Formwork corrugated metal fixture fastening structure in building construction

A technology for fastening structures and building construction, which is applied to building structures, on-site preparation of building components, construction, etc. It can solve the problems of secondary flute deviation, large deviation, and easy instability, and achieve the steel frame stress The effect of uniformity, low cost and low comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

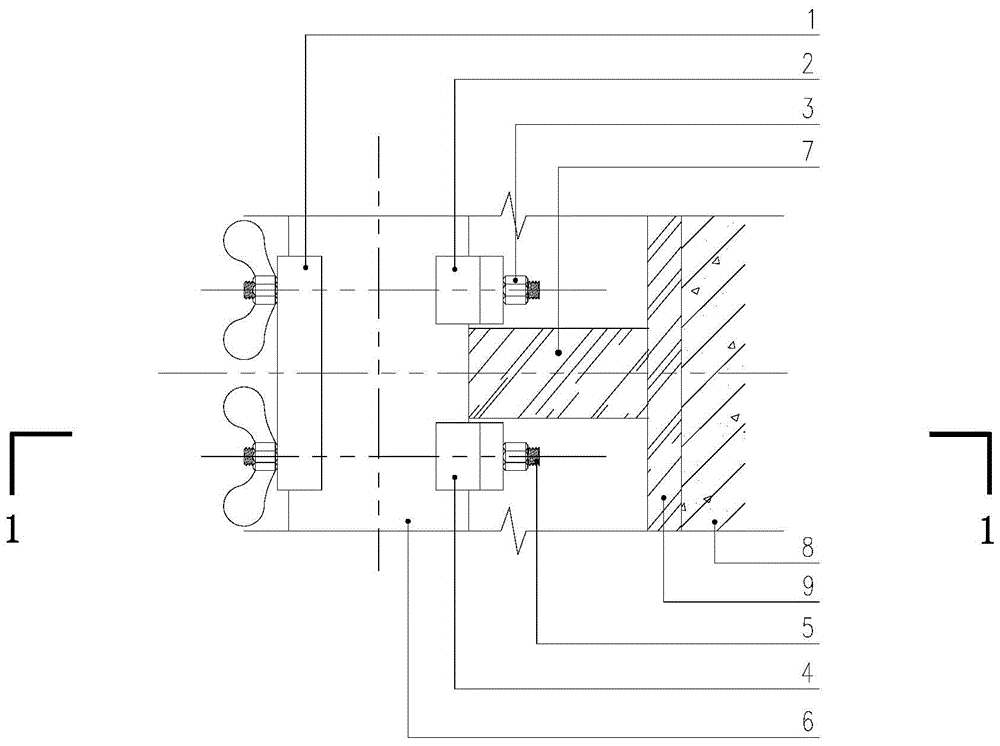

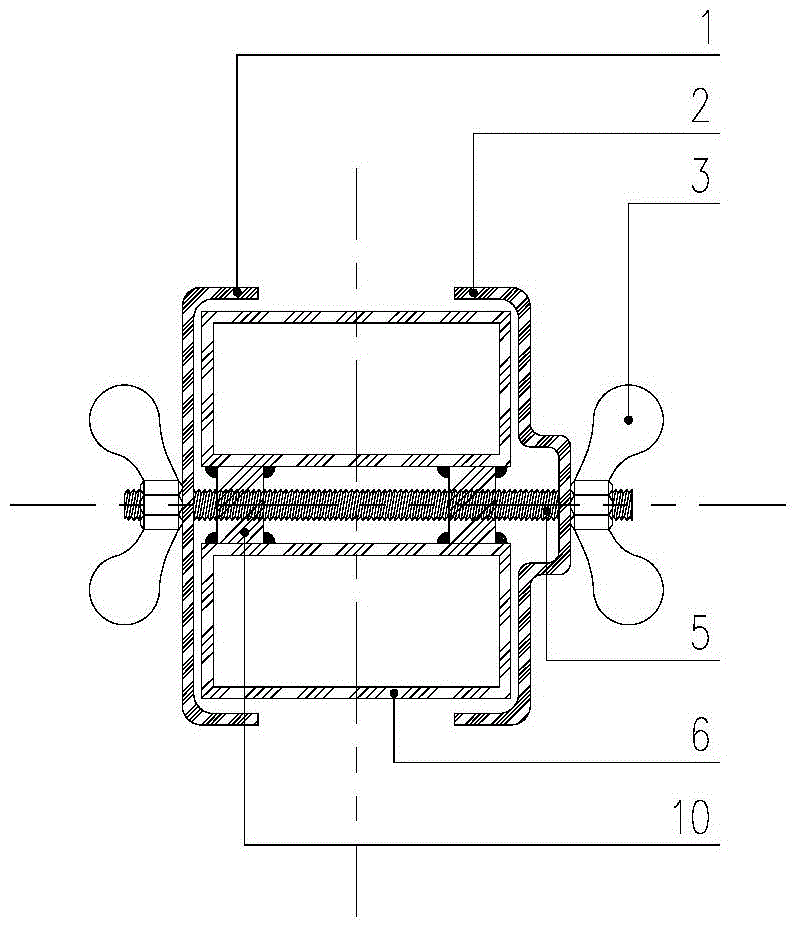

[0020] In conjunction with the accompanying drawings, the fastening structure of the formwork corrugated metal fixture in the building construction of the present invention is described.

[0021] like figure 1 , 2 As shown, in the building construction of the present invention, the template secondary corrugated metal fixture fastening structure, the distance between the main corrugated 6 and the secondary corrugated 7 in the mold is fixed by the fixture fastening structure, and the main corrugated 6 is arranged on the outside of the secondary corrugated 7. The fixture fastening structure includes an outer U-shaped card 1 , a first inner U-shaped card 2 , a second inner U-shaped card 4 , a fixing nut 3 , and a threaded screw rod 5 . The metal fixture fastens the outer U-shaped card 1, the first inner U-shaped card 2, and the second inner U-shaped card 4 on the main flute 6 through the fixed nut 3 and the through-fastening screw 5, and the main flute 6 is made of metal. Fang ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com