Patents

Literature

83results about How to "Smooth molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

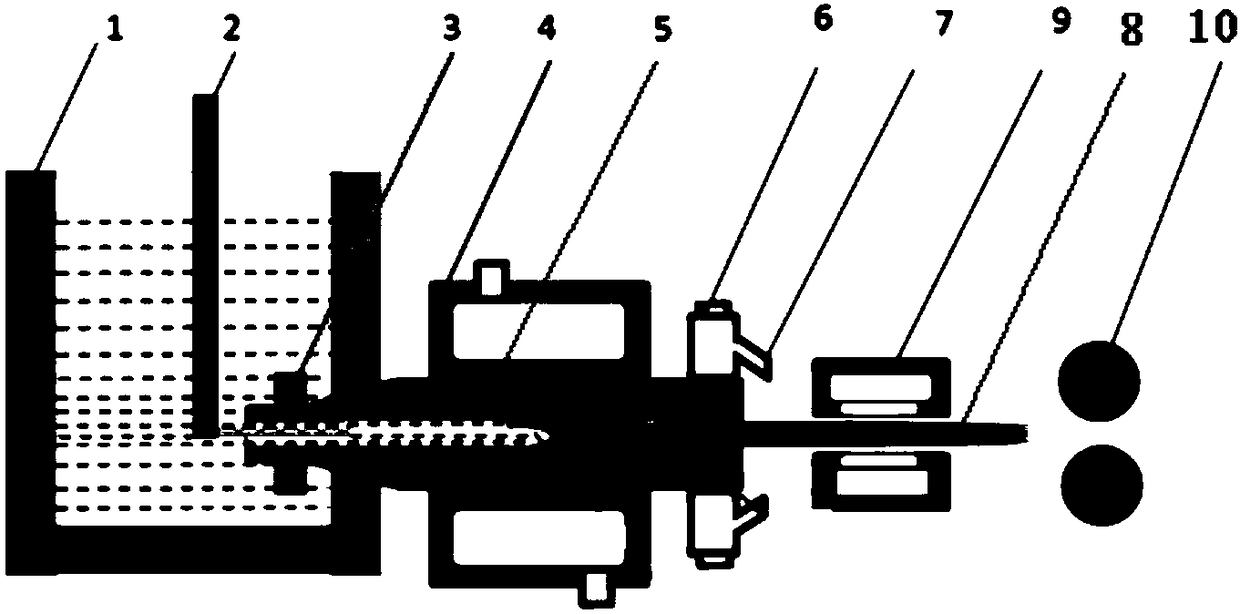

Method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for metal 3D printer

ActiveCN104353832ALow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyMolecular sieveSolenoid valve

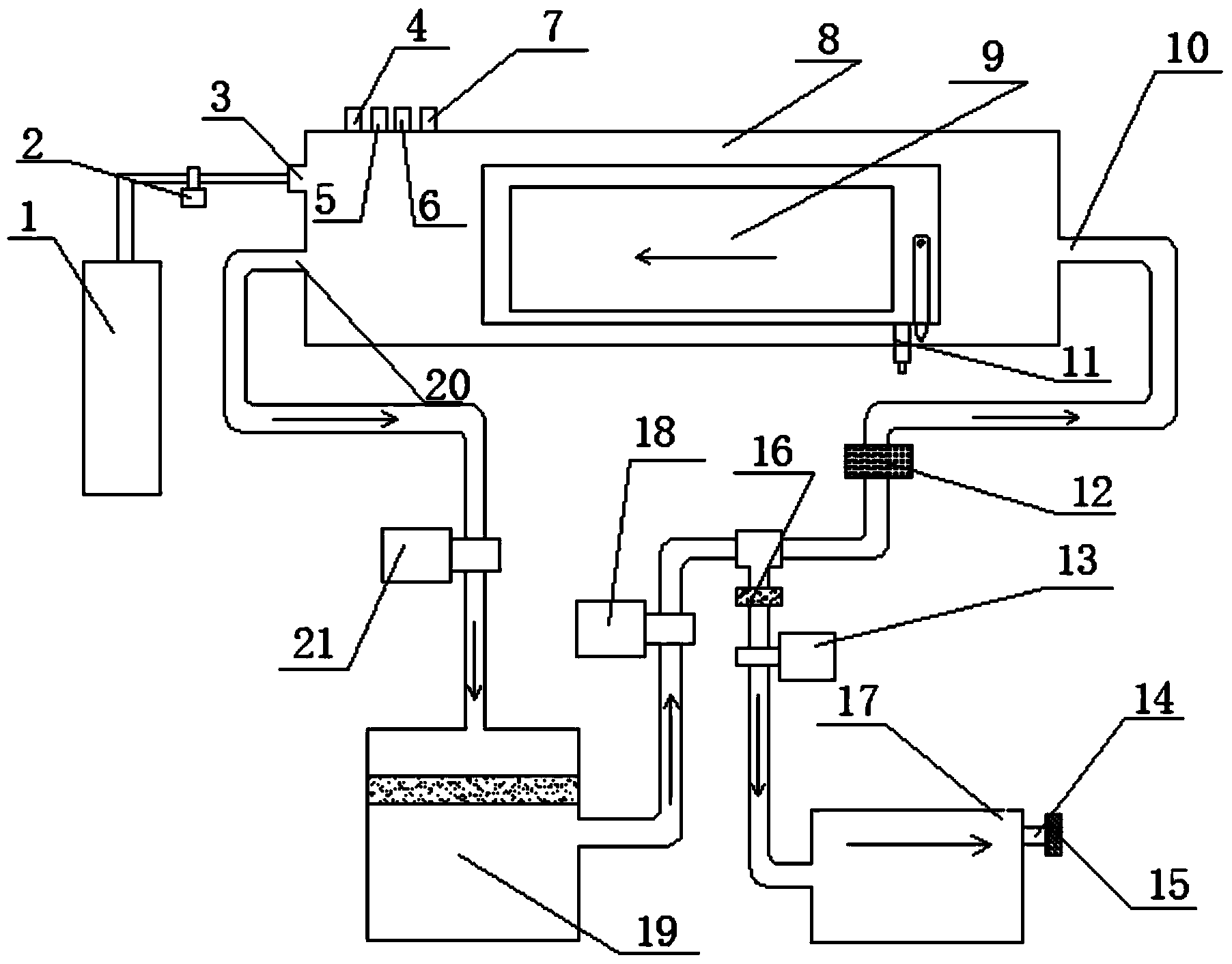

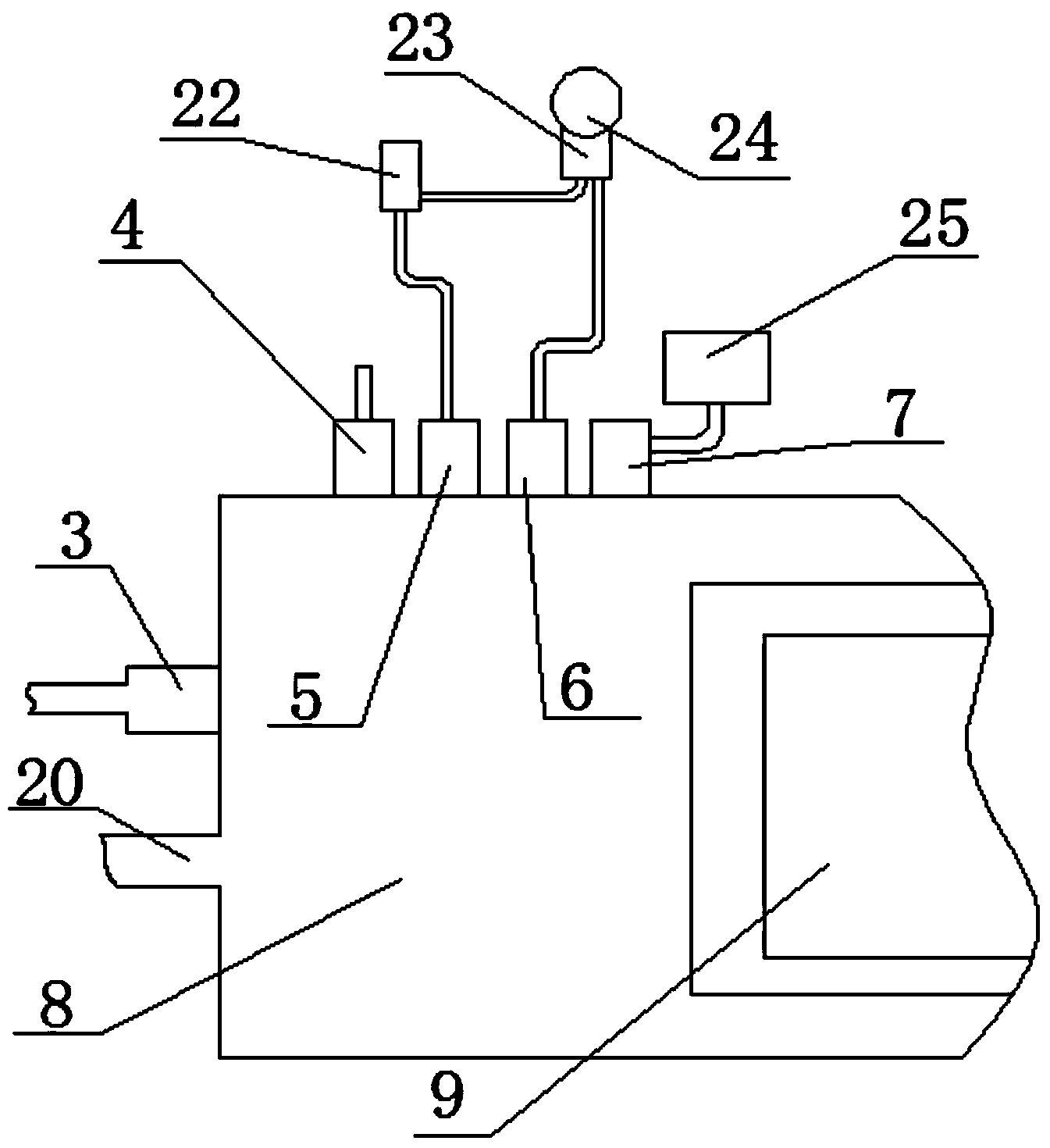

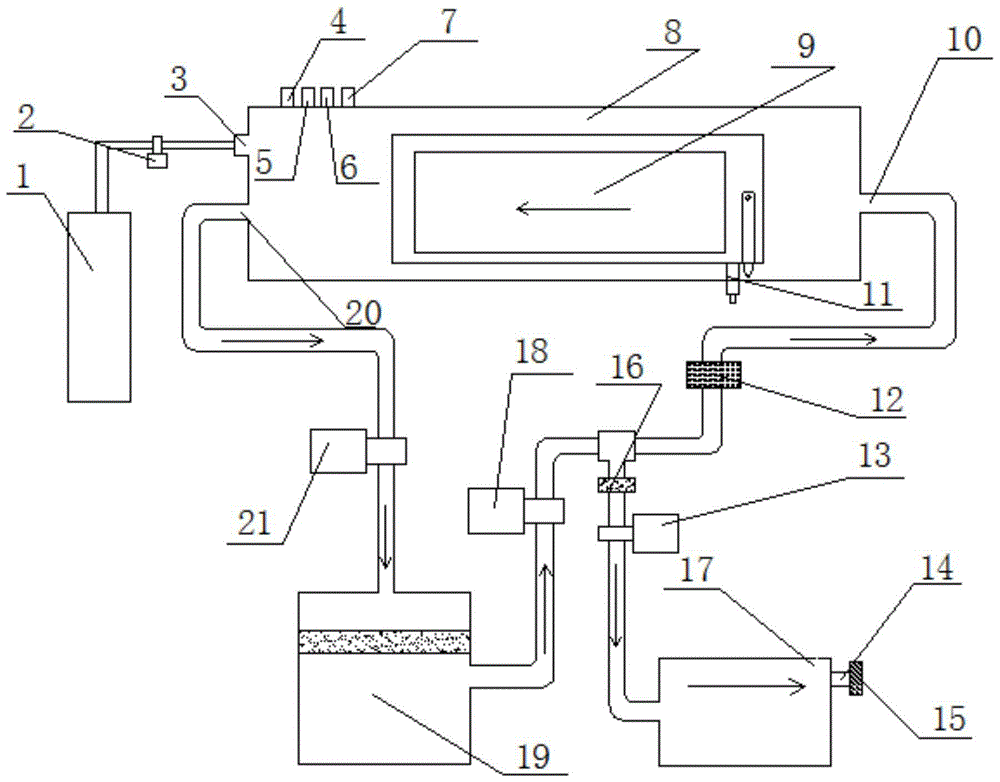

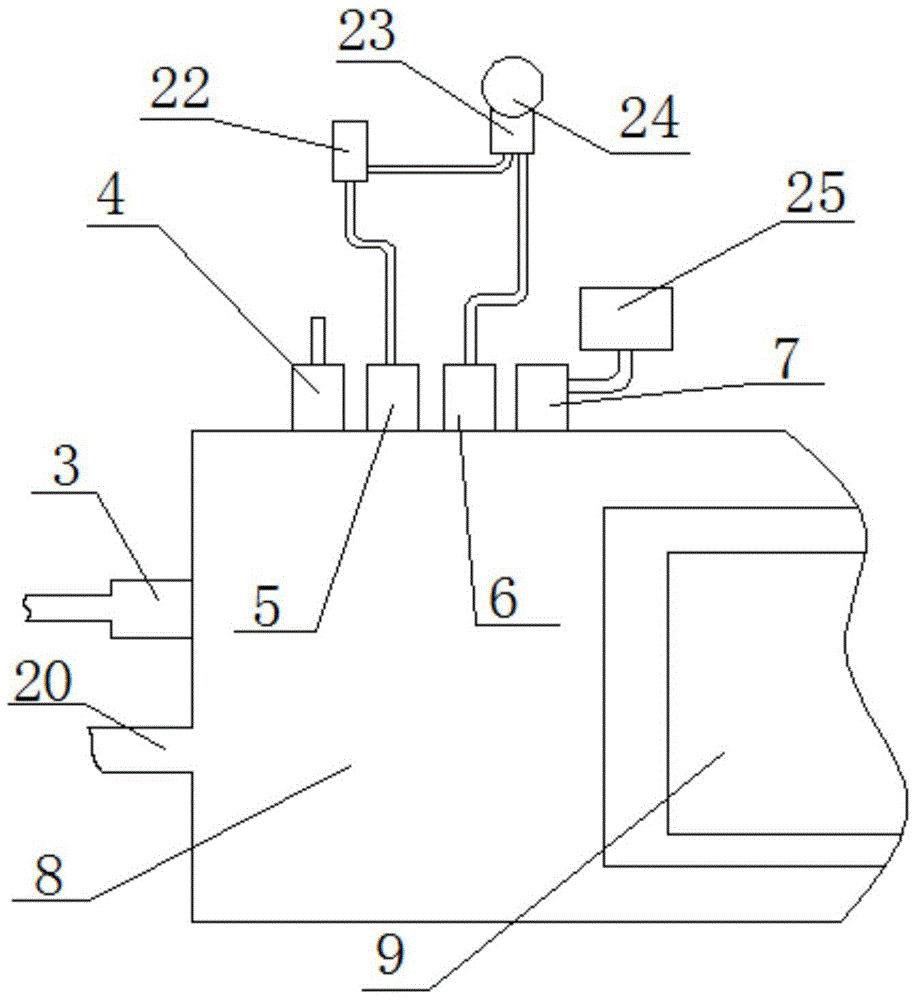

The invention discloses a method and equipment of sealed chamber atmosphere deoxygenization and circulating purification for a metal 3D printer. A gas inlet and a gas outlet are respectively formed in two ends of a forming chamber; the gas inlet and the gas outlet are mutually connected through a gas circulating pipeline; a first pneumatic butterfly valve, a dust purifier, a second pneumatic butterfly valve and a water removal drier are arranged on the gas circulating pipeline; a branch pipeline is arranged on the gas circulating pipeline between the second pneumatic butterfly valve and the water removal drier; the tail end of the branch pipeline is connected with a vacuum pump; a molecular sieve and a vacuum pipeline solenoid valve are arranged on the branch pipeline; the forming chamber is connected with an inert gas source. According to the method, firstly the oxygen content in the forming chamber is reduced to a required range before machining, and gas circulating purification is started during machining, so that gas purity degree in the forming chamber is kept; pressure detection and oxygen content detection are introduced, so that the oxygen content and pressure are within a reasonable range at all time during machining. The method and the equipment improve the forming efficiency and quality of the 3D printer, and guarantee the safety and the reliability of the machining process.

Owner:SOUTH CHINA UNIV OF TECH

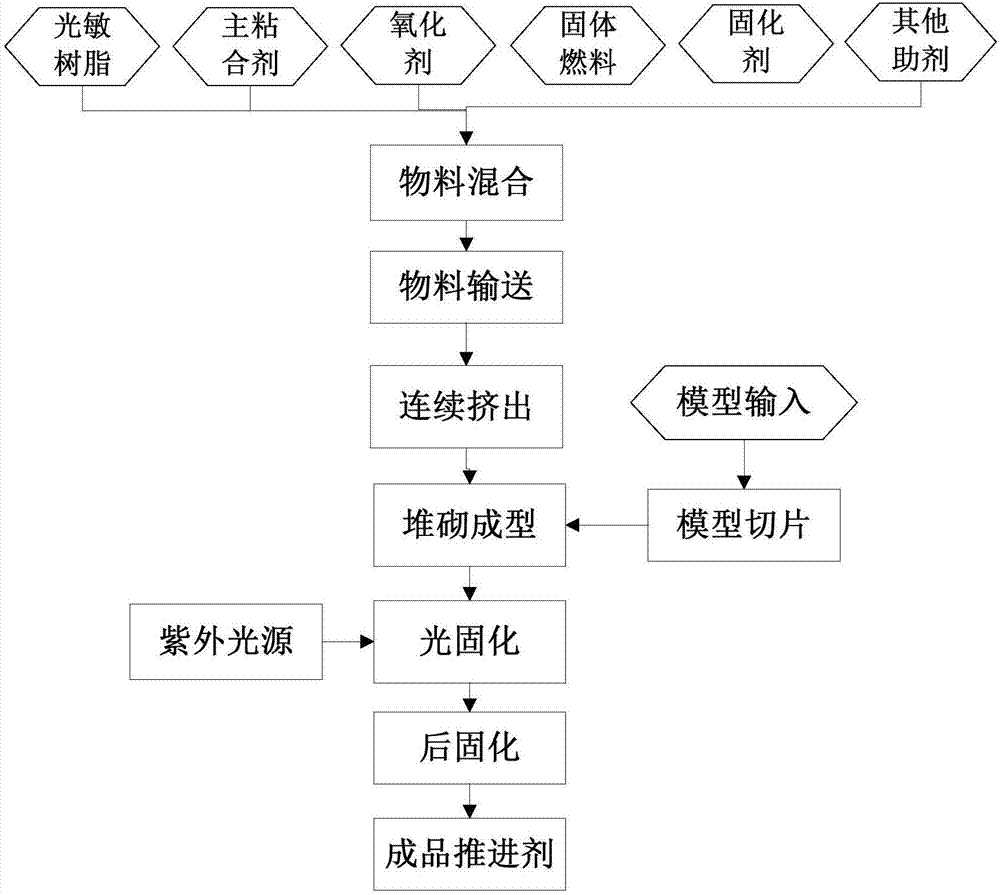

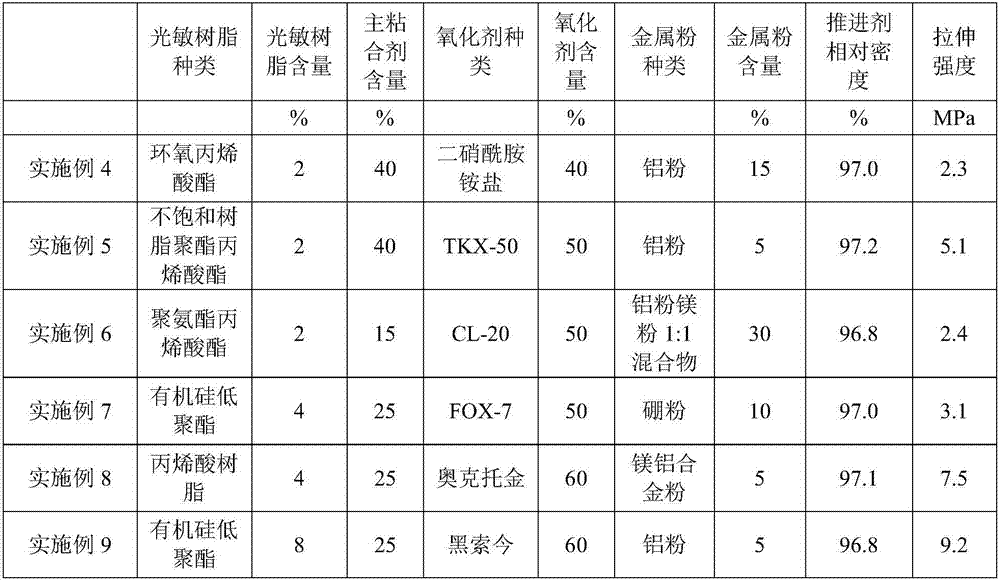

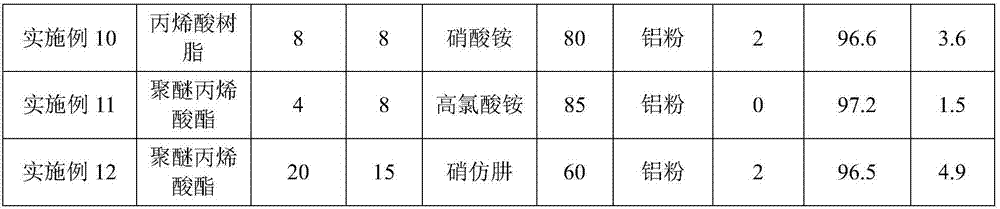

Solid propellant 3D printing and forming method based on ultraviolet light solidification

InactiveCN107283826AAvoid safety hazardsSmooth moldingAdditive manufacturing apparatus3D object support structuresAdhesiveSolid fuel

The invention discloses a solid propellant 3D printing and forming method based on ultraviolet light solidification. Photosensitive resin, a main adhesive, a solidification agent, an oxidizing agent, solid fuel and other raw materials are uniformly mixed, the materials are conveyed to an extrusion spray head to be extruded continuously, ultraviolet light is conveyed to the extrusion spray head, and the extruded materials are subjected to continuous solidification. 3D printing software is adopted to control the movement path of the extrusion spray head and the extrusion speed of the materials, stacking is performed layer by layer, and solidification is performed layer by layer; and finally, a formed sample is further subjected to heat preservation and solidification in a constant temperature oven. By means of the method, thermosetting solid propellants of any shape can be prepared safety at a low temperature and low pressure, and the method has the characteristics of being safe in process, free of a forming mold and wide in application range.

Owner:NANJING UNIV OF SCI & TECH

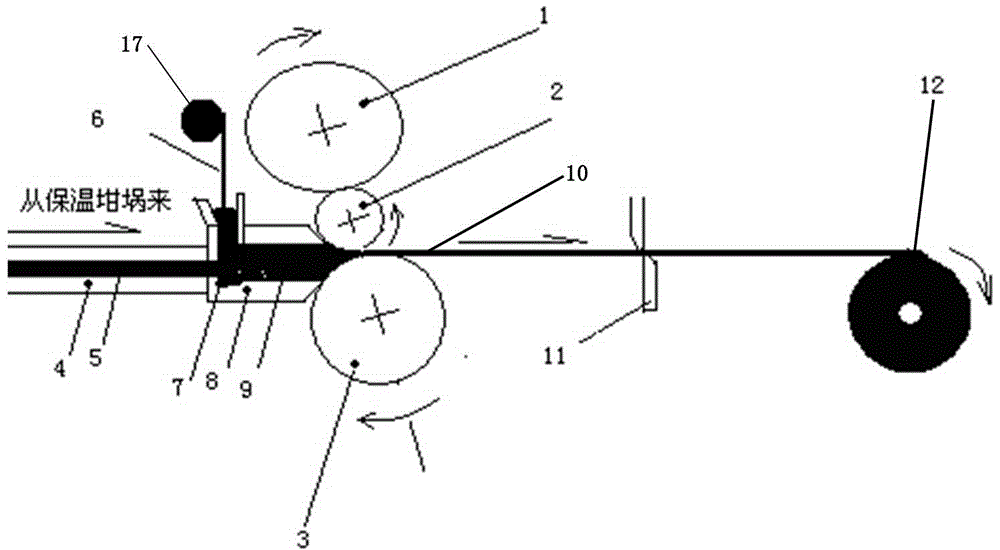

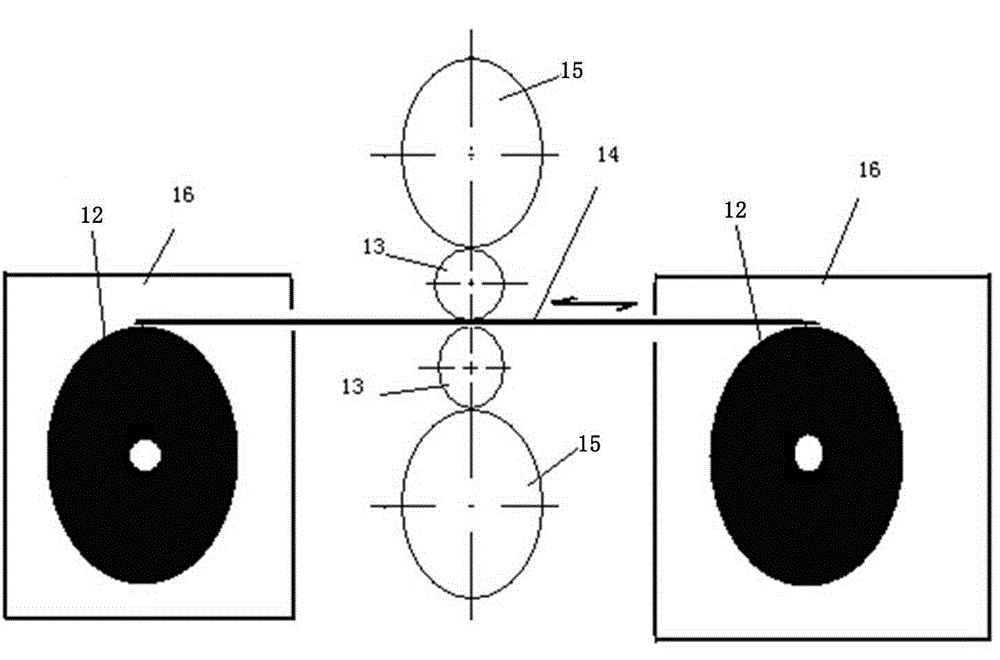

CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device

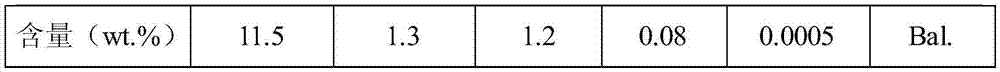

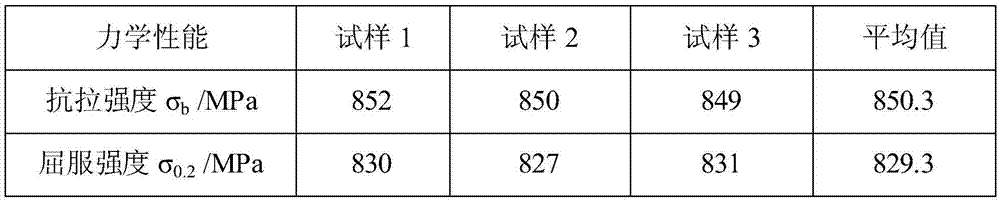

The invention discloses a CuNiSn series alloy and strip billet composition external field horizontal continuous casting preparation method and device. A CuNiSn series alloy is in a Cu matrix, and meanwhile contains microalloying elements comprising B, Sr and V. The content sum of the microalloying elements comprising B, Sr and V is smaller than or equal to 0.3% of the mass of a CuNiSn series elastic copper alloy matrix. The preparation method comprises the steps of alloy melting and horizontal continuous casting. The technological process of horizontal continuous casting comprises stretching,primary standstill, reverse push, secondary standstill and stretching. The outlet end of a crystallizer of the horizontal continuous casting equipment is provided with a nitrogen nozzle which forms agas curtain on the periphery of a strip billet. An ultrasonic generator sealed by a boron nitride ceramic casing pipe with high heat resistance and low ultrasonic attenuation is further arranged in aheat insulation furnace. The inlet of the crystallizer is annularly sleeved with an electromagnetic induction coil. The prepared CuNiSn series elastic copper alloy has the characteristics of super strength, high stress relaxation resistance and the like, and is applicable to high-performance conductive elastic devices for spaceflight, aviation and microelectronics industry.

Owner:CENT SOUTH UNIV +1

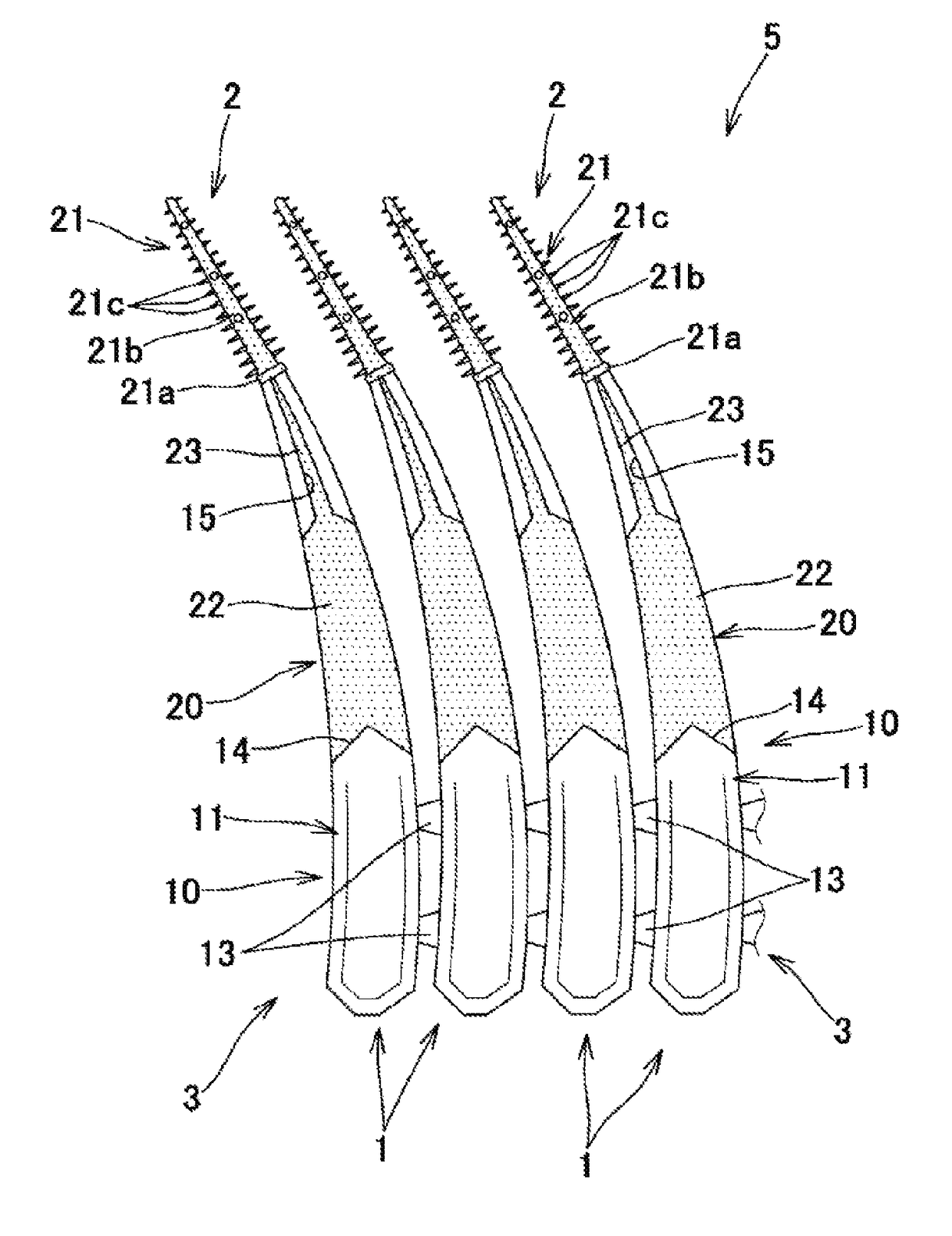

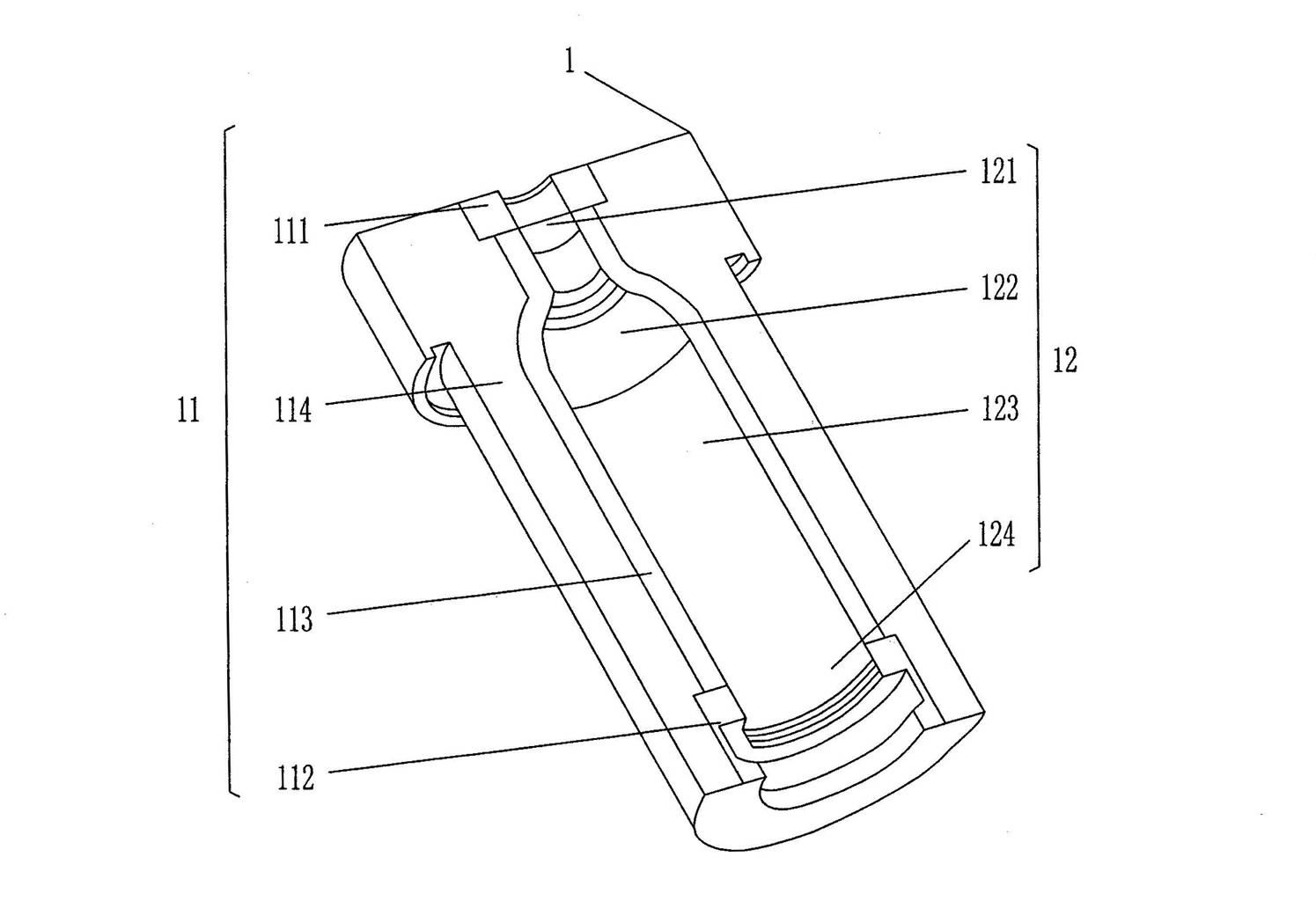

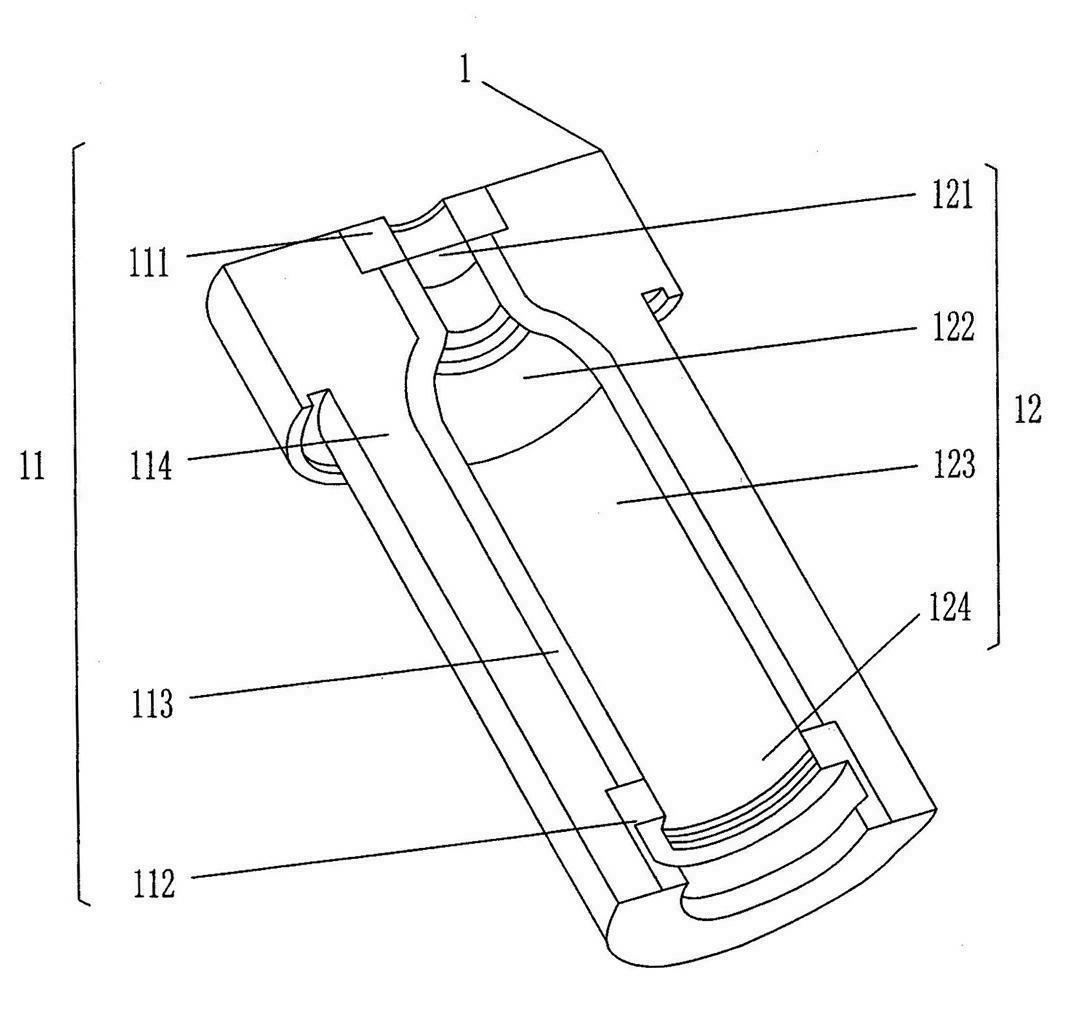

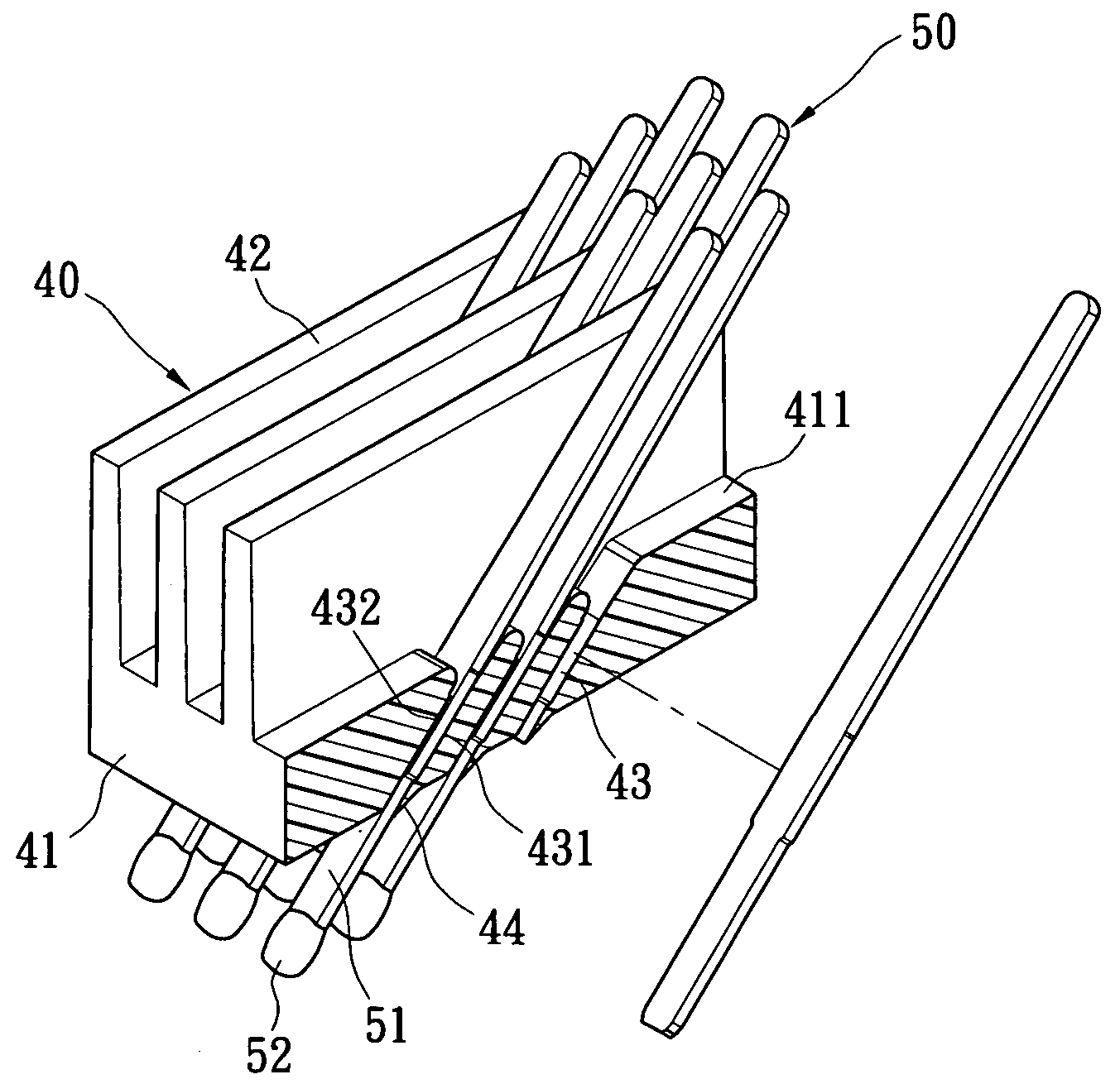

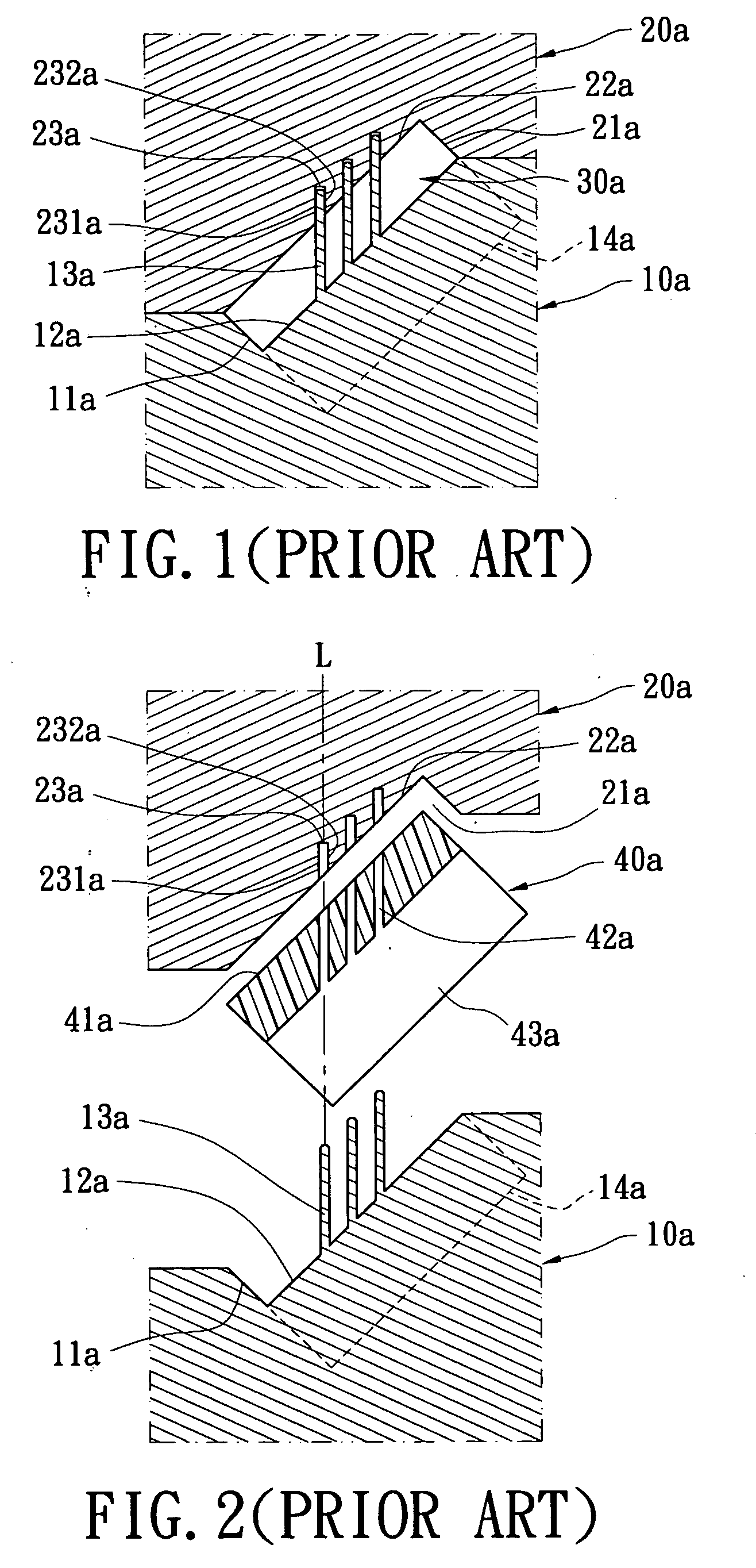

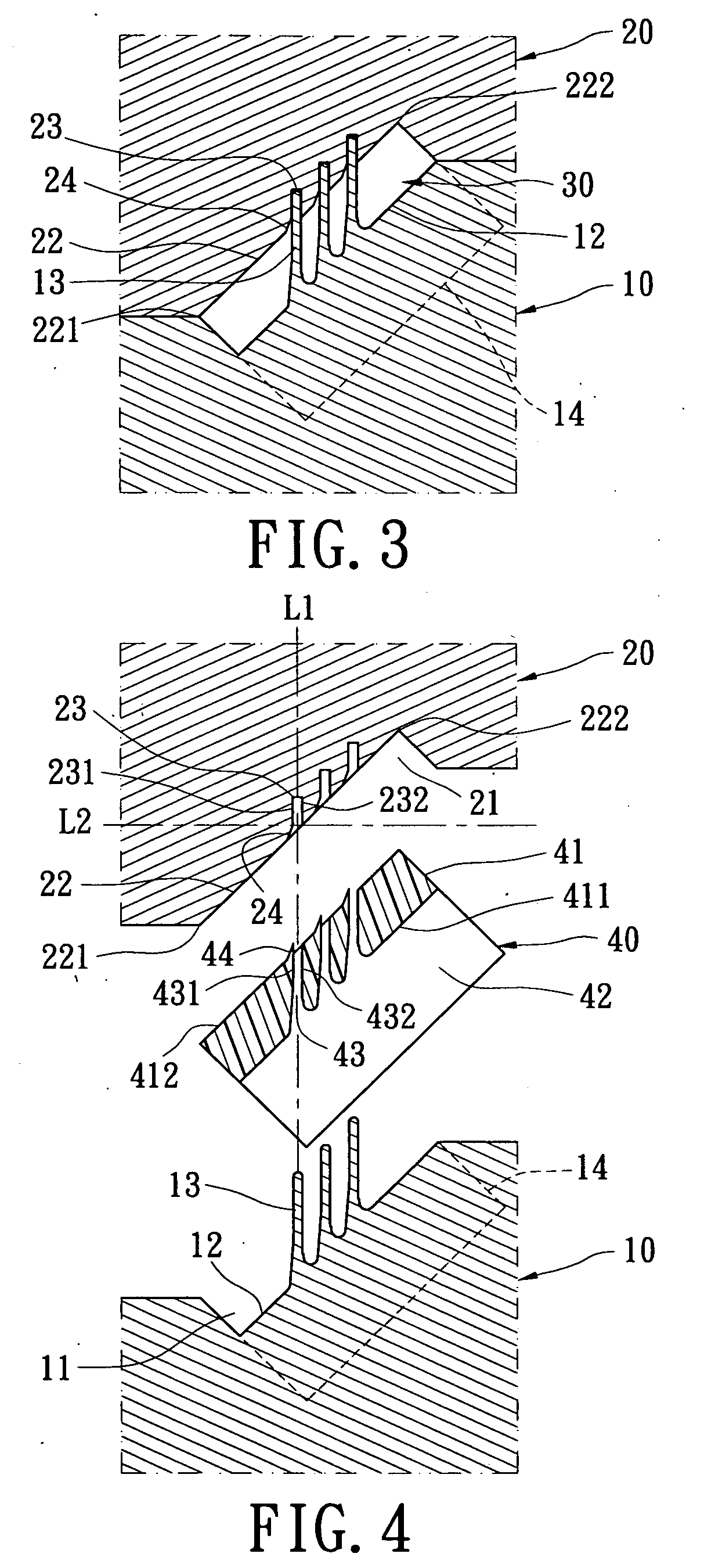

Method for manufacturing interdental cleaning device

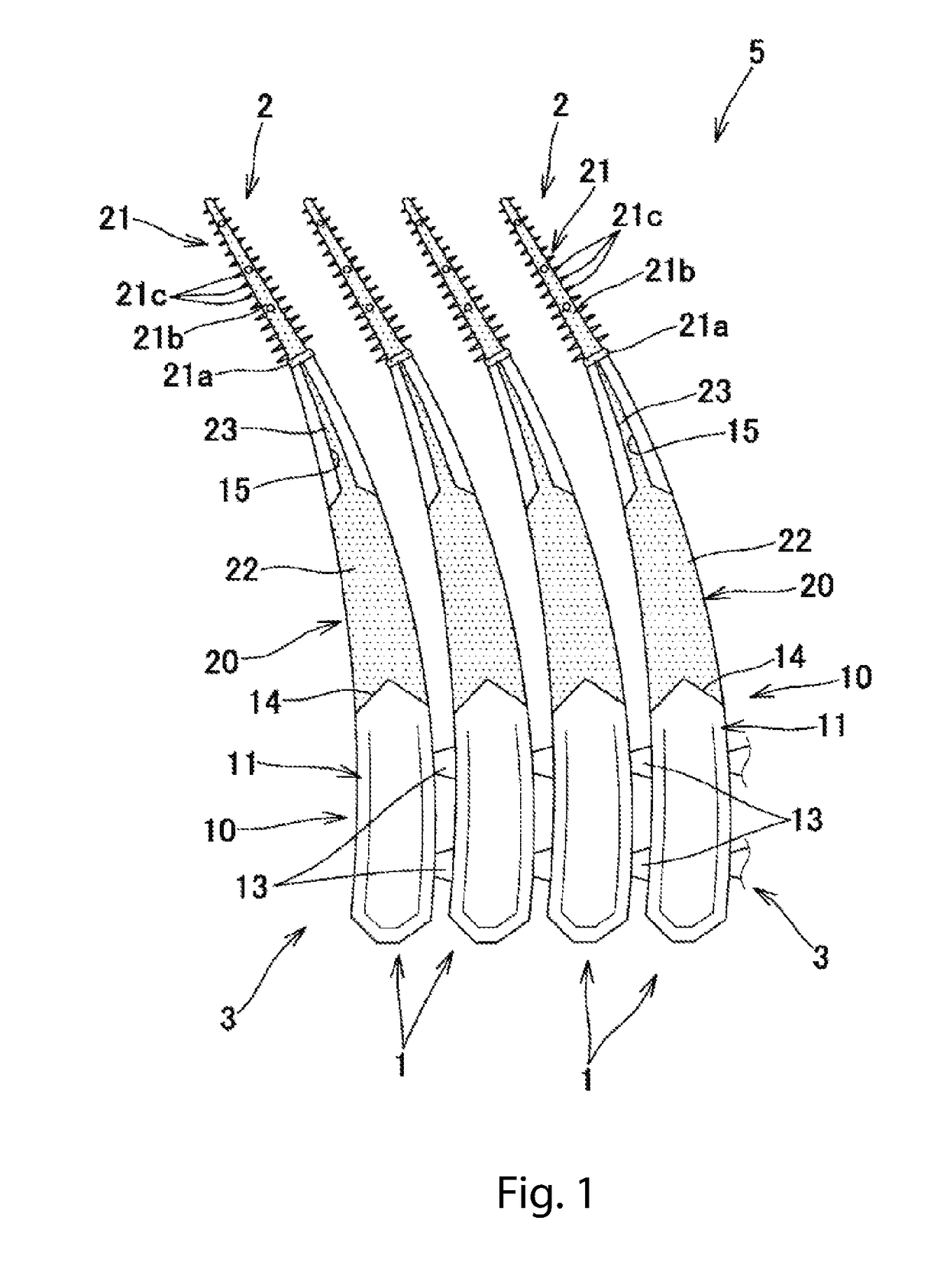

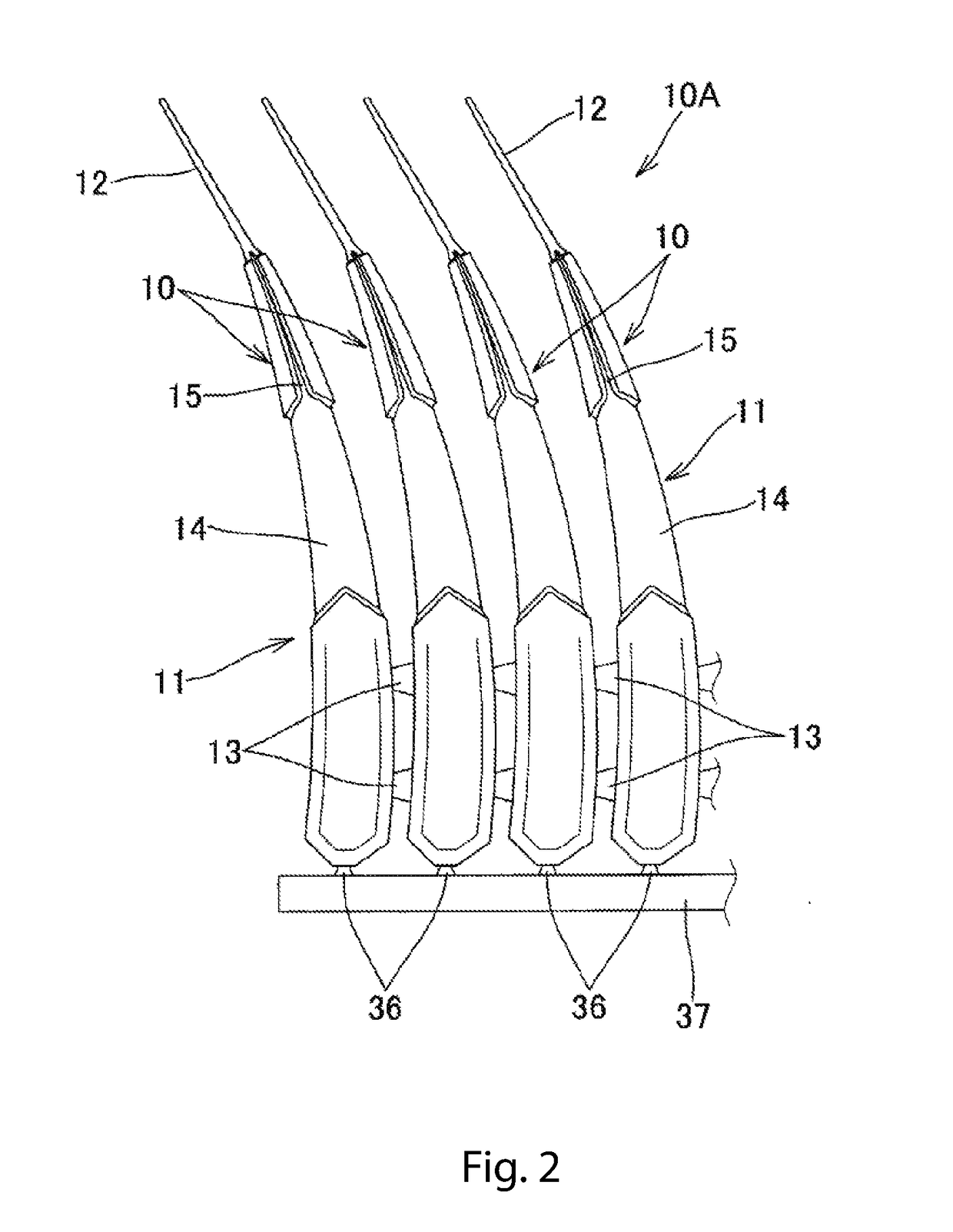

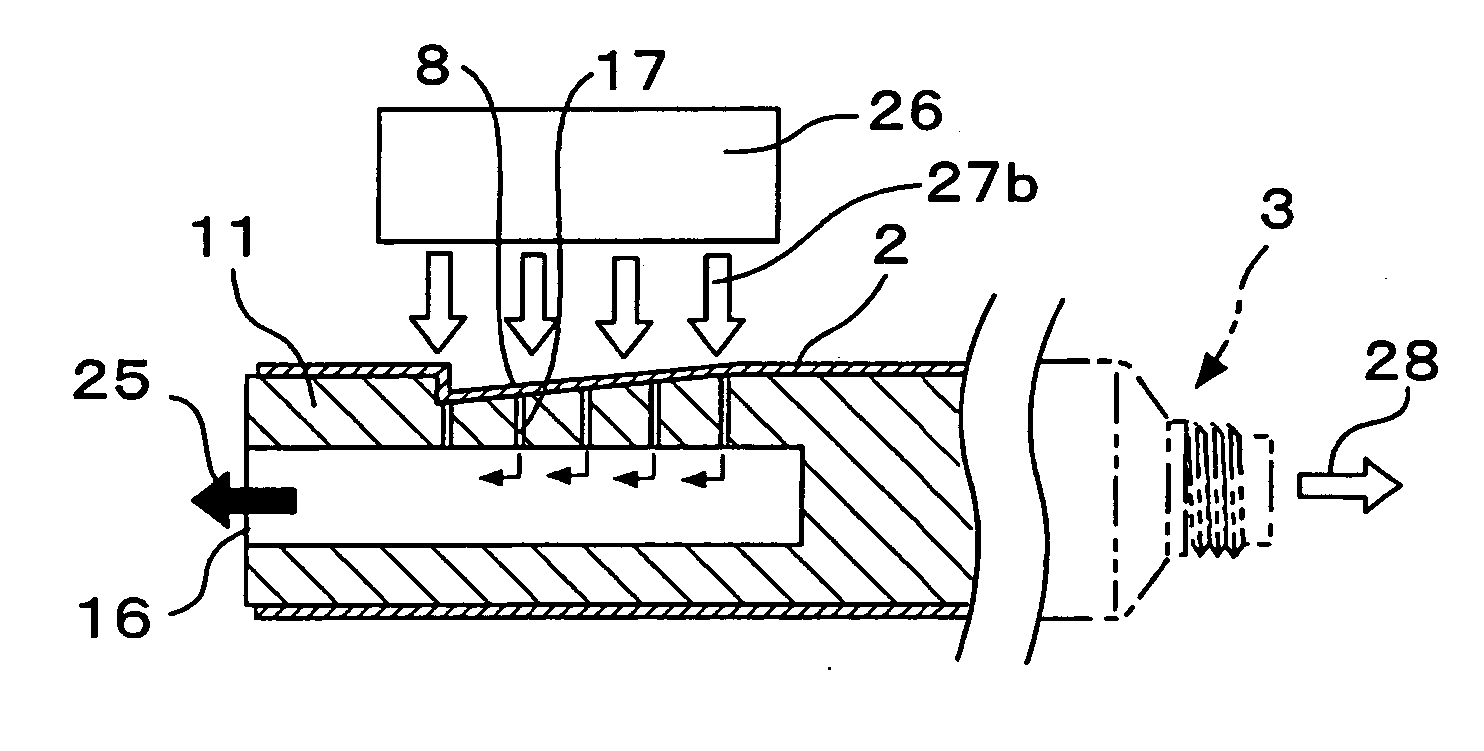

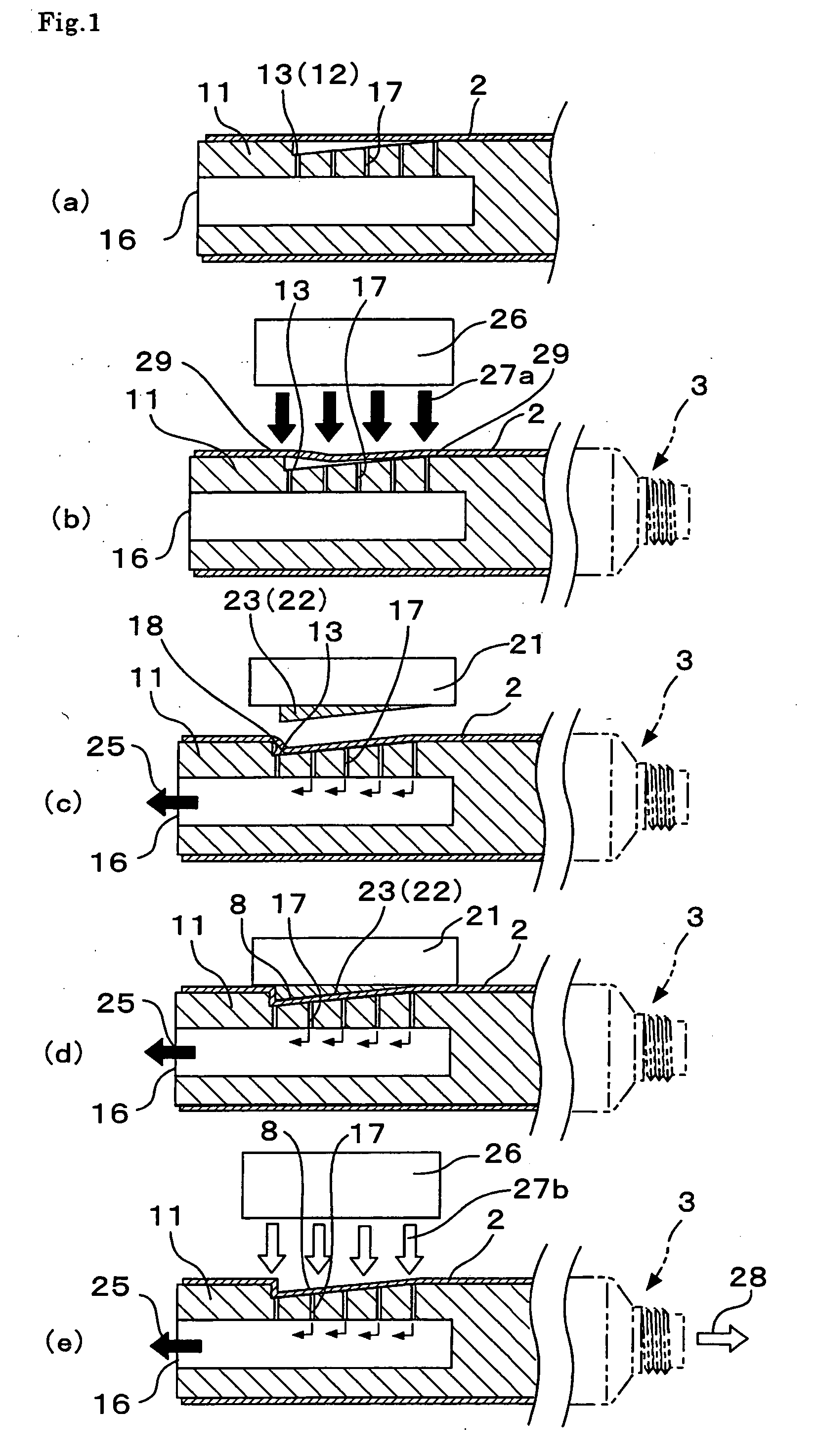

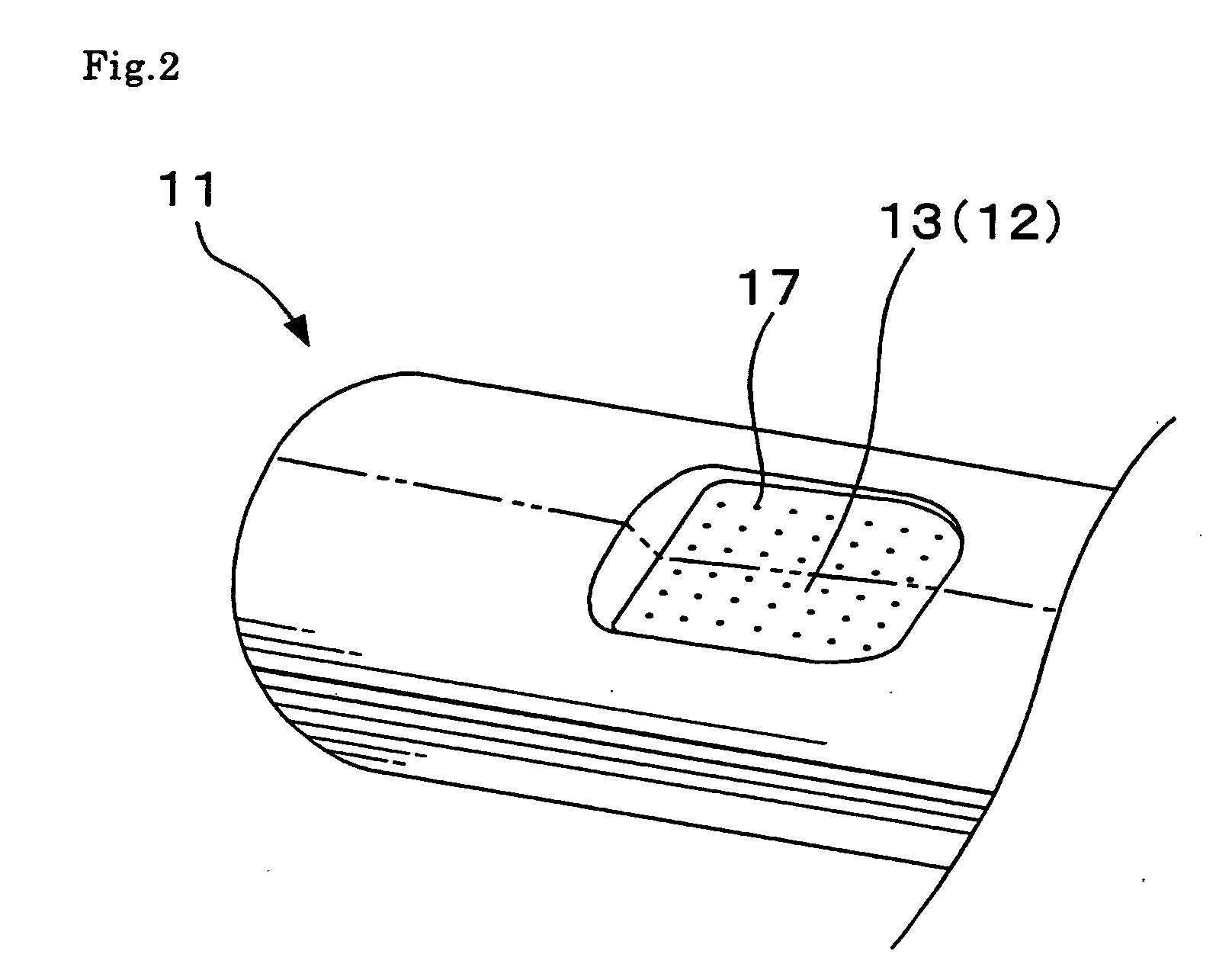

Provided is a method for manufacturing an interdental cleaning device (1) including a base portion (10) having a handle portion (11) and a core portion (12); and a soft portion (20) having a cleaning soft portion (21), a non-slip portion (22), and connecting portions (23) extending from two sites of the non-slip portion (22) and being connected to the cleaning soft portion (21). The method includes causing a second gate (49) of second molds (40) and (41) for molding the soft portion (20) to open at a position substantially equally distant from positions of two communicating openings (48a) of a non-slip molding space (47) for molding the non-slip portion (22), the two communicating openings (48a) communicating with connecting portion molding spaces (48) for molding the connecting portions (23); and charging the elastomeric material from the second gate (49) into a second molding space (42) for molding the soft portion (20) to fill the molding space (42).

Owner:SUNSTAR SUISSE SA

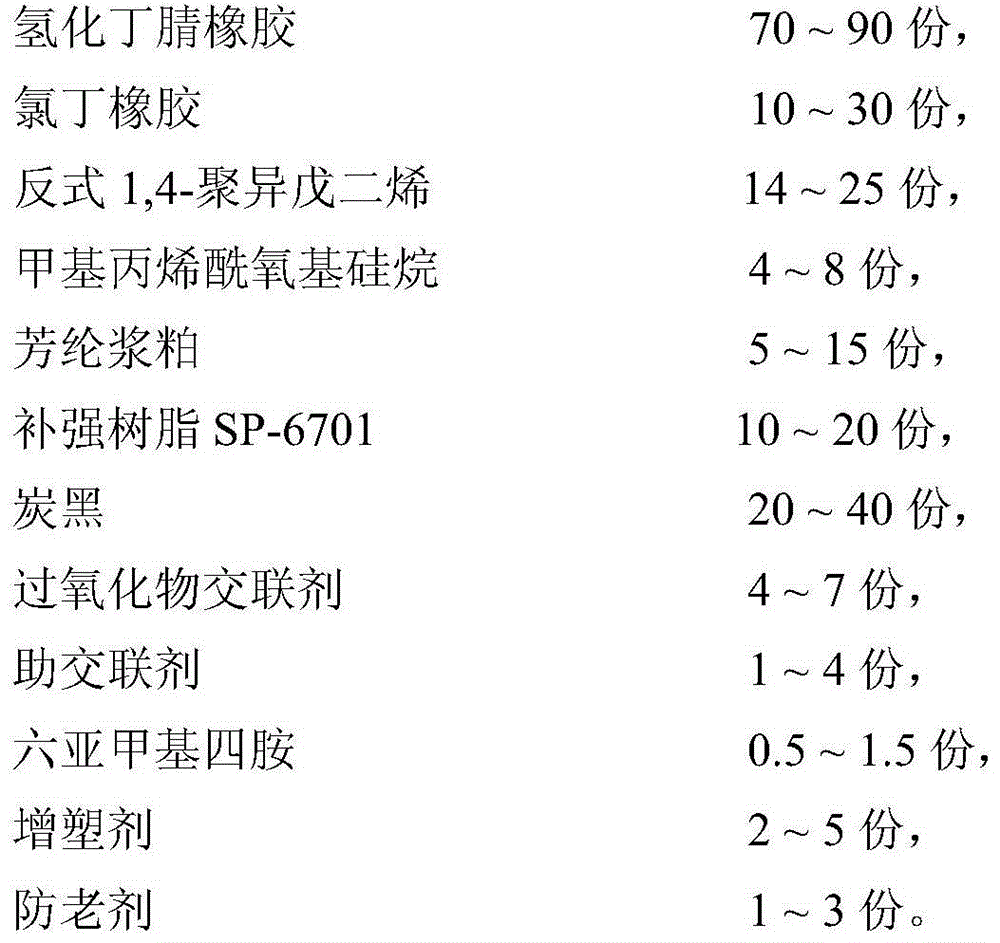

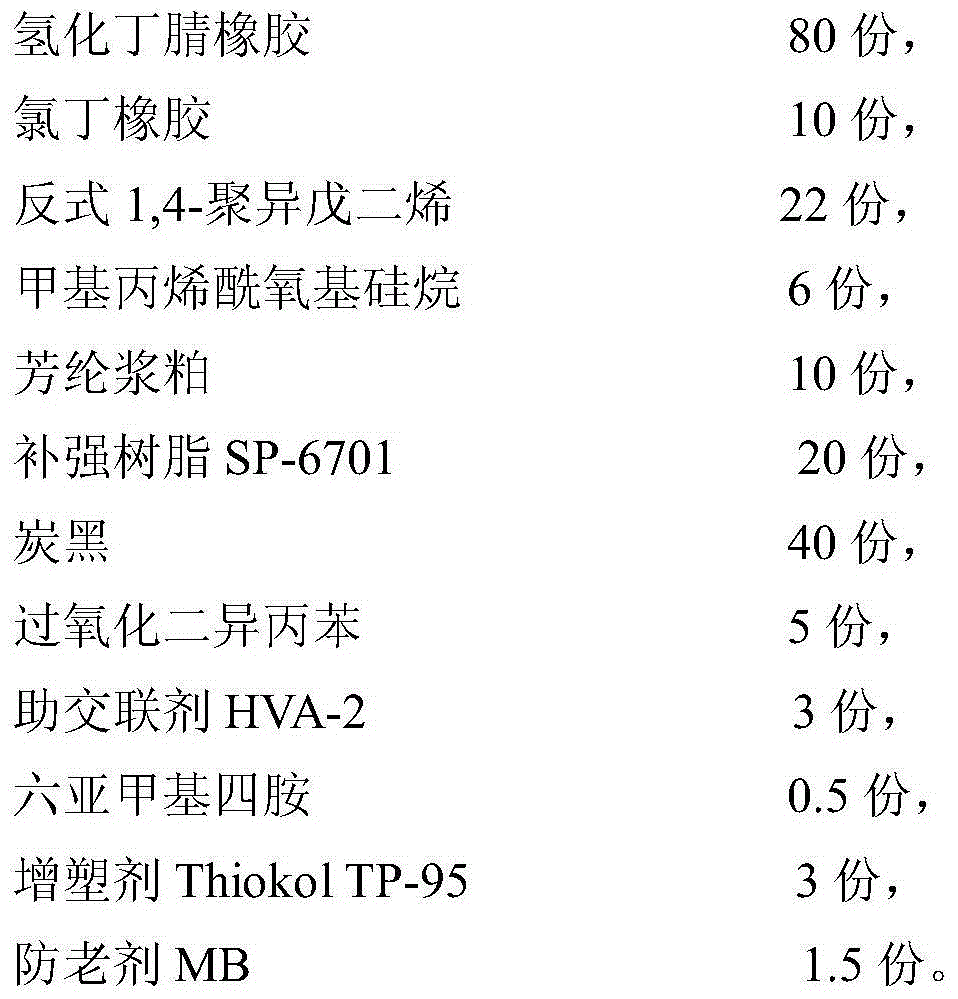

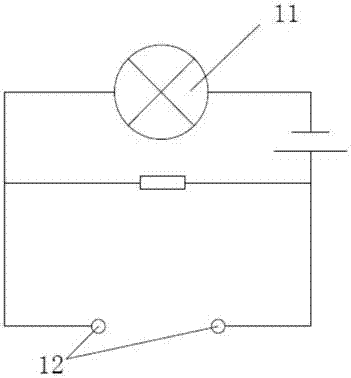

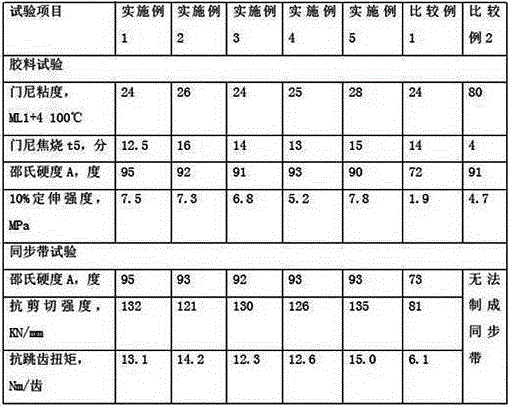

High-strength synchronous belt and manufacturing method thereof

ActiveCN104675922AGood wear resistanceImprove heat resistanceDriving beltsMonocomponent synthetic polymer artificial filamentCarbon blackPlasticizer

The invention relates to a high-strength synchronous belt. The synchronous belt comprises a synchronous belt framework and an adhesive piece attached to the outer side of the synchronous belt frame. The adhesive piece comprises the following components in parts by weight: 70-90 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of chloroprene rubber, 14-25 parts of trans 1, 4-polyisoprene, 4-8 parts of methylacryloyl silane, 5-15 parts of aramid pulp, 10-20 parts of reinforced fiber SP-6701, 20-40 parts of carbon black, 4-7 parts of peroxide crosslinking agent, 1-4 parts of assistant crosslinking agent, 0.5-1.5 parts of hexamine, 2-5 parts of plasticizer and 1-3 parts of antiaging agent. The invention also relates to a manufacturing method of the synchronous belt. According to the high-strength synchronous belt and the manufacturing method thereof, the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are used together, so that the performances of the hydrogenated butadiene-acrylonitrile rubber and the chloroprene rubber are complementary, and thus the wear resistance and the heat resistance of the adhesive piece of the synchronous belt can be effectively improved; the shear strength and the quality stability of the synchronous belt are improved by use of the trans 1, 4-polyisoprene, the methylacryloyl silane and the aramid pulp.

Owner:NINGBO FULONG SYNCHRONOUS BELT

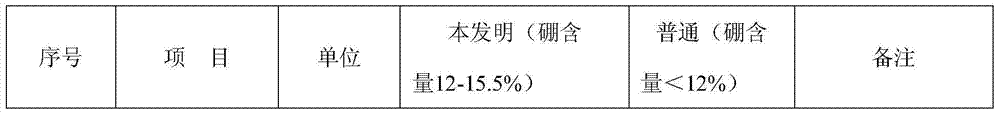

Vacuum insulation board core material and manufacturing method thereof

The invention discloses a vacuum insulation board core material and a manufacturing method thereof. The core material comprises the following components in parts by mass: 50-70 parts of SiO2, 0-7 parts of Al2O3, 2-15 parts of CaO, 0-6 parts of MgO, 8-20 parts of Na2O+K2O, 12-15.5 parts of B2O3, 0.1-7.0 parts of ZnO and at most 1.0 part of other components. By adopting the high-boron-content glass wool microfiber, the core material has the advantages of high fiber strength, high fiber smoothness and smooth molding process, and can be the best core material for a high-performance vacuum insulation board; and since the high-boron-content vacuum insulation board core material has the advantages of high fiber strength and high smoothness, only a small amount of the glass dust drops in the process of producing the core material and manufacturing the dry-process vacuum insulation board, thereby effectively improving the manufacturing environment of the operator and greatly reducing the dust treatment cost of the enterprise.

Owner:安徽吉曜玻璃微纤有限公司

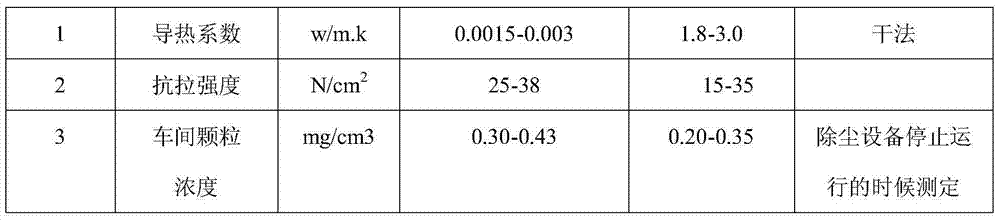

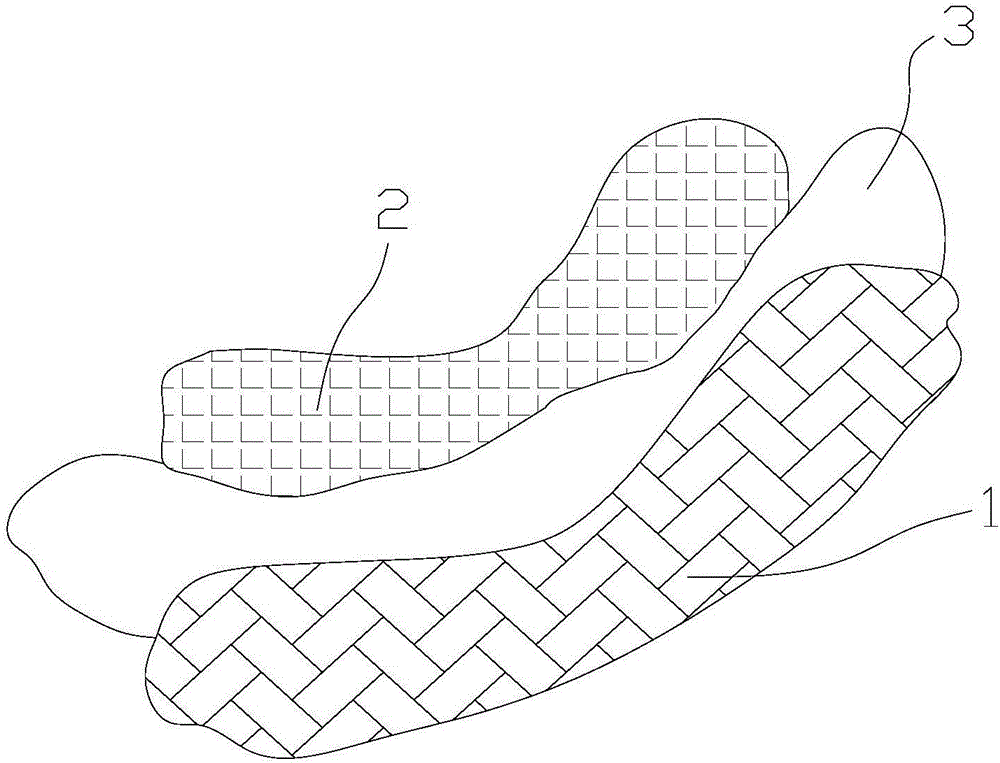

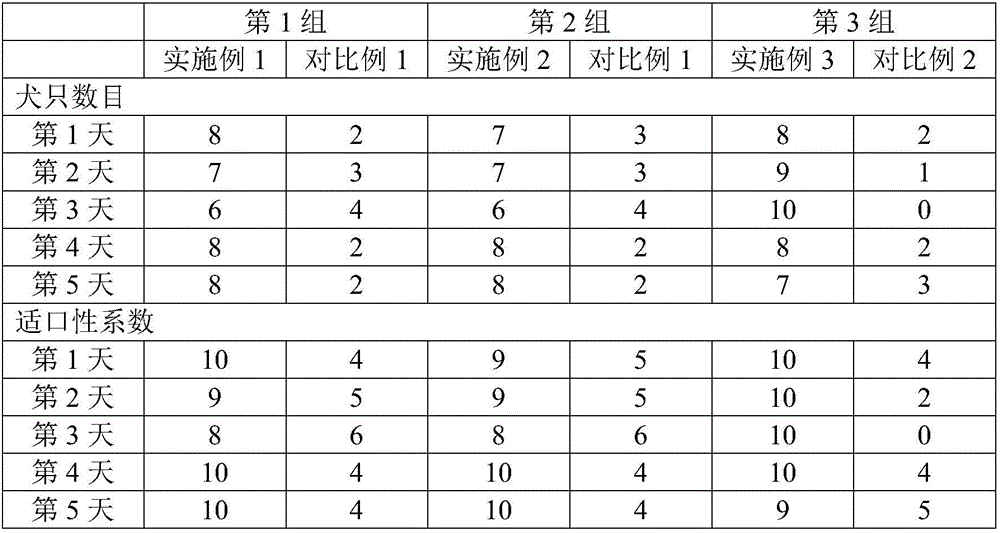

Tooth grinding hotdog for pets and preparation method of tooth grinding hotdog

ActiveCN106720946APrevent obesityReasonable collocationAnimal feeding stuffAccessory food factorsHydrolysateFish oil

The invention discloses a tooth grinding hotdog for pets. The tooth grinding hotdog is prepared from an inner-layer sausage, interlayer stuffing and an outer-layer pork skin, wherein the inner-layer sausage is prepared from a first meat material, a component A and a component B; the interlayer stuffing is prepared from a second meat material, a component C and a component D; the component A is prepared from rice flour, vegetable protein, white granulated sugar, yeast hydrolysate, sweet potato flour, table salt, citric acid, garlic powder and functional auxiliary materials; the component B is prepared from glycerol and smoking spice; the component C is prepared from starch and table salt; the component D is prepared from glycerol and fish oil. The tooth grinding hotdog for the pets, disclosed by the invention, has balanced nutrients, bright color and very good layering, has the effects of cleaning teeth and grinding the teeth, and can also be used for improving digestion and refreshing the breath. The invention further discloses a preparation method of the tooth grinding hotdog for the pets; the preparation method has the advantages of a few of steps, simple flow and safety in operation.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

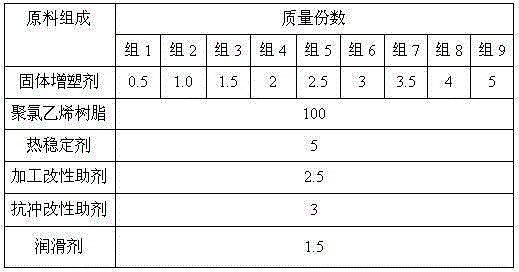

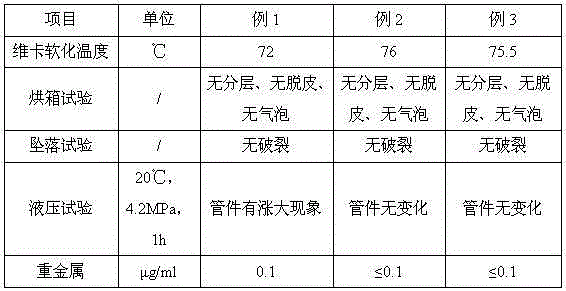

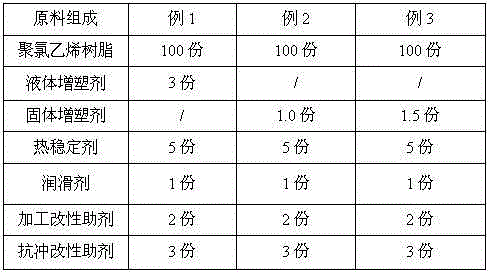

U-PVC plastic, pipe fitting made of U-PVC plastic and preparing method of pipe fitting

The invention discloses U-PVC plastic, a pipe fitting made of the U-PVC plastic and a preparing method of the pipe fitting. The U-PVC plastic is prepared from, by mass, 100 parts of PVC resin, 0.5-5 parts of solid plasticizer, 1-6 parts of heat stabilizer, 1-5 parts of processing performance additive, 2-10 parts of anti-shock performance additive and 0.1-2 parts of lubricant. The solid plasticizer is a compound formed by copolymerization of polyether and alcohol ester or one or a mixture of compound ester compounds. The U-PVC plastic can be well applied to preparation of the U-PVC pipe fitting, and the processing requirement is met; the solid plasticizer is a non-toxic high-molecular polymer, is good in compatibility with PVC, cannot dissolve out to move to the surface of a product in the using process and can obviously improve the rigidity strength of materials and the vicat and hydraulic performance of the product, and the overall quality of the product can be improved.

Owner:LIANSU TECH DEV GUIYANG

Composites and methods for producing plastic-steel square timber and straw foamed plastic square timber

The invention relates to composites and methods for producing a plastic-steel square timber and a straw foamed plastic square timber. The composite for producing the plastic-steel square timber comprises the components of PVC (polyvinyl chloride), light calcium carbon powder, a PVC stabilizer, a PVC foaming regulator, an AC (azodicarbonamide) foaming agent, a stearic acid, PE (polyethylene) wax, ACR (acrylate), titanium dioxide, calcium stearate and DOP (dioctyl-phthalate). The composite for producing the straw foamed plastic square timber is prepared from straw power in addition to the components of the composite for producing the plastic-steel square timber. The methods for producing the plastic-steel square timber and the straw foamed plastic square timber from the composites comprise the following steps: proportioning materials, blending materials, adding materials, extruding, molding, cooling by water, quickly freezing, dragging and forming. The plastic-steel square timber and the straw foamed plastic square timber can replace the original wooden timber, are made of single materials, are convenient to product and recycle and can be smashed for secondary machining and shaping.

Owner:李兵

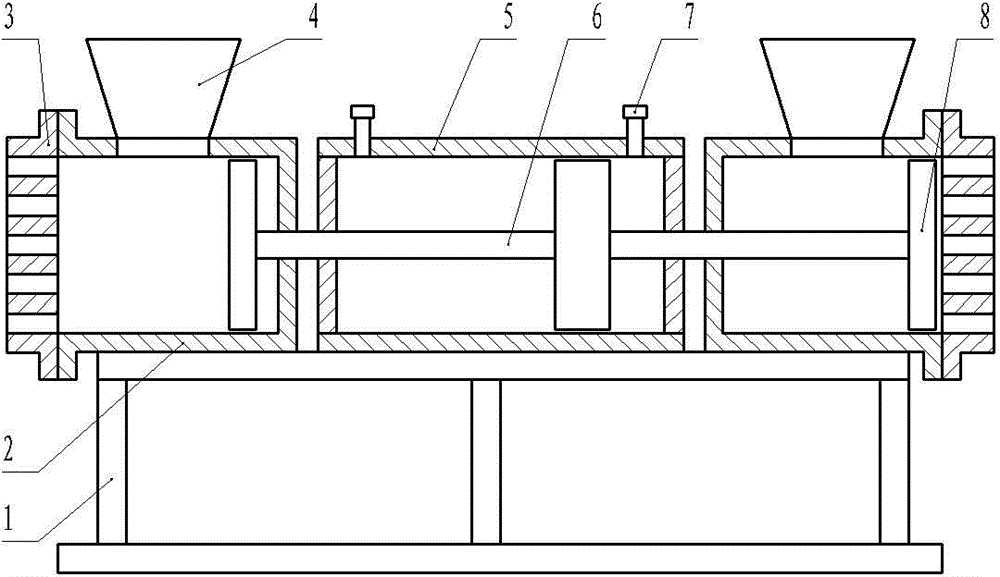

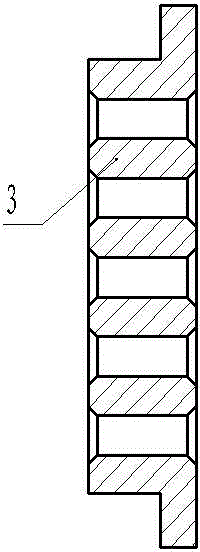

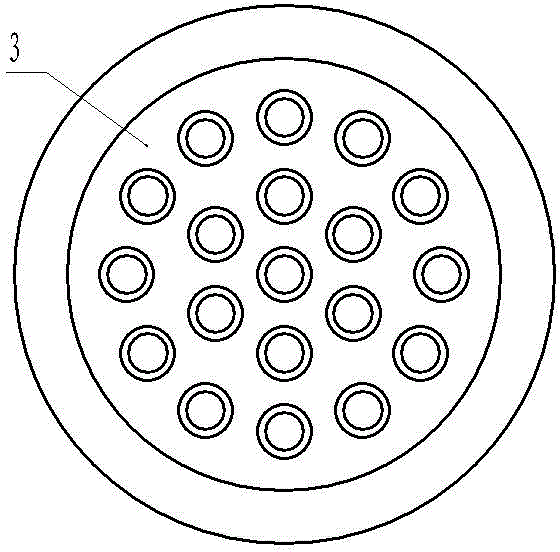

Biomass solid fuel forming machine

InactiveCN104479787ASimple structureReduce manufacturing costBiofuelsSolid fuelsSolid fuelEngineering

The invention discloses a biomass solid fuel forming machine relating to the technical field of manufacturing of biomass solid fuel forming equipment. The biomass solid fuel forming machine comprises two housings which are oppositely arranged on a rack, wherein a feeding hopper is arranged at the upper end of each housing, a forming die plate is arranged at the outer side of each housing, a forming die hole is formed in the forming die plate, a dual-rod power cylinder is arranged between the two housings, pipe joints are respectively arranged at two ends of the dual-rod power cylinder, two piston rods of the dual-rod power cylinder respectively extend into the housings, and pushing plates are arranged at extending ends of the piston rods. Compared with the prior art, the biomass solid fuel forming machine has the advantages that the two piston rods of the dual-rod power cylinder reciprocate so as to respectively extrude a biomass fuel in the two housings to be formed from the forming die holes of the forming die plates by virtue of the pushing plates; the biomass solid fuel forming machine is simple in structure, low in manufacturing cost, and high in working efficiency.

Owner:柳州东侯生物能源科技有限公司

Illuminant ceramic mud composition for mud extruding process and preparation method thereof

InactiveCN107473707AGorgeous fluorescent propertiesGood light transmissionAdditive manufacturing apparatusCeramic materials productionSodium BentoniteSprayer

The invention relates to the field of a ceramic material and especially relates to an illuminant ceramic mud composition for a mud extruding process. The illuminant ceramic mud composition comprises the following components in a weight ratio: kaoline, bentonite, potassium feldspar, albite, anorthite, quartz, pyrochlore, fluorite, talcum powder, mullite, waste ceramic powder, Jiepai mud, a plasticizer, a liquefaclent, a flocculant, a brightening agent, a high temperature protective agent, an anti-cracking agent, a wetting agent, a tackifier, a rare earth trichromatic phosphor, a sintering additive and water. The illuminant ceramic mud composition prepared according the formula and preparation method provided by the invention has magnificent fluorescence characteristic and light transmittance performance. The illuminant ceramic mud has higher liquidity than that of common mud, difficultly blocks a sprayer in a forming process and has higher plasticity than that of common mud, and meanwhile, a green body is difficult to deform in the forming process.

Owner:JINGDEZHEN CERAMIC INSTITUTE

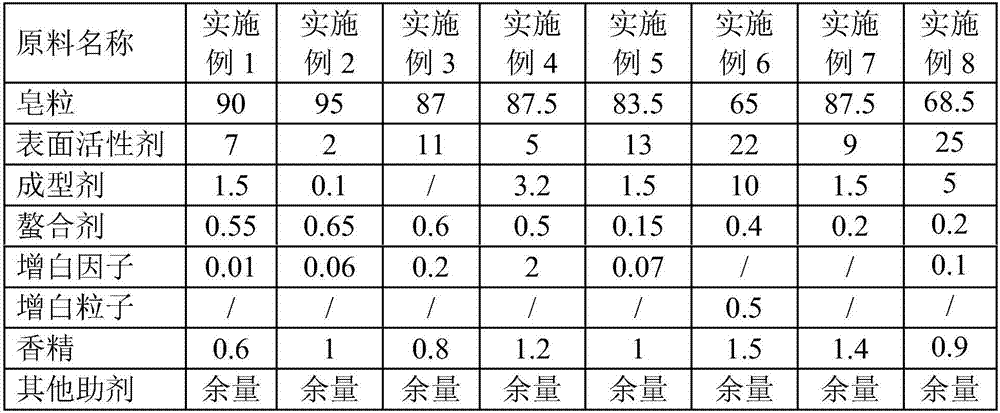

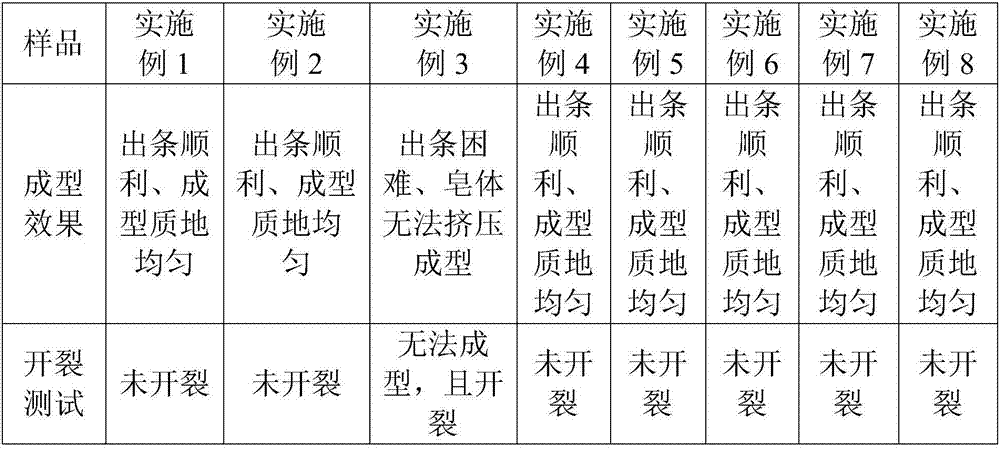

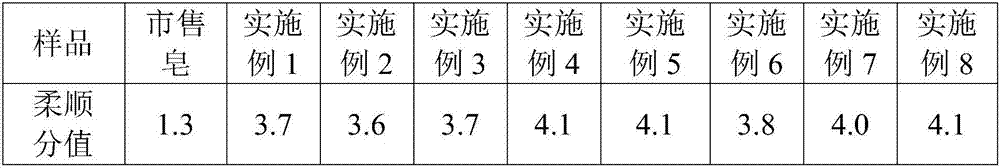

Laundry soap composition capable of softening and brightening clothes, and preparation method thereof

ActiveCN107446732AWhitening effectBreak through the limitations of efficacy that cannot be addedPolymeric surface-active compoundsSoftening compositionsChemical productsLaundry

The invention belongs to the technical field of daily chemical product, and more specifically discloses a laundry soap composition capable of softening and brightening clothes, and a preparation method thereof. The laundry soap composition is capable of improving the softness of fabric after washing, reducing deposition of soap scum on clothes, and avoiding yellowing of clothes caused by soap scum on fabric; brightening factors contained by the laundry soap composition are capable of maintaining the bright color of clothes. The laundry soap composition is capable of avoiding defects of conventional laundry soap in washing, washing effects of laundry soap are increased, and washing functions of laundry soap products are improved.

Owner:GUANGZHOU LIBY

Mould for manufacturing glass container

ActiveCN102617015AReduce fit areaExtended service lifeGlass blowing apparatusGlass productionBottle neckPhysics

The invention provides a mould for manufacturing a glass container, belonging to the technical field of a glass mould. The mould comprises a pair of bottle half modules, wherein each bottle half module is provided with a joint close surface and a bottle mould chamber composed of a bottleneck chamber, a neck shoulder chamber, a bottle body chamber and a bottle bottom chamber; the joint close surface comprises a bottle opening matching region located at the chamber opening part of the bottleneck chamber, a middle matching region corresponding to the chamber opening part of the bottle body chamber, a bottle bottom matching region corresponding to the chamber opening part of the bottle bottom chamber, and a peripheral matching region located at the outer side of the middle matching region. The mould is characterized in that: the planes of the bottle opening matching region and the bottle bottom matching region are located at the same height, the plane of the middle matching region is lower than the plane of the bottle opening matching region, and the plane of the peripheral matching region is lower than the middle matching region. The mould provided by the invention has the advantages that: a matching area of the matching surface is reduced, the deformation amount of the mould in a work process is compensated, the production efficiency is improved, the service life is prolonged, and the resource is saved.

Owner:CHANGSHU JIANHUA MOLD TECH

Producing method of hot-rolled alloy plate for automobile body

ActiveCN104550231AImprove performanceMeet the requirementsMetal rolling arrangementsAuto industryManufacturing technology

The invention relates to a magnesium alloy plate manufacturing technology. Based on existing mature conventional magnesium alloy which is good in comprehensive performance but cannot completely meet the plate requirement of an automobile body, a micron quasi-crystal intermediate alloy online mixed melting technology, a magnesium alloy plate cast rolling technology and a dynamic recrystallization hot rolling technology are adopted to modify the magnesium alloy and enable the performance of the magnesium alloy to be improved. By means of the producing method, the production cost can be remarkably reduced, the performance of the plate can be improved, and index can be closer to the requirement for sheet metal parts in the automobile industry.

Owner:山西银光华盛镁业股份有限公司

Method for preparing spherical aluminum oxide by oil column forming process

PendingCN111056563ASolve the blockageSmooth moldingPhysical/chemical process catalystsAluminium oxide/hydroxide preparationIsobutanolPtru catalyst

The invention discloses a method for preparing spherical aluminum oxide by an oil column forming process, and is characterized in that low-carbon alcohol is added into aluminum sol, and the mass of the low-carbon alcohol accounts for 2%-10% of that of the aluminum sol generally. The low-carbon alcohol is one or a mixture of ethanol, propanol, isopropanol, butanol, isobutanol, ethylene glycol, propylene glycol, glycerol, butanediol and the like. The particle size of the spherical aluminum oxide obtained by the method is generally 1.6-2.0 mm, and the spherical aluminum oxide can be used as a catalyst or a carrier to be widely applied to the field of petrochemical engineering or fine chemical engineering.

Owner:LIMING RES INST OF CHEM IND

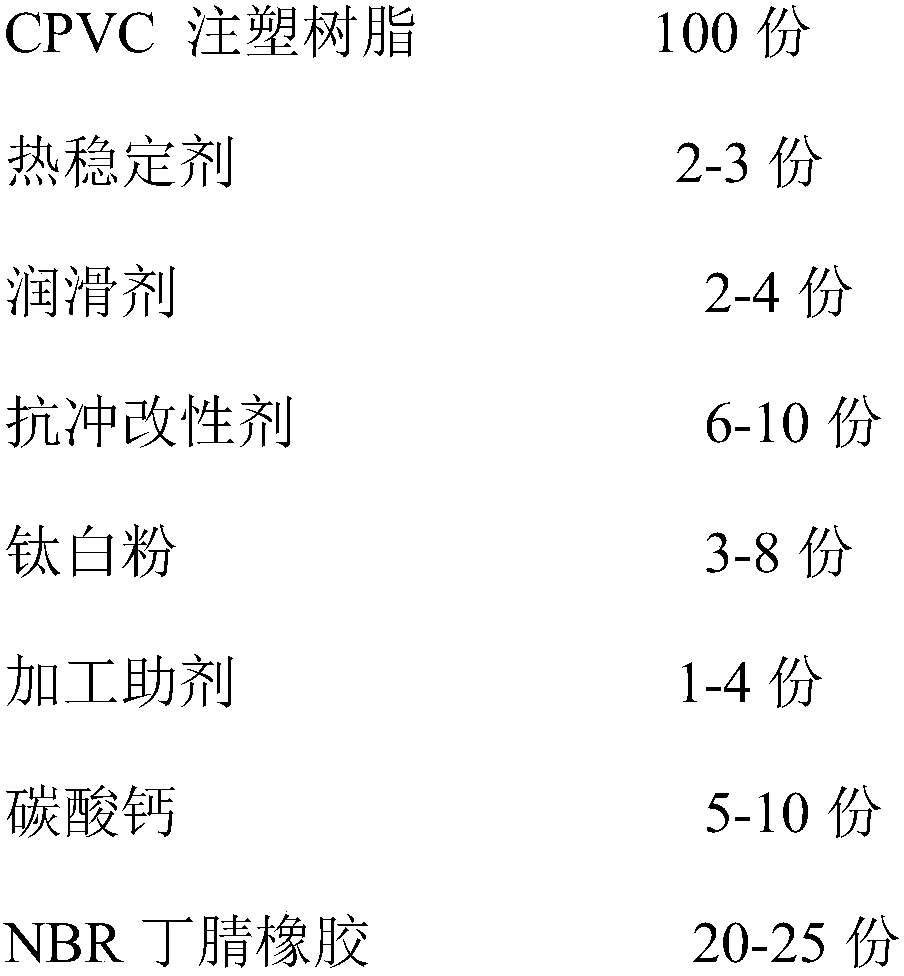

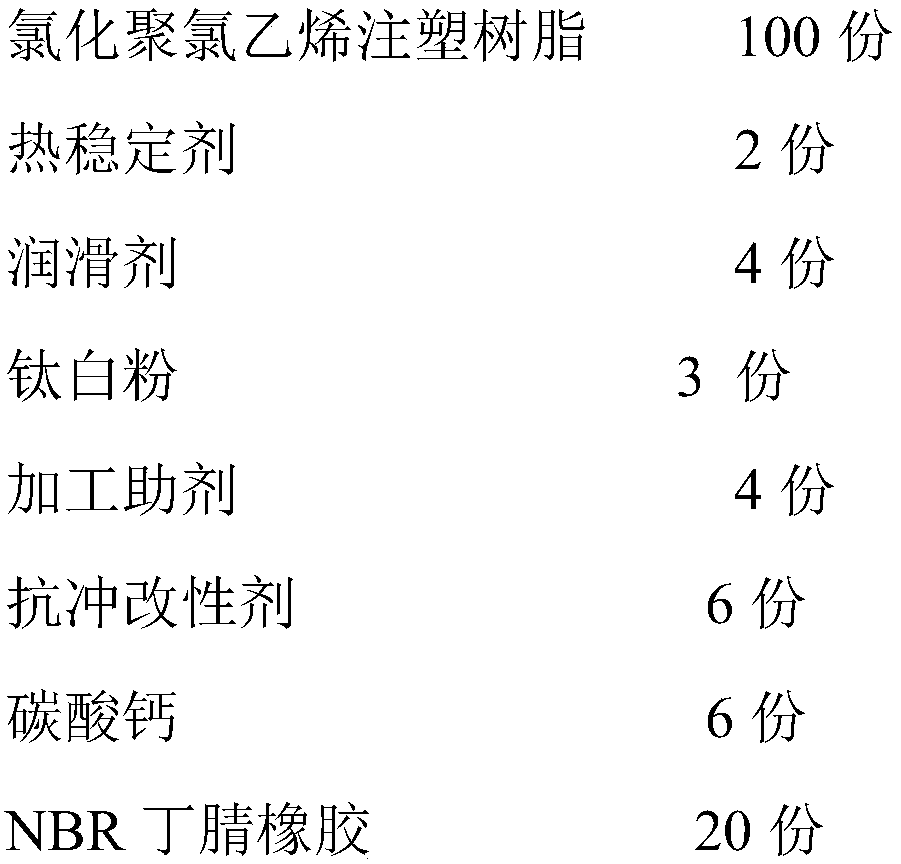

Composition containing chlorinated polyvinyl chloride resin for preparing football shoe sole and preparation method

InactiveCN109370124APromote plasticizationImprove liquiditySolesChlorinated polyvinyl chlorideNational standard

The invention discloses a composition containing chlorinated polyvinyl chloride resin for preparing a football shoe sole and a preparation method. The composition containing the chlorinated polyvinylchloride resin for preparing the football shoe sole comprises the following components in parts by weight: 100 parts of CPVC (Chlorinated Polyvinyl Chloride) injection-molding resin, 2-3 parts of heatstabilizer, 2-4 parts of lubricating agent, 6-10 parts of impact-resistant modifier, 3-8 parts of titanium dioxide, 1-4 parts of processing aid, 5-10 parts of calcium carbonate and 20-25 parts of NBR(nitrile-butadiene rubber) butyronitrile rubber. The composition disclosed by the invention has the beneficial effects that by addition of the regulating agent and the lubricating agent and use of the NBR butyronitrile rubber, the plasticization of the materials can be effectively improved, the fluidity can be improved, so that the materials can be smoothly molded in injection molding; the composition has special wear resistance of the CPVC material, is high in toughness and good in durability, simultaneously has elasticity and softness of the rubber, and all the other physical properties reach the national standards.

Owner:SHANGHAI CHLOR ALKALI CHEM

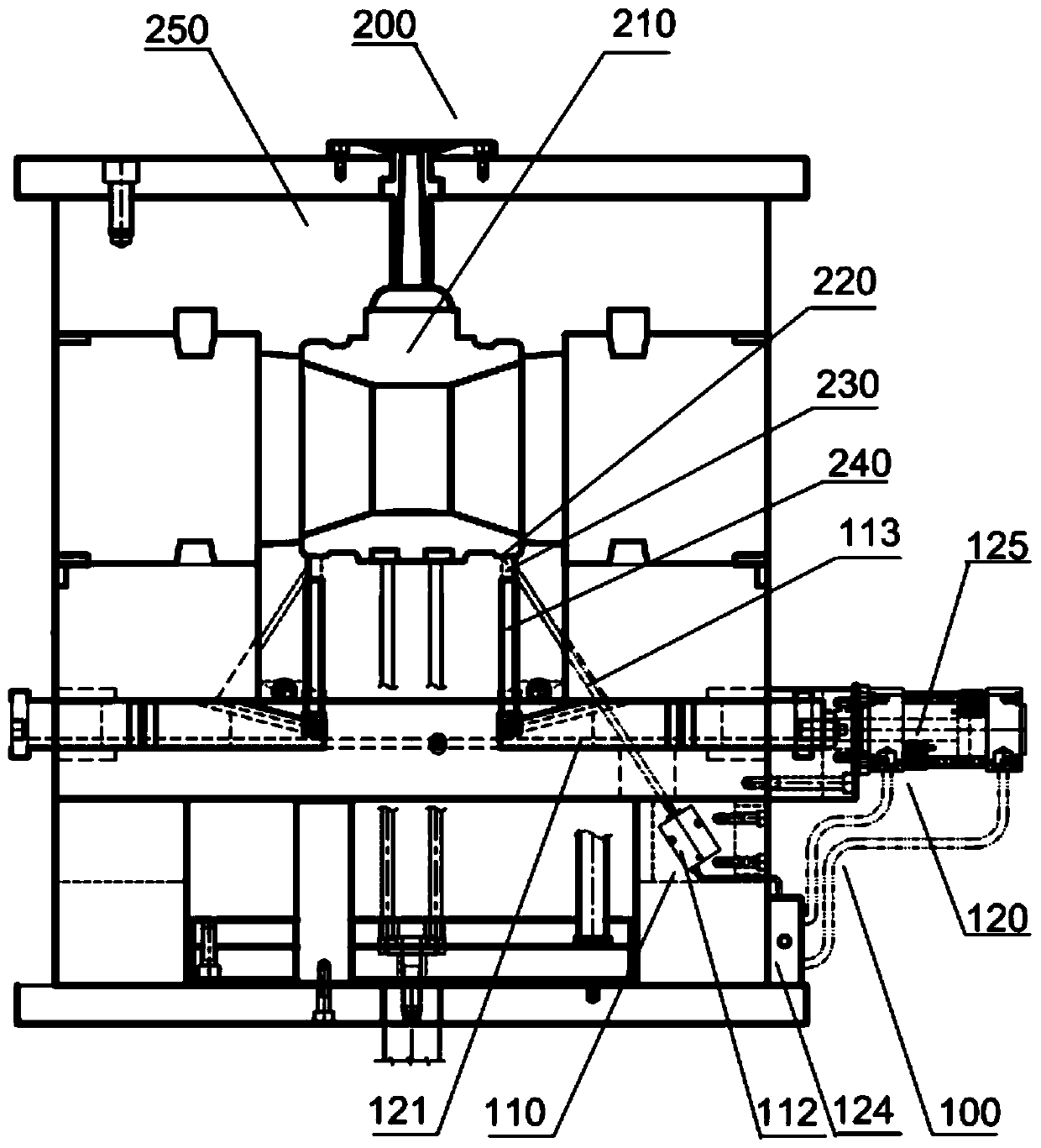

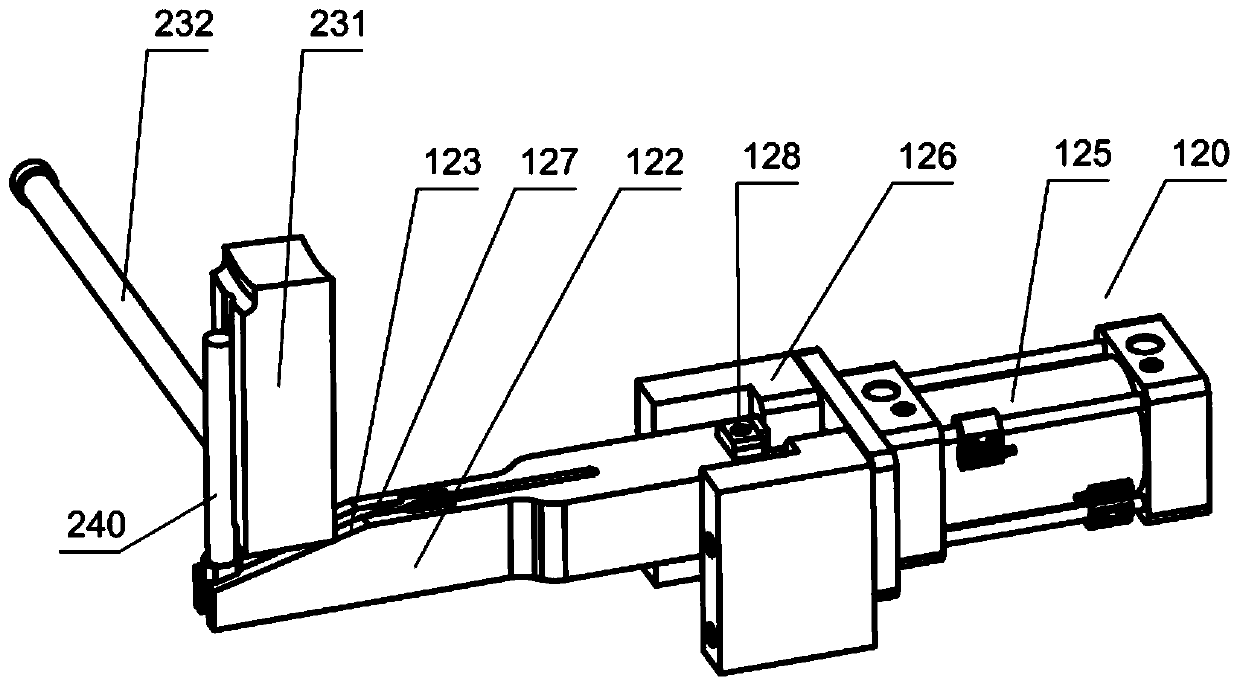

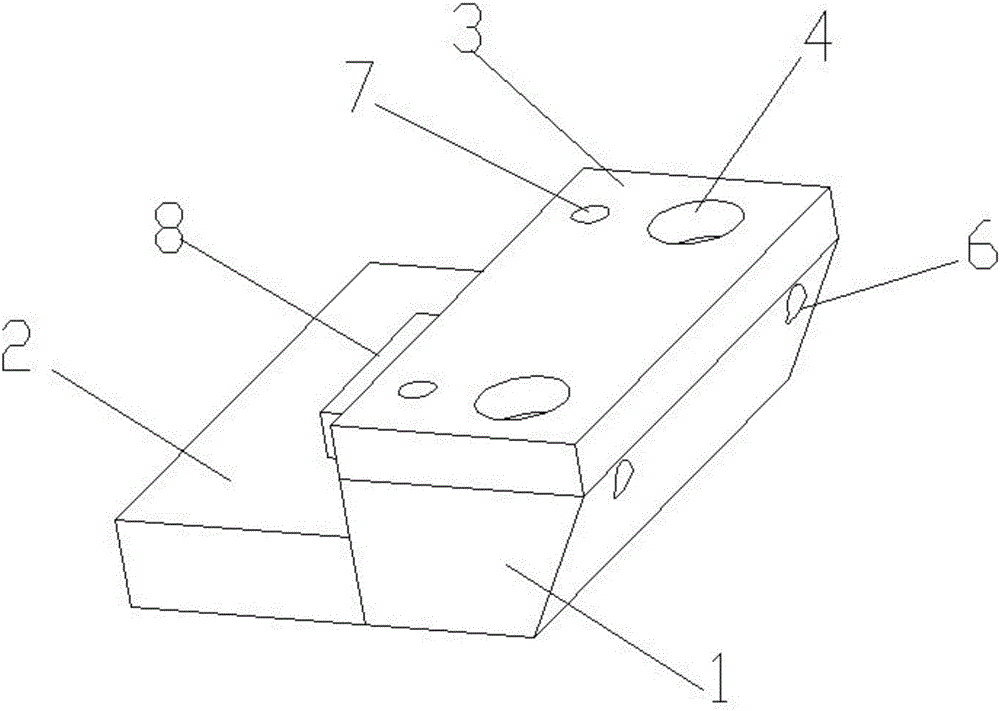

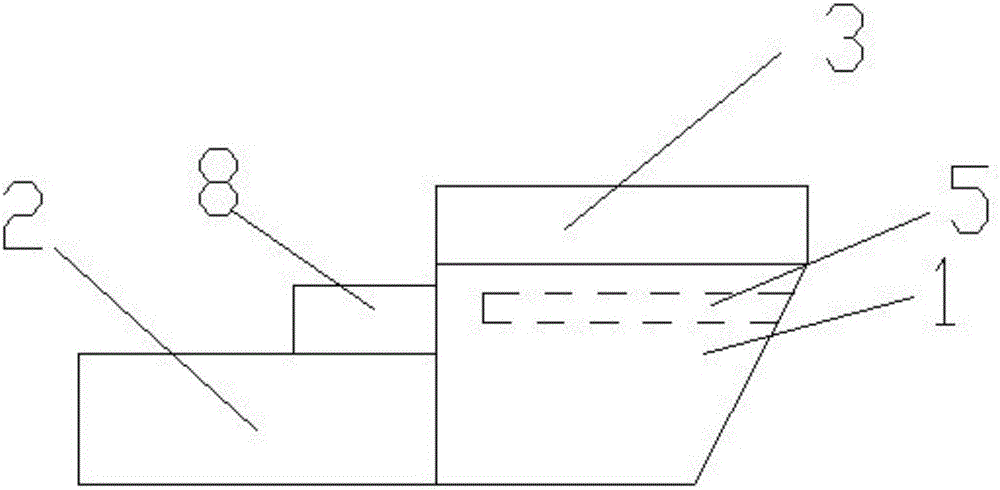

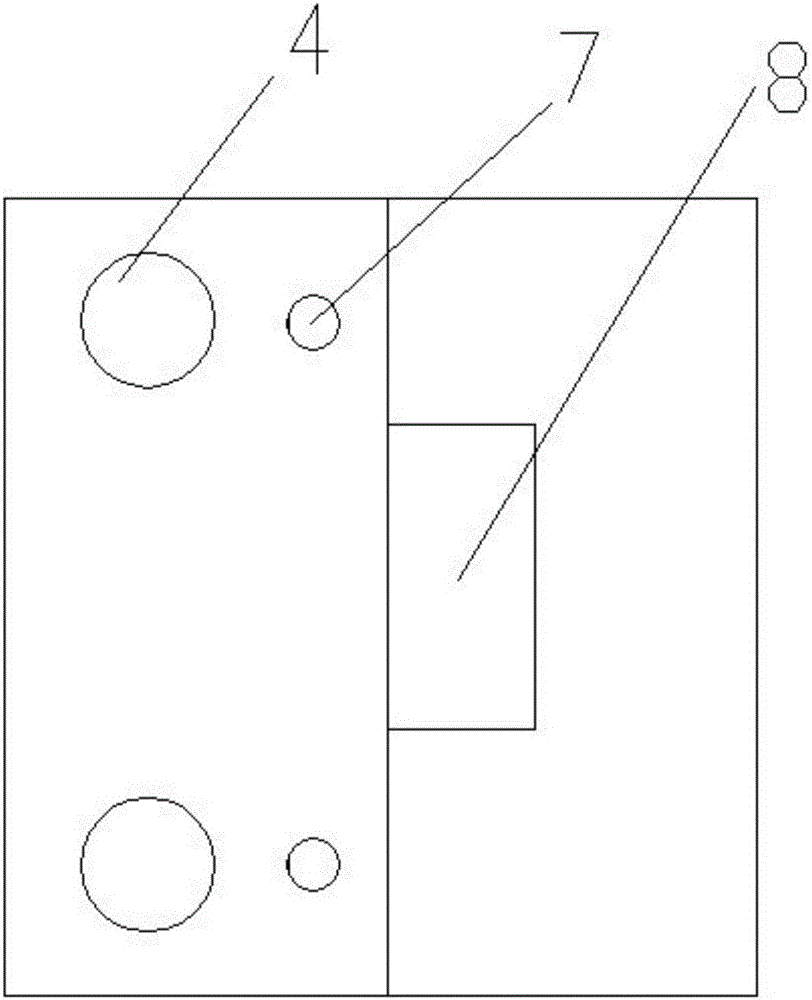

Die-cast formation die and die-cast formation method

The invention provides a die-cast formation die. The die-cast formation die is provided with a die cavity (3), a sprue (1) and a feeding device (11) which is communicated with the sprue (1) and is used for filling raw materials, wherein one end of the die cavity (3) is communicated with the sprue (1) by a transverse pouring gate (2) and the other end of the die cavity (3) is communicated with a riser (5) by an exhausting pipeline (4); the feeding device (11) is connected with numerical control equipment and is used for controlling the speed of injecting raw materials into the die cavity (3) from the sprue (1). By virtue of the die-cast formation die, bubbles in the raw materials can be crushed and the product quality is improved. The invention further provides a die-cast formation method. By adopting the method, the production efficiency is improved and the production cost is reduced.

Owner:深圳市建升科技股份有限公司

High-modulus rubber compound and high-load synchronous belt

The invention discloses a high-modulus rubber compound and a high-load synchronous belt. The scorching time of rubber is prolonged, and the Mooney viscosity of the rubber is reduced, so that the rubber can be better mixed evenly and can be smoothly calendered and formed, the mobility of the rubber in sulfurization is increased, tooth filling is easier, the obtained synchronous belt has better integrated uniformity, the local stress aggregation phenomenon is difficult to occur, the anti-shearing strength of teeth of the synchronous belt and the tooth jumping prevention capability of the belt can be enhanced, and thus the loading capability of the synchronous belt is effectively improved and the service life of the synchronous belt is prolonged.

Owner:上海翎宝传动科技有限公司

Connector and manufacturing method thereof

ActiveUS20090017698A1Form evenlyMaintenance savingElectrically conductive connectionsContact member cases/bases manufactureEngineeringElectrical and Electronics engineering

Owner:LOTES

A metal 3D printer airtight chamber atmosphere deoxygenation and circulation purification method and equipment

ActiveCN104353832BLow oxygenReduce usageAdditive manufacturingIncreasing energy efficiencyPurification methodsSolenoid valve

Owner:SOUTH CHINA UNIV OF TECH

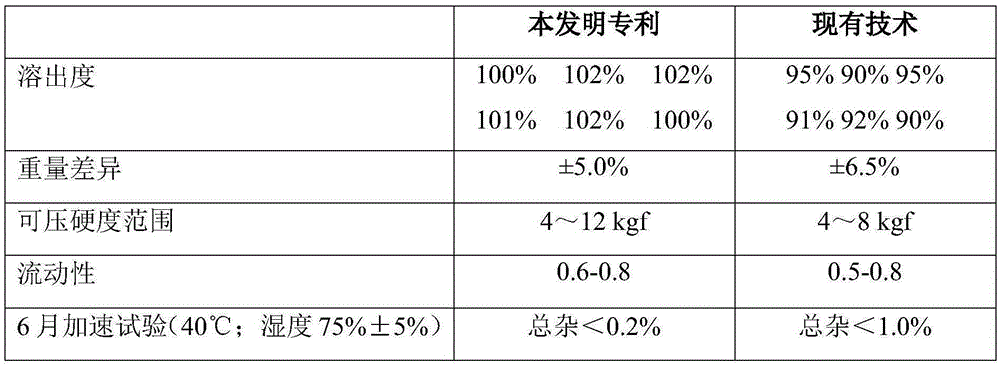

Composition containing amlodipine besylate and preparation method of composition

InactiveCN105395495AHigh hardnessWeight Variation ImprovementOrganic active ingredientsPill deliveryFiller ExcipientMedicine

The invention relates to the technical field of medicine preparation, in particular to a composition containing amlodipine besylate and a preparation method of the composition. The composition consists of the following components in parts by weight: 5 parts of amlodipine besylate, 90-195 parts of a filling agent, 0.4-2.7 parts of a disintegrating agent and 1.1-3.1 parts of a lubricating agent; and the method for preparing the composition containing the amlodipine besylate comprises the following steps: preparing materials, adding 3 / 4 of the filling agent to the amlodipine besylate and premixing for the first time, sieving, premixing for the second time, adding the rest 1 / 4 of the filling agent, premixing for the third time, adding the disintegrating agent to a material 4 and premixing for the fourth time, adding the lubricating agent and premixing for the fifth, and tabletting. According to the preparation method disclosed by the invention, the uniformly mixed powder is directly compressed into a tablet core by virtue of a tablet press; and compared with an existing wet-process granulation process, the tablet prepared by the method disclosed by the invention is dissolved out more thoroughly, simple in production process, simple in equipment, low in production cost and stable in product property, and the hardness of the tablet core is enhanced and weight difference is significantly improved.

Owner:YICHANG HEC CHANGJIANG PHARMA CO LTD

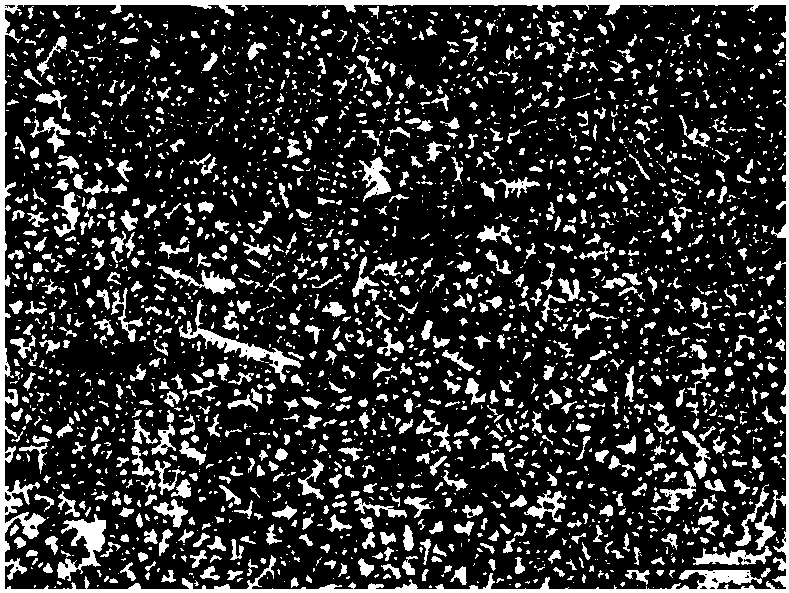

Aluminum alloy with high zinc content and preparing method of aluminum alloy

ActiveCN105441755ASmooth moldingSuccessful realization of moldingFiltration techniqueMaterials processing

The invention relates to an aluminum alloy with the high zinc content and a preparing method of the aluminum alloy, and belongs to the material processing field. The standard requirements of various industries for materials are gradually converted into the requirements for ultra-high strength and ultra-low weight, and the demand is particularly obvious in the aerospace and other military fields. Under the condition that the same bearing capability is provided, the higher the strength of the materials is, the fewer the needed supporting materials is, and therefore the total mass is reduced. Due to the fact that the heat transferring, mass transferring, fluid flowing and the like of melt are decided through a casting technology, the casting technology becomes the important factor for deciding the final microscopic structure of the melt. Same level hot-top water-cooling semi-continuous casting is adopted, the multi-layer ceramic melt filtering technology and the chlorine and argon mixed gas refining technology are combined, the ultra-high-strength aluminum alloy with the Zn content of 11.5-13.5 % is prepared, forming of an aluminum alloy ingot casting with the high zinc content is smoothly achieved while the superior interior quality is guaranteed, and the excellent surface quality is achieved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

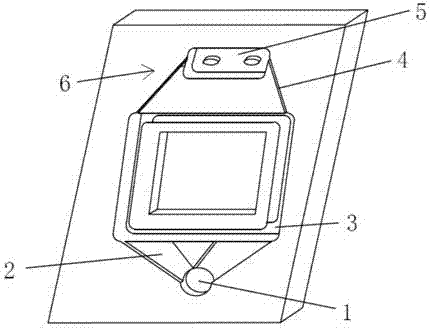

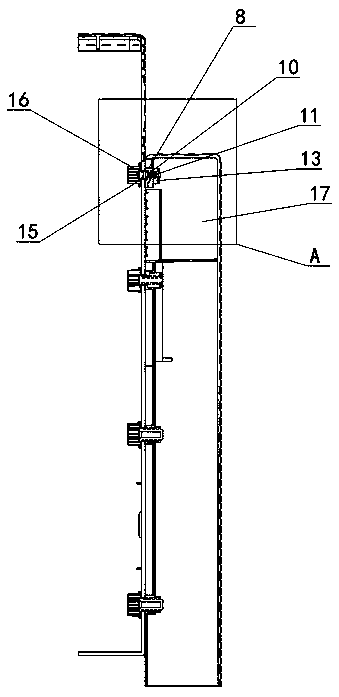

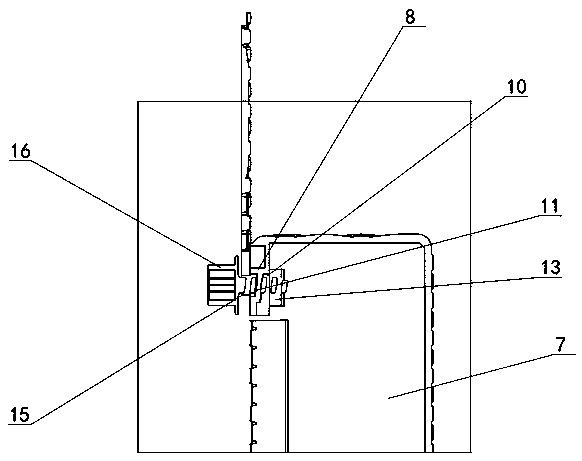

Exhaust device, exhaust control method and mold structure with exhaust device

The invention relates to the technical field of plastic molding, in particular to an exhaust device, an exhaust control method and a mold structure with the exhaust device. The exhaust device is applied to the mold structure, wherein a cavity capable of communicating with the external environment is arranged in the mold structure, and a temperature sensing point is arranged at the bottom of the cavity; the exhaust device comprises a controller, a temperature sensing mechanism connected to the input end of the controller and a mechanical sliding block mechanism connected to the output end of the controller, and the temperature sensing mechanism is in signal connection with the temperature sensing point; and a guide hole communicating with the cavity is arranged in the mold structure, and asealing insert needle capable of rising by the action of the mechanical sliding block mechanism to seal the cavity is arranged in the guide hole. According to the exhaust device, the exhaust control method and the mold structure with the exhaust device, the open type cavity is adopted to inject plastic products firstly, so that the air exhaust is quickly carried out in time, and the defective phenomena of gas entrapment, charring, insufficient welding, bursting in performance test and the like of the plastic products are effectively avoided; and when high-temperature fluid plastic flows to thetemperature sensing point, the mechanical sliding block mechanism is triggered to drive the sealing insert needle to rise to seal the cavity, so that it is ensured that the injection molding processof the plastic products is smoothly completed.

Owner:HESHAN LESSO IND DEV

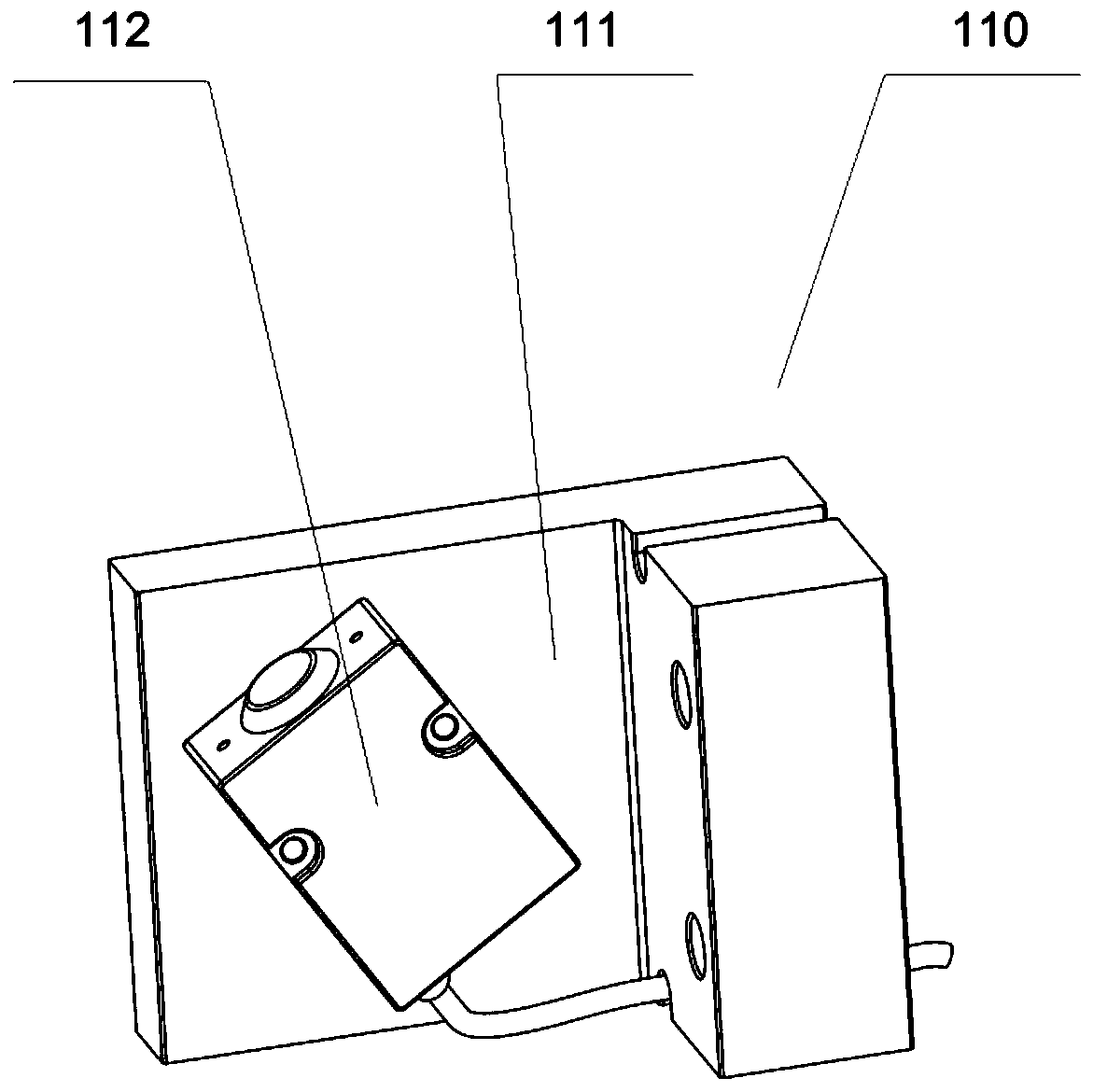

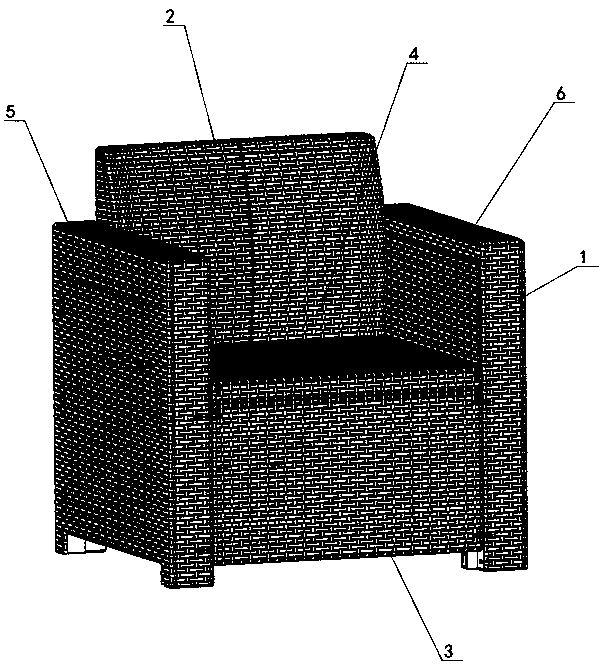

Combination sofa integrated threaded connection mechanism and processing mold thereof

A combination sofa integrated threaded connection mechanism comprises a seat plate, a back plate, a front retainer, a rear retainer, a left armrest plate, and a right armrest plate which are made witha plastic material by injection molding. The left armrest plate, the right armrest plate, the seat plate, the back plate, the front retainer and the rear retainer are fixedly assembled and fixed through a connection mechanism. The connection mechanism includes hollow pillars arranged on the two sides of the left armrest plate and right armrest plate respectively; a connection post is arranged onthe inner wall of each hollow pillar; a connection hole is arranged in each connection post; a screw threaded is integrally formed in each connection hole; a gap is arranged between the start and stopof each screw thread; the rear walls of the left and right armrest plates, corresponding to the screw threads, are provided with through channels; the assembly connections of the seat plate, the backplate, the front retainer, the rear retainer, the left armrest plate and the right armrest plate are provided with corresponding through holes; the through holes are fixedly connected with the connection holes having the screw thread through plastic screws.

Owner:印象家居(浙江)有限公司

Golf tee and preparation method thereof

The invention belongs to the technical field of sports equipment, and particularly relates to a golf tee and a preparation method thereof. The golf tee is mainly prepared from gum-containing pine barks, elm barks and / or banyan barks and cassava, and extra binders are omitted. The preparation method includes the steps: firstly, collecting and crushing various raw materials; secondly, performing high-temperature treatment and extrusion to form the golf tee. The method is simple in preparation process and convenient in operation. The golf tee turns into soil particles within 2 minutes when touching water, the golf tee can be effectively combined with soil and can be absorbed by a lawn after degradation to generate fertilizers, the problems of foot and tire stabbing properties and difficulty in recovery of other tees are solved, a large number of manpower and material resources are saved, and environments are protected. Besides, the transverse pressure resistance of the golf tee is 3-5 kilograms, the vertical pressure resistance of the golf tee is 15-20 kilograms, the golf tee is broken once being hit, a golf club cannot be blocked, and technical indexes of the golf tee are variously demonstrated at home and abroad to prove that the golf club cannot be damaged, and accuracy is improved.

Owner:朱君

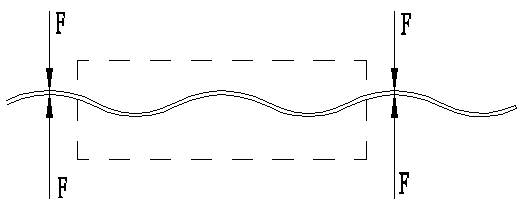

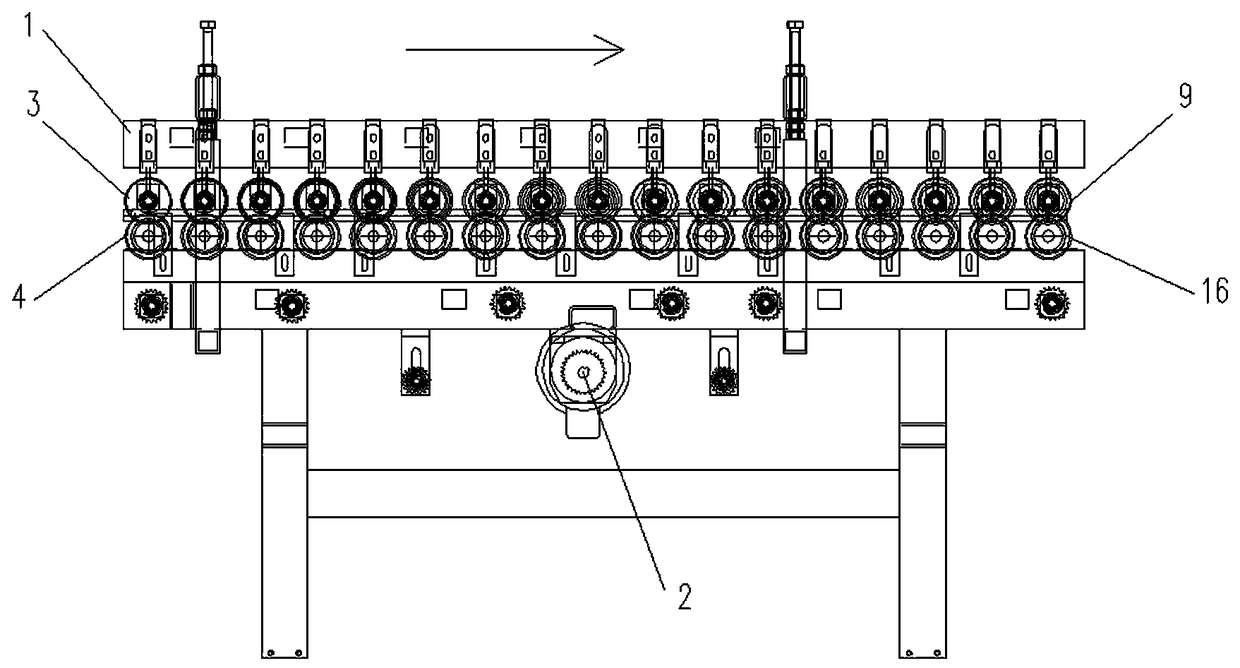

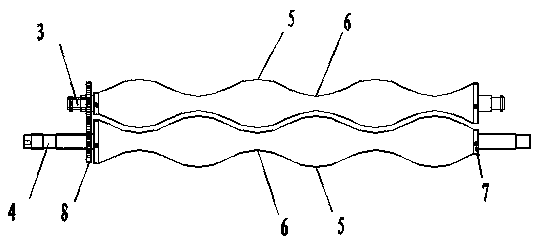

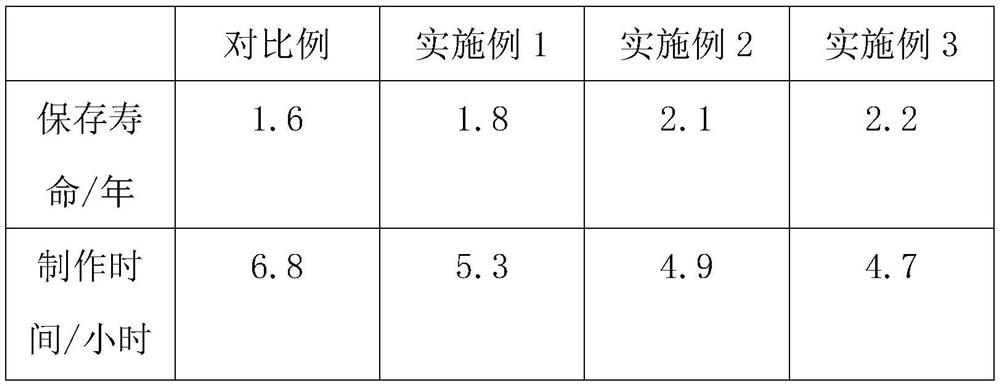

Grouped continuous gradient forming method and forming equipment for corrugated glass

PendingCN109133590AAvoid problems such as deformation difficultiesSatisfy mass productionGlass reforming apparatusEngineeringGlass sheet

The invention relates to a grouped continuous gradient forming method for corrugated glass, a forming section alternately gradually form different to-be-formed areas on a glass plate; forming equipment comprises a rack and a plurality of upper roller ways and lower roller ways, the upper roller ways and the lower roller ways are arranged along the moving direction of the glass plate; the upper roller ways and the lower roller ways correspond up and down to form a forming roller way group, then the forming section is formed, the forming section is divided into more than two forming units arranged along the conveying direction, each forming unit is divided into a forming part and a supporting part along the direction vertical to the moving direction of the glass plate, the forming part and the supporting part both comprise turning surfaces of the upper roller way and the lower roller way, the corresponding generatrix of the turning surface is a wavy curve extending along the central axisof the roller way, and the peak height and the trough depth of the wavy curve gradually increase from an inlet end to an outlet end of the forming section in the forming parts formed in the same areaof the glass plate. The forming accuracy is high, the production requirement on batch and continuous production of the corrugated glass is met, and the forming equipment has the advantages of simplestructure and easiness in operation.

Owner:LUOYANG LANDGLASS TECH CO LTD

Additive manufacturing and processing method of polyetheretherketone skull implant

InactiveCN110253888AComplete moldingSmooth moldingAdditive manufacturing apparatusManufacturing data aquisition/processingSelective laser sinteringCranial implant

The invention discloses an additive manufacturing and processing method of a polyetheretherketone skull implant. The method comprises the following steps of acquiring medical image data of a skull to-be-implanted part of a patient, performing Mimics data processing to reversely construct a three-dimensional digital model of the skull implant, and acquiring a Gcode format file of a skull model; and preparing a polyether-ether-ketone wire rod, setting parameters of a commercial 3D printer, printing, taking out a skull piece, and preserving heat. The integral forming of the skull implant is realized through forming process parameters adopted by a melt deposition forming technology based on polyetheretherketone materials. Compared with that of traditional subtractive manufacturing such as milling, the material utilization rate can be improved, and the material loss can be reduced. Compared with that of a selective laser sintering method, the processing cost is low, the environment is protected, and the manufactured skull implant is high in mechanical property.

Owner:SHANGHAI JIAO TONG UNIV

Manufacturing method of arsenic rod for molecular beam epitaxy

InactiveCN112030224AAvoid Poor Molding EffectsSmooth moldingFrom chemically reactive gasesFrom condensed vaporsPhysical chemistryImpurity

The invention discloses a manufacturing method of an arsenic rod for molecular beam epitaxy. The manufacturing method specifically comprises the following steps: step 1, basic treatment of related equipment; step 2, basic operation of a quartz tube; step 3, primary processing of arsenic particles; step 4, high-order processing of the arsenic particles; step 5, secondary melting of the arsenic particles; and step 6, basic forming of the arsenic particles. The invention relates to the technical field of arsenic rods. According to the manufacturing method of the arsenic rod for molecular beam epitaxy, the arsenic particles can be primarily melted through high-order processing and then are thoroughly melted in a high-temperature high-pressure furnace through secondary melting, so the arsenic particles can be smoothly formed subsequently, poor forming effect caused by incomplete melting of the arsenic particles is avoided, and the percent of pass and the product quality of later-period products are indirectly improved; and the raw material, namely the arsenic particles can directly enter a helium protection environment, so oxidation of the arsenic particles is effectively avoided, and impurities are prevented from being generated in the arsenic rod manufacturing process.

Owner:武汉拓材科技有限公司

Method of processing synthetic resin tubular body and tube container

InactiveUS20060188677A1Minimize wrinkle formationAttractive shapeSynthetic resin layered productsHollow wall articlesWide areaEngineering

The technical problem of this invention is to establish a method of processing a synthetic resin tube, in which the shape of a part of the tube wall is changed to form easily an attractively hollowed and / or raised portion in a fairly wide area of the tube wall. The object of this invention is to provide a tubular container having excellent decorativeness, appearance, or functionality that has never been found before. A method of processing a synthetic resin tube comprises utilizing a mandrel having a mold portion, which has at least a shape selected from a hollowed shape, a raised shape, and a hollowed and raised shape formed in a part of outer surface of the mandrel, and which is also provided with small through-holes in this mold portion; inserting a bottomed cylindrical mandrel into a synthetic resin tube, while bringing the inner wall of the tube in contact with the mandrel; heating and softening the tube in the portion facing the mold portion; deaerating the tube via a central opening and the through-holes to mold the softened portion of the tube in a manner similar to vacuum molding; and forming in the tube wall at least one of the portions selected from a hollowed portion, a raised portion, and a hollowed and raised portion.

Owner:YOSHINO KOGYOSHO CO LTD

Special-shaped sliding block

Owner:汪在林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com