Combination sofa integrated threaded connection mechanism and processing mold thereof

A thread connection and thread processing technology, which is applied in the field of integrated sofa thread connection mechanism, can solve the problems of pad scrapping, failure to set up, troublesome installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

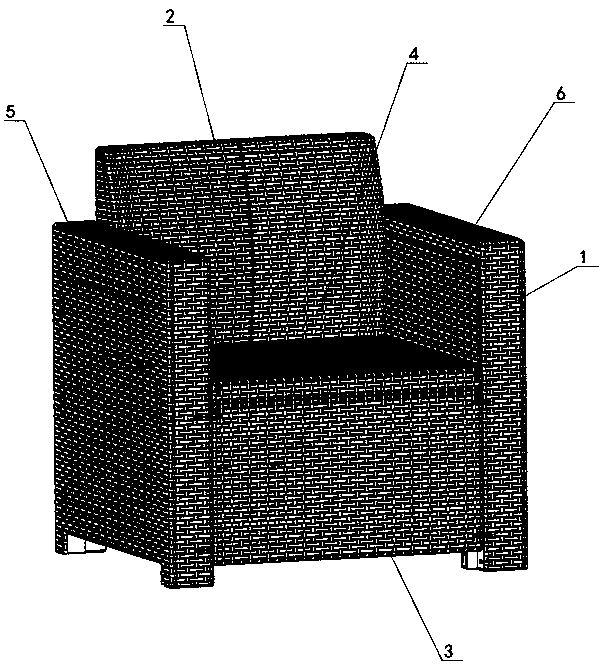

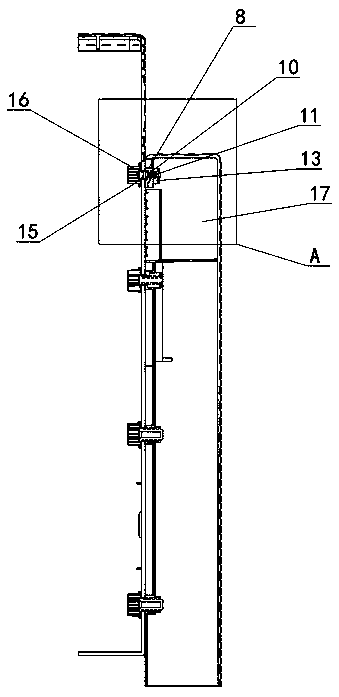

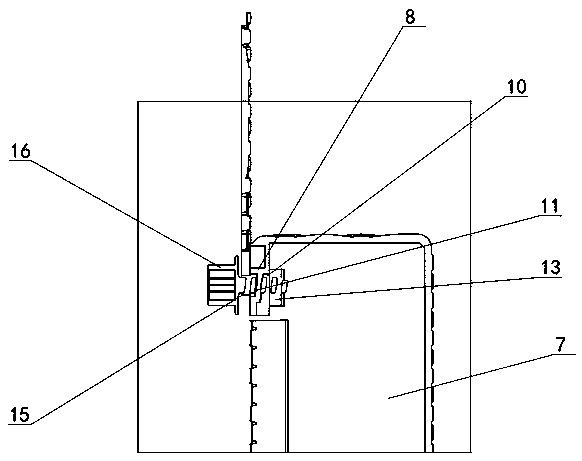

[0017] The invention relates to an integrated thread connection mechanism for a combined sofa, such as figure 1 — Figure 4 As shown, it includes a seat board 1, a back board 2, a front board 3, a rear board 4, a left board 5, a right board 6, and a left board 5, a right board 6 and a seat board by injection molding of plastic materials. 1. The backboard 2, the front baffle 3, and the rear baffle 4 are assembled and connected by a connecting mechanism. The connecting mechanism includes setting hollow columns 7 on both sides of the left buttress 5 and the right buttress 6. A connecting column 8 is arranged on the inner side wall of the column, and a connecting hole 10 is opened in the connecting column. An integrally formed thread 11 is arranged in the connecting hole. The thread 11 has only one spiral, and there is a fracture between the beginning and the end of the spiral. 12. A hollow groove 13 is provided on the rear side wall of the left buttress 5 and the right buttress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com