Automatic quilt production equipment

A technology of automatic production and equipment, which is applied to sewing machines, textiles and paper making, household appliances, etc. for sewing quilts. The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

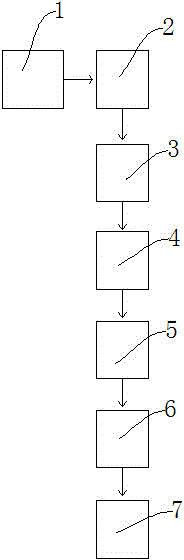

[0021] Such as figure 1 As shown, the quilt automatic production equipment described in this embodiment is characterized in that it includes a carding machine 1, a laying conveying device 2, a pattern sewing device 3, a longitudinal cutting device 4, a tension buffer device 5, and a transverse cutting device 6 and delivery device 7;

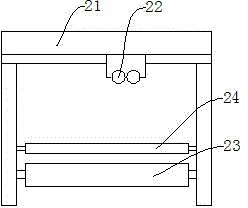

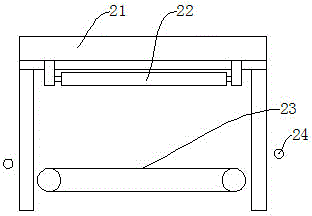

[0022] Such as figure 2 , image 3 As shown, wherein the tiling conveying device 2 includes a No. 1 frame 21, a guide roller group 22 that moves laterally is arranged on the No. The conveying direction is perpendicular to the direction of motion of the guide roller group 22, and the range of motion of the guide roller group 22 is within the width range of the conveyor belt 23. A face cloth roller 24 is arranged at both ends of the motion direction of the conveyor belt 23, and the face cloth roller 24 Parallel to the axial direction of the conveyor belt 23;

[0023] Such as Figure 4 As shown, the longitudinal cutting device 4 includes a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com