Patents

Literature

469results about "Work lubrication devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additives for lubricating agents used in the lamination of lithium sheets into thin films

InactiveUS6019801AReduce water contentQuality improvementElectrode rolling/calenderingPrimary cellsLithiumPolymer science

These additives are represented by the following general formula:L-Y-Sin which L designates a hydrocarbon radical which serves as lubricating segment; S designates an oligomer segment which serves as solvating segment of metallic salts and Y designates a chemical bond which joins the hydrocarbon radical and the oligomer segment. With these additives there is no more need to subsequently wash the surface of laminated lithium.

Owner:BATHIUM CANADA

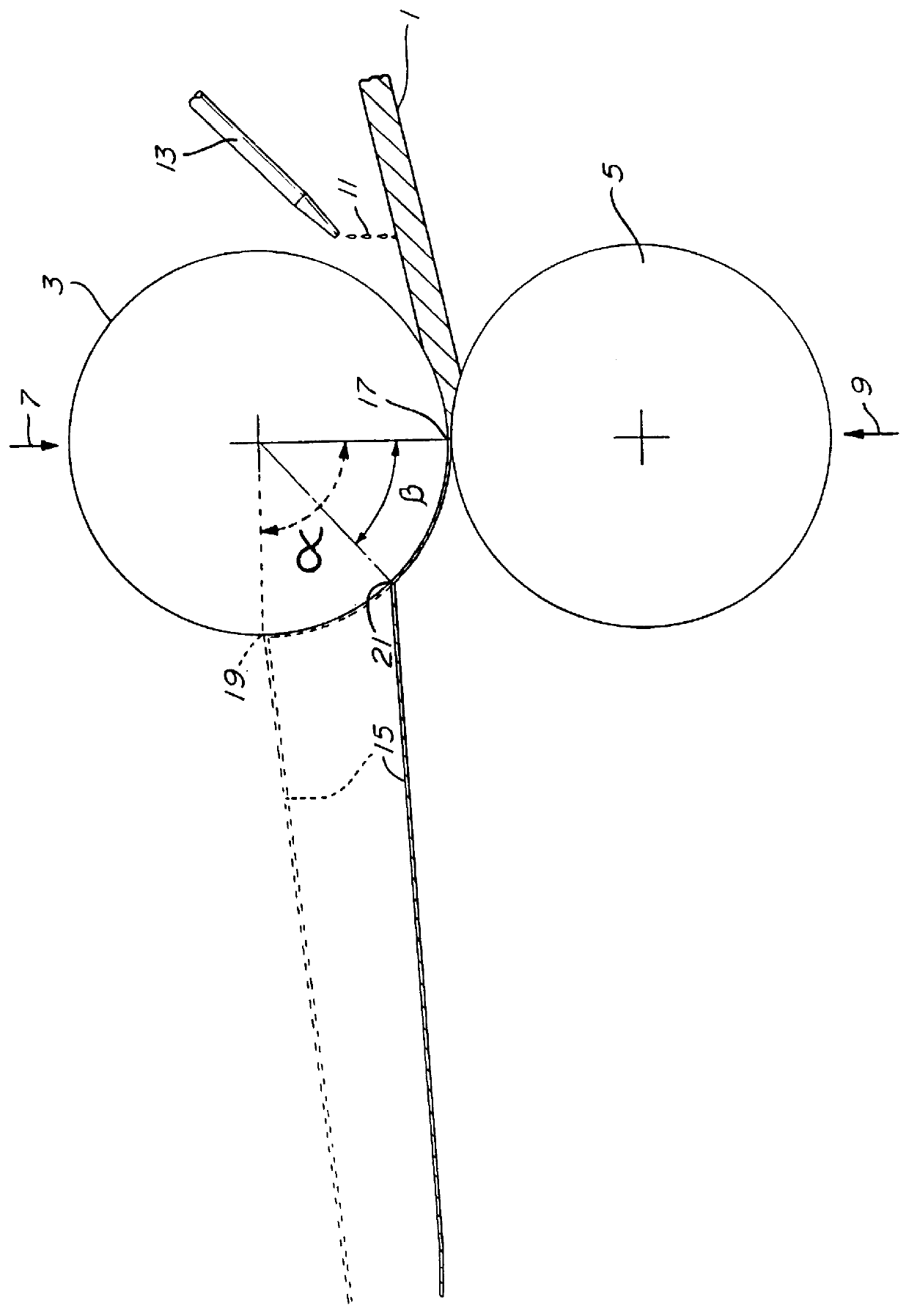

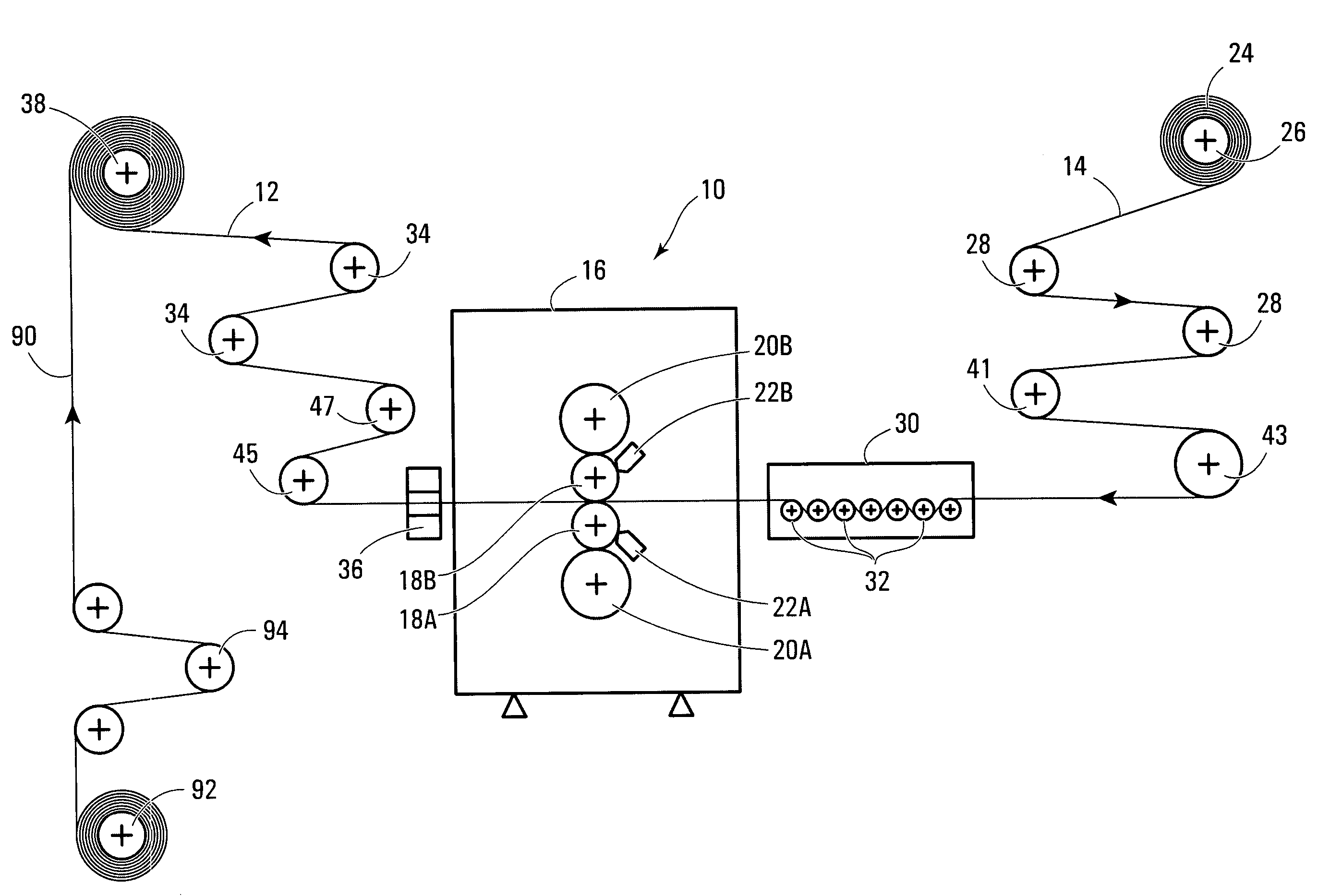

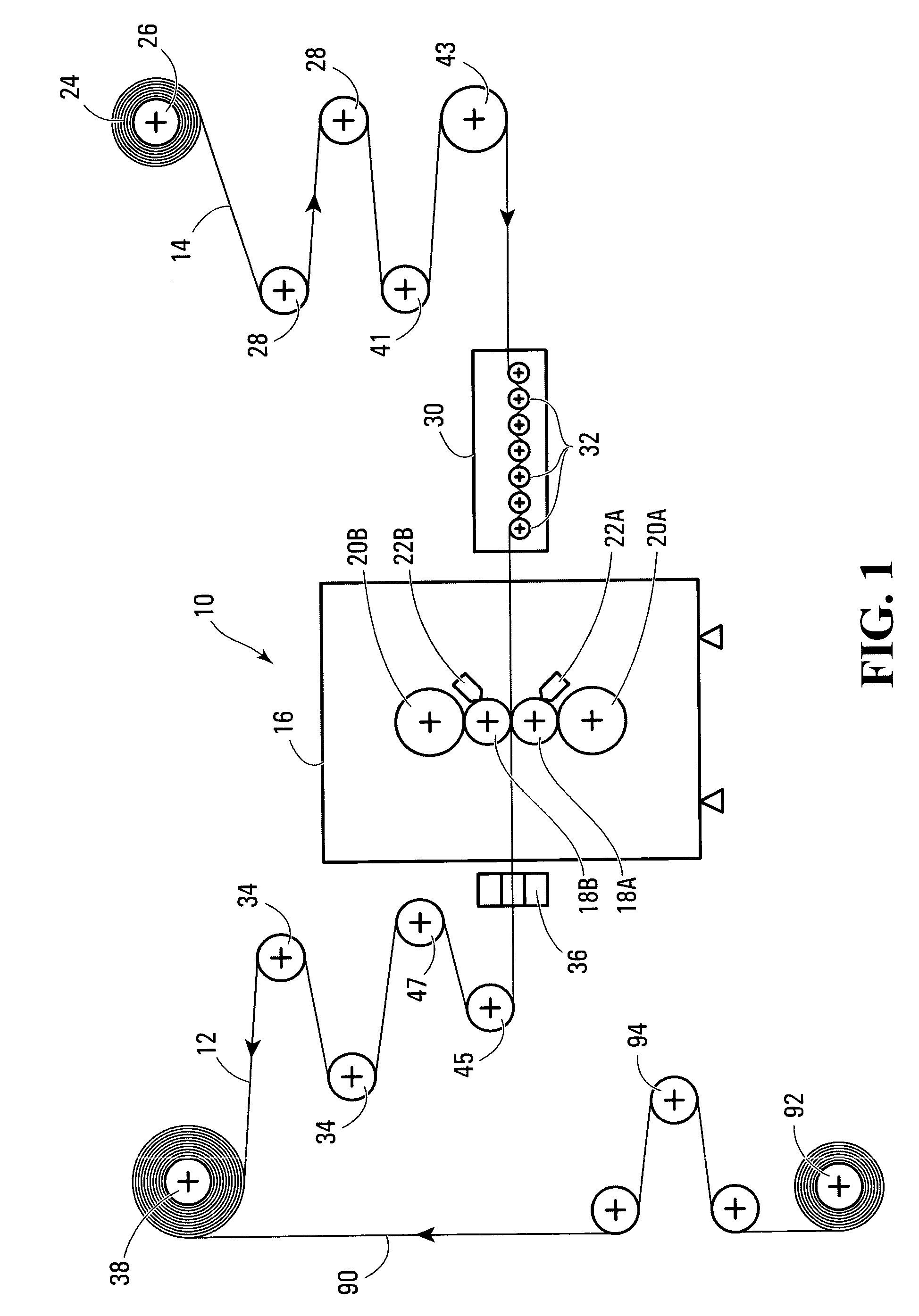

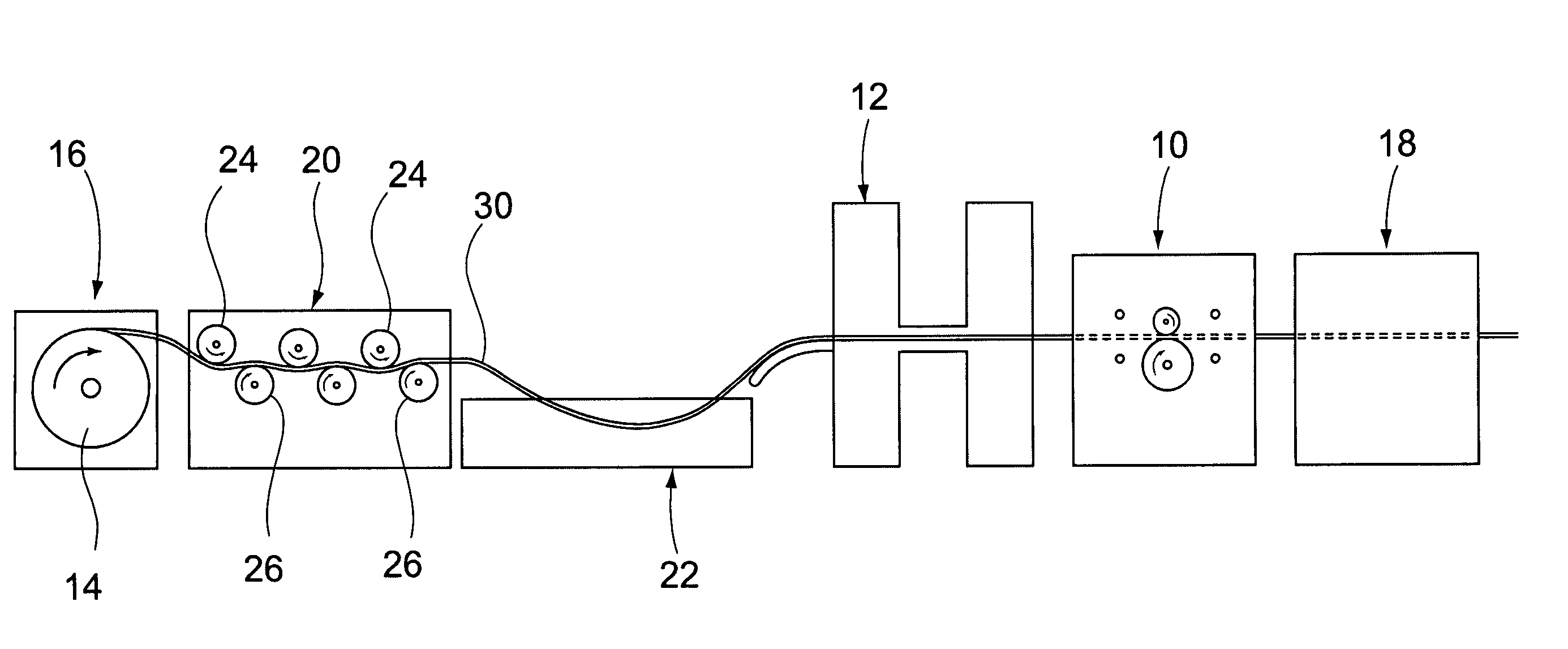

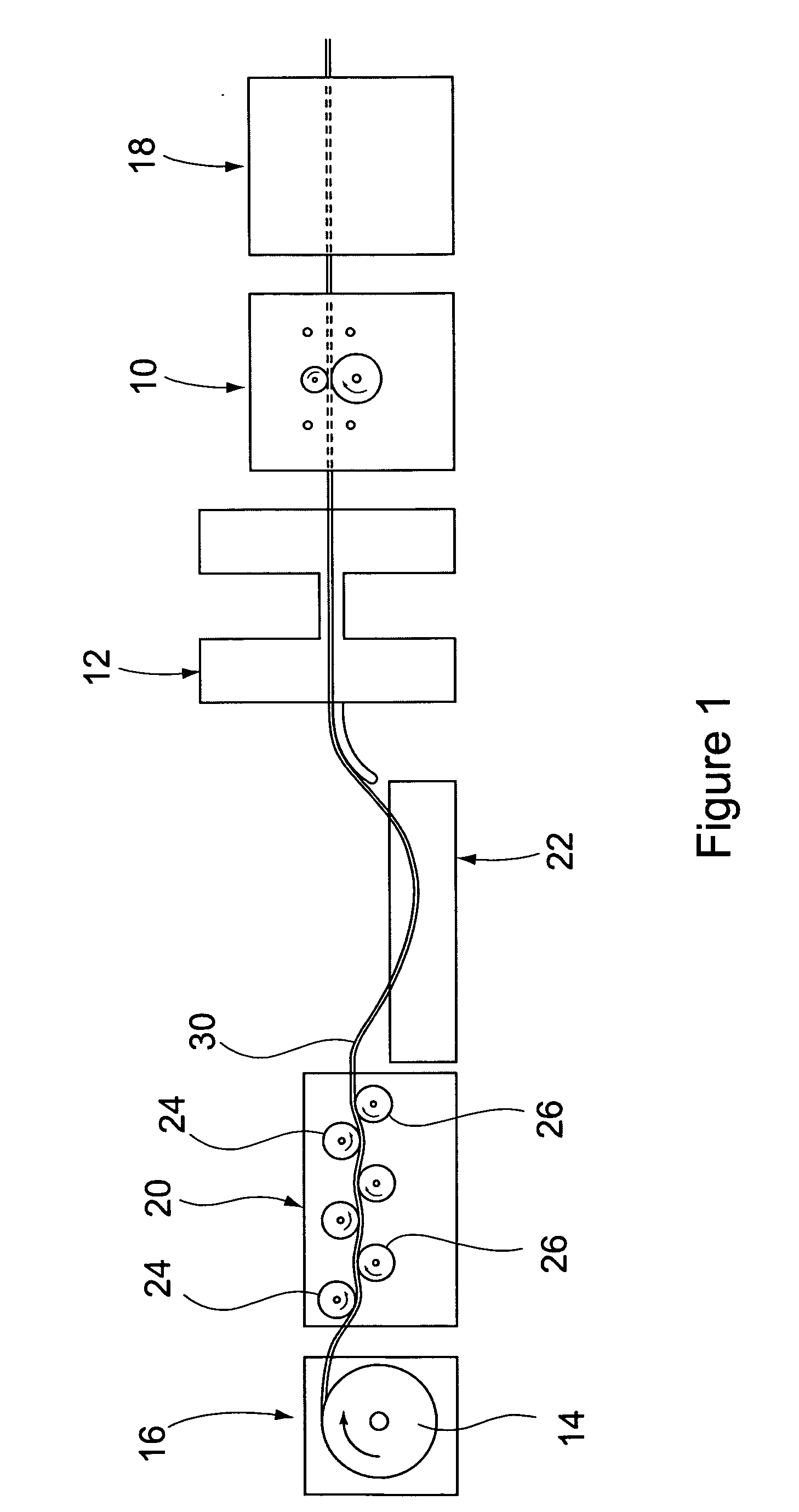

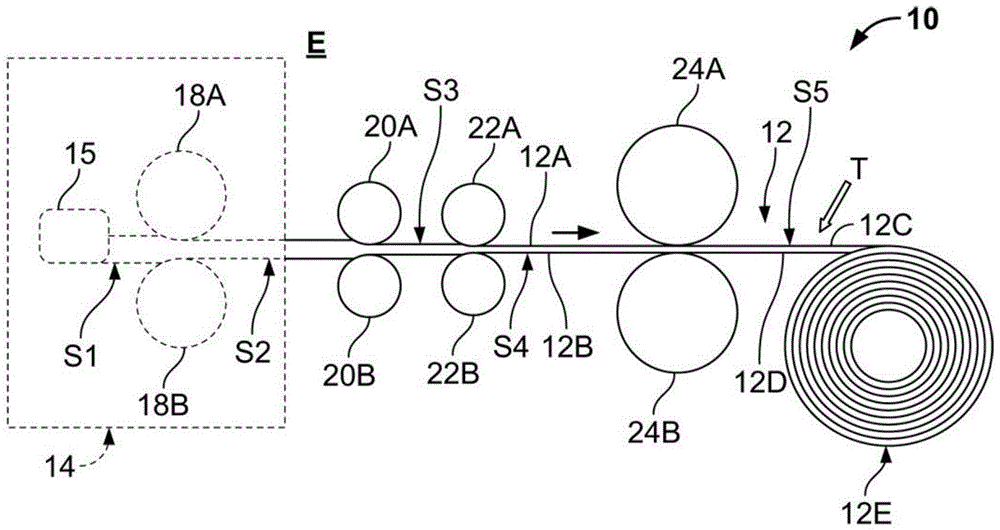

Lamination process and apparatus for alkali metals or alloys thereof

ActiveUS7513136B2Reduce thicknessElectrode rolling/calenderingRoll force/gap control deviceLithiumElectrical battery

An apparatus for and method of manufacturing lithium or lithium alloy anodes for electrochemical cells by a lamination process wherein a lithium or lithium alloy sheet is reduced into a thin lithium or lithium alloy film. The method and apparatus provide adjustments of the profile defined by the meeting surfaces of a pair of working rollers to compensate for thermal dilation of the working rollers or to compensate for irregular thickness of the lithium or lithium alloy sheet to control the shape and profile of the lithium or lithium alloy film being laminated.

Owner:BATHIUM CANADA

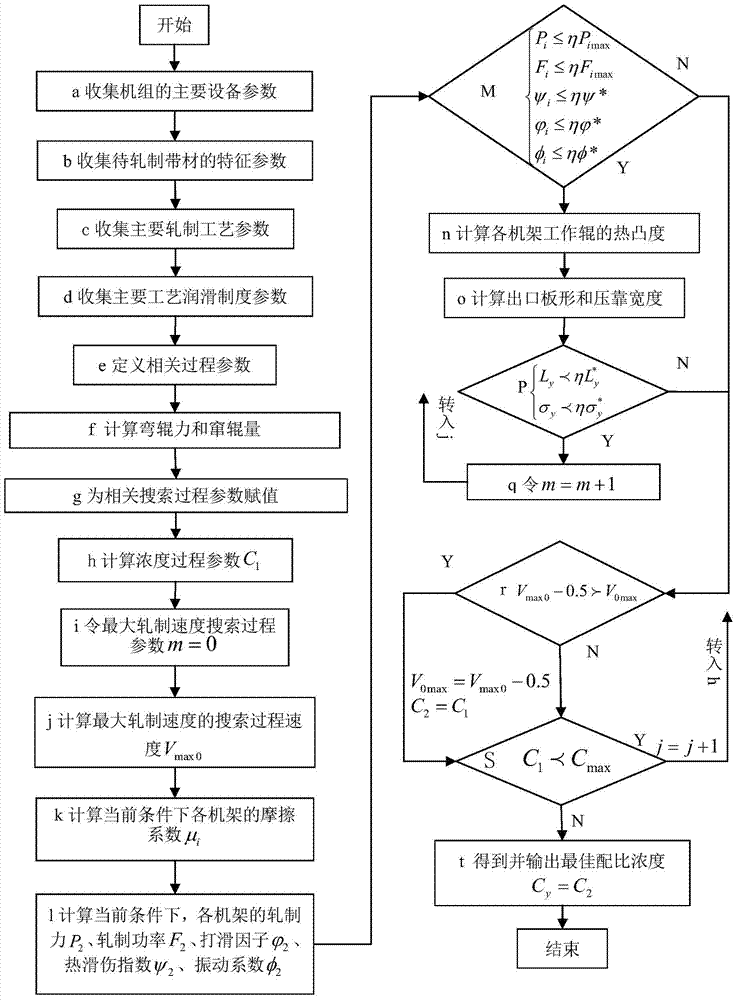

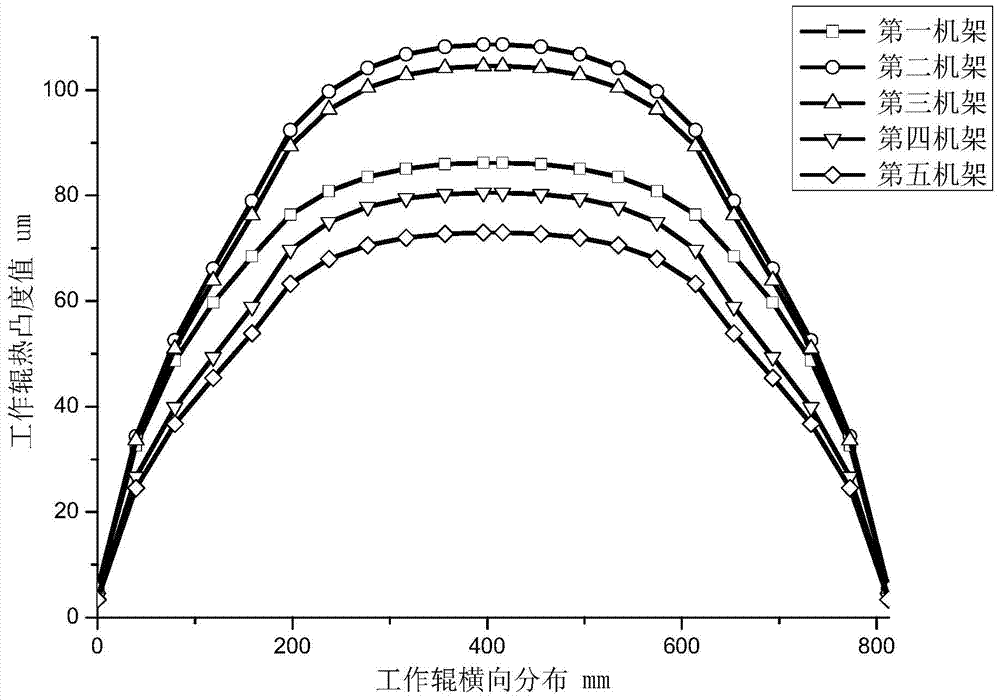

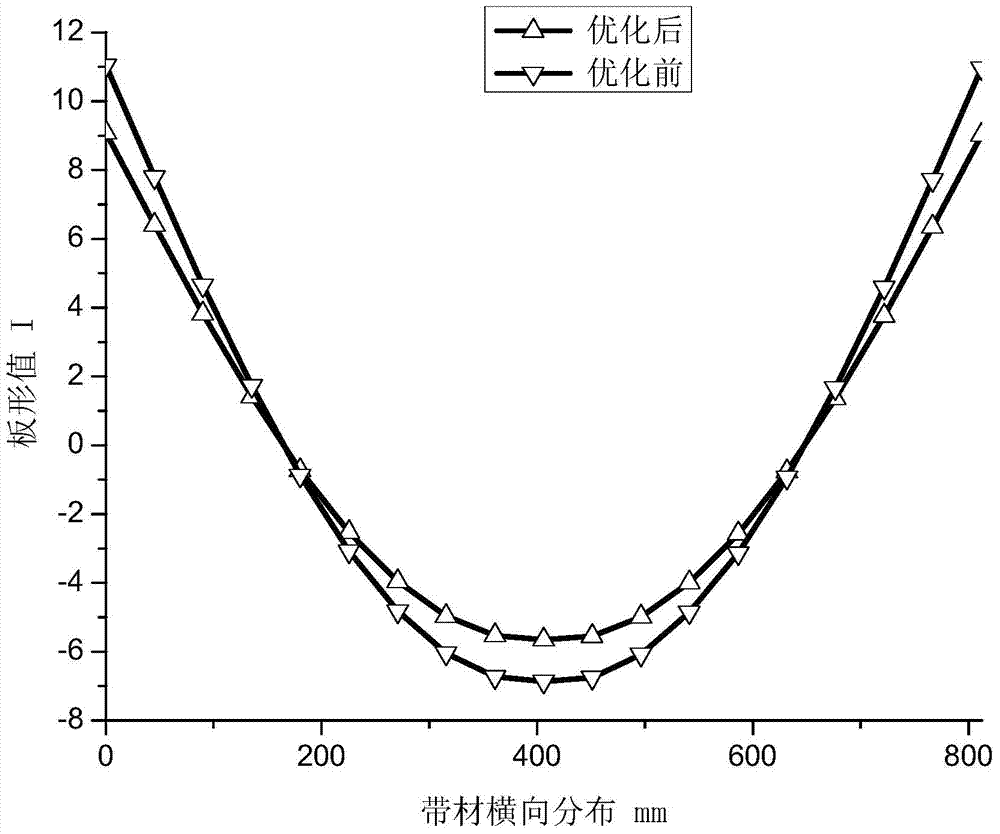

Method for setting concentration of emulsion in rolling of five-rack cold continuous rolling unit extremely thin band

InactiveCN103544340AIncrease rolling speedGuaranteed rolling efficiencyVibration control deviceSpecial data processing applicationsEmulsionBending force

The invention discloses a method for setting concentration of emulsion in rolling of a five-rack cold continuous rolling unit extremely thin band. The method includes the following steps: (1) collecting characteristic parameters of main devices of a unit and to-be-rolled bands, main rolling process parameters and process lubricating system parameters, (2) defining related process parameters, (3) computing roll bending force and the roll channeling amount, (4) assigning related search process parameters, (6) computing concentration process parameters, (6) computing the search process speed of the highest rolling speed, (7) computing friction coefficients of various racks under the current condition, (8) computing rolling force, rolling power, slip factors, heat slip damage indexes and vibration coefficients of the various racks under the current condition, (9) computing heat convexity degrees of working rollers of the various racks, (10) computing an exit plate shape and the pressing width, and (11) obtaining and outputting the optimum proportion concentration. The steps are executed by a computer. According to the method, the rolling speed can be quickened, the rolling efficiency can be guaranteed, slip, heat slip damage and vibration are avoided, and it is guaranteed that the exit plate shape of the final rack and the pressing width of the roller ends of the working rollers are the smallest.

Owner:唐山扬邦钢铁技术研究院有限公司

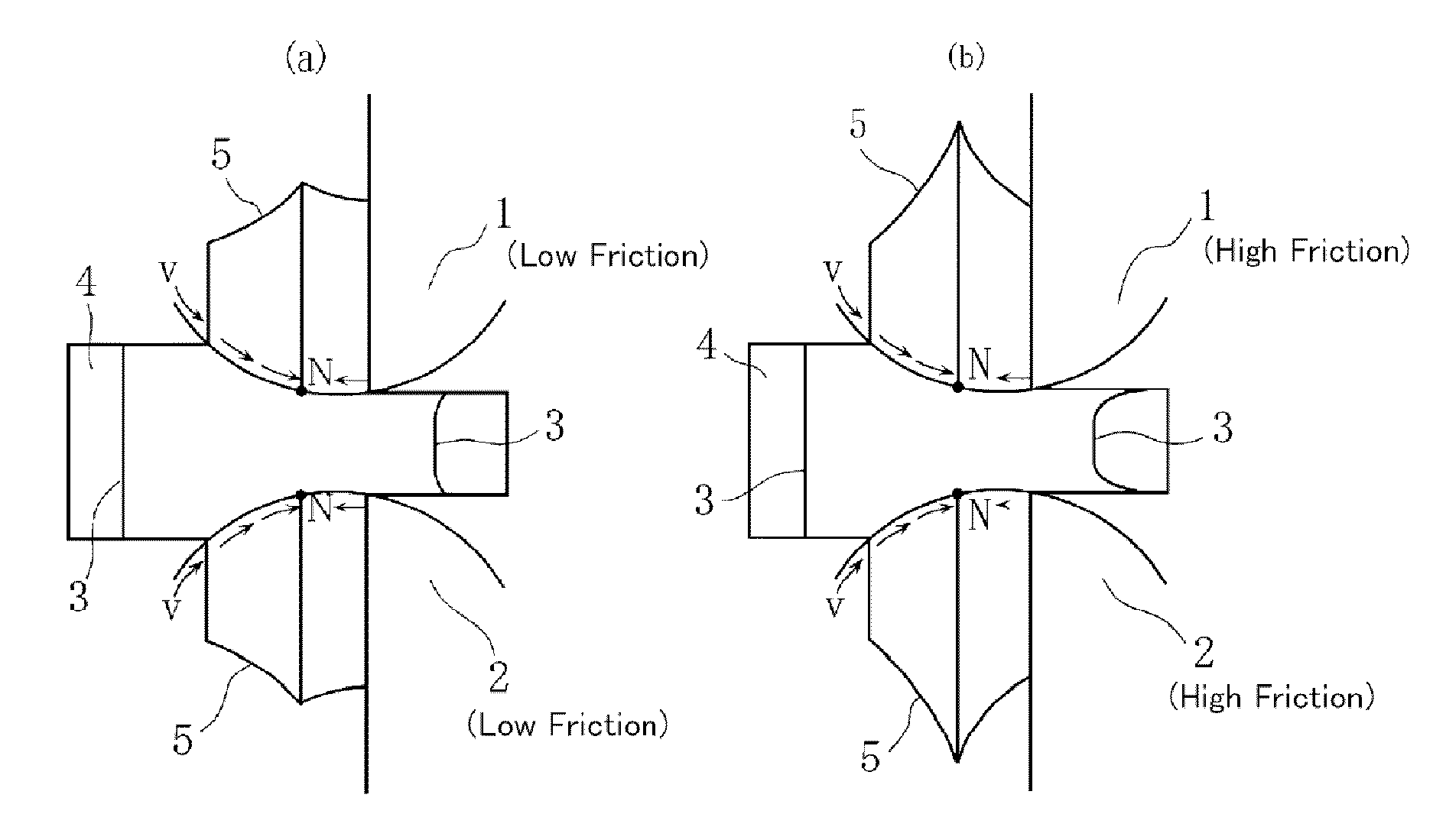

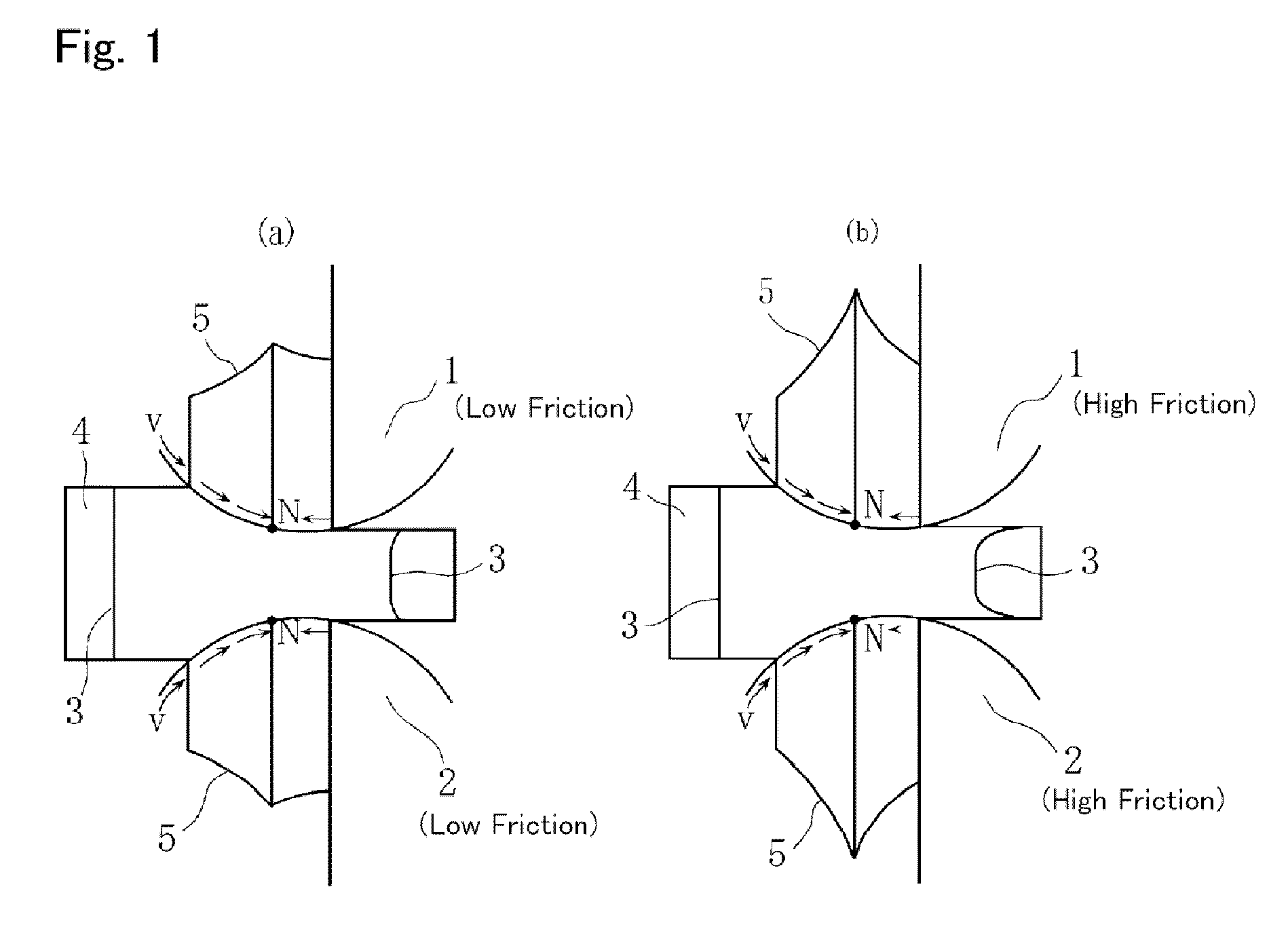

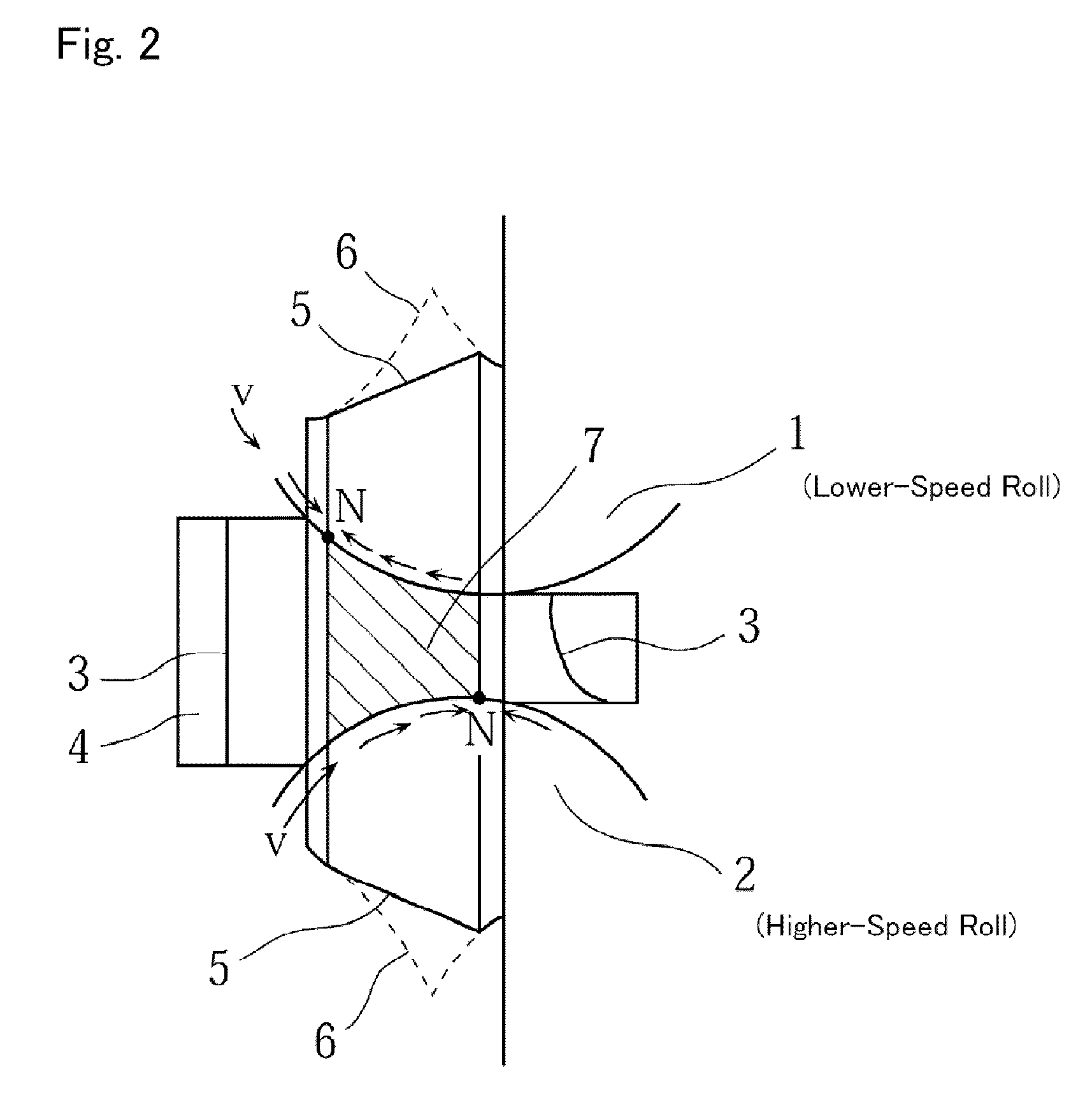

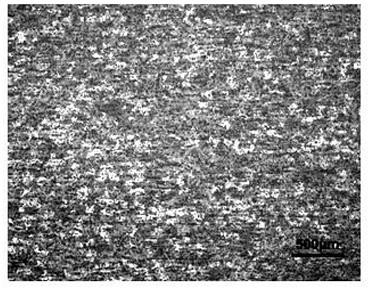

Metal sheet rolling method and rolled sheet manufactured by metal sheet rolling method

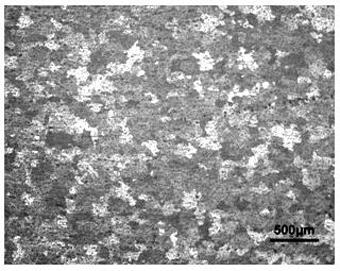

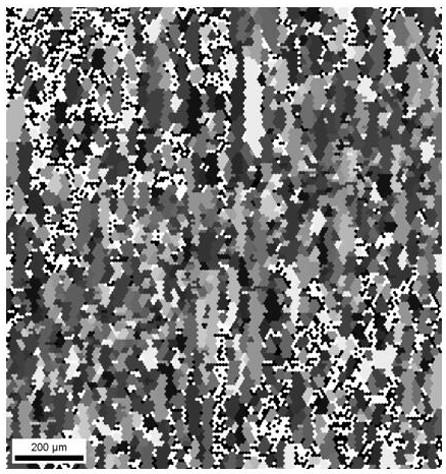

ActiveUS20100009212A1Low costImprove electromagnetic performanceLayered productsRollsMetal sheetLubrication

The present invention provides a metal sheet rolling method of rolling a metal sheet with a pair of rolls, as well as a rolled sheet manufactured by the metal sheet rolling method. In the metal sheet rolling method, respective interfaces between the pair of rolls and the metal sheet have mutually different frictions. Additionally at least one of the interfaces may be lubricated by a procedure other than lubrication by coating of a liquid lubricant agent. Alternatively at least one of the interfaces may be subjected to surface treatment by a procedure other than lubrication, or otherwise the pair of rolls may be made of mutually different materials.

Owner:NGK INSULATORS LTD

Cold rolling method for preventing high-silicon strip steel from being broken

InactiveCN102476131AImprovement of strip breakage in cold rollingGood effectTemperature control deviceMetal rolling stand detailsEmulsionEconomic benefits

The invention discloses a cold rolling method for preventing high-silicon strip steel from being broken. The Si content of the high-silicon strip steel is more than or equal to 2.3 percent by weight; when cold rolling is started, the temperature of strip steel at an inlet is higher than 45 DEG C; and in a cold rolling process, an emulsion is sprayed onto the strip steel, the emulsion flow at the inlet along a rolling direction is smaller than or equal to 3,500 liters per minute, and the emulsion flow at an outlet along the rolling direction is 1,500-4,000 liters percent minute, so that the temperature of the strip steel is over 45 DEG C on the premise of ensuring process lubricating. The cold rolling method disclosed by the invention has remarkable effects of reducing strip breakage on a head and a tail, increasing rolled piece yield, increasing production efficiency, and the like, and has a remarkable economic benefit.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of removing scale and inhibiting oxidation and galvanizing sheet metal

InactiveUS20050136184A1Prevent oxidationLess-expensive and troublesomePretreated surfacesCleaning using toolsSurface conditionsZinc

A method of removing iron oxide scale and galvanizing sheet metal bonds galvanizing zinc to a wustite layer of the sheet metal. The iron oxide scale on the sheet metal generally comprises three layers prior to surface conditioning: a wustite layer, a magnetite layer, and a hematite layer. The wustite layer is bonded to a base metal substrate of the sheet metal. The magnetite layer is bonded to the wustite layer, and the hematite layer is bonded to the magnetite layer. Conditioning the surface of the sheet metal includes bringing a surface conditioning member into engagement with the surface of the sheet metal in a manner to remove substantially all of the hematite and magnetite layers from the surface, and in a manner to remove some but not all of the wustite layer from the surface. The portion of the wustite layer that remains bonded to the base metal substrate of the sheet metal protects the surface from oxidation until the surface is galvanized.

Owner:THE MATERIAL WORKS

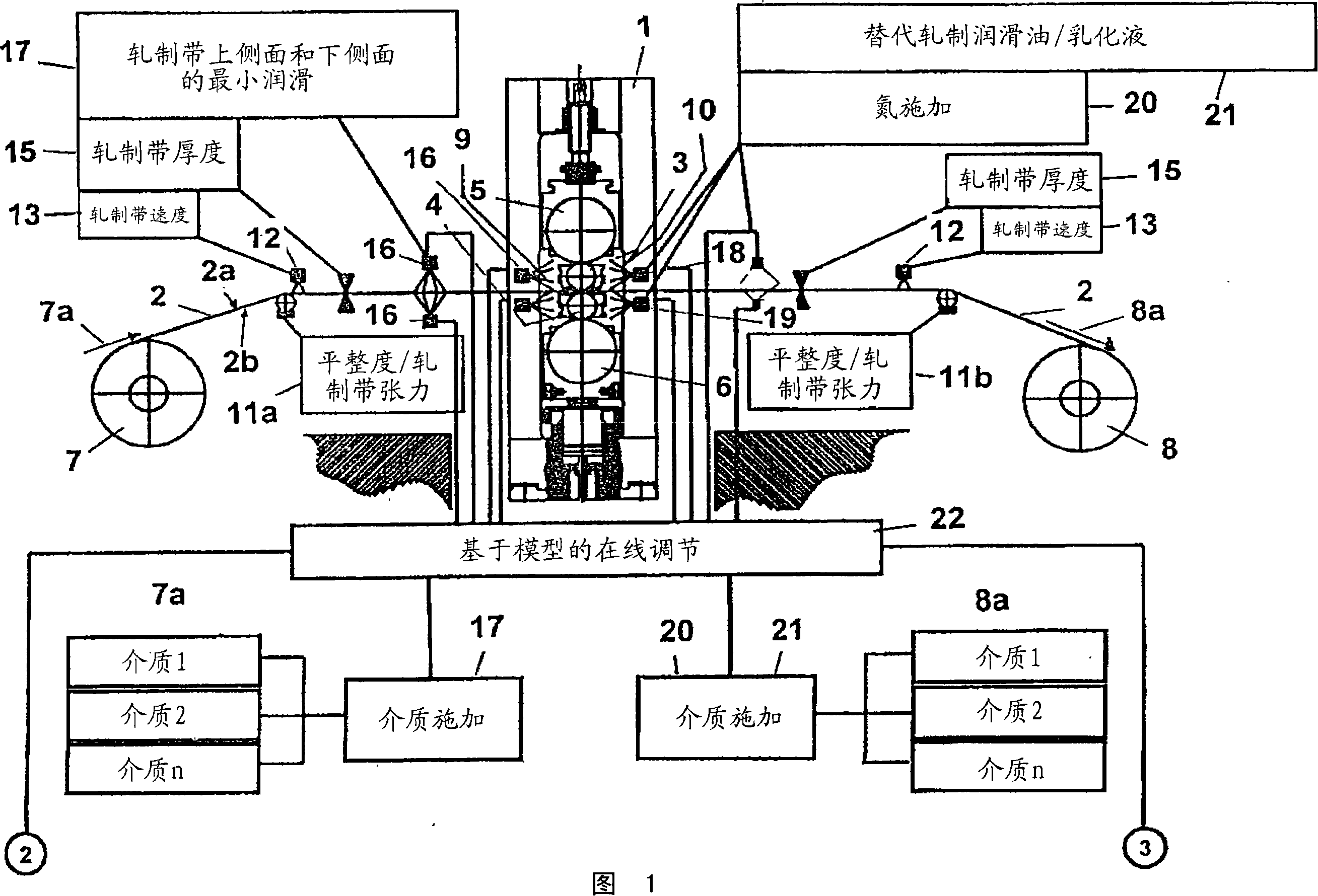

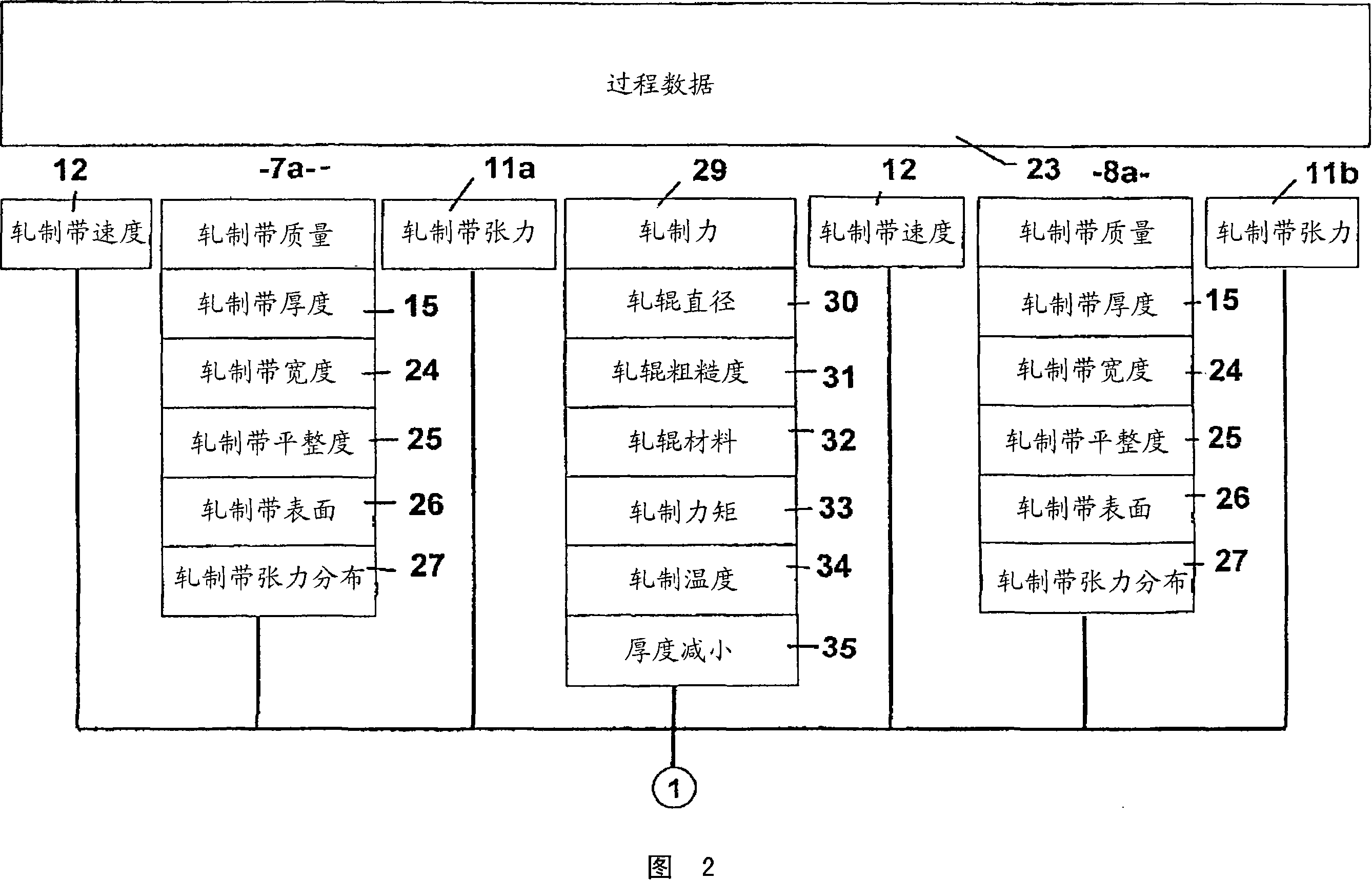

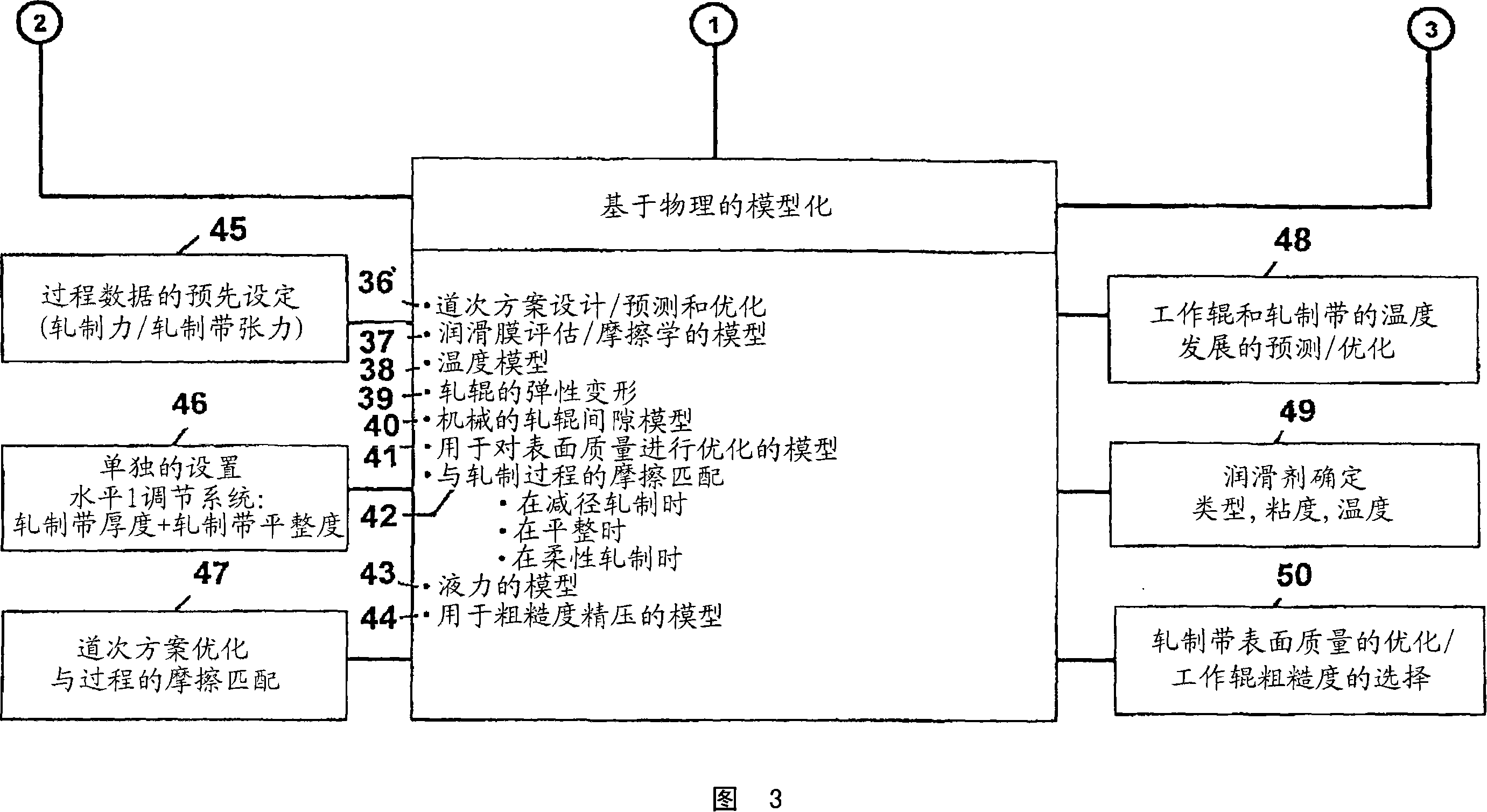

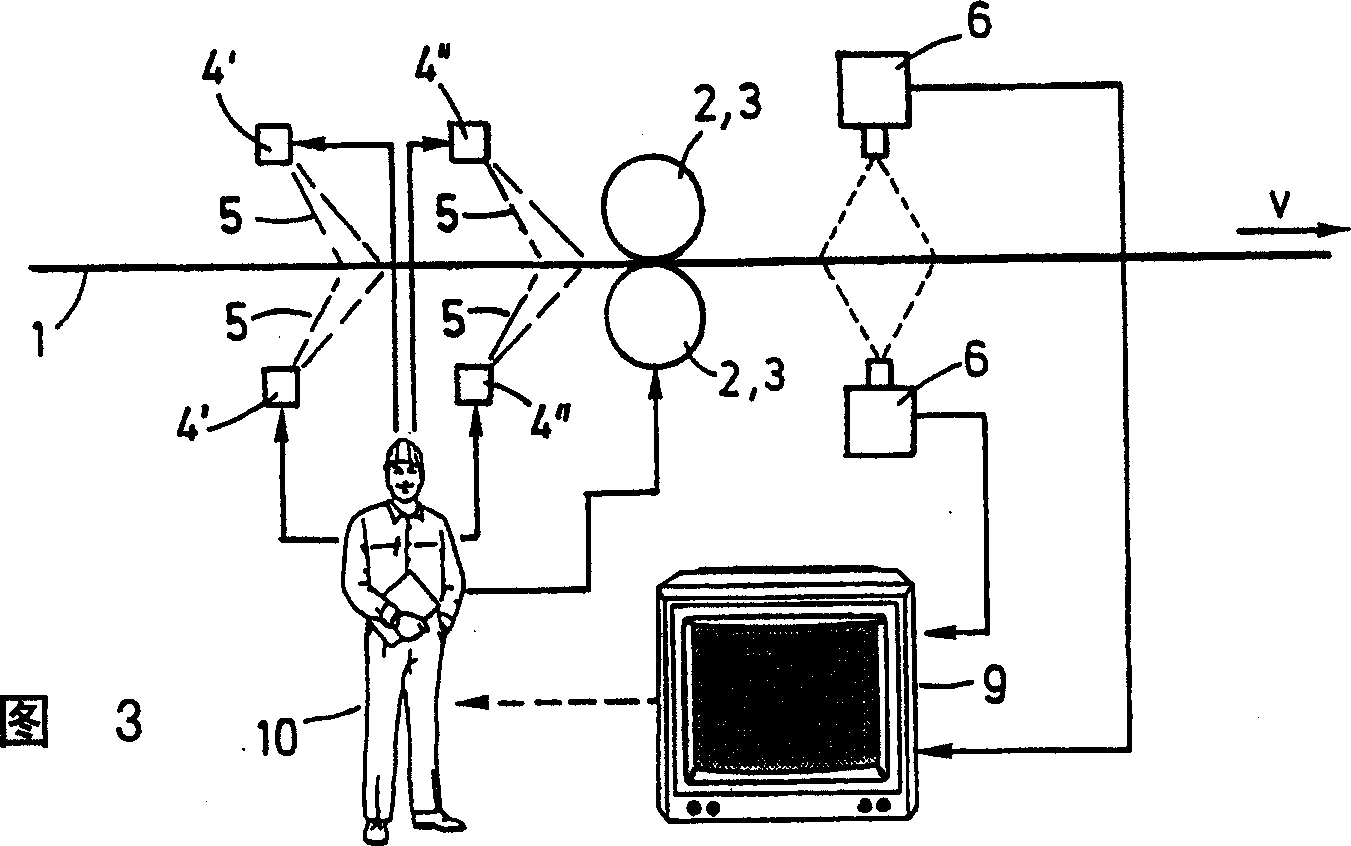

Method for lubricating and cooling rollers and metal strips on rolling in particular on cold rolling of metal strips

InactiveCN101253007ARolled strip of good qualityAchieving Friction MatchingRollsWork cooling devicesMetal stripsControl manner

The invention relates to a method for lubricating and cooling rollers (3,4,5,6) and metal strips (2) on rolling in particular, on cold rolling of metal strips (2), wherein, on the inlet side (7a) a minimal amount of pure lubricant (9) without a high water content is continuously supplied in an online controlled manner with a controlled viscosity and lubricity depending on a number of process data measurements (23) by means of a physical computer model (22) and the equivalent process data measurements (23) from the outlet side (8a) are also used online by the physical computer model (22).

Owner:SMS DEMAG AG

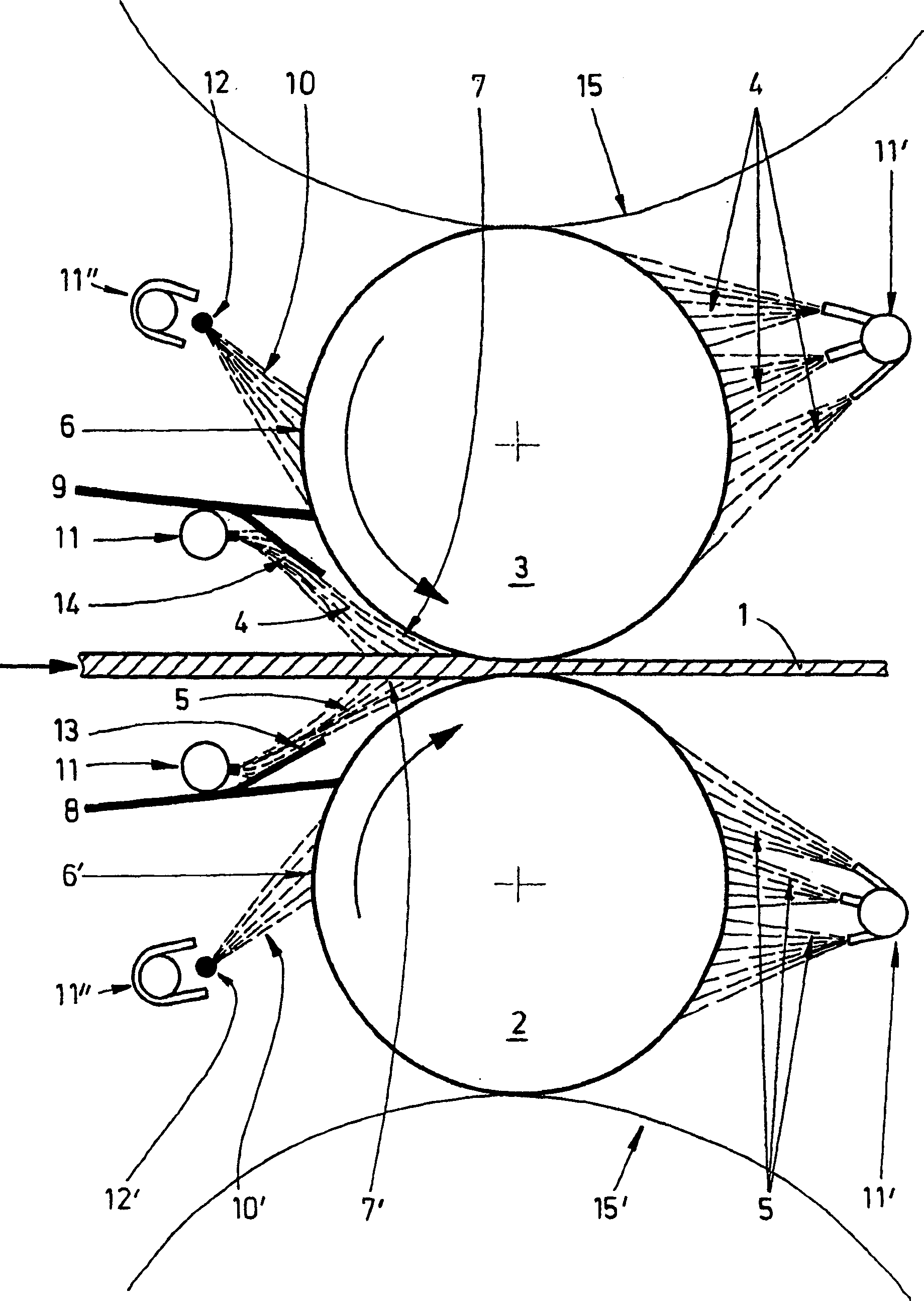

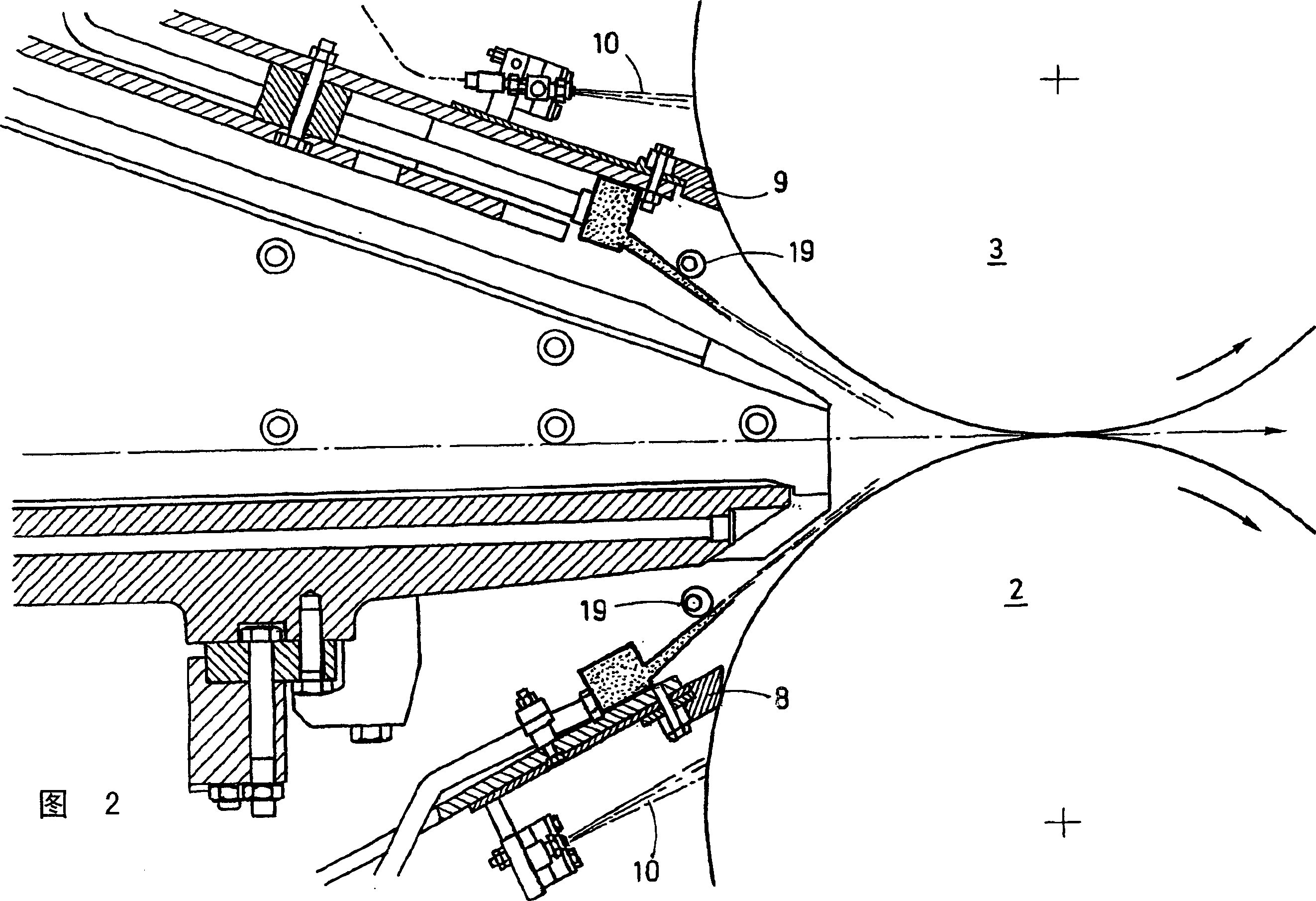

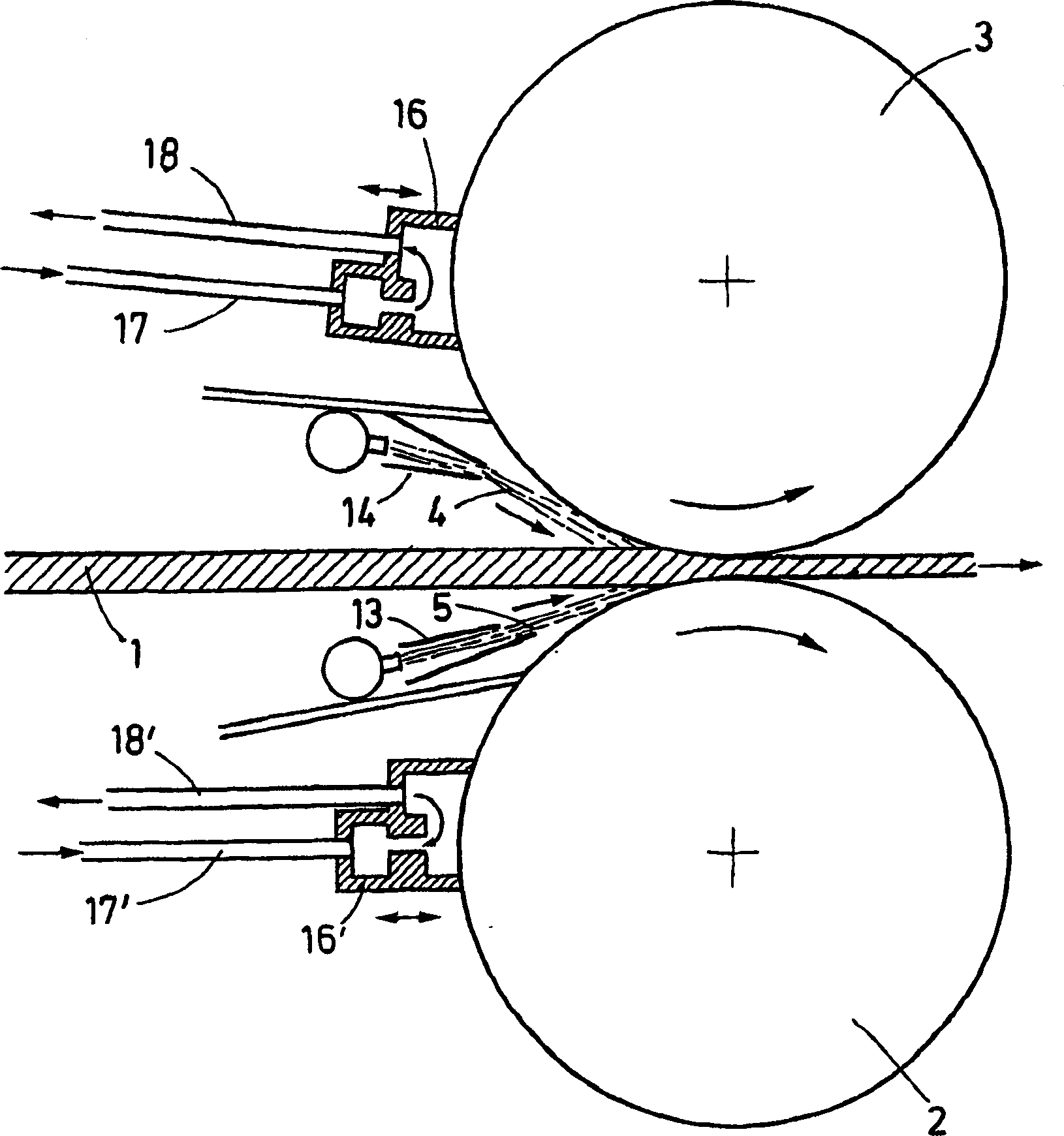

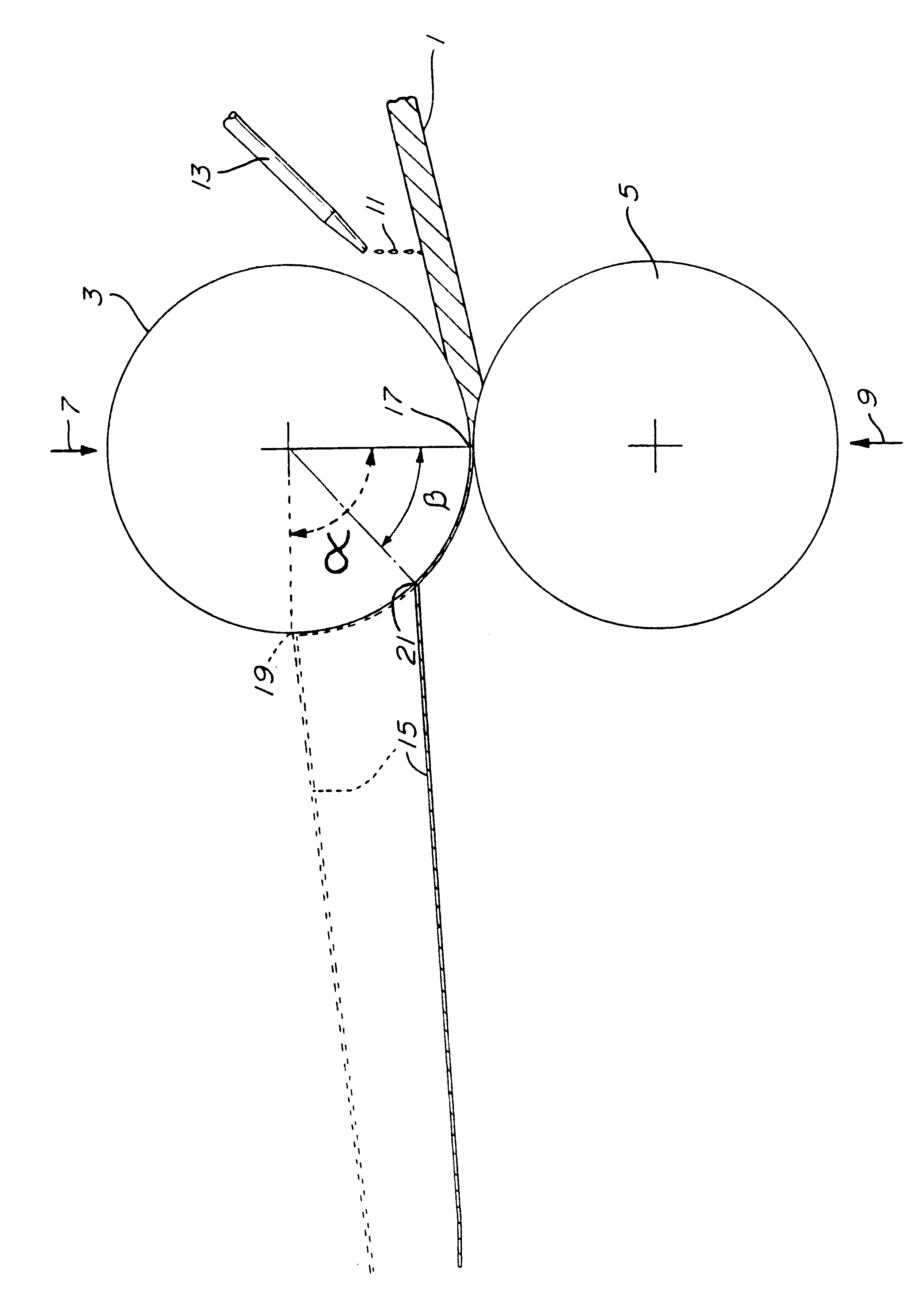

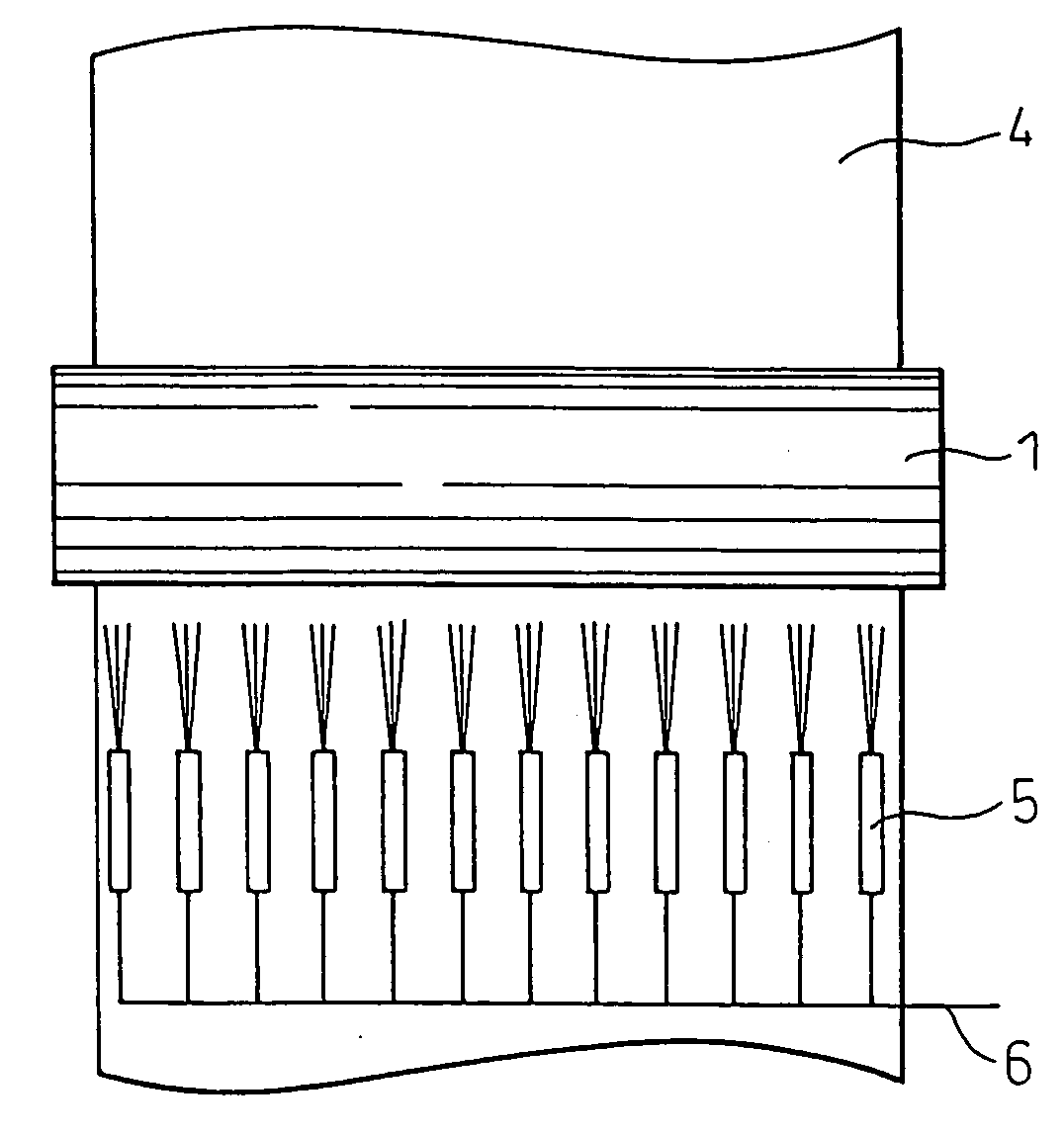

Method for cooling and lubricating rollers on rolling stand

InactiveCN1537035AIncrease stressPeeling suppressionRollsWork cooling devicesOil and greaseSuper cooling

The invention relates to a method and a device for cooling and / or lubricating rollers, in particular the working rollers (2, 3) on a rolling stand and a rolled strip (1), rolled between the above rollers and transported onwards, using water in the form of spray jets (4, 5) as cooling medium and oil, oil / air mix, oil / water mix, oil / air / water mix or grease mixtures as lubricant. In order to improve the lubricating and cooling effects, a combined application of super-cooling the strip and roller surfaces and roller lubrication on the input side of the stand is disclosed, in which both media, water and lubricant, are separately fed to the rollers (2, 3) and the rolled strip and applied to the roller surface at different application points. Separate reservoirs for water and lubricant and separate lines to the spraying bar (11) for water and the spraying bar (12) for the lubricant are provided.

Owner:SMS DEMAG AG

Additives for lubricating agents used in the lamination of lithium sheets into thin films

InactiveUS6517590B1Lower impedanceEasy to controlElectrode rolling/calenderingPrimary cellsLithiumOligomer

These additives are represented by the following general formula:in which L designates a hydrocarbon radical which serves as lubricating segment; S designates an oligomer segment which serves as solvating segment of metallic salts and Y designates a chemical bond which joins the hydrocarbon radical and the oligomer segment. With these additives there is no more need to subsequently wash the surface of laminated lithium.

Owner:BATHIUM CANADA

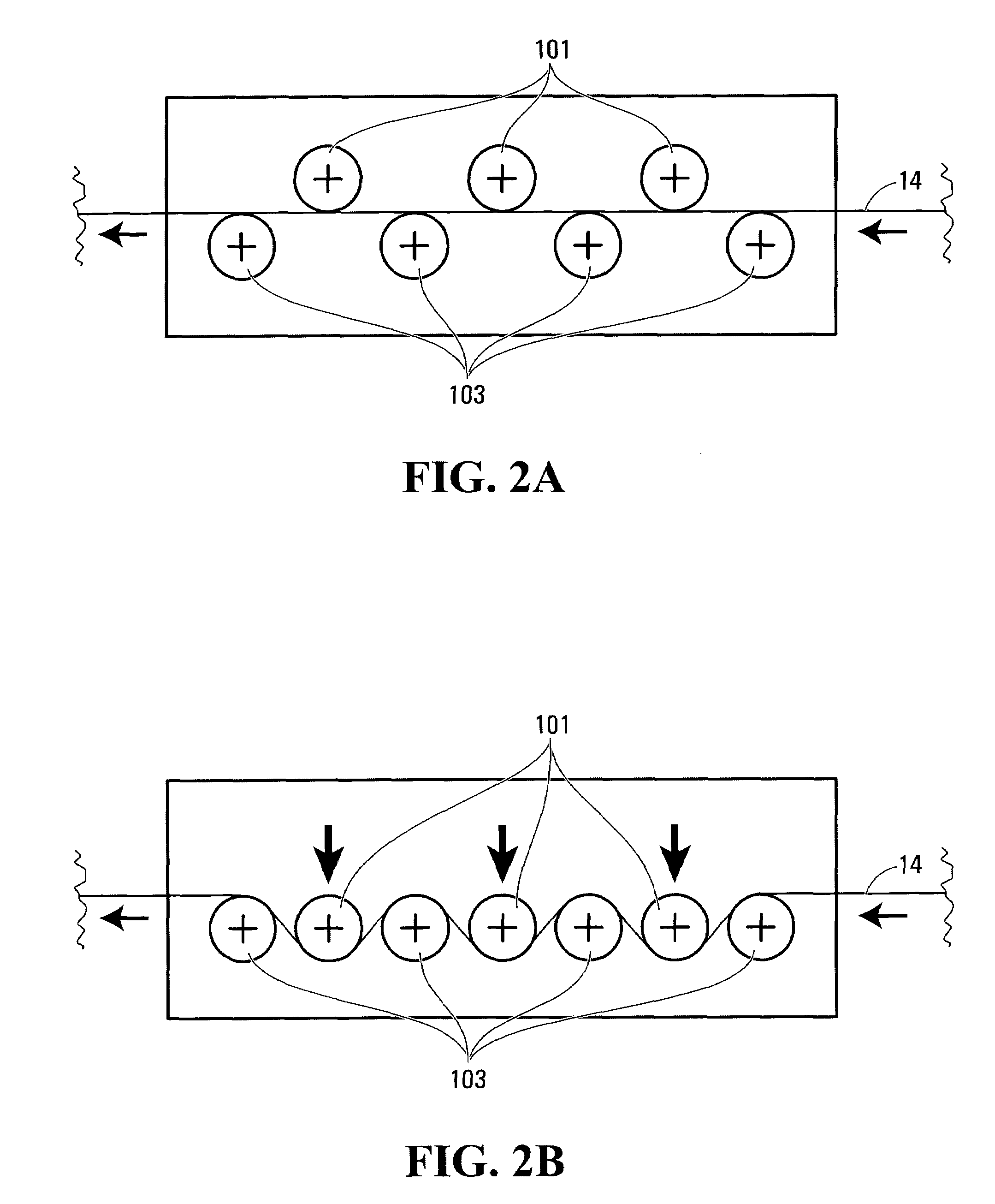

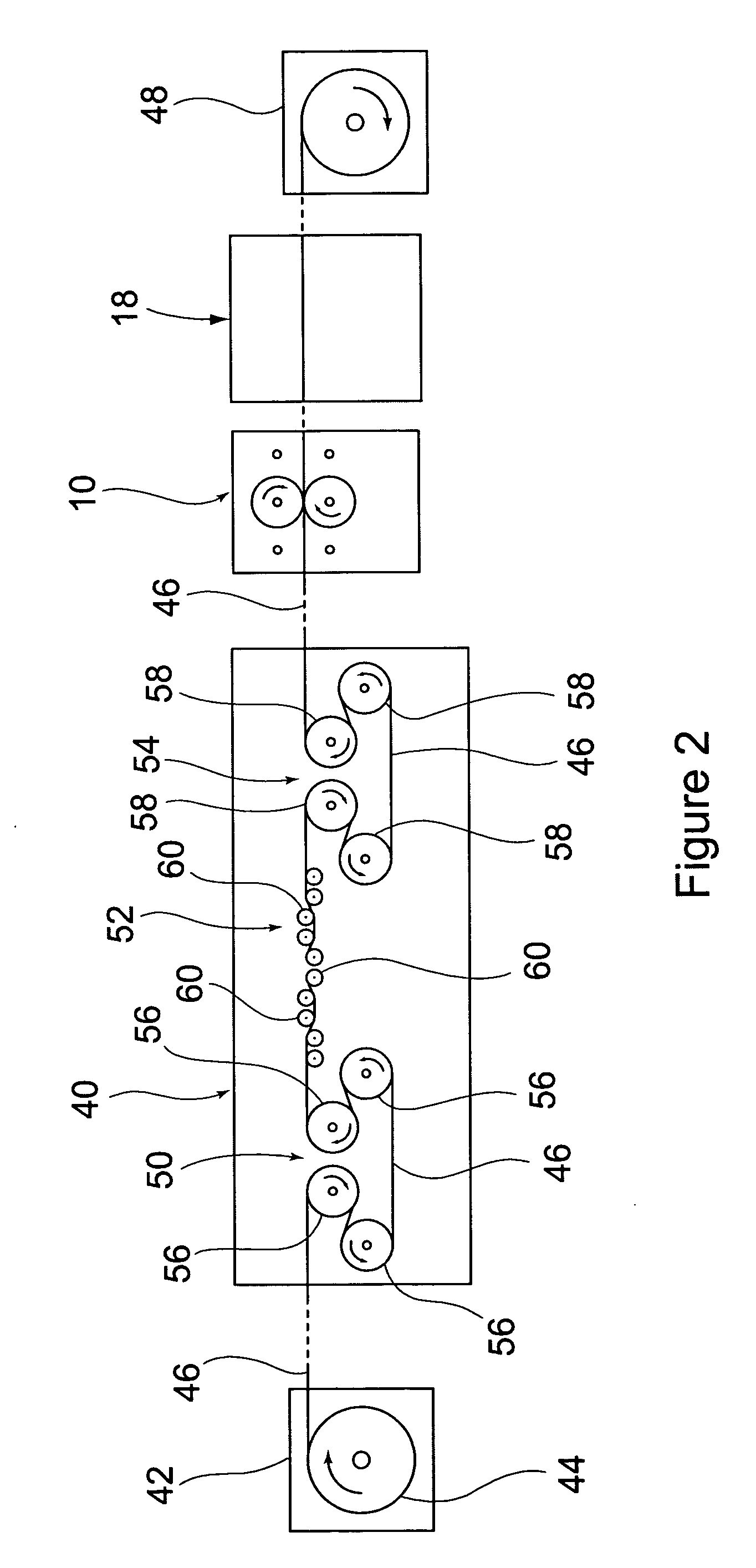

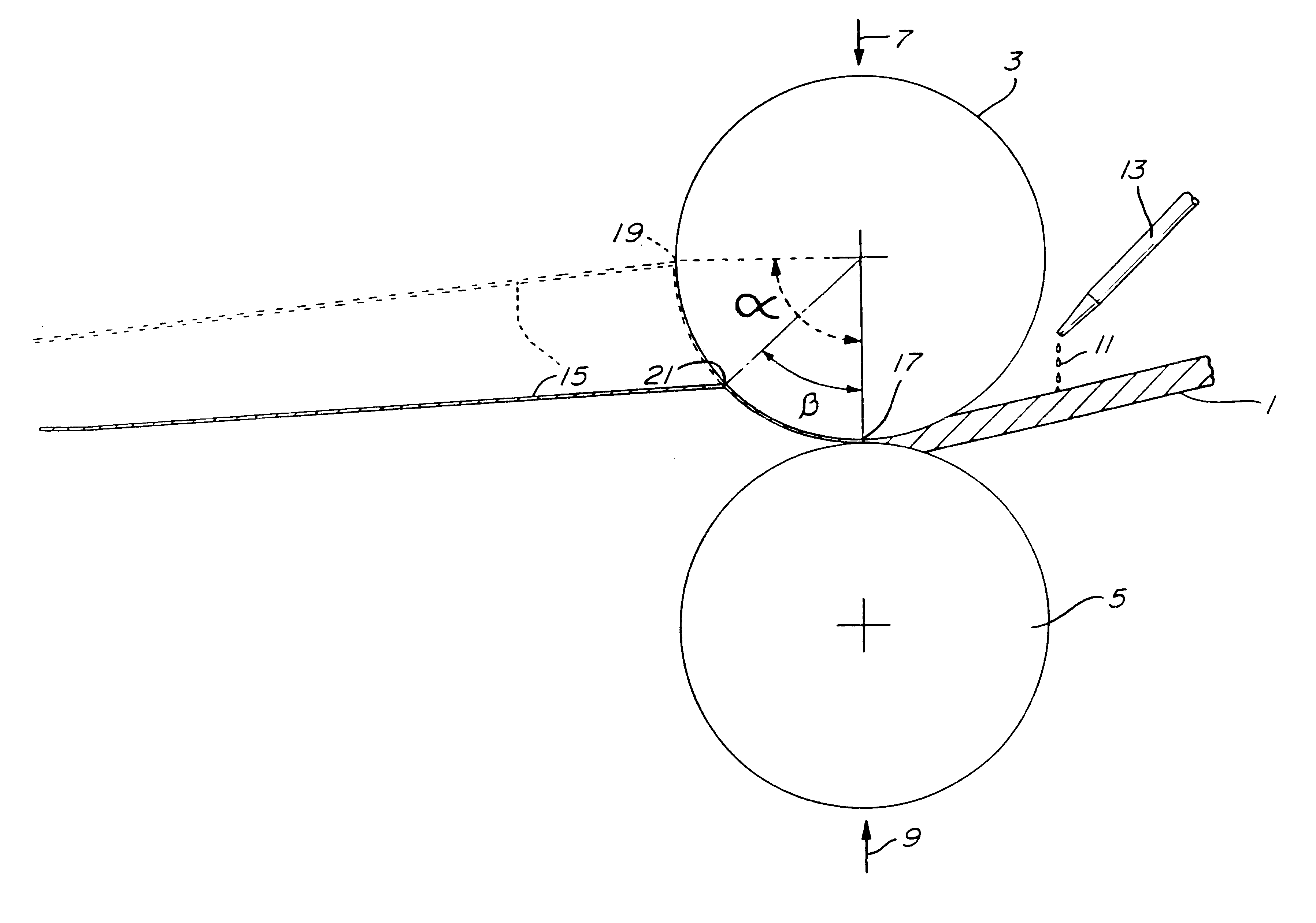

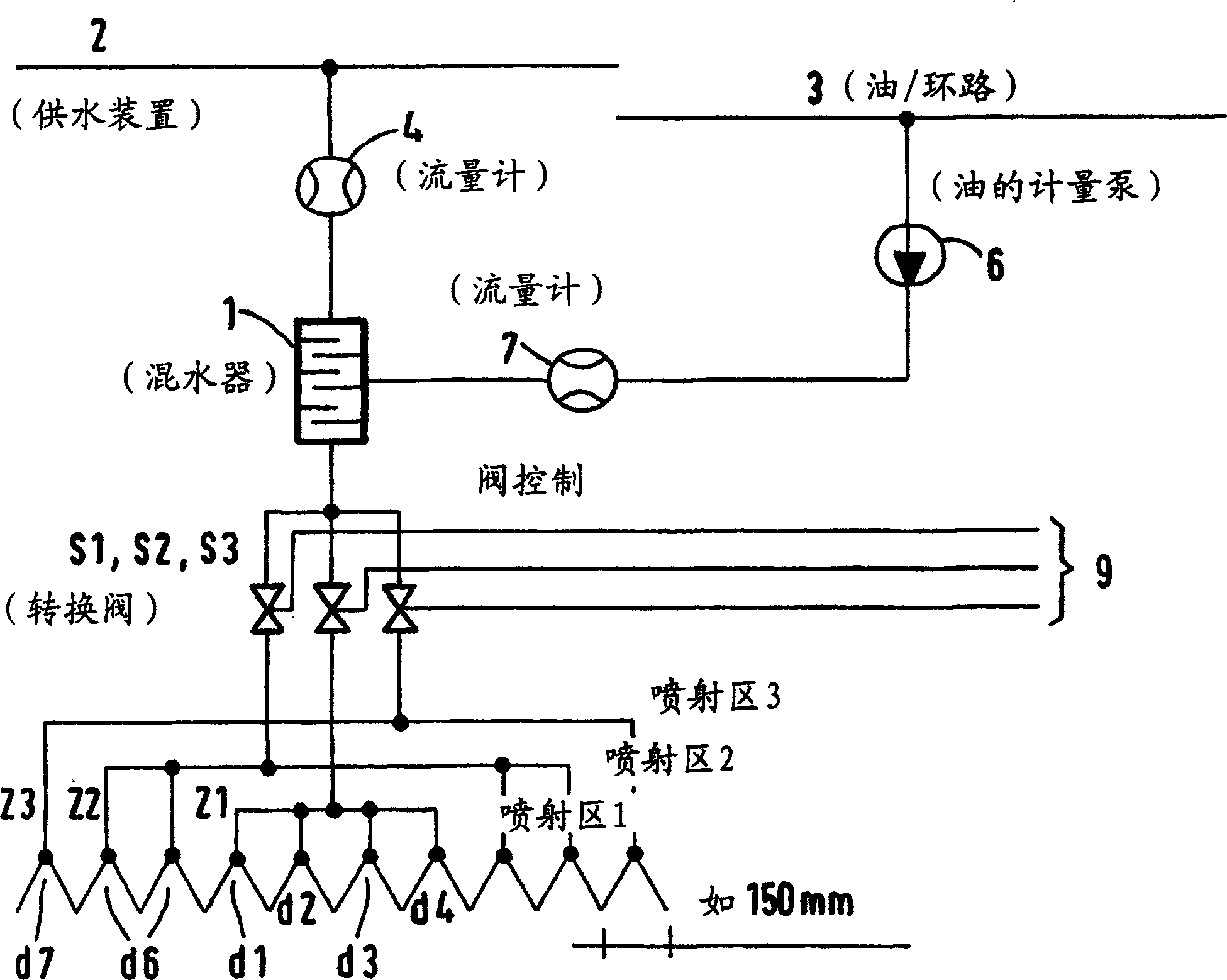

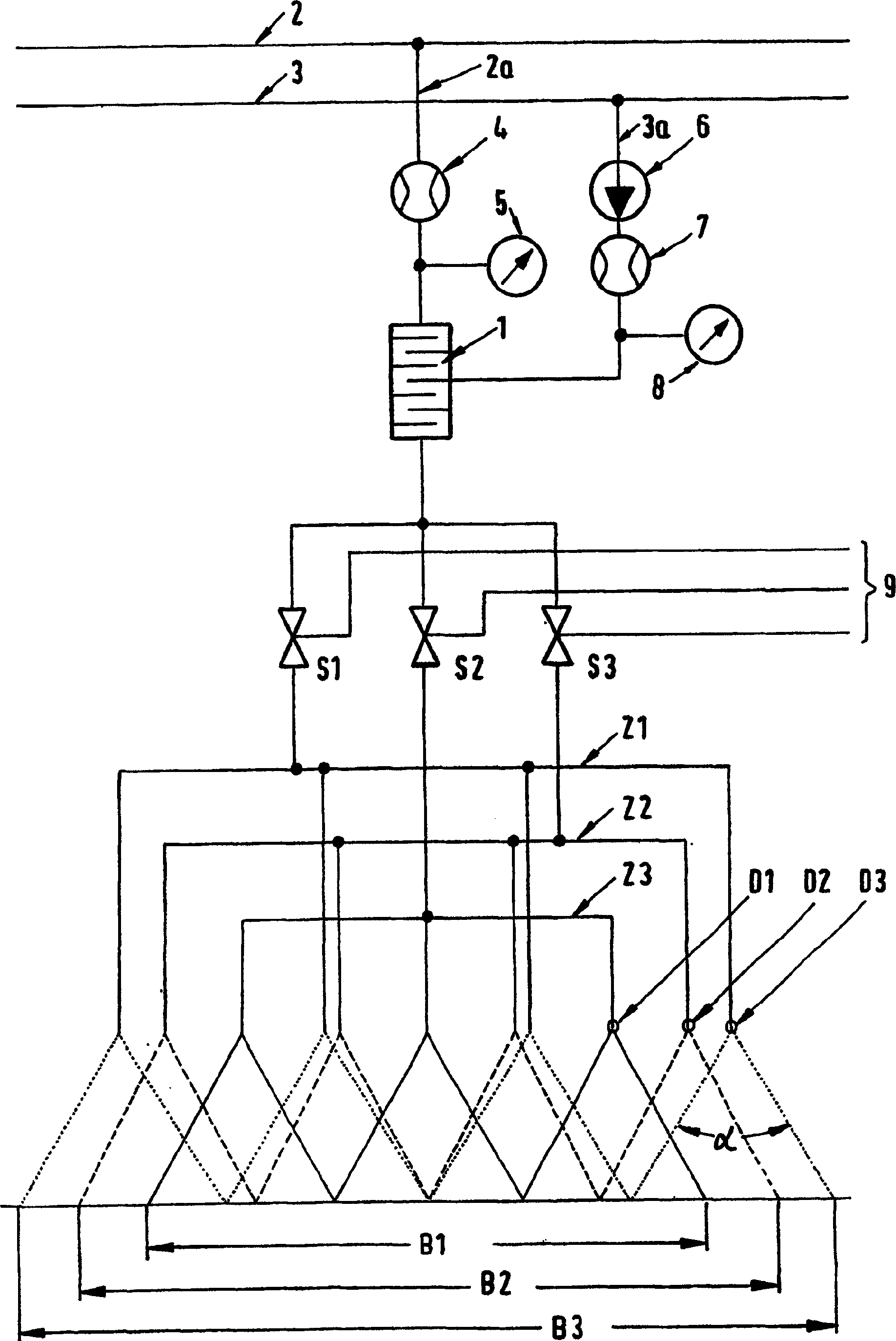

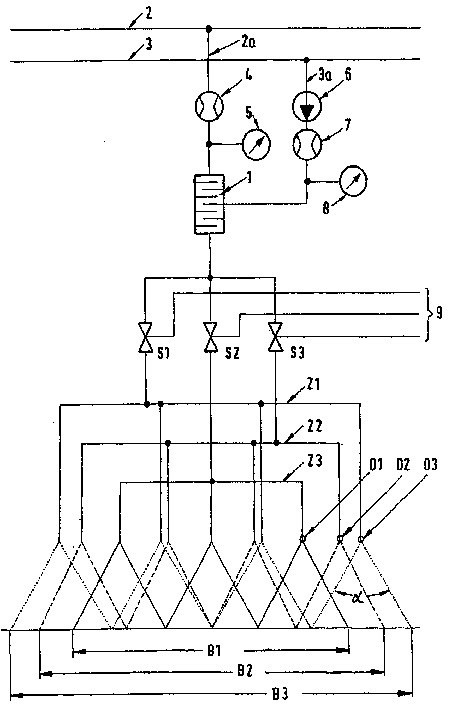

Method and nozzle arrangement for variable-width lubrication of rolling nip of rolling stand

The invention relates to a method for lubricating rolls, in particular for lubricating a rolling nip in rolling stands for rolled strips. According to the invention, said lubrication takes place using an oil-in-water dispersion whilst maintaining both a predetermined blend characteristic and a volumetric flow of the dispersion. The dispersion is prepared in the form of a homogeneous blend in a mixer (1) using adjustable quantities of water and oil. The dispersion is supplied to various spray zones (Zi) for a distribution (Bi) that is variable in width. Said method for roll lubrication can be improved by the allocation of at least one row of nozzles (Di) to each spray zone (Zi), which has a corresponding spray range width (Bi), each nozzle being controlled by at least one relay valve (Si).

Owner:SMS DEMAG AG

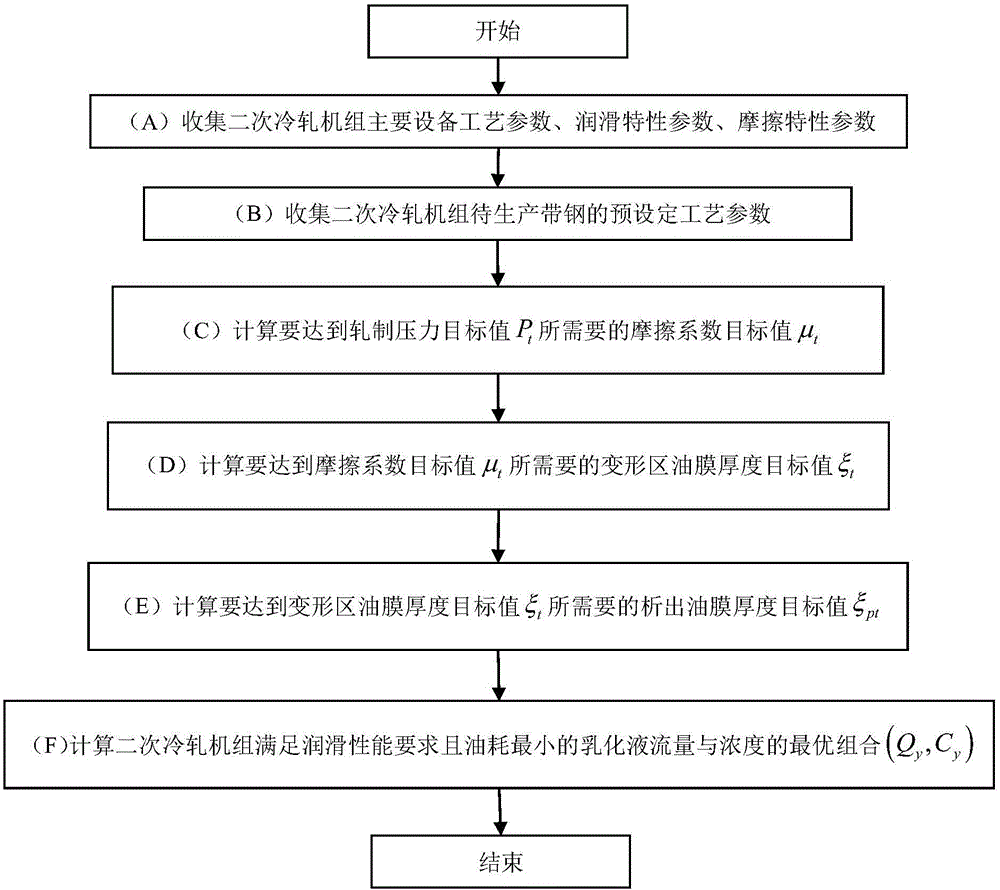

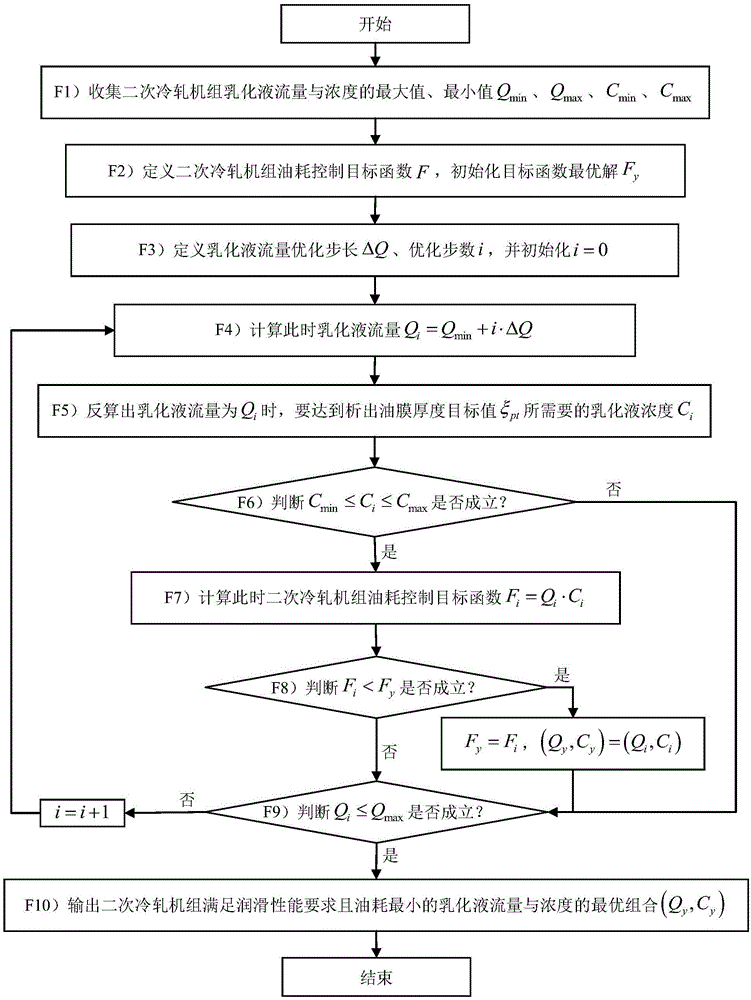

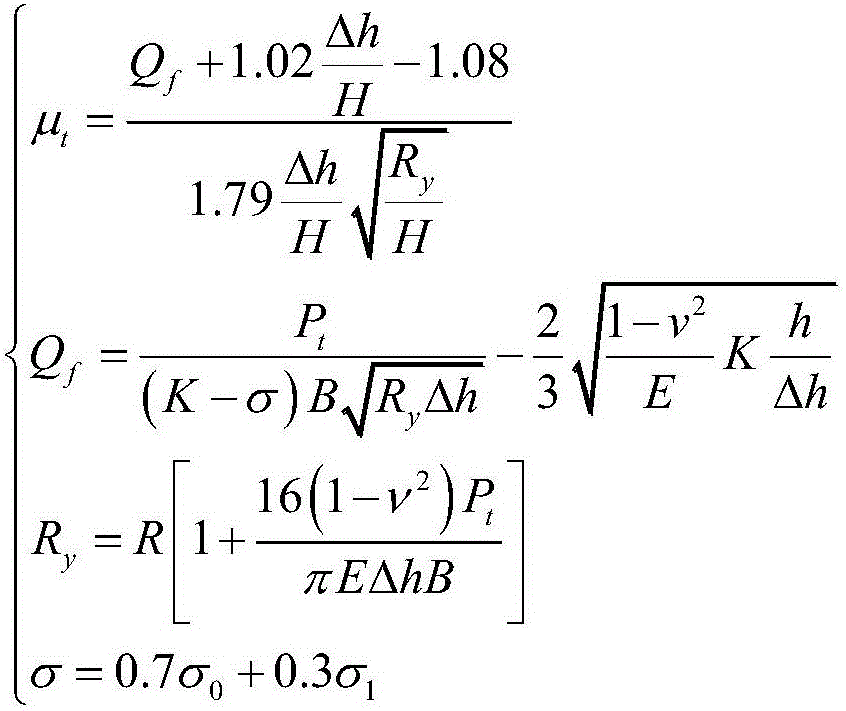

Emulsified liquid process optimization method taking oil consumption control as target by secondary cold rolling unit

InactiveCN107520253AReduce on-site production costsMinimum consumptionMass flow control deviceMetal rolling arrangementsProcess optimizationFrictional coefficient

The invention relates to an emulsified liquid process optimization method taking oil consumption control as a target by a secondary cold rolling unit. The method comprises the following steps executed by a computer; (A) collecting a primary equipment process parameter, a lubricating characteristic parameter and a frictional characteristic parameter of the secondary cold rolling unit; (B) collecting a preset process parameter of to-be-produced strip steel of the secondary cold rolling unit; (C) calculating a frictional coefficient target value [mu]t needed to reach a rolling pressure target value Pt; (D) calculating a deformation region oil film thickness target value xit needed to reach the frictional coefficient target value [mu]t; (E) calculating a separated out oil film thickness target value xipt needed to reach the deformation region oil film thickness target value xit; and (F) calculating the optimum combination (Qy and Cy) of flow and concentration f an emulsified liquid, wherein the secondary cold rolling unit meets the demand on the lubricating performance and the oil consumption is the minimum. By comprehensively optimizing concentration and flow of the emulsified liquid, the minimum consumption of rolling oil is achieved, and the field production cost of the secondary cold rolling unit and the sewage treatment cost of the emulsified liquid are lowered.

Owner:唐山格诺金属科技有限公司

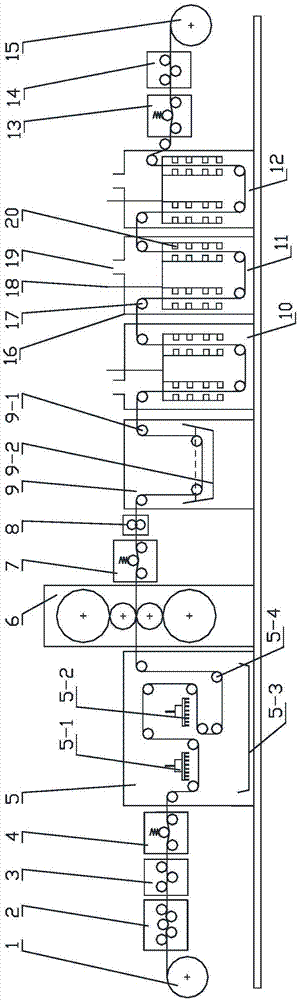

Method of Supplying Lubrication Oil in Cold Rolling

ActiveUS20080116011A1Improve productivityIncrease consumptionRolling equipment maintainenceRollsProduction rateEmulsion

The present invention provides a method of supplying lubrication oil in cold rolling for stable rolling without heat scratches or slip and realizing high productivity and improvement of the specific consumption of lubrication oil, that is, a method of supplying lubrication oil in cold rolling for lubricating rolling in cold tandem rolling of metal sheet by supplying a predetermined kind of emulsion lubrication oil comprised of a mixture of rolling oil and water at the rolling stand inlet side from nozzles, the method of supplying lubrication oil in cold rolling characterized by measuring or estimating the pressure in the lubrication nozzle pipe (lubrication nozzle pressure), controlling the lubrication nozzle pressure of any rolling stand where lubrication is liable to become excessive with the predetermined emulsion lubrication oil to 0.5 MPa or more, and, while doing so, supplying the lubrication oil to the roll bite inlet of the stand by direct injection.

Owner:NIPPON STEEL CORP +1

Method for producing ultra-thin metal lithium strip

InactiveCN107052047ARealize automatic roll productionIncrease productivityWork cleaning devicesMetal rolling arrangementsThin metalLithium–sulfur battery

The invention discloses a method for producing an ultra-thin metal lithium strip. The method includes the following steps that (1) the surface of a base material is coated with a lubricating agent; (2) rolling is conducted; (3) edge cutting is performed; (4) oil stains on the surface of the lithium strip are cleaned; and (5) the lithium strip is subjected to air drying, and surface impurities are removed. By the adoption of the method, the rolling technology is adopted, the base material is subjected to surface treatment before rolling, cleaning and air drying are carried out after rolling, the thickness of the obtained ultra-thin metal lithium battery strip can reach 0.02mm or below, and the lithium strip is mainly applied to high-capacity secondary batteries like a lithium-sulfur battery, a lithium air battery, a lithium negative electrode full-solid-state battery, a lithium polymer battery and other secondary batteries using lithium as the negative electrode; and automatic coiling production can be achieved, small-batch slicing production can also be conducted, production efficiency can be greatly improved, product quality is well guaranteed, and a foundation is laid for research, development and follow-up production of the high-capacity lithium ion secondary batteries.

Owner:CHINA ENERGY LITHIUM

Ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and method

PendingCN107309272AImprove deformationFulfil requirementsWork cleaning devicesMetal rolling arrangementsTinningEmulsion

The invention provides ultrathin uncoated tinplate base high elongation percentage wet leveling technological equipment and a method. By arranging a leveling liquid system taking a low-concentration emulsion as a medium in a two-stand leveling unit, the wet leveling elongation percentage of strip steel is raised substantially; by reasonably arranging a splashing prevention device, the splashing of leveling liquid is effectively prevented; equipped with an alkali liquor washing system and a strip steel cleaning system, the surface of the strip steel is subjected to alkali liquor washing and soft water cleaning, so that the leveling liquid remained on the surface of the strip steel is cleaned, and spots of the leveling liquid are effectively controlled; by adopting a curtain wall air knife type air knife blowing system, high-output and low-noise efficient blowing is realized; and equipped with a hot air drying system, surface cleanness and dryness of the strip steel are guaranteed. By adopting the leveling liquid system taking the low-concentration emulsion with the concentration being 0.5-1.5% as the medium, the elongation percentage and the antirust capability of the strip steel are raised and improved significantly, steel plate deformation is improved substantially and the elongation percentage can reach 5-10%, the high elongation percentage wet leveling can repair and cover a part of surface defects, and thus the plate surface quality and the product overall quality are improved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

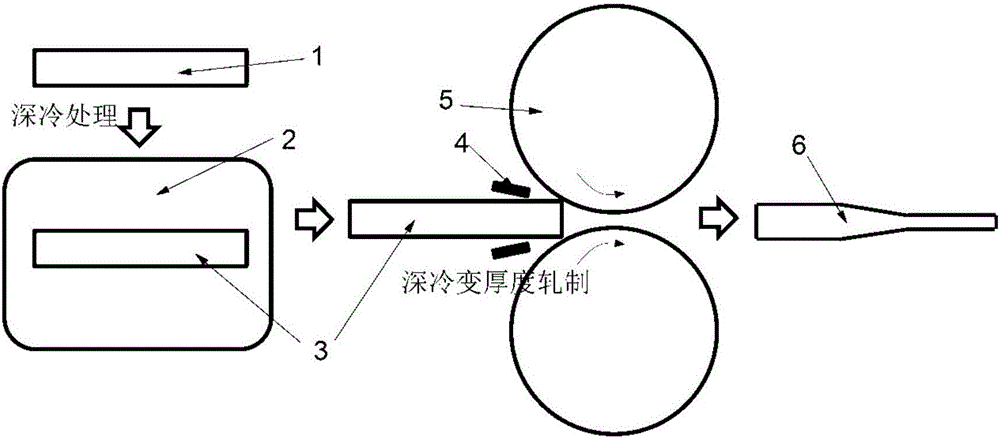

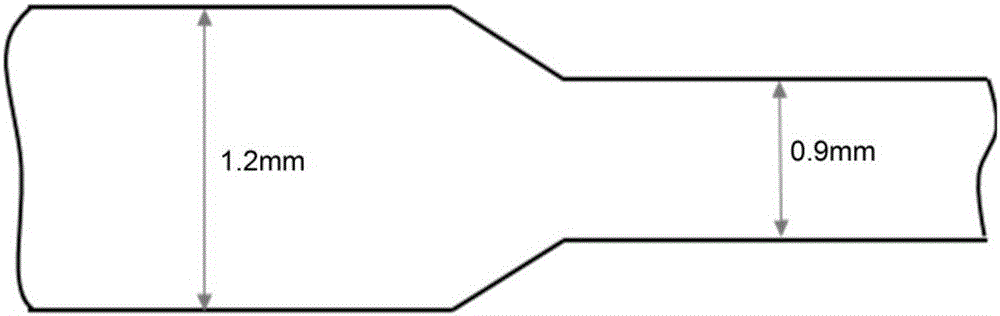

Aluminum alloy deep cooling variable-thickness rolling process

ActiveCN107520270AHigh strengthImprove toughnessWork cooling devicesMetal rolling arrangementsVariable thicknessLiquid nitrogen

The invention discloses an aluminum alloy deep cooling variable-thickness rolling process. An aluminum alloy plate strip serves as a raw material, and is machined into a piece-shaped material with a certain size, the material is placed into liquid nitrogen to be cooled, after cooling, deep cooling variable-thickness rolling is carried out, and high-performance aluminum alloy variable-thickness strip is produced. According to the process, ultra-low temperature plastic deformation is used, the strength and the toughness of the aluminum alloy are synchronously improved, at the same time, variable-thickness rolling is used, and a high-strength toughness aluminum alloy thickness difference plate capable of being directly used for car parts can be prepared.

Owner:CENT SOUTH UNIV

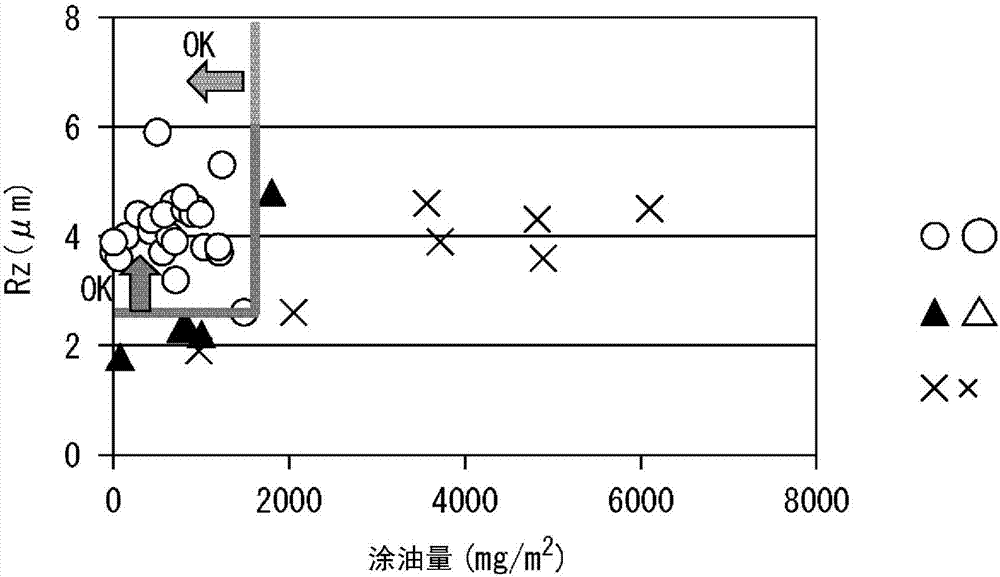

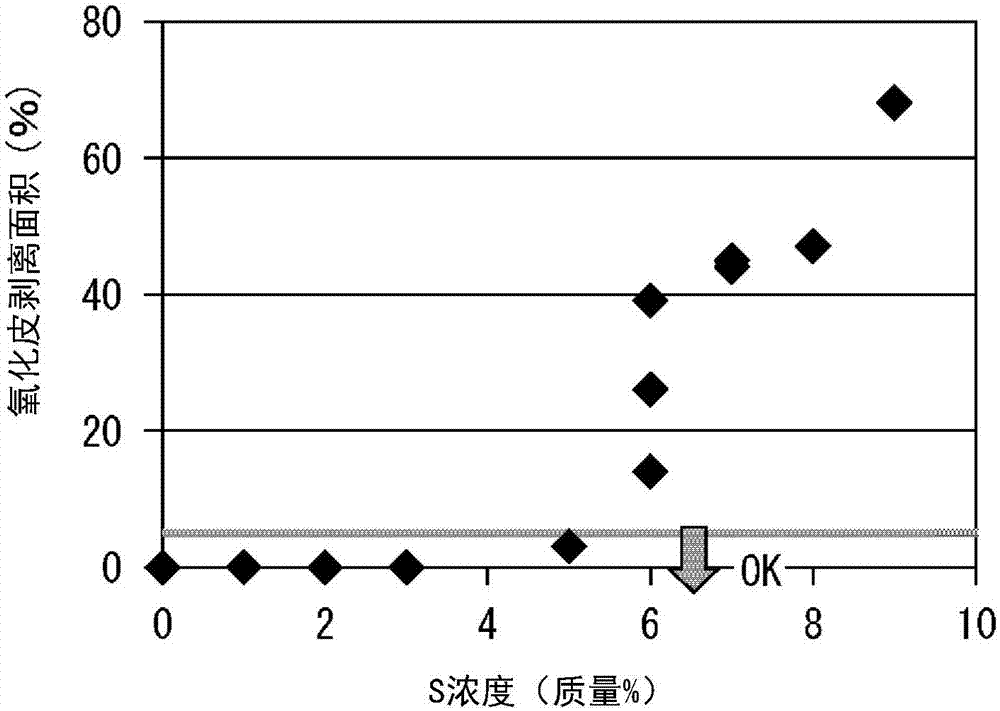

Steel Sheet For Hot Stamping, Method For Manufacturing Same, And Hot Stamp Molded Article

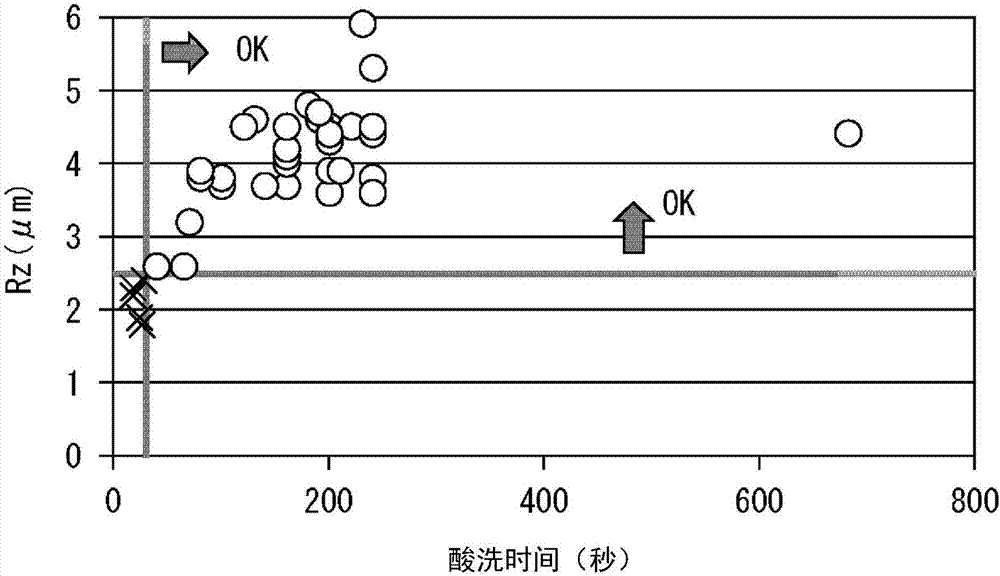

ActiveCN107427889AExcellent adhesionFurnace typesWork lubrication devicesHot stampingSurface roughness

A steel sheet for hot stamping contains, in percentage by weight, C: 0.100%-0.600%, Si: 0.50%-3.00%, Mn: 1.20%-4.00%, Ti: 0.005%-0.100%, B: 0.0005%-0.100%, P: 0.100% or less, S: 0.0001%-0.0100%, Al: 0.005%-1.000%, and N: 0.100% or less, with the remainder comprising Fe and impurities. The steel sheet surface roughness is such that Rz > 2.5 mum, and the surface is coated with 50 mg / m2 1,500 mg / m2 of oil coated thereon.

Owner:NIPPON STEEL CORP

Copper belt production technology for new energy automobile connector

ActiveCN105420647AAvoid the phenomenon of rolling partsEasy to set upWork cooling devicesMetal rolling arrangementsNew energyEngineering

The invention discloses a copper belt production technology for a new energy automobile connector, and belongs to the technical field of the copper plate belt production technology. The technology comprises the first step of cast ingot smelting, the second step of face milling, the third step of hot rolling, the fourth step of rough rolling, the fifth step of one-time annealing, the sixth step of one-time cleaning, the seventh step of intermediate rolling, the eighth step of two-time annealing, the ninth step of two-time cleaning, the tenth step of intermediate rolling, the eleventh step of three-time annealing, the twelfth step of three-time cleaning, the thirteenth step of finish rolling, the fourteenth step of four-time cleaning and the fifteenth step of leveling, wherein in the fourth step of rough rolling, after rough rolling, the regulated thickness of a belt roll is 2.5 mm. By means of the technical scheme, the copper belt annealing technology quality and the copper belt surface quality can be improved, and therefore the workshop cost can be reduced, and the productive profit can be increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

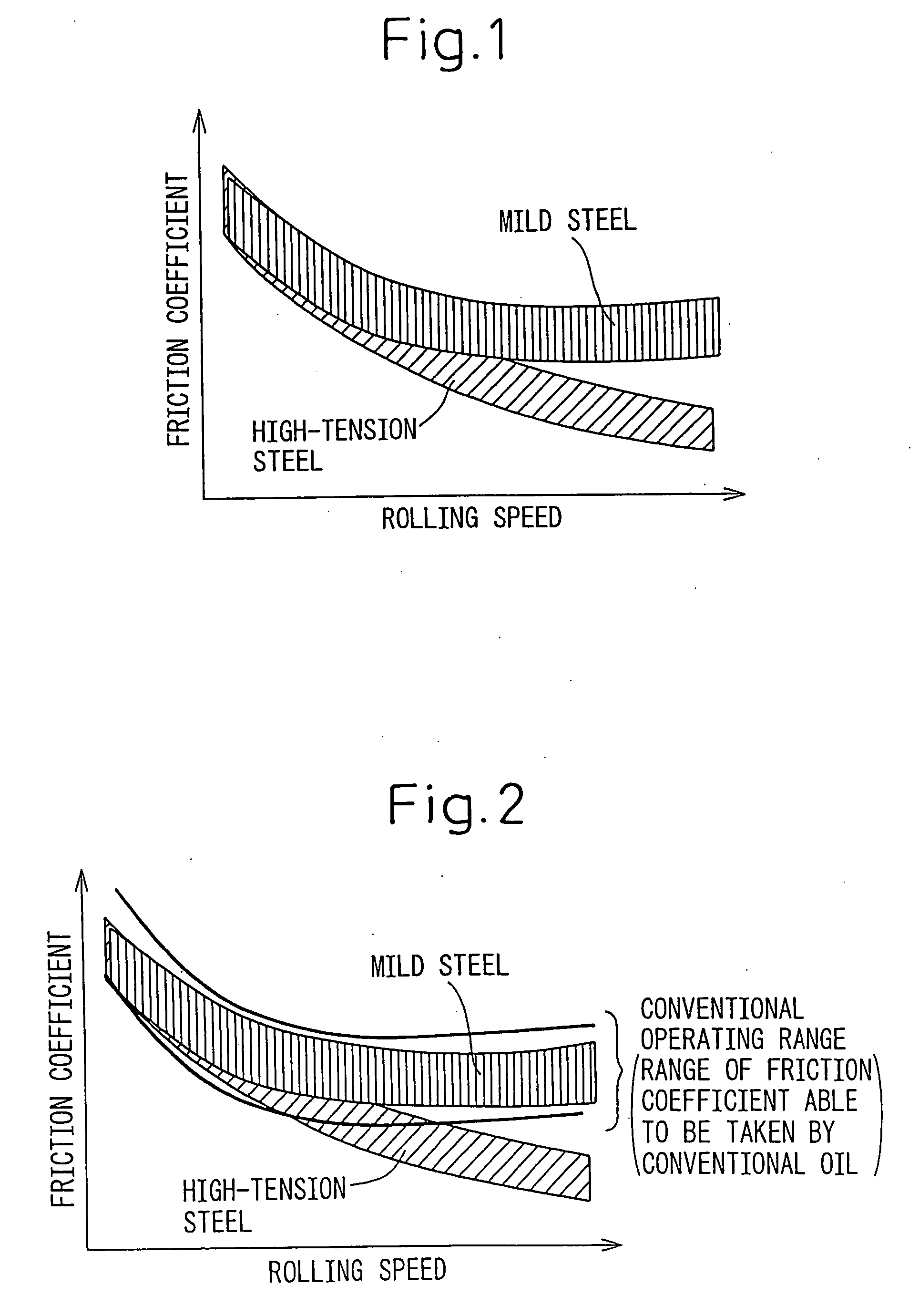

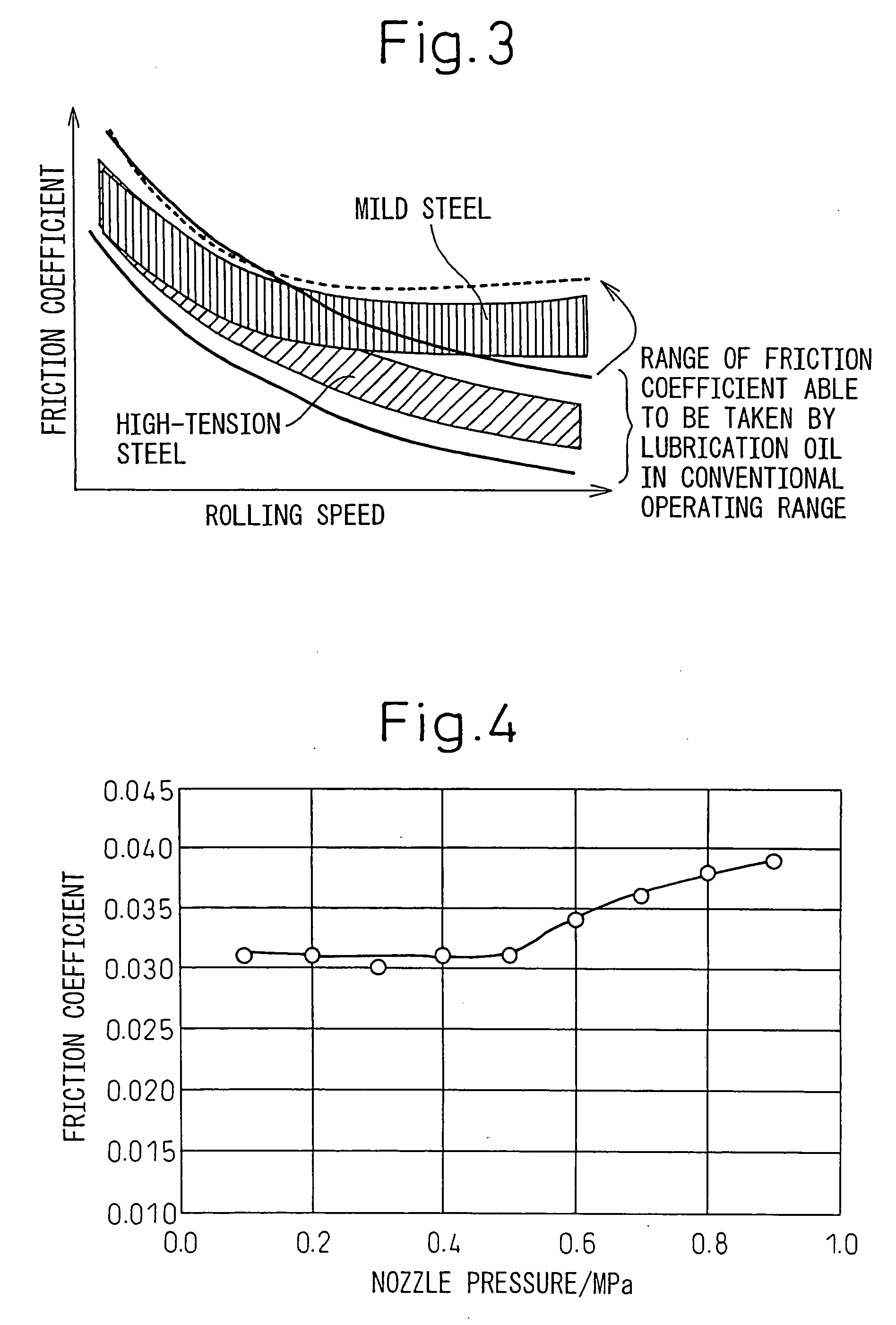

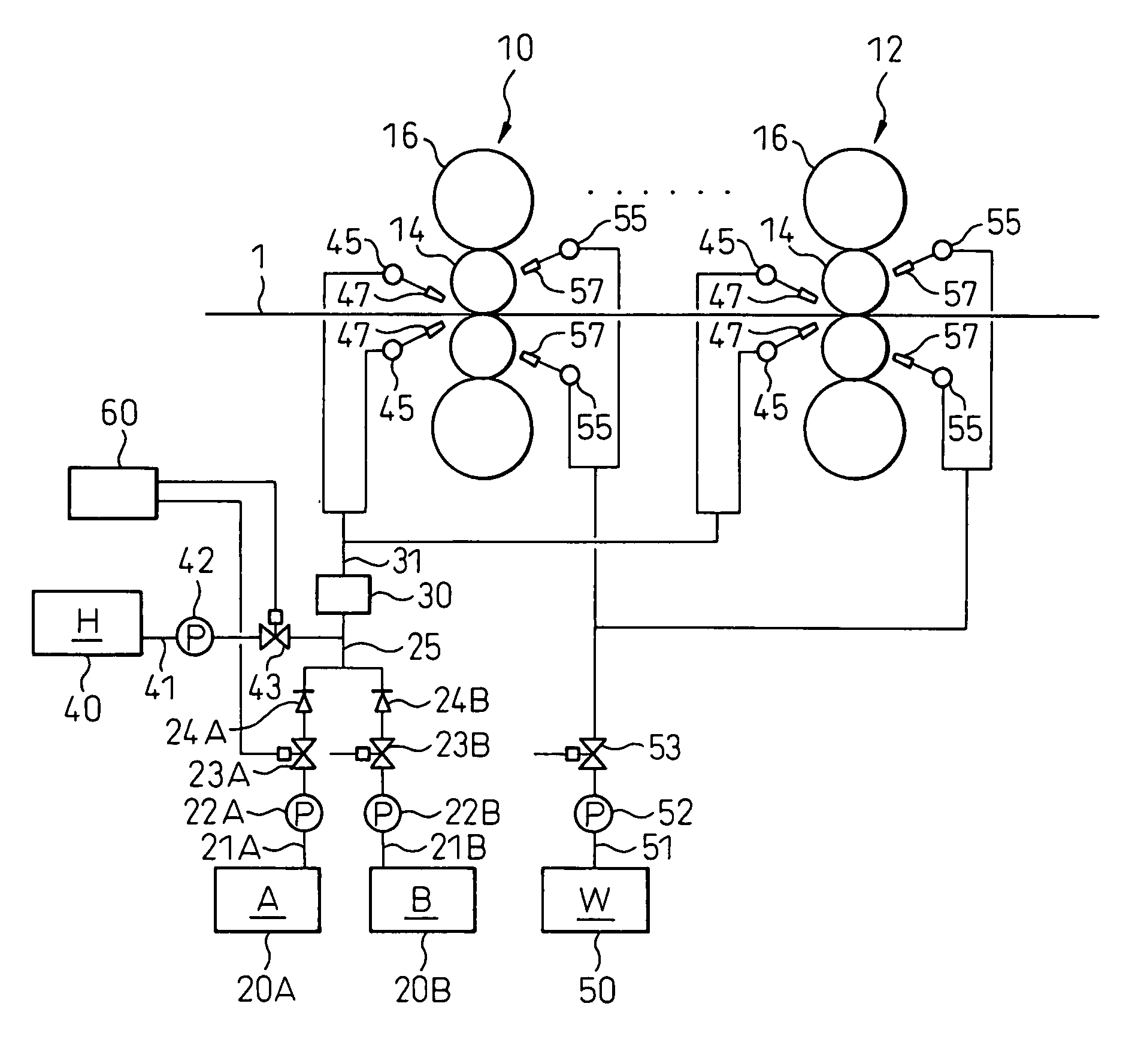

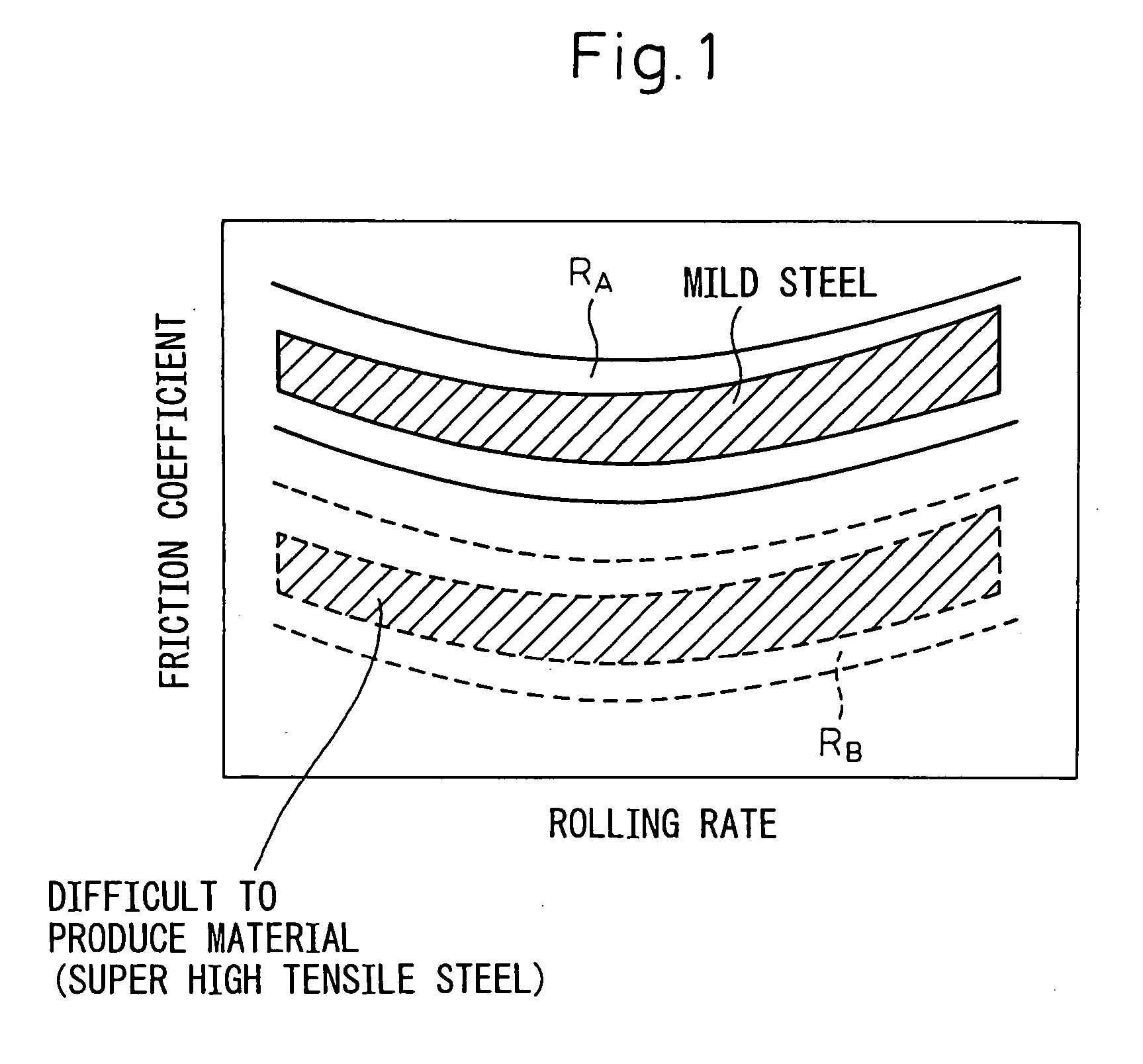

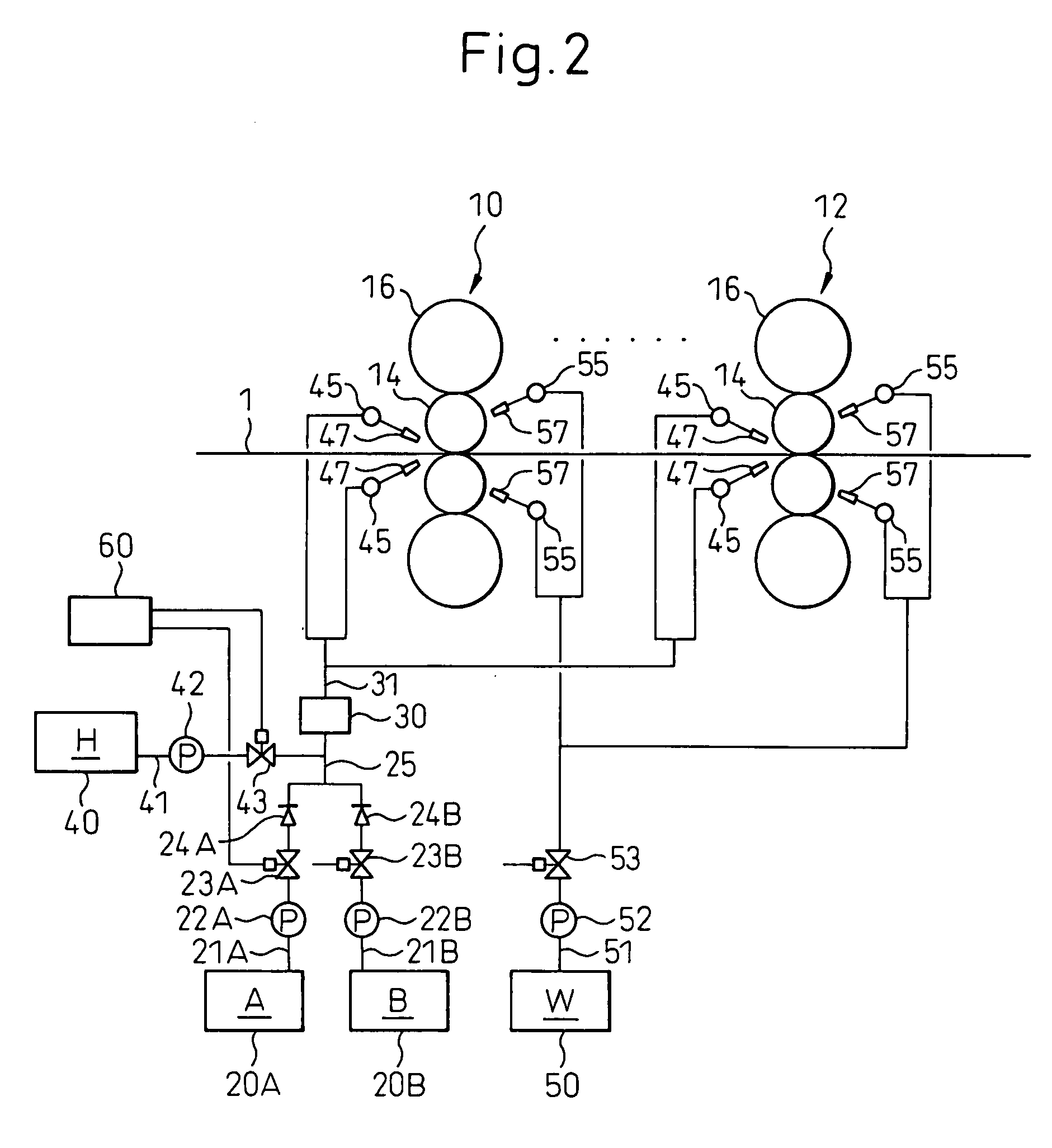

Method Of Supplying Lubrication Oil In Cold Rolling

The present invention provides a method for supplying lubricant to various kinds of steel sheets with different qualities in cold rolling without any restrictions, such as lubricant supplying apparatus or lubrication conditions. This method comprises storing two or more kinds of lubricant such as A and B, having different compositions, selecting one lubricant or a mixture lubricant of the above A and B in accordance with the friction coefficient between the steel sheet to be cold rolled and a work-rolls, and supplying an emulsion comprising a mixture of the lubricant A and / or B and heated water.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL +1

Lubricant composition for plastic working

InactiveCN1938410AEasy to operateStrong degreasing performanceShaping toolsThickenersSulfonateNonferrous metal

Disclosed is a lubricant composition for plastic working which is excellent in workability, degreasing property and working conditions. The lubricant composition is suitably used in fields of plastic working, particularly in fields of warm press forming, of various metal materials, especially of magnesium-base or aluminum-base nonferrous metal materials. Also disclosed are a warm forming process using such a lubricant composition and a method for producing a warm press-formed metal material. The lubricant composition for plastic working contains a solid lubricant and (B) at least one selected from (i) calcium sulfonates and (ii) non-volatile compounds, and the mass ratio between the component (A) and the component (B) in the composition is from 90:10 to 10:90.

Owner:IDEMITSU KOSAN CO LTD

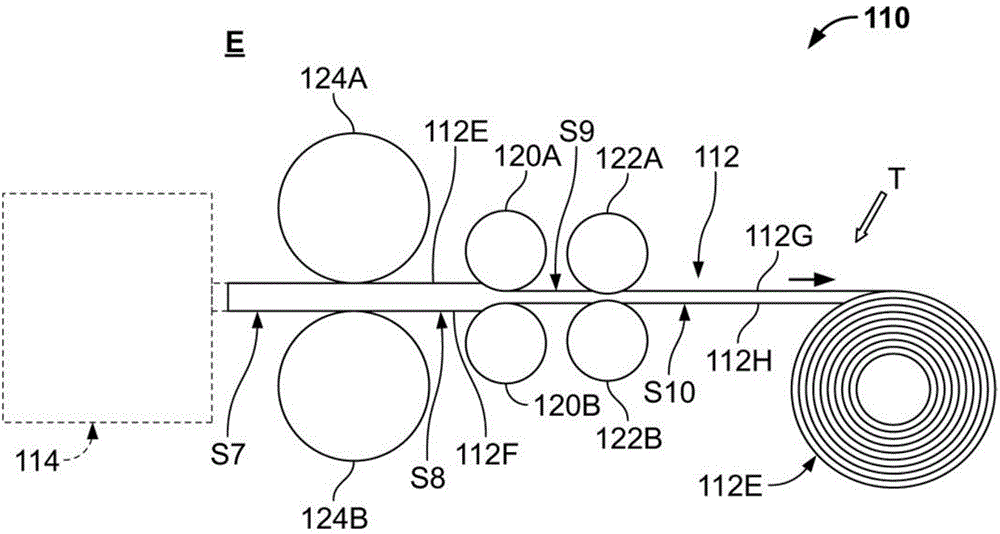

Apparatus and method for rolling metal

Owner:ARCINIC INC

Production technology for preventing 'core collapse' defect of ultrathin steel coil

InactiveCN104475448AReduce manufacturing costEliminate "collapsed core" defectsTension/compression control deviceMetal rolling arrangementsStrip steelTension stress

The invention discloses a production technology for preventing 'core collapse' defect of ultrathin steel coil. The production technology comprises: uncoiling a raw material steel coil by an uncoiling machine, clamping the head portion of the band steel by a clamping jaw of a recoiling machine, and coiling 1.5 circles of the band steel, then rolling the band steel for 5 to 7 times, rolling the band steel of 2.5 to 3.0 mm thick into a thin band steel whose thickness is less than 0.3 mm, and then coiling the finished steel coil by the recoiling machine, putting the finished steel coil into a warehouse after coil discharging, weighing, and bundling. A high tension start technology is used for coiling the finished coils, the core portion start tension is increased to 1.6 to 2 times of the set coiling tension stress, then the core portion start tension is gradually reduced and returned to the set tension stress of 70 N / mm2 when the outer diameter of the steel coil is 800 mm; the clamping jaw is reversed after the coiling block is shrank for 2 degrees during the coil discharging. The production technology for preventing 'core collapse' defect of ultrathin steel coil employing a hard core tension cold rolling method without increasing the number of coiling circles is able to saved the cost of manufacturing sleeves and the cost of transportation, thereby effectively removing the 'core collapse' defect of ultrathin steel coil, and increasing the production rhythm and efficiency.

Owner:SHANDONG IRON & STEEL CO LTD

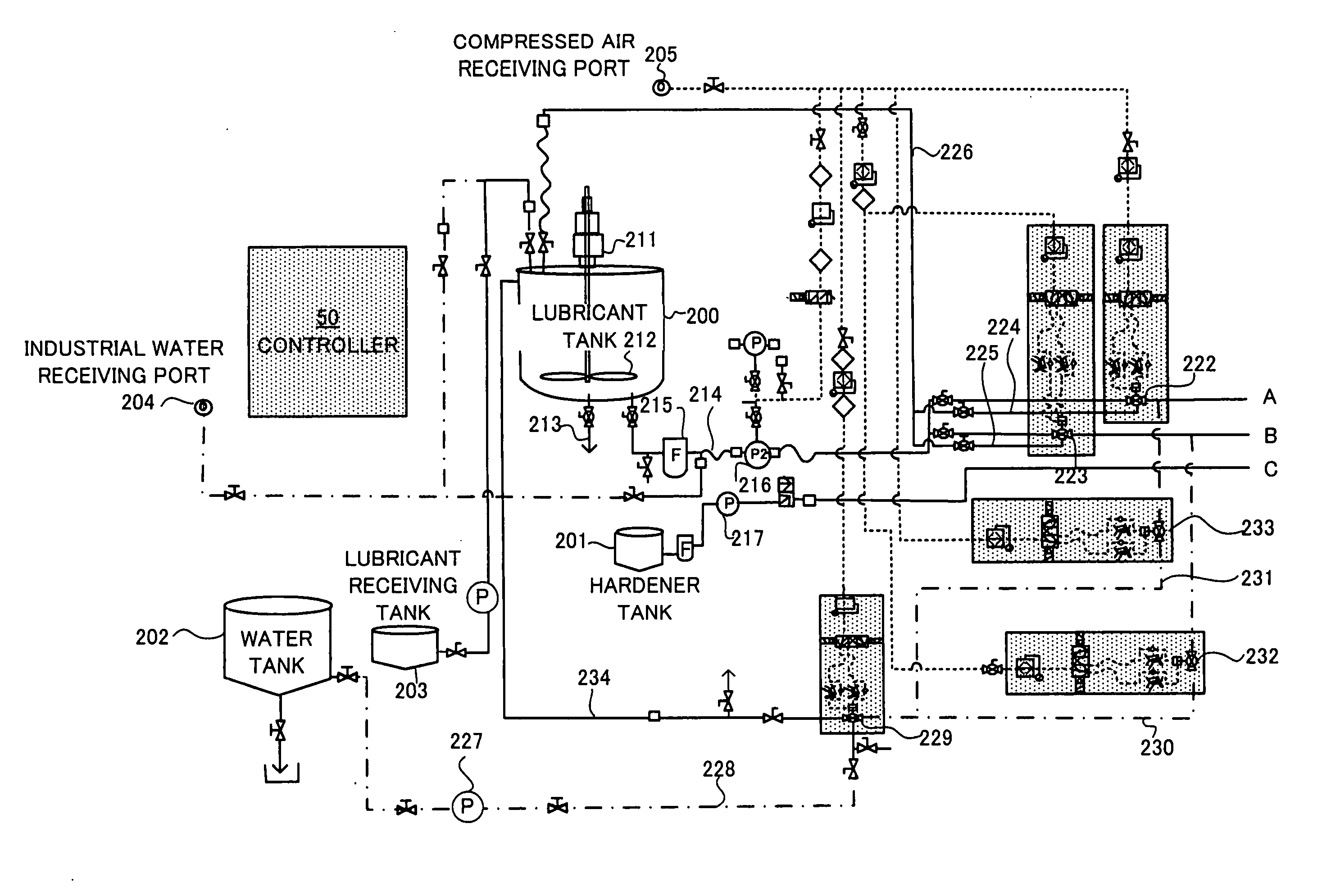

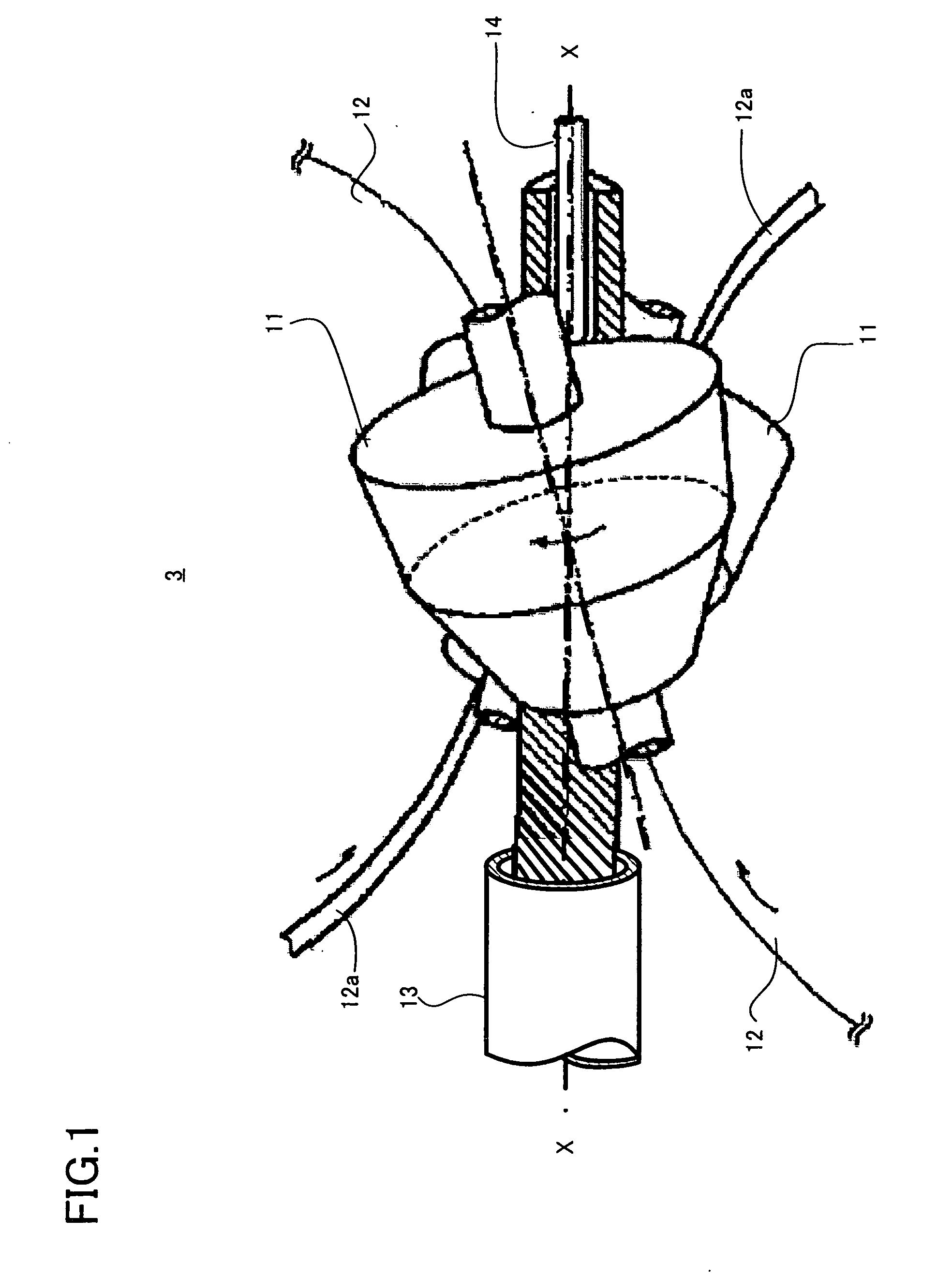

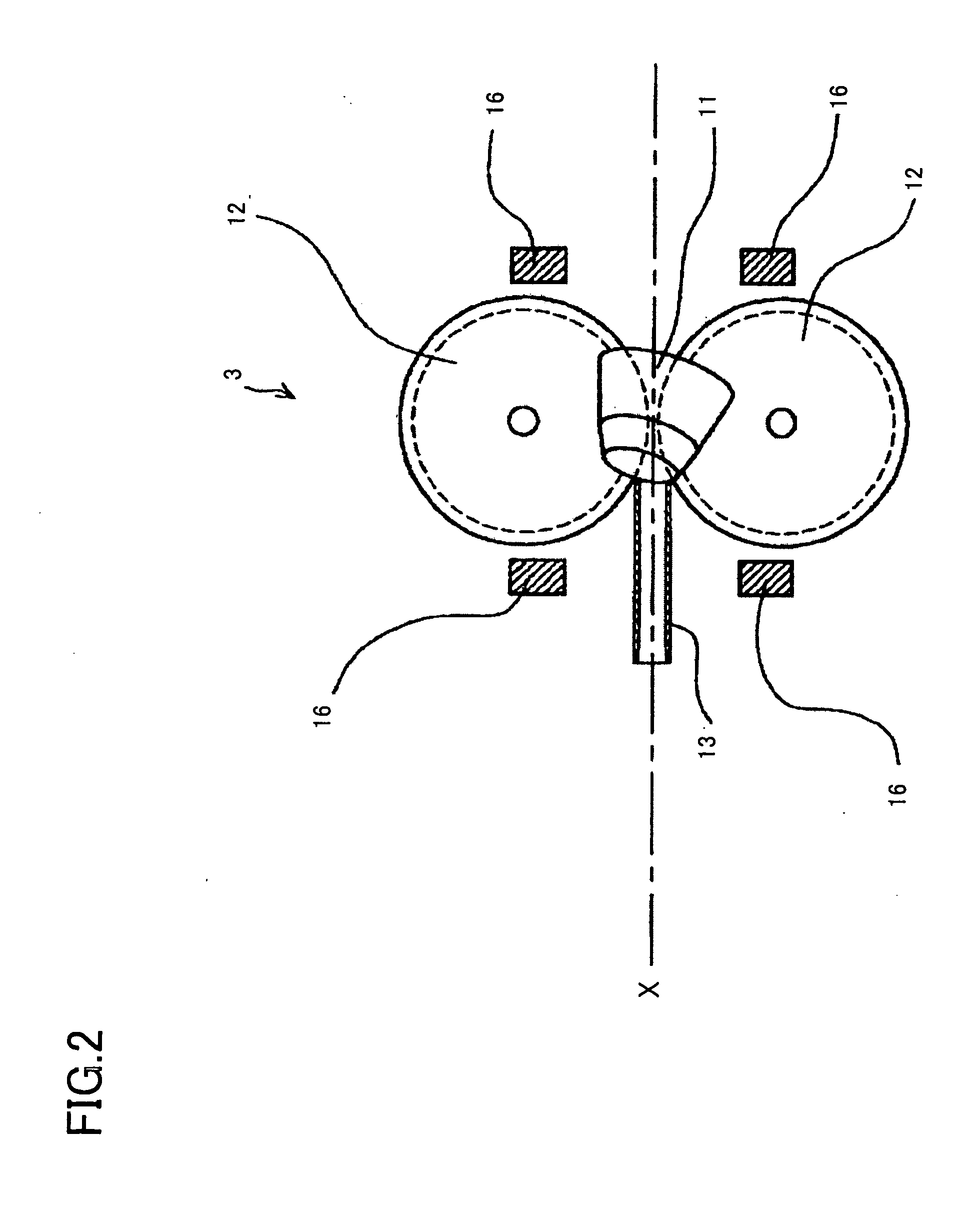

System For Supplying Lubricant, Apparatus For Manufacturing Seamless Pipes Or Tubes, And Method Of Manufacturing Seamless Pipes Or Tubes

The present invention provides a system for supplying a lubricant necessary for efficiently manufacturing high-quality seamless pipes or tubes in a piercing mill, an apparatus for manufacturing seamless pipes or tubes having the supply system, and seamless pipes or tubes manufacturing method. The system for supplying a lubricant has a storage tank of the lubricant, a plumbing extending from the storage tank to a position near disk rolls, a nozzle provided at the tip of the plumbing, a device for switching flow direction provided in some midpoint of the plumbing, a plumbing extending from the device for switching flow direction to the storage tank, and a device for releasing pressure in a plumbing, provided between the switching device and the nozzle.

Owner:NIPPON STEEL CORP

Production method of aluminum and aluminum alloy plates and strips for new energy power battery case

ActiveCN111074110AIncrease the amount of controlReduce in quantityRoll force/gap control deviceTemperature control devicePower batteryMetallurgy

The invention provides a production method of aluminum and aluminum alloy plates and strips for a new energy power battery case. The method comprises the following steps of aluminum melt preparing, continuous casting and rolling, homogenizing annealing, cold rolling, intermediate annealing or final annealing. The method can be used for producing 3003 alloy plate and strip products in the states of"O", "H12" and "H14" for the new energy power battery case, and the strength and the yield ratio of material of the obtained products can be effectively enhanced.

Owner:广西润泰铝业有限公司

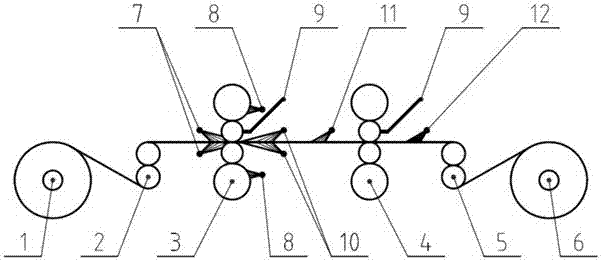

Rolling method for single-face periodically variable thickness plate strip materials

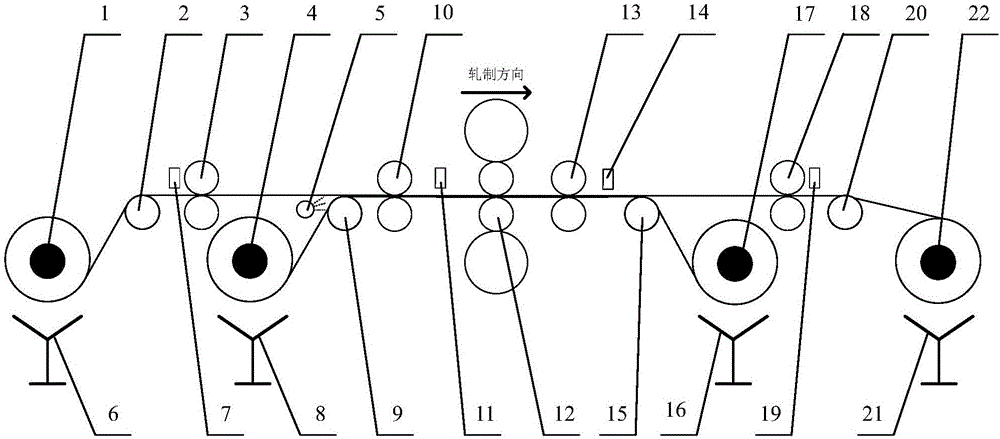

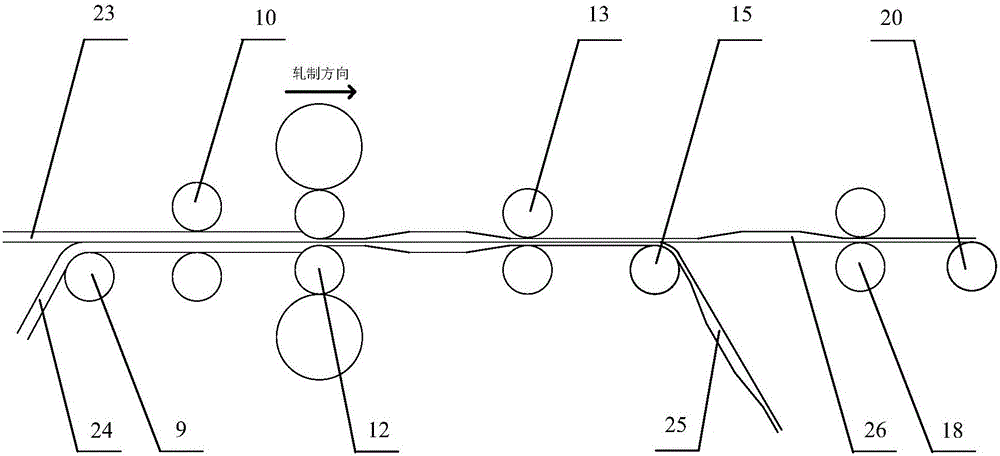

ActiveCN106513436AAchieve productionImprove rolling efficiencyTension/compression control deviceWork lubrication devicesVariable thicknessMetal

The invention disclose a rolling method for single-face periodically variable thickness plate strip materials, and belongs to the technical field of metal rolling. According to the method, double-strip synchronous variable-thickness ply rolling is conducted through two uncoilers and two coilers, that is, the two uncoilers and the two coilers are arranged on two sides of a rolling mill correspondingly. The rolling method includes the specific steps that (1) feeding is carried out, specifically, upper-layer raw plate strip materials and lower-layer raw plate strip materials are installed on the corresponding uncoilers; (2) strip penetrating is conducted, specifically, the upper-layer raw plate strip materials and the lower-layer raw plate strip materials are welded to guide strips of the corresponding coilers separately through guide strip movement and welding, so that strip penetrating is completed; (3) variable-thickness rolling is conducted, specifically, setting of rolling parameters and control over alignment, speed, thickness, tension and the like in the rolling process are included; and (4) the single-face periodically variable thickness plate strip materials are obtained and moved out. By the adoption of the method, rolling of the single-face periodically variable thickness plate strip materials and double-face periodically variable thickness plate strip materials can be realized, different production requirements are met, the rolling efficiency is greatly improved, and the production cost is lowered.

Owner:NORTHEASTERN UNIV

Preparing method for large-size beta-gamma TiAl alloy plate

InactiveCN107267902APrevent oxidationGood removal effectTemperature control deviceWork lubrication devicesHot workingLarge size

The invention discloses a preparing method for a large-size beta-gamma TiAl alloy plate and relates to a preparing method for the TiAl alloy plate. According to the purpose, the problems that due to the fact that a TiAl alloy hot working window is narrow, the plate is likely to be cracked and is hardly formed in the large-size TiAl alloy plate preparing process due to cooling in the non-isothermal rolling process, and secondary cracking of the plate is caused in the machining sheath removing process are solved. The method includes the steps that firstly, a TiAl alloy blank is prepared; secondly, a sheath is machined; thirdly, a glass lubricating agent is sprayed; fourthly, the TiAl alloy blank is subjected to sealing; fifthly; a high-temperature rolling stage is conducted; sixthly, residual stress is removed through homogenizing heat treatment; and seventhly, the sheath is removed through machining, and the large-size beta-gamma TiAl alloy plate is obtained. The preparing method is suitable for preparing of the large-size beta-gamma TiAl alloy plate.

Owner:HARBIN INST OF TECH

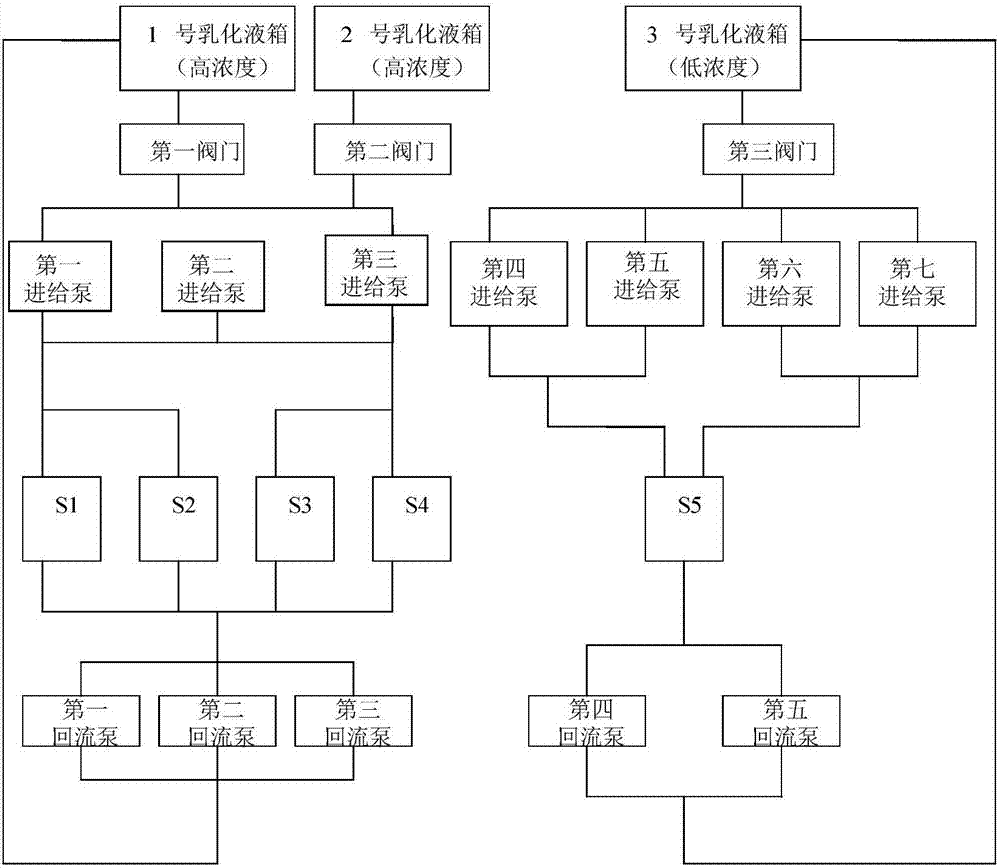

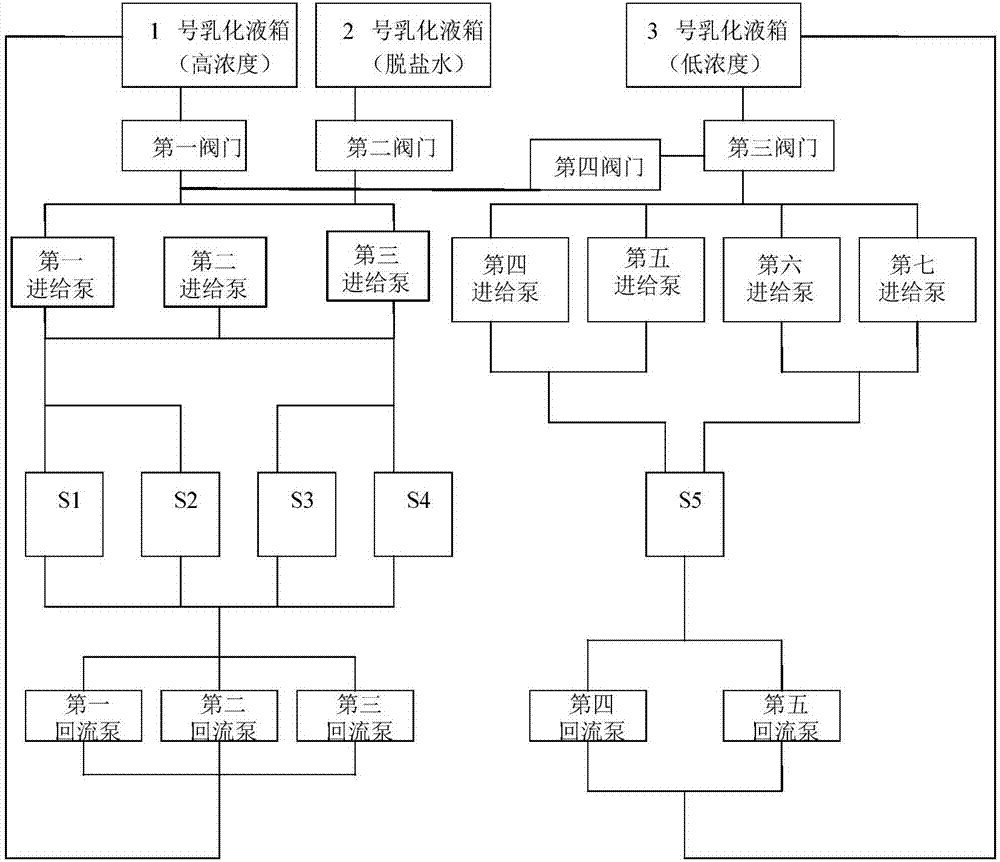

Method for decreasing emulsion concentration of five-rack continuous-rolling unit rolling mill emulsion system

InactiveCN107243513AReduce dosagePrevent channelingWork lubrication devicesMetal rolling arrangementsHigh concentrationEmulsion

The invention discloses a method for reducing the emulsification concentration of the rolling mill emulsion system of a five-stand continuous rolling mill. The method includes: transforming the existing five-stand continuous rolling mill mill emulsion system, between No. 1 emulsion tank, No. 2 emulsion tank and No. 3 emulsion tank of the five-stand continuous rolling mill emulsion system In the production process, the low-concentration emulsion in the No. 3 emulsion tank is realized by adding rolling oil, and the desalted water that meets the preset temperature requirements is prepared in the No. 2 emulsion tank; The concentration difference between the pump group of the system and the high-concentration and low-concentration emulsion directly realizes the channeling between the emulsion tanks and realizes the change of the emulsion concentration. The method can effectively save the amount of compressed air, and the operation is convenient, and the emulsion does not need to be discharged, which saves the cost.

Owner:BAOTOU IRON & STEEL GRP

Cold rolling method for high-silicon steel with Si content equal to or higher than 2.5%

InactiveCN108213077AAchieve continuous rollingFix bugsRoll force/gap control deviceRollsEmulsionLubrication

The invention relates to a cold rolling method for high-silicon steel with the Si content equal to or higher than 2.5%. The cold rolling method includes uncoiling blank steel coils, then directly loading and rolling the blank steel coils by the aid of six-roller rolling mills and carrying out cold rolling by the aid of single-cold-rolling processes or double-cold-rolling processes; carrying out technological lubrication and cooling by means of emulsion spraying in rolling procedures; carrying out reeling after rolling is completed. The flow of emulsion on inlet sides of pass is 1000-6000 L / min, flow of emulsion on outlet sides of the pass is completely cut off, and the rolling deformation temperatures of the pass are 100-300 DEG C under the control. The cold rolling method has the advantages that cold rolling can be carried out on the high-silicon steel with the Si content equal to or higher than 2.5% by the aid of the conventional six-roller rolling mills and can be continuously rolled by the aid of the six-roller rolling mills without frequent roller change, and accordingly the production efficiency can be improved by 30%; rolling deformation zones of the six-roller rolling millsare long in cold rolling procedures, the six-roller rolling mills are low in deformation speed, dramatic plastic deformation can be prevented, rolled pieces are free of strip shape quality defect, and products are excellent in surface quality.

Owner:武汉钢铁有限公司

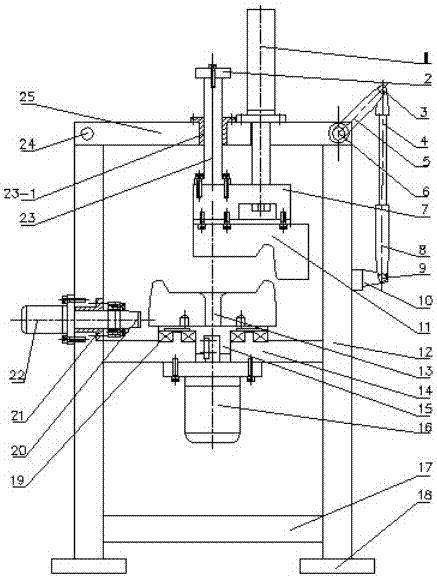

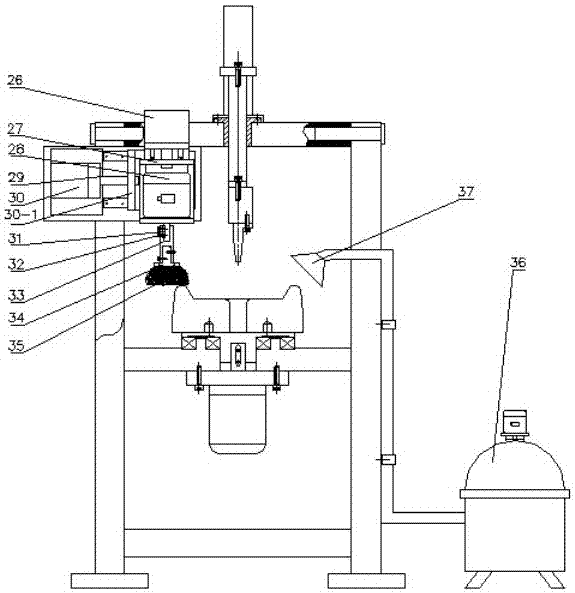

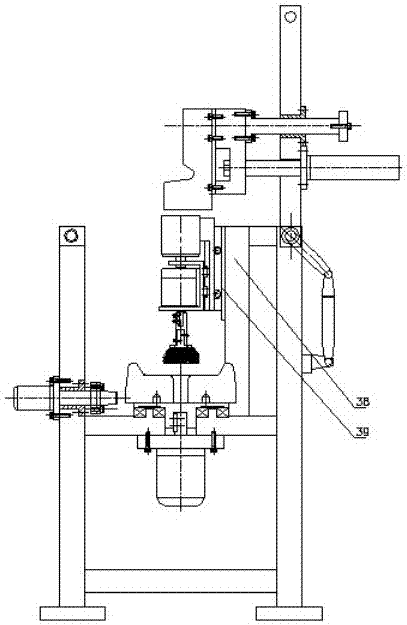

Improved automatic lubricant cleaning device for hub forging die

PendingCN107350188AImprove labor efficiencyReduce production intensitySpraying apparatusHollow article cleaningHydraulic cylinderEngineering

The invention discloses an improved automatic lubricant cleaning device for a hub forging die. The improved automatic lubricant cleaning device is composed of a hydraulic lifting cylinder, a limit block, a hinge A, a hydraulic piston rod, a fixed connection rod, a hinge shaft, a connection plate, a hydraulic cylinder, a hinge B and the like. The improved automatic lubricant cleaning device disclosed by the invention is capable of increasing labor efficiency and lowering production intensity, and high in universality; and corresponding cleaning scraping plates can be arranged according to surface shapes of different hub dies, and changed through a universal bolt connector, so that an equipment cost is saved.

Owner:CITIC DICASTAL

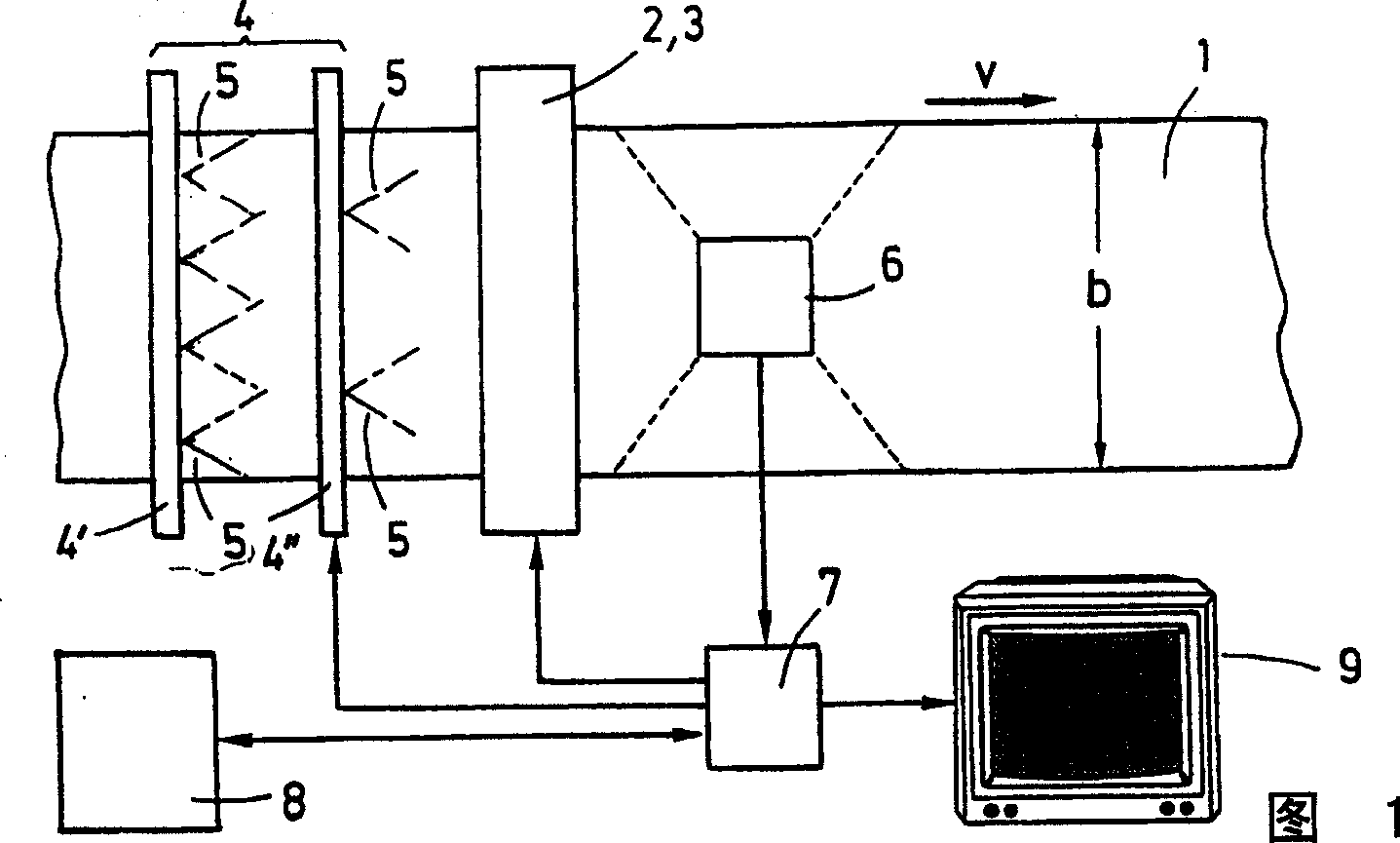

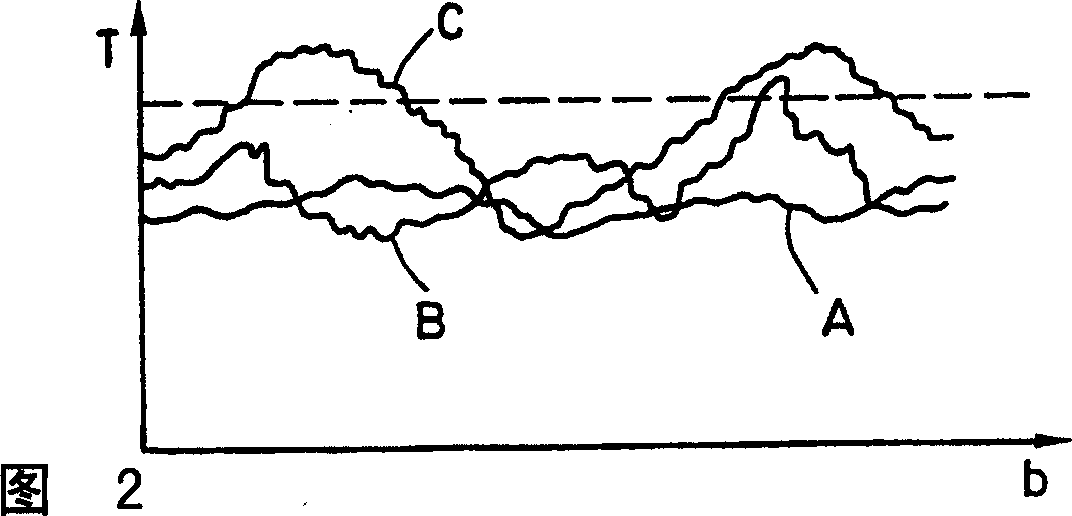

Rolling process for metal strip and corresponding rolling device

The invention relates to a rolling process for a metal strip (1) having width (b), wherein the metal strip (1) is rolled in at least one rolling stand (2), wherein an amount of lubricant is applied and spread on the width (b) of the metal strip (1), wherein the lubrication process on the width (b) of the metal strip is detected behind the rolling stand (2) and used for regulating the amount and / or distribution of the lubricant (5) and / or at least one rolling parameter (v).

Owner:SMS DEMAG AG

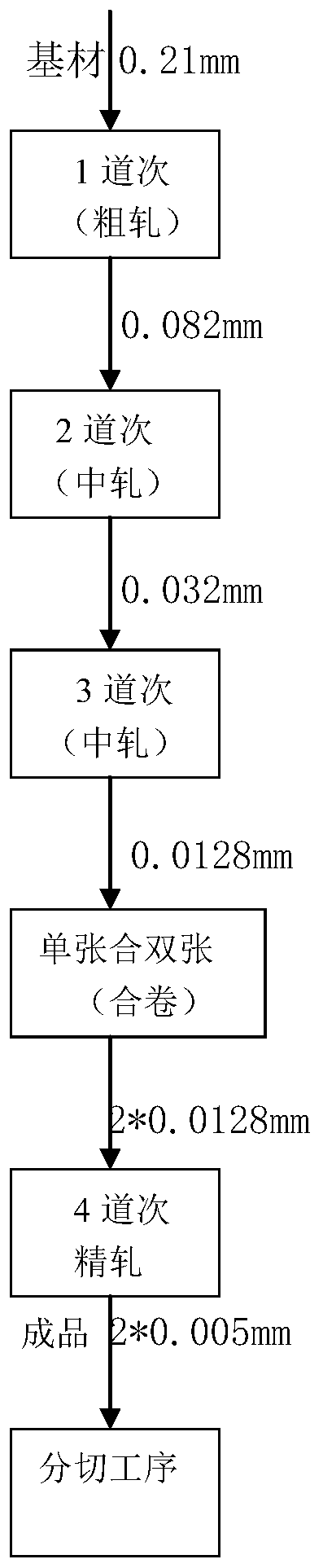

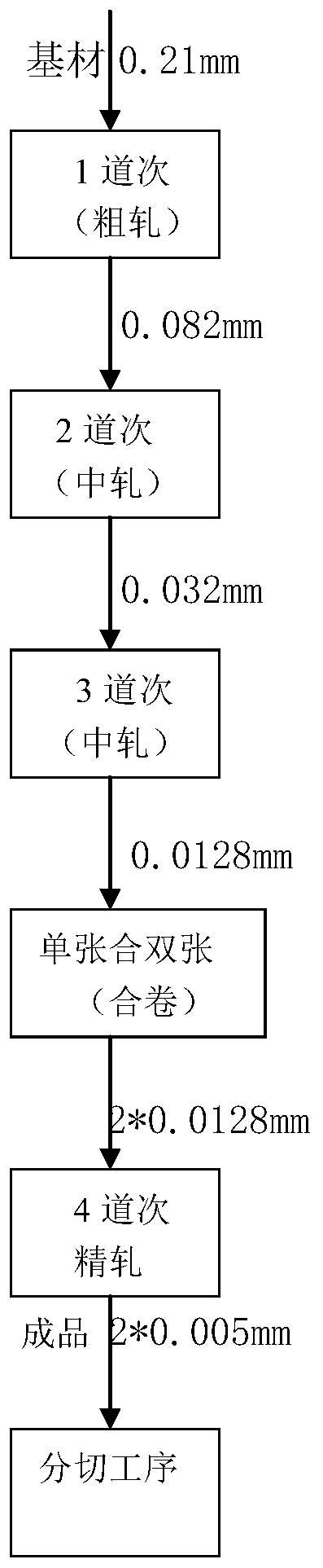

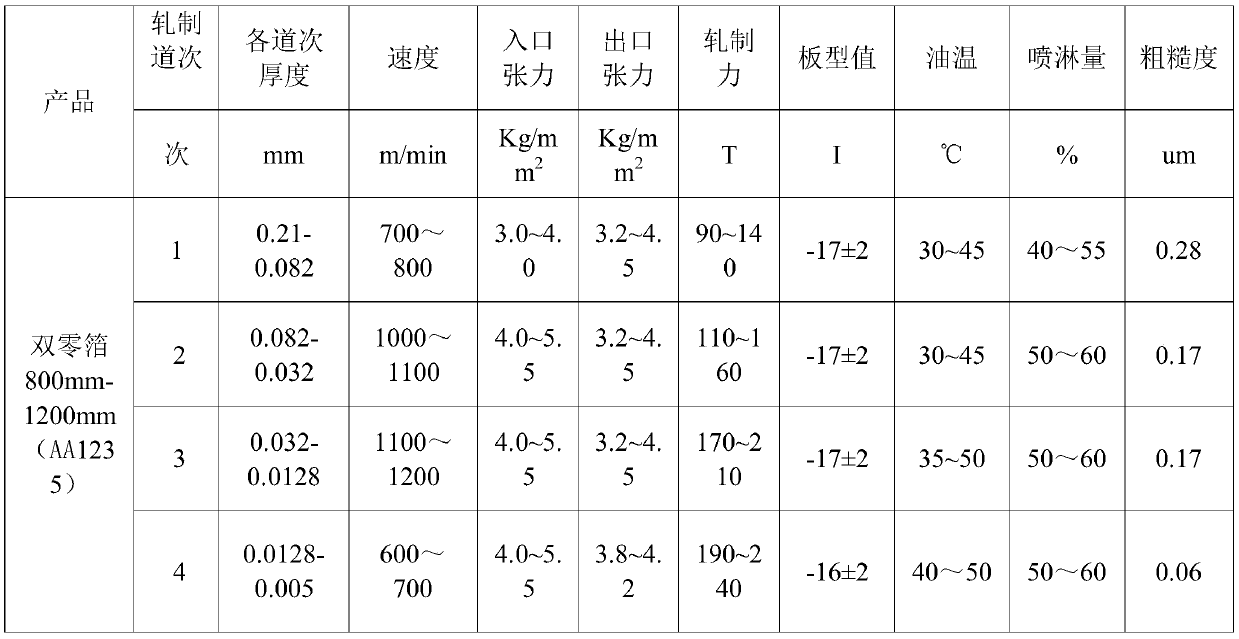

Four-pass rolling method for aluminum foil with thickness being 0.005 mm

ActiveCN110000209AReduced number of foil passesHigh speedRoll force/gap control deviceTemperature control deviceAluminum foilRolling mill

The invention relates to foil rolling preparation of 0.005 mm ultra-thin aluminum foil, in particular to a four-pass rolling method for aluminum foil with the thickness being 0.005 mm. As for a foil rolling preparation method, by adjusting process oils of a foil rolling mill and optimizing foil rolling pass distribution, original five-pass foil rolling is reduced to four-pass foil rolling, so as to obtain the aluminum foil with the thickness being 0.005 mm. According to the four-pass rolling method for the aluminum foil with the thickness being 0.005 mm, the number of foil rolling passes is decreased, and the overall efficiency of foil rolling is improved by 15% or above.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com