Patents

Literature

88results about How to "Rapid cooling and setting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

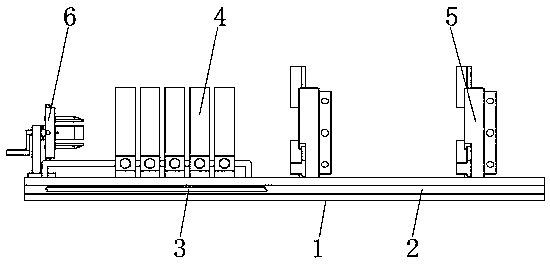

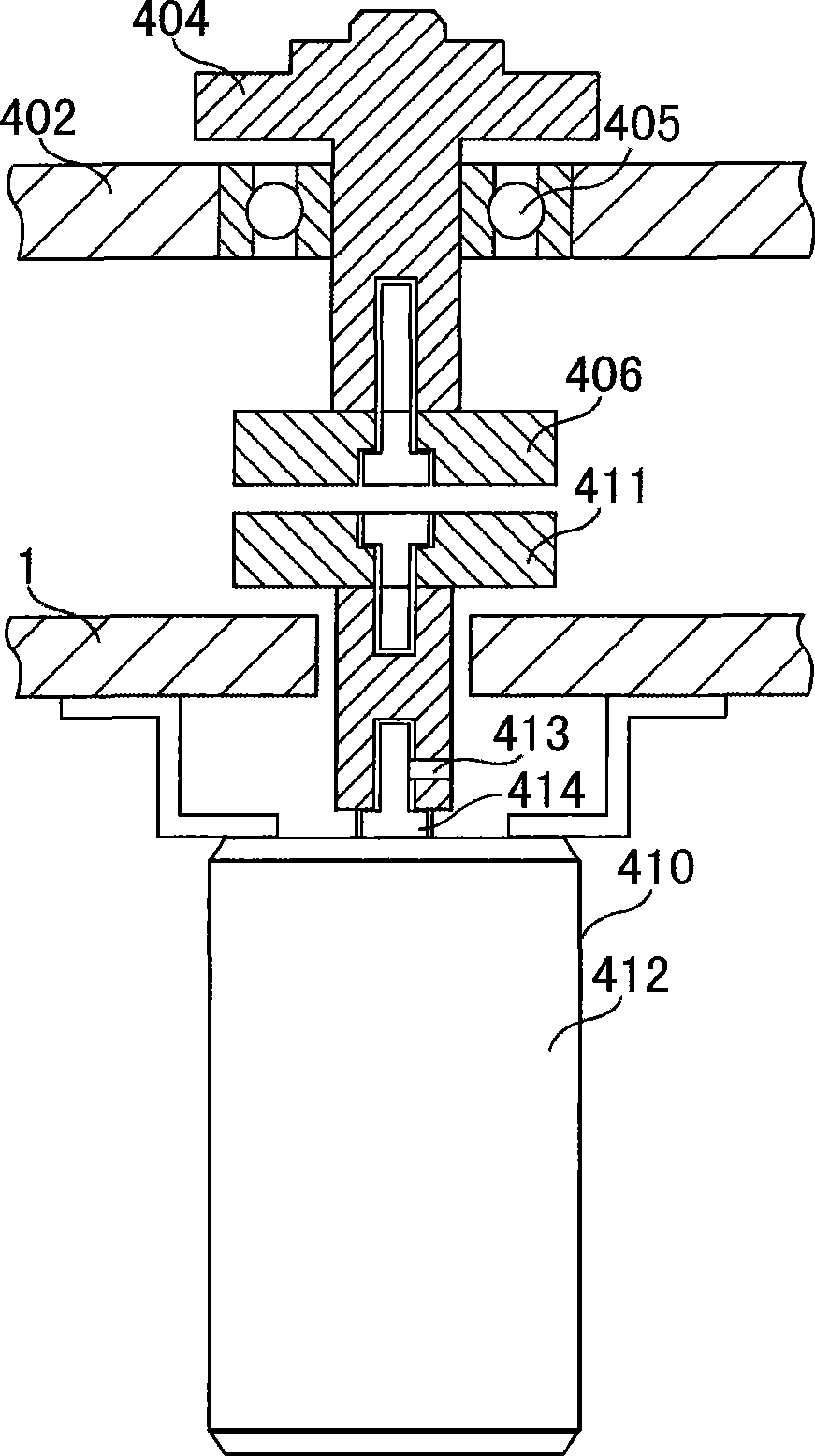

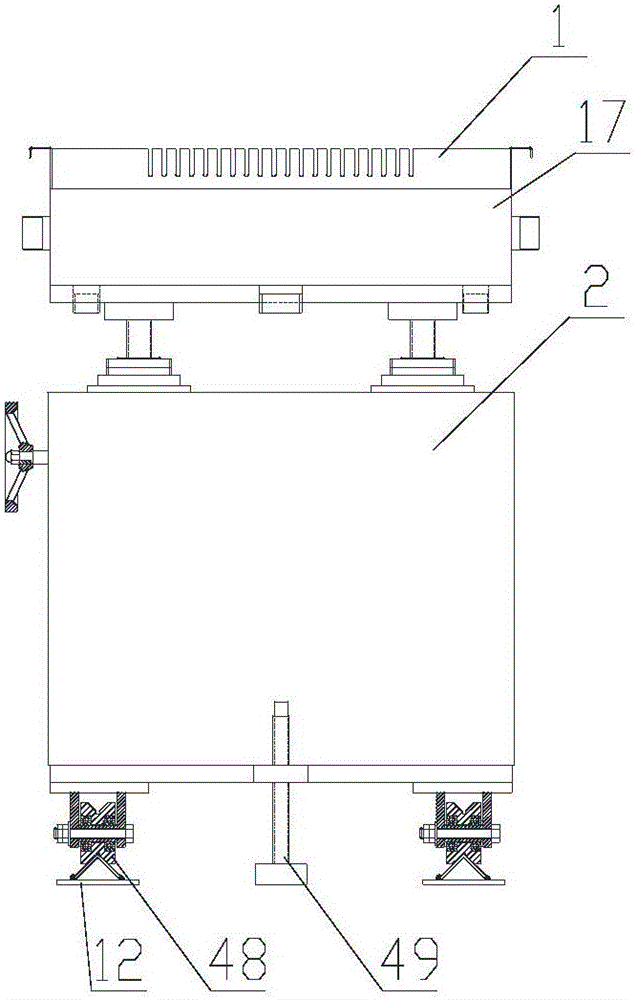

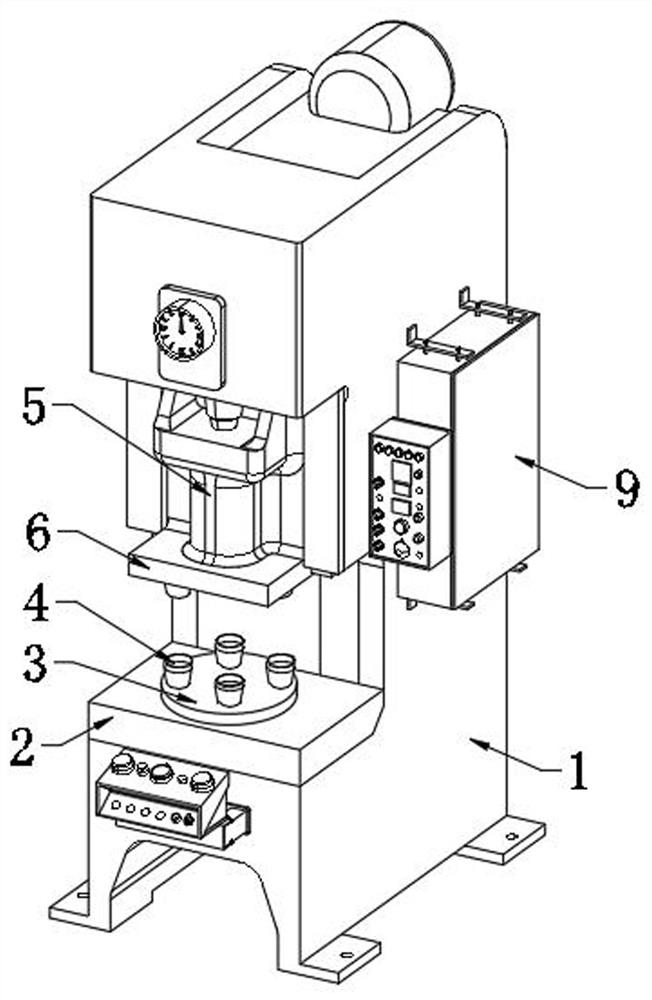

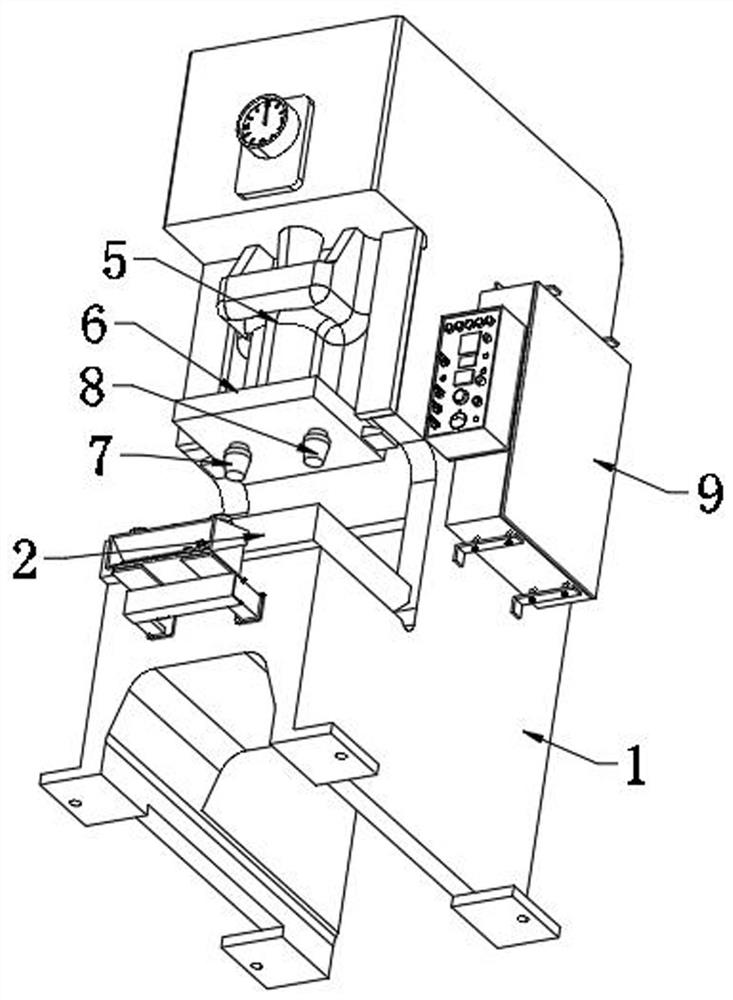

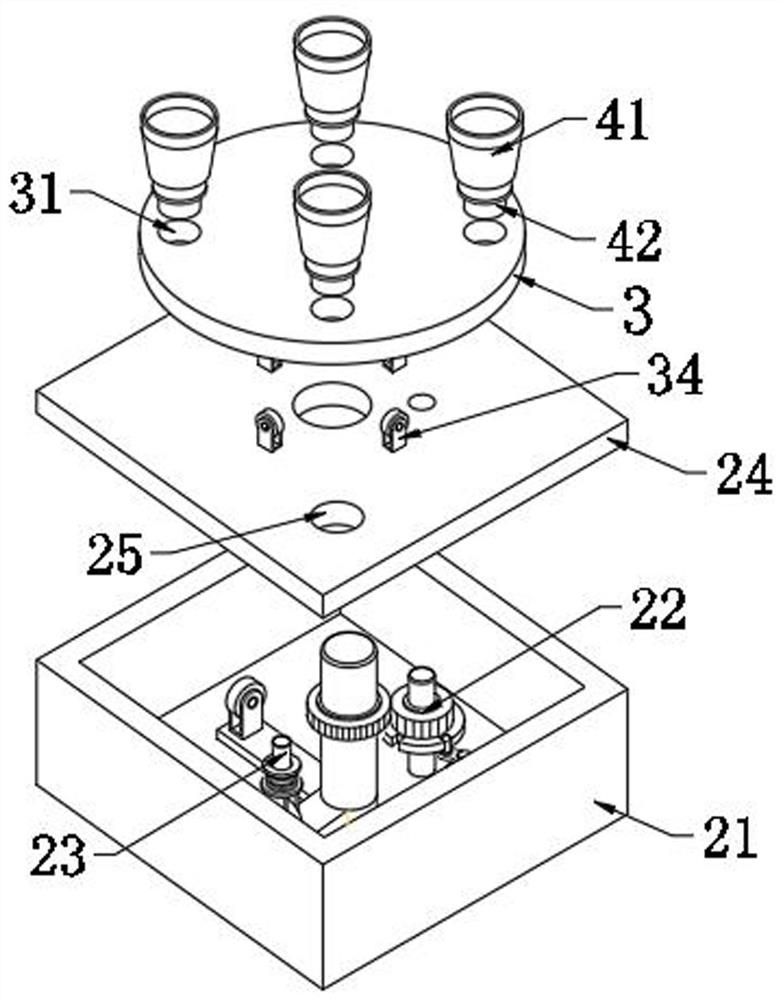

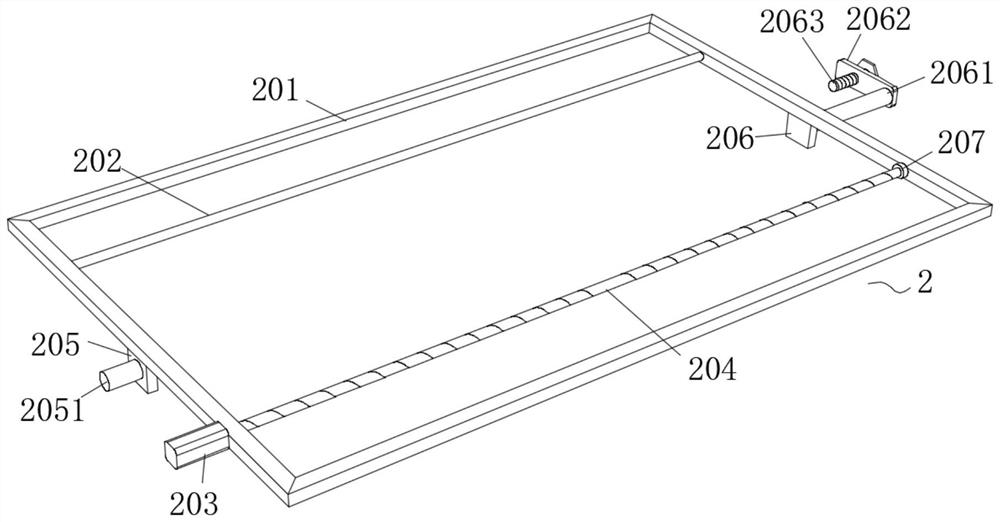

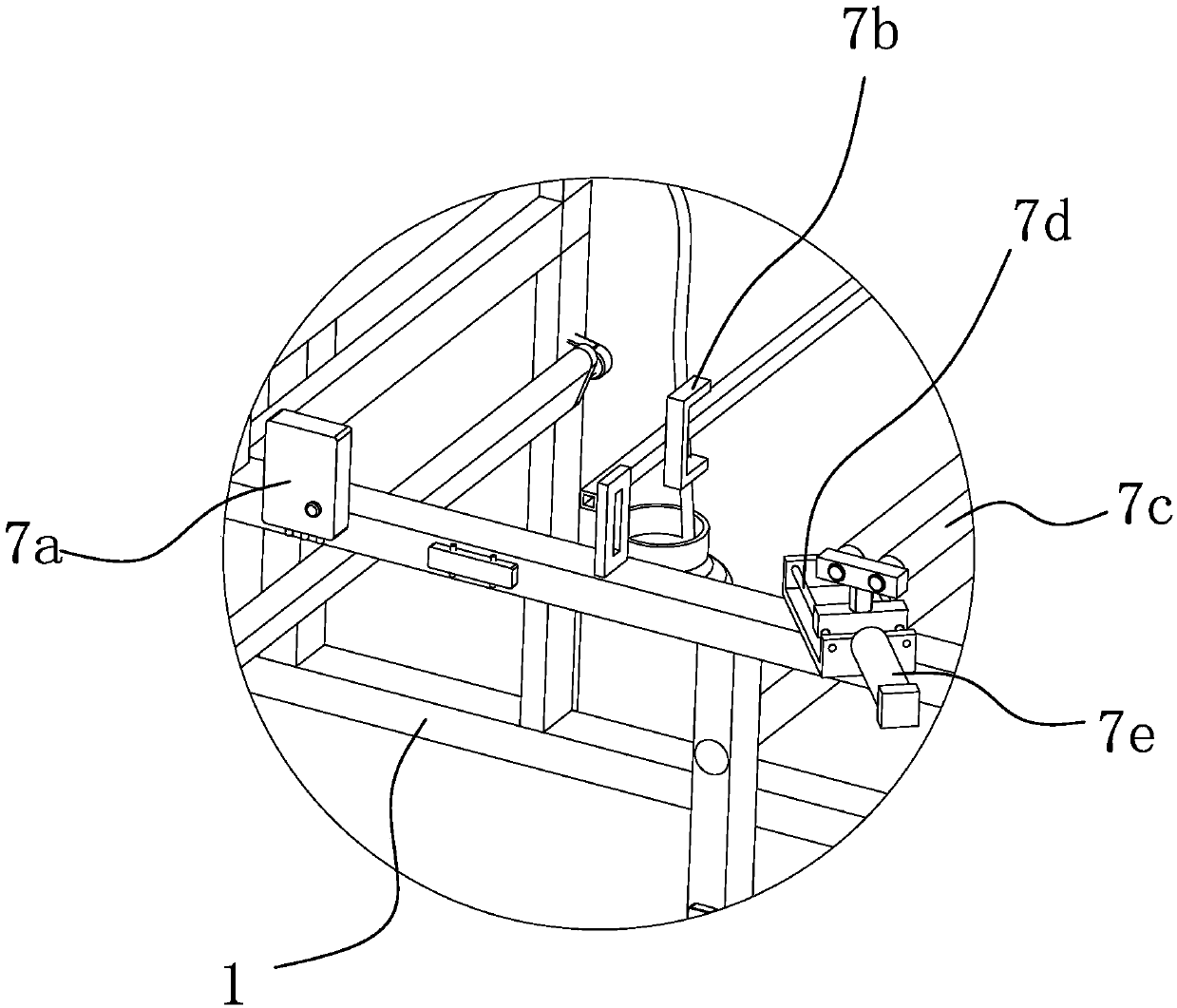

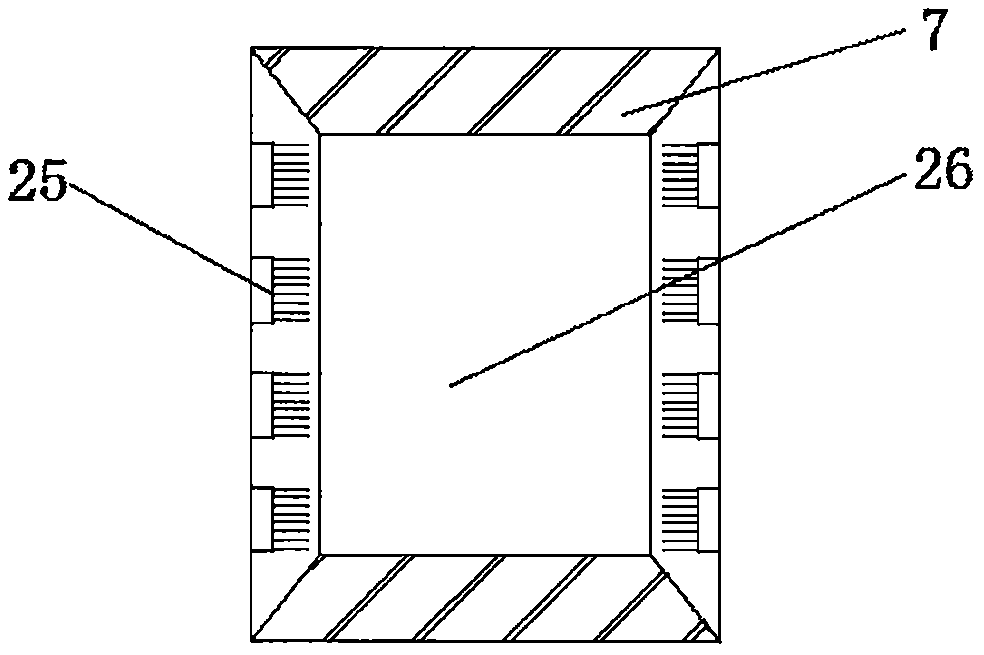

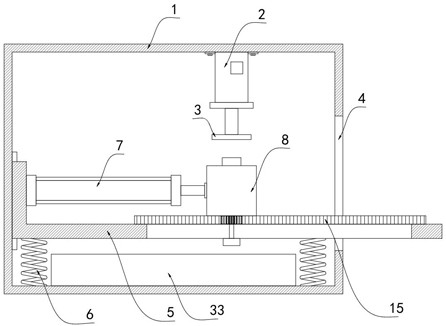

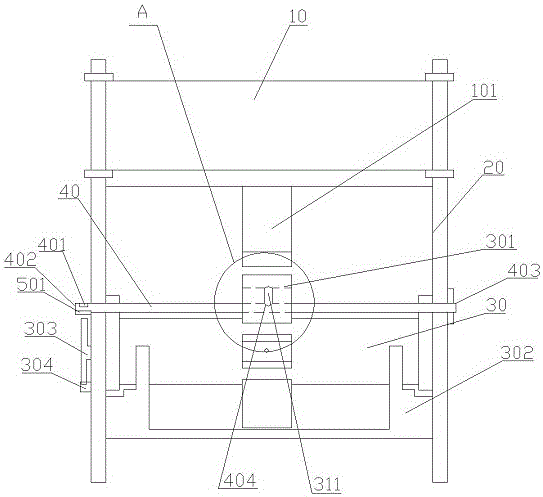

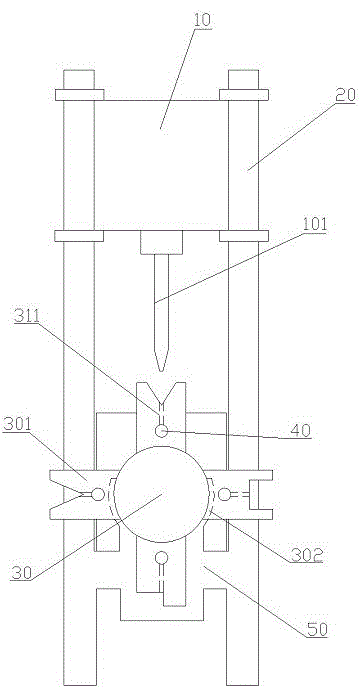

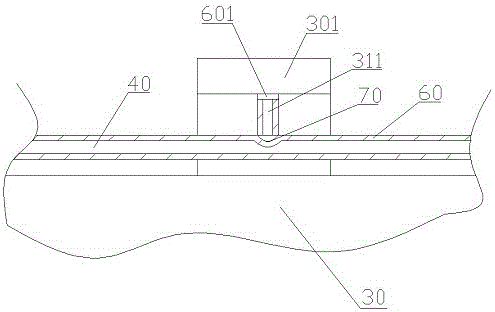

Punch die fast replacing device

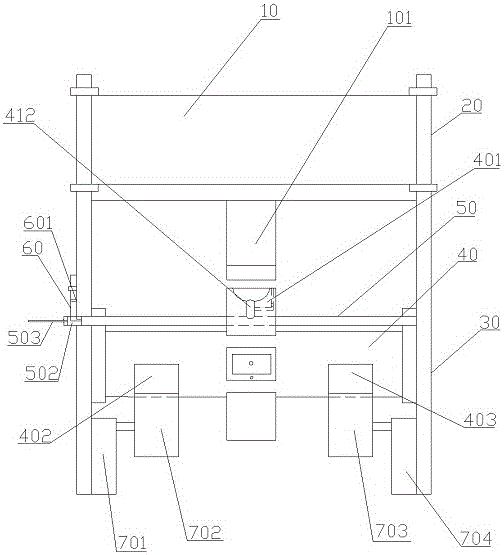

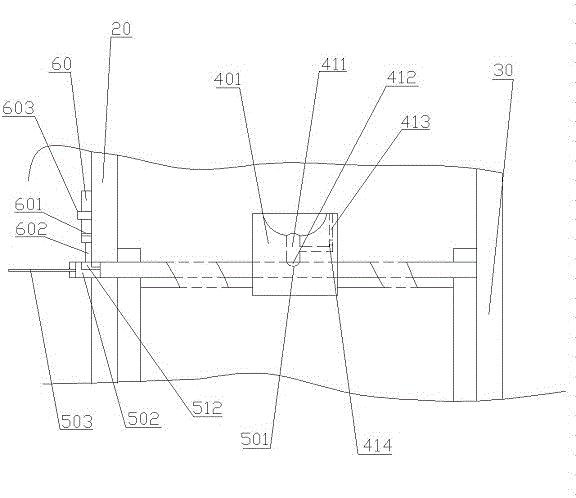

The invention relates to the field of machining and particularly discloses a punch die fast replacing device. The punch die fast replacing device comprises a hydraulic table and a rack. The hydraulic table is arranged at the upper end of the rack and is vertically and slidably connected with the rack; the lower surface of the hydraulic table is parallel to the horizontal plane; a machine table is fixedly mounted at the lower end of the rack; an upper die is detachably mounted on the lower surface of the hydraulic table; a rotary shaft rotationally connected with the machine table is horizontally arranged on the machine table; a plurality of different types of lower dies are mounted on the rotary shaft circumferentially; the upper die faces the rotary shaft; and the axes of the lower dies are perpendicular t to the axis of the rotary shaft. The punch die fast replacing device further comprises a first motor and a first driving gear which are both arranged at the lower end of the rack; the first driving gear is fixedly connected with the power output end of the first motor; and first transmission teeth engaged with the first driving gear are disposed at the end, close to the rack, of the rotary shaft. By means of the scheme, fast replacement of the lower dies can be achieved.

Owner:DOOR IND CO LTD CHONGQING DTOMO

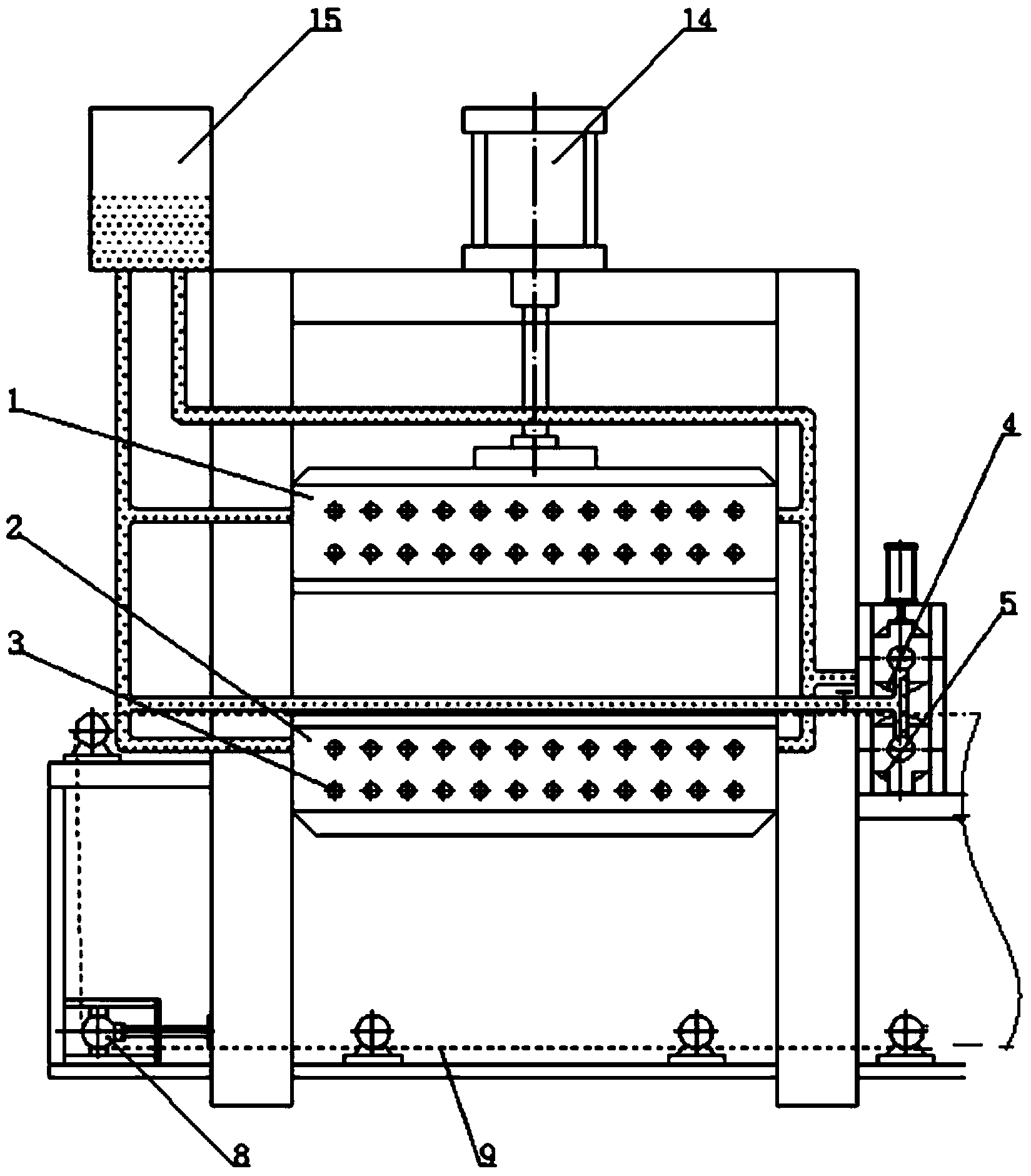

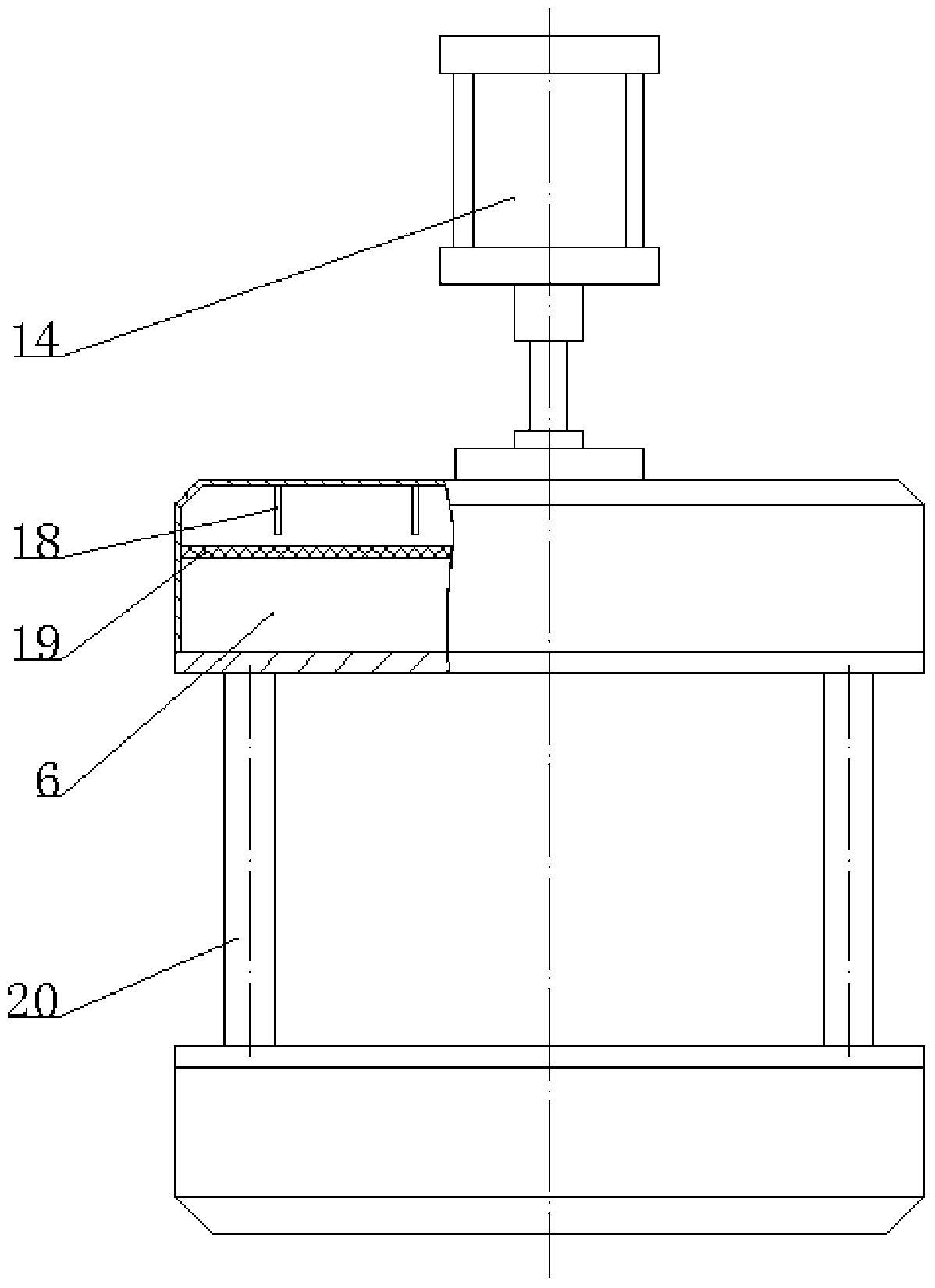

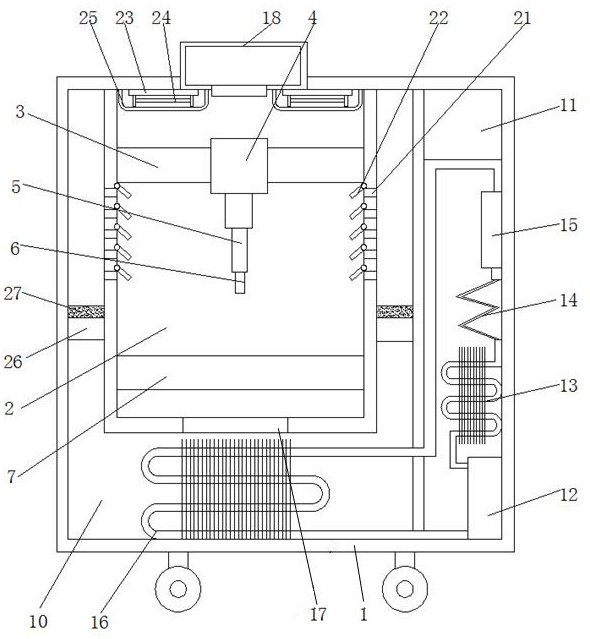

Hot-pressing sizing device

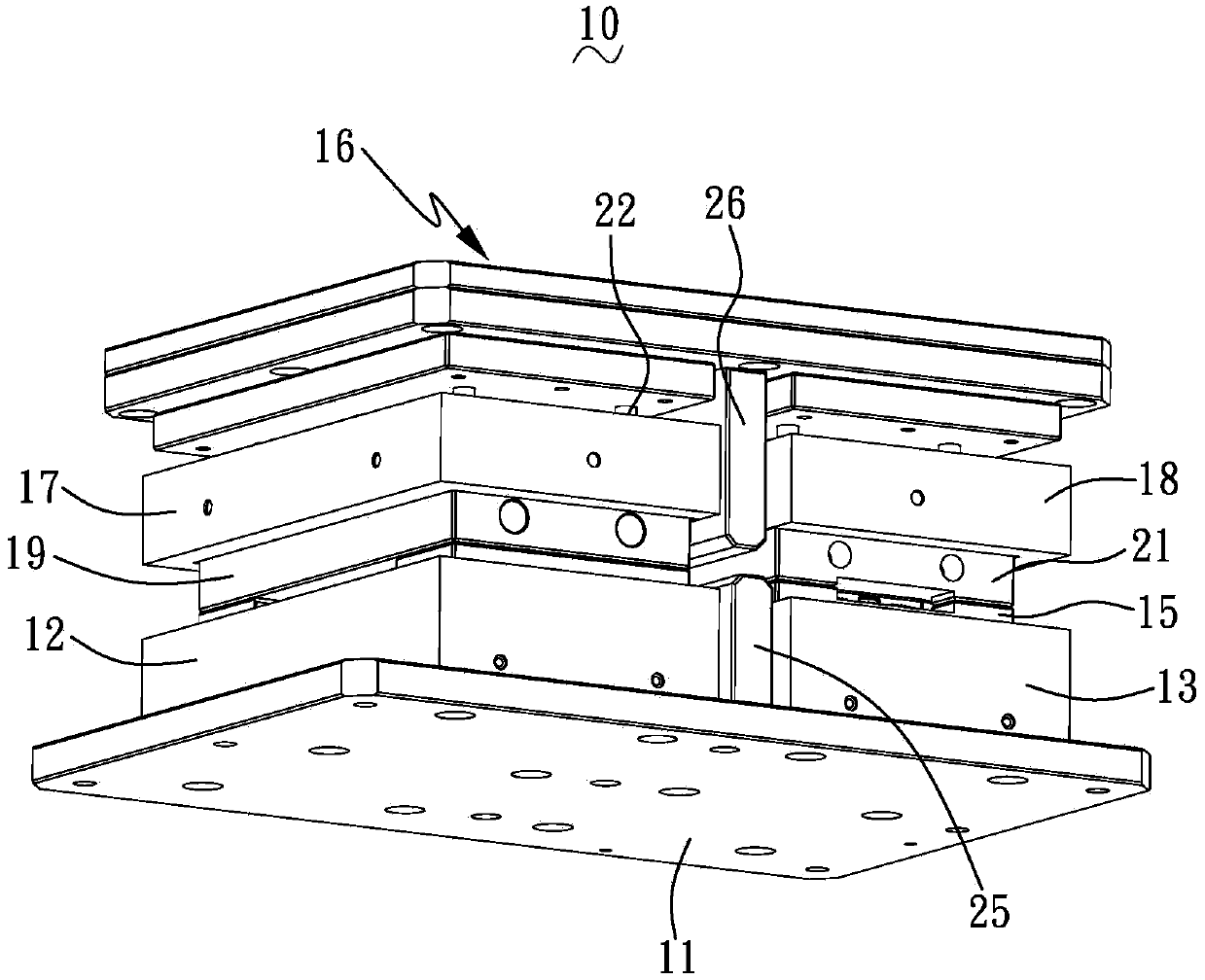

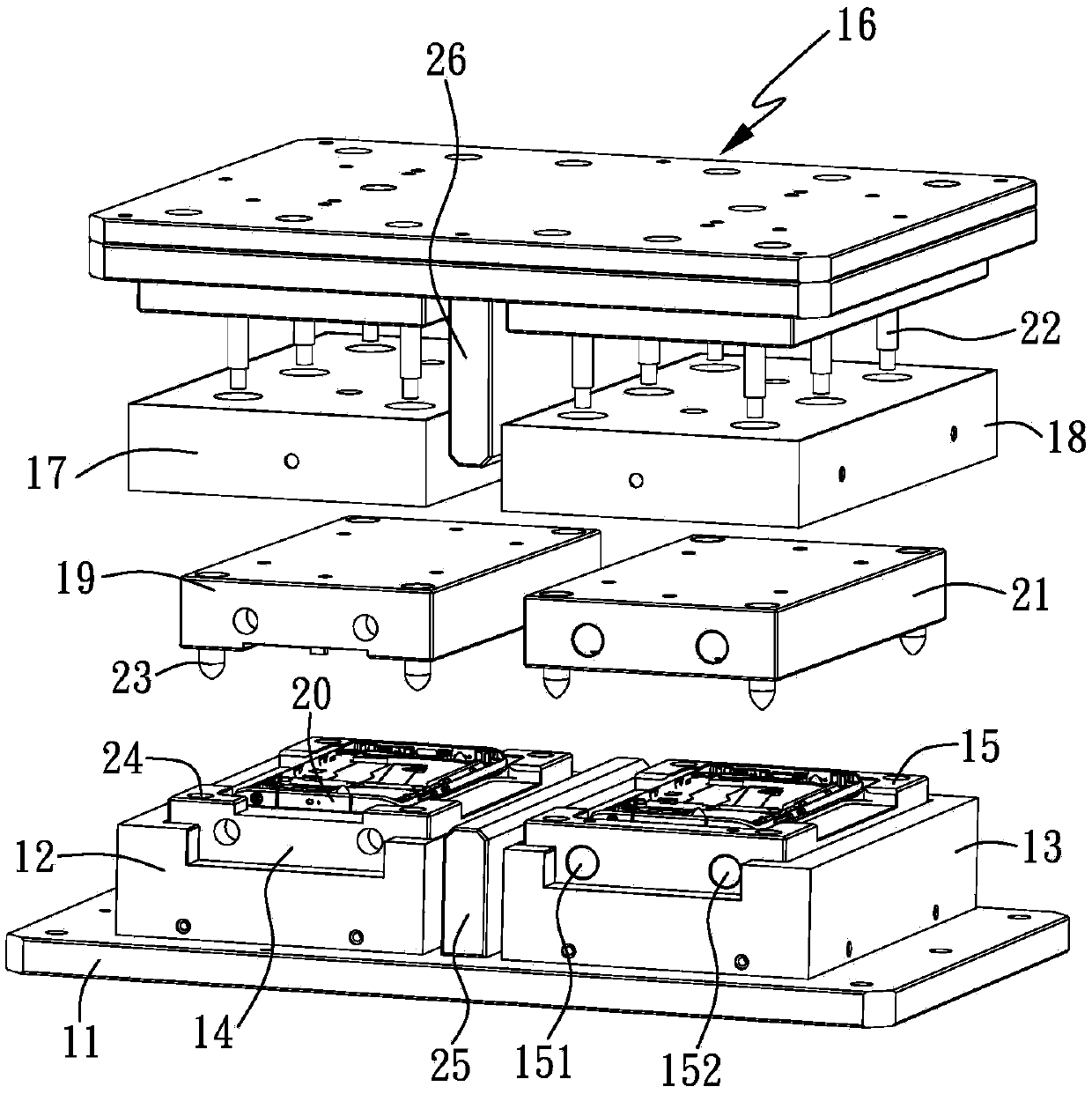

The invention relates to a hot-pressing sizing device. The hot-pressing sizing device comprises a base, a first heat insulation piece, a second heat insulation piece, a heating lower die, a cooling lower die, a pressing base, a third heat insulation piece, a fourth heat insulation piece, a heating upper die, a cooling upper die, a plurality of guiding columns and buffer springs, wherein the heating lower die and the cooling lower die are arranged in the first heat insulation piece and the second heat insulation piece in an inlaid mode respectively; the heating upper die is arranged in the third heat insulation piece in an inlaid mode; the cooling upper die is arranged in the fourth heat insulation piece in an inlaid mode; the multiple guiding columns are fixed to the pressing base and sleeved with the buffer springs. Heating rods are arranged in the heating lower die and / or the heating upper die. The cooling lower die and / or the cooling upper die are provided with water inlets, water outlets and pipelines which are communicated with the water inlets and the water outlets. A cell phone middle frame is clamped between the heating lower die and the heating upper die, the cell phone middle frame is deformed at a preset high temperature through the heating rods, and the flatness is restored. Then the cell phone middle frame which is affected at the preset high temperature is taken out and clamped between the cooling lower die and the cooling upper die, and the cell phone middle frame can be cooled and sized rapidly by pouring circulating water flow. According to the hot-pressing sizing device, the sizing effect is good, and the production cost is reduced.

Owner:GUANGDONG TIANJI IND INTELLIGENT SYST CO LTD +1

Plastic pipe expanding device capable of processing pipe openings in different sizes

The invention discloses a plastic pipe expanding device capable of processing pipe openings in different sizes. The plastic pipe expanding device comprises a supporting base and a lead; an external wire slot is formed in the outer side of the supporting base, and the lead is fixed inside the external wire slot; a heating mechanism, a fixing mechanism and an expanding mechanism are mounted on the upper side of the supporting base, the heating mechanism is positioned between the fixing mechanism and the expanding mechanism, an internal wire slot is formed in the upper side of the supporting base, and the heating mechanism is mounted on the upper side of the internal wire slot. The plastic pipe expanding device capable of processing the pipe openings in different sizes, disclosed by the invention, has the benefits that as the heating mechanism, the fixing mechanism and the expanding mechanism are arranged on the device, the use of a connector during the plastic pipe connection can be avoided, and the problem that the use cost of plastic pipes is increased due to the use of the connector is also solved; only one connection position can exist between the two plastic pipes, so that the probability of leakage at the connection of the plastic pipes is reduced, and the service performances of the plastic pipes are improved.

Owner:重庆西洲管业有限公司

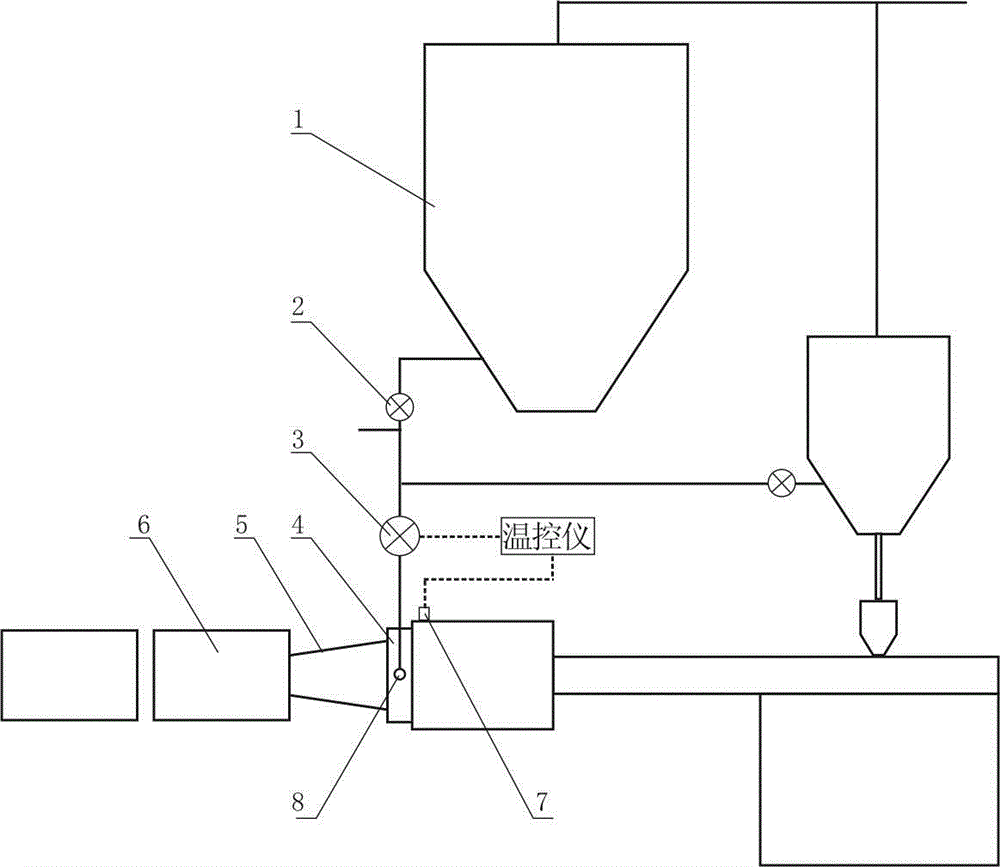

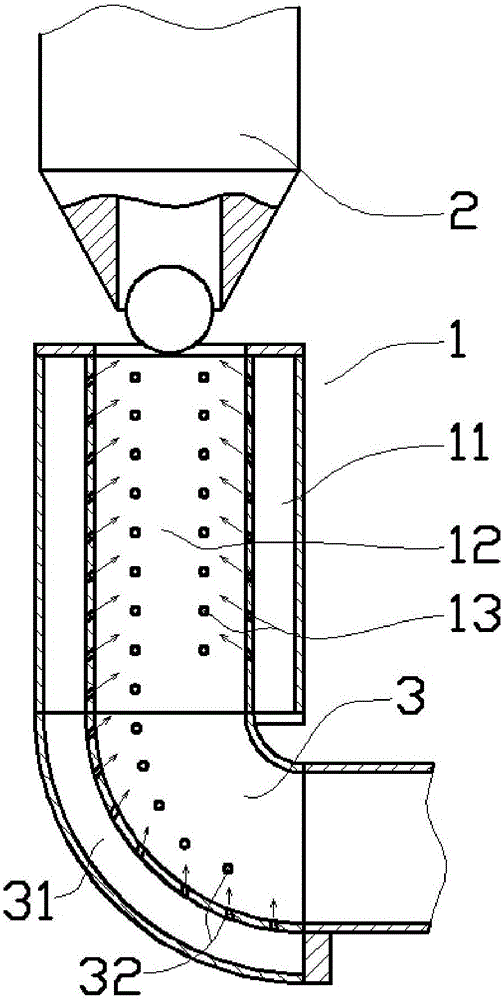

Waste heat recovering and utilizing system and method of plastic pipe production line

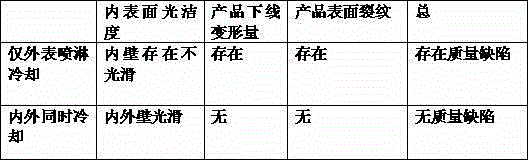

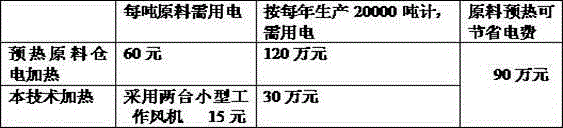

InactiveCN104527013ABalance the temperature difference between inside and outsideUniform textureThermodynamicsProcess engineering

The invention discloses a waste heat recovering and utilizing system and method of a plastic pipe production line. The waste heat recovering and utilizing system comprises a heat recovering device arranged at an extrusion molding core mould, wherein the heat recovering device is connected with a raw material preheating bin; the heat recovering device comprises a heat recovering hole connected in from the core mould and connected with the center of an extruded plastic pipe. The waste heat recovering and utilizing method disclosed by the invention comprises the following steps: obtaining the temperature of the center of the plastic pipe of the extrusion core mould; sucking the heat by adopting a negative pressure fan; conveying the heat to the raw material preheating bin and other heat utilizing occasions; detecting the temperature in the core mould in real time, regulating a working parameter of the negative pressure fan; and detecting the temperature in the raw material preheating bin in real time so as to regulate inlet air heat. According to the waste heat recovering and utilizing system and method, high-temperature air is sucked from the interior of the plastic pipe and the sucked heat is used in production. Because the inner wall of the plastic pipe is effectively cooled, the difference of the temperatures inside and outside the plastic pipe is balanced, and no cracks are easily formed. Because the cooling speed of the plastic pipe is relatively high, the delivery speed of the pipe is high, and the yield is increased. Meanwhile, heat energy is recycled, so that the energy consumption is reduced.

Owner:SICHUAN QINGCHUAN PIPES CO LTD

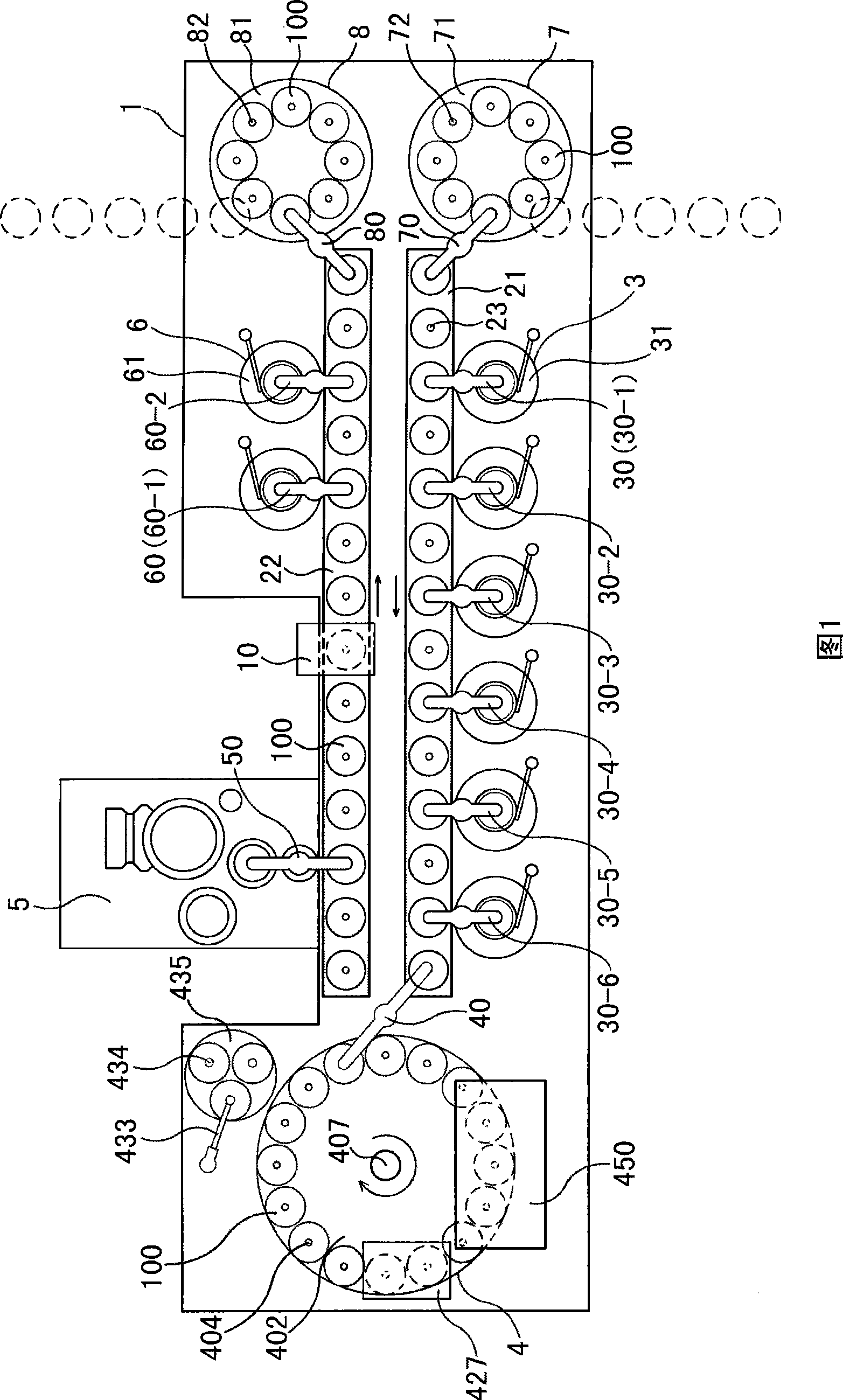

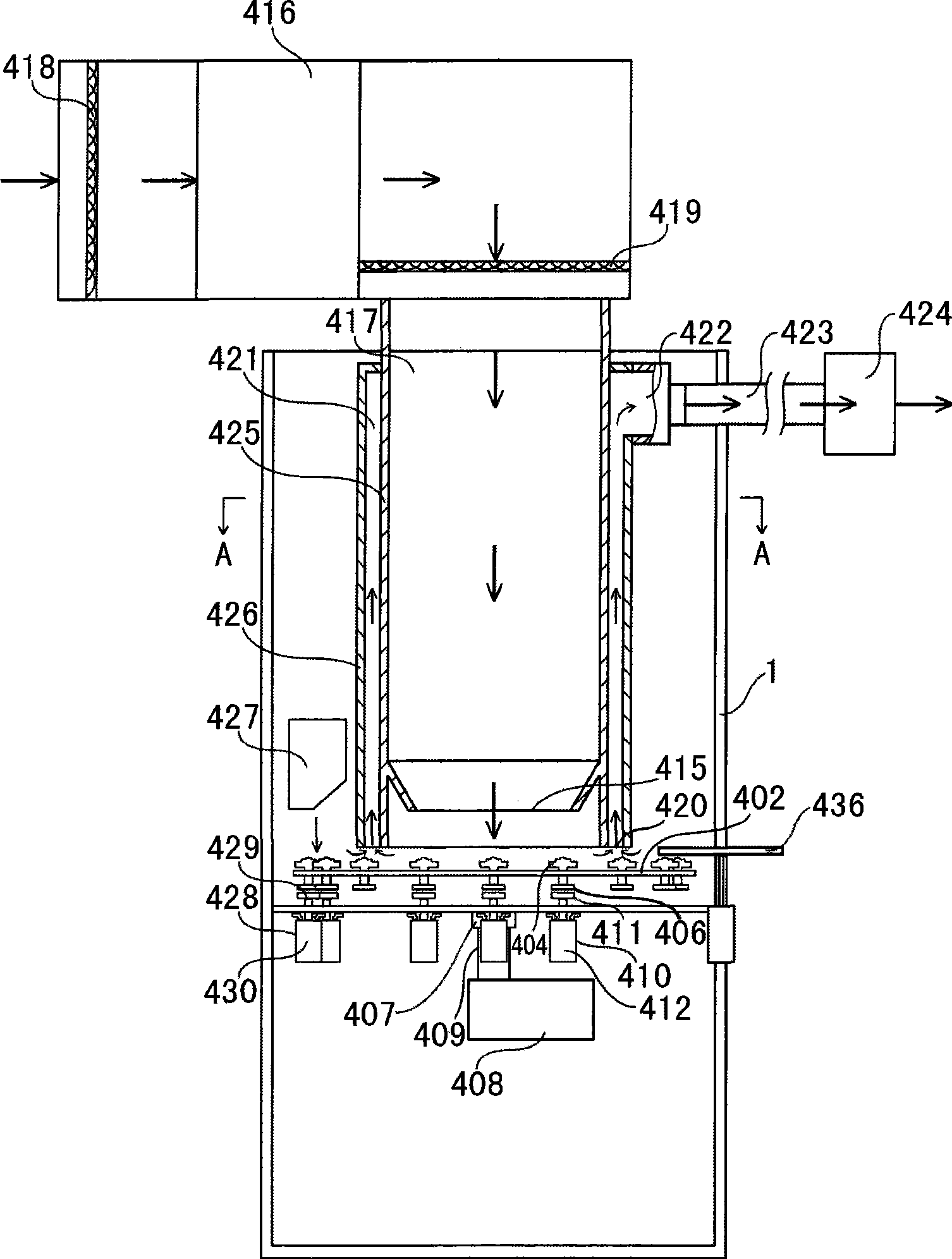

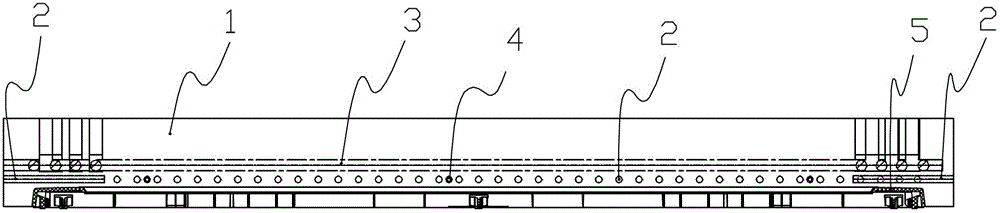

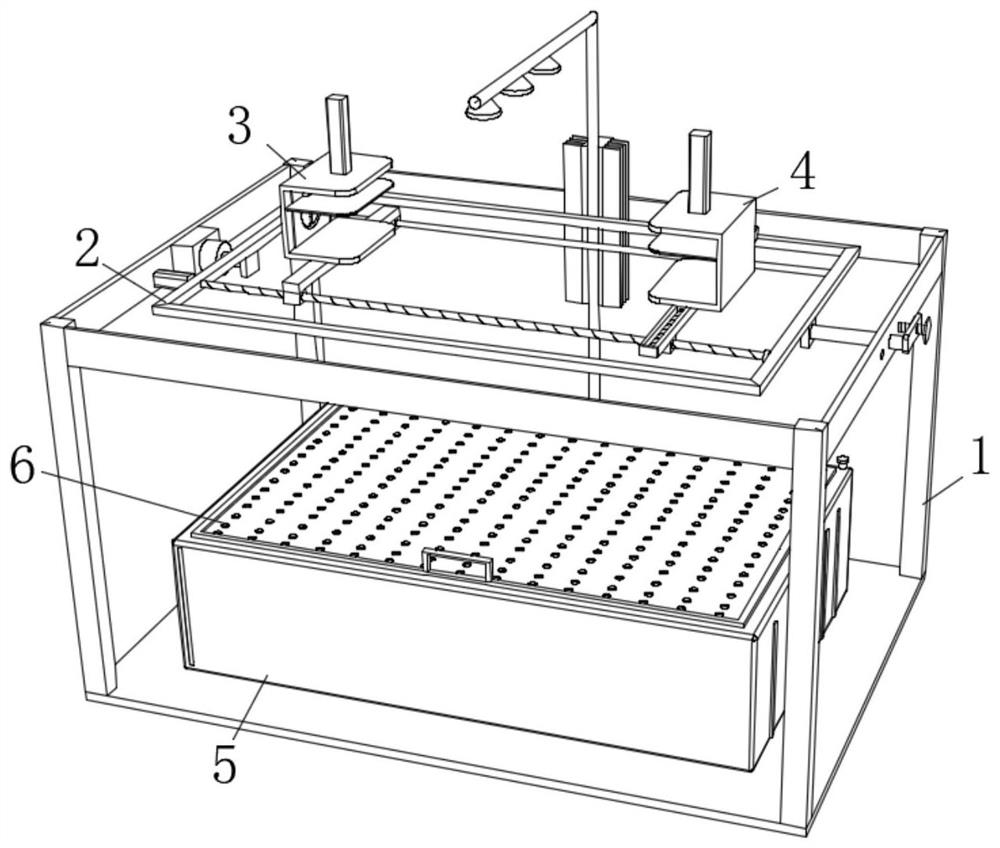

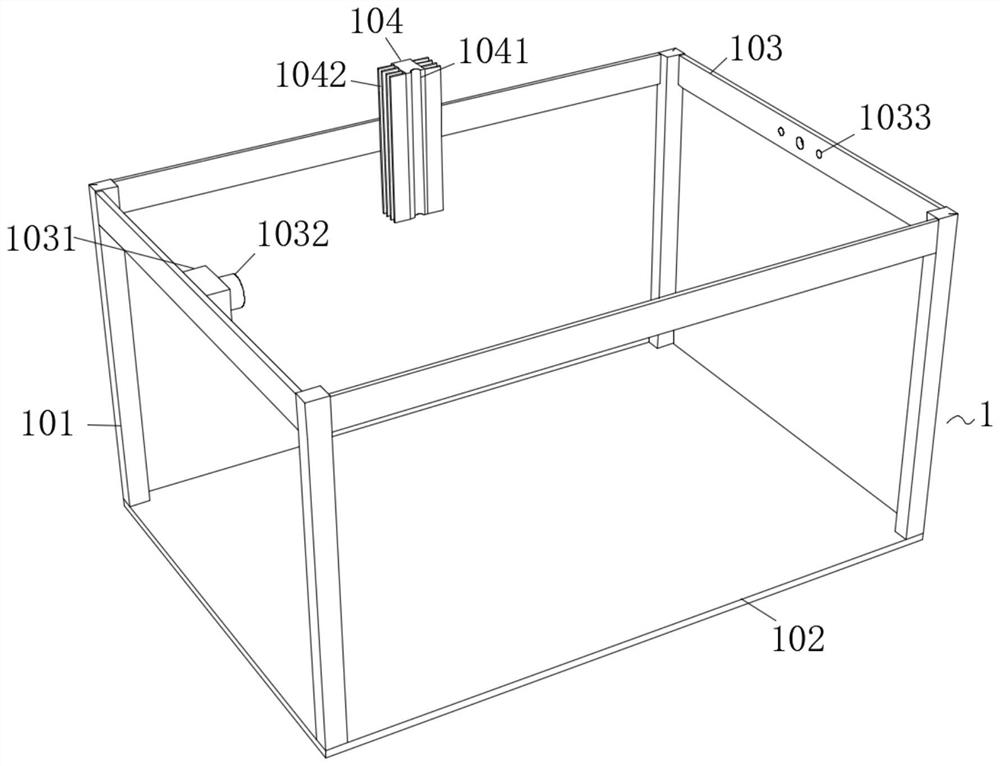

Recording type compact disc production line

InactiveCN101373620AAvoid deformationRapid cooling and settingOptical record carrier manufactureManufacturing cost reductionProduction line

A recordable compact disc production line comprises a frame, a conveying belt arranged on the frame, and a dye spin-coating device, an oven-drying device, a sputtering device and an edge washing device which are sequentially arranged on the frame from front to back along the compact disc substrate conveying direction of the conveying belt, wherein a disc feeding mechanism is arranged on the frame in a position corresponding to the front end of the conveying belt; a disc collection mechanism is arranged on the frame in a position corresponding to the rear end of the conveying belt; the support surface of a compact disc substrate base on the conveying belt on the work surface of the conveying belt is in the horizontal direction; the oven-drying device includes an oven-drying rotary table; and the support surface of a second compact disc substrate base on the oven-drying rotary table is in the horizontal direction. In each procedure, the compact disc substrate is always in the horizontal direction without inverting. On one hand, the recordable compact disc production line has the advantages of simpler and compacter structure, lowered manufacture cost and reduced occupied area. On other hand, the recordable compact disc production line can reduce the fault rate and the deformation probability of the compact disc substrate, thereby ensuring normal production and effectively preventing deformation of the compact disc substrate.

Owner:广东粤华磁电实业有限公司

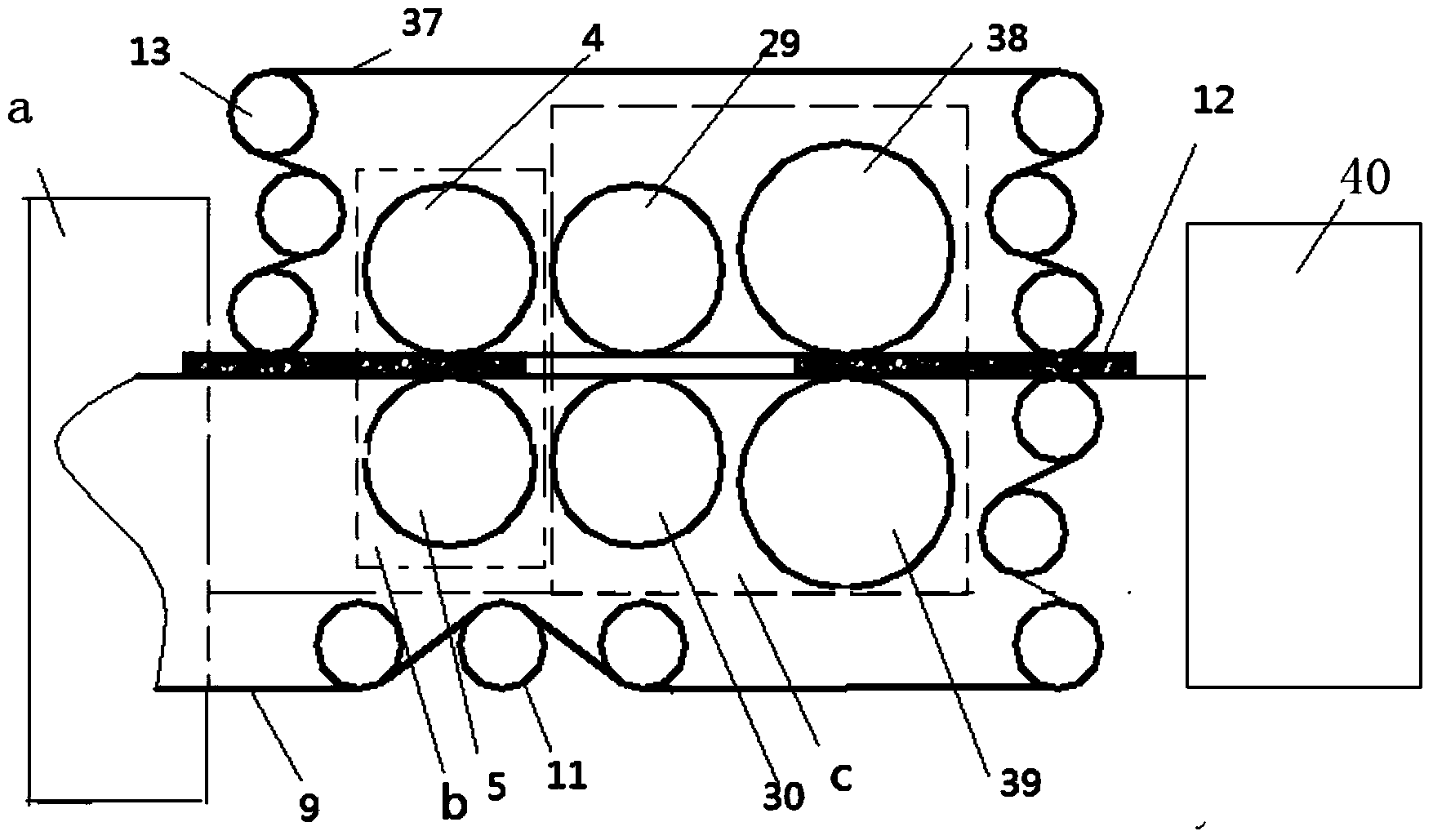

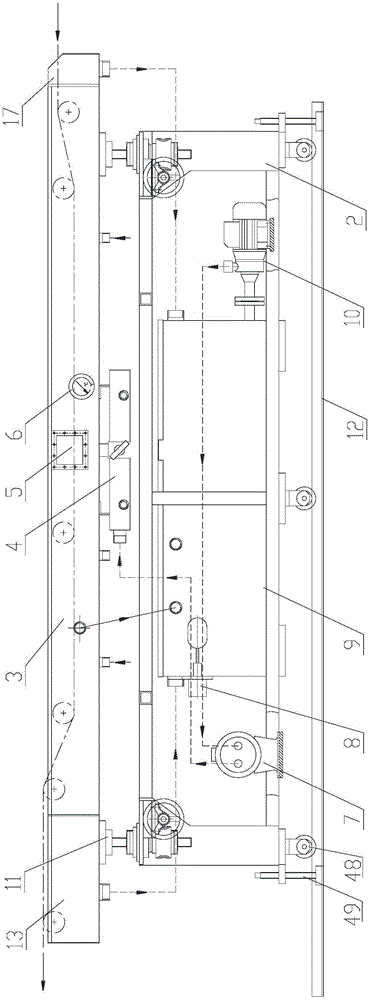

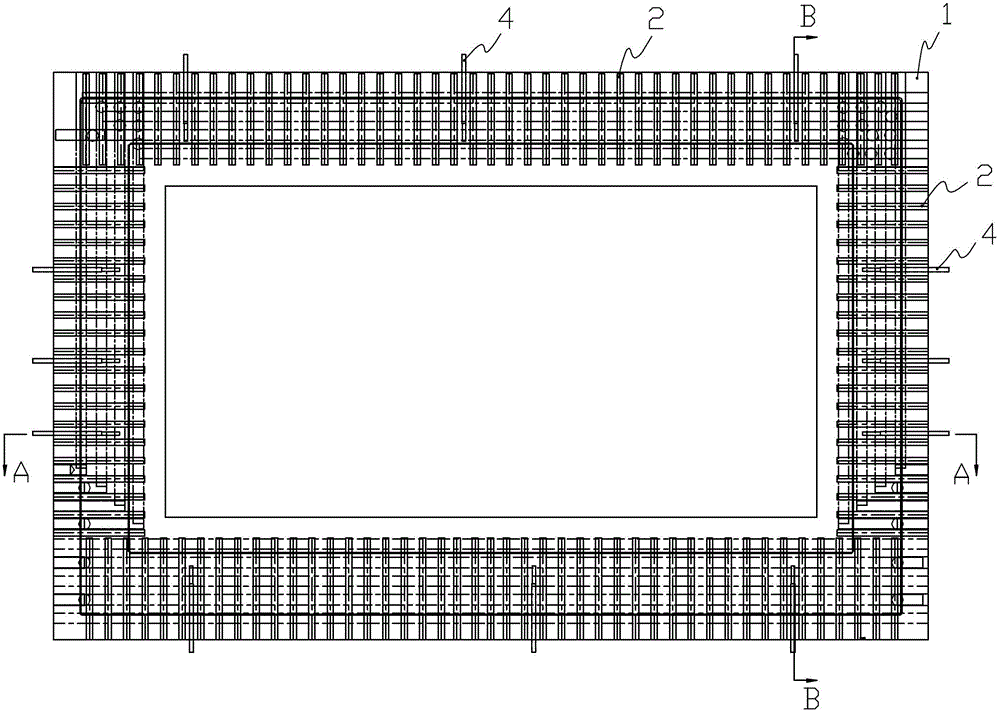

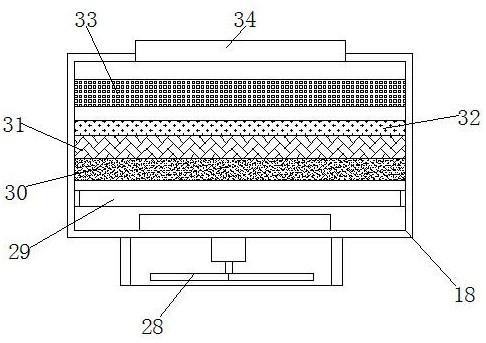

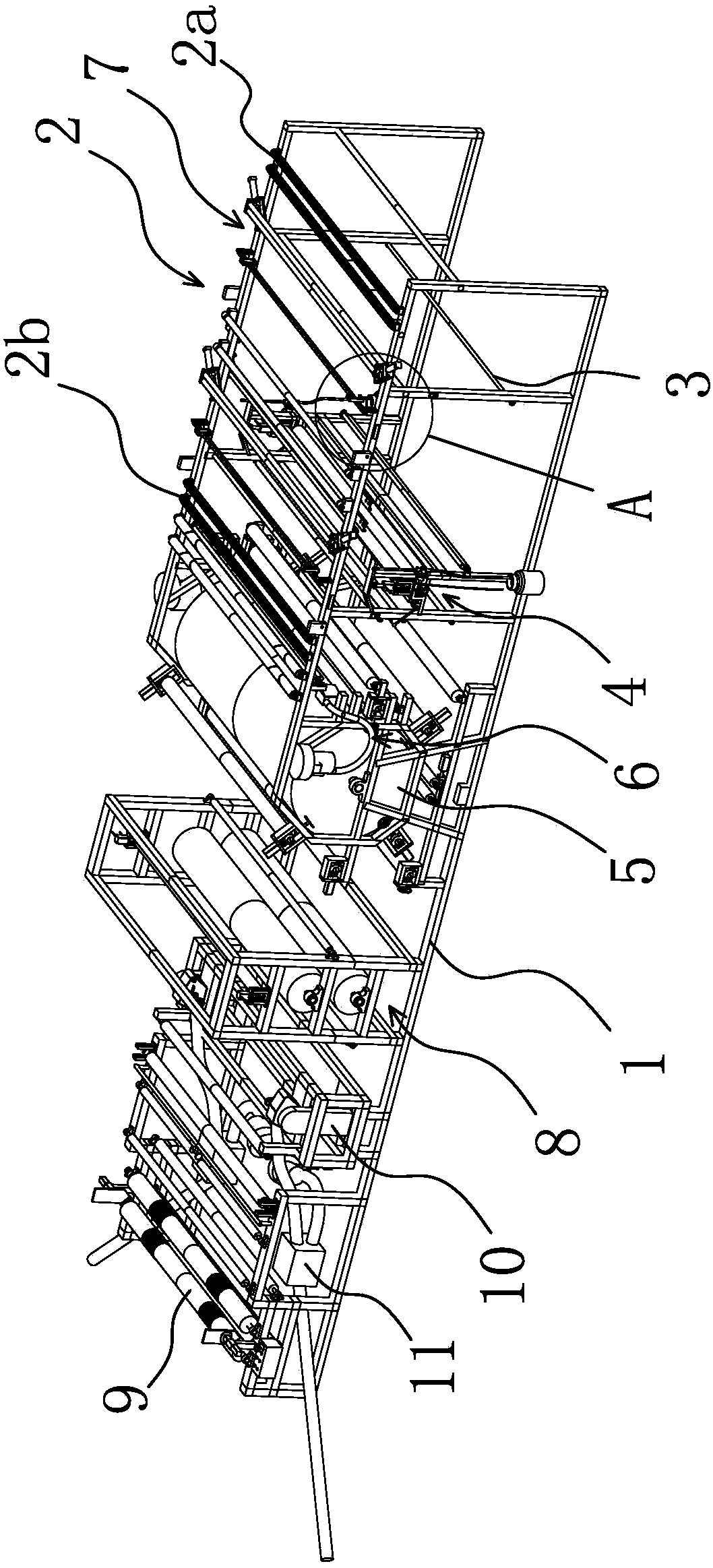

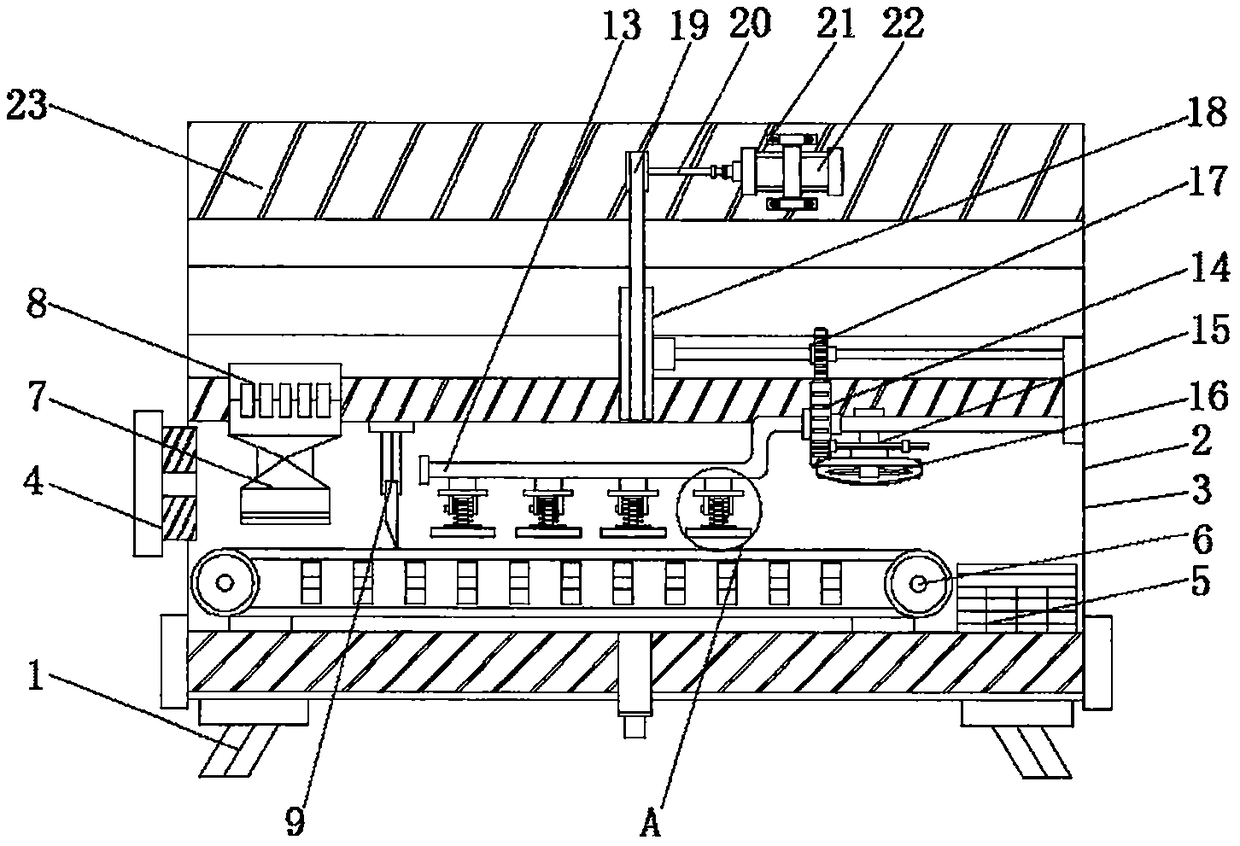

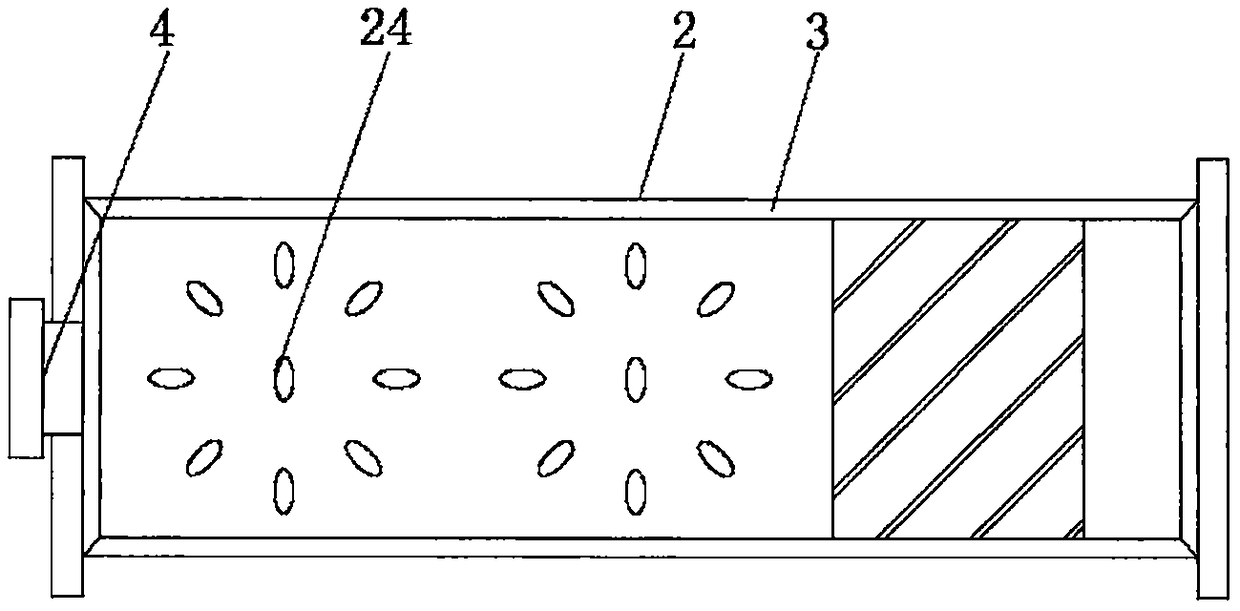

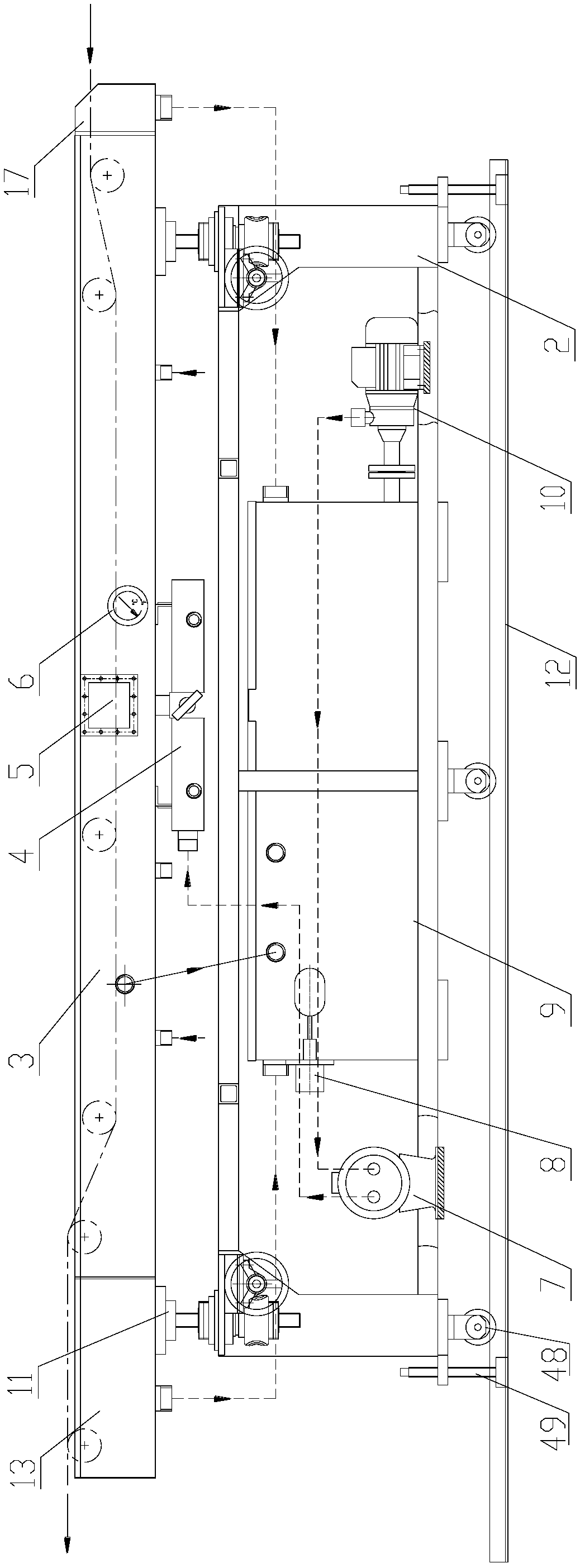

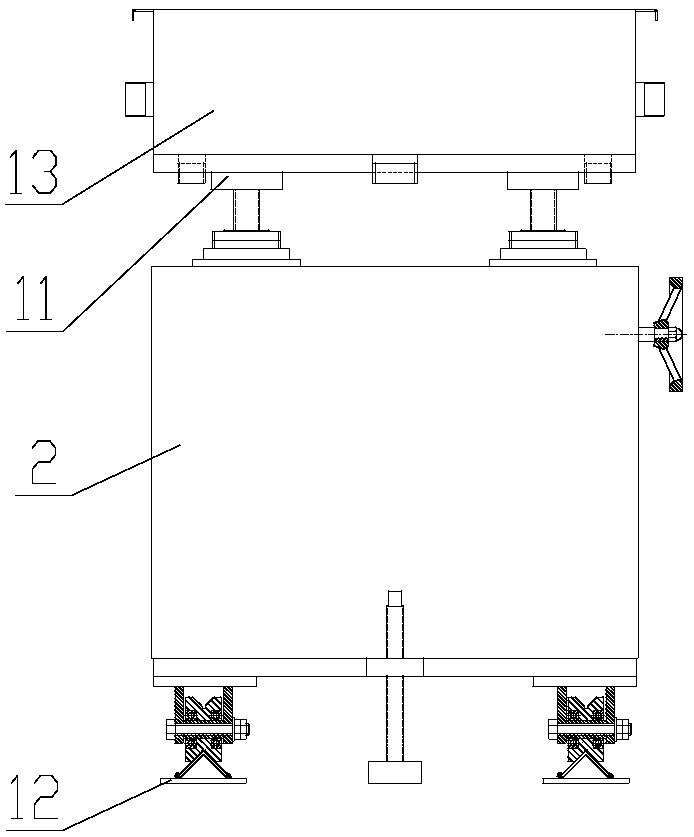

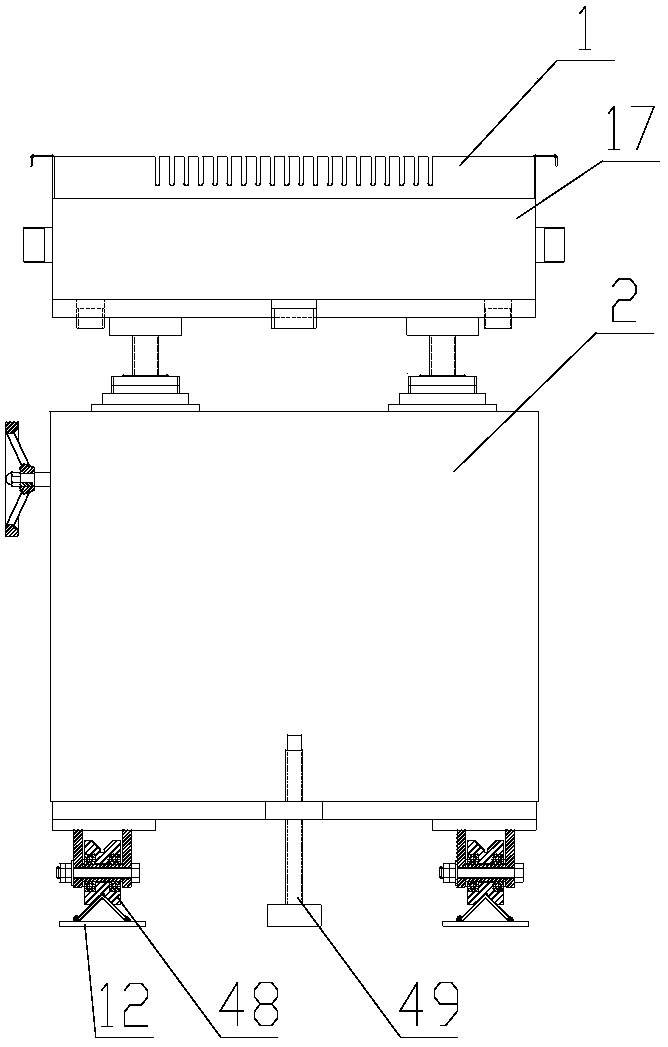

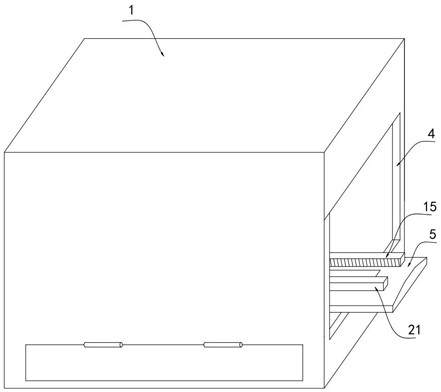

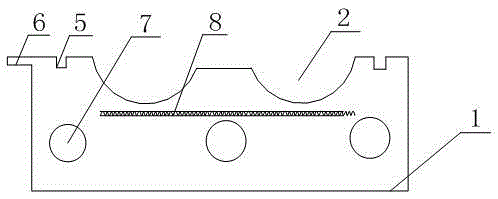

GMT sheet production system for teaching experiments

The invention discloses a GMT sheet production system for teaching experiments. The production system comprises a conveying system, a heating and baking system (a), a heating and dipping system (b) and a cooling and shaping system (c), wherein the conveying system is provided with a lower conveying belt (9), and the heating and baking system (a), the heating and dipping system (b) and the cooling and shaping system (c) are connected in sequence through the lower conveying belt (9); the heating and baking system comprises a heating oil tank (15) and a heating pressing plate assembly, and the heating pressing plate assembly is composed of an upper heating pressing plate (1) and a lower heating pressing plate (2); the heating and dipping system comprises at least one heating and dipping assembly, and each heating and dipping assembly is composed of an upper heating compression roller (4) and a lower heating compression roller (5); the cooling and shaping system comprises at least one cooling and shaping assembly, and each cooling and shaping assembly is composed of an upper cooling compression roller and a lower cooling compression roller. The production system is small in occupied area, low in cost, capable of achieving the effects of even heating and sufficient dipping and quite suitable for teaching research.

Owner:HUNAN UNIV

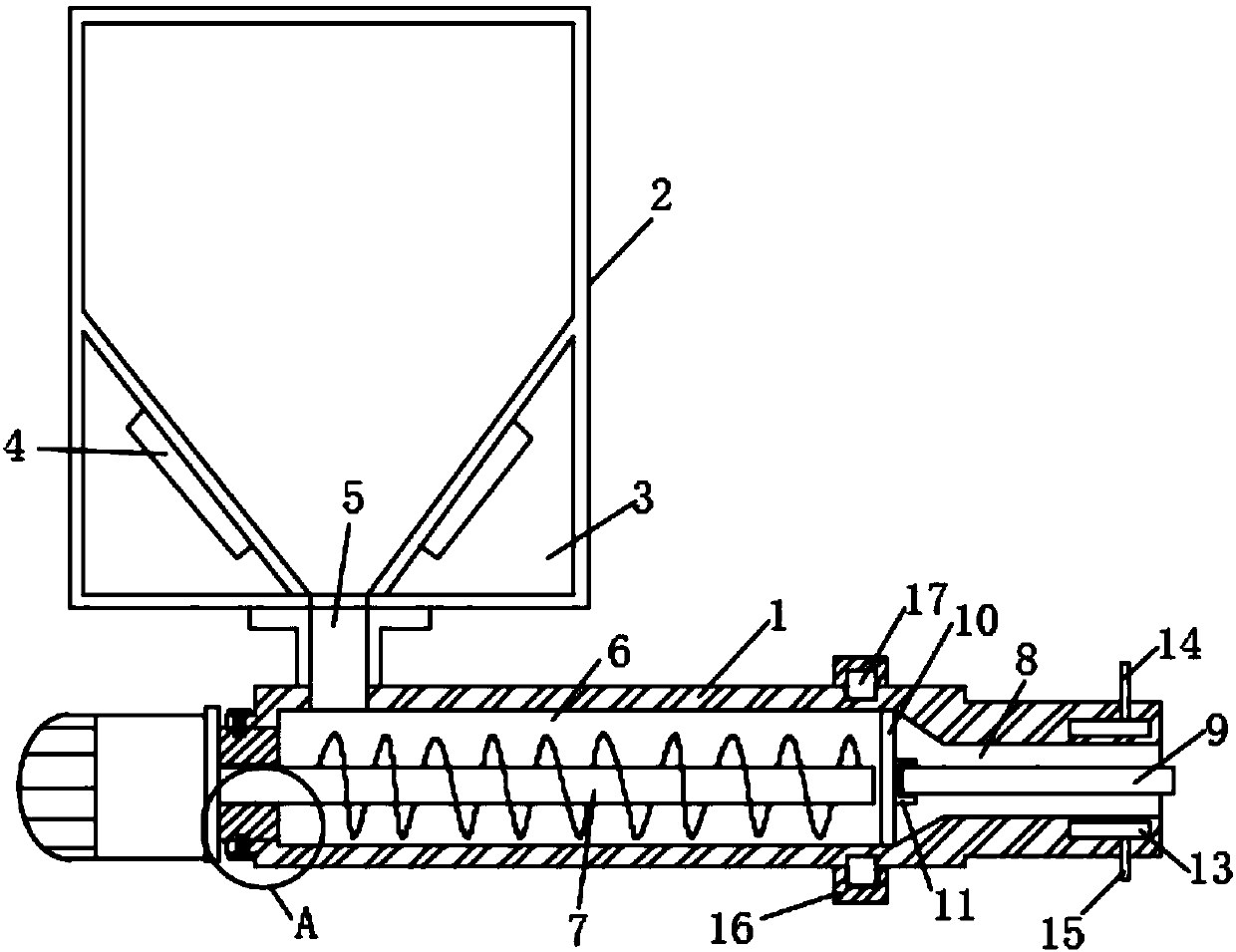

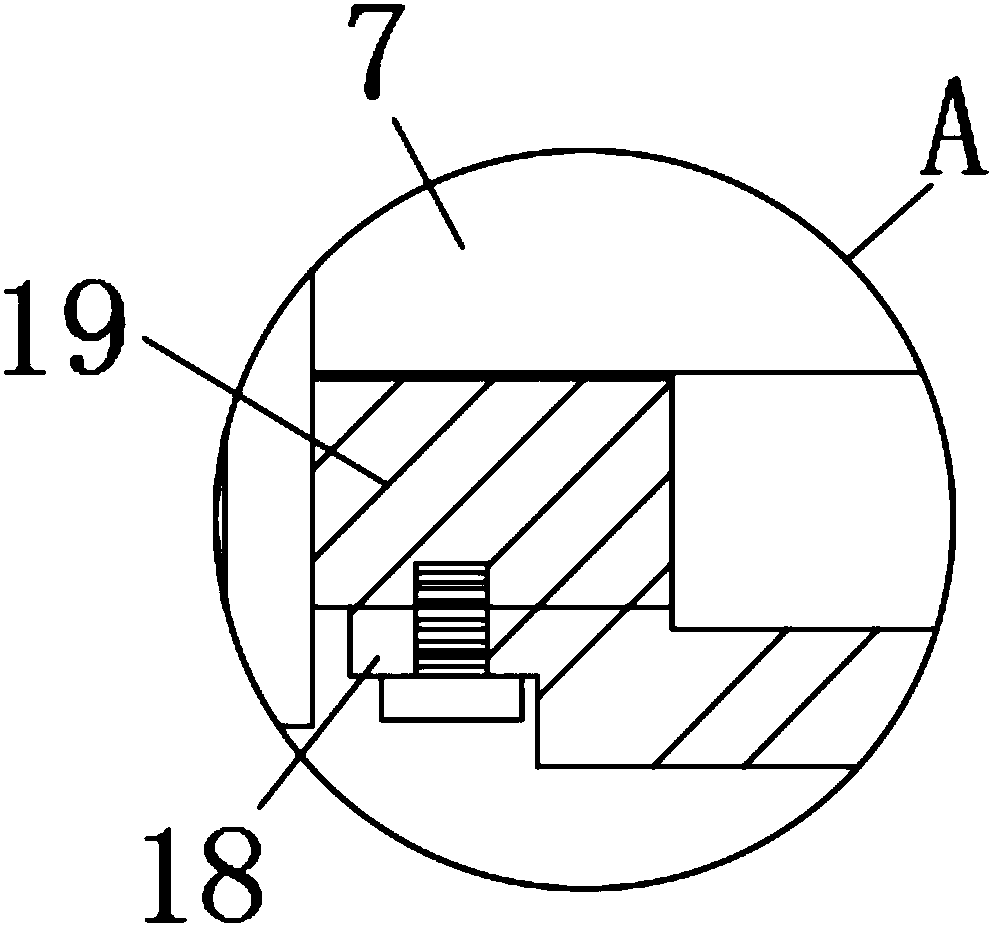

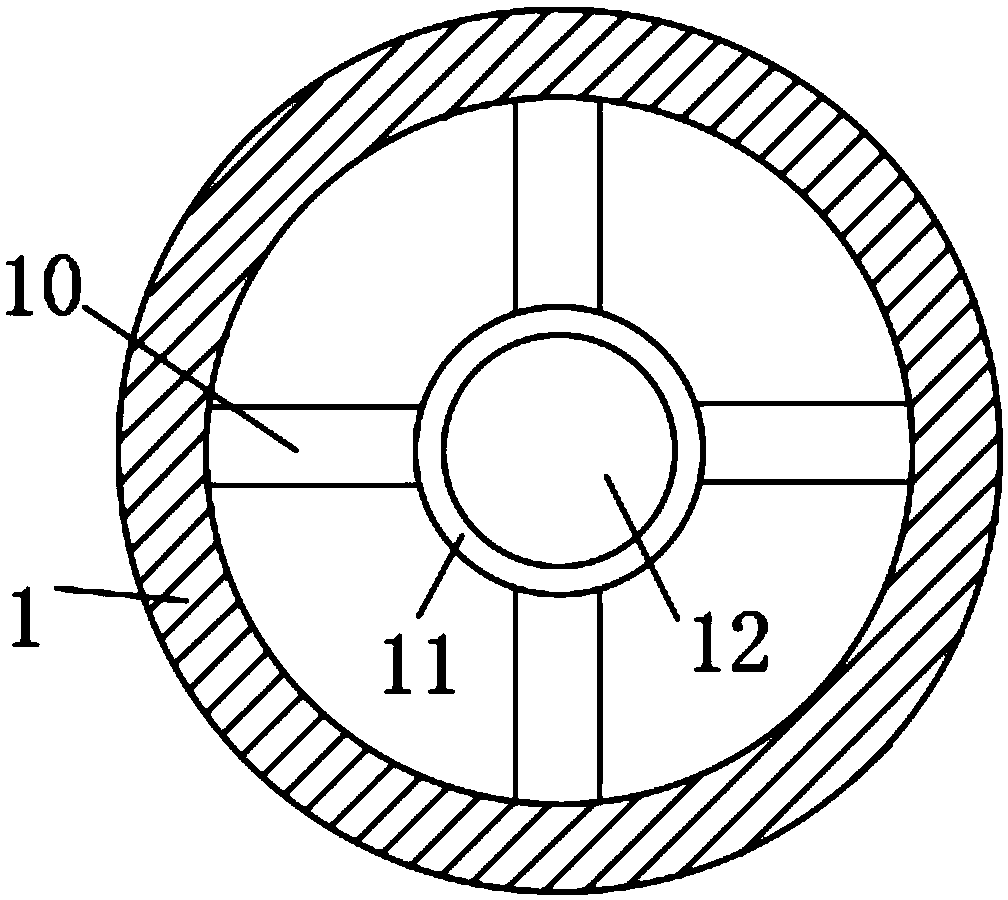

High-flowability polyethylene pipe fitting molding extrusion equipment

The invention provides high-flowability polyethylene pipe fitting molding extrusion equipment which comprises an extruder shell. Multiple sets of heating plates are arranged in a vacuum cavity. A clamp plate is fixedly mounted in a through hole through a bolt. The left side end of a spiral blade rod is movably inserted to the middle of the surface of the clamp plate. A limiting disc is arranged onthe right side surfaces of four sets of supporting rods. A threaded hole is formed in the middle of the right side surface of the limiting disc. A core roller is cooperatively connected with the threaded hole through an external thread. A heating ring is mounted in an annular protruding ring. According to the high-flowability polyethylene pipe fitting molding extrusion equipment, by means of thecontinuous heating function of the heating plates, the flowability of a polyethylene dissolution material in a blanking opening can be guaranteed; by means of the function of the heating ring, the polyethylene dissolution material can smoothly enter an extrusion channel; the bolt is demounted down, and the spiral blade rod can be conveniently demounted from a conveying channel; the core roller isrotated so that the core roller can be conveniently demounted from the limiting disc, and cleaning of the spiral blade rod and the core roller is facilitated; and the efficiency of work of next time of an extruder can be guaranteed.

Owner:HUANGSHENG GRP CHONGQING PIPE IND

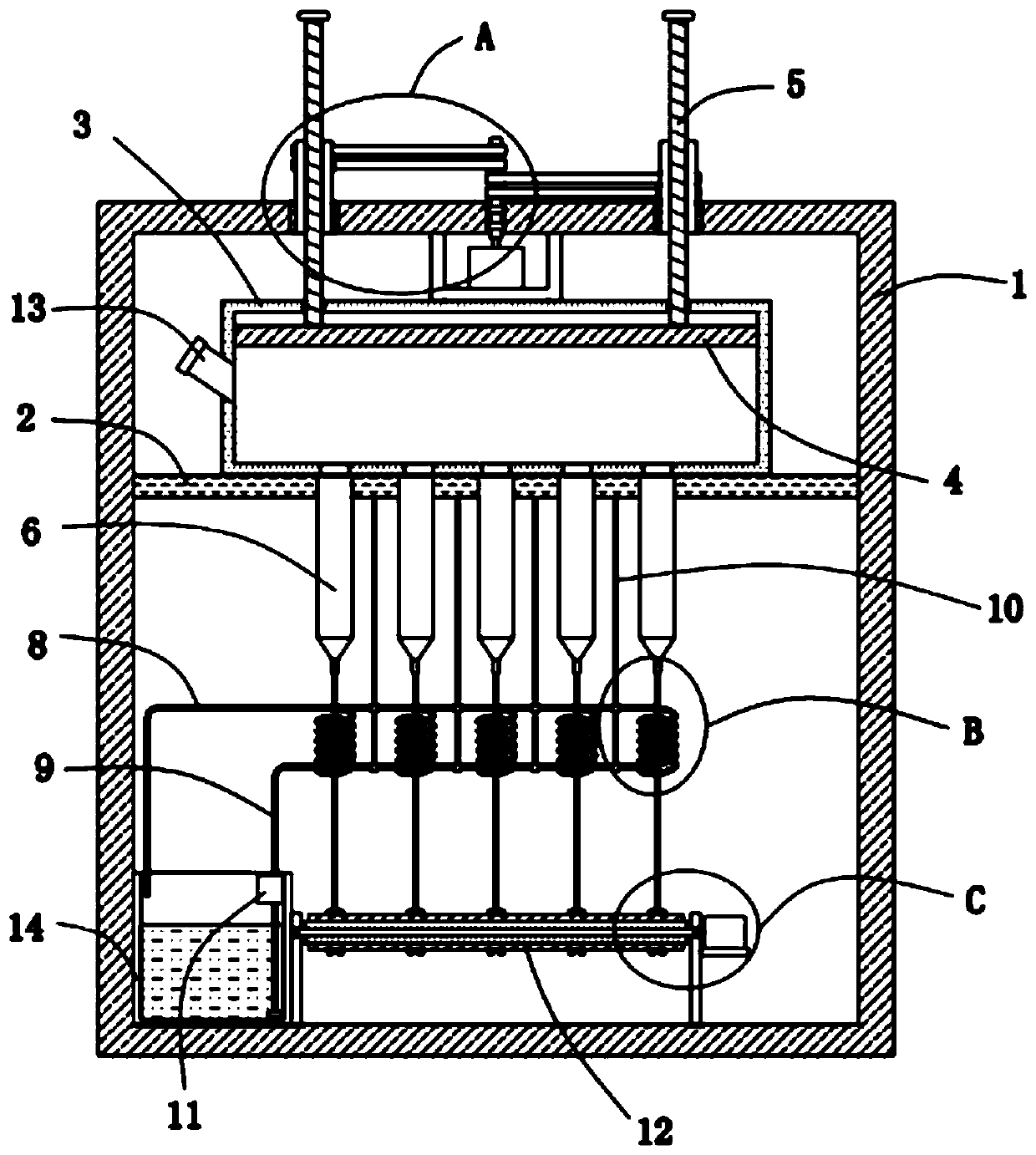

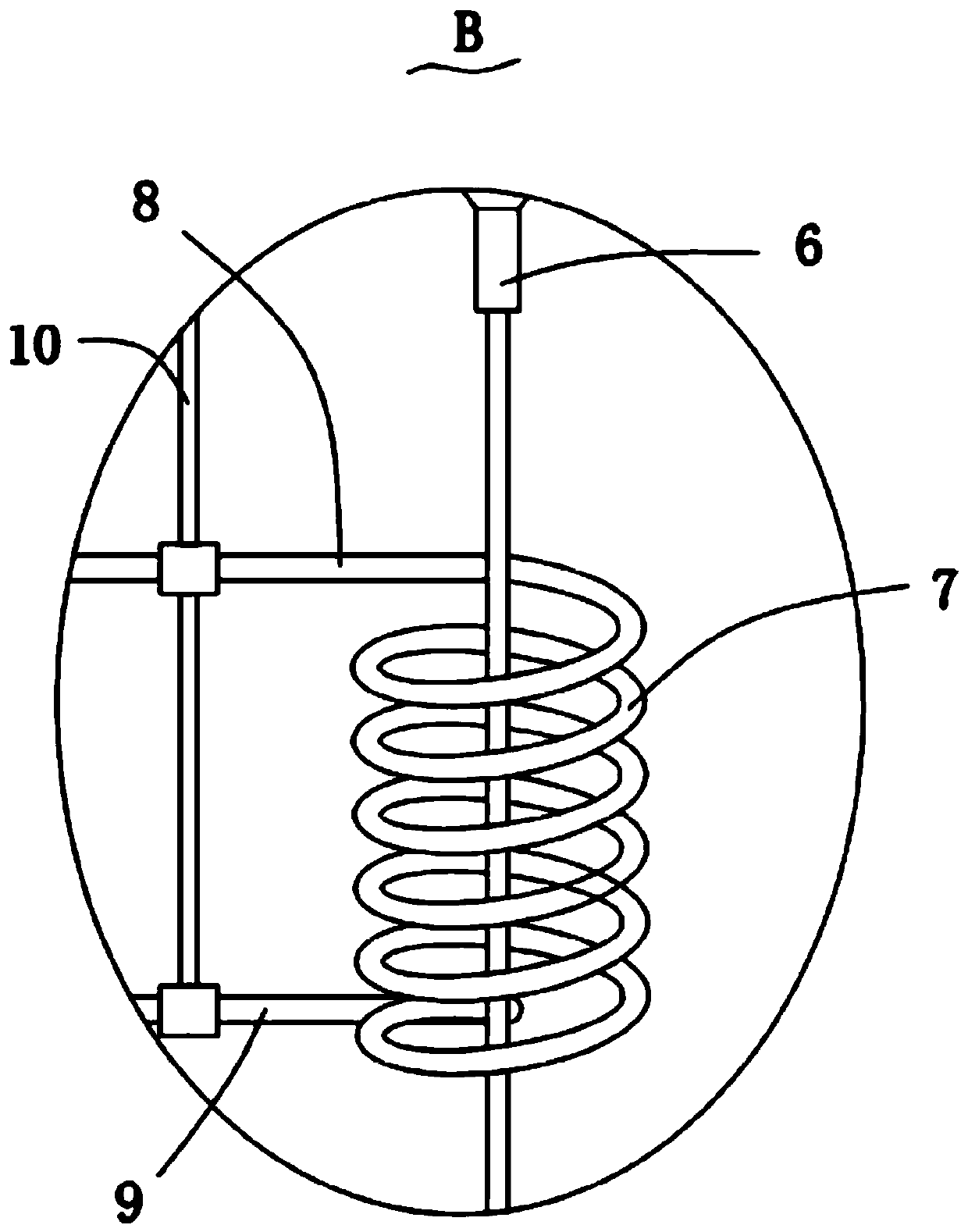

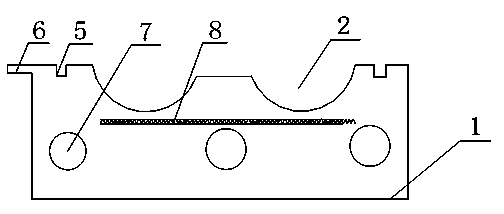

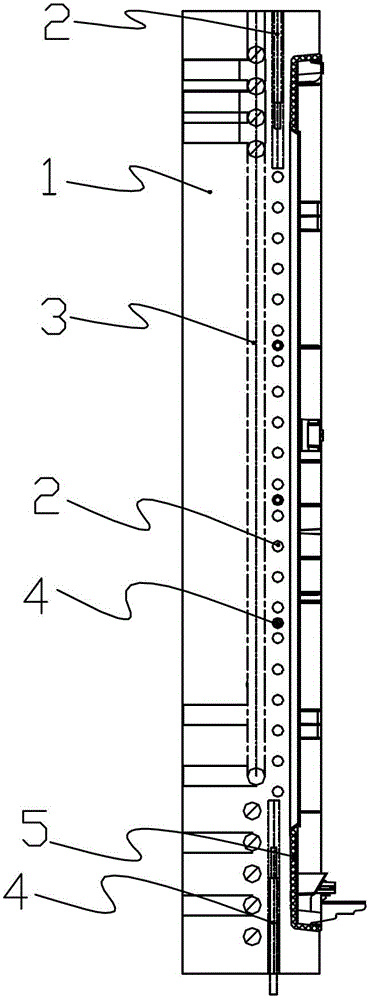

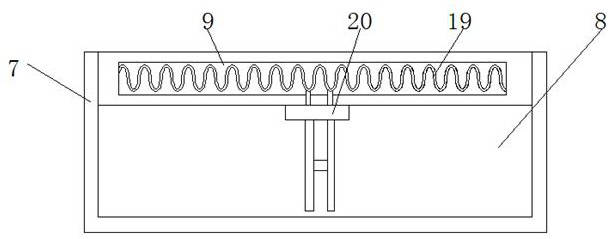

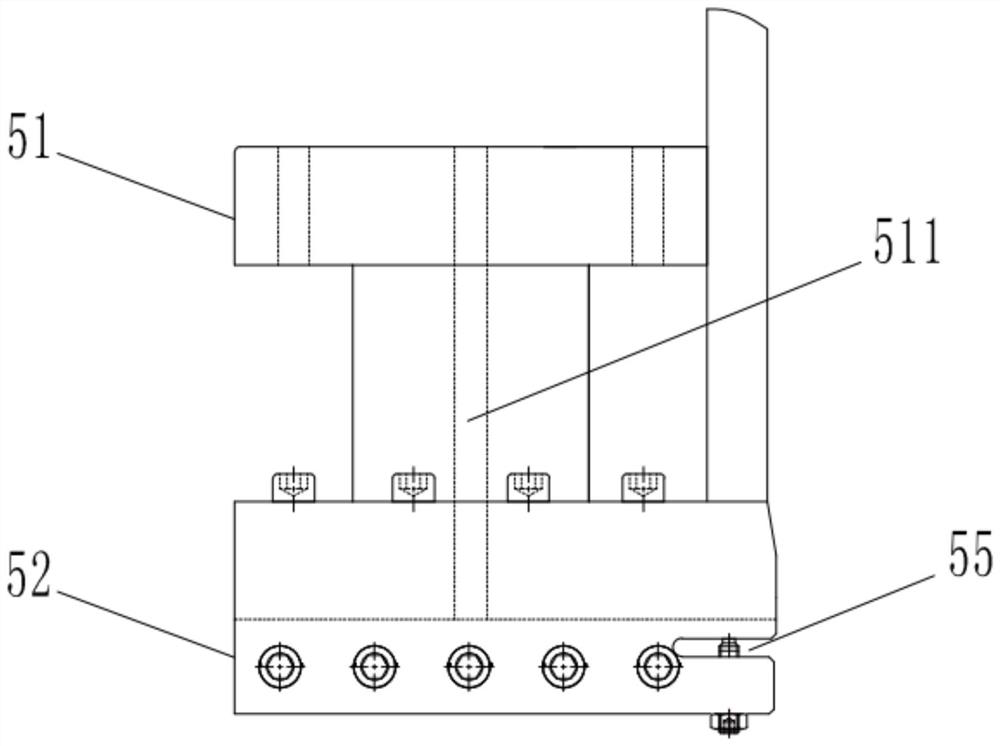

Chemical fiber spinning box and application method thereof

InactiveCN110747527AReduce the chance of injuryRapid cooling and settingArtificial thread manufacturing machinesYarnCooling coil

The invention provides a chemical fiber spinning box and an application method thereof. The chemical fiber spinning box comprises a support frame; a support plate fixedly mounted in the support frame;a heating box fixedly mounted at the top of the support plate; a push plate arranged in the heating box in a slidable and hermetic manner; a pushing mechanism mounted on the support frame and connected with the push plate; a plurality of yarn discharge pipes linearly arranged in the heating box; a plurality of cooling coils respectively positioned below the plurality of yarn discharge pipes; a liquid outgoing pipe connected with one ends of the cooling coils; and a liquid incoming pipe connected with the other ends of the cooling coils. The chemical fiber spinning box and the application method thereof have the advantages of good convenience of use, low cost and good setting effect.

Owner:福建新创锦纶实业有限公司

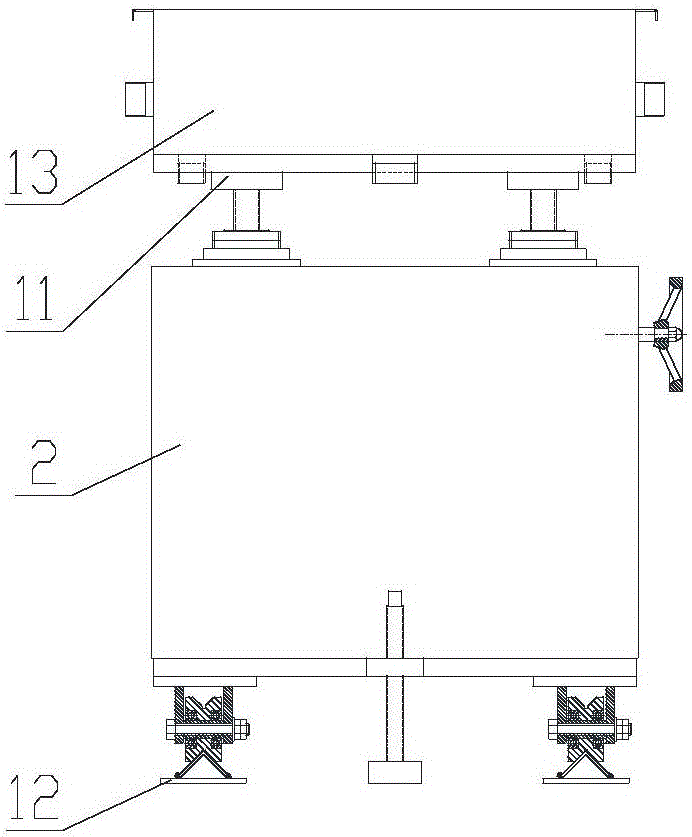

Cooling water tank

The invention discloses a cooling water tank, which comprises a chassis component, wherein the lower part of the chassis component is provided pulleys; the upper part of the chassis component is provided with height-adjustable up-down displacing devices; a water tank component, a water receiving case and an air-drying water receiving case are connected into a whole, and are mounted at the upper parts of the up-down displacing devices; the water tank component is provided with sliver roller components, water supply pipes and side water discharge components; the water receiving case and the air-drying water receiving case are both provided with water discharge interfaces; the air-drying water receiving case is also provided with a sliver roller component; a water storage box component is arranged inside the chassis component; a water inlet interface of the water storage box is connected with a water discharge interface; a water outlet interface of the water storage box component is connected with a water inlet interface of a water-cooled heat exchanger through a water pump; and a water outlet interface of the water-cooled heat exchanger is connected with the water supply pipes through a water system component. By using the cooling water tank which is provided by the invention, the water temperature and the water level of cooling water can be effectively controlled; the consumption of a clean water resource is a little; meanwhile, the walking distance, in the cooling water, of a material strip of a reinforced composite material can be also regulated; and the appearance quality of the material strip is guaranteed.

Owner:NANJING GIANT MACHINERY

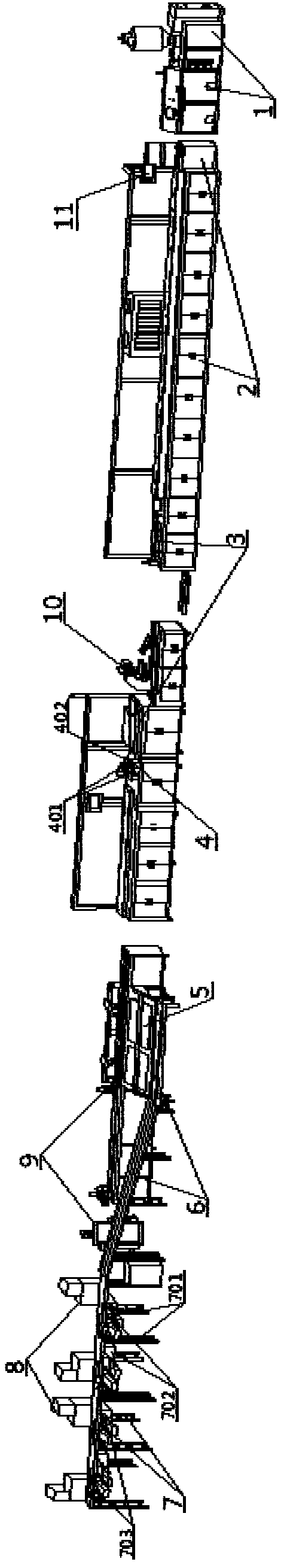

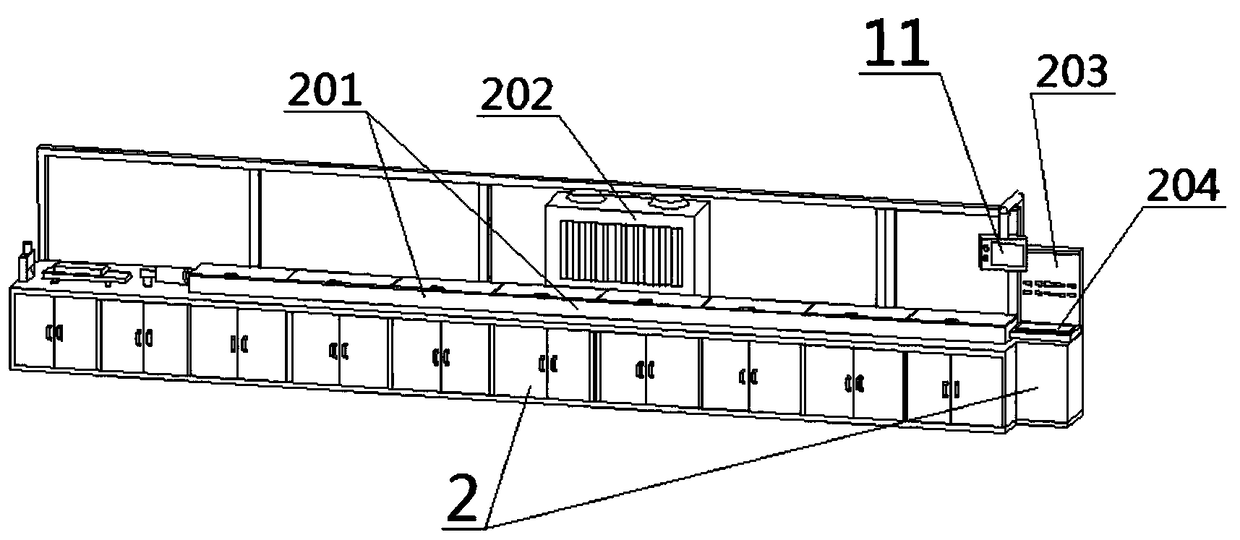

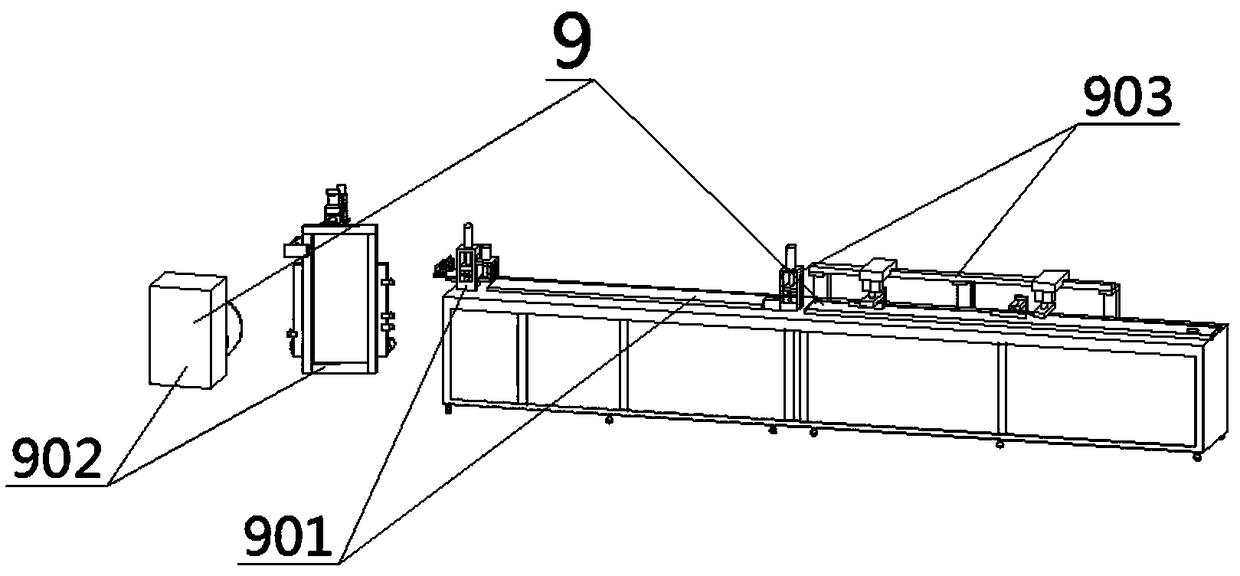

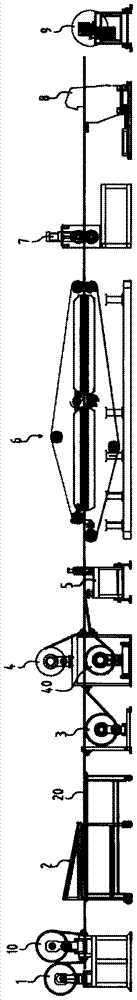

Production line of intelligent refrigerator door seal

InactiveCN108973156ARapid cooling and settingReduce CooldownDomestic cooling apparatusLighting and heating apparatusProduction lineEngineering

The invention discloses a production line of an intelligent refrigerator door seal. The production line is characterized by comprising an extrusion machine, a cooling device, a traction machine, a perforating machine, a cutting device, a magnet penetrating device, a slope guide drive device, a conveying belt, a distribution device, a welding device and a control device, wherein the perforating machine is arranged at the starting end of the production line; the cooling device, the traction device, the perforating machine, the cutting device and the magnet penetrating device are sequentially arranged at the left side of the extrusion machine; the slope guide drive device is arranged in front of the magnet penetrating device; one end of the conveying belt is connected with the slope guide device, and the other end of the conveying belt is connected with the distribution device; the welding device is arranged behind the distribution device; the control device is respectively connected withthe extrusion machine, the cooling device, the cutting device, the magnet penetrating device and the distribution device through wire bundles. The production line has the advantages that the multipleprocedures of extrusion, cooling, cutting, magnet penetrating, welding and the like are jointly completed in the production process of the door seal, so as to realize the whole intelligent unmanned production; the production efficiency is high, the continuity is good, the product quality is stable, and the production line is suitable for being popularized and applied in the production process ofthe refrigerator door seal.

Owner:ANHUI HIGASKET PLASTICS CO LTD

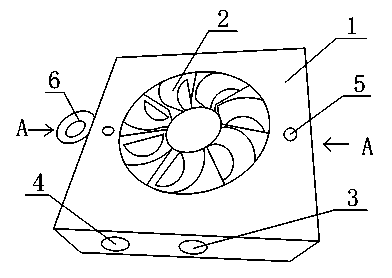

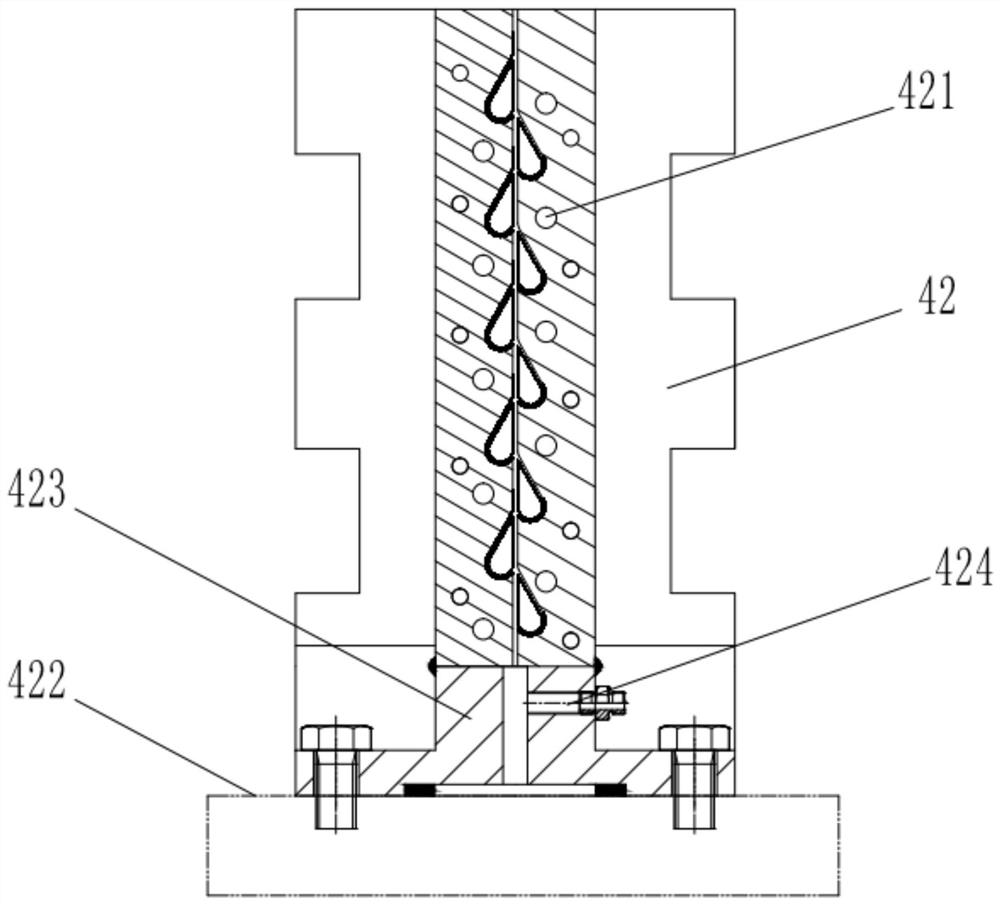

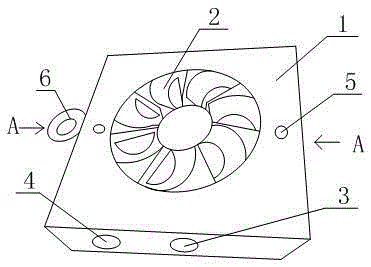

Forming mold for fan blades

InactiveCN103407078ARapid cooling and settingAccelerate cooling and setting speedWater flowCooling effect

The invention discloses a forming mold for fan blades, which comprises a mold female body and a mold male body matched with the mold female body, wherein injection molding grooves for the fan blades are formed in the mold female body; a cold water flowing channels are formed in the mold female body and below the injection molding grooves for the fan blades, and are positioned at the bottoms of the injection molding grooves for the fan blades; a heating module is arranged in the mold female body; a pull ring is fixed on the mold female body. The forming mold has the advantages that the fan blades subjected to injection molding are high in quality, and the mold has an excellent cooling effect, and can increase the forming rate of the fan blades.

Owner:成都万顺达模具零件有限公司

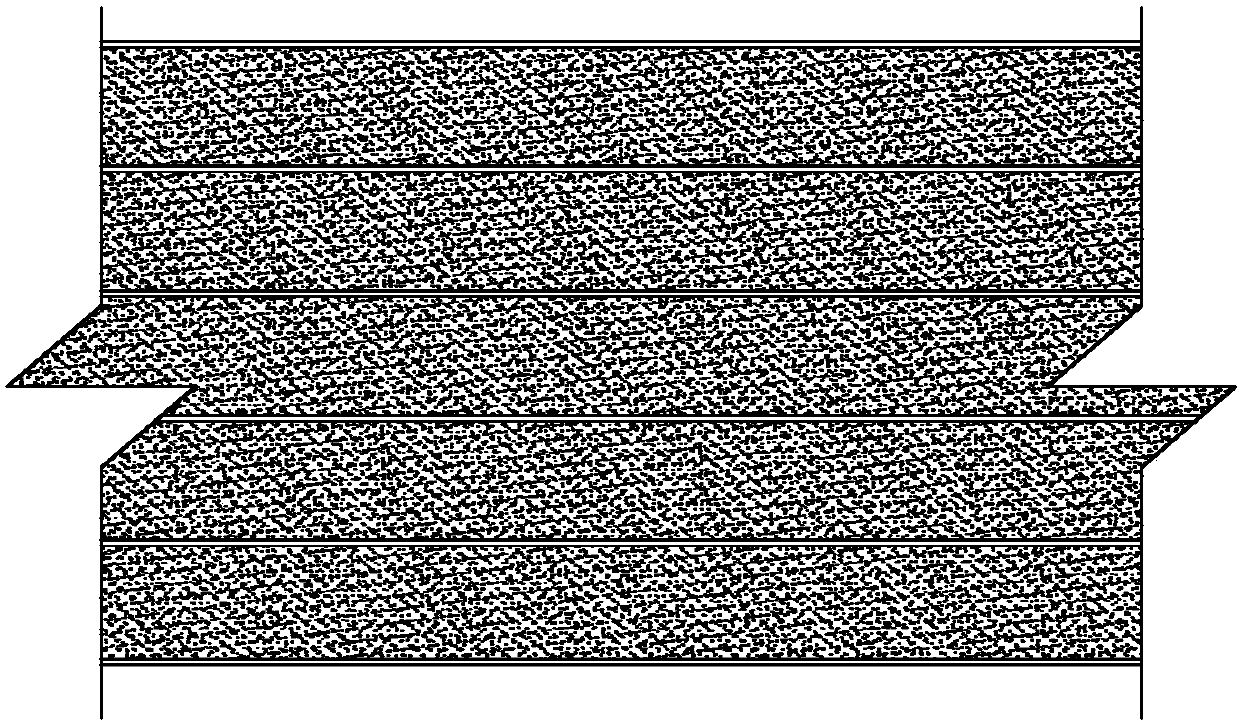

Manufacturing equipment for veneer-plastic composite floor

InactiveCN107662265ARealize continuous productionRapid cooling and settingLaminationLamination apparatusEngineeringPlastic film

The invention discloses manufacturing equipment for a veneer-plastic composite floor. The equipment aims at manufacturing the veneer-plastic composite floor. The equipment is provided with a veneer supply device, a plastic film supply device, a heating rolling device, a milling device, a rolling cold pressing device and a cutting device. The veneer supply device is provided with a veneer conveyingassembly, a veneer pretreating assembly and a coupling agent coating assembly which are connected in sequence. The heating rolling device is provided with an inlet end and an outlet end, the veneer supply device and the plastic film supply device are connected with the inlet end of the heating rolling device, the outlet end of the heating rolling device is connected with the milling device and then connected with the rolling cold pressing device, the cutting device is located at the front end or the rear end of the rolling cold pressing device, and the veneer supply device and the plastic film supply device are arranged in a spaced and staggered mode. The manufacturing equipment has the beneficial effects that layered laying of veneers and plastic films can be achieved, and continuous production of the veneer-plastic composite floor is achieved.

Owner:BEIJING FORESTRY UNIVERSITY

Quick cooling type production mould for pedal main body of sea farming net cage

InactiveCN106079358AAvoid deformationGuaranteed molding effectFlat articlesVacuum coolingVacuum pumping

The invention relates to the technical field of production moulds, in particular to a quick cooling type production mould for a pedal main body of a sea farming net cage. The quick cooling type production mould comprises an extrusion mould head, a vacuum cooling and molding mould and a vacuum molding water tank, which are sequentially connected. According to the quick cooling type production mould, an inner rib and an inner wall of the pedal main body are cooled by a metal air guide tube of the extrusion mould head, vacuum-pumping is carried out by utilizing a ring-shaped vacuum slot of the vacuum cooling and molding mould, and frozen water is injected to quickly cool and mould the outer wall of the pedal main body, and finally, continuous cooling and vacuum-pumping are carried out in the vacuum molding water tank for strengthening molding. According to the quick cooling type production mould, integral molding and cooling speed of a pedal is increased, production efficiency is improved, and dimension and performance of the pedal main body are guaranteed to meet standard requirements.

Owner:HESHAN LESSO IND DEV

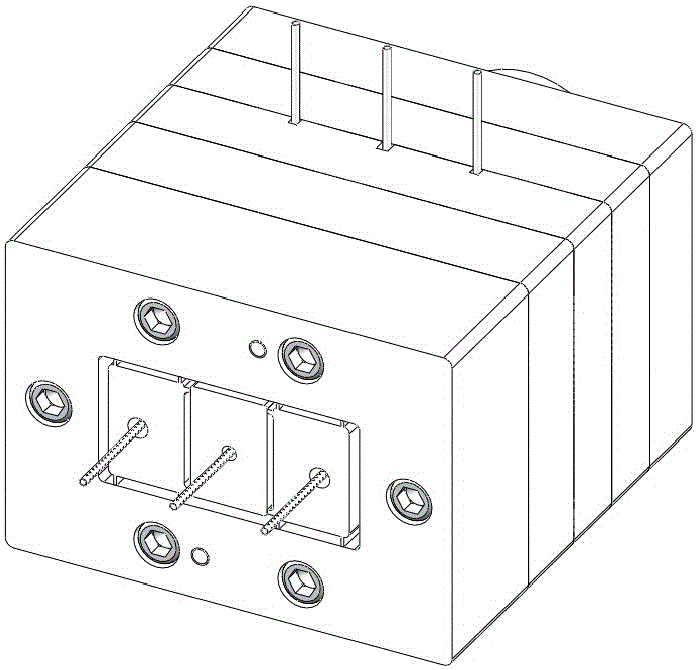

Highlight die and temperature control system thereof

InactiveCN102744844AThe mold structure is compactReduce mechanical action linksElectric heatingCooling channel

The invention discloses a highlight die and a temperature control system thereof, wherein the highlight die comprises a movable die, a fixed die or a cavity plate; an electric heating rod, a thermoelectric couple and a cooling channel are arranged on the fixed die or the cavity plate; the temperature control system comprises an electric heating control sub-system, a circulation water cooling sub-system and a compression air sub-system; the electric heating control sub-system is connected with the electric heating rod and the thermoelectric couple on the highlight die and is used for heating and controlling the temperature of the die; the circulation water cooling sub-system and the compression air sub-system are connected with the cooling channel on the highlight die to form a cooling loop for cooling the die; a 1# electromagnetic valve is arranged on a water supply pipeline of the circulation water cooling sub-system; a 2# electromagnetic valve is arranged on an air supply pipeline of the compression air sub-system; and various electromagnetic valves are connected with the electric heating control sub-system and are used for switching cooling water and compression air leaded to the die cooling channel. The highlight die and the temperature control system thereof disclosed by the invention have the characteristics of being convenient for use, short in forming period, high in production efficiency, energy-saving and the like.

Owner:QINGDAO HISENSE MOLD

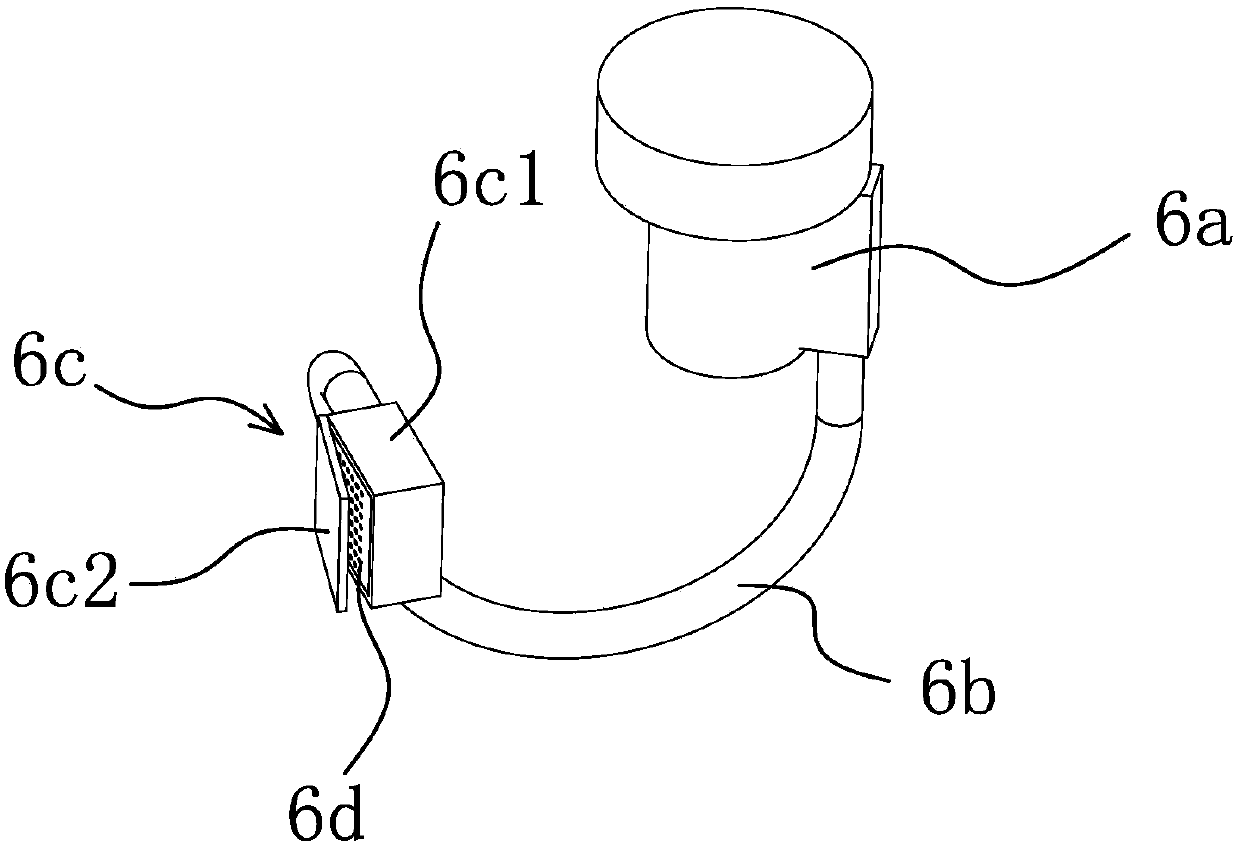

Novel 3D printing equipment

InactiveCN111660561AEfficient use ofRapid coolingAdditive manufacturing apparatusSpace heating and ventilation detailsCold airCooling chamber

The invention provides novel 3D printing equipment. The 3D printing equipment comprises a case, a printing chamber is formed in the case, a cross shaft is connected into the printing chamber, an installation seat is arranged on the surface of the cross shaft, a lifting device is installed at the bottom of the installation seat, a printing head is installed at the bottom of the lifting device, a printing table is installed in the printing chamber, a water tank is installed in the printing table, a temperature reduction chamber is formed in the printing table, and a cooling chamber is formed between the outer side of the printing chamber and the inner wall of the case. According to the novel 3D printing equipment, a refrigeration loop is formed by a compressor, a condenser, a capillary tube,a drying filter and an evaporator, sufficient cold air can be provided, under the action of a circulating fan, the cold air can be circulated among air outlets, the printing chamber, the cooling chamber and a return air port, the cold air can be effectively utilized, the cold air is blown out through multiple air outlets, cooling is uniform and quick, and the printing efficiency is improved.

Owner:陈金杰

Heat dissipation mechanism of automatic bottom sealing machine for quartz glass sleeves

PendingCN112179044ARapid cooling and settingReduce the temperatureMachines using electric/magnetic effectsGlass reforming apparatusCold airThermodynamics

The invention discloses a heat dissipation mechanism of an automatic bottom sealing machine for quartz glass sleeves. The heat dissipation mechanism comprises a bottom sealing machine body, wherein driving seats are symmetrically connected to the bottom sealing machine body in a sliding manner, a fixed seat is fixedly connected to the bottom sealing machine body, a flamethrower is arranged on thefixed seat, a first cavity and a second cavity are respectively formed in the bottom sealing machine body, semiconductor chilling plates are symmetrically and fixedly installed on the bottom wall of the first cavity, heat conduction mechanisms are arranged on the bottom sides of the semiconductor chilling plates, and a double-shaft motor is fixedly installed in the bottom sealing machine body. According to the heat dissipation mechanism, a first output shaft is driven by the double-shaft motor to rotate quickly, so that a fan rotates to blow air, meanwhile, the temperature of air in the firstcavity is reduced quickly under the action of the semiconductor chilling plates, cold air flow dried by a drying plate is blown out through the fan, a glass pipeline with the bottom sealed is cooled and shaped quickly, and the heat dissipation effect is better.

Owner:连云港汇德石英玻璃有限公司

Thick glass cup forming mechanism

The invention discloses a thick glass cup forming mechanism in the technical field of glassware production and manufacturing, and the thick glass cup forming mechanism comprises a forming machine body, the top of the forming machine body is fixedly provided with a material containing mechanism, the material containing mechanism comprises a feeding mechanism and an ejection mechanism, and the top of the material containing mechanism is rotatably provided with a material containing disc; the top of the material containing disc is fixedly provided with four lower die bases distributed in a circle, the top of the forming machine body is fixedly provided with a hydraulic rod, the bottom end of the hydraulic rod is fixedly provided with a connecting plate, the connecting plate is located over the material containing disc, and the bottom of the connecting plate is fixedly provided with a cooling cylinder and a pressing die core. In the process of pressing and forming a glass blank, a formed glass cup can be cooled, so that the glass cup can be quickly cooled and formed, the glass cup and a pressing mold can be quickly separated, workers can conveniently unload the glass cup, the glass blank can be continuously pressed and formed at a time, and a secondary processing process is avoided.

Owner:南通明艺玻璃科技有限公司

Sheet metal part welding tool with cooling device

InactiveCN112139710AImprove work efficiencyImproved soldering resultsWelding/cutting auxillary devicesAuxillary welding devicesSpray nozzleEngineering

The invention discloses a sheet metal part welding tool with a cooling device, and relates to the technical field of sheet metal part machining. The sheet metal part welding tool comprises a supporting frame assembly. A work frame assembly is arranged at the upper end of the supporting frame assembly. A fixed base assembly is arranged on one side of the upper end of the work frame assembly. A movable base assembly is arranged on the other side of the upper end of the work frame assembly. A water collecting assembly is arranged at the position, under the work frame assembly, inside the supporting frame assembly. A filtering assembly is arranged at the upper end of the water collecting assembly. The supporting frame assembly comprises a fixed base, a fixed supporting frame is fixedly installed at the upper end of the fixed base, and an installation frame is fixedly installed at the upper end of the fixed supporting frame. By means of the sheet metal part welding tool, the two welding endfaces of a sheet metal part can be subjected to welding processing conveniently, the sheet metal part welding tool can meet the requirements of different welding working conditions of the sheet metalpart, water is sprayed to the welding end face of the sheet metal part through spray nozzles, rapid cooling and shaping of the welding end face are promoted, the sheet metal part welding working efficiency is improved, and the improvement of the sheet metal part welding processing effect is facilitated.

Owner:马鞍山金瓦格机械科技有限公司

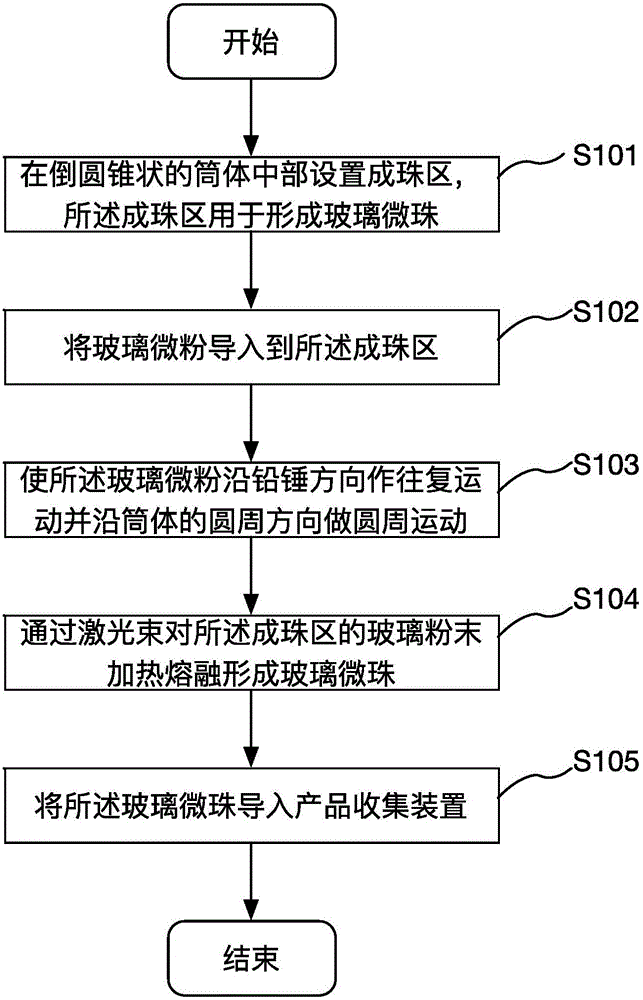

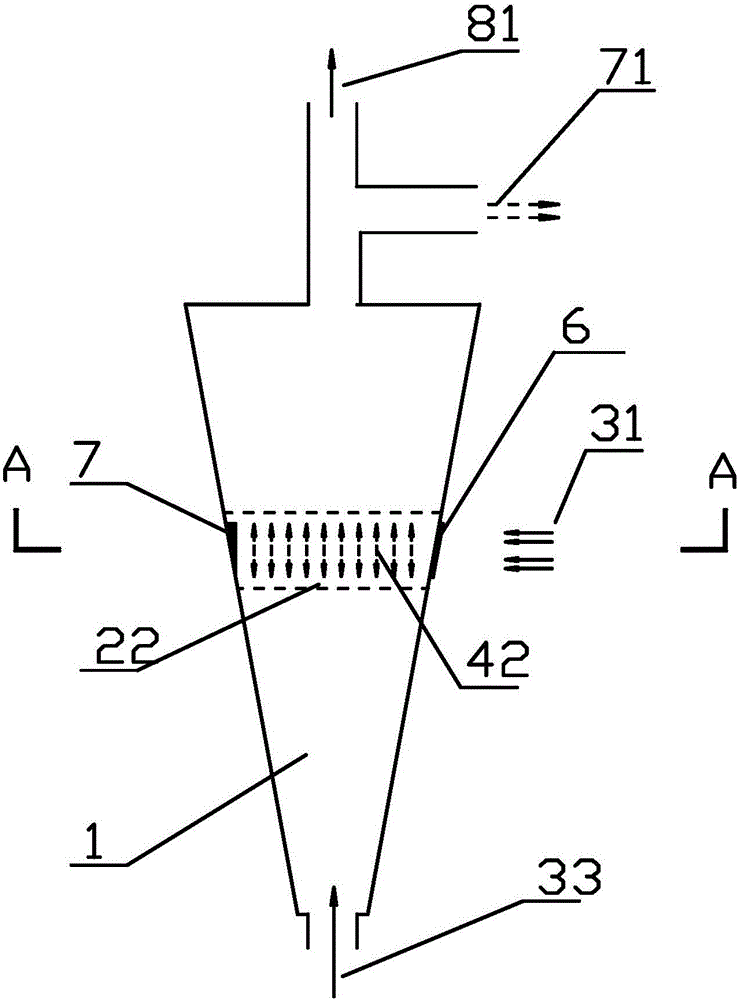

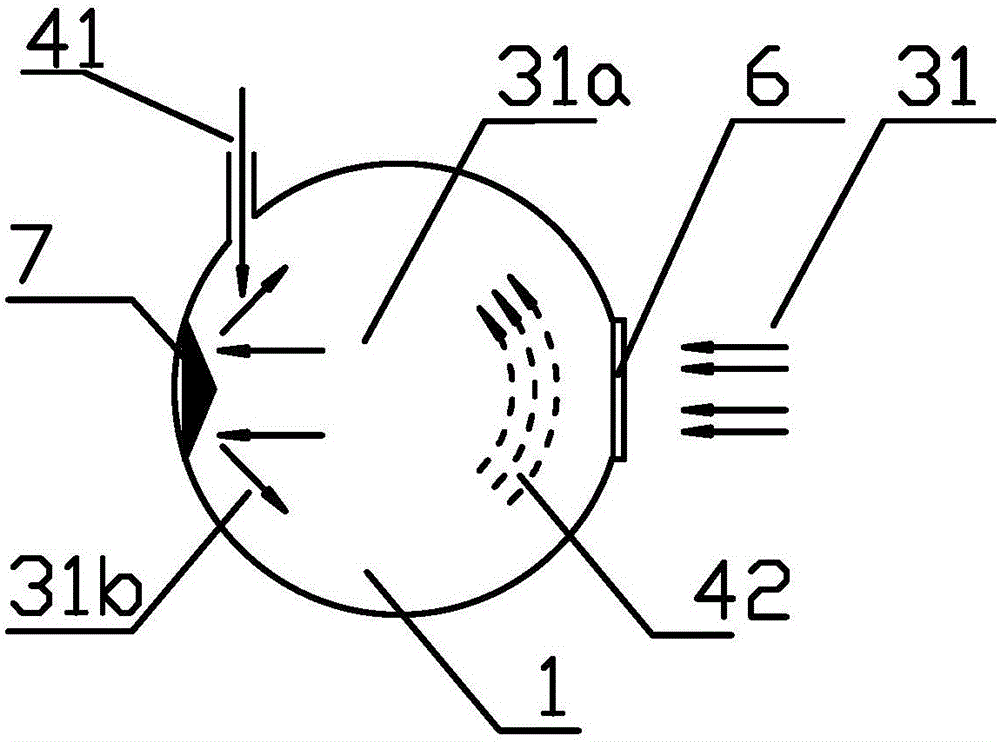

Production method for glass micro-beads and apparatus for same

ActiveCN105906191AEven heating and meltingFully heated and meltedGlass shaping apparatusGlass productionMetallurgyAir blower

The invention discloses a production method for glass micro-beads and an apparatus for same. The production method includes the steps of: a) arranging a bead forming area in the middle of an inverted conical cylinder body; b) feeding glass micro-powder to the bead forming area; c) enabling the glass micro-powder to move in a circulated reciprocating manner in the bead forming area; d) heating the glass micro-powder with laser to melt the powder to form the glass micro-beads; and e) feeding the glass micro-beads into a product collection apparatus. The apparatus includes the cylinder body, a three-way pipe communicated with the top of the cylinder body, a laser device, a side air blower and a material feeder which are arranged at one side of the cylinder body, a laser incident port, a laser reflecting mirror, a side air inlet and a material inlet which are arranged on a side wall of the cylinder body, and a valve board arranged in the three-way pipe. In the invention, the glass micro-powder is irradiated by laser beam, so that the glass micro-powder is heated and melted quickly, uniformly and completely to form the glass micro-beads which are then quickly cooled and shaped, thereby avoiding a problem of agglomeration and wall adhesion. The method and the apparatus save energy and improve yield rate.

Owner:CHINA TRIUMPH INT ENG

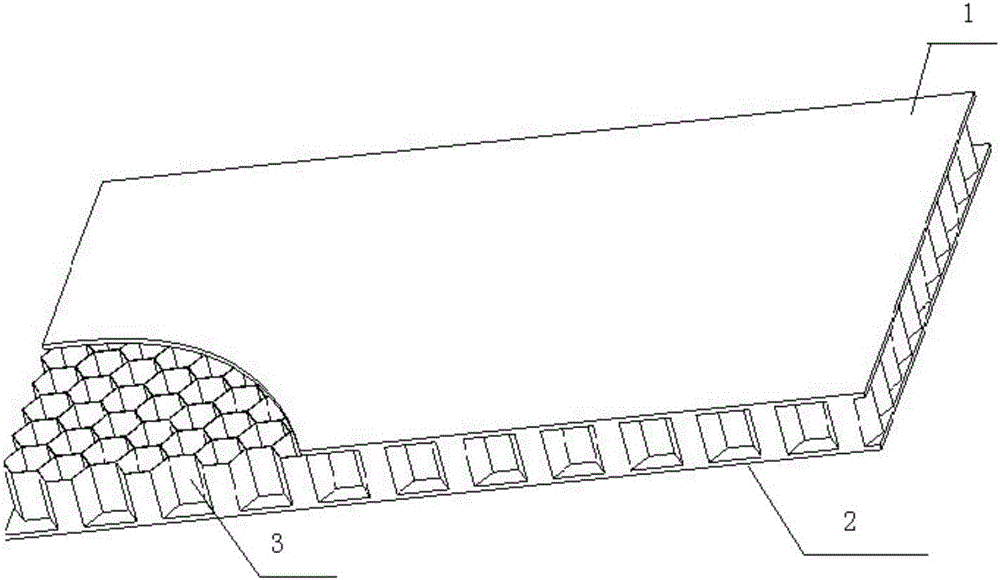

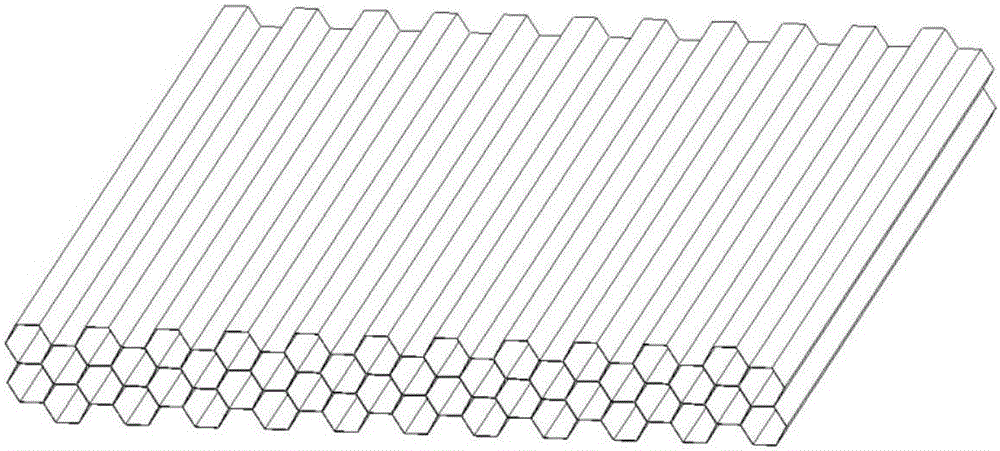

Production method for plastic cellular board

ActiveCN106113538AIncrease productivityAvoid bondingHollow wall articlesCELLULAR SHEETCeramic materials

The invention discloses a production method for a plastic cellular board. The production method includes the following steps that firstly, a plastic cellular core raw material is extruded through an extrusion die of an extruder; secondly, the plastic cellular core raw material is cooled and shaped; thirdly, the outer wall of the plastic cellular core raw material is pressed, so that the plastic cellular core raw material is pressed into a plastic cellular piece; fourthly, the plastic cellular piece is cut in a fixed-length mode, so that a series of plastic cellular strips are formed; fifthly, the upper surface of the i plastic cellular strip and the lower surface of the (i+1) plastic cellular strip are bonded, or the lower surface of the i plastic cellular strip and the upper surface of the (i+1) plastic cellular strip are bonded, so that a plastic cellular core block is formed through bonding, wherein i is a natural number; sixthly, the plastic cellular core block is stretched to form a plastic cellular core; and seventhly, an upper panel and a lower panel are bonded to the plastic cellular core, so that the plastic cellular board is formed.

Owner:TIANJIN UNIV OF SCI & TECH

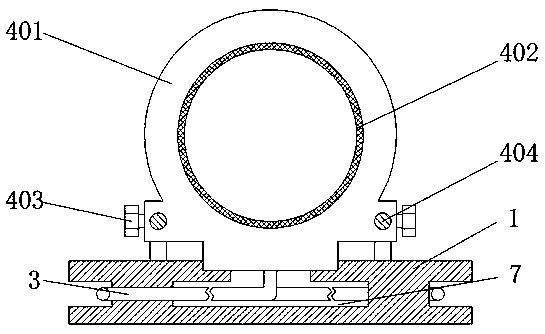

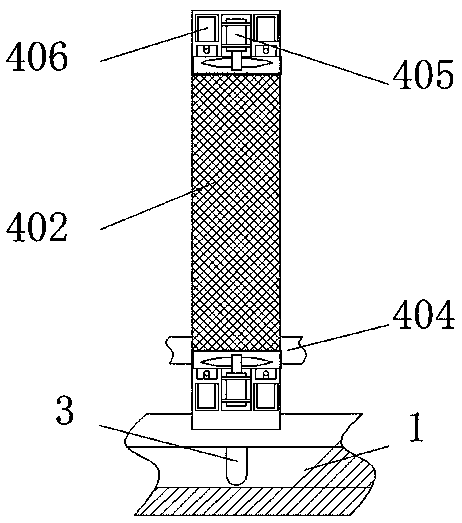

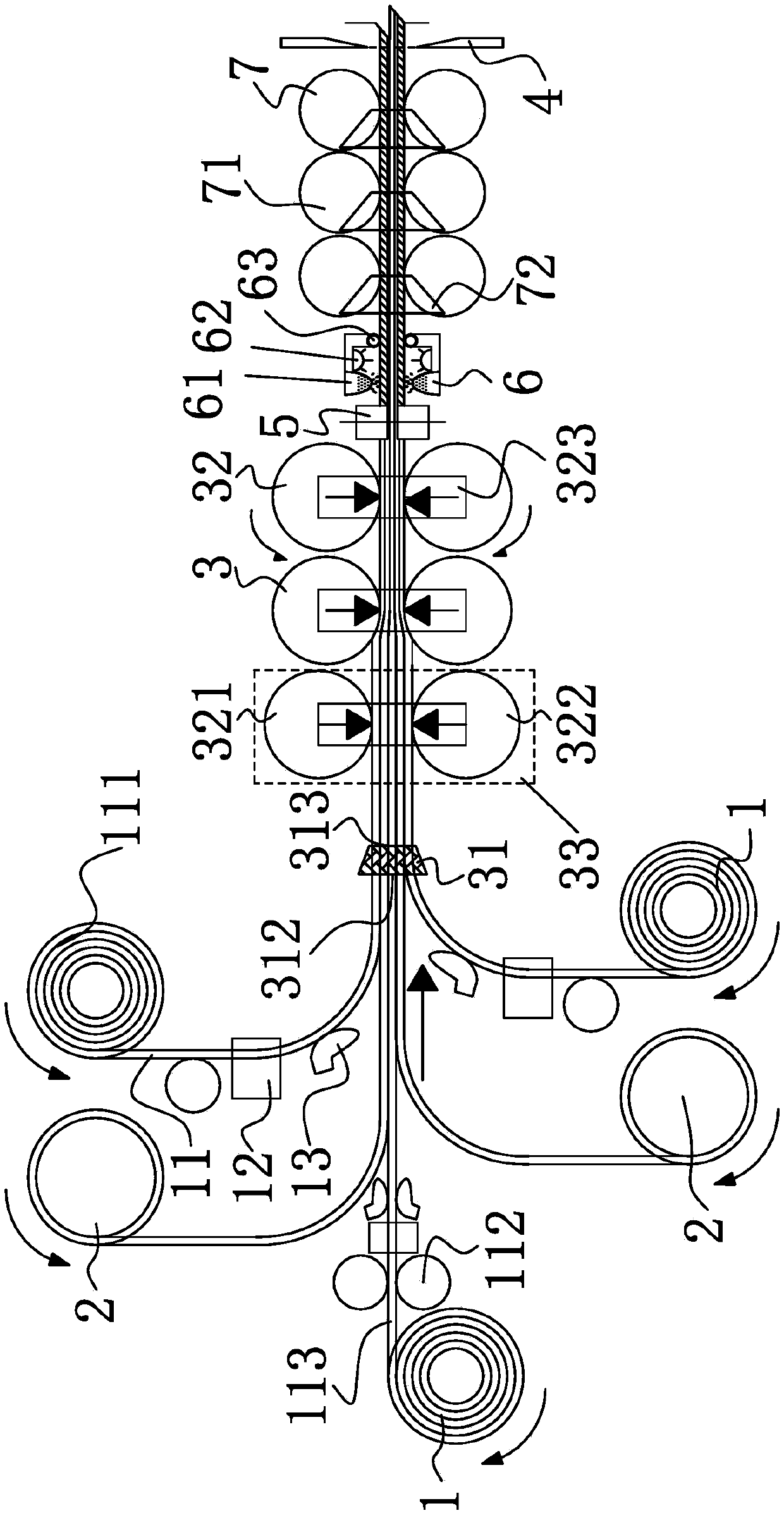

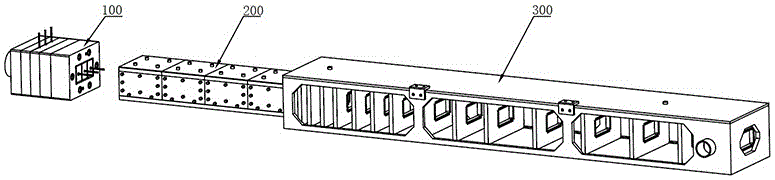

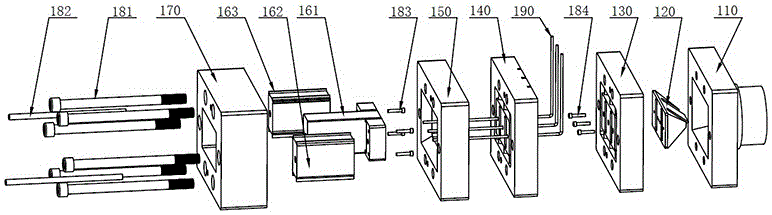

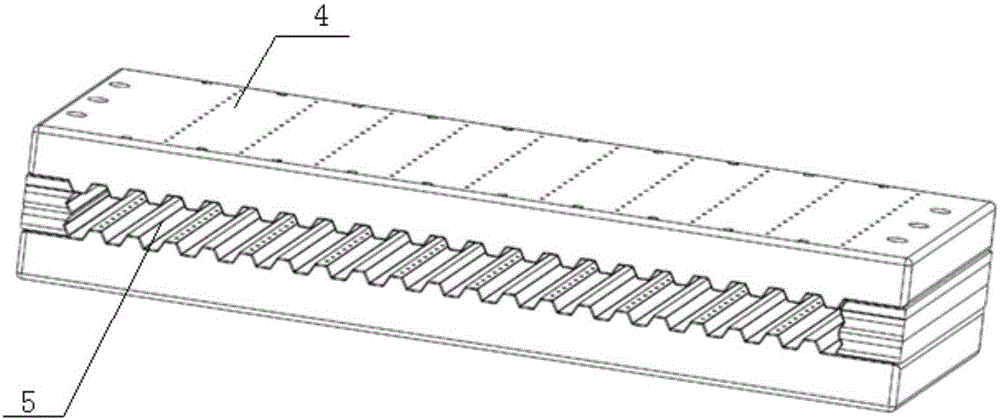

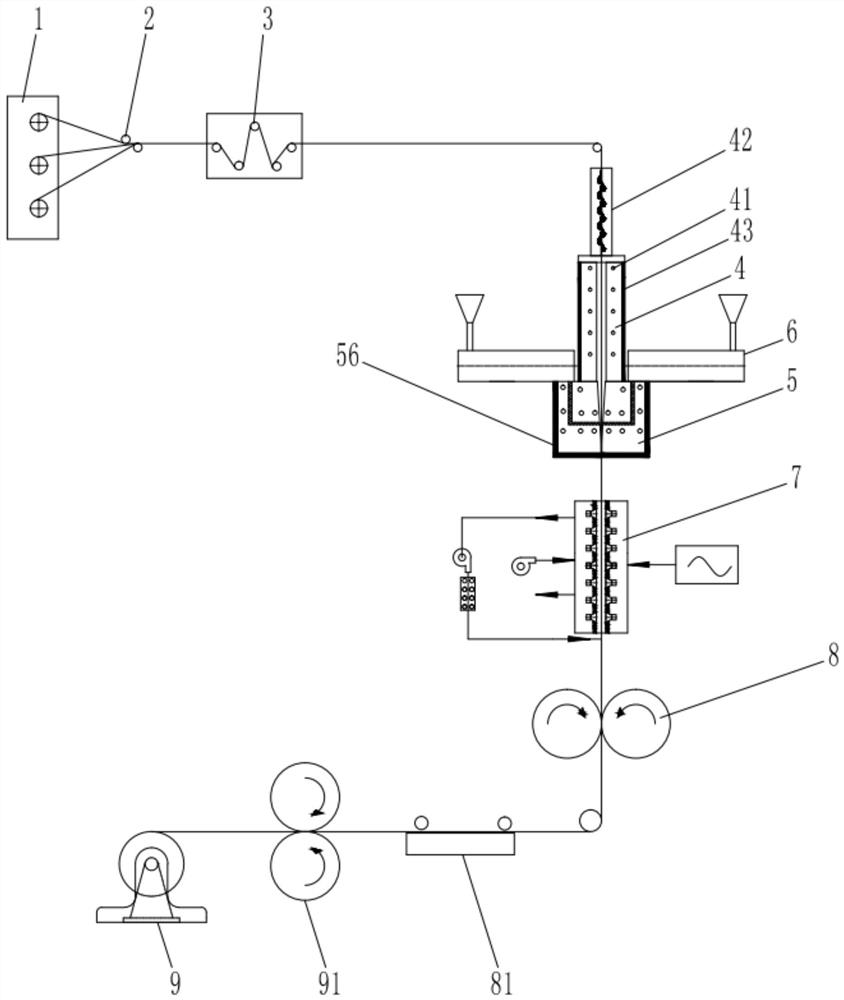

High-frequency vibration continuous fiber prepreg production device

The invention discloses a high-frequency vibration continuous fiber prepreg production device, relates to the technical field of continuous fiber prepreg production, and is mainly used for solving the problem that prepregs are difficult to soak in methods or equipment adopted for continuous fiber prepreg production at present. The primary structure of the device is that the device comprises a creel, a guide roller group, a yarn spreading roller group, a drying oven, an extrusion forming mold group, an ultrasonic impregnation module group, an extrusion roller group, a cooling platform, a pull roll group and a winding mechanism which are arranged in sequence. According to the high-frequency vibration continuous fiber prepreg production device provided by the invention, continuous fibers before being coated with resin are vacuumed through a negative pressure vacuum channel, and ultrasonic vibration is applied to the continuous fibers coated with the resin through ultrasonic impregnation modules, so that the fibers can be fully infiltrated by the resin.

Owner:四川兴宇航科技有限公司

Chocolate ball auto-forming production apparatus

InactiveCN105746823AIncrease production speedSmooth horizontal roll-off outputCocoaEngineeringSlurry

The invention provides a chocolate ball auto-forming production apparatus, comprising a forming module, an injecting head and a discharging module.The forming module is provided with a vertical circular air cavity, a vertical cylindrical-cavity feeding passage is designed in the middle of the air cavity, a circular wall of the feeding passage is distributed air holes in communication with the air cavity, the injecting head injects molten spherical chocolate slurry into the feeding passage, the discharging module is in the shape of an arc tube, the discharging module is provided with a vertical inlet end and a horizontal outlet end, the upper inlet end of the discharging module is connected to a lower outlet of the feeding passage in the forming module, and an outlet end of the discharging module is connected with chocolate packaging equipment.The chocolate ball auto-forming production apparatus has greatly increased production speed of chocolate, and roundness of chocolate spheres is improved greatly.

Owner:SUZHOU HONGQIRUI AUTOMATION

Cloth sponge compounding machine

ActiveCN107672276AAvoid crimping againImprove flatnessLamination ancillary operationsLaminationEngineeringMechanical engineering

The present invention provides a cloth sponge compounding machine, belongs to the technical field of machinery, and solves the problems that folds and turned edges are easy to produce when cloth and sponge are compounded in the prior art. The cloth sponge compounding machine comprises a frame, a cloth feeding device is arranged above the front end of the frame, a thermal compounding device is arranged at the back of the cloth feeding device, each of the two sides of the frame is provided with an anti-curling device, each anti-curling device is located between the cloth feeding device and the thermal compounding device, each anti-curling device comprises a fan I, a venting tube and an air-out component, the air-out component is in communication with the fan I through the venting tube, the air-out component is arranged at a position near the edge of a cloth feeding path on the frame, and the air-out component is provided with an air outlet facing the edge of the cloth feeding path. By use of the cloth sponge compounding machine, the edge of a compounded cloth finished product is neat and regular, and processing efficiency is high.

Owner:HIGHER TECH CO LTD

Tableting device for manufacturing supercapacitor pole piece

ActiveCN108922797AEasy to useEffective isolationCapacitor manufactureHybrid/EDL manufactureSupercapacitorEngineering

The invention discloses a tableting device for manufacturing a supercapacitor pole piece, which comprises a support rod and a collecting box, wherein a casing is mounted above the support rod; an anti-corrosion layer is arranged on the outer side of the casing; a feed port is mounted on the left side of the casing; a conveyor belt is arranged above a collection box; and an adjusting block is arranged above the conveyor belt. According to the tableting device for manufacturing a supercapacitor pole piece in the invention, a collection box, a conveyor belt, an adjusting block, a moving block, ahydraulic plate, a hairbrush and a groove are arranged; a processing material can be put on the conveyor belt when being used by a user; the conveyor belt can transmit the processing material automatically; when the user feeds the material, the adjusting block can adjust the pole piece, thereby bringing convenience for pressing on the later state; the hairbrush can clean impurities on the pole piece; after the pole piece is transmitted through the conveyor belt and processed, a fan is turned on; the fan can transmit the temperature of a refrigeration sheet to the processed pole piece so that the pole piece can be quickly cooled and shaped; and the working efficiency of the device is improved.

Owner:湖南耐普恩节能技术有限公司

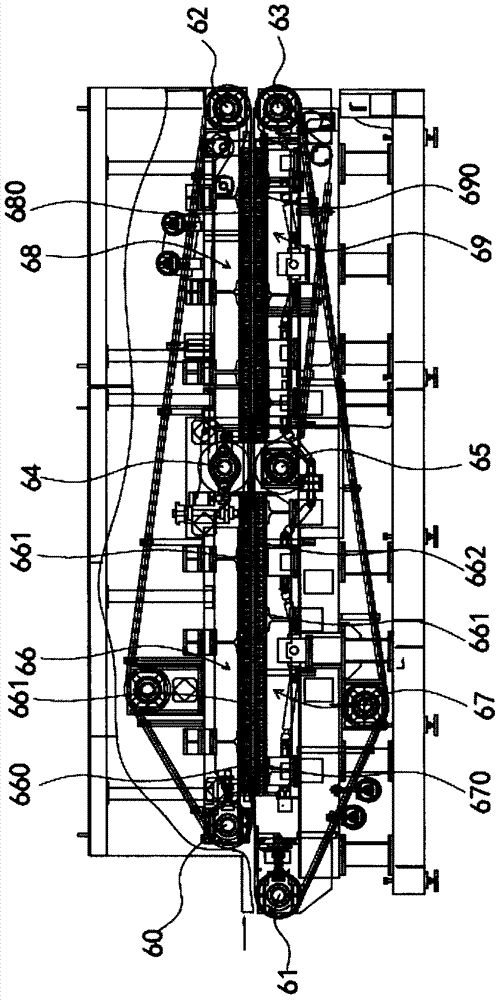

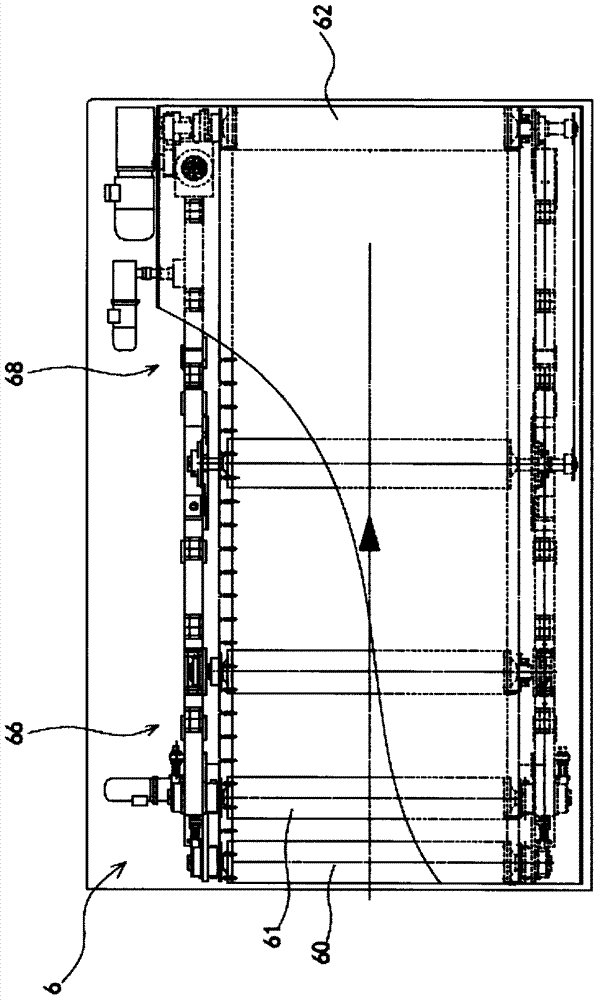

A continuous fiber plane hot-press composite equipment

ActiveCN105751663BImprove yieldReduce power consumptionLaminationLamination apparatusFiberEngineering

The invention discloses a continuous fiber plane hot-pressing compound device.The continuous fiber plane hot-pressing compound device comprises a combined unreeling machine, a transverse feeder, a high-low unreeling machine, a roll-in compound machine, a traction cutting machine, a transverse trimming machine and a reeling machine, all of which are sequentially connected.The operating direction of a composite material serves as reference, an upper heating region is arranged in the region, between an upper inlet roller and an upper pressure roller, of the roll-in compound machine, and an upper cooling region is arranged in the region, between the upper pressure roller and an upper outlet roller, of the roll-in compound machine.A lower heating region is arranged in the region between a lower inlet roller and a lower pressure roller, a lower cooling region is arranged in the region between the lower pressure roller and a lower outlet roller, heating bodies are arranged in the heating regions, and cooling bodies are arranged in the cooling regions.The continuous fiber plane hot-pressing compound device is reasonable in structural arrangement, good in reliability, high in yield and better in compound effect, by means of the assembly line arrangement, the working efficiency of the hot-pressing compound device is greatly improved, the device is suitable for high-strength continuous fiber plant hot-pressing compound operation, and operation of the mechanical device is simple and user-friendly.

Owner:常州贝弗勒机械有限公司

Cooling tank

The invention discloses a cooling water tank, which comprises a chassis component, wherein the lower part of the chassis component is provided pulleys; the upper part of the chassis component is provided with height-adjustable up-down displacing devices; a water tank component, a water receiving case and an air-drying water receiving case are connected into a whole, and are mounted at the upper parts of the up-down displacing devices; the water tank component is provided with sliver roller components, water supply pipes and side water discharge components; the water receiving case and the air-drying water receiving case are both provided with water discharge interfaces; the air-drying water receiving case is also provided with a sliver roller component; a water storage box component is arranged inside the chassis component; a water inlet interface of the water storage box is connected with a water discharge interface; a water outlet interface of the water storage box component is connected with a water inlet interface of a water-cooled heat exchanger through a water pump; and a water outlet interface of the water-cooled heat exchanger is connected with the water supply pipes through a water system component. By using the cooling water tank which is provided by the invention, the water temperature and the water level of cooling water can be effectively controlled; the consumption of a clean water resource is a little; meanwhile, the walking distance, in the cooling water, of a material strip of a reinforced composite material can be also regulated; and the appearance quality of the material strip is guaranteed.

Owner:NANJING GIANT MACHINERY

Machining extrusion device for mine

ActiveCN113579042AEasy accessImprove work efficiencyShaping toolsMetal-working feeding devicesHydraulic cylinderStructural engineering

The invention belongs to the technical field of mine machining, and particularly relates to a machining extrusion device for a mine. The machining extrusion device comprises a box body, a hydraulic cylinder is fixedly installed on the inner top face of the box body, an extrusion plate is fixedly arranged at the output end of the hydraulic cylinder, an opening is formed in the side wall of the box body, and a horizontal working plate is arranged at the opening. One end of the working plate is connected to the inner side wall of the box body in a sliding mode, the other end of the working plate extends out of the opening, the bottom of the working plate is elastically connected with the bottom face of the box body through a supporting spring, an electric push rod is fixedly installed on the working plate, and the output end of the electric push rod is fixedly connected with a pressure bearing cylinder. The parts are pushed to move out of and move into the box body through the electric push rod, workers can conveniently take and place the parts, the parts can be automatically fixed when the parts are moved into the box body, the parts can be cooled and subjected to chip removal treatment when the parts are moved out of the box body, the working stability is high, and the labor intensity can be reduced and the product quality can be improved.

Owner:南通祥昊机械制造有限公司

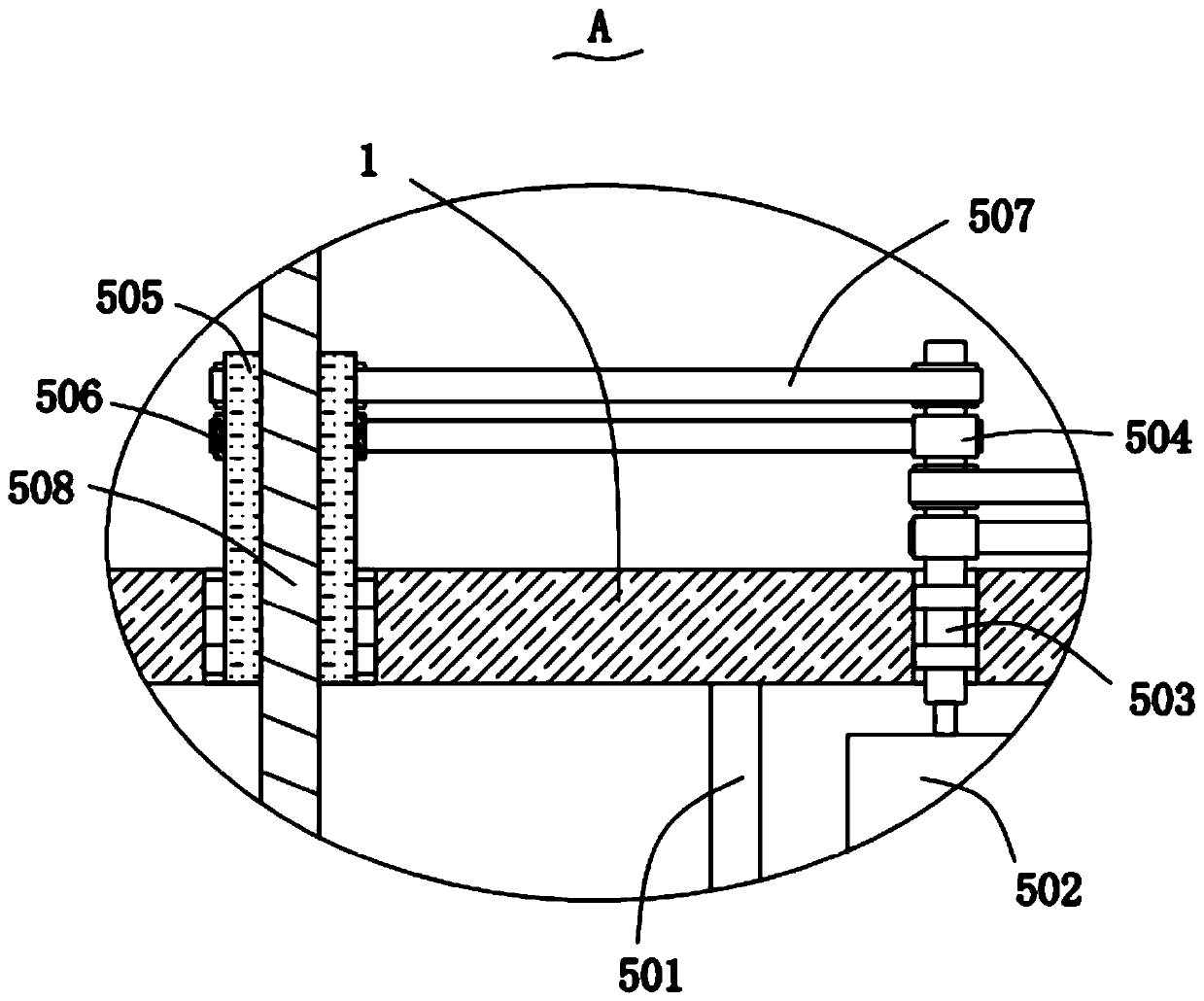

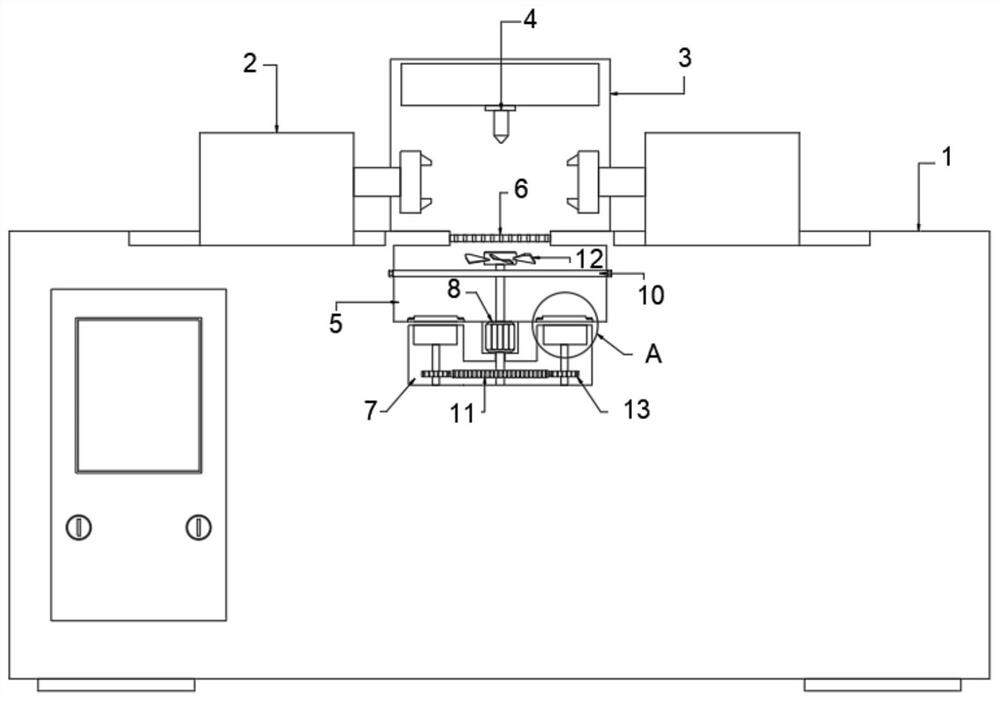

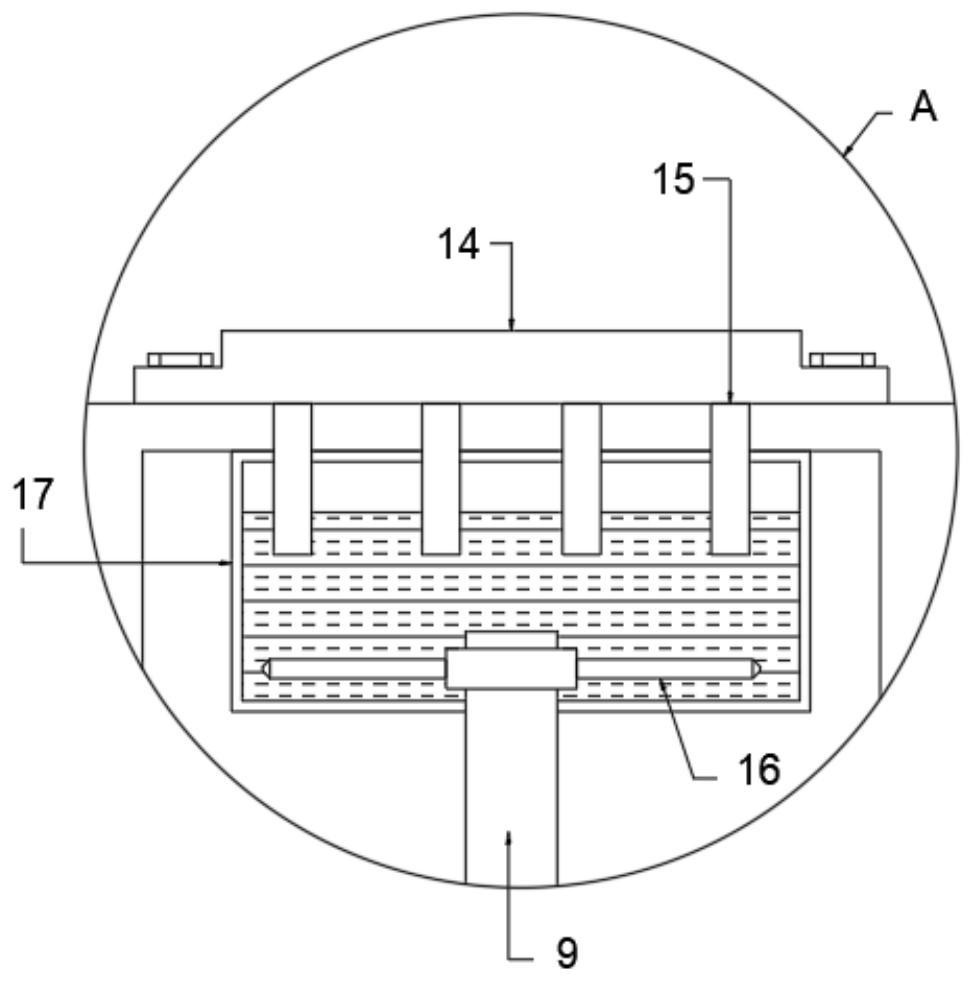

Sheet metal stamping device

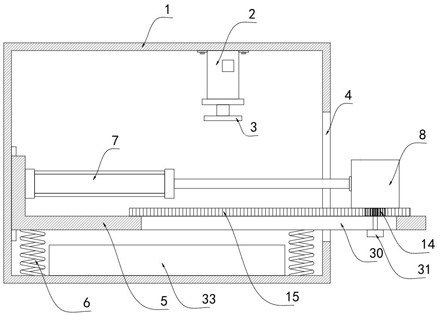

ActiveCN106694639AAvoid replacementAvoid shakingShaping toolsMetal working apparatusSheet metal stampingMachining

The invention relates to the field of machining, and particularly discloses a sheet metal stamping device which comprises a hydraulic pressure platform, a rack, sealing elements and a machine platform which are connected from top to bottom, wherein an upper die is detachably mounted on the lower surface of the hydraulic pressure platform; a rotating shaft rotatably connected with the machine platform is horizontally arranged on the machine platform; a plurality of lower dies of different models are circumferentially mounted on the rotating shaft; the lower dies are perpendicular to the rotating shaft; the sheet metal stamping device further comprises a hollow limiting rod; the limiting rod penetrates through the lower dies to be detachably connected with the machine platform; a first through hole is formed in the center of each of the lower dies; a second through hole allowing the limiting rod to be communicated with the first through holes is formed in the limiting rod; the sealing elements are fixedly mounted at the lower ends of the first through holes; a water inlet and a water outlet are formed in the limiting rod; a laser generator is arranged at the water inlet, a transparent glass reinforced plastic pipe is sleeved and connected with each of the limiting rod and the first through holes, and the outer walls of the glass reinforced plastic pipes are in contact with the inner walls of the limiting rod and the first through holes. According to the sheet metal stamping device provided by the invention, the lower dies can be quickly replaced; therefore, the processing efficiency is improved.

Owner:DOOR IND CO LTD CHONGQING DTOMO

Fan Blade Forming Mold

InactiveCN103407078BRapid cooling and settingAccelerate cooling and setting speedWater flowFan blade

The invention discloses a forming mold for fan blades, which comprises a mold female body and a mold male body matched with the mold female body, wherein injection molding grooves for the fan blades are formed in the mold female body; a cold water flowing channels are formed in the mold female body and below the injection molding grooves for the fan blades, and are positioned at the bottoms of the injection molding grooves for the fan blades; a heating module is arranged in the mold female body; a pull ring is fixed on the mold female body. The forming mold has the advantages that the fan blades subjected to injection molding are high in quality, and the mold has an excellent cooling effect, and can increase the forming rate of the fan blades.

Owner:成都万顺达模具零件有限公司

Central air conditioning sheet moulding foaming molding method and automated production technology thereof

A central air conditioning sheet moulding foaming molding method and an automated production technology thereof are disclosed. The method comprises the following steps: (1) plastic beads added with afoaming agent are manufactured; (2) the beads are expanded to a certain extent by heating; (3) the pre-foamed granular material is stored for a period of time for absorbing a certain amount of air; and (4) a mold cavity is fully filled with the matured granular material, steam passes through the mold cavity for further expanding particles to enlarge the volume, the space of the mold cavity is fully filled with the expanded particles, and the particles are fused as a whole, and cooled and molded. The central air conditioning sheet moulding foaming molding method has the advantages of short plasticizing time, fast cooling and molding, good fusing of the beads in plastic parts, stable quality and high production efficiency, and can realize mechanization and automatic production.

Owner:ANHUI HONGYUAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com