Assembled parallel straight-through type sunlight heating curing kiln and installation method thereof

A curing kiln and straight-through technology, which is applied in the field of assembling parallel straight-through sunlight heating curing kilns, can solve the problems of large volume, untimely supply of prefabricated components, and high cost of prefabricated components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

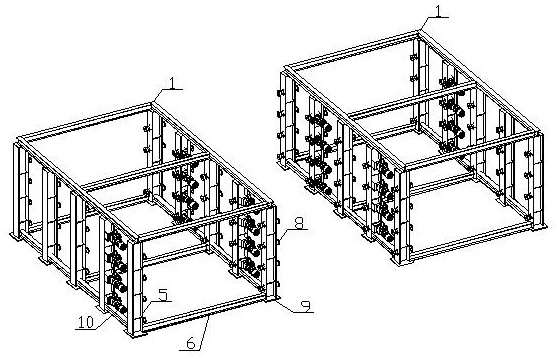

[0040] An assembled parallel straight-through sunlight heating and curing kiln, said assembled and parallel straight-through sunlight heating and curing kiln is assembled horizontally and / or vertically by the integrated section steel support unit 1 of N multi-layer stacked component production mold table;

[0041] The integrated profiled steel support unit of the multi-layer stacked member production mold table is a rectangular frame structure formed by a plurality of vertical steel supports 5 and a plurality of horizontal steel supports 6, each of the vertical steel supports Multi-layer cantilever guides are fixed along the height direction, and the cantilever guides with multiple vertical steel supports located on the same floor have the same height;

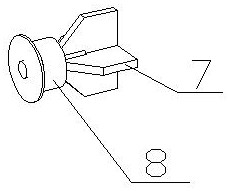

[0042] One or both sides of the vertical steel support are vertically fixed with at least one set of drive devices, and the drive devices on the vertical steel support are vertically connected to the vertical steel support in m...

Embodiment 2

[0044] According to the assembled parallel straight-through solar heating curing kiln described in Embodiment 1, when the integrated steel support units of N multi-layer stacked component production mold sets are assembled, the integrated type of horizontally adjacent two multi-layer stacked component production mold sets The steel support units are fixed by connecting steel supports 2, and 2N-1 storage or transfer passages are formed between the integrated steel support units of two adjacent multi-layer stacked component production mold tables in the transverse direction.

Embodiment 3

[0046] According to the assembled parallel straight-through solar heating curing kiln described in embodiment 1 or 2, said N is a positive integer greater than or equal to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com