Patents

Literature

32results about How to "Eliminate quality risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

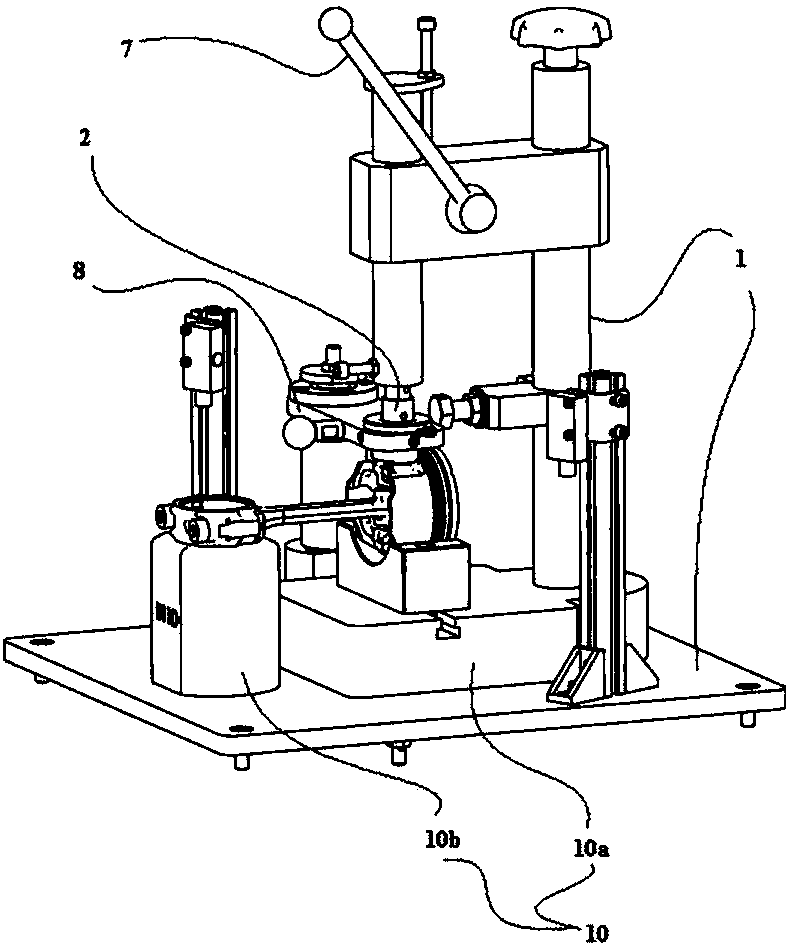

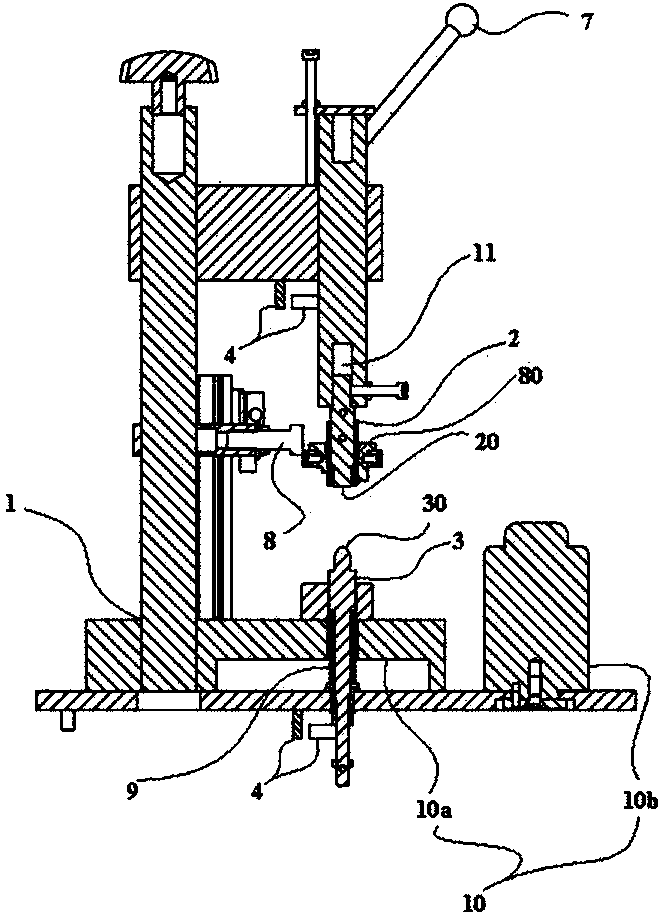

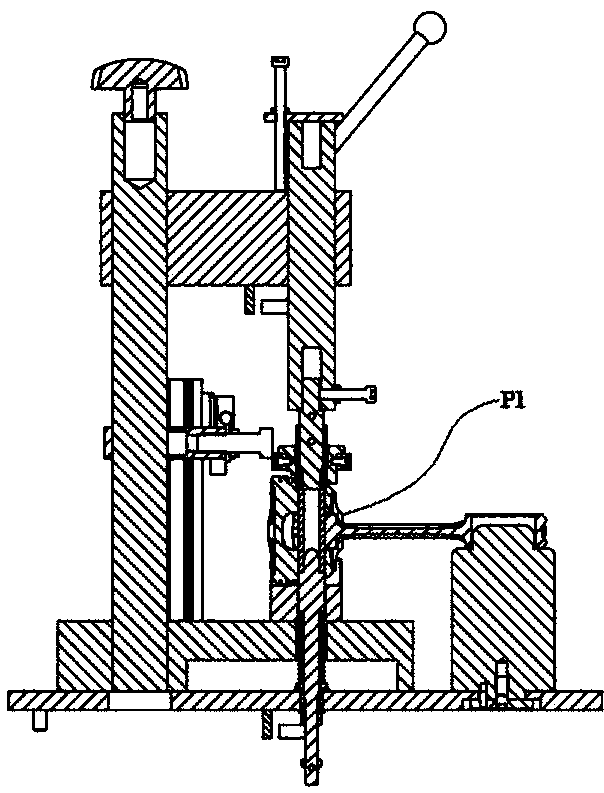

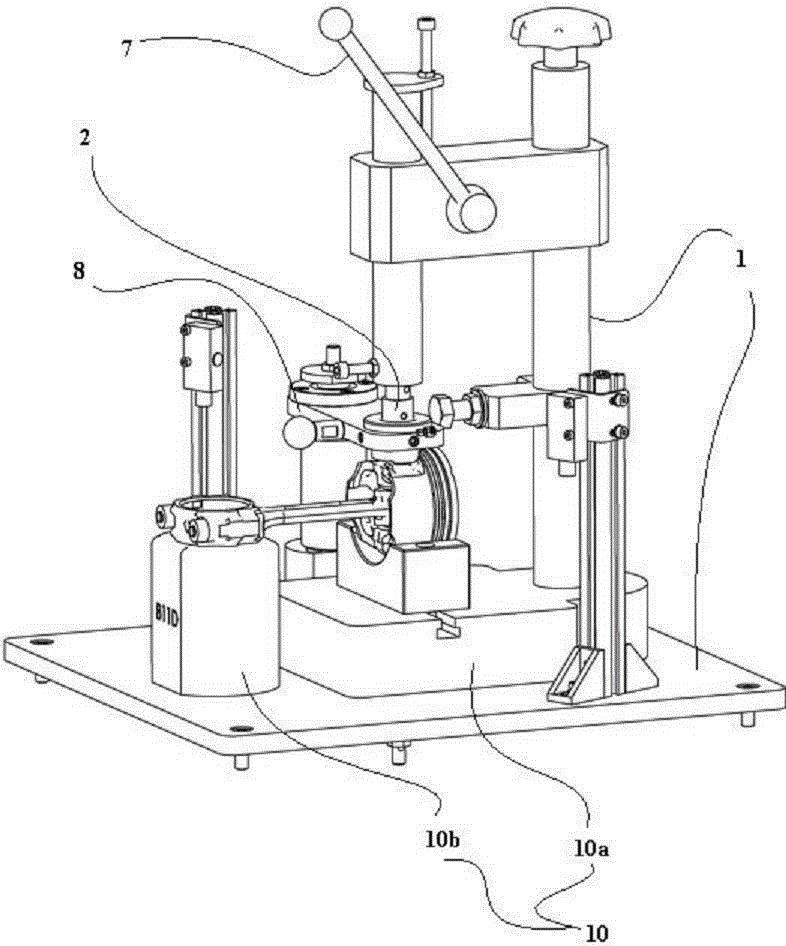

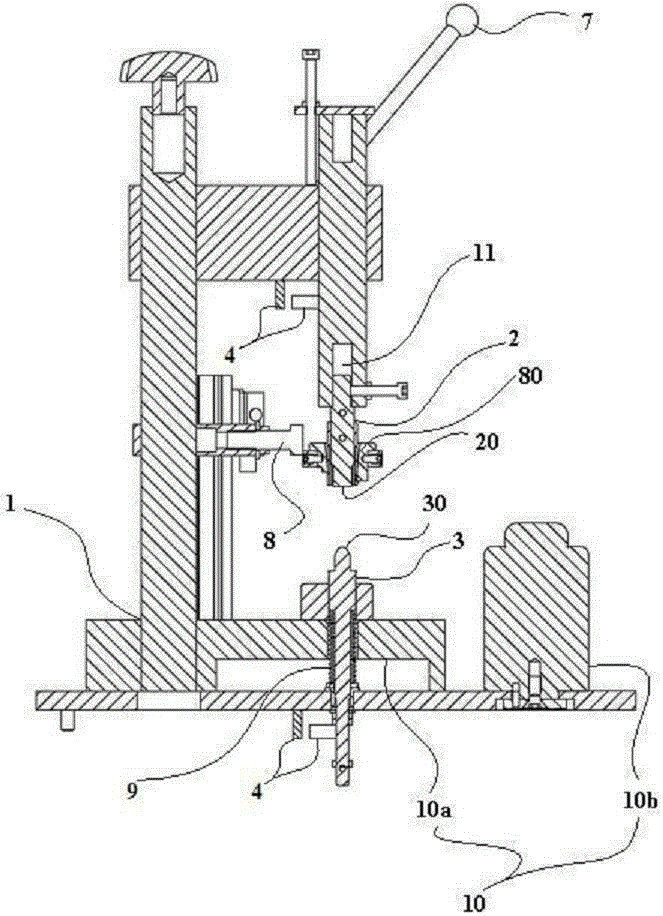

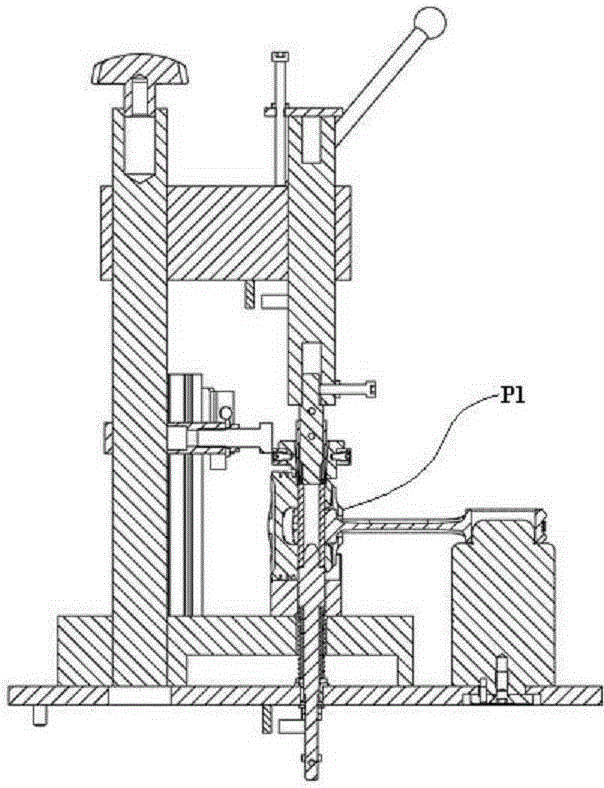

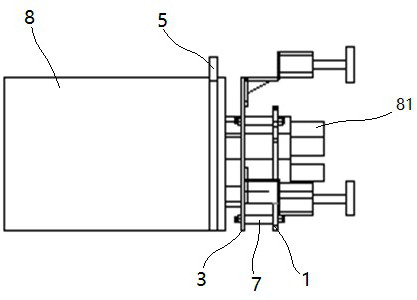

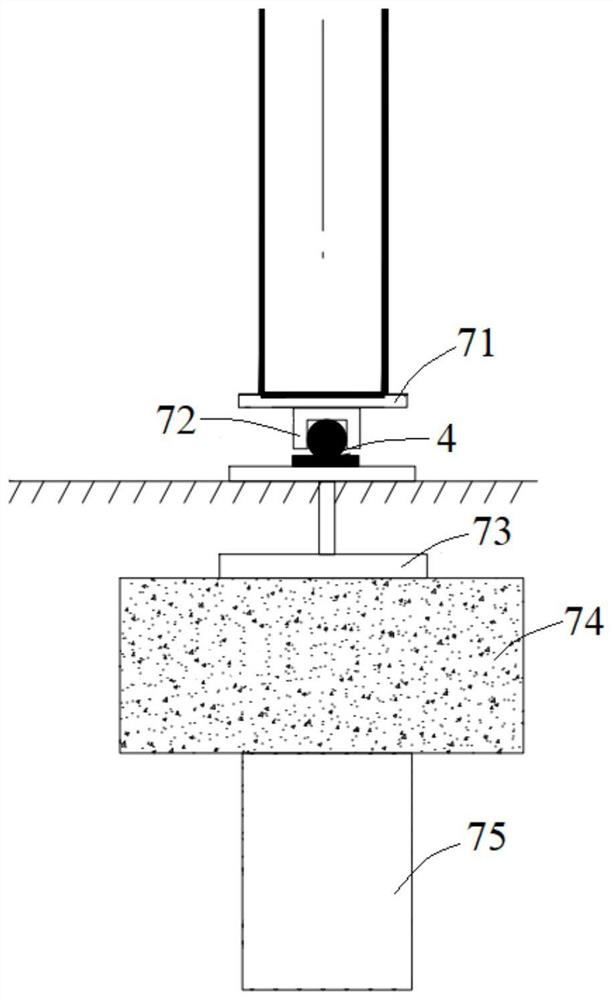

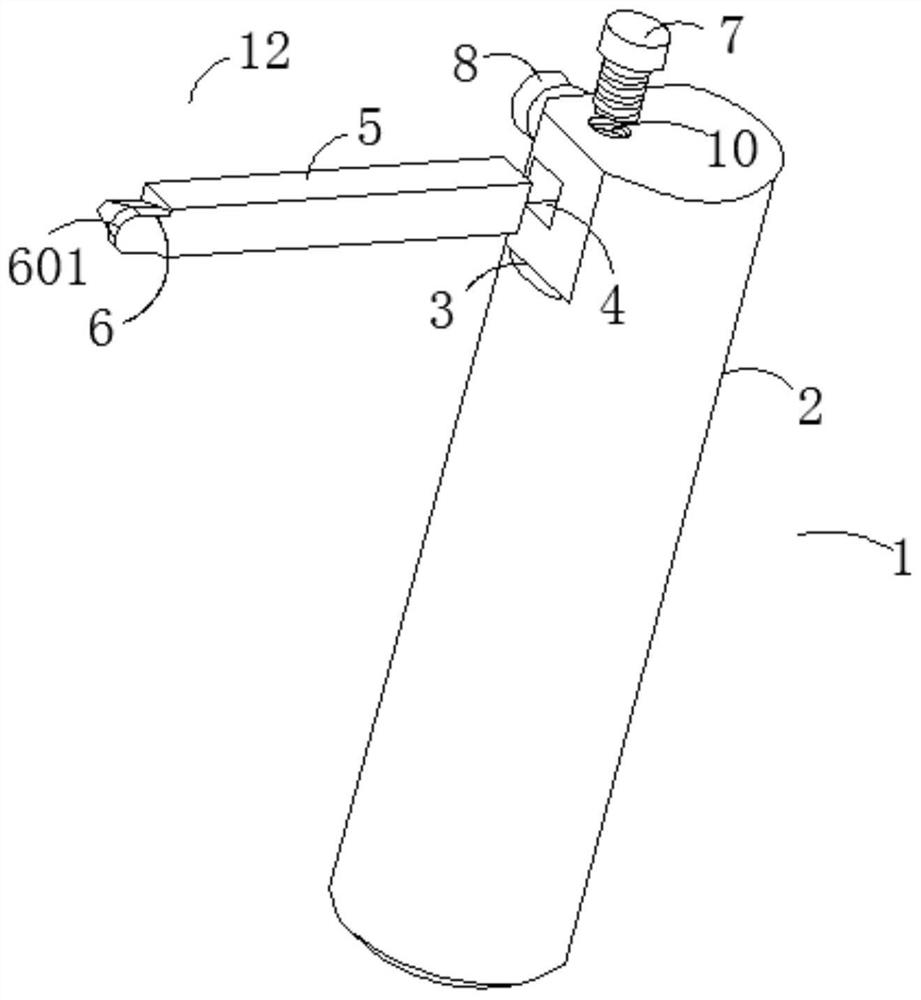

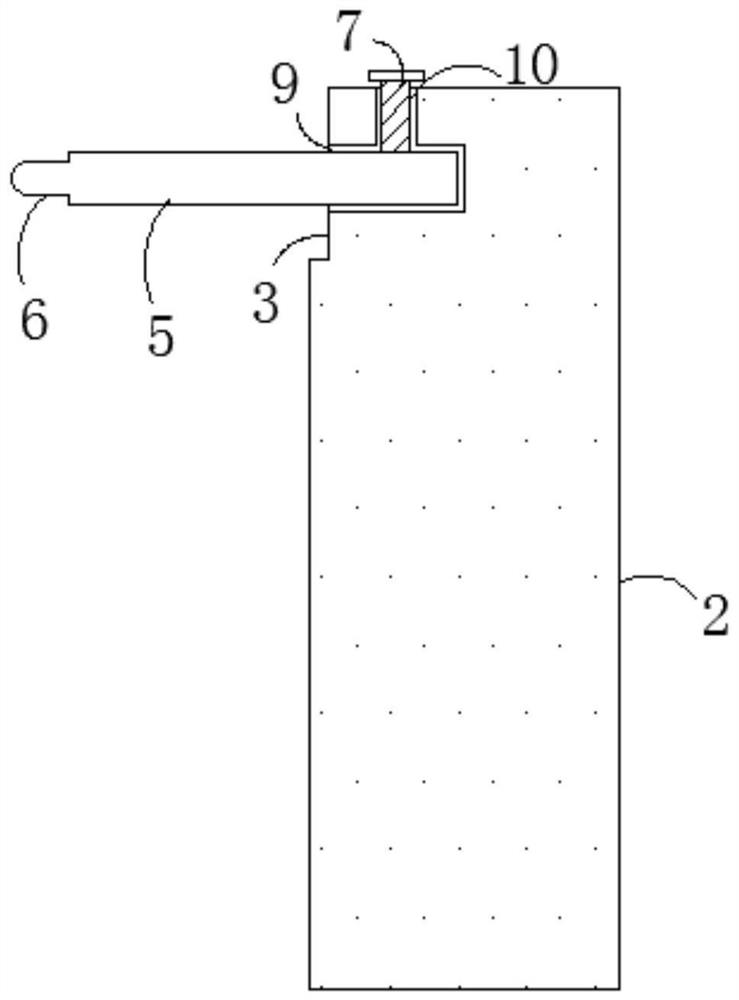

Engine piston pin snap ring press fitting tool

The invention provides an engine piston pin snap ring press fitting tool. The engine piston pin snap ring pressing fitting tool comprises a support and a press rod, wherein the press rod is fixed to the support and can be controlled to stretch, the support comprises a supporting seat, the position of the press rod corresponds to that of the supporting seat, an upper boss is arranged on the middle section of the press rod, and a displacement sensor used for detecting the displacement of the press rod is fixedly arranged beside the press rod and on the support. Through the adoption of the technical scheme, if a snap ring at the upper end of a piston is not assembled or the assembling of the snap ring is not in place, the displacement sensor at the upper end of the press rod senses whether the snap ring at the upper end of the piston is neglected or not or whether the assembling of the snap ring is in place or not through the moving of a press head of the press rod, the problems of error assembling and neglected assembling can be found out in time, the production rhythm can be improved, and manpower can be saved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

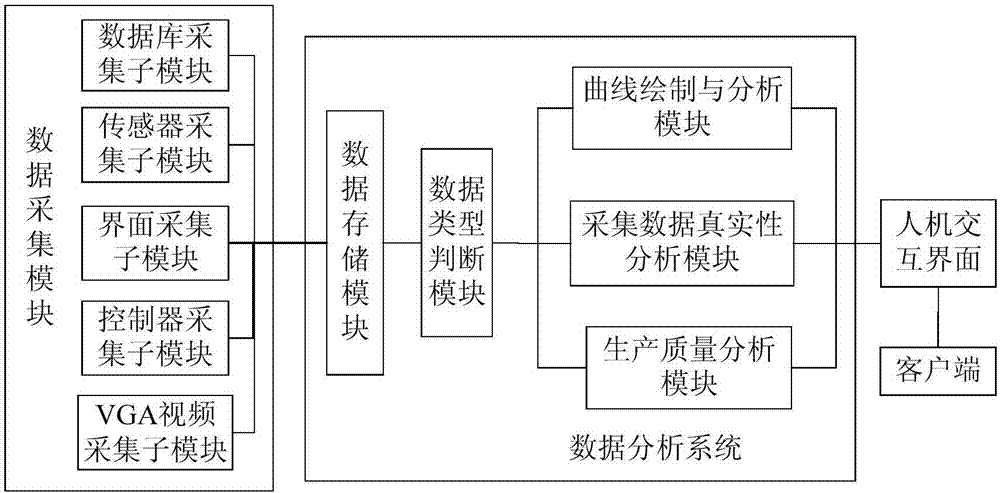

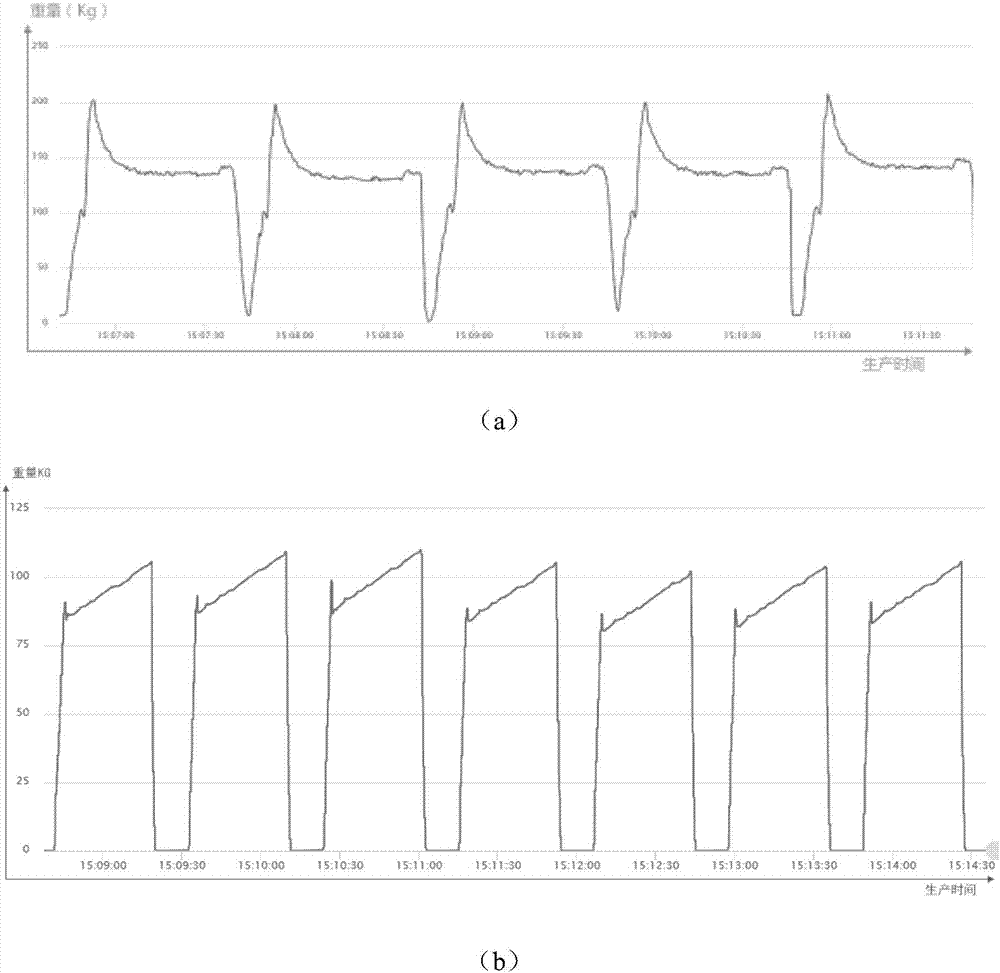

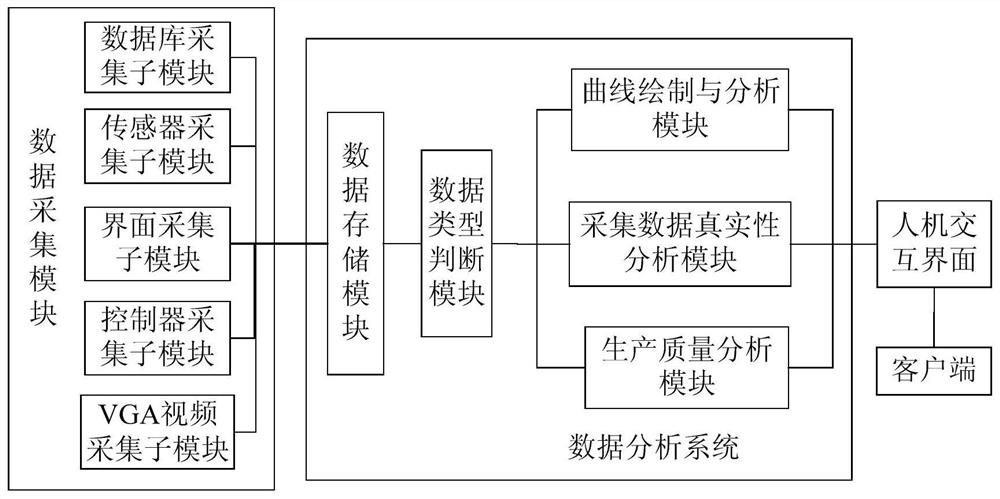

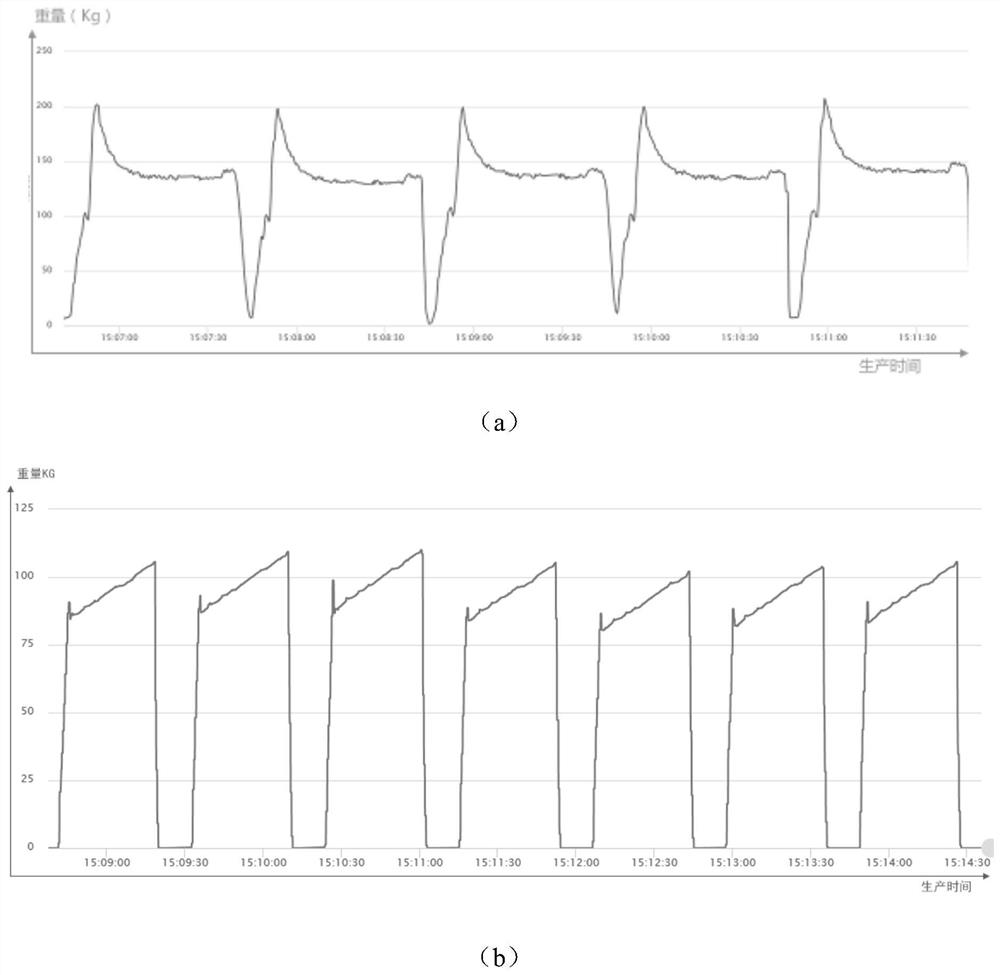

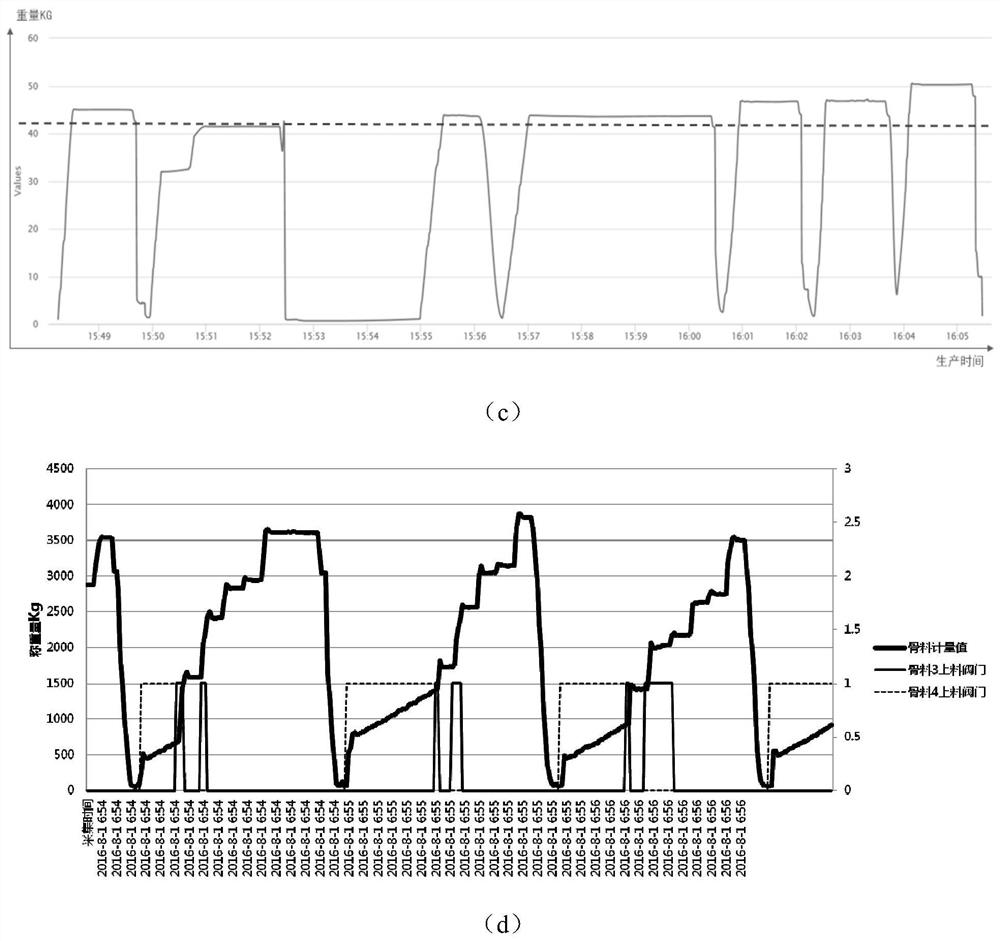

Stirring device production quality monitoring system based on multiple data sources and method

InactiveCN106952033AMonitor Dynamic Weighing AccuracyRealize intelligent early warningResourcesManufacturing computing systemsData authenticityData acquisition

The invention provides a stirring device production quality monitoring system based on multiple data sources and a method, and relates to the technical field of stirring device production quality monitoring. A data acquisition module is used for acquiring production data; a data storage module, a data type judgment module, a curve drawing and analysis module, an acquired data authenticity analysis module and a production quality analysis module in a data analysis system are used for carrying out deep analysis on the production data and monitoring operation states of stirring devices, authenticity of the acquired data and whether the production quality meets a regulated requirement. A human-machine interaction interface displays monitoring results. According to the invention, dynamic weighing accuracy of stirring devices in a blending process can be effectively monitored; it is achieved that an intelligent early warning is given out for fault stirring devices, and the operation states of the stirring devices, whether the acquired data is true and accurate and whether the production quality meets a regulated requirement are monitored, so quality risks are effectively eliminated, and powerful technical support is provided for stabilized soil / concrete / mixture quality monitoring of a construction project.

Owner:沈阳新一代信息技术有限公司

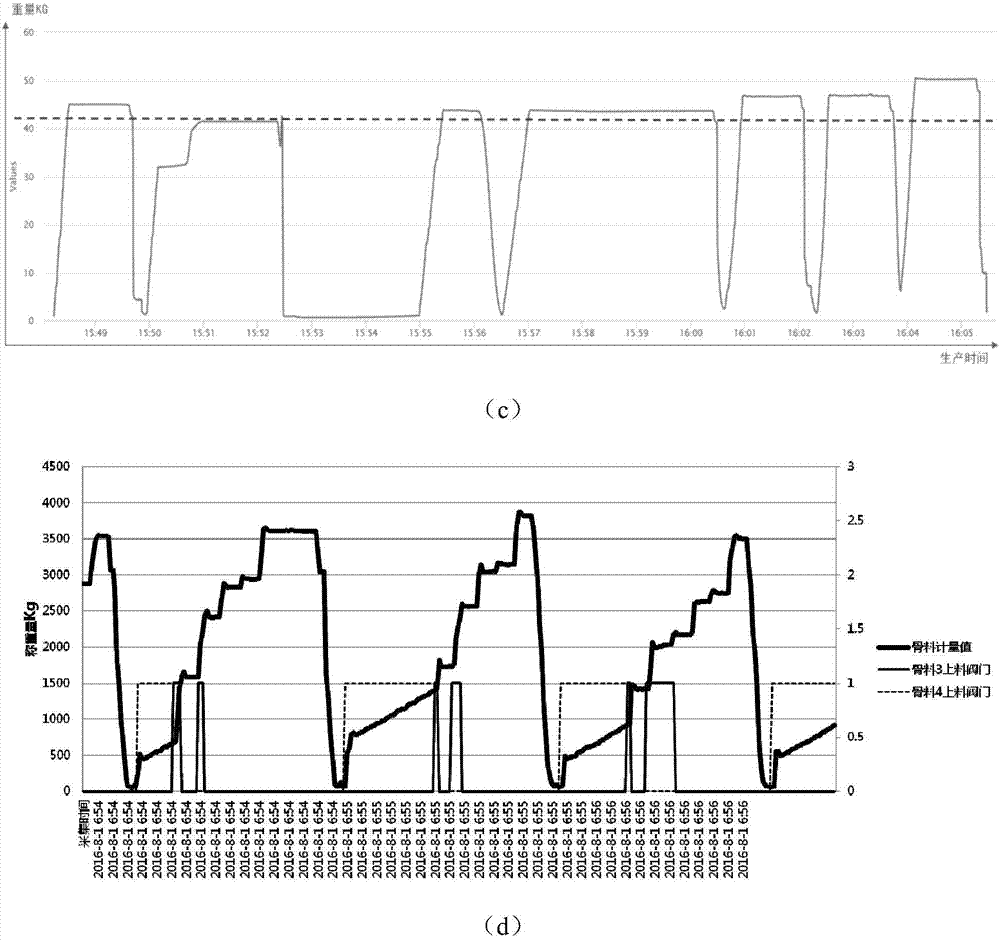

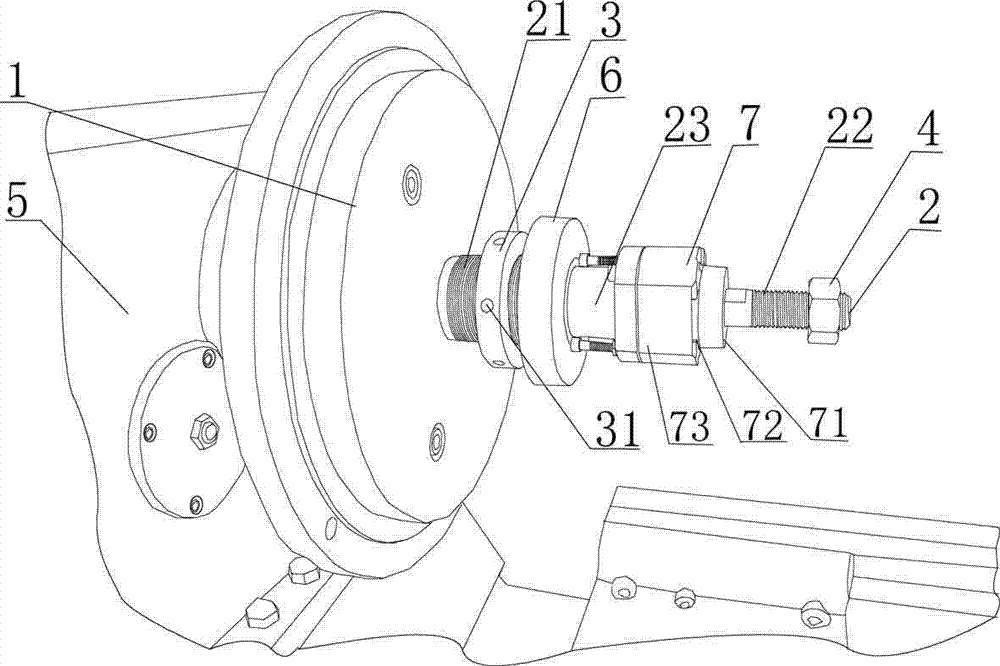

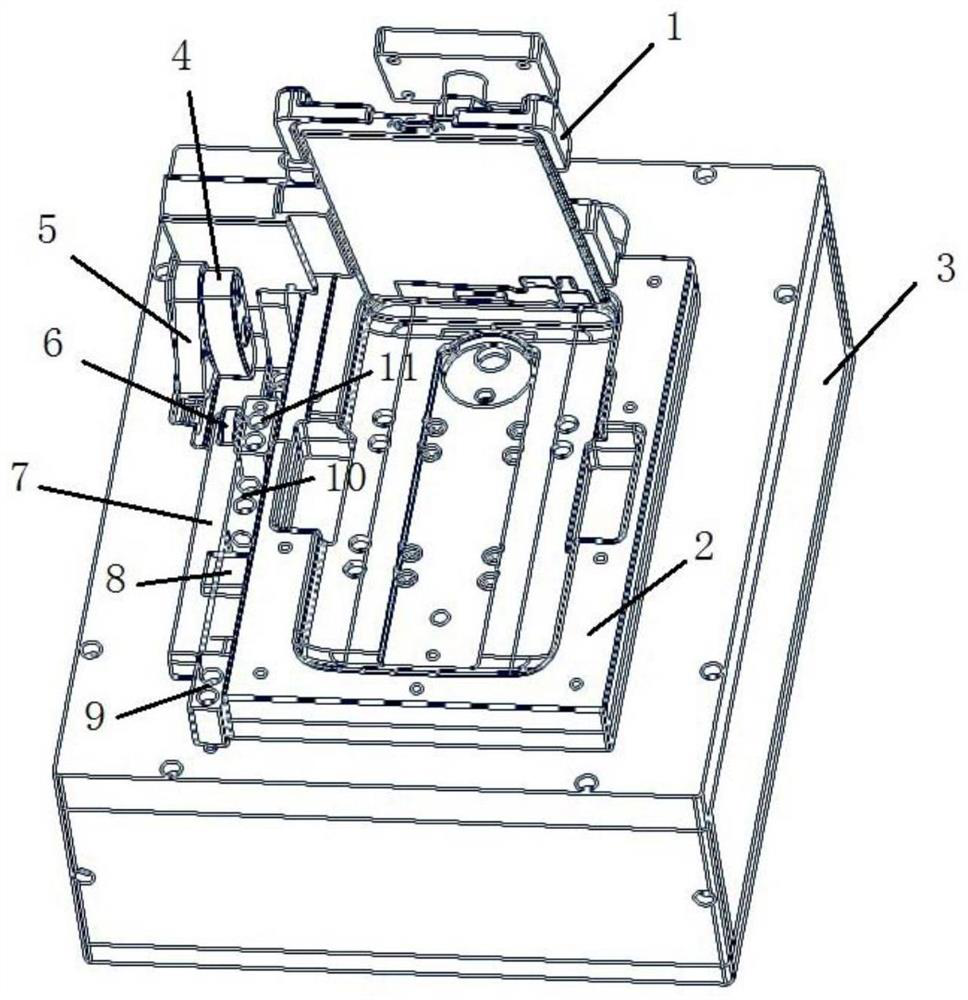

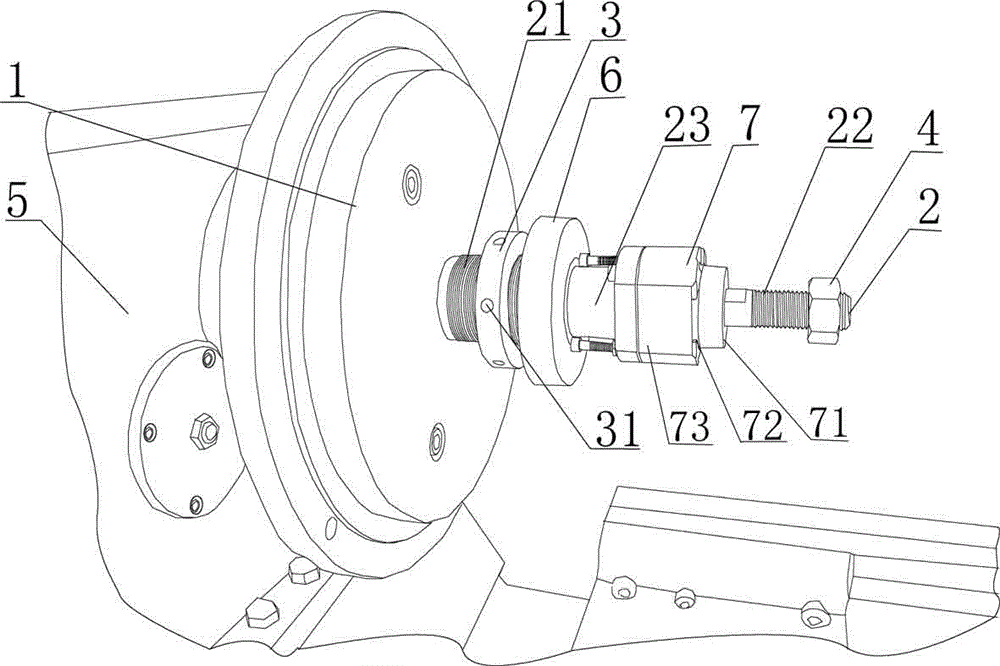

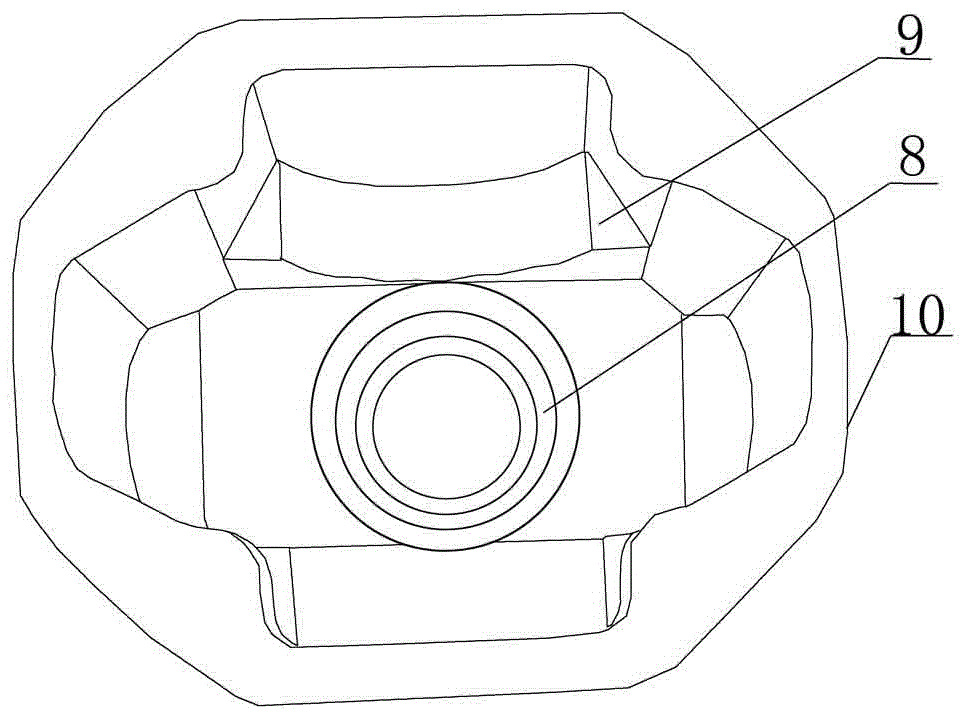

Rapid-positioning correction-free clamp

ActiveCN103878618APrecise positioningImprove pass ratePositioning apparatusMetal-working holdersScrew threadMachining

The invention relates to the field of rapid-positioning correction-free clamps. The rapid-positioning correction-free clamp comprises a rotary wheel, a rotary shaft, a locking rotary disc, a positioning orientation block and a pressing disc, wherein the back surface of the rotary wheel is fixedly installed on a common lathe rotary mechanism, the rotary shaft is installed in the center of the front surface of the rotary wheel and is divided into three sections, the section near the rotary wheel is a large cylindrical rotary shaft, the section far away from the rotary wheel is a small cylindrical rotary wheel, the middle section is a middle cylindrical rotary shaft, the large cylindrical rotary shaft is provided with a thread, and the locking rotary wheel is screwed at the thread on the large cylindrical rotary shaft. The positioning orientation block comprises a rear central positioning block and a front central positioning block, wherein the rear central positioning block is installed on the large cylindrical rotary shaft at the outer side of the locking rotary disc in a sleeved mode, a low positioning block is installed at the front end of the middle cylindrical rotary shaft of the rotary shaft, the small cylindrical rotary shaft is provided with a thread, and the pressing disc is installed on the small cylindrical rotary shaft. The rapid-positioning correction-free clamp has the advantages of being simple in design, convenient and rapid to use and capable of accurately positioning, centering, clamping and safely and reliably machining a medium-load pump shell body, largely improving production and machining efficiency and pass percentage of machined products, and saving time and labor.

Owner:江苏力源金河铸造有限公司

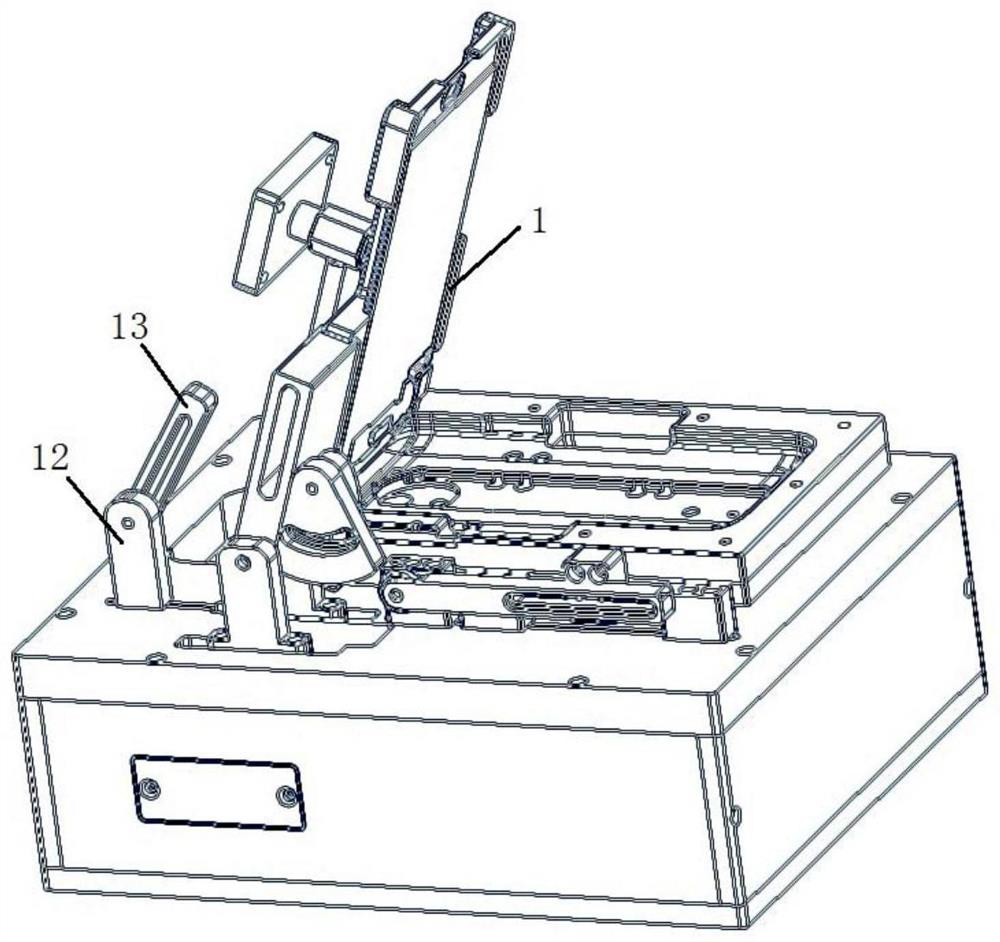

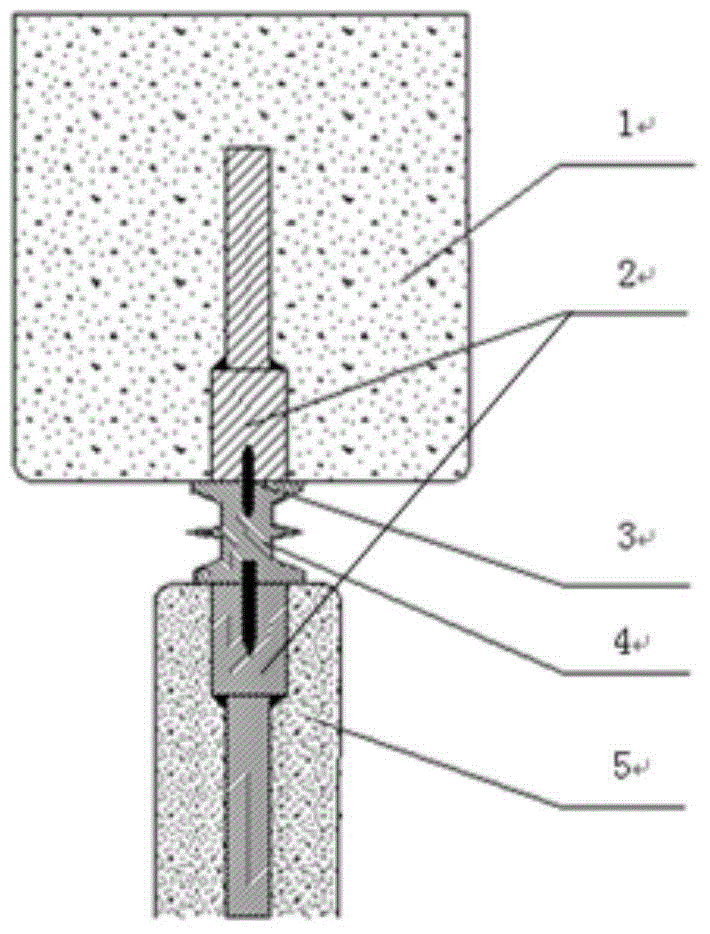

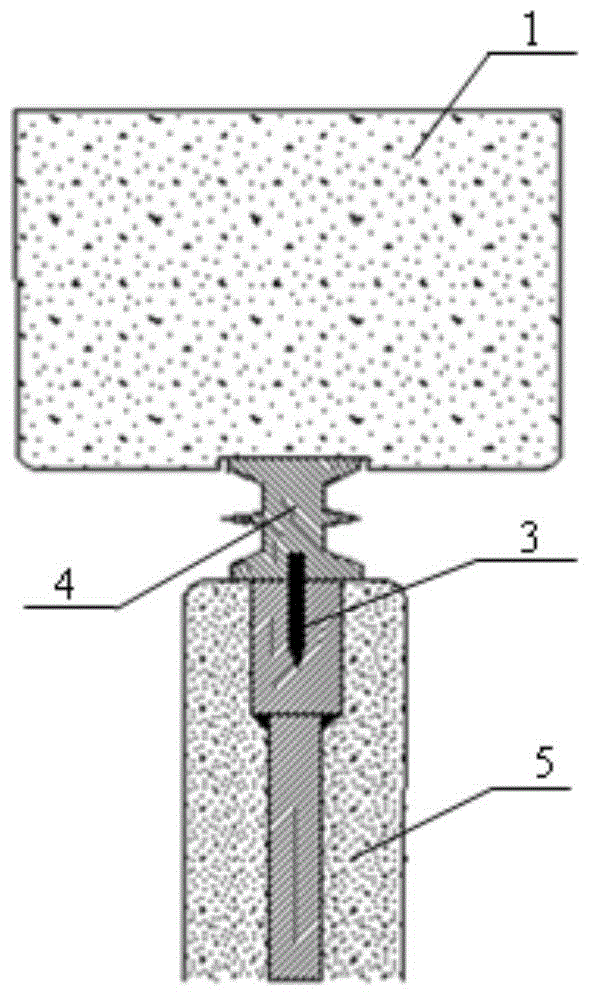

Press-fitting tooling for engine piston pin snap ring

The invention provides an engine piston pin snap ring press fitting tool. The engine piston pin snap ring pressing fitting tool comprises a support and a press rod, wherein the press rod is fixed to the support and can be controlled to stretch, the support comprises a supporting seat, the position of the press rod corresponds to that of the supporting seat, an upper boss is arranged on the middle section of the press rod, and a displacement sensor used for detecting the displacement of the press rod is fixedly arranged beside the press rod and on the support. Through the adoption of the technical scheme, if a snap ring at the upper end of a piston is not assembled or the assembling of the snap ring is not in place, the displacement sensor at the upper end of the press rod senses whether the snap ring at the upper end of the piston is neglected or not or whether the assembling of the snap ring is in place or not through the moving of a press head of the press rod, the problems of error assembling and neglected assembling can be found out in time, the production rhythm can be improved, and manpower can be saved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

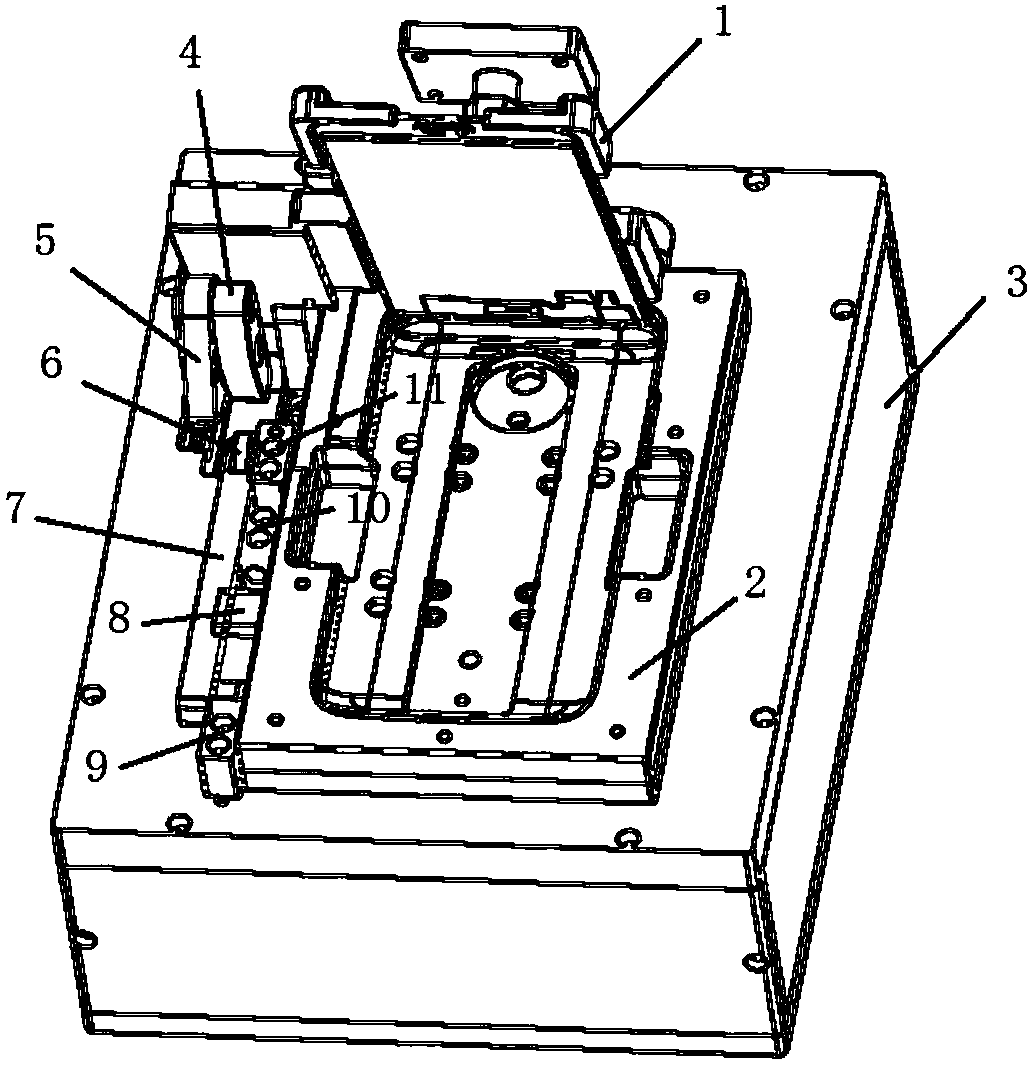

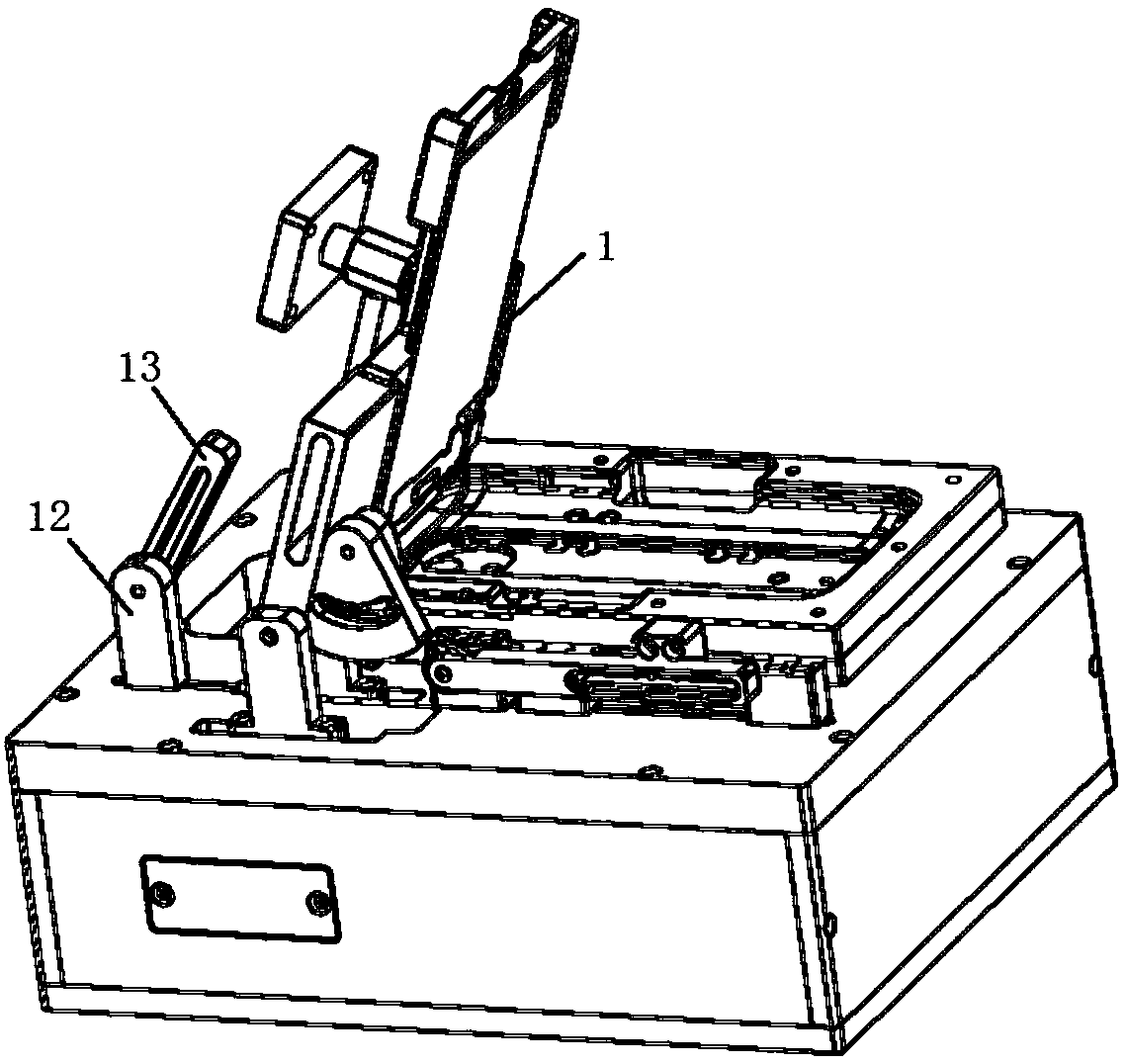

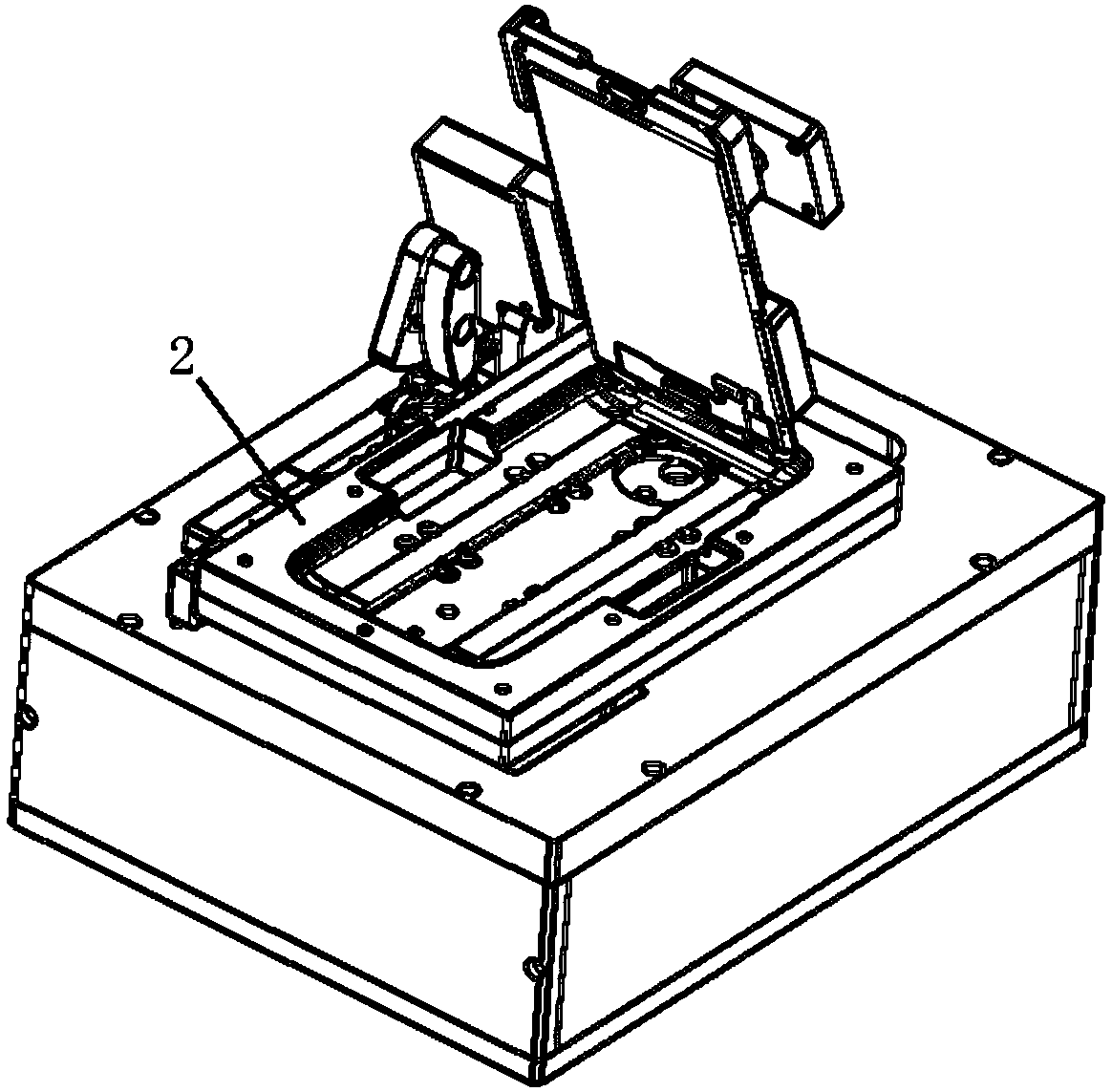

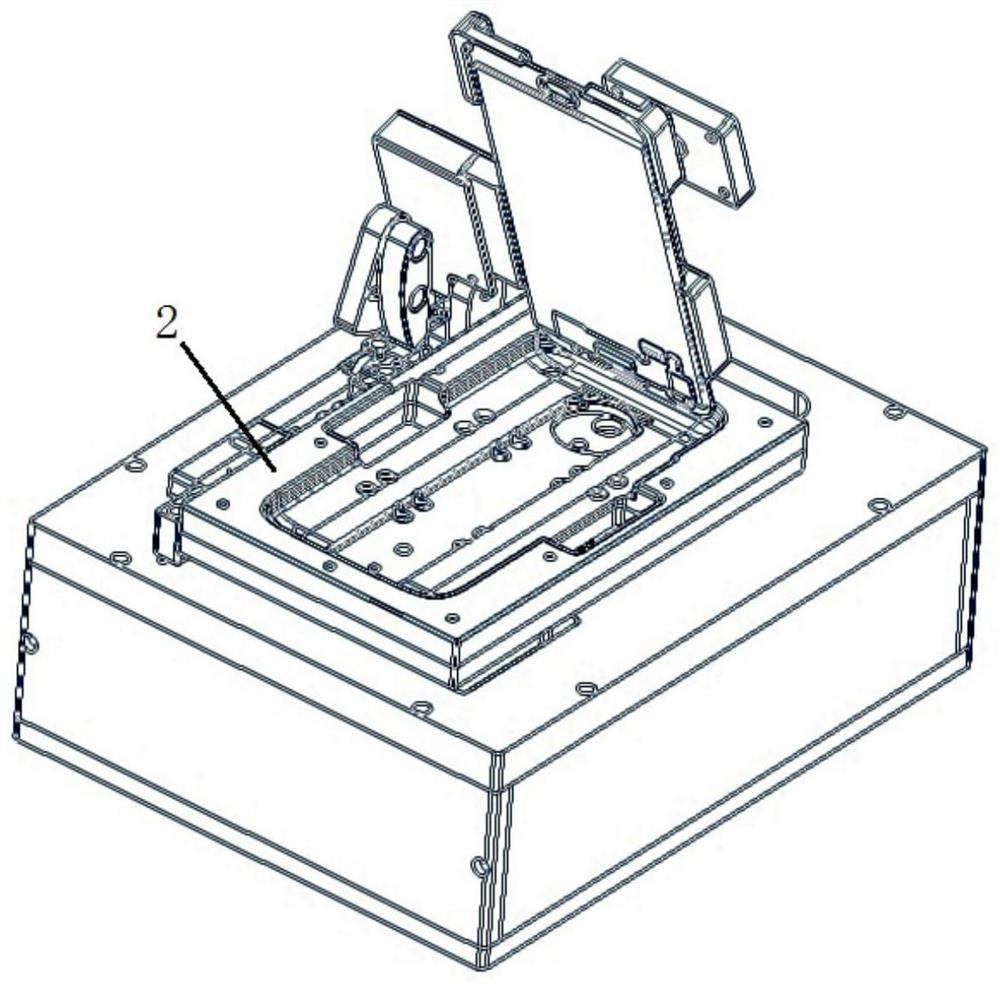

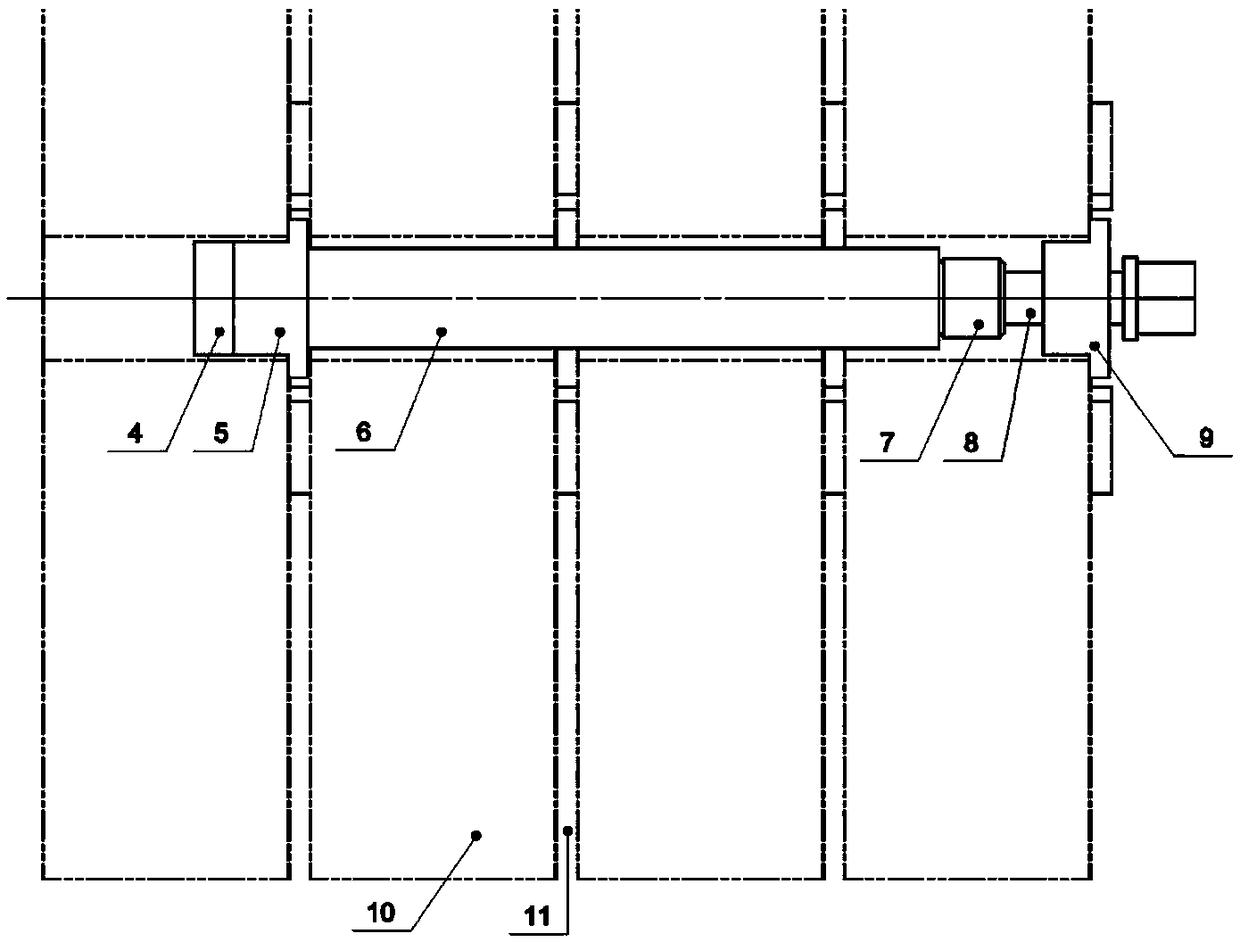

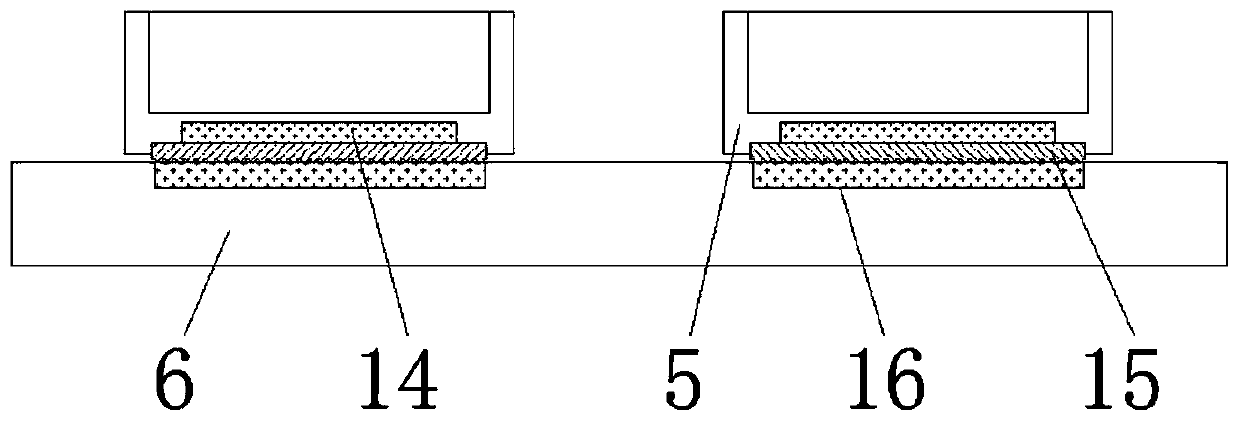

Adjustable device for matched installation of display module and mobile terminal base

ActiveCN109551407AImprove consistencyGuarantee product qualityMaterial gluingWork holdersEngineeringComputer terminal

The invention discloses an adjustable device for matched installation of a display module and a mobile terminal base. The device comprises an LCM module fixing device, a front shell assembly fixing device, a negative pressure pneumatic adsorption device, a distance adjusting transmission device and a base platform device. The LCM module fixing device is rotatably connected with the base platform device. The negative pressure pneumatic adsorption device is mounted on the LCM module fixing device, for adsorbing the LCM module on the LCM module fixing device. The distance adjusting transmission device is mounted on the base platform device. When the LCM module fixing device drives the LCM module to press down, the front shell assembly fixing device is driven by the distance adjusting transmission device to move forward, so that a FPC just matches when the LCM module and the front shell assembly are installed, so as to prevent the FPC from being too short and broken by strong force pulling.

Owner:SHENZHEN WENYAO ELECTRONICS TECH CO LTD

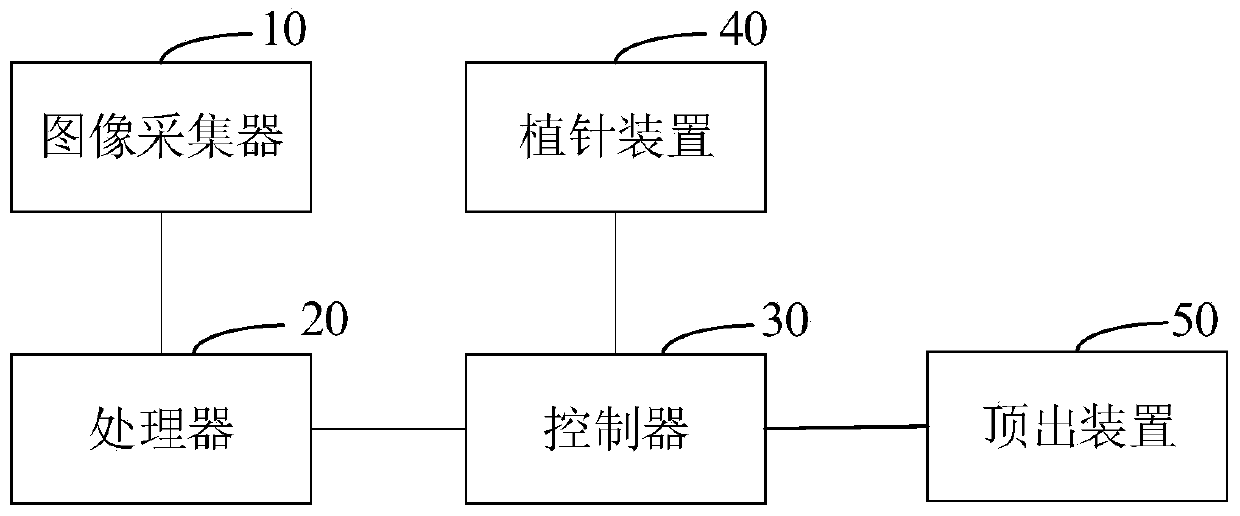

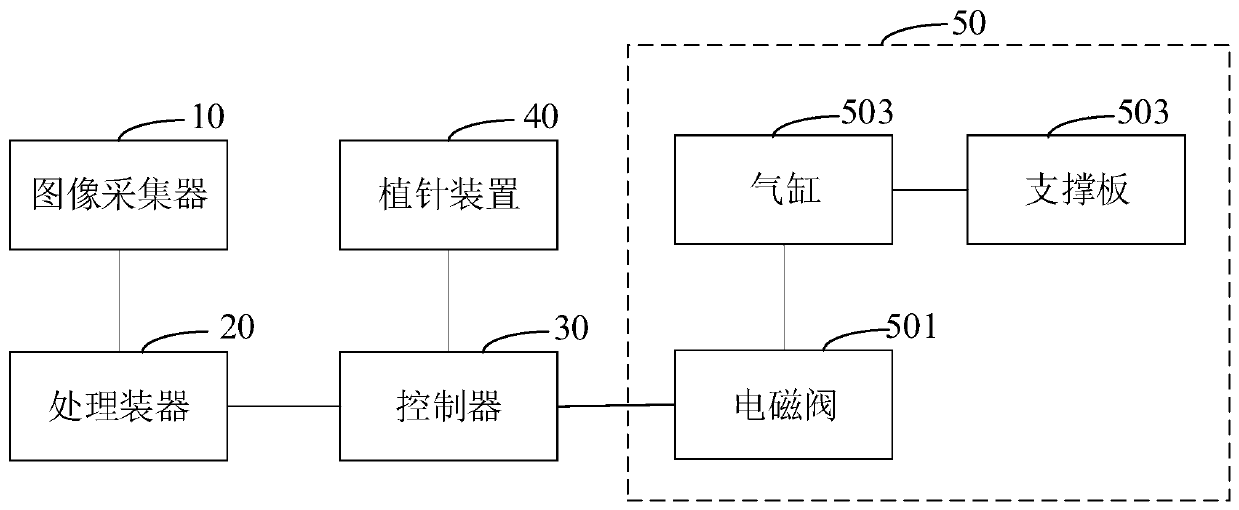

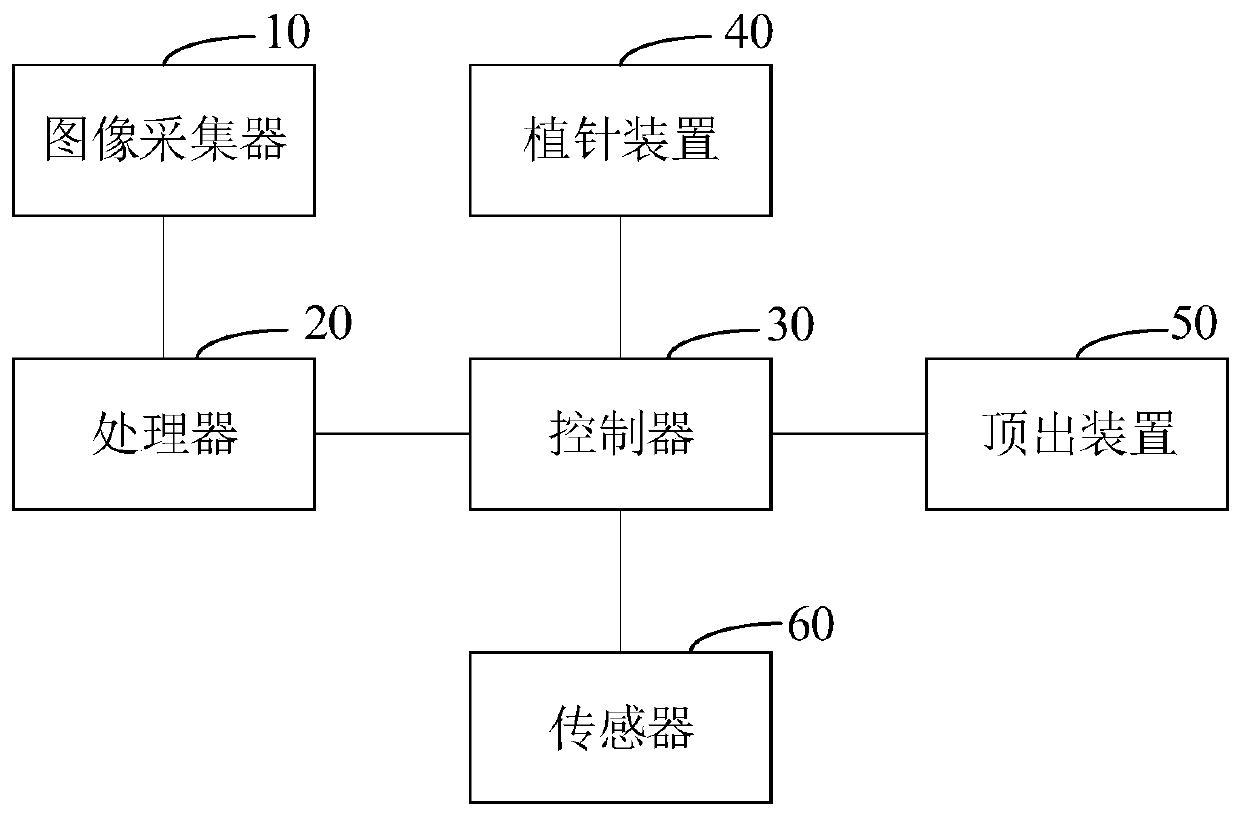

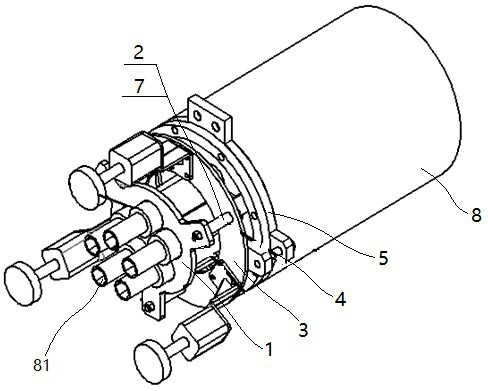

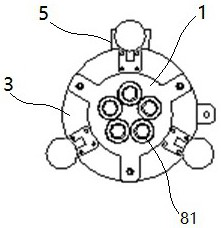

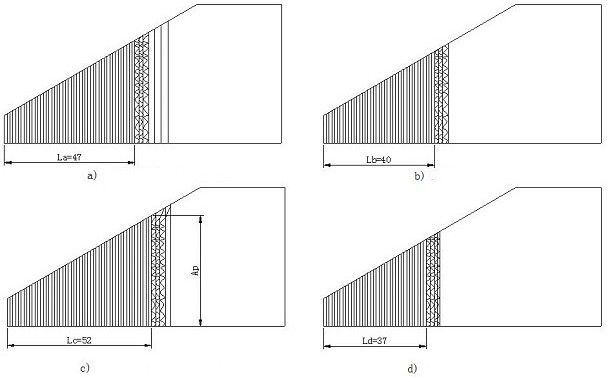

Ejector pin arrangement equipment, method, and device

InactiveCN110461139AEliminate quality risksShorten the timeElectrical componentsImplanted deviceEngineering

This application relates to ejector pin arrangement equipment, method, and device. The ejector pin arrangement equipment includes an image acquisition device, a processor, a controller, a pin implanting device and an ejection device, wherein the image acquisition device is connected with the processor; the controller is connected with the processor, the pin implanting device and the ejection device respectively; the image acquisition device is used for performing image acquisition on a PCB at a board stopping position on a conveying belt and transmitting the acquired image information to the processor; the processor analyzes the image information to obtain a target position, and the target position is transmitted to the controller; the controller indicates the pin implanting device to place the ejector pin at the corresponding position on the ejection device according to the target position; and after the pin implanting device is detected to complete ejector pin placement, the controller indicates the ejection device to act until the ejector pin contacts the PCB. Through the ejector pin arrangement equipment provided in the invention, the ejector pin arrangement position can be accurately positioned, the actual of manually arranging an ejector pin is replaced, and the overall work efficiency is improved.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

Application of pressure transmitter on gluing robot system

InactiveCN110479550AEliminate quality risksLow input costLiquid surface applicatorsCoatingsRobotic systemsEngineering

The invention discloses an application of a pressure transmitter on a gluing robot system. The application is characterized in that a pressure sensor is additionally arranged on the position, close toa rubber gun end, of a rubber pipe to detect the pressure in the rubber pipe, the pressure signal is transmitted to a robot, the robot system performs logic judgment through a emitted glue gun opening / closing signal and the pressure value feeding back to the robot through the additionally arranged pressure sensor, and judges whether a glue gun is correctly opened / closed according to the control signal of the robot to carry out gluing. According to the technical scheme, gluing equipment is improved, the defects that an alarm cannot be given when a gluing machine which is not provided with a quantitative system breaks down and cannot stop the operation of the gluing equipment through the interlocking signals are overcome, under the condition that the gluing equipment is not provided with the quantitative system, the existing technology and equipment are adopted, through the design of careful selection and installation positions and the reasonable design of the judgment logic on the robot program, and the leakage-coating accident of the gluing machine is effectively avoided.

Owner:HANTENG AUTOMOBILE CO LTD

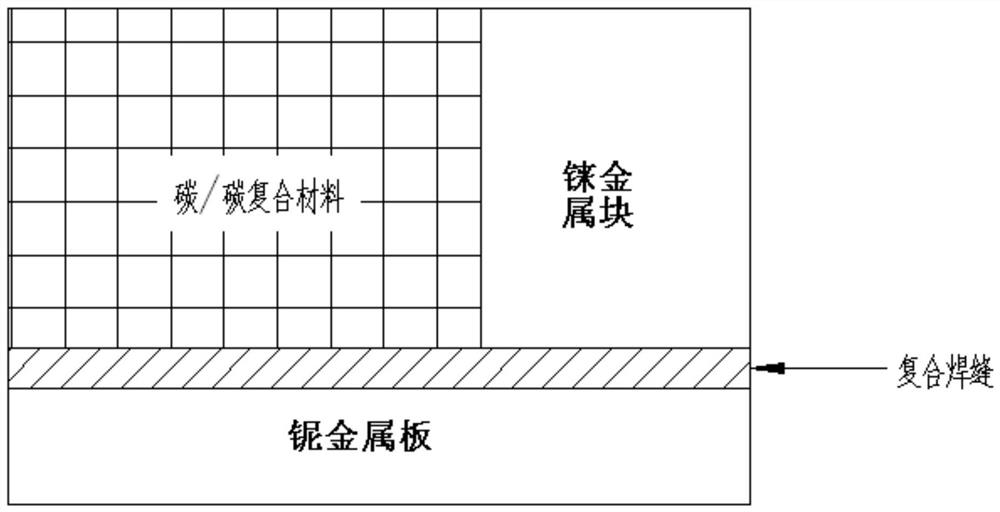

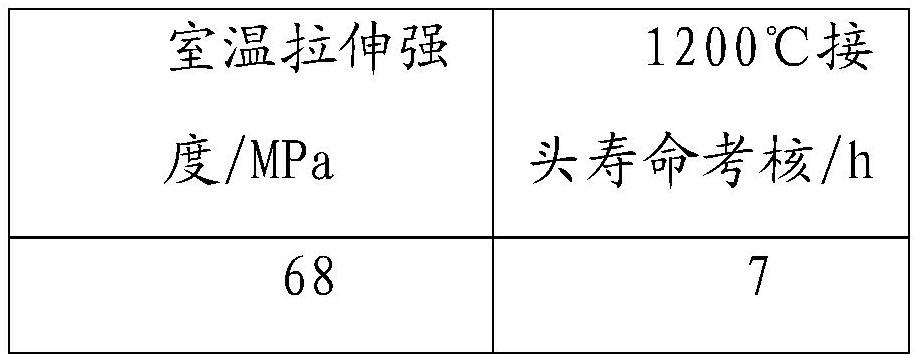

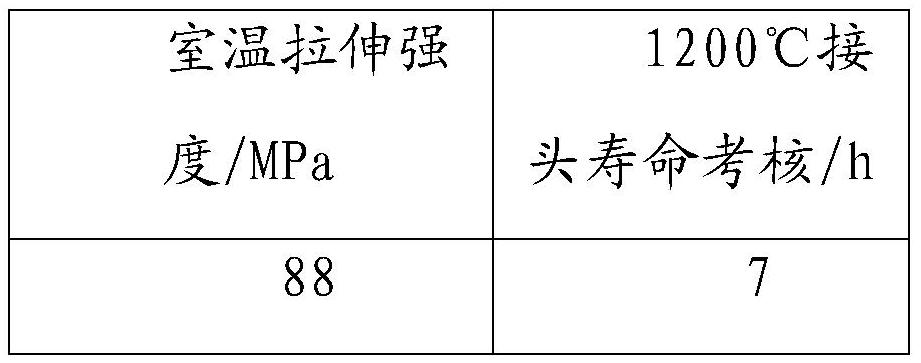

A brazing connection method of rhenium-carbon/carbon composite material and niobium

ActiveCN110539048BImprove high temperature mechanical propertiesGood miscibilityWelding/cutting media/materialsWelding/soldering/cutting articlesCarbon compositesRhenium

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

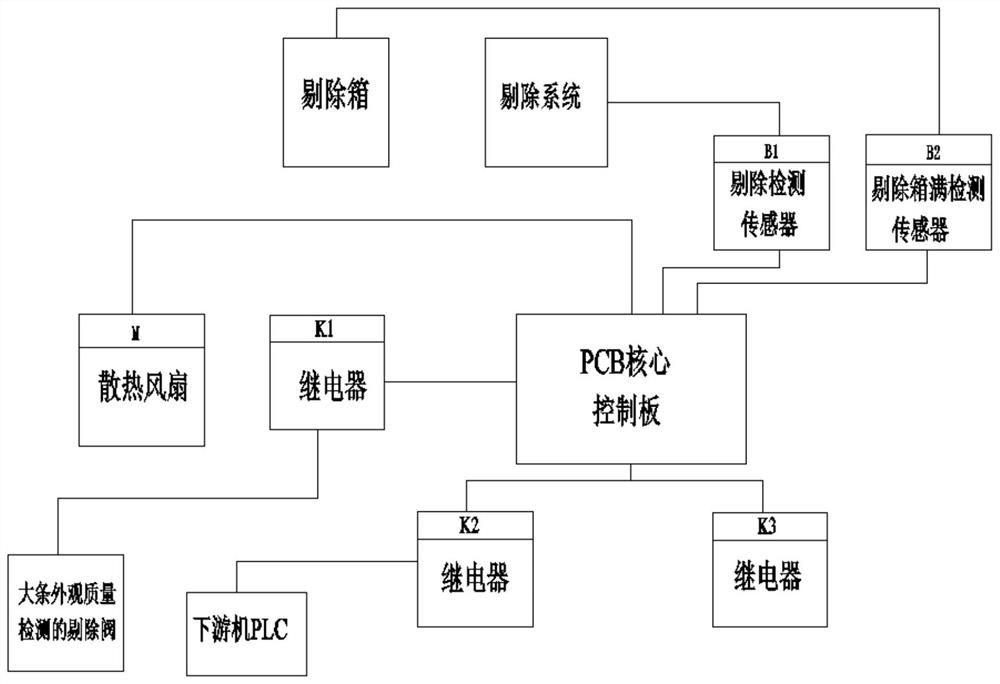

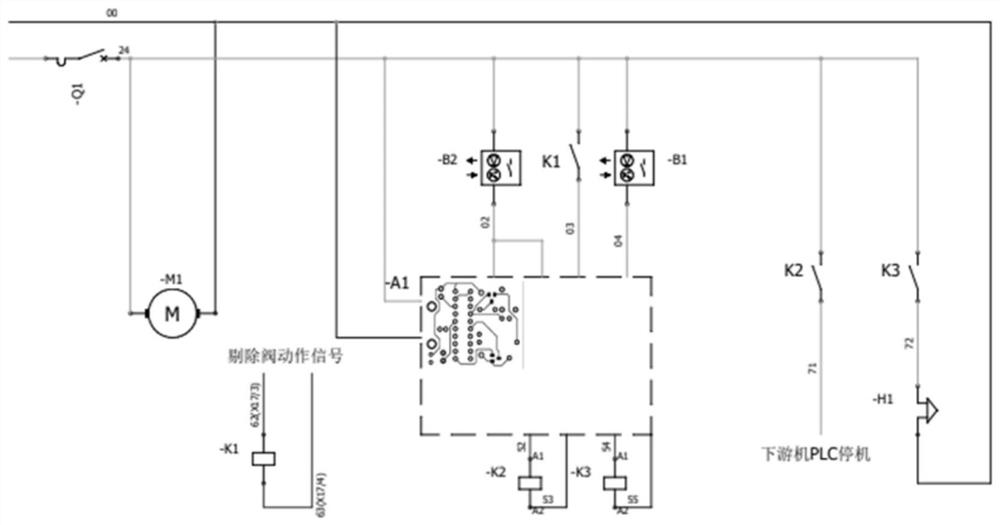

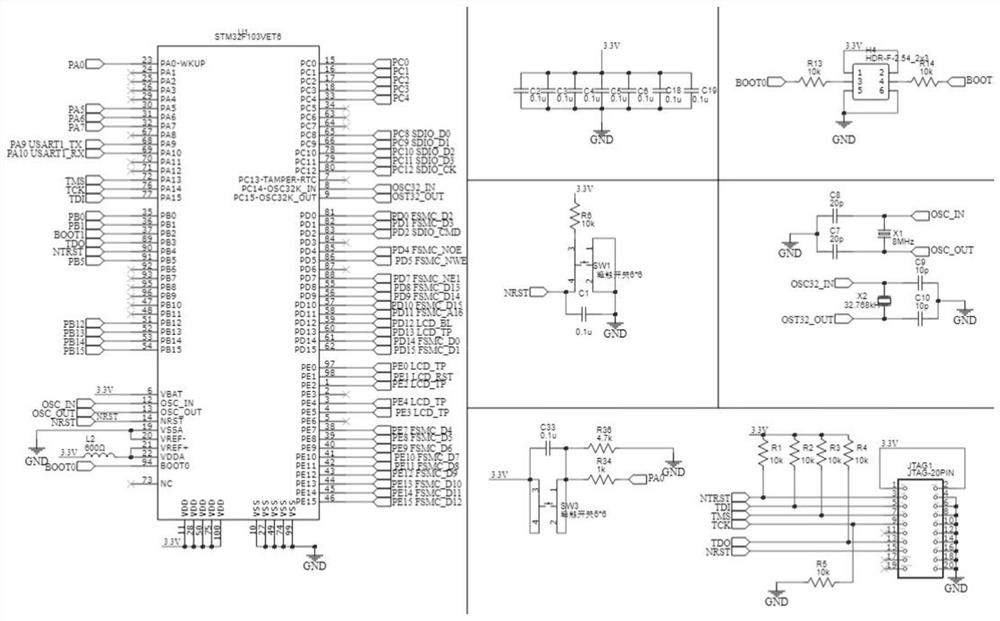

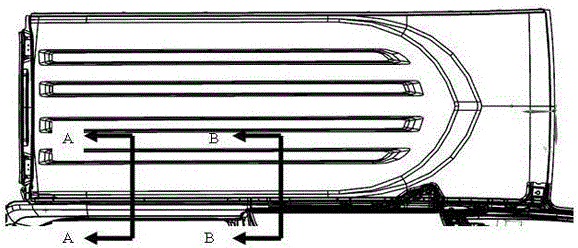

Intelligent tracking device for cigarette carton appearance detection and elimination

PendingCN114560124AReduce hardware costsEliminate quality risksPackaging cigarettePackaging cigarsAutomotive engineeringPrinted circuit board

The invention provides an intelligent tracking device for appearance detection and removal of cigarette cartons, which belongs to the technical field of quality detection of cigarette packaging equipment and comprises a PCB (printed circuit board) core control board, a peripheral detection circuit and a control program. In order to solve the problems that in the prior art, no full box detection exists, defective cigarettes are not thoroughly removed, and consequently defective cigarettes flow into downstream equipment, the intelligent tracking device capable of detecting the appearance quality of the cigarettes and detecting whether the defective cigarettes are successfully removed or not is provided. And the monitoring device is used for monitoring whether each bad cigarette detected by the cigarette appearance quality detection device is successfully rejected or not, outputting an alarm or shutdown signal if the bad cigarette is not successfully rejected, reminding an operator to take out the cigarette which is not rejected, monitoring the rejecting box at the same time, and outputting an alarm signal when the rejecting box is full, so as to remind the operator to empty the rejecting box.

Owner:CHINA TOBACCO SHAANXI IND

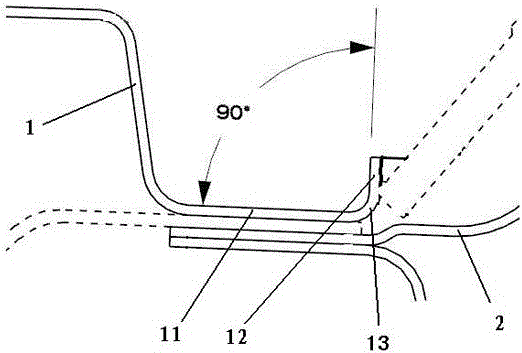

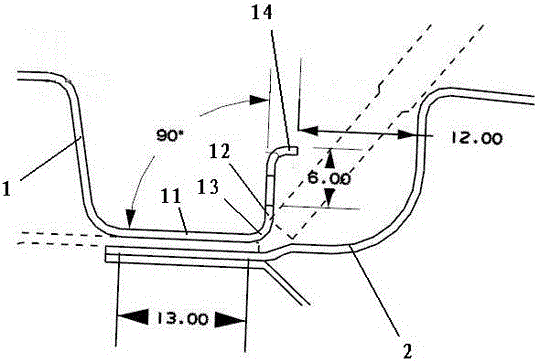

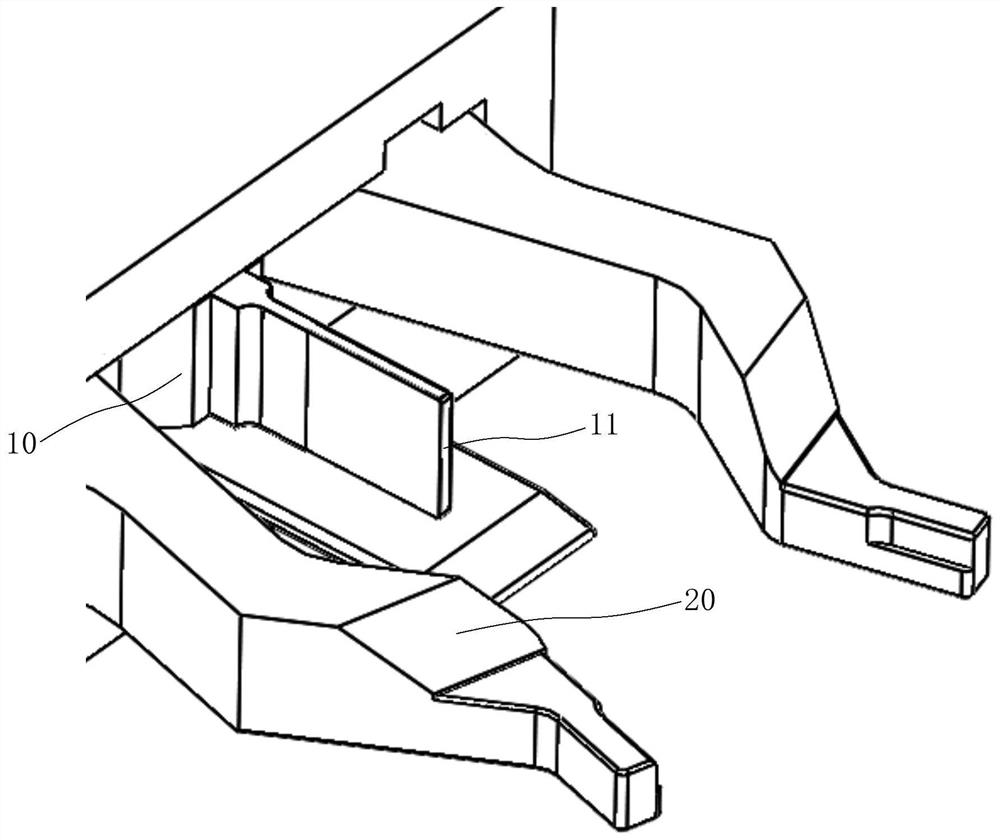

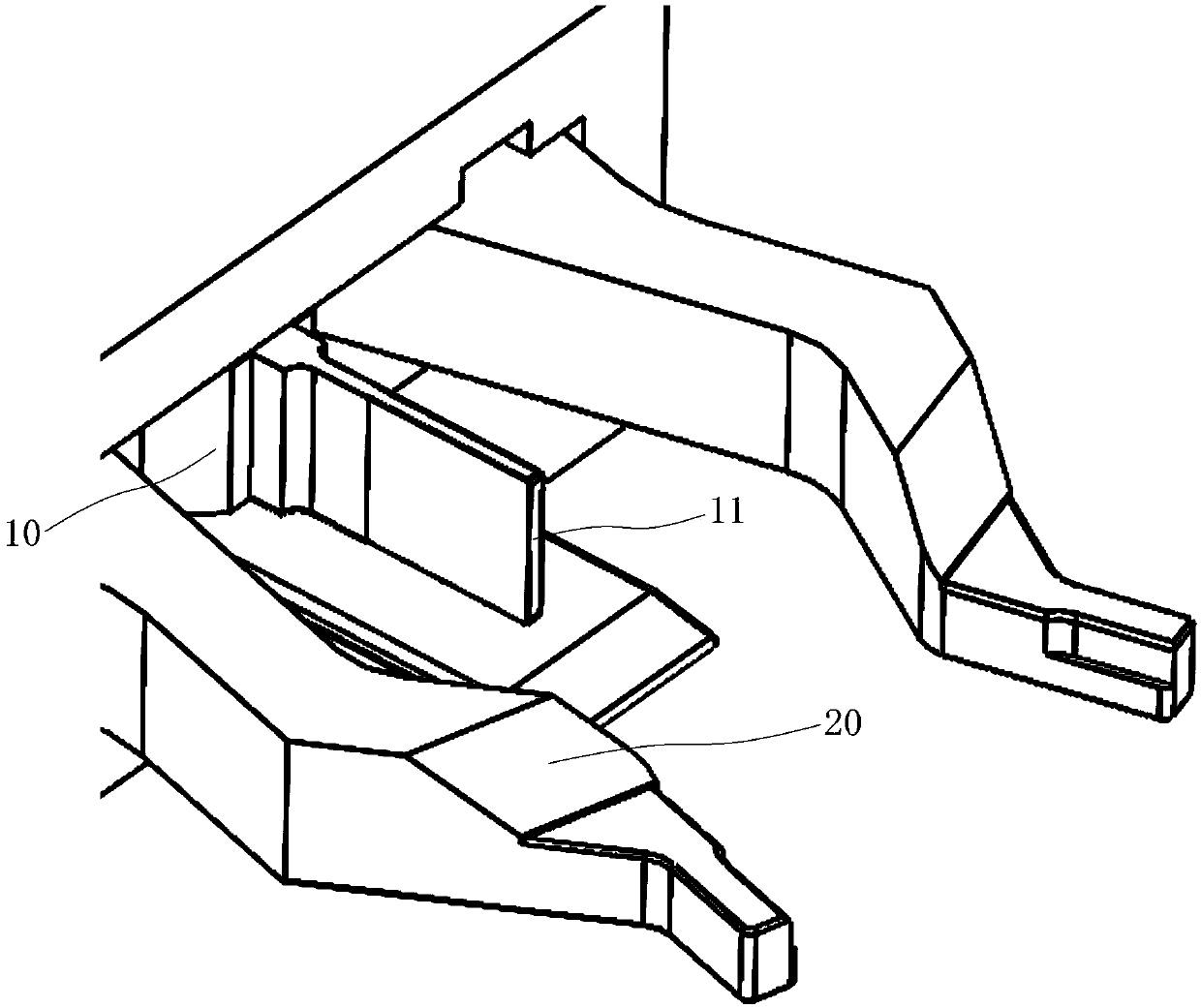

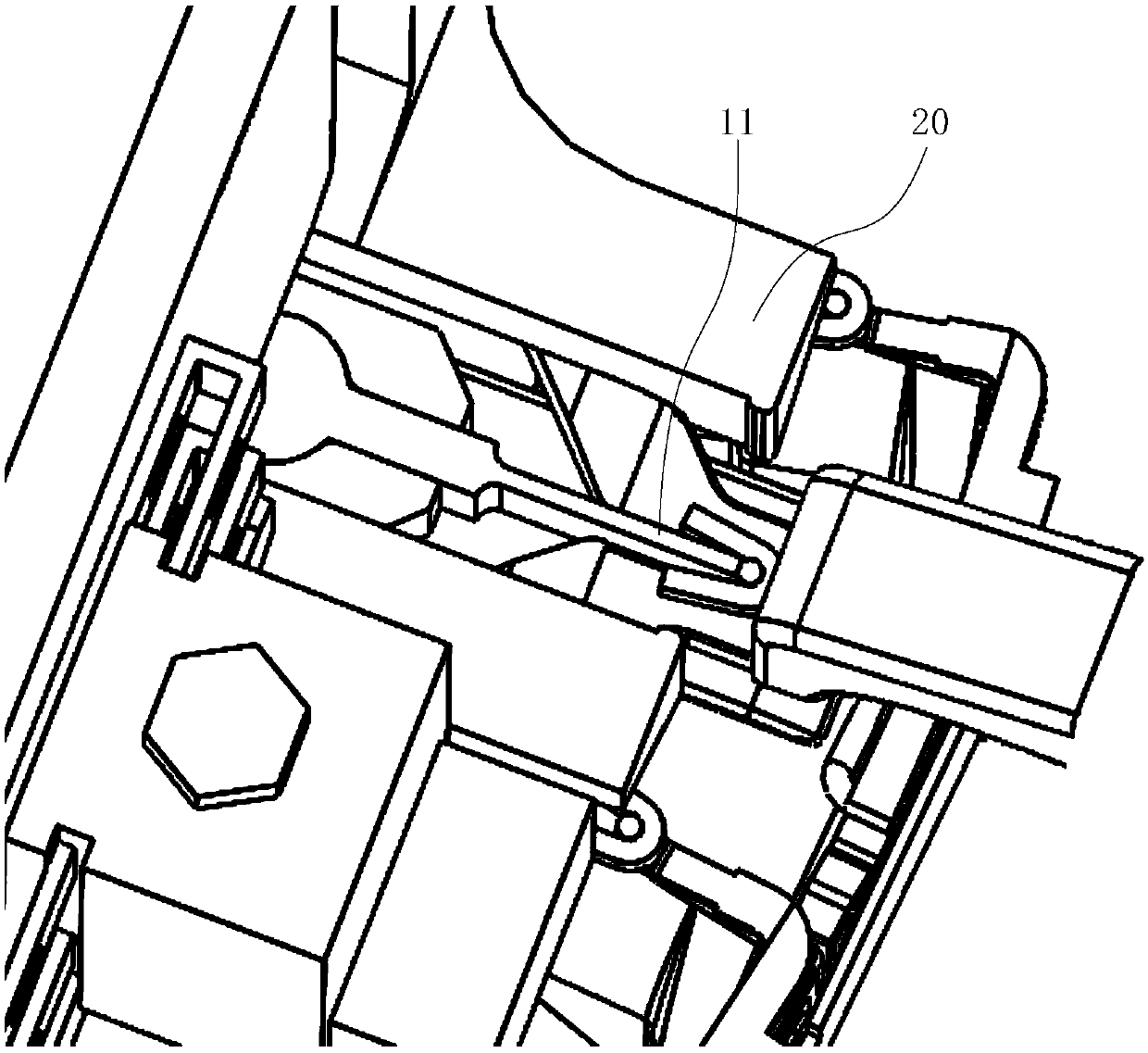

A sink structure for the roof of a minibus

InactiveCN103847805BSimple structureEasy to assembleSuperstructure subunitsEngineeringMechanical engineering

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

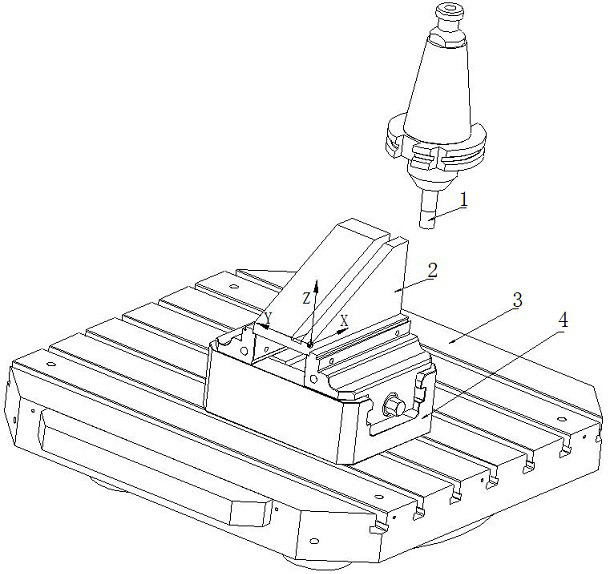

A zero point calibration method and clamping device for a five-axis machine tool

ActiveCN110293431BSolve the problem of zero driftSolve driftMeasurement/indication equipmentsPositioning apparatusNumerical controlMachine parts

The invention discloses a five-axis machine tool zero point calibrating method and a clamping device. The clamping device is used for clamping cuboid blanks, a machine tool is used for carrying out rough milling and finish milling on two planes of the cuboid blanks in the XOY plane of a machine tool coordinate system, the distance between the two planes after finish milling is used as a basis forpre-determining whether a zero point of the machine tool meets process requirements or not; firstly, the real-time working parameters of the machine tool are obtained by using the machine tool to carry out rough milling and finish milling on the two planes in the X, O, and Y planes of the cuboid blanks under the machine tool coordinate system, and then by comparing the theoretical plane distance parameters after finish milling with the working parameters of the two planes after actual finish milling of the machine tool, the out-of-range condition is compensated, therefore, the problem of zerodrift of a numerical control machine tool in the process of machining parts due to the influence of factors such as the temperature change of a factory building is solved, the quality risk caused by the zero drift is eliminated, the stability of the machining process is further guaranteed, and the measurement data is more reliable; and through the co-use of a movable clamping mechanism, the work intensity of operators is reduced.

Owner:AECC AVIATION POWER CO LTD

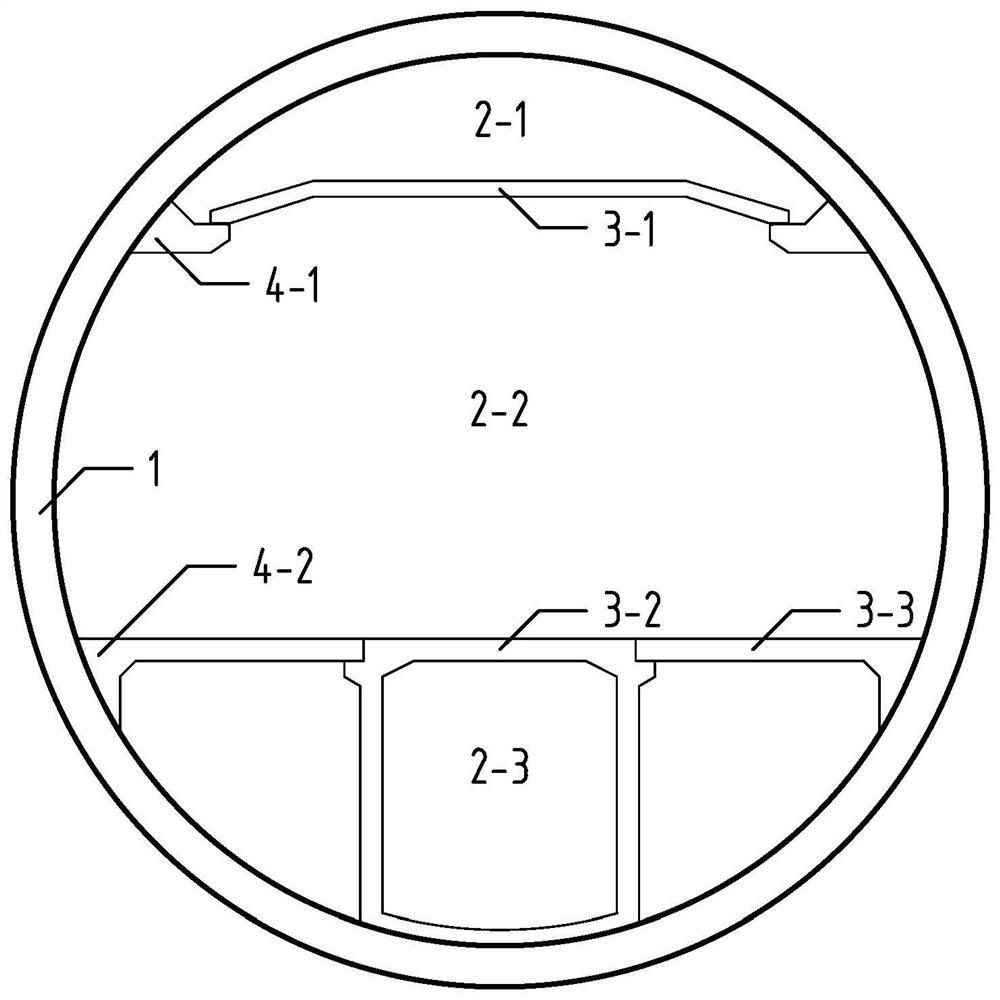

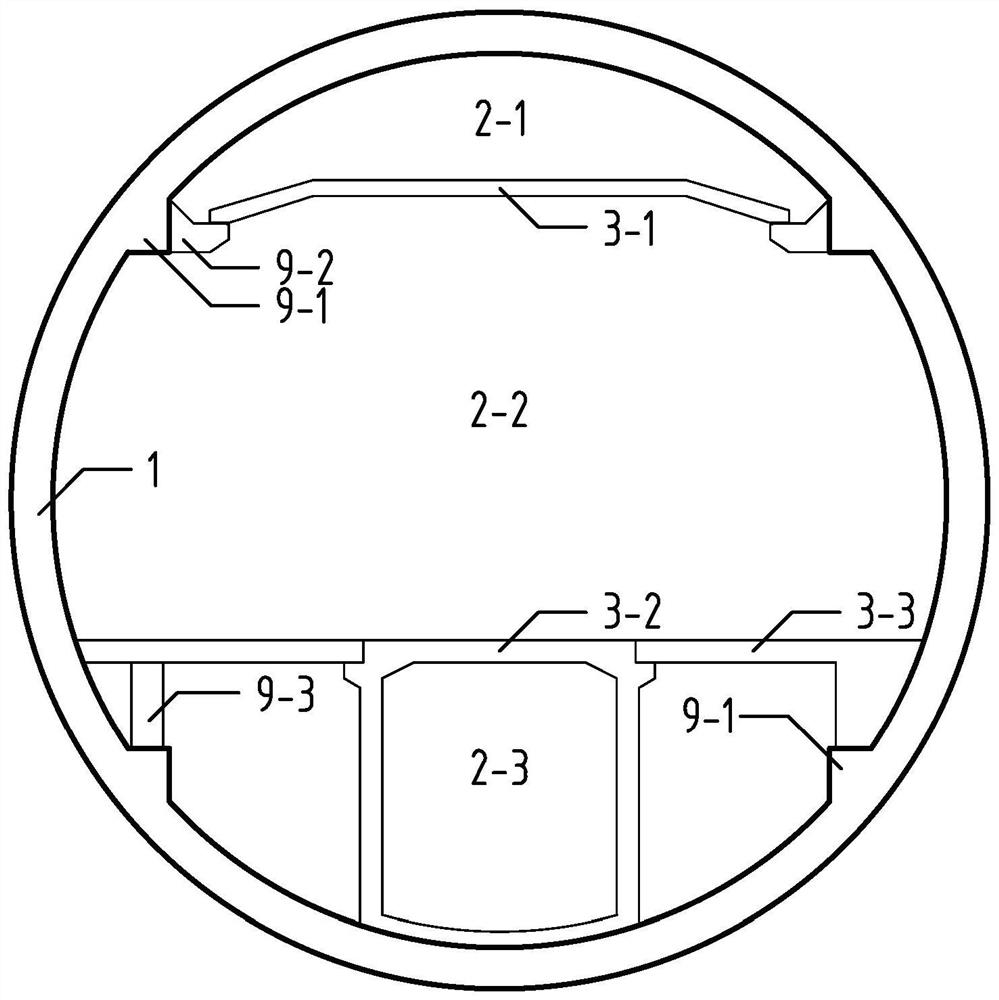

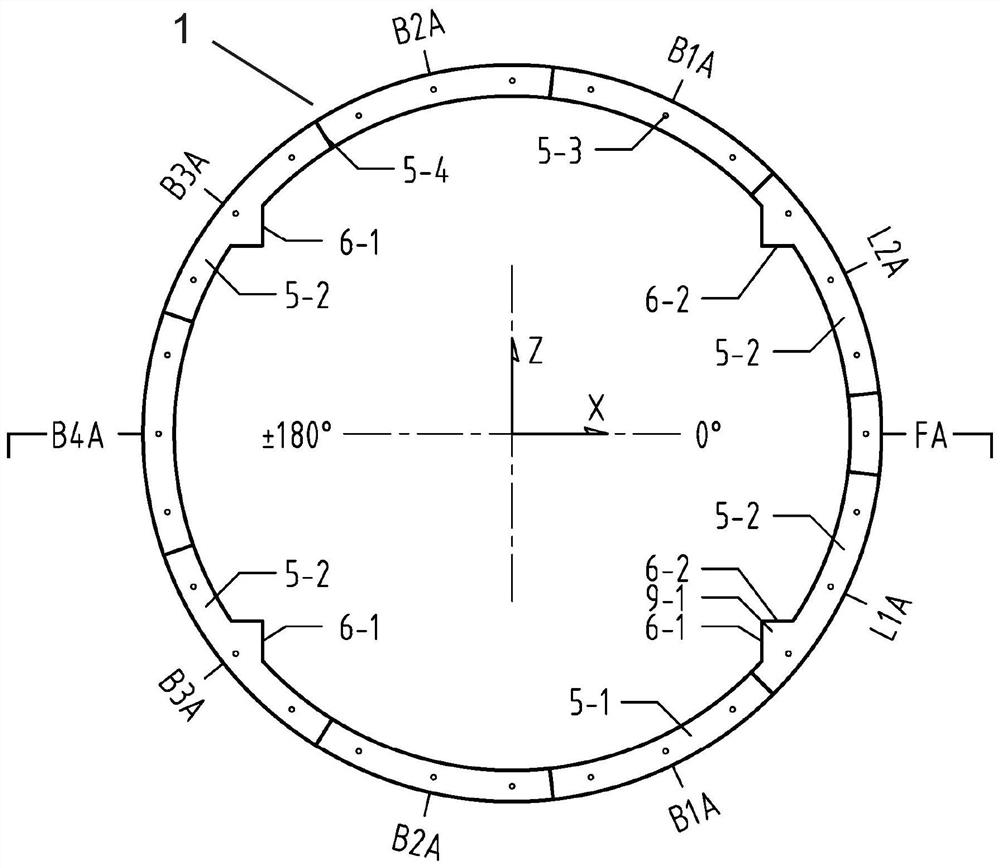

Lining circular ring assembled by prefabricated segments with corbel connecting bases and assembling method of lining circular ring

PendingCN112412494AEliminate quality risksSimplified form factorUnderground chambersTunnel liningVertical planeEngineering

The invention discloses a lining circular ring assembled by prefabricated segments with corbel connecting bases and an assembling method of the lining circular ring. The lining circular ring is provided with symmetrical double-sided wedge-shaped rings. The capping block assembling point is located at the 0-degree position of the lining circular ring, the ring width of the outer diameter of the circular ring at the point is the minimum value or the maximum value, the point, opposite to the capping block, of the 180-degree point is a first standard block, and the points, adjacent to the two sides of the first standard block, of the capping block are second standard blocks. The inner arc surface of the second standard block and the inner arc surface of the adjacent block are each provided with a corbel connecting base which is integrally formed and protrudes out of the inner arc surfaces, each corbel connecting base is composed of a connecting base face in the horizontal plane direction and a connecting base face in the vertical plane direction, the four corbel connecting bases are symmetrically distributed in the lining circular ring, and the formed lining circular ring is in a mode1 or a mode 4. The top sealing block and the adjacent blocks on the two sides are spliced into a whole to rotate by 180 degrees around the Y axis to be in place, and the first standard block and the standard blocks sequentially spliced with the first standard block are spliced into a whole to rotate by 180 degrees around the Z axis to be in place in a mirroring mode to form a lining circular ringin a mode 2 or a mode 3. The universality of the segment is improved, and drilling and steel bar planting on the inner arc surface of the segment are avoided.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

A production quality monitoring system and method for mixing equipment based on multiple data sources

InactiveCN106952033BMonitor Dynamic Weighing AccuracyRealize intelligent early warningResourcesManufacturing computing systemsData authenticityData acquisition

The invention provides a stirring device production quality monitoring system based on multiple data sources and a method, and relates to the technical field of stirring device production quality monitoring. A data acquisition module is used for acquiring production data; a data storage module, a data type judgment module, a curve drawing and analysis module, an acquired data authenticity analysis module and a production quality analysis module in a data analysis system are used for carrying out deep analysis on the production data and monitoring operation states of stirring devices, authenticity of the acquired data and whether the production quality meets a regulated requirement. A human-machine interaction interface displays monitoring results. According to the invention, dynamic weighing accuracy of stirring devices in a blending process can be effectively monitored; it is achieved that an intelligent early warning is given out for fault stirring devices, and the operation states of the stirring devices, whether the acquired data is true and accurate and whether the production quality meets a regulated requirement are monitored, so quality risks are effectively eliminated, and powerful technical support is provided for stabilized soil / concrete / mixture quality monitoring of a construction project.

Owner:沈阳新一代信息技术有限公司

An adjustable device for matching and installing a display module and a mobile terminal base

ActiveCN109551407BImprove consistencyGuarantee product qualityMaterial gluingWork holdersEngineeringMechanical engineering

The invention discloses an adjustable device for matched installation of a display module and a mobile terminal base. The device comprises an LCM module fixing device, a front shell assembly fixing device, a negative pressure pneumatic adsorption device, a distance adjusting transmission device and a base platform device. The LCM module fixing device is rotatably connected with the base platform device. The negative pressure pneumatic adsorption device is mounted on the LCM module fixing device, for adsorbing the LCM module on the LCM module fixing device. The distance adjusting transmission device is mounted on the base platform device. When the LCM module fixing device drives the LCM module to press down, the front shell assembly fixing device is driven by the distance adjusting transmission device to move forward, so that a FPC just matches when the LCM module and the front shell assembly are installed, so as to prevent the FPC from being too short and broken by strong force pulling.

Owner:SHENZHEN WENYAO ELECTRONICS TECH CO LTD

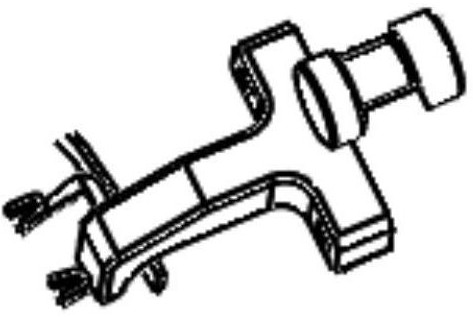

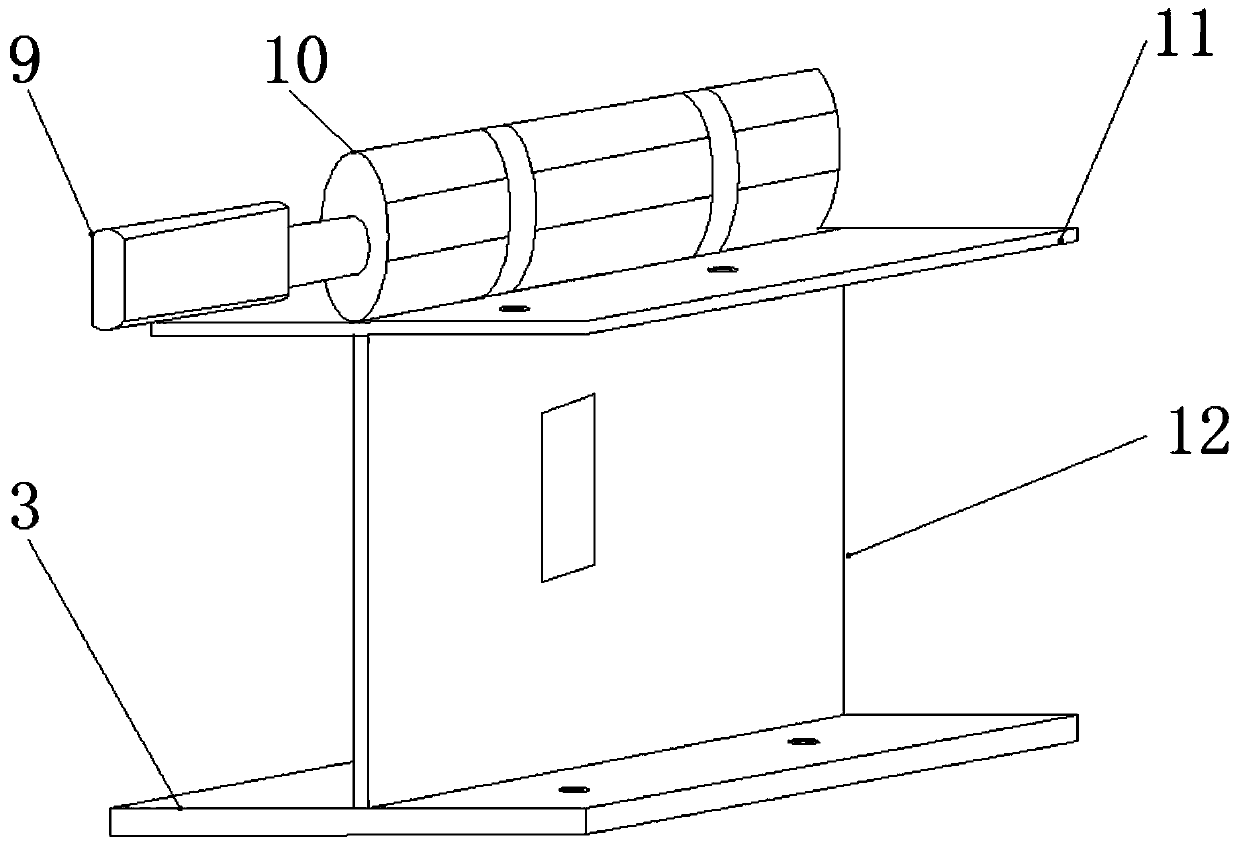

A tire bolt tightening machine calibration auxiliary device

ActiveCN111609966BReduce swing floatEliminate quality risksMeasurement of torque/twisting force while tighteningMetal working apparatusMachineControl theory

The invention relates to a calibration auxiliary device for a tire bolt tightening machine, which is characterized in that it includes a calibration fixing seat, a tightening shaft clamping device and a calibration plate base, and the calibration fixing seat is fixedly connected with the outer shell of the tire bolt tightening machine. During calibration, The tightening shaft clamping device is fixedly connected with the calibration fixed seat; the calibration plate base is provided with a calibration bolt simulator; the tightening shaft clamping device includes a tightening shaft clamping sleeve and a clamping arm; the The clamping sleeve of the tightening shaft is connected with the clamping arm through the fixing pin I. The invention is simple in structure, low in cost, easy to operate, can greatly reduce the swing and float of the tightening shaft, meets the requirement of static calibration, and further eliminates the quality risk caused by inaccurate calibration torque of the tire tightening machine.

Owner:CHERY AUTOMOBILE CO LTD

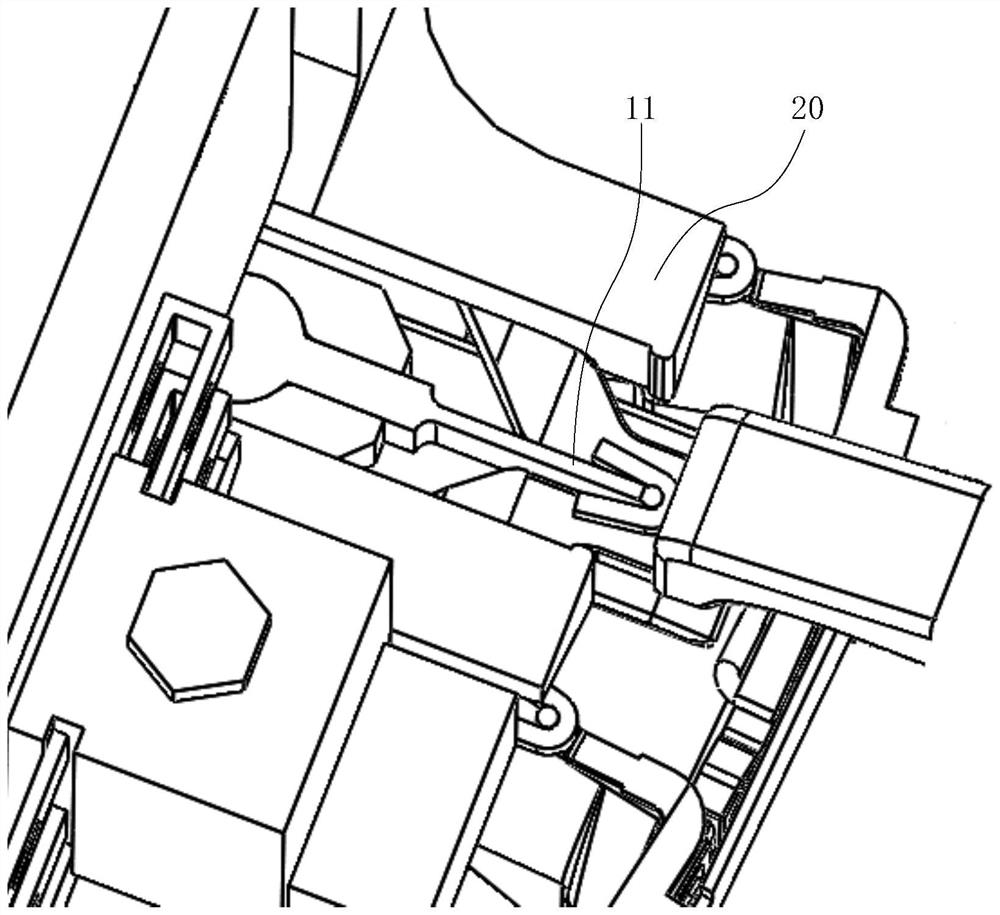

Wire fastening device and method

ActiveCN110912357BAchieve the purpose of the jobMeet production requirementsEmbedding prefabricated windingsWire rodProduction line

The invention provides a wire management and fastening device and a method for processing wires and wire components. The wire management and fastening device includes a displacement sensor, a servo mechanism, a wire management mechanism and a fastening mechanism. The displacement sensor is used for Determine the position of the wire assembly, the servo mechanism moves and adjusts the position according to the position of the wire assembly, the wire management mechanism includes a regularization block, the wire is regulated to the set position through the regularization block, and the fastening The mechanism fixes the wire and the wire assembly. The wire tightening device provided by the present invention is used for the processing of wire rods and wire rod assemblies. The displacement sensor determines the relative position, and the servo mechanism realizes the movement. The fixing mechanism fixes the wire rod and the wire rod assembly, which meets the production requirements, achieves the operation purpose of the automatic production line, improves the production efficiency, and greatly eliminates the quality risk caused by manual work.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

Wire arranging and fastening device and method

ActiveCN110912357AAchieve the purpose of the jobMeet production requirementsEmbedding prefabricated windingsWire rodProduction line

The invention provides a wire arranging and fastening device and method, which are used for processing wires and wire assemblies. The wire arranging and fastening device comprises a displacement sensor, a servo mechanism, a wire arranging mechanism and a fastening mechanism, wherein the displacement sensor is used for determining the position of the wire rod assembly, the servo mechanism moves toadjust the position according to the position of the wire rod assembly, the wire arranging mechanism comprises a correcting block, the wire rod is corrected to a set position through the correcting block, and the fastening mechanism fixes the wire rod and the wire rod assembly. The wire arranging and fastening device is used for processing wires and wire assemblies, the displacement sensor determines the relative position, the servo mechanism moves, the wire rod is aligned to a set position through the alignment block of the wire arranging mechanism, and the wire rod and the wire rod assemblyare fixed through the fastening mechanism, so that the production requirement is met, the operation purpose of an automatic production line is achieved, the production efficiency is improved, and thequality risk caused by manual operation is greatly eliminated.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

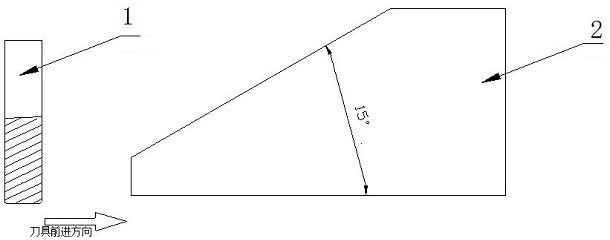

A Method for Fast Trial Cutting and Cutting Parameters Optimization of CNC Milling Tool

ActiveCN113182567BFast processing performanceQuick access to processabilityAutomatic control devicesFeeding apparatusMachined surfaceProcess engineering

The invention discloses a method for rapid trial cutting and cutting parameter optimization of a numerically controlled milling tool, which belongs to the technical field of mechanical processing. In this method, at the production site, a standard trial cutting piece is used for trial cutting for different brands of cutting tools to be tested. The processing performance under the condition; and the optimal experimental method of the golden section is adopted to quickly obtain the optimal cutting parameters of the cutting tool, thereby improving the efficiency of the tool trial cutting, shortening the tool trial cutting cycle, and eliminating the quality risk of the product trial cutting.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

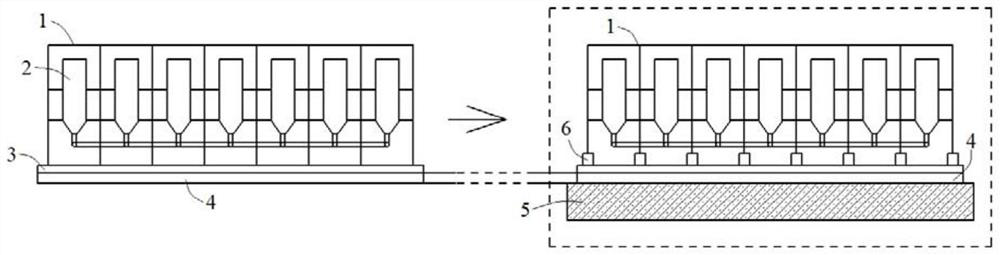

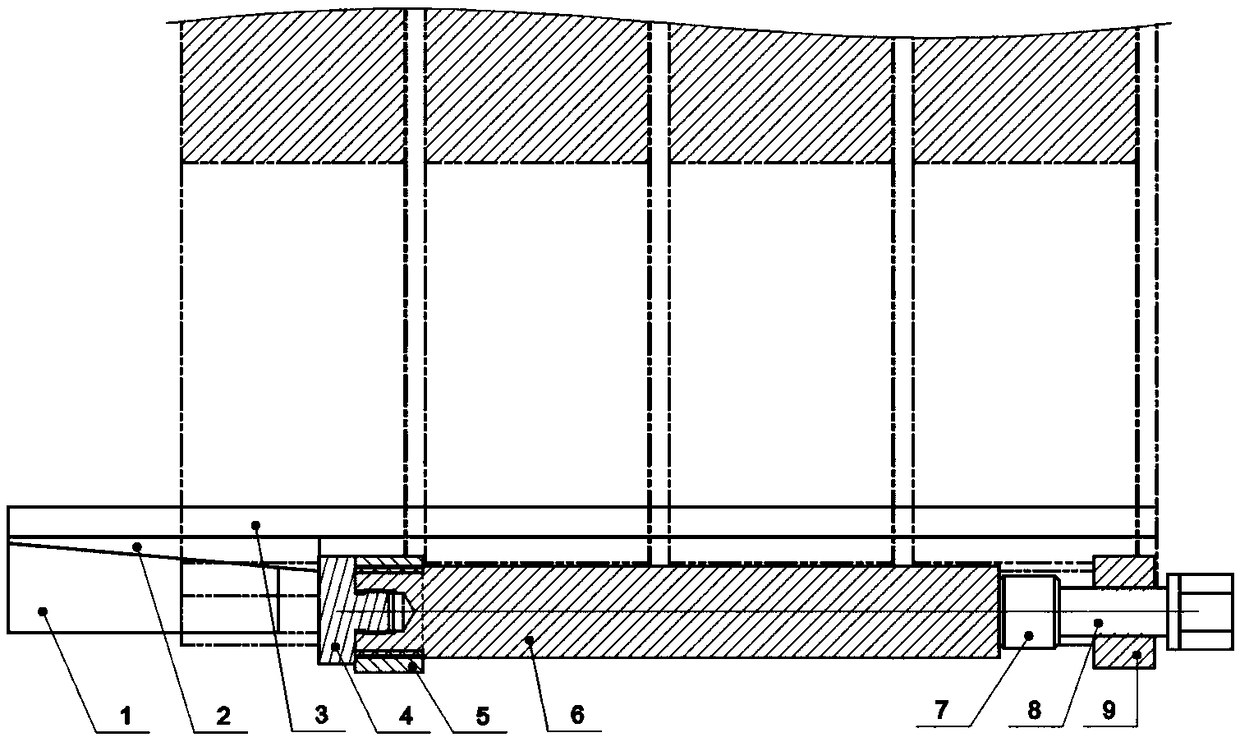

Rapid transformation method and device for in-situ dry dedusting of blast furnace wet dedusting

ActiveCN113699296AShorten the construction periodReduce construction riskBlast furnace detailsExhaust gas handlingDust controlEnvironmental engineering

The invention discloses a rapid transformation method and device for in-situ dry dedusting of blast furnace wet dedusting, and belongs to the technical field of gas system transformation. The device comprises a dust removal frame, a frame foundation built on an original wet dust removal site and a pushing and moving structure used for moving, the pushing and moving structure is arranged at the lower part of a bottom frame at the bottom of the dust removal frame and supports the bottom frame, a stand column foundation is built on the upper portion of the frame foundation, the dust removal frame is temporarily fixed beside the frame foundation, and the dust removal frame is connected to the frame foundation through rails. According to the rapid transformation method and device, construction of a dry-method dust removal structure and equipment is completed before furnace shutdown, construction of a dry-method dust removal foundation and part of the translation rails is only conducted after the furnace shutdown, the dry-method dust removal system structure is connected to the foundation through the rail translation technology, and finally dry-method dust removal transformation is completed, so that the construction period is greatly shortened, and the transformation of dry dust removal and wet dust removal in situ is completed within the limited time of overhaul of the blast furnace.

Owner:MAANSHAN IRON & STEEL CO LTD

Technical method for installing steam turbine generator stator slot wedge by hydraulic power

InactiveCN109347272AEasy to controlAccurate control of assembly preloadManufacturing stator/rotor bodiesEngineeringDynamo

The invention relates to a technical method for installing a large steam turbine generator stator slot wedge by hydraulic power. Through a hydraulic tool, supporting force is applied to a tapered wedge under a stator slot wedge, and the problems generated by assembling the large steam turbine generator stator slot wedge with a traditional method that the hitting power of the slot wedge and the tapered wedge is greatly affected by manual influence factors, hitting power is uncontrollable and more plate hitting fragments are generated in a hitting process can be solved. The traditional method isunfavorable for cleaning the inner part of a generator stator slot, and the misoperation of operation personnel may knock the generator stator with a hammer to cause potential quality hazards. By useof the technical method disclosed by the invention, the operation efficiency of operators is improved, and quality risks are lowered.

Owner:HARBIN ELECTRIC MASCH CO LTD

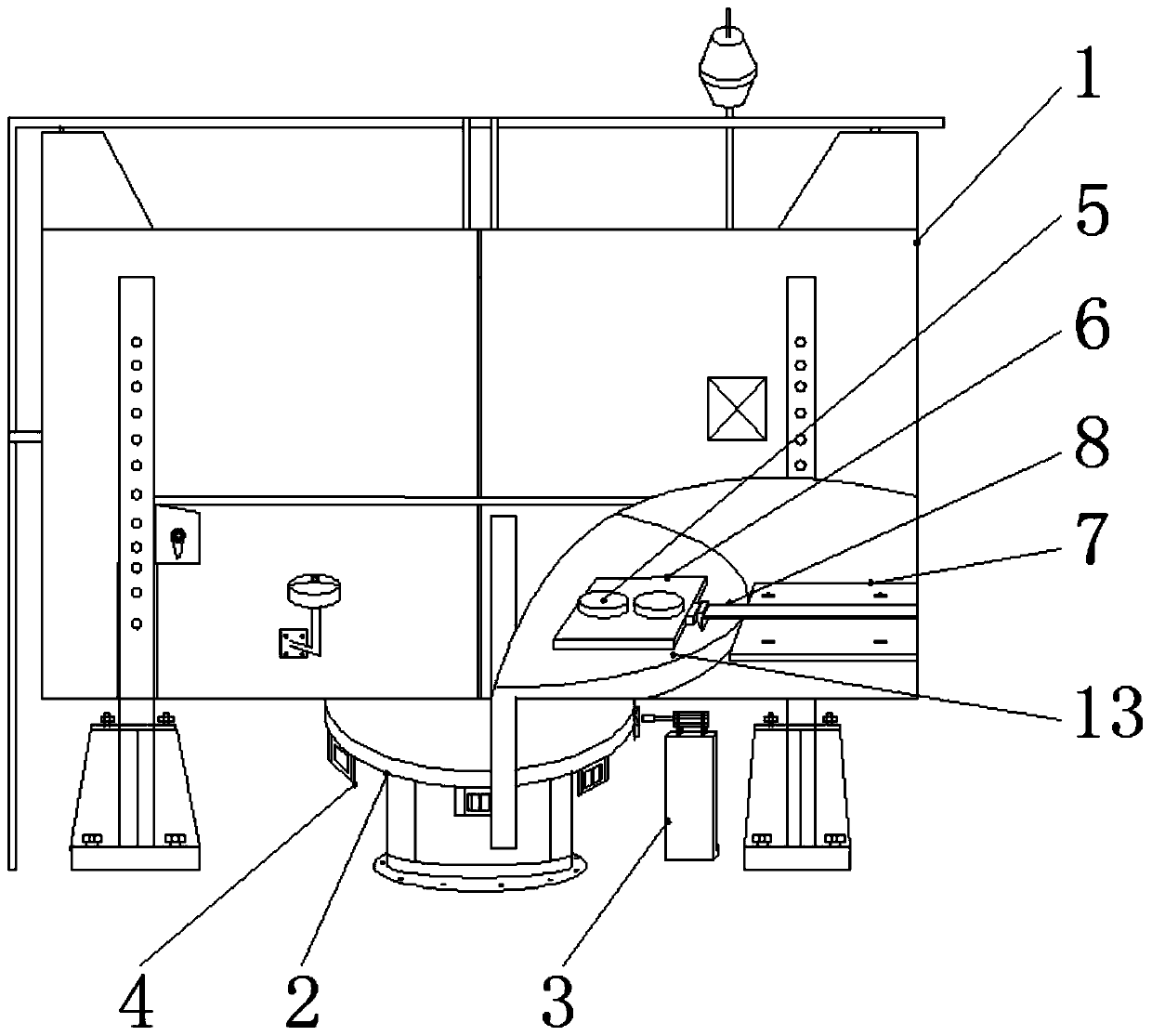

Precise positioning device for high-precision isothermal quenching rotary hearth furnace

PendingCN110819787AEliminate stuck problemsAvoid collisionFurnace typesHeat treatment furnacesEngineeringHearth

The invention discloses a precise positioning device for a high-precision isothermal quenching rotary hearth furnace. The precise positioning device comprises an isothermal quenching furnace main body, a feeding and discharging mechanism and a cylinder, wherein a guide base plate is arranged below the isothermal quenching furnace main body, a positioning device is arranged on the right side of theguide bottom plate, and the feeding and discharging mechanism is fixedly installed on the right side of the isothermal quenching furnace main body; a rotary furnace bottom is arranged at the lower end of the isothermal quenching furnace main body, and the air cylinder is arranged on the right side of the guide base plate; and a first limiting plate is embedded in the bottom end of a bearing sleeve ring, and a first limiting plate and a second limiting plate are mutually attracted. According to the precise positioning device for the high-precision isothermal quenching rotary hearth furnace, the phenomena such as blocking, collision and side wall failure of a friction channel in the feeding and discharging process of a material tray are avoided, and the fault maintenance cost is reduced; and meanwhile, the production efficiency is improved, and the risk that the product quality problem occurs due to furnace shutdown maintenance caused by material tray stuck, collision and the like is eliminated.

Owner:南京天马轴承有限公司

Device for precisely calibrating dynamic shape precision of grinding wheel for numerical control cutter grinder

PendingCN112706009ASimplify the precision tuning processRealize accurate data importMilling cuttersAbrasive surface conditioning devicesNumerical controlMilling cutter

The invention discloses a device for precisely calibrating the dynamic shape precision of a grinding wheel for a numerical control cutter grinder. The device comprises a precision calibration device, the precision calibration device comprises a debugging cutter bar, a cutter bar assembly is inserted into one side, close to the top, of the debugging cutter bar, and the cutter bar assembly comprises a molded line edge cutter bar and a grinding wheel grinding finishing head. By the cooperative use of the debugging cutter bar, the molded line edge cutter bar and the grinding wheel grinding finishing head, error calibration of three parameters of the grinding wheel is conducted through debugging molded line errors, the precision debugging process of a formed milling cutter is greatly simplified, the debugging difficulty is greatly reduced, the debugging time is greatly shortened, the one-time accurate calibration of the precision of a molded line cutting edge of the formed milling cutter can be quickly realized without risk within 20 minutes, accurate data import of grinding wheel parameters can be achieved, a large amount of debugging time for the grinding precision of the cutting edge of the complex forming milling cutter is saved, and the quality risk of scrapping caused by repeated debugging of the cutter is directly eliminated.

Owner:成都戴莱克刀具有限公司

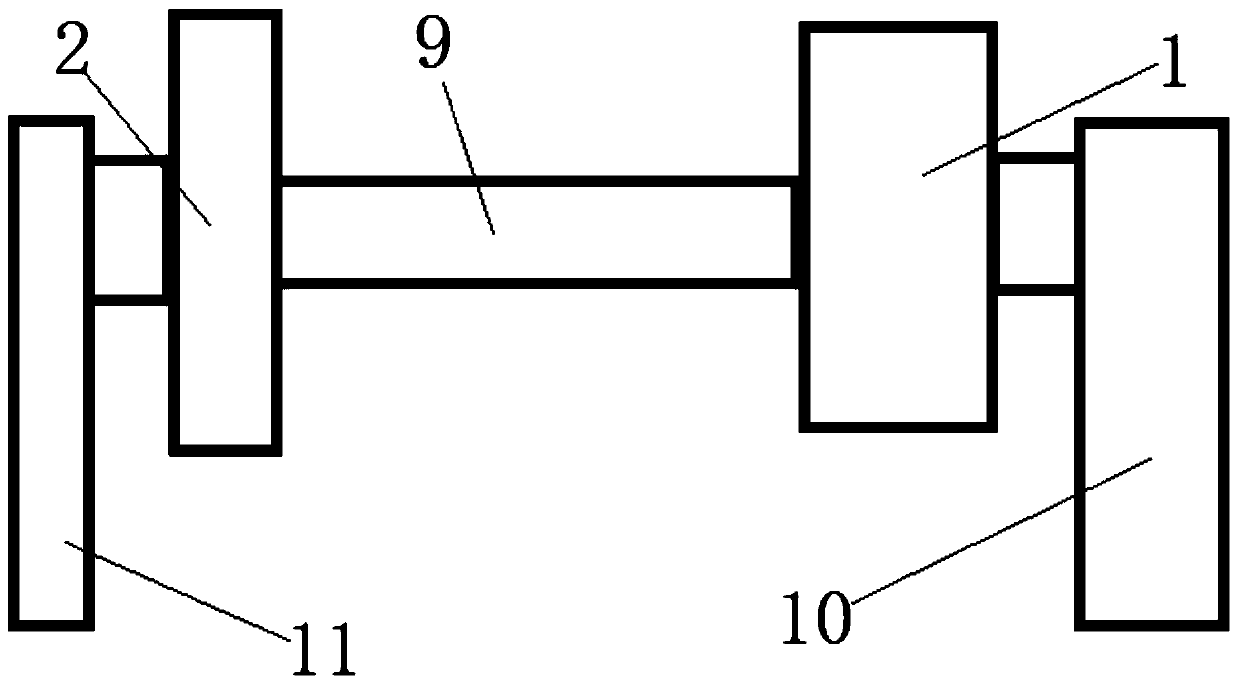

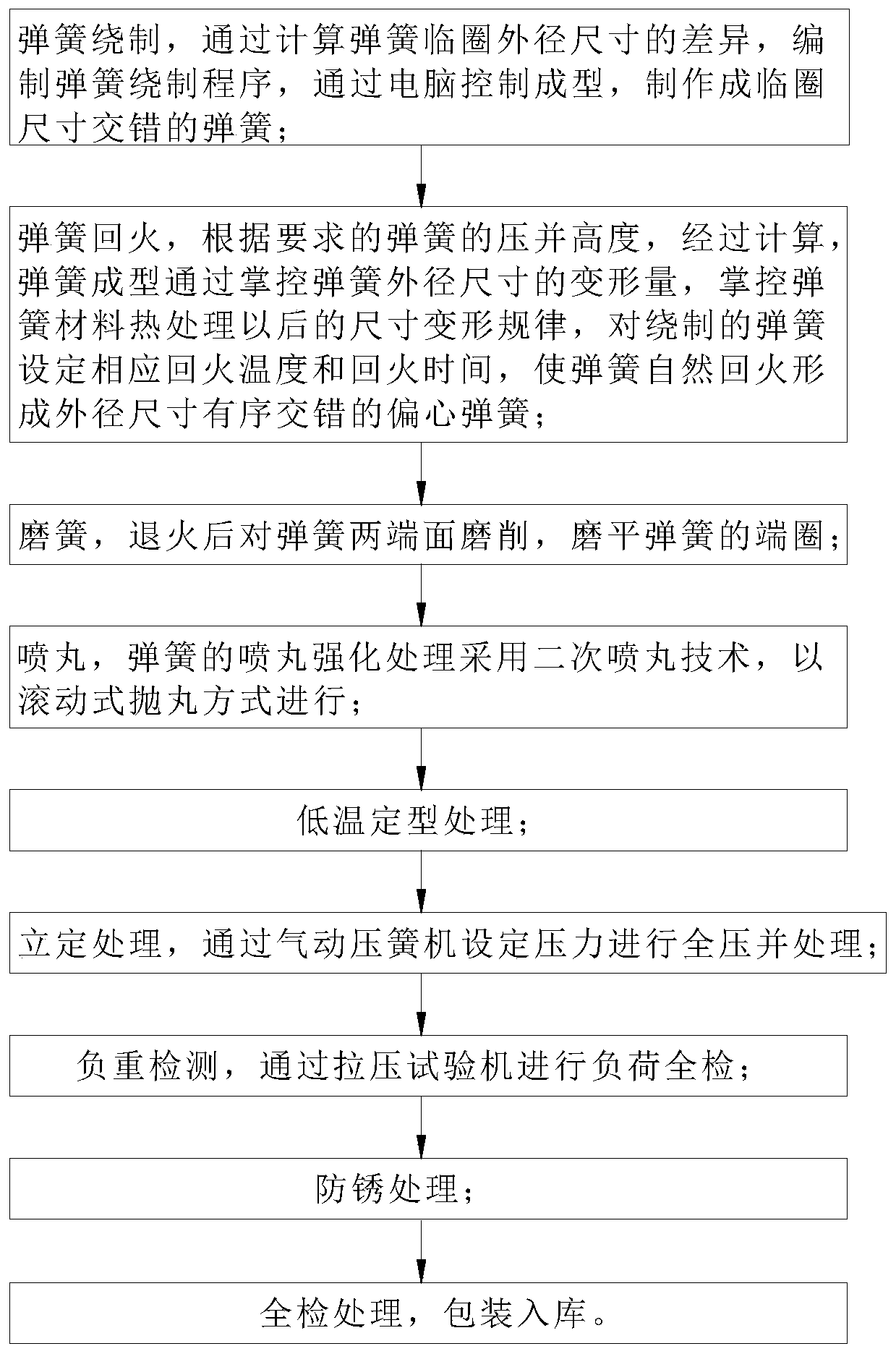

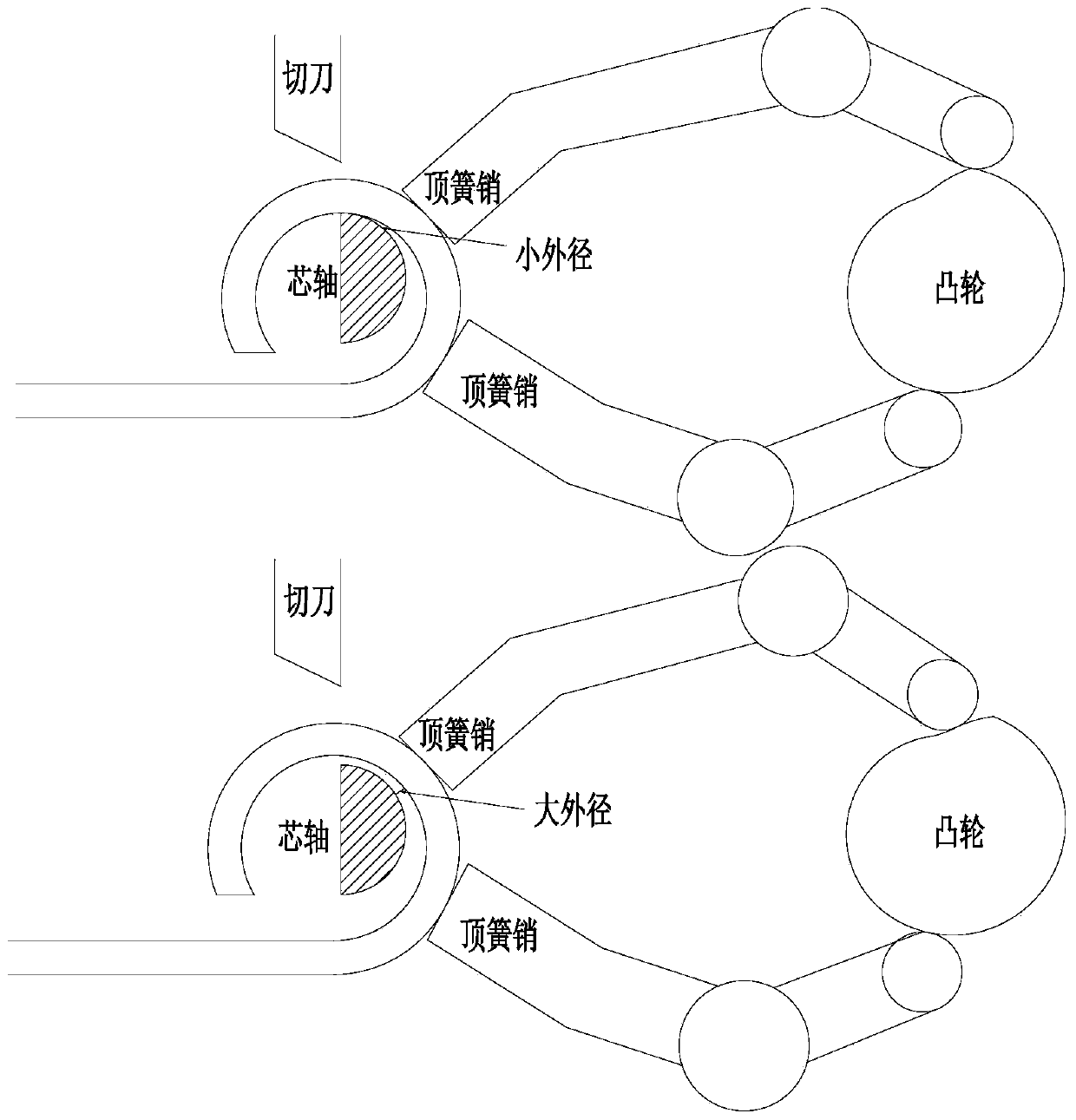

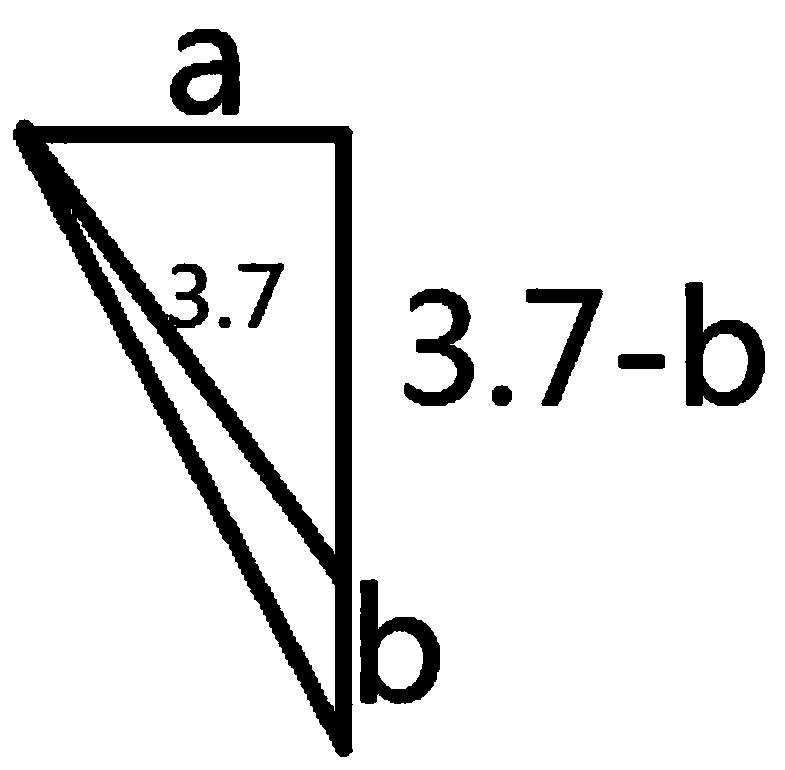

Manufacturing process of helical compression eccentric spring and its spring products

ActiveCN107838329BSimple designImprove the safety of useFurnace typesMetal working apparatusTemperingMechanical engineering

The invention discloses a manufacturing process of a spiral compression eccentric spring and a spring product thereof, and belongs to the technical field of spring manufacturing processes. The manufacturing process comprises the following steps: spring winding: spring winding programs are established through calculation of the outer diameter size differences of near rings of springs; and the springs with staggered sizes of the near rings are manufactured through computer control molding; and spring tempering: according to requested solid heights of the springs, the springs are molded through mastering the outer diameter size deformations of the springs by calculation; the size deformation rules after heat treatment of spring materials are mastered; corresponding tempering temperatures andtempering time are set for the wound springs; and the springs are naturally tempered to form eccentric springs with ordered and staggered outer diameter sizes. Under the preconditions of not changingtraditional designed material wire diameters, outer diameter and circle numbers, the solid heights of the spring products can be effectively reduced, and the working travels and the loads are increased.

Owner:QUFU TIANBO AUTO ELECTRIC CO LTD

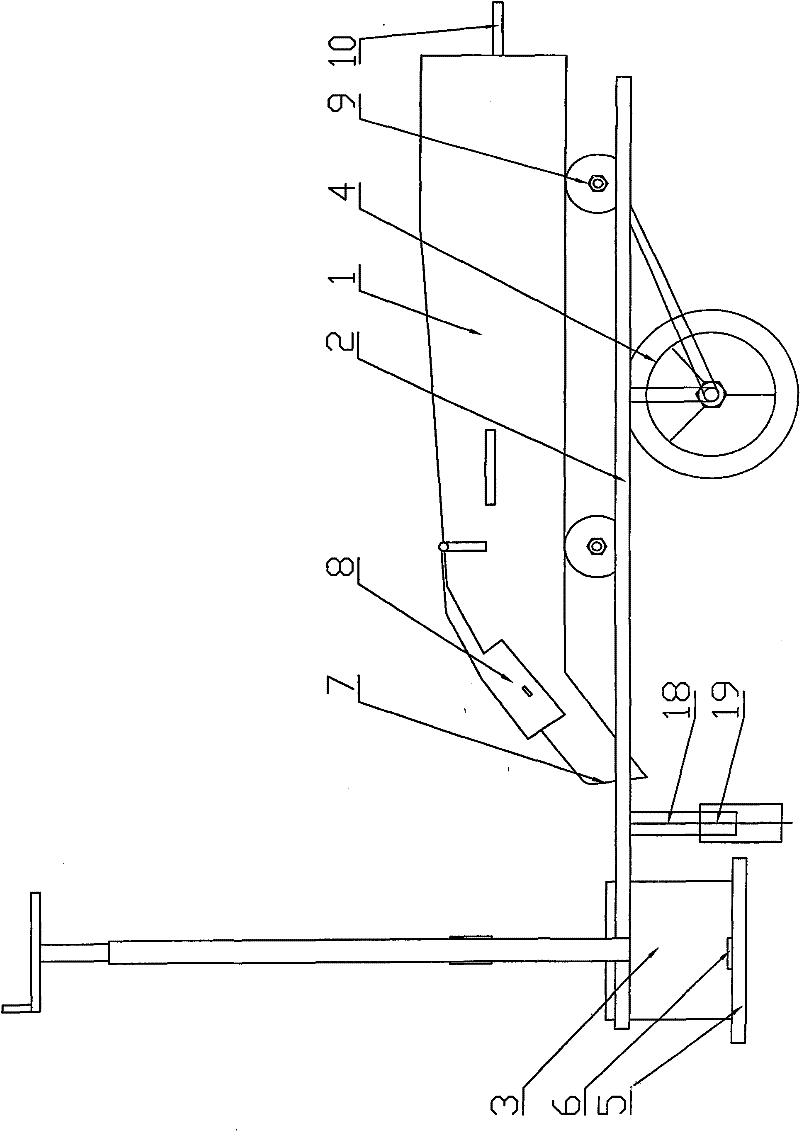

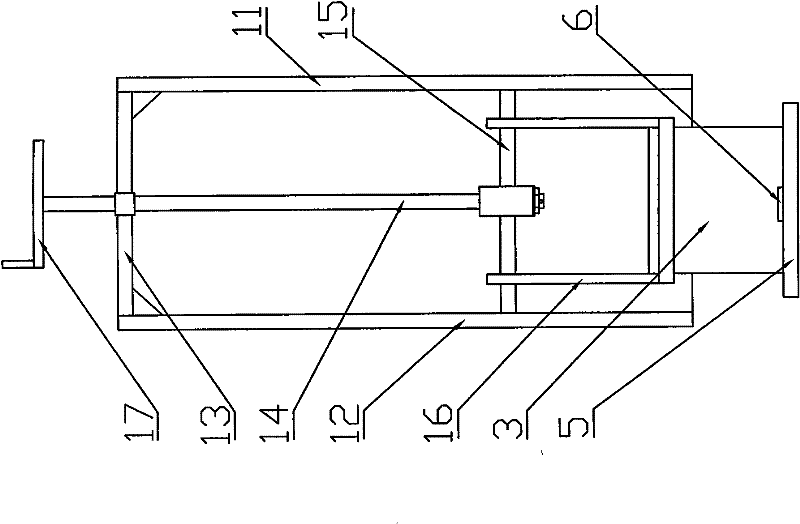

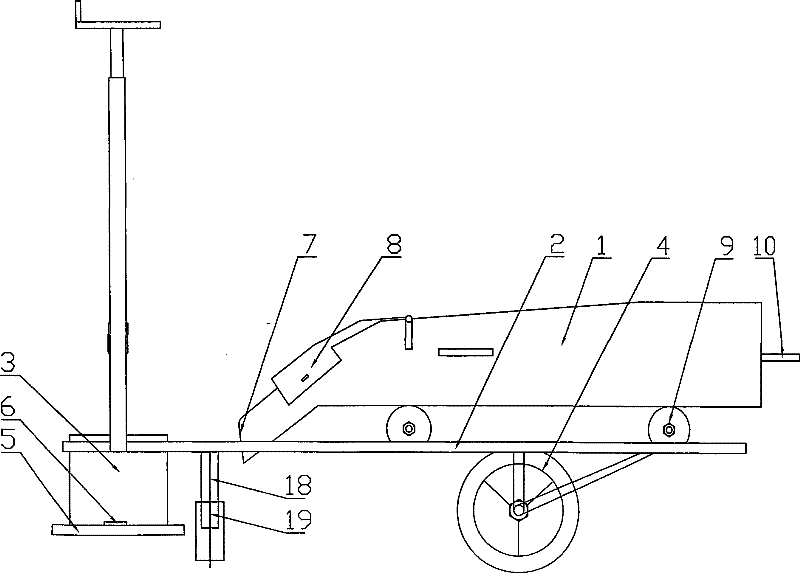

Aluminum-replacing trough cart

The invention relates to the technical field of a refined aluminum trough aluminum-replacing device, in particular to an aluminum-replacing trough cart. The cart comprises an aluminum-containing trough, a frame and a buffer tank; wheels are arranged at the bottom of the frame, the upper end of the buffer tank is arranged at the left part of the frame, a buffer flow-splitting disk is arranged at the bottom of the buffer tank, an aluminum outlet hole which is corresponding to the buffer flow-splitting disk is arranged at the lower end of the buffer tank, the aluminum-containing trough is arranged on the frame and the left part thereof is provided with an aluminum outlet, the aluminum outlet is arranged above the buffer tank. The invention features compact structure and convenient use. First, with the buffer tank adopted, work efficiency is improved, labor intensity of workers is lowered, quality risk caused by misoperation of the relates personnel is removed; in addition, as a trough cap is arranged on the aluminum-containing, the potential security hazard that the workers directly carry out high temperature operation and get hurt by splashed aluminum liquid is avoided.

Owner:XINJIANG JOINWORLD CO LTD

Fast positioning and correction-free fixture

ActiveCN103878618BPrecise positioningImprove pass ratePositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to the field of rapid-positioning correction-free clamps. The rapid-positioning correction-free clamp comprises a rotary wheel, a rotary shaft, a locking rotary disc, a positioning orientation block and a pressing disc, wherein the back surface of the rotary wheel is fixedly installed on a common lathe rotary mechanism, the rotary shaft is installed in the center of the front surface of the rotary wheel and is divided into three sections, the section near the rotary wheel is a large cylindrical rotary shaft, the section far away from the rotary wheel is a small cylindrical rotary wheel, the middle section is a middle cylindrical rotary shaft, the large cylindrical rotary shaft is provided with a thread, and the locking rotary wheel is screwed at the thread on the large cylindrical rotary shaft. The positioning orientation block comprises a rear central positioning block and a front central positioning block, wherein the rear central positioning block is installed on the large cylindrical rotary shaft at the outer side of the locking rotary disc in a sleeved mode, a low positioning block is installed at the front end of the middle cylindrical rotary shaft of the rotary shaft, the small cylindrical rotary shaft is provided with a thread, and the pressing disc is installed on the small cylindrical rotary shaft. The rapid-positioning correction-free clamp has the advantages of being simple in design, convenient and rapid to use and capable of accurately positioning, centering, clamping and safely and reliably machining a medium-load pump shell body, largely improving production and machining efficiency and pass percentage of machined products, and saving time and labor.

Owner:江苏力源金河铸造有限公司

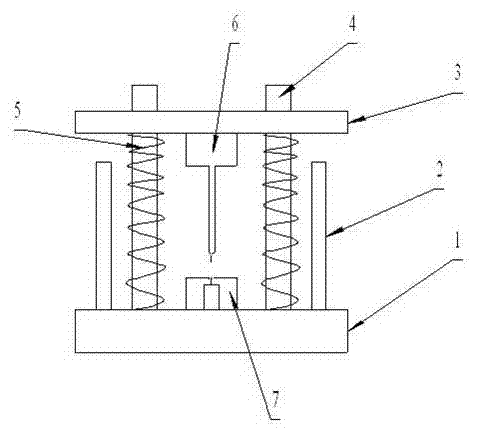

Manual punching supplementation device

The invention discloses a manual punching supplementation device, which comprises a lower plate, an upper plate, sliding columns, a punching needle and an insert, wherein the lower plate is provided with spacing columns, the sliding columns and the insert; the sliding columns are provided with compressed springs; the upper plate passes through the sliding columns to be installed above the compressed springs; the punching needle is installed below the upper plate; and the punching needle is positioned above the insert. The manual punching supplementation device has the advantages of simple structure and complete function, the stamping-missing position of an oil ring wire can be effectively subjected to punching supplementation, and the quality risk in the subsequent processing is avoided.

Owner:大连环新新材料科技有限公司

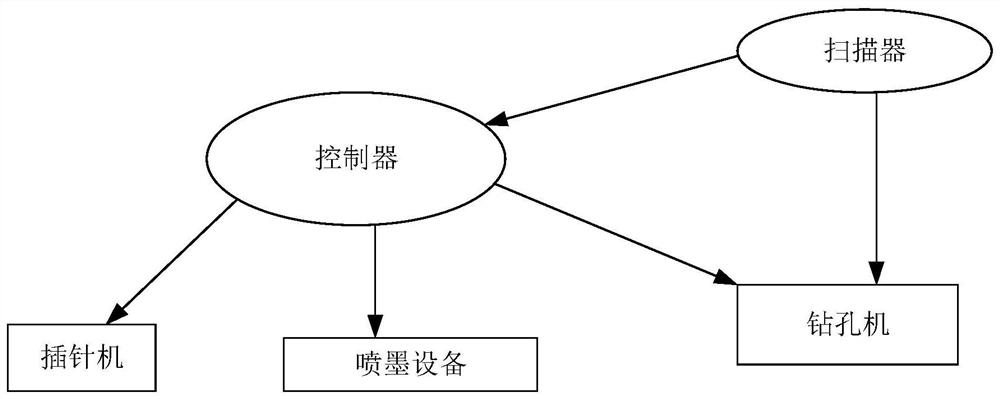

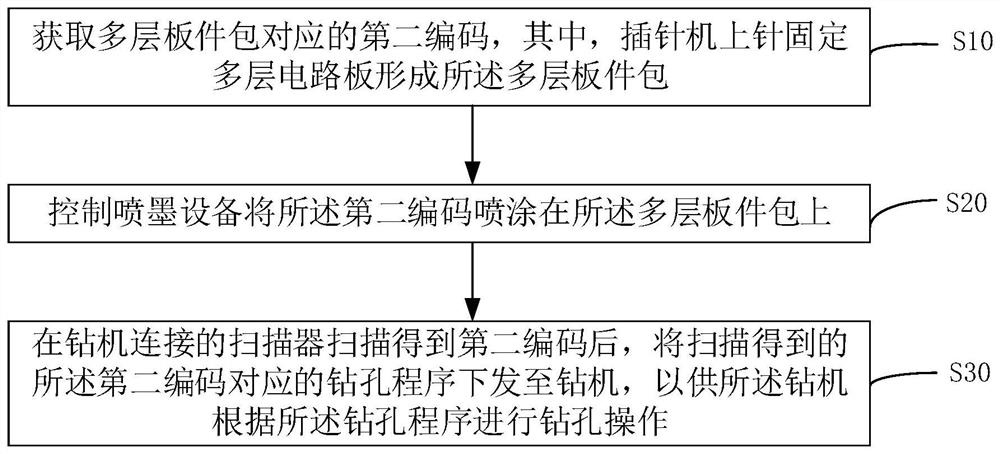

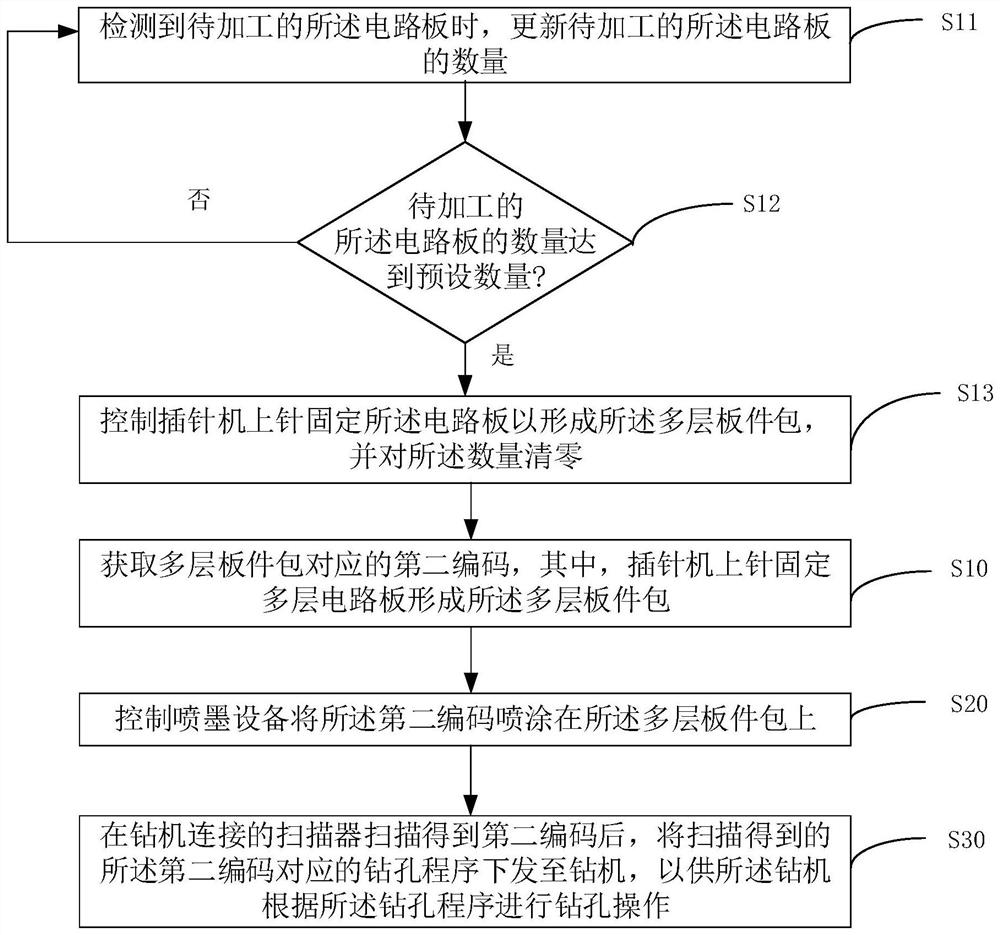

Drilling control method for multi-layer board

ActiveCN111010806BEliminate quality risksReduce manual labor intensityPrinted circuit manufactureControl engineeringMechanical engineering

The present invention provides a drilling control method for multi-layer boards. The method for controlling drilling of multi-layer boards includes: obtaining the second code corresponding to the multi-layer board package, wherein the pin insertion machine fixes the multi-layer The circuit board forms the multi-layer board package; the inkjet equipment is controlled to spray the second code on the multi-layer board package; after the scanner connected to the drilling machine scans to obtain the second code, all the scanned codes are scanned The drilling program corresponding to the second code is sent to the drilling machine for the drilling machine to perform drilling operations according to the drilling program. The drilling control method for multi-layer boards provided by the present invention enables the system to automatically send processing parameters to equipment, effectively eliminates quality risks caused by manual misoperations, and reduces manual labor intensity.

Owner:南通深南电路有限公司

A process for preventing local weak sand mold from crushing in core assembly

ActiveCN103537628BUnique methodQuicksand compactionFoundry mouldsFoundry coresMaterials scienceMetal

The invention relates to a positioning and supporting method for weak sand core and sand mold in a sand mold cast core assembly, in particular to a process method for preventing crushing of a local weak sand mold in core assembly. The method comprises the following steps: mounting a positioning pin on a corresponding part of an outer mold at a mold manufacturing stage; manufacturing a metal supporting rod welding part; inserting the manufactured metal supporting rod to the positioning pin of the outer mold in a molding process, drawing and burying the supporting rod in the sand mold; during core assembly, nailing a core support with an iron nail for positioning in a pin hole of the metal supporting rod, wherein the manufacturing depth of the corresponding part of the core is 3-5 mm, the diameter is slightly greater than that of a positioning pit on the outer circle of the core support, and the core is supported according to the position. The process method is unique, guarantees the accuracy of core assembly and positioning, eliminates the crushing risk which probably occurs in the assembly and casting processes, improves the product quality and simplifies the operation.

Owner:KOCEL EQUIP

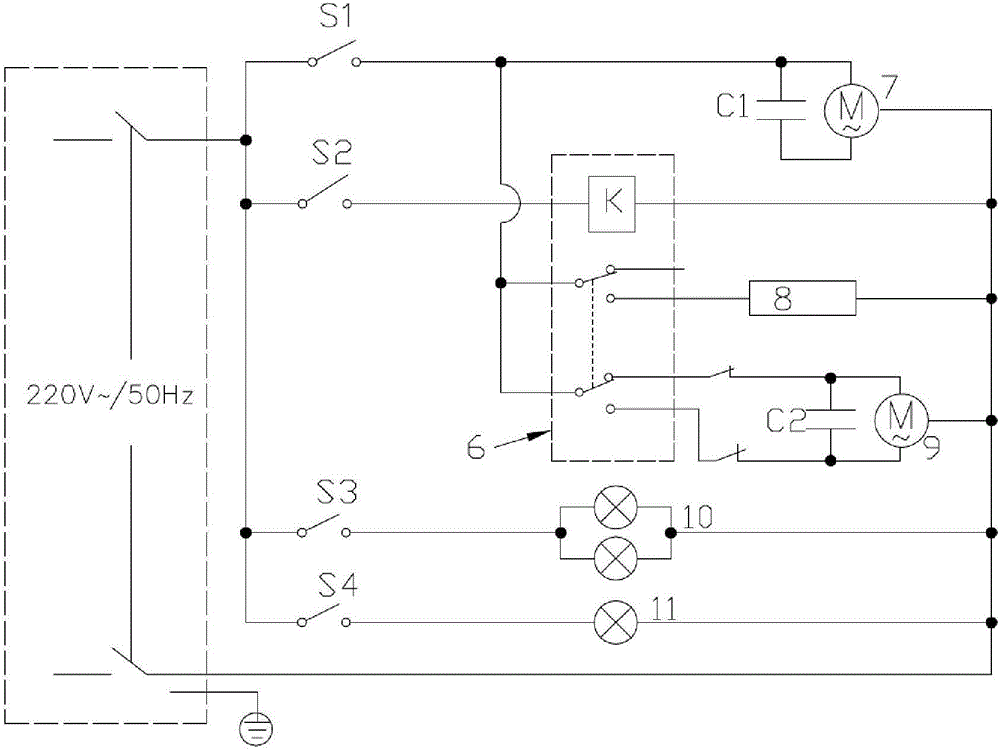

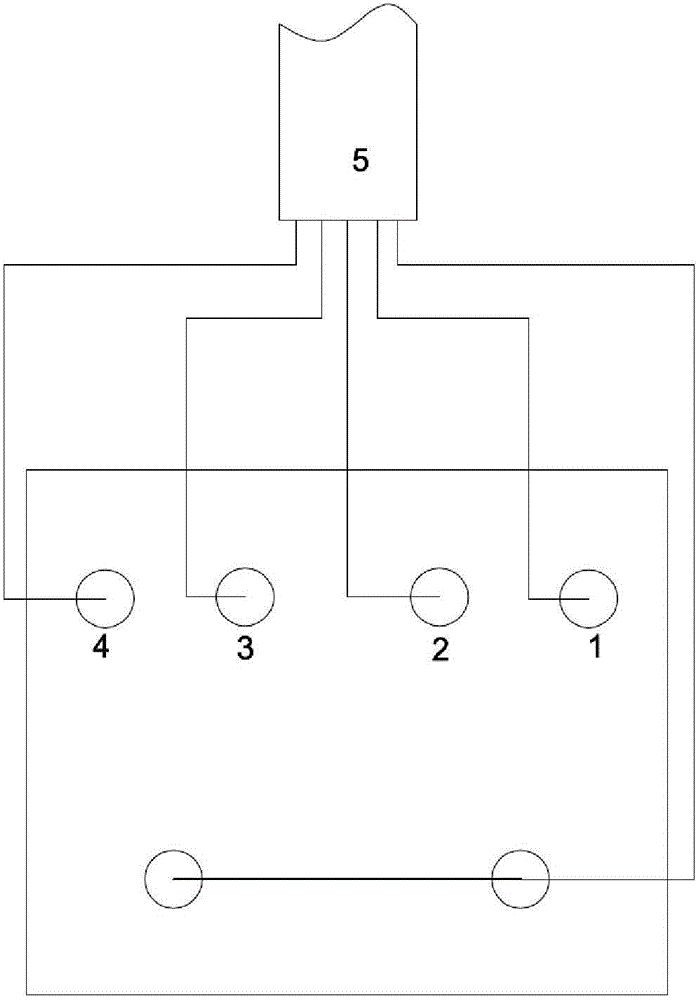

Improved bathroom warmer circuit

InactiveCN103335358ASimplify Special RequestsEliminate quality risksElectric light circuit arrangementSpace heating and ventilation detailsElectricityEffect light

The invention discloses an improved bathroom warmer circuit, comprising a fan wiring terminal, a wind heating wiring terminal, a lamp heating wiring terminal, a lighting wiring terminal, a ventilation fan, an electric heater, an electric heater auxiliary fan, a warming lamp, a lighting lamp and a relay, wherein the relay is adopted to control the electric heater and the electric heater auxiliary fan, the complicated wiring of a multi-control switch in the prior art is transplanted to the electromagnetic relay, no intervention is required during mounting, and the wiring is simpler and clearer; even if the wrong wiring situation occurs, the situations of product function fault and function failure cannot be caused, the function malposition situation of a switch key only exists and can be easily found out and corrected, and quality risk of products is eliminated; and the improved bathroom warmer puts an end to the situations of product function fault and function failure due to wrong mounting wiring, simplifies the special requirement on mounting wiring and reduces the labor cost on product mounting as well.

Owner:上海龙胜实业有限公司

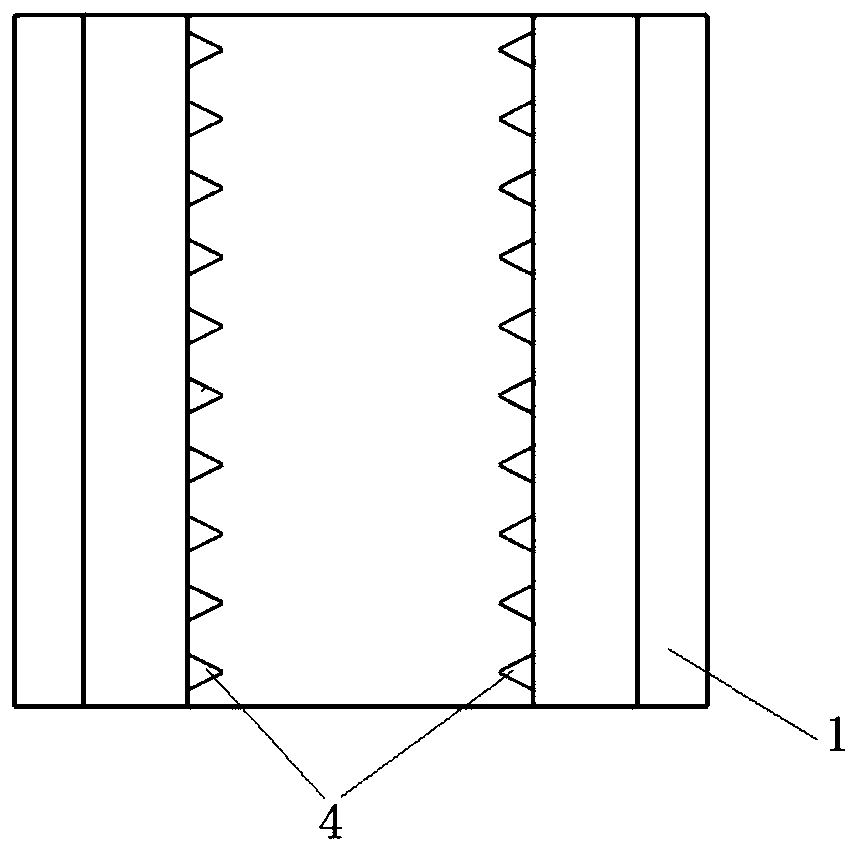

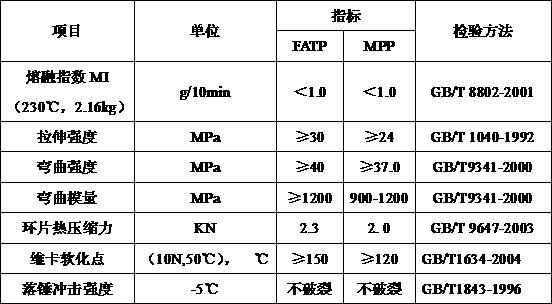

Trenchless corrugated pipe special for electric power and preparation method thereof

The invention discloses a trenchless corrugated pipe special for electric power. The trenchless corrugated pipe comprises the following raw materials in percentage by mass: 65 to 75 percent of polypropylene, 15 to 20 percent of nylon, 2 to 7 percent of glass fibers, 1 to 5 percent of compatilizer, 0.2 to 2.5 percent of coupling agent, 0.1 to 0.5 percent of antioxidant, 0.1 to 0.5 percent of anti-ultraviolet absorber, 0.1 to 0.4 percent of lubricating agent and 0.4 to 1.0 percent of toner. A method for preparing the trenchless corrugated pipe special for electric power (FATP) comprises the following steps of: 1) loading and drying; 2), mixing and extruding; 3) cooling for forming; 4) cutting and coiling; and 5) inspecting for warehousing. According to the trenchless corrugated pipe, the polypropylene is modified by introducing the nylon material reasonably, so that the heat resistance, tensile strength and abrasive resistance of the product are improved; and the glass fibers in a certain ratio are added to improve the ring plate thermocompression force of the product, and the comprehensive performance indexes of the product are improved to a certain degree.

Owner:福建晟扬管道科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com