Preparation method of reaction injection molding interpenetrating network sweating wear-resistant screen

An injection molding and interpenetrating network technology, which is applied in the field of preparation of reaction injection molding interpenetrating network sweating and wear-resistant screens, can solve the problems of low wear rate, poor application effect, low oil content, etc., to improve production efficiency, Conducive to production energy consumption and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

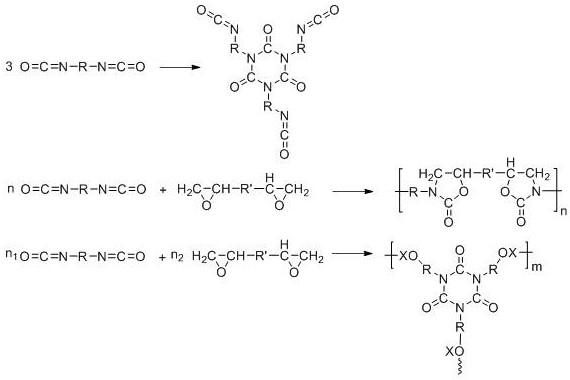

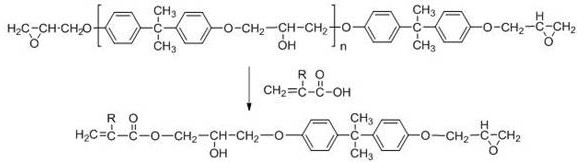

Method used

Image

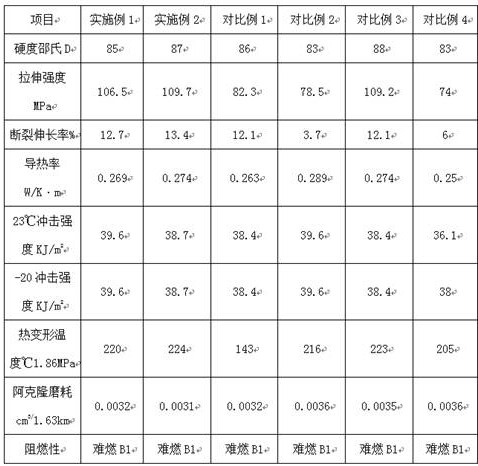

Examples

Embodiment 1

[0032] The first step is to prepare sweating microcapsules: in parts by weight, add 93 parts of water and 37 parts of melamine into a reaction kettle with a stirrer and a thermometer, heat up to 57°C, add 45 parts of cyanuric acid, and use triethylene Adjust the pH of the system to 9 with diamine, raise the temperature to 96°C and stir the reaction for 3 hours, then add 14 parts of aminoethylaminopropyl polydimethylsiloxane and mix evenly to obtain an oil phase liquid, and 37 parts of polytetrafluoroethylene dispersion emulsion Add 0.2 parts of emulsifier and disperse in 112 parts of deionized water, use a shear dispersion emulsifier at 6000r / min to emulsify for 4 minutes to obtain an emulsion, add the prepared oil phase liquid to the emulsion, and keep it for 5 minutes to obtain Uniformly stabilize the microcapsule emulsion, transfer the microcapsule emulsion to another reaction kettle, raise the temperature to 90°C, start stirring, and keep warm for 5 hours to obtain a viscou...

Embodiment 2

[0034] The first step is to prepare sweating microcapsules: in parts by weight, add 93 parts of water and 37 parts of melamine into a reaction kettle with a stirrer and a thermometer, heat up to 57°C, add 41 parts of cyanuric acid, and use triethylene Adjust the pH of the system to 8.5 with diamine, raise the temperature to 93°C and stir the reaction for 2 hours, then add 12 parts of aminoethylaminopropyl polydimethylsiloxane and mix evenly to obtain an oil phase liquid, and 32 parts of polytetrafluoroethylene dispersion emulsion Add 0.1 part of emulsifier to disperse in 104 parts of deionized water, use a shear dispersion emulsifier at 4000r / min to emulsify for 2 minutes to obtain an emulsion, add the prepared oil phase liquid to the emulsion, and keep it for 3 minutes to obtain Uniformly stabilize the microcapsule emulsion, transfer the microcapsule emulsion to another reaction kettle, raise the temperature to 85°C, start stirring, and keep warm for 3 hours to obtain a viscou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com