Loader

A technology of loaders and booms, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., which can solve problems such as low efficiency of shovel loading operations, and achieve improved bucket fullness and change The effect of small area and not easy to spill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation will be described below in conjunction with the accompanying drawings.

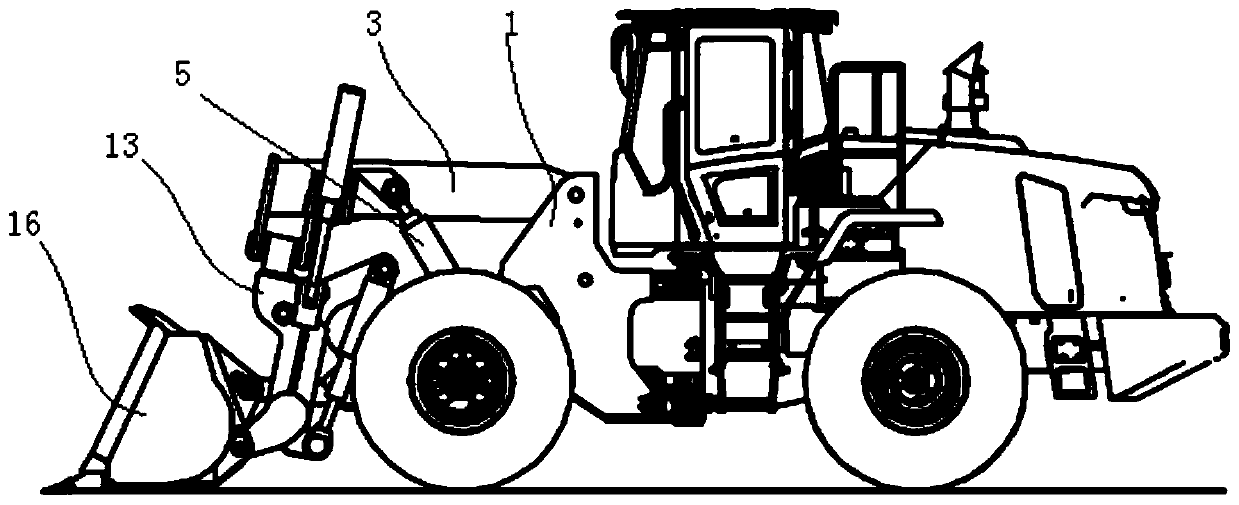

[0034] Such as figure 1 As shown, the structure of the main engine of the loader in this embodiment is basically the same as that of the existing loader main engine. Bucket mechanism, rotary drive device.

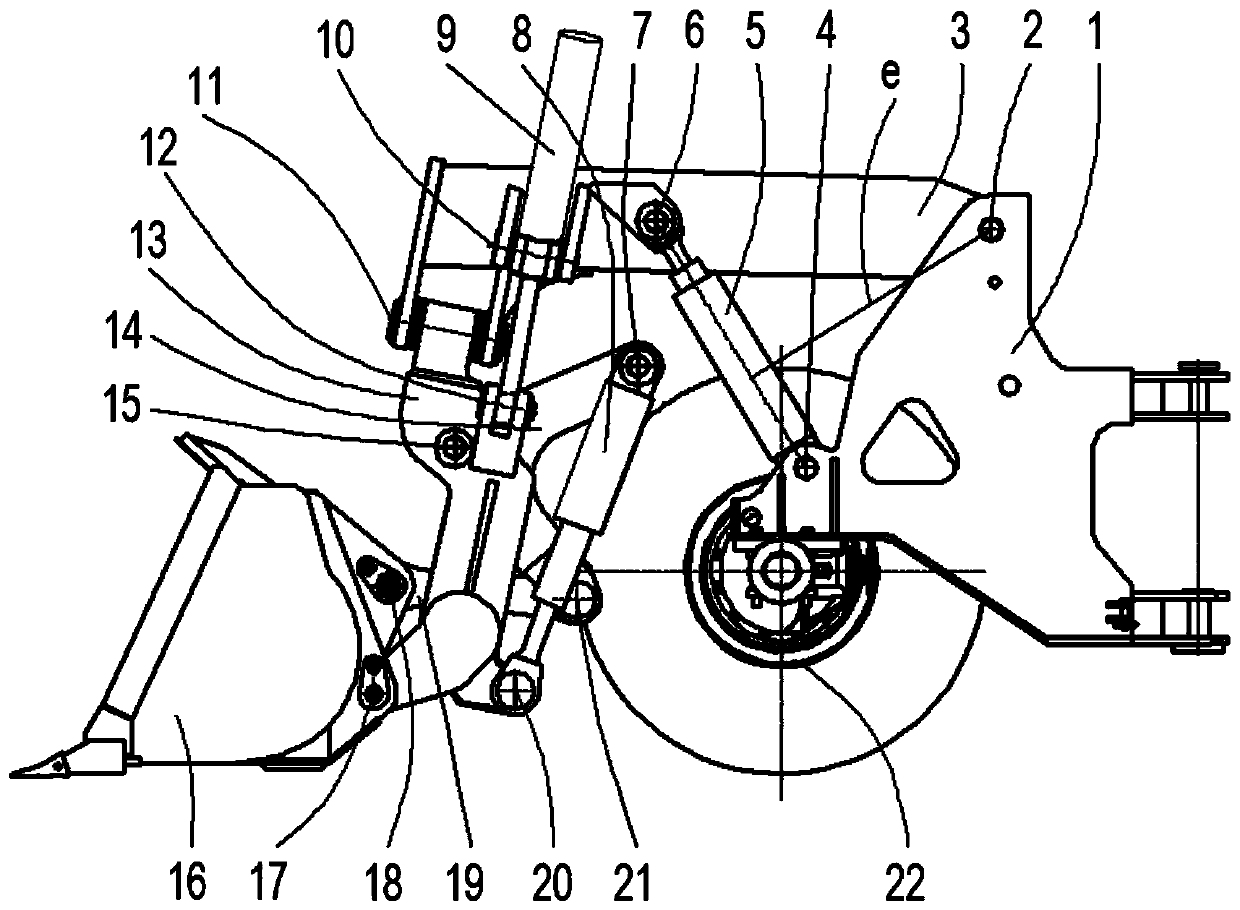

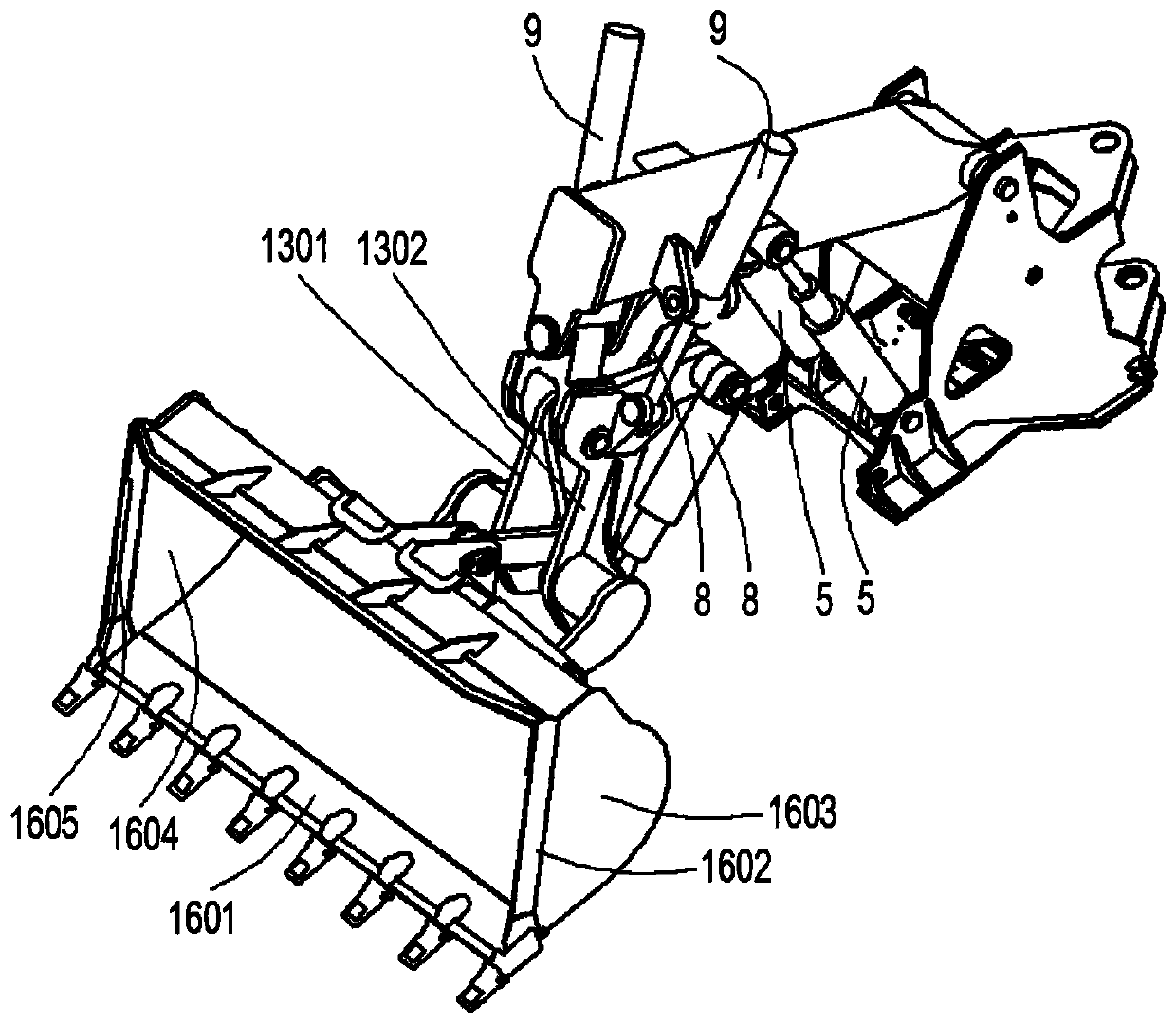

[0035] Such as figure 2 image 3 Figure 4 As shown, the boom 3 is a single-arm boom, the boom 3 is arranged in the center, its rear end is hinged to the front frame 1 through the boom pin 2 , and the front end is provided with a rotary support 302 . A boom oil cylinder 5 is respectively arranged on both sides of the boom 3, and the lower ends of the two boom oil cylinders 5 are hinged with the front frame 1 through the lower pin shaft 4 of the boom oil cylinder respectively, and the upper ends of the two boom oil cylinders 5 pass through the boom respectively. Pin shaft 6 on the oil cylinder is correspondingly hinged with the left and right bearings on the boom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com