A Method for Fast Trial Cutting and Cutting Parameters Optimization of CNC Milling Tool

A cutting parameter, CNC milling technology, applied in the field of metal cutting, can solve the problems of no tool test cutting force measuring equipment, tool wear detection equipment, inability to use the cutting performance of the tested cutting tool, and increase the workload of programmers. Eliminate quality risks, avoid repeated modification of processing procedures, and improve the efficiency of trial cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for rapid trial cutting and cutting parameters optimization of CNC milling tools, which is suitable for production sites, and includes the following steps:

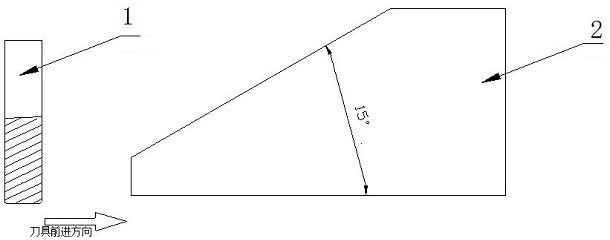

[0046] Step 1. Design as figure 2 The shown inclined block is used as the processed standard trial cutting piece 2 of the cutting tool 1 to be tested, and the angle of the inclined plane is 10-15 degrees.

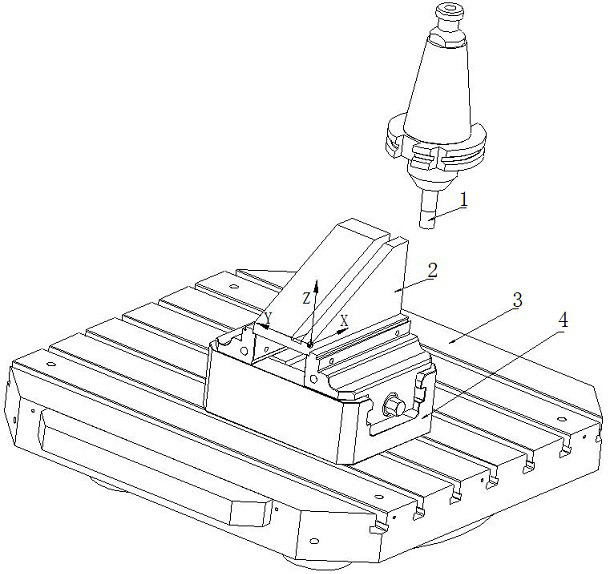

[0047] Step 2: Install the general-purpose vise on the machine table 3 and align it, and use the vise 4 to clamp the standard trial-cut piece to establish a processing coordinate system.

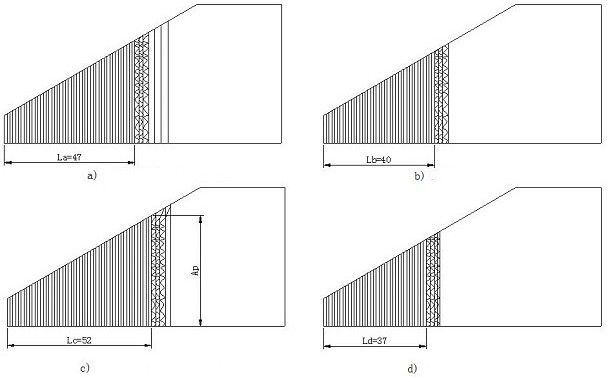

[0048] Step 3: call the standard trial cutting processing program, and modify the cutting parameter variables of the standard trial cutting processing program as required. The standard trial cutting process is shown in Table 1.

[0049] Among them, the standard trial cutting processing program is designed with a macro program, and the main axis speed Vc, tool diameter D, tool feed per tooth...

Embodiment 2

[0077] On the basis of embodiment 1, more specifically, according to the reference cutting parameters provided by the tool supplier and the processing experience of the enterprise, such as, the cutting line speed Vc of a certain tool (diameter d=10mm, number of teeth Z=5) processing superalloy material =60~80m / min, feed per tooth Fz=0.05~0.12mm / tooth, then the calculation method of the optimal feed per tooth Fz and cutting linear speed Vc of the tool is as follows:

[0078] Parameter selection for the first experiment: According to the principle of the golden section method "(big-small)*0.618+small", that is

[0079] Fz1=((0.12-0.05)*0.618)+0.05≈0.093;

[0080] Vc1=((80-60)*0.618)+60≈72.36

[0081] Parameter selection for the second experiment: According to the principle of the golden section method, "the next point is selected as: (big + small - previous point)", that is:

[0082] Fz2=0.12+0.05-0.093=0.077

[0083] Vc2=80+60-72.36=67.64

[0084] Parameter selection for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com