Cast-in-situ bored pile hole forming method

A technology of bored piles and cast-in-place piles, which is applied in the direction of drilling equipment and methods, drill pipes, drill pipes, etc., which can solve the problems of large cleaning costs and achieve the effects of reducing pollution and expanding the outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

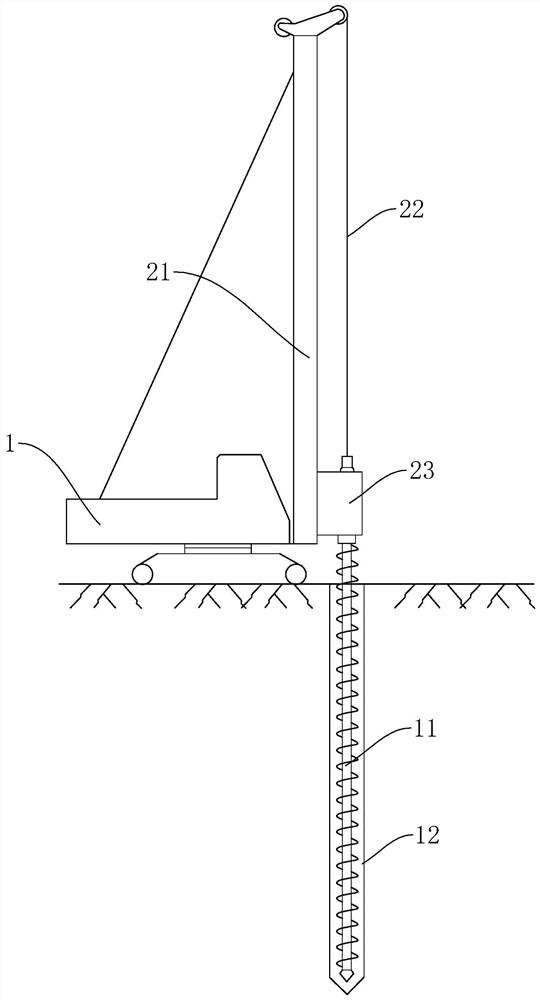

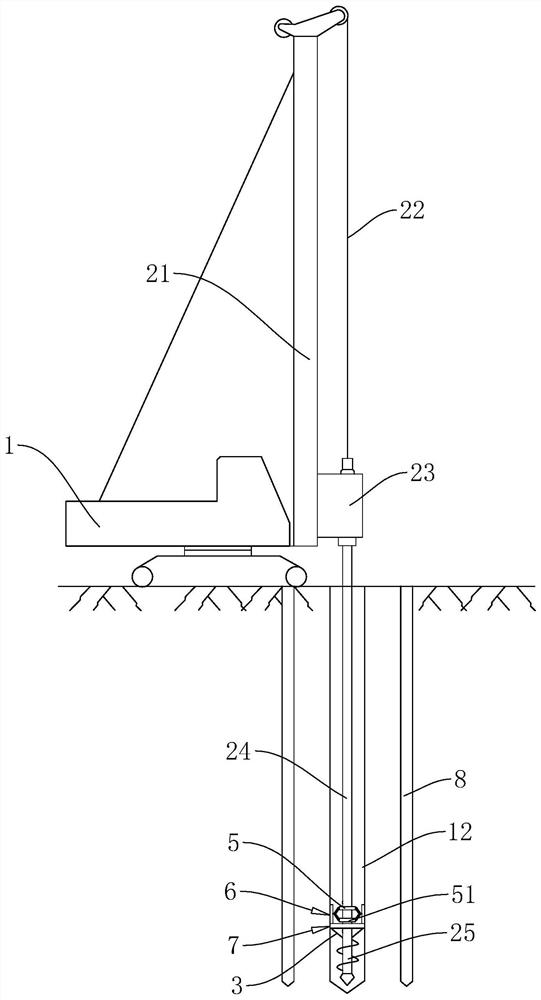

[0050] The following is attached Figure 1-5 The application is described in further detail.

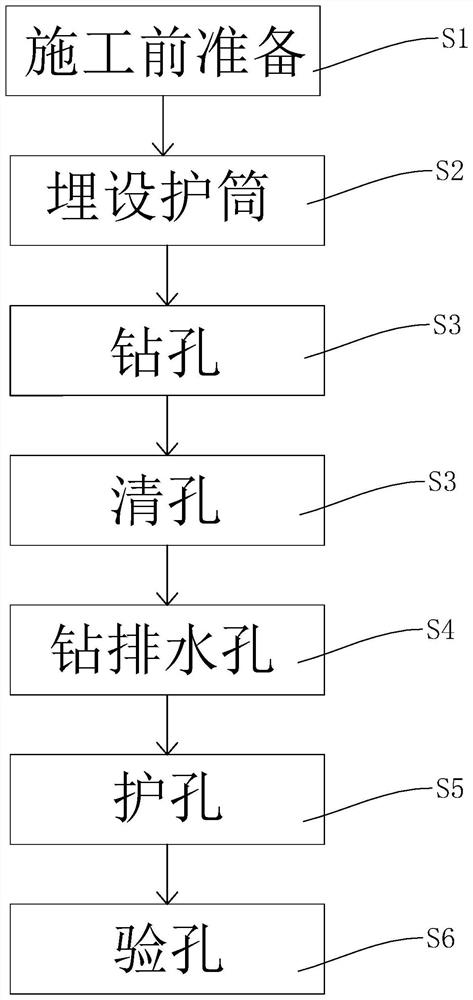

[0051] The embodiment of the present application discloses a method for forming holes of bored piles. refer to figure 1 , the hole-forming method comprises the following steps: preparation before construction, burying the casing, drilling, clearing the hole, drilling drainage hole 8, reaming, and the specific implementation method of each step is as follows:

[0052] S1: Preparations before construction, conduct geological and topographic surveys on site, measure and set out lines, and then clean up the working face for hole forming operations, and determine the pile positions. The deviation of pile positions must not exceed the requirements of specifications and designs. Construction engineering drilling rig 1, measuring instrument, casing, hole finder and other equipment and construction materials such as steel cage and concrete enter the site.

[0053] S2: Bury the casing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com