Method for fabricating a vehicle interior trim part and vehicle interior trim part

A technology for vehicle interior and trim parts, which is applied in the field of vehicle interior parts and can solve problems such as damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

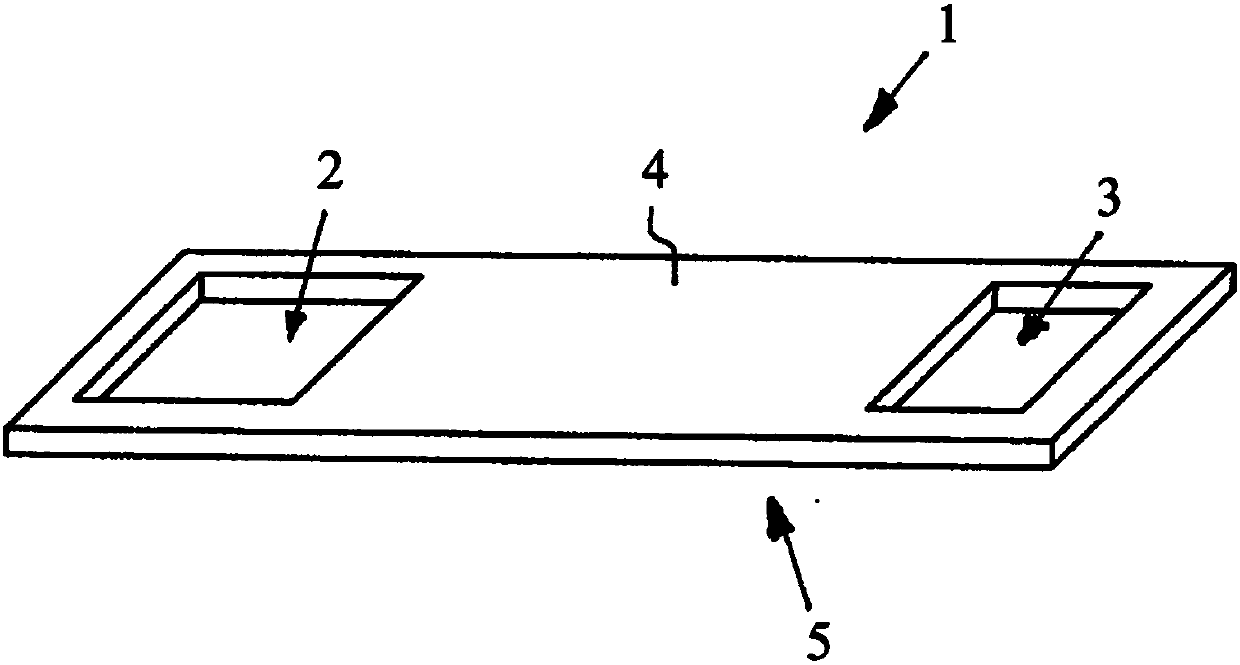

[0035] Figure 1a A first step of a method for producing a vehicle interior part is shown. The figure shows a flat and optically transparent glass panel 1 comprising two openings 2 , 3 . The opening 2 and the opening 3 connect the front side 4 of the glass pane 1 with the rear side 5 of the glass pane 1 . For example, the thickness of the glass panel 1 can be up to 0.5 mm. The glass panel 1 can consist of aluminosilicate glass. The depicted glass panel 1 has a rectangular shape. However, other shapes are also possible.

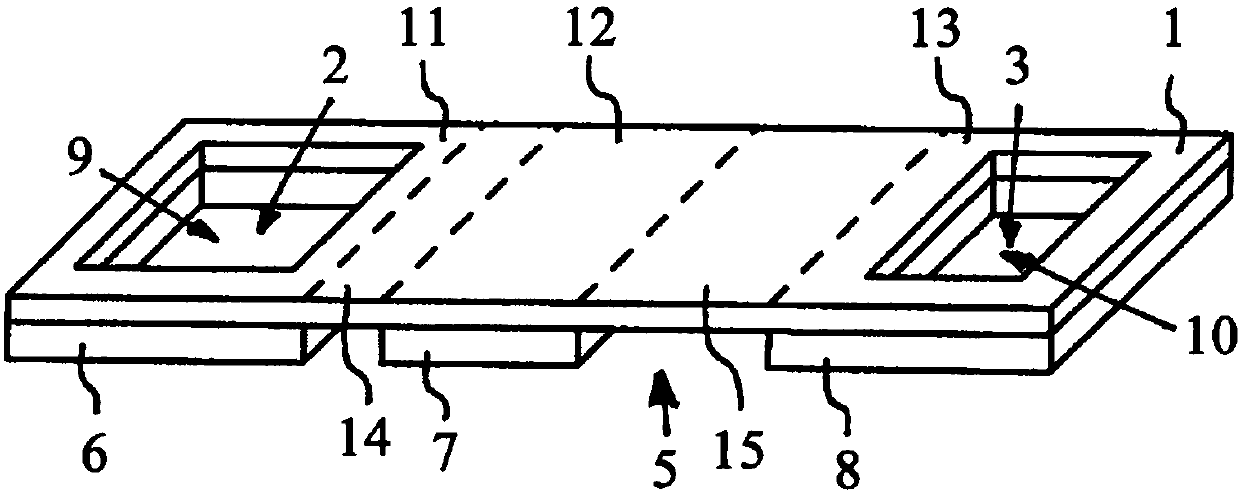

[0036] Figure 1b The glass panel 1 is shown after the three stiffeners 6 , 7 , 8 have been attached to a part of the backside 5 of the glass panel 1 . Figure 1b Corresponding features to those shown in the following figures are indicated by the same reference numerals. In this embodiment, the reinforcement is a planar reinforcement having a planar surface corresponding to the planar backside of the glass panel. The reinforcement 6 , 7 and 8 each have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com