Patents

Literature

344results about How to "Neat edges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

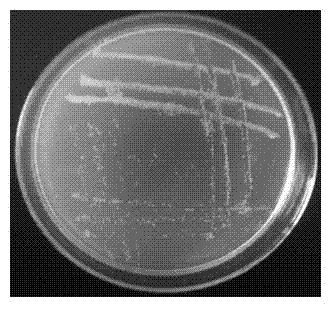

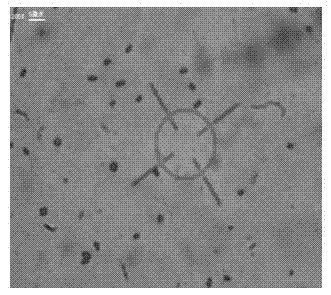

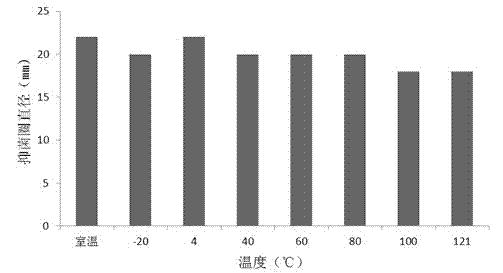

Broad-spectrum antibacterial bacillus amyloliquefaciens strain and application thereof

ActiveCN103173397ASimple cultivation conditionsPromote growthBiocideBacteriaBiotechnologyBacillus amylolyticus

The invention relates to bacillus amyloliquefaciens NCPSJ7 and further relates to an application of the strain in treating plant diseases, diseases before and after harvesting fruits and vegetables as well as in preventing food-borne pathogenic bacteria and putrefying bacteria. The strain is preserved in China Center for Type Culture Collection (CCTCC) on March 22, 2013, wherein the preservation number is CCTCC NO: M2013098 and the strain is named as bacillus amyloliquefaciens NCPSJ7. The thallus and fermentation liquor of the strain disclosed by the invention has the effects of treating plant diseases caused by plant pathogenic fungus including antagonistic peach root rotten disease, fusarium wilt of cucumber, botrytis cinerea, jujube anthracnose, pear black spot, pear blue mould, apple brown rot, apple altermaria leaf spot, watermelon fusarium wilt and the like, as well as diseases after harvesting fruits and vegetables and food-borne pathogenic bacteria and putrefying bacteria including antagonistic staphylococcus aureus, salmonella paratyphi A, vibrio parahaemolyticus, yeast and the like; moreover, the bacillus amyloliquefaciens is broad in spectrum and antibacterial and great in potential in developing novel, efficient and natural biological control and biological preservative and fresh-keeping preparation.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

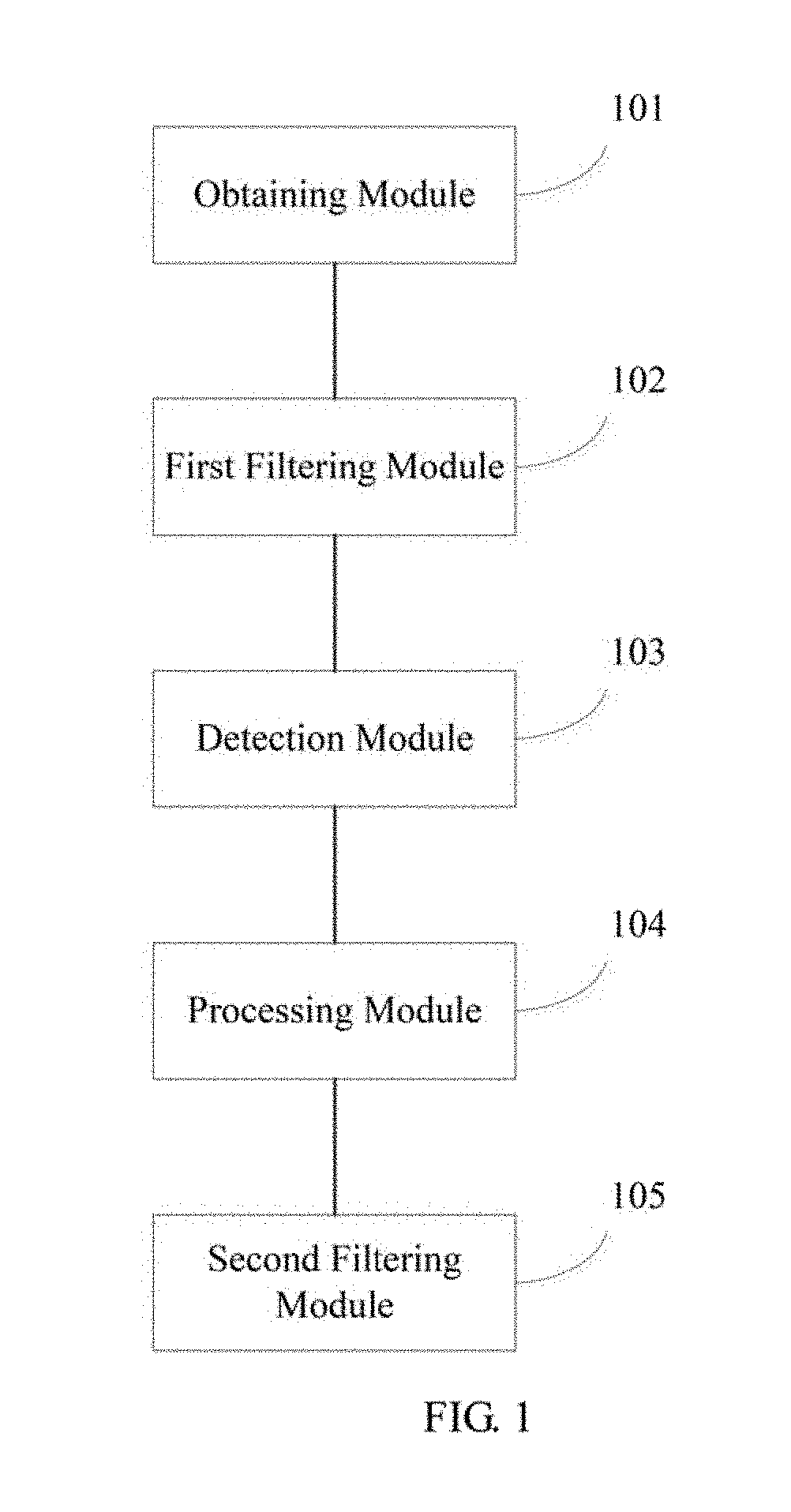

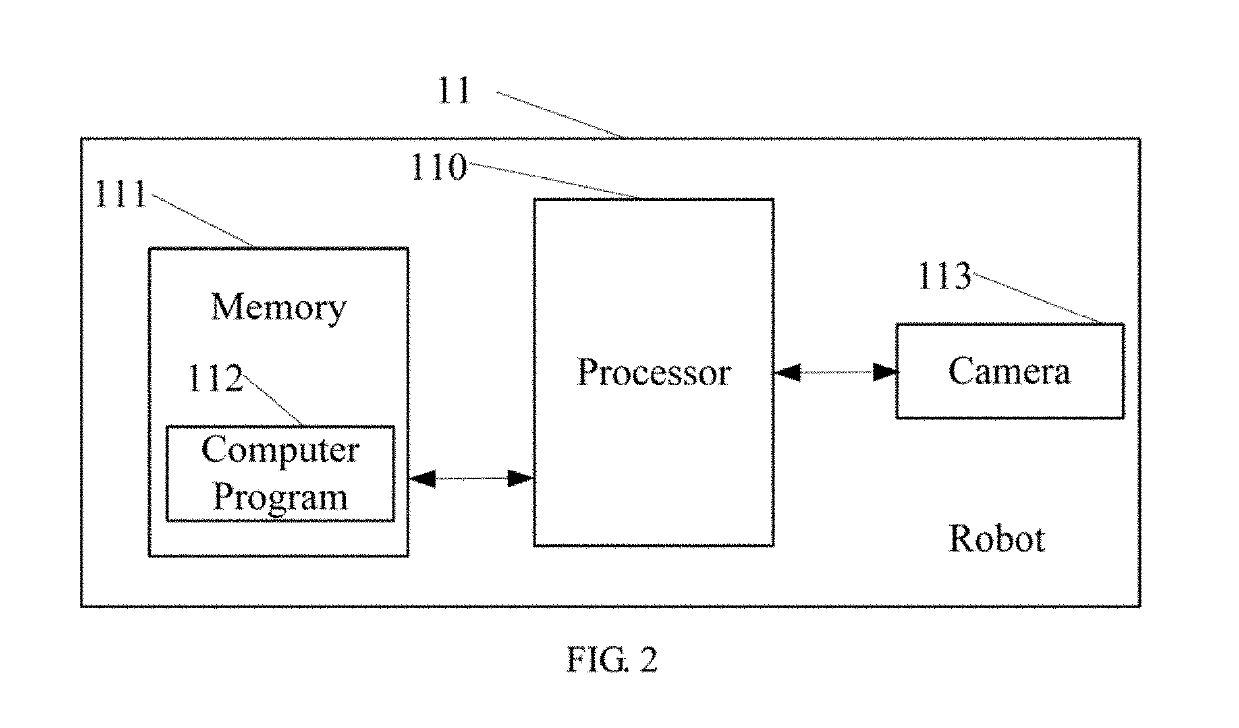

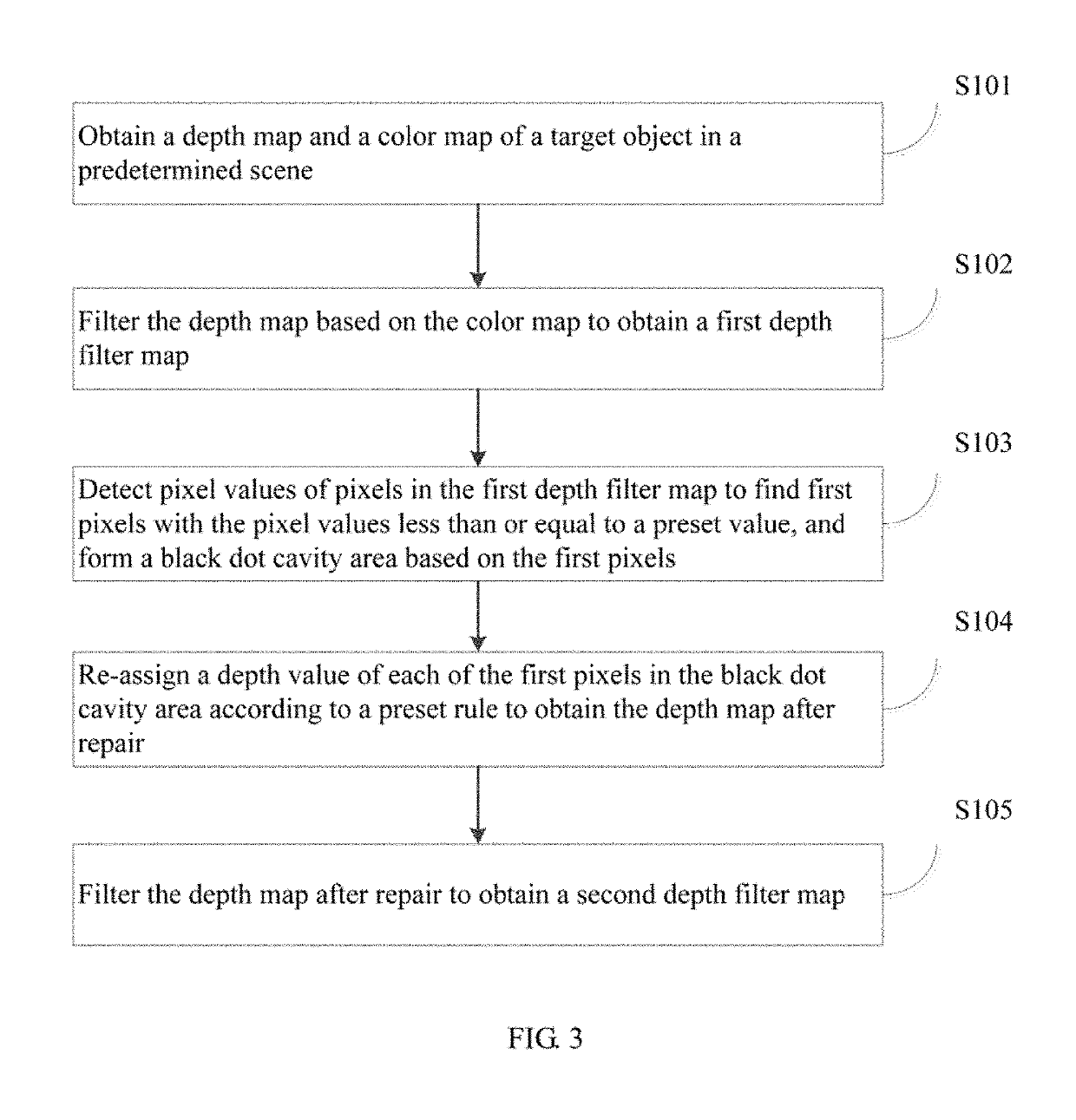

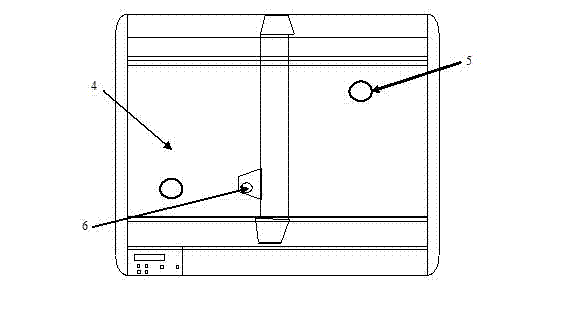

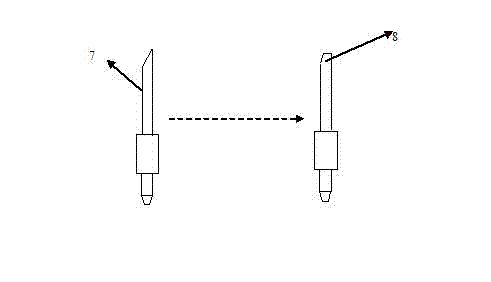

Method and apparatus for image processing, and robot using the same

InactiveUS20190197735A1Quality improvementImprove practicalityImage enhancementImage analysisImaging processingColor map

The present disclosure provides a method and an apparatus for image processing, and a robot using the same. The method includes: obtaining a depth map and a color map of a target object in a predetermined scene; filtering the depth map based on the color map to obtain a first depth filter map; detecting pixel values of pixels in the first depth filter map to obtain one or more first pixels, and forming a black dot cavity area based on the one or more first pixels; re-assigning a depth value of each of the one or more first pixels in the black dot cavity area according to a preset rule to obtain the depth map after repair; and filtering the depth map after repair to obtain a second depth filter map. The present disclosure is capable of improving the quality of the depth map.

Owner:UBTECH ROBOTICS CORP LTD

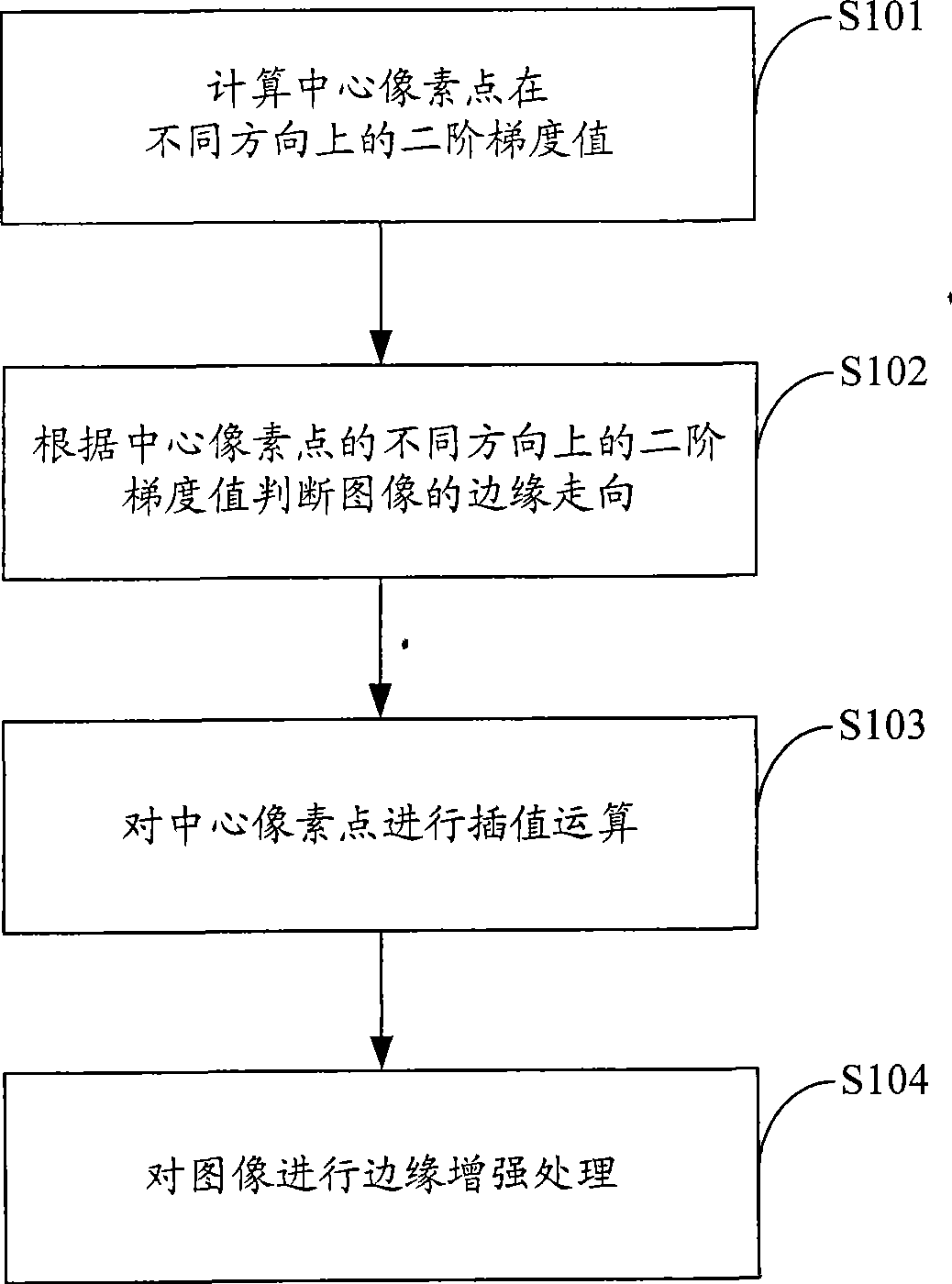

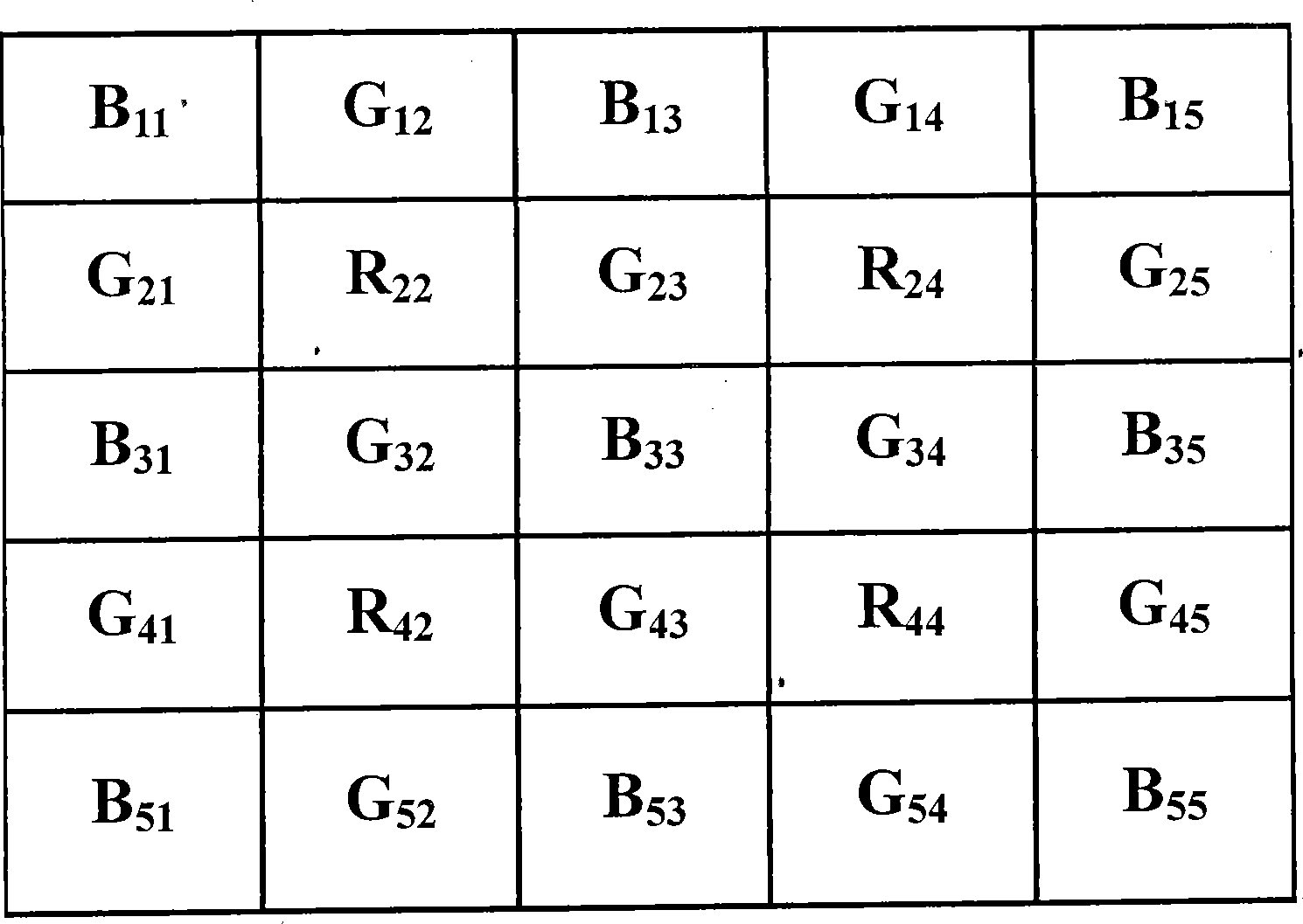

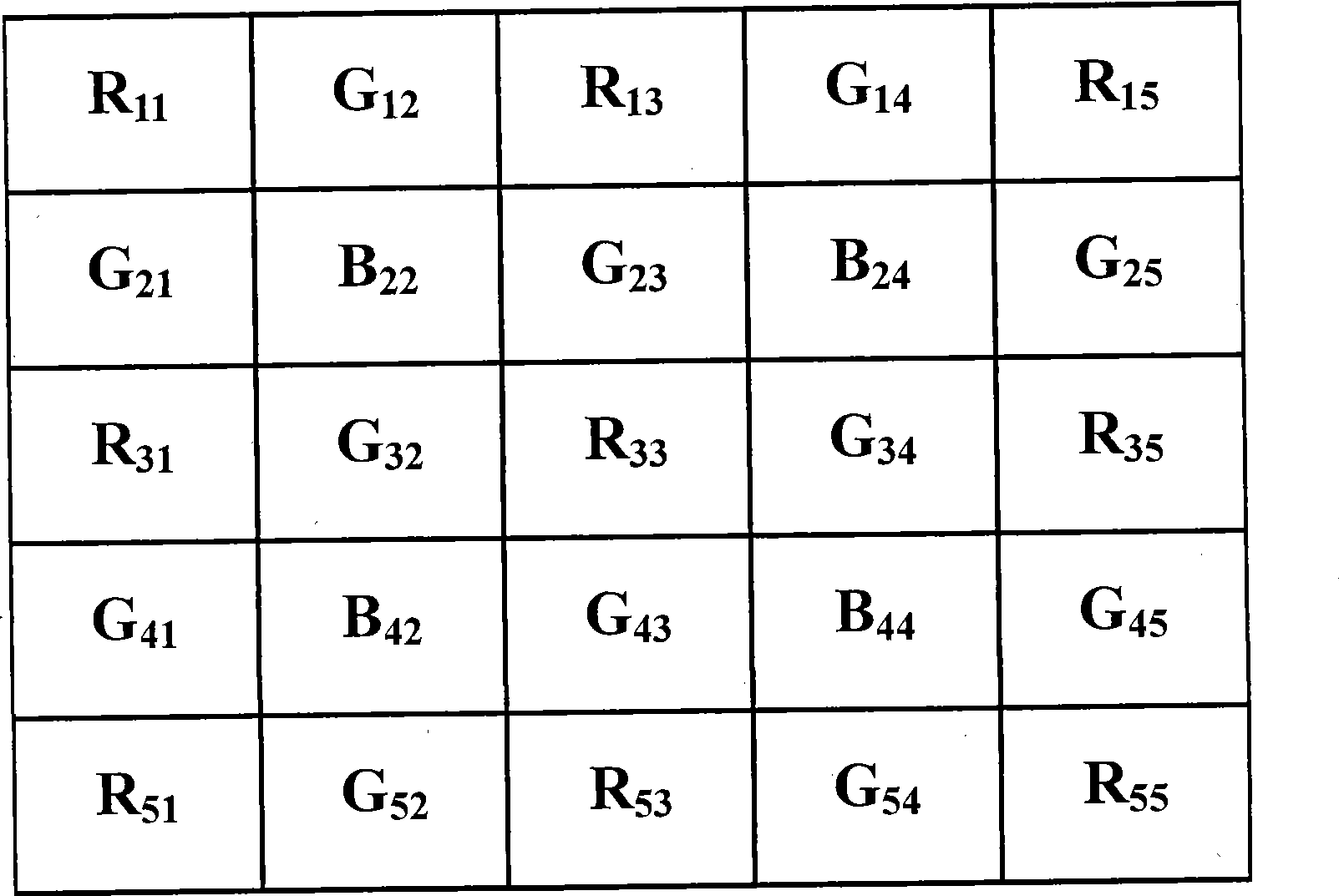

Image edge enhancing method

The invention is applicable to the field of digital image processing and provides an image edge enhancing method. The method comprises: according to the two-step gradients of central pixel point in different directions, judging the edge orientation of an image; carrying out the interpolation of the central pixel point and calculating the lost color component of pixel points; and on the basis of Bayer data, enhancing the edge of the image in an interpolation template according to the color of the original component of the central pixel point and the edge orientation of the image. The embodiment of the invention takes the influences of green component values of different pixel points around the central pixel point into full consideration while carrying out edge enhancement of the image, adopts an adaptive edge enhancement algorithm, eliminates the possible influences of noises on the edge, achieves uniform image edge and helps the processed images to achieve good effect. Meanwhile, due to the edge enhancement processing in the interpolation template on the basis of Bayer data, the method saves SRAM required by single edge enhancement processing, as well as saves large areas of elements and costs.

Owner:BYD SEMICON CO LTD

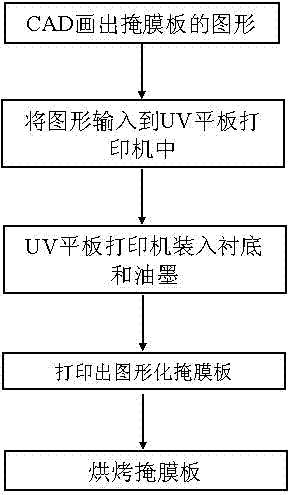

UV-curing ink and method for preparing masking plate by using ink

InactiveCN104710869ASimple preparation routeFast trackInksOriginals for photomechanical treatmentSemiconductor electrodeCooking & baking

The invention belongs to the technical field of semiconductor manufacture, and particularly relates to a UV-curing ink and a method for preparing a masking plate using the ink. The UV-curing ink is composed of a photoactive pre-polymer, a photoinitiator, an active monomer, pigment and additives. The UV-curing ink is put into a UV plate inkjet printer; a graphical masking plate is printed on a substrate through the UV plate inkjet printer; the graphical masking plate is put into an oven for baking to prepare the masking plate; and furthermore, electrodes of organic electronic devices are prepared on the masking plate through photolithography. The masking plate prepared by the method in the invention is tidy in appearance edge and smooth in surface, has no stain, is simple in operation process, requires no special technology and special equipment, is suitable for the normal masking plate for manufacturing semiconductor electrodes, and is easy for popularization and use.

Owner:方圆环球光电技术盐城有限公司 +1

White board pen ink and its making process

The white board pen ink has the recipe comprising pigment 3.5-5.0 %, uncapping agent 1.0-5.0 %, alcohol 48.0-71.0 %, propanol 15.0-25.0 %, erasing agent 5.0-10.0 %, resin 3.5-5.0 %, and dispersant 1.0-2.0 %. Its making process includes the following steps: mixing all the materials via stirring, grinding for 20-30 hr to reach pigment granularity of D50=120-200 nm, and discharging. The white board pen ink has fluent writing and high storage stability, is suitable for writing on white board, glass, plastic product, etc, and may be fitted to various kinds of pens.

Owner:苏州三威纳米科技有限公司

Method for making local laser metal color on surface of printing material

InactiveCN101905581ASolve the prominent visual effectEnhance local visual effectsVacuum evaporation coatingSputtering coatingUV curingUltraviolet

The invention discloses a method for making local laser metal color on the surface of a printing material, and aims to overcome the defects that the conventional whole laser embossing layer influences the local protruding visual effect of a printed matter, and the local laser method has deficient technical means, poor laser effect and low production efficiency. The technical scheme has the key points that: the method comprises the following steps of: coating a release agent on a specific film; printing image-text on a release layer; making the laser embossing layer on the image-text; plating aluminium on the laser embossing layer; gluing the aluminium plating layer; compounding the film and the printing material; peeling the film; and remaining the image-text, the laser embossing layer and the aluminium plating layer on the printing material; and the method is characterized in that: the step of making the laser embossing layer on the image-text comprises the substeps of: intagliating an area range needing the laser embossing layer on a gravure printing device on a cylinder; locally printing UV-cured gloss oil on the image-text; embossing laser grains on a UV-cured gloss oil area by using an embossing device; and curing the UV-cured gloss oil area by using a UV curing device to obtain the local laser embossing layer.

Owner:SHANTOU KINGSPACK TECH

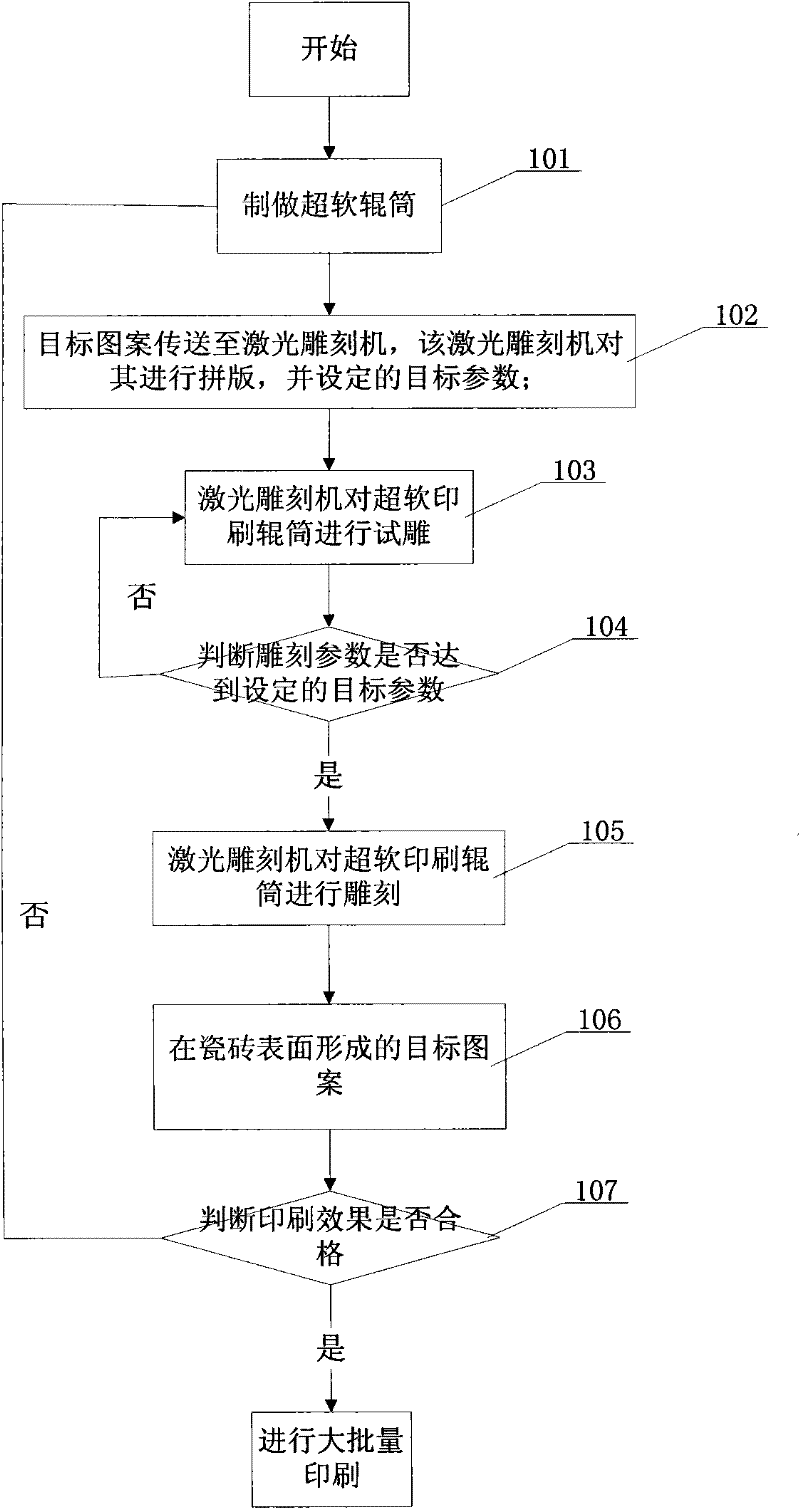

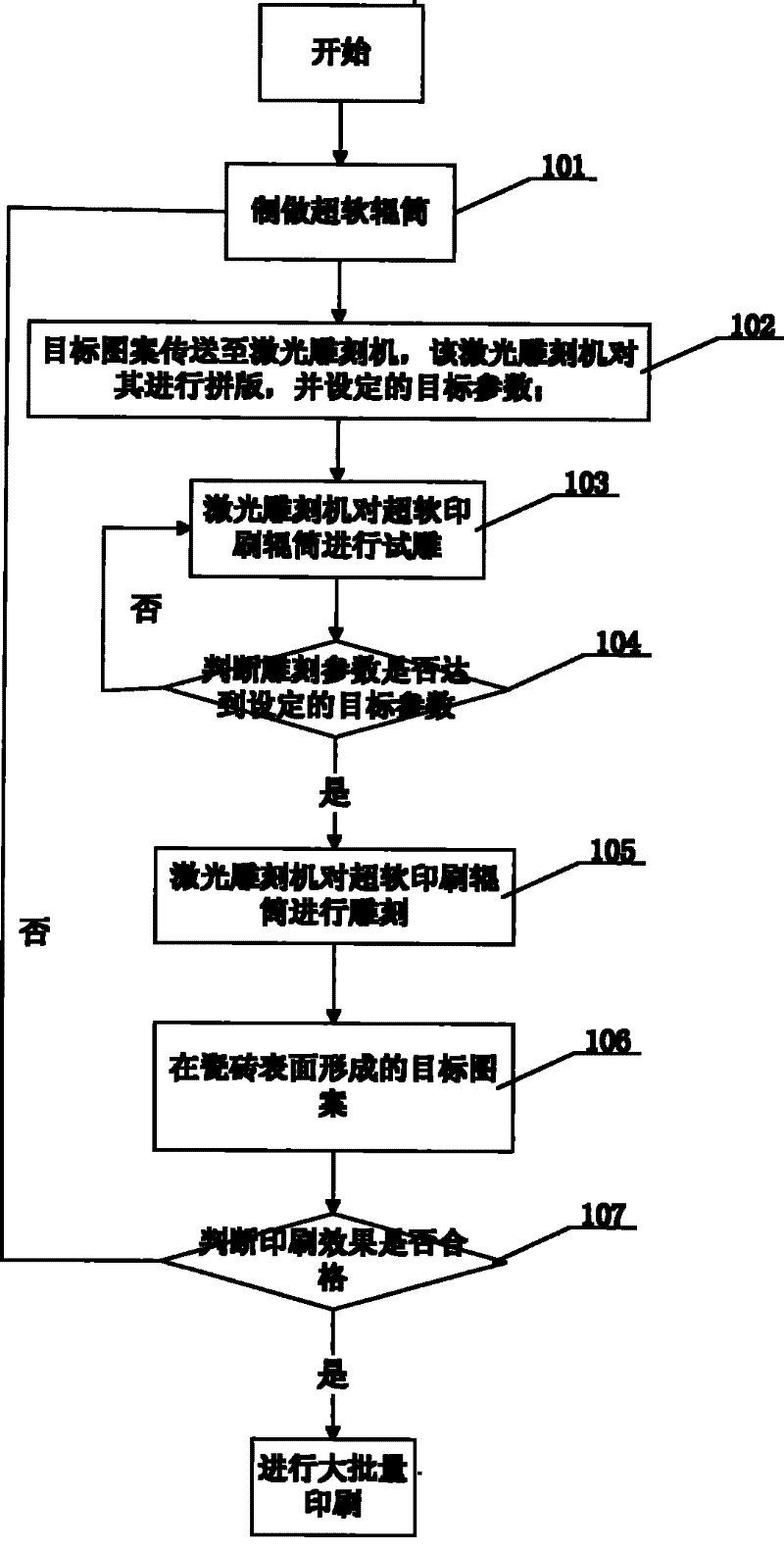

Laser engraving processing method and device for ultra-soft printing roller

InactiveCN102343705AImprove yieldThe edge of the mesh hole is neatForme preparationLaser engravingEngineering

The invention relates to a laser engraving processing method for an ultra-soft printing roller, comprising the following steps: 1) processing silica gel into the ultra-soft printing roller; 2) transmitting a target pattern to a laser engraving machine through a PC, carrying out imposition on the target pattern by the laser engraving machine, and setting target parameters for laser engraving by the laser engraving machine; 3) carrying out pilot engraving on the ultra-soft printing roller by the laser engraving machine; 4) determining whether the engraving parameters reach the set target parameters, if yes, executing the step 5), if not, returning to the step 3); 5) engraving the ultra-soft printing roller by the laser engraving machine to form complete and burnished printing network points on the silica gel surface after engraving; 6) filling glaze materials in the network points to form the target pattern on the surface of the ceramic tile; and 7) determining whether the printing effect is qualified, if not, returning to the step 1). Compared with the prior art, the invention has the advantages of high laser engraving wires, delicate printed pattern, high yield of the ceramic tile product and the like.

Owner:SHANGHAI YUNAN PLATE MAKING

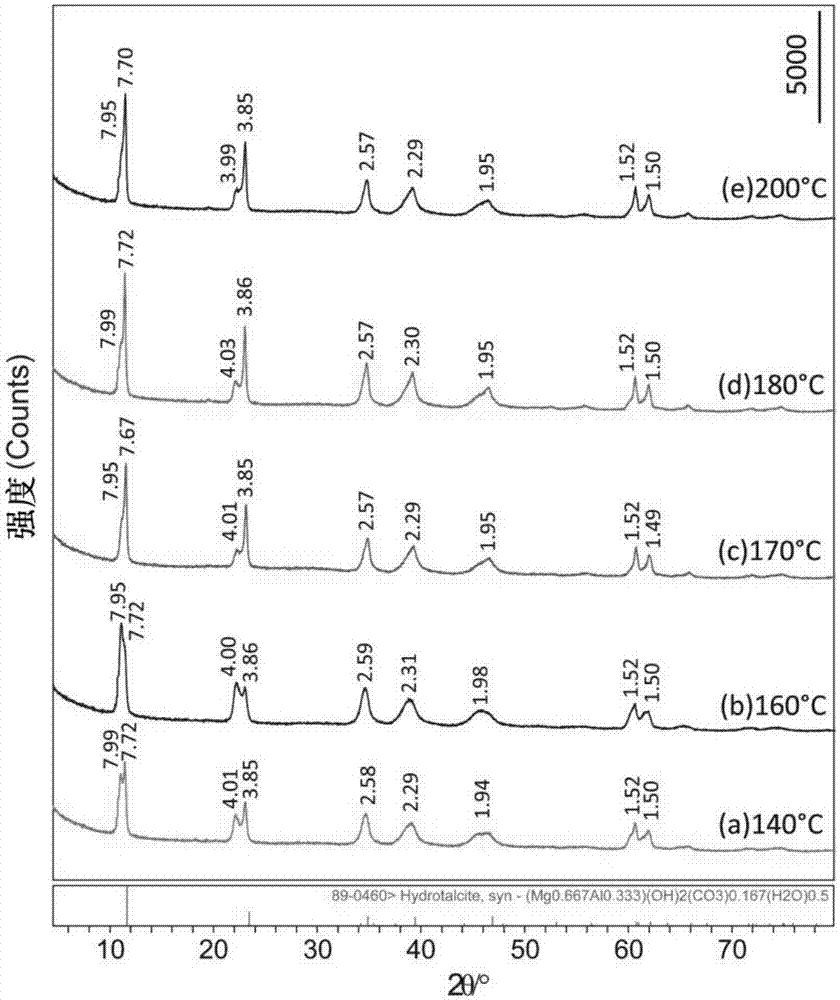

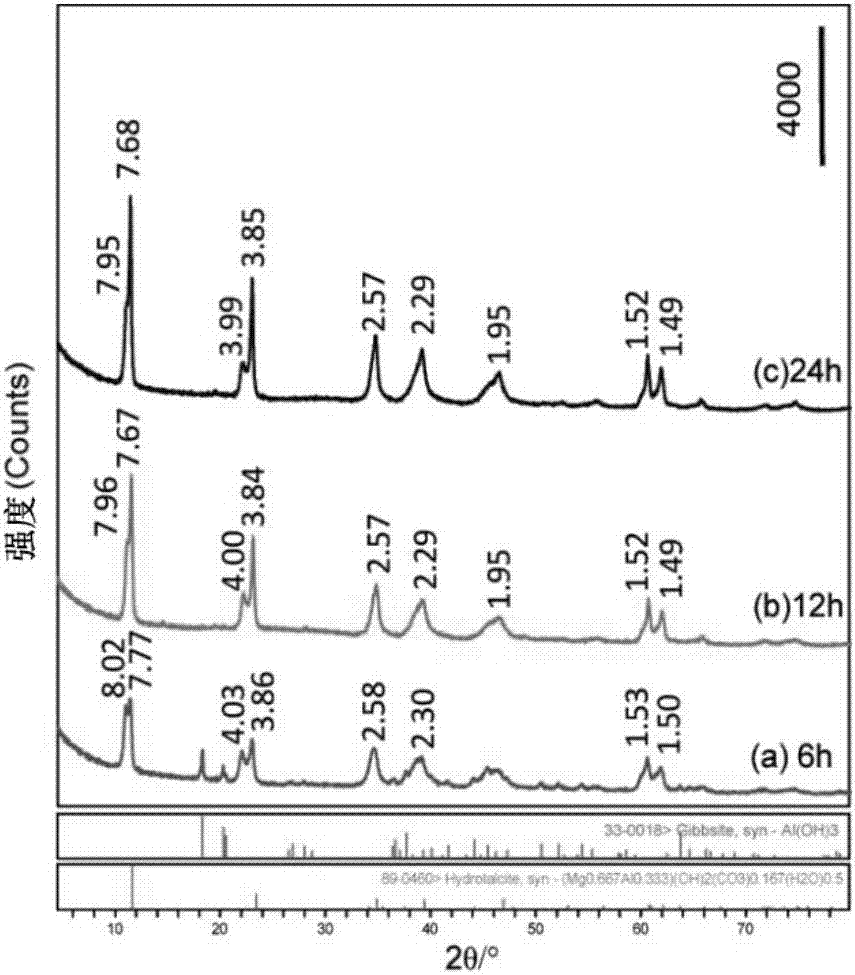

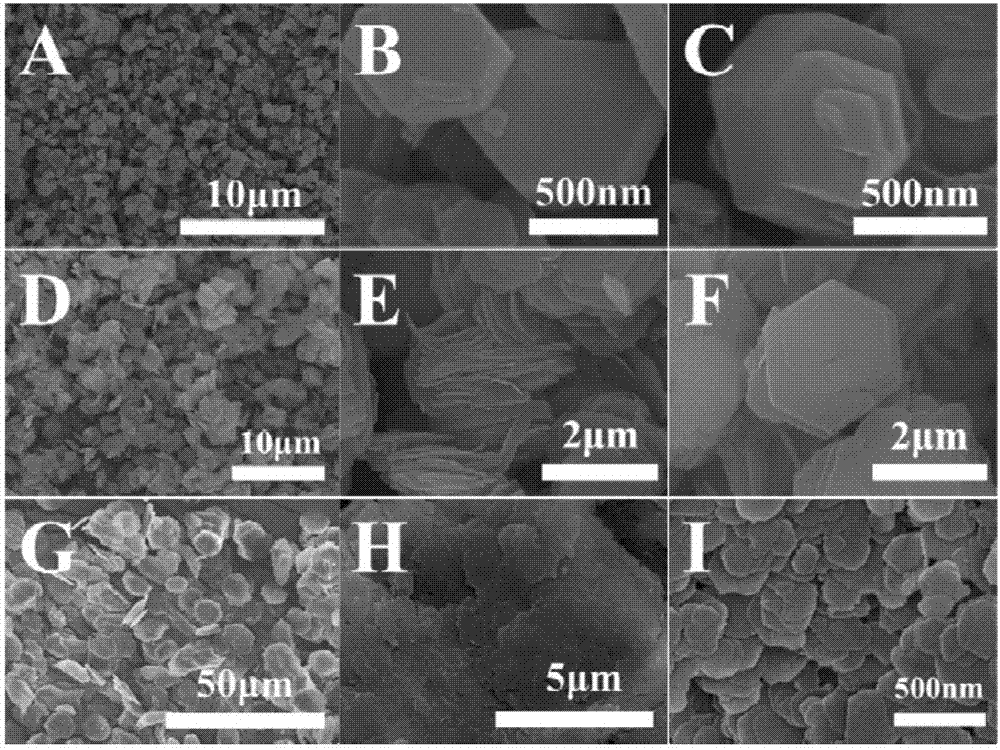

Layered bimetal hydroxide preparation method, and product prepared therethrough

InactiveCN107128879AKeep the basic shapeSuitable for mass productionAluminium compoundsOxide/hydroxide preparationDivalent metalBuffer solution

The embodiment of the invention provides a layered bimetal hydroxide preparation method, and a product prepared therethrough. The layered bimetal hydroxide preparation method comprises the following steps: mixing a trivalent metal hydroxide, a divalent metal salt and a buffer solution with the pH value of 9-10 to obtain a reaction mixture; and carrying out a reaction on the reaction mixture at 100-300 DEG C for 10 h or above, and separating and washing the obtained reaction product after the reaction ends in order to obtain layered bimetal hydroxide. The trivalent metal hydroxide is adopted as a precursor, the layered bimetal hydroxide is prepared in the weakly alkaline buffer solution, and the obtained layered bimetal hydroxide keeps the basic morphology of the precursor trivalent metal hydroxide, and also has the characteristics of regularly edge and structured arrangement. The improvement of the above microstructure expands the application of the layered bimetal hydroxide in the fields of catalysis and drug delivery. The method has a simple process flow, and is suitable for the large-scale production of the layered bimetal hydroxide.

Owner:BEIJING NORMAL UNIVERSITY +1

Method for making local laser marks on surface of printing material

InactiveCN101947895AEnhance local visual effectsGood partial visual effectPattern printingOther printing apparatusPhysical chemistryThin membrane

The invention relates to a method for making local laser marks on the surface of a printing material and aims to overcome the defects that the laser marks on the entire surface in the prior art affect the conspicuous vision of a projecting part of a printed product and the conventional thought for making the local laser masks lacks a practical technical measure, has poor laser effect and low production efficiency and is not accordant with high-speed continuous operation. The technical scheme comprises the following process steps of: selecting a specific membrane; coating a release agent on the membrane; printing pictures and texts on a release layer; making a laser mask layer; coating glue on the laser mask layer; compounding the membrane with the printing material; stripping the membrane; and transferring the pictures and texts and the laser mask layer onto the printing material. The method is characterized in that: the process for making the laser mask layer comprises the following steps of: locally printing ultraviolet-cured gloss oil on the pictures and texts through a gravure printing device for carving a laser mask layer region range on a version roller; stamping laser masks on the ultraviolet-cured gloss oil by using a die pressing device; and curing the ultraviolet-cured gloss oil by using an ultraviolet curing device so as to obtain a local laser mask layer.

Owner:GUANGDONG MAGNOLIA PACKING MACHINERY

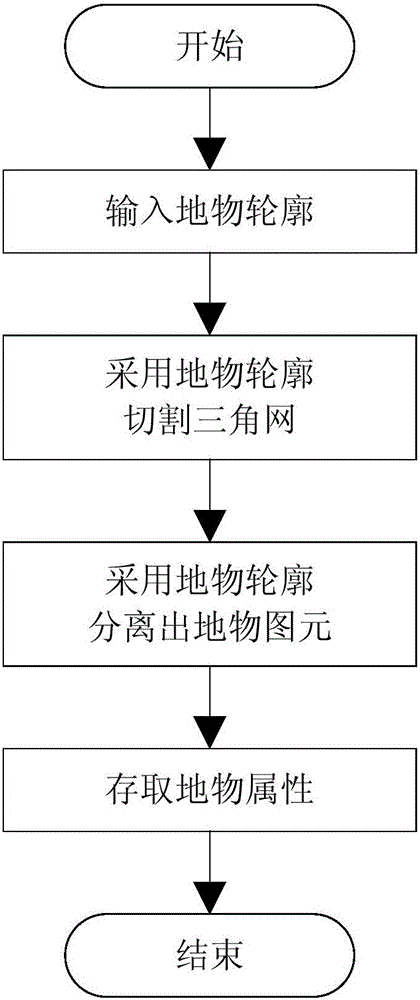

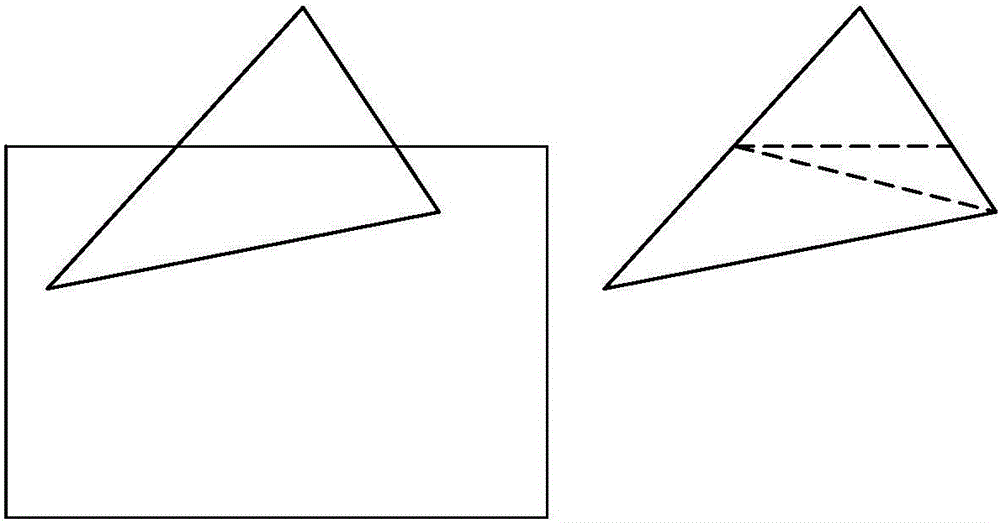

Method for extracting surface features from tilt measurement scene

InactiveCN106251331ANeat edgesNeat and beautiful edgesImage enhancementImage analysisCollision detectionComputer vision

The invention discloses a method for extracting ground objects in an inclination measurement scene, which can ensure that the ground objects such as houses and trees are truly separated from the inclination measurement scene and that the edges of the ground objects are neat, and can obtain ground object graphic element information for ray collision detection, Operations such as distance calculation, and attribute information such as feature category, feature number, feature name, and selected status can be added to meet the requirements of power line design. It includes steps: (1) start; (2) set the contour of the object to define the boundary line of the object to be extracted; (3) cut the triangular network by using the contour of the object: use the contour of the object to cut the triangular figure in the scene After cutting, each contour line has a triangle side coincident with it, and there is no triangle side intersecting with the contour line; (4) separate the feature primitive by using the feature outline; (5) access the feature attribute ; (6) end.

Owner:BEIJING DAOPOWER

Seaweed, fruit and vegetable milk slice and production method thereof

InactiveCN102090454AGuaranteed DissolutionModerate sweetnessMilk preparationFlavorMagnesium stearate

The invention relates to a seaweed, fruit and vegetable milk slice and a production method thereof. The production method comprises the following steps: weighing seaweeds, fruits and vegetables in a certain proportion, mixing, adding a proper amount of water, pulping, carrying out flash extraction, and separating to obtain a supernatant; carrying out vacuum concentration on the supernatant to obtain a seaweed, fruit and vegetable water extract; evenly mixing the seaweed, fruit and vegetable water extract with defatted milk powder, dextrin and magnesium stearate; and placing the mixture into a tablet machine for tabletting to obtain the seaweed, fruit and vegetable milk slice which comprises the following components in parts by weight: 30-45% of seaweed, fruit and vegetable water extract, 35-45% of defatted milk powder, 10-15% of xylitol, 5-10% of dextrin and 3-5% of magnesium stearate. The milk slice provided by the invention has the advantages of mixed flavor of seaweed, fruit and vegetable, moderate sweet, rich nutrition, smooth and fine surface and complete piece shape, simple manufacture method, reasonable process and strong program, is convenient in operation and is suitable for industrial scale production.

Owner:SHANDONG HOMEY AQUATIC DEV +1

Clostridium beijerinckii for hydrogen generation via fermentation as well as fermentation method and application of clostridium beijerinckii

ActiveCN104164395ALow costImprove competitivenessBacteriaMicroorganism based processesWater bathsBiofuel

The invention discloses clostridium beijerinckii for hydrogen generation via fermentation as well as a fermentation method and an application of the clostridium beijerinckii. The clostridium beijerinckii is preserved in the China General Microbiological Culture Collection Center (CGMCC) of the China Committee for Culture Collection of Microorganisms (CCCCM), and has the preservation number of CGMCC No.9411. The culture method of the clostridium beijerinckii comprises the following steps: firstly, carrying out anaerobic culture on a freeze-stored liquid of the clostridium beijerinckii so as to obtain a cultured bacterial culture solution; centrifuging the bacterial culture solution and then resuspending thalli so as to obtain a resuspended bacterial solution taken as an inoculant source; inoculating the inoculant source into a hydrogen generation culture solution and carrying out photophobic culture on a constant-temperature shaking water bath for generating hydrogen until the hydrogen generation is finished. The clostridium beijerinckii can be fermented to generate hydrogen by utilizing a carbon source and a nitrogen source which are common in natural world and are difficultly utilized by the majority of microorganisms, and ethyl alcohol, butyl alcohol and other biofuels are generated while the hydrogen generation is carried out via the fermentation. The clostridium beijerinckii disclosed by the invention is the first novel multifunctional clostridium beijerinckii strain in the current report, and can be applied to the hydrogen generation of biomass via fermentation, the production of biofuels such as ethyl alcohol and butyl alcohol. Thus, the clostridium beijerinckii disclosed by the invention has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

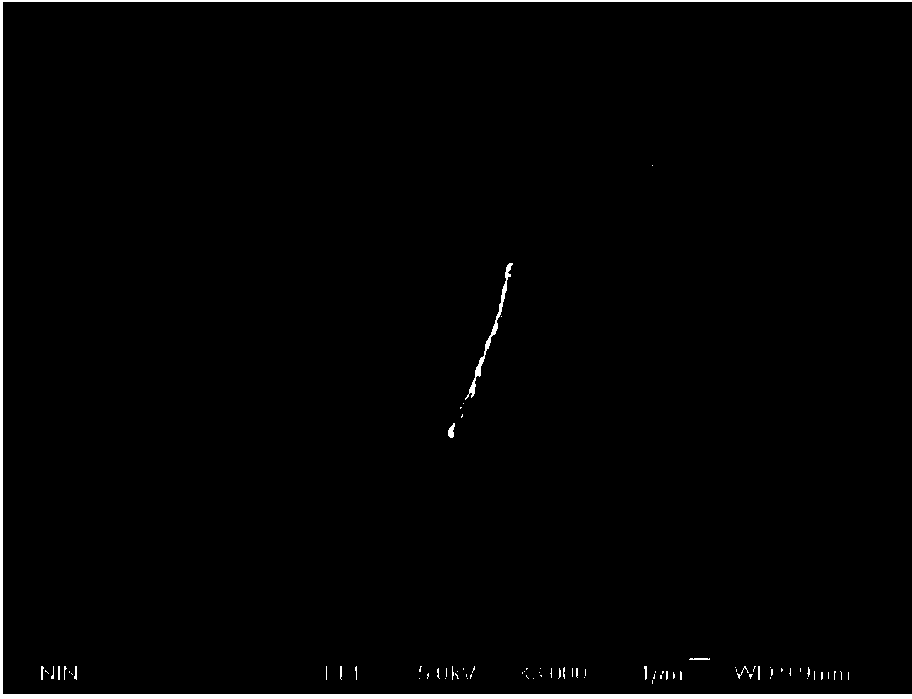

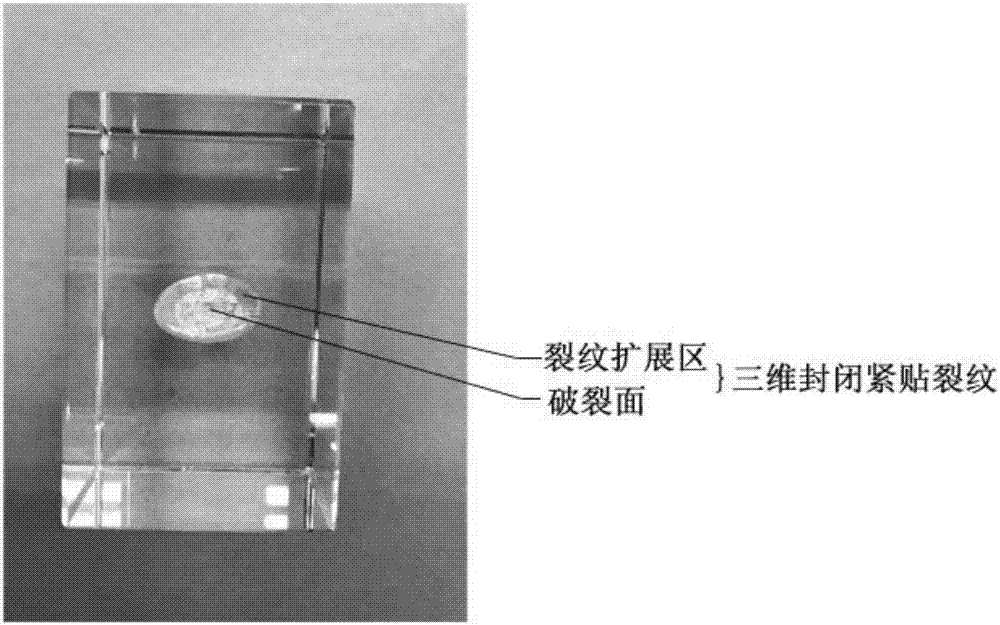

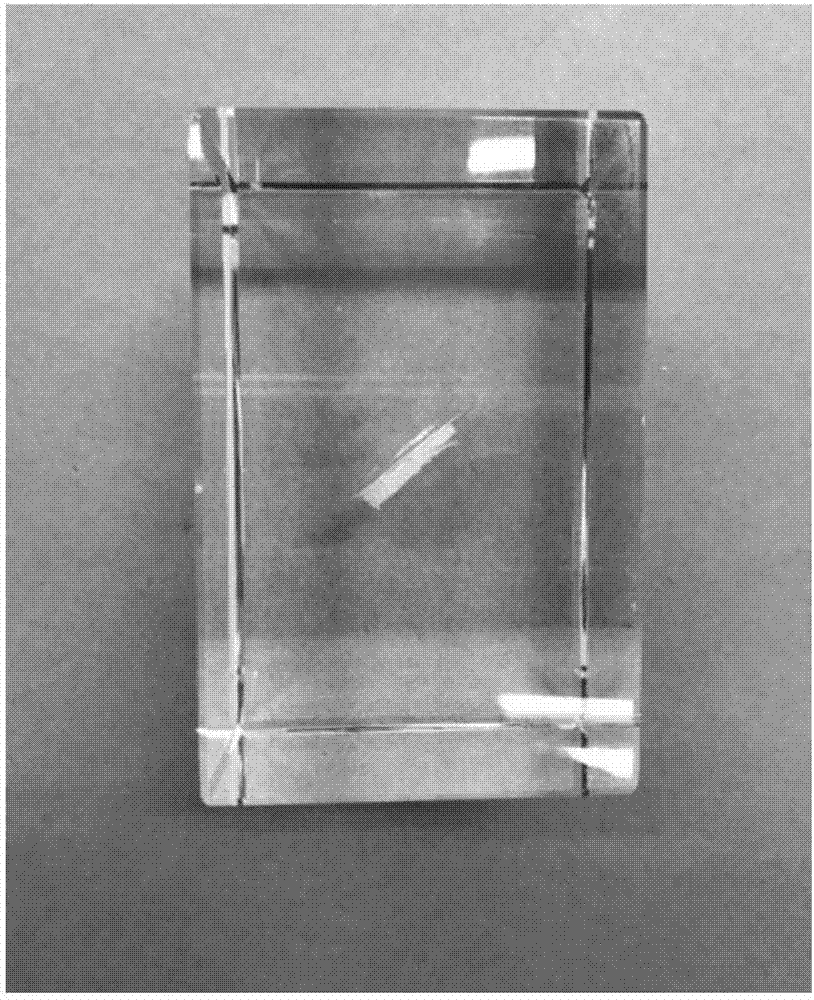

Method for simulating three-dimensional closed and clung cracks in rocks

ActiveCN107328625AReasonable methodShort preparation cyclePreparing sample for investigationEngineeringLaser

The invention provides a method for simulating three-dimensional closed and clung cracks in rocks. The method comprises the following steps: taking a complete transparent material, and selecting a position and a range of precast cracks in the transparent material; focusing laser to the position through a lens; in a focusing process, enabling the position to generate a cracking point when laser energy exceeds a damage threshold value of the material; repeating the process, focusing the laser at the periphery of the cracking point and generating one group of cracking points; continuously inputting the laser energy, and simultaneously enabling the generated cracking points to be subjected to continual damage expansion and connecting the cracking points to form a cracking surface; meanwhile, along with the input of the energy, continually carrying out the damage expansion on an outward edge of the cracking point at the outermost periphery to form one circle of crack expansion region (annular surface) to be connected with the cracking surface; forming the three-dimensional closed and clung cracks at the position of the precast cracks, and keeping an original shape of other parts of the transparent material. The method provided by the invention is reasonable and is rapid and efficient; other surplus cracks are not formed, and edges are ordered; a test piece is complete and is not damaged; the property of the test piece is close to that of a rock material, and the simulation degree is high.

Owner:NANJING HYDRAULIC RES INST

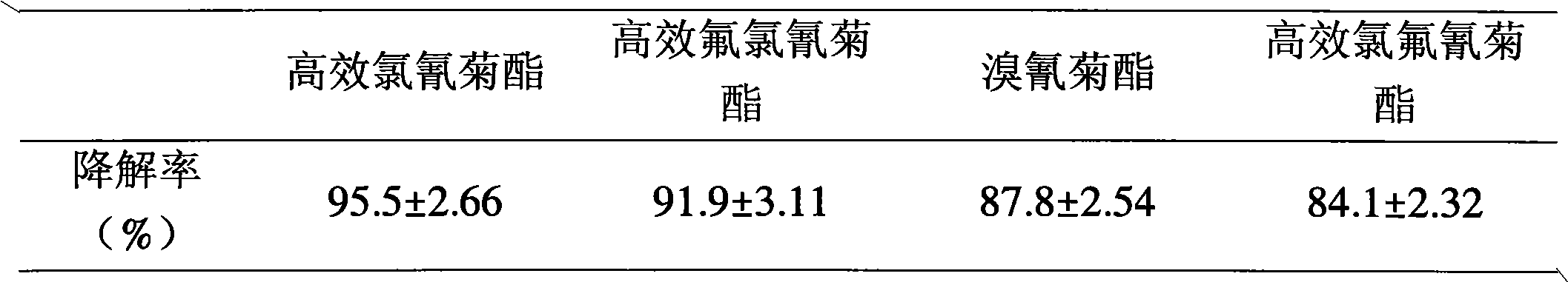

Degrading bacteria for pyrethroids insecticides and bactericide thereof

ActiveCN101974454ASolve usabilityEfficient solutionBacteriaMicroorganism based processesCypermethrinStreptomyces

The invention discloses degrading bacteria for pyrethroids insecticides. The degrading bacteria are HP-S-01 and are identified to be streptomyces (Streptomyces sp.), wherein the collection number of the strain is CCTCC M 2010096; and Genbank access number of 16S rDNA of the strain is HM016873. The invention discloses a method for preparing bactericide by using the degrading bacteria at the same time. The bactericide is low in cost, convenient and desirable in degradation effect, can directly used to reduce cypermethrin pesticide residues in crops by over 80 percent, solves the problem of excessive cypermethrin pesticide residue in the agricultural production, is suitable to be used in national fruit and vegetable production and export bases or places with a green food brand mark on a large scale, and has a great significance for promoting the production of green vegetables and green food.

Owner:SOUTH CHINA AGRI UNIV

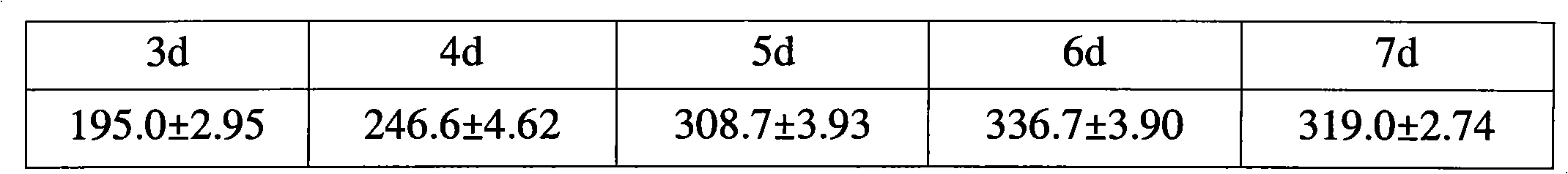

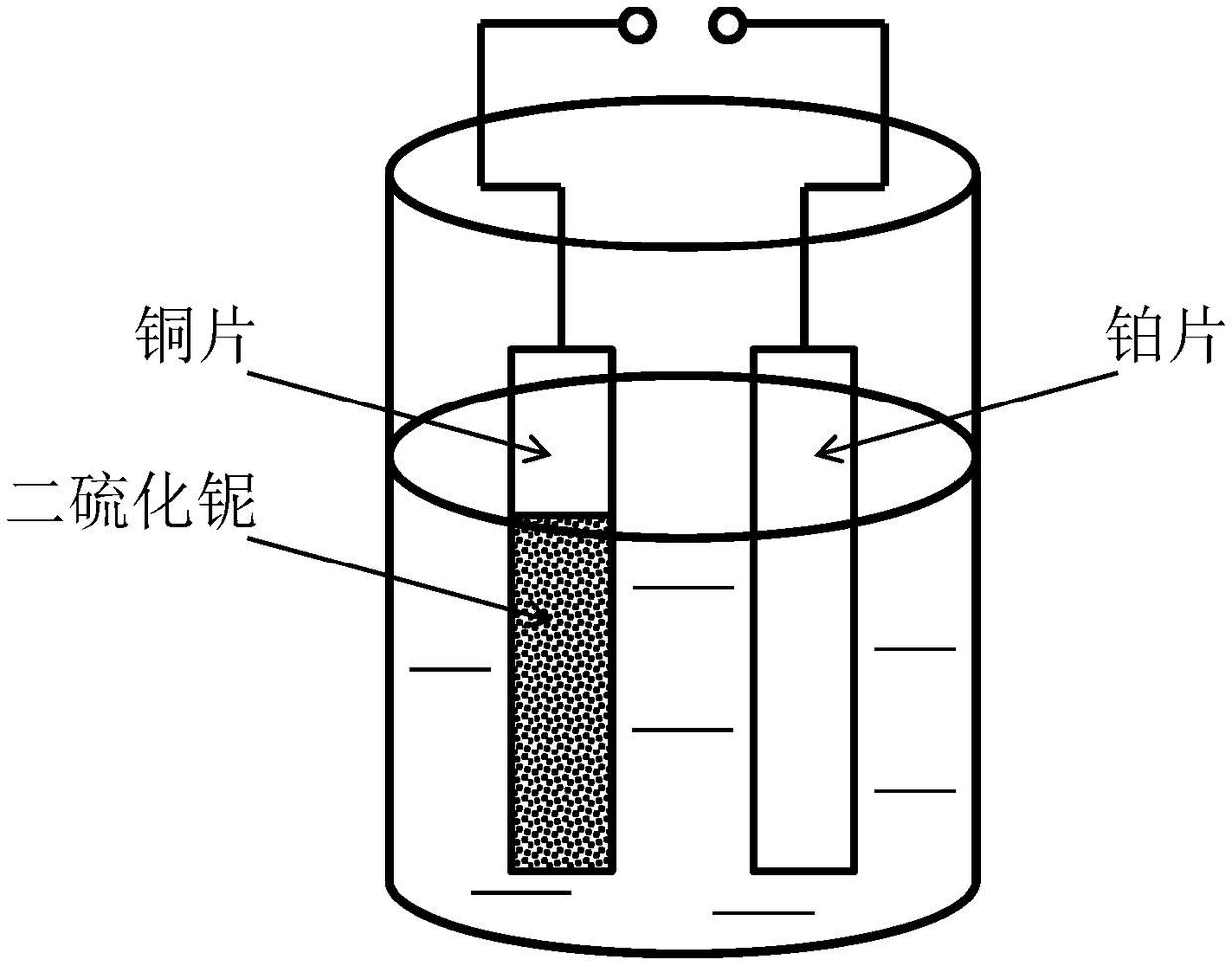

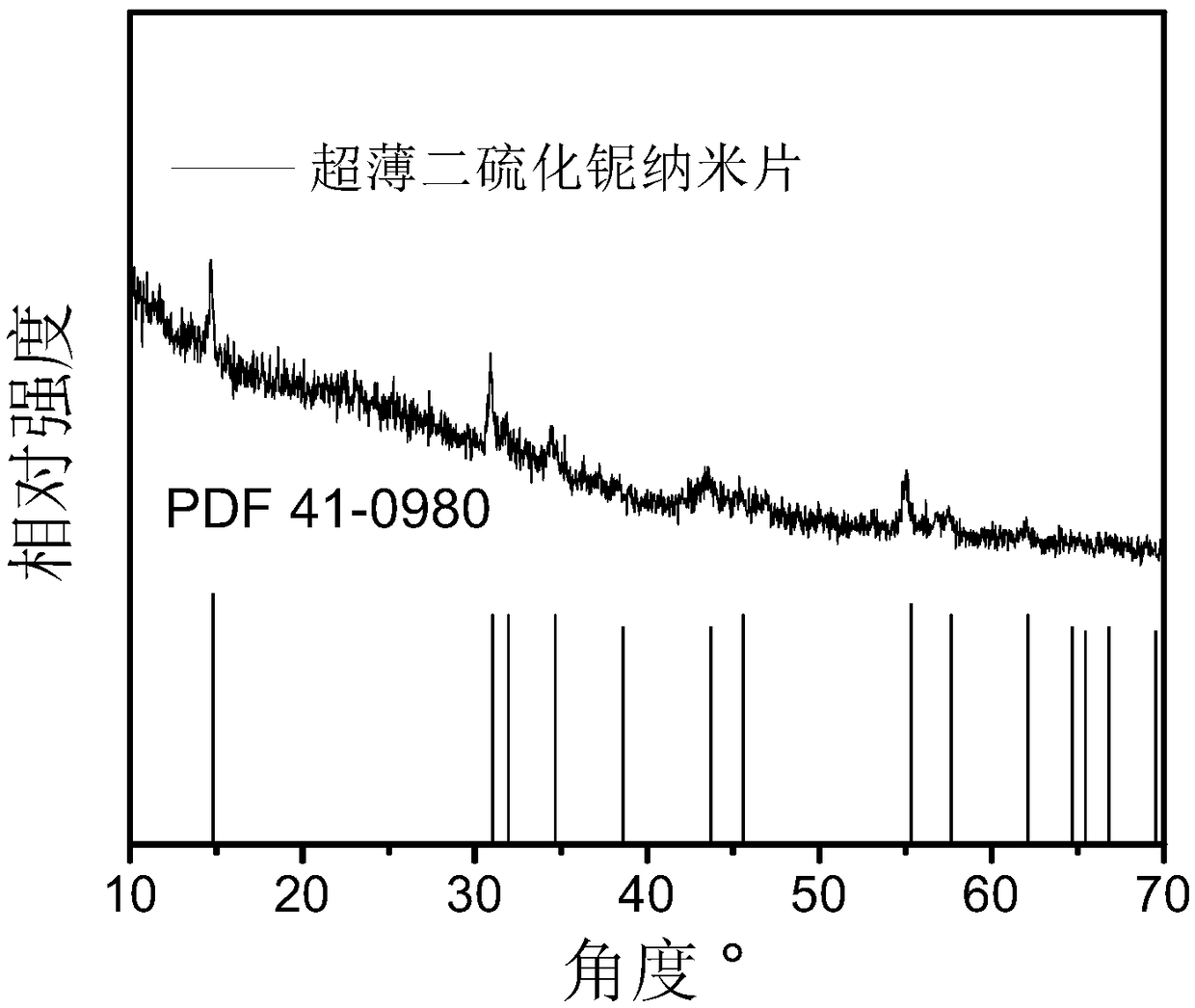

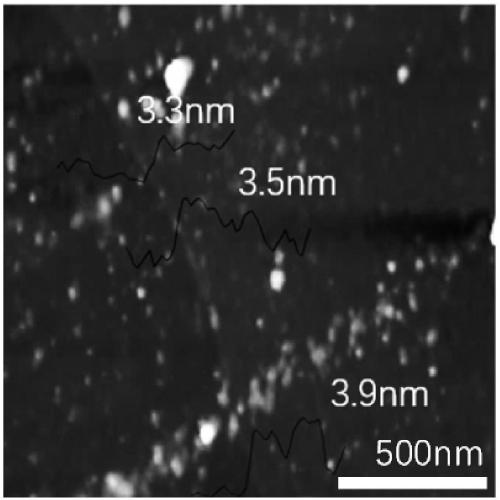

Preparation method of two-dimensional ultra-thin niobium disulfide nanosheet and product and application

The invention discloses a preparation method of a two-dimensional ultra-thin niobium disulfide nanosheet and a product and an application. The preparation method comprises the steps that niobium disulfide powder is solidified and adhered to a copper sheet through conductive silver paint and serves as a working electrode, a platinum sheet is used as a counter electrode, an aqueous solution containing H2SO4 is used as an electrolyte, and the niobium disulfide powder and the platinum sheet are immersed into the electrolyte; the positive voltage and the negative voltage are repeatedly and alternately applied to the working electrode; the electrolyte containing niobium disulfide thin sheets is filtered in a vacuum mode; and after the niobium disulfide thin sheets are washed and dried, the niobium disulfide thin sheets are dispersed in a dispersing solvent, after the ultrasonic crushing treatment, the centrifugal separation is carried out, and freezing and drying are carried out, and finallythe two-dimensional ultra-thin niobium disulfide nanosheet is obtained. The average thickness of the two-dimensional ultrathin molybdenum disulfide nanosheet is not more than 4 nm, the two-dimensional ultra-thin niobium disulfide nanosheet can be an electrolytic water cathode material, and the electrochemical performance is excellent and the stability is good. The technical scheme has the advantages of being simple and efficient, low in cost, high in controllability, good in reproducibility, suitable for industrial production and the like.

Owner:ZHEJIANG UNIV

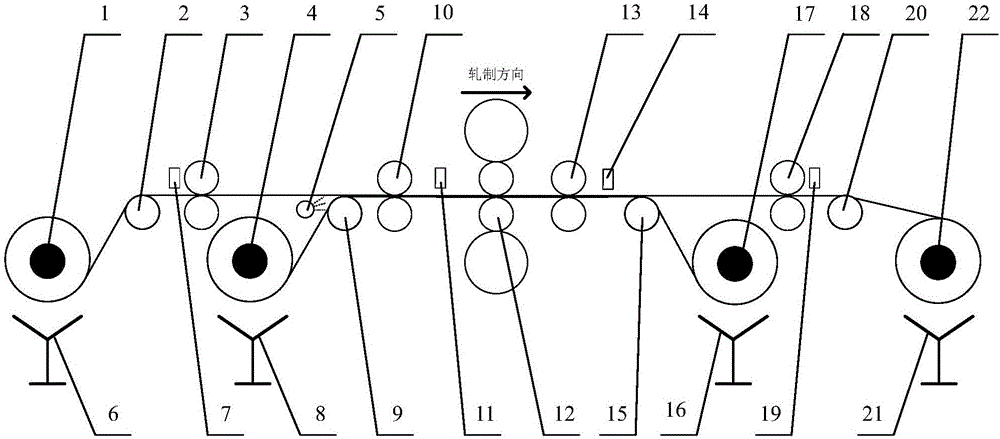

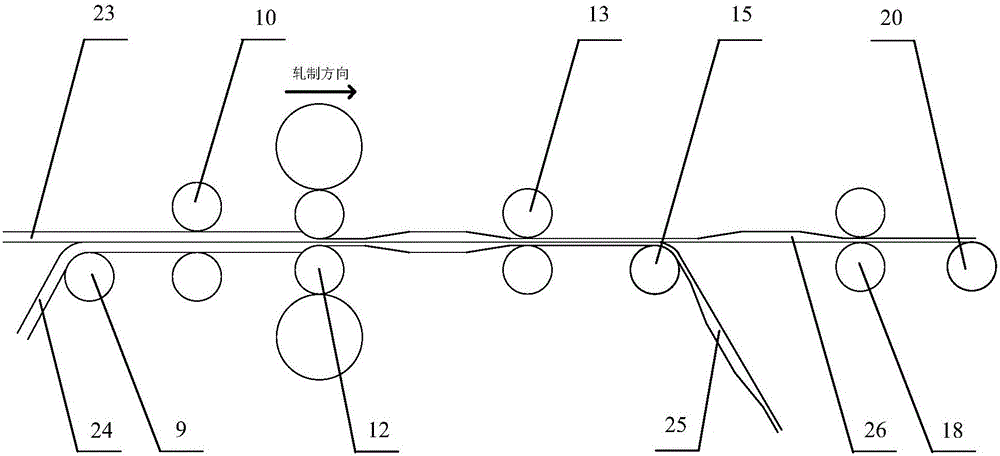

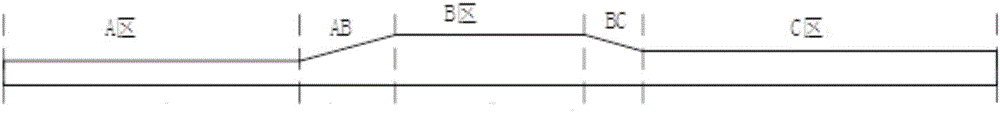

Rolling method for single-face periodically variable thickness plate strip materials

ActiveCN106513436AAchieve productionImprove rolling efficiencyTension/compression control deviceWork lubrication devicesVariable thicknessMetal

The invention disclose a rolling method for single-face periodically variable thickness plate strip materials, and belongs to the technical field of metal rolling. According to the method, double-strip synchronous variable-thickness ply rolling is conducted through two uncoilers and two coilers, that is, the two uncoilers and the two coilers are arranged on two sides of a rolling mill correspondingly. The rolling method includes the specific steps that (1) feeding is carried out, specifically, upper-layer raw plate strip materials and lower-layer raw plate strip materials are installed on the corresponding uncoilers; (2) strip penetrating is conducted, specifically, the upper-layer raw plate strip materials and the lower-layer raw plate strip materials are welded to guide strips of the corresponding coilers separately through guide strip movement and welding, so that strip penetrating is completed; (3) variable-thickness rolling is conducted, specifically, setting of rolling parameters and control over alignment, speed, thickness, tension and the like in the rolling process are included; and (4) the single-face periodically variable thickness plate strip materials are obtained and moved out. By the adoption of the method, rolling of the single-face periodically variable thickness plate strip materials and double-face periodically variable thickness plate strip materials can be realized, different production requirements are met, the rolling efficiency is greatly improved, and the production cost is lowered.

Owner:NORTHEASTERN UNIV

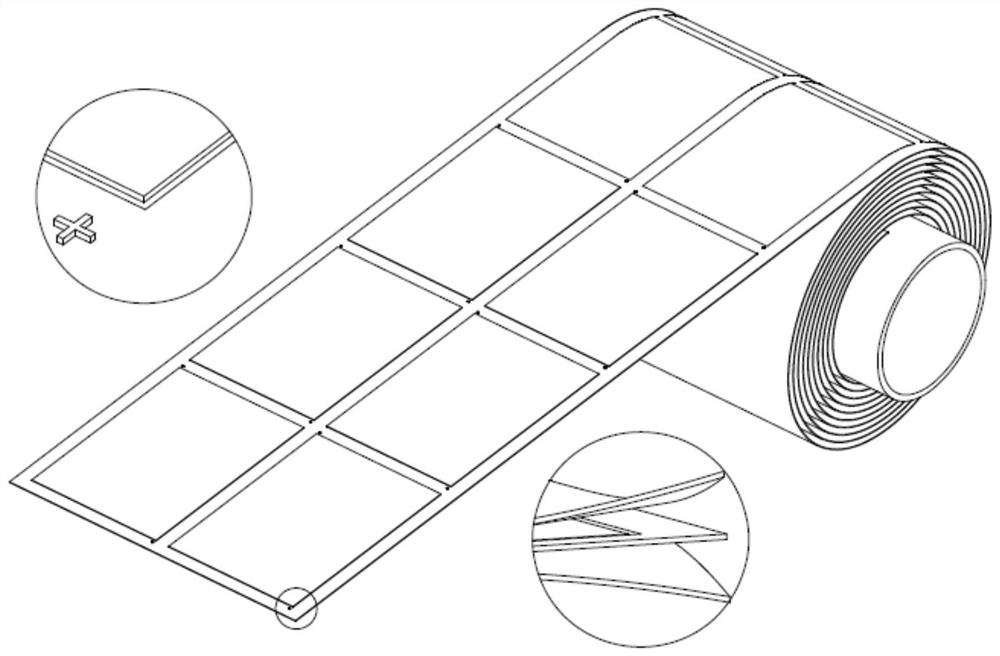

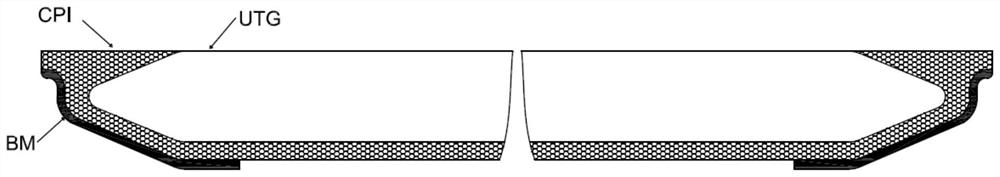

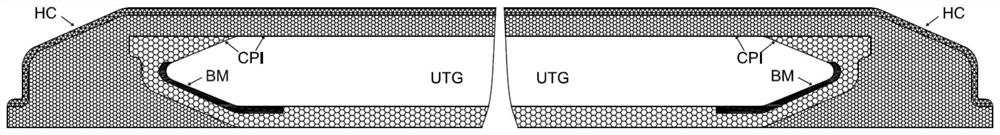

Ultrathin glass-organic film composite cover plate based on roll-to-roll process and manufacturing method thereof

ActiveCN112248581ASolve the problem of stiffnessUniform coating on the surfaceLamination ancillary operationsSynthetic resin layered productsOrganic filmLaser cutting

The invention discloses an ultrathin glass-organic film composite cover plate based on a roll-to-roll process and a manufacturing method thereof, the composite cover plate comprises ultrathin glass, afirst organic film layer at least formed on the surface of one side of the ultrathin glass and a black pattern layer located on the surface of the first organic film layer or below the first organicfilm layer, and the composite cover plate is manufactured by adopting the roll-to-roll process. According to the manufacturing method, the UTG stiffness problem is solved by attaching the UTG to the surface of the support, and meanwhile, the support can also be used as a part of a product protective film so that the manufacturing process can be reduced, and the cost can be saved; the thickness balance dielectric layer is increased around the UTG, and the UTG is subjected to surface treatment so that the surface energy of the UTG and the surface energy of the balance dielectric layer are unified, and it is ensured that a whole surface coating film of the UTG is uniform and consistent; a side coating is naturally wrapped so that the influence of UTG side microcracks is weakened, and the product performance is improved; laser cutting ensures that the edge of a product is tidy, the defects of residual films, burrs and the like are avoided, and compared with a piece-to-piece mode, the roll-to-roll manufacturing mode is large in productivity and high in benefit.

Owner:CHENGDU TOMI SHUANG DU OPTOELECTRONICS CO LTD

Fiber anti-counterfeiting identification strip

ActiveCN102682659ASimplify anti-counterfeiting production processSave huge investmentStampsIdentification meansFiberAdhesive

The invention provides a fiber anti-counterfeiting identification strip. A fiber anti-counterfeiting identification layer is formed by randomly spreading fibers on a thin film strip which is printed with a local adhesive, the random distribution characteristic information of fibers is scanned, acquired and stored in a computer anti-counterfeiting query system database which accesses a telephone network and / or the internet, and truth can be determined by people; and a user can laminate the fiber anti-counterfeiting identification layer on an article which is required to be anti-counterfeited by using the conventional labeling machine. By adoption of the fiber anti-counterfeiting identification strip, the heavy investment of the user is saved, production process is simplified, production efficiency is improved, and production cost is reduced.

Owner:HAINAN PPK NETWORK TECH

Cloth rolling machine

The invention provides a cloth rolling machine which sequentially comprises a conveying belt, a front locating device and a rear rolling device sequentially from left to right. The front locating device comprises two locating clamping plates which are arranged oppositely front and back and are the same in structure. The locating clamping plates are shaped like a question mark. Each locating clamping plate comprises an upper end clamping plate, a lower end clamping plate and a connecting plate for connecting the left side of the upper end clamping plate and the left side of the lower end clamping plate. Multiple pressing plates are connected to the portion, parallel to the corresponding upper end clamping plate, of the bottom of each upper end clamping plate. The two ends of each pressing plate are connected to the bottom surface of each upper end clamping plate through an adjusting rod. The tops of the locating clamping plates are provided with air cylinders for controlling the adjusting rods to telescope. The rear rolling device comprises a first guide frame, a second guide frame and a cloth rolling frame. The cloth rolling machine has the beneficial effects that the overall structure is simple, the industry cloth rolling efficiency is extremely high, the edges of rolled cloth are uniform, and wrinkling of a cloth body is avoided.

Owner:ANHUI HUAYE ADVANCED MATERIALS CO LTD

Solvent type gold-mixed oil for gravure and flexible print

The present invention relates to one special mixture comprising resin, organic solvent, platicizer and pigment for mixing with gold powder in printing. Specially, it consists of thermoplastic methylmethacrylate / butyl methacrylate copolymer resin 10-50 wt%, ethyl acetate 30-80 wt%, propylene glycol methyl ether acetate 1-25 wt%, dioctyl o-phthalate 1-15 wt% and pigment 1-10 wt%. It may be used in compounding gold ink with high adhesivity to base material, and this can reduce the consumption of gold powder, lower cost and makes it possible to realize large-area printing, gold stamping, etc.

Owner:山西精华科工贸有限公司

Production method for partial laser holography transfer paper

PendingCN110453534AFast penetrationIlliquidFlexible coversWrappersPolyethylene terephthalate glycolPolyethylene terephthalate

The invention belongs to the field of laser holography anti-fake packaging materials and in particular relates to a production method for partial laser holography transfer paper. The production methodcomprises the following steps: (1) performing coating, namely according to layout designing requirements of partial transfer paper, manufacturing a special edition coating anilox roller, and partially coating a PET (polyethylene terephthalate) base membrane by a transfer coating; (2) performing mold pressing, namely performing mold pressing on laser holography anti-fake information on a mold pressing machine, wherein holography information is mold-pressed in an area coated by the transfer coating, and an area without the transfer coating is not provided with the holography information; (3) performing aluminum plating, namely performing aluminum plating according to a normal laser holography aluminum plating process, enabling an aluminum layer to adhere to the coating in the area coated bythe transfer coating, and enabling an aluminum layer to adhere to the PET base membrane in the area without the transfer coating; and (4) performing combining peeling, namely smearing a transfer adhesive in a whole edition on a combining machine to combine an aluminum layer surface of the laser holography partial transfer membrane with paper, and peeling off the PET base membrane, so as to obtainpartial transfer paper. The edge of the partial transfer paper obtained by using the method is tidy, and the packaging molding speed can be greatly increased, that is, is up to 800 pieces of paper / minute at most.

Owner:湖北华工图像技术开发有限公司

Ink for white board marker and method for manufacturing same

The invention discloses a white-board pen ink and preparing method, which comprises the following parts: 3.5-5.0% dye,1.0-5.0% decapping agent,48.0-71.0% alcohol,15.0-25.0% propanol,5.0- 10.0% erasable agent,3.5-5.0% resin and 1.0-2.0% dispersant. the preparing method comprises the following steps: adding alcohol and propanol in the predispersing stove; stirring to add decapping agent, erasable agent, resin and dispersant until dissolving evenly; adding dye; stirring completely; grinding for 20-30h until the grain size D50 of dye particle reaches 120-200nm; discharging.

Owner:苏州三威纳米科技有限公司

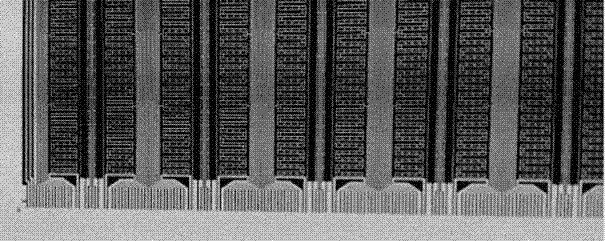

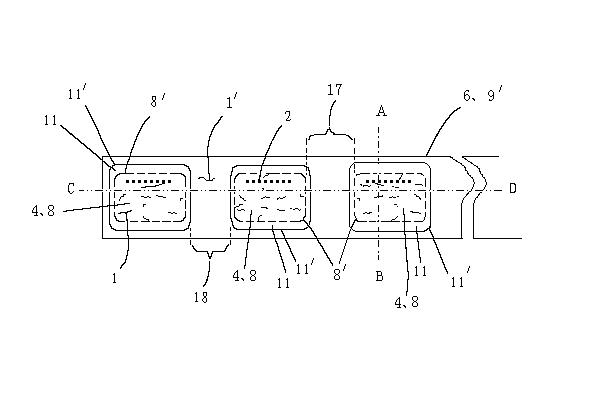

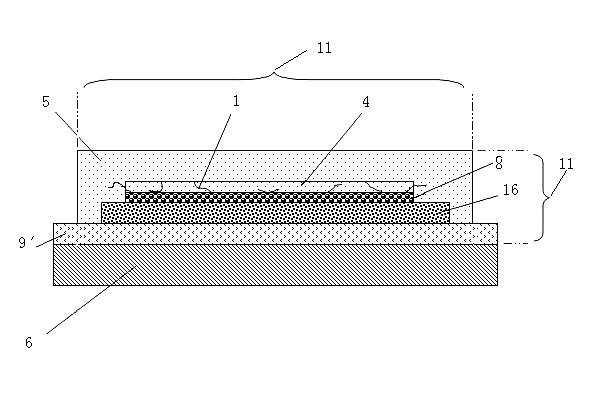

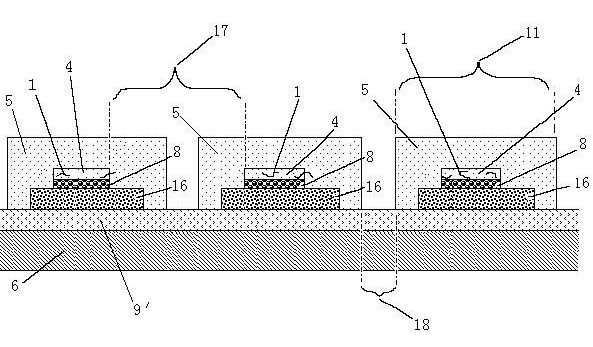

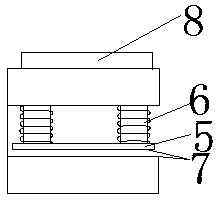

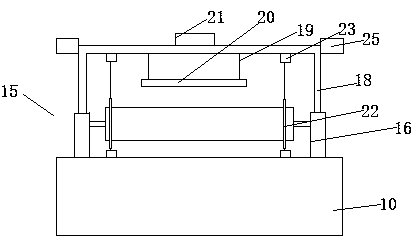

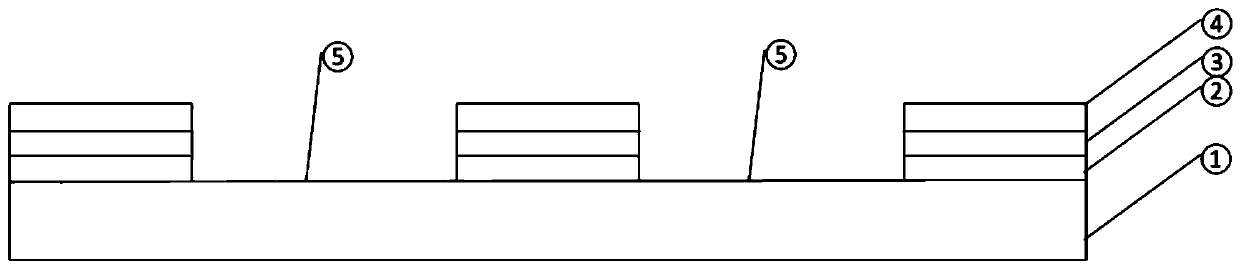

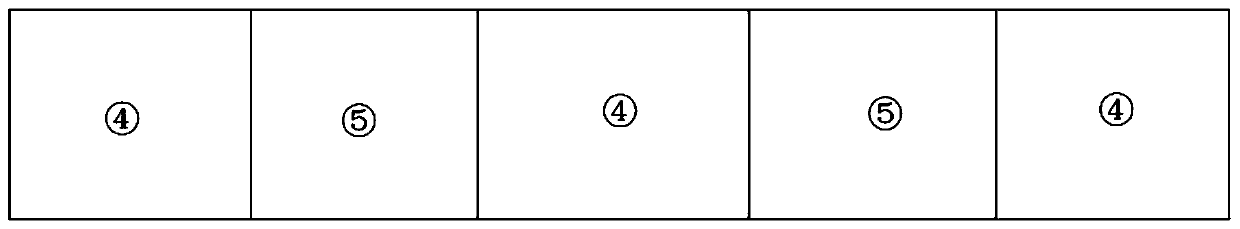

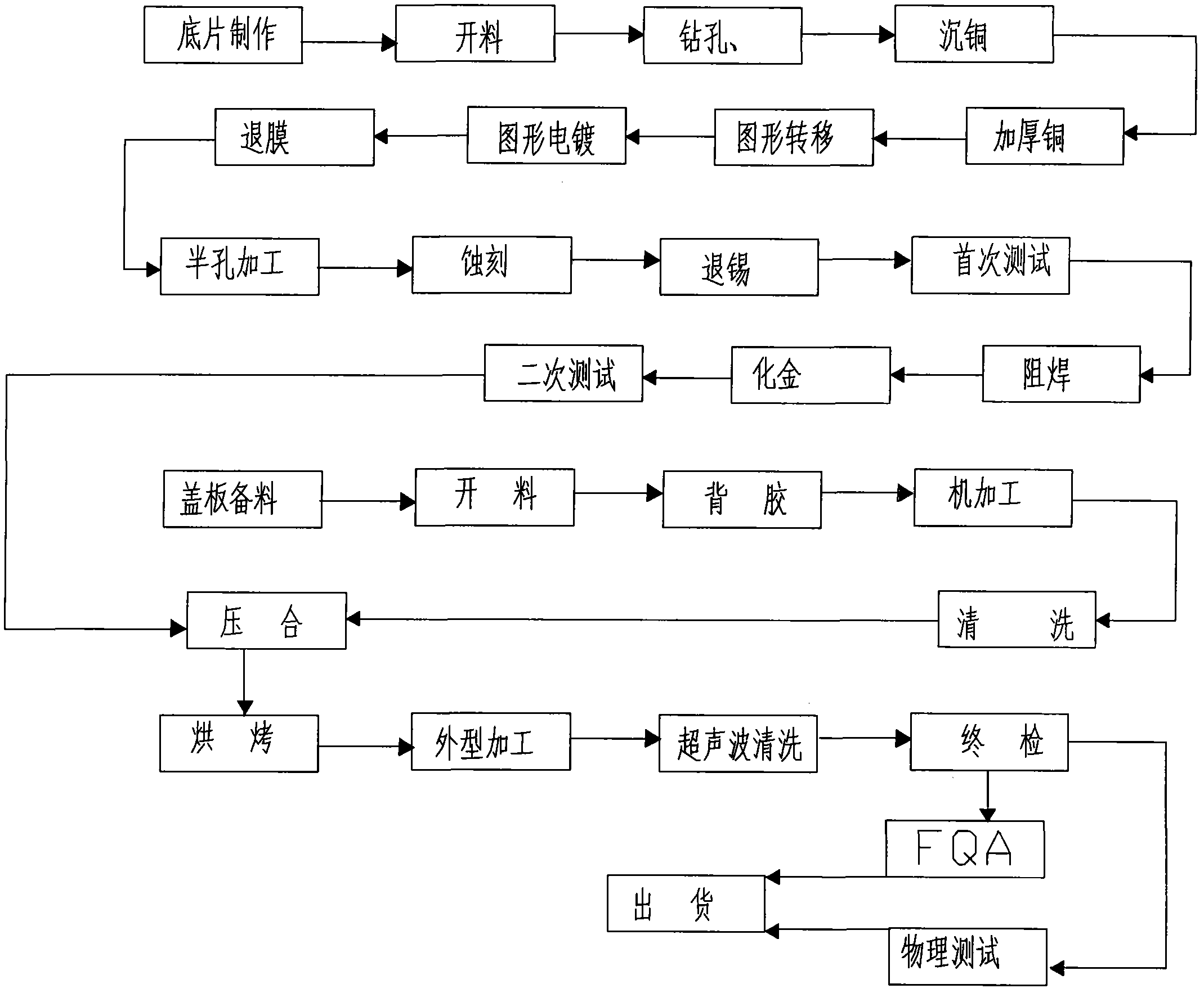

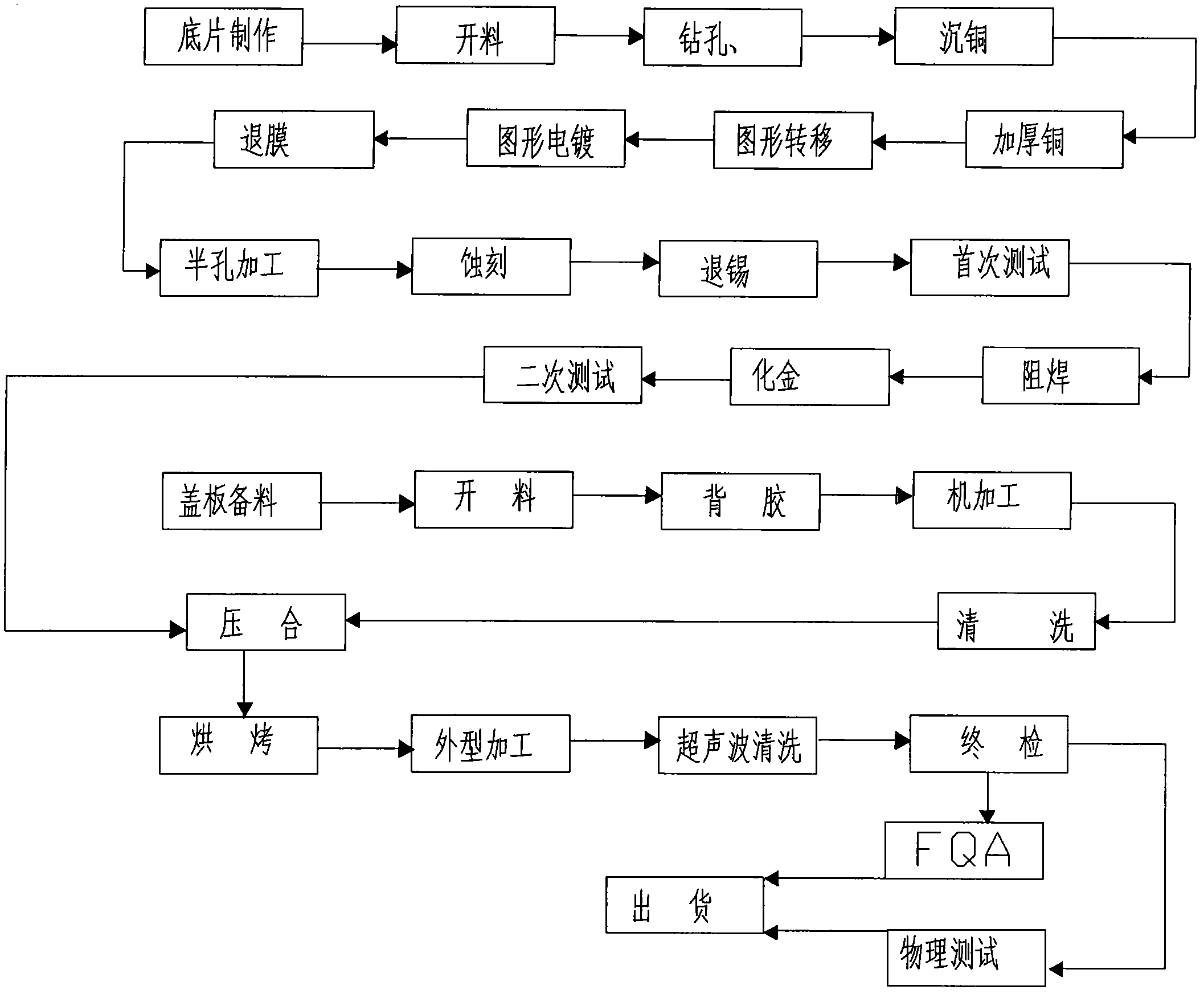

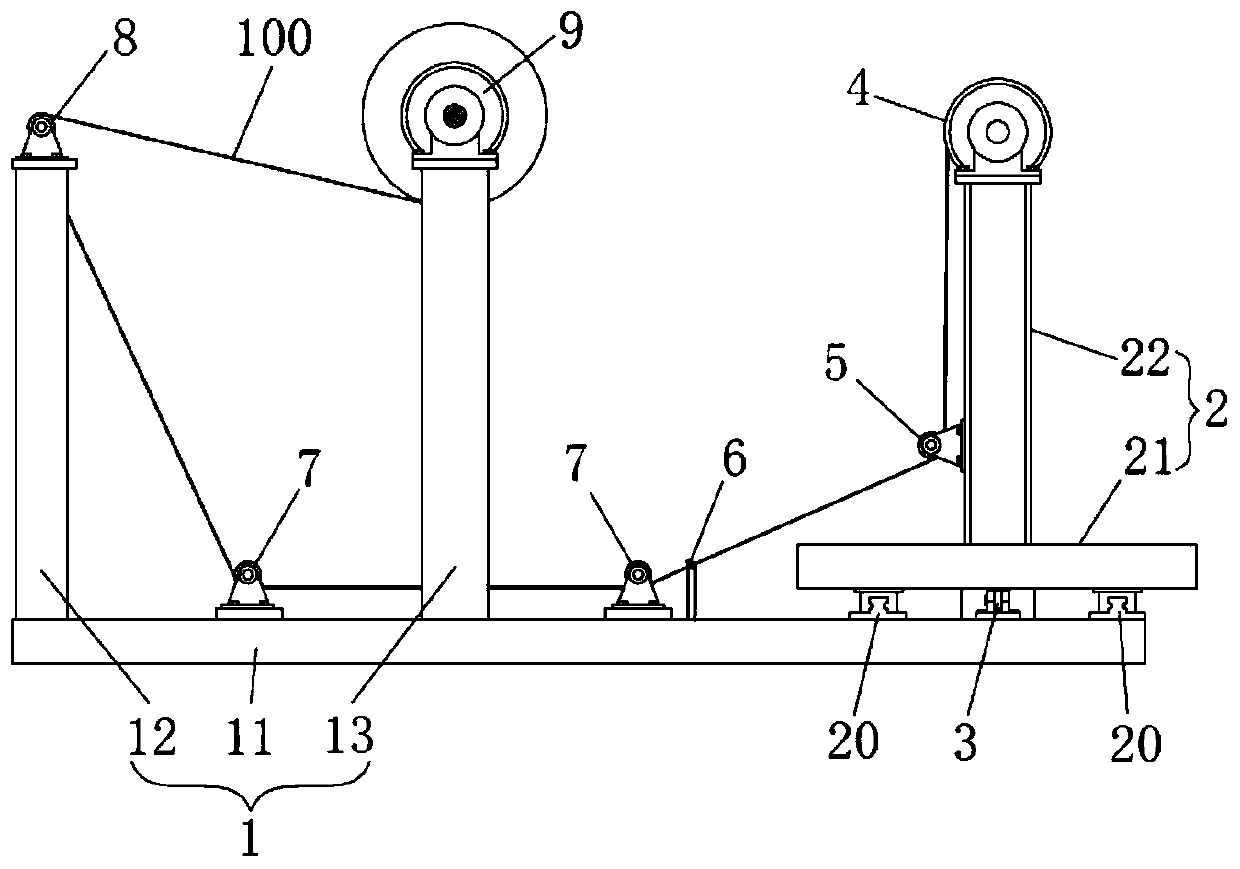

New ic packaging manufacturing process

InactiveCN102290354AHigh precisionNo residual copperSemiconductor/solid-state device manufacturingCooking & bakingEngineering

A new type of IC packaging manufacturing process, including the back plate manufacturing process, the cover plate manufacturing process and the packaging process of the back plate and the cover plate, wherein the back plate manufacturing process includes film production; material cutting; drilling; sinking copper; thickening copper; pattern transfer ;Graphic electroplating; Stripping film; Half-hole processing; Etching; Stripping tin; Solder mask; Gold plating; Cover plate manufacturing process includes cover plate preparation; The process includes pressing; baking; cleaning; final inspection. The beneficial effects of the present invention are: the manufactured lines have high precision, no residual copper and smooth lines after etching, no deformation of the cover plate, no serious glue overflow, the bonding force between the cover plate and the main board reaches more than 10KG, and the substrate has no separation after machining. Layers, half holes without burrs, neat edges and no dust.

Owner:慈溪市永旭丰泰电子科技有限公司

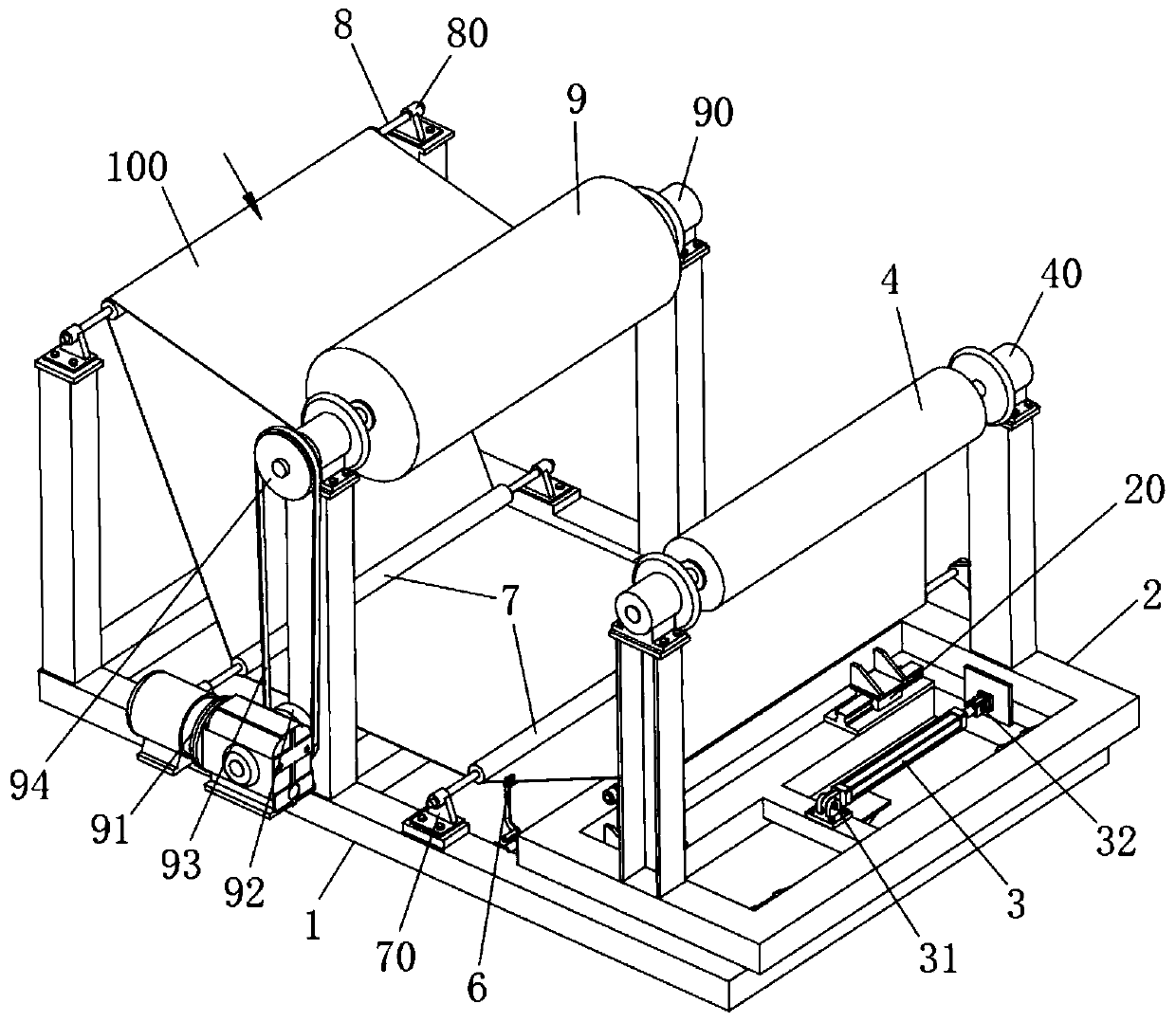

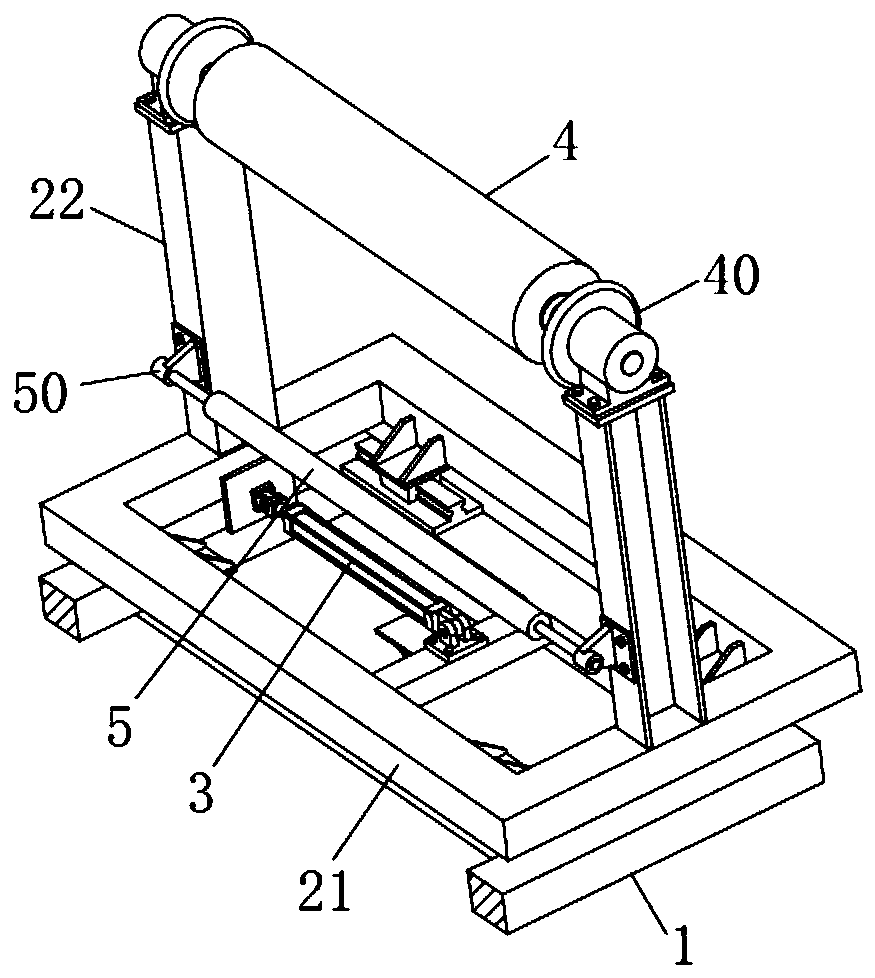

Cloth rolling device and method for producing glue canvas

PendingCN110697478ALow costIncrease productivityArticle deliveryWebs handlingGlue lineMechanical engineering

The invention discloses a cloth rolling device and method for producing glue canvas and belongs to the technical field of glue canvas production. The cloth rolling device comprises a cloth roller anda winding roller horizontally arranged, a primary bracket for mounting the winding roller, a secondary bracket for mounting the cloth roller, a driving device for driving the secondary bracket to moveleft and right relative to the primary bracket, and a detecting device for detecting cloth deviation, wherein the secondary bracket is movably connected onto the primary bracket; and the detecting device is arranged on one side of cloth between the cloth roller and the winding roller. During the production process, the detecting device detects that cloth deviates, then, the secondary bracket is controlled to move to change the position of the cloth roller, so that the purpose of correcting cloth deviation is further realized; the glue line at the edge of the produced glue canvas is in order,the edge does not to be cut during the using process, so that the material cost is lowered, and the production efficiency is improved; and moreover, during the production process, the glue line does not exceed the cloth edge to be glued to the cloth rolling device, so that the periodic cleaning cost is reduced.

Owner:马鞍山锐生工贸有限公司

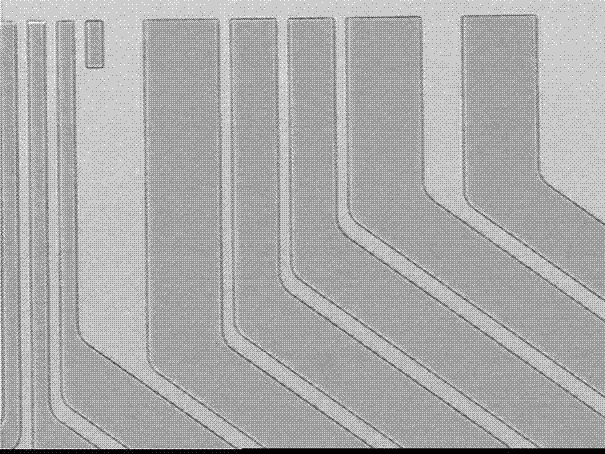

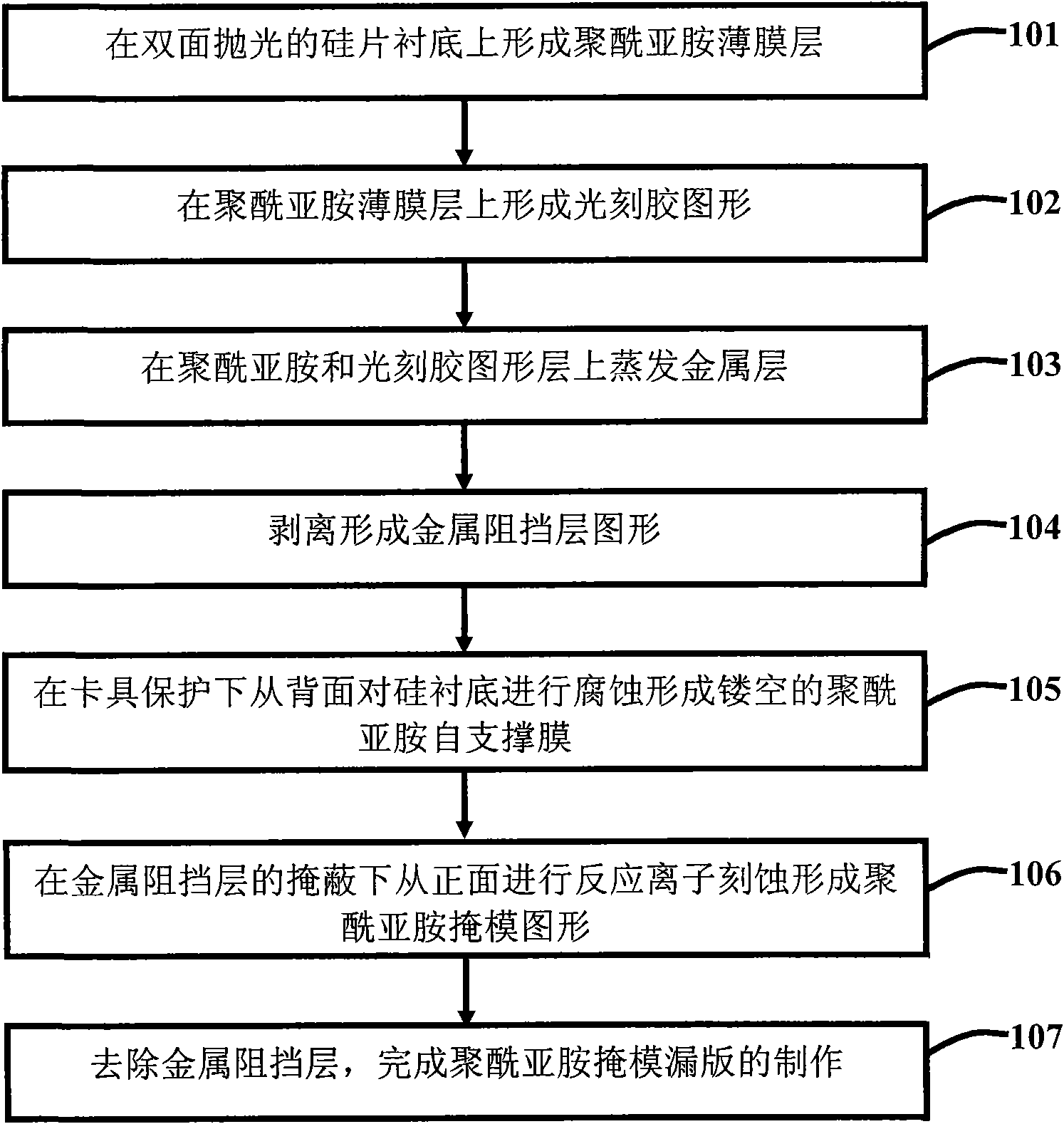

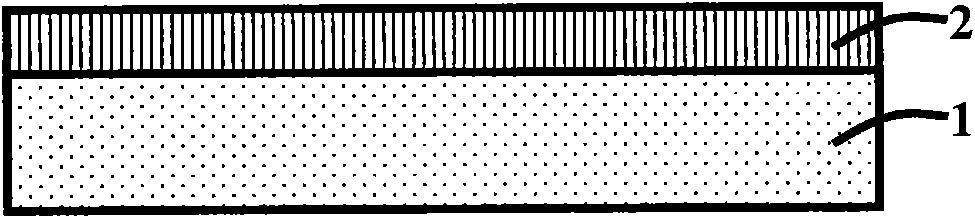

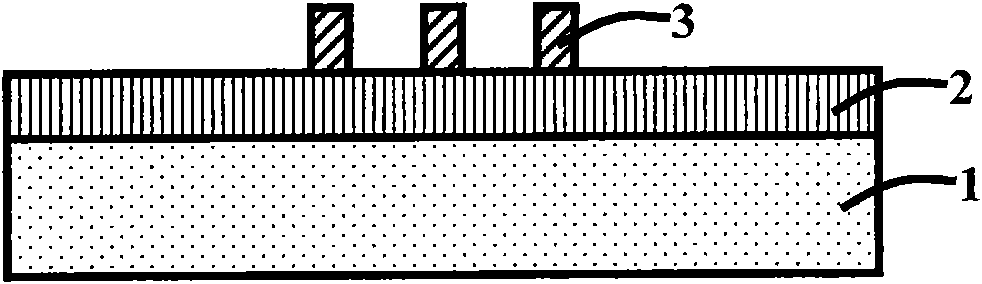

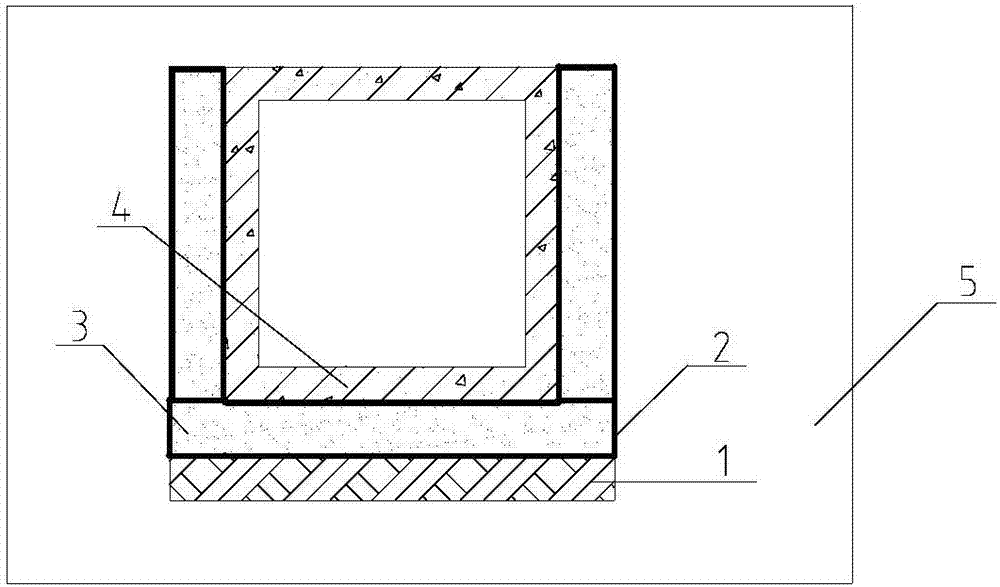

Method for preparing hollowed-out polyimide evaporation shadow mask

ActiveCN101566799AReduce processing costsGraphic size is accuratePhotomechanical apparatusEvaporationReactive-ion etching

The invention discloses a method for preparing an evaporation shadow mask for manufacturing semiconductor devices, which comprises the process steps: 1, forming a polyimide film layer on a silicon chip substrate with double-sided polishing; 2, forming a photoresist pattern on the polyimide film layer; 3, evaporating a metal layer on a polyimide layer and a photoresist pattern layer; 4, peeling to form a metal barrier layer; 5, corroding a silicon substrate from the back side under the protection of a fixture to form a hollowed-out polyimide self-supporting film; 6, performing reactive ion etching from the right side under the masking of the metal barrier layer to form a polyimide mask pattern; and 7, removing the metal barrier layer to finish the production of a polyimide shadow mask. The method for producing the shadow mask by utilizing a polyimide material has small process difficulty, high precision of graphic dimensions and low manufacturing cost, and is suitable for large-area graphization process of the field of the preparation of organic semiconductor devices.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

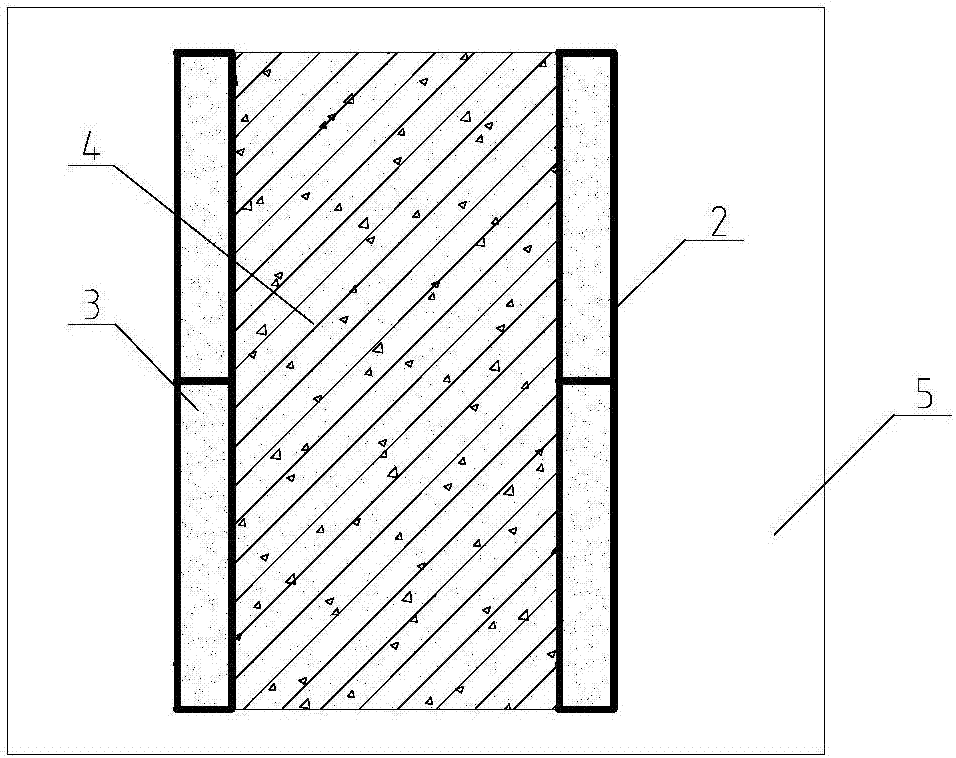

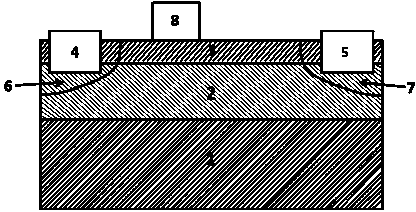

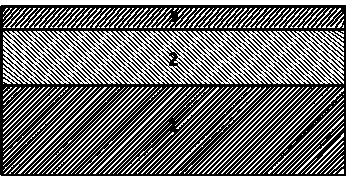

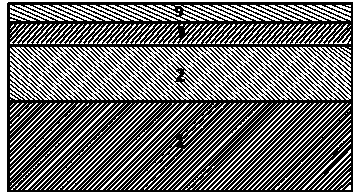

Sand cushion isolation and shock absorption device for comprehensive pipe gallery and building method thereof

ActiveCN106869171AInexpensive and convenient materialsLow costArtificial islandsProtective foundationStructure of the EarthBuilding construction

The invention provides a sand cushion isolation and shock absorption device for a comprehensive pipe gallery and a building method thereof. The sand cushion isolation and shock absorption device has the advantages of simple structure, convenience in construction, low cost of construction, high applicability and convenience in popularization and implementation. The sand cushion isolation and shock absorption device comprises a foundation isolation and shock absorption device and side wall isolation and shock absorption devices. The comprehensive pipe gallery is buried in a stratum and is formed by foundation mats at the bottom, side walls on the two sides and top plates at the top in a surrounded mode. A foundation isolation and shock absorption layer is arranged under the foundation mats of the comprehensive pipe gallery and is formed by packing coarse sand by earthwork cloth, and a rammed 37 lime earth layer is arranged under the foundation isolation and shock absorption layer. Side wall isolation and shock absorption layers are arranged on the earth meeting surfaces of the side walls of the comprehensive pipe gallery and are formed by packing coarse sand by earthwork cloth. The foundation isolation and shock absorption device and the side wall isolation and shock absorption devices surround the three surfaces of the comprehensive pipe gallery except for the top plates, thereby forming an isolation and shock absorption layer.

Owner:XI AN JIAOTONG UNIV

Ohmic contact production method of aluminum gallium nitride and gallium nitride HEMT (High Electron Mobility Transistor)

ActiveCN104112658AAvoid destructionGuaranteed reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesMetallic electrodeOhmic contact

The invention provides an ohmic contact production method of an aluminum gallium nitride and gallium nitride HEMT (High Electron Mobility Transistor). The ohmic contact production method comprises step 1, injecting doped ions in a designated area, activating the ions at the high temperature through annealing, defining graphics of the injection area by a lithography method, depositing a metal mask and performing stripping, enabling injection required positions to be exposed out, serving metal as a mask defined injection area during injection and serving silicon ions as injection ions and step 2, etching an aluminum gallium nitride barrier layer of part of the injection area and depositing the metal at the positions where the aluminum gallium nitride is etched to be in direct contact with a gallium nitride layer. According to the ohmic contact production method of the aluminum gallium nitride and gallium nitride HEMT, the ohmic contact resistivity can be low; a metal electrode is good in surface smoothness and reliability; the ohmic contact of the aluminum gallium nitride and gallium nitride HEMT can be achieved without an aluminum contained multilayer metal system and accordingly the damage of the follow-up process to the ohmic contact due to the fact that chemical properties of the aluminum metal are lively is avoided and the reliability of the ohmic contact is improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

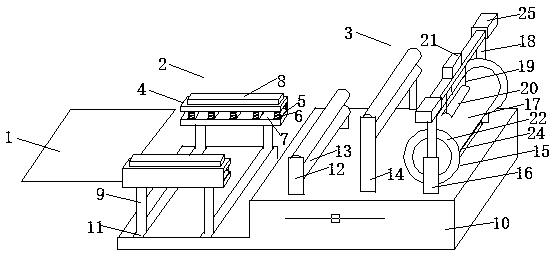

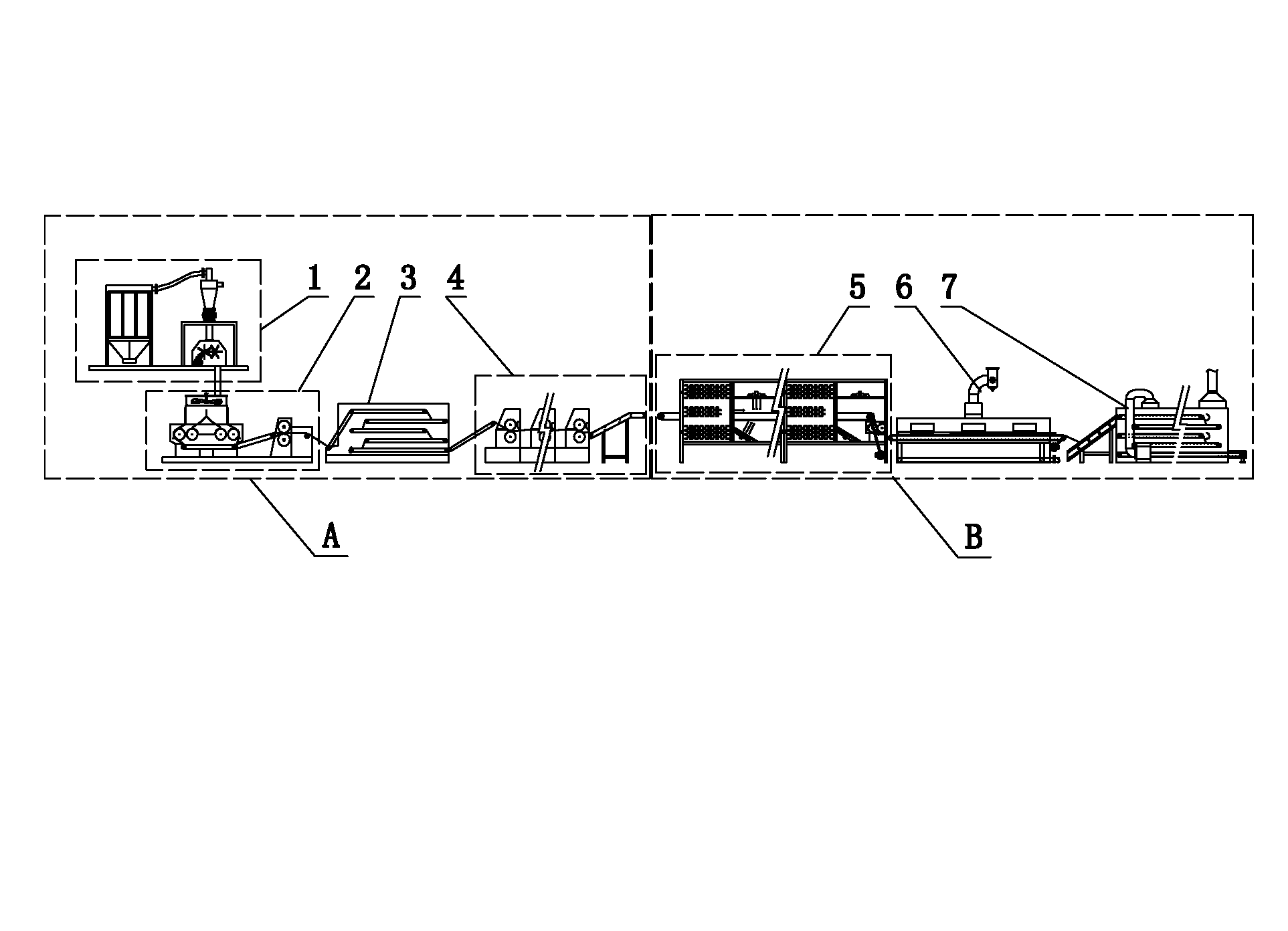

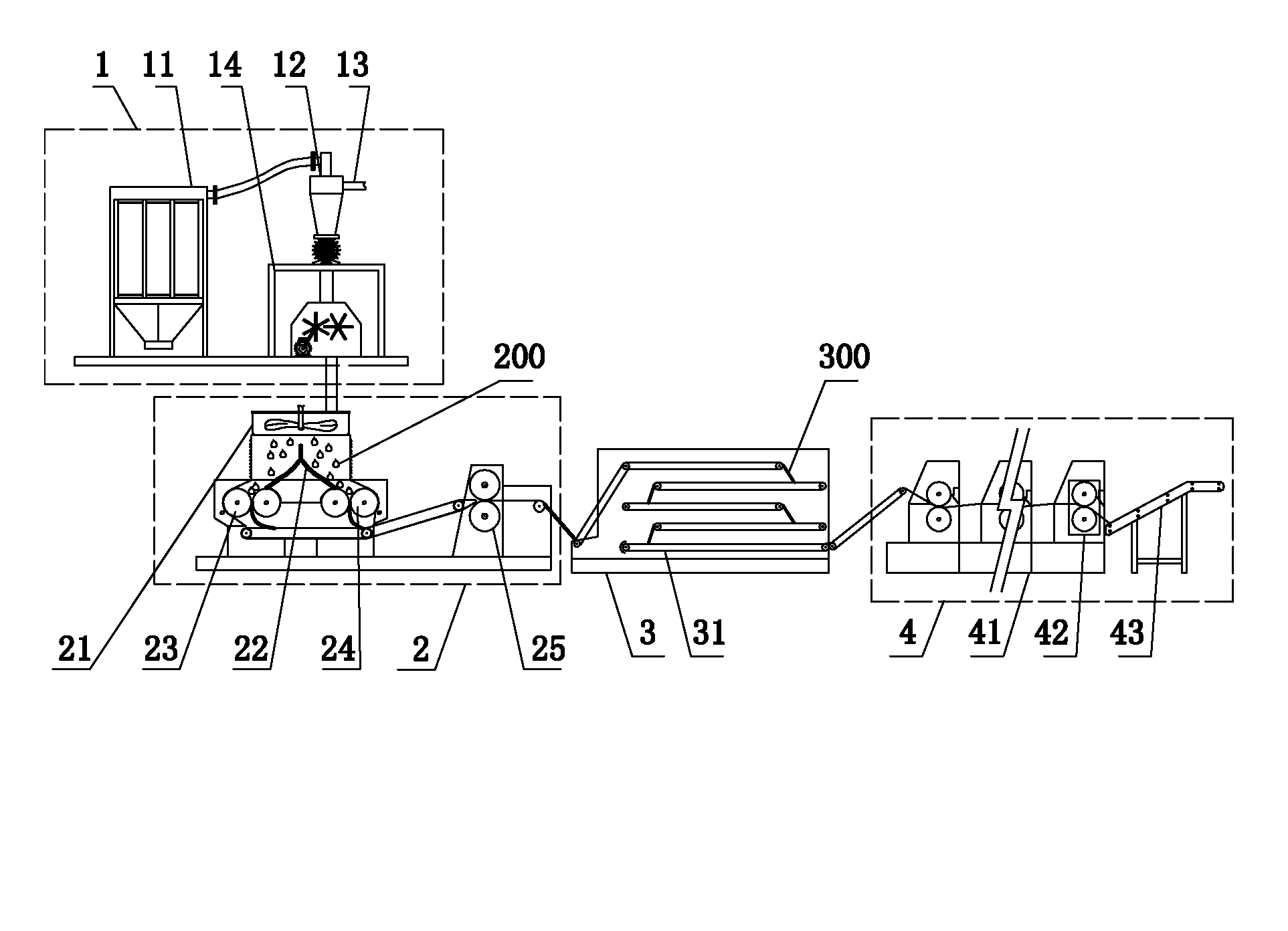

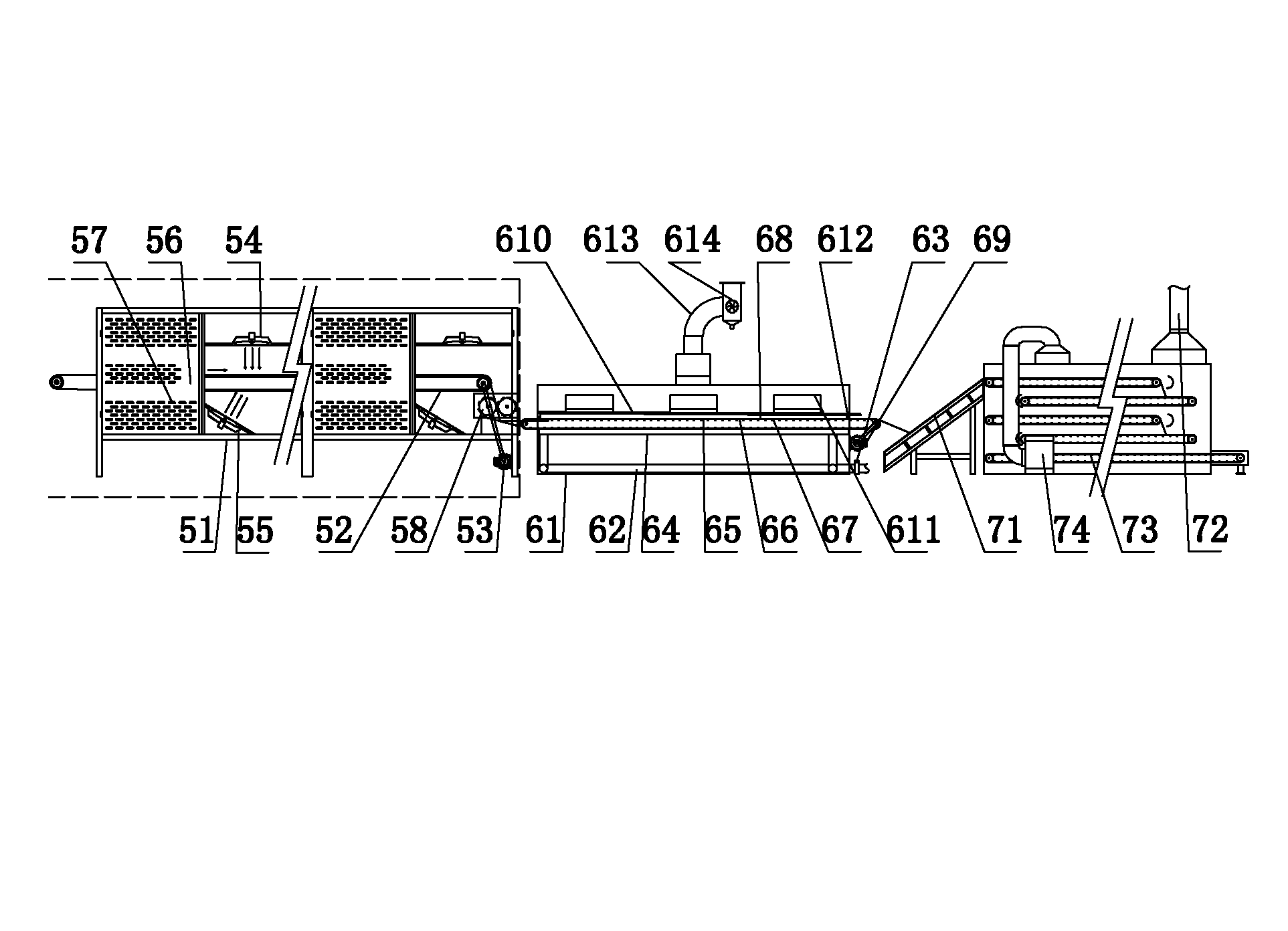

Novel sliced noodle production line

ActiveCN102919687AIncrease contact areaReduced Chances of ContaminationFood preparationHigh concentrationProduction line

The invention discloses a novel sliced noodle production line, which comprises a dough making machine, a wheat belt combining machine, an aging machine, a rolling device, drying devices, and a sliced noodle heating device. The wheat belt combining machine is arranged below the dough making machine; the aging machine is arranged on the right side of the wheat belt combining machine; the rolling device is arranged on the right side of an aging machine; a first drying device is arranged on the right side of the rolling machine; the sliced noodle heating device is arranged on the right side of the first drying machine; and a second drying device is arranged on the right side of the sliced noodles heating device. The production line has the characteristics of high concentration, high automation, high production efficiency, low energy consumption and the like. The novel sliced noodle production line can complete automatic feeding, dough making, combining, rolling, steaming, cutting, drying and other processes. Cut by the dough cutting roll with uniform edge, the noodles are in good shape and easy to pack. The novel sliced noodle production line is very suitable for fast and instant food processing and therefore has a bright market prospect in the industry.

Owner:HUBEI GUDASAO FOOD

Preparation method for peelable glue protection graph of capacitive touch screen

InactiveCN102929450AImprove yieldNeat edgesMetal working apparatusInput/output processes for data processingEngineeringComputer Aided Design

The invention relates to a preparation method for a peelable glue protection graph of a capacitive touch screen. The method provided by the invention is characterized by comprising the following steps: firstly, uniformly printing a layer of peelable glue on a whole ITO (indium tin oxide) graph of a touch screen substrate by means of screen printing; secondly, drying the printed substrate in a drying oven; thirdly, putting the dried substrate on a table board of a cutting machine, aligning MARK points made on the substrate and a CCD (charge coupled device) on the cutting machine, inputting a CAD (computer aided design) file to be cut and cutting corresponding graphs by using a specifically grinded cutting head; and finally manufacturing the required peelable glue protection graph by tearing off the peelable glue on regions no longer needing to be covered and retaining the peelable glue on the region needing to be protected. The peelable glue protection graph formed by the invention is not only accurate in size and position but also convenient to adjust; edges of the peelable glue are also trim; pollution to the substrate by the drying of the peelable glue is well avoided; and the yield is effectively improved when leads at the periphery of the touch screen substrate are plated with gold.

Owner:PANDA ELECTRONICS GROUP

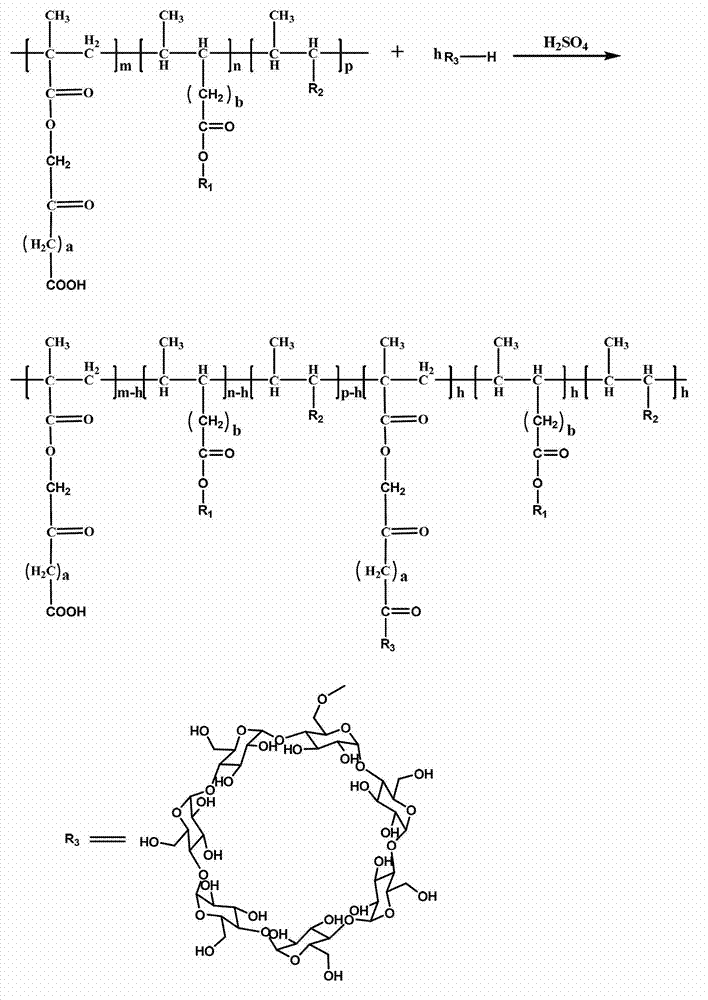

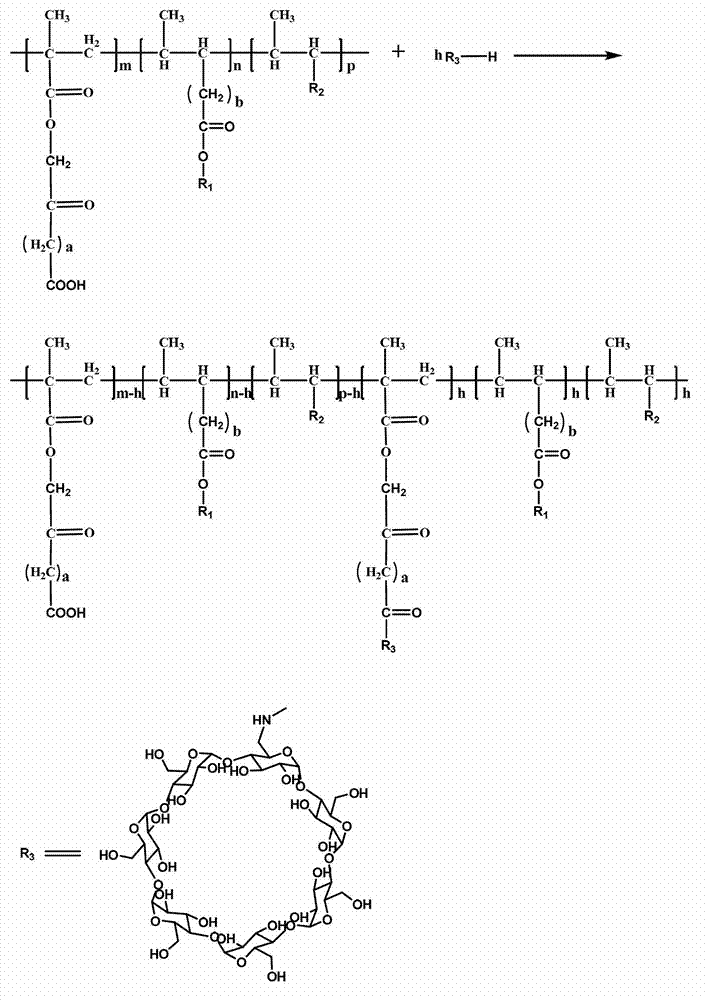

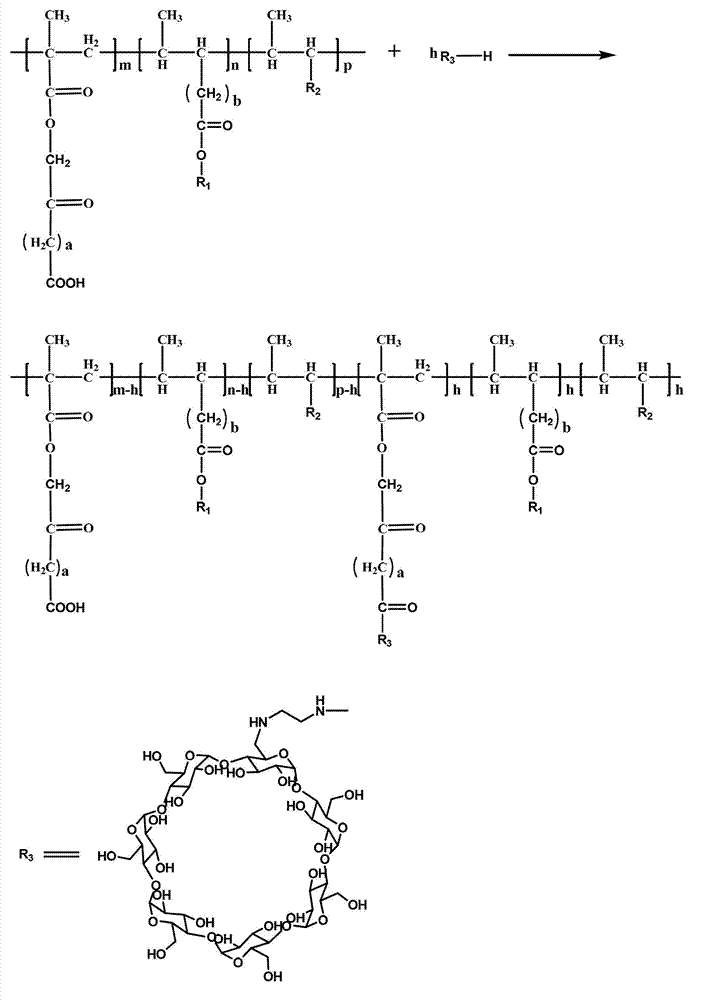

Alkali-soluble resin, preparation method of alkali-soluble resin and photoresist

ActiveCN102898561AImprove compatibilityImprove stabilityPhotosensitive materials for photomechanical apparatusEster bondPhotoresist

The invention provides alkali-soluble resin, a preparation method of the alkali-soluble resin and a photoresist. The alkali-soluble resin is modified by beta-cyclodextrin or a derivative of the beta-cyclodextrin, the beta-cyclodextrin or the derivative of the beta-cyclodextrin is bonded with the alkali-soluble resin through an ester bond or an amido bond. The alkali-soluble resin can be used for preparing the photoresist. The alkali-soluble resin contributes to improvement of stability of the photoresist, contributes to promotion of developing natures, reduces production of residues and obtains uniform, smooth and flat graph surfaces.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com