Outdoor waterborne woodenware penetration paint and preparation method thereof

A water-based wood paint and outdoor technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of not being able to effectively prevent wood cracking and deformation, achieve wide application range, good weather resistance, and reduce shear damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

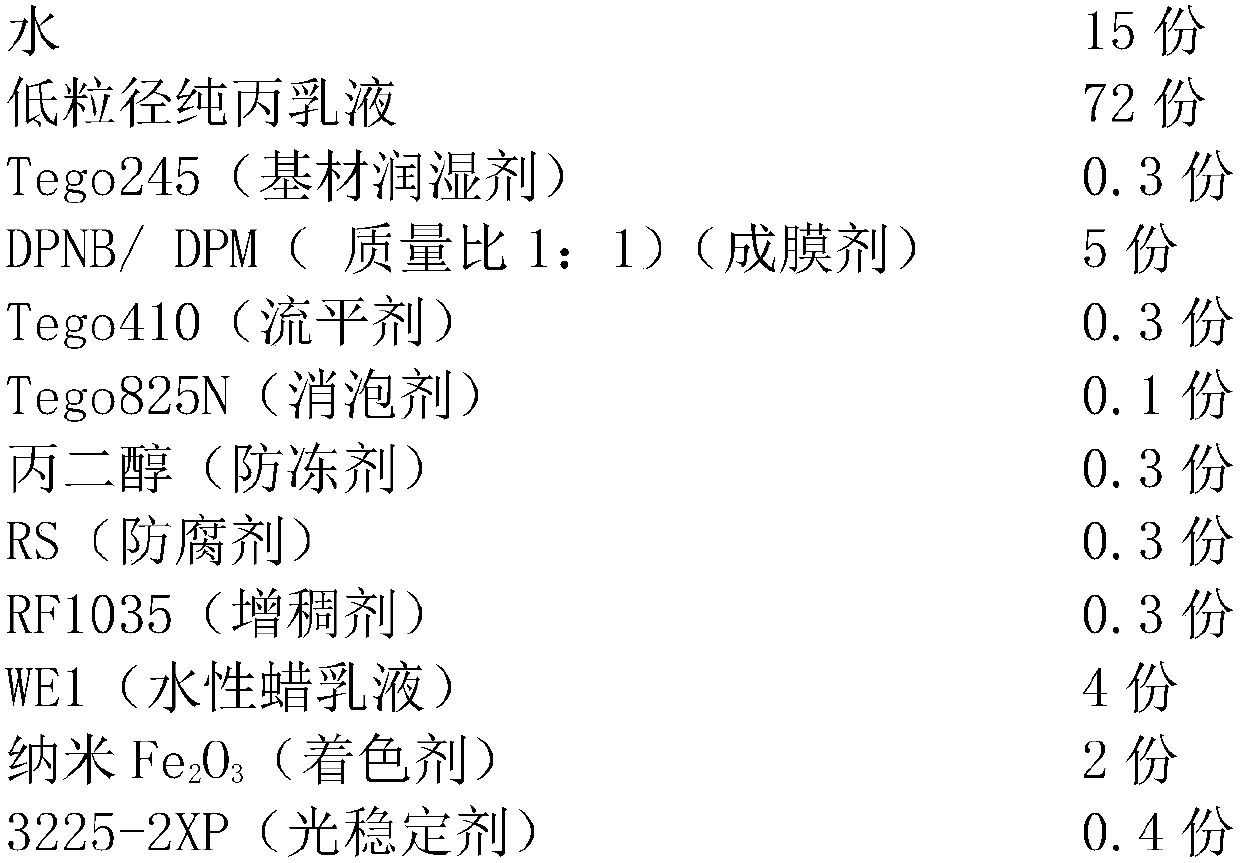

[0036] A penetrating outdoor water-based wood paint, configured according to the following formula in parts by weight:

[0037]

[0038] In the above example:

[0039] The low particle size acrylic emulsion in the formula is a low particle size pure acrylic emulsion with a particle size of <60nm. The emulsion is a core-shell type self-crosslinking acrylic emulsion, preferably DSM's AQ-2538.

[0040] The above-mentioned products are all commercially available products.

[0041] The above-mentioned permeable outdoor wood paint preparation steps are as follows:

[0042] (1) Start the disperser and adjust the speed to 400-500 rpm. At this speed, first add 72 parts of water-based emulsion with low particle size pure acrylic emulsion, add 4 parts of film-forming aid to 5-10 parts of water, and then Slowly add to the above aqueous emulsion and stir for 10-20min;

[0043](2) Then add 0.3 parts of water-based leveling agent, 0.1 part of defoamer, 0.3 part of substrate wetting age...

Embodiment 2

[0047] The low particle size pure acrylic emulsion with a particle size < 60nm in the formula of Example 1 was replaced with a low particle size styrene-acrylic emulsion with a particle size < 60nm, a styrene-acrylic emulsion with a core-shell structure. The content of the remaining substances is the same as formula 1, and the production steps are also the same as formula 1.

[0048] The low particle size styrene-acrylic emulsion in the above formula is preferably Meijinsi Chemical 1092.

Embodiment 3

[0050] The low particle size pure acrylic emulsion in the formula of Example 1 was replaced with the low particle size aliphatic polyurethane emulsion with particle size<60nm. The content of the remaining substances is the same as formula 1, and the production steps are also the same as formula 1.

[0051] The low particle size aliphatic polyurethane emulsion in the above formulation is preferably Lubrizol's 2026C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com