Patents

Literature

69results about How to "Fully packaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

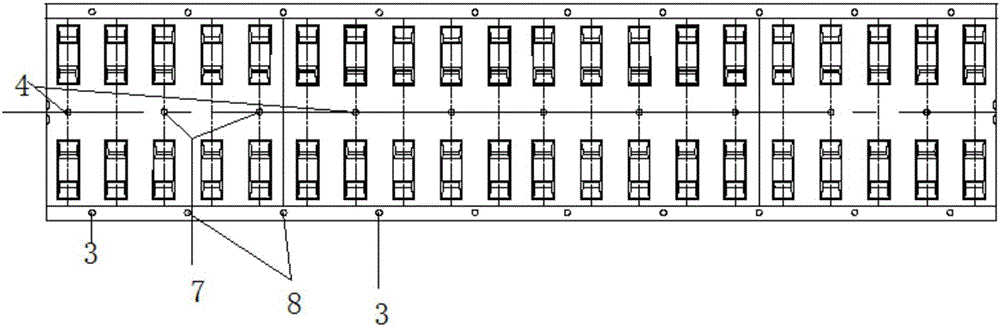

Ballastless track grouting lifting and lifting correcting method

InactiveCN106758591AFast constructionPractical and reliableRailway track constructionEngineeringHigh polymer

The invention discloses a ballastless track grouting lifting and lifting correcting method. The method comprises the following steps: step 1: before lifting, using a high-precision level gauge to measure the track surface and under-track empty area, according to the measuring result, determining the lifting position and lifting quantity of a track board, and determining the arrangement position, space distance, hole diameter and hole depth of a grouting hole; step 2: calculating and determining the cutting position of a closing layer, and cutting the closing layer; step 3: arranging the grouting holes in the position to be lifted, preparing a polymer bag and arranging holes in the polymer bag; step 4: inserting a grouting pipe into the polymer bag, and fixing; step 5: installing the grouting pipe and the polymer bag in the grouting hole; step 6: executing the grouting lifting, monitoring in real time during the lifting process, and guaranteeing the track lifting elevation; and step 7: after executing certain amount of the grouting lifting, correcting the part to be corrected, monitoring the correcting process in real time, and guaranteeing the correcting displacement of the track. After completing the grouting, the high polymer bag and a grouting material carry out the compaction with the surrounding soil so as to form a self-formation pile. The solution is capable of realizing the rapid and accurate lifting of the upper structure of the track.

Owner:BEIJING RUIWEI TIEKE HIGH SPEED RAIL ENG CO LTD

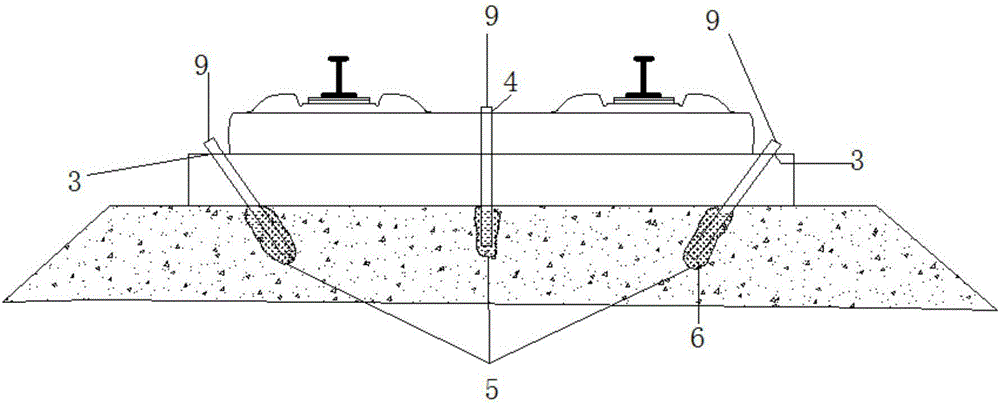

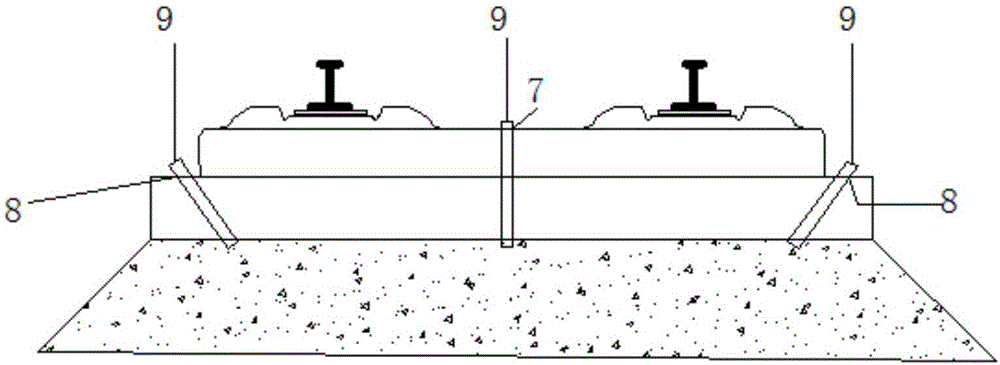

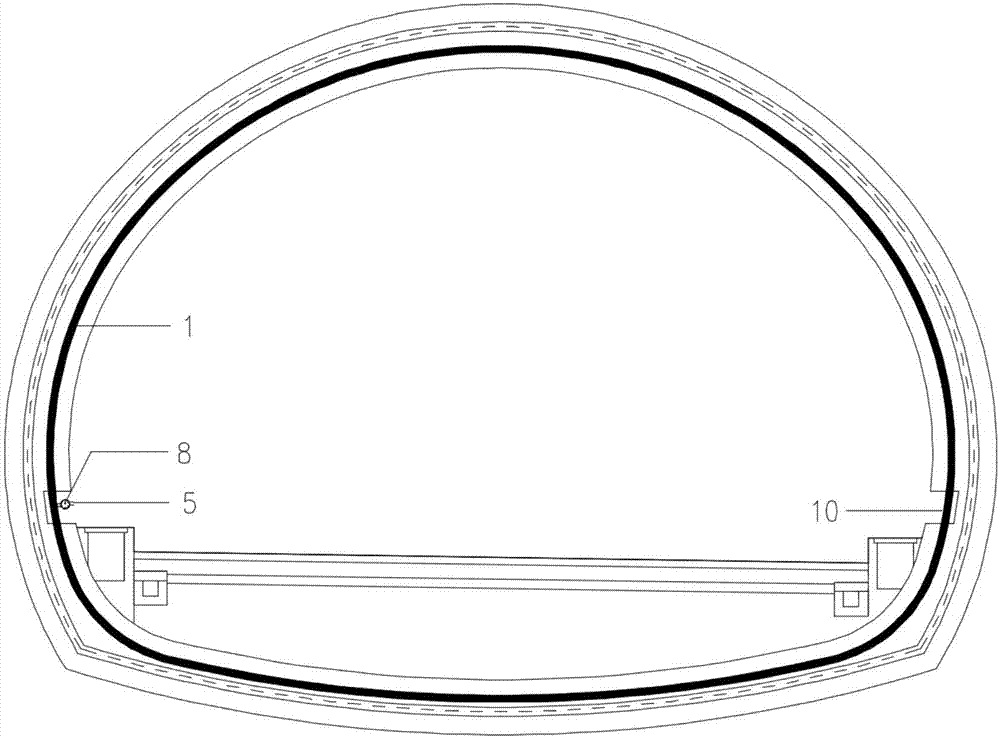

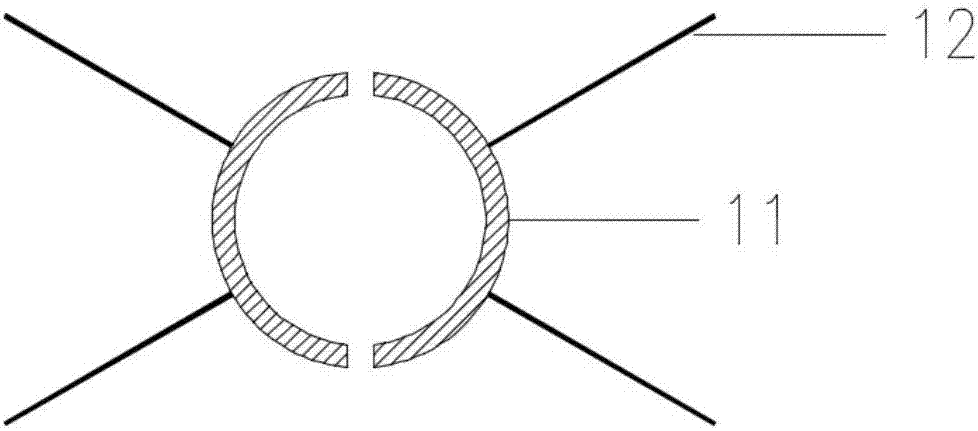

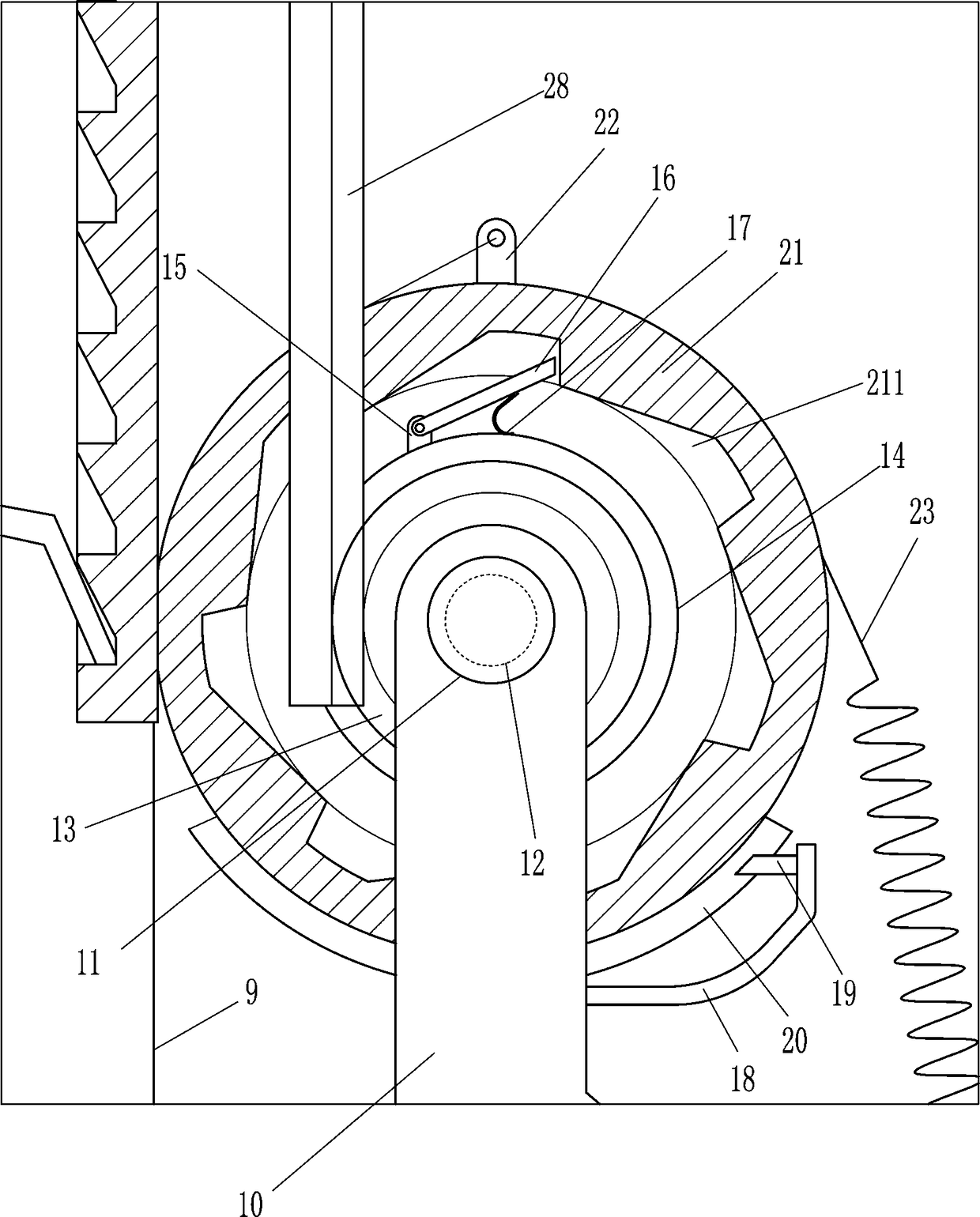

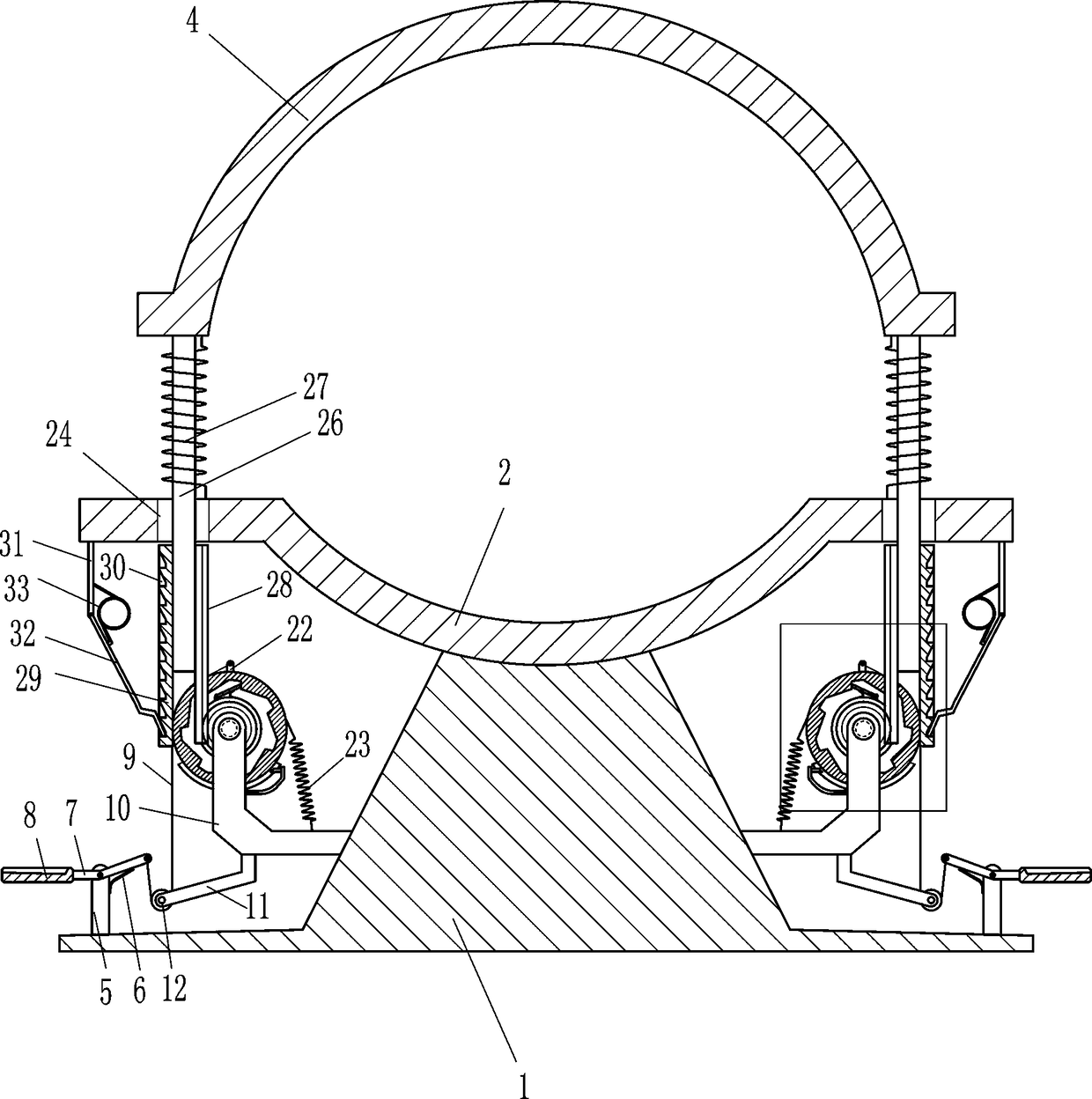

Replaceable and inflatable type water stopping belt used for mining method tunnel

PendingCN107489435AReduce the difficulty of replacementEasy to maintain laterUnderground chambersTunnel liningWater leakageEngineering

The invention discloses a replaceable and inflatable type water stopping belt used for a mining method tunnel. The problem that an existing water stopping belt cannot effectively solve the problems of water seepage and water leakage of a tunnel in the prior art is effectively solved. The replaceable and inflatable type water stopping belt has the effects that construction is convenient, the waterproof capacity in tunnel expansion joints can be improved, and replacing can be convenient during tunnel operation period. According to the technical scheme, the replaceable and inflatable type water stopping belt comprises an airbag groove, the airbag groove and an airbag are arranged in a fitting mode, and the airbag groove comprises two arc-shaped tube pieces which are arranged oppositely; a set gap is formed between the end parts of the two arc-shaped tube pieces, and the positions between the inner sides of the arc-shaped tube pieces and the airbag are filled and coated with waterproof mineral grease; and a plurality of anchoring pieces are arranged on the outer sides of the arc-shaped tube pieces.

Owner:JINAN MUNICIPAL ENG DESIGN & RES INSITITUTE GRP

Method for preparing aluminum oxide for catalyst

InactiveCN102658114AWell mixedFully packagedMetal/metal-oxides/metal-hydroxide catalystsCerium nitrateManufacturing technology

A method for preparing aluminum oxide for catalysts relates to the improvement of the preparation method of activated aluminum oxide used in catalysis field such as petrochemical engineering, industrial catalysis, automobile exhaust purification and the like. The method is characterized in that one or any two of lanthanum nitrate, zirconium nitrate and cerium nitrate is / are added in a reaction tank preparing pseudoboehmite and is / are used as modifying agents, and action is performed; slurry is processed through suction filtration, washing and drying after reaction and then modified pseudoboehmite powders are obtained; and the powders that are dried are roasted and then the aluminum oxide for the catalysts is obtained. The method is adopted to process the pseudoboehmite slurry through doping modification, is closely combined with the manufacturing process of the pseudoboehmite, effectively simplifies the manufacturing technology, lowers the manufacturing cost, achieves good surface modification effect, improves the heat stability of activated aluminum oxide powders, and improves the service performance of the activated aluminum oxide powders.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

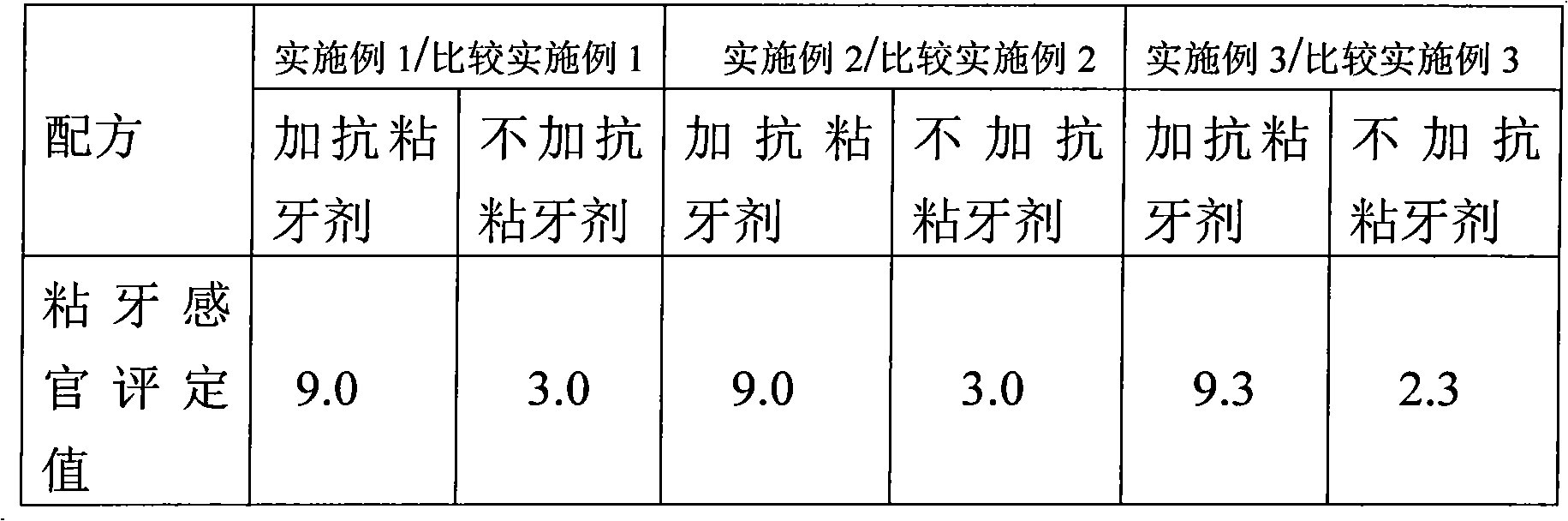

Solid honey candy and preparation method thereof

InactiveCN102058004AChange the curing characteristicsImprove product valueConfectionerySweetmeatsSucroseMicrowave

The invention relates to a solid honey candy and a preparation method thereof. The solid honey candy comprises the following components in percentage by weight: 100 percent of liquid pure honey, 3 to 6 percent of edible solid gum and 0.7 to 3 percent of teeth stick-resisting agent, wherein the edible solid gum is selected from arabic gum, konjac gum and pectin, and the teeth stick-resisting agentis selected from lecithin, sucrose fatty acid ester and water-soluble glycerol monostearate. The preparation method of the solid honey candy comprises the following steps of: weighing the components in a weight ratio, dissolving the edible solid gum and the teeth stick-resisting agent in hot water, adding the solution into the liquid pure honey, dehydrating the obtained mixed liquid by a vacuum microwave heating method to ensure that water content is below 3 percent, performing cast molding at the temperature of between 60 and 70 DEG C, cooling and demolding to obtain the solid honey candy. The honey content of the solid honey candy is above 90 percent; the color, aroma, taste and nutrients of the original liquid honey are basically not changed; a solid shape can be kept at room temperature; and the edible teeth stick-resisting agent is added into the formula, so that the solid honey candy is not sticky to teeth and has good mouthfeel during chewing. The preparation method is easy.

Owner:JIANGNAN UNIV

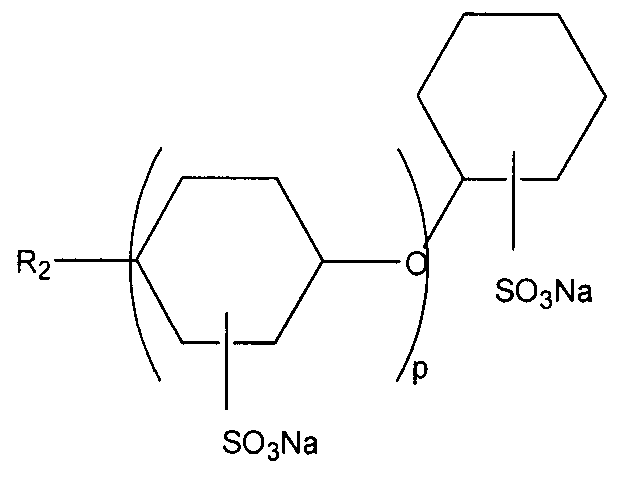

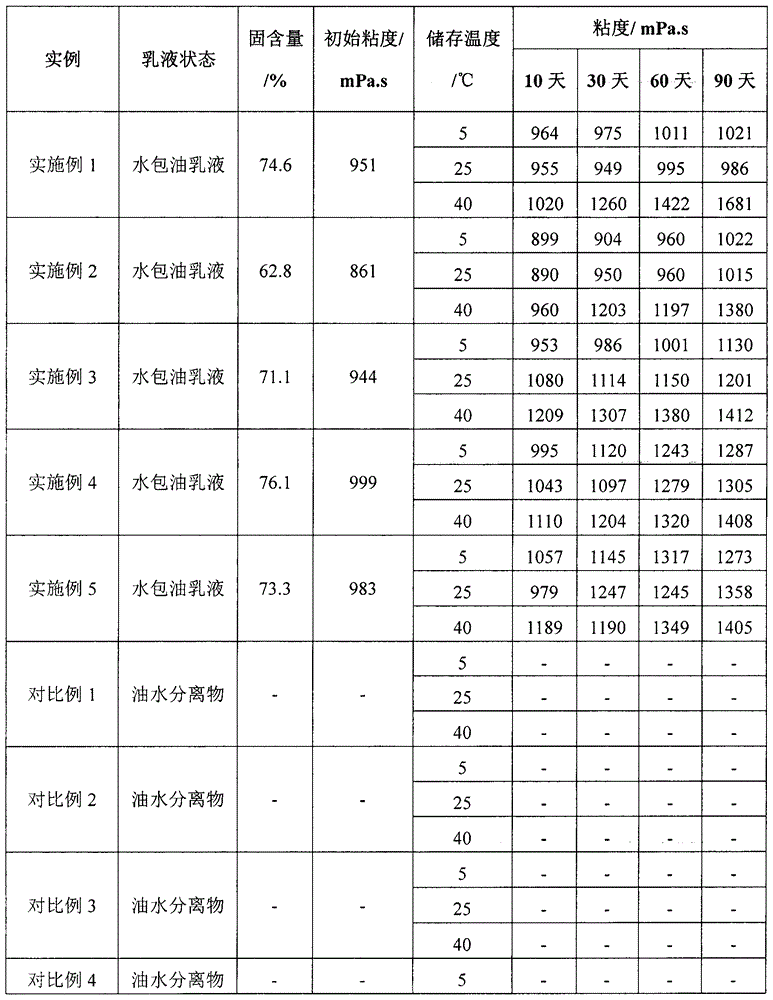

Preparation method of stable oil-in-water emulsion with high solid content

The invention relates to a special emulsification method. According to the method, stirring is stopped in the emulsification process, a mixture of W / O and little water or W / O / W is formed through standing, stirring is started, instantaneous inner shear force in unit area is increased, and formation of the O / W emulsion is facilitated; meanwhile, a hydrophilic emulsifier is dropwise added into the mixture during standing, the formation of the O / W emulsion is facilitated, and full wrapping and dispersing of droplets are facilitated to make the emulsion more stable; in the post-processing stage, the volume of the non-oil phase is increased by adding a stabilizer. By means of the preparation method, the problem that the viscosity of the emulsion with the high solid content is high is solved; meanwhile, the stability of the emulsion with the high solid content is improved, the preparation method is widely suitable for emulsification of hydrocarbons and oxygen-containing derivatives thereof, and the application range is wider.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

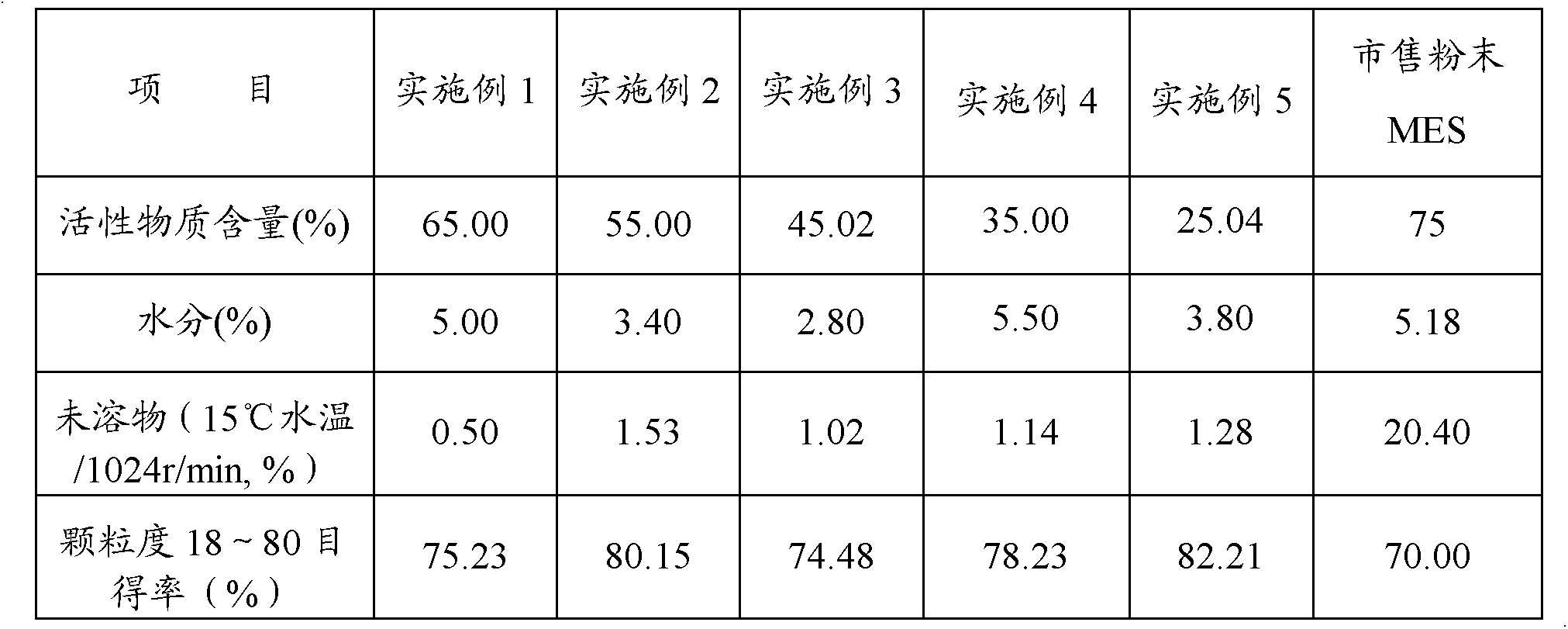

Particles containing sodium fatty acid methyl ester sulfonate and preparation method thereof

ActiveCN103320235AFully packagedIncrease package volumeSurface-active detergent compositionsDetergent mixture composition preparationSolubilitySulfonate

The invention discloses particles containing sodium fatty acid methyl ester sulfonate and a preparation method thereof. The preparation method comprises the following steps: mixing a wrapper and 20-75 parts by weight of paste sodium fatty acid methyl ester sulfonate, granulating by a wet process, drying, and screening. The wrapper is a composition comprising the following components in parts by weight: 1-40 parts of zeolite, 1-40 parts of silicate, 1-30 parts of modified starch and 0-30 parts of bentonite. The mass percent of the sodium fatty acid methyl ester sulfonate in the particles containing sodium fatty acid methyl ester sulfonate can be up to 65%; the particles containing sodium fatty acid methyl ester sulfonate can be used as a raw material for preparing washing powder or directly used as a detergent; and the invention effectively solves the problems of poor stability, high decomposition tendency, high lumping tendency, poor low-temperature solubility and the like in the use process of sodium fatty acid methyl ester sulfonate.

Owner:NICE GROUP

Fruit juice soft sweets coated with collagen casings and preparation method of soft sweets

InactiveCN107821714AImprove plasticityPleasant chewing sensationSugar food ingredientsConfectioneryFruit juiceGlycerol

The invention discloses fruit juice soft sweets coated with collagen casings and a preparation method of the soft sweets, and belongs to the technical field of food processing. The outermost layer ofthe soft sweets is wrapped with collagen casings. The moisture content of the soft sweets is 20% or above, and pH value of the soft sweets is 4.0 or below. The soft sweets comprise the following components in parts by weight: 16 to 35 parts of white granulated sugar, 30 to 55 parts of glucose syrup, 4 to 15 parts of fruit juice, 2 to 8 parts of glycerol, 0.1 to 1.0 part of gellan gum, 0.1 to 1.0 part of locust bean gum, 0.1 to 1.0 part of xanthan gum, 0.3 to 0.7 part of citric acid, 0.1 to 0.4 part of malic acid, 0.01 to 0.15 part of calcium hydrogen phosphate, and a proper amount of collagencasings, essence for foods and pigment. The preparation method comprises the following steps of: preparing a gellan gum solution, boiling sugar, conducting mixing, heat insulation and stewing, preparing the fruit juice, and conducting blending, filling, kinking, solidification, shearing, drying and packaging. According to the invention, the collagen casings are used for wrapping the fruit juice soft sweets, so that package is novel; mouth feel is chewy; a juice flavor is fully reserved; the soft sweets are delicious with slight sweetness and sour; and variety of the fruit juice can be changedaccording to different taste preferences.

Owner:奇峰(福建)食品有限公司 +1

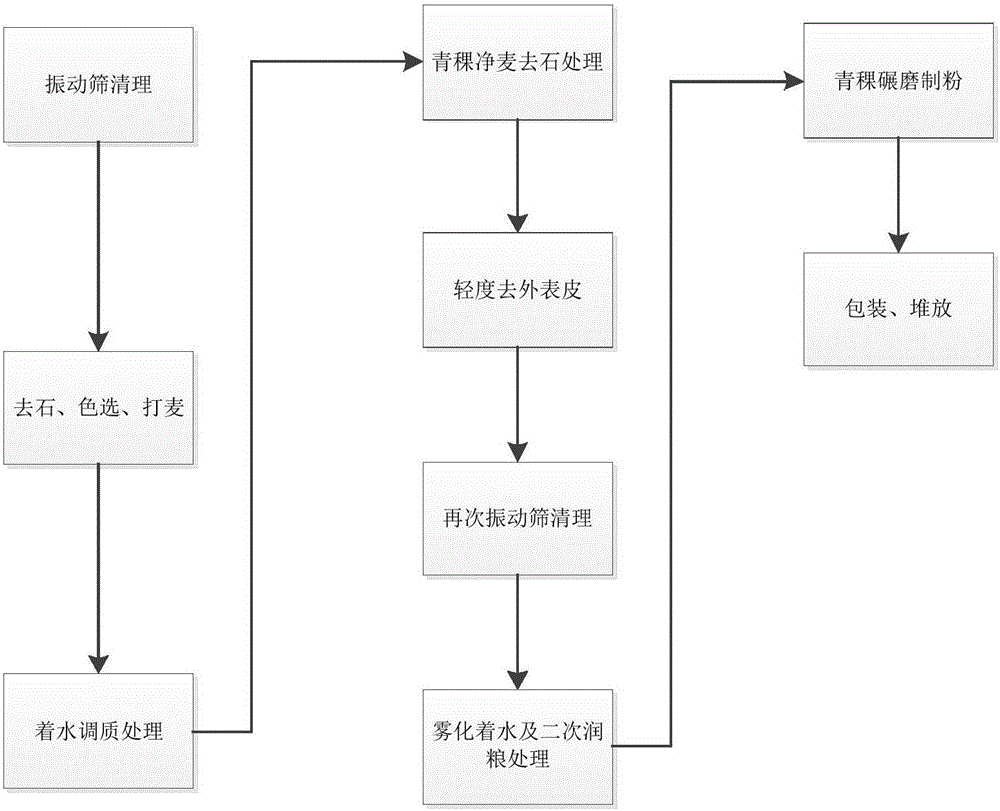

Technique for processing highland barley flour

ActiveCN106269016AControl contentKeep intactGrain huskingGrain polishingHazardous substanceExodermis

The invention provides a technique for processing highland barley flour. The technique includes the step of dehusking, specifically, outer husks are slightly removed. The technique for processing highland barley flour further includes the color sorting step; and multiple times of slight milling and multistage flour production including 4-6 times of break milling, 1-3 times of impacting flour production, 4-7 times of reduction milling, 1-2 times of residue milling, 1-4 times of clear flour purification and 2-4 times of bran finishing are adopted in the flour milling stage. By means of the technique for processing highland barley flour, raw materials such as different-color grains and moldy grains which do not meet requirements can be removed, the highland barley flour production rate is high, efficiency is high, quality is high, finished highland barley flour contains only a few impurities and microorganisms, the quantity of harmful substances such as residual pesticides and heavy metal is small, and food safety is guaranteed; meanwhile, original nutrients of highland barleys are reserved; the highland barley flour can be automatically produced on a large scale, development of highland barley processing is promoted, and the competitiveness of highland barley products is improved; bran completeness is high, and subsequent deep processing of bran is facilitated.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

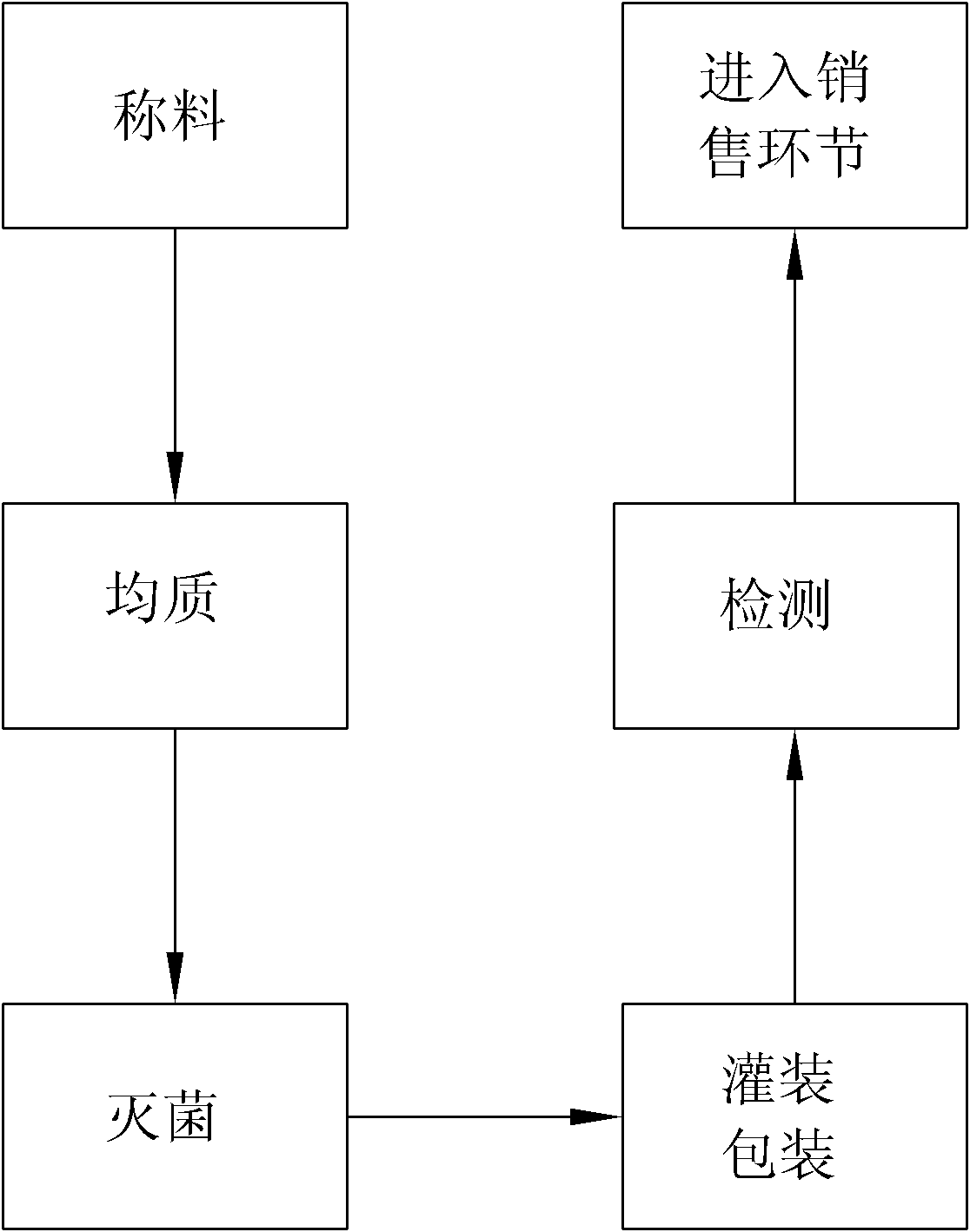

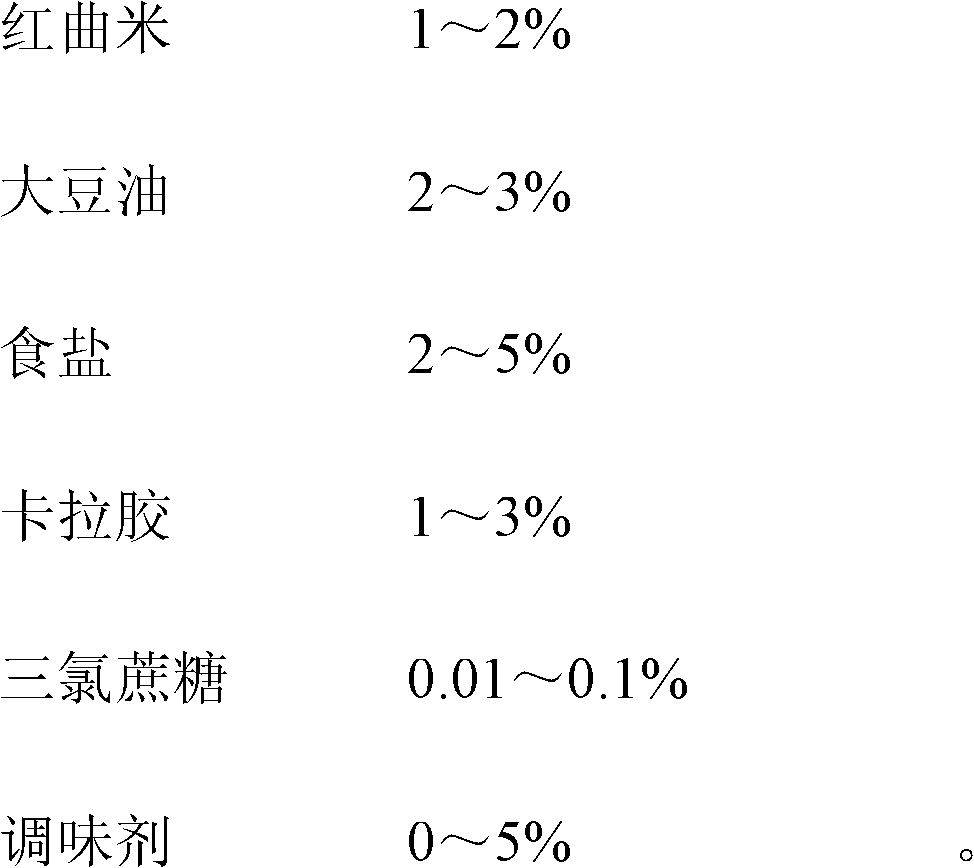

Preserved bean curd sauce and preparation method thereof

ActiveCN102349637AReduce wasteDon't worry about brokenFood preparationRed yeast riceAdditive ingredient

The invention discloses preserved bean curd sauce and a preparation method thereof, which belong to the food processing field. The preserved bean curd sauce consists of the following ingredients in percentage by weight: 80 to 88 percent of preserved bean curd, 5 to 10 percent of fermented soybeans, 1 to 2 percent of red yeast rice, 2 to 3 percent of soybean oil, 2 to 5 percent of salt, 1 to 3 percent of carrageenin, 0.01 to 0.1 percent of sucralose and 0 to 5 percent of flavoring. The preparation method comprises the following steps that: weighing raw materials according to the proportion, homogenizing and mixing, high-temperature sterilizing, filling and packing when the obtained product is still hot. The defective preserved bean curd with unqualified appearance in the production of block-shaped preserved bean curd is adopted to produce the preserved bean curd sauce, so the waste of the resource can be reduced, the breaking of the block-shaped preserved bean curd caused by high temperature is not worried, high-temperature sterilizing and inactivating enzyme operation is adopted; the subsequent filling production can realize the mechanization and automation, so the production efficiency can be greatly improved; and at the same time the preserved bean curd sauce is free from being subject to the packing of traditional glass bottles, the packing of a preserved bean curd sauce product can be more flexible and varied, and the requirement of modern people on portable flavoring can be satisfied.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD

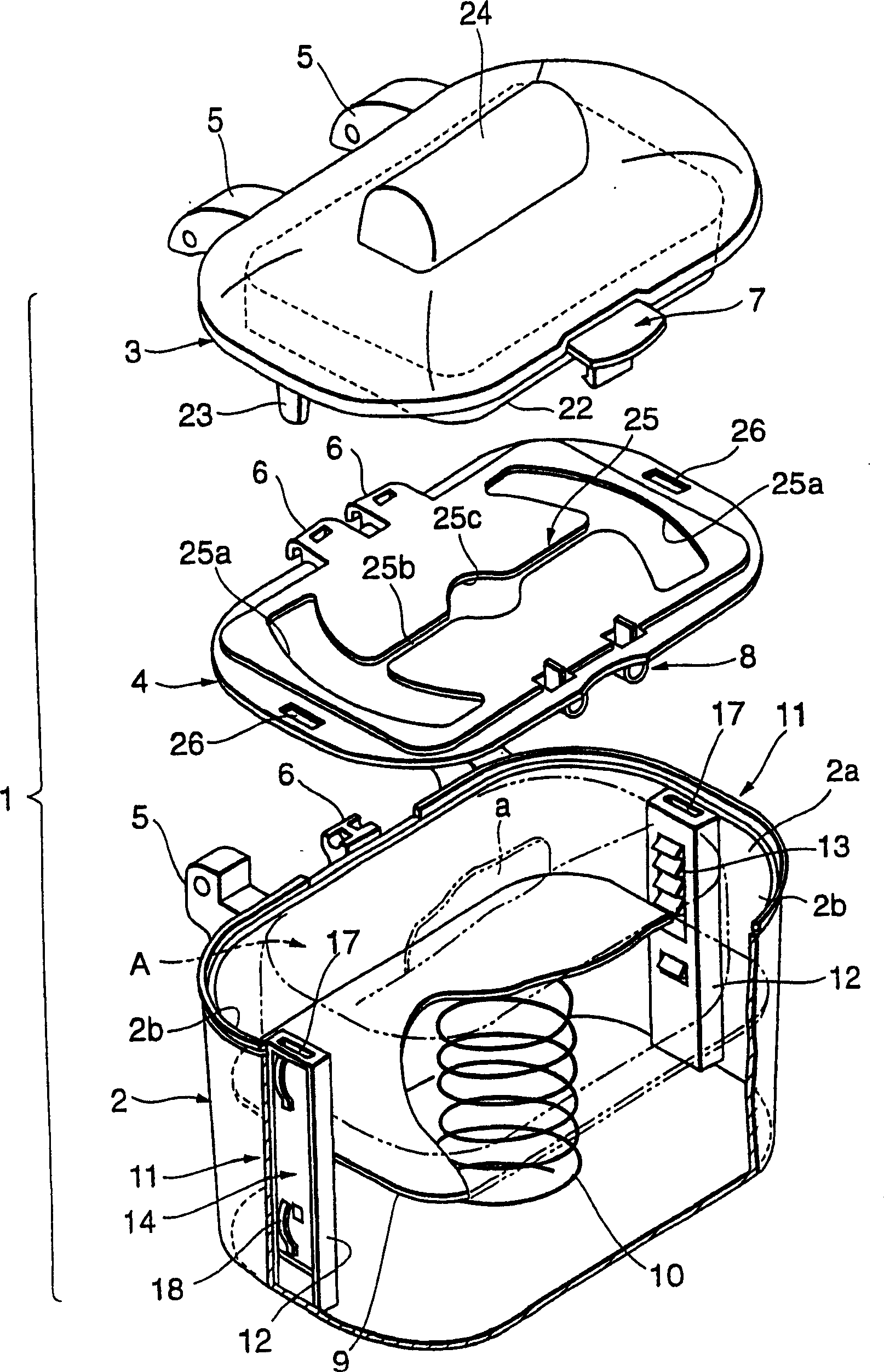

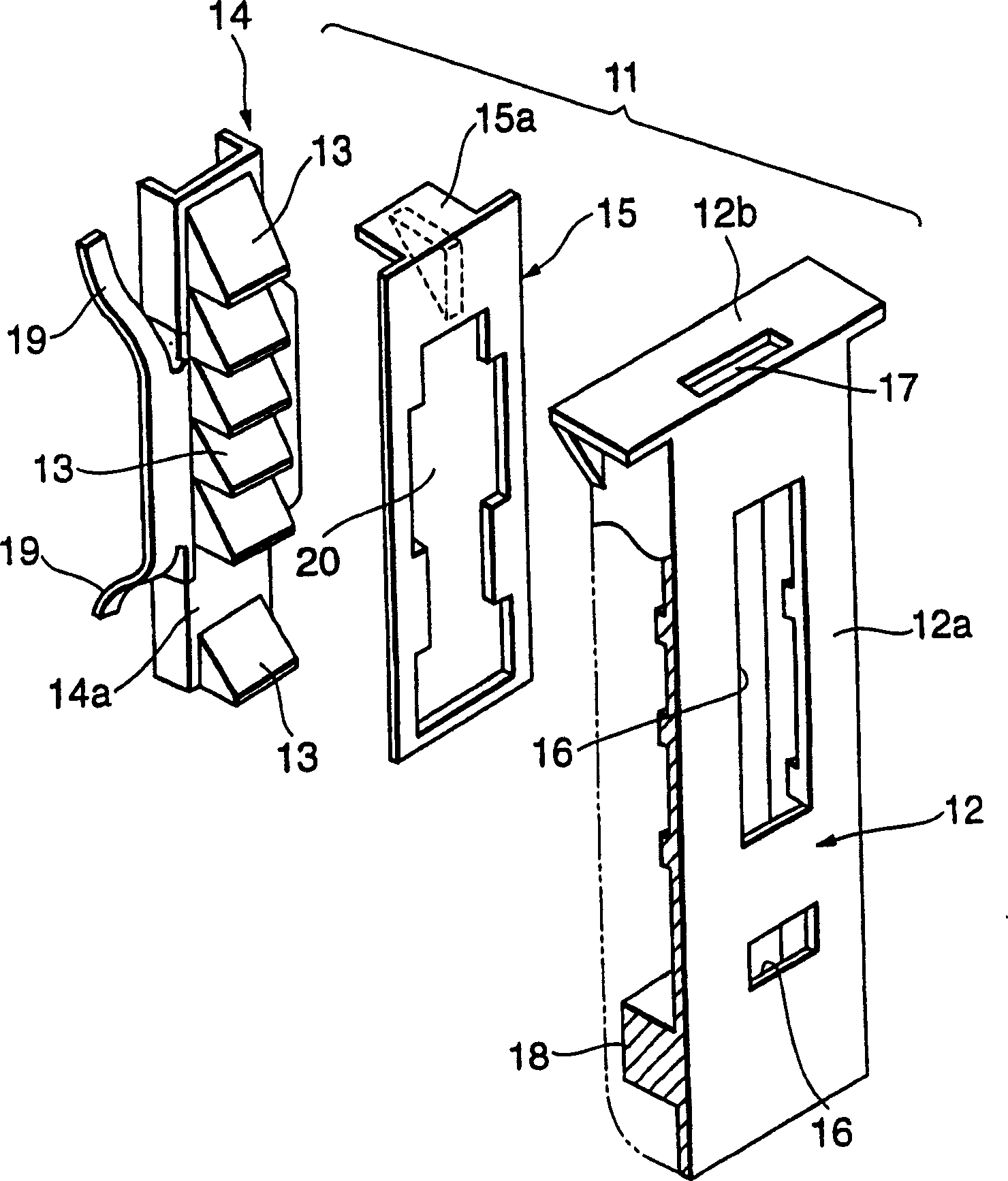

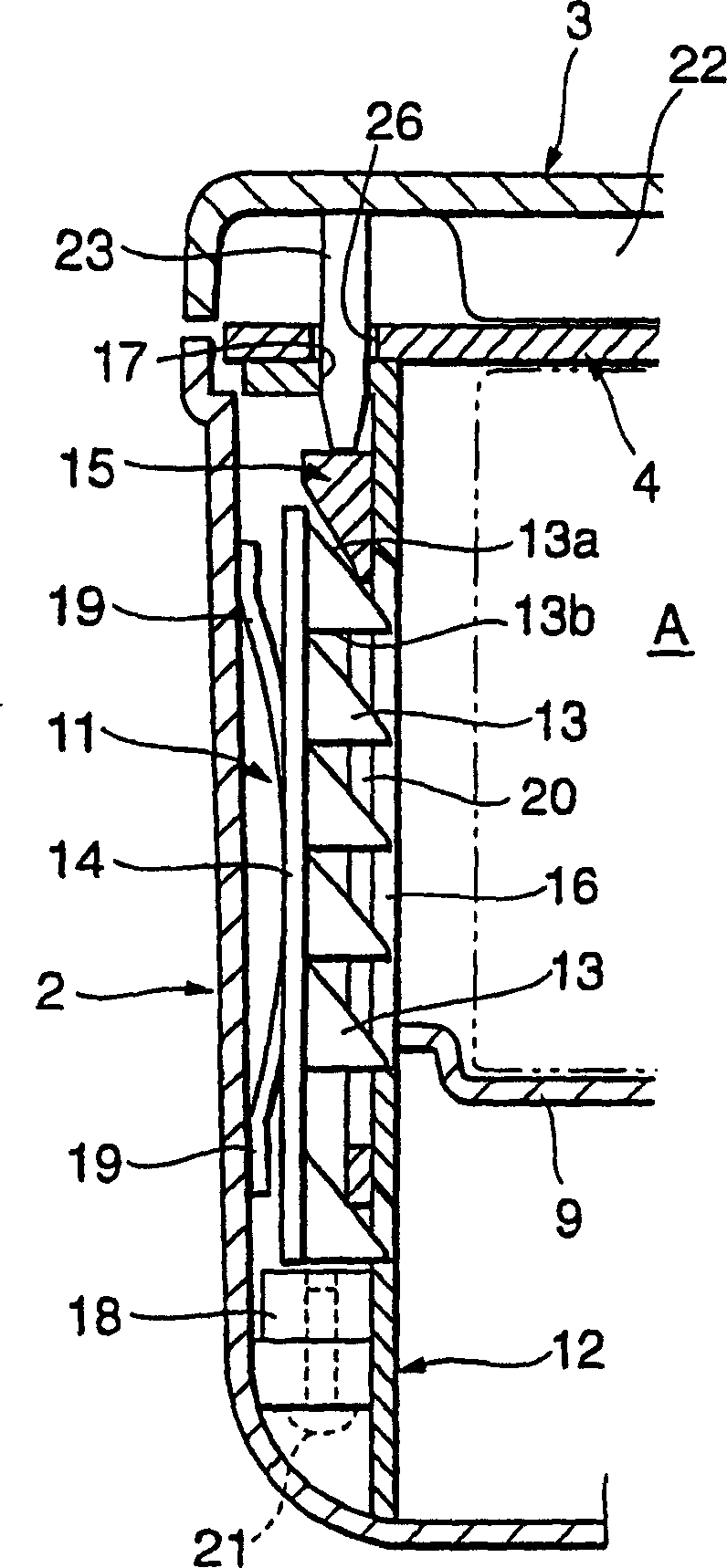

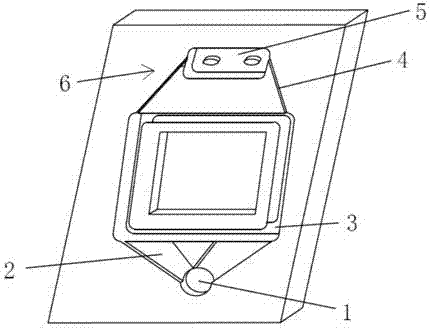

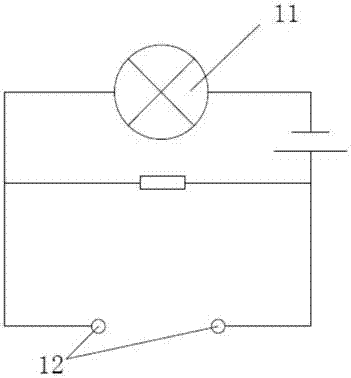

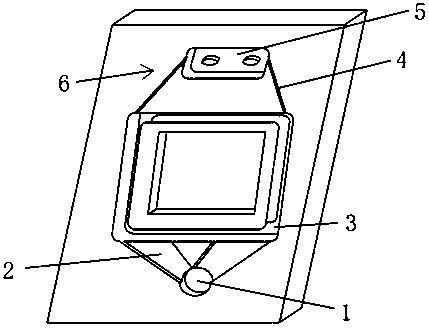

Wet tissue warmer

InactiveCN1593318AInhibition biasFully packagedBathroom accessoriesHeating arrangementEngineeringMechanical engineering

A wet tissue warmer includes: a case (2) having an open end (2a), a lid (3) removably put on the case (2) so as to cover the open end (2a) of the case (2) and internally provided with a heater, and a lifting plate (9) placed in the case (2)and biased upward. When the lid (3) is closed, a wet tissue package (A) mounted on the lifting plate (9) is kept in contact with the lid (3) to heat the wet tissue package (A). Lifting plate locking devices (11) are disposed in the case (2). The lifting plate (9) is locked at the present position by the lifting plate locking devices (11) when the lid (3) is opened.

Owner:COMBI CORP

Catalytic iron internal electrolysis biological fluidization filler and preparation method thereof

InactiveCN102826646ASolve the disadvantages of easy cloggingStrong reductionTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesElectrolysisPhysical chemistry

The invention discloses a catalytic iron internal electrolysis biological fluidization filler and a preparation method thereof, falling into the field of wastewater treatment. The filler comprises the following materials by weight: 10-15% of a casing, 80-90% of catalytic iron, and 0-5% of specific gravity regulating material. The preparation method comprises the steps of pressing catalytic iron into catalytic iron internal electrolysis material of certain shape, and filling the catalytic iron internal electrolysis material and specific gravity regulating material into the casing, or directly filling the catalytic iron internal electrolysis material into the casing with regulating function, to obtain fluidizable biological filler. According to the invention, the defect of easy blocking of catalytic iron internal electrolysis is solved, while the technical merits of catalytic iron internal electrolysis filler, such as low cost, easy availability, environment friendliness, strong reducing ability, good effect, and wide pH adaptability, are fully retained.

Owner:TONGJI UNIV

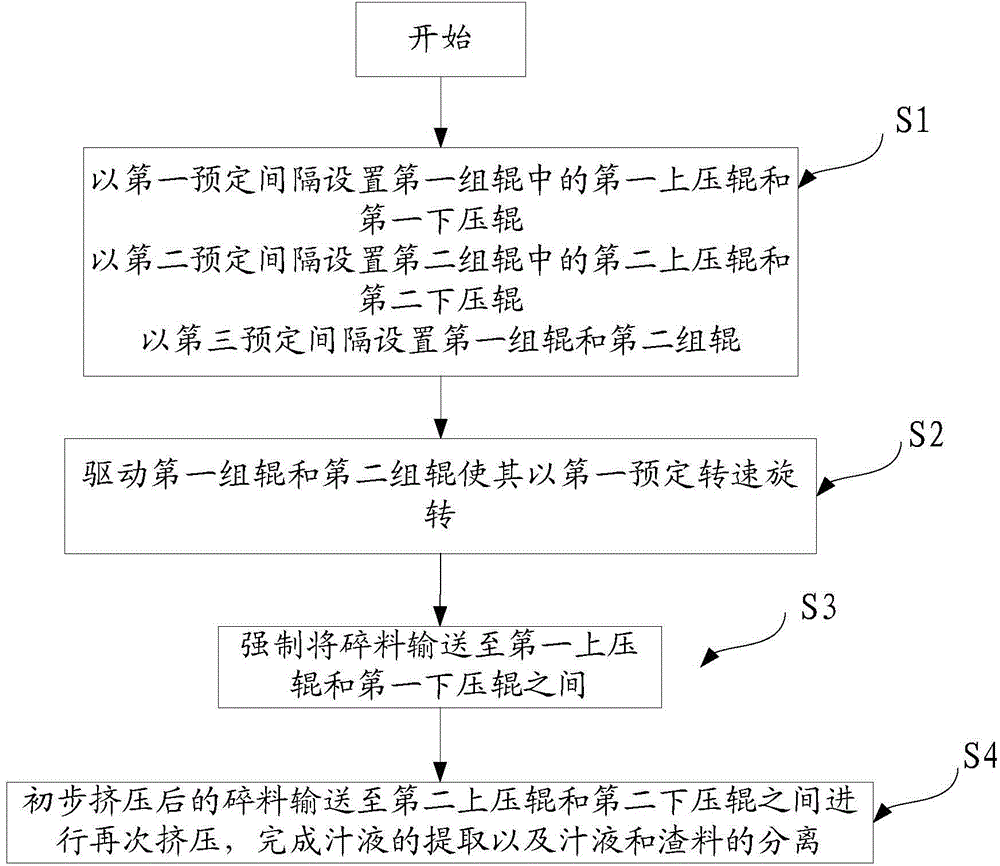

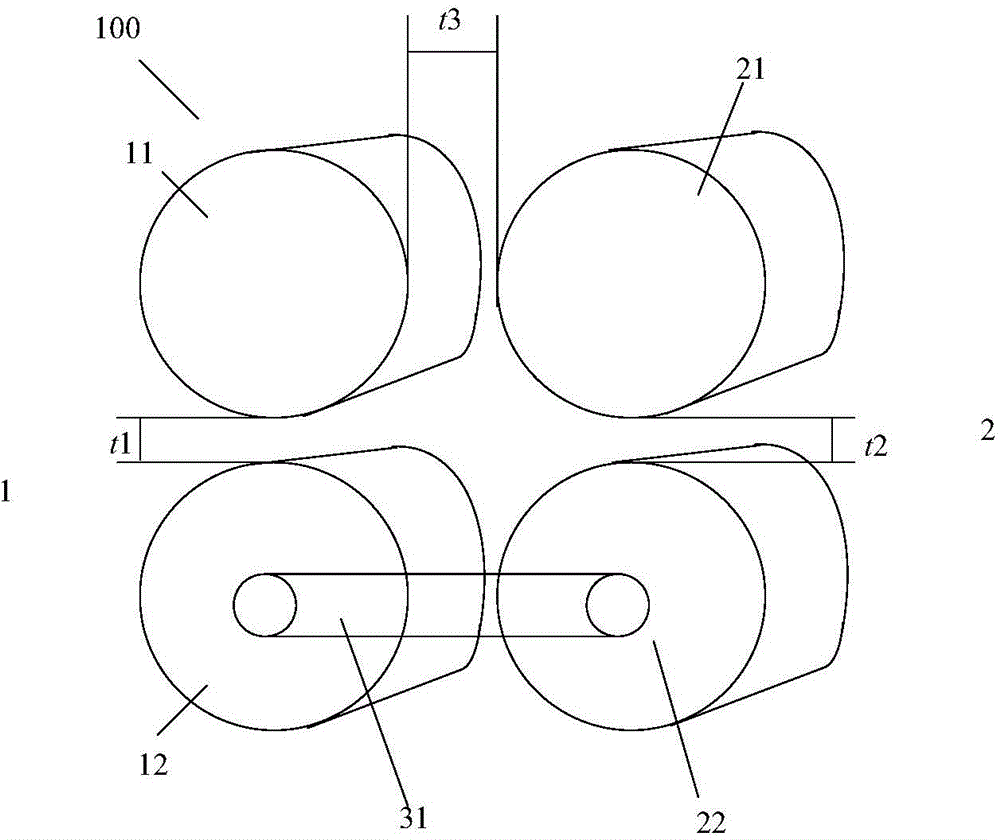

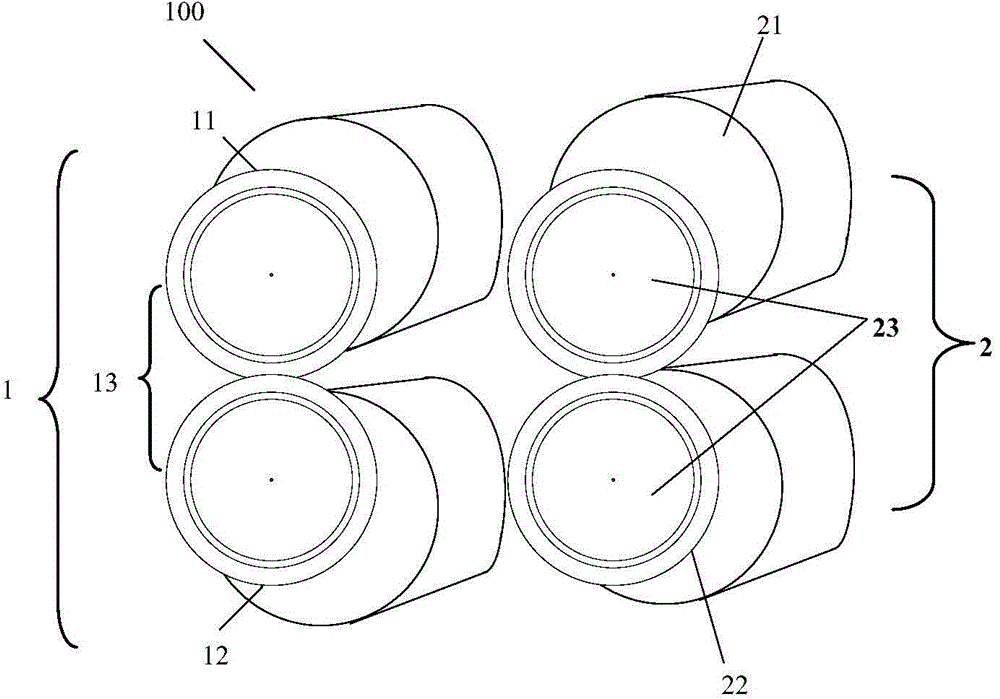

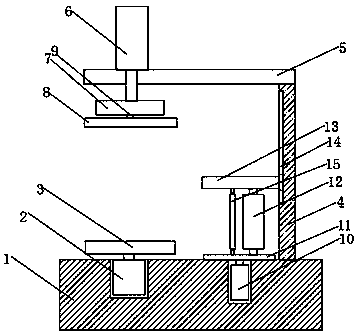

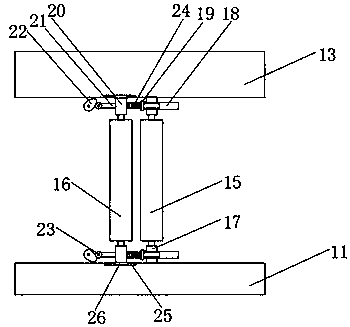

Juice and dreg separation method

The invention provides a juice and dreg separation method. According to the method, a first upper press roller and a first lower press roller are arranged from up to down with a preset interval; and the first upper press roller and the first lower press roller are connected through a first synchronizer, so that the first upper press roller and the first lower press roller can rotate with the same rotating speed. A juice and dreg separation device provided by the invention can extract the juice of straw fragments according to the function of dregs after the juice of the straw fragments is extracted, so that straw can be fully utilized.

Owner:雄县牛宝秸秆青草加工有限公司

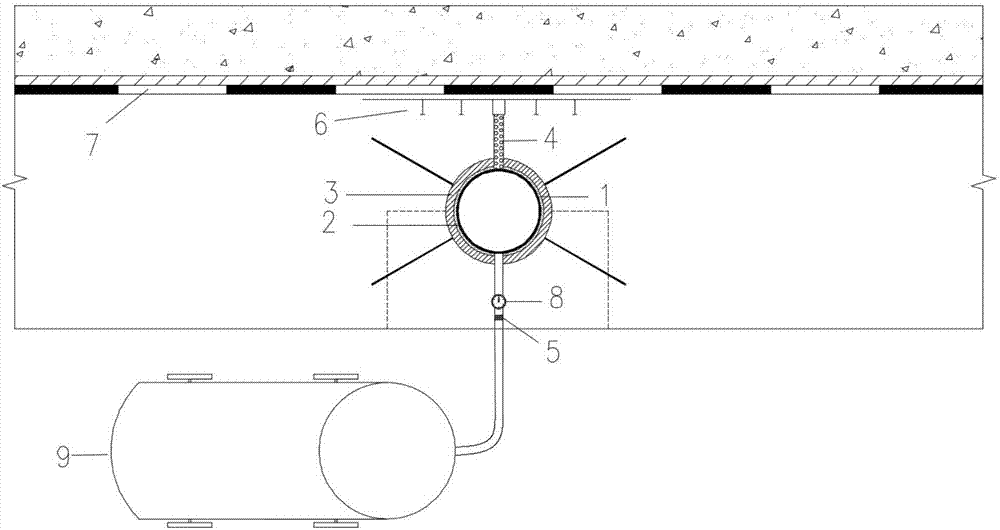

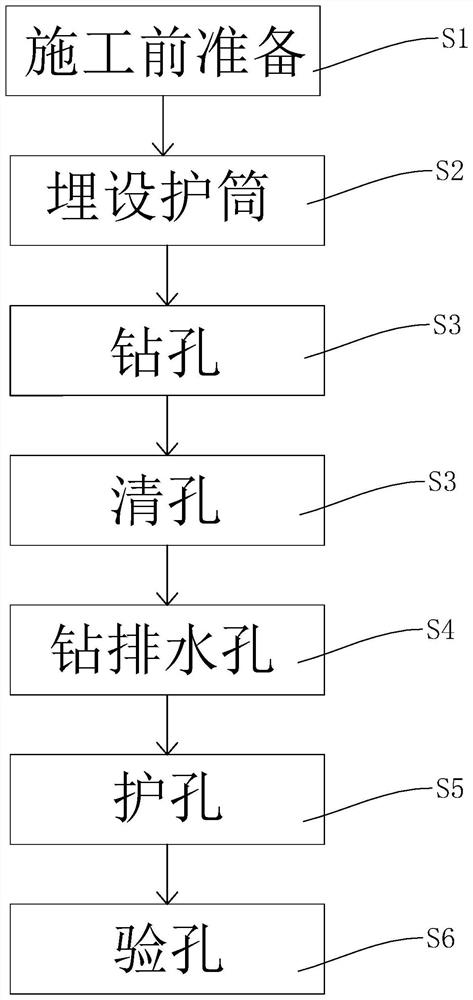

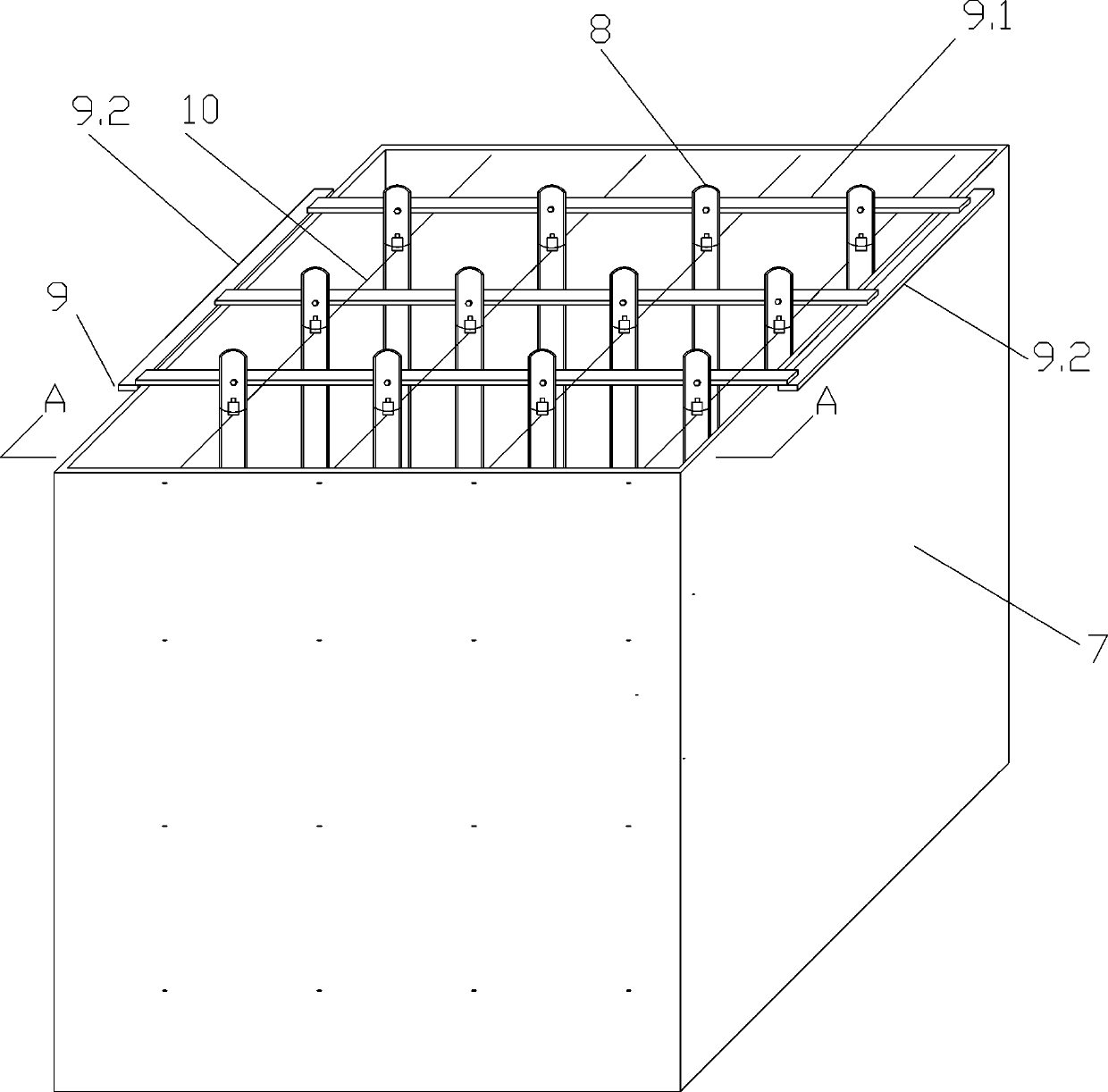

Cast-in-situ bored pile hole forming method

ActiveCN111946259AReduce shippingReduce pollutionDrill bitsDrilling rodsSoil scienceStructural engineering

The invention relates to the technical field of geotechnical investigation construction, in particular to a cast-in-situ bored pile hole forming method. The cast-in-situ bored pile hole forming methodcomprises the steps of carrying out preparation before construction, carrying out pile casing burying, carrying out drilling, carrying out hole cleaning, carrying out drainage hole drilling, carryingout chambering and the like, and in the chambering step, a pre-drilled pile hole during drilling is gradually squeezed to the designed pile hole diameter through three times of squeezing and chambering. The method has the effects that a small amount of soil is discharged in the hole forming process so that pollution to the construction environment can be reduced, and the construction pollution discharge cost is reduced.

Owner:江苏省岩土工程勘察设计研究院

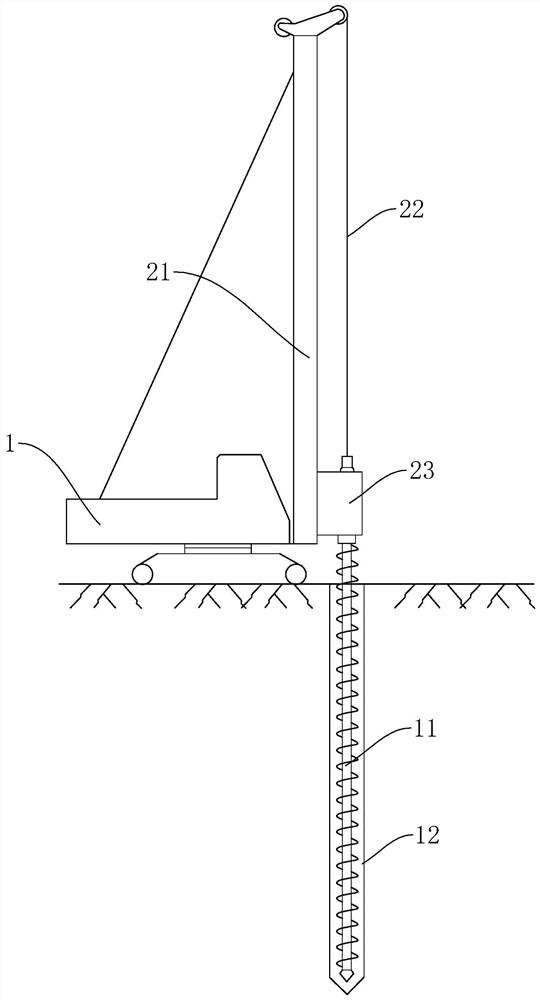

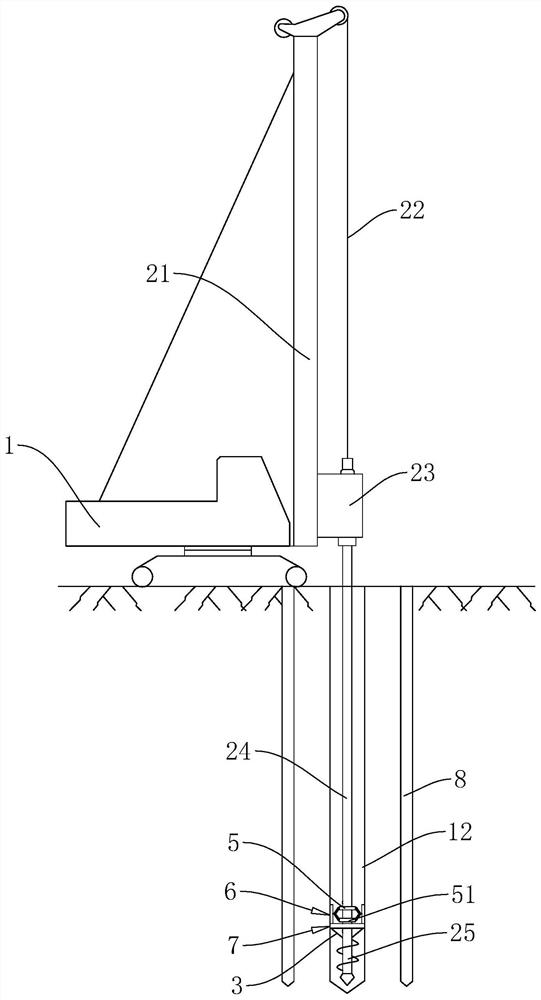

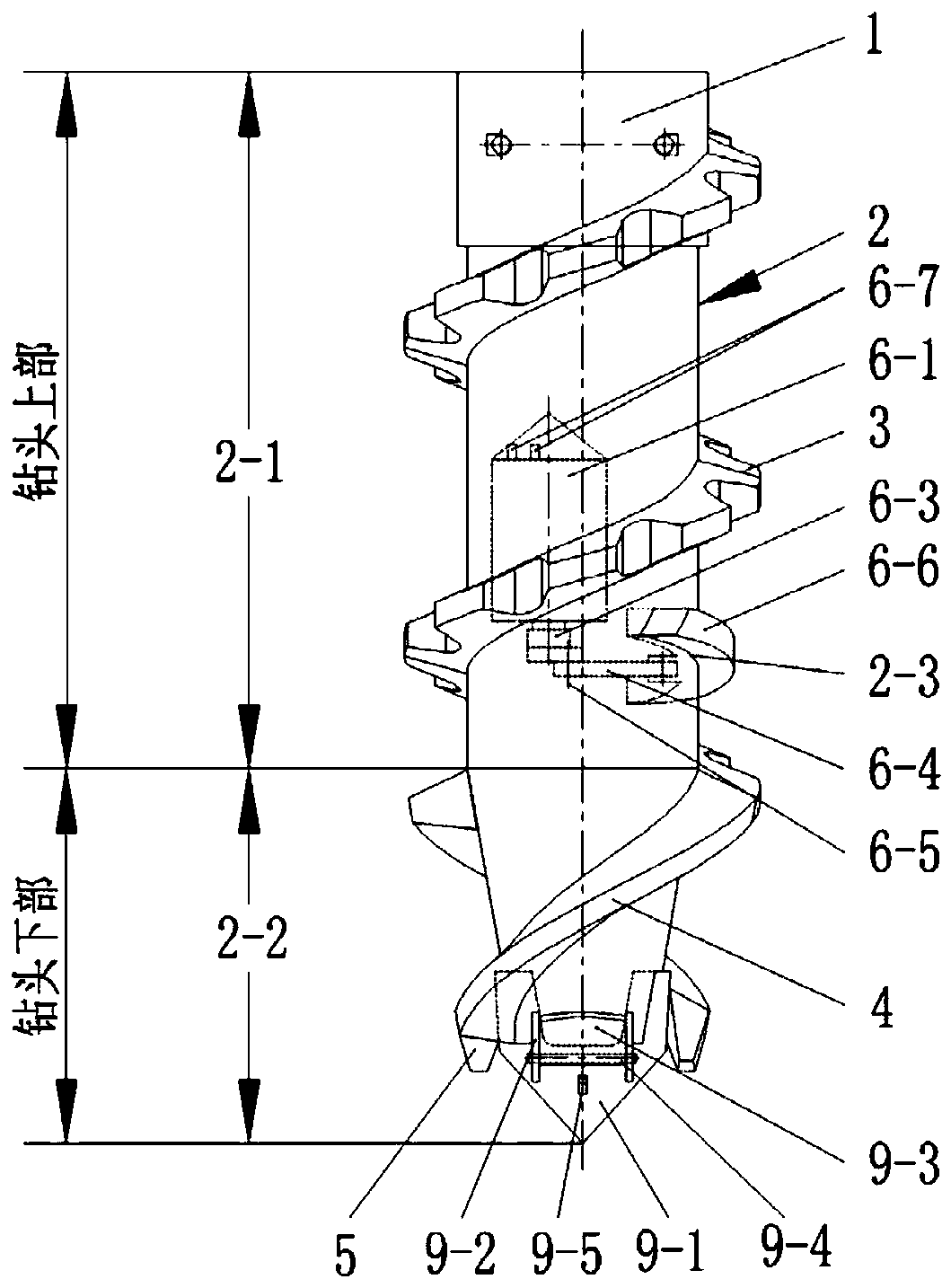

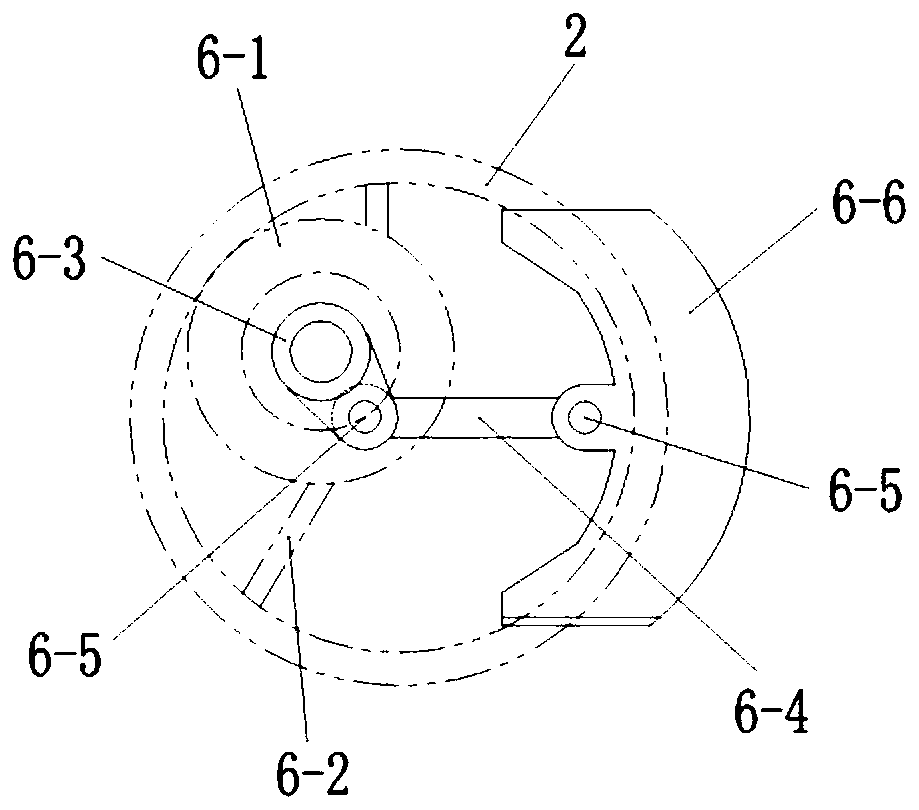

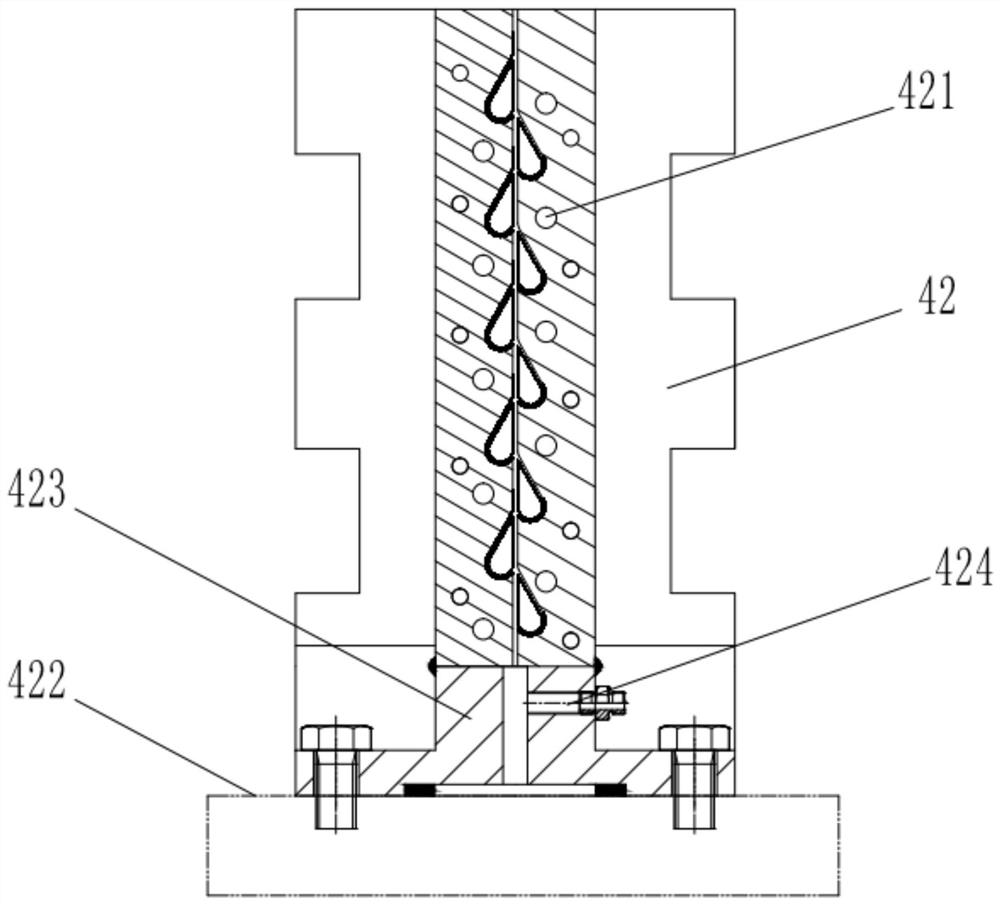

Spiral soil squeezing recompaction cast-in-place concrete pile, pile forming drill bit and construction method

PendingCN111005366AEmission reductionPromote environmental protectionDrill bitsBulkheads/pilesSoil scienceStructural engineering

The invention relates to a spiral soil squeezing recompaction cast-in-place concrete pile, a pile forming drill bit and a construction method. According to the adopted technical scheme, the spiral soil squeezing recompaction cast-in-place concrete pile comprises a primary soil squeezing pile section and a plurality of recompaction sections, the primary soil squeezing pile section is a concrete pile I, concrete piles II arranged inside the recompaction sections, the outer diameter of the concrete piles II is larger than that of the concrete pile I, the concrete piles II are wrapped by a recompaction layer formed by mixing rock soil and concrete, and the concrete pile I and the concrete piles II are of an integrated structure. The spiral soil squeezing recompaction cast-in-place concrete pile can carry out strengthened compaction on a rock soil layer with the large compressibility in the pile depth range, the pile bearing capacity is further improved, and energy conservation and emissionreduction are achieved.

Owner:刘守进 +1

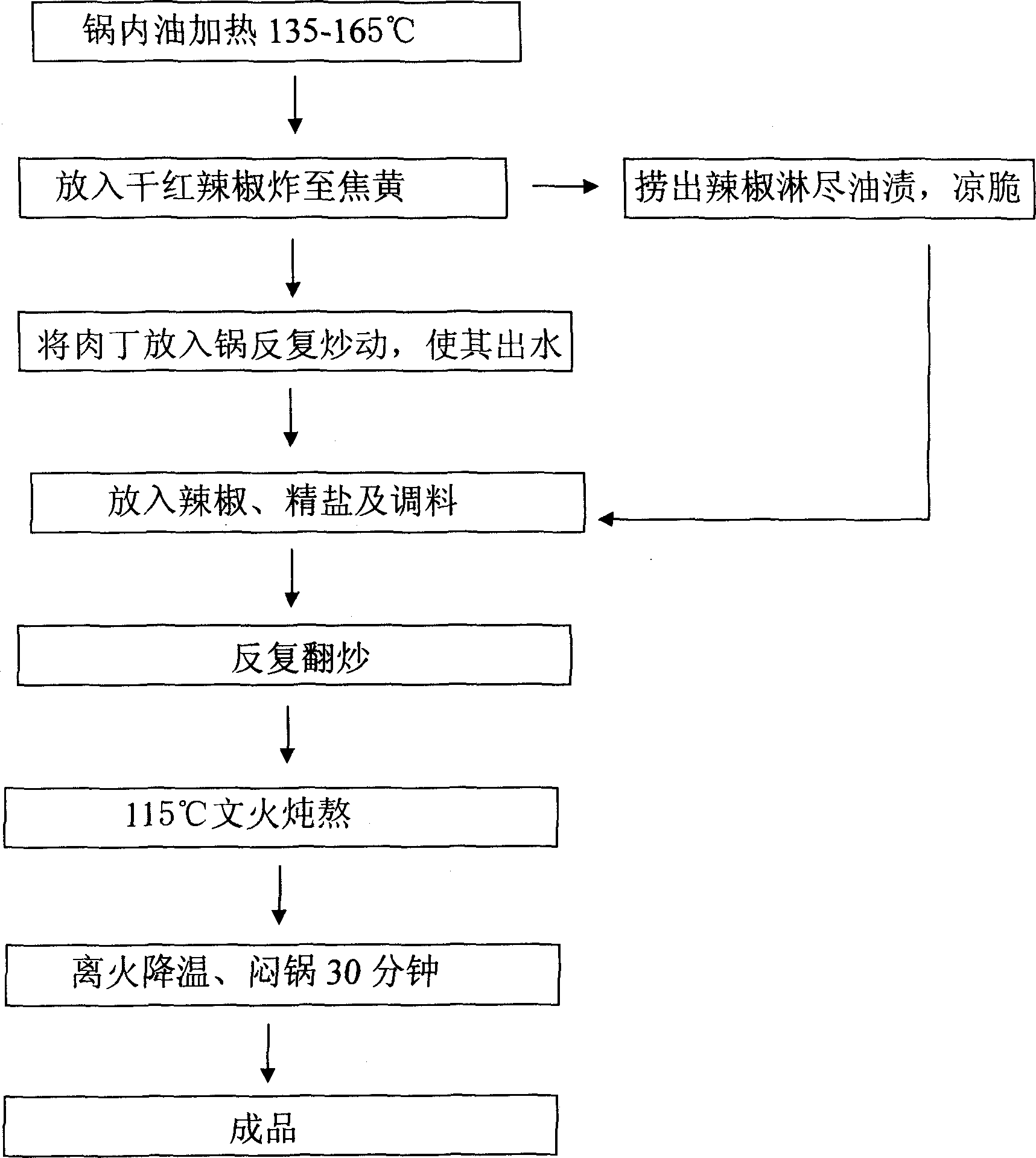

Oiled beaf and lamb mince and its preparation

InactiveCN1711915AEasy to eatScientific Nutritional IngredientsFood preparationHot peppersEdible oil

A method for cooking the fried-in-oil diced beef or mutton used as the flavouring dish of noodles includes such steps as heating edible oil in pot, frying hot pepper in the oil, coding the fried hot pepper, parching the diced beef or mutton in said oil, sequentially adding 11 flavouring materials including said fried hot pepper, salt, anis, Chinese prickly ash, etc, and stewing with slow fire.

Owner:马国龙

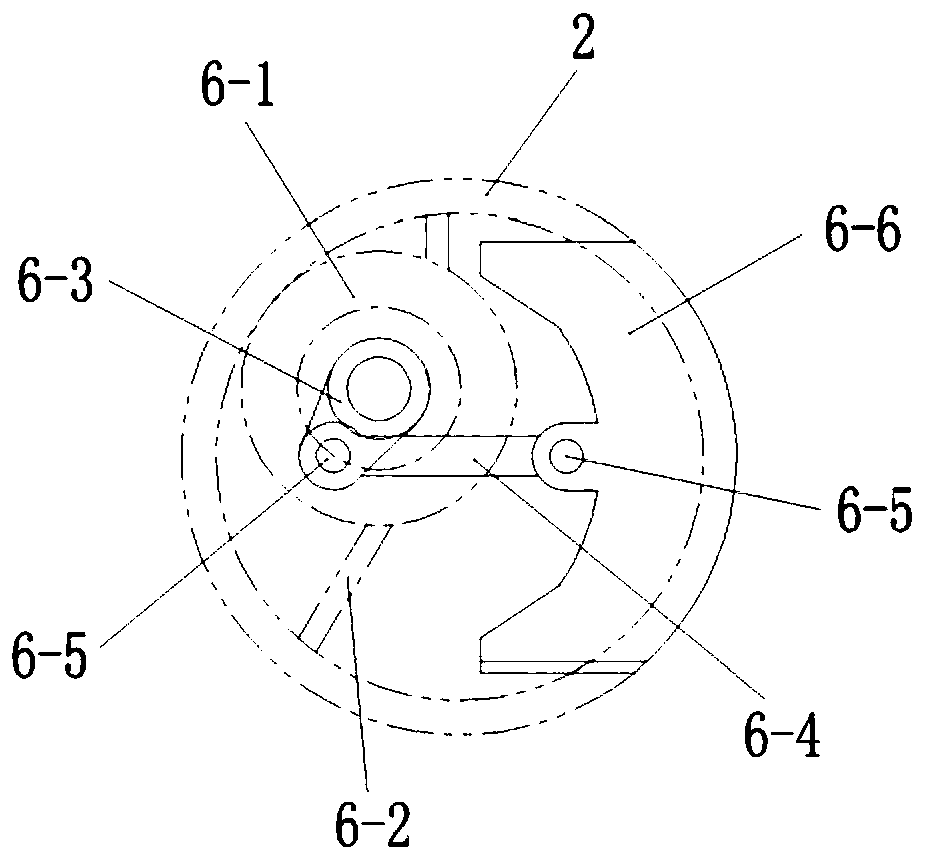

Novel winding machine winding method and device thereof

InactiveCN110589051AFully packagedChange gapWrapping material feeding apparatusWrapping with article rotationWinding machineElectric machinery

The invention provides a novel winding machine winding method and device thereof, and relates to the technical field of winding machines. The novel winding machine winding device comprises a base, a vertical plate is welded to one side of the top of the base, a top seat is vertically welded to the top of the vertical plate, a servo motor is embedded in one side of the interior of the base, a driving end of the servo motor penetrates through the top of the base to be fixedly connected with a rotating disc, the side, close to the vertical plate, of the interior of the base is fixedly connected with a first air cylinder, the piston end of the first air cylinder is fixedly connected with a bottom plate through the base, a top plate is arranged above the bottom plate, and a winding roller is arranged between one side of the top of the bottom plate and the top plate. By means of the arranged moving mechanism, a second tensioning roller can be driven to move, so that the distance between a first tensioning roller and the second tensioning roller is changed, so that the tensioning degree of a winding film is changed, and the object is wound more tightly.

Owner:玉门金环密封材料有限公司

Preparation method of release paper with simulated watermark pattern

ActiveCN102392393AFully packagedHelp to attractSpecial paperPattern printingOrganic solventPrinting ink

The invention discloses a preparation method of release paper with a simulated watermark pattern, which comprises the following steps of: firstly, manufacturing a printing roller; secondly, preparing a release agent: the release agent comprises 1 part by weight of silicone oil, 8 / 1000 parts by weight of catalyst, 3-6 parts by weight of food special organic solvent, the catalyst is a noble metal catalyst, and the food special organic solvent is No. 6 solvent oil or edible aromatic hydrocarbon; thirdly, printing the watermark pattern: installing the manufactured printing roller on a printing press, taking the release agent as printing ink and printing the watermark pattern on greaseproof paper; and fourthly, drying: drying the printed release paper in a drying tunnel, ensuring that the temperature of the drying tunnel is 80-120 DEG C, the air quantity in the drying tunnel is 7000-9000 m3 / h, and the drying time is 15-30s and obtaining the release paper with the simulated watermark pattern. The preparation method has simple process and lower cost; and the prepared release paper with the simulated watermark pattern can fully satisfy the demands of food packaging.

Owner:杭州广联复合材料有限公司

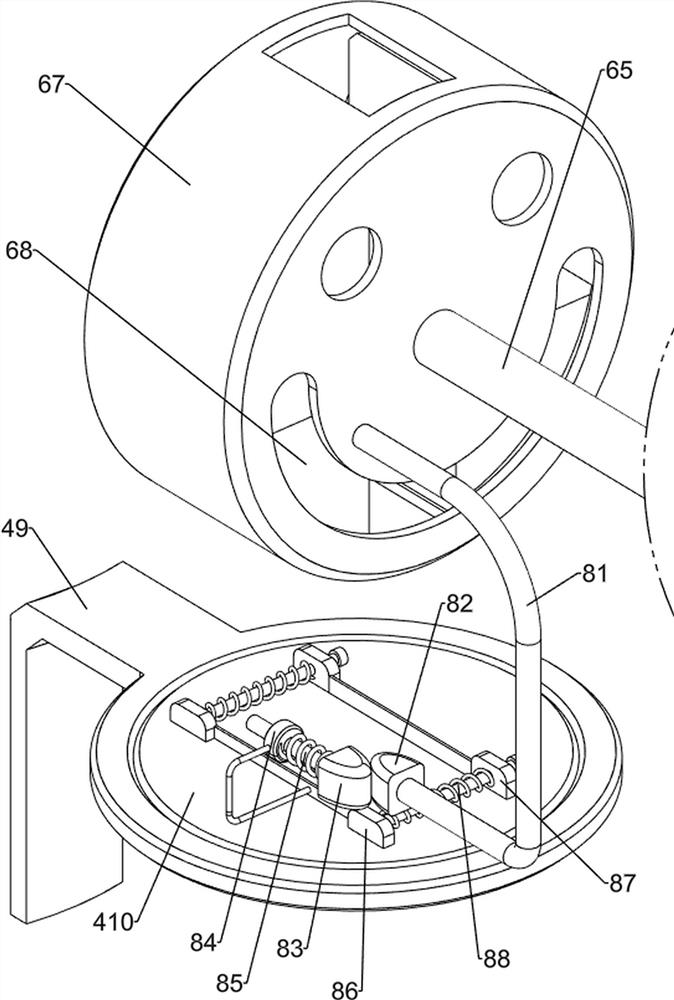

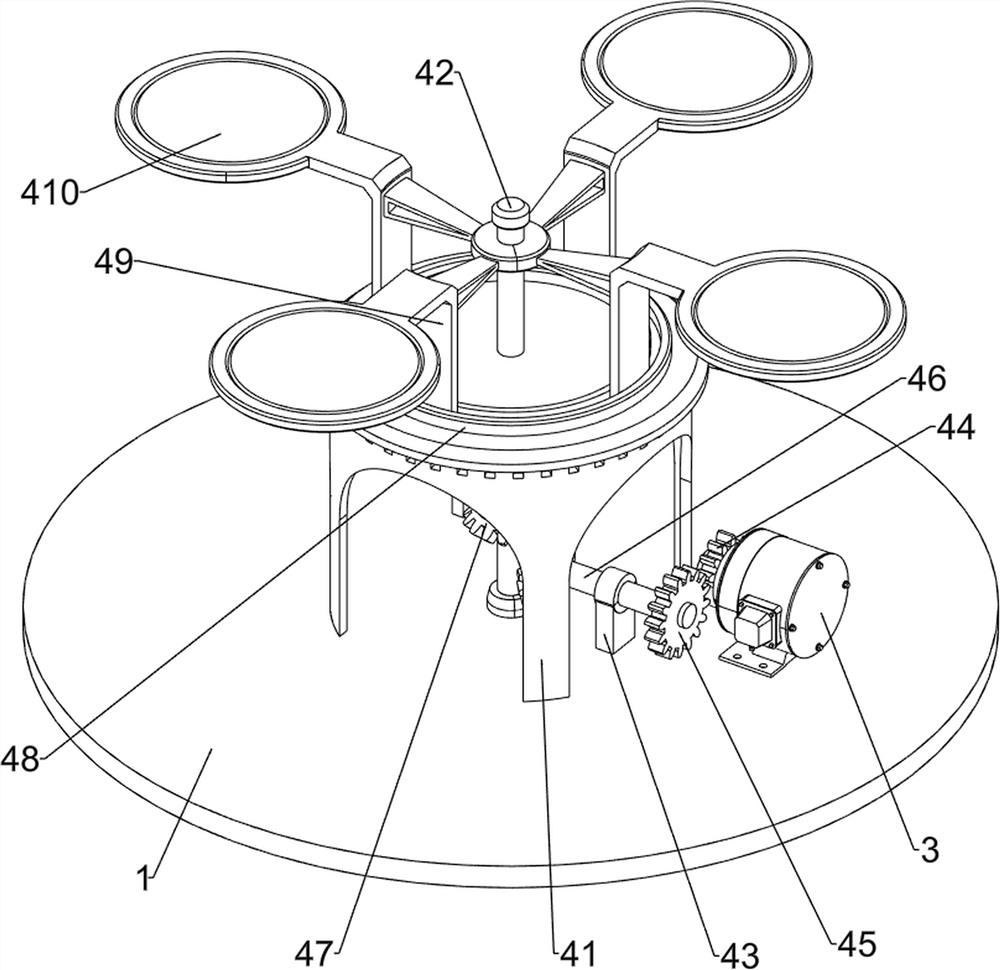

Tobacco packaging press device

The invention relates to a packaging press device, in particular to a tobacco packaging press device. Thus, the tobacco packaging press device aims at achieving the technical purpose that tobacco canbe fully pressed for packaging quickly. The tobacco packaging press device is characterized by including a base, an arc-shaped placing plate, an arc-shaped pressing plate, first supporting rods, firstspring pieces, swinging rods and the like. The arc-shaped placing plate is connected to the top of the base, the first supporting rods are connected to the left and right sides of the base respectively, and the first spring pieces are connected to the upper portion of the right side of the left first supporting rod and the upper portion of the left side of the right first supporting rod respectively. Two users tread on pedals downwards at the same time, inner clamping rings are driven by pulling cords to rotate, first clamping strips are driven to rotate through the rotation of the inner clamping rings, correspondingly gears are rotated, then racks move downwards to drive first supporting plates to move down, and therefore the arc-shaped pressing plate moves down to press the tobacco. Inthis way, the tobacco can be quickly and fully pressed for packaging.

Owner:TAIZHOU HONGLIN IND DESIGN CO LTD

Packaging method for packaging device of rubbish packaging machine

The invention relates to a packaging method for a packaging device of a rubbish packaging machine. A compressing box is arranged above a bracket in the middle of an automatic rubbish packaging machine; a packaging box is arranged at one end of the compressing box; a pushing plate is arranged in the packaging box; a rubbish bag sleeves the packaging box; the bottom of the packaging bag is corresponding to an opening of the packaging box; the packaging box, the compressing box and a compressing oil cylinder are coaxially arranged; rubbish of the compressing box is compressed into bulks before being packaged, the rubbish is pushed into the packaging box by an oil cylinder pushing rod of the compressing oil cylinder, and meanwhile, the bottom of the rubbish bag is pushed into the packaging box by the rubbish; the rubbish bag enters into the packaging box following the running of the rubbish; when the rubbish completely enters into the packaging box, the rubbish is completely wrapped in the rubbish bag; when the packaging box returns, the rubbish packaged by the rubbish bag is prevented from being moved by the pushing plate at the bottom of the packaging box, and then the rubbish packaging is finished. The packaging is complete; the packaging speed is high; the labor intensity of operators is reduced; the working efficiency is increased; the harm of the rubbish pollution to the operators is reduced.

Owner:洛阳盛豫重工机械有限公司

Nature bamboo fiber kitchen towels with high antibacterial property and preparation method

InactiveCN110565427AHigh strengthReserved naturePaper/cardboardPulping with inorganic basesHigh concentrationQuinone

The invention discloses nature bamboo fiber kitchen towels with high antibacterial property and a preparation method. The preparation method comprises the following steps: S1, washing bamboo sheets, removing impurities of the bamboo sheets and performing dehydration for subsequent use; S2, steaming and cooking the bamboo sheets by adopting an alkali method; S3, screening out bamboo joints and coarse fiber bundles of pulps which are obtained after steaming and cooking, and processing the bamboo joints and the coarse fiber bundles by adopting a hot water counter-current washing method; S4, concentrating the obtained nature bamboo pulp fibers through a press filter, and performing high-concentration pulp grinding and low-concentration pulp grinding to obtain paper pulps; S5, performing dilution, sand removal, molding, dehydration, drying, wrinkling and rolling on the paper pulps to obtain raw paper; and S6, slicing and packaging the raw paper. The nature bamboo fiber kitchen towels with the high antibacterial property disclosed by the invention adopts a sulfur-free steaming and cooking process, an oxygen delignification step which is adopted generally in the industries is eliminated,and chloride-containing bleaching treatment is avoided, and therefore, a production process is green and environmentally friendly, the properties of bamboo raw materials are kept to the maximum extent, the nature bamboo fiber kitchen towels have a faint fragrance of bamboos, and bamboo quinone contained in the pulp has a more natural antibacterial effect.

Owner:四川环龙生活用品有限公司

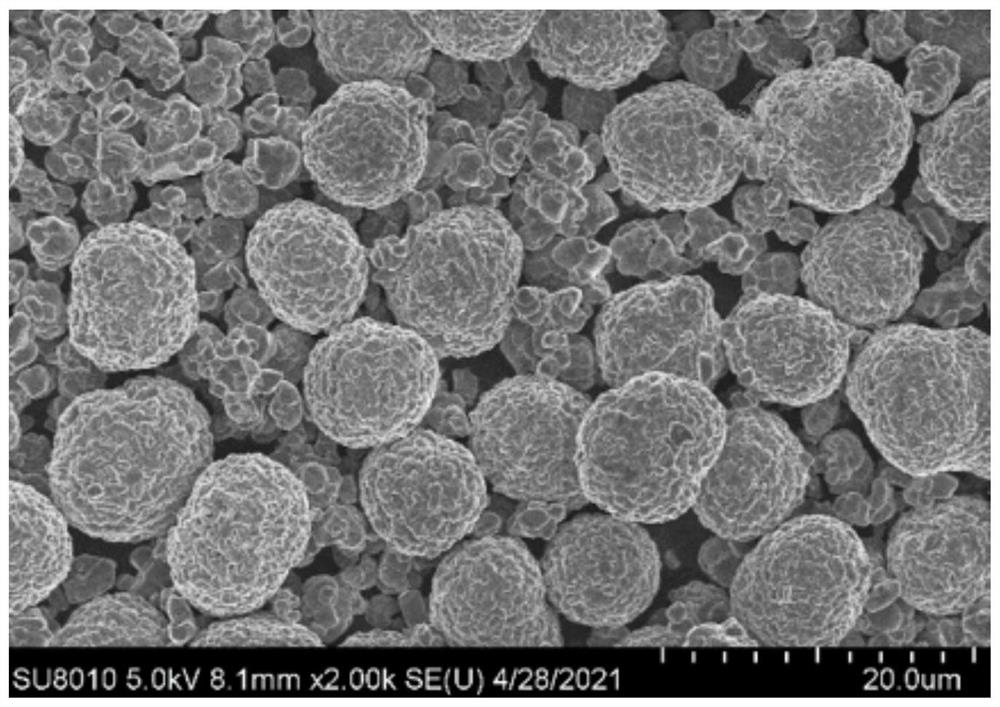

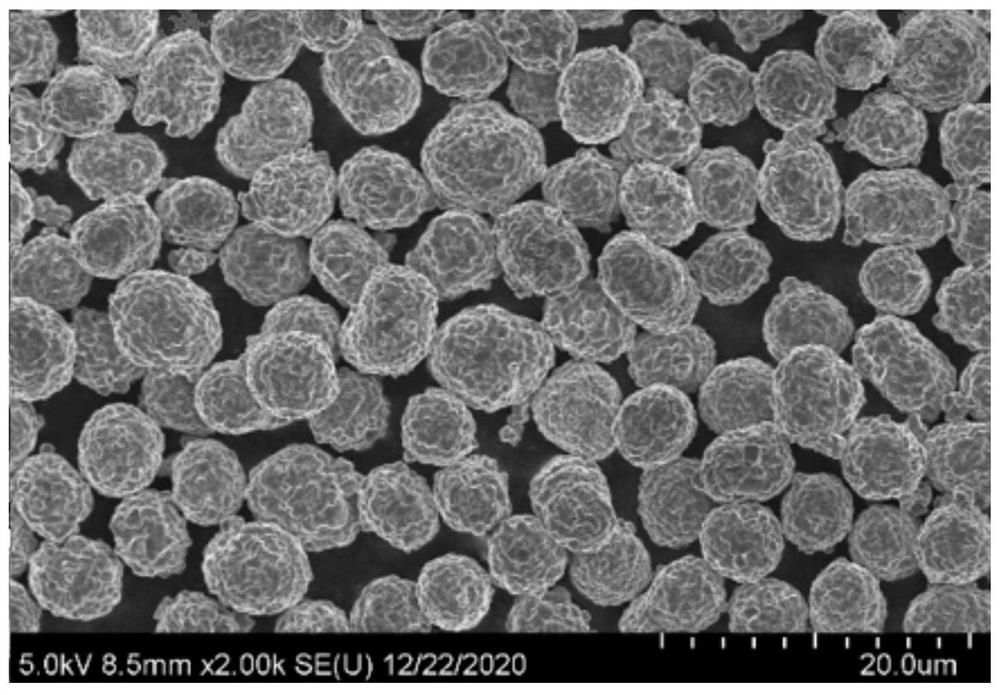

High-compaction and high-energy-density ultrahigh-nickel ternary positive electrode material

PendingCN113921782AHigh discharge specific capacitySimplify the production processSecondary cellsPositive electrodesHigh energyElectrical conductor

The invention discloses a high-compaction and high-energy-density ultrahigh-nickel ternary positive electrode material, the general formula of the positive electrode material is LinNiaCobMncMdNeO2, and the positive electrode material comprises a polycrystalline material and a single crystal material; the polycrystalline material accounts for 45-90 parts by weight, and the single crystal material accounts for 10-55 parts by weight; the D50 of the polycrystalline material and the D50 of the single crystal material meet the relational expression: K=(D1-D2) / D2, wherein K is more than or equal to 0 and less than or equal to 4. The ternary positive electrode material has the beneficial effects that: the polycrystalline material and the single crystal material with different particle sizes are mixed according to a proper ratio, so that the single crystal material can be fully filled in gaps of the polycrystalline material, a washing link is canceled in the preparation process, a dry process is adopted, a coating agent reacts with free lithium on the surface of the material to generate a fast ion conductor to coat the surface of the material, so that the specific discharge capacity is improved, the production process is simplified, the cost is reduced, and meanwhile, the cycle and DCR performance is improved.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Die-cast formation die and die-cast formation method

The invention provides a die-cast formation die. The die-cast formation die is provided with a die cavity (3), a sprue (1) and a feeding device (11) which is communicated with the sprue (1) and is used for filling raw materials, wherein one end of the die cavity (3) is communicated with the sprue (1) by a transverse pouring gate (2) and the other end of the die cavity (3) is communicated with a riser (5) by an exhausting pipeline (4); the feeding device (11) is connected with numerical control equipment and is used for controlling the speed of injecting raw materials into the die cavity (3) from the sprue (1). By virtue of the die-cast formation die, bubbles in the raw materials can be crushed and the product quality is improved. The invention further provides a die-cast formation method. By adopting the method, the production efficiency is improved and the production cost is reduced.

Owner:深圳市建升科技股份有限公司

Pickling fermentation method of Chinese sauerkraut and processing technology thereof

The invention relates to the field of food technology, especially to a pickling fermentation method of Chinese sauerkraut and a processing technology thereof. Raw materials for the pickling fermentation method of Chinese sauerkraut and the processing technology comprise 200-400 g of Chinese sauerkraut, 400-500 g of streaky pork, 100-300 g of blood sausage, 100-150 g of pork bone, 90-110 g of bean curd, 40-60 g of vermicelli, 30-50 g of green Chinese onion, 5-10 g of ginger, 2-5 g of Chinese prickly ash, 4-7 g of anise, 10-12 g of cassia, 4-6 g of myrcia, 9-12 g of salt, 10-30 g of chili oil and 7-12 g of monosodium glutamate. The above raw materials are processed according to the following steps: putting the raw materials into a tank; adding auxiliary materials; pressing the tank; sealing the tank; fermenting; and drying. By the pickling fermentation method of Chinese sauerkraut and the processing technology thereof, the product is ready to eat after heated without adding any preservative. The product meets modern people's requirements on a rapid pace of life. The Chinese sauerkraut fermented by the method has pure sour flavor, mellow taste, moderate acidity and rich fragrance of Chinese sauerkraut, has no peculiar smell, has good brittleness, has complete shape without damage, has short fermentation period, and has low content of nitrite. The raw materials are easily available, and the technology is simple.

Owner:凤城市莲澳香精品美食有限公司

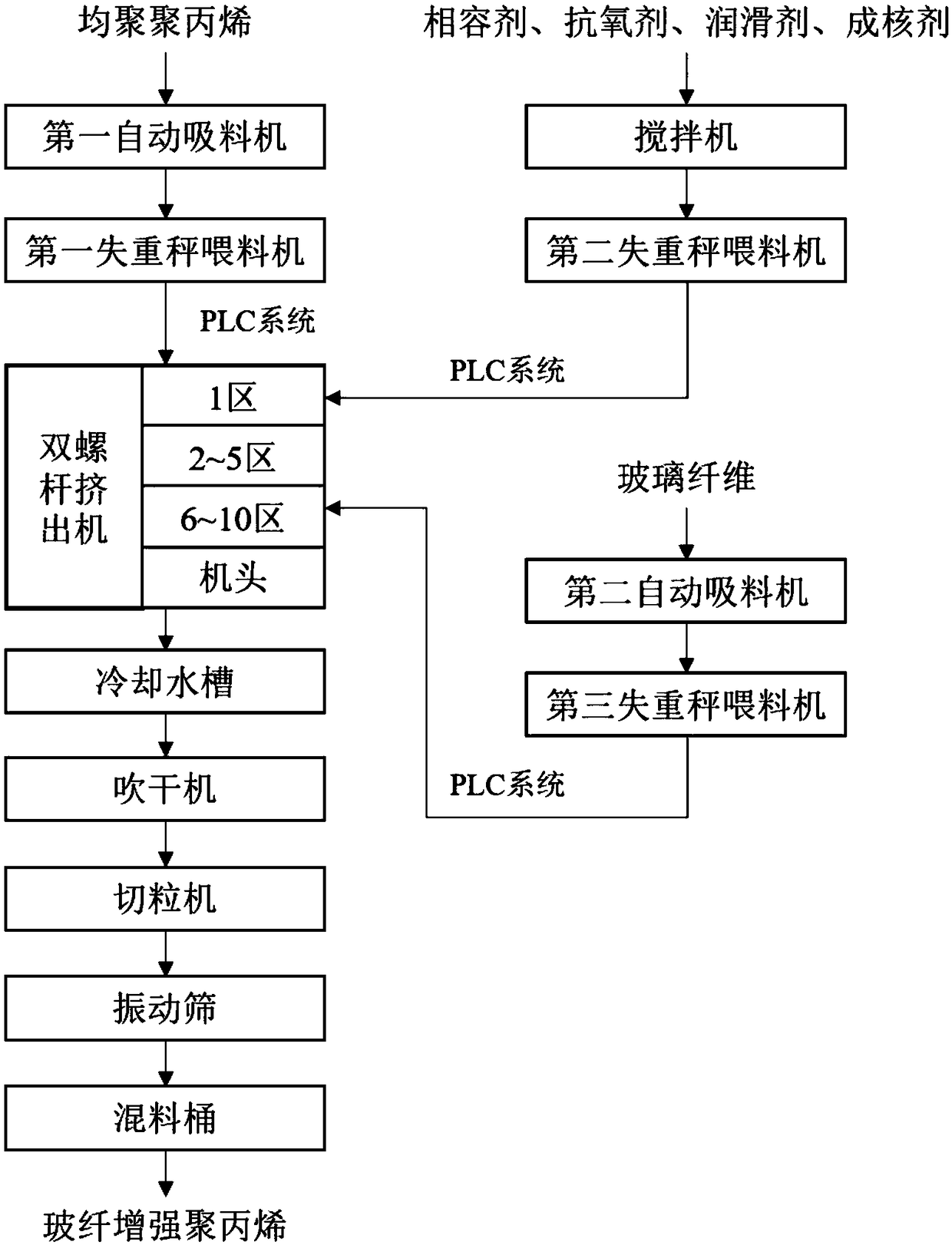

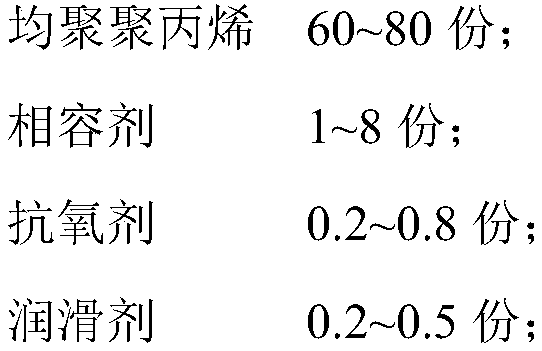

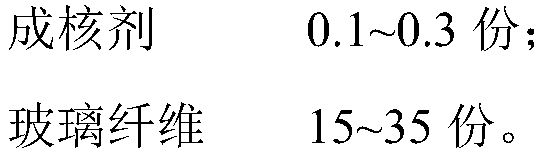

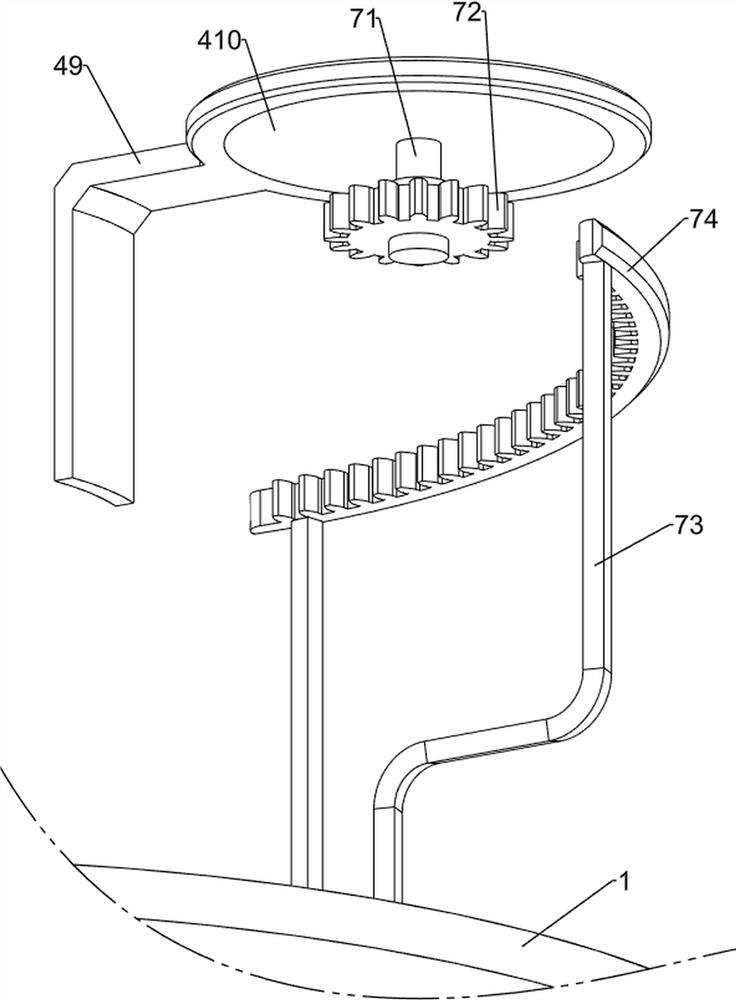

High-rigidity glass fiber reinforced polypropylene material and preparation equipment and preparation method thereof

The invention discloses a high-rigidity glass fiber reinforced polypropylene material and preparation equipment and a preparation method thereof. The high-rigidity glass fiber reinforced polypropylenematerial consists of the following raw materials: homo-polypropylene, a compatilizer, an antioxidant, a lubricating agent, a nucleating agent and glass fibers. Meanwhile, the invention discloses theequipment for preparing the polypropylene material and a method for preparing the high-rigidity glass fiber reinforced polypropylene material by using the equipment. In addition, the invention furtherdiscloses application of the high-rigidity glass fiber reinforced polypropylene material. The polypropylene material has high bending strength and modulus, is excellent in anti-impact property and good in thermal stability, resists hydrolysis, and can be widely applied to automotive panels, washing machine drums, handles of thermal jugs and the like.

Owner:GUANGDONG JUSHI CHEM CO LTD

Automatic thermoplastic packaging device for lithium battery

The invention relates to a thermoplastic packaging device, and particularly relates to an automatic thermoplastic packaging device for a lithium battery. The invention mainly provides the automatic thermoplastic packaging device for the lithium battery, which does not need a worker to contact a thermoplastic tool, avoids scalding, drives the lithium battery to rotate by means of a machine, and simultaneously rotates to carry out sufficient thermoplastic. The automatic thermoplastic packaging device for the lithium battery comprises a bottom plate, a motor and a thermoplastic mechanism, whereinthe top of the bottom plate is connected with a workbench; the workbench is connected with a conveying mechanism; the right side of the top of the bottom plate is connected with the motor; the conveying mechanism is in transmission fit with the motor; and the eccentric position of the front side of the top of the bottom plate is connected with the thermoplastic mechanism in a sliding manner. Through the arrangement of a feeding plate, the worker does not need to directly place the lithium battery, and is prevented from being injured by hot air sprayed by a thermoplastic device in the placement process.

Owner:岳阳鑫鹏新能源有限公司

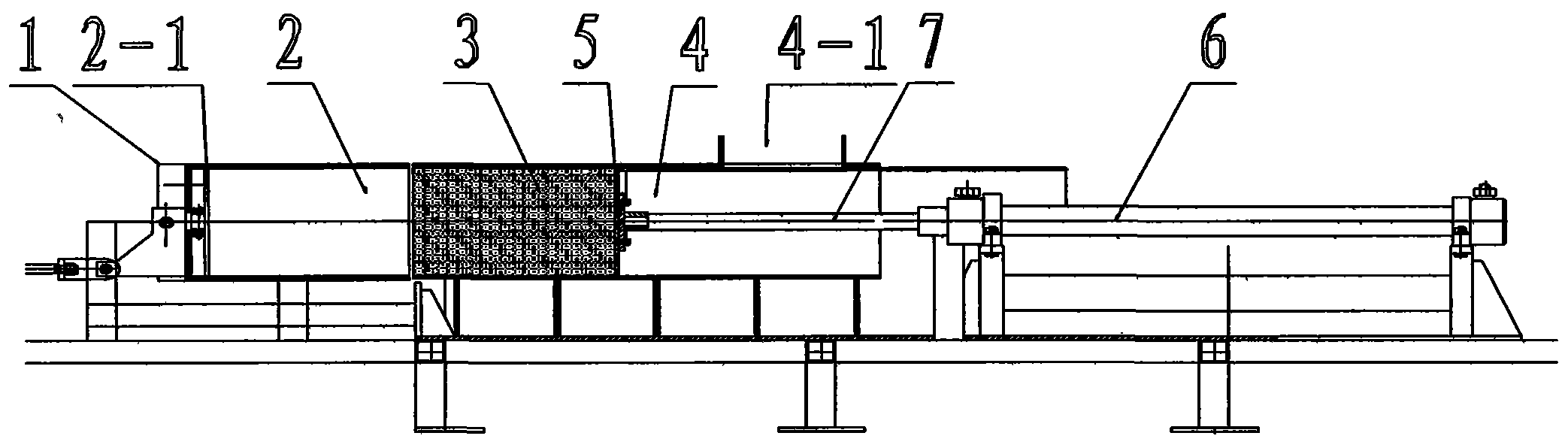

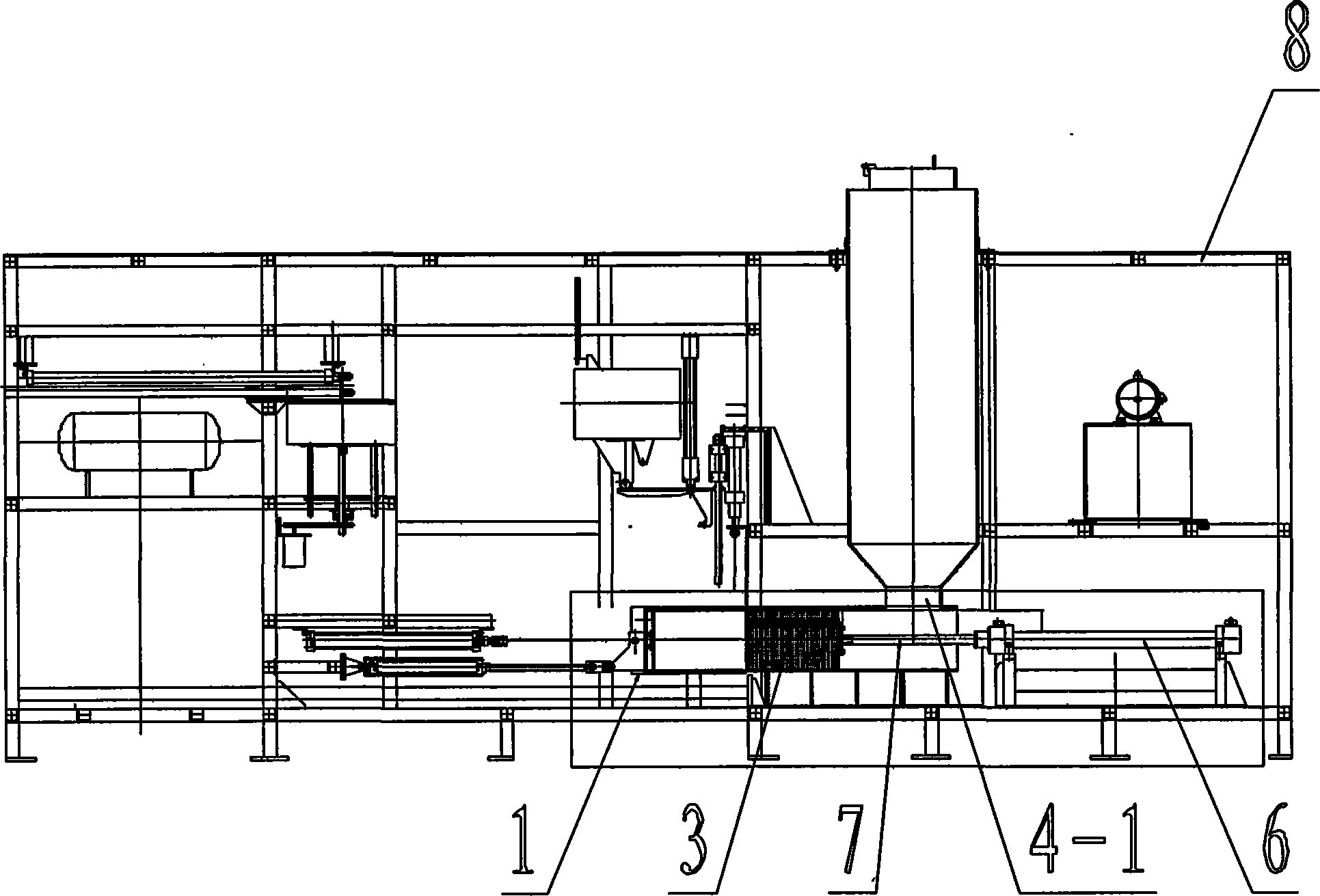

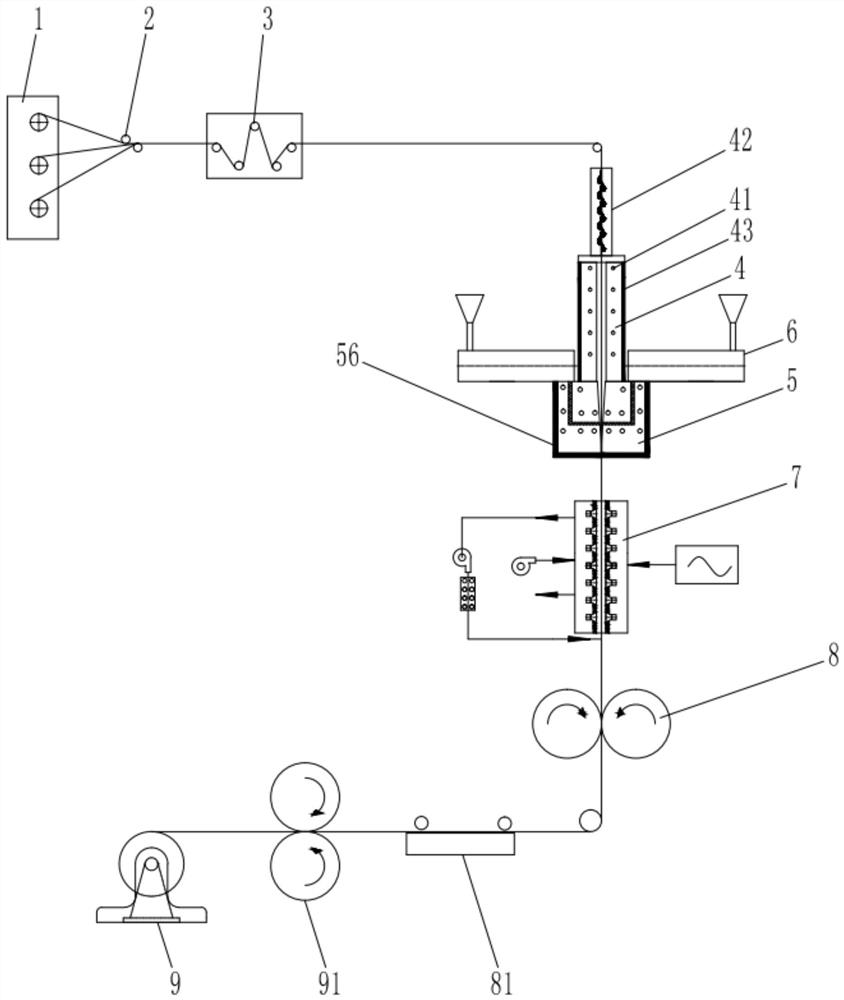

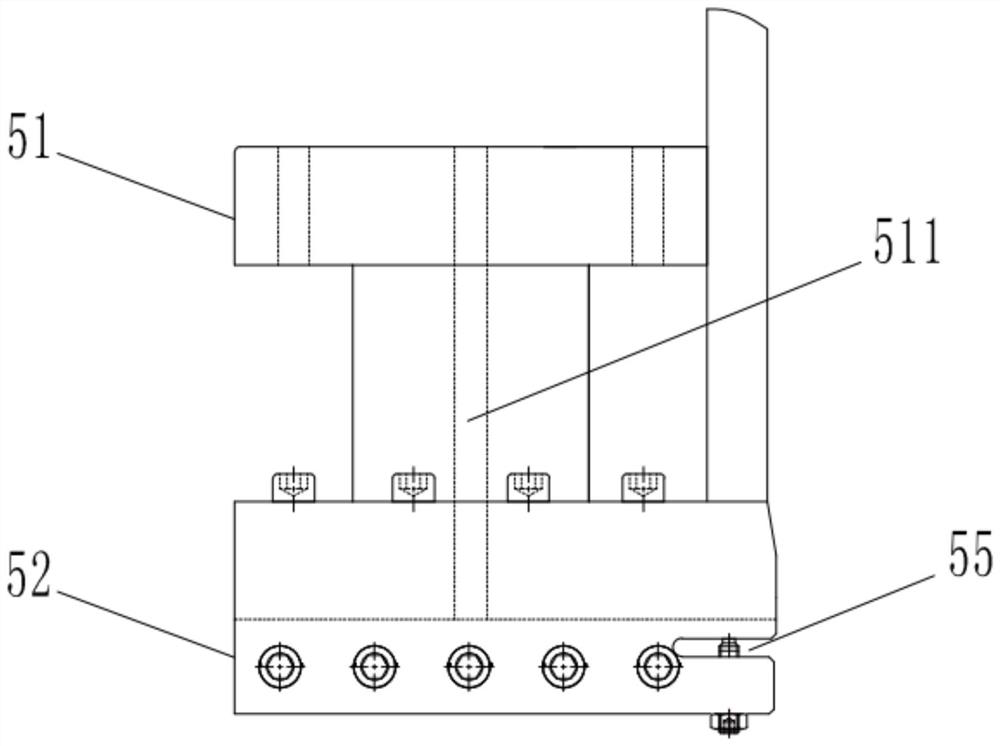

High-frequency vibration continuous fiber prepreg production device

The invention discloses a high-frequency vibration continuous fiber prepreg production device, relates to the technical field of continuous fiber prepreg production, and is mainly used for solving the problem that prepregs are difficult to soak in methods or equipment adopted for continuous fiber prepreg production at present. The primary structure of the device is that the device comprises a creel, a guide roller group, a yarn spreading roller group, a drying oven, an extrusion forming mold group, an ultrasonic impregnation module group, an extrusion roller group, a cooling platform, a pull roll group and a winding mechanism which are arranged in sequence. According to the high-frequency vibration continuous fiber prepreg production device provided by the invention, continuous fibers before being coated with resin are vacuumed through a negative pressure vacuum channel, and ultrasonic vibration is applied to the continuous fibers coated with the resin through ultrasonic impregnation modules, so that the fibers can be fully infiltrated by the resin.

Owner:四川兴宇航科技有限公司

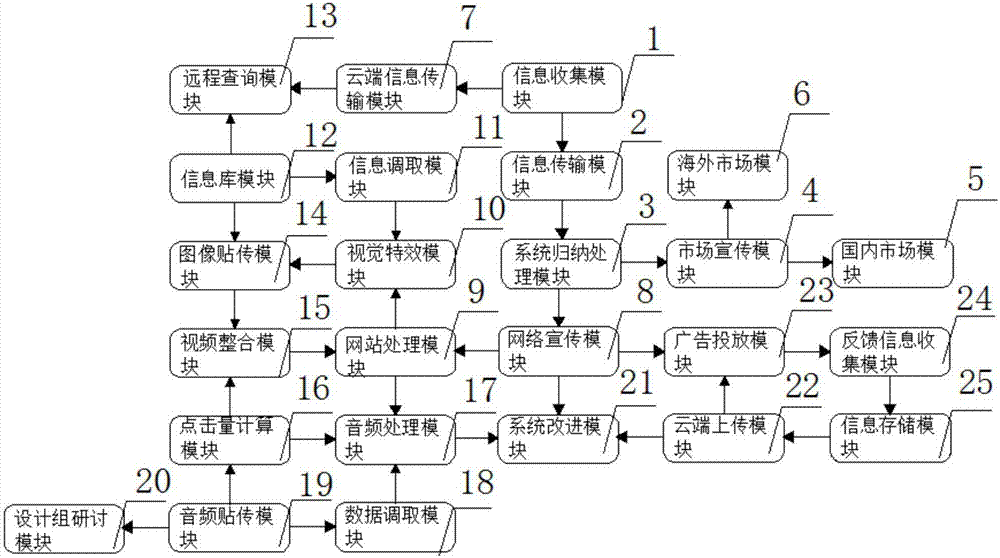

Packaging system for enterprise image

InactiveCN107093102AIncrease awarenessIncrease influenceAdvertisementsMarket data gatheringSocial benefitsInformation transmission

The invention discloses a packaging system for an enterprise image. The packaging system comprises an information collection module, an information transmission module, a system induction module, a marketing promotion module, a domestic market module, a foreign market module, a cloud information transmission module, a network publicity module, a website processing module, a click rate calculation module, an audio processing module, a data transfer module, an audio posting module, a design group discussion module, a system improvement module, a cloud upload module, an advertisement delivery module, a feedback information collection module and an information storage module. The invention has the advantages that the system starts from the collection of impression information of users on an enterprise so that the enterprise image is closer to the people's lives, the advertisement delivery module improves the recognition of the enterprise by means of other platforms, the system is further improved, the website processing module starts from the packaging of the enterprise itself to increase the click rate of the enterprise website, and the enterprise image is ensured to be more comprehensively packaged; and the system has good economic and social benefits.

Owner:南京译海网络科技股份有限公司

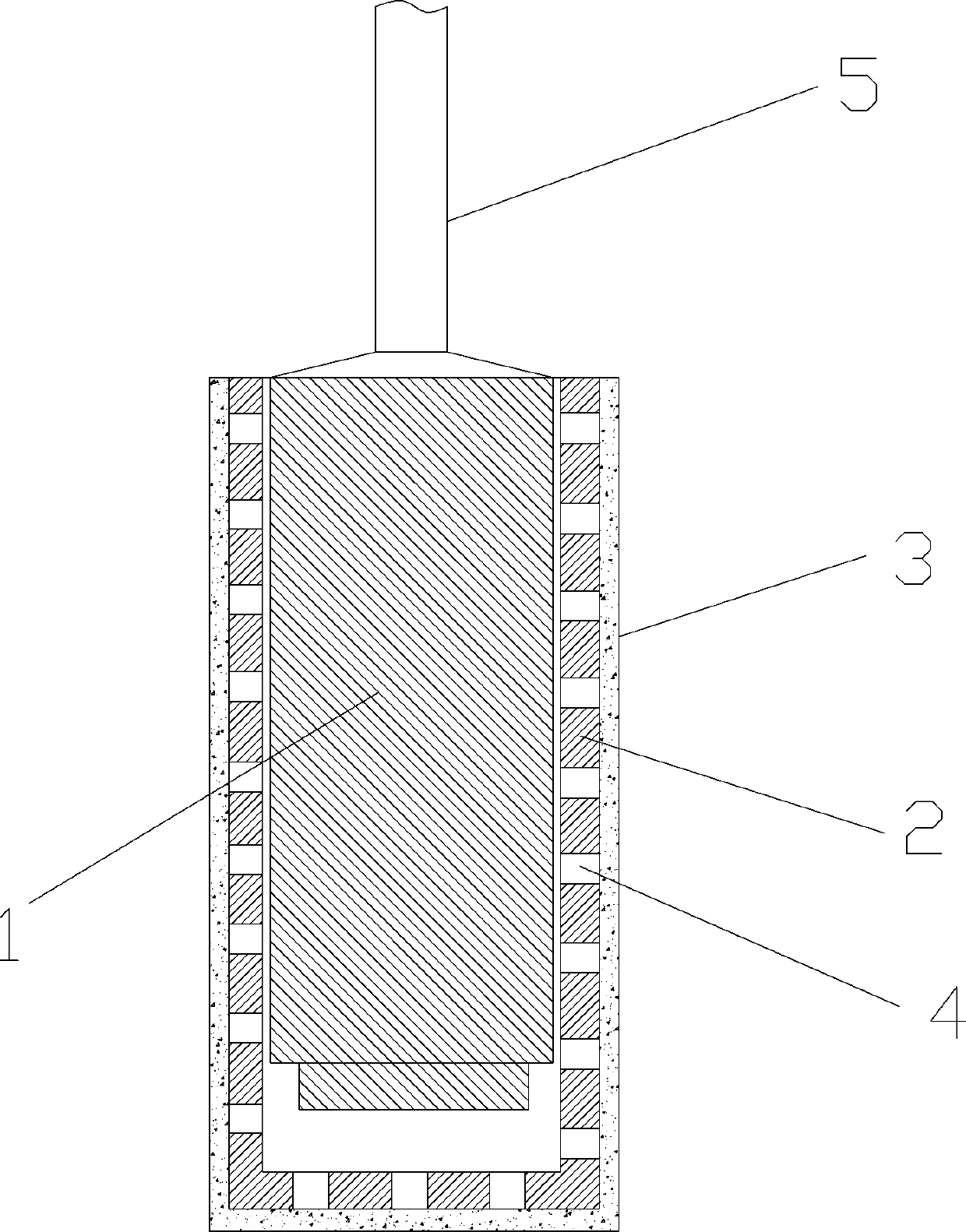

Device for measuring internal humidity of concrete and arrangement method thereof

ActiveCN111596043AQuick and easy setupGuaranteed validityMaterial testing goodsMeasurement apparatus housingsMeasurement deviceEnvironmental geology

The invention discloses a device for measuring internal humidity of concrete and an arrangement method of the device. The device comprises a humidity sensor, and is characterized in that the humiditysensor is arranged in a protective shell body, the surface of the protective shell body is covered with a layer of concrete slurry, and a plurality of breathable filter holes are formed in the surfaceof the protective shell body. In addition, the invention further discloses the arrangement method corresponding to the device. According to the device and the arrangement method, concrete internal humidity data can be effectively measured for a long time, the device can be quickly and conveniently arranged in combination with a concrete pouring construction process, the phenomenon that the measuring device is damaged in concrete pouring construction is effectively avoided, data support is provided for researching humidity distribution and evolution characteristics in concrete, and the deviceand the arrangement method have positive guiding significance for preventing and treating concrete cracks.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Die-casting mold and die-casting method

The invention provides a die-cast formation die. The die-cast formation die is provided with a die cavity (3), a sprue (1) and a feeding device (11) which is communicated with the sprue (1) and is used for filling raw materials, wherein one end of the die cavity (3) is communicated with the sprue (1) by a transverse pouring gate (2) and the other end of the die cavity (3) is communicated with a riser (5) by an exhausting pipeline (4); the feeding device (11) is connected with numerical control equipment and is used for controlling the speed of injecting raw materials into the die cavity (3) from the sprue (1). By virtue of the die-cast formation die, bubbles in the raw materials can be crushed and the product quality is improved. The invention further provides a die-cast formation method. By adopting the method, the production efficiency is improved and the production cost is reduced.

Owner:深圳市建升科技股份有限公司

Healthy honey lollipop and making method for same

The invention discloses a healthy honey lollipop and a making method for the same. The lollipop is prepared from the following raw materials in parts by weight: 15 to 30 parts of honey, 15 to 30 parts of agar, 10 to 20 parts of cocoa powder, 10 to 20 parts of milk powder, 5 to 15 parts of chocolate cream, 0.5 to 1.5 parts of edible solid gum and 0.1 to 0.8 part of an anti-sticking agent. The healthy honey lollipop and the making method for the same have the advantages that the curing characteristic of the honey is changed, a flexible aluminum-plastic paper packaging material can be used, the shape and package of a product can also be diversified, and the commercial value of a solid honey product is improved; moreover, the lollipop is convenient to eat and carry, the product can be prevented from sticking to teeth, and the mouth-feel of the solid honey product is improved. The formula of the healthy honey lollipop and a production process thereof are simple in making, convenient, low in cost and easy to operate.

Owner:安徽省丰康农业科技有限公司蚌埠农业科技研发中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com