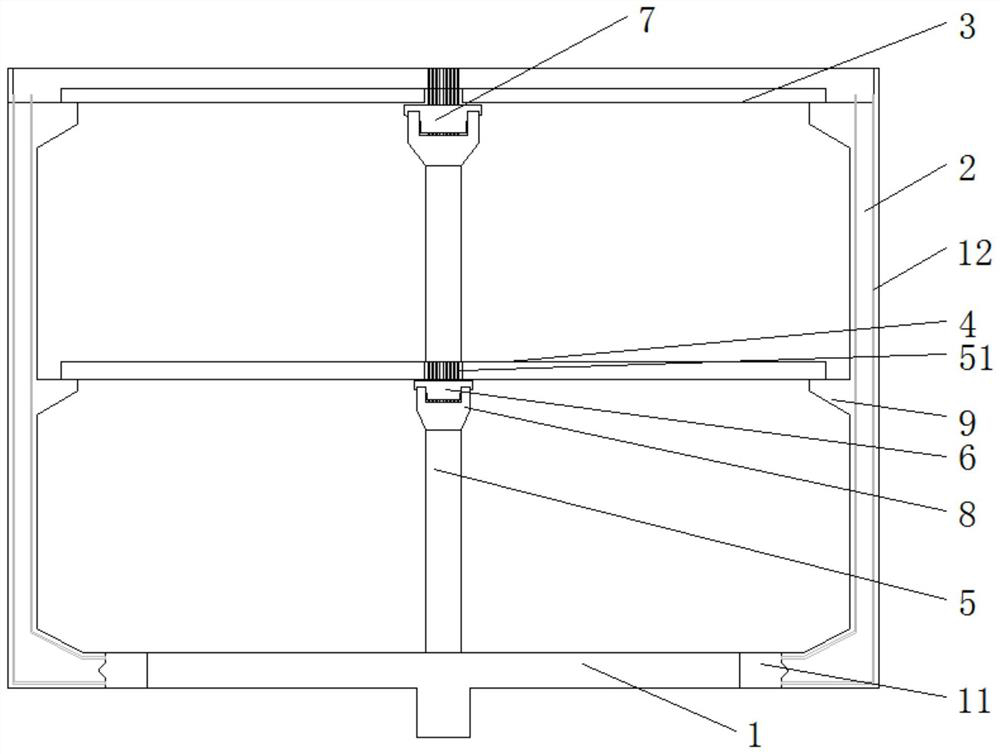

Assembled integral type subway station structure

PendingCN114875965AEasy to transportImprove integrityArtificial islandsProtective foundationArchitectural engineeringSubway station

The invention discloses an assembled integral subway station structure which comprises a cast-in-place bottom plate, prefabricated side walls, a prefabricated top plate, a prefabricated middle plate, a prefabricated middle column, a middle longitudinal beam and a top longitudinal beam. The prefabricated side walls are arranged on the two sides of the cast-in-place bottom plate, and the prefabricated middle column is arranged on the middle side of the upper portion of the cast-in-place bottom plate; the top longitudinal beam and the middle longitudinal beam are arranged on the upper portion and the middle of the prefabricated middle column respectively, and the prefabricated middle column is a double-layer integrated segment column. According to the assembled integral type subway station structure, through organic combination of a prefabricated structure and cast-in-place and UHPC post-pouring at the joints, rigid connection of the joints is achieved, the structural integrity is good, safety and reliability are achieved, compared with full prefabrication, components are lighter, transportation and hoisting are convenient, the requirement for prefabrication and installation precision is low, the construction period can be shortened by 20%, and mold-free and support-free effects are basically achieved; and the on-site labor amount is reduced.

Owner:青岛中科坤泰装配建筑科技有限公司

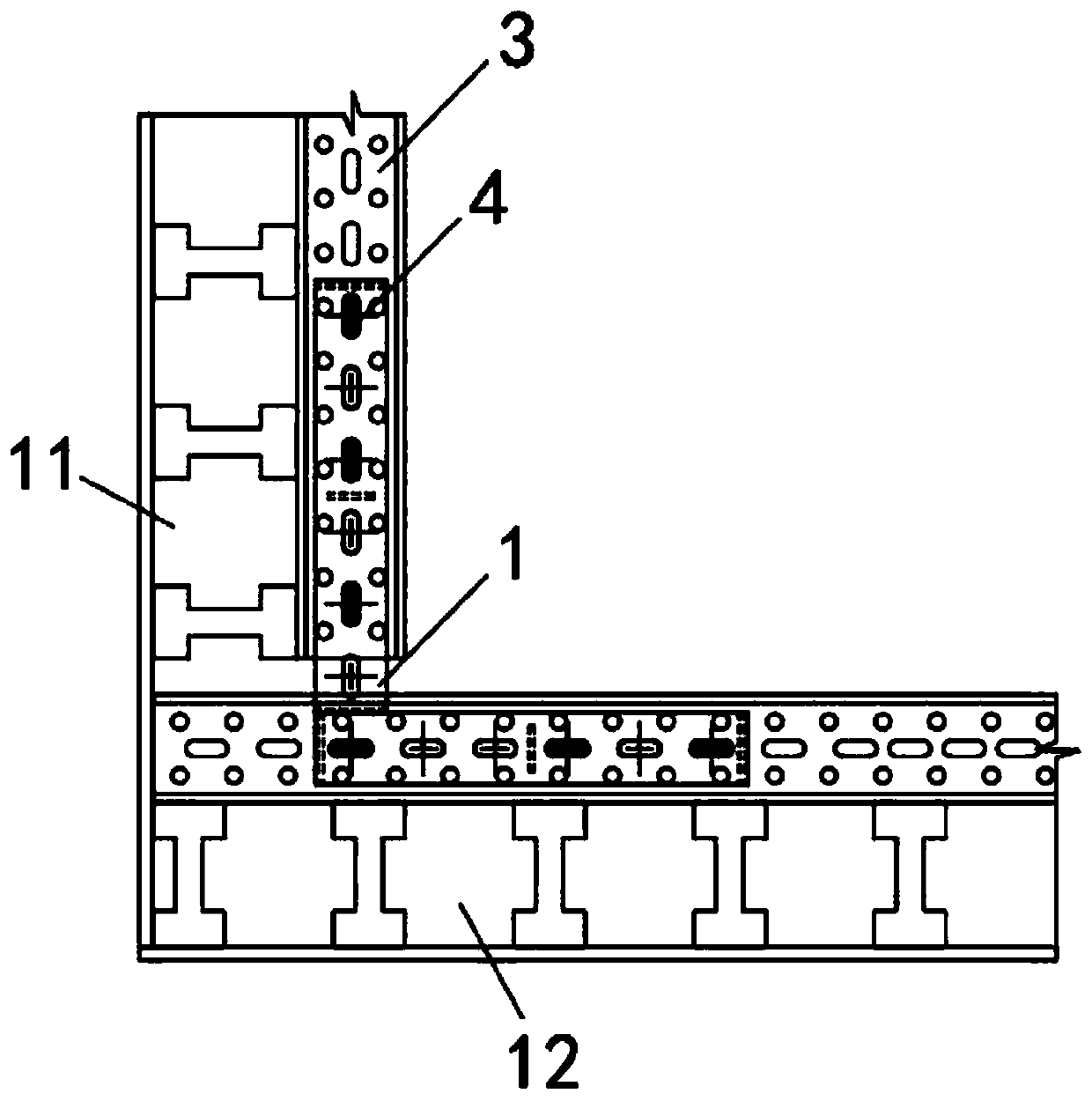

Inner corner reinforcing structure applied to super-thick vertical concrete structure formwork system

PendingCN110593554AAvoid deformationReliable forceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksKeelEngineering

The invention discloses an inner corner reinforcing structure applied to a super-thick vertical concrete structure formwork system. The inner corner reinforcing structure applied to the super-thick vertical concrete structure formwork system comprises a first keel and a second keel, wherein an L-shaped core belt plate is installed between the first keel and the second keel; the L-shaped core beltplate comprises a core belt stiffening plate, an upper core belt plate and a lower core belt plate; the core belt stiffening plate is located between the upper core belt plate and the lower core beltplate; the sidewall of the upper core belt plate is connected with the sidewall of the first keel; the sidewall of the lower core belt plate is connected with the sidewall of the second keel; and a keel bayonet pin is connected among the first keel, the second keel and the L-shaped core belt plate in a penetrating manner. With the adoption of the manner of reinforcing through the keels and in combination with the core belt plate, the inner corner reinforcing structure applied to the super-thick vertical concrete structure formwork system is not liable to be deformed and displaced during concrete pouring, stable and reliable, not liable to cause mold burst and mold swelling, high in concrete shaping quality, simple in reinforcing structure, light in member, and simple and convenient to operate, so that the construction period is shortened, and the working efficiency is increased; and the keel bayonet pin is adopted for fixing, and is convenient to detach, and capable of being utilized in a turnover manner, so that the material is saved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

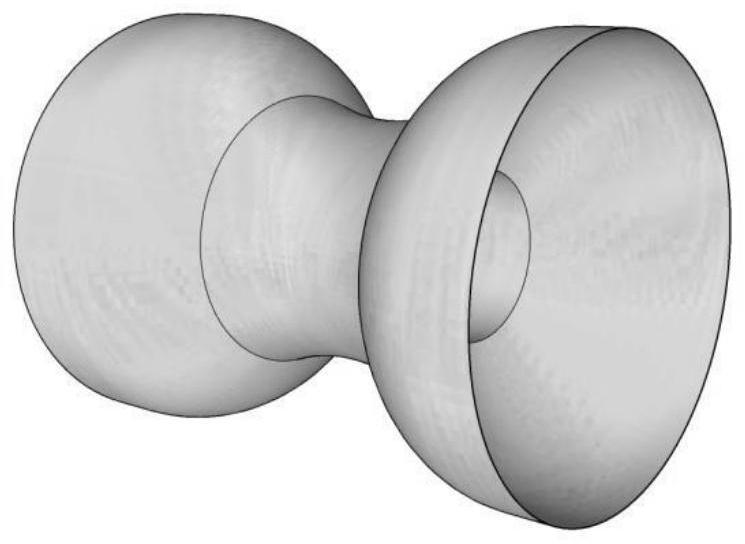

Fabricated foam concrete filled dumbbell-shaped thin-walled pipe bridge pier anti-collision device

PendingCN112746555AAvoid damageRealize flexible protectionBridge structural detailsBridge materialsFoam concreteArchitectural engineering

The invention discloses a fabricated foam concrete filled thin pipe self-buckling system bridge pier anti-collision device; when the device is collided, firstly, a corrugated plate disperses stress, the corrugated plate and regenerated rubber deform to dissipate energy, then a dumbbell-shaped self-buckling system can effectively dissipate energy through mutual friction and plastic deformation, and the impact effect of axle impact on a bridge pier and a vehicle is relieved. After foam concrete is injected into an aluminum pipe, deformation of the aluminum pipe can be restrained, and the impact resistance of a protection device is effectively improved. The dumbbell-shaped aluminum pipe self-buckling system and foam concrete cooperate for protection, rigidity and softness are combined, the bridge pier is protected against damage after being impacted, and the safety of the vehicle and personnel on the vehicle is protected. The device has the advantages of being low in strength, high in energy consumption, convenient to maintain and replace, small in occupied area, environmentally friendly and the like, and the anti-collision requirement of the pier can be met.

Owner:BEIJING UNIV OF TECH

A hydraulic cylinder testing device

ActiveCN110792656BEfficient measurementImprove reliabilityMachine part testingFluid-pressure actuator testingHydraulic cylinderControl system

Owner:国家康复辅具研究中心

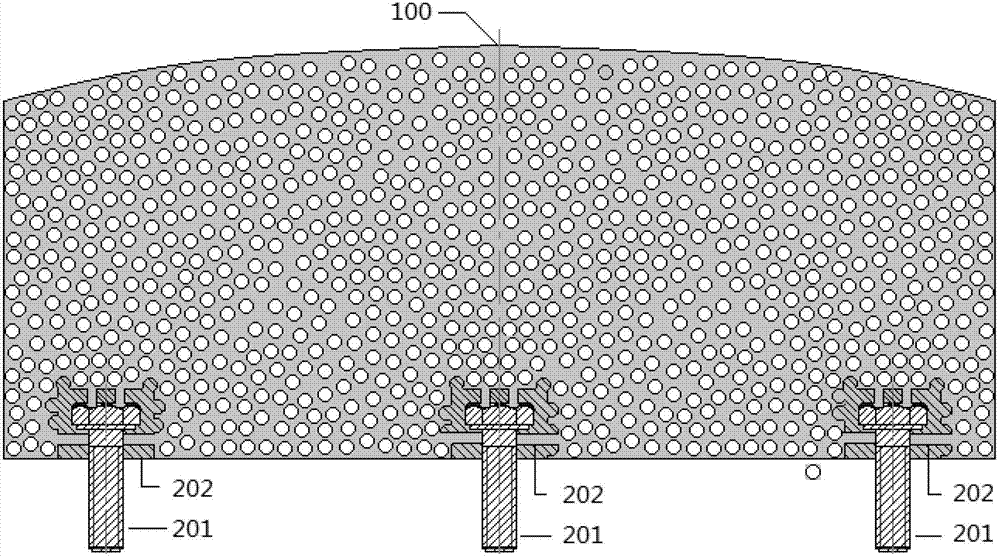

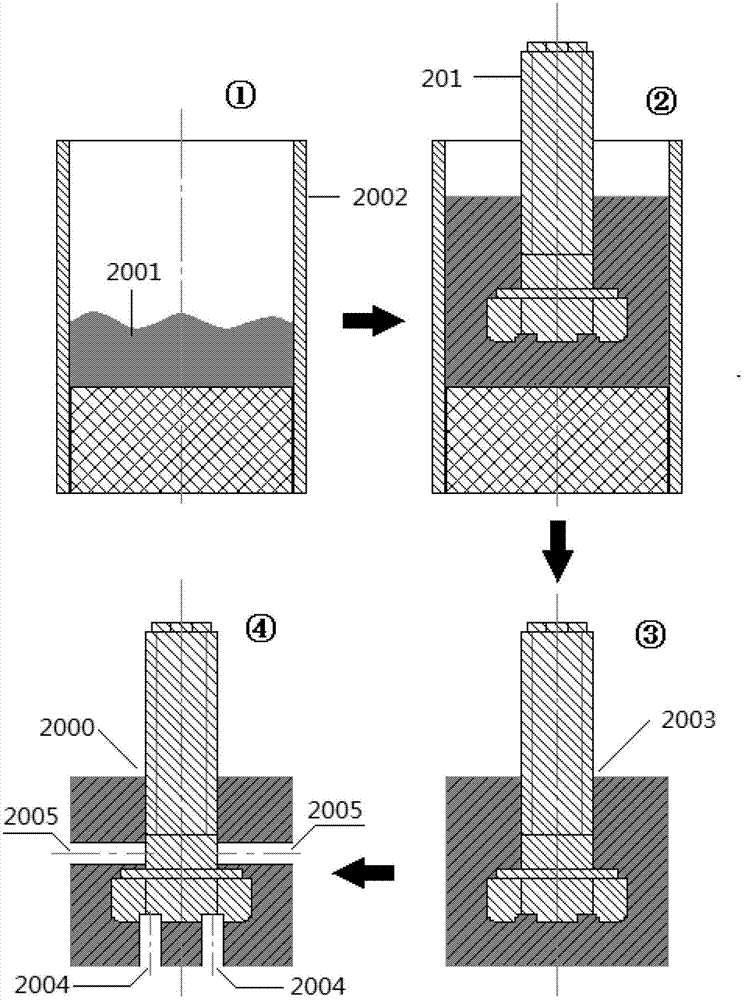

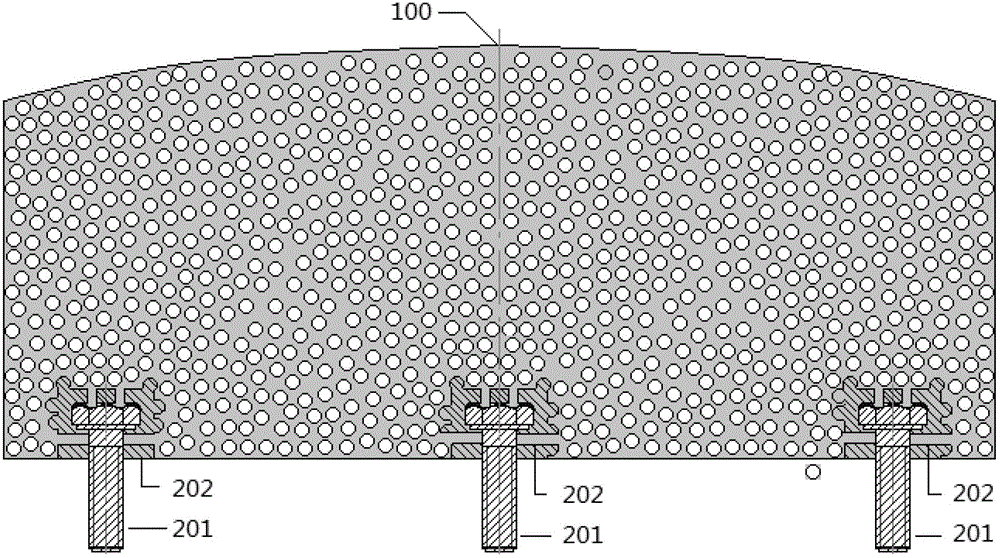

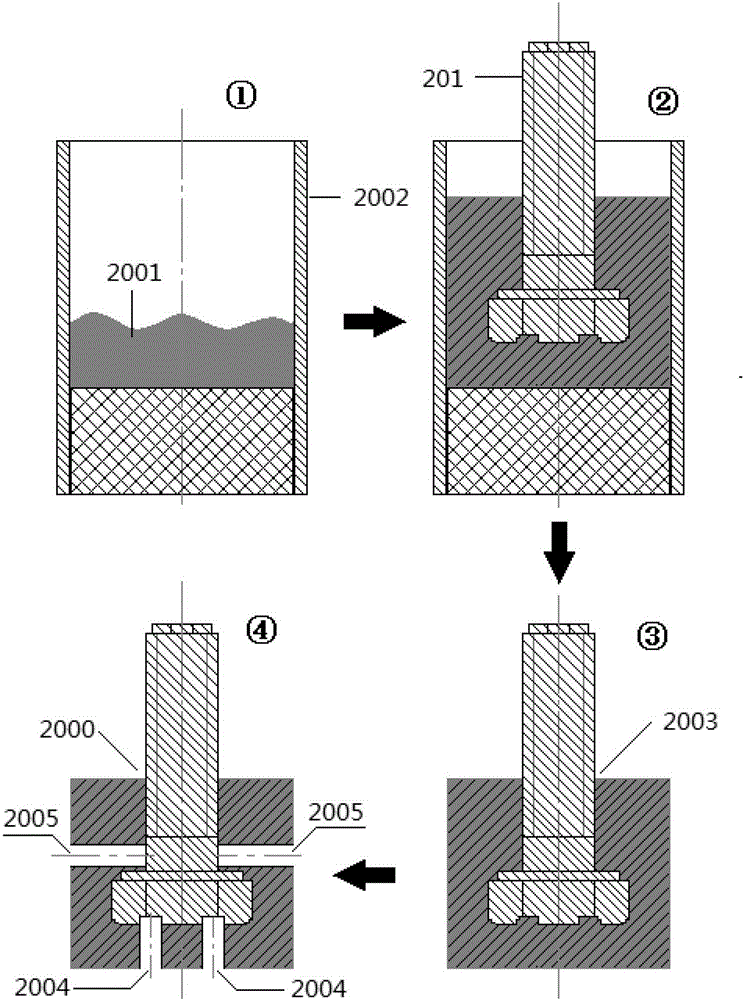

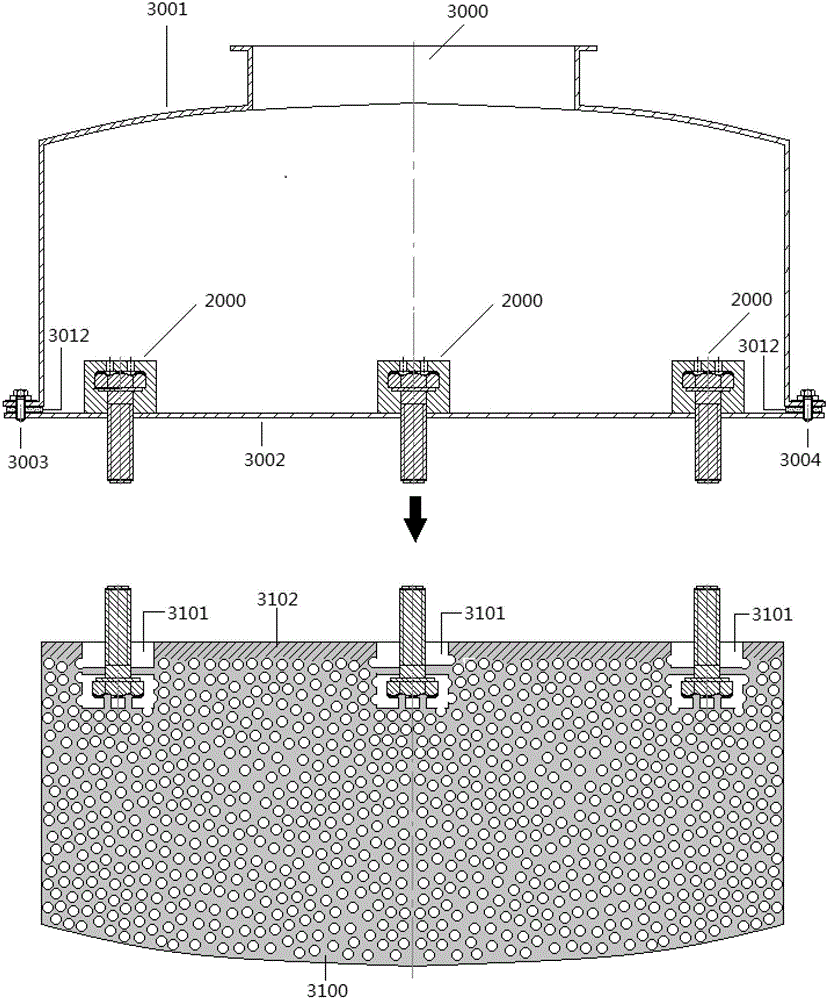

Closed-hole foamed aluminum component being easy to install and preparation method thereof

The invention discloses a closed-hole foamed aluminum component being easy to install and a preparation method thereof. The closed-hole foamed aluminum component is that bolts for being in connection with other parts are pre-buried in a closed-cell aluminum component body, and aluminum solid bodies are arranged at the pre-buried bolts. The preparation method of the closed-cell foamed aluminum component being easy to install comprises the following steps of: preparing a soluble-scattered prefabticated member containing the bolts, assembling and preheating a closed-hole aluminum component mould, injecting a foaming melt in a component mould after preheating, dissolving and scattering the prefabticated member, injecting molten aluminum on the prefabticated member, cutting and removing a foam-free layer and the like. The closed-hole foamed aluminum component and the preparation method thereof provided by the invention have the advantages that the prepared closed-hole aluminum component can realize the connection with the other parts, a connecting part does not collapse as being subjected to an external force, in addition, the aluminum dosage at the connecting part is small, and thus the porous aluminum component with the light weight is obtained.

Owner:LIAONING RONGDA NEW MATERIALS TECH CO LTD

Two-in-one rope forming machine and method for making rope with it

InactiveCN101654880BIncrease productionLightweight componentsRope making machinesCapital equipmentSprocket

The invention discloses a two-in-one rope forming machine, which comprises a strand twisting device and a rope closing device, the strand twisting device and the rope closing device are connected through a second shaft, and the strand twisting device is provided with a first sprocket set and a main winding shaft , the first shaft and three strand-making devices placed in parallel. The rope closing device is composed of an over-twist limiter and a rope-forming device. The over-twist limiter is equipped with a V-belt pulley, a second sprocket set, a shaft coupling, Three sprocket sets, over-twisting device, triangular tape and motor, the second sprocket set is composed of A wheel and B wheel, the A wheel and B wheel are connected by a chain, and each strand making device is equipped with a winding shaft and a strand The spindle seat and the over-twisting limiter are connected to the rope forming device through a shaft; the two-in-one rope forming method comprises the following steps: before the machine runs; threading; pre-twisting; rope making; rope forming; coil unloading. The invention has the advantages of small occupied area, reduced equipment and labor capital, and improved work efficiency.

Owner:JIANGSU JIAOLONG HEAVY IND GROUP

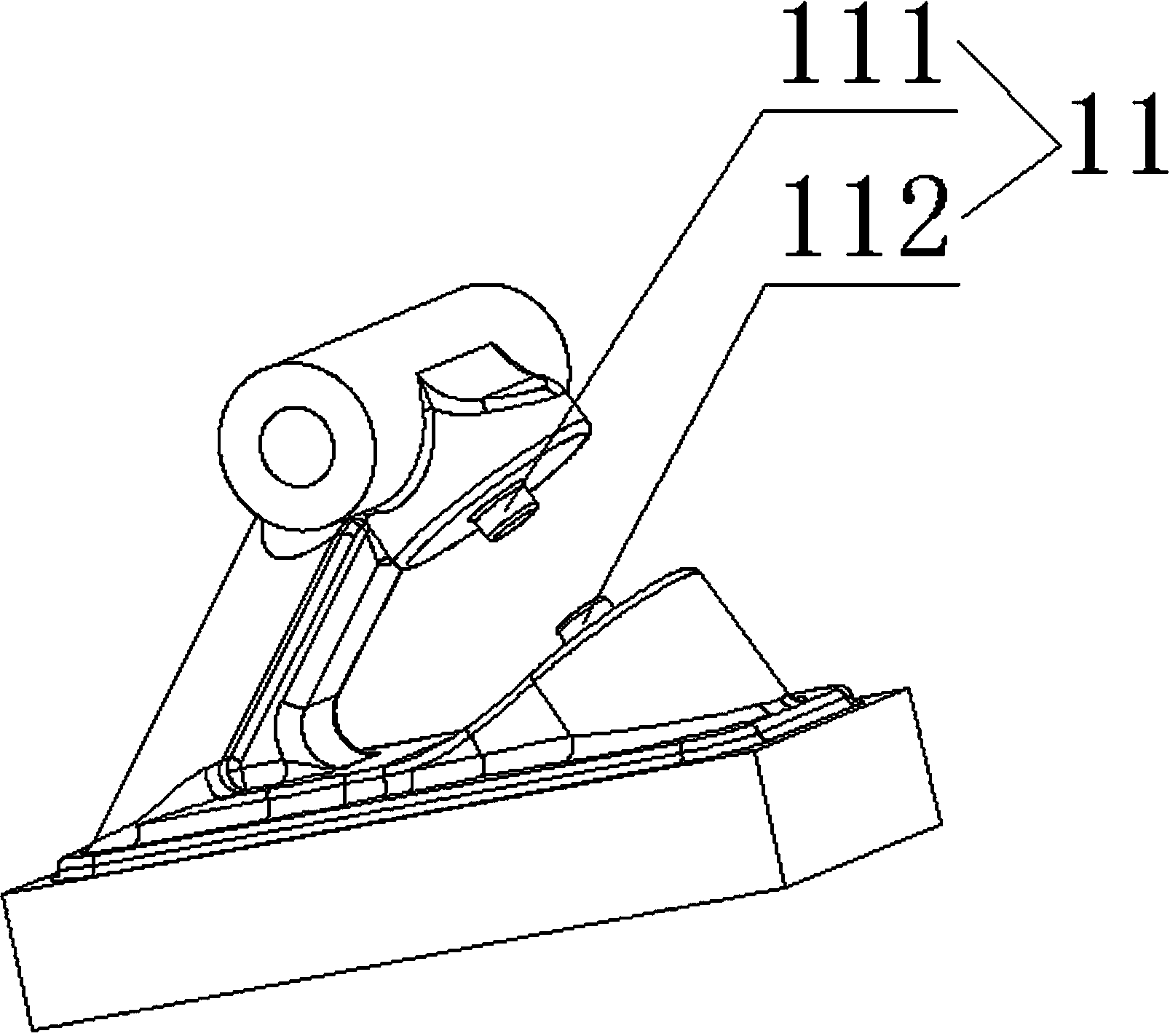

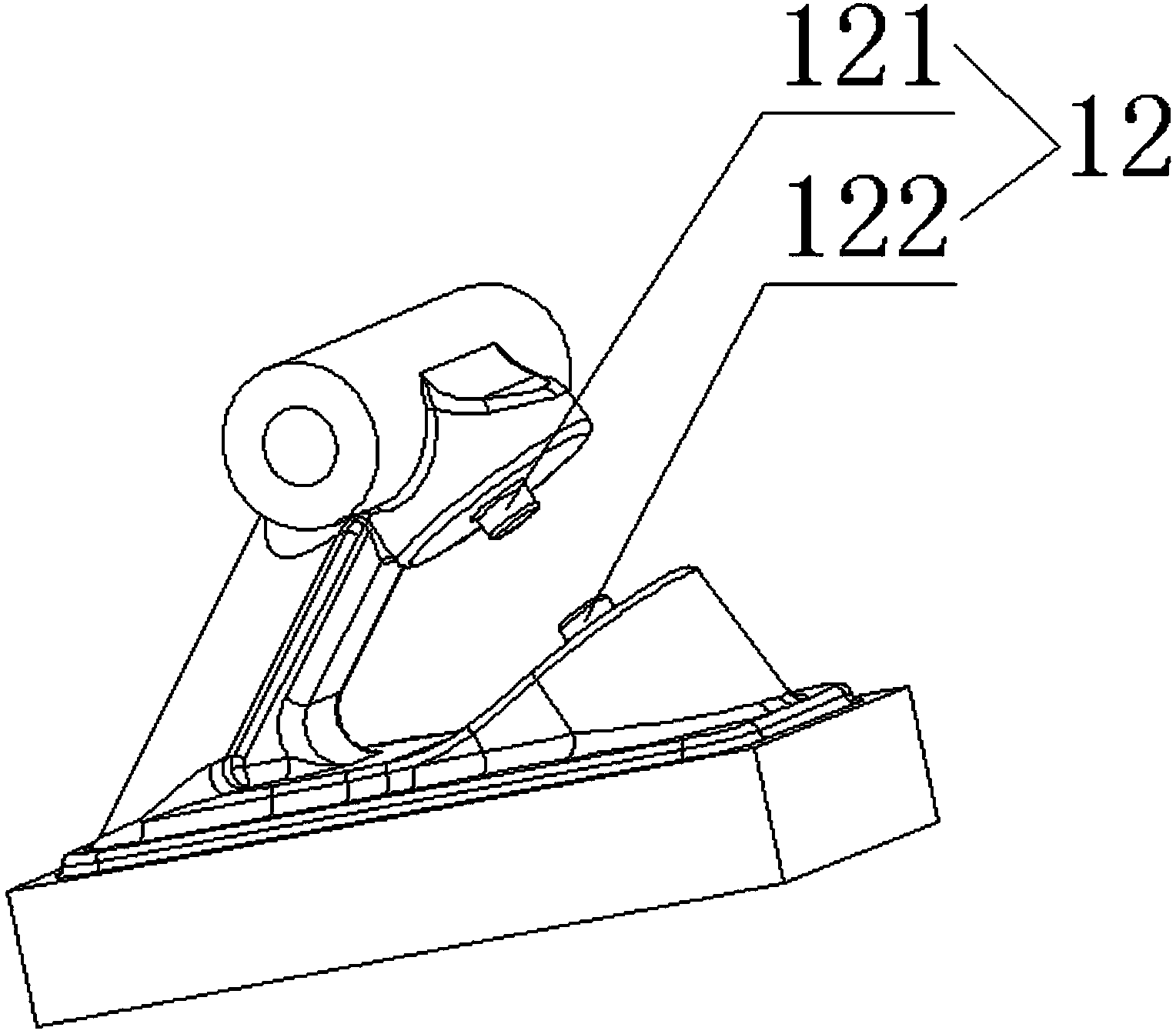

Planet cutting mechanism of three-knife trimming machine

The invention discloses a planetary cutting mechanism of three-face trimmer, which comprises the following parts: inner gear on the stand, planetary gear to gear inner gear, rotary disc with the same center with inner gear, wherein the rotary shaft of planetary gear is set on the rotary disc, which is output shaft through declaration mechanism for motor, the pin is set on the deviated rotary shaft position on the planetary gear, which connects the connecting rod with the other end connecting sliding block in the groove.

Owner:宁波联创印刷机械有限公司

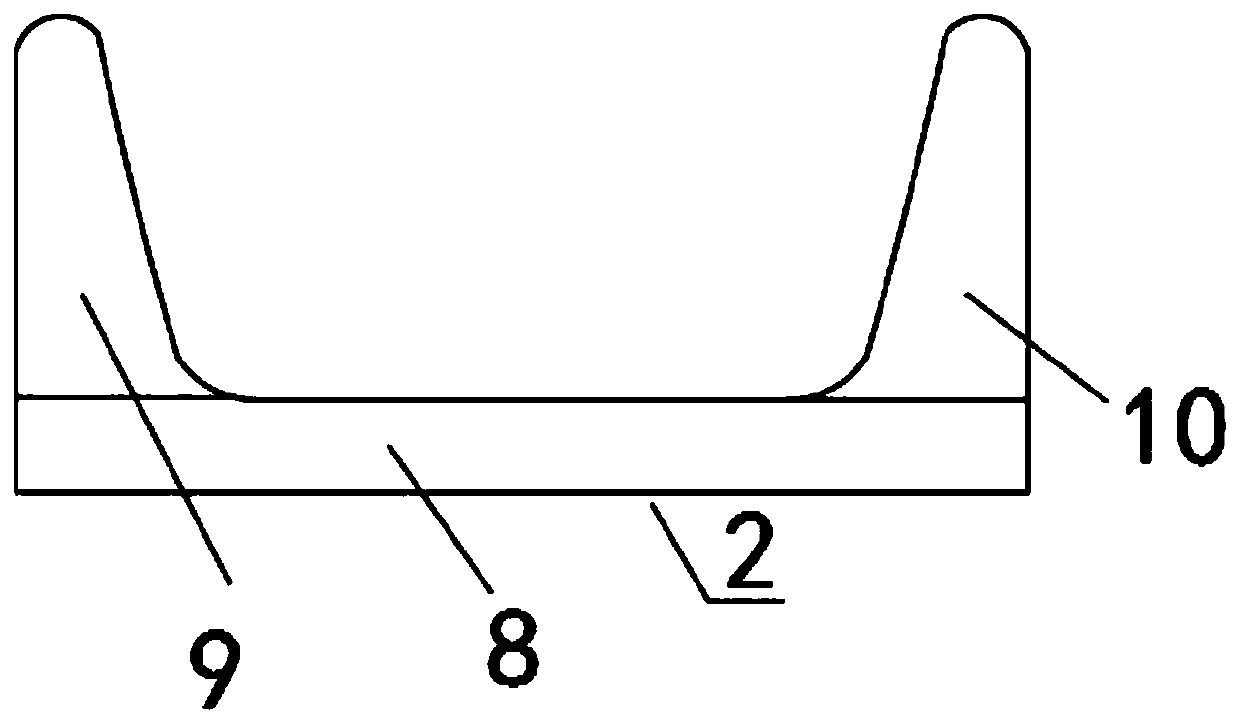

Anti-rollover trapezoid device utilizing cantilever I-shaped steel embedded ring

PendingCN113969614ALightweight componentsEasy to operateBuilding constructionsClassical mechanicsFire - disasters

The invention belongs to the field of cantilever I-shaped steel, and particularly relates to an anti-rollover trapezoidal device utilizing a cantilever I-shaped steel pre-embedded ring. The anti-rollover trapezoidal device comprises a trapezoidal piece, a groove is formed in the top of the trapezoidal piece, the two sides of the groove are opened, a fixing block is fixedly mounted at the bottom of one side of the trapezoidal piece, and a fixing bolt is mounted on the fixing block in a threaded manner. The trapezoidal structural member is light and handy, is simple to mount and operate, and effectively solves the problems that materials are wasted, the environment is polluted, a fire disaster is prone to being caused to form potential safety hazards, disassembly is inconvenient and manpower is wasted due to random cutting.

Owner:CHINA AEROSPACE CONSTR ENG GRP CO LTD

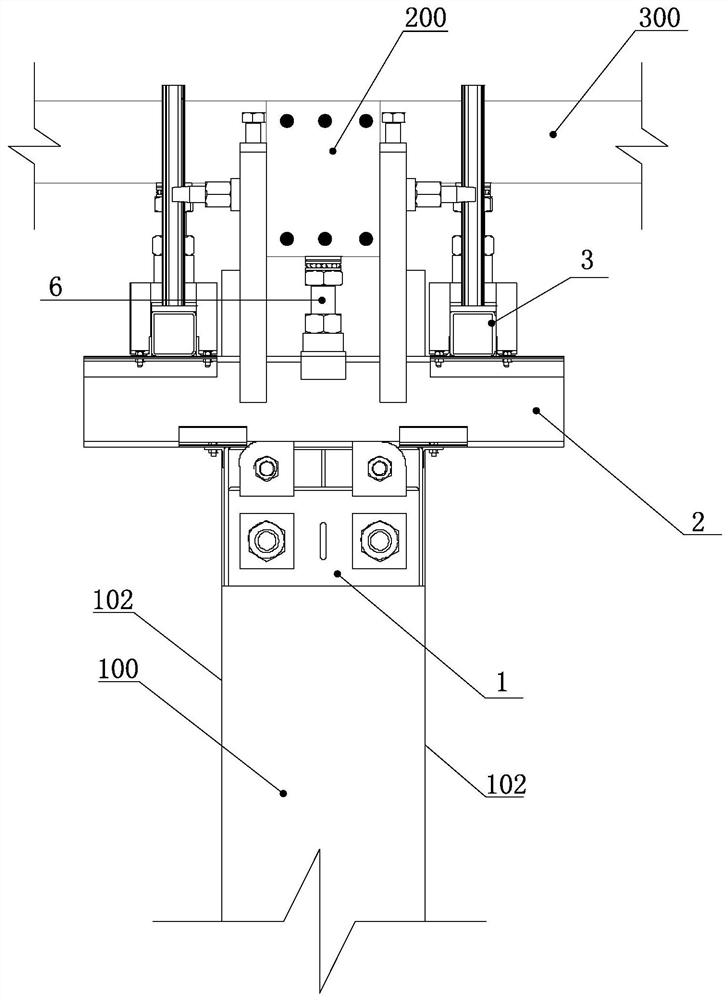

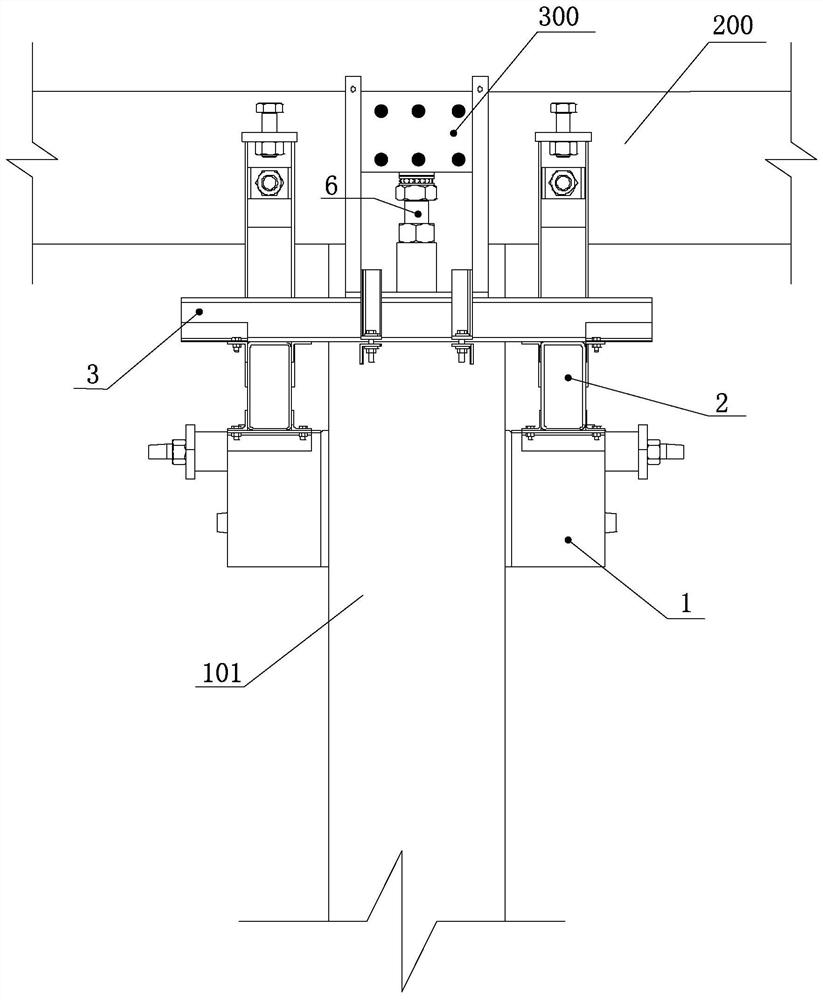

Scaffold-free prefabricated frame structure beam column mounting method

ActiveCN112962981ALightweight componentsEasy to operateBuilding reinforcementsBuilding material handlingClassical mechanicsEngineering

The invention provides a scaffold-free prefabricated frame structure beam column mounting method. The scaffold-free prefabricated frame structure beam column mounting method comprises the steps of prefabricating and mounting a prefabricated column, a main beam and a secondary beams, wherein the upper end of the prefabricated column mounted in place is connected with a beam supporting device during mounting, the main beam is placed on stirrups of a main bracket in the beam supporting device, the main beam is located in a main beam anti-torsion mechanism at the same time, the secondary beam is placed on stirrups of a secondary bracket of the beam supporting device, and the secondary beam is located in a secondary beam anti-torsion mechanism at the same time; the end face of the main beam, the end face of the secondary beam and the top face of the prefabricated column serve as formworks to define a mold cavity, concrete is poured, and the main beam, the secondary beam and the prefabricated column are connected into a whole. The scaffold-free prefabricated frame structure beam column mounting method can be combined with factory prefabrication, is convenient to operate, is economical and reasonable, and is favorable for accelerating the construction period, controlling the construction cost and promoting the industrial development of buildings.

Owner:ZHEJIANG TOHIGH BUILDING MATERIALS GROUP +1

Arch-shaped and omega-shaped combined device for preventing rollover by using overhanging I-shaped steel embedded ring

PendingCN113969623ALightweight componentsEasy to operateBuilding constructionsRolloverClassical mechanics

The invention belongs to the field of overhanging I-shaped steel, and particularly relates to an arch-shaped and omega-shaped combined device for preventing rollover by using an overhanging I-shaped steel embedded ring. The arch-shaped and omega-shaped combined device comprises the I-shaped steel, front-end I-shaped steel embedded ring anchor bolts and two rear-end I-shaped steel embedded ring anchor bolts. The arch-shaped and omega-shaped combined device for preventing rollover by using the overhanging I-shaped steel embedded ring is characterized in that the front-end I-shaped steel embedded ring anchor bolts are located at the front end of the lower portion of the I-shaped steel, the two rear-end I-shaped steel embedded ring anchor bolts are located at the rear end of the lower portion of the I-shaped steel, omega-shaped pieces are arranged outside the front-end I-shaped steel embedded ring anchor bolts, and first adjusting bolts are installed in the centers of the omega-shaped pieces. The bottom of a first adjusting bolt extends to the lower portion of an omega-shaped piece, and a U-shaped clamp is fixedly installed on the top of the first adjusting bolt. According to the arch-shaped and omega-shaped combined device for preventing rollover by using the overhanging I-shaped steel embedded ring, the combined device is light in component and easy to install and operate, and the problems that materials are wasted and the environment is polluted due to random cutting, meanwhile, fire disasters are likely to be caused to form potential safety hazards, dismounting is inconvenient, and manpower is wasted are effectively solved.

Owner:CHINA AEROSPACE CONSTR ENG GRP CO LTD

Anti-rollover omega-shaped piece device using cantilever I-steel single embedded ring

PendingCN113969663ALightweightLightweight componentsScaffold accessoriesClassical mechanicsFire - disasters

The invention belongs to the field of cantilever I-shaped steel, and particularly relates to an anti-rollover omega-shaped piece device using a cantilever I-steel single embedded ring. The anti-rollover omega-shaped piece device comprises the I-shaped steel and I-shaped steel embedded ring anchor bolts, the I-shaped steel embedded ring anchor bolts are positioned below the I-shaped steel, and omega-shaped pieces are arranged outside the I-shaped steel embedded ring anchor bolts. An adjusting bolt is installed in the center of an omega-shaped piece, the bottom of the adjusting bolt extends to the position below the omega-shaped piece, a U-shaped clamp is fixedly installed at the top of the adjusting bolt, and the U-shaped clamp is clamped to an I-shaped steel embedded ring anchor bolt. According to the omega-shaped structural piece, the component is light and handy, installation and operation are easy, the problems that materials are wasted, the environment is polluted, fire disasters are easily caused to form potential safety hazards, disassembly is not convenient, and manpower is wasted due to random cutting are effectively solved.

Owner:ZHONG HANG TIAN CONSTR ENG COMPANY

Closed-hole foamed aluminum component being easy to install and preparation method thereof

The invention discloses a closed-hole foamed aluminum component being easy to install and a preparation method thereof. The closed-hole foamed aluminum component is that bolts for being in connection with other parts are pre-buried in a closed-cell aluminum component body, and aluminum solid bodies are arranged at the pre-buried bolts. The preparation method of the closed-cell foamed aluminum component being easy to install comprises the following steps of: preparing a soluble-scattered prefabticated member containing the bolts, assembling and preheating a closed-hole aluminum component mould, injecting a foaming melt in a component mould after preheating, dissolving and scattering the prefabticated member, injecting molten aluminum on the prefabticated member, cutting and removing a foam-free layer and the like. The closed-hole foamed aluminum component and the preparation method thereof provided by the invention have the advantages that the prepared closed-hole aluminum component can realize the connection with the other parts, a connecting part does not collapse as being subjected to an external force, in addition, the aluminum dosage at the connecting part is small, and thus the porous aluminum component with the light weight is obtained.

Owner:LIAONING RONGDA NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com