Method for improving edge touch accuracy of infrared touch screen

An infrared touch screen and edge touch technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of low touch accuracy and low density of optical network arrays, and achieve enhanced scanning accuracy and improved Touch precision, effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

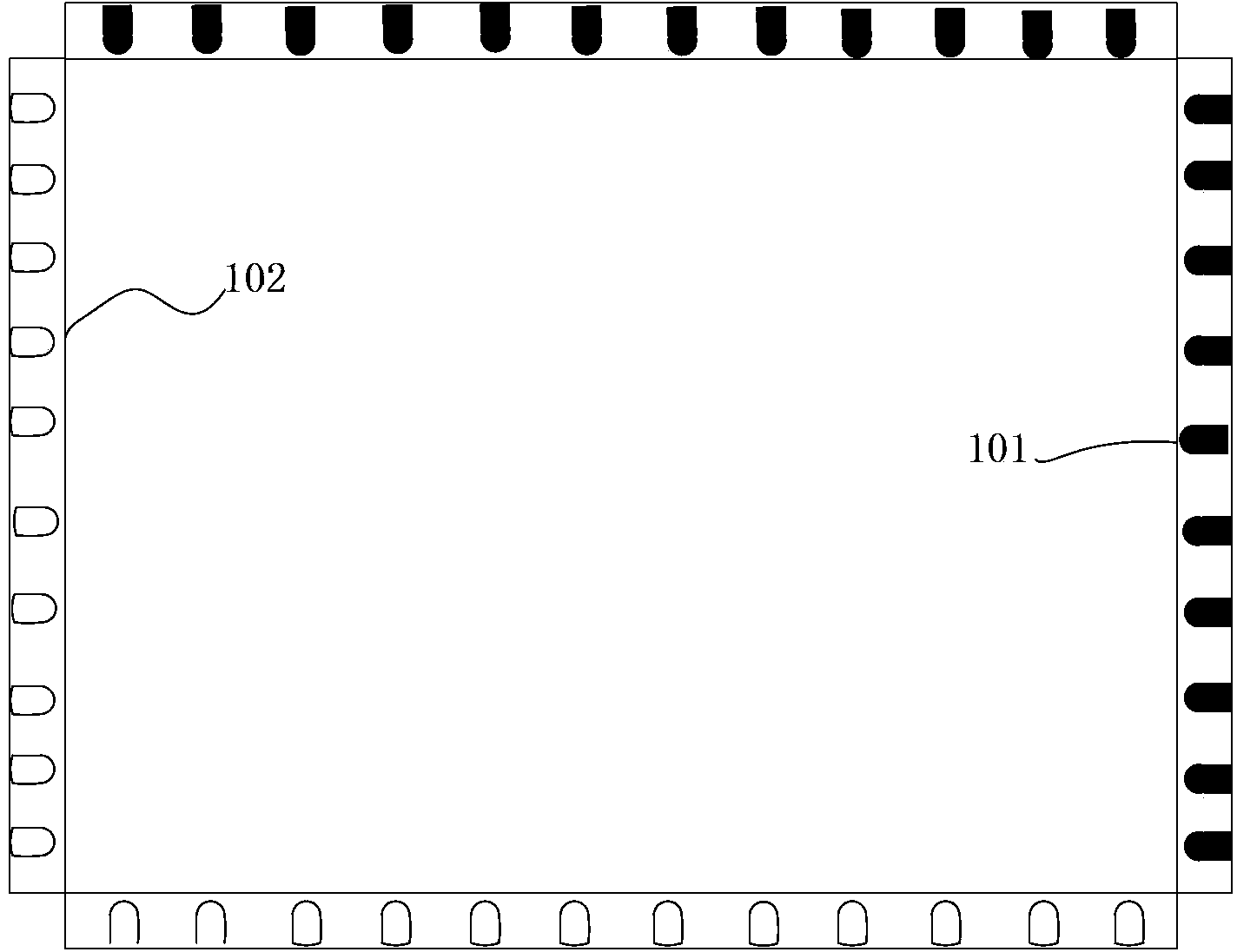

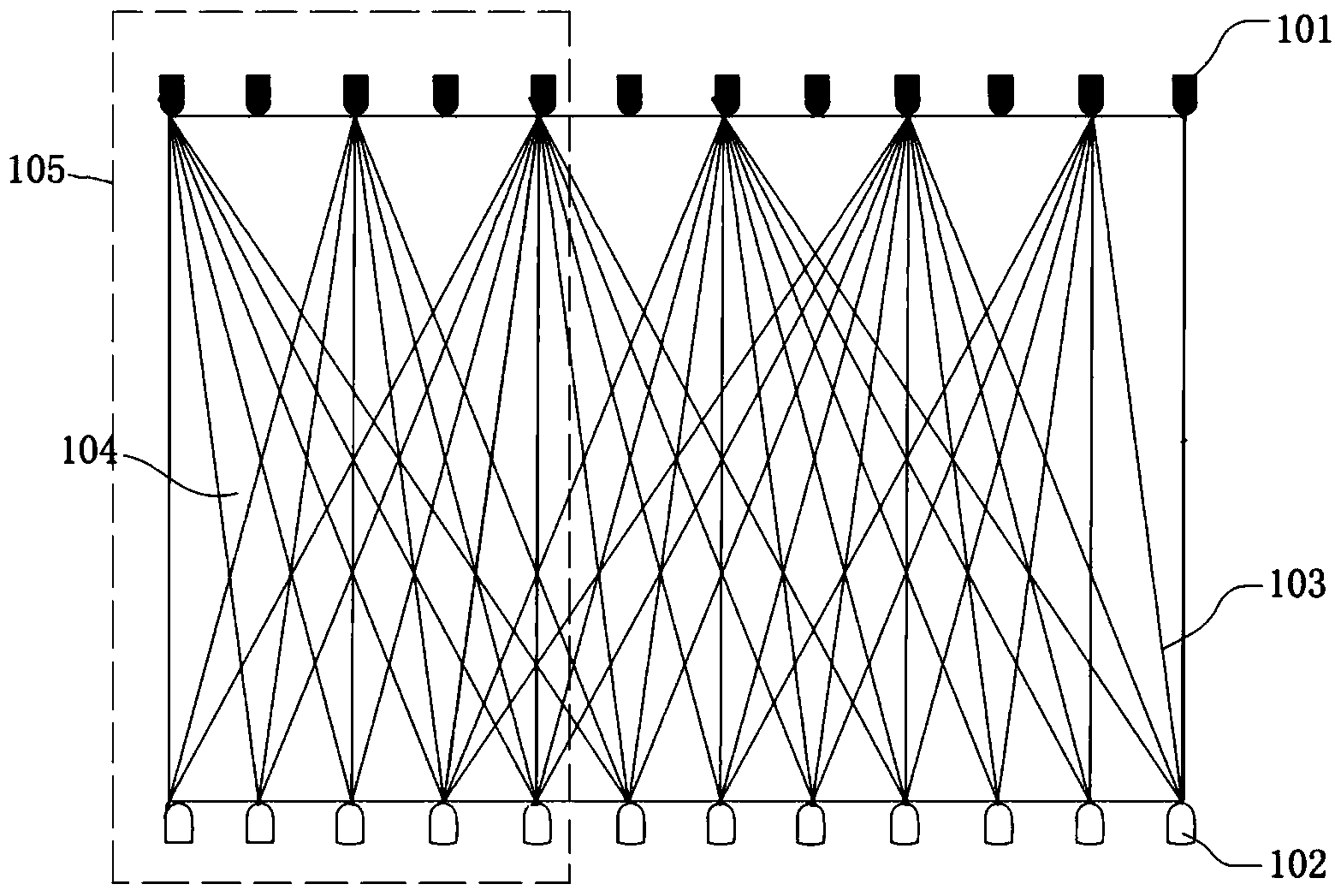

[0031] As an embodiment of the present invention, such as figure 2 As shown, the method for improving the edge touch accuracy of the infrared touch screen is to reduce the edge area of the infrared touch screen by increasing the density of the scanning light 103 in at least one edge area 105 of the infrared touch screen, so that the density of the scanning light 103 in the area near the frame of the infrared touch screen is increased. The area of the optical grid 104 in 105 reduces the size of the largest optical grid 104, improves the resolution of the edge area 105, improves the touch accuracy of the edge area 105, and achieves the purpose of enhancing the touch accuracy of the infrared touch screen. As shown in the figure, the edge area 105 is the area from the frame of the infrared touch screen to the nth infrared emitting tube 101 / infrared receiving tube 102, wherein n is a natural number and ( is the sign of rounding up), and N is the number of infrared receiving...

Embodiment 2

[0040] In this embodiment, a method different from that in Embodiment 1 is adopted to increase the density of the scanning light 103 in the edge region 105 .

[0041] As a specific implementation of this embodiment, the infrared emitting tube 101 and the infrared receiving tube 102 of each edge area 105 adopt a sequential scanning method.

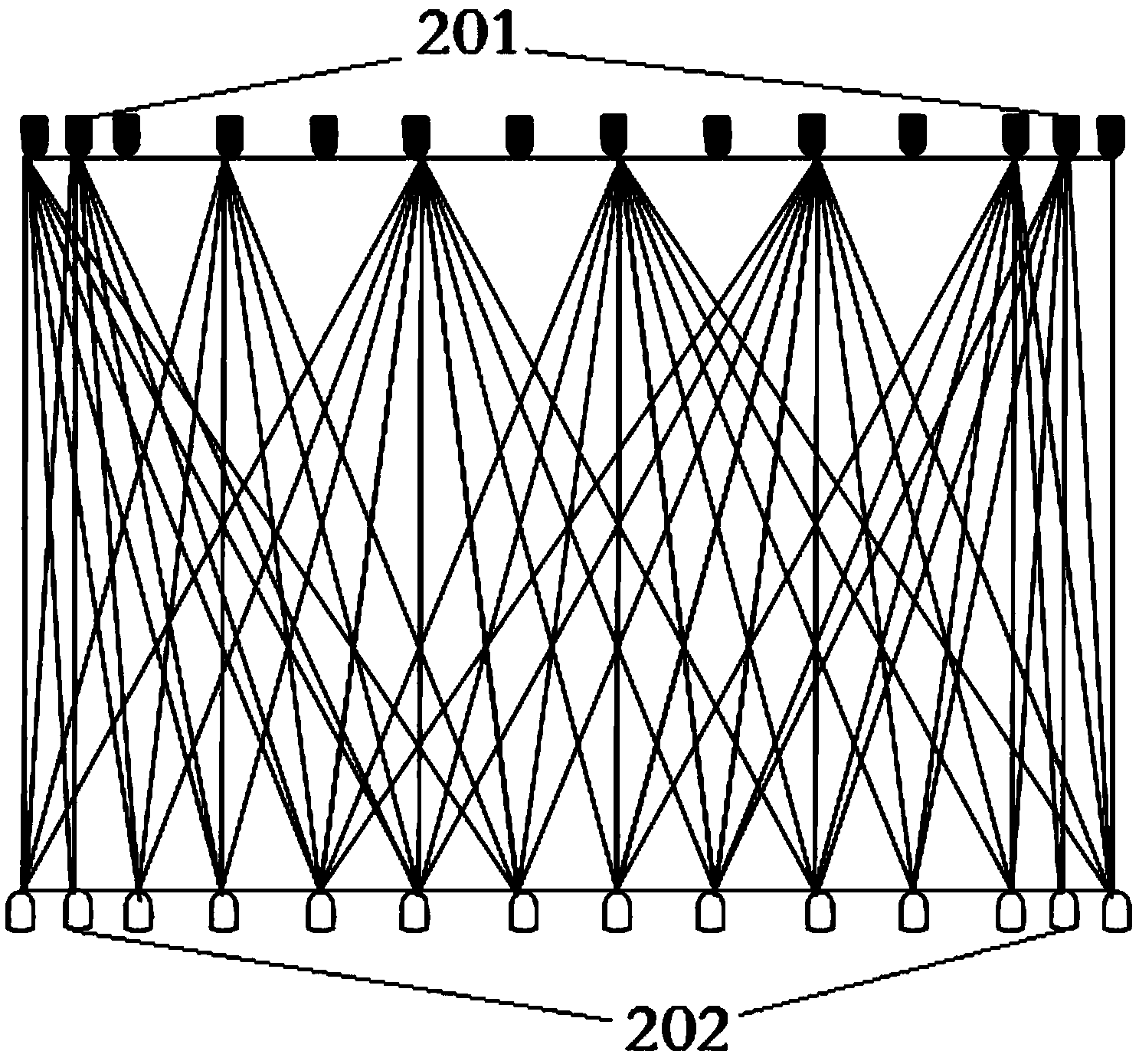

[0042] As another specific implementation of this embodiment, the density of the infrared emitting tube 101 and the infrared receiving tube 102 in the edge area 105 can be increased and the scanning mode of the infrared emitting tube 101 and the infrared receiving tube 102 in the edge area 105 can be changed simultaneously. achieve, such as Figure 6 As shown, the infrared emitting tube 101 , the additional infrared emitting tube 201 , the infrared receiving tube 102 and the additional infrared receiving tube 202 of each of the edge regions 105 adopt a sequential scanning method. through with figure 2 Compared with the method without pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com