Technique for processing highland barley flour

A processing technology, highland barley flour technology, applied in the direction of grain processing, application, grain pod removal, etc., can solve the problems of uncontrolled heavy metals and other harmful substances, and food safety cannot be guaranteed, so as to increase farmers' income and benefit the human body. Health, the effect of alleviating overproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

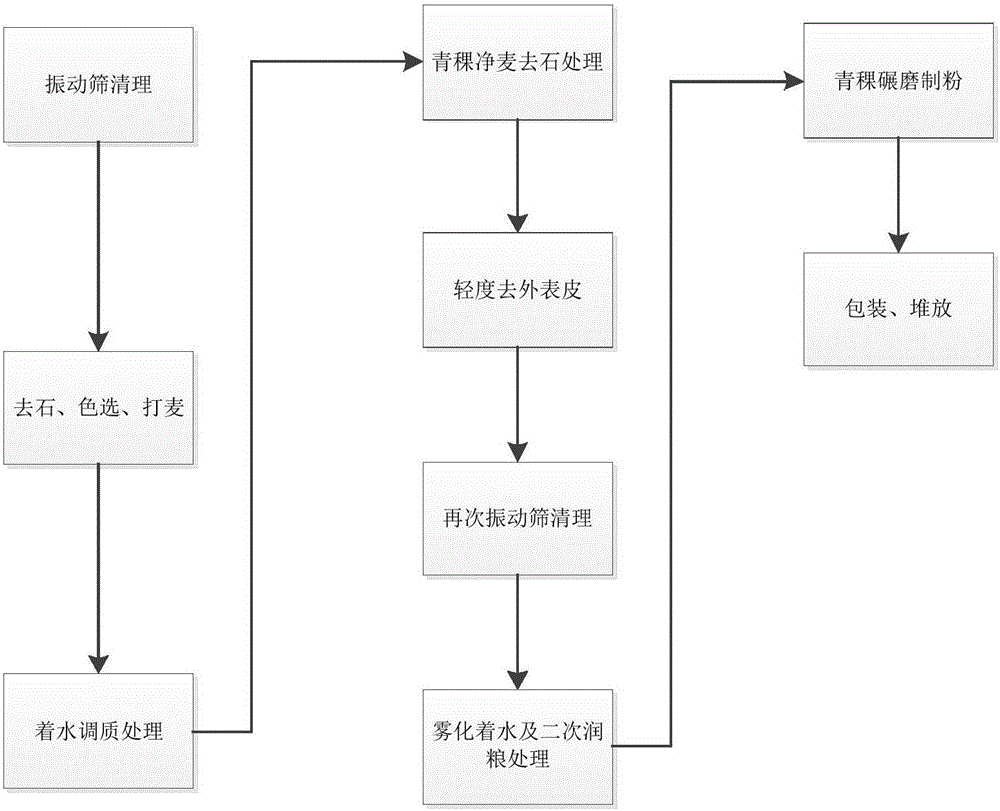

[0054] A kind of highland barley flour processing technology, such as figure 1 As shown, the following steps are included in sequence:

[0055] (1) Cleaning of wool wheat

[0056] A. Screen and classify the highland barley raw material with a vibrating screen to remove large impurities, small impurities and light impurities, and separate and recycle the unqualified highland barley;

[0057] B. The screened and graded highland barley is destoned and color sorted in turn to remove moldy kernels, white highland barley, black highland barley, side-by-side stones, glass particles, plastic particles, heterogeneous raw materials (such as peas or others) and other foreign-colored impurities, and improve Color, control microorganisms, and ensure food safety;

[0058] C. Threshing the highland barley obtained in step B effectively reduces the ash content of the highland barley powder finished product, improves color and luster, and ensures food safety;

[0059] D. Water conditioning ...

Embodiment 21

[0082] A kind of highland barley powder processing technology, differs from embodiment 1, when carrying out step F, described light off outer skin refers to removing the outer skin that accounts for about 0.8% of highland barley weight.

Embodiment 22

[0084] A kind of highland barley powder processing technology, differs from embodiment 1, when implementing step F, described light off outer skin refers to removing the outer skin that accounts for about 1% of highland barley weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com