Preserved bean curd sauce and preparation method thereof

A technology of fermented bean curd sauce and spices, applied in the field of food processing, to achieve the effects of flexible packaging, reducing waste and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

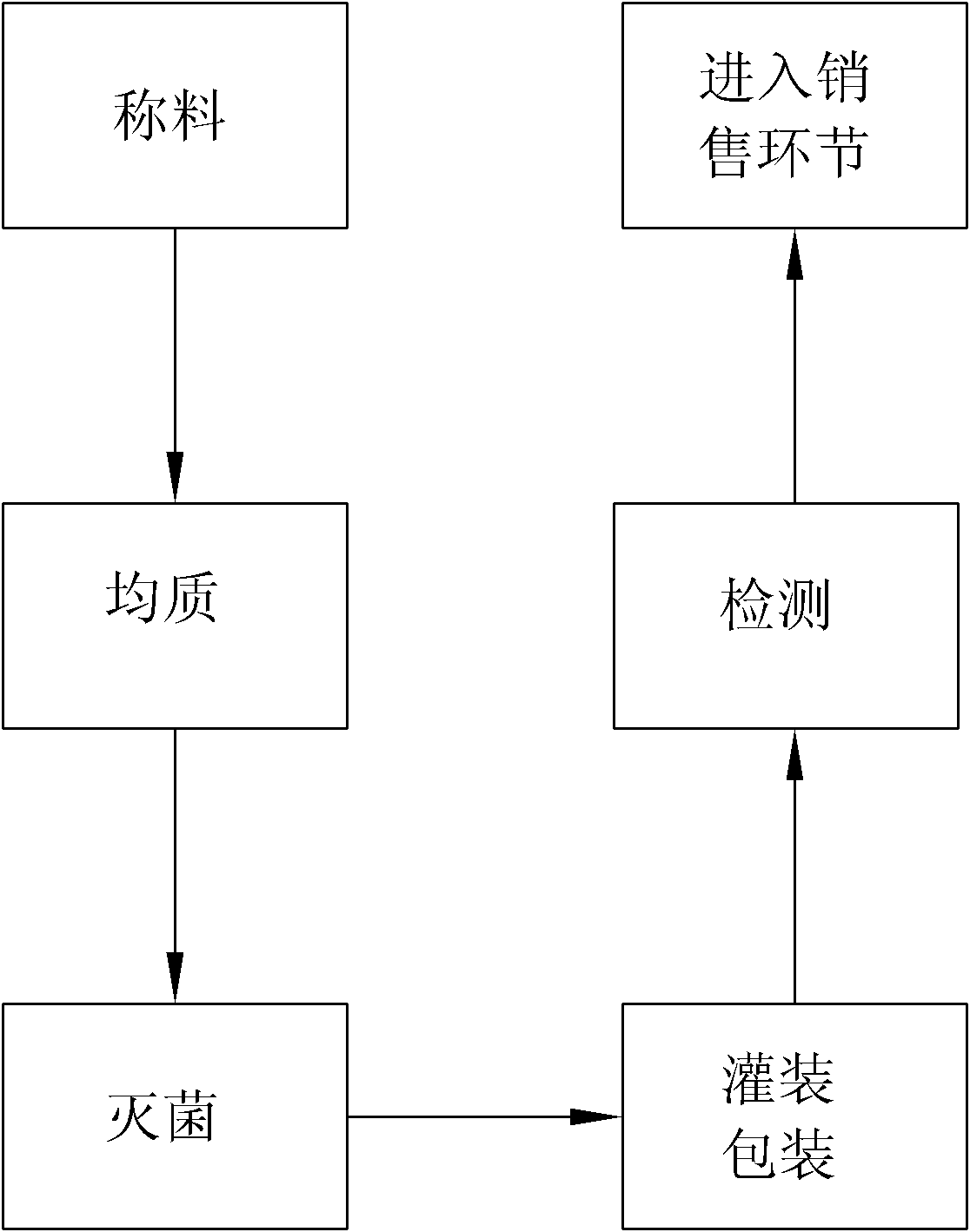

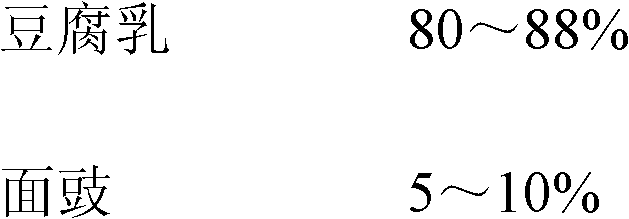

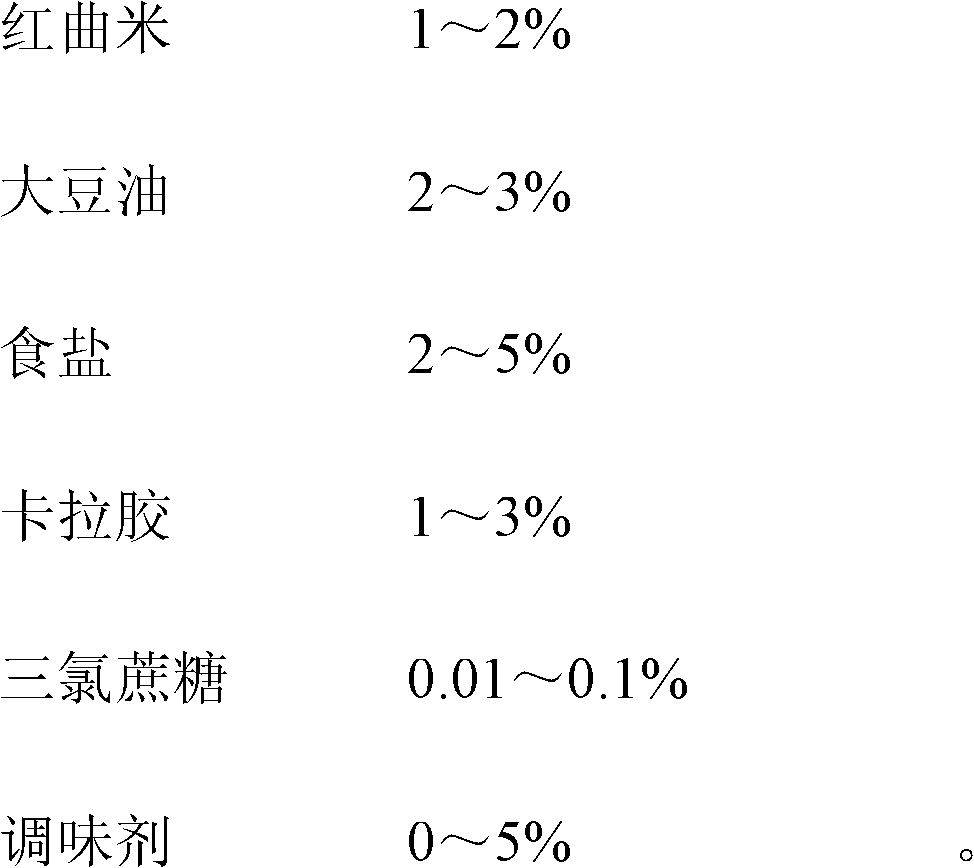

[0024] A fermented bean curd sauce is composed of the following components by weight percentage: 80-88% of fermented bean curd, 5-10% of soy sauce, 1-2% of red yeast rice, 2-3% of soybean oil, 2-5% of table salt, carrageenan 1~3%, sucralose 0.01~0.1%, flavoring agent 0~5%, its preparation method is as follows figure 1 The following steps are shown:

[0025] 1) Weighing: according to the production formula, weigh the raw materials of each component in proportion;

[0026] 2) Homogenization: use a colloid mill to homogenize the weighed raw materials, and mix them evenly to obtain semi-finished products;

[0027] 3) Sterilization: the homogenized semi-finished product is heated and boiled and kept boiling for 30 minutes, and then the heating is stopped to obtain fermented bean curd sauce.

[0028] The preparation method of the fermented bean curd sauce further comprises a packaging step: filling and packaging the sterilized fermented bean curd sauce while hot to achieve a good ...

Embodiment 1

[0035] A method for preparing spicy fermented bean curd sauce A, comprising the following steps:

[0036] 1) Weighing: Weigh the raw materials of each component in the following proportions,

[0037] 80% fermented bean curd, 7.95% soy sauce, 2% red yeast rice, 2% soybean oil, 2% salt, 2% carrageenan, 0.05% sucralose, 4% pepper;

[0038] 2) Homogenization: the ingredients weighed in step 1) are homogenized and refined with a colloid mill, so that each component is mixed evenly until it feels fine and smooth, and the color is uniform;

[0039] 3) Sterilization: heat the homogeneous semi-finished product in step 2) to boiling, keep boiling for 30 minutes, stop heating, and obtain the spicy fermented bean curd sauce;

[0040] 4) Packaging: fill and pack the finished product obtained in step 3) while it is still hot, and enter the sales link after passing the test.

[0041] The detection result of the present embodiment spicy fermented bean curd sauce A is:

[0042] Average valu...

Embodiment 2

[0047] A method for preparing spicy fermented bean curd sauce B, comprising the following steps:

[0048] 1) Weighing: Weigh the raw materials of each component in the following proportions,

[0049] 82% fermented bean curd, 5.49% soy sauce, 1% red yeast rice, 2.5% soybean oil, 3% salt, 1% carrageenan, 0.01% sucralose, 5% pepper;

[0050] 2) Homogenization: the ingredients weighed in step 1) are homogenized and refined with a colloid mill, so that each component is mixed evenly until it feels fine and smooth, and the color is uniform;

[0051] 3) Sterilization: heat the homogeneous semi-finished product in step 2) to boiling, keep boiling for 30 minutes, stop heating, and obtain the spicy fermented bean curd sauce;

[0052] 4) Packaging: fill and pack the finished product obtained in step 3) while it is still hot, and enter the sales link after passing the test.

[0053] The detection result of the present embodiment spicy fermented bean curd sauce B is:

[0054] Average va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com