Cloth sponge compounding machine

A composite machine and fabric technology, applied in the field of composite machines and fabric sponge composite machines, can solve the problems of uneven alignment of fabric and sponge, uneven product edge thickness, and low product qualification rate, so as to reduce the degree of deviation and improve Cutting effect, effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

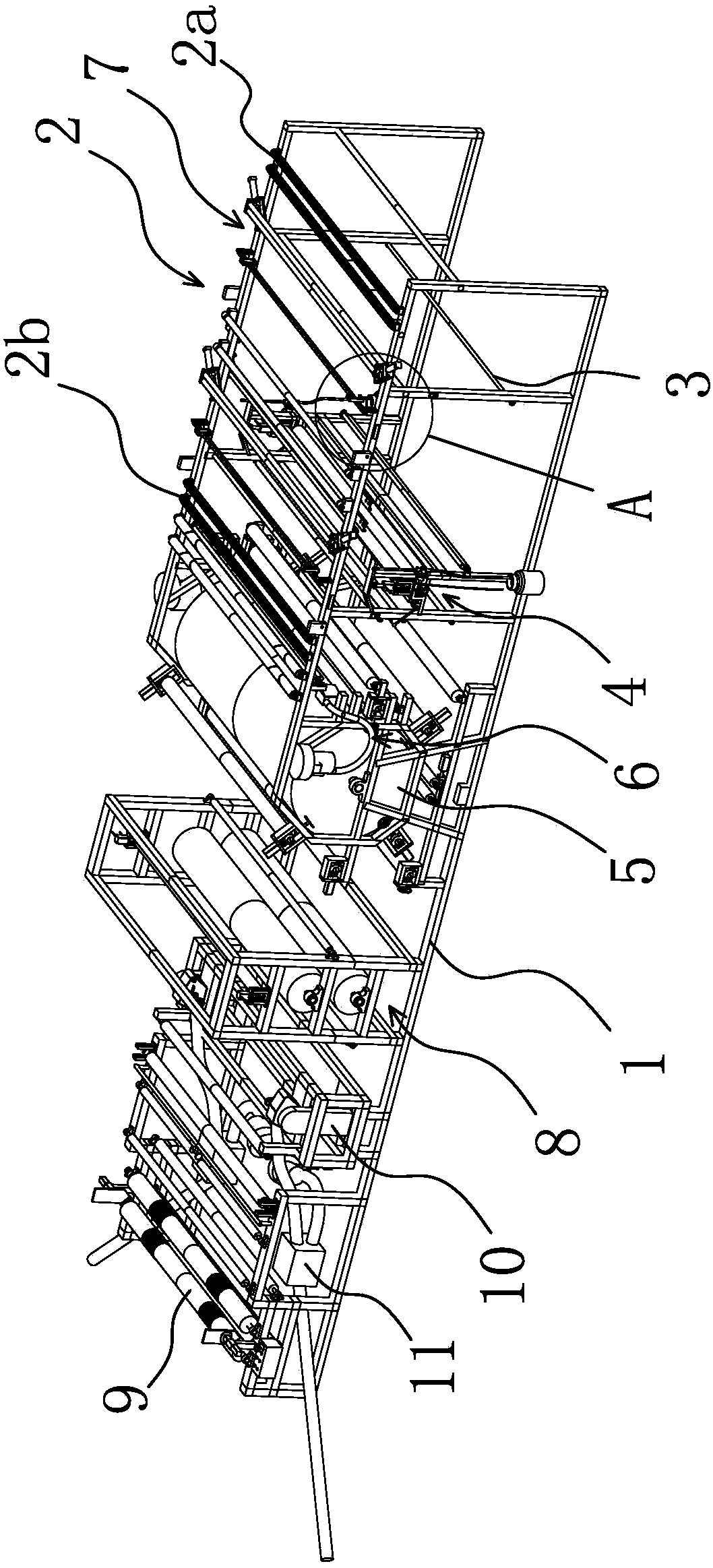

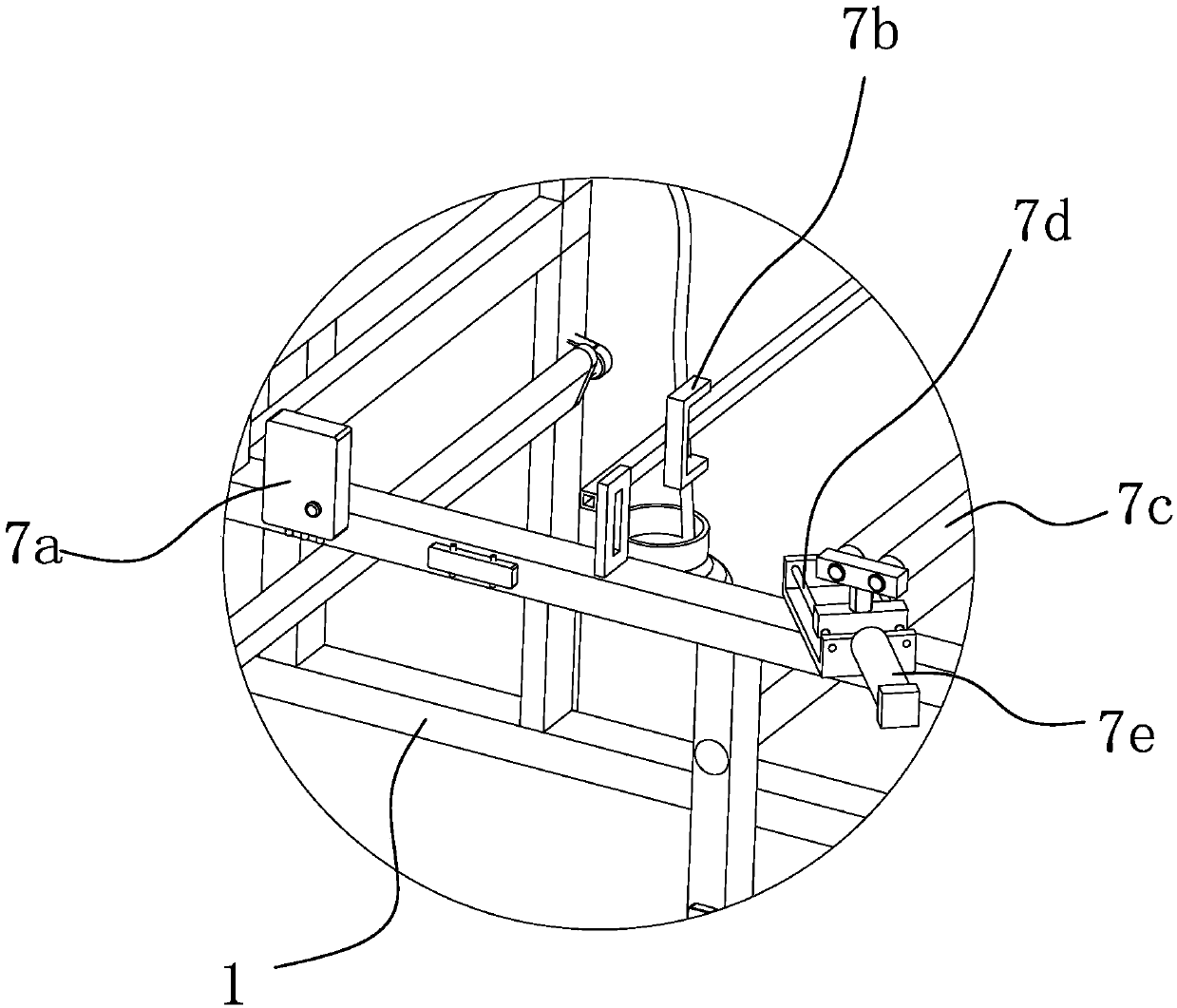

[0047] like figure 1 As shown, the fabric and sponge composite machine includes a frame 1, a fabric feeding device 2 is arranged above the front end of the frame 1, and a sponge roll holder 3, a gluing device 4, and a cloth feeding device 2 are arranged below the fabric feeding device 2. The rear is provided with thermal lamination device 5, and both sides of frame 1 are respectively provided with an anti-curl device 6, and anti-curl device 6 is positioned between cloth feeding device 2 and thermal lamination device 5, and the machine of thermal lamination device 5 rear Cooling device 8 trimming device 10 and take-up device 9 are arranged successively on frame 1, and trimming device 10 is arranged on frame 1 both sides respectively, and trimming device 10 can carry out trimming to finished cloth; A receiving device 11 is arranged. The cloth enters the anti-curling device 6 through the cloth feeding device 2, and the edge of the cloth is unfolded by the anti-curling device 6, ...

Embodiment 2

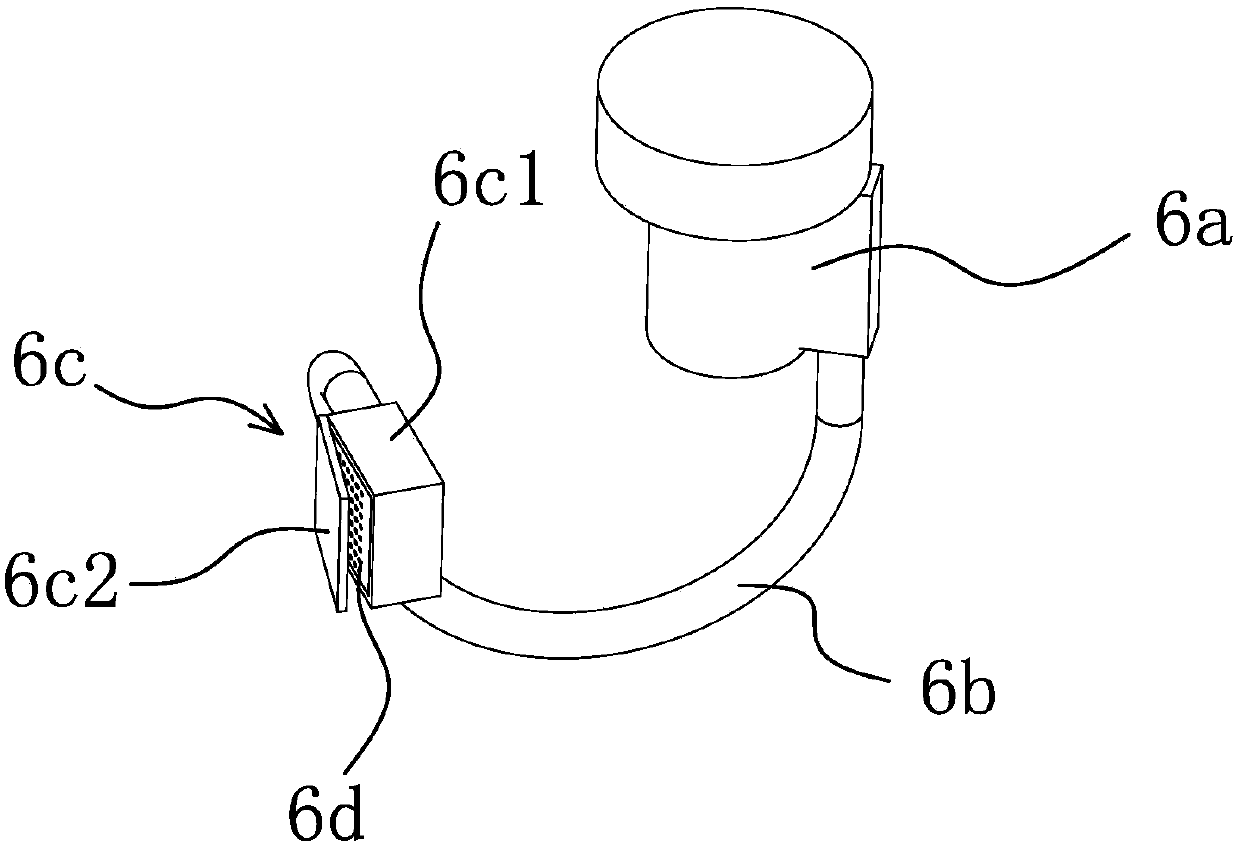

[0056] In this embodiment, the basic mechanism of the fabric and sponge composite machine is the same as that of Embodiment 1. The difference lies in: Figure 10As shown, the air outlet assembly 6c includes two opposite air boxes 6c1, and there is a gap between the two air boxes 6c1 for the edge of the cloth to pass through, that is, the two air boxes 6c1 are respectively located on both sides of the cloth advancing path. The side wall of each bellows 6c1 close to the cloth side is provided with some air outlets to form air outlets 6d, and each air outlet is inclined from the side of the bellows 6c1 near the center of the frame 1 to the side of the bellows 6c1 near the edge of the frame 1. When the fabric passes through the bellows 6c1, the wind blown by fan 1 6a enters the bellows 6c1 through the ventilation pipe 6b, and then blows out through the air outlet. The air outlet of the bellows blows air, no matter which side the edge of the fabric is bent, it can be blown flat by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com