New ic packaging manufacturing process

A manufacturing process and packaging process technology, applied in the field of IC packaging process, can solve the problems of easily changing cover plates, low packaging precision, and uneven etching lines, etc., and achieve the effect of neat shape edges and high line precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is described in further detail below:

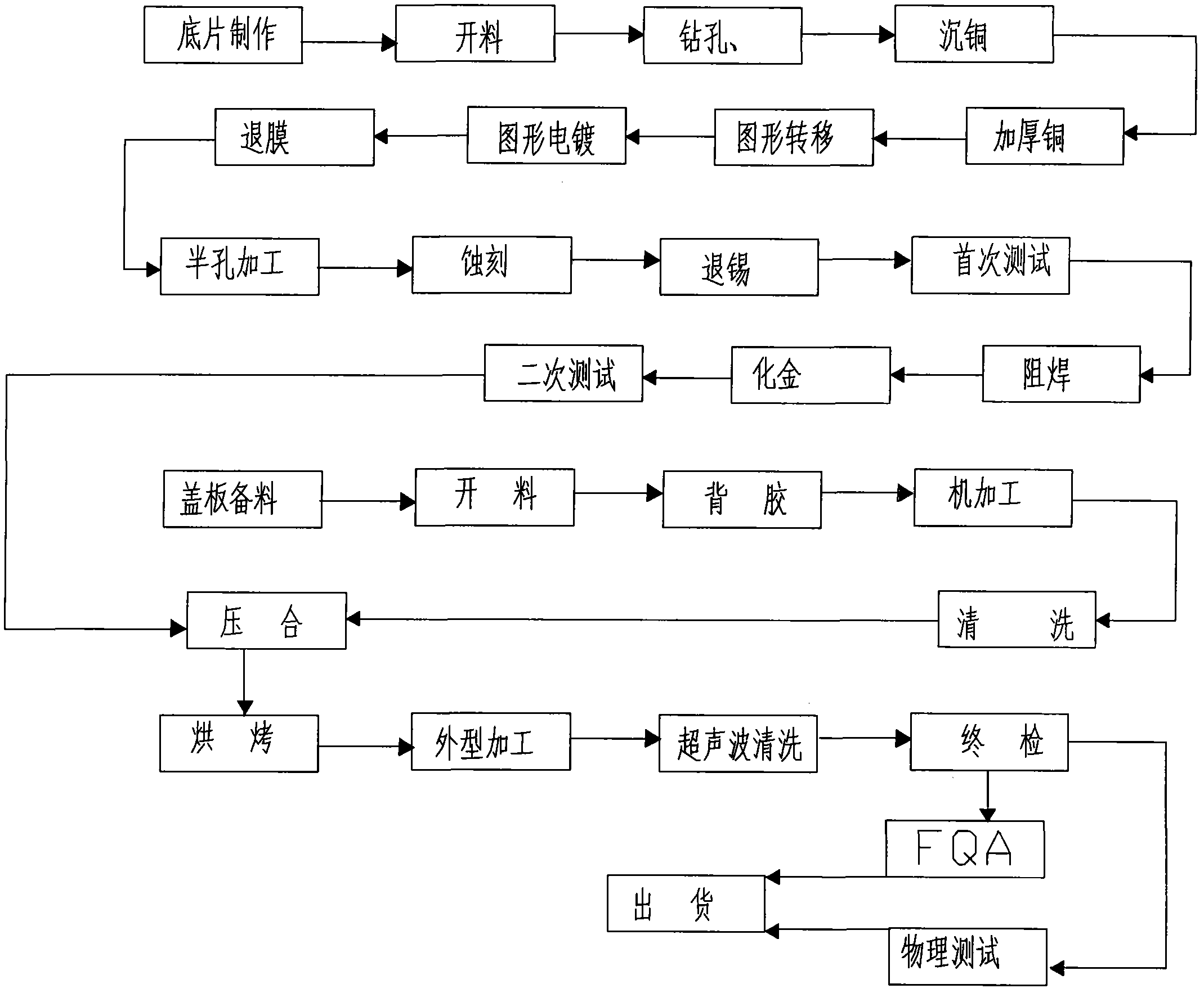

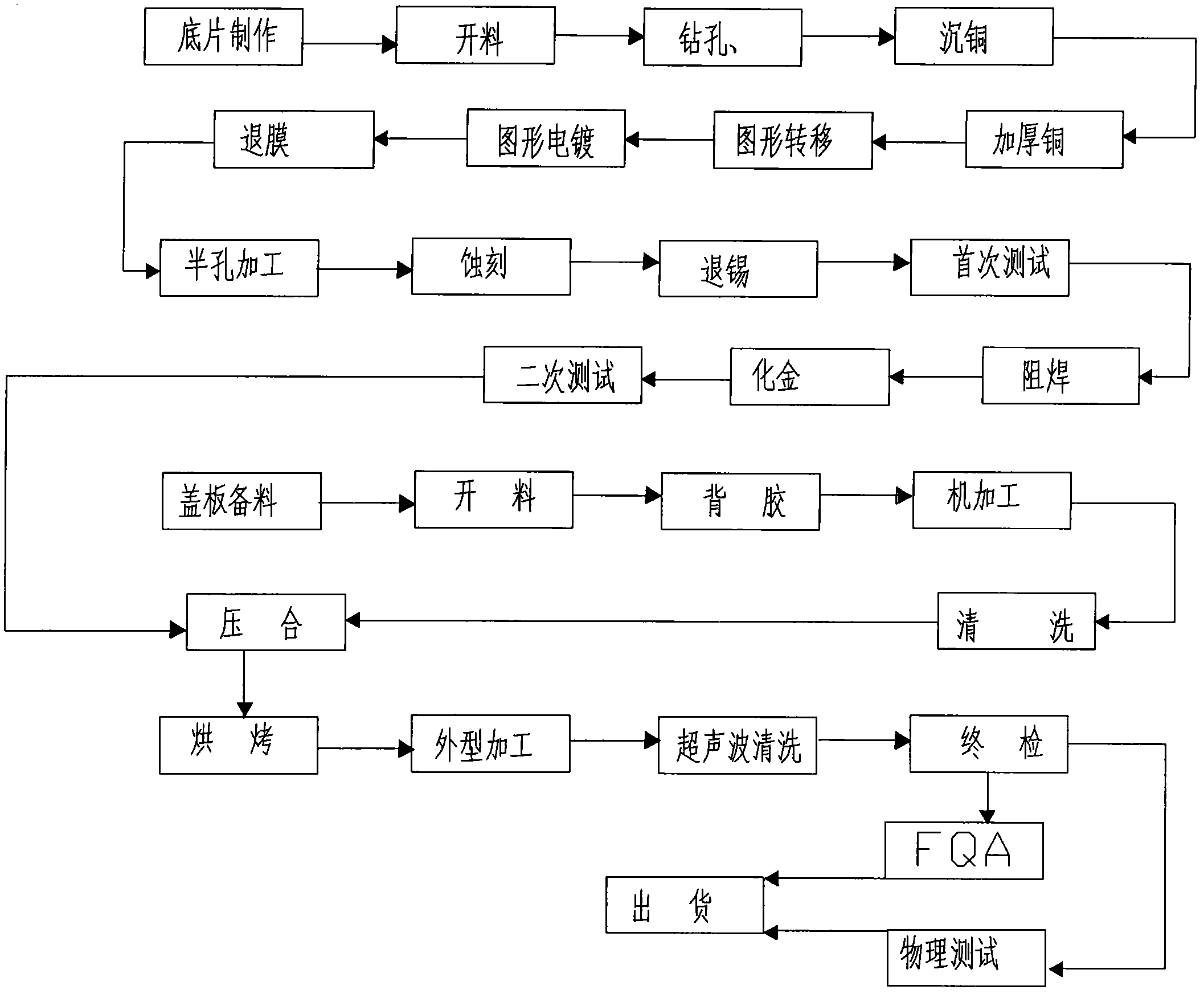

[0047] Such as figure 1 As shown, a new type of IC packaging manufacturing process, including the bottom film manufacturing process, the cover plate manufacturing process and the packaging process of the bottom film and the cover plate,

[0048] Described film manufacturing process comprises:

[0049] Step 1.1, negative film production, that is, the production of light-painted negative film; process compensation must be carried out when performing light-painted negative film, and the process compensation must be determined based on measuring the side etching of Cu with different thicknesses. The negative film is a positive film, and the line width compensation method Yes: formula [loss amount (MIL) = base copper (MIL) / 1.2], for example: 35UM base copper has a loss amount of 35 / 25.4*1.2=1.2miL, and its loss amount is line width loss amount + compensation amount, The line width can be adjusted within the requ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com