Method for improving high heat input welding performance of thick steel plates

A large energy input welding and thick steel plate technology, applied in the field of iron and steel metallurgy and iron and steel materials, can solve the problem of insufficient improvement of the toughness of the welding heat affected zone, so as to improve the welding performance of large input energy, promote growth, and inhibit the growth of grains big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

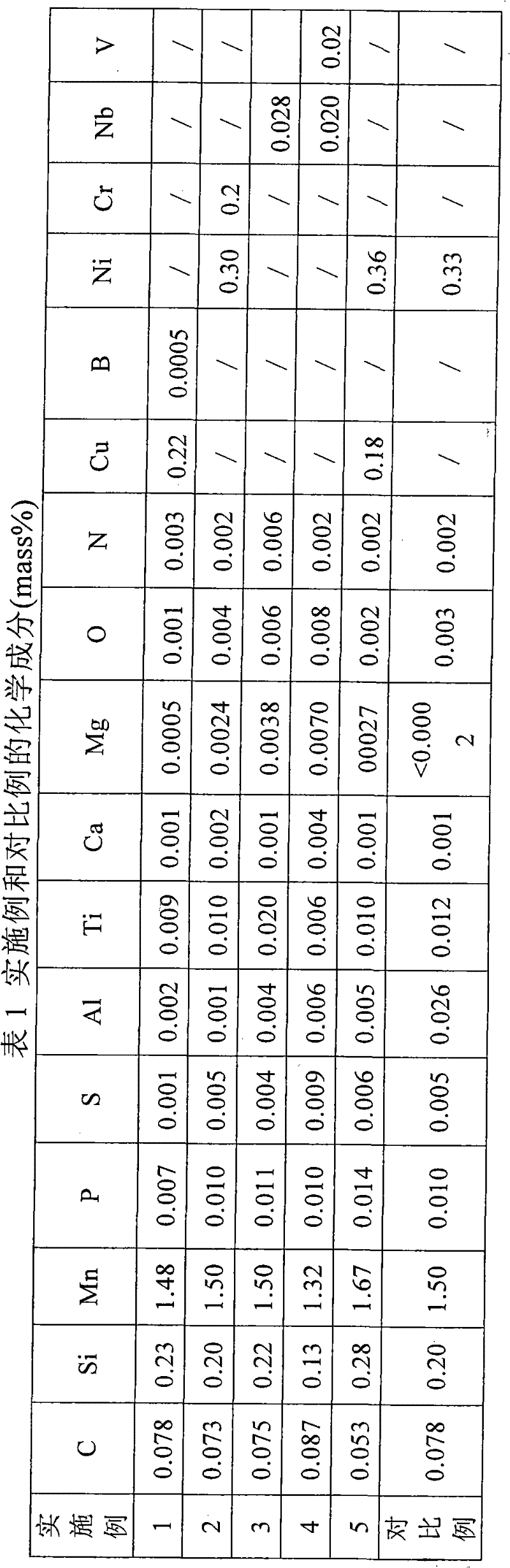

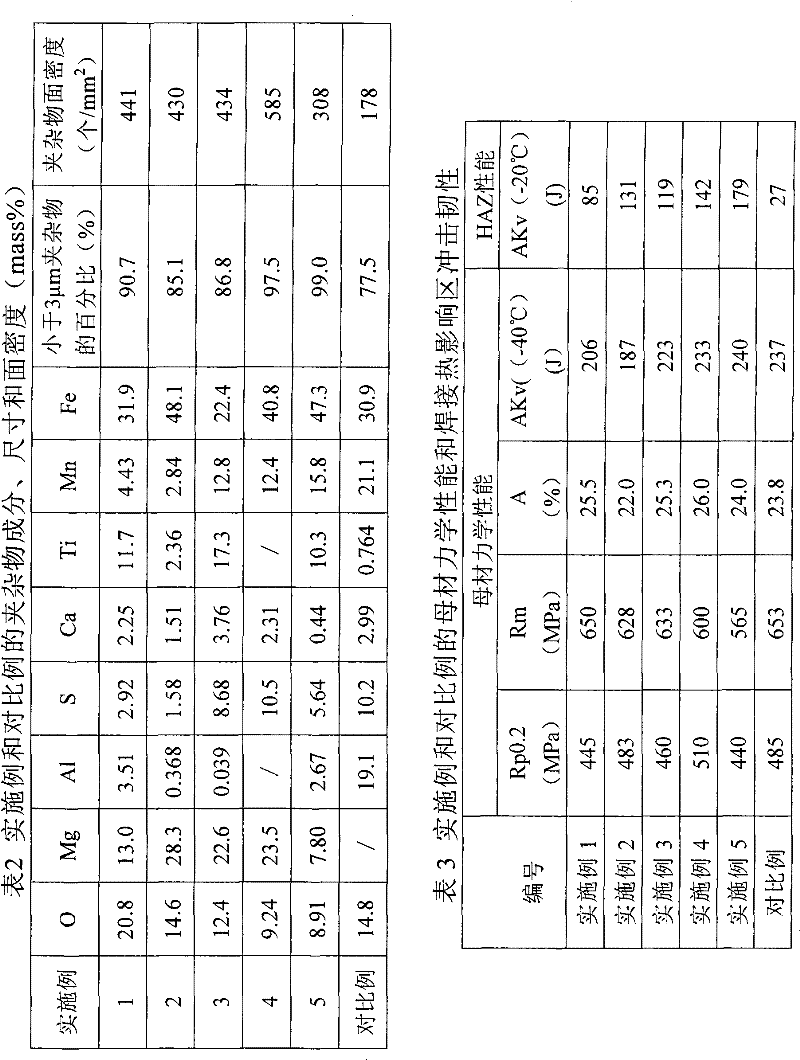

[0046] The present invention will be further described below in conjunction with embodiment.

[0047] In this embodiment, the smelting process is carried out in a 50kg vacuum induction furnace. The furnace lining is made of magnesia with 1.2% boric acid dry-mixed and then sintered, and cast with high-alumina refractory material ingot mold. Add 40kg of pure iron to the induction furnace and add CaO at the same time. The method of simply adding CaO to make slag ensures a lower oxygen position in the slag. While vacuuming, the temperature rises, and the vacuum degree can reach 30Pa after the charge is melted. After filling the induction furnace with Ar gas to 0.05MPa, adjust the alloy composition in the molten steel. And deoxidize by adding alloys of corresponding elements in the order of Si, Mn, Al, Ti, Ca. Sampling and online analysis of alloy composition, while ensuring the alloy composition, finally add NiMg alloy and Fe at the bottom of the casting ingot mold 2 o 3 Pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com