Preparation method of two-dimensional ultra-thin niobium disulfide nanosheet and product and application

A technology of niobium disulfide and ultra-thin bismuth is applied in the field of preparation of two-dimensional ultra-thin niobium disulfide nanosheets, which can solve the problems of long time consumption, low feasibility, and difficult operation, and achieves low cost and controllability. High and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Preparation of niobium disulfide powder

[0058] (1) Sulfur powder and niobium powder are mixed according to the stoichiometric ratio, and after fully grinding, the mixture is sealed in a vacuum quartz glass tube;

[0059] (2) Use a tube furnace to heat the mixture from room temperature, the heating temperature is 1050°C, the holding time is 10h, the heating rate is 5°C / min, and the temperature is naturally lowered after the heating is completed to obtain niobium disulfide powder.

[0060] 2. Electrolyte Preparation

[0061] Take 83.4mL of concentrated sulfuric acid, pour it into an appropriate amount of water to dilute, transfer to a 1000mL volumetric flask, set the volume to the mark, and shake well to obtain 1.5M H 2 SO 4 electrolyte.

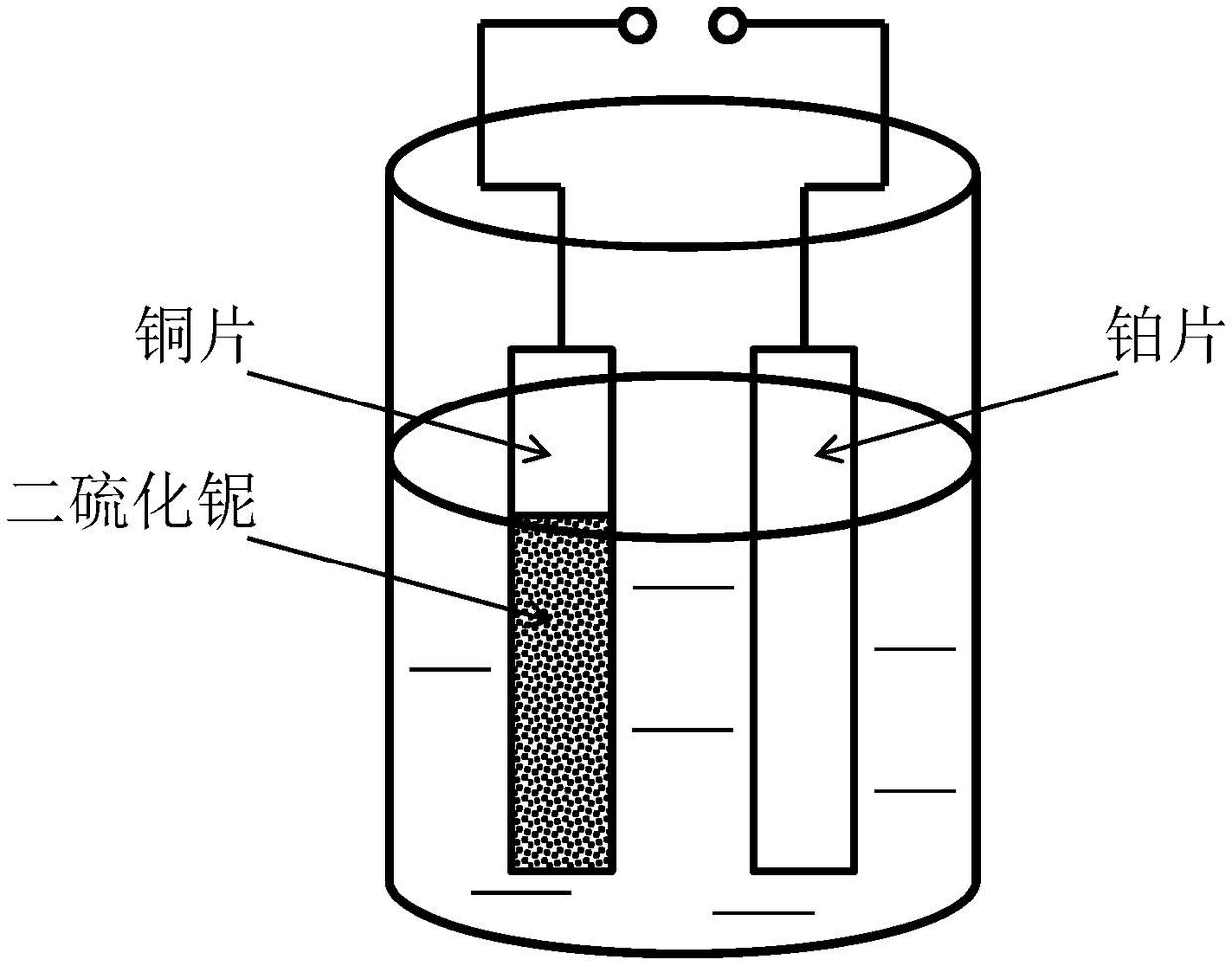

[0062] 3. If figure 1 As shown, the niobium disulfide powder was peeled off alternately by electrochemical positive and negative electrodes

[0063] (1) The niobium disulfide powder is cured and bonded on the copper sheet thro...

Embodiment 2

[0093] Compared with Example 1, the only difference is that the dispersion solvent used in the ultrasonic process is isopropanol, and other conditions are the same. Such as Figure 9 As shown, the obtained two-dimensional ultrathin niobium disulfide nanosheets exhibited an overpotential of -494mV in an acidic electrolyte.

Embodiment 3

[0095] Compared with Example 1, the only difference is that the dispersion solvent used in the ultrasonic process is dimethyl sulfoxide, and other conditions are the same. Such as Figure 9 As shown, the obtained two-dimensional ultrathin niobium disulfide nanosheets exhibited an overpotential of -386mV in an acidic electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

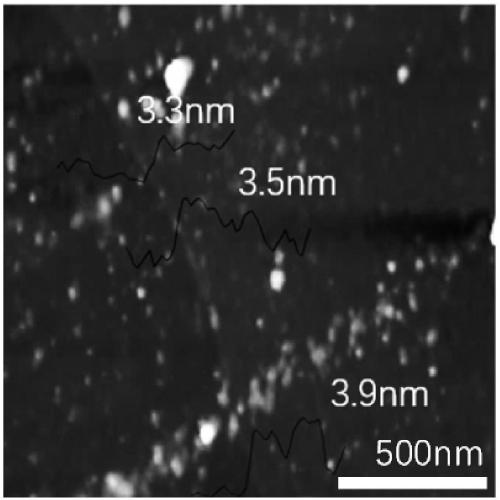

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com