Patents

Literature

31results about How to "Improve high heat input welding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

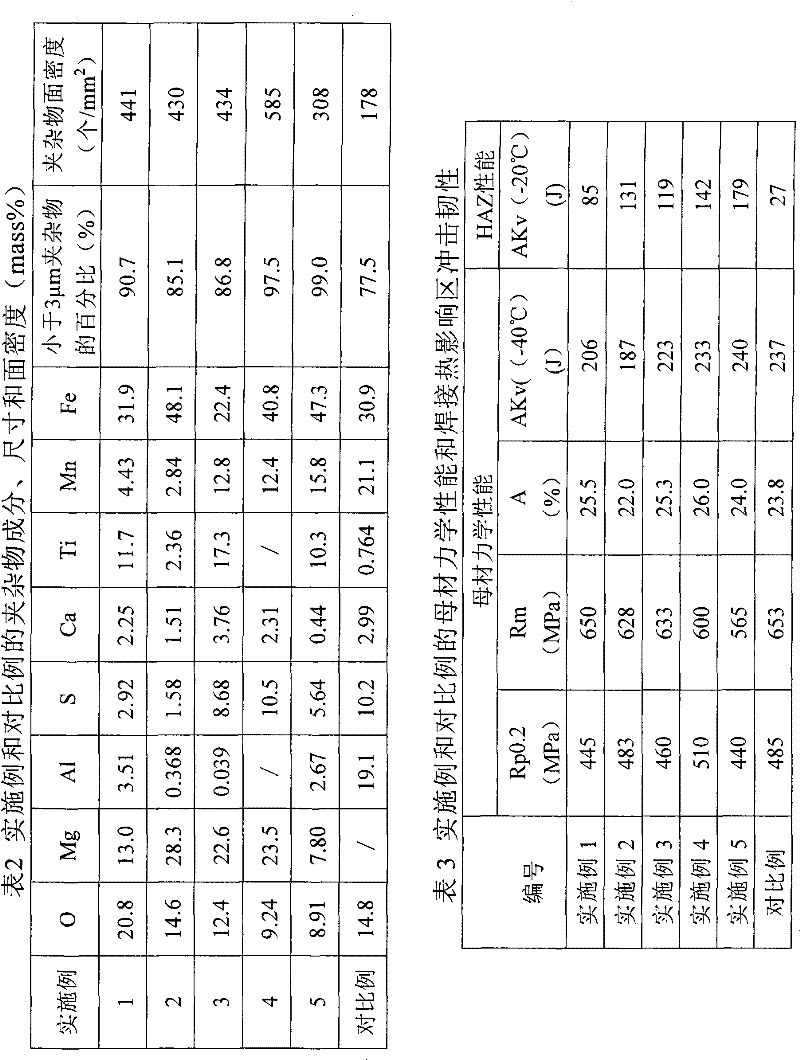

High-heat-input welding thick steel plate and manufacturing method thereof

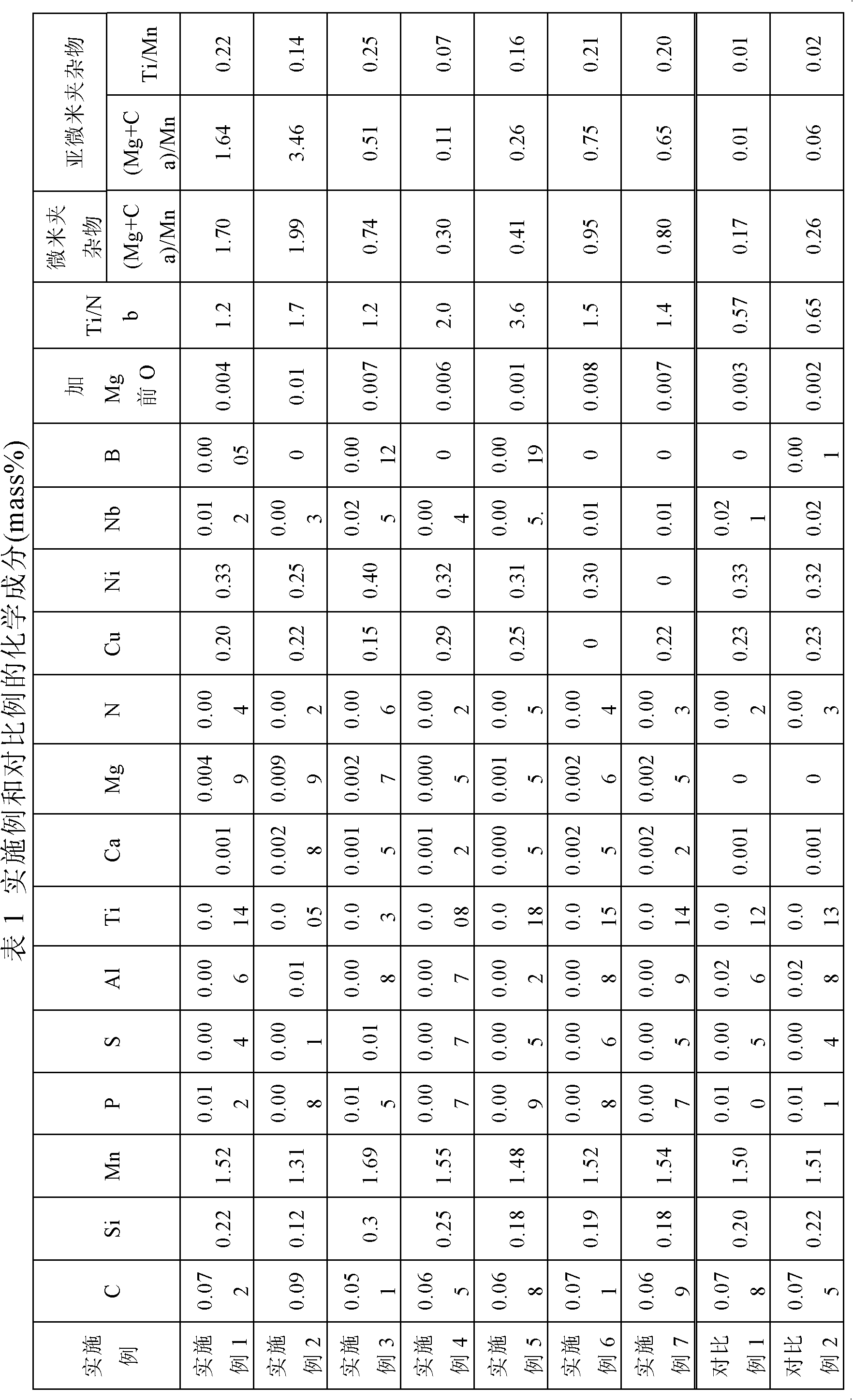

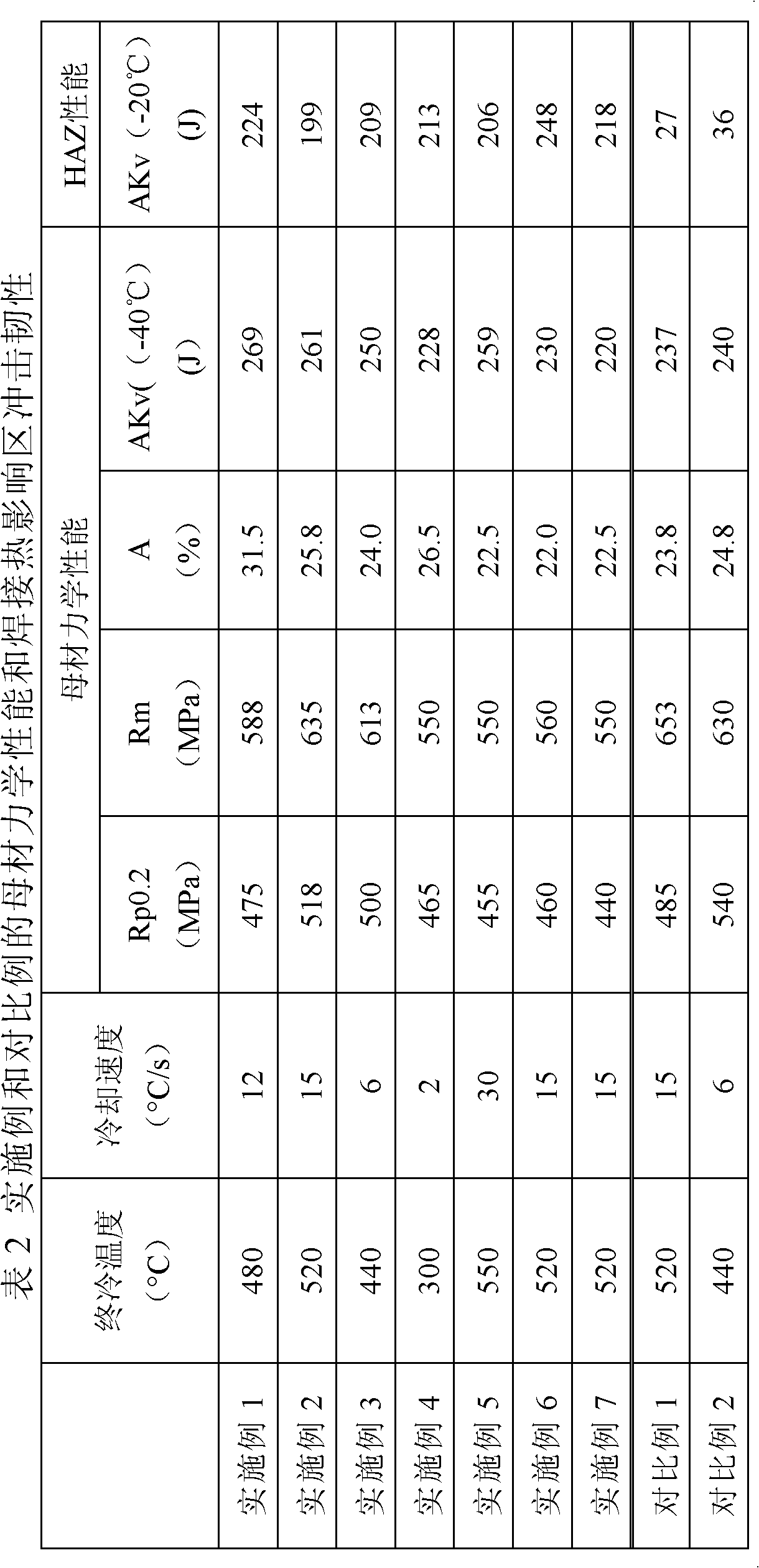

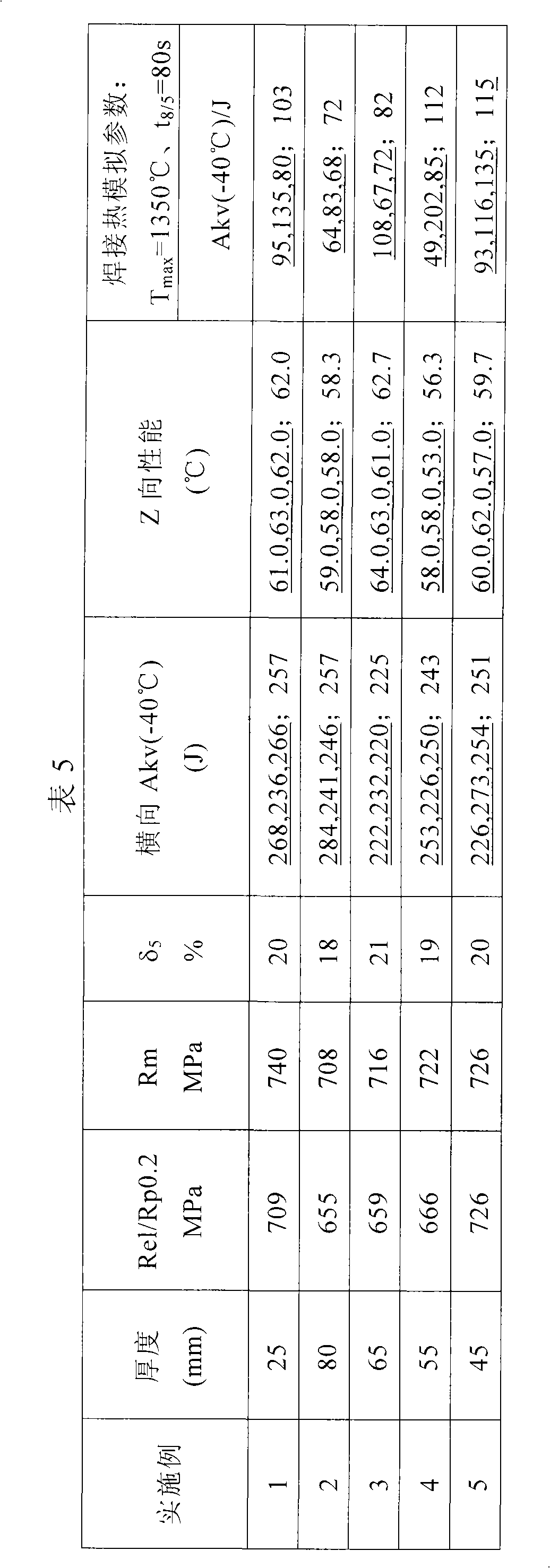

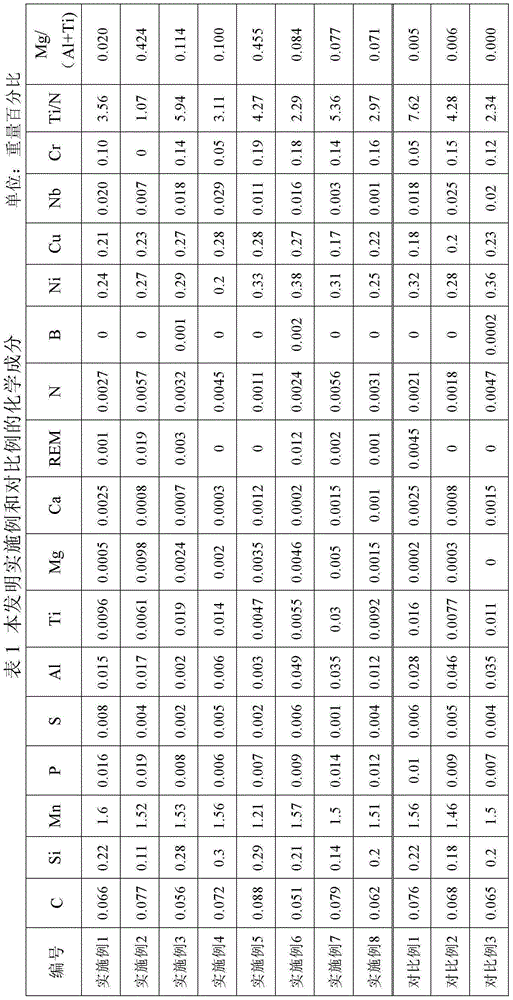

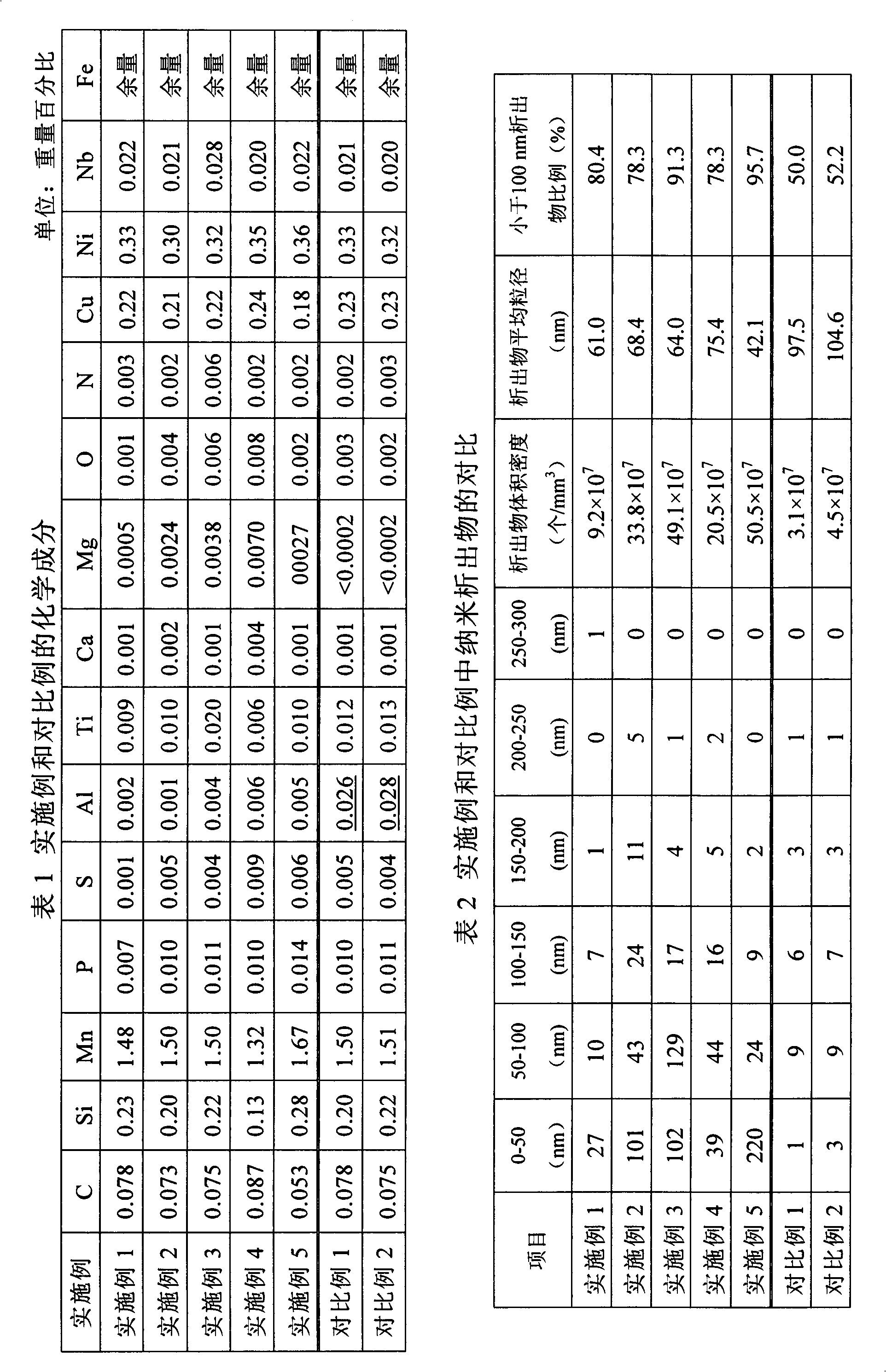

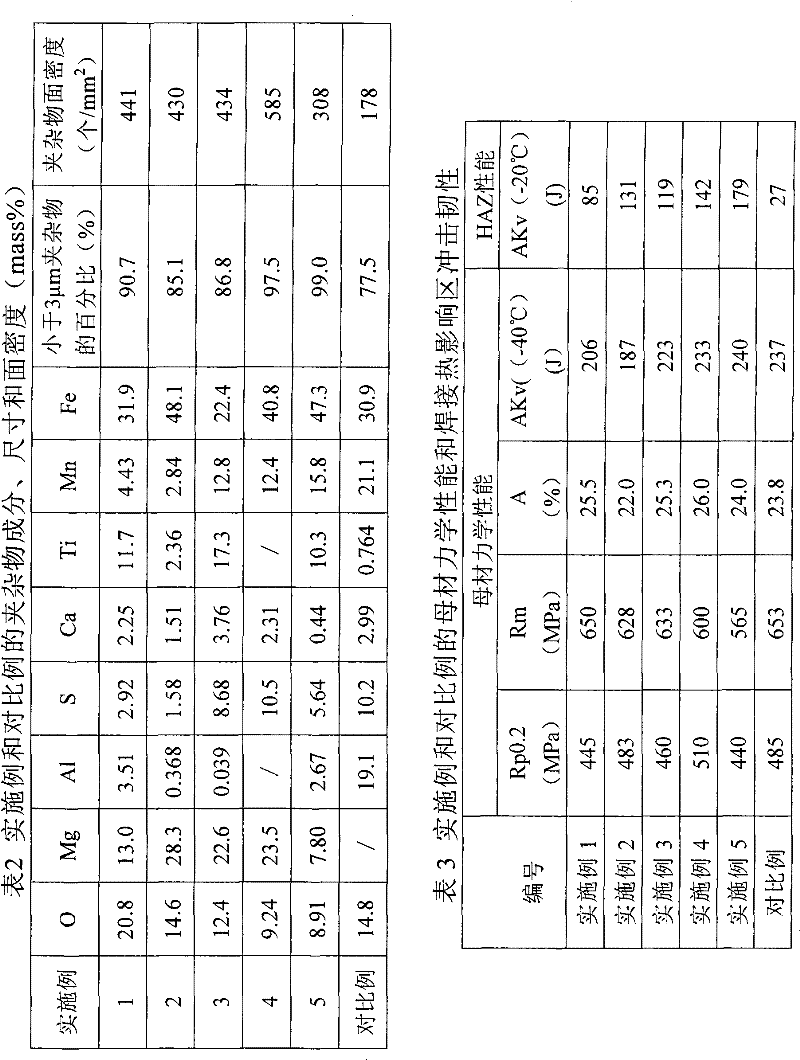

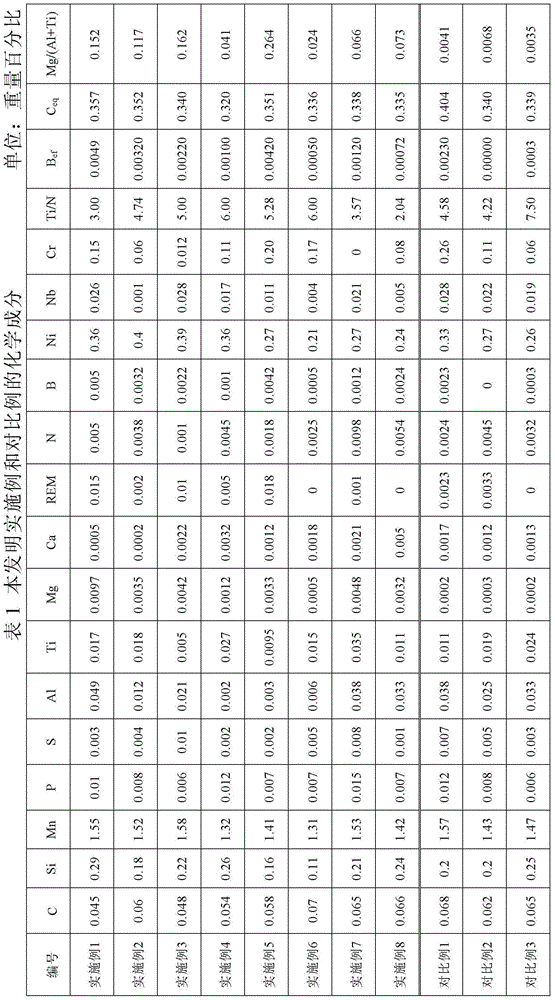

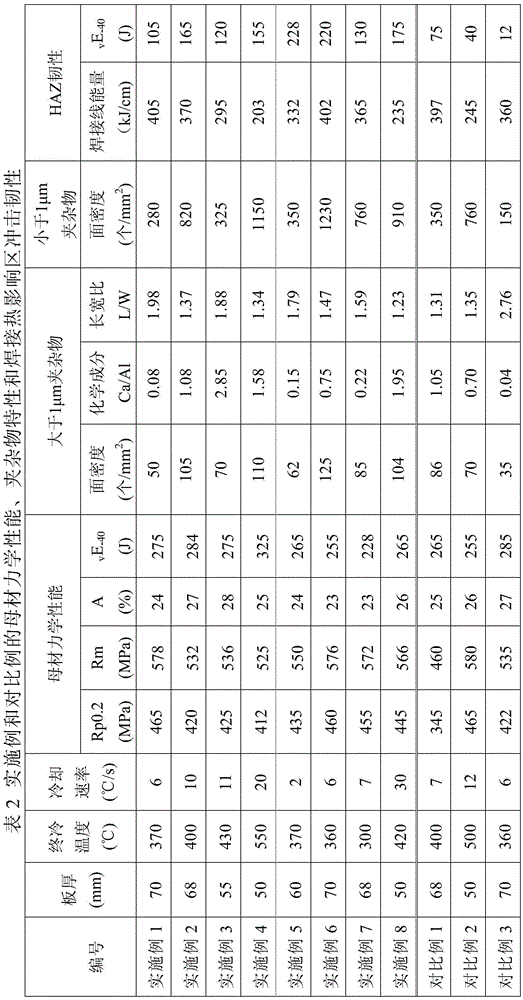

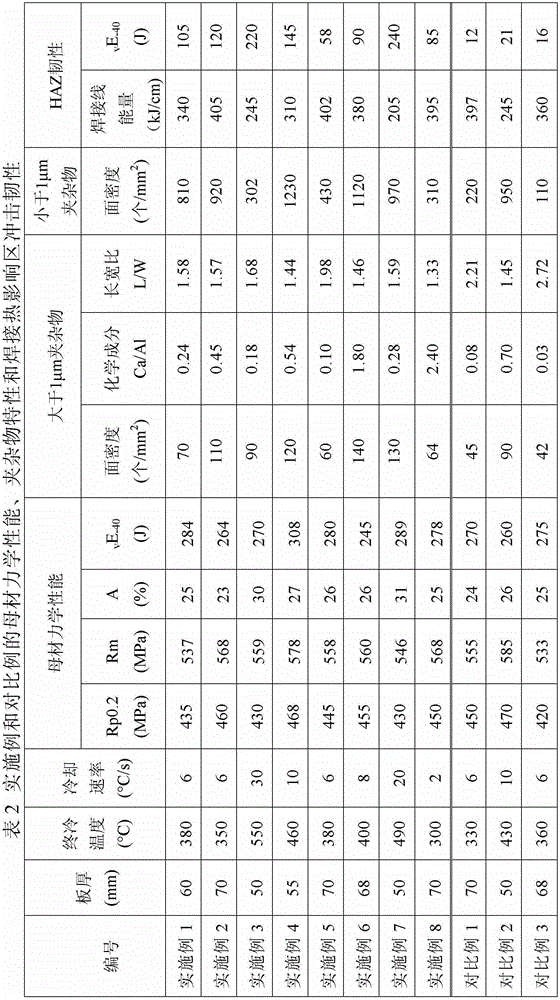

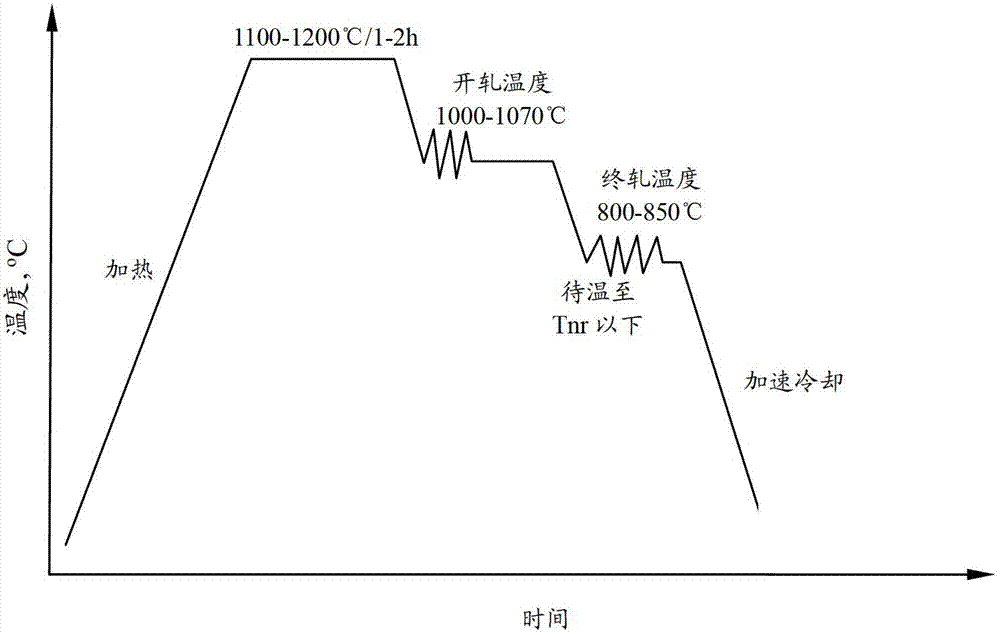

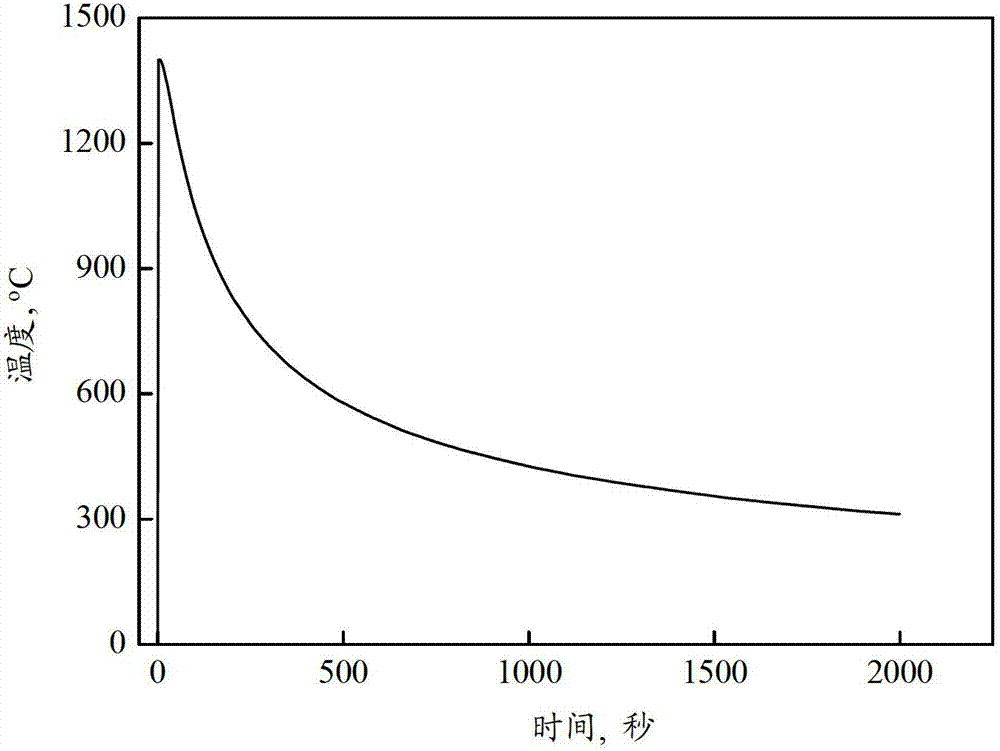

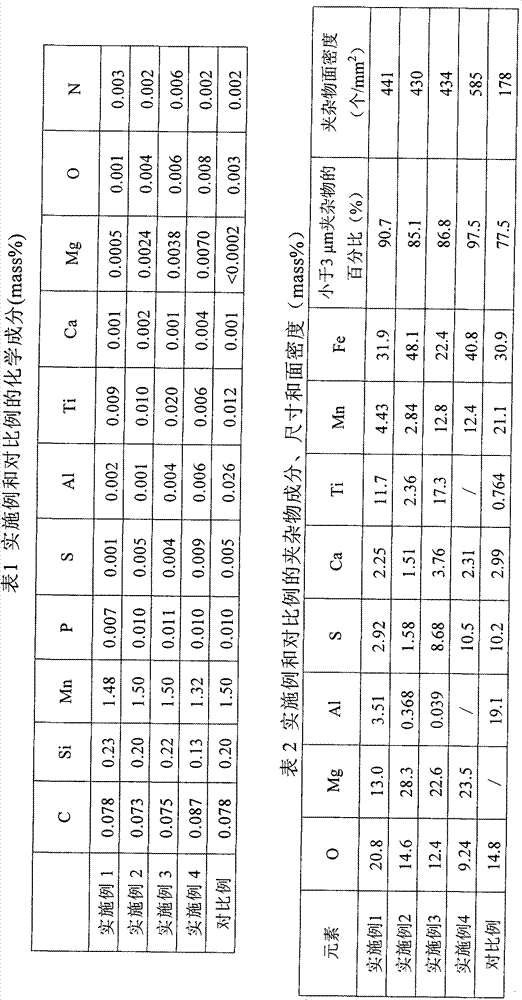

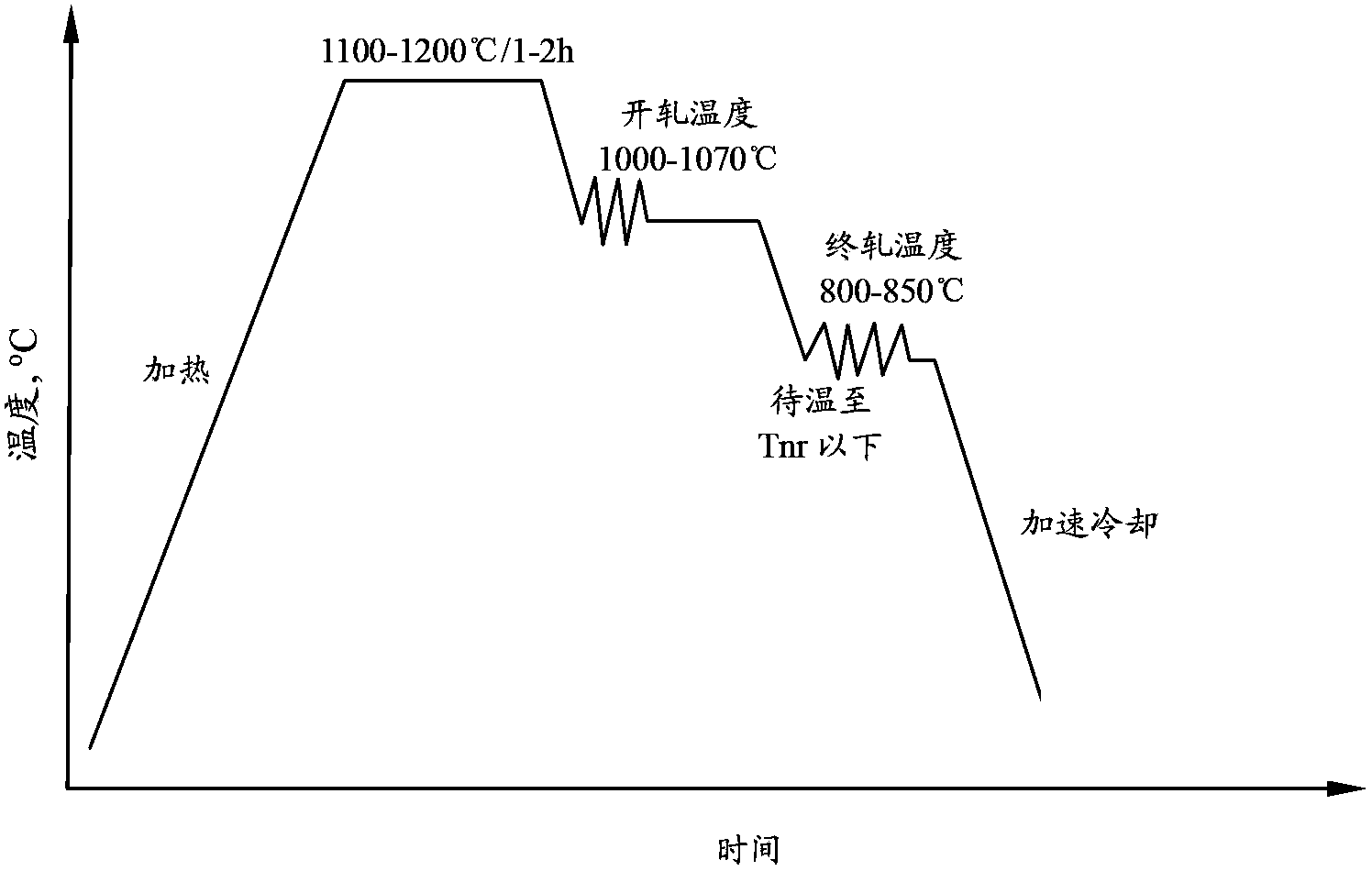

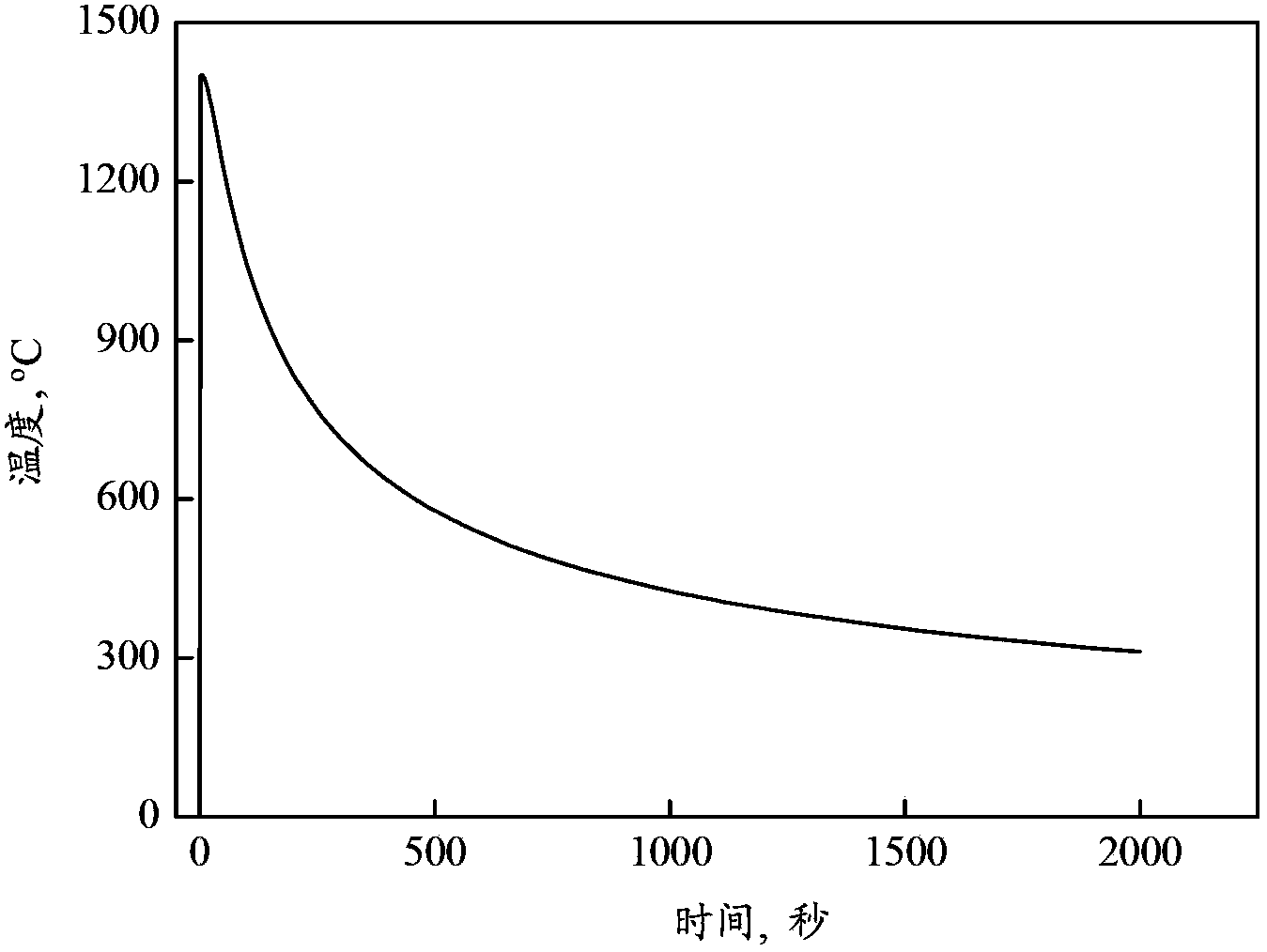

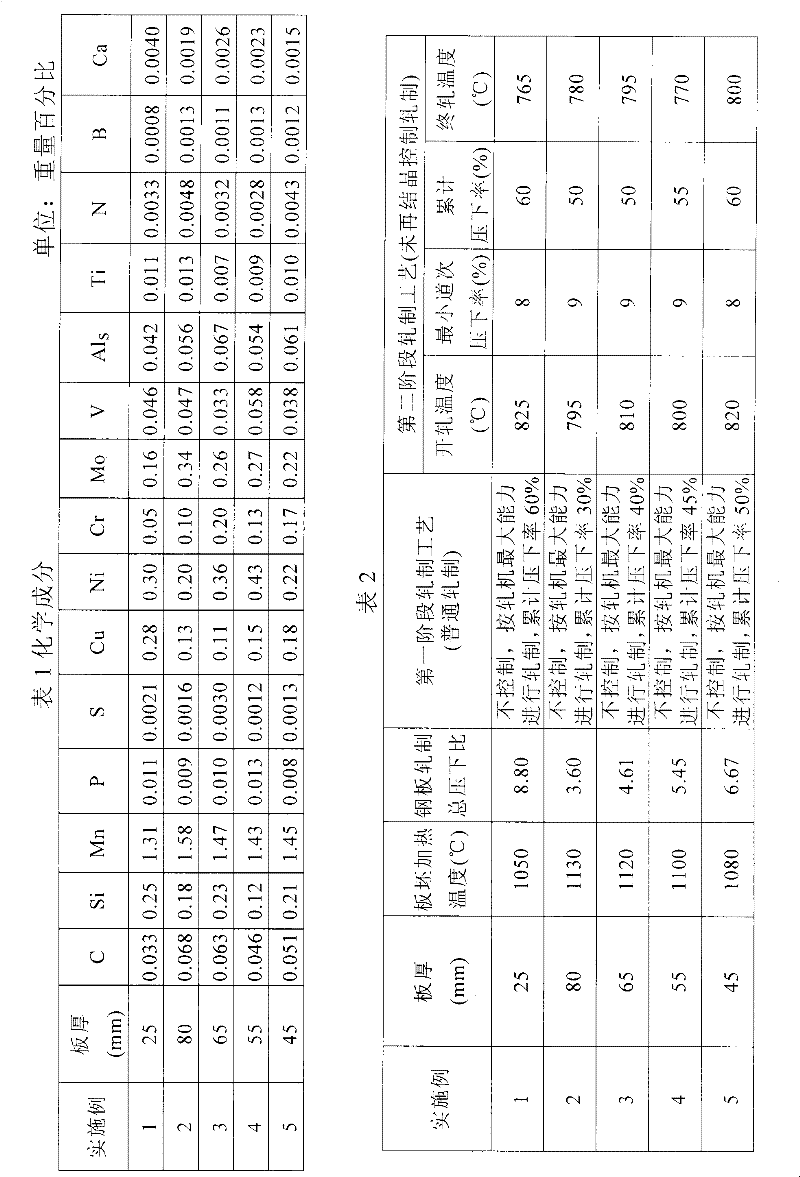

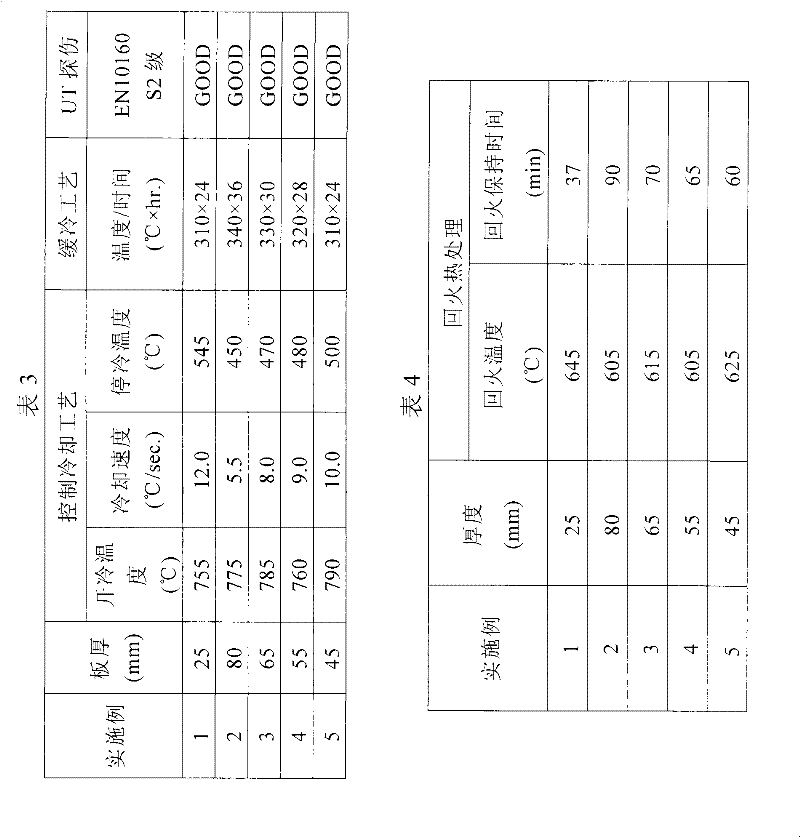

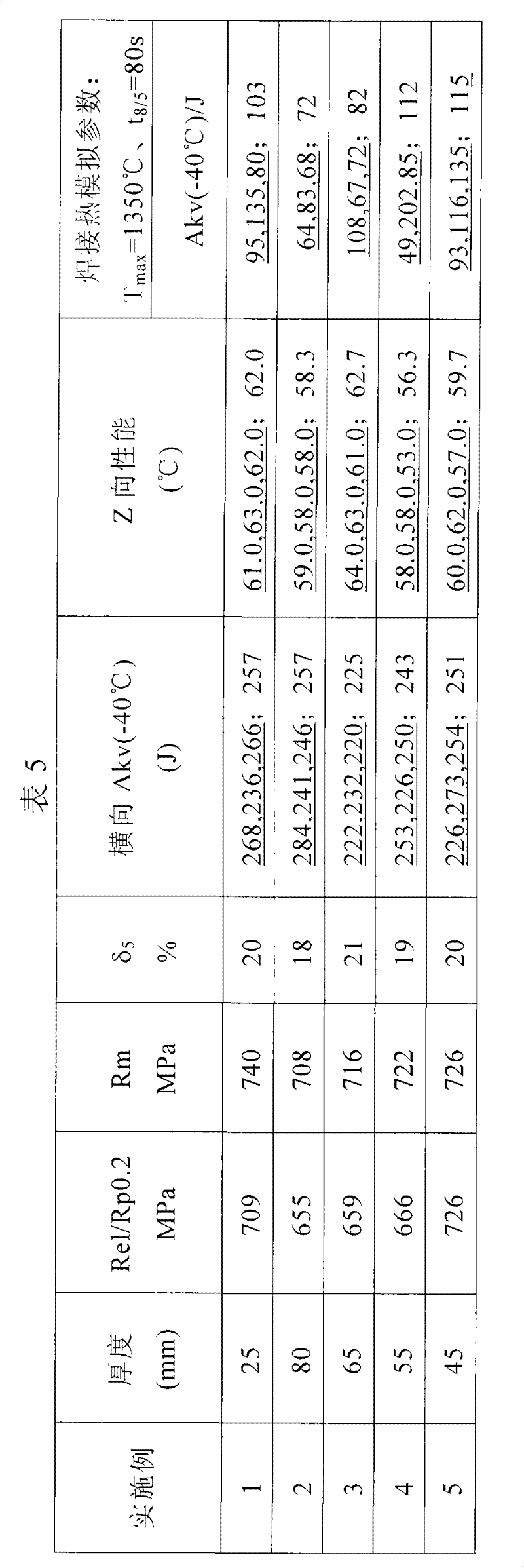

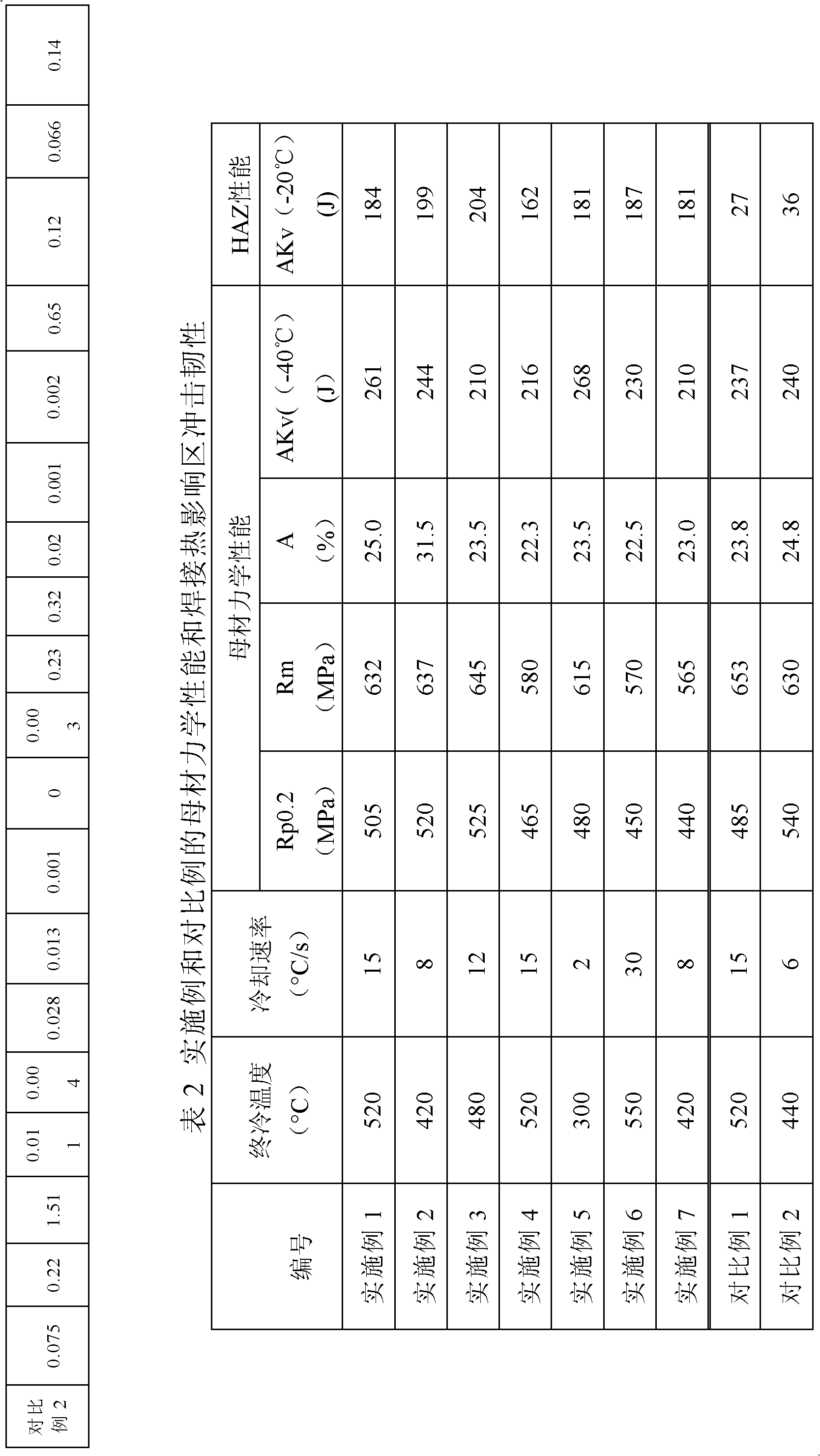

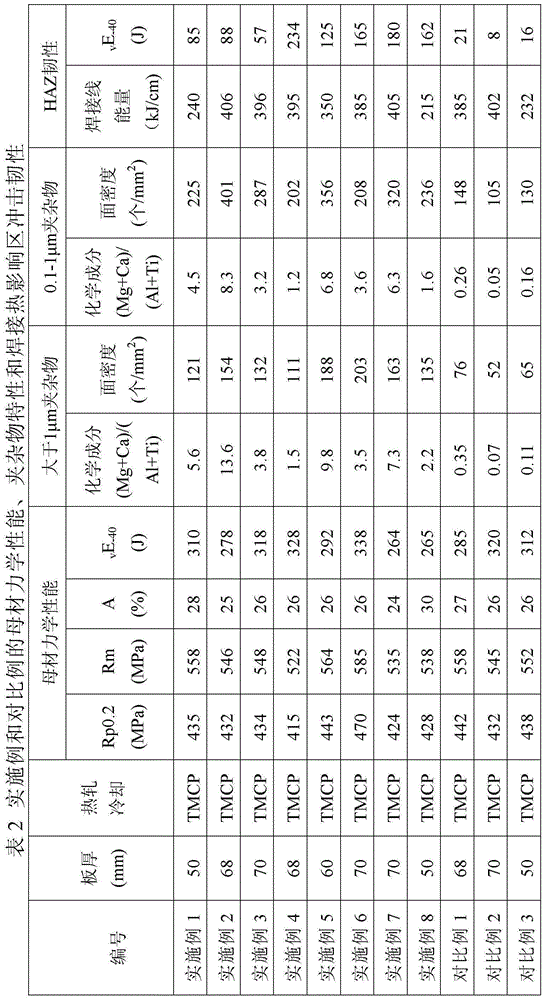

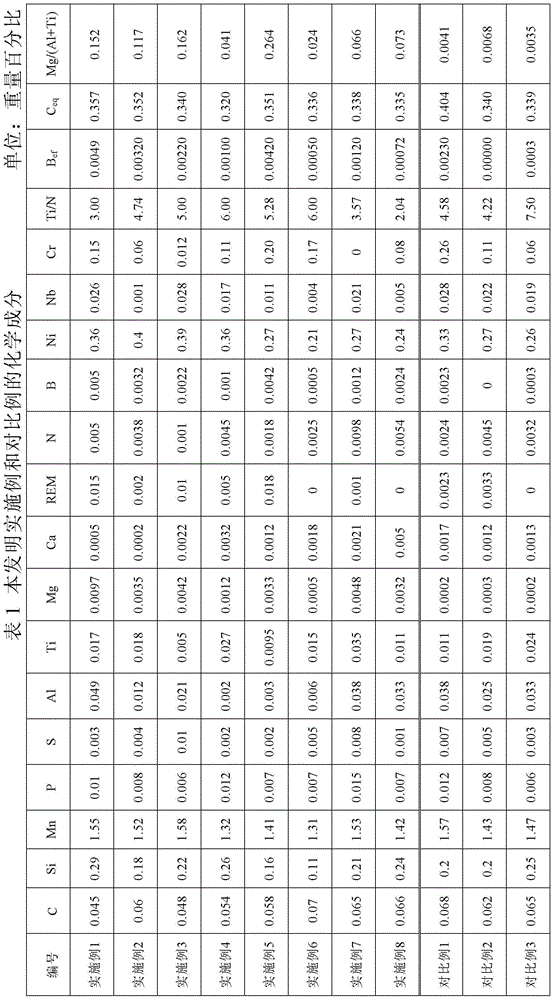

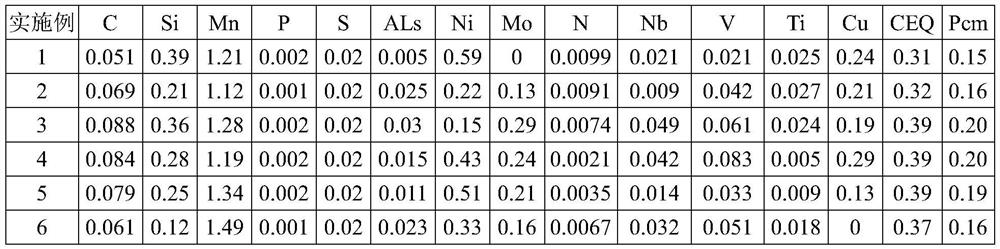

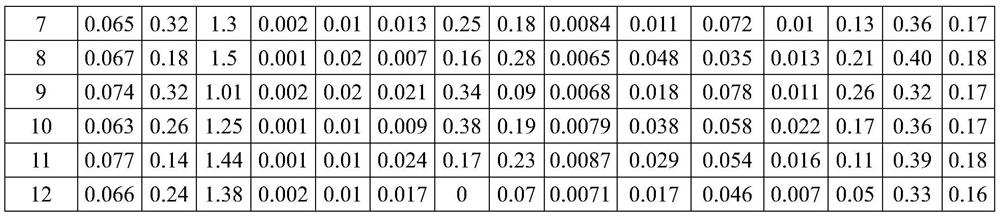

Disclosed are a high-heat-input welding thick steel plate and a manufacturing method thereof. The manufacturing method includes following steps: a) smelting, refining and continuous casting; b) rolling; and c) cooling. Steel consists of components including, by weight percentage, from 0.05 to 0.09% of C, from 0.10 to 0.30% of Si, from 1.3 to 1.7% of Mn, from 0.005 to 0.03% of Ti, from 0.003 to 0.025% of Nb, from 0.001 to 0.01% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.006% of N, from 0.0005 to 0.01% of Mg, smaller than or equal to 0.01% of Al, smaller than or equal to 0.003% of Ca, more than one of smaller than or equal to 0.3% of Cu, smaller than or equal to 0.4% of Ni and smaller than or equal to 0.002% of B, and the balance Fe; and Ti / Nb is larger than or equal to 1.2, deoxidant Mn, Si, Al, Ti, Ca and Mg are successively added in a steel liquid deoxidizing process, wherein (Mg+Ca) / Mn is larger than or equal to 0.3 for micrometer impurities with the grain size larger than or equal to 1.0 micrometer in the steel, (Mg+Ca) / Mn is larger than or equal to 0.1 for sub-micron impurities with the grain size ranging from 0.1 micrometer to 1.0 micrometer in the steel, and Ti / Mn is larger than or equal to 0.07. A large quantity of impurities which are distributed in a dispersion manner are formed, growth of austenite grains in a welding heat affected zone can be restrained, growth of intra-granular ferrite is promoted, and the high-heat-input welding performance of the thick plate is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate HT690 capable of being subjected to high heat input welding and manufacturing method thereof

ActiveCN102041459AImprove performanceShorten the manufacturing cycleRoll force/gap control deviceTemperature control deviceWater pipeThermo mechanical

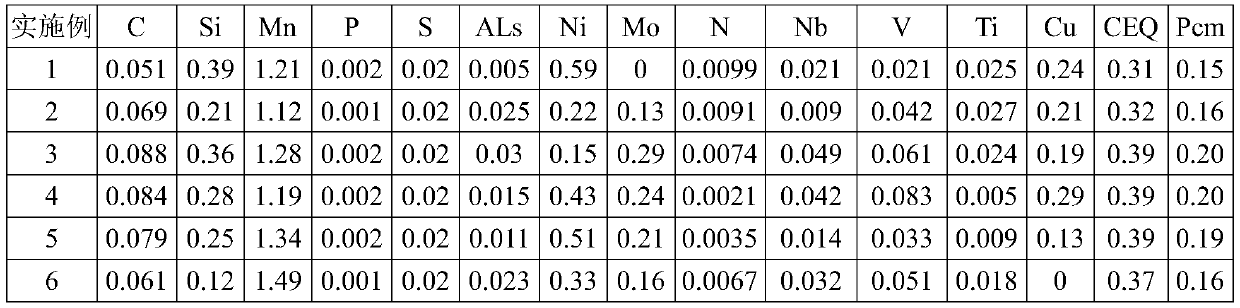

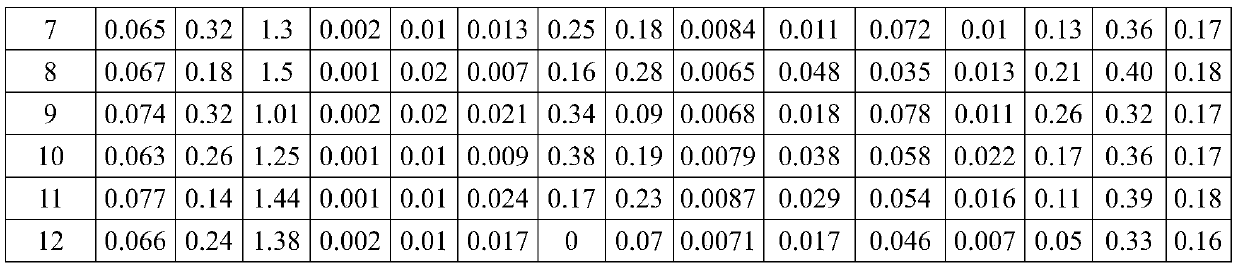

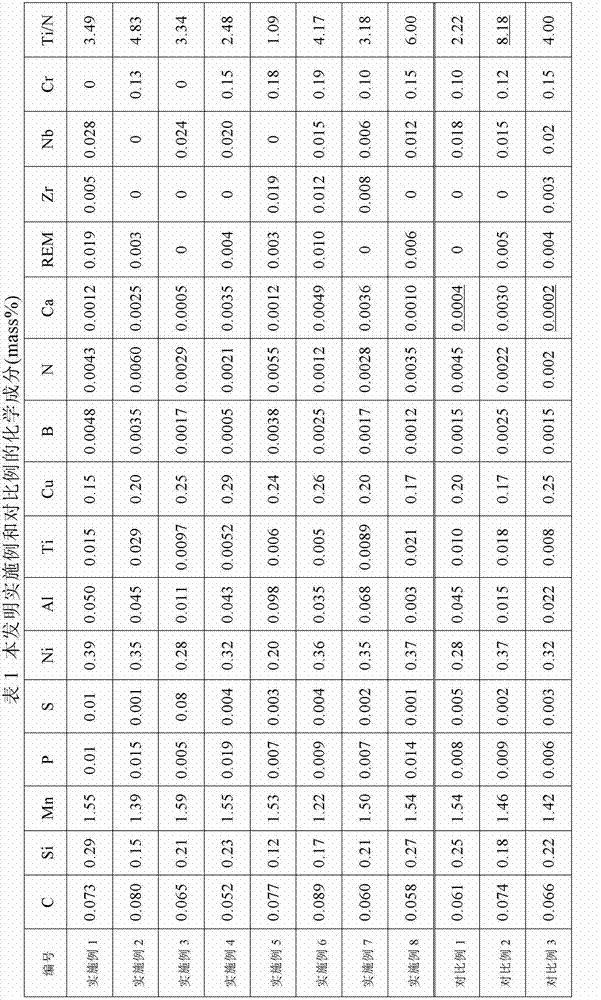

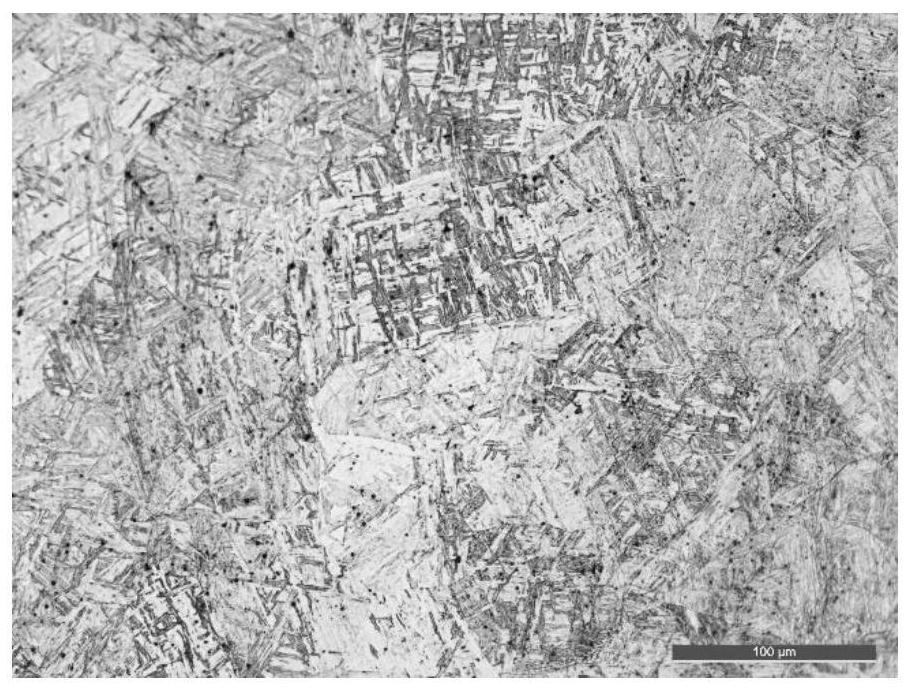

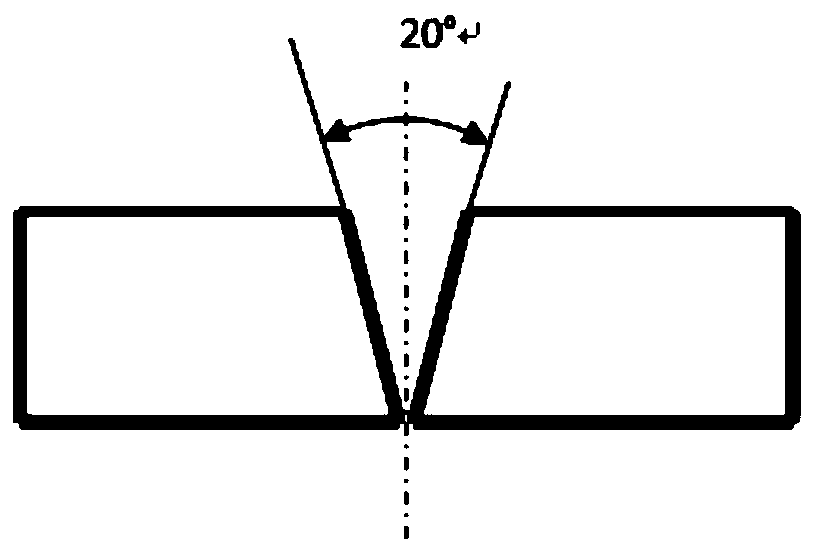

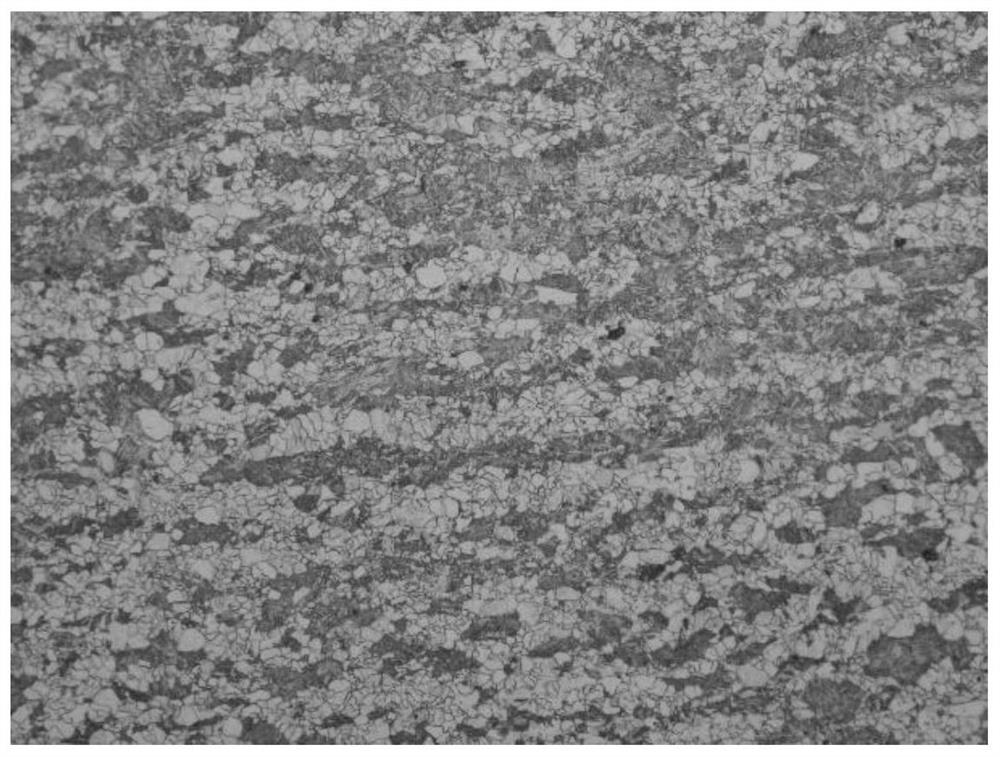

The invention relates to an HT690 steel plate capable of being subjected to high heat inputwelding and a manufacturing method thereof. A component system treated by low C-high Mn-(Nb+V+B) microalloying-ultramicro Ti is adopted, the acid-soluble Als content in steel is properly improved, the Als is not less than (Mn equivalent / C)*(Ntotal-0.292Ti), (Mn equivalent) / C is between 20 and 40, Pcm is not more than 0.205 percent, the Ti / N is between 2.0 and 4.0, (Cu+Ni+Mo+Cr) is alloyed and Ni / Cu is not less than 1.0, the Ca is treated and the Ca / S ratio is between 0.80 and 3.00 and the F*DI index is controlled to be not less than 0.80*finished steel plate thickness, a TMCP (Thermo-Mechanical Control Process) and a tempering process are optimized to ensure that the microscopic structure of a finished steel plate is fine tempering bainite, and the average crystal cluster size is below 25mum. The steel plate can bear high heat input welding at the same time of obtaining the properties of uniform and excellent obdurability and strong plasticity matching, is especially suitable for large steel structures of a hydroelectric pressure water pipe, a vortex, a sea platform and the like, and can realize low-cost and stable batch industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

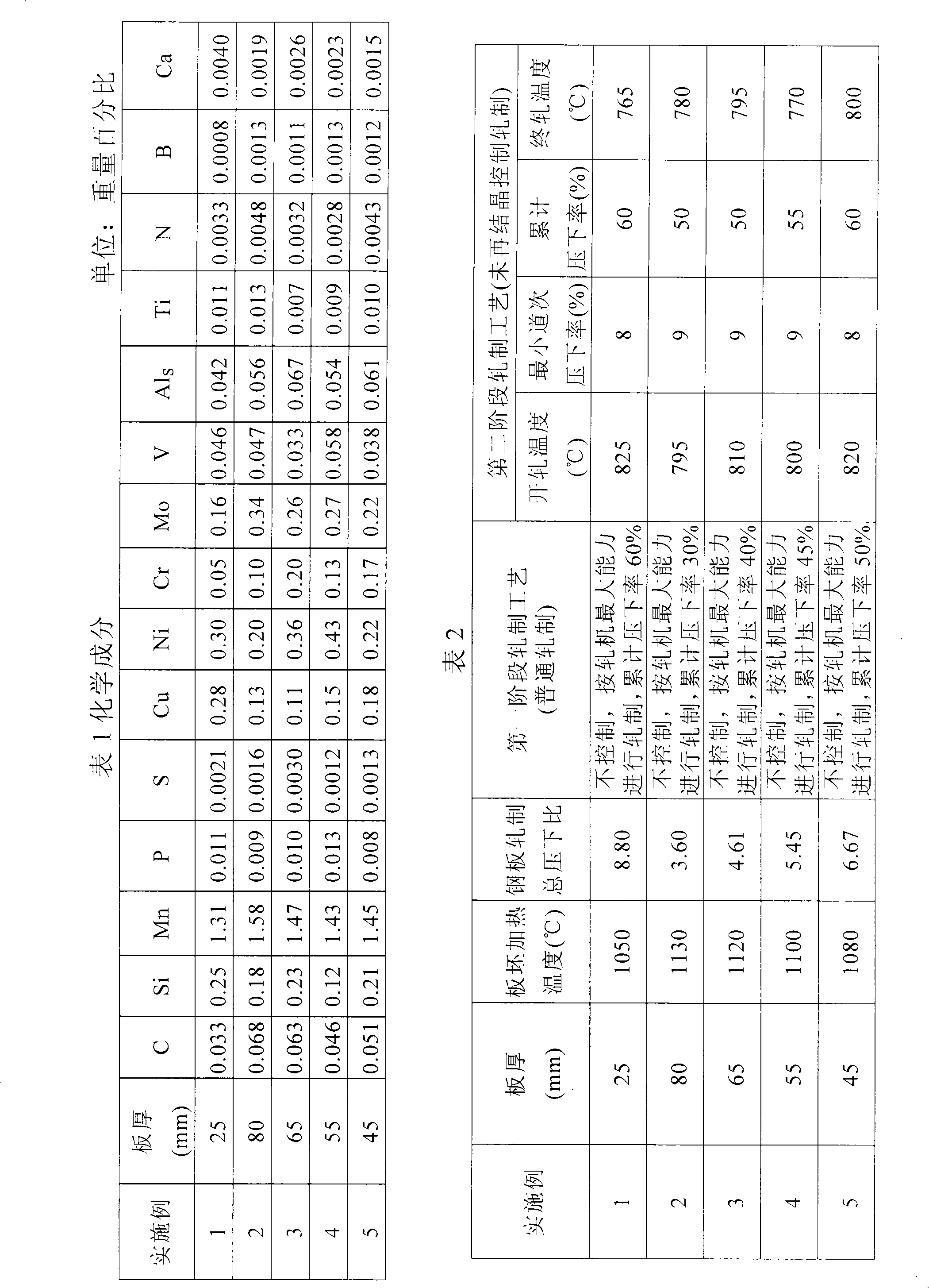

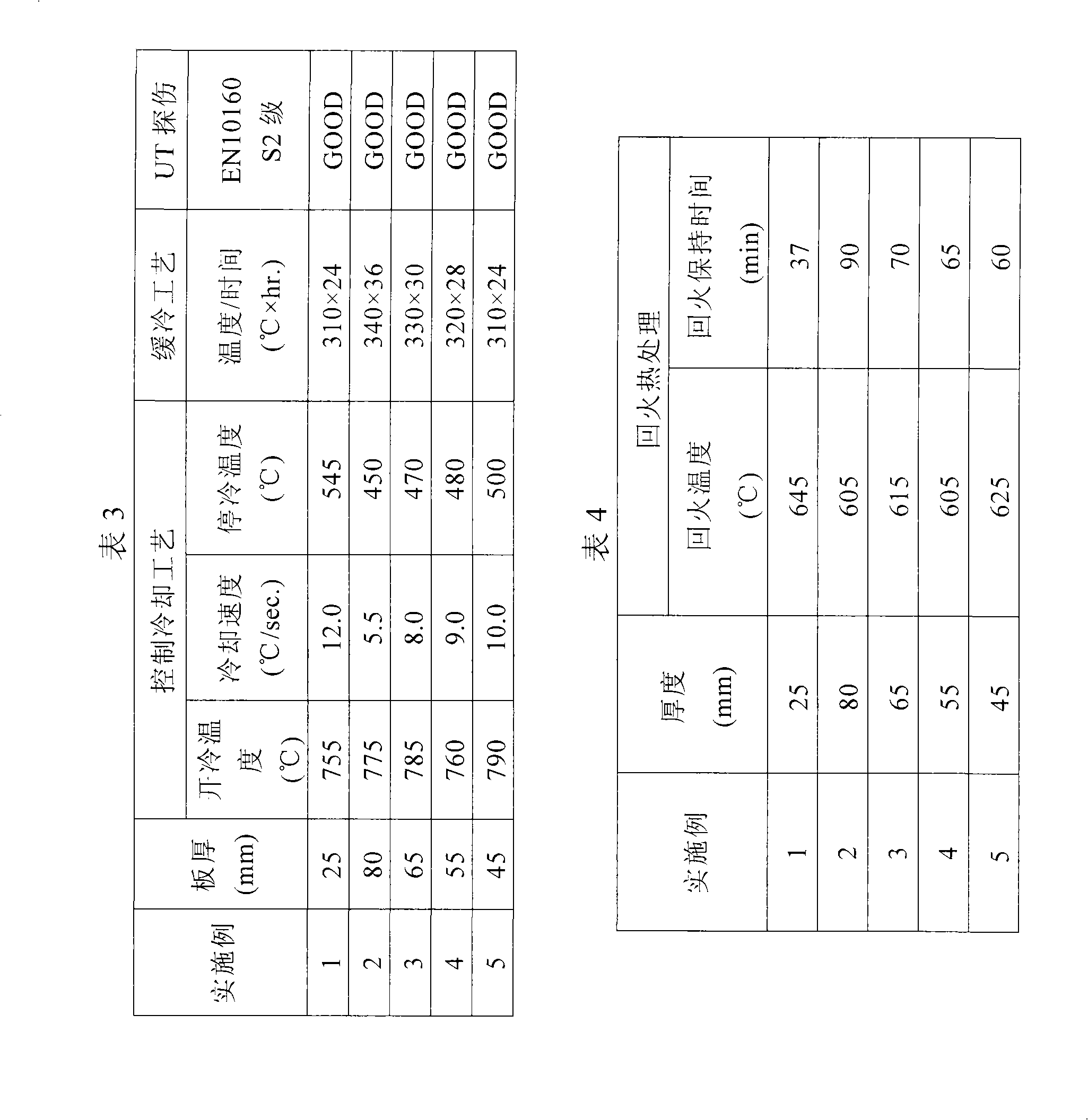

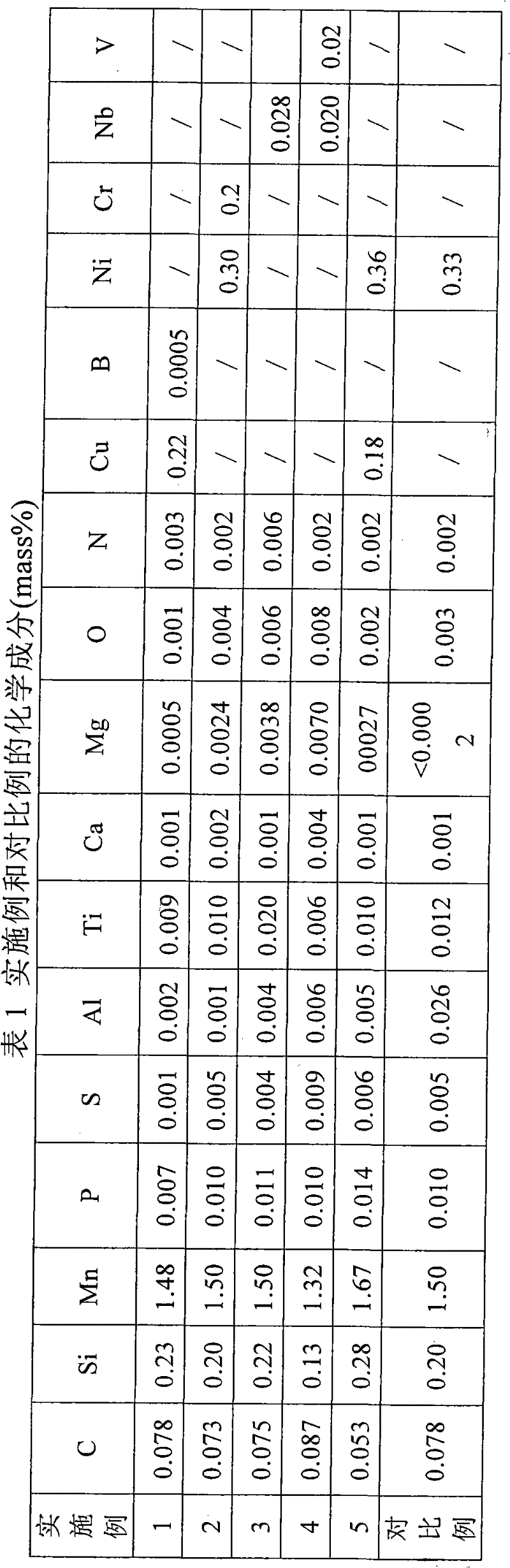

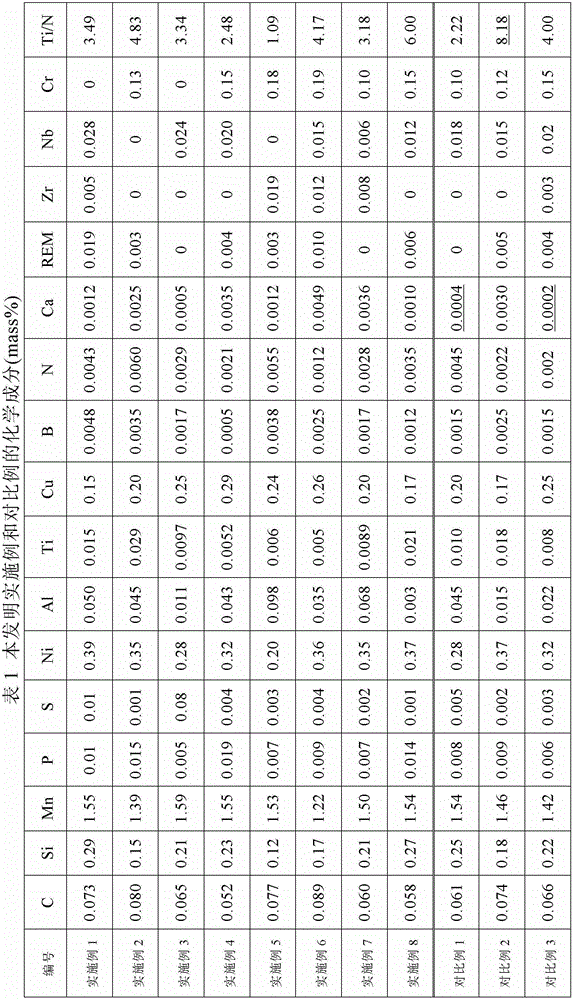

Preparation method of easy welding high strength toughness X80 pipe line steel for magnesium treatment

InactiveCN102181802AImprove performanceImprove high heat input welding performanceTemperature control deviceLine tubingHigh intensity

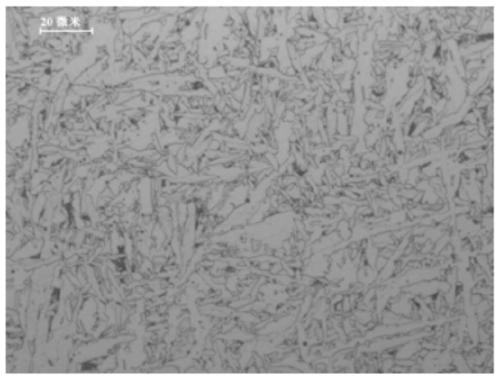

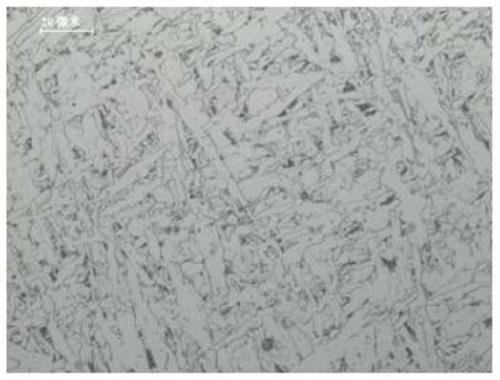

A preparation method of easy welding high strength toughness X80 pipe line steel for magnesium treatment belongs to the production field of low alloy high strength steel, including first preparing materials according to constituent mixing rate, then smelting in a vacuum induction furnace, forging casting blank and controlling rolling and cooling. The preparation method is characterized in that the heating temperature is 1170-1230 DEG C prior to forging blank residues; the thermal time is 60-120min; and the beginning temperature of coarse rolling is 1100-1180 DEG C; the finishing temperature of coarse rolling is no less than 980 DEG C, the temperature-holding thickness of intermediate blank is 45-50mm; the beginning temperature of finish rolling is no more than 880 DEG C; the finishing temperature of finish rolling is 780-810 DEG C; the pressing rate of finish rolling is more than 3T (T: target thickness of finished products); and the target thickness of finished products is 10-15mm. After finish rolling, the product rapidly enters ACC for cooling control, with the cooling speed being 15-35 DEG C / s. the self-tempering temperature is 400-550 DEG C. The produced high strength toughness X80 pipe line steel has typical acicular ferrite tissue, as well as favorable comprehensive mechanical property and high input energy welding property.

Owner:UNIV OF SCI & TECH BEIJING

Thick steel plate capable of being welded at large heat input and manufacturing method thereof

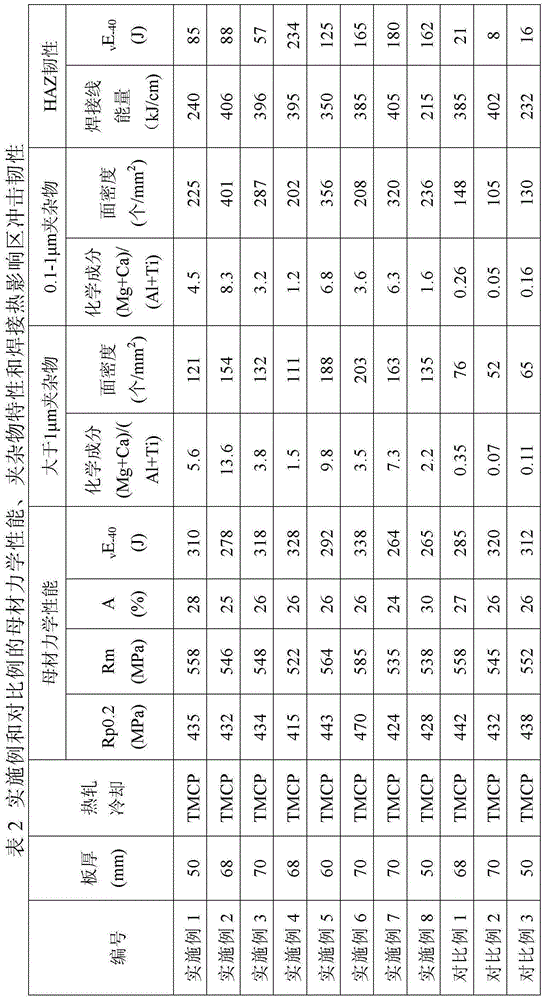

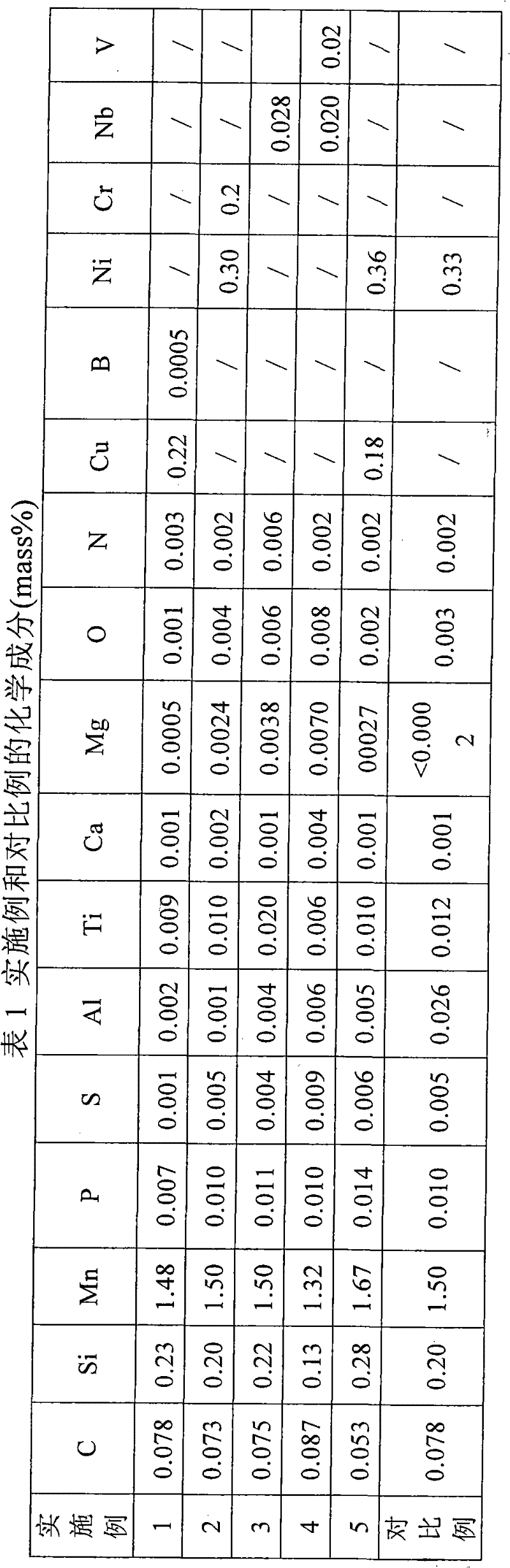

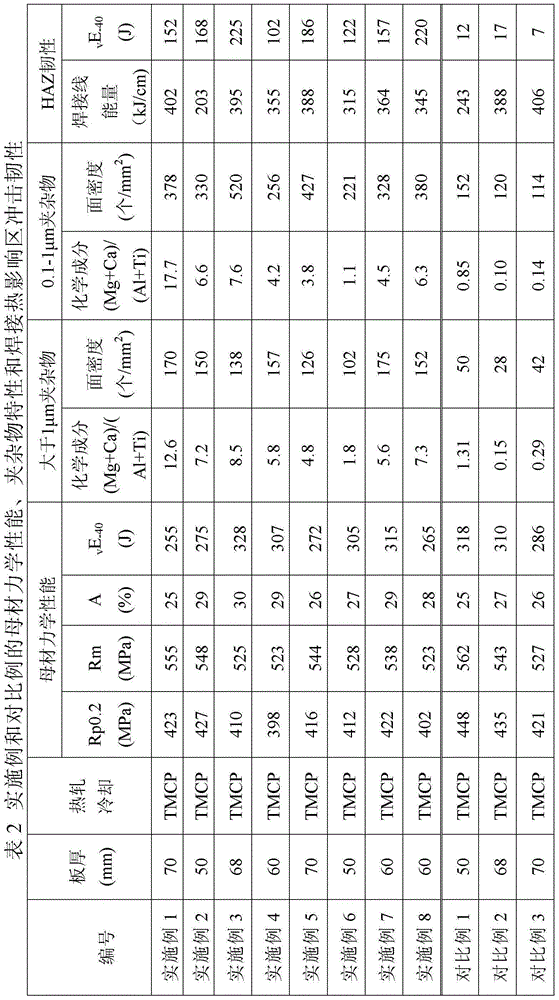

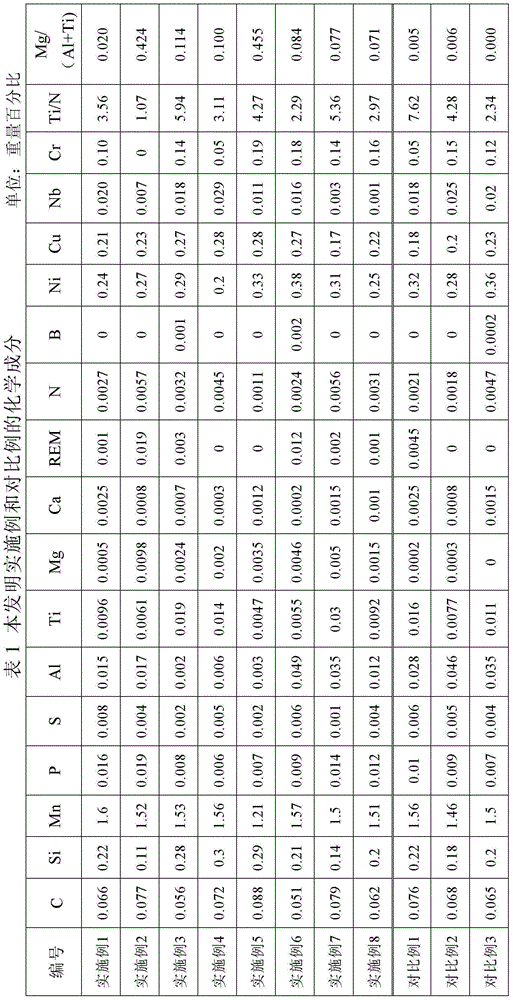

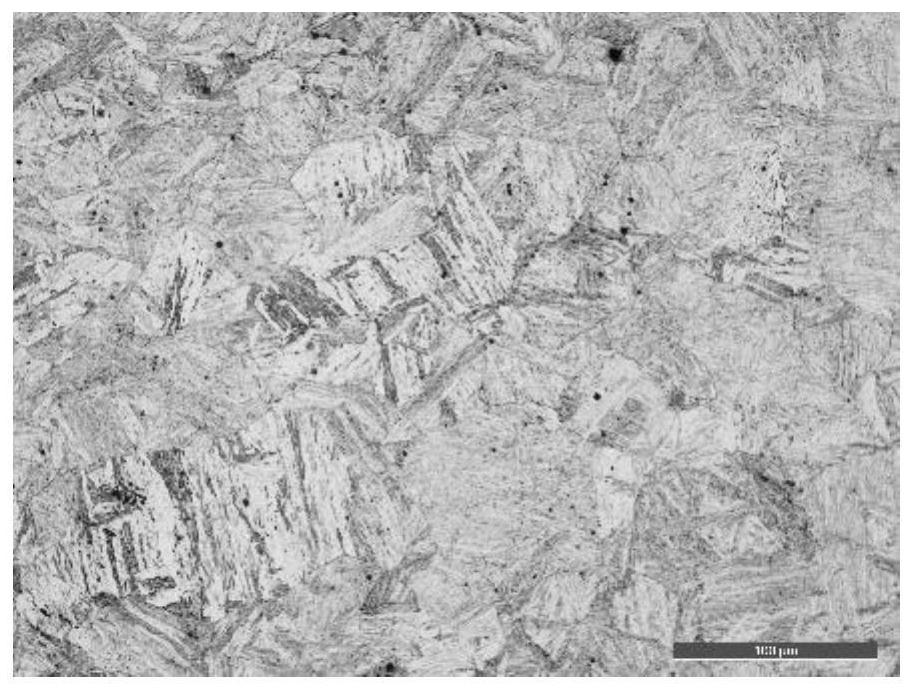

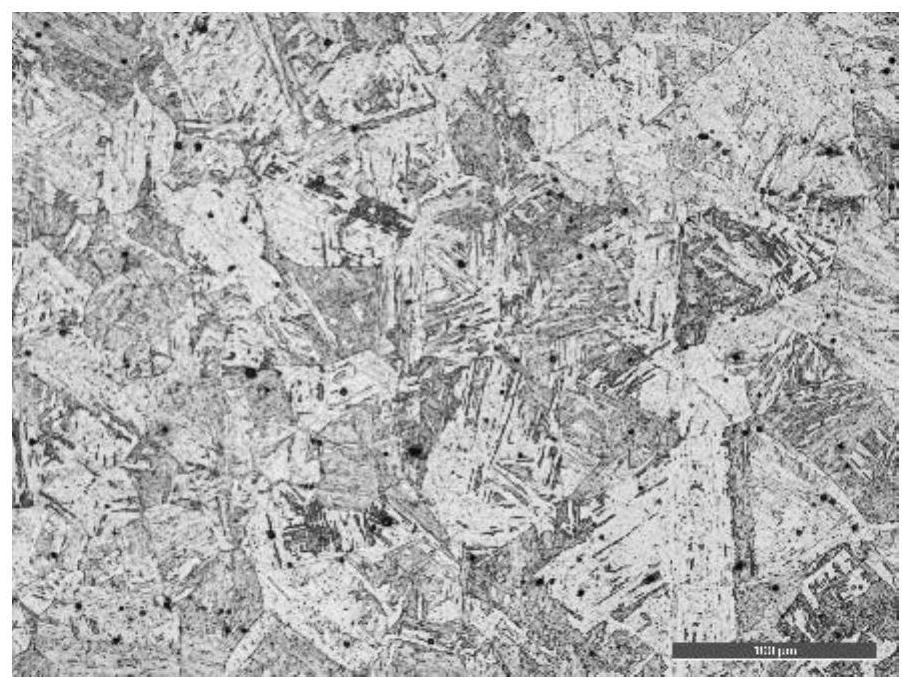

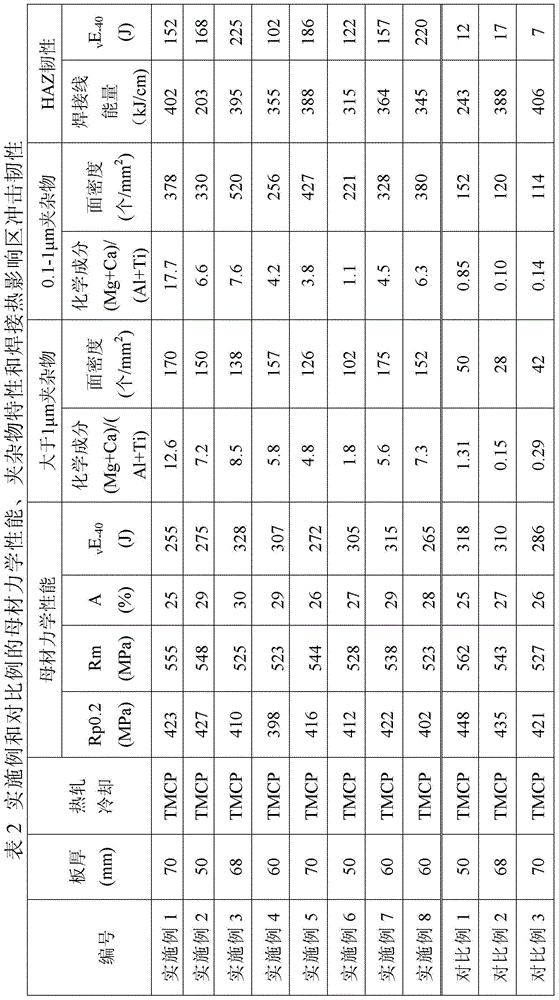

The invention provides a thick steel plate capable of being welded at a large heat input and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) smelting and casting, wherein the thick steel plate is prepared from the following components in percent by weight: 0.05-0.09% of C, 0.10-0.30% of Si, 1.2-1.6% of Mn, not greater than 0.02% of P, 0.001-0.006% of S, 0.2-0.4% of Ni, 0.15-0.3% of Cu, 0.005-0.03% of Ti, 0.0005-0.01% of Mg, 0.001-0.006% of N, not greater than 0.05% of Al, not greater than 0.005% of Ca, not greater than 0.02% of REM, and not greater than 0.003% of B and the balance of Fe and unavoidable impurities, and Ti / N is no less than 1 and is not greater than 6, and Mg / (Al+Ti) is no less than 0.02; (2) rolling; (3) cooling. According to the thick steel plate capable of being welded at the large heat input and the manufacturing method thereof, tiny dispersion-distribution inclusion can be formed; by controlling the (Mg+Ca) / (Al+Ti) ratio and the surface density of micron inclusion with the diameter of no less than 1 micrometer and the (Mg+Ca) / (Al+Ti) ratio and the surface density of sub-micron inclusion with the diameter of 0.1-1 micrometer, a base metal with the tensile strength of no less than 510 MPa is obtained; when the welding heat input is 200-400 kJ / cm, the average charpy impact energy of the steel plate at -40 DEG C is more than 50 J.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-temperature steel for engineering machinery and production method thereof

InactiveCN102409233AImprove high heat input welding performanceImprove toughnessTemperature control deviceHeat-affected zoneMechanical property

The invention relates to low-temperature steel for engineering machinery and a production method thereof. The steel is suitable for higher heat input welding and comprises the following chemical components by weight percent: 0.06-0.08% of C, 0.15-0.25% of Si, 1.6-1.9% of Mn, 0.05-0.07% of Nb, 0-0.30% of Mo, 0-0.0020% of B, 0.08-0.14% of Ti, 0.01-0.06% of Al, not more than 0.02% of P, not more than 0.010% of S, not more than 0.008% of N and the balance of Fe and inevitable impurities. The production method is characterized by controlling the heating temperature, precision rolling inlet temperature, finish rolling temperature, finished cooling temperature and annealing temperature. The material can ensure the transverse universal coiling impact energy at minus 20 DEG C to be more than 47J, and meanwhile, the HAZ (heat affected zone) strength and toughness of the steel plate can meet the mechanical property requirements of the base metal under 20KJ / cm welding property energy.

Owner:SHOUGANG CORPORATION

Method for raising large heat input weldability of thick steel plate

ActiveCN102373371AIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneAustenite

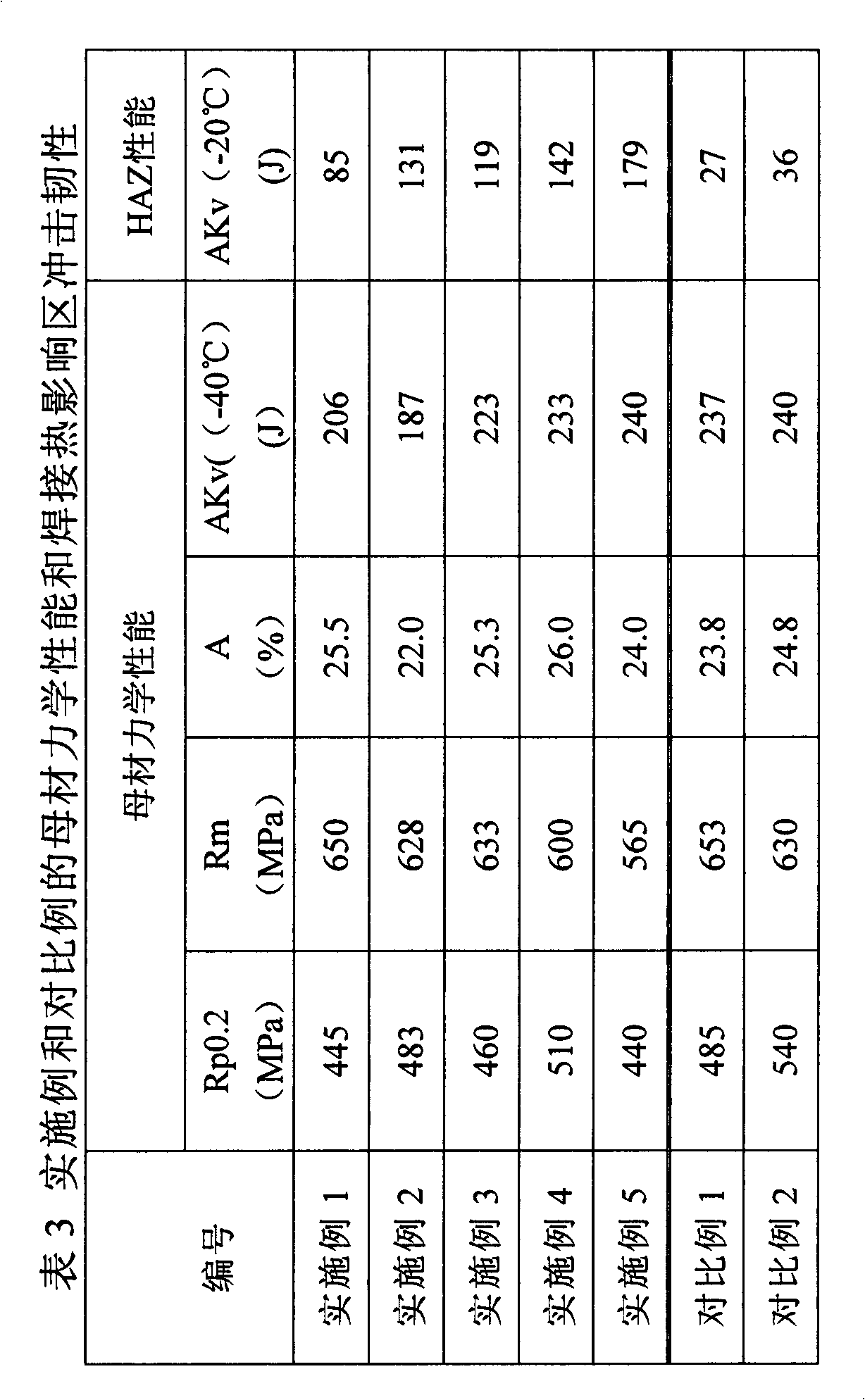

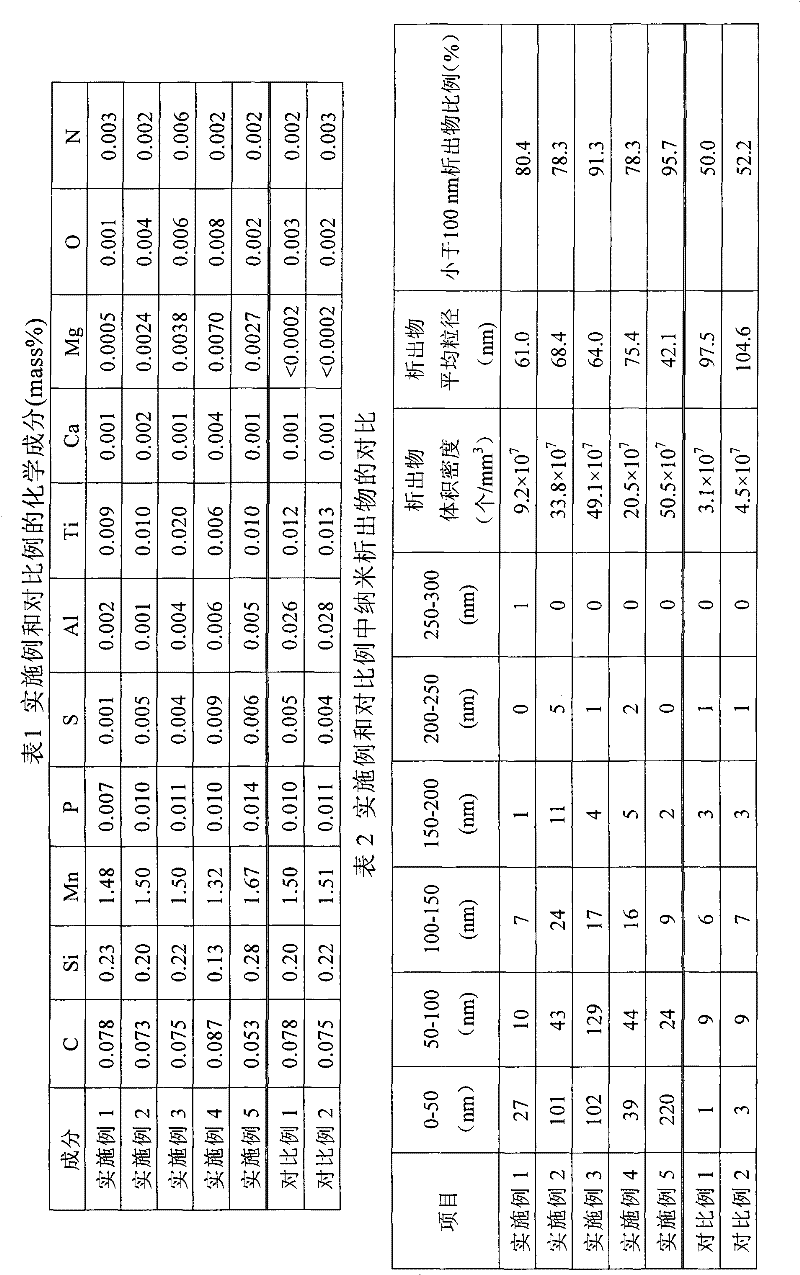

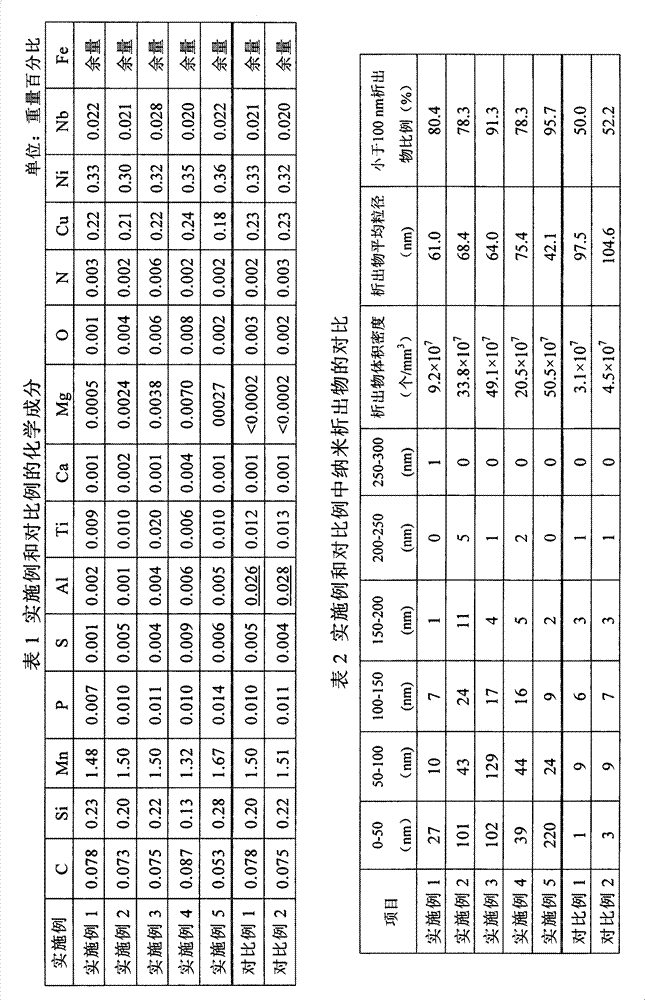

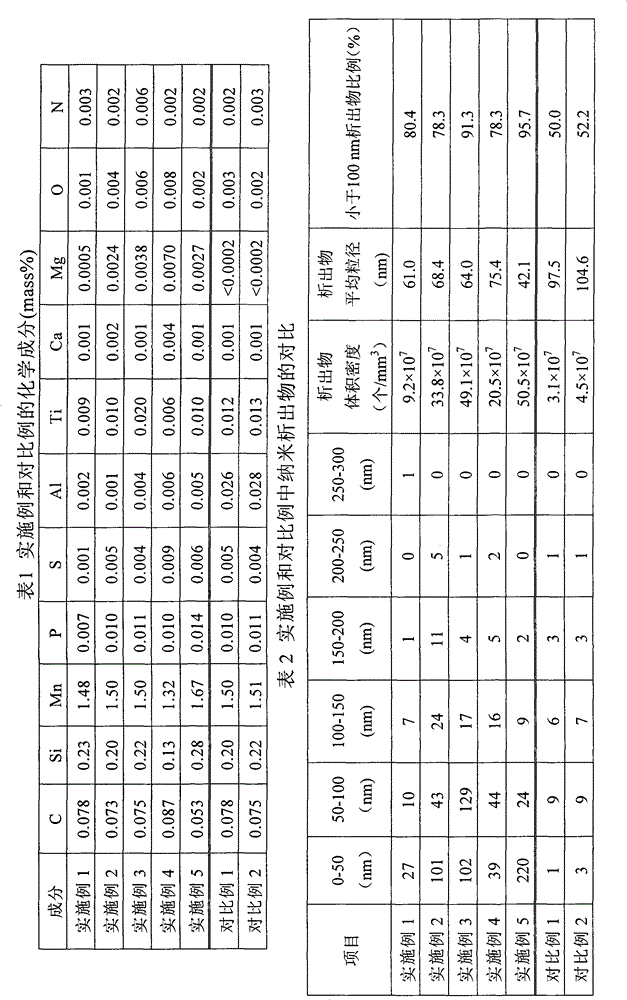

The invention discloses a method for raising large heat input weldability of a thick steel plate, comprising the following steps: 1) smelting and casting to form a steel plate: adding deoxidizers in the deoxidation process of the liquid steel according to the following types and order: Mn, Si, Al, Ti, and Ca and / or Mg, controlling the initial oxygen place in the liquid steel when Mn deoxidation is carried out in casting, adding Fe2O3 powder to let the oxygen content in the liquid steel be 0.001-0.008 wt%, wherein, the steel plate comprises 0.05-0.09 wt% of C, 0.10-0.30 wt% of Si, 1.3-1.7 wt% of Mn, 0.005-0.02 wt% of Ti, no larger than 0.015 wt% of P, no larger than 0.01 wt% of S, no larger than 0.006 wt% of N, no larger than 0.004 wt% of Ca, and the balance consisting of Fe; in the steel, the volumn density of TiN deposition with the particle size of less than 500 nm is larger than 9.0*107 PCs / mm<3>, the average particle size is less than 80 nm, and the proportion of the deposition with the particle size of less than 100 nm is larger than 75 %; 2) rolling and cooling. The large amount of nano TiN deposition with dispersive distribution formed by the invention can inhibit the growth of austenite crystals in the heat affected zone, and greatly raise the large heat input weldability of the thick steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving high heat input welding performance of thick steel plates

ActiveCN102191429AIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneSheet steel

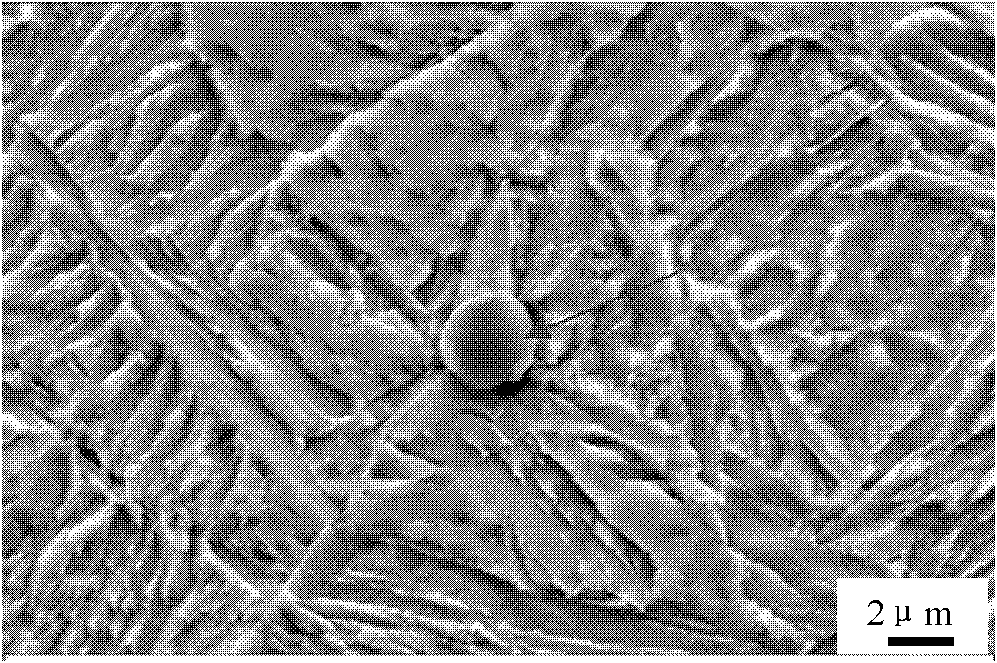

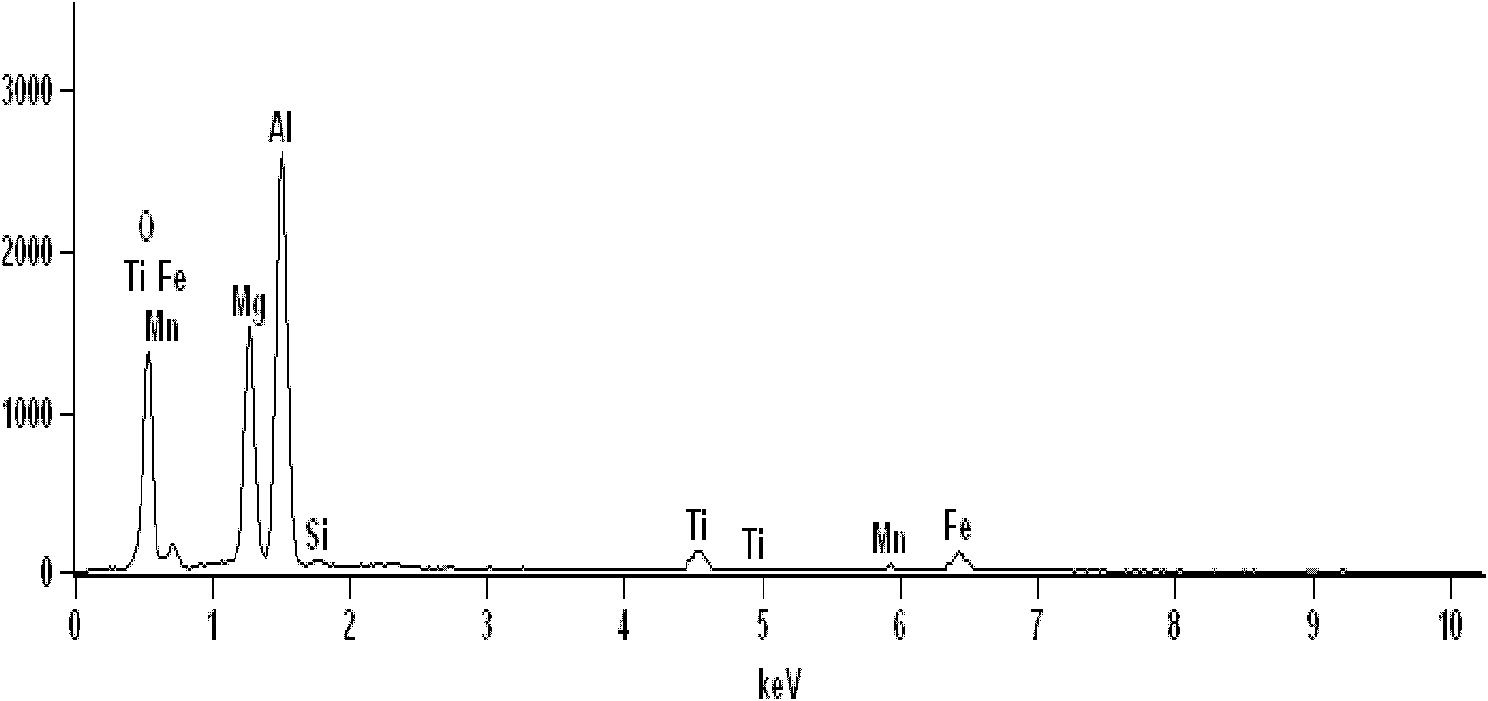

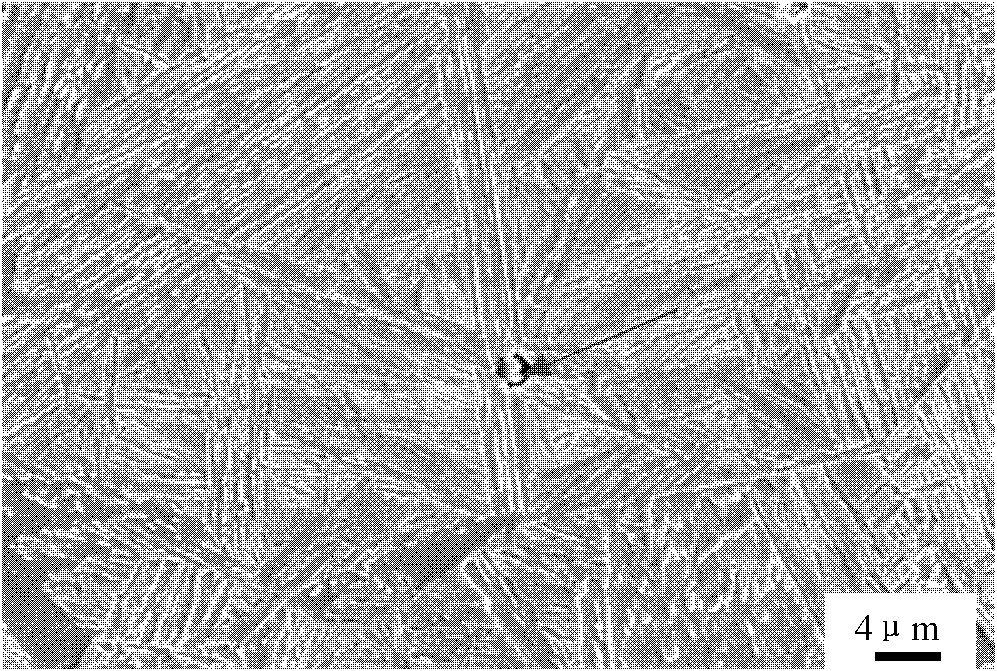

The invention discloses a method for improving the high heat input welding performance of thick steel plates. The method comprises the following steps of: 1) smelting and casting to obtain an ingot, wherein deoxidants are added in the deoxidation process of molten steel, the adding sequence of the deoxidants is Mn and Si, Al, Ti, and Ca, a Mg deoxidant is added in the casting process of the molten steel, and the initial oxygen potential during the deoxidation of Mg is accurately controlled by adding Fe2O3 powder into a casting ingot mould; and 2) rolling and cooling. In the method, microfine dispersive distribution and Mg-containing inclusions, which are formed by adding the deoxidants in the deoxidation process of the molten steel and adding the Fe2O3 powder into the casting ingot mould to accurately control the oxygen potential during the deoxidation of the Mg, can inhibit the growth of austenite grains in a welding heat affected zone, and promotes the growth of ferrite in the grains, so that the high heat input welding performance of the thick steel plates is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

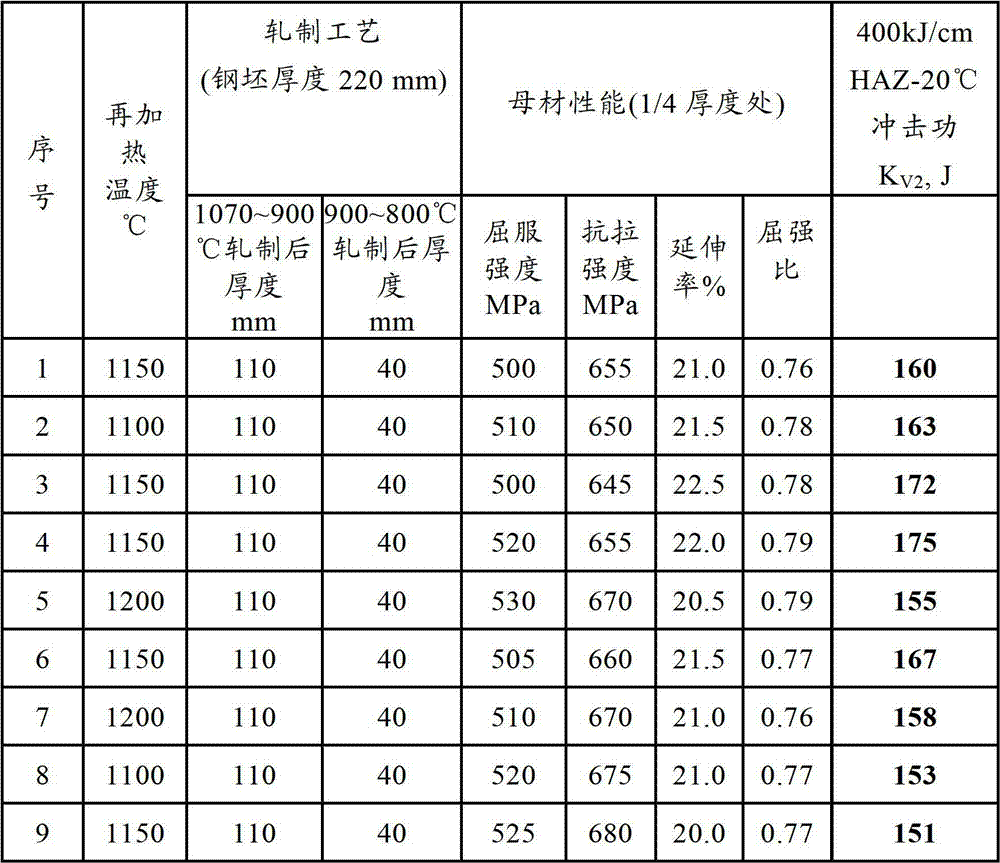

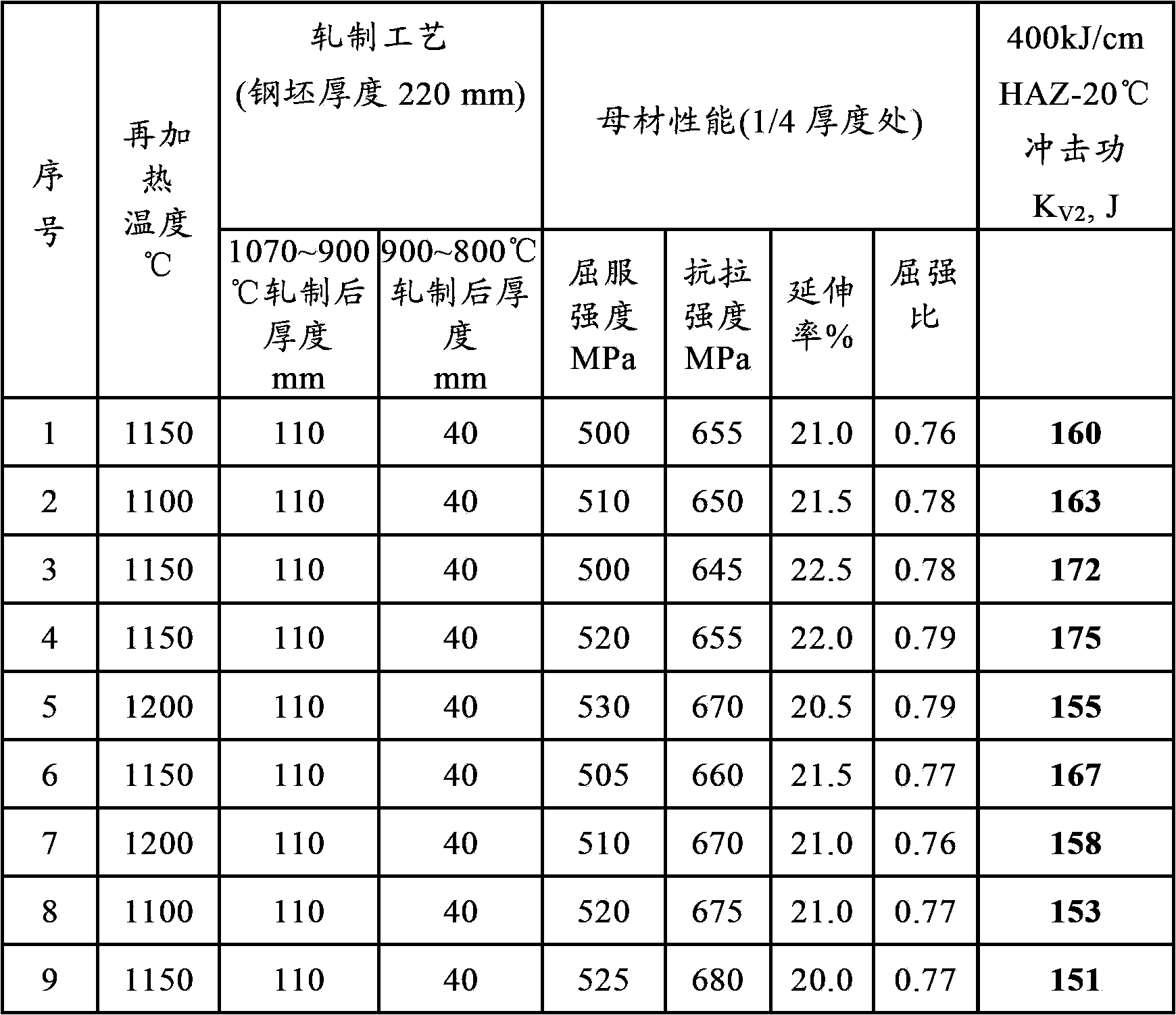

Large heat input energy welding high-strength EH36 steel plate and making method thereof

The invention relates to a large heat input energy welding high-strength EH36 steel plate which is made of the following components in percentage by weight through smelting: 0.06-0.18% of C, 0.15-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, less than or equal to 0.010% of Al, 0.010-0.030% of Ti, 0.001-0.010% of Ca and the balance of Fe and inevitable impurities. The maximum thickness of the steel plate is 100mm, the yield strength of the steel plate is greater than or equal to 355MPa, the tension strength of the steel plate is greater than or equal to 510MPa, and the low-temperature impact absorption energy KV2 of the steel plate at minus 40 DEG C is greater than or equal to 150KJ. A production method of the steel plate comprises the following steps: carrying out smelting, LF / RH (Ladle Furnace / Ruhrstahl Heraeus) refining, continuous casting, heating, rolling, and rapid cooling, thereby obtaining a finished product of the steel plate. The steel plate produced by using the method provided by the invention has the characteristics of high purity, high strength, good low-temperature impact resistance, good toughness when the maximum input line energy is 300KJ / CM, and the like, can be widely applied to fields such as shipbuilding, bridges and building structures, and has wide application prospects.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Thick steel plate with low carbon equivalent and excellent welding heat affected zone toughness and manufacturing method of same

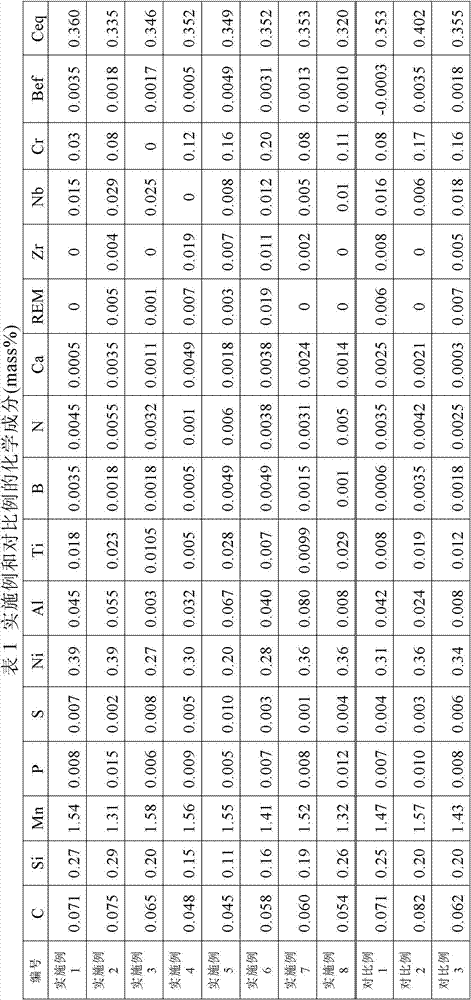

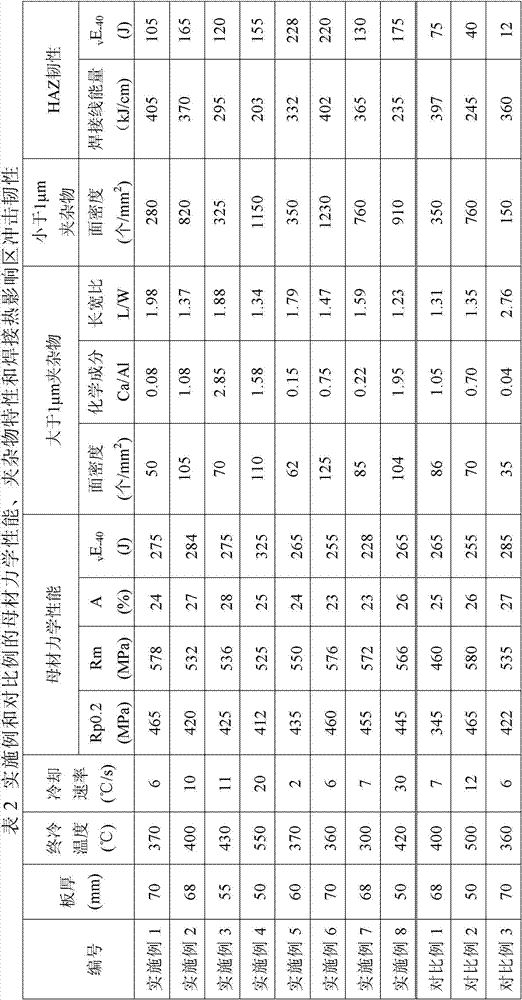

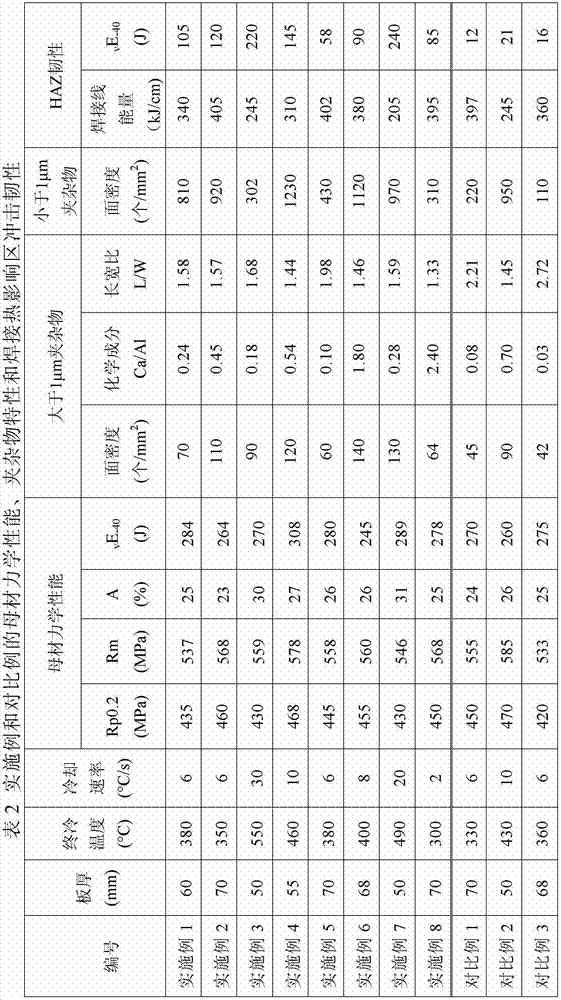

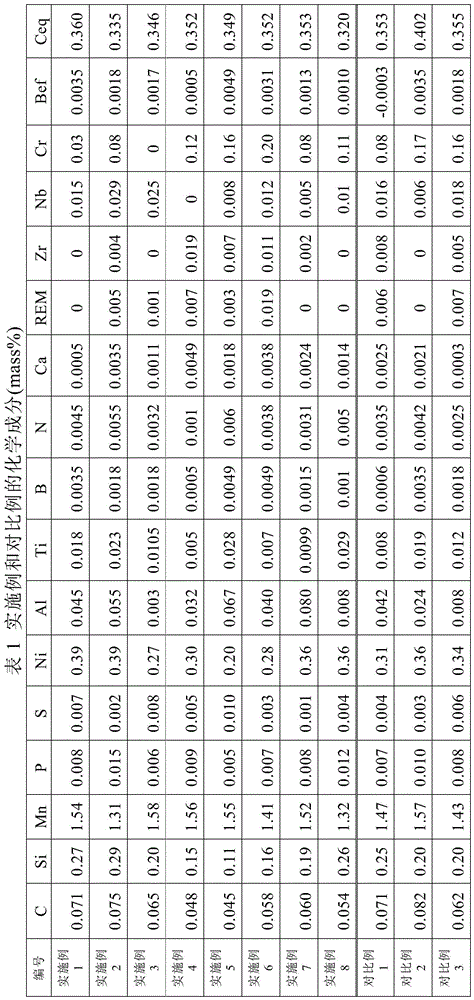

The invention discloses a thick steel plate with a low carbon equivalent and excellent welding heat affected zone toughness and a manufacturing method of the same. The manufacturing method comprises the following steps: 1) smelting, refining and continuously casting the ingredients in the following percentage by mass: 0.045-0.075% of C, 0.10-0.30% of Si, 1.3-1.6% of Mn, not greater than 0.015% of P, 0.001-0.01% of S, 0.20-0.40% of Ni, 0.005-0.03% of Ti, 0.003-0.08% of Al, 0.0005-0.005% of Ca, not greater than 0.02% of REM, not greater than 0.02% of Zr, 0.0005-0.005% of B, 0.001-0.006% of N, 0.32-0.36% of Ceq, 0.0005-0.005% of Bef, and the balance of Fe and inevitable impurities; 2) rolling; and 3) cooling. According to the manufacturing method disclosed by the invention, inclusions with fine dispersed distribution can be formed, and by controlling the surface density of the micron inclusions with diameters of not less than 1 micron, Ca / Al ratio, the length-width ratio of the inclusions and the surface density of the submicron inclusions with diameters of less than 1 micron, the tensile strength of the base material is not less than 510 MPa, the weld heat input is 200-400 kJ / cm, and the average Charpy impact energy of a welding heat affected zone at minus 40 DEG C is greater than 100 J, therefore, excellent impact toughness is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-yield-ratio marine steel plate with good welding performance and manufacturing method thereof

ActiveCN110791702ARaise the finishing temperatureHigh red temperatureMaterials preparationYield ratio

The invention belongs to the field of steel material preparation, and particularly relates to a low-yield-ratio marine steel plate with good welding performance and a manufacturing method thereof. Thelow-yield-ratio marine steel plate comprises the following components of, by weight, 0.05%-0.09% of C, 0.1%-0.4% of Si, 1.0%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.02%of S, 0.005%-0.03% of Als, 0%-0.6% of Ni, 0%-0.3% of Cu, 0.008%-0.05% of Nb, 0.005%-0.03% of Ti, 0.002%-0.01% of N, 0.02%-0.08% of V, 0%-0.3% of Mo, and the balance Fe and inevitable impurities, wherein the yield ratio of the steel plate is less than or equal to 0.80, the carbon equivalent Ceq is less than or equal to 0.41, and Pcm is less than or equal to 0.21. According to the low-yield-ratio marine steel plate with the good welding performance and the manufacturing method thereof, a certain content of N element is added, and second phase dispersion precipitation of V, Ti element is matched,so that the high-heat input welding performance and the low-temperature impact toughness of the steel plate are improved; and chemical components and the processes of high finish rolling temperature,low water inlet high red returning temperature and low cooling speed are combined, so that the high service safety with the yield ratio being less than or equal to 0.8 can be obtained, and a corresponding production process is formed while the high-service safety steel plate which is easy to weld with high heat input is obtained.

Owner:ANGANG STEEL CO LTD

Low-carbon-equivalent large heat input welding thick steel plate with and preparation method thereof

The invention relates to a low-carbon-equivalent large heat input welding thick steel plate and a preparation method thereof. The preparation method comprises the following steps: 1) smelting and casting, wherein the steel plate comprises the following components in percentage by weight: 0.045-0.07% of C, 0.10-0.30% of Si, 1.3-1.6% of Mn, less than or equal to 0.015% of P, 0.001-0.01% of S, 0.2-0.4% of Ni, 0.005-0.035% of Ti, 0.0005-0.01% of Mg, 0.001-0.01% of N, 0.0005-0.005% of B, less than or equal to 0.05% of Al, less than or equal to 0.05% of Ca, less than or equal to 0.02% of REM and the balance of Fe and inevitable impurities and further comprises more than one of less than or equal to 0.03% of Nb or less than or equal to 0.2% of Cr; Ti / N is greater than or equal to 2 but less than or equal to 6, Mg / (Al+Ti) is greater than or equal to 0.024, Ceq is 0.32-0.36% and Bef is 0.0005-0.005%; 2) rolling; 3) cooling. By controlling the (Mg+Ca) / (Al+Ti) ratio and areal density of micron inclusions with the diameter which is greater than or equal to 1 micron as well as the (Mg+Ca) / (Al+Ti) ratio and areal density of submicron inclusions with the diameter which is 0.1-1 micron, for the steel plates with the thickness being 50-70 mm and the base material tensile strength being greater than or equal to 510 MPa, the steel plates are welded with the weld heat input of 200-400kJ / cm, and the average Charpy impact energy of a welding heat affected zone at -40 DEG C reaches 100J above.

Owner:BAOSHAN IRON & STEEL CO LTD

Control method of nano-precipitates in thick steel plate for high heat input welding

The invention discloses a control method for a nano-scaled precipitate in a thick steel plate for high heat input welding. Deoxidizers are added during smelting and casting of molten steel, wherein the types and the adding sequence for the deoxidizers are that: (Mn+Si), Al, Ti and (Ca+Mg); Mg content is 0.0005-0.007 percent; oxygen level in the molten steel is required to be adjusted during Mg deoxidization; accurate control is performed by adding Fe2O3 powder into a cast ingot casting mould; the amount of added Fe2O3 powder is 0.001-0.008 percent of oxygen content in the molten steel; the volume density of the precipitates of less than 500nm in steel is more than 9.0*107 per cubic millimeter; the average particle size is less than 80.0nm; and the proportion of the precipitates of less than 100nm is more than 75 percent. A large number of nano-scaled precipitates with small sizes are formed by the method and are finely dispersed and distributed in the steel; suppression of austenite grain growth of a welding heat affected zone is facilitated; and the high heat input welding performance of the thick plate is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate with excellent tenacity for excellent-tenacity welding heat affected zone and manufacturing method thereof

The invention discloses a thick steel plate with excellent tenacity for an excellent-tenacity welding heat affected zone and a manufacturing method thereof. The method comprises the following steps: 1) smelting, refining and continuously casting, wherein the thick steel plate comprises the following components by mass percent: 0.05-0.09% of C, 0.10-0.30% of Si, 1.2-1.6% of Mn, no more than 0.02% of P, 0.001-0.006% of S, 0.20-0.40% of Ni, 0.15-0.3% of Cu, 0.005-0.03% of Ti, 0.003-0.1% of Al, 0.0005-0.005% of Ca, no more than 0.02% of REM, no more than 0.02% of Zr, 0.0002-0.005% of B, 0.001-0.006% of N and the balance of Fe and inevitable impurities, wherein Ti / N is smaller than or equal to 6 and greater than or equal to 1; 2) rolling; 3) cooling. By adopting the manufacturing method, occluded foreign inclusions in fine dispersed distribution can be formed. By controlling the surface density of a micron occluded foreign substance of which the diameter is greater than or equal to 1 micron, the Ca / Al ratio and the length-width ratio of the occluded foreign inclusions, the surface density, the Ca / Al ratio and the length-width ratio of micron inclusions of which the diameter is greater than or equal to 1 micron, the surface density of a submicron occluded foreign substance of which the diameter is smaller than 1 micron, the tensile strength of base metal is greater than or equal to 510MPa, the welding line energy is 200-400 kJ / cm, and the welding heat affected zone has good impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Yield strength 690 MPa class steel plate capable of bearing high heat input welding and manufacturing method

The invention belongs to the technical field of low-alloy high-strength steel and particularly relates to a yield strength 690 MPa class steel plate capable of bearing high heat input welding and a manufacturing method of the yield strength 690 MPa class steel plate. The steel plate comprises chemical components including 0.01%-0.04% of C, 0.1%-0.3% of Si, 1.7%-2.2% of Mn, 0.01%-0.05% of Nb, 0.01%-0.05% of V, 0.005%-0.025% of Ti, 0.001%-0.008% of P, 0.001%-0.005% of S, 0.05%-0.5% of Cu, 0.05%-0.5% of Ni, 0.05%-0.5% of Cr, 0.05%-0.5% of Mo, 0.0005%-0.0025% of B, 0.001%-0.005% of N, 0.00002%-0.0002% of H, 0.001%-0.005% of O 0.001%-0.015% of Al, one of Mg and Ca and the balance Fe. Ti-Mg-O or Ti-Ca-O compound occluded foreign substances accounts for 10% or higher in occluded foreign substances with the size being 0.2 micron to 3 microns, and in addition, an average of 1%-50% of Ti is contained; and the number of the occluded foreign substances with the size being 3 microns or higher in the steel plate is smaller than or equal to 120 pieces / mm<3>. An LD-RH-LF-RH smelting process is adopted, and when oxygen in molten steel is fixed to be 150 ppm to 300 ppm, Ti and Mg or Ca are added; and two-stage controlled rolling and controlled cooling are adopted. The steel plate has good toughness performance and can bear 100 kJ / cm to 200 kJ / cm high heat input welding.

Owner:NORTHEASTERN UNIV

A thick steel plate with excellent toughness in low-carbon equivalent welding heat-affected zone and manufacturing method thereof

ActiveCN103695776BPromote growthImprove high heat input welding performanceHeat-affected zoneImpurity

The invention discloses a thick steel plate with a low carbon equivalent and excellent welding heat affected zone toughness and a manufacturing method of the same. The manufacturing method comprises the following steps: 1) smelting, refining and continuously casting the ingredients in the following percentage by mass: 0.045-0.075% of C, 0.10-0.30% of Si, 1.3-1.6% of Mn, not greater than 0.015% of P, 0.001-0.01% of S, 0.20-0.40% of Ni, 0.005-0.03% of Ti, 0.003-0.08% of Al, 0.0005-0.005% of Ca, not greater than 0.02% of REM, not greater than 0.02% of Zr, 0.0005-0.005% of B, 0.001-0.006% of N, 0.32-0.36% of Ceq, 0.0005-0.005% of Bef, and the balance of Fe and inevitable impurities; 2) rolling; and 3) cooling. According to the manufacturing method disclosed by the invention, inclusions with fine dispersed distribution can be formed, and by controlling the surface density of the micron inclusions with diameters of not less than 1 micron, Ca / Al ratio, the length-width ratio of the inclusions and the surface density of the submicron inclusions with diameters of less than 1 micron, the tensile strength of the base material is not less than 510 MPa, the weld heat input is 200-400 kJ / cm, and the average Charpy impact energy of a welding heat affected zone at minus 40 DEG C is greater than 100 J, therefore, excellent impact toughness is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for improving high heat input welding performance of thick steel plates

ActiveCN102191429BIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneSheet steel

The invention discloses a method for improving the high heat input welding performance of thick steel plates. The method comprises the following steps of: 1) smelting and casting to obtain an ingot, wherein deoxidants are added in the deoxidation process of molten steel, the adding sequence of the deoxidants is Mn and Si, Al, Ti, and Ca, a Mg deoxidant is added in the casting process of the molten steel, and the initial oxygen potential during the deoxidation of Mg is accurately controlled by adding Fe2O3 powder into a casting ingot mould; and 2) rolling and cooling. In the method, microfine dispersive distribution and Mg-containing inclusions, which are formed by adding the deoxidants in the deoxidation process of the molten steel and adding the Fe2O3 powder into the casting ingot mould to accurately control the oxygen potential during the deoxidation of the Mg, can inhibit the growth of austenite grains in a welding heat affected zone, and promotes the growth of ferrite in the grains, so that the high heat input welding performance of the thick steel plates is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate with excellent toughness in welding heat-affected zone and manufacturing method thereof

The invention discloses a thick steel plate with excellent tenacity for an excellent-tenacity welding heat affected zone and a manufacturing method thereof. The method comprises the following steps: 1) smelting, refining and continuously casting, wherein the thick steel plate comprises the following components by mass percent: 0.05-0.09% of C, 0.10-0.30% of Si, 1.2-1.6% of Mn, no more than 0.02% of P, 0.001-0.006% of S, 0.20-0.40% of Ni, 0.15-0.3% of Cu, 0.005-0.03% of Ti, 0.003-0.1% of Al, 0.0005-0.005% of Ca, no more than 0.02% of REM, no more than 0.02% of Zr, 0.0002-0.005% of B, 0.001-0.006% of N and the balance of Fe and inevitable impurities, wherein Ti / N is smaller than or equal to 6 and greater than or equal to 1; 2) rolling; 3) cooling. By adopting the manufacturing method, occluded foreign inclusions in fine dispersed distribution can be formed. By controlling the surface density of a micron occluded foreign substance of which the diameter is greater than or equal to 1 micron, the Ca / Al ratio and the length-width ratio of the occluded foreign inclusions, the surface density, the Ca / Al ratio and the length-width ratio of micron inclusions of which the diameter is greater than or equal to 1 micron, the surface density of a submicron occluded foreign substance of which the diameter is smaller than 1 micron, the tensile strength of base metal is greater than or equal to 510MPa, the welding line energy is 200-400 kJ / cm, and the welding heat affected zone has good impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

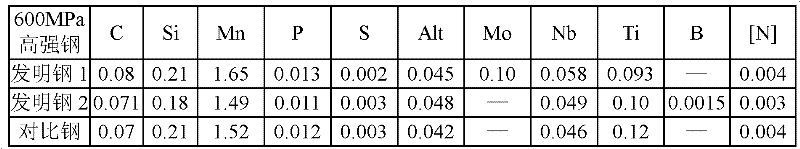

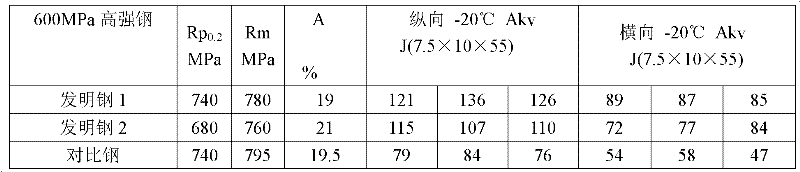

High-strength thick steel plate for large heat input welding

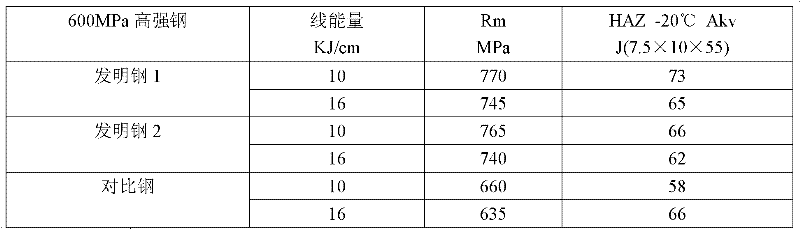

The invention relates to a high-strength thick steel plate for large heat input welding. The high-strength thick steel plate comprises, by weight percent, 0.07-0.10% of C, 0.05-0.15% of Si, 1.5-1.8% of Mn, not more than 0.01% of P, not more than 0.005% of S, 0.02-0.10% of Al, 0.006-0.02% of N, 0.005-0.015% of Ti, 0.10-0.25% of Cr, 0.0015-0.0025% of B, not more than 0.0030% of O, and the balance Fe and other inevitable impurity. A manufacture method of the high-strength thick steel plate includes: smelting in a converter or an electric furnace, secondary refining in a vacuum furnace, casting ingots, reheating the ingots, and performing TMCP (thermal mechanical control processing) and fast cooling to obtain the steel plate. The thick steel plate with a high strength of 600MPa is low in cost, and has excellent low-temperature toughness in the large heat input welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Control method of inclusions in thick steel plate used for high heat input welding

The invention relates to a control method of inclusions in a thick steel plate used for high heat input welding, which is characterized by adding a deoxidizing agent during steel liquid pouring, wherein the components and adding order of the deoxidizing agent are as follows: Mn and Si, Al, Ti, Ca and Mg; the Mg content is 0.0005-0.007%, when Mg is added for deoxidizing, the oxygen content in steel liquid needs to be adjusted and precisely controlled through adding Fe2O3 powder to a casting ingot mold, and the adding amount of the Fe2O3 powder is such that the oxygen content in the steel liquid is maintained at 0.001-0.008%; the Al content in steel is lower than 0.006%; the ratio of the inclusions with size smaller than 3mu m in the steel liquid is not lower than 80%, and the surface density of the inclusions is not smaller than 300 inclusions / mm<2>; the main components in the center of the inclusions are MgO or MgO and Ti2O3, and the main component on the external surface of the inclusions is MnS. The inclusions formed by using the method provided by the invention can favorably inhibit the growth of austenite crystal in a welding heat-affected zone and promote the growth of intracrystalline ferrite, thus improving the high heat input welding performance of the thick plate.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate for high-strength high-energy-input welding

The invention relates to a high-strength thick steel plate for large heat input welding. The high-strength thick steel plate comprises, by weight percent, 0.07-0.10% of C, 0.05-0.15% of Si, 1.5-1.8% of Mn, not more than 0.01% of P, not more than 0.005% of S, 0.02-0.10% of Al, 0.006-0.02% of N, 0.005-0.015% of Ti, 0.10-0.25% of Cr, 0.0015-0.0025% of B, not more than 0.0030% of O, and the balance Fe and other inevitable impurity. A manufacture method of the high-strength thick steel plate includes: smelting in a converter or an electric furnace, secondary refining in a vacuum furnace, casting ingots, reheating the ingots, and performing TMCP (thermal mechanical control processing) and fast cooling to obtain the steel plate. The thick steel plate with a high strength of 600MPa is low in cost, and has excellent low-temperature toughness in the large heat input welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate HT690 capable of being subjected to high heat input welding and manufacturing method thereof

ActiveCN102041459BImprove performanceShorten the manufacturing cycleRoll force/gap control deviceTemperature control deviceWater pipeHigh heat

Owner:BAOSHAN IRON & STEEL CO LTD

Method for raising large heat input weldability of thick steel plate

ActiveCN102373371BIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneAustenite

The invention discloses a method for raising large heat input weldability of a thick steel plate, comprising the following steps: 1) smelting and casting to form a steel plate: adding deoxidizers in the deoxidation process of the liquid steel according to the following types and order: Mn, Si, Al, Ti, and Ca and / or Mg, controlling the initial oxygen place in the liquid steel when Mn deoxidation is carried out in casting, adding Fe2O3 powder to let the oxygen content in the liquid steel be 0.001-0.008 wt%, wherein, the steel plate comprises 0.05-0.09 wt% of C, 0.10-0.30 wt% of Si, 1.3-1.7 wt% of Mn, 0.005-0.02 wt% of Ti, no larger than 0.015 wt% of P, no larger than 0.01 wt% of S, no larger than 0.006 wt% of N, no larger than 0.004 wt% of Ca, and the balance consisting of Fe; in the steel, the volumn density of TiN deposition with the particle size of less than 500 nm is larger than 9.0*107 PCs / mm<3>, the average particle size is less than 80 nm, and the proportion of the deposition with the particle size of less than 100 nm is larger than 75 %; 2) rolling and cooling. The large amount of nano TiN deposition with dispersive distribution formed by the invention can inhibit the growth of austenite crystals in the heat affected zone, and greatly raise the large heat input weldability of the thick steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

A steel plate with a yield strength of 690mpa that can withstand large heat input welding and its manufacturing method

The invention belongs to the technical field of low-alloy high-strength steel, and in particular relates to a 690MPa grade steel plate with a yield strength that can withstand large linear energy welding and a manufacturing method thereof. The chemical composition of the steel plate includes C 0.01~0.04%, Si 0.1~0.3%, Mn 1.7~2.2%, Nb 0.01~0.05%, V 0.01~0.05%, Ti 0.005~0.025%, P 0.001~0.008%, S 0.001~0.005 %, Cu 0.05~0.5%, Ni 0.05~0.5%, Cr 0.05~0.5%, Mo 0.05~0.5%, B 0.0005~0.0025%, N 0.001~0.005%, H 0.00002~0.0002%, O 0.001~0.005%, Al 0.001~0.015%, and one of Mg and Ca, the balance is Fe; among the inclusions with a size of 0.2~3μm in the steel plate, Ti‑Mg‑O or Ti‑Ca‑O composite inclusions account for more than 10% , and contains an average of 1 to 50% Ti; the number of inclusions with a size of 3 μm or more in the steel plate is ≤120 / mm 3 . Using the LD‑RH‑LF‑RH smelting process, Ti and Mg or Ca are added when the molten steel is oxygenated at 150 to 300 ppm; two-stage controlled rolling and cooling are adopted. The steel plate of the present invention has excellent strength and toughness and can withstand large line energy welding of 100-200kJ / cm.

Owner:NORTHEASTERN UNIV LIAONING

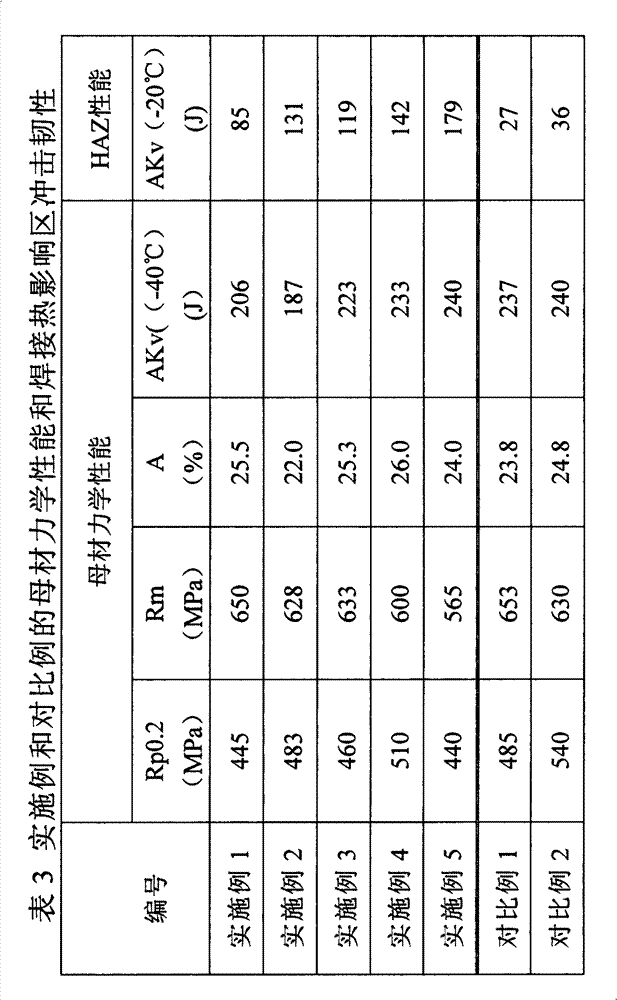

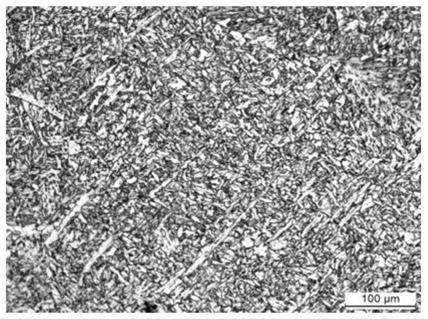

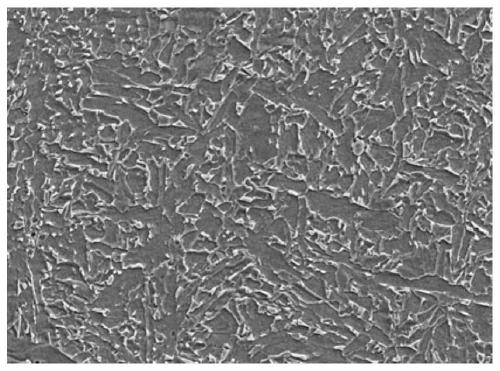

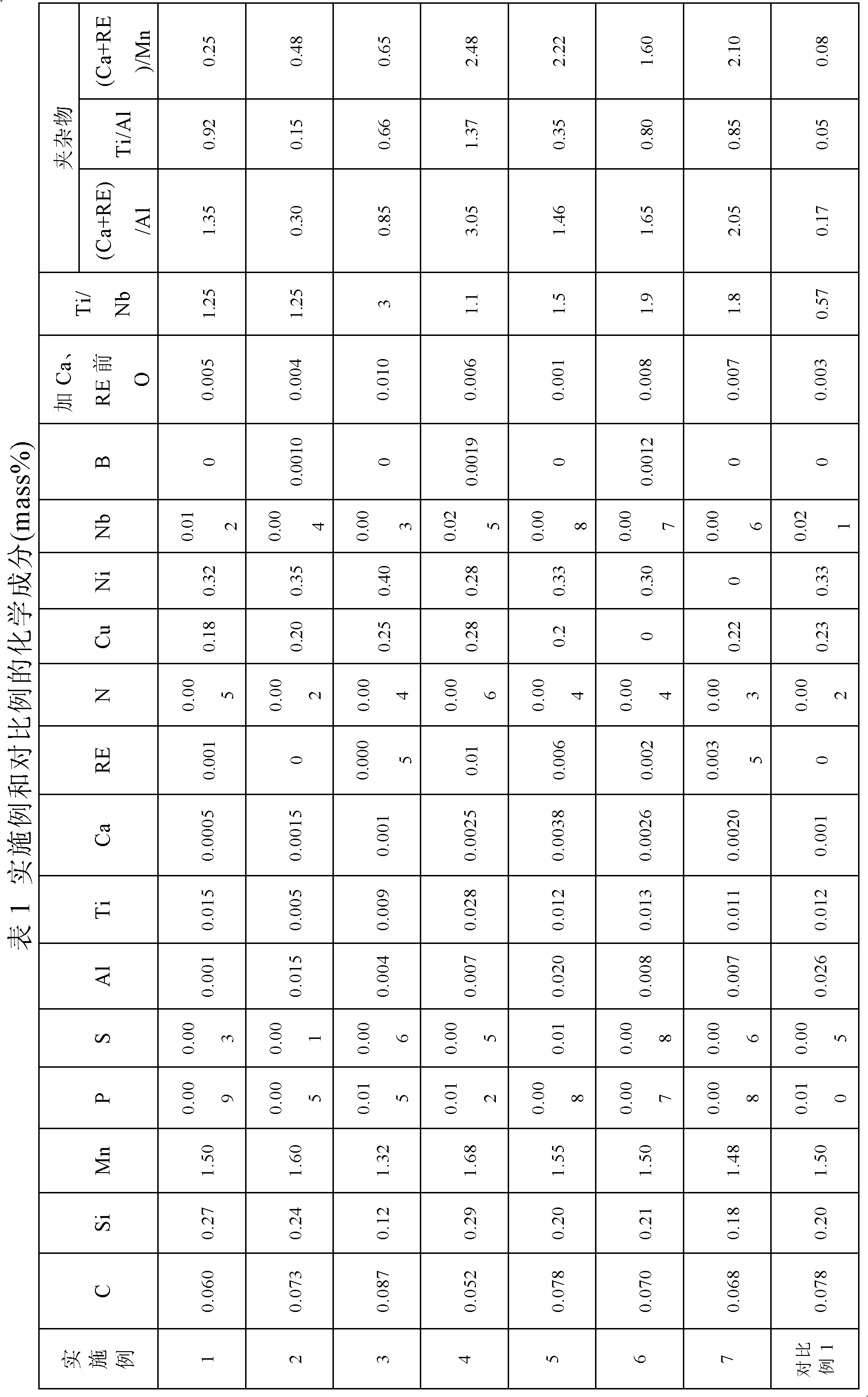

Thick steel plates for high heat input welding and production method thereof

Disclosed are thick steel plates for high heat input welding and a production method thereof. The method includes the steps: firstly, smelting, refining and continuous casting; adding deoxidizer in deoxidation of molten steel according to a sequence of Mn, Si, Al and Ti; finally adding Ca and / or RE deoxidizer, adding Fe2O3 powder to accurately control an initial oxygen level in Ca and / or RE deoxidation of the molten steel; secondly, rolling; and thirdly cooling, wherein molten steel comprises, in weight percentage, 0.05-0.09% of C, 0.10-0.30% of Si, 1.3-1.7% of Mn, 0.005-0.03% of Ti, 0.003-0.025% of Nb, 0.001-0.01% of S, not more than 0.05% of P, not more than 0.006% of N, 0.0005-0.001% of Al, 0.0005-0.004% of Ca, not more than 0.01% of RE, the balance of Fe, and unavoidable impurities. Fine scattered Ca and / or RE oxide and sulfide inclusions can be formed, ratios of (Ca+RE) / Al, Ti / Al and (Ca+RE) / Mn in the inclusions are reasonably controlled, growth of intra-granular ferrite in a welding heat affected zone is promoted, and the performance of high heat input welding of the thick steel plates can be improved greatly.

Owner:BAOSHAN IRON & STEEL CO LTD

A thick steel plate capable of large heat input welding and its manufacturing method

The invention provides a thick steel plate capable of being welded at a large heat input and a manufacturing method thereof. The manufacturing method comprises the following steps: (1) smelting and casting, wherein the thick steel plate is prepared from the following components in percent by weight: 0.05-0.09% of C, 0.10-0.30% of Si, 1.2-1.6% of Mn, not greater than 0.02% of P, 0.001-0.006% of S, 0.2-0.4% of Ni, 0.15-0.3% of Cu, 0.005-0.03% of Ti, 0.0005-0.01% of Mg, 0.001-0.006% of N, not greater than 0.05% of Al, not greater than 0.005% of Ca, not greater than 0.02% of REM, and not greater than 0.003% of B and the balance of Fe and unavoidable impurities, and Ti / N is no less than 1 and is not greater than 6, and Mg / (Al+Ti) is no less than 0.02; (2) rolling; (3) cooling. According to the thick steel plate capable of being welded at the large heat input and the manufacturing method thereof, tiny dispersion-distribution inclusion can be formed; by controlling the (Mg+Ca) / (Al+Ti) ratio and the surface density of micron inclusion with the diameter of no less than 1 micrometer and the (Mg+Ca) / (Al+Ti) ratio and the surface density of sub-micron inclusion with the diameter of 0.1-1 micrometer, a base metal with the tensile strength of no less than 510 MPa is obtained; when the welding heat input is 200-400 kJ / cm, the average charpy impact energy of the steel plate at -40 DEG C is more than 50 J.

Owner:BAOSHAN IRON & STEEL CO LTD

Large heat input welding 670MPa-grade steel plate and manufacturing method thereof

The invention discloses a large heat input welding 670MPa-grade steel plate. The large heat input welding 670MPa-grade steel plate comprises the following chemical elements in percentage by mass: 0.08%-0.12% of C, 0.80%-1.20% of Mn, 0.2%-0.6% of Cr, 1.5%-1.9% of Ni, 0.3%-0.5% of Mo, 0.1%-0.3% of Cu, 0.02%-0.05% of V, 0.001%-0.01% of Al, 0.006%-0.012% of Ti, 0.0008%-0.0014% of B, 0.001%-0.006% of N and the balance of Fe and other inevitable impurities. In addition, the invention also discloses a manufacturing method of the large heat input welding 670MPa-grade steel plate. The manufacturing method comprises the following steps: (1) smelting and casting; (2) rolling; and (3) quenching and tempering thermal treatment, wherein the quenching heating temperature is 900-980 DEG C, and then water quenching is carried out; and the tempering heating temperature is 600-700 DEG C. The large heat input welding 670MPa-grade steel plate has good energy welding performance and aging impact performance, and can be effectively used as a welding structure material to be applied to the field of ocean engineering.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of thick steel plate for welding with low carbon equivalent and large input energy and its manufacturing method

Owner:BAOSHAN IRON & STEEL CO LTD

A high-strength eh36 steel plate for large heat input welding and its manufacturing method

ActiveCN109161671BHigh impact energy at low temperatureImprove toughnessUltimate tensile strengthToughness

The invention relates to a large heat input energy welding high-strength EH36 steel plate which is made of the following components in percentage by weight through smelting: 0.06-0.18% of C, 0.15-0.50% of Si, 1.10-1.60% of Mn, less than or equal to 0.012% of P, less than or equal to 0.003% of S, 0.10-0.40% of Ni, 0.010-0.030% of Nb, less than or equal to 0.010% of Al, 0.010-0.030% of Ti, 0.001-0.010% of Ca and the balance of Fe and inevitable impurities. The maximum thickness of the steel plate is 100mm, the yield strength of the steel plate is greater than or equal to 355MPa, the tension strength of the steel plate is greater than or equal to 510MPa, and the low-temperature impact absorption energy KV2 of the steel plate at minus 40 DEG C is greater than or equal to 150KJ. A production method of the steel plate comprises the following steps: carrying out smelting, LF / RH (Ladle Furnace / Ruhrstahl Heraeus) refining, continuous casting, heating, rolling, and rapid cooling, thereby obtaining a finished product of the steel plate. The steel plate produced by using the method provided by the invention has the characteristics of high purity, high strength, good low-temperature impact resistance, good toughness when the maximum input line energy is 300KJ / CM, and the like, can be widely applied to fields such as shipbuilding, bridges and building structures, and has wide application prospects.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A low yield ratio marine steel plate with good welding performance and its manufacturing method

ActiveCN110791702BPromote nucleationImprove high heat input welding performanceMaterials preparationYield ratio

The invention belongs to the field of steel material preparation, and particularly relates to a low-yield-ratio marine steel plate with good welding performance and a manufacturing method thereof. Thelow-yield-ratio marine steel plate comprises the following components of, by weight, 0.05%-0.09% of C, 0.1%-0.4% of Si, 1.0%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.02%of S, 0.005%-0.03% of Als, 0%-0.6% of Ni, 0%-0.3% of Cu, 0.008%-0.05% of Nb, 0.005%-0.03% of Ti, 0.002%-0.01% of N, 0.02%-0.08% of V, 0%-0.3% of Mo, and the balance Fe and inevitable impurities, wherein the yield ratio of the steel plate is less than or equal to 0.80, the carbon equivalent Ceq is less than or equal to 0.41, and Pcm is less than or equal to 0.21. According to the low-yield-ratio marine steel plate with the good welding performance and the manufacturing method thereof, a certain content of N element is added, and second phase dispersion precipitation of V, Ti element is matched,so that the high-heat input welding performance and the low-temperature impact toughness of the steel plate are improved; and chemical components and the processes of high finish rolling temperature,low water inlet high red returning temperature and low cooling speed are combined, so that the high service safety with the yield ratio being less than or equal to 0.8 can be obtained, and a corresponding production process is formed while the high-service safety steel plate which is easy to weld with high heat input is obtained.

Owner:ANGANG STEEL CO LTD

Control method for nano-scaled precipitate in thick steel plate for high heat input welding

The invention discloses a control method for a nano-scaled precipitate in a thick steel plate for high heat input welding. Deoxidizers are added during smelting and casting of molten steel, wherein the types and the adding sequence for the deoxidizers are that: (Mn+Si), Al, Ti and (Ca+Mg); Mg content is 0.0005-0.007 percent; oxygen level in the molten steel is required to be adjusted during Mg deoxidization; accurate control is performed by adding Fe2O3 powder into a cast ingot casting mould; the amount of added Fe2O3 powder is 0.001-0.008 percent of oxygen content in the molten steel; the volume density of the precipitates of less than 500nm in steel is more than 9.0*107 per cubic millimeter; the average particle size is less than 80.0nm; and the proportion of the precipitates of less than 100nm is more than 75 percent. A large number of nano-scaled precipitates with small sizes are formed by the method and are finely dispersed and distributed in the steel; suppression of austenite grain growth of a welding heat affected zone is facilitated; and the high heat input welding performance of the thick plate is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com