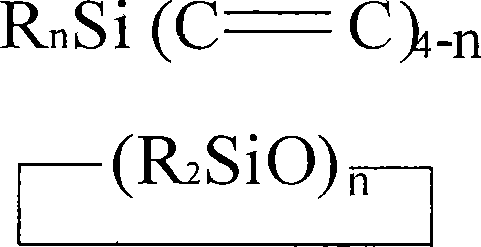

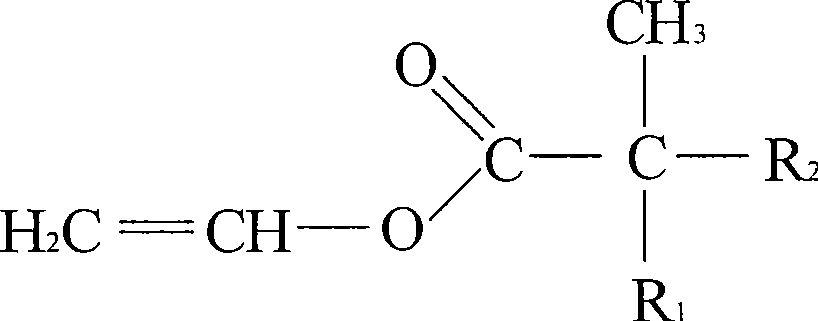

Organosilicon modified tert-fluoro emulsion and preparation of luminescent coating with the emulsion as base material

A tertiary fluorine emulsion and organosilicon technology, applied in the field of coatings, can solve the problems of poor performance of modified products, and achieve the effects of low cost, safe use and good marking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] To prepare the emulsion:

[0058] a. mixing and stirring the monomer with water and an emulsifier to form an emulsion, and preparing a core monomer pre-emulsion and a shell monomer pre-emulsion;

[0059] b. In a reactor equipped with a stirrer, a reflux condenser, a constant-speed dripping peristaltic pump, a thermometer and an external heating jacket, add potassium persulfate solution, core layer monomer pre-emulsion and shell layer monomer pre-emulsion respectively solution into the reaction kettle, the reaction temperature is 75°C, and the dropping time is 2.5 to 4 hours. After adding the potassium sulfate solution and the monomer pre-emulsion liquid dropwise, add tert-butyl hydroperoxide-formaldehyde sulfoxylate sodium, After the addition, continue to keep warm and stir for 3-5 hours. After the reaction is completed, cool down to 20-40°C and discharge to obtain an emulsion.

[0060] Above-mentioned emulsion raw material content (weight percentage) is as follows:

...

Embodiment 2

[0094] a. mixing and stirring the monomer with water and an emulsifier to form an emulsion, and preparing a core monomer pre-emulsion and a shell monomer pre-emulsion;

[0095] b. In a reactor equipped with a stirrer, a reflux condenser, a constant-speed dripping peristaltic pump, a thermometer and an external heating jacket, add potassium persulfate solution, core layer monomer pre-emulsion and shell layer monomer pre-emulsion respectively liquid into the reaction kettle, the reaction temperature is 80°C, and the dropping time is 3 to 6 hours. After adding the potassium sulfate solution and the monomer pre-emulsion dropwise, add tert-butyl hydroperoxide-sodium formaldehyde sulfoxylate, After the addition, continue to keep warm and stir for 2.5 hours. After the reaction is complete, cool down to 20-40°C and discharge to obtain an emulsion.

[0096] Above-mentioned emulsion raw material content (weight percentage) is as follows:

[0097] Nuclear Layer Monomer:

[0098] Styren...

Embodiment 3

[0129] a. mixing and stirring the monomer with water and an emulsifier to form an emulsion, and preparing a core monomer pre-emulsion and a shell monomer pre-emulsion;

[0130] b. In a reactor equipped with a stirrer, a reflux condenser, a constant-speed dripping peristaltic pump, a thermometer and an external heating jacket, add potassium persulfate solution, core layer monomer pre-emulsion and shell layer monomer pre-emulsion respectively solution into the reaction kettle, the reaction temperature is 75°C, and the dropping time is 2.5 to 4 hours. After adding the potassium sulfate solution and the monomer pre-emulsion liquid dropwise, add tert-butyl hydroperoxide-formaldehyde sulfoxylate sodium, After the addition, continue to keep warm and stir for 3-5 hours. After the reaction is completed, cool down to 20-40°C and discharge to obtain an emulsion.

[0131] Above-mentioned emulsion raw material content (weight percentage) is as follows:

[0132] Nuclear Layer Monomer:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com