Two-in-one rope forming machine and method for making rope with it

A two-in-one, rope-forming technology, which is applied in rope-making auxiliary devices, textiles and papermaking, textile cables, etc., can solve the problems of reducing work efficiency, occupying a large area, increasing equipment and labor capital, etc., and improving work efficiency. Efficiency, small footprint, reduced equipment and labor capital effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

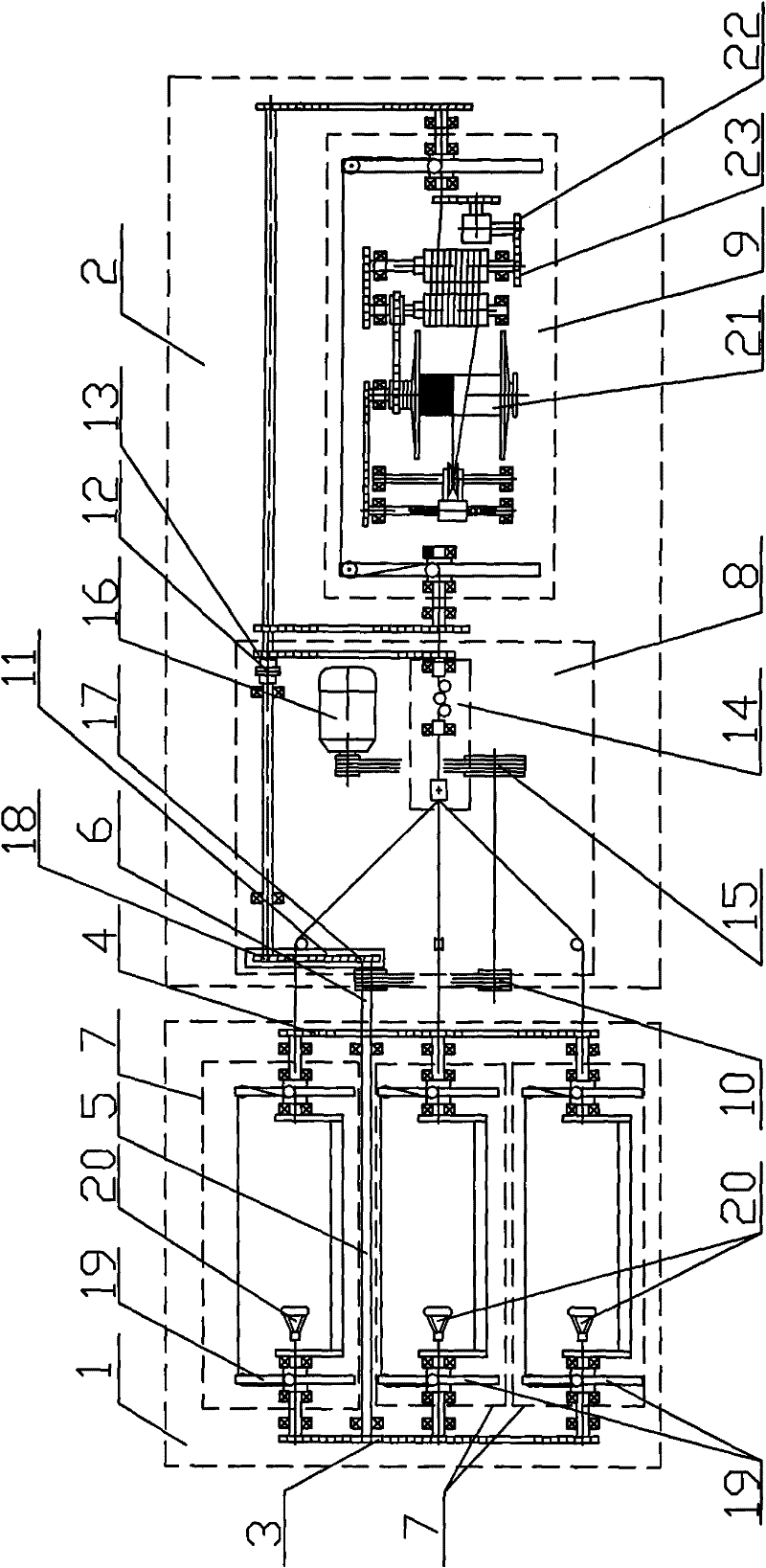

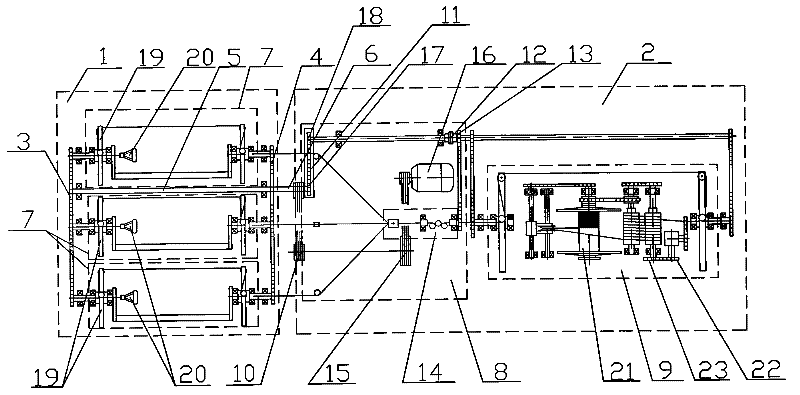

[0016] Such as figure 1 A specific embodiment of the two-in-one rope forming machine of the present invention is shown, including a strand twisting device 1 and a rope closing device 2, the strand twisting device 1 and the rope closing device 2 are connected by a second shaft 6, and in the twisting strand device 1 The first sprocket group 3, the main winding shaft 4, the first shaft 5 and three strand-making devices 7 placed in parallel are provided. The rope closing device 2 is composed of an over-twisting limiter 8 and a rope-forming device 9. The limiter 8 is a device located after the twisting device 1 and before the rope forming device 9. It ensures that the strands in the rope mold are twisted accurately, so as to avoid excessive twisting of the strands and to prevent the self-twisting of the rope. One of the necessary devices for high-quality ropes, the over-twisting limiter 8 is equipped with a V-belt pulley 10, a second sprocket set 11, a coupling 12, a third sprocket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com