Production method for partial laser holography transfer paper

A technology of laser holography and production method, applied in the field of laser holographic anti-counterfeiting packaging materials, can solve the problems of uneven edges, affect the packaging effect, and many waste products, and achieve the effect of neat edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

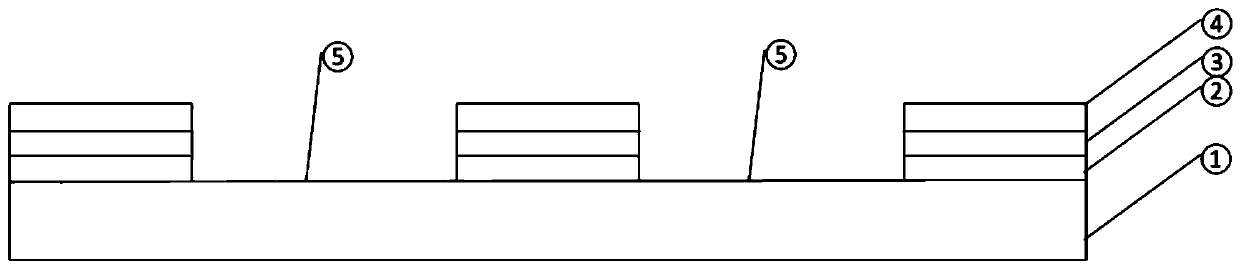

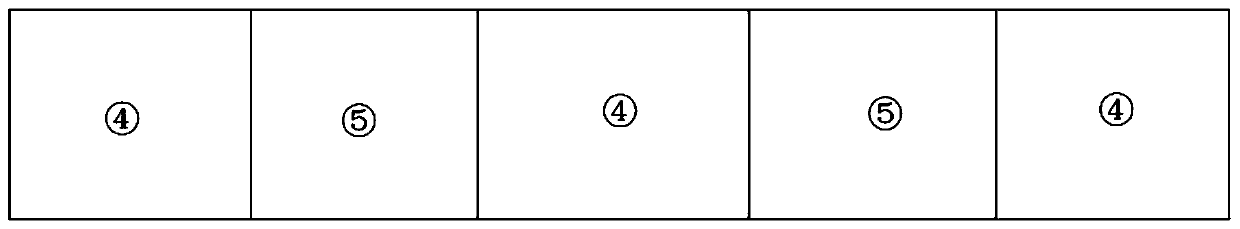

[0019] Such as figure 1 As shown, a partial laser holographic transfer paper of the present invention includes a paper 1 , an adhesive 2 , an aluminized layer 3 , a transfer coating layer 4 , and a partially hollowed out area 5 . Multiple sets of aluminum-coated layers 3 and transfer paint layers 4 are arranged on the paper 1, the transfer paint layers 4 are arranged on the aluminum-coated layers 3, and there is a partially hollowed out area 5 between adjacent aluminum-plated layers 3 and transfer paint layers 4, and the partially hollowed out Area 5 is the base paper, and the aluminum-plated layer 3 is fixed on the paper 1 through the adhesive 2 .

[0020] Paper 1 of the present invention can be coated paper, cardboard or frame paper, and the grammage range is 90-400g, namely 90-400g / m 2 , the thickness of the paper 1 can be determined acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com