Assembly type stairway installation structure

An installation structure and prefabricated technology, which is applied in the direction of stepped structures, stairs, building structures, etc., can solve the problems of large construction of prefabricated stair modules, increased difficulty, and low installation efficiency, so as to save transportation costs and reduce construction difficulty , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

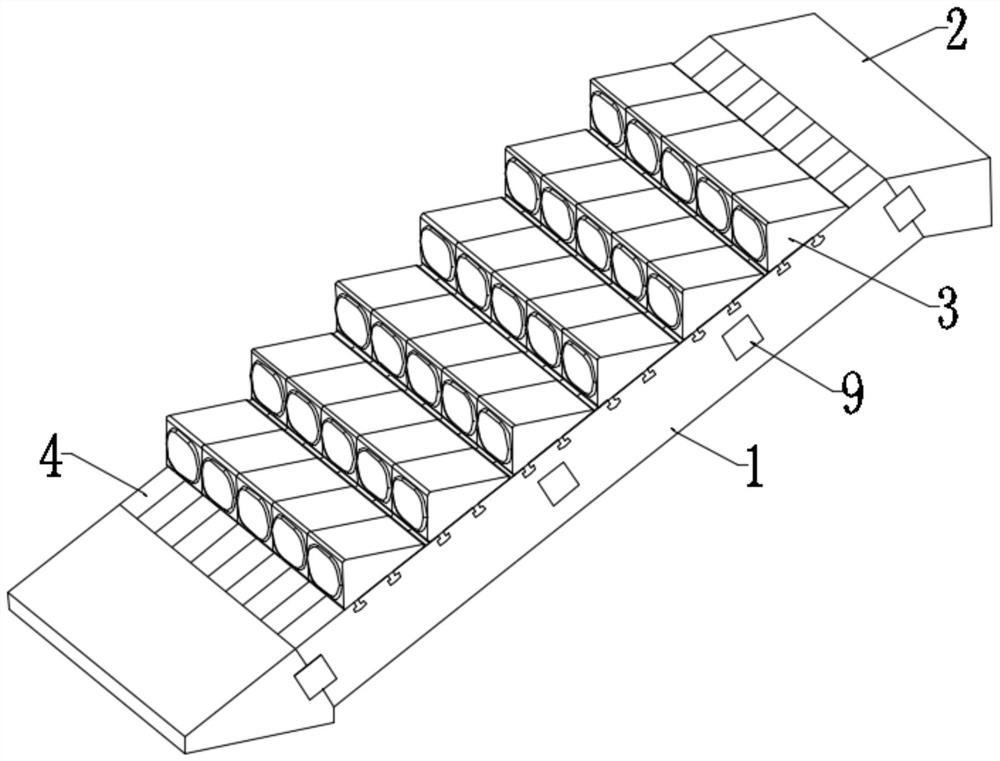

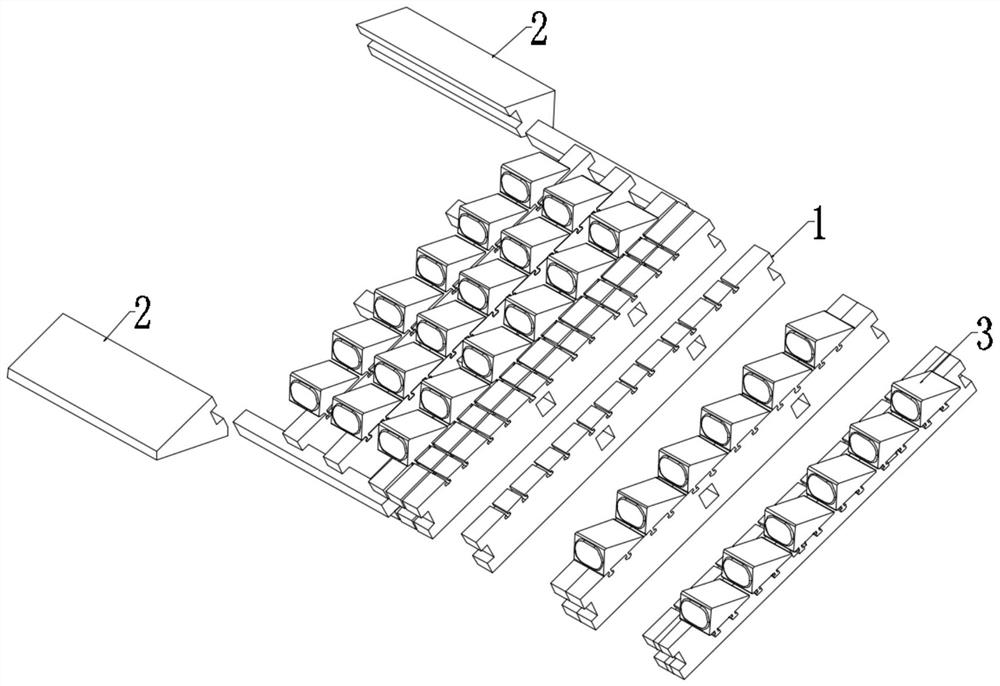

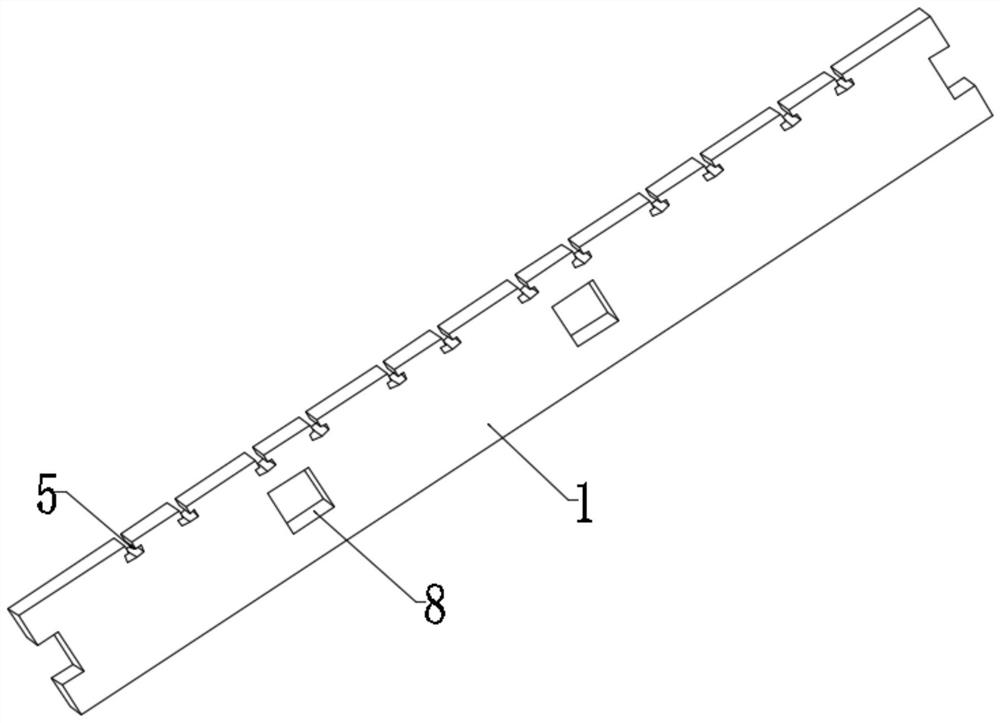

[0025] see Figure 1 to Figure 4 , this embodiment provides a prefabricated stair installation structure, wherein, firstly, a base plate 1, a prefabricated part 2 and a step block 3 are provided, and the two ends of the base plate 1 are respectively clamped on two prefabricated parts 2, and the multi-block foundation The board 1 is clamped on the prefabricated part 2 to form a stair slab 4, and the end faces of two adjacent foundation boards 1 are bonded together. The surface of the foundation board 1 is provided with a plurality of tenon grooves 5, and the step block 3 is a column with a right-angled triangle cross section. Body, the slope 6 of the step block 3 is provided with a plurality of tenons 7, the tenons 7 are clamped in the tenon groove 5, and the slope 6 is attached to the surface of the stair plate 4.

[0026] Specifically, see Figure 1 to Figure 4 The foundation board 1 is provided with a plurality of positioning holes 8, and the beam 9 passes through the posit...

Embodiment 2

[0034] see Figure 1 to Figure 4 , the figure shows a prefabricated stair installation structure provided by Embodiment 2 of the present invention. On the basis of the above embodiment, this embodiment further makes the following technical solution as an improvement: the tongue and groove 5 are equidistant Evenly arranged, there are two tenon heads 7, and the two tenon heads 7 are clamped in two adjacent tenon grooves 5.

[0035] Specifically, see Figure 1 to Figure 4 , the tenon 7 is a T-shaped boss structure, and the tenon and groove 5 is a T-shaped groove structure.

[0036] Specifically, see Figure 1 to Figure 4 , the thickness of the step block 3 is equal to twice the thickness of the base plate 1 .

[0037] The thickness of the step blocks 3 is twice the thickness of the base plate 1, so that one step block 3 is clamped on two base plates 1, and the staggered arrangement improves the stability of the staircase structure.

Embodiment 3

[0039] see Figure 1 to Figure 4 , the figure shows a prefabricated stair installation structure provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the base plate 1 and the horizontal The included angle is 25°-30°, and the included angle between the inclined plane 6 and the base plate 1 is the same as that of the horizontal.

[0040] The inclined plane 6 and the base plate 1 need to maintain the same angle with the horizontal, so that the two right-angled surfaces on the step block 3 are in the horizontal and vertical states respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com