Patents

Literature

34results about How to "Low amortized cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

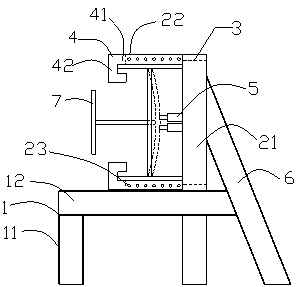

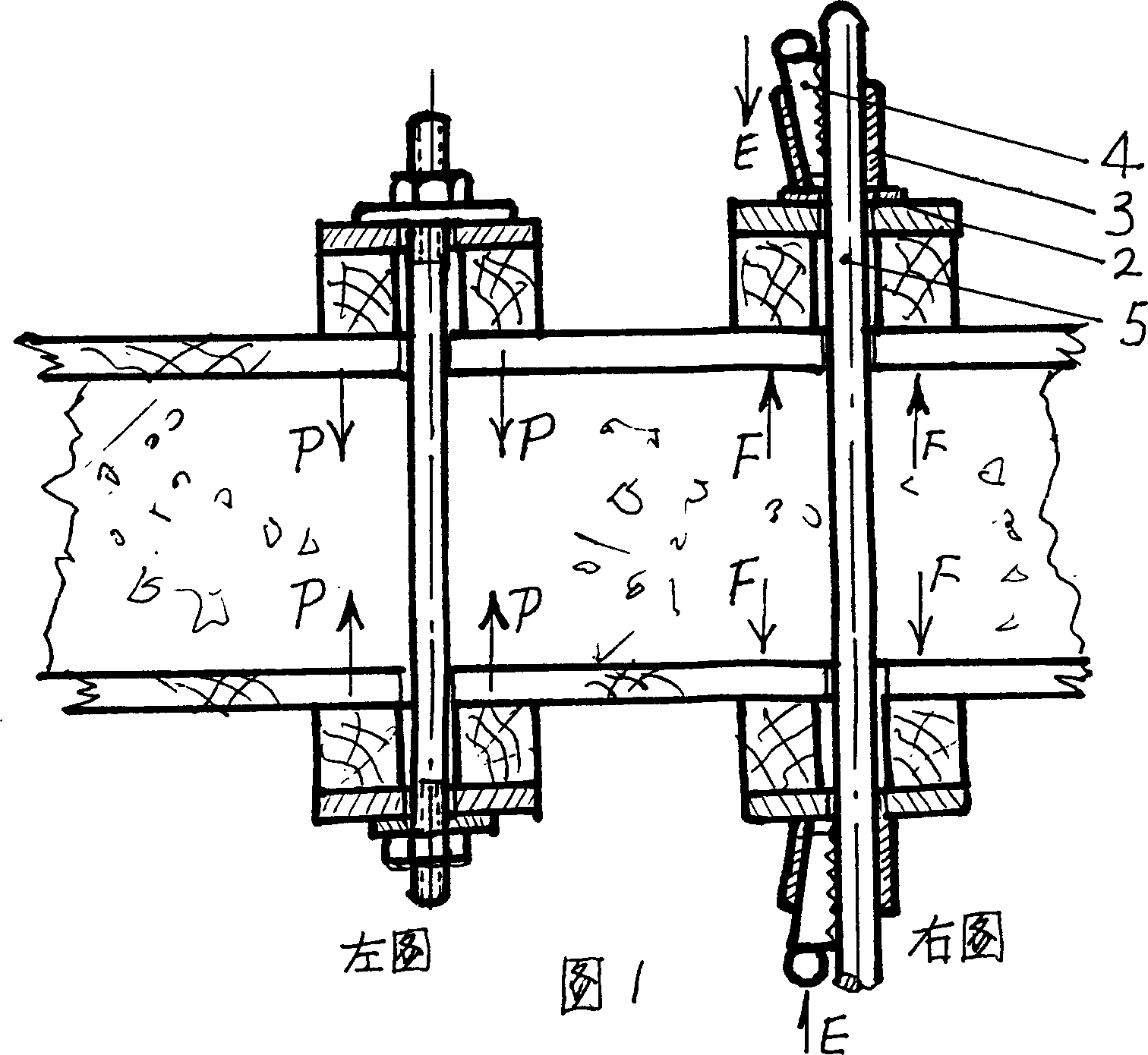

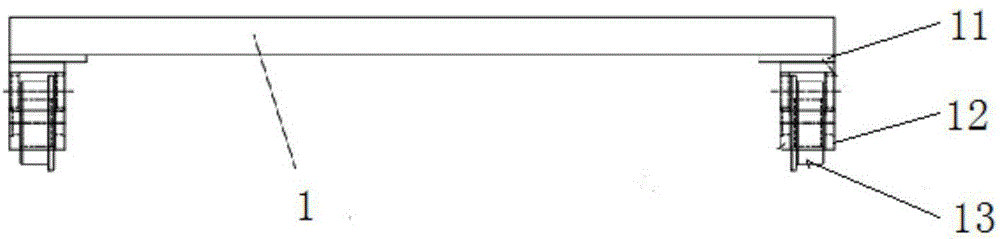

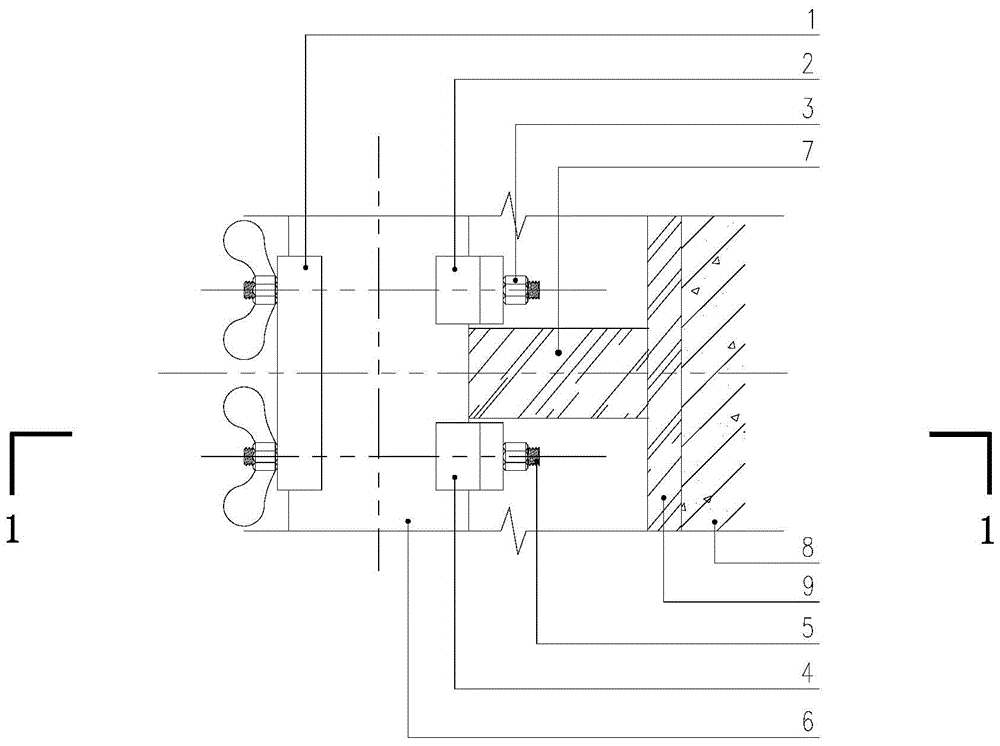

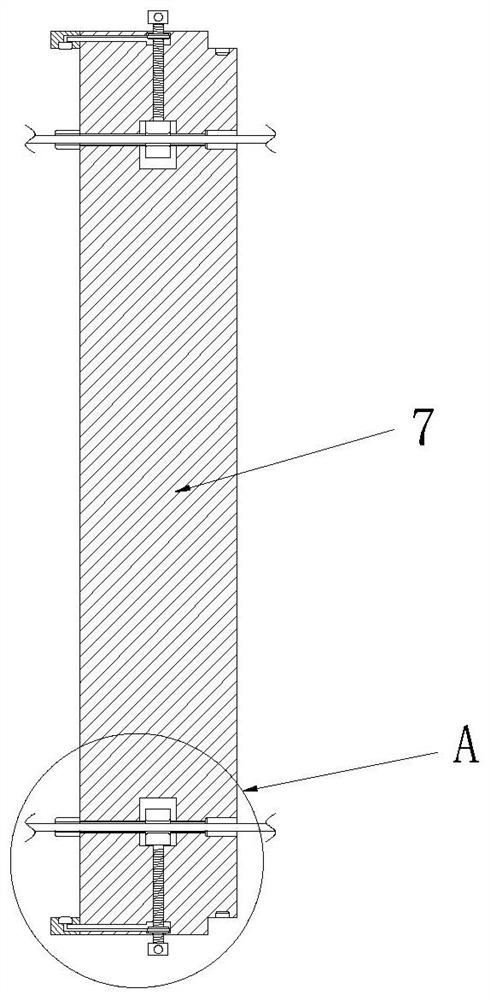

Welded combined T-shaped steel column correcting device and method

The invention discloses a welded combined T-shaped steel column correcting device and method. The correcting device is composed of multiple correcting units which are on the same straight line. Each correcting unit comprises a platform support, two L-shaped clamps and a jack. Each platform support is formed by welding two stand columns and a cross beam. A vertical beam is arranged on the upper surface of each cross beam, wherein each vertical beam is perpendicular to the corresponding cross beam. The two ends of each vertical beam are provided with two rectangular connecting blocks, wherein every two rectangular connecting blocks are parallel with the corresponding cross beam. Each connecting block is uniformly provided with multiple threaded holes. Each L-shaped clamp is integrally formedby a transverse plate and a vertical plate. Each transverse plate is provided with threaded holes matched with the threaded holes in the connecting blocks. Threaded connecting pieces penetrate the threaded holes in the transverse plates and the threaded holes in the connecting blocks, so that the two L-shaped clamps are fixedly connected with the two connecting blocks correspondingly. Each jack is arranged between the corresponding vertical beam and a to-be-corrected welded H-shaped profile steel web plate. A base of each jack tightly jacks the corresponding vertical beam. The stroke end of each jack tightly jacks the corresponding to-be-corrected welded H-shaped profile steel web plate. The welded combined T-shaped steel column correcting device has the advantages of being simple in structure, easy to operate, low in cost, high in efficiency and the like.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

U-shaped force-bearing seat and construction method of steel beam-reinforced concrete floor slab structure

InactiveCN102444281AReduce labor intensityMeet the main construction progress requirementsAuxillary members of forms/shuttering/falseworksBuilding material handlingFloor slabReinforced concrete

Owner:潘克远

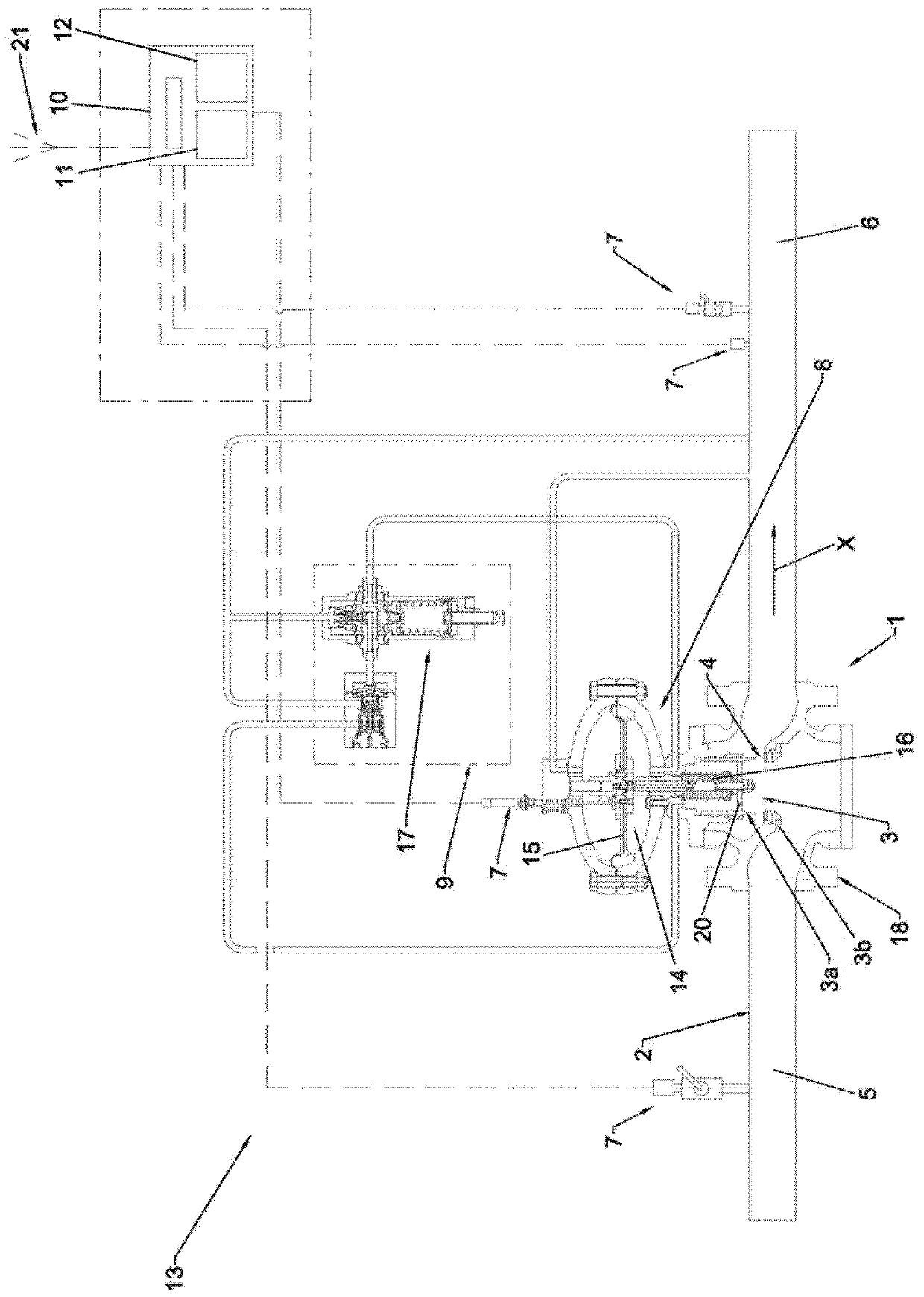

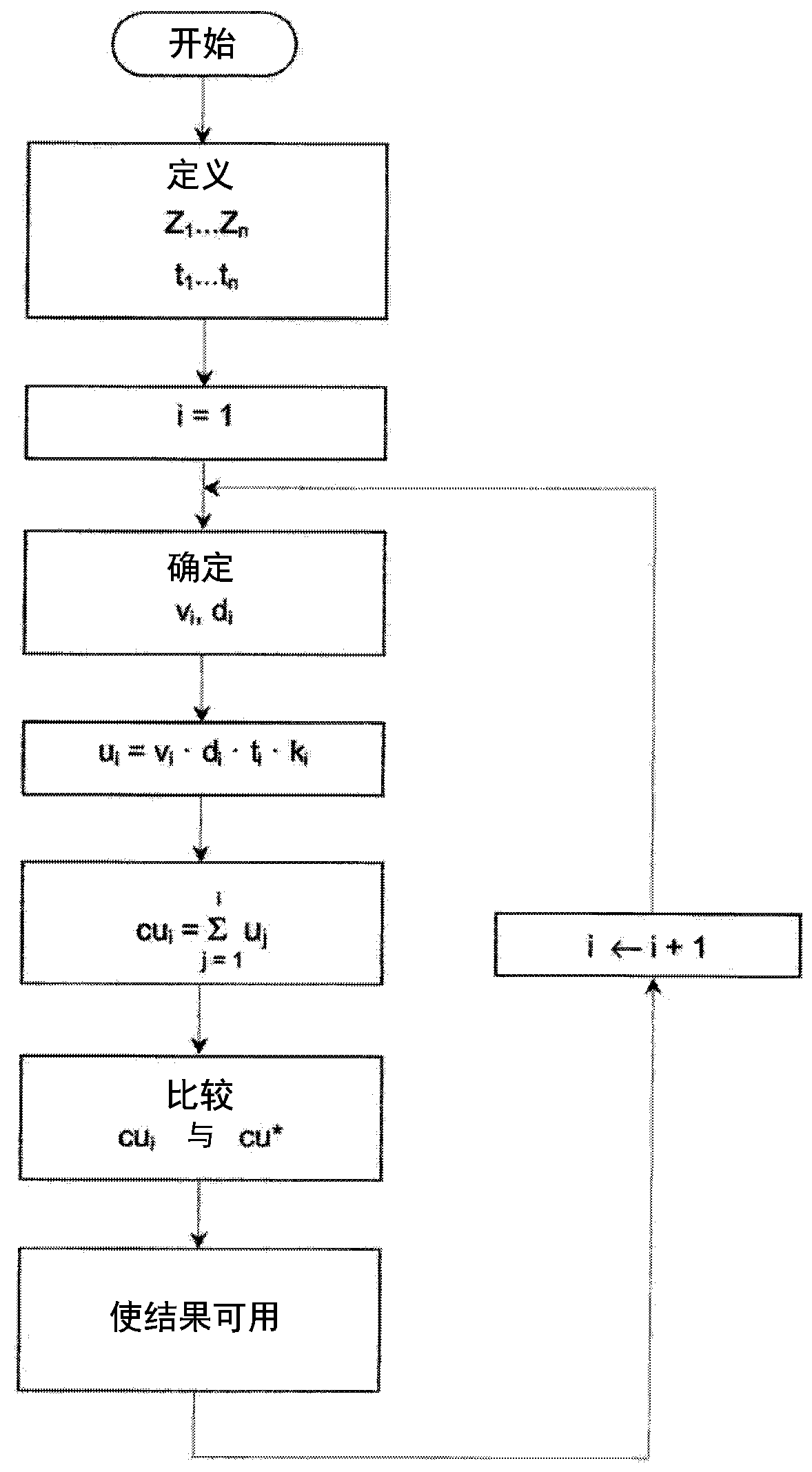

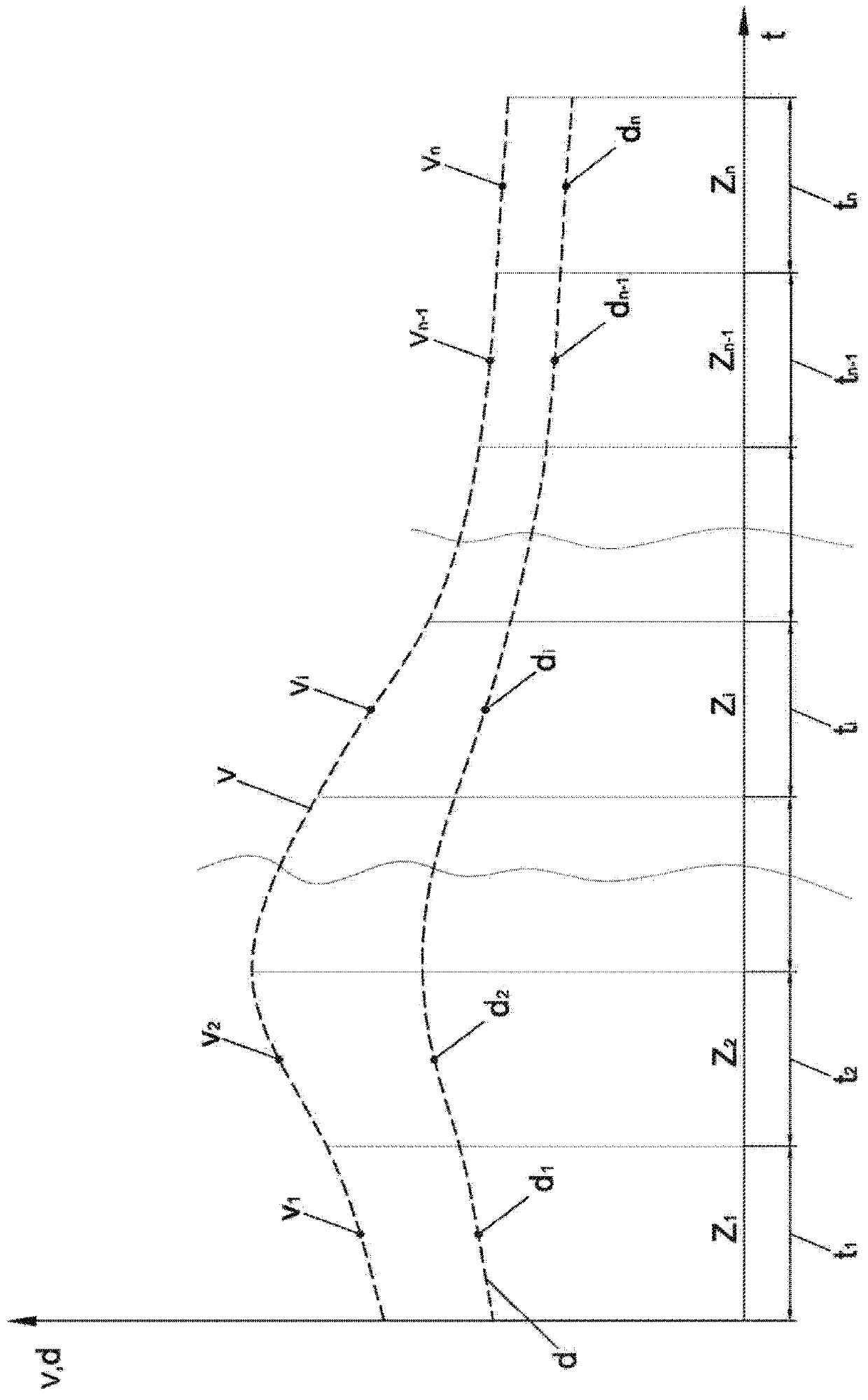

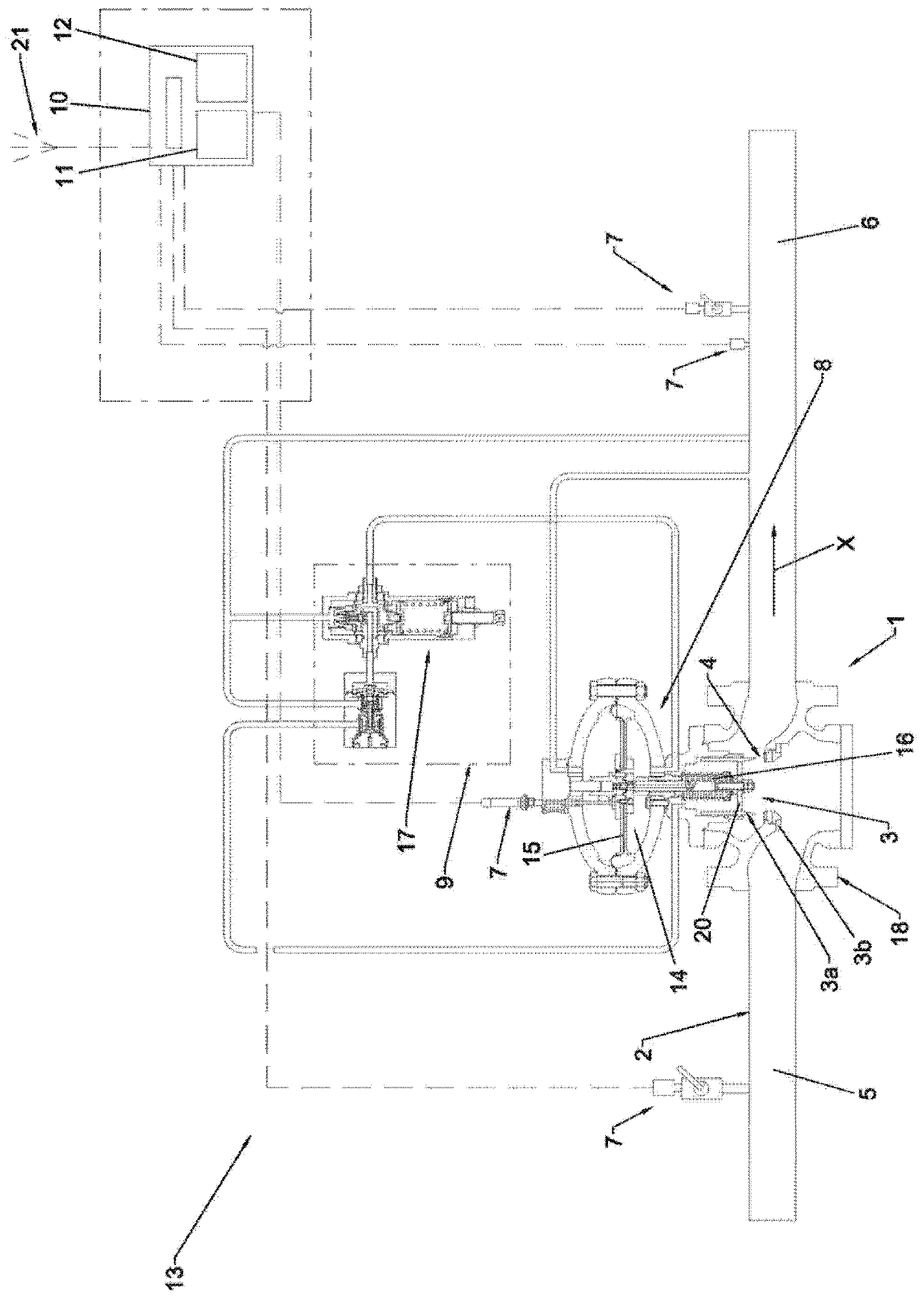

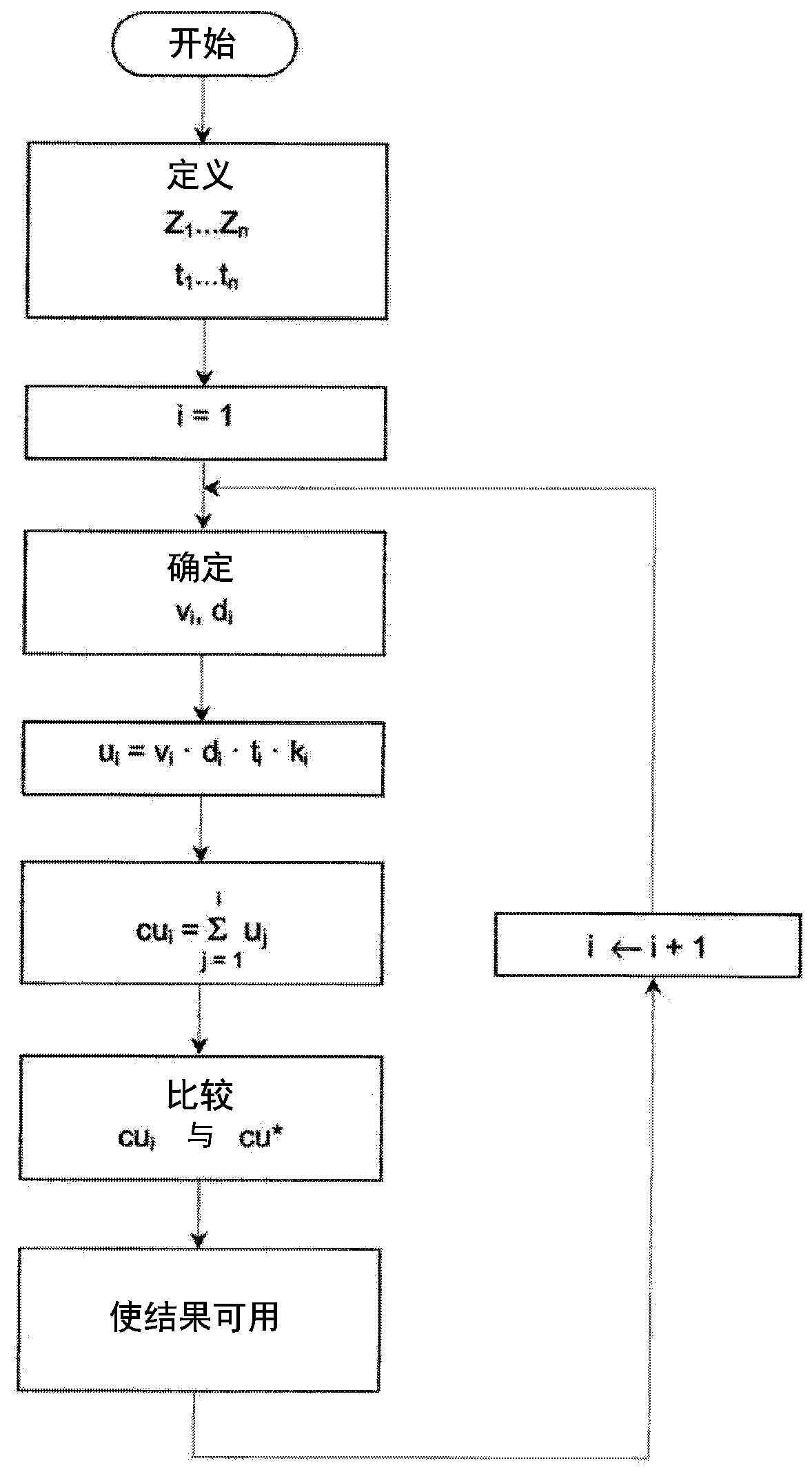

A method for monitoring a device for regulating the flow of a gas and a regulating system employing said method

ActiveCN109716002ALow amortized costEarly maintenance workOperating means/releasing devices for valvesFluid pressure control using electric meansControl theoryMechanics

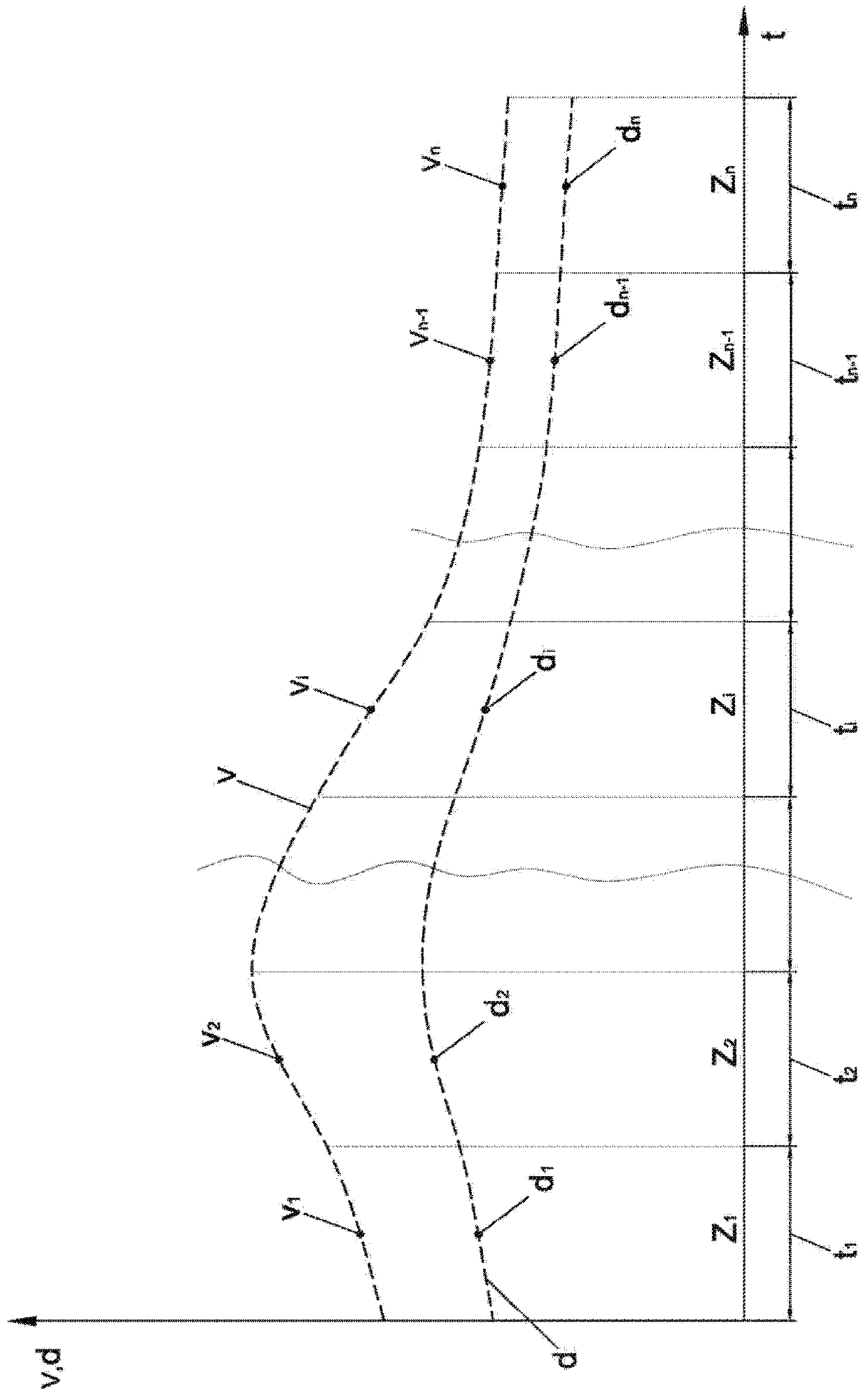

A method for monitoring a device (1) for regulating the flow of a gas, comprising a flow conduit (2) and a shutter assembly (3) that defines a restriction (4) in the flow conduit (2). The method comprises the following operations: causing the transit of gas through the flow conduit (2); defining a sequence of time intervals (Z1...Zn) of corresponding durations (t1...tn); during each time interval(Zi), determining a value of density (di) and a value of velocity (Vi) of the gas at the restriction (4); calculating the product of the value of density (di), of the value of velocity (Vi), of the duration (ti) of the time interval (Zi) and of a correction coefficient (ki) to obtain a corresponding value of equivalent wear (ui); for each time interval (Zi), adding all the values of equivalent wear (u1... ui) calculated for the current time interval (Zi) and for the preceding time intervals (Z1...Z(i-1)) to obtain a cumulative value (cui); comparing the cumulative values (cui) with a predefined limit value (cu*), corresponding to a condition of maximum wear allowable for the shutter assembly (3), to obtain an indication of the condition of efficiency of the shutter assembly (3).

Owner:PIETRO FIORENTINI SPA

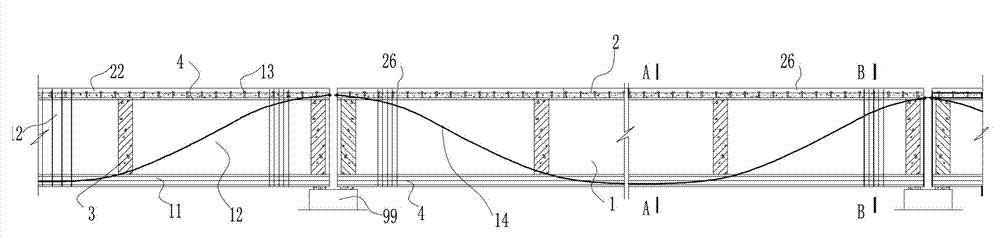

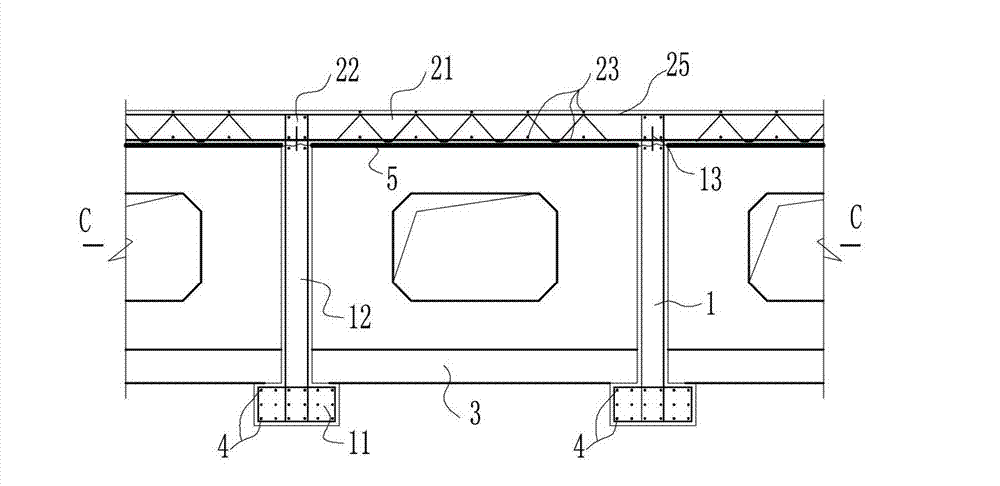

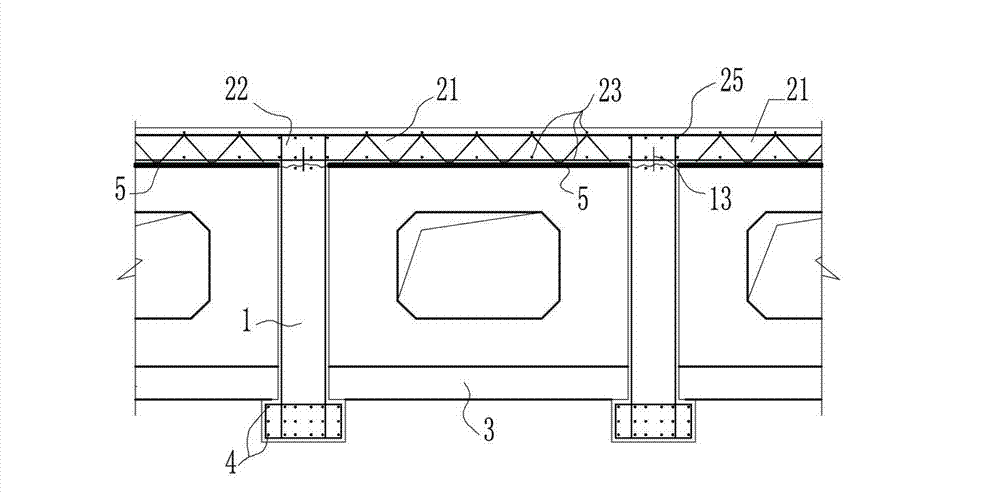

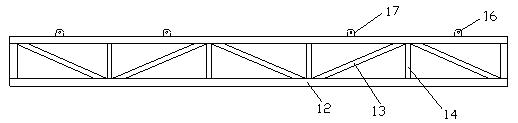

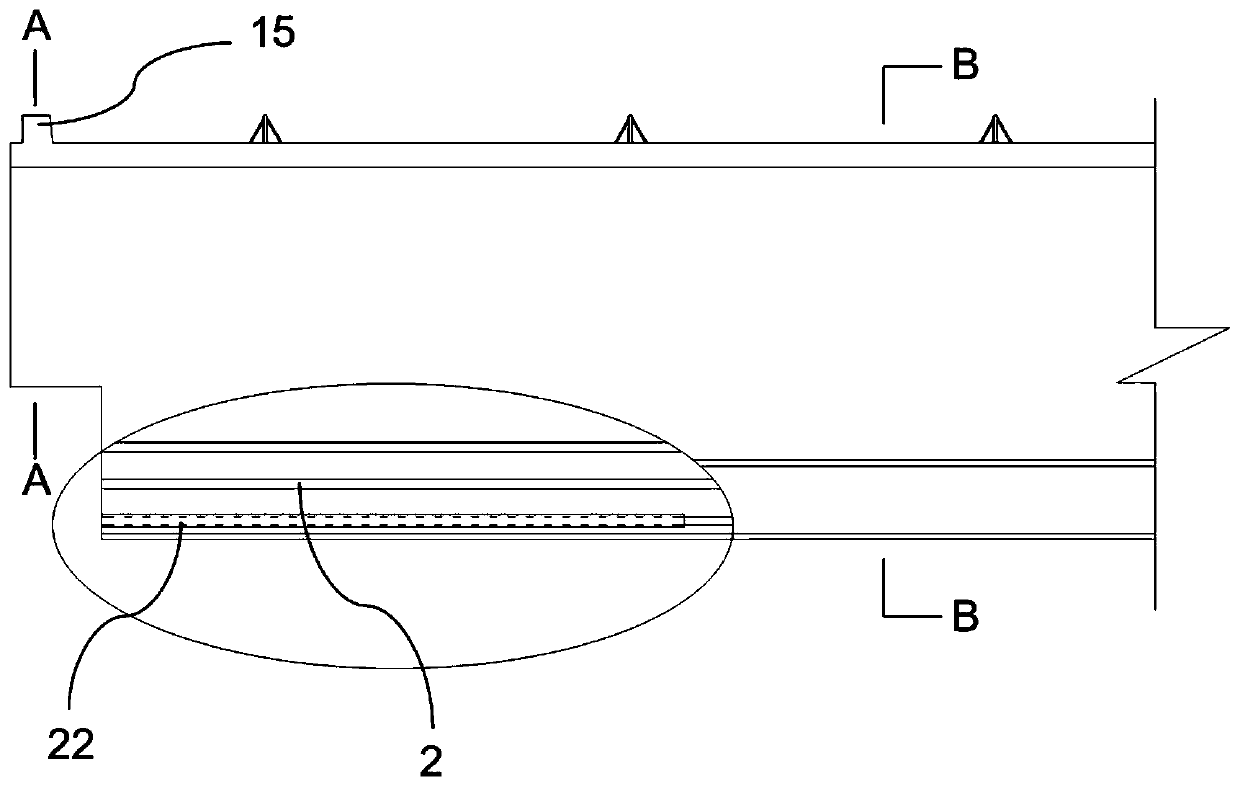

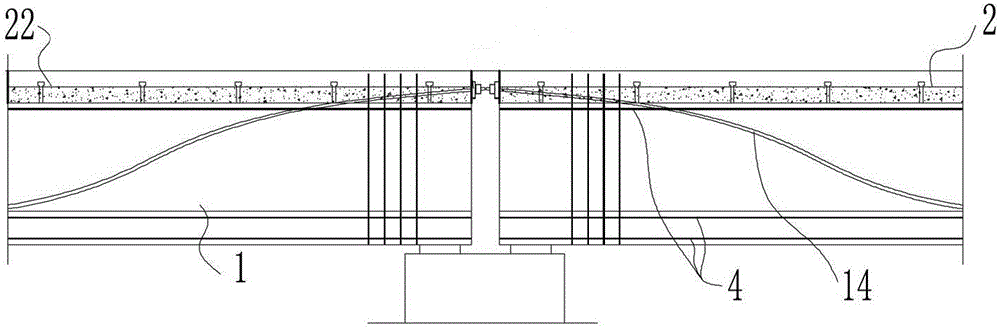

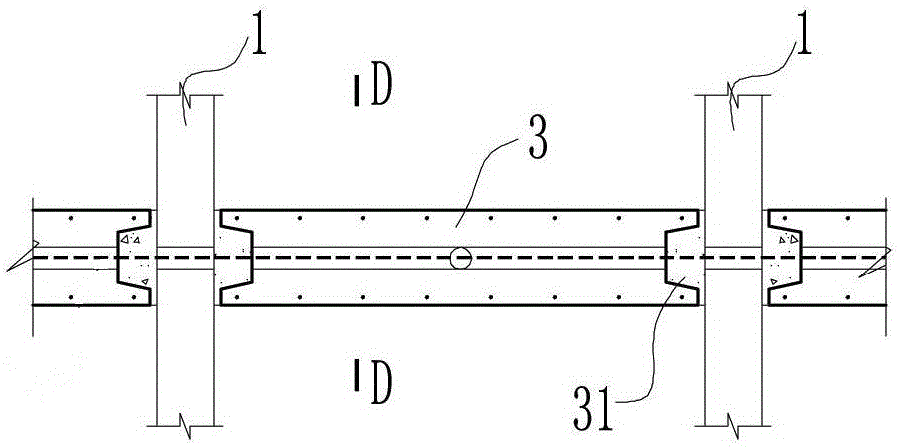

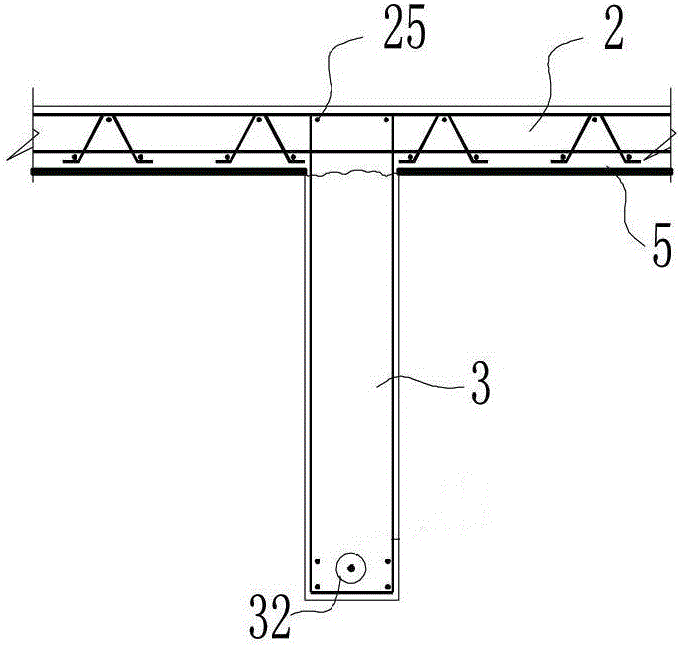

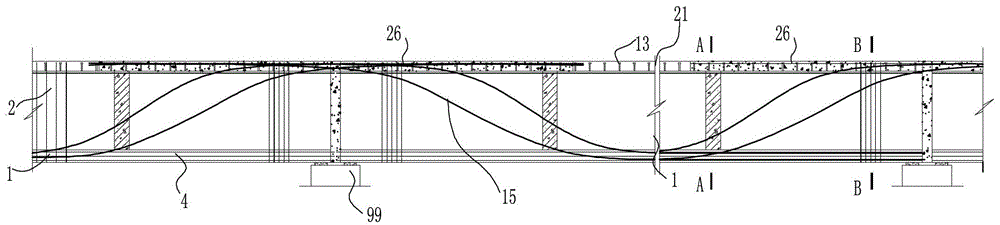

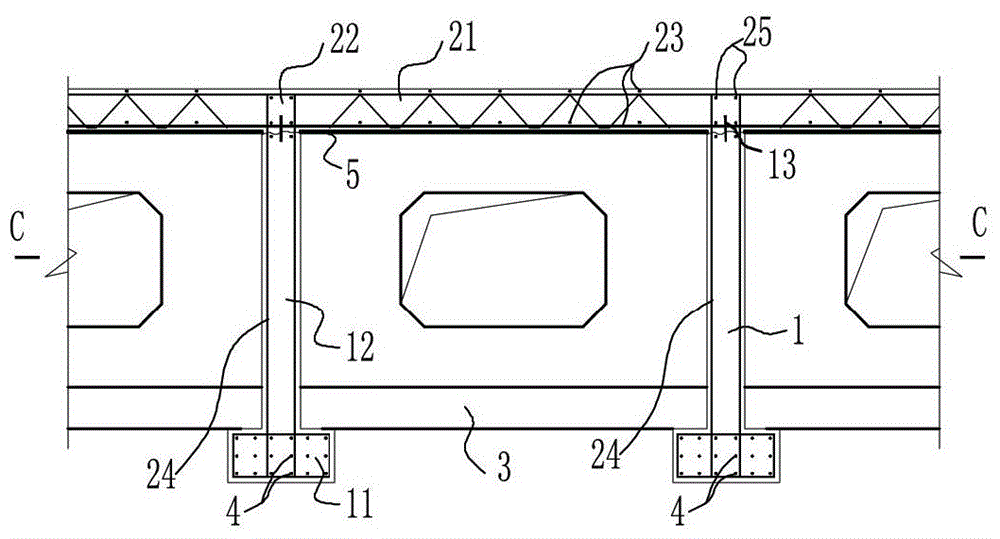

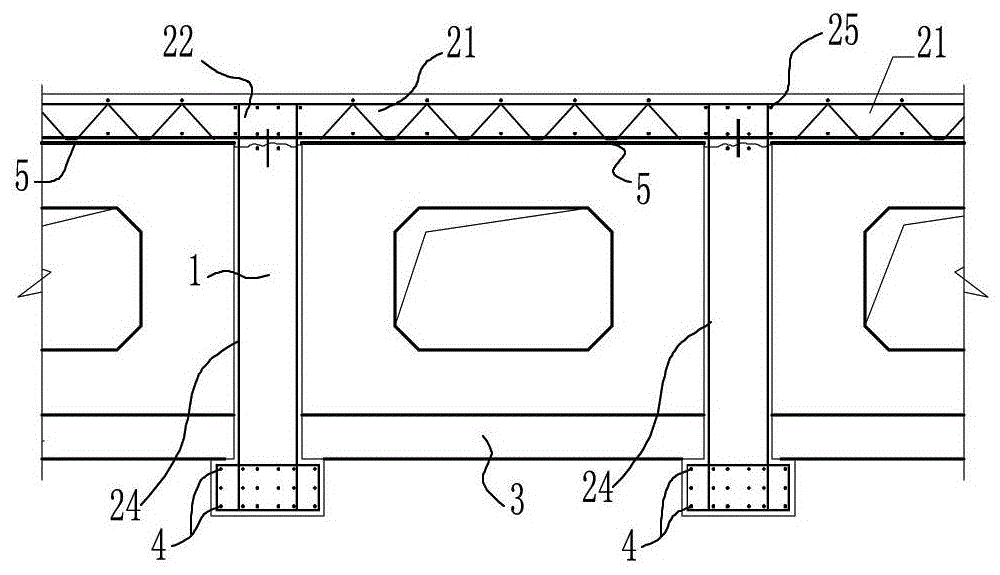

Simply supported prefabricated integrally-cast superposed bridge and construction method thereof

ActiveCN102808372ALight weightEasy to transport and installBridge erection/assemblyPre stressInverted t

The invention discloses a simply supported prefabricated integrally-cast superposed bridge. The prefabricated integrally-cast superposed bridge comprises inverted T-shaped prestressed prefabricated beam parts, cast-in-situ parts and horizontal baffles, and is characterized in that each cast-in-situ part comprises a cast-in-situ plate and a cast-in-situ superposed part at the upper part of the beam part; pretensioned prestressed steel strands are embedded in the upper parts of a web plate and a lower flange of each inverted T-shaped prestressed prefabricated beam part; the horizontal baffles adopt prefabricated plates, and are longitudinally arranged at intervals between the web plates of the adjacent prefabricated beam parts at the two ends of each beam part and positioned above the flanges of the prefabricated beam parts; and the inverted T-shaped prestressed prefabricated beam parts adopt manufacturing moulds commonly used with buildings, and mould plates are good in commonality, convenient to mount and dismount, high in working efficiency and low in amortized cost.

Owner:杨众 +1

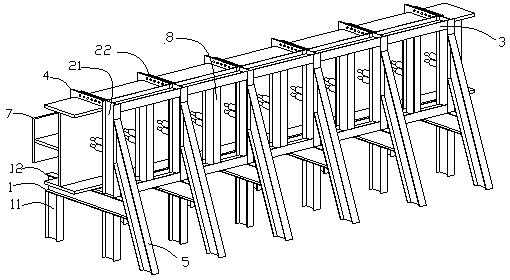

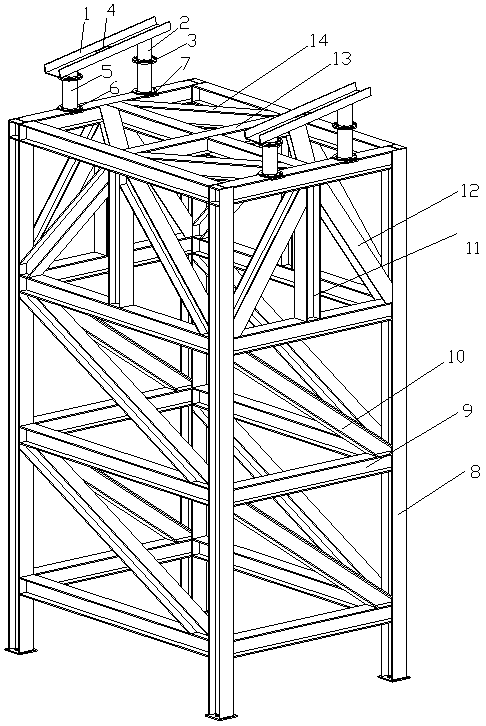

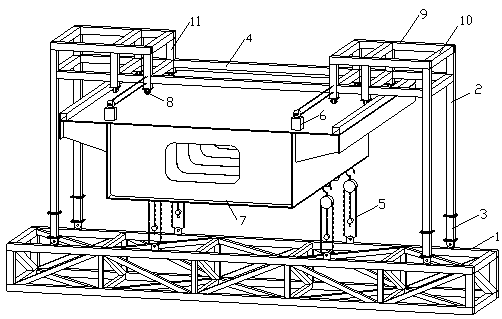

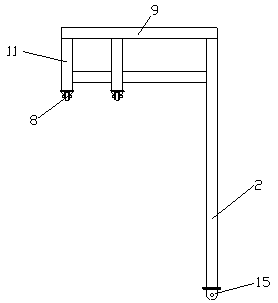

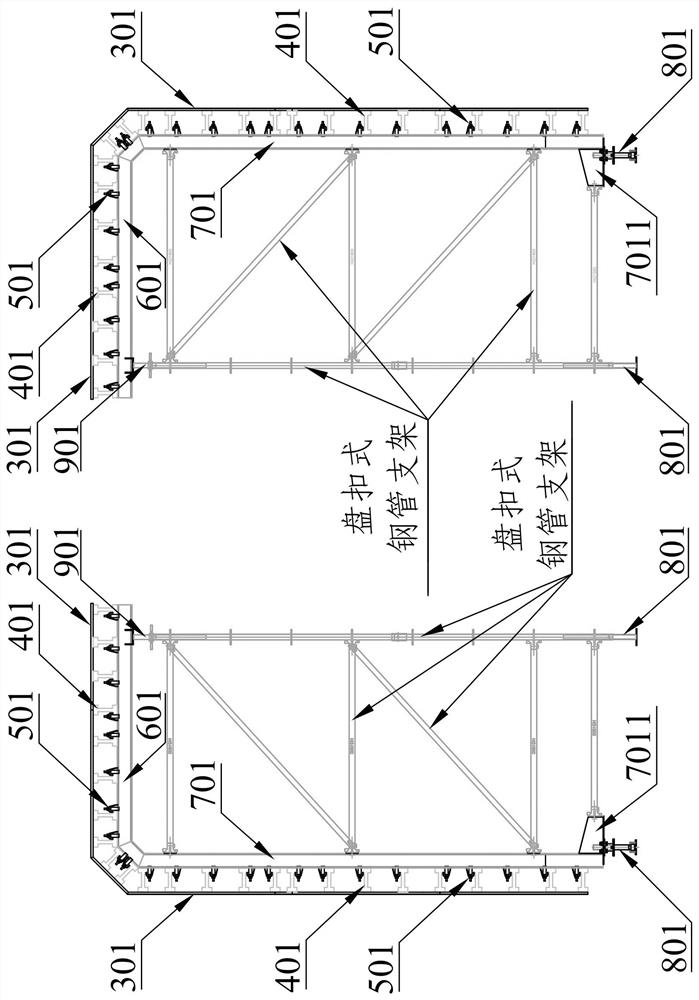

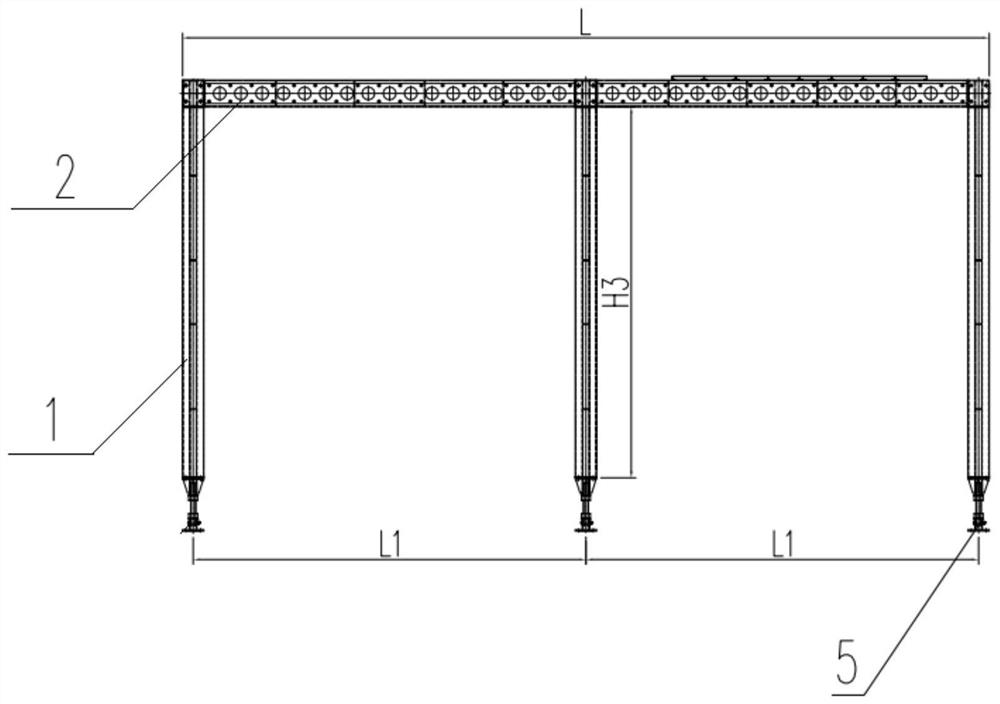

Large-span truss subsection hoisting high-altitude closure measure device and construction method

The invention discloses a large-span truss subsection hoisting high-altitude closing measure device and a construction method. The measure device comprises a plurality of bracket units and a support platform; each bracket unit is composed of a U-shaped groove, two support columns and two flange plates I; the support platform is of a rectangular frame structure and is composed of a plurality of stand columns, a cross beam and support columns; each bracket unit is arranged at the top end of the support platform through two adjusting columns and arranged on a cross beam or a connecting beam in the length direction of the support platform; a plurality of flange plates III corresponding to the bracket units are arranged on the upper surface of the cross beam or the connecting beam in the lengthdirection of the top end of the support platform; flange plates II are arranged at the two ends of each adjusting column; the flange plates II at the top ends of the adjusting columns are correspondingly and fixedly connected with the flange plates I at the bottom ends of the supporting columns; and the flange plates II at the bottom ends of the adjusting columns are correspondingly and fixedly connected with flange plates III arranged on the upper surface of the support platform top beam or connecting beam. The device is high in utilization rate, the butt joint precision of truss main pipesis improved, and the safety of the truss unloading construction process is guaranteed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

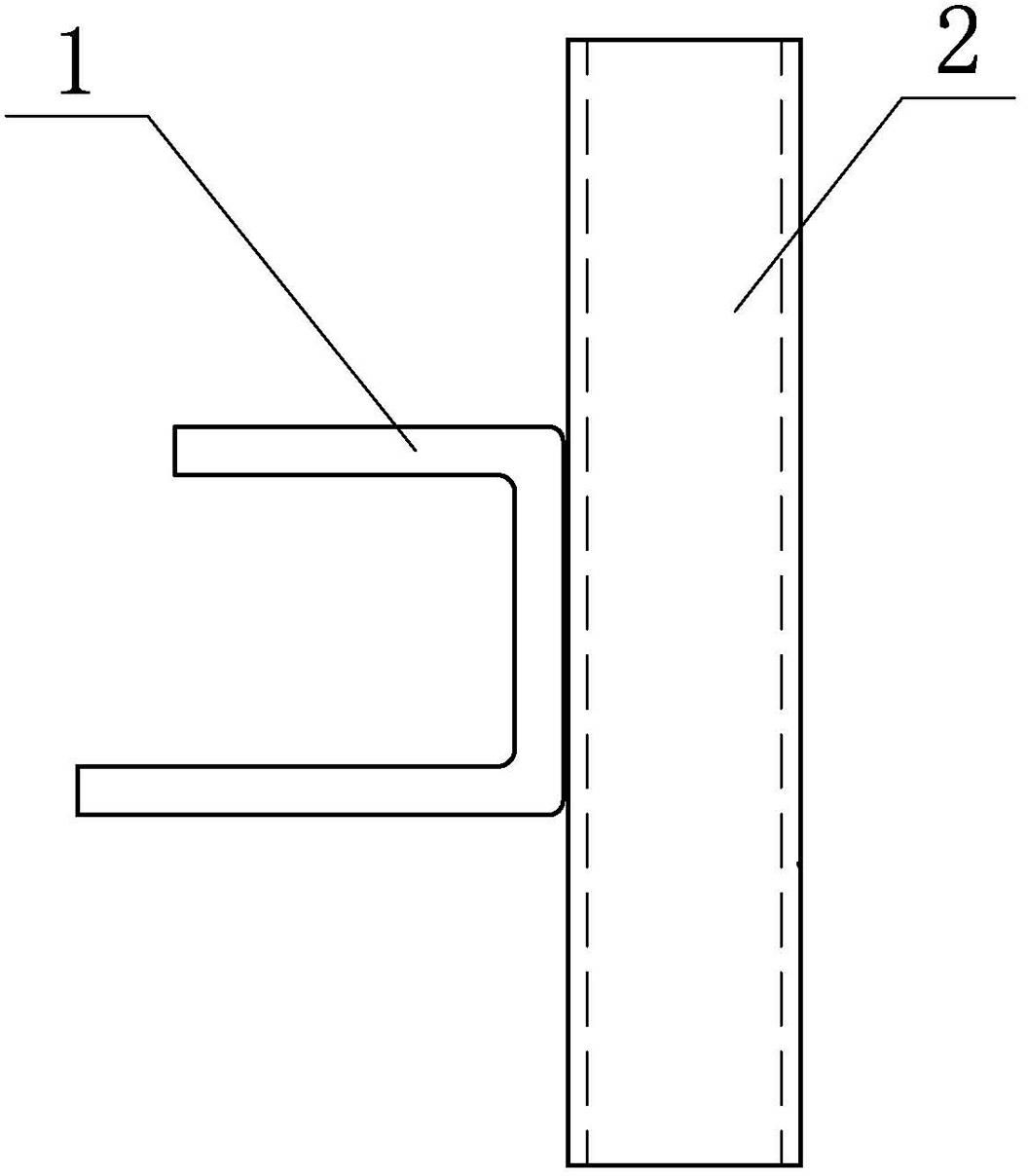

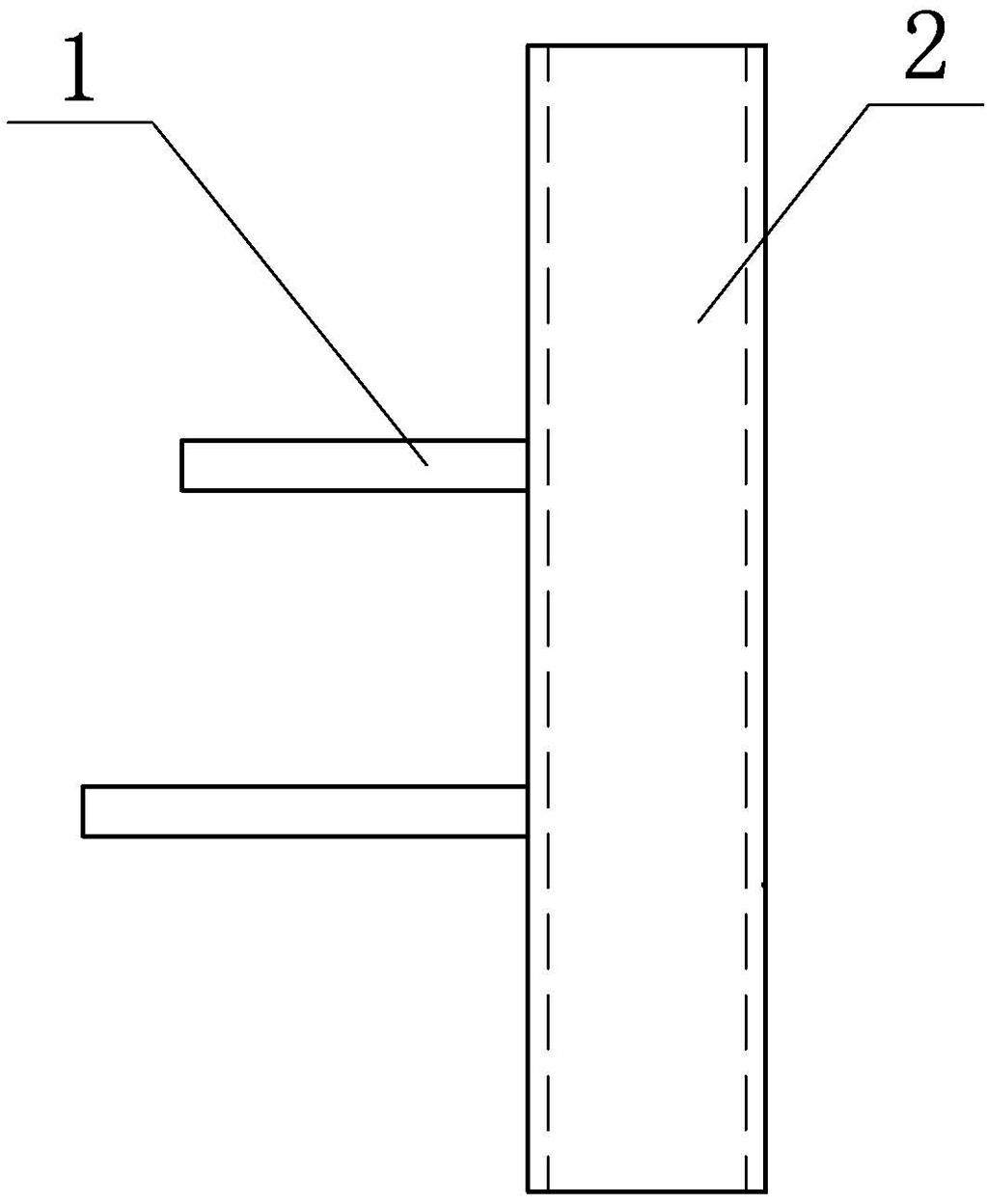

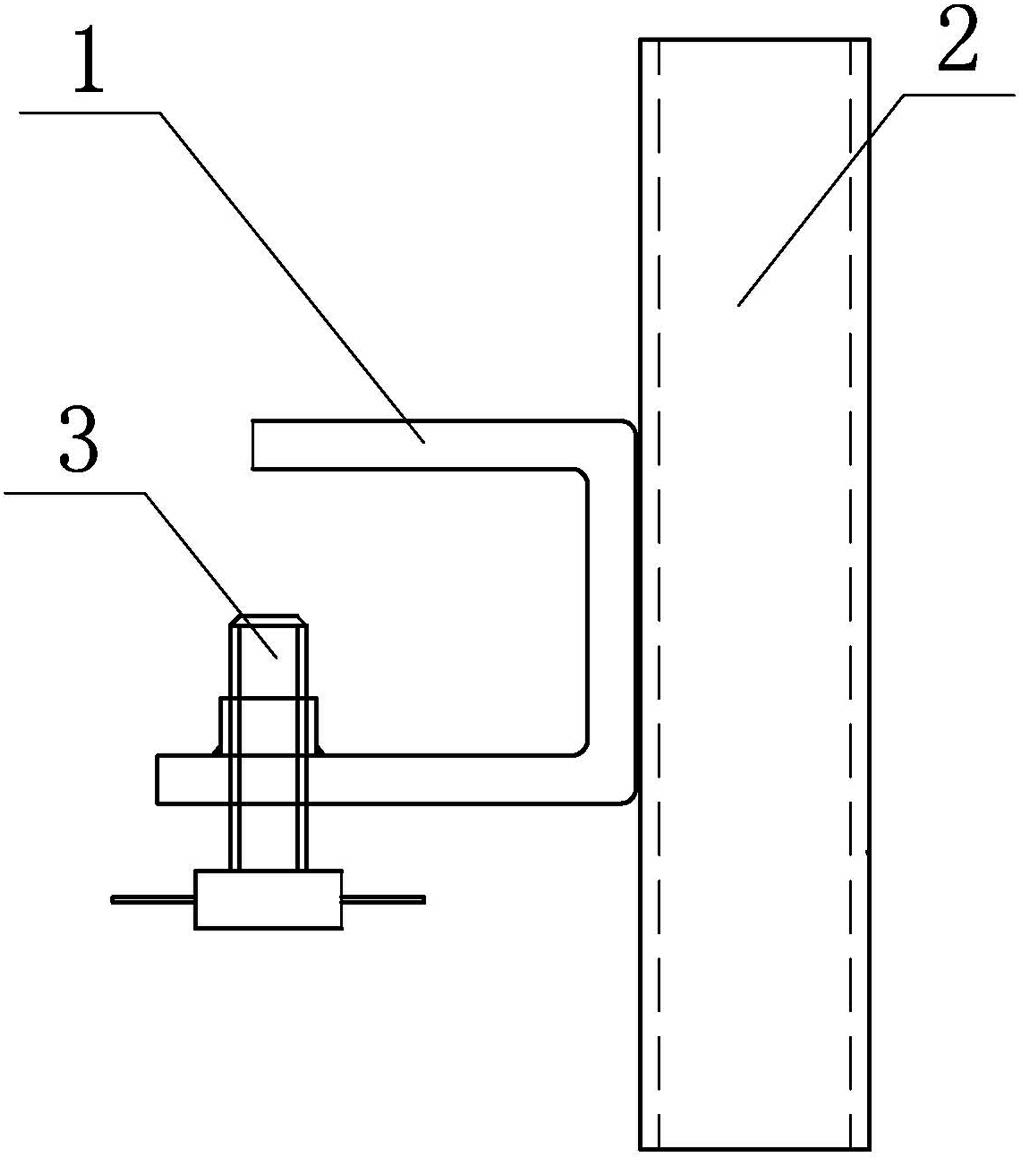

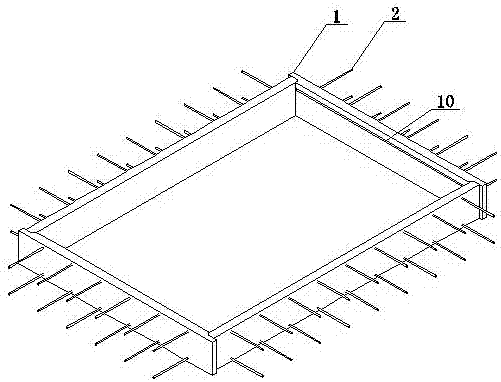

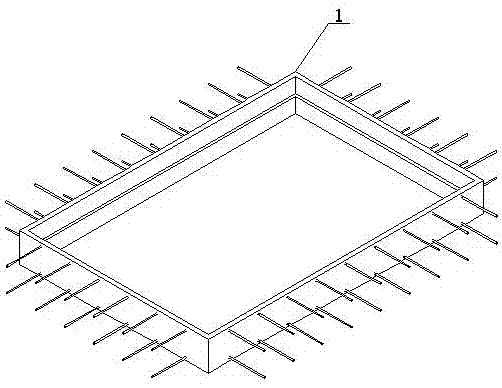

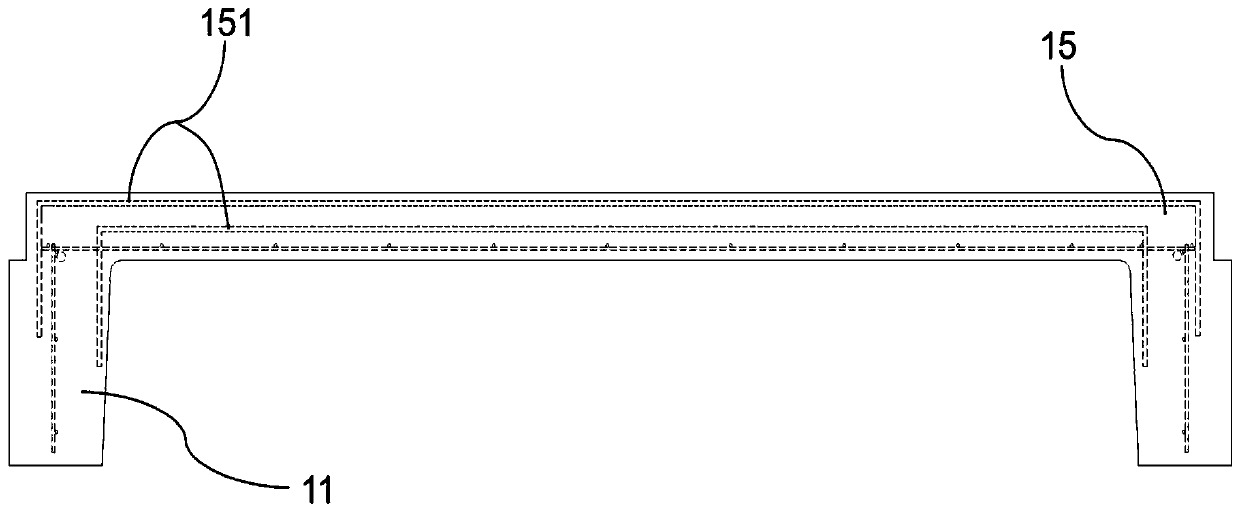

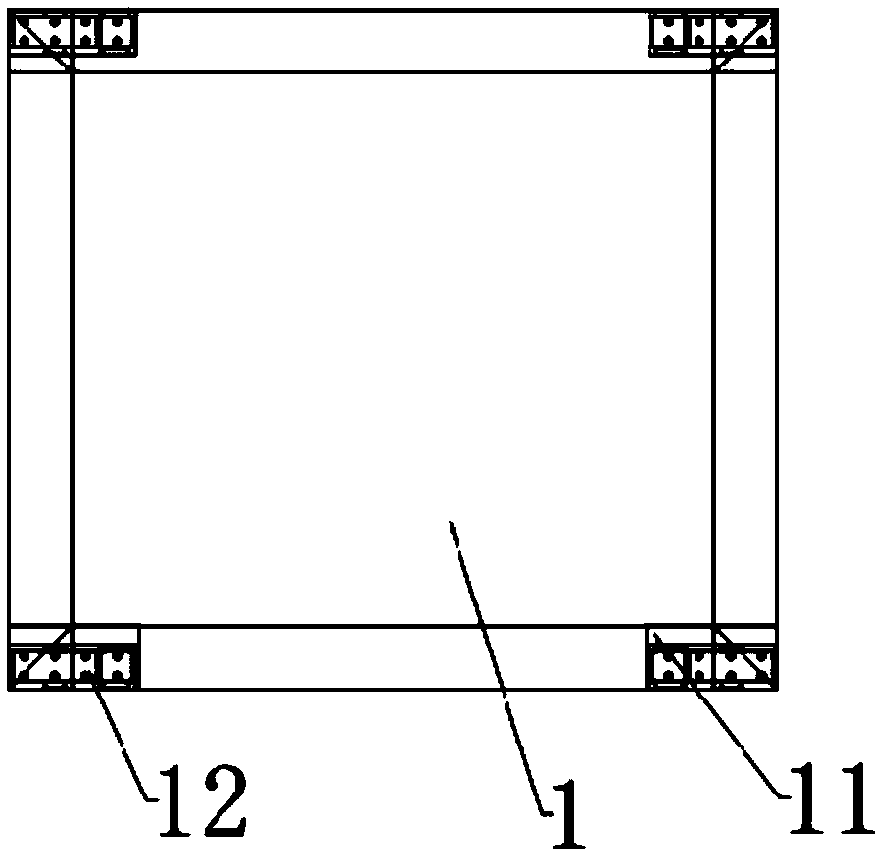

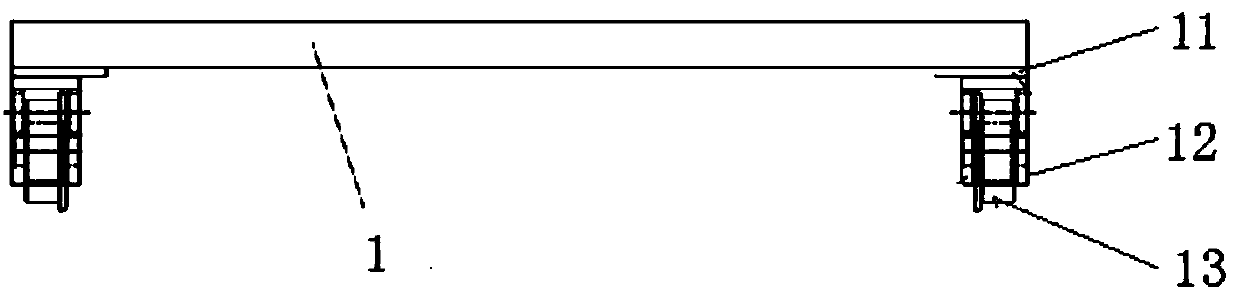

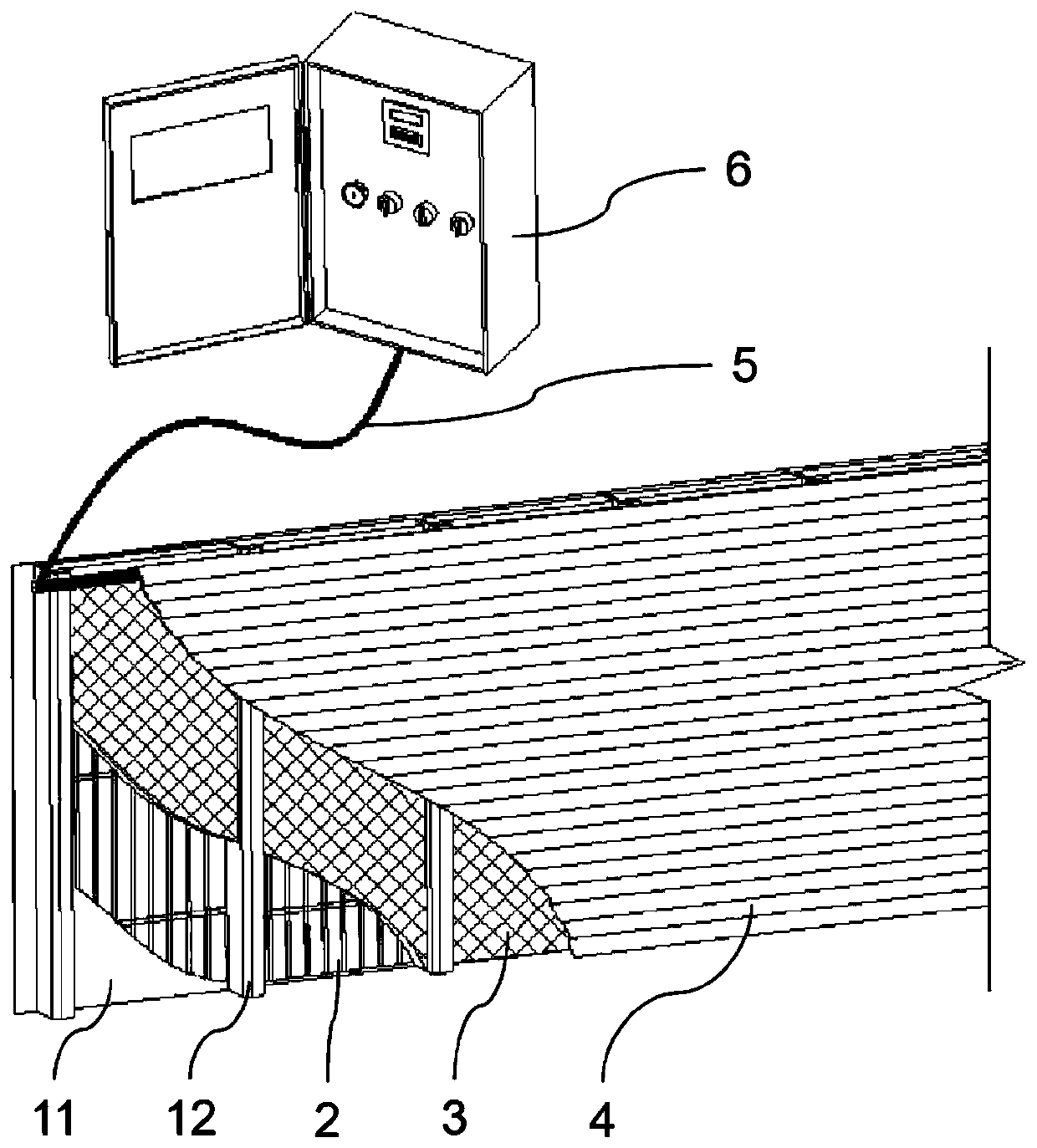

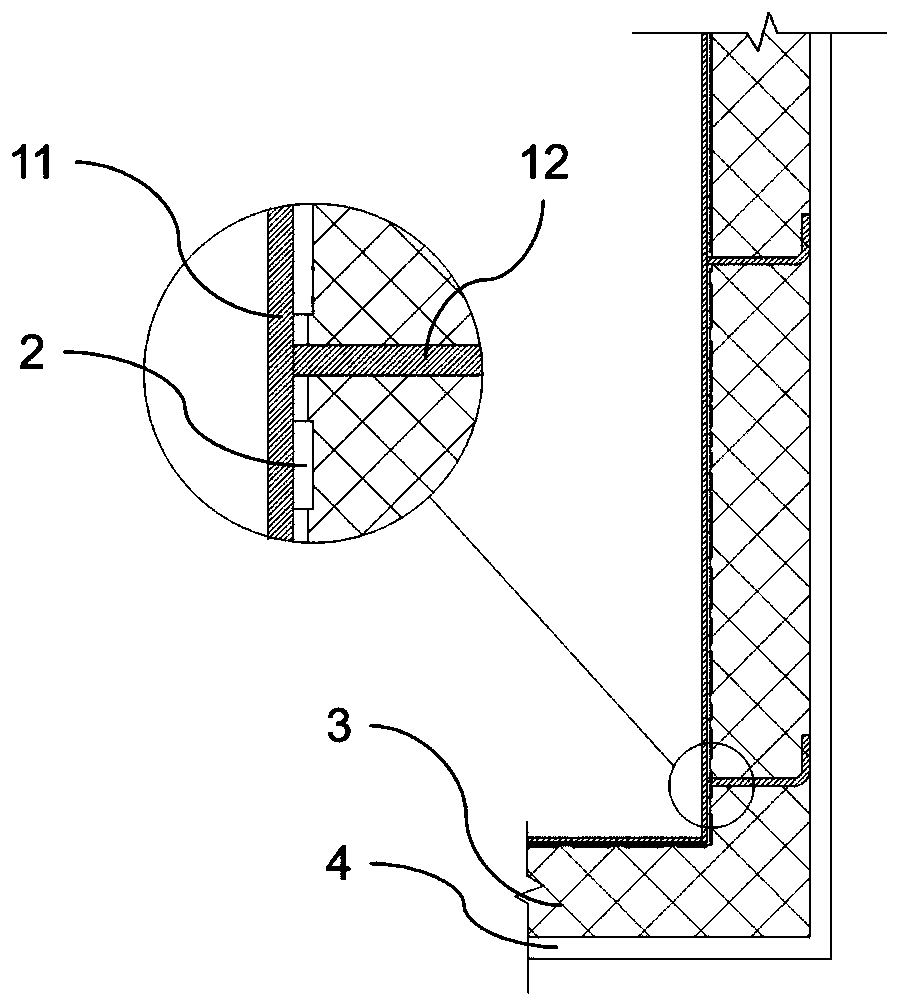

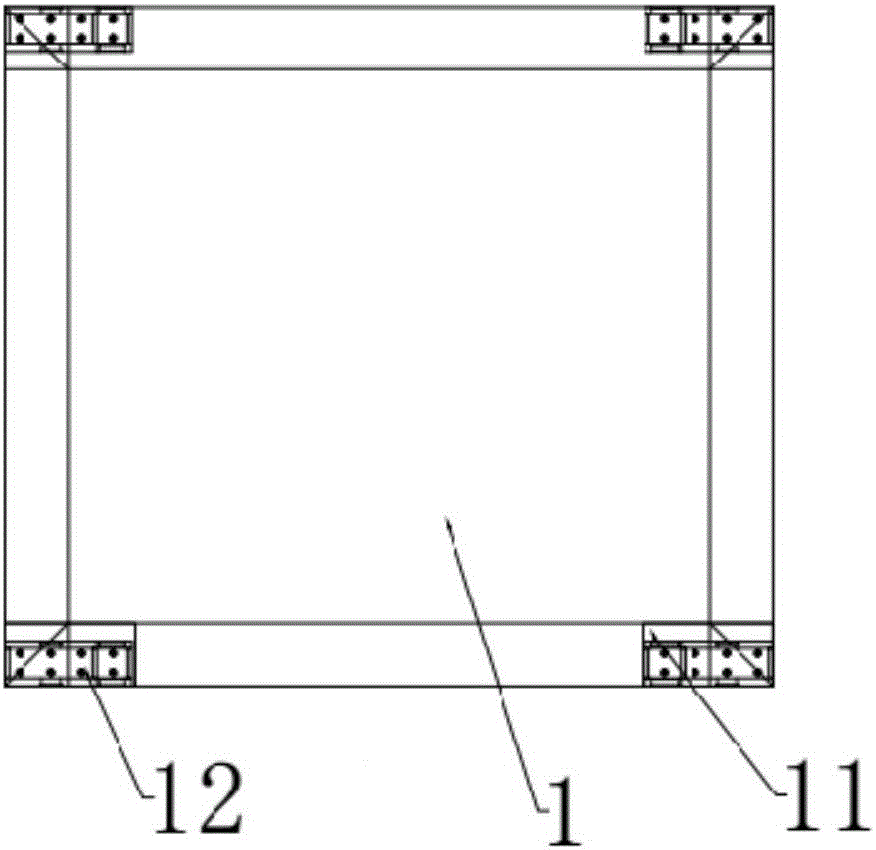

Prefabricated wall concrete door and window frame and construction method

PendingCN107299695ALow amortized costLow costWallsBase framesArchitectural engineeringPrecast concrete

The invention relates to a prefabricated wall concrete door and window frame and a construction method. In existing prefabricated concrete wall manufacturing, the template is large in amortizing amount, when a laminating plate type concrete wall is manufactured, the wall is poor in integrity, and the strength cannot meets transportation and hoisting requirements. The prefabricated wall concrete door and window frame comprises a prefabricated concrete door and window frame body (1), the prefabricated concrete door and window frame body is a straight strip plate spliced in a square box shape or an integral square box shape, an outward extending tie bar (2) is installed at the outer side of the straight strip plate or at the periphery of the integral square box, and the outward extending tie bar extends into wall bodies (3) of all sides of windows and doors. The construction method is used for the prefabricated wall concrete door and window frame.

Owner:湖北宇辉中工建筑产业化有限公司

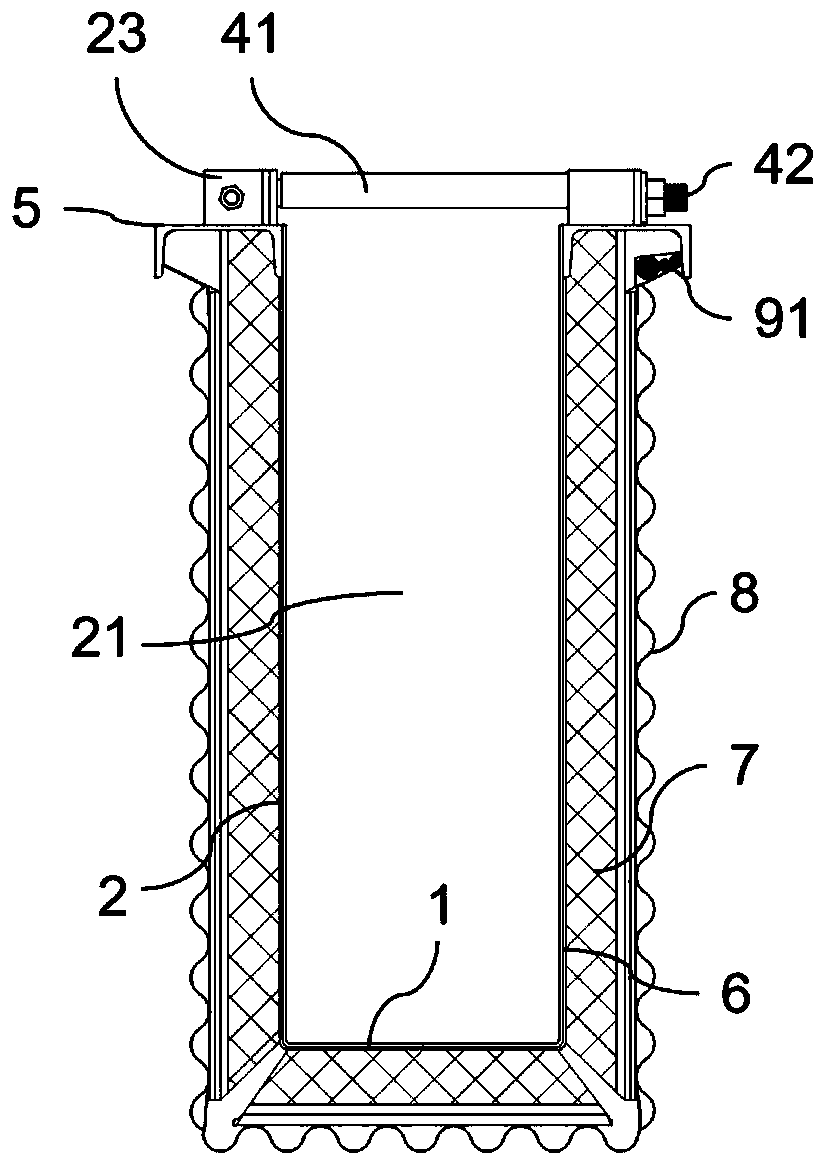

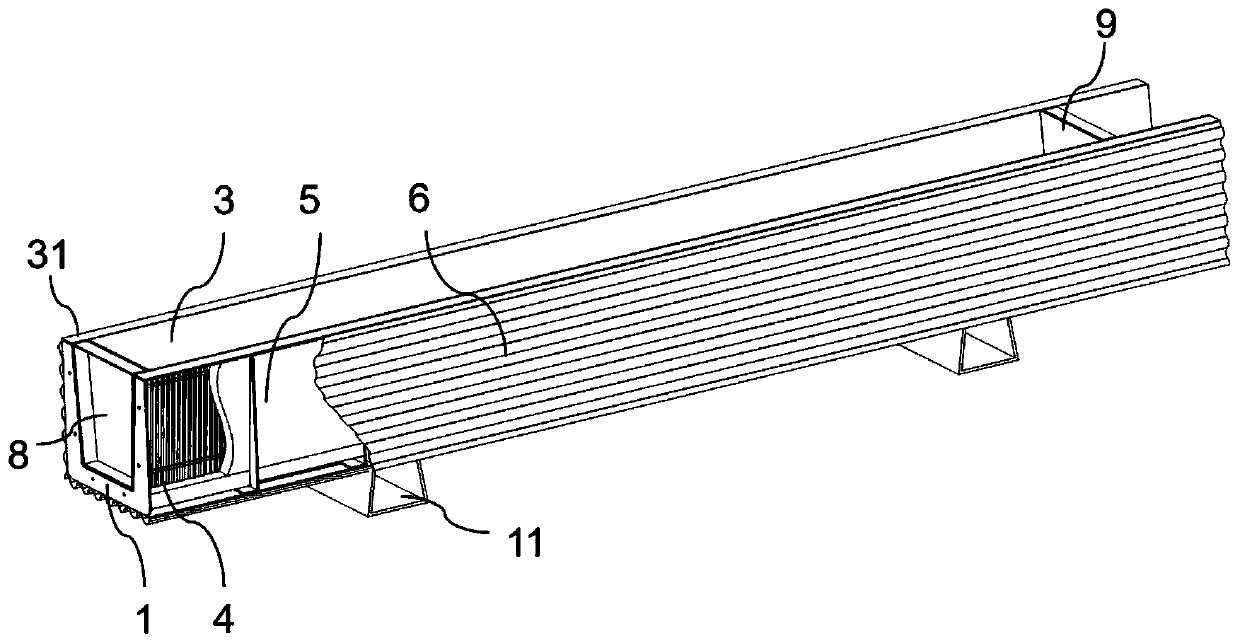

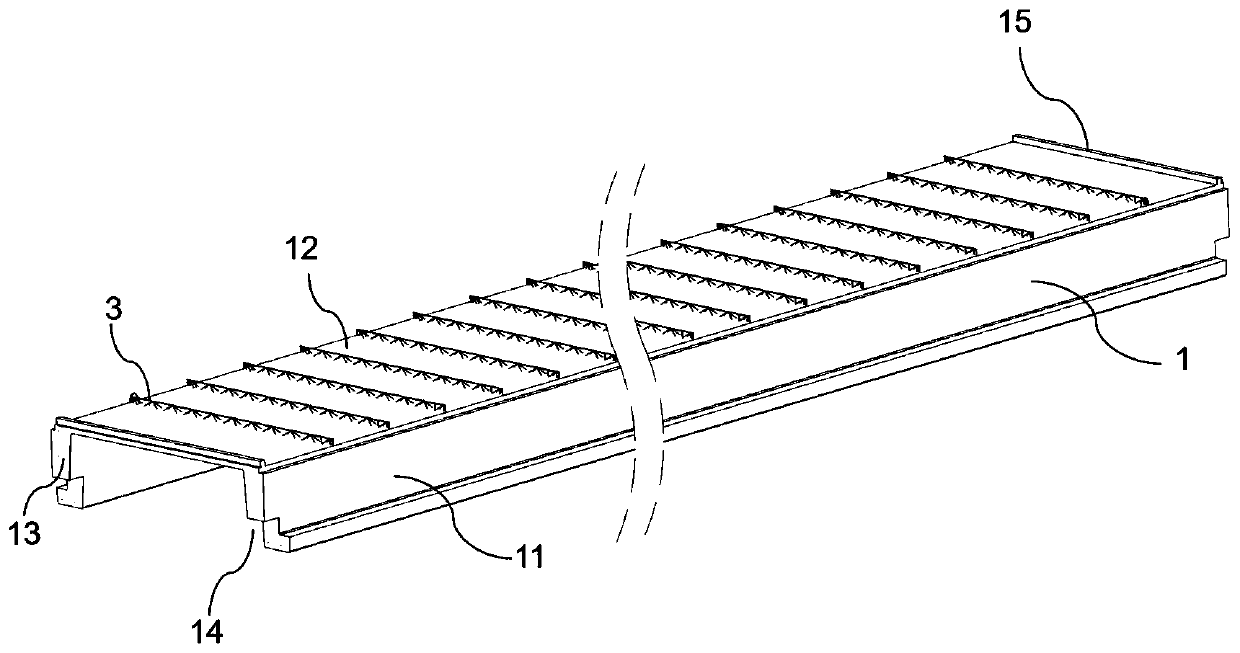

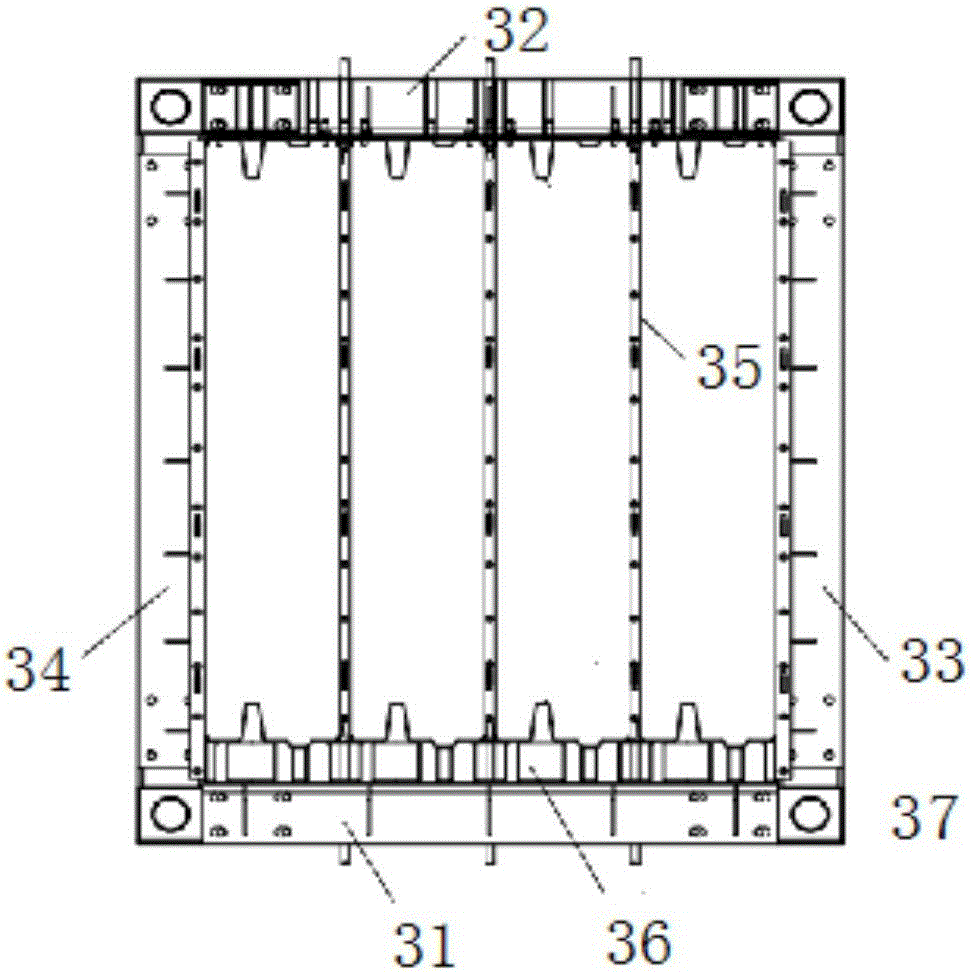

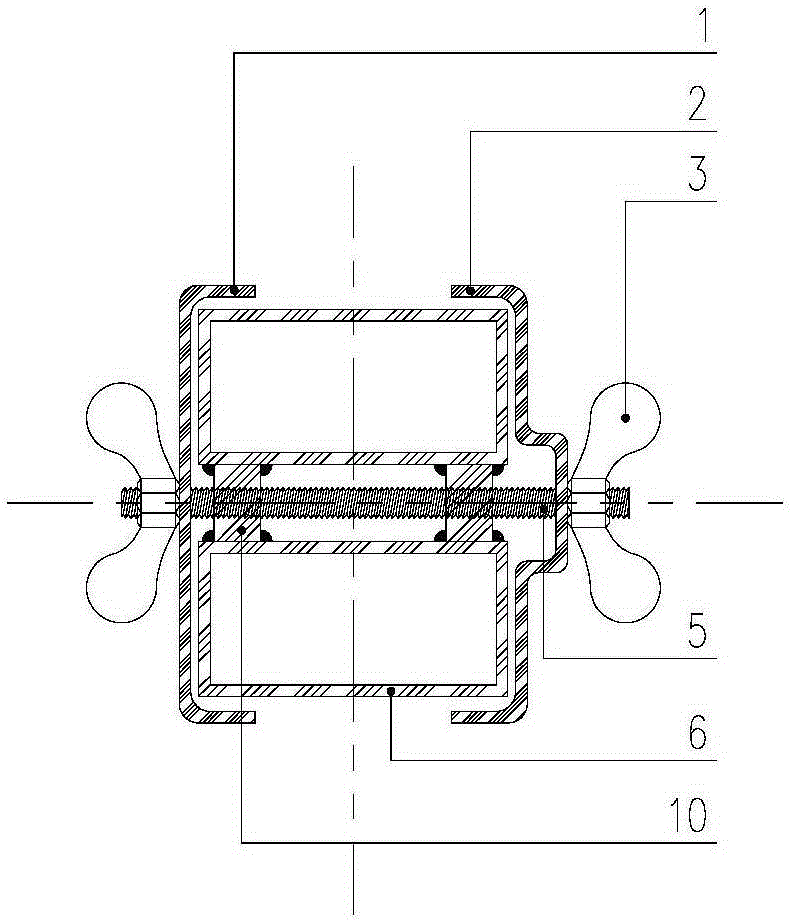

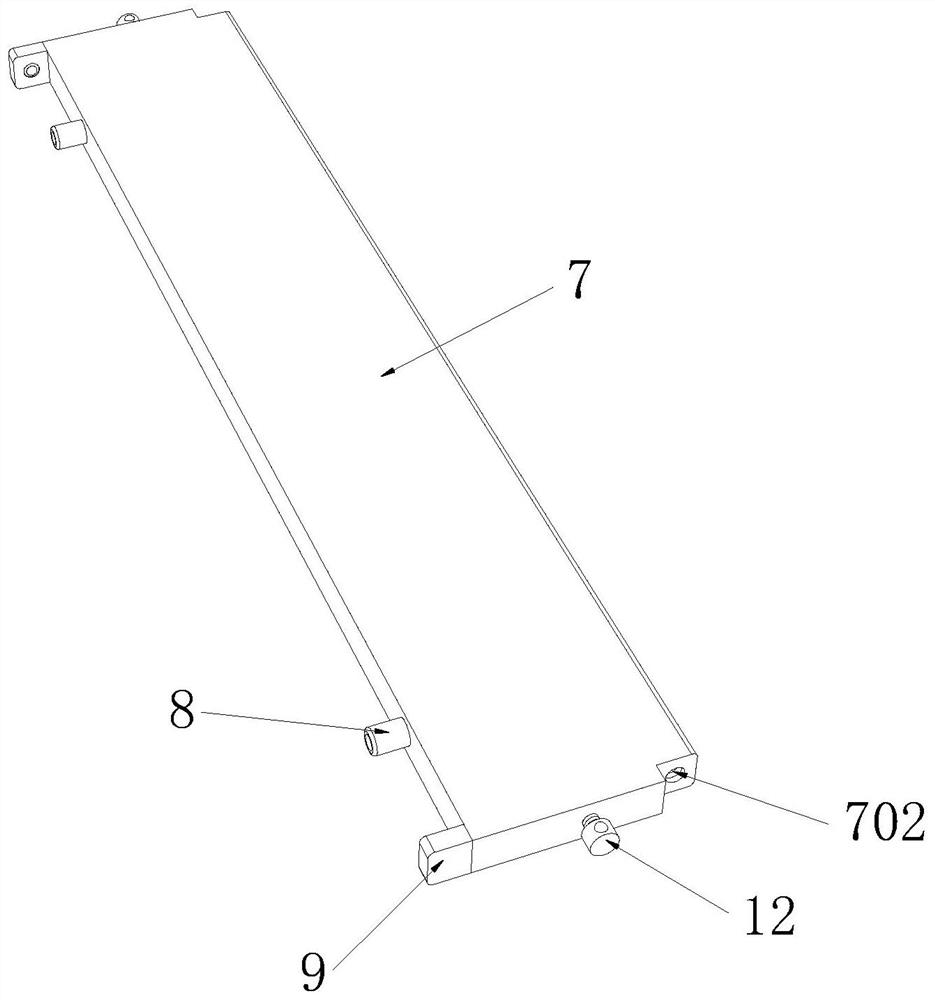

Electric heating film cured precast beam integral mould

PendingCN111360979AImprove construction efficiencyGood surface molding qualityMouldsMould fastening meansStructural engineeringHeat energy

The invention provides an electric heating film cured precast beam integral mould. The electric heating film cured precast beam integral mould comprises a baseplate, side plates, flexible corners, a pull rod, a horizontal beam, electric heating films, heat preservation plates and protecting plates, wherein cavities with upper openings are formed in the baseplate and the side plates; the flexible corners are arranged at the joints of the baseplate and the side plates; the baseplate, the side plates, and the flexible corners are connected to form a whole; the side plates at the two sides are connected through the pull rod at the upper openings; vertical ribs which are spaced by certain distance are welded on the side plates and are perpendicular to the side plates; the vertical ribs are in welded connection with the horizontal beam; baseplate stiffening ribs are welded on the baseplate; the electric heating films are pasted on the surfaces of the baseplate and the side plates; and the heat preservation plates and the protecting plates are arranged on the outer sides of the electric heating films. The electric heating film cured precast beam integral mould greatly improves the work efficiency of the integral beam mold construction, does not need to suffer partitioned supporting and disassembly, has fast mold release speed, good surface forming quality, high heat energy conversionrate, low cost and high curing efficiency, and is cured by using peak electricity; and the turnover speed of the mold is fast.

Owner:宁波优造建筑科技有限公司

Bridge steel box girder aerial work operation platform and construction method thereof

PendingCN109881590ADoes not affect normal trafficAvoid settingBridge erection/assemblyWinchUtilization rate

The invention discloses a bridge steel box girder aerial work operation platform and a construction method thereof. The operation platform comprises a steel pipe truss, two movable hanging racks and two winches, wherein the steel pipe truss is of a cuboid structure; the two movable hanging racks are symmetrically arranged on the left side and the right side of a steel box girder to be operated bytaking the longitudinal central line of the steel box girder to be operated as a symmetrical axis, each movable hanging rack comprises two F-shaped supports and a plurality of connecting rods, each F-shaped support comprises a main rod and two transverse rods, two vertical rods are arranged between the two transverse rods of each F-shaped support, the lower end of each vertical rod extends downwards and is lower than each lower transverse rod, and a wheel is arranged at the lower end of each vertical rod extending downwards; two upper chord main pipes of the steel pipe truss are fixedly connected with the two movable hanging racks; the two winches are arranged at a longitudinal end of the upper surface of a top plate of the steel box girder to be operated and are connected with the movablehanging racks through a steel wire rope; a bottom plate of the steel box girder to be operated is connected with two upper chord main pipes of the steel pipe truss through four inverted chains. The operation platform does not influence the traffic under the bridge, and has low cost and high utilization rate.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

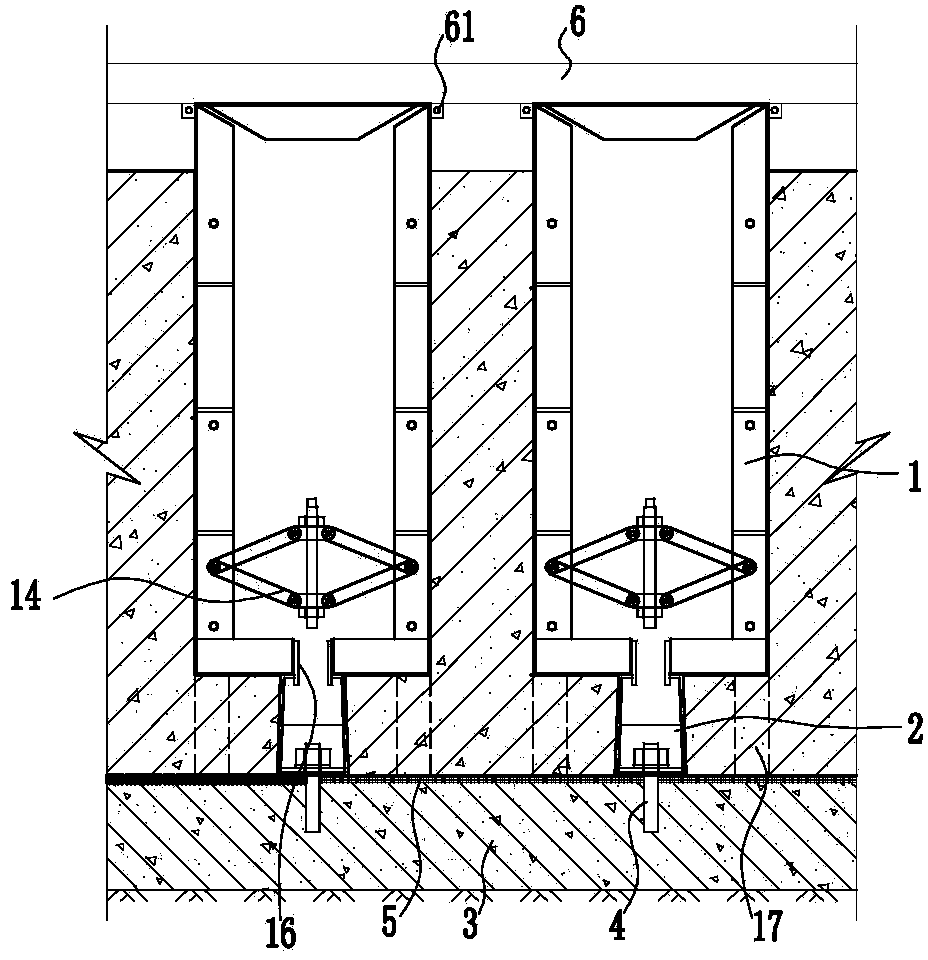

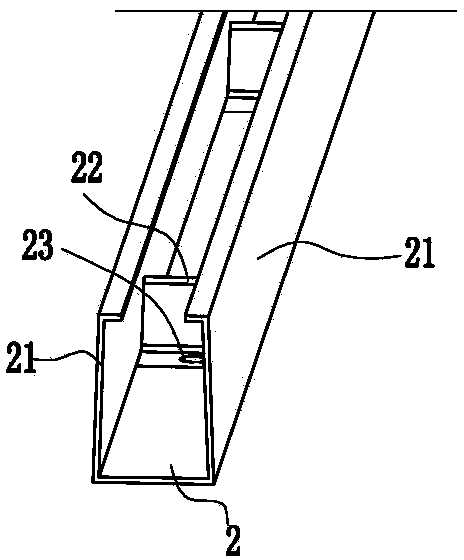

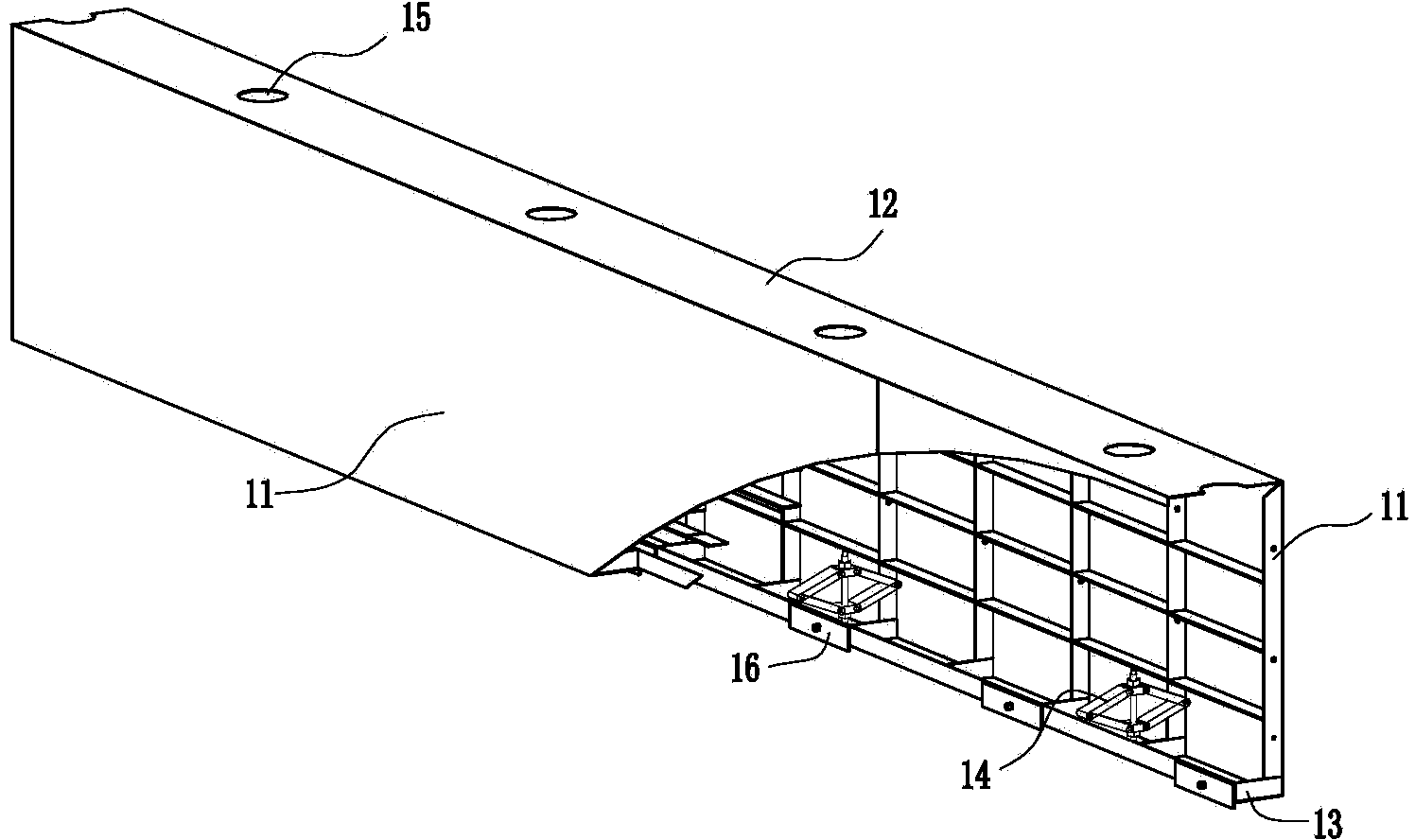

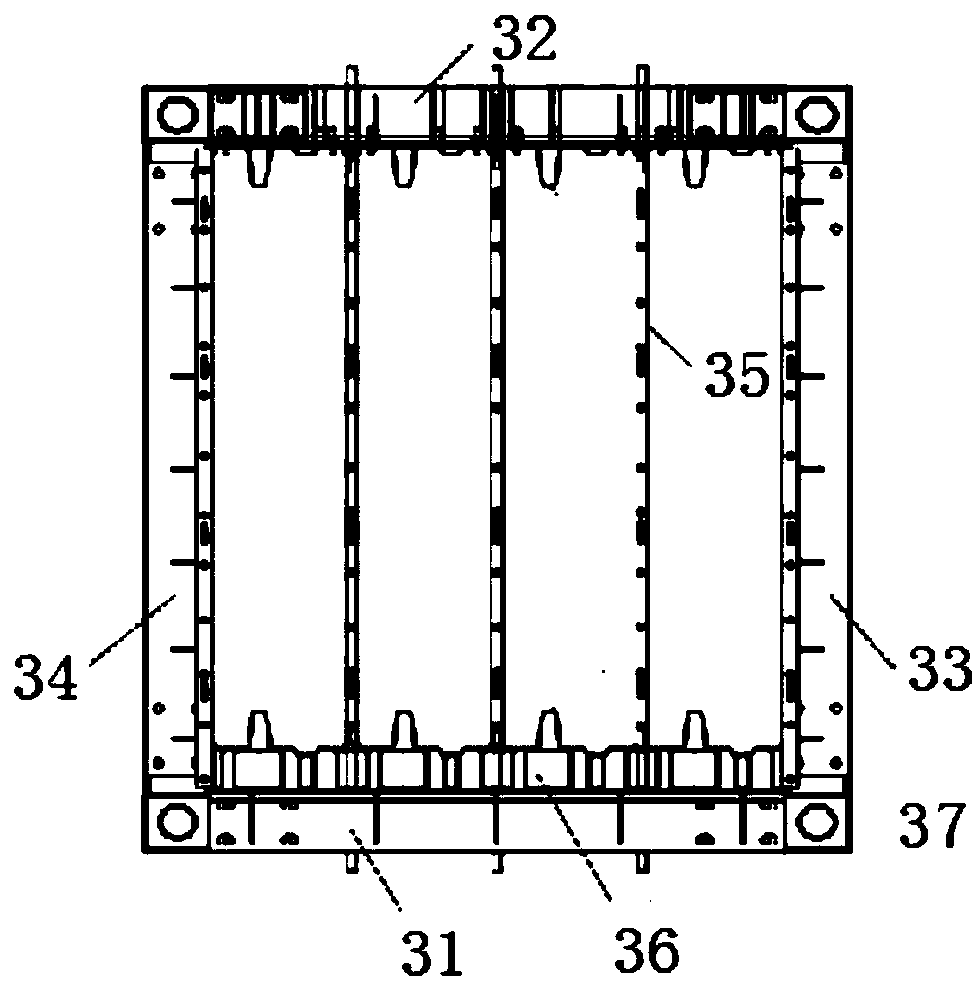

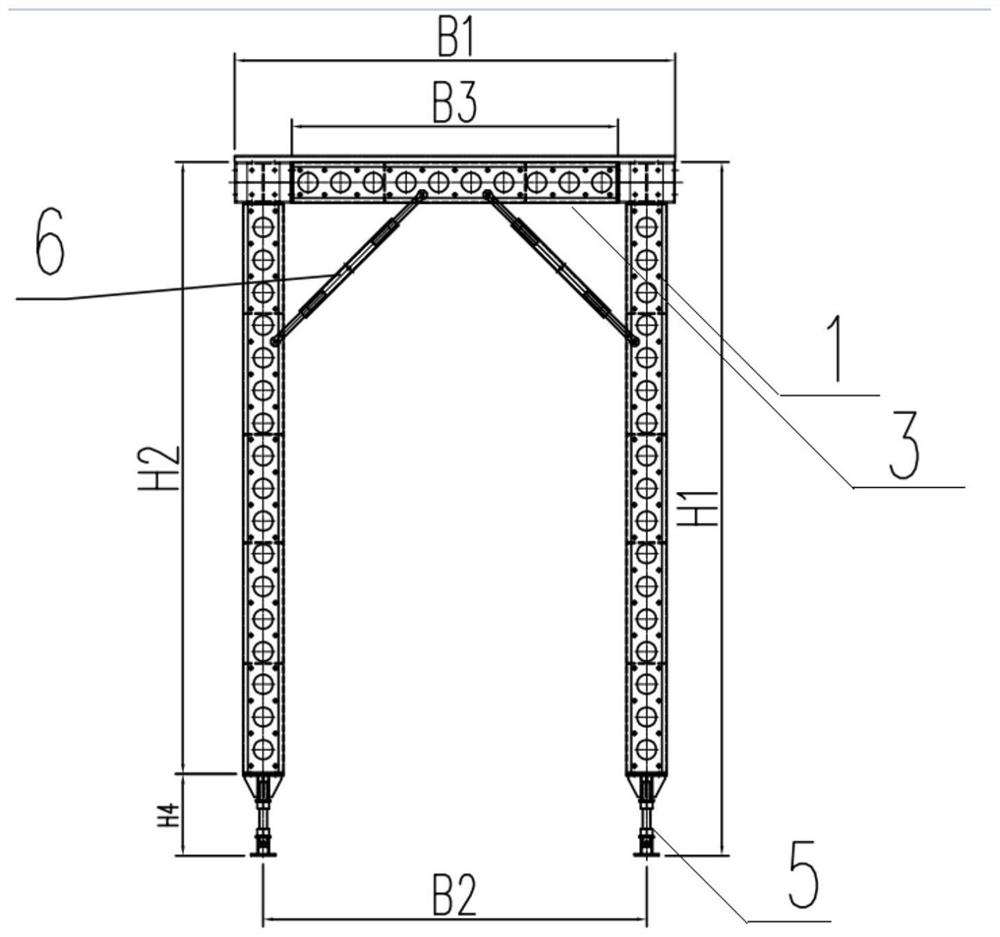

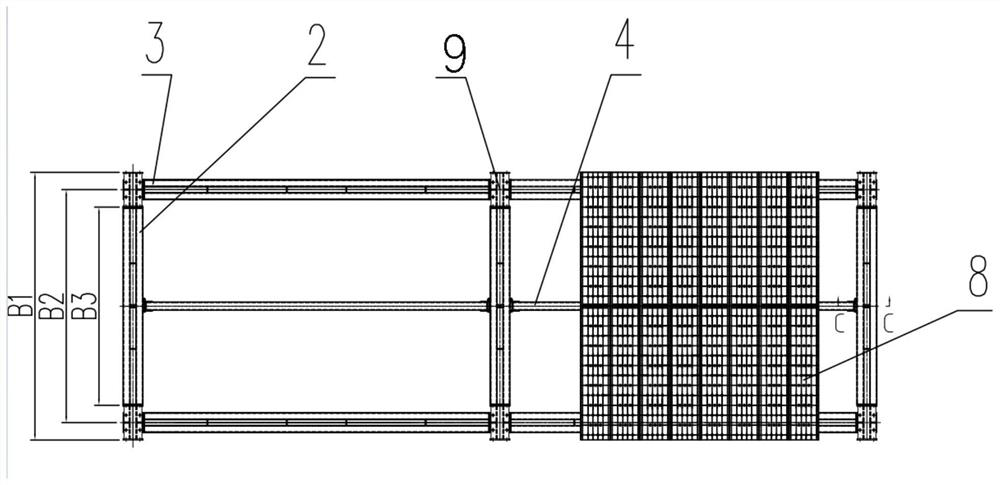

T-shaped component manufacturing die

A T-shaped component manufacturing die comprises a web side die body, a flange side die body and a pedestal terrace. The T-shaped component manufacturing die is characterized in that the web side die body comprises two vertical boards and a top board, the lower ends of the two vertical boards are connected with horizontal L-shaped beams and connected with rhombic retraction jacks in a spaced mode in the longitudinal direction, the flange side die body comprises two side boards and is connected with the pedestal terrace through a bolt, and the width of the upper opening of the flange side die body is smaller than that of the lower opening of the flange side die body. As a door-shaped side die body is adopted, not only can a rectangular component be manufactured, but also a T-shaped or inverted-T-shaped column and a T-shaped or inverted-T-shaped beam can be manufactured by combining the flange side die body, T-shaped columns or beams with different widths and different heights can be manufactured, universality is high, and use efficiency is high.

Owner:宁波优造建筑科技有限公司

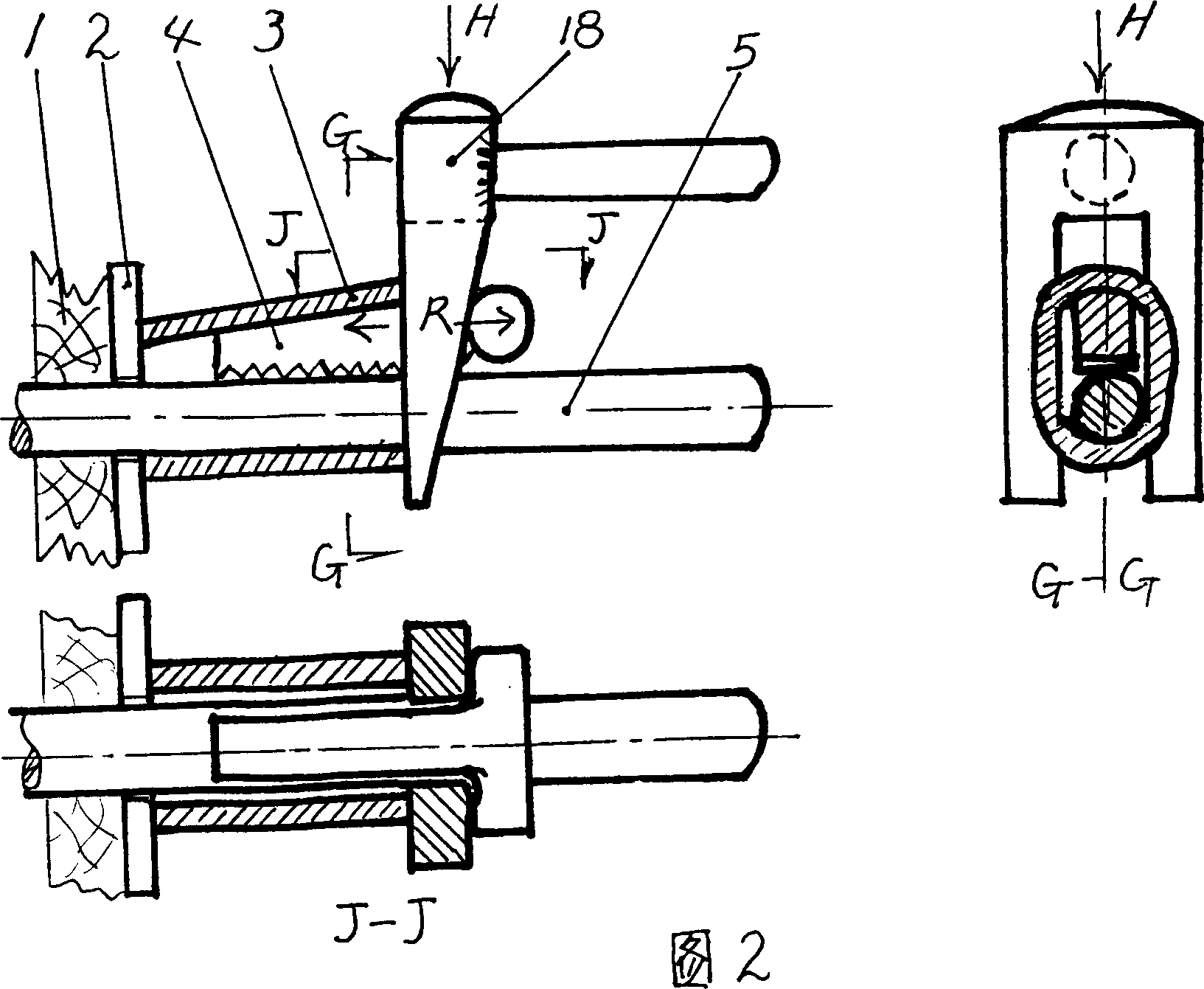

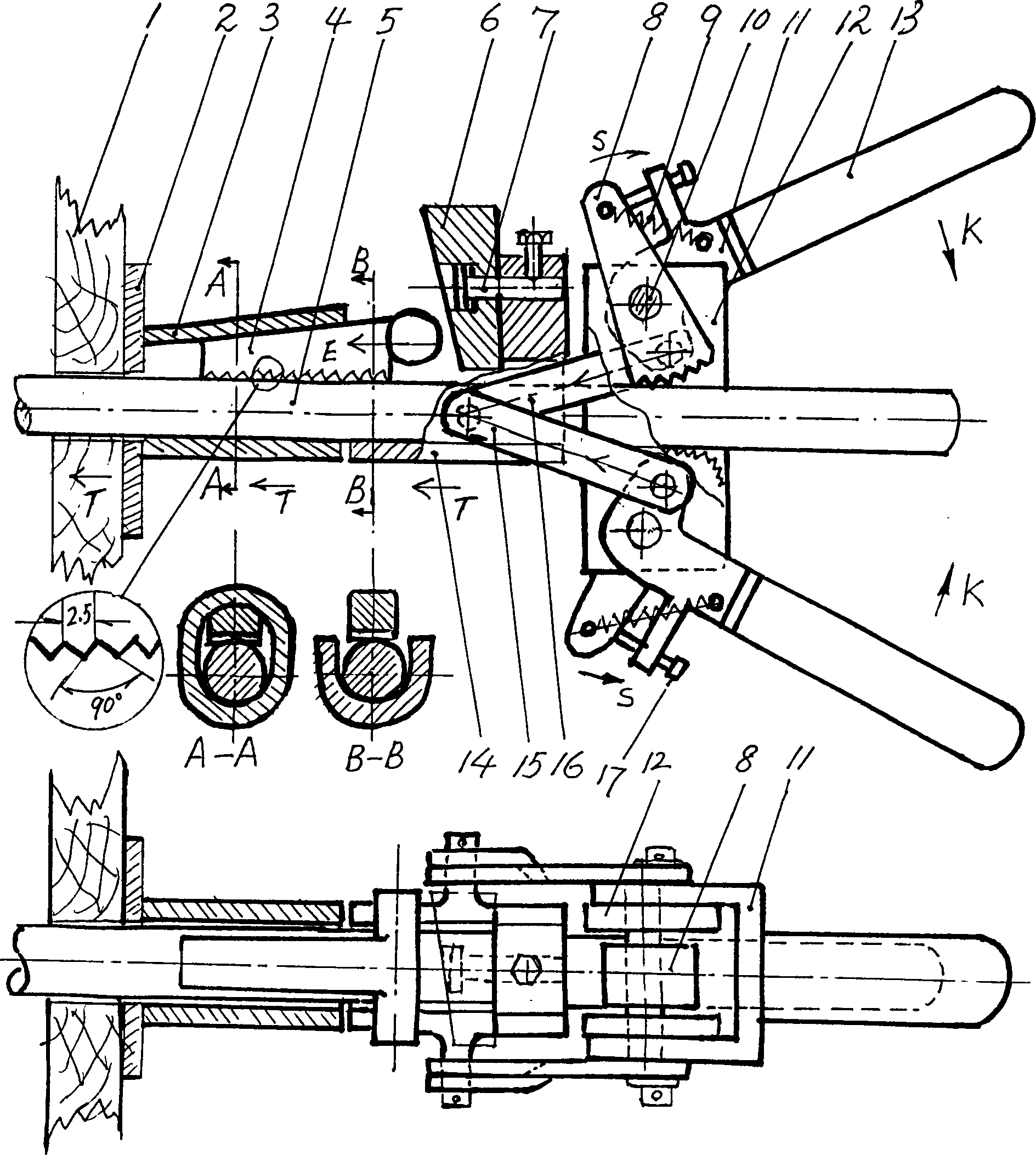

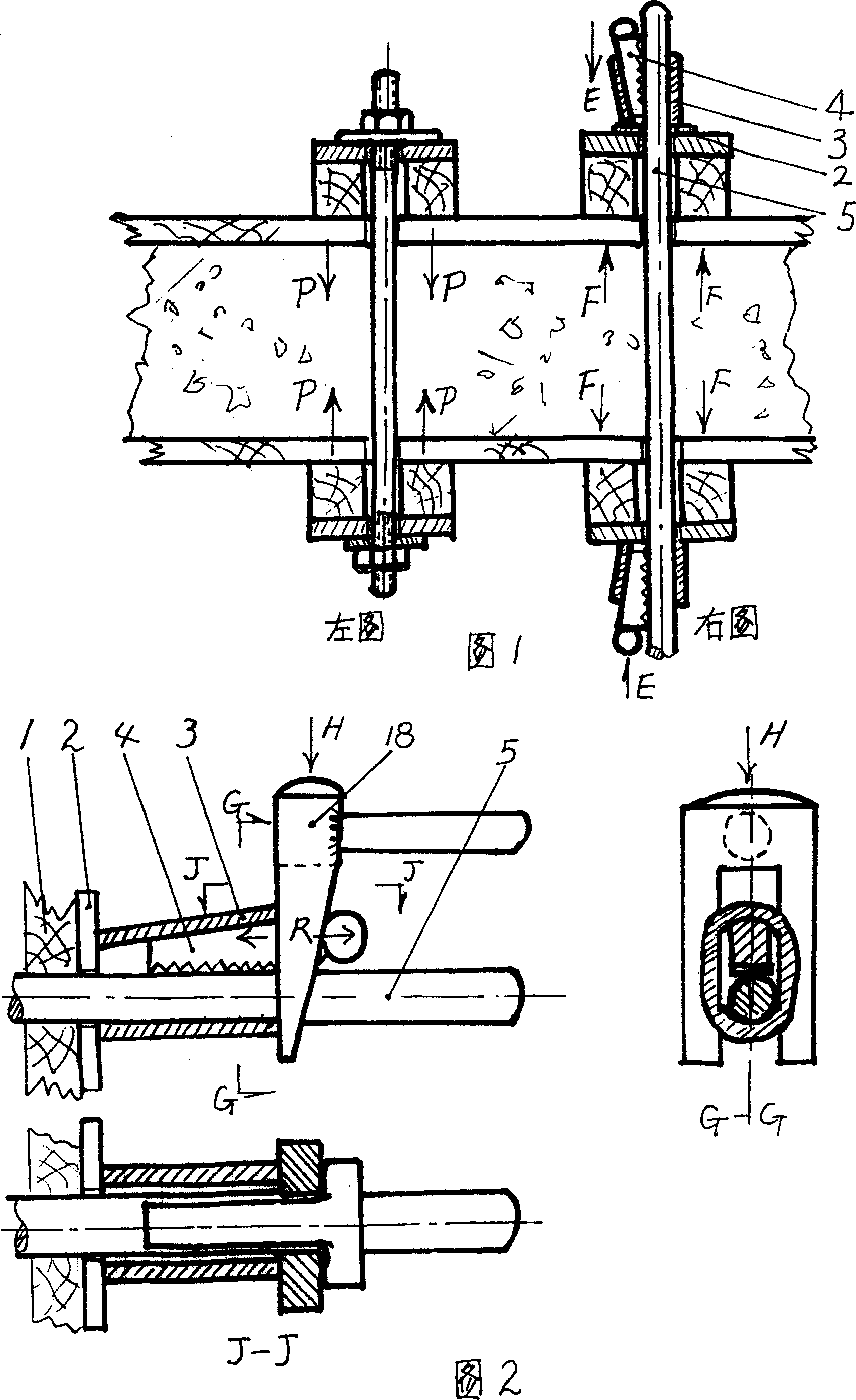

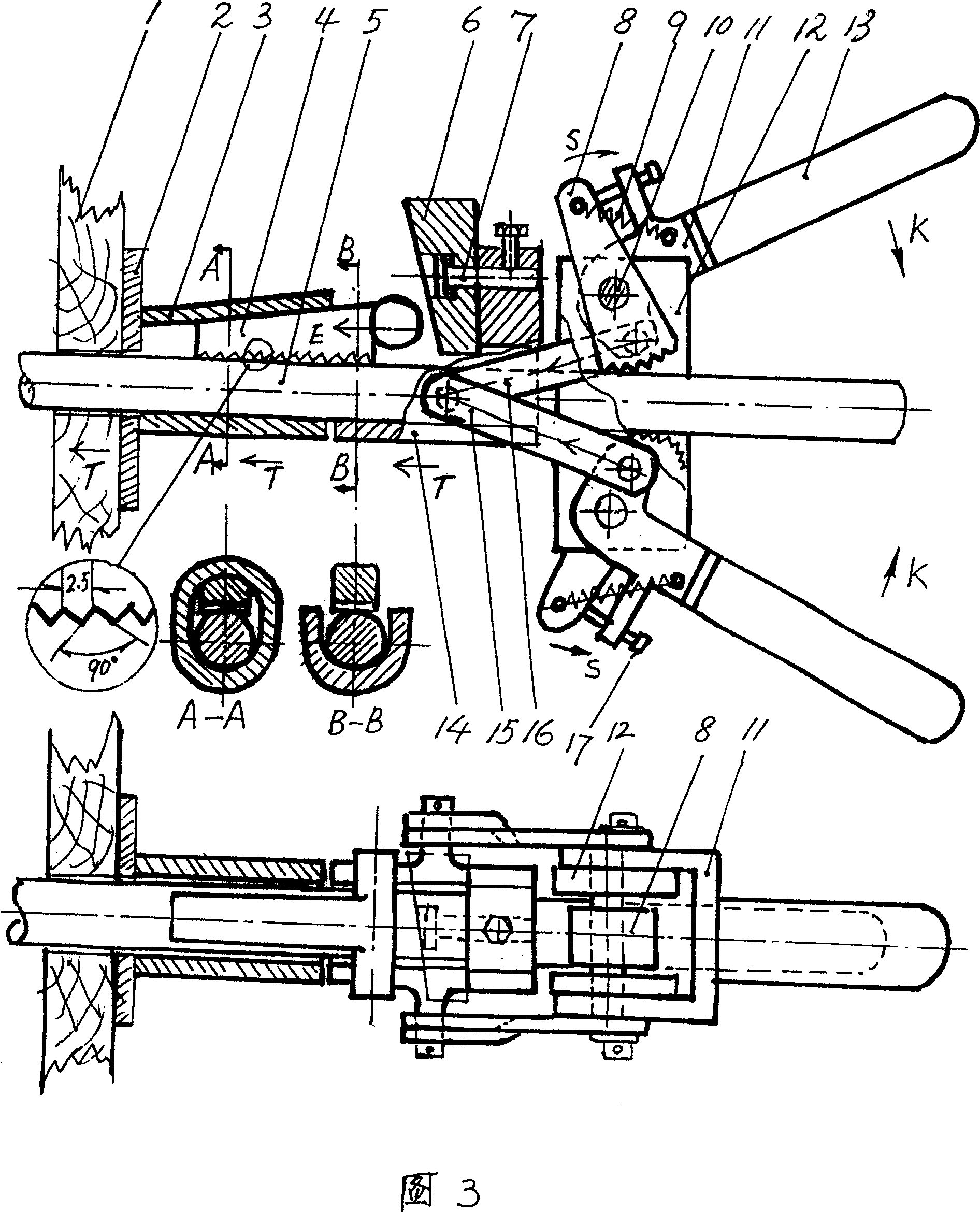

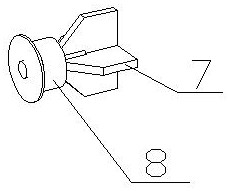

Sloping wedge clamp of building moulding board and mounting, unloading tool thereof

InactiveCN1521381AEliminate limitations that cannot be usedSimple assembly and disassembly toolsAuxillary members of forms/shuttering/falseworksForm treatmentSteel tubeCrank

The inclined wedged fixture and assembling and disassembling tool for building formwork includes polished rod, inclined wedge and characterized inclined sleeve being one long flat steel pipe with hole in the same axial inclination as that of the inclined wedge. The polished rod is penetrated into the hole of the inclined sleeve, and the inclined wedge is wedged into the interval between the polished rod and the inclined sleeve hole. The present invention has separated fixture and assembling and disassembling tool, the formwork position may be regulated with installing pliers with crank link mechanism, and the fixture may be detached with the inclined wedge. The technology of the present invention is simple and reliable, and has easy assembling and disassembling and low cost.

Owner:潘颖聪

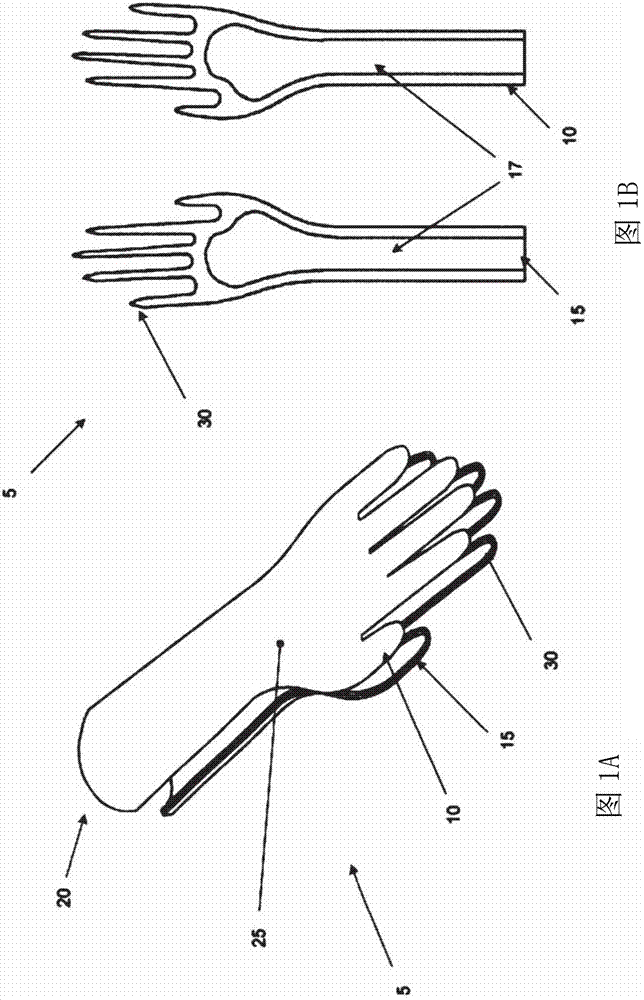

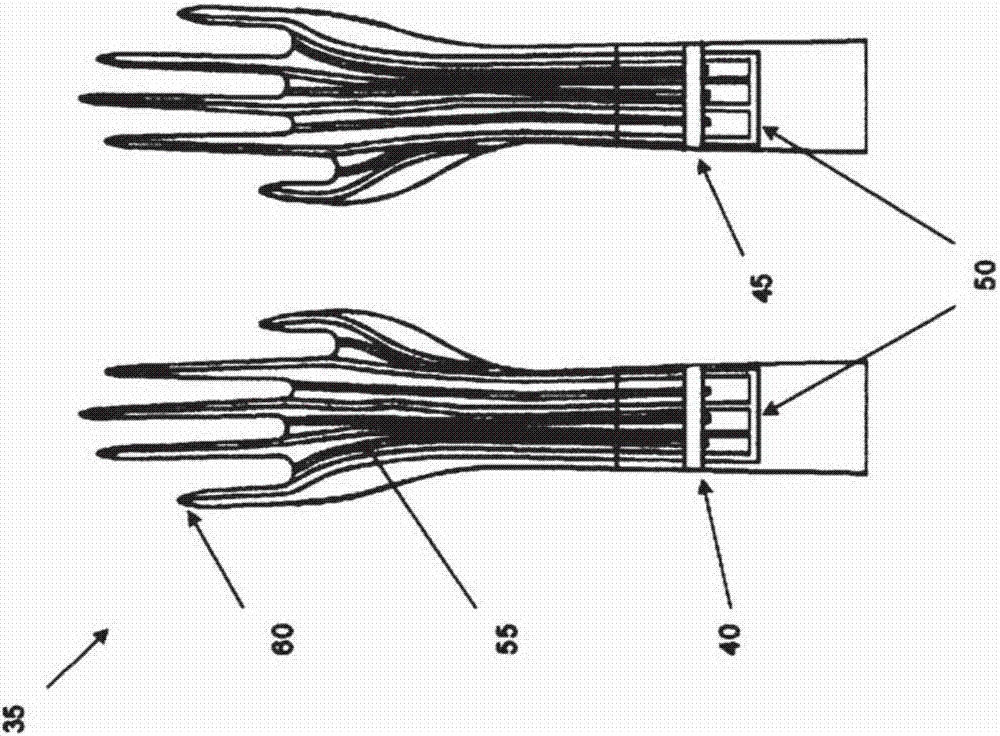

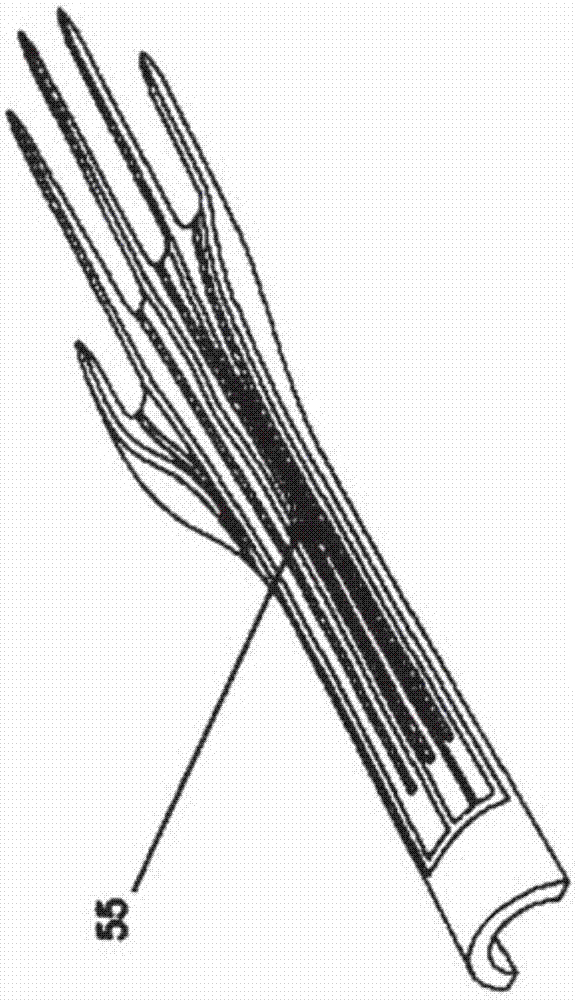

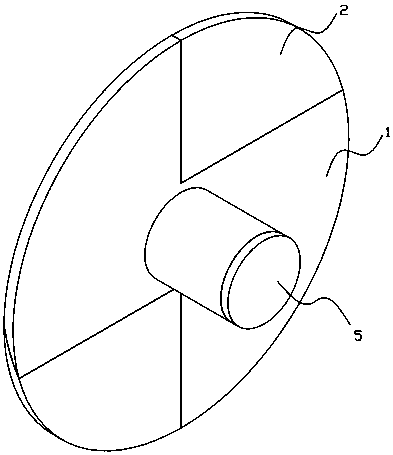

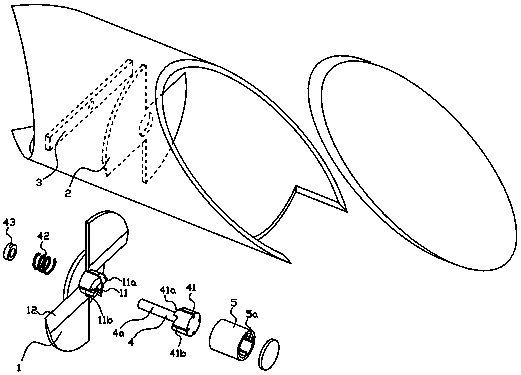

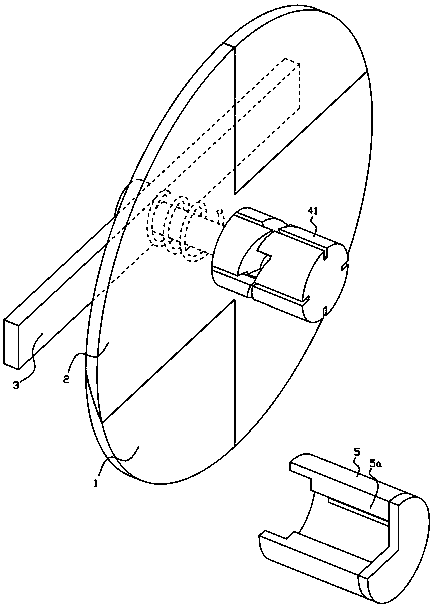

New dipping former for producing elastic articles

InactiveCN107405805ALow amortized costShorten the lengthLiquid surface applicatorsGlovesElastomerEngineering

A former assembly for the manufacture of dip product comprises: a thermally conductive outer layer in the shape of said product, said outer layer arranged to receive a film of elastomer; a mounting for mounting said former assembly to a former holder for engagement with a conveyor chain; a heating medium within said outer layer, said heating medium in communication with an energy source for heating said medium, wherein said heating medium is arranged to apply heat through said outer layer so as to cure said resin.

Owner:翁凯理查德梅

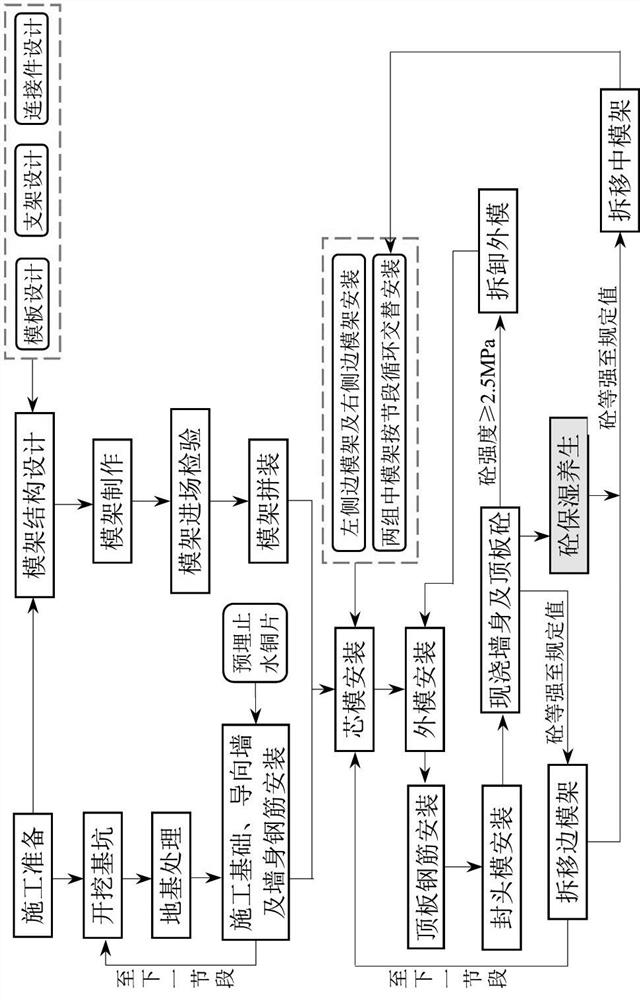

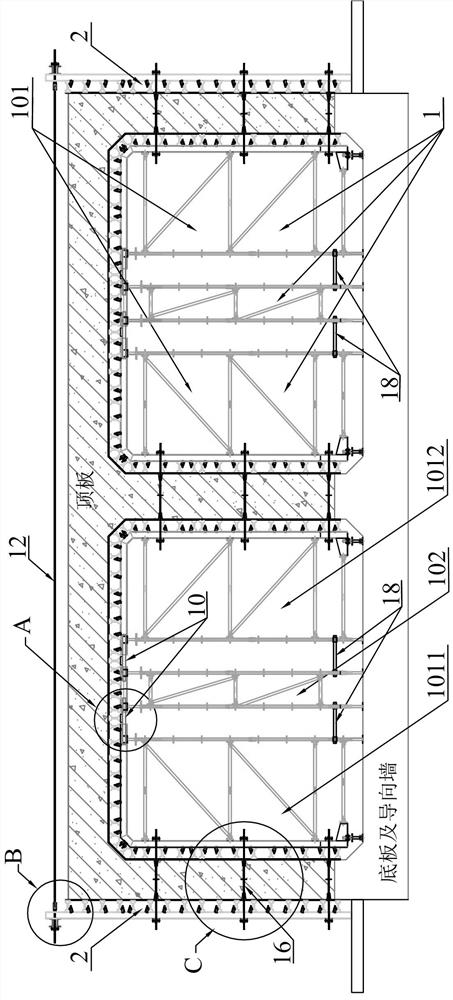

Construction method of movable assembled light formwork cast-in-place box culvert

InactiveCN112681162ASmooth and beautifulNot easy to damageGround-workReinforced concreteArchitectural engineering

The invention discloses a construction method of a movable assembled light formwork cast-in-place box culvert. The construction technological process is as follows; step 1, an assembled light formwork structure is designed and manufactured; step 2, formwork entry inspection and assembly are carried out; step 3, a box culvert foundation pit is excavated, and a foundation is treated; step 4, a construction bottom plate, a guide wall and wall body reinforcing steel bars are installed; step 5, a core mold and an outer mold are installed; step 6, roof reinforcing steel bars are installed; step 7, a plug plate is installed; step 8, the side wall and top plate concrete are poured and the concrete is cured; step 9, the outer mold is disassembled; step 10, the edge formwork is disassembled and moved; step 11, the middle formwork is disassembled and moved; and step 12, subsequent segment construction is conducted. The cast-in-place reinforced concrete box culvert is suitable for cast-in-place reinforced concrete box culvert construction in highway, railway, water conservancy and municipal pipe gallery projects.

Owner:四川路航建设工程有限责任公司

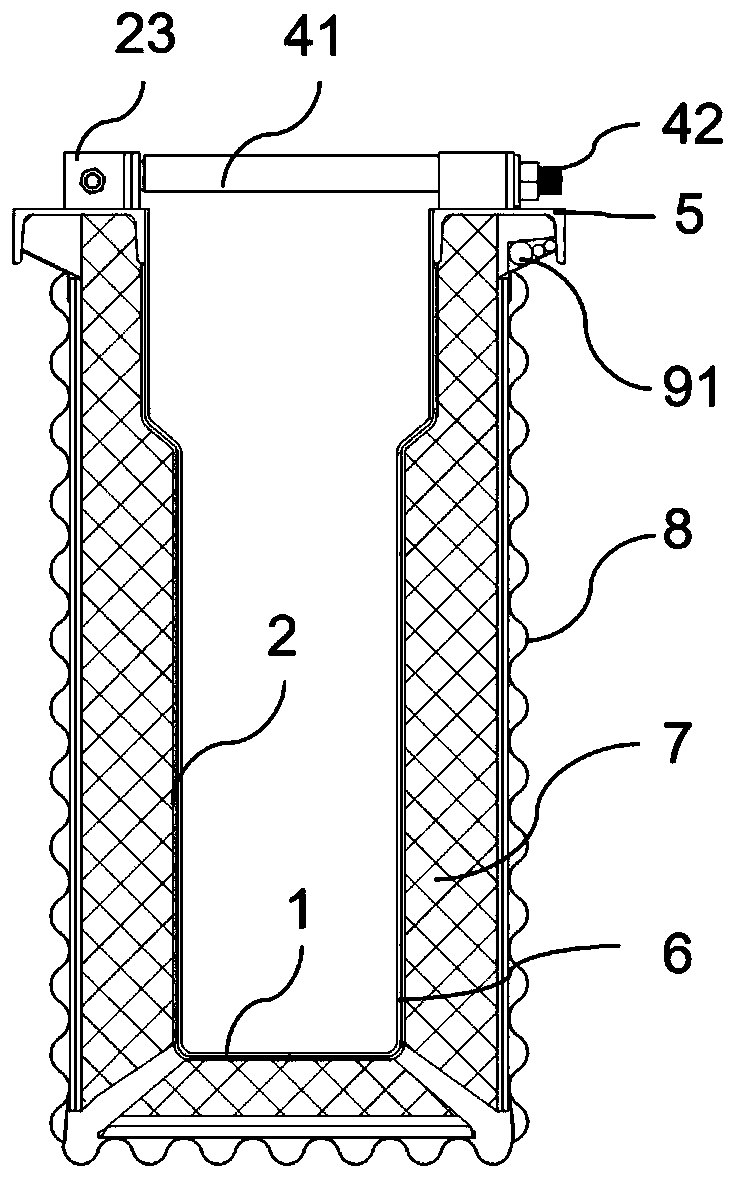

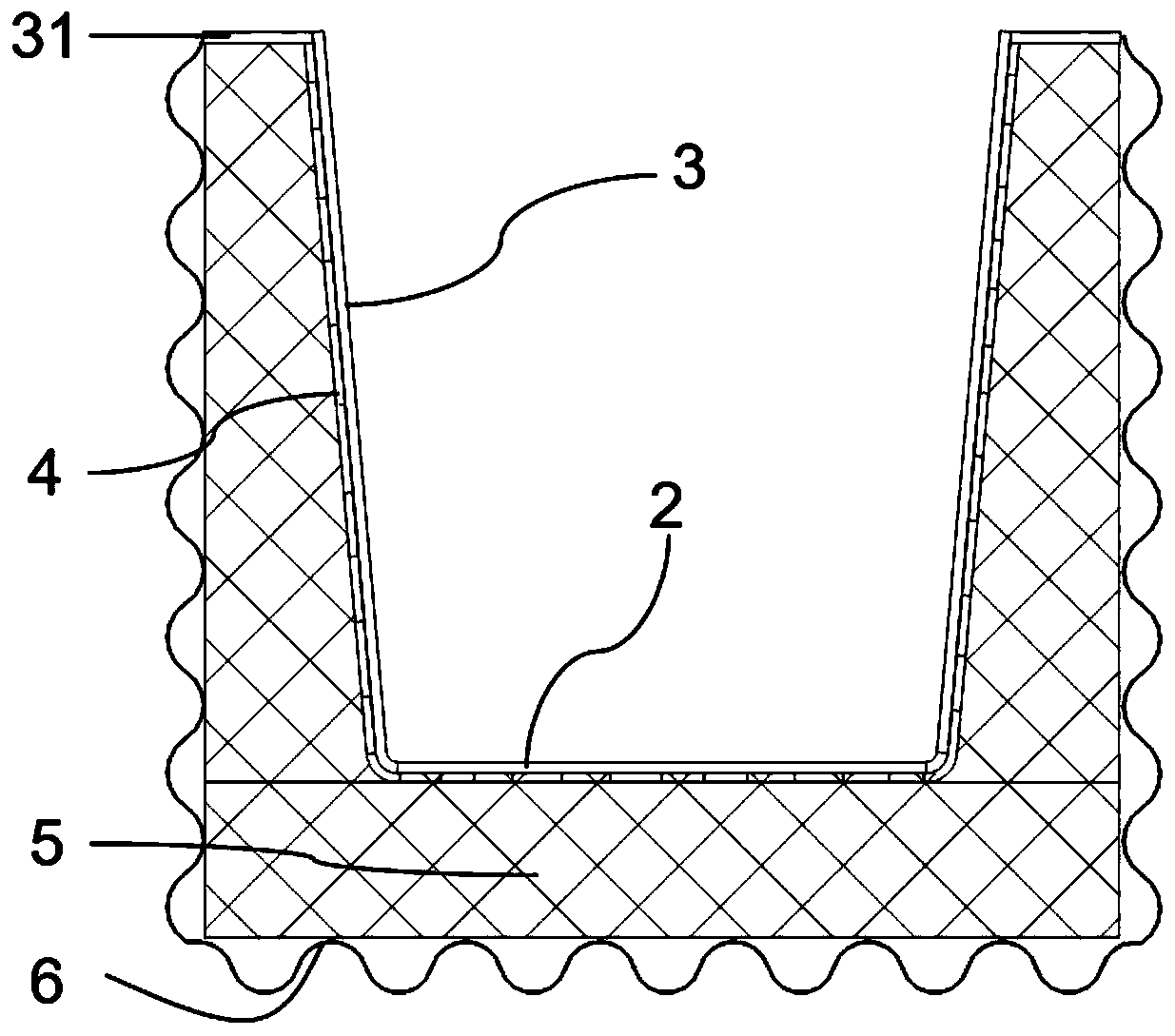

Electric heating film maintaining trapezoidal beam film

PendingCN111391081AImprove general performanceSimple structureCeramic shaping apparatusInsulation layerMold removal

The invention relates to an electric heating film maintaining trapezoidal beam film. The electric heating film maintaining trapezoidal beam film comprises a U-shaped rib, a bottom plate, a side plate,a horizontal rib, an electric heating film, a heat-insulating layer and a protective plate, wherein the horizontal rib is arranged on the upper part of the side plate and extends outwards; the bottomplate and the side plate are in rigid connection; the bottom plate and the side plate are shaped like a horn mouth with a big upper part and a small lower part; the electric heating film adheres to the outer surfaces of the bottom plate and the side plate; the heat-insulating layer is arranged on the outer side of the electric heating film; and the protective plate covers the outer side of the heat-insulating layer. After concrete is formed in a mold, the surface of the mold can be directly heated, so that the electric heating film maintaining trapezoidal beam film is simple to operate and high in maintenance speed; furthermore, the horn mouth-shaped template is adopted, a bottom mold and a side mold are connected into a whole, and a precast beam can directly perform lifting and demolding, so that the mold supporting and disassembling process is omitted.

Owner:宁波优造建筑科技有限公司

Prestressed special-shaped trough plate

PendingCN110629925AReduce the overall heightImprove carrying capacityConstruction materialJoint actionNotching

The invention provides a prestressed special-shaped trough plate. The prestressed special-shaped trough plate comprises a special-shaped concrete slab body and prestressed steel strands buried in thespecial-shaped concrete slab body and taken as main reinforcements. The prestressed special-shaped trough plate is characterized in that the special-shaped concrete slab body comprises a face plate and ribbed beams, the face plate and the ribbed beams are integrated into a whole by pouring, an expanded section flange is arranged at the bottom of each ribbed beam, and longitudinal placing notches are formed in the two sides of the face plate. With the adoption of the prestressed special-shaped trough plate provided with the expanded section flanges at the bottoms of the ribbed beams, the bending resistance of the component is greatly improved, the bearing capacity is improved under the condition of the fixed height of the trough plate, the height of the trough plate is reduced under the condition of the same live load, and meanwhile, the invert arch cracking of the component is effectively controlled under the joint action of the special-shaped concrete slab body and the prestressed steel strands.

Owner:宁波优造建筑科技有限公司

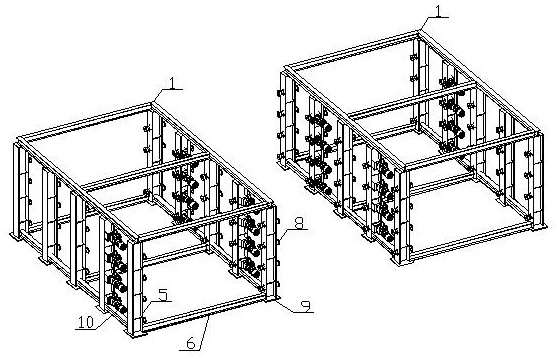

A multi-functional three-dimensional combined transformation mold

ActiveCN106426523BLow amortized costEfficient use ofMouldsCeramic shaping mandrelsEngineeringCushion

The invention discloses a multifunctional stereoscopic combined transformation die, which comprises a moving chassis, a bottom lattice beam, a first die, a second die, a third die A, a third die B and an inner side compartmenting die. Four corners of the moving chassis are provided with four reinforcing cushion blocks, a wheel frame is mounted under the reinforcing cushion blocks, wheels are arranged on the wheel frame, the bottom lattice beam is fixed on the moving chassis, four hook openings of the third die A, the third die B and the inner side compartmenting die and a plurality of die core holes are arranged in the bottom lattice die, and the bottom lattice beam is connected to the first die, the second die, the third die A, the third die B and fasteners of a lower opening of the inner side compartmenting die. A middle lattice beam covers the tops of the first die, the second die, the third die A, the third die B and the inner side compartmenting die, and four hook openings which correspond to the bottom lattice beam and are along a straight line up and down and die core holes are arranged in the bottom of the middle lattice beam. According to the multifunctional stereoscopic combined transformation die, the production manner of a traditional prefabricated part is improved to space stereoscopic production from planar production, such that a production space of a plant can be effectively used, investment of a land capital is reduced and a production amortization cost of the member is reduced.

Owner:南通联泷装配式建筑科技有限公司

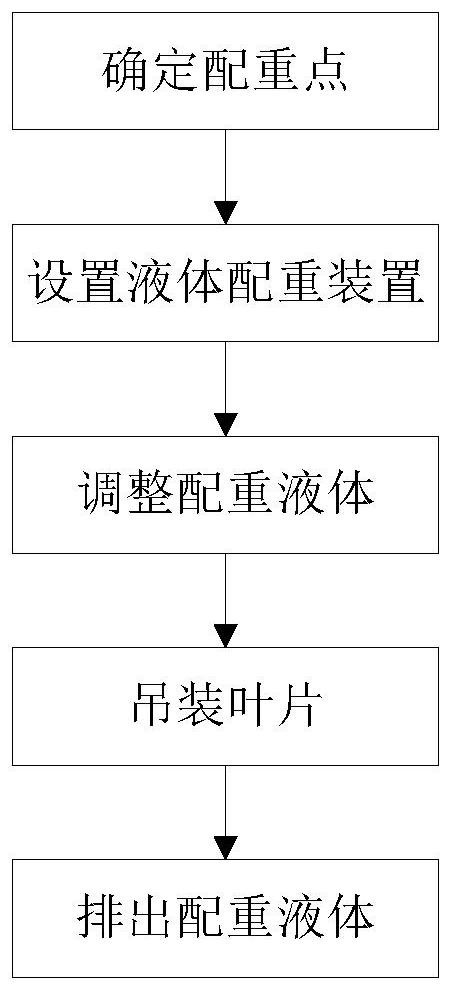

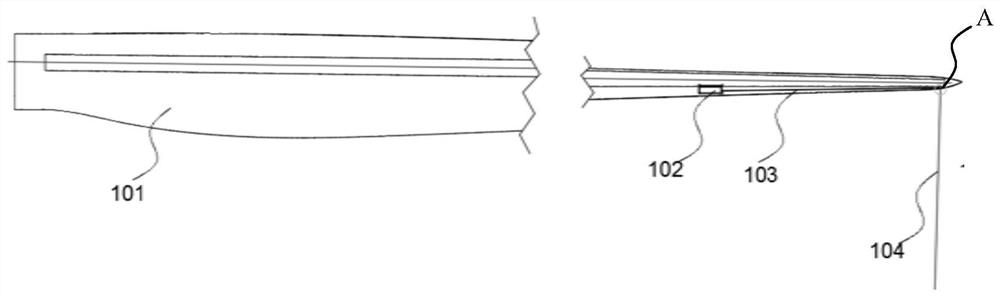

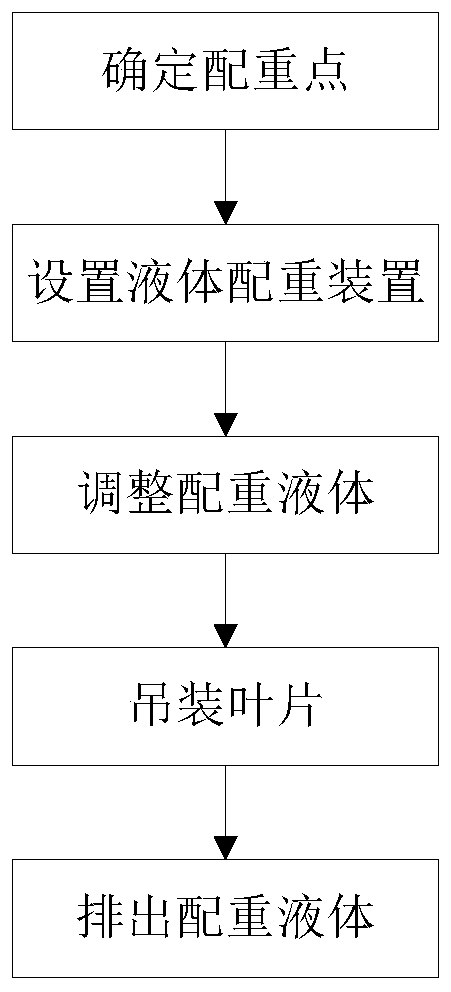

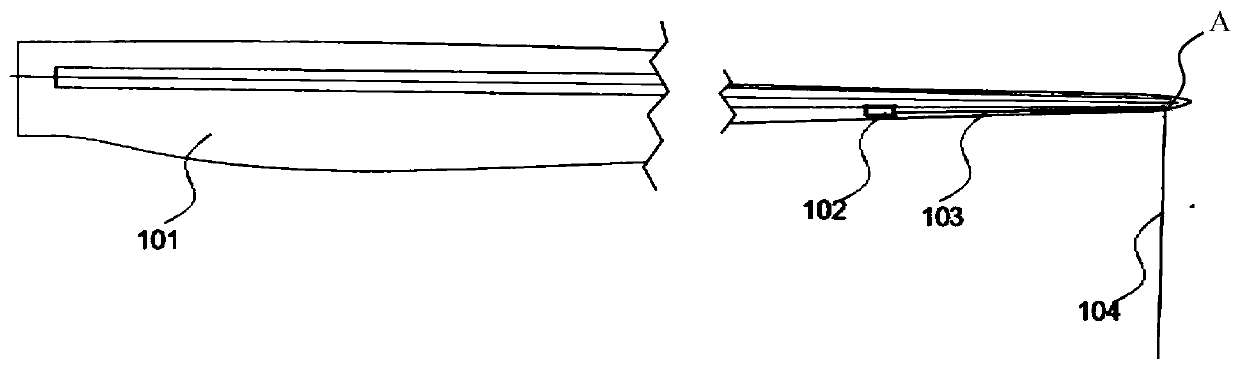

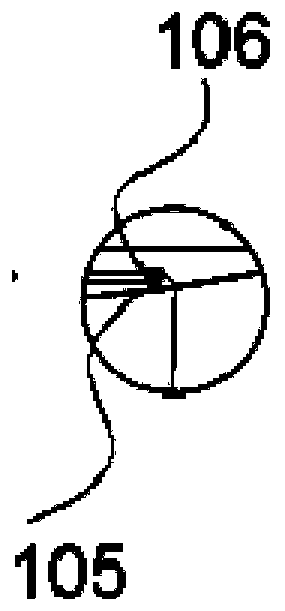

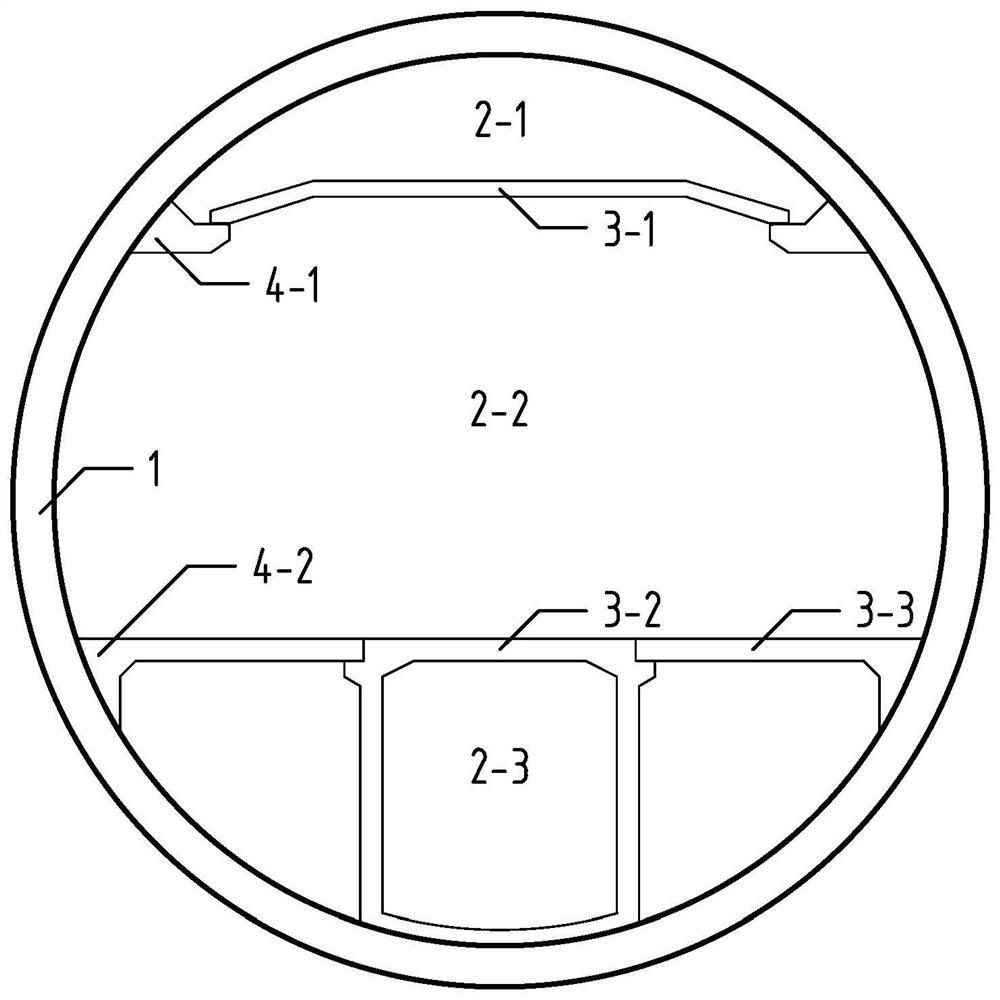

A method and device for adjusting the position of the center of gravity of a wind turbine blade

ActiveCN110342388BMinor design changesLow amortized costWind motor assemblyCounterweightsTurbine bladeClassical mechanics

According to the method and device for adjusting the position of the gravity center of a blade of a wind driven generator. A counterweight point is determined on the blade of the wind driven generatorto be hoisted, a liquid balancing device is arranged on the counterweight point, a built-in counterweight device arranged in the blade of the wind driven generator or an external counterweight devicearranged outside the blade of the wind driven generator, and the gravity center position of the blade of the wind driven generator to be hoisted is adjusted to the position of the gravity center of the blade required by a single-blade lifting appliance by adjusting the mass of the counterweight liquid in the liquid balancing device. According to the method and device, universality of the single-blade lifting appliance is greatly improved, the using efficiency of the single-blade lifting appliance is improved, the unit development progress is accelerated, and the hoisting and spreading cost ofblade is reduced.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

A simple-supported prefabricated monolithic composite bridge and its construction method

ActiveCN102808372BLight weightEasy to transport and installBridge erection/assemblyPre stressEngineering

The invention discloses a simply supported prefabricated integrally-cast superposed bridge. The prefabricated integrally-cast superposed bridge comprises inverted T-shaped prestressed prefabricated beam parts, cast-in-situ parts and horizontal baffles, and is characterized in that each cast-in-situ part comprises a cast-in-situ plate and a cast-in-situ superposed part at the upper part of the beam part; pretensioned prestressed steel strands are embedded in the upper parts of a web plate and a lower flange of each inverted T-shaped prestressed prefabricated beam part; the horizontal baffles adopt prefabricated plates, and are longitudinally arranged at intervals between the web plates of the adjacent prefabricated beam parts at the two ends of each beam part and positioned above the flanges of the prefabricated beam parts; and the inverted T-shaped prestressed prefabricated beam parts adopt manufacturing moulds commonly used with buildings, and mould plates are good in commonality, convenient to mount and dismount, high in working efficiency and low in amortized cost.

Owner:杨众 +1

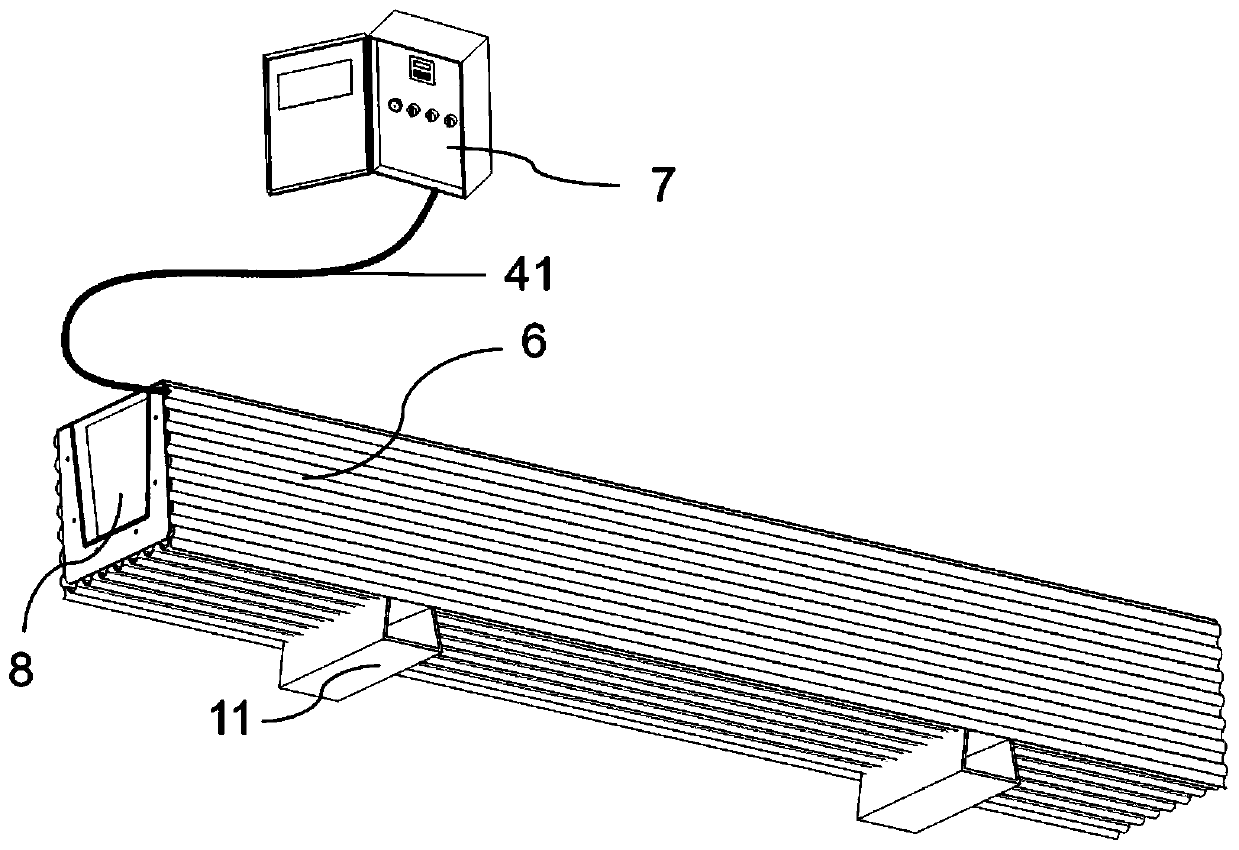

Electric heating film curing prefabricated component die

PendingCN111409181AReduce manufacturing costReduce shipping costsCeramic shaping apparatusHeat energyElectric heating

An electric heating film curing prefabricated component die comprises a concrete prefabricated component forming template, an electric heating film and a heat preservation layer. The concrete prefabricated component forming template comprises a panel making direct contact with the concrete surface. The electric heating film is attached to the outer side of the panel. The outer side of the electricheating film is provided with the heat preservation layer. After concrete is poured in the die and formed, temperature rise can be directly conducted on the surface of the die, operation is simple, construction is convenient, the heat energy conversion rate is high, the curing speed is high, the die circulation efficiency is high, and the electric heating film curing prefabricated component die can be used for manufacturing prefabricated components in any site.

Owner:宁波优造建筑科技有限公司

Sloping wedge clamp of building moulding board and mounting, unloading tool thereof

InactiveCN100374673CSimple assembly and disassembly toolsEasy to adjustAuxillary members of forms/shuttering/falseworksForm treatmentSteel tubeEngineering

The inclined wedged fixture and assembling and disassembling tool for building formwork includes polished rod, inclined wedge and characterized inclined sleeve being one long flat steel pipe with hole in the same axial inclination as that of the inclined wedge. The polished rod is penetrated into the hole of the inclined sleeve, and the inclined wedge is wedged into the interval between the polished rod and the inclined sleeve hole. The present invention has separated fixture and assembling and disassembling tool, the formwork position may be regulated with installing pliers with crank link mechanism, and the fixture may be detached with the inclined wedge. The technology of the present invention is simple and reliable, and has easy assembling and disassembling and low cost.

Owner:潘颖聪

Method and device for adjusting position of gravity center of blade of wind driven generator

ActiveCN110342388AMinor design changesLow amortized costWind motor assemblyCounterweightsWind drivenGravity center

According to the method and device for adjusting the position of the gravity center of a blade of a wind driven generator. A counterweight point is determined on the blade of the wind driven generatorto be hoisted, a liquid balancing device is arranged on the counterweight point, a built-in counterweight device arranged in the blade of the wind driven generator or an external counterweight devicearranged outside the blade of the wind driven generator, and the gravity center position of the blade of the wind driven generator to be hoisted is adjusted to the position of the gravity center of the blade required by a single-blade lifting appliance by adjusting the mass of the counterweight liquid in the liquid balancing device. According to the method and device, universality of the single-blade lifting appliance is greatly improved, the using efficiency of the single-blade lifting appliance is improved, the unit development progress is accelerated, and the hoisting and spreading cost ofblade is reduced.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

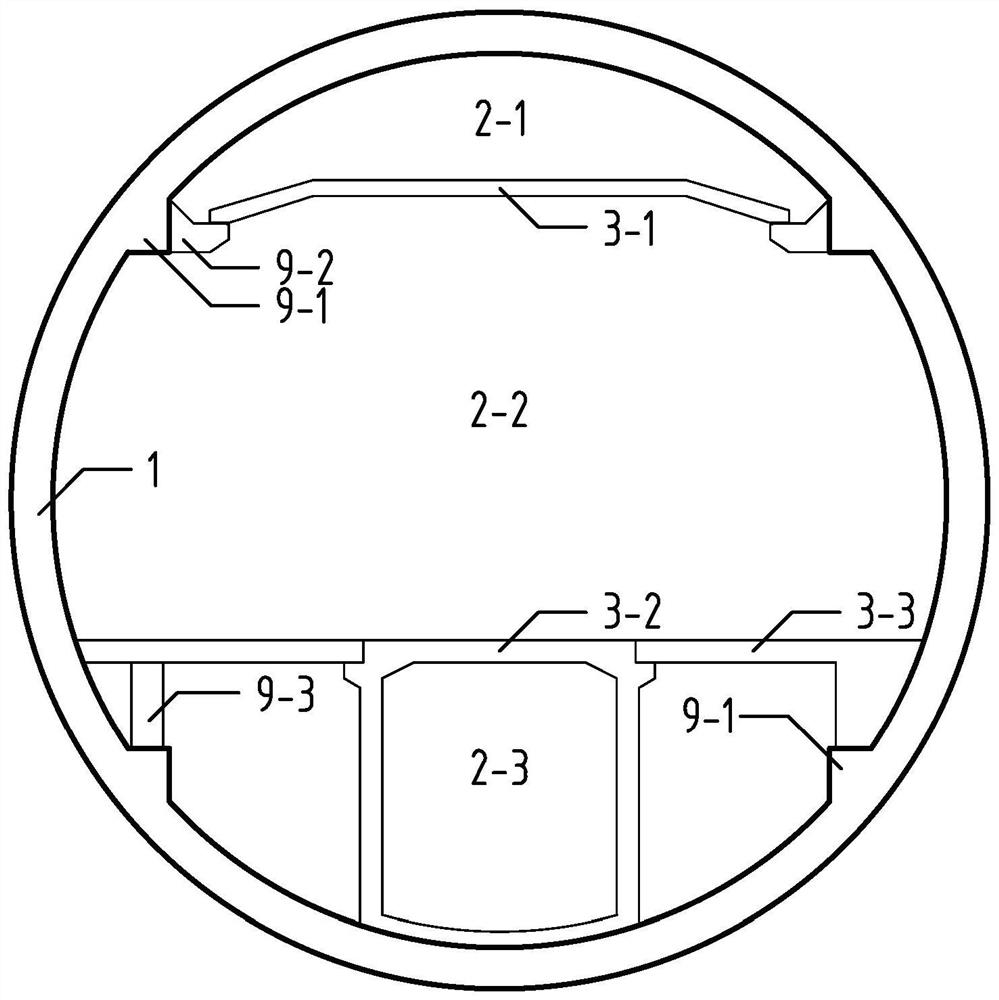

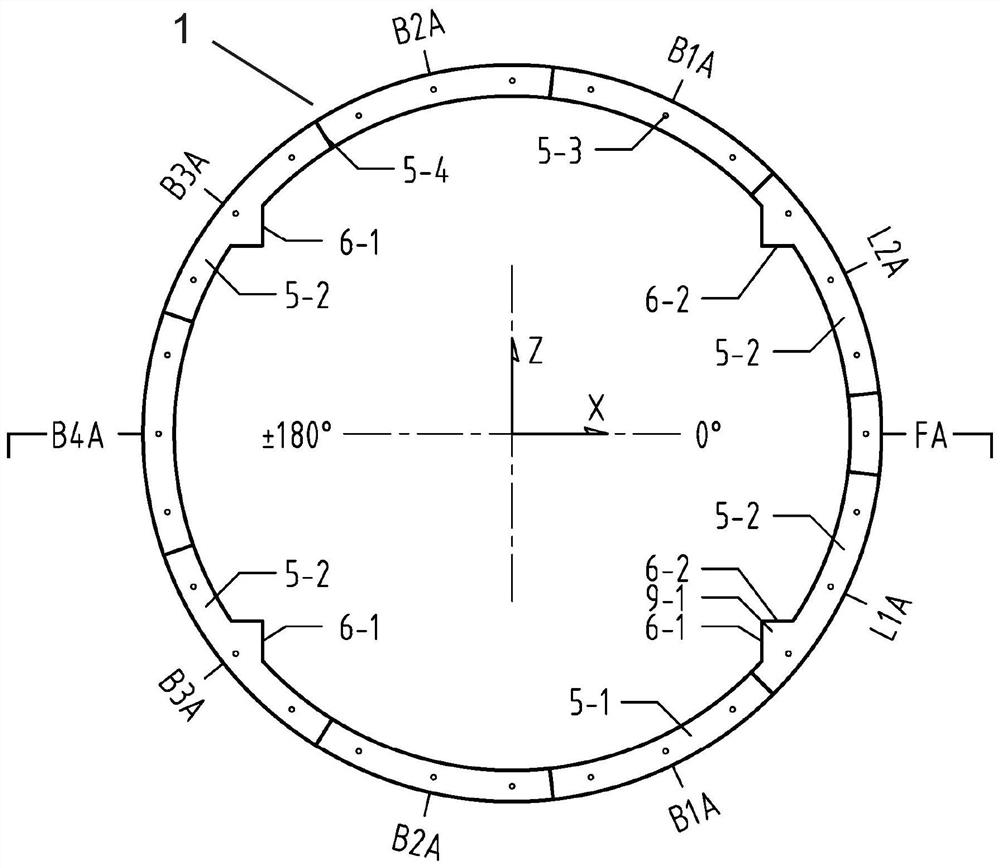

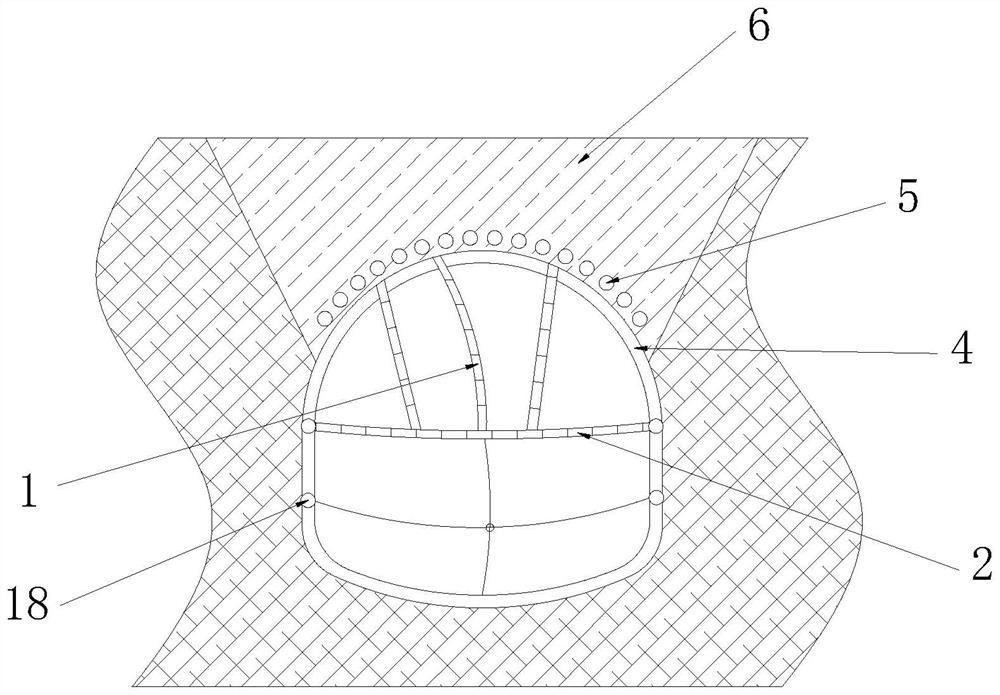

Lining circular ring assembled by prefabricated segments with corbel connecting bases and assembling method of lining circular ring

PendingCN112412494AEliminate quality risksSimplified form factorUnderground chambersTunnel liningVertical planeEngineering

The invention discloses a lining circular ring assembled by prefabricated segments with corbel connecting bases and an assembling method of the lining circular ring. The lining circular ring is provided with symmetrical double-sided wedge-shaped rings. The capping block assembling point is located at the 0-degree position of the lining circular ring, the ring width of the outer diameter of the circular ring at the point is the minimum value or the maximum value, the point, opposite to the capping block, of the 180-degree point is a first standard block, and the points, adjacent to the two sides of the first standard block, of the capping block are second standard blocks. The inner arc surface of the second standard block and the inner arc surface of the adjacent block are each provided with a corbel connecting base which is integrally formed and protrudes out of the inner arc surfaces, each corbel connecting base is composed of a connecting base face in the horizontal plane direction and a connecting base face in the vertical plane direction, the four corbel connecting bases are symmetrically distributed in the lining circular ring, and the formed lining circular ring is in a mode1 or a mode 4. The top sealing block and the adjacent blocks on the two sides are spliced into a whole to rotate by 180 degrees around the Y axis to be in place, and the first standard block and the standard blocks sequentially spliced with the first standard block are spliced into a whole to rotate by 180 degrees around the Z axis to be in place in a mirroring mode to form a lining circular ringin a mode 2 or a mode 3. The universality of the segment is improved, and drilling and steel bar planting on the inner arc surface of the segment are avoided.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Multifunctional stereoscopic combined transformation die

ActiveCN106426523ALow amortized costEfficient use ofMouldsCeramic shaping mandrelsEngineeringFastener

The invention discloses a multifunctional stereoscopic combined transformation die, which comprises a moving chassis, a bottom lattice beam, a first die, a second die, a third die A, a third die B and an inner side compartmenting die. Four corners of the moving chassis are provided with four reinforcing cushion blocks, a wheel frame is mounted under the reinforcing cushion blocks, wheels are arranged on the wheel frame, the bottom lattice beam is fixed on the moving chassis, four hook openings of the third die A, the third die B and the inner side compartmenting die and a plurality of die core holes are arranged in the bottom lattice die, and the bottom lattice beam is connected to the first die, the second die, the third die A, the third die B and fasteners of a lower opening of the inner side compartmenting die. A middle lattice beam covers the tops of the first die, the second die, the third die A, the third die B and the inner side compartmenting die, and four hook openings which correspond to the bottom lattice beam and are along a straight line up and down and die core holes are arranged in the bottom of the middle lattice beam. According to the multifunctional stereoscopic combined transformation die, the production manner of a traditional prefabricated part is improved to space stereoscopic production from planar production, such that a production space of a plant can be effectively used, investment of a land capital is reduced and a production amortization cost of the member is reduced.

Owner:南通联泷装配式建筑科技有限公司

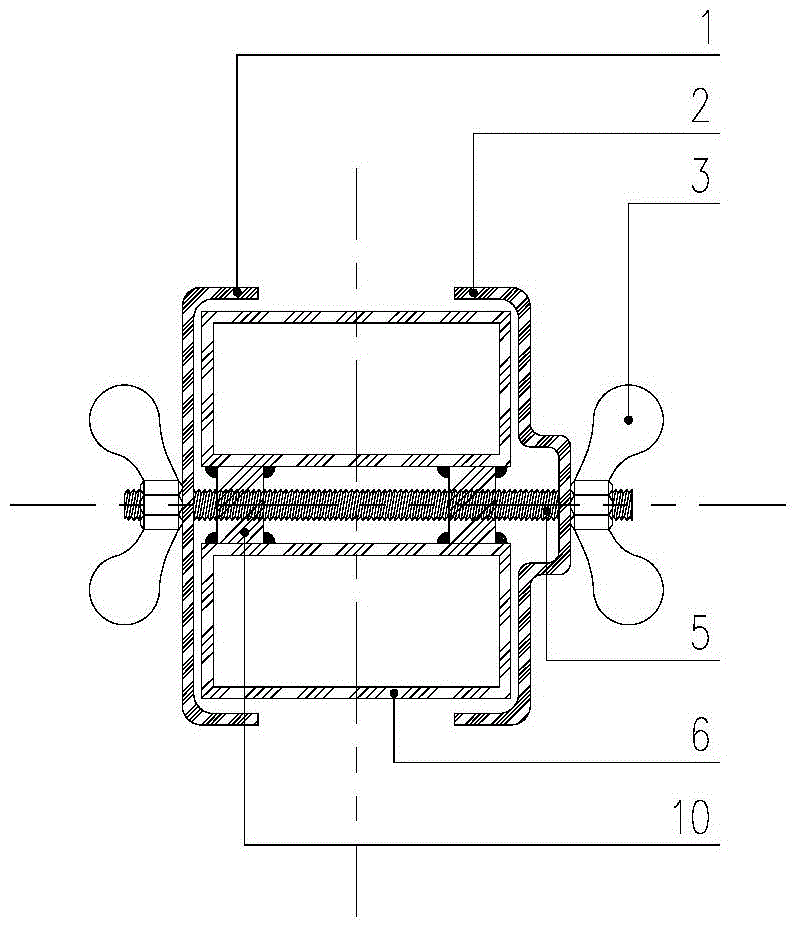

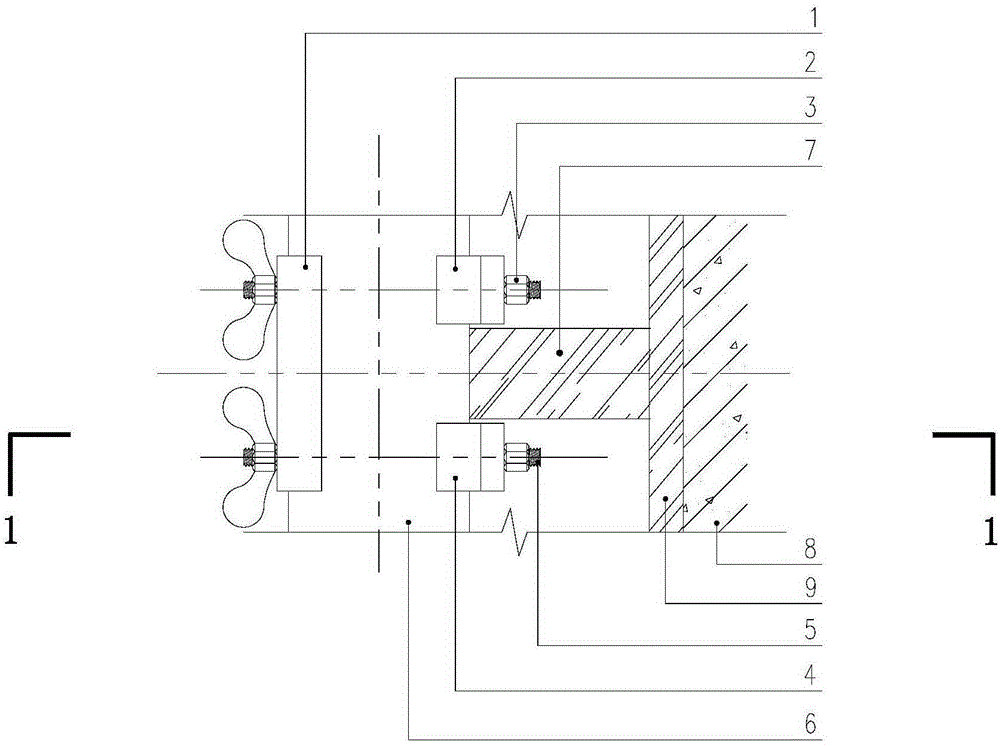

Formwork corrugated metal fixture fastening structure in building construction

ActiveCN105178600BPrecise position controlPrecise Control of SpacingAuxillary members of forms/shuttering/falseworksArchitectural engineeringMetal

The invention provides a metal clamp fastening structure for template secondary ridges in building construction. Top surfaces of a first inner U-shaped clamping sheet and a second inner U-shaped clamping sheet of the clamp fastening structure are provided with U-shaped bulged ends and are respectively fixed at the two sides of each secondary ridge; an outer U-shaped clamping sheet is arranged at one side of each of two primary ridges; a first inner U-shaped clamping sheet and the second inner U-shaped clamping sheet are arranged at the other sides of the primary ridges; an all-thread screw sequentially penetrates through the outer U-shaped clamping sheet at one side of each secondary ridge, two round steel brackets and the first inner U-shaped clamping sheet, and the two ends of the all-thread screw are fastened through fixing bolts; and the all-thread screw sequentially penetrates through the outer U-shaped clamping sheet at one side of each secondary ridge, two round steel brackets and the second inner U-shaped clamping sheet, and the first inner U-shaped clamping sheet, and the two ends of the all-thread screw are fastened through fixing bolts. The metal clamp fastening structure has the effect that: the positions of the secondary ridges and distance of the secondary ridges can be precisely controlled and fixed; the stability of the secondary ridges can be greatly improved; the operation process is simple and convenient; the comprehensive cost is low; and rigidity and reliability of a mould are effectively improved, so that the quality of a concrete component is greatly improved.

Owner:天津住总集团有限公司 +1

A simple-supported and then continuous prefabricated monolithic composite continuous bridge and its construction method

ActiveCN102808371BLight weightEasy to transport and installBridge erection/assemblyShaped beamPre stress

A simply-supported-to-continuous prefabricated integrally-cast superposed continuous bridge comprises inverted-T-shaped pre-stress prefabricated beams, a cast-in-place portion and a transverse partition plate, and is characterized in that the cast-in-place portion comprises a cast-in-place plate and cast-in-place superposition portions on the upper portions of the beams, pre-tensioning pre-stressed steel wires are embedded into the bottom flange and the upper portion of a web of each inverted-T-shaped pre-stress prefabricated beam, a galvanized steel plate is arranged on the cast-in-place plate bottom surface between the two prefabricated beams, and the transverse partition plate is a prefabricated plate and perpendicularly arranged between the webs of the adjacent inverted-T-shaped beams above the flanges of the inverted-T-shaped beams at a certain distance. The inverted-T-shaped prefabricated beams are light in dead weight so as to be convenient to transport and mount and high in construction speed.

Owner:杨众 +1

Method for monitoring a device for regulating gas flow and regulating system using said method

ActiveCN109716002BLow amortized costEarly maintenance workOperating means/releasing devices for valvesFluid pressure control using electric meansEngineeringMechanical engineering

A method for monitoring a device (1) for regulating the flow of gas, comprising a flow conduit (2) and a shutter assembly (3) defining a restriction (4) in the flow conduit (2). The method comprises the following operations: causing the gas to pass through the flow conduit (2); defining the corresponding duration (t 1 ...t n ) time interval sequence (Z 1 ...Z n ); at each time interval (Z i ), determine the density of the gas at the restriction (4) (d i ) and velocity (v i ) value; calculate the density (d i ) value, velocity (v i ), the time interval (Z i ) duration (t i ) and correction factor (k i ) to get the corresponding equivalent wear (u i ) values; for each time interval (Z i ), will be the current time interval (Z i ) and the preceding time interval (Z 1 ...Z i‑1 ) calculated for all equivalent wear (u 1 ... u i ) are added together to obtain the cumulative value (cu i ); will accumulate the value (cu i ) is compared with a predefined extreme value (cu*) corresponding to the maximum wear condition allowed for the closure assembly (3) to obtain an indication of the efficiency condition of the closure assembly (3).

Owner:PIETRO FIORENTINI SPA

Metal clamp fastening structure for template secondary ridges in building construction

ActiveCN105178600APrecise position controlPrecise Control of SpacingAuxillary members of forms/shuttering/falseworksMechanical engineeringMetal

The invention provides a metal clamp fastening structure for template secondary ridges in building construction. Top surfaces of a first inner U-shaped clamping sheet and a second inner U-shaped clamping sheet of the clamp fastening structure are provided with U-shaped bulged ends and are respectively fixed at the two sides of each secondary ridge; an outer U-shaped clamping sheet is arranged at one side of each of two primary ridges; a first inner U-shaped clamping sheet and the second inner U-shaped clamping sheet are arranged at the other sides of the primary ridges; an all-thread screw sequentially penetrates through the outer U-shaped clamping sheet at one side of each secondary ridge, two round steel brackets and the first inner U-shaped clamping sheet, and the two ends of the all-thread screw are fastened through fixing bolts; and the all-thread screw sequentially penetrates through the outer U-shaped clamping sheet at one side of each secondary ridge, two round steel brackets and the second inner U-shaped clamping sheet, and the first inner U-shaped clamping sheet, and the two ends of the all-thread screw are fastened through fixing bolts. The metal clamp fastening structure has the effect that: the positions of the secondary ridges and distance of the secondary ridges can be precisely controlled and fixed; the stability of the secondary ridges can be greatly improved; the operation process is simple and convenient; the comprehensive cost is low; and rigidity and reliability of a mould are effectively improved, so that the quality of a concrete component is greatly improved.

Owner:天津住总集团有限公司 +1

Assembly type multifunctional safety operation standard beam and protection channel

PendingCN112127607AImprove bearing capacitySmall footprintBuilding insulationsScaffold accessoriesSupporting systemFalsework

The invention provides an assembly type multifunctional safety operation standard beam and protection channel. The standard beam comprises a hexahedron beam frame, first cavities and second cavities,wherein the hexahedron beam frame is a cuboid, the first cavities penetrate through the middles of any two opposite surfaces of the cuboid, and the second cavities penetrate through the vertex anglesof any two opposite surfaces of the cuboid. According to the standard beam and protection channel, the supporting system is suitable for exterior decoration and transformation of frontage buildings inbustling blocks and buildings in narrow and small streets and alleys, and through the supporting system, the installation simplification and occupied area minimization are achieved, and normal passing of blocks and alleys is not hindered while the construction operation is conducted; a current scaffold and portal frame are replaced, and the problems that the occupied area is large, the installation is complex, labor-consuming and time-consuming, and the transportation cost and the maintenance cost are high are solved; the construction period is ensured, and the cost is reduced; and the construction quality is guaranteed.

Owner:北京星河模板脚手架工程有限公司

Improved CRD construction method tunnel construction process

PendingCN114718581AImprove firmnessPrevent collapseUnderground chambersHydro energy generationSupporting systemArchitectural engineering

The invention relates to the technical field of building construction, and discloses an improved CRD construction method tunnel construction technology which comprises the following steps that S1, backfilling and back pressing are conducted on a collapse area; s2, a pipe shed is constructed at the bottom of the backfill area; s3, an arch cavity is backfilled and compacted through concrete; s4, excavating a left upper step, and primarily supporting the left parts of the longitudinal partition wall and the transverse partition wall to form a ring; s5, excavating an upper step on the right side, and primarily supporting the right side parts of the longitudinal partition wall and the transverse partition wall to form a ring; s6, the transverse partition walls and the longitudinal partition walls are dismantled; s7, excavating and supporting a lower step on the left side; s8, excavating and supporting a lower step on the right side; s9, arranging an inverted arch and filling concrete; according to the construction method, through back pressure backfilling of the collapse area and supporting of the backfilling area through the pipe shed, the firmness of the overall structure of the tunnel is good, the using amount of temporary supporting materials is reduced, the construction period is shortened, the spreading cost of tunnel excavation and supporting system equipment is reduced, and the construction efficiency is improved.

Owner:CCCC TUNNEL ENG +1

Ultra-high speed and high pressure precision pneumatic feed delivery valve

ActiveCN104585110BLow amortized costReduce openingOperating means/releasing devices for valvesClimate change adaptationUltra high speedEngineering

Owner:ZHEJIANG OCEAN UNIV

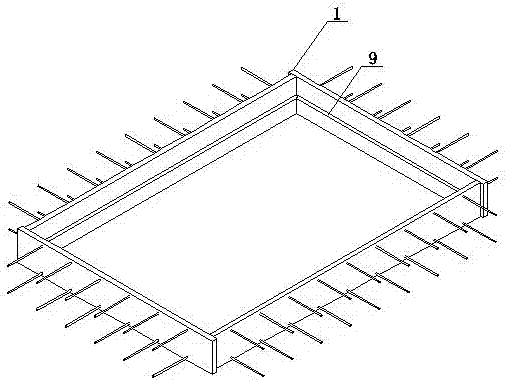

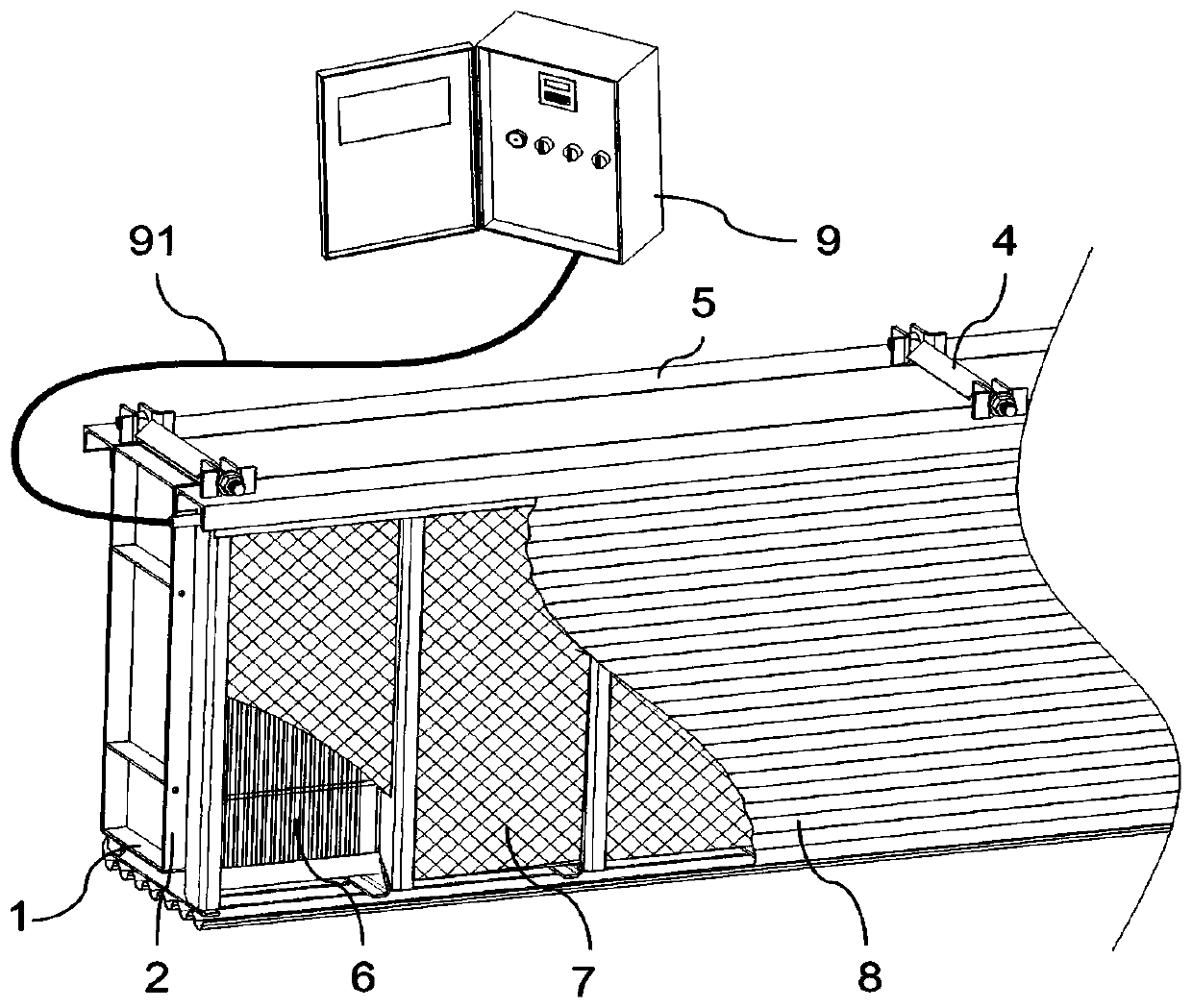

Assembled parallel straight-through type sunlight heating curing kiln and installation method thereof

PendingCN112809898AQuick assemblySolve excess capacityAuxillary shaping apparatusThermodynamicsEngineering

The invention relates to an assembled parallel straight-through type sunlight heating curing kiln and an installation method thereof. In an existing prefabricated part supply mode, prefabricated parts are produced in advance through a prefabricated part factory and then conveyed to a construction site through a transport vehicle, the prefabricated part factory is usually far away from the construction site, and the mode prefabricated part factory needs operation cost as an enterprise main body. The assembled parallel straight-through type sunlight heating curing kiln is formed by transversely and / or longitudinally assembling N integrated type steel supporting units (1) of a multi-layer stacking part production die table. Each integrated type steel supporting unit of the multi-layer stacking part production die table is of a rectangular frame structure defined by a plurality of vertical steel supports (5) and a plurality of transverse steel supports (6), each vertical steel support is fixedly provided with a plurality of layers of cantilever guiders in the height direction, and the cantilever guiders, located on the same layer, of the multiple vertical steel supports are the same in height. The installation method is used for the assembled parallel straight-through type sunlight heating curing kiln.

Owner:湖北宇辉智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com