Production method of aluminum and aluminum alloy plates and strips for new energy power battery case

An aluminum alloy strip and power battery technology, which is applied in the field of aluminum alloy casting, can solve the problems of high production cost, high rate of punching and drawing of finished products, and difficulty in meeting the requirements, so as to achieve the advantages of improving plasticity and increasing tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

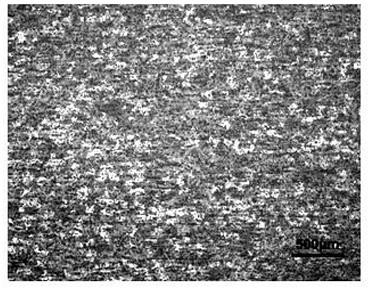

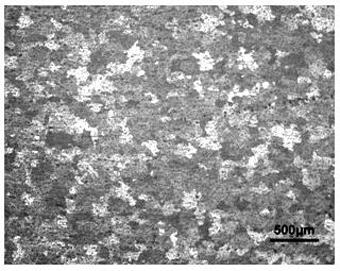

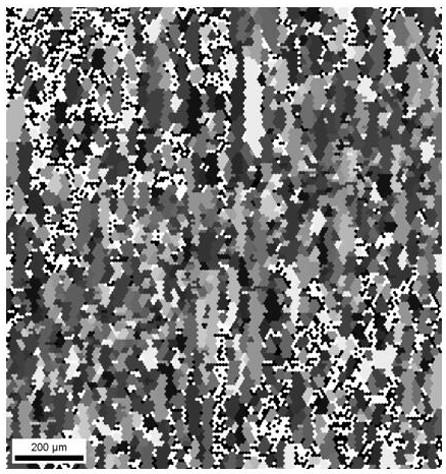

Image

Examples

Embodiment 1

[0041] A 1.0mm thick 3003 alloy "O" state power battery casing aluminum and aluminum alloy plate and strip preparation method.

[0042] S1. The chemical composition of the optimized 3003 alloy battery case aluminum strip, in terms of mass percentage: silicon 0.1%, iron 0.35%, copper 0.15%, manganese 1.05%, titanium 0.025%, and the balance is Al.

[0043] Put 70wt% electrolytic aluminum liquid, 30wt% aluminum ingot with aluminum content ≥99.7wt%, and various alloy additives into the melting furnace for melting, slag removal, adjustment of alloy chemical composition, refining, and standing to prepare aluminum melt , the aluminum melt treated in the smelting furnace is degassed by online SNIF and filtered online, the hydrogen content of the melt is 0.010ml / 100g Al, and the hydrogen content of alkali metal Na is 1ppm.

[0044] During refining, one end of the refining equipment is connected to the intake pipe, and the other end is inserted into the aluminum melt. The mixed gas of a...

Embodiment 2

[0053] A 1.2mm thick 3003 alloy "H12" and "H14" state power battery casing aluminum and aluminum alloy plate, strip preparation method.

[0054] S1. The chemical composition of the optimized aluminum strip for 3003 alloy battery case, the mass percentage of each component is: silicon 0.1%, iron 0.35%, copper 0.15%, manganese 1.00%, titanium 0.025%, and the balance is Al.

[0055] Put 70wt% electrolytic aluminum liquid, 30wt% aluminum ingot with aluminum content ≥ 99.7wt%, and various alloy additives into the melting furnace for melting, control the furnace temperature at 735~745°C, remove slag, adjust the chemical composition of the alloy , Refining, standing still to prepare aluminum melt, the aluminum melt treated in the smelting furnace is degassed by online SNIF and filtered online, the hydrogen content of the aluminum melt is controlled to 0.010ml / 100g Al, and the alkali metal Na content is 1ppm.

[0056] S2. During continuous rolling, the rolling distribution scheme is 1...

Embodiment 3

[0064] A 2.0mm thick 3003 alloy "O" state power battery casing aluminum and aluminum alloy plate, strip production method.

[0065] S1. The chemical composition of the optimized aluminum strip for 3003 alloy battery case, the mass percentage of each component is: silicon 0.09%, iron 0.37%, copper 0.14%, manganese 1.08%, titanium 0.025%, and the balance is Al.

[0066] Put 65wt% electrolytic aluminum liquid, 35wt% aluminum ingots with an aluminum content ≥ 99.7 wt%, and various alloy additives into the melting furnace for melting, control the furnace temperature at 735~745°C, remove slag, adjust the chemical composition of the alloy , Refining, standing still to prepare aluminum melt, the aluminum melt treated in the smelting furnace is degassed by online SNIF and filtered online, the hydrogen content in the aluminum melt is controlled to 0.010ml / 100g Al, and the alkali metal Na content is 1ppm.

[0067] During refining, one end of the refining equipment is connected to the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com