Method for achieving synchronous control of two shafts

A technology of synchronous control and synchronous algorithm, applied in the direction of digital control, electrical program control, etc., can solve the problems of increased cost, resource waste, expensive price, etc., and achieve the effect of fast response speed, large output pulse gap, and poor positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

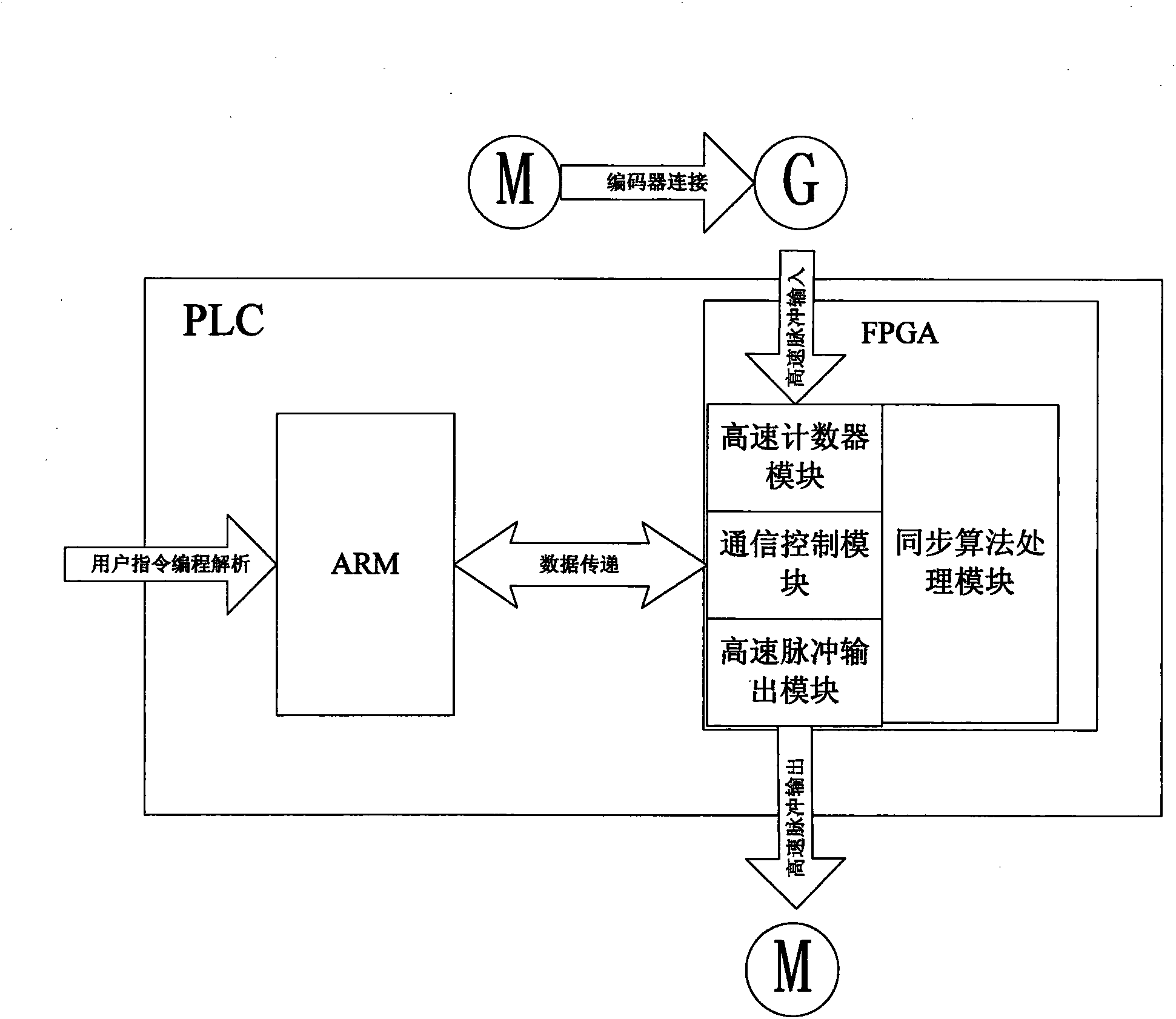

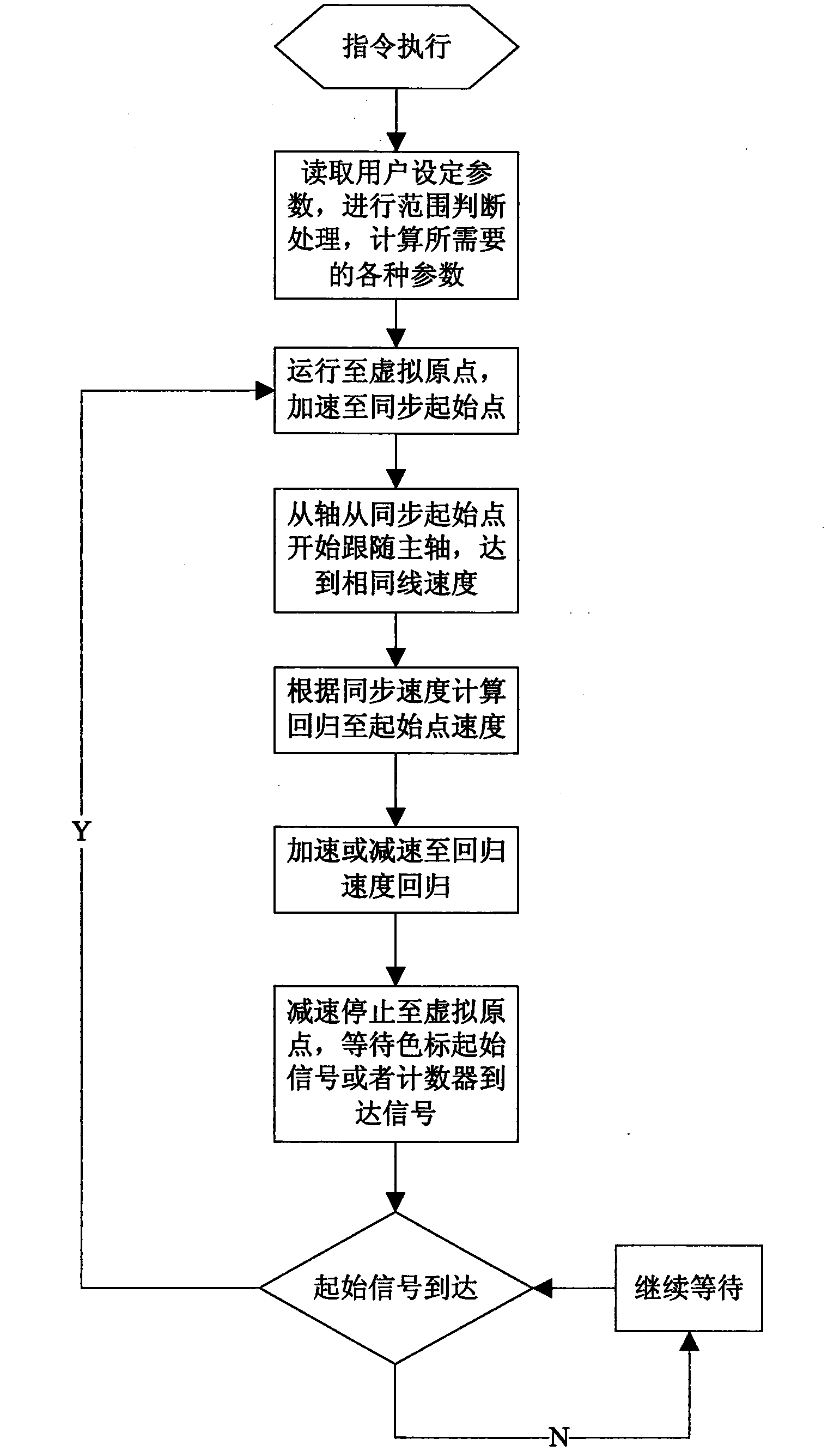

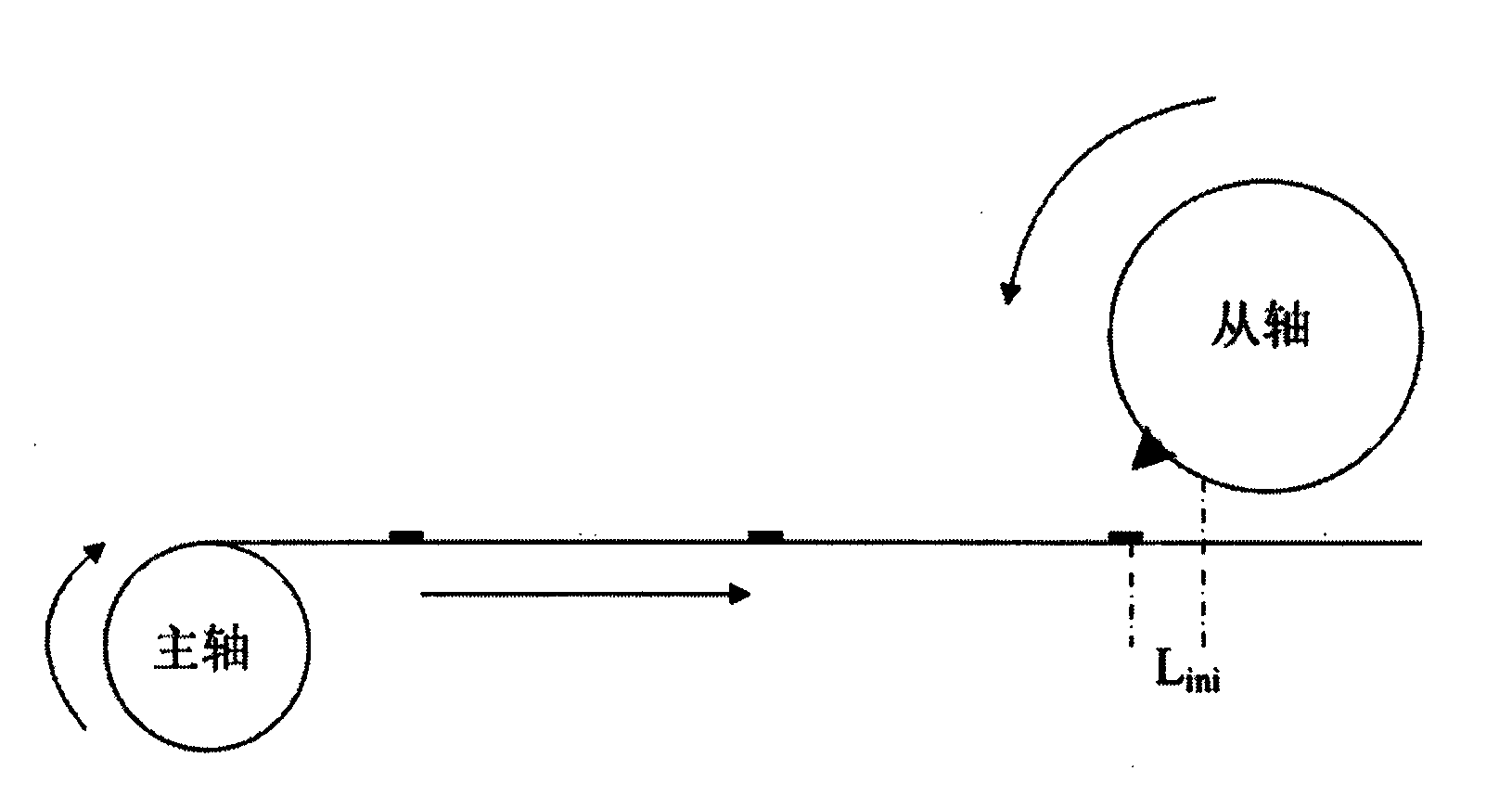

[0028]The method for realizing the synchronous control of two shafts provided by the present invention can complete the synchronous function of master and slave shafts only by using one command. The PLC host in the present invention adopts a main control unit and a synchronous control unit. In this embodiment, the main control unit is realized by an ARM chip, and the synchronous control unit is realized by a large-capacity programmable logic device FPGA. FPGA is responsible for high-speed pulse input sampling, synchronous algorithm processing and high-speed pulse output and other functions. The realization of the synchronization function is completed in the FPGA, and the separation design from the main chip ARM greatly reduces the workload of the main chip and reduces the scanning cycle of the entire PLC.

[0029] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com