Slide with plastic supports

A technology for plastic brackets and skateboards, which is applied to skateboards, ice skating, roller skates, etc., can solve the problems of broken front and rear axle brackets, no shock-absorbing parts, and bulkiness, and achieves lightweight components, firm structure, and reduced The effect of fracture risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

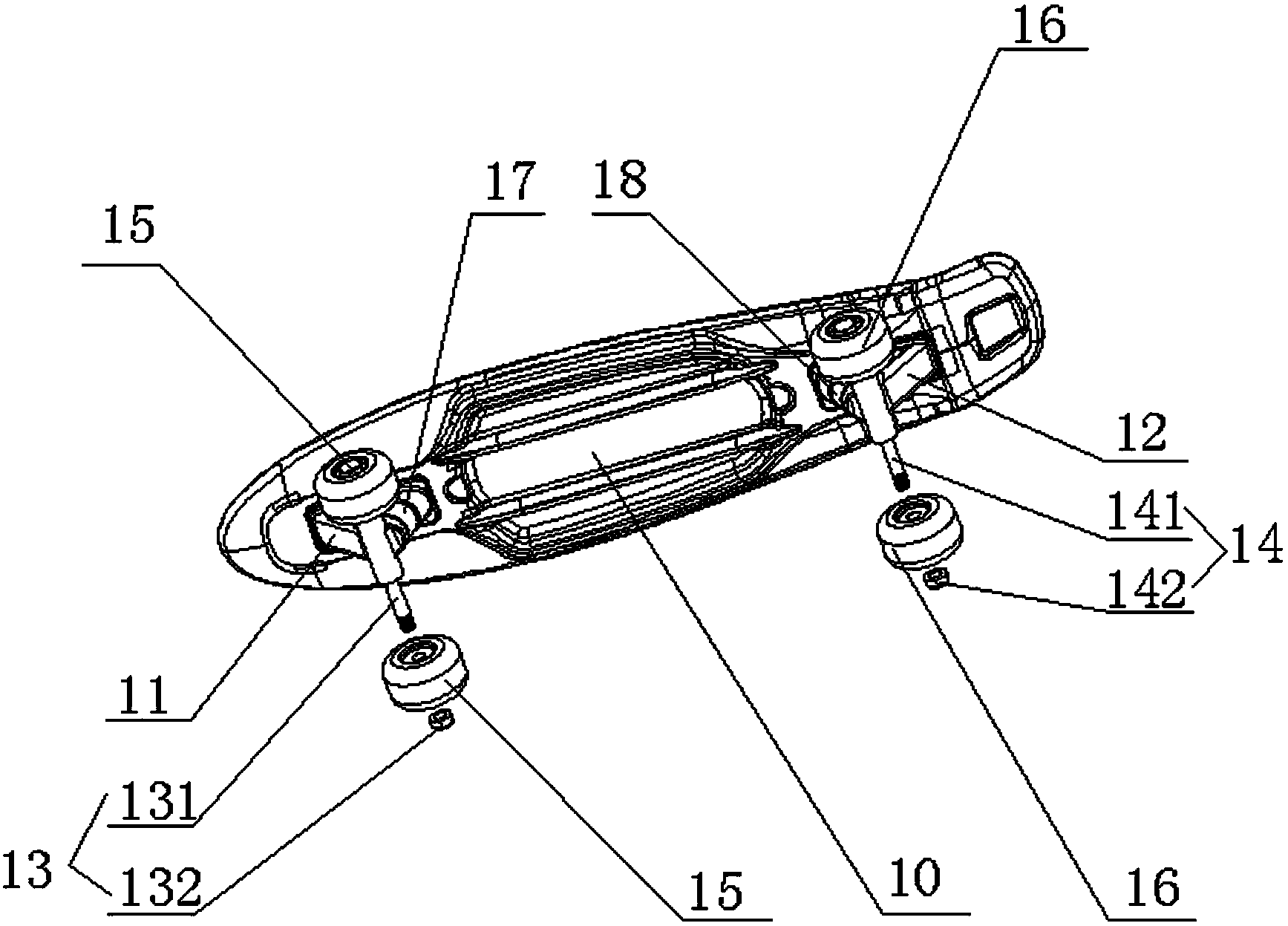

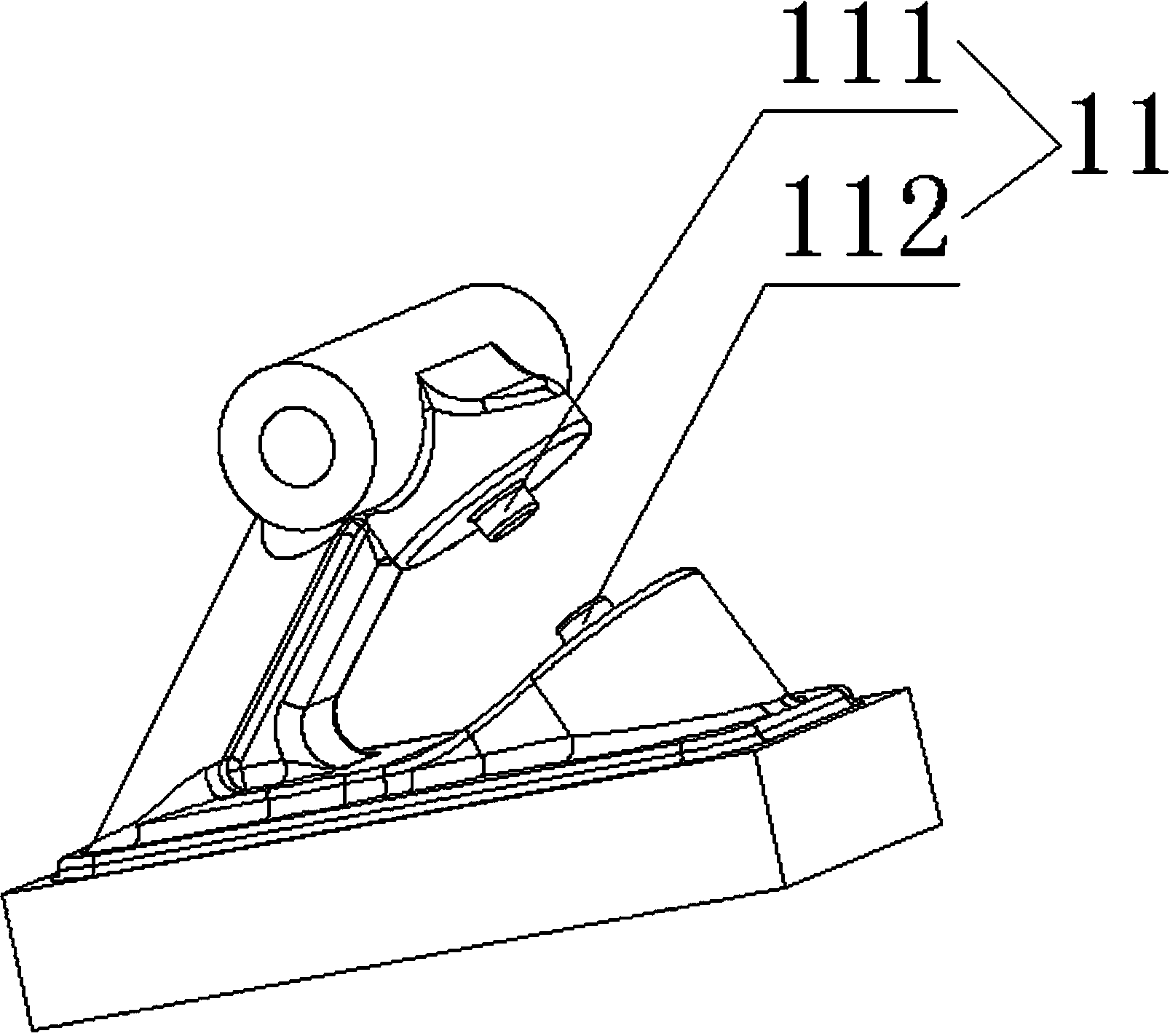

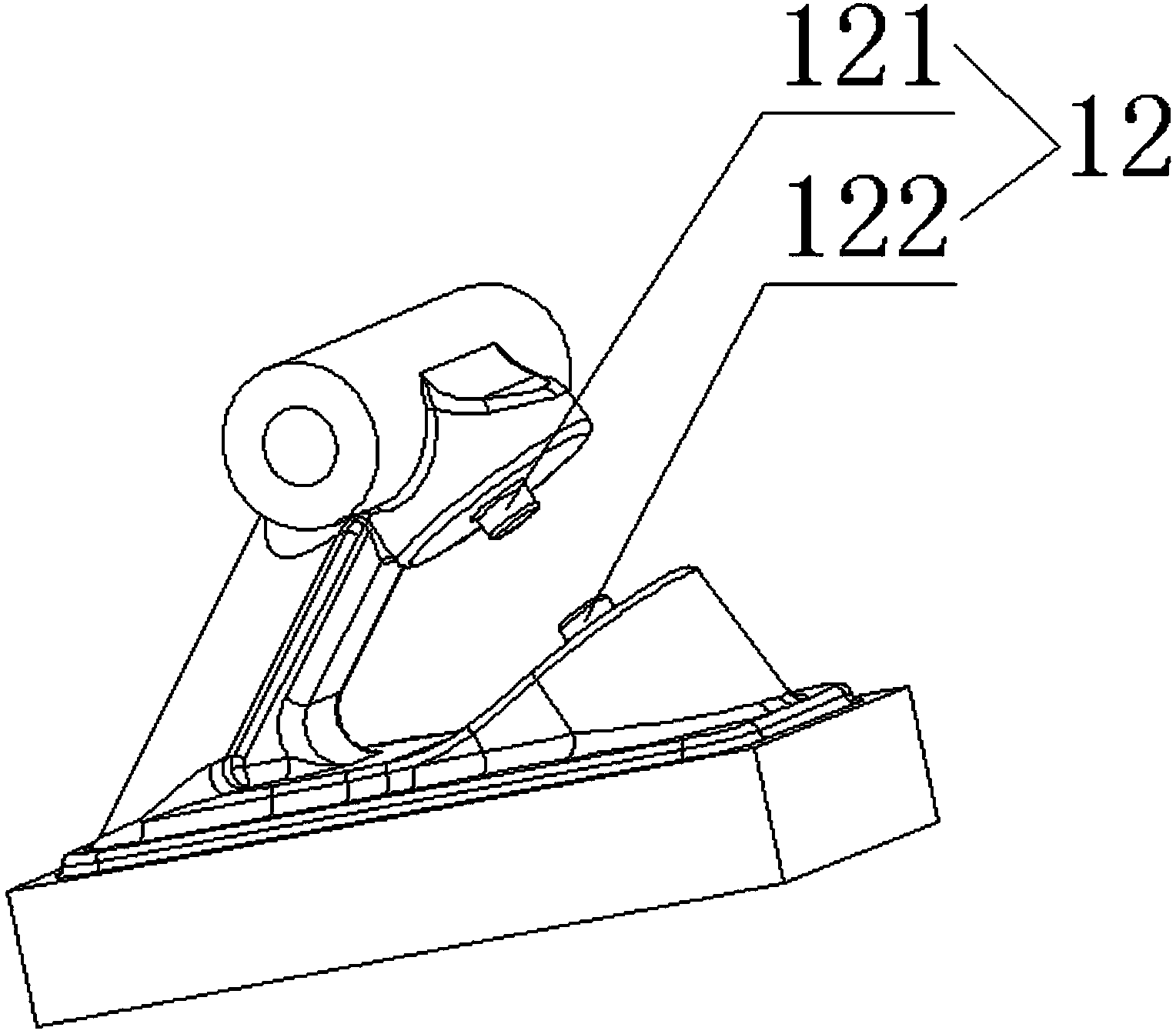

[0036] see Figure 1-9 , the plastic bracket skateboard provided by the present invention comprises a pedal 10, a front axle bracket 11, a rear axle bracket 12, a front axle 13, a rear axle 14, two front wheels 15 and two rear wheels 16, and the two front wheels 15 pass through the front Axle 13 is movably fixed on the front axle support 11, and two rear wheels 16 are movably fixed on the rear axle support 12 through the rear axle 14; the front axle support 11 and the rear axle support 12 are plastic supports and integrally formed with the pedal 10; The skateboard also includes a front shock absorber 17 and a rear shock absorber 18; the front axle bracket 11 is provided with a first protrusion 111 and a second protrusion 112, and the first protrusion 111 and the second protrusion 112 are opposite and all sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com