Flexible display device and manufacturing method thereof

A flexible display and manufacturing method technology, applied to semiconductor devices, electric solid devices, electrical components, etc., can solve the problems of high manufacturing cost, difficult manufacturing, and poor reliability of flexible displays, so as to improve the service life and reduce the breakage of metal wires risk, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

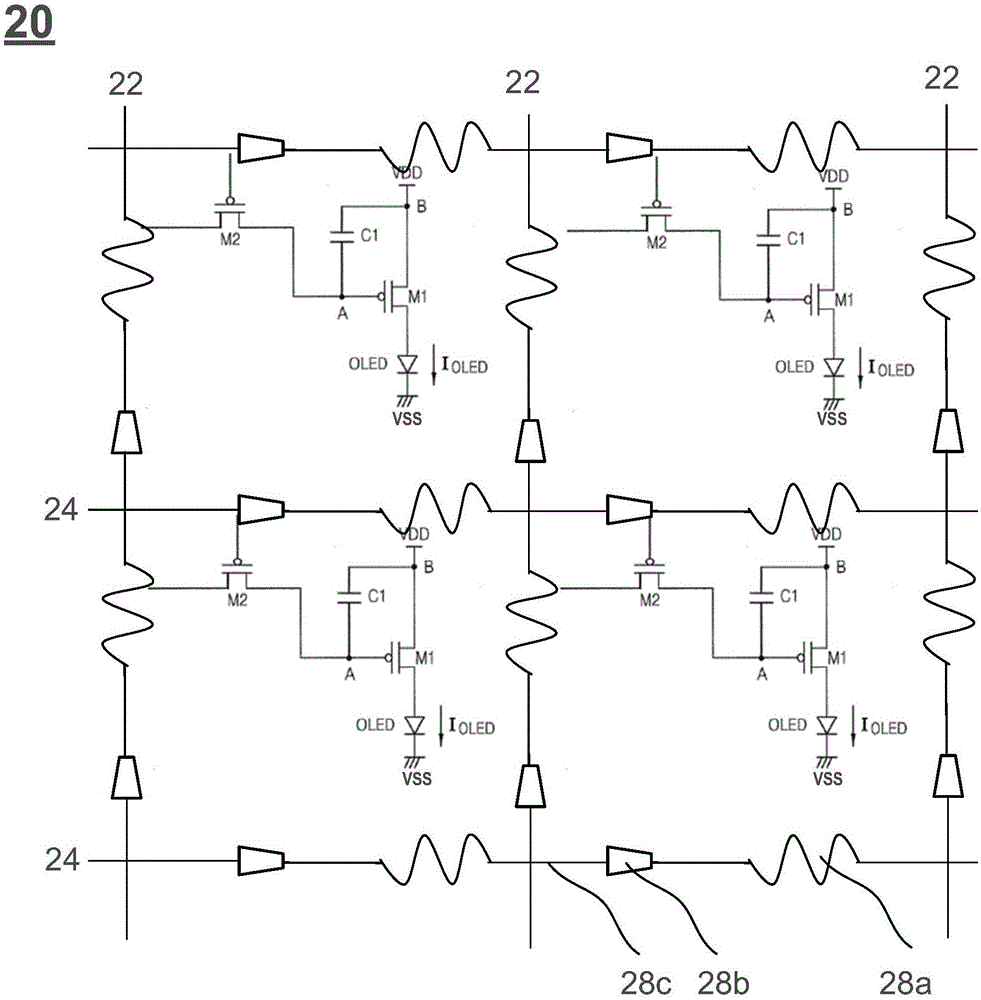

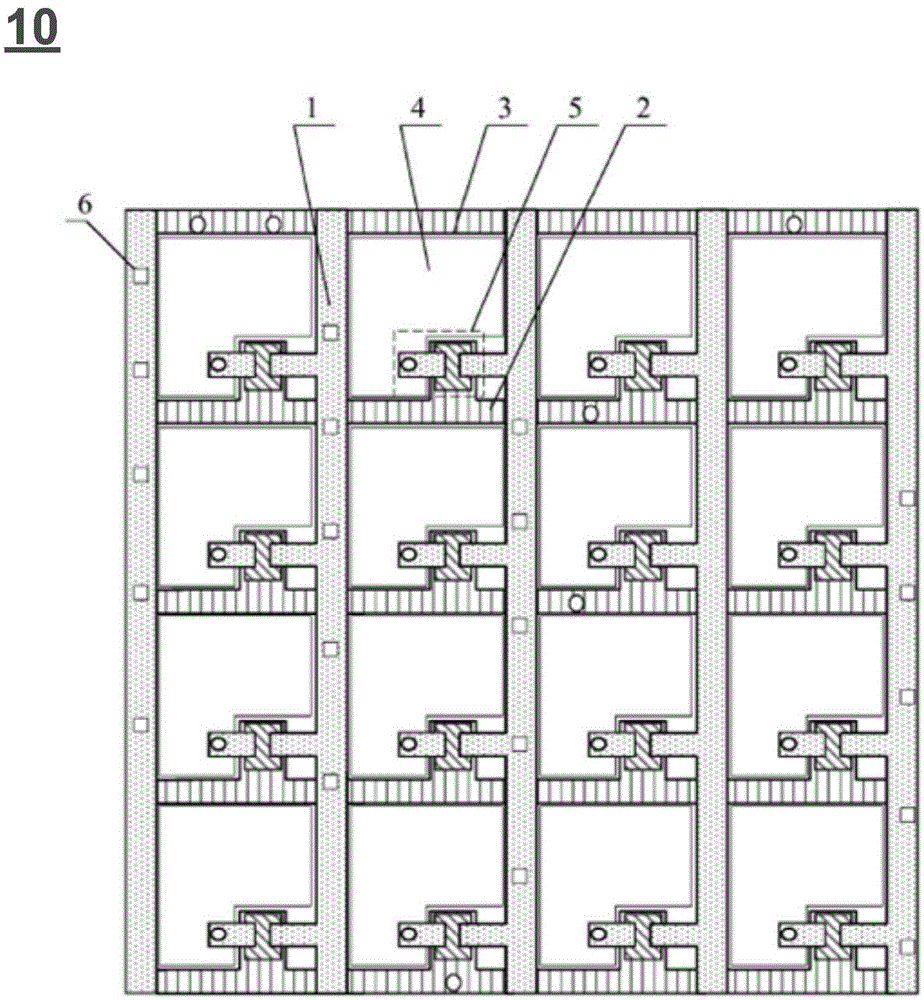

[0035] Please refer to figure 2 , which is a schematic structural diagram of a flexible display device according to Embodiment 1 of the present invention. like figure 2 As shown, the flexible display device 20 includes: a flexible substrate (not shown in the figure) and a metal wire disposed on the flexible substrate, and a part of the metal wire is an arc-shaped segment.

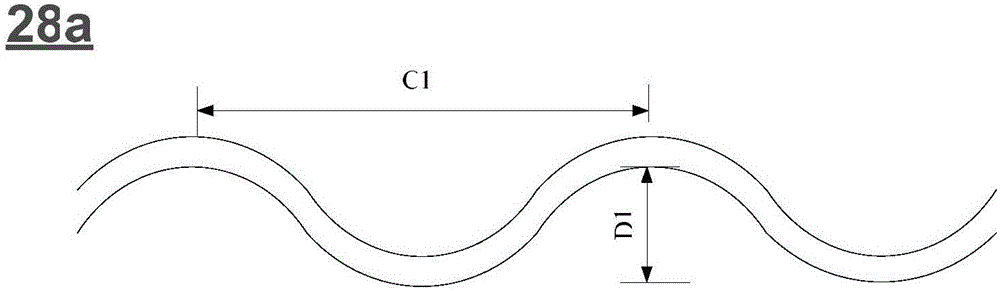

[0036] Specifically, the metal lines include a plurality of data lines 22 and a plurality of gate lines 24 that are intersected and independent from each other. The plurality of data lines 22 and several gate lines 24 form a plurality of intersection nodes, and each adjacent At least one first arc line segment 28a, at least one second arc line segment 28b, and a straight line segment 28c connected to the first arc line segment 28a and the second arc line segment 28b are arranged between the intersection nodes, and the straight line The cross-section and longitudinal section of the segment 28c are straig...

Embodiment 2

[0061] Please refer to Figure 5 , which is a schematic structural diagram of a flexible display device according to Embodiment 2 of the present invention. like Figure 5 As shown, the flexible display device 20 includes: a flexible substrate (not shown in the figure) and a metal wire disposed on the flexible substrate, and a part of the metal wire is an arc-shaped segment.

[0062] Specifically, the metal lines include a plurality of data lines 22 and a plurality of gate lines 24 that are intersected and independent from each other. The plurality of data lines 22 and several gate lines 24 form a plurality of intersection nodes, and each adjacent At least one helical arc line segment 28d is arranged between the intersection nodes.

[0063] The difference between this embodiment and Embodiment 1 is that the shape of the arc-shaped segment in the metal wire is helical, and the helical arc-shaped segment can bear stress in both the cross-sectional direction and the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com