High-frequency vibration continuous fiber prepreg production device

A continuous fiber and production device technology, which is applied in the field of high-frequency vibration continuous fiber prepreg production devices, can solve problems such as difficulty in pressing resin into fibers, and achieve the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

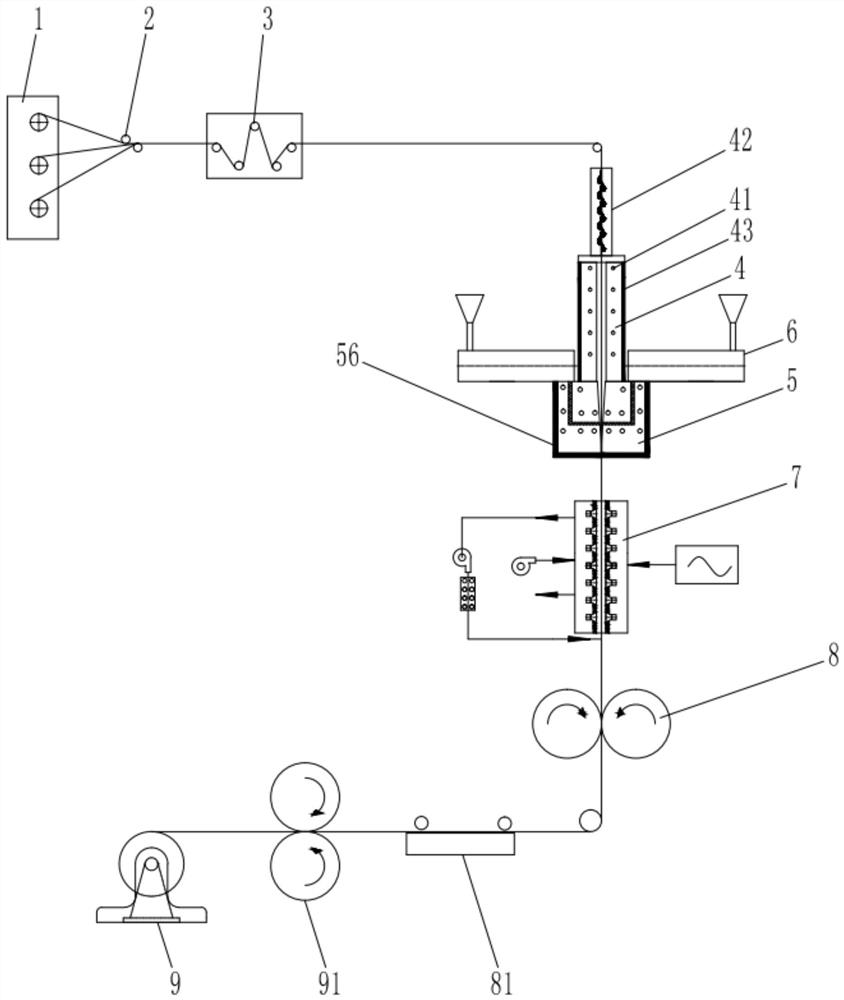

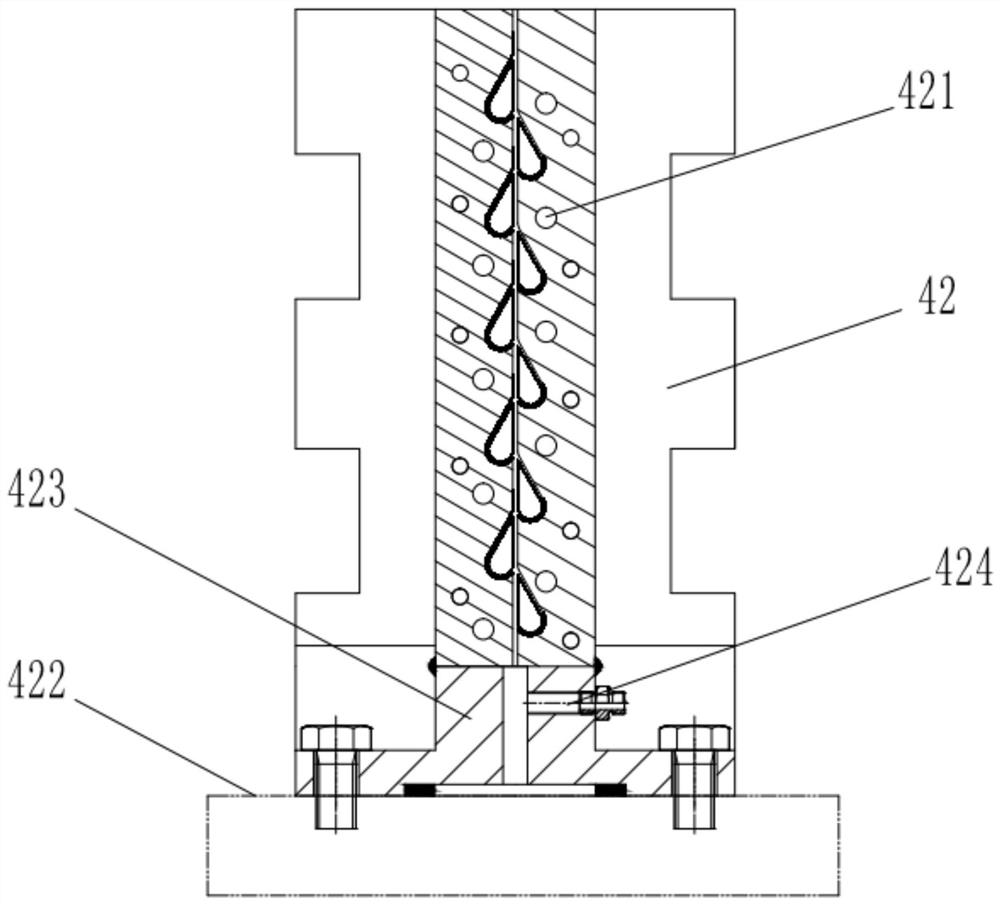

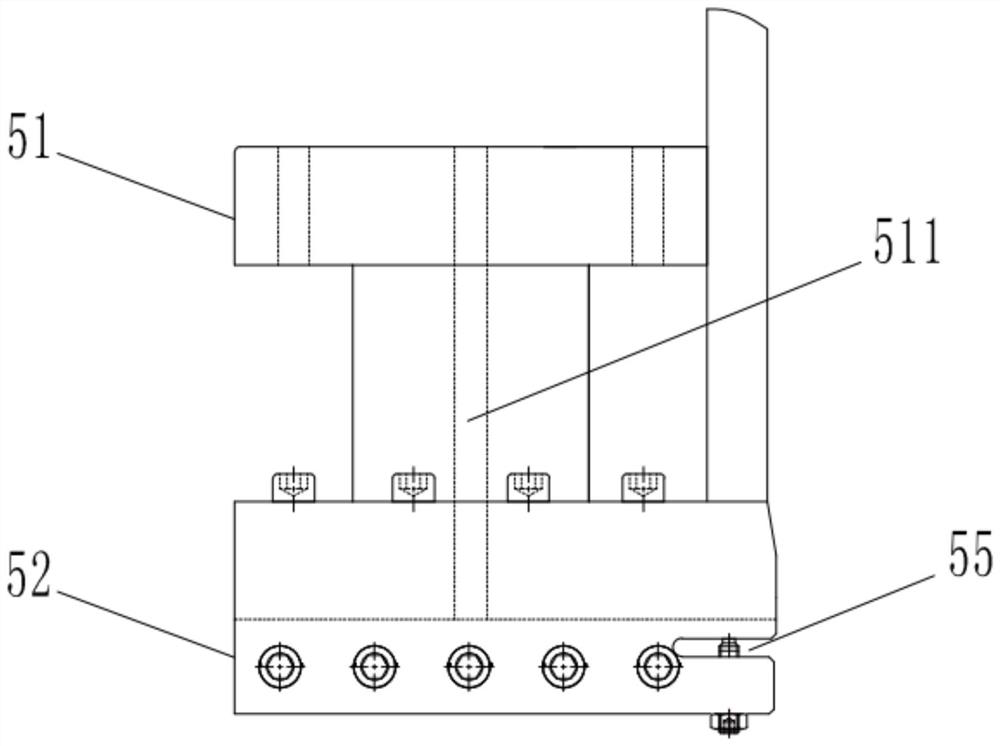

[0042] This embodiment discloses a high-frequency vibration continuous fiber prepreg production device, such as Figure 1-8 As shown, it includes creel 1, guide roller group, spreader roller group, oven 4, extrusion molding die group, ultrasonic dipping module group, extrusion roller group, cooling platform 81, traction roller group arranged in sequence along the feeding direction And the winding mechanism 9. Wherein, the inlet end of the oven 4 is connected with a negative pressure vacuum channel 42 arranged along the feeding direction. The extrusion molding die set is installed on the outlet end of the oven 4, and it includes two extrusion molding dies 5 that are oppositely arranged on both sides of the feeding direction. The extrusion mold 5 is connected with a glue supply mechanism 6 . The ultrasonic dipping module group includes two ultrasonic dipping modules 7 oppositely arranged on both sides of the feeding direction.

[0043] When in use, first, several continuous f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com